Page 1

1. Read this manual carefully until you

completely understand and can follow all

safety notes, precautions, and operating

instructions before using of the unit.

2. Do not operate this tool when you are tired,

ill, or under the influence of alchohol, drugs,

or medication.

3. Always wear eye or face protection and

hearing protection.

4. Do not wear loose clothing, jewelry, short

trousers, sandals, or go barefoot. Do not

wear anything which might be caught by

branches or moving part of the unit. Secure

hair so it is above shoulder length.

5. Never start or run the engine inside a

closed room or building. Exhaust gases

contain dangerous carbon monoxide.

6. Before starting the engine, inspect the

entire unit for loose fasteners and fuel

leakage. Make sure that the cutting

attachment is properly installed and

securely fastened.

7. Be sure the blade guard is attached in

place.

8. Fuel is highly flammable. Always keep open

flames and sparks away from the unit and

fuel depot. Do not smoke while refueling the

unit or mixing fuel.

9. When refueling the unit, make sure to stop

the engine and allow it to cool down. Wipe

spilled fuel completely from the unit. Move

at least 3 meters away from fueling site

For safe operation

115 32 08-26 (001)

OWNER’S MANUAL

15

m

(50ft)

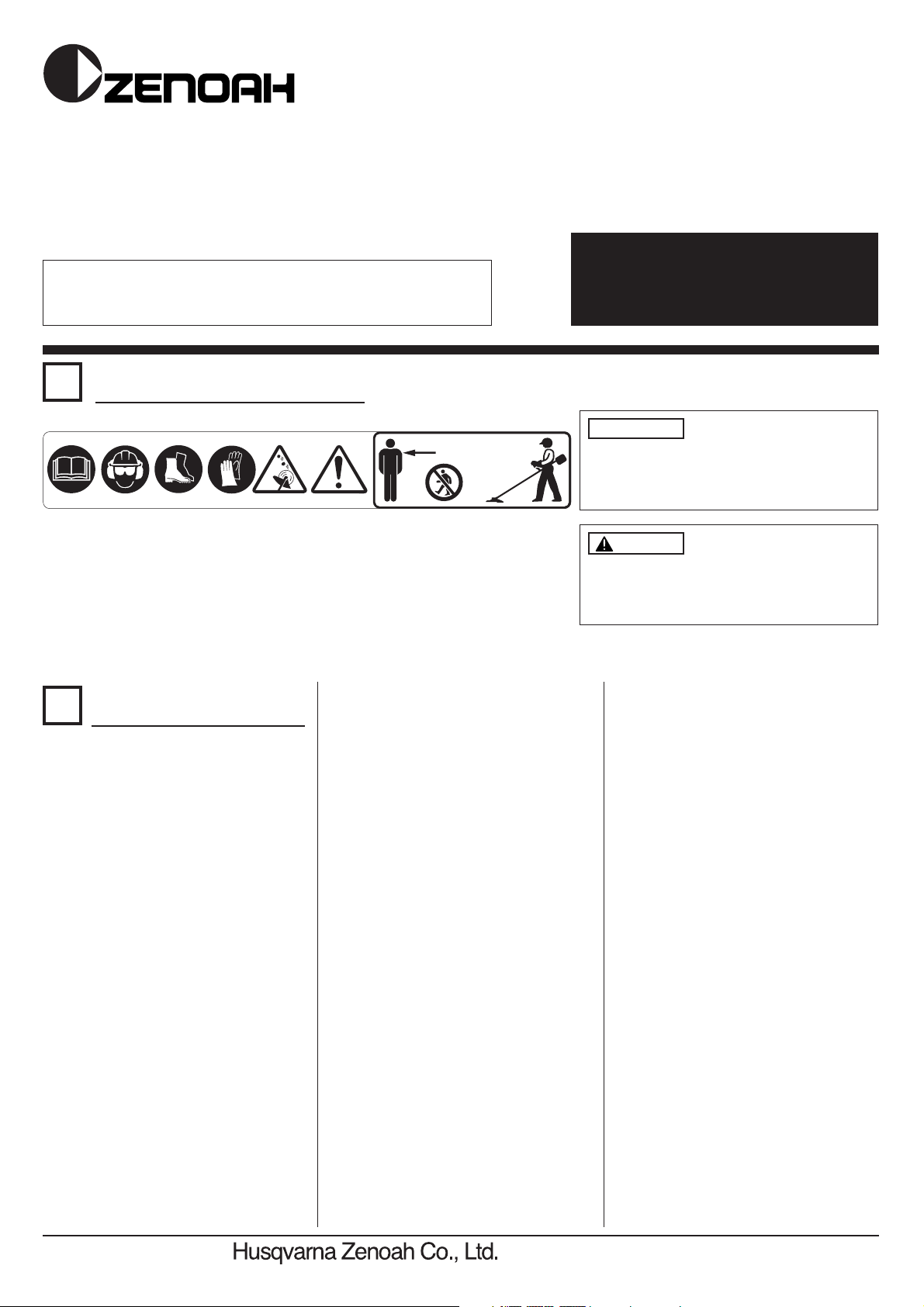

(1) (2) (3) (4) (5) (6) (7)

1

2

(1) Read owner’s manual before operating this machine.

(2) Wear head, eye and ear protection.

(3) Wear foot protection.

(4) Wear gloves.

(5) Beware of thrown objects.

(6) Warning / Attention

(7) Keep all children, bystanders and helpers 15 meters away from the machine.

Explanation of pictorials

before starting the engine.

10. Check the condition of working area to

avoid any accident by hitting hidden

obstacles such as stumps, stones, cans, or

broken grass.

11. Keep bystanders and animals at least 15

meters away from the operating point, If

you are approached, immediately stop the

engine.

12. Keep firm footholds and balance at all

times. Do not use the unit where footing is

unsteady or slippery.

13. Keep cutting attachment below waist level.

14. Keep all parts of your body away from the

rotating cutting attachment and hot

surfaces.

15. Warn the operator of the danger of blade

thrust. (Kick back)

Blade thrust may occur when the spinning

blade contacts a solid object in the critical

area. A dangerous reaction may occur

causing the entire unit and operator to be

thrust violently. This reaction is called Kick

back. As a result, the operator can lose

control of the unit which can cause serious

or fatal injury. Kick back is more likely to

occur in areas where it is difficult to see the

material to be cut.

16. When inspecting or servicing the unit, make

sure to stop the engine and disconnect the

spark plug as necessary.

17. Cover the blade when the transporting or

storing the unit. Secure the unit before for

storage or transporting to prevent loss of

fuel, damage or injury.

18. When replacing cutting attachment or other

components, be sure to use the parts

supplied or recommended by ZENOAH.

19. When the unit is turned off, make sure the

cutting attachment has stopped before the

unit is set down.

20. For units equipped with a clutch, be sure

the cutting attachment stops turning when

the engine idles.

21. Use only for tasks explained in the

instruction handbook.

22. Discard blades that are bent, warped,

cracked, broken or damaged in any way.

23. Instructions on stopping a coasting blade.

A blade can injure while it continues to spin

after the engine is stopped or throttle

control is released.

24. Stop the engine and blade before removing

material that is blocking or entangling the

cutting attachment.

25. Use a sharp blade. A dull blade is more

likely to snag and thrust. Replace the

fastening nut according to the

manufacturer's instruction.

26. Cut only material recommended by the

manufacturer. Do not let the blade contact

material it cannot cut, such as rocks, metal

etc.

27. Always wear safety boots, additionally a

helmet is required if there is a risk of

contact with falling objects.

Thank you for purchasing a ZENOAH product.

Before using our brushcutter, please read this manual carefully

to understand the proper use of your unit.

1-9 Minamidai, Kawagoe, Saitama, 350-1165 Japan

BRUSHCUTTERS

BC4350FW

If warning label peels off or becomes soiled and

impossible to read, you should contact the dealer

from which you purchased the product to order new

labels and affix them in the required location(s).

IMPORTANT

Never modify your machine.

We won’t warrant the machine, if you use the

remodeled brushcutter or if you don’t observe

the proper usage written in the manual.

WARNING

Page 2

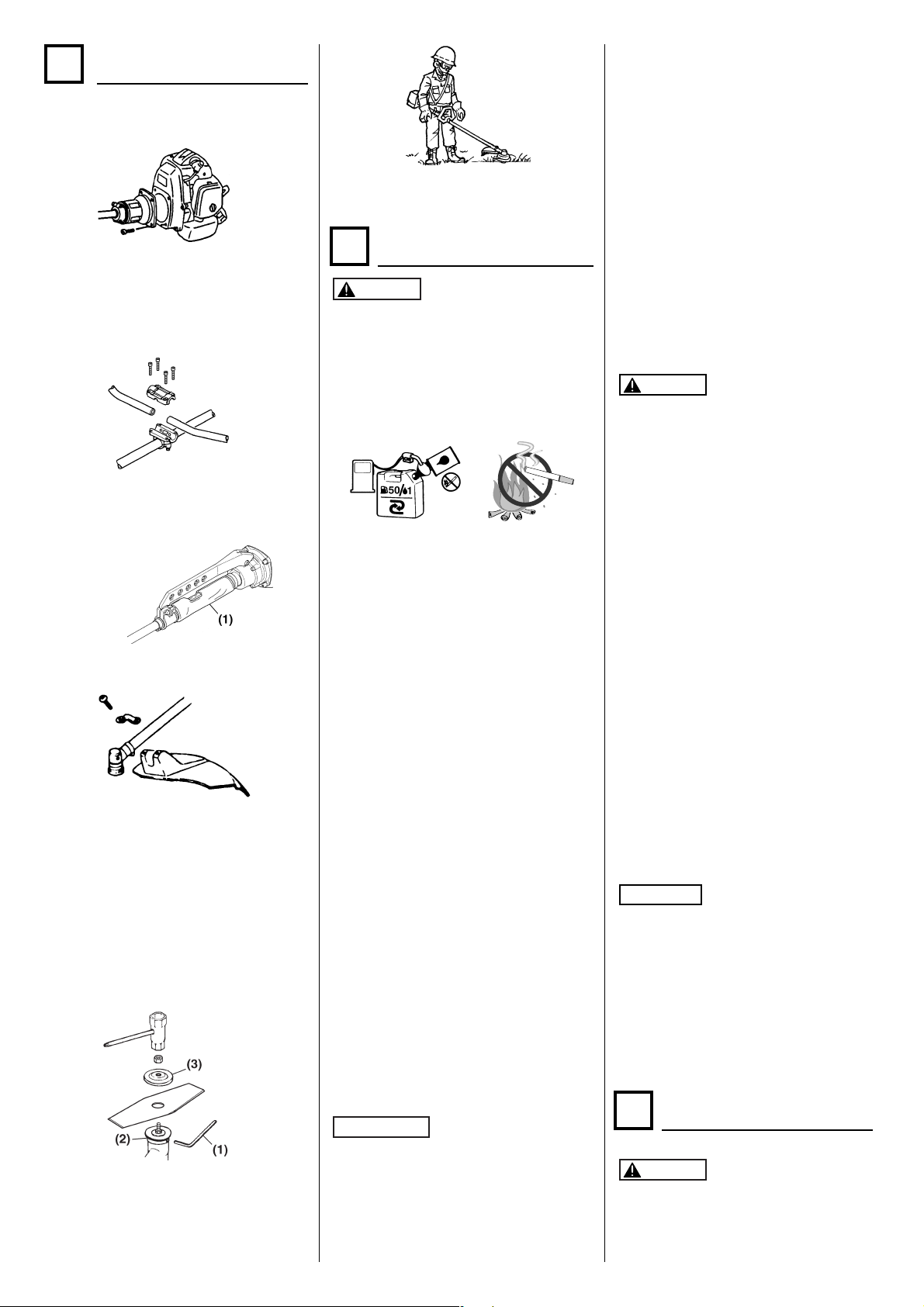

■ ENGINE

• Using attached 4 socket screws, secure the

connection firmly with equal force.

■ HANDLE

1. Loosen the 4 bolts on the upper cap and

insert the handles equally. Retighten the

bolts.

2. Put the handle assembly into the bracket

and put the upper cap over it. Tighten the

cap securely.

■ PROTECTOR

Wrap the protector around the outer pipe as

shown in the figure, and fasten the magic

fastener.

(1) Protector

■ BLADE GUARD

Attach the guard on the outer pipe. Fix it with 2

bolts.

■ INSTALLING BLADE

Remove the guard skirt of debris guard,

when using metal blade.

1. Put the angled bar(1) into the side holes of

the inner holder and the gearcase.

2. Remove the nut(Left-handed) and the outer

holder(3) from the gearshaft.

3. Put the blade onto the inner holder(2). Make

the marked side face the holder.

4. Put the outer holder(3) onto the gearshaft

making the recessed side face the blade.

5. Fasten the blade by the nut.

■ BALANCE UNIT

1. Put on strap and attach unit to strap.

2. Slide clamp up or down until unit balances

with head aparting from the ground when

using it.

• Gasoline is very flammable. Avoid

smoking or bringing any flame or sparks

near fuel. Make sure to stop the engine

and allow it cool before refueling the

unit. Select outdoor bare ground for

fueling and move at least 3m (10ft) away

from the fueling point before starting the

engine.

RECOMMENDED MIXING RATIO

GASOLINE 50:OIL 1

(when using ZENOAH genuine oil)

• The Zenoah engines are lubricated by oil

specially formulated for air-cooled 2-cycle

gasoline engine use. If Zenoah oil is not

available, use an anti-oxidant added quality

oil expressly labeled for air-cooled 2-cycle

engine use. (JASO FC GRADE OIL or ISO

EGC GRADE)

• Do not use BIA or TCW (2-stroke watercooling type) mixed oil.

• Exhaust emission are controlled by the

fundamental engine parameters and

components (eq., carburation, ignition

timing and port timing) without addition

of any major hardware or the introduction

of an inert material during combustion.

• These engines are certified to operate on

unleaded gasoline.

• Make sure to use gasoline with a minimum

octane number of 89 RON (USA/Canada:

87AL)

• If you use a gasoline of a lower octane value

than prescribed, there is a danger that the

engine temperature may rise and an engine

problem such as piston seizing may

consequently occur.

• Unleaded gasoline is recommended to

reduce the contamination of the air for the

sake of your health and the environment.

• Poor quality gasolines or oils may damage

sealing rings, fuel lines or fuel tank of the

engine.

■ HOW TO MIX FUEL

Pay attention to agitation.

1. Measure out the quantities of gasoline and

oil to be mixed.

2. Put some of the gasoline into a clean,

approved fuel container.

3. Pour in all of the oil and agitate well.

4. Pour In the rest of gasoline and agitate again

IMPORTANT

■ STARTING ENGINE

The cutting head will start rotating upon the

engine starts.

1. Feed fuel into the fuel tank and tighten the

cap securely.

WARNING

5

Operation

4

Fuel

for at least one minute. As some oils may be

difficult to agitate depending on oil

ingredients, sufficient agitation is necessary

for the engine to last long. Be careful that, if

the agitation is insufficient, there is an

increased danger of early piston seizing due

to abnormally lean mixture.

5. Put a clear indication on the outside of the

container to avoid mixing up with gasoline or

other containers.

6. Indicate the contents on outside of container

for easy identification.

■ FUELING THE UNIT

1. Untwist and remove the fuel cap. Rest the

cap on a dustless place.

2. Put fuel into the fuel tank to 80% of the full

capacity.

3. Fasten the fuel cap securely and wipe up

any fuel spillage around the unit.

1. Select bare ground for fueling.

2. Move at least 10feet (3meters) away from

the fueling point before starting the

engine.

3. Stop the engine before refueling the unit.

At that time, be sure to sufficiently agitate

the mixed gasoline in the container.

FOR YOUR ENGINE LIFE, AVOID;

1. FUEL WITH NO OIL(RAW GASOLINE) – It

will cause severe damage to the internal

engine parts very quickly.

2. GASOHOL – It can cause deterioration of

rubber and/or plastic parts and disruption of

engine lubrication.

3. OIL FOR 4-CYCLE ENGINE USE – It can

cause spark plug fouling, exhaust port

blocking, or piston ring sticking.

4. Mixed fuels which have been left unused

for a period of one month or more may

clog the carburetor and result in the

engine failing to operate properly.

5. In the case of storing the product for a long

period of time, clean the fuel tank after

rendering it empty. Next, activate the engine

and empty the carburetor of the composite

fuel.

6. In the case of scrapping the used mixed oil

container, scrap it only at an authorized

repository site.

As lot details of quality assurance, read the

description in the section Limited Warranty

carefully. Moreover, normal wear and change

in product with no functional influence are not

covered by the warranty. Also, be careful that,

if the usage in the instruction manual is not

observed as to fhe mixed gasoline, etc.

described therein, if may not be covered by the

warranty.

NOTE

3

Setup

WARNING

WARNING

Page 3

2. Rest the unit on a flat, firm place. Keep the

cutting head off the ground and clear of

surrounding objects, as it will start rotating

upon starting of the engine.

3. Open the fuel tank cock.

(1) Choke lever

(2) Close

(3) Open

(4) Fuel tank cock

(5) Close

(6) Open

4. Move the choke lever to the closed position.

5. Set the stop switch to the “RUN” position.

Place the unit on a flat, firm place.

Keep the cutting head clear of everything

around it.

(1) Stop switch

6. While holding the unit firmly, pull out the

starter rope quickly until engine fires.

The product is equipped with a centrifugal

clutch mechanism, so the cutting

attachment begins to rotate as soon as the

engine is started by putting the throttle into

the start position. When starting the engine,

place the product onto the ground in a flat

clear area and hold it firmly in place so as

to ensure that neither the cutting part nor

the throttle come into contact with any

obstacle when the engine starts.

Avoid pulling the rope to its end or returning it

by releasing the knob. Such actions can cause

starter failures.

7. Move the choke lever downward to open the

choke. And restart engine.

8. Allow the engine to warm up for a several

minutes before starting operation.

1. When restarting the engine immediately after

stopping it, leave the choke open.

2. Overchoking can make the engine hard to

start due to excess fuel. When the engine

failed to start after several attempts, open

the choke and repeat pulling the rope, or

remove the spark plug and dry it.

NOTE

IMPORTANT

■ STOPPING ENGINE

1. Release the throttle trigger and run the

engine for half a minute.

2. Shift the stop switch to the STOP position.

(1) Stop switch

Except for an emergency, avoid stopping the

engine while pulling the throttle lever.

■ ADJUSTING THROTTLE CABLE

• The normal play is 1 or 2 mm when

measured at the carburetor side end.

Readjust with the cable adjuster as required.

■ ADJUSTING IDLING SPEED

1. When the engine tends to stop frequently at

idling mode, turn the adjusting screw

clockwise.

2. When the cutting head keeps rotating after

releasing the trigger, turn the adjusting

screw counter-clockwise.

Warm up the engine before adjusting the idling

speed.

■ CUTTING WORK

• By using the shoulder strap, hang the unit on

your right side. Adjust the strap length so

that the cutting head may become parallel to

the ground.

(1) Shoulder strap

• Choose a suitable recommended cutting

attachment according to the object to be cut.

Never use other cutting attachment not

approved by ZENOAH.

NOTE

IMPORTANT

6

Maintenance

(1) Cable adjuster

(1) Idle adjusting screw

Make sure that the engine has stopped and

is cool before performing any service to the

machine. Contact with moving cutting head

or hot muffler may result in a personal

injury.

■ AIR FILTER

The air filter, if clogged, will reduce the engine

performance. Check and clean the filter

element in warm, soapy water as required. Dry

completely before installing. If the element is

broken or shrunk, replace with a new one.

(1) Air filter

■ FUEL FILTER

When the engine runs short of fuel supply,

check the fuel cap and the fuel filter for

blockage.

(1) Fuel filter

■ SPARK PLUG

Starting failure and misfiring are often caused

by a fouled spark plug. Clean the spark plug

and check that the plug gap is in the correct

range. For a replacement plug, use the correct

type specified by ZENOAH.

REPLACEMENT PLUG IS A CHAMPION

RCJ6Y.

• Note that using any spark plug other than

those designated may result in the engine

failing to operate properly or in the engine

becoming overheated and damaged.

• To install the spark plug, first turn the plug

until it is finger tight, then tighten it a quarter

turn more with a socket wrench.

Tightning torque:

9.8~11.8N.m. (1.0~1.2kgm))

IMPORTANT

(1)

(1)

WARNING

WARNING

0.6~0.7mm

Page 4

■ PROCEDURES TO BE PERFORMED

AFTER EVERY 100 HOURS OF USE

1. Remove the muffler, insert a screwdriver into

the vent, and wipe away any carbon buildup.

Wipe away any carbon buildup on the

muffler exhaust vent and cylinder exhaust

port at the same time.

2. Tighten all screws, bolts, and fittings.

3. Check to see if any oil or grease has worked

its way in between the clutch lining and

drum, and if it has, wipe it away using oilfree, lead-free gasoline.

■ MAINTENANCE BEFORE STORAGE

• Old fuel left in the carburetor may cause

starting failure. When a series of operation

finished, make sure to empty the fuel tank

and drain the carburetor.

• Check all parts and the functions. If the

failured or damaged parts have been found,

replace them with new ones.

■ GEAR CASE

• The reduction gears are lubricated by

multipurpose, lithium-based grease in the

gear case. Supply new grease every 25

hours of use or more often depending on the

job condition.

• Remove the bolt opposit to the grease nipple

before installing new grease to arrange for

old grease to exit.

■ INTAKE AIR COOLING VENT

• Never touch the cylinder, muffler, or

spark plugs with your bare hands

immediately after stopping the engine.

The engine can become very hot when in

operation, and doing so could result in

severe burns.

• When checking the machine to make sure

that it is okay before using it, check the

area around the muffler and remove any

wood chips or leaves which have

attached themselves to the brushcutter.

Failing to do so could cause the muffler

to become overheated and that in turn

could cause the engine to catch on fire.

Always make sure that the muffler is

clean and free of wood chips, leaves, and

other waste before use.

WARNING

Specifications

7

MODEL CODE Unit BC4350FW

Overall size

Length mm 1845

Width mm 650

Height mm 560

Dry weight Kg 7.8

Engine model ✽ G45L-F

Displacement cc 41.5

Carburetor ✽ Float

Fuel (Mixture ratio) ✽ 50:1 (Gasoline and 2cycle oil)

Fuel tank capacity litter 0.8

Service range rpm 5000~8000

Spark plug ✽ Champion RCJ6Y

Clutch system ✽ Two-shoe Centrifugal-Type

Anti-vibration system

Housing ✽ Yes

Handle-bracket ✽ No

Gearhead

Neck angle deg 60

Reduction ratio ✽ 1.400

Blade rotation ✽ Counter-clockwise

Handle type ✽ Double

Throttle lever ✽ Trigger Type (With Safety-lock)

Standard cutter ✽ 2 Teeth Blade

Harness type ✽ Double

Quick release ✽ Yes

Standard accessories

Fuel-Tank ✽●

Tool-kit ✽●

Owner's manual ✽●

Specifications are subject to change without notice.

• Check the intake air cooling vent and the

area around the cylinder cooling fins after

every 25 hours of use for blockage, and

remove any waste which has attached

itself to the brushcutter. Note that it is

necessary to remove the engine cover

shown in in order to be able to view the

upper part of the cylinder.

If waste gets stuck and causes blockage

around the intake air cooling vent or between

the cylinder fins, it may cause the engine to

overheat, and that in turn may cause

mechanical failure on the part of the

brushcutter.

(1) Cylinder

(2) Intake air cooling vent

■ IMUFFLER

• Inspect periodically, the muffler for loose

fasteners, any damage or corrosion. If

any sign of exhaust leakage is found,

stop using the machine and have it

repaired immediately.

• Note that failing to do so may result in the

engine catching on fire.

WARNING

IMPORTANT

Loading...

Loading...