Page 1

SERVICE MANUAL

Model Series:

Product Type: VCR DVD Combo

Chassis: D35E Combo

Manual Series: VR168

Manual Part #: 923-03485

Model Line: E

Product Year: 2002

General Info ................................................. 1

Service Menu ................................................ 2

Servicing ..................................................... 3

Parts List ..................................................... 4

Diagrams ...................................................... 5

Schematics ................................................... 6

XBV243

CONTENTS

Published March 2002

by Technical Publications

Zenith Electronics Corporation

201 James Record Road

Huntsville, Alabama 35824-1513

Copyright 2002 by Zenith Electronics Corporation

Page 2

PRODUCT SAFETY SERVICING GUIDELINES FOR AUDIO-VIDEO PRODUCTS

A

d

IMPORTANT SAFETY NOTICE

This manual was prepared for use only by properly trained audio-video service

technicians.

When servicing this product, under no circumstances should the original

design be modified or altered without permission from Zenith Electronics

Corporation. All components should be replaced only with types identical to

those in the original circuit and their physical location, wiring and lead dress

must conform to original layout upon completion of repairs.

Special components are also used to prevent x-radiation, shock and fire hazard.

These components are indicated by the letter “x” included in their component

designators and are required to maintain safe performance. No deviations are

allowed without prior approval by Zenith Electronics Corporation.

Circuit diagrams may occasionally differ from the actual circuit used. This way,

implementation of the latest safety and performance improvement changes into

the set is not delayed until the new service literature is printed.

CAUTION: Do not attempt to modify this product in any way. Never perform

customized installations without manufacturer’s approval. Unauthorized

modifications will not only void the warranty, but may lead to property damage

or user injury.

Service work should be performed only after you are thoroughly familiar with

these safety checks and servicing guidelines.

GRAPHIC SYMBOLS

The exclamation point within an equilateral triangle is intended

to alert the service personnel to important safety information in

the service literature.

The lightning flash with arrowhead symbol within an equilateral

triangle is intended to alert the service personnel to the presence

of noninsulated “dangerous voltage” that may be of sufficient

magnitude to constitute a risk of electric shock.

The pictorial representation of a fuse and its rating within an

equilateral triangle is intended to convey to the service personnel

the following fuse replacement caution notice:

CAUTION: FOR CONTINUED PROTECTION AGAINST RISK OF FIRE,

REPLACE ALL FUSES WITH THE SAME TYPE AND RATING AS MARKED

NEAR EACH FUSE.

SERVICE INFORMATION

While servicing, use an isolation transformer for protection from AC line shock.

After the original service problem has been corrected, make a check of the

following:

FIRE AND SHOCK HAZARD

1. Be sure that all components are positioned to avoid a possibility of

adjacent component shorts. This is especially important on items transported to and from the repair shop.

2. Verify that all protective devices such as insulators, barriers, covers,

shields, strain reliefs, power supply cords, and other hardware have been

reinstalled per the original design. Be sure that the safety purpose of the

polarized line plug has not been defeated.

3. Soldering must be inspected to discover possible cold solder joints, solder

splashes, or sharp solder points. Be certain to remove all loose foreign

particles.

4. Check for physical evidence of damage or deterioration to parts and components, for frayed leads or damaged insulation (including the AC cord), and

replace if necessary.

5. No lead or component should touch a high current device or a resistor

rated at 1 watt or more. Lead tension around protruding metal surfaces

must be avoided.

6. After reassembly of the set, always perform an AC leakage test on all exposed

metallic parts of the cabinet (the channel selector knobs, antenna terminals,

handle and screws) to be sure that set is safe to operate without danger of

electrical shock. DO NOT USE A LINE ISOLATION TRANSFORMER DURING THIS

TEST. Use an AC voltmeter having 5000 ohms per volt or more sensitivity in

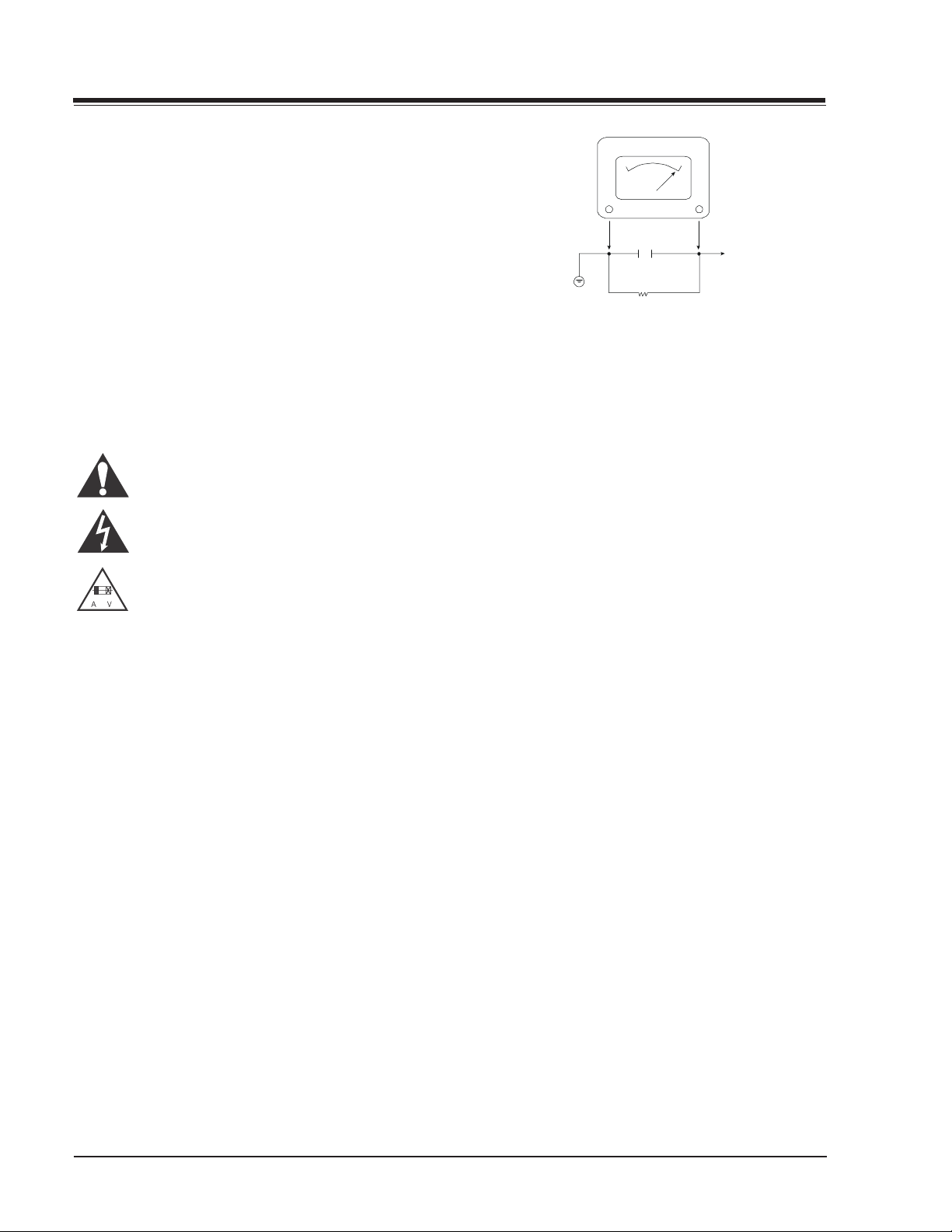

the following manner: Connect a 1500 ohm, 10 watt resistor, paralleled by

a .15 mfd 150V AC type capacitor between a known good earth ground

water pipe, conduit, etc.) and the exposed metallic parts, one at a time.

Measure the AC voltage across the combination of 1500 ohm resistor and

.15 mfd capacitor. Reverse the AC plug by using a non-polarized adaptor

and repeat AC voltage measurements for each exposed metallic part. Voltage

measured must not exceed 0.75 volts RMS. This corresponds to 0.5 milliamp

AC. Any value exceeding this limit constitutes a potential shock hazard and

must be corrected immediately.

.C. Voltmeter

Good Earth Ground

such as the Water

Pipe, Conduit, etc.

0.15uF

1500 OHM

10 WATT

Place this probe

on each expose

metal part.

X-RADIATION

1. Be sure procedures and instructions to all service personnel cover the

subject of x-radiation. The only potential source of x-rays in current TV

receivers is the picture tube. However, this tube does not emit x-rays when

the HV is at the factory-specified level. The proper value is given in the

applicable schematic. Operation at higher voltages may cause a failure of

the picture tube or high-voltage supply and, under certain circumstances

may produce radiation in excess of desirable levels.

2. Only factory-specified CRT anode connectors must be used.

3. It is essential that the service personnel have available an accurate and

reliable high-voltage meter.

4. When the high-voltage circuitry is operating properly, there is no possibility

of an x-radiation problem. Every time a chassis is serviced, the brightness

should be run up and down while monitoring the high voltage with a

meter, to be certain that the high voltage does not exceed the specified

value and that it is regulating correctly.

5. When troubleshooting and making test measurements in a product with a

problem of excessively high voltage, avoid being unnecessarily close to

the picture tube and the high voltage power supply. Do not operate the

product longer than necessary to locate the cause of excessive voltage.

6. Refer to the CRT Anode High Voltage Measurement and Shutdown Adjustment

procedures described in the appropriate text (where used).

IMPLOSION

1. All direct view picture tubes are equipped with an integral implosion

protection system; take care to avoid damage during installation.

2. Use only the recommended factory replacement tubes.

TIPS ON PROPER INSTALLATION

1. Never install any receiver in a closed-in recess, cubbyhole, or closely

fitting shelf space over, or close to, a heat duct, or in the path of heated

air flow.

2. Avoid conditions of high humidity such as: outdoor patio installations

where dew is a factor, near steam radiators where steam leakage is a factor,

etc.

3. Avoid placement where draperies may obstruct venting. The customer

should also avoid the use of decorative scarves or other coverings that

might obstruct ventilation.

4. Wall- and shelf-mounted installations using a commercial mounting kit

must follow the factory-approved mounting instructions. A product mounted

to a shelf or platform must retain its original feet (or the equivalent

thickness in spacers) to provide adequate air flow across the bottom. Bolts

or screws used for fasteners must not touch any parts or wiring. Perform

leakage tests on customized installations.

5. Caution customers against mounting a product on a sloping shelf or in a

tilted position, unless the receiver is properly secured.

6. A product on a roll-about cart should be stable in its mounting to the cart.

Caution the customer on the hazards of trying to roll a cart with small

casters across thresholds or deep pile carpets.

7. Caution customers against using a cart or stand that has not been listed

by Underwriters Laboratories, Inc. for use with its specific model of

television receiver or generically approved for use with TVs of the same or

larger screen size.

8. Caution customers against using extension cords. Explain that a forest of

extensions, sprouting from a single outlet, can lead to disastrous

consequences to home and family.

VR168 - 923-03485 D35E COMBO - SAFETY

i

Page 3

TABLE OF CONTENTS

SECTION 1 SUMMARY 1-1

SPECIFICATIONS ..........................................1-1

KEY TO ABBREVIATIONS ................................1-2

SERVICING PRECAUTIONS ..............................1-3

PACKAGE CONTENTS .....................................1-4

SECTION 2 CHASSIS 2-1

CABINET .................................................... 2-1

EXPLODED DIAGRAM .....................................2-1

SELF DIAGNOSTICS .......................................2-2

CABINET DISASSEMBLY ................................. 2-3

CIRCUIT BOARD DISASSEMBLY........................2-4

SECTION 3 ELECTRICAL 3-1

DVD TROUBLESHOOTING ................................ 3-1

VCR TROUBLESHOOTING .............................. 3-17

SECTION 4 MECHANICAL 4-1

VCR DECK MECHANISM .................................. 4-1

VCR ALIGNMENT ........................................ 4-13

MAINTENANCE/INSPECTION PROCEDURE ......... 4-19

VCR MECHANISM TROUBLESHOOTING ............. 4-23

DVD DECK MECHANISM ............................... 4-29

MECHANISM DISASSEMBLY........................... 4-30

DECK MECHANISM ADJUSTMENT ................... 4-32

SECTION 5 PARTS 5-1

COMPONENT PARTS .......................................... 5-2

SECTION 6 DIAGRAMS 6-1

EXPLODED VIEW ........................................... 6-1

VCR EXPLODED VIEW .....................................6-2

DVD EXPLODED VIEW ..................................... 6-3

MAIN BLOCK DIAGRAM ..................................6-4

POWER BLOCK DIAGRAM ................................ 6-5

TUNER-IF BLOCK DIAGRAM.............................6-6

Y/C BLOCK DIAGRAM ..................................... 6-7

AUDIO BLOCK DIAGRAM ................................. 6-8

HIFI BLOCK DIAGRAM ................................... 6-9

SYSTEM BLOCK DIAGRAM ............................. 6-10

SECTION 7 SCHEMATICS 7-1

POWER SUPPLY CIRCUIT ................................7-1

TUNER/IF CIRCUIT ....................................... 7-2

AV CIRCUIT ................................................. 7-3

HIFI CIRCUIT ..............................................7-4

SYSTEM CIRCUIT .......................................... 7-5

DVD CIRCUIT ...............................................7-6

DRIVE RF CIRCUIT ........................................ 7-7

MPEG CIRCUIT .............................................7-8

AUDIO CIRCUIT............................................7-9

MICRO CIRCUIT.......................................... 7-10

JACKPACK CIRCUIT ..................................... 7-11

VCR PCB LAYOUT ........................................ 7-12

DVD PCB LAYOUT TOP.................................. 7-13

DVD PCB LAYOUT BOTTOM ............................ 7-14

OTHER PCB LAYOUTS ................................... 7-15

WAVEFORMS .............................................. 7-16

VR168 - 923-03485 D35E COMBO - TOC

TOC-1

Page 4

- TOC-2 -

Page 5

section 1 SUMMARY

SUMMARY

SPECIFICATIONS

DVD PART

Power supply ........................................ AC 120 V, 60 Hz

Power .................................................. 23 W

Mass .................................................... 3.0kg(6.6lbs)

External dimensions .............................. 430 x 88 x 247 (W x H x D)

Signal system ....................................... PAL 625/50, NTSC 525/60

Laser ................................................... Semiconductor laser, wavelength 650nm

Frequency range ................................... (digital audio) 4 Hz to 20 kHz

Signal-to-noise ratio ............................. (digital audio) More than 100 dB (EIAJ)

Audio dynamic range ............................. (digital audio) More than 95 dB (EIAJ)

Harmonic distortion .............................. (digital audio) 0.008%

Wow and flutter ....................................Below measurable level (less than +0.001% (W.PEAK) (EIAJ)

Operating Temperature ........................... 5°C (41°F) to 35°C (95°F)

OUTPUTS

Video outputs ...................................... 1.0V (p-p), 75., negative sync., RCA jack x 1

S video outputs .................................... (Y) 1.0V (p-p), 75., negative sync.,Mini DIN 4-pin x 1

(C)0.3V(p-p), 75.

Component video .................................. output (Y) 1.0 V (p-p), 75 ., negative sync., RCA jack x 1

(Pb)/(Pr) 0.7 V (p-p), 75 .

Audio output ....................................... (digital audio) 0.5V (p-p), 75., RCA jack X 1

Audio output ....................................... (optical audio) Optical connector x 1

Audio output ....................................... (analog audio) 2.0Vrms (1kHz,0dB), RCA jack (L,R) x 1

VHS PART

Video Head System ................................ Double azimuth 4 heads, helical scanning

RF Modulator........................................ UHF 28-68 (Adjustable)

Tape format .......................................... Tape width 12.7 mm (0.5 inch)

Timer ................................................... 24 hours display type

*Designs and specifications are subject to change without notice.

*Weight and dimensions shown are approximate.

VR168 - 923-03485 1-1 D35E COMBO - SUMMARY

Page 6

KEY TO ABBREVIATIONS

A

AC

ACC

ADJ

A/E

AFC

AFT

AGC Automatic Gain Control

ALC

AM

AMP

ANT

APC

ASS’Y

AUD

AUTO

AUX

B

B

C

BPF

BW or B/W

C

CAN

CAP

CATV

CBA

CCD

CFG

CH

CHROMA

CLK

CNR

COMB

COMP

CONV

CS

CST

CTL

CUR

CYL

D

dB

DC

DEMOD

DET

DEV

DHP

DIGITRON

DL

DOC

D/V

E

EE

EMP

EP

EQ

ES

F

FB

FBC

FE

FF

FG

FL

FM

F/R

FS

FSC

F/V

FWD

GEN

GND

H

Hz

IC

IF

INS

I/O

L

LD

LECHA

LP

LPF

D

E

F

G

H

I

L

Alternating Current

Automatic Color Control

Adjust

Audio Erase

Automatic Frequency Control

Automatic Fine Tuning

Automatic Level Control

Amplitude Modulation

Amplifier

Antenna

Automatic Phase Control

Assembly

Audio

Automatic

Auxiliary

Base

Bandpass Filter

Black and White

Capacitor, Chroma, Collector

Cancel

Capstan

Cable Television

Circuit Board Assembly

Charge Coupled Device

Capstan Frequency Generator

Channel

Chrominance

Clock

Chroma Noise Redution

Combination

Comb Filter

Comparator

Composite

Compensation

Converter

Chip Select

Cassette

Control

Current

Cylinder

Drum, Digital, Diode, Drain

Decibel

Direct Current

Demodulator

Detector

Deviation

Double High Pass

Digital Display Tube

Delay line

Drop Out Compensator

Dummy Vertical

Emitter

Electric to Electric

Emphasis

Extended Play

Equalizer

Electrostatically Sensitive

Fuse

Feed Back

Feed Back Clamp

Full Erase

Fast Forward

Frequency Generator

Filter

Frequency Modulation

Front/Rear

Frequency Synthesizer

Subcarrier Frequency

Frequency Voltage

Forward

Generator

Ground

High, Horizontal

Hertz

Integrated Circuit

Intermediate Frequency

Insert

Input/Output

Low, Left, Coil

LED

Letter Character

Long Play

Low Pass Filter

SUMMARY

M

MAX

MD

MIC

MIN

MIX

MM

MMV

MOD

MODEM

NR

OSC

OSD

PB

PCB

PG

PLL

P. P

PRE-AMP

PS

PWM

Q

QH

QSR

QTR

QV

R

RE(or RC)

REC

REF

REG

REMOCON

REV

REW

RF

R/P

RTC

S

SH

SHARP

SIF

SLD

S/N

SP

SUB

SW or S/W

SYNC

SYSCON

T

TP

TR

TRK

TRANS

TU

UHF

UNREG

V

VA

VCO

VGC

VHF

VISS

VR

V-SYNC

VTG

VV

VXO

W

WHT

W.O

X-TAL

Y/C

YNR

ZD

N

O

P

Q

R

S

T

U

V

W

X

Y

Z

Maximum

Modulator

Microphone

Minimum

Mixer, Mixing

Monostable, Multivibrator

Mono Multi Vibrator

Modulation, Modulator

Modulator-Demodulator

Noise Reduction

Oscillator

On Screen Display

Playback

Printed Circuit Board

Pulse Generator

Phase Locked Loop

Peak-to-Peak

Preamplifier

Phase Shift

Pulse Width Modulation

Transistor

Quasi Horizontal

Quick Setting Record

Quick Timer Record

Quasi Vertical

Resistor, Right

Remocon, Receiver

Recording

Reference

Regulated, Regulator

Remote Control(unit)

Reverse

Rewind

Radio Frequency

Record/Playback

Reel Time Counter

Serial

Shift

Sharpness

Sound Intermediate Frequency

Side Locking

Signal to Noise Ratio

Standard Play

Subtract, Subcarrier

Switch

Synchronization

System Control

Coil

Test Point

Transistor

Tracking

Transformer

Tuner,Take-up

Ultra High Frequency

Unregulated

Volt, Vertical

Always Voltage

Voltage Controlled Oscillator

Voltage Gain Control

Very High Frequency

VHS Index Search

Variable Resistor or Volume

Vertical Synchronization

Voltage

Voltage to Voltage

Voltage X-tal Oscillator

Watt

White

With out

Crystal

Luminance/Chrominance

Luminance Noise Reduction

Zener Diode

VR168 - 923-03485 1-2 D35E COMBO - SUMMARY

Page 7

SUMMARY

SERVICING PRECAUTIONS

CAUTION: Before servicing the product covered by this

service data and its supplements and addends, read and

follow the SAFETY PRECAUTIONS.

NOTE: if unforeseen circumstances create conflict between

the following servicing precautions and any of the

safety precautions in this publication, always follow

the safety precautions.

GENERAL SERVICING PRECAUTIONS

1. Always unplug the product AC power cord from the

AC power source before:

(1) Removing or reinstalling any component, circuit

board, module, or any other assembly.

(2) Disconnecting or reconnecting any internal elec-

trical plug or other electrical connection.

(3) Connecting a test substitute in parallel with an

electrolytic capacitor.

CAUTION: A wrong part substitution or incorrect polarity

installation of electrolytic capacitors may result in

an explosion hazard.

2. Do not spray chemicals on or near this product or

any of its assemblies.

3. Unless specified otherwise in this service data, clean

electrical contacts by applying an appropriate contact cleaning solution to the contacts with a pipe

cleaner, cotton-tipped swab, or comparable soft applicator. Unless specified otherwise in this service

data, lubrication of contacts is not required.

4. Do not defeat any plug/socket B+ voltage interlocks

with which instruments covered by this service

manual might be equipped.

5. Do not apply AC power to this product and/or any of

its electrical assemblies unless all solid-state device

heat sinks are correctly installed.

6. Always connect the test instrument ground lead to

the appropriate ground before connecting the test

instrument positive lead. Always remove the test instrument ground lead last.

INSULATION CHECKING PROCEDURE

Disconnect the attachment plug from the AC outlet and

turn the power on. Connect an insulation resistance meter

(500V) to the blades of the attachment plug. The

insulation resistance between each blade of the

attachment plug and accessible conductive parts should

be more than 1Mohm. Accessible conductive parts

include metal panels, input terminals, earphone jacks,

etc.

ELECTROSTATICALLY SENSITIVE (ES) DEVICES

Some semiconductor (solid state) devices can be

damaged easily by static electricity. Such components

commonly are called Electrostatically Sensitive (ES)

Devices. Examples of typical ES devices are integrated

circuits and some field effect transistors and

semiconductor chip components. The following

techniques should be used to help reduce the incidence

of component damage caused by static electricity.

1. Immediately before handling any semiconductor component or semiconductor-equipped assembly, drain

off any electrostatic charge on your body by touching a known earth ground. Alternatively, obtain and

wear a commercially available discharging wrist strap

device, which should be removed for potential shock

reasons prior to applying power to the unit under

test.

2. After removing an electrical assembly equipped with

ES devices, place the assembly on a conductive surface such as aluminum foil, to prevent electrostatic

charge buildup or exposure of the assembly.

3. Use only a grounded-tip soldering iron to solder or

unsolder ES devices.

4. Use only an anti-static solder removal device. Some

solder removal devices not classified as “anti-static”

can generate electrical charges sufficient to damage

ES devices.

5. Do not use freon-propelled chemicals. These can generate an electrical charge sufficient to damage ES

devices.

6. Do not remove a replacement ES device from its protective package until immediately before you are

ready to install it. (Most replacement ES devices are

packaged with leads electrically shorted together by

conductive foam, aluminum foil, or comparable conductive material).

7. Immediately before removing the protective material from the leads of a replacement ES device, touch

the protective material to the chassis or circuit assembly into which the device will be installed.

Caution: Be sure no power is applied to the chassis or circuit,

and observe all other safety precautions.

8. Minimize bodily motions when handling unpackaged

replacement ES devices. (Normal harmless motion such

as the brushing together of your clothes fabric or

the lifting of your foot from a carpeted floor can

generate static electricity sufficient to damage an

ES device.)

VR168 - 923-03485 1-3 D35E COMBO - SUMMARY

Page 8

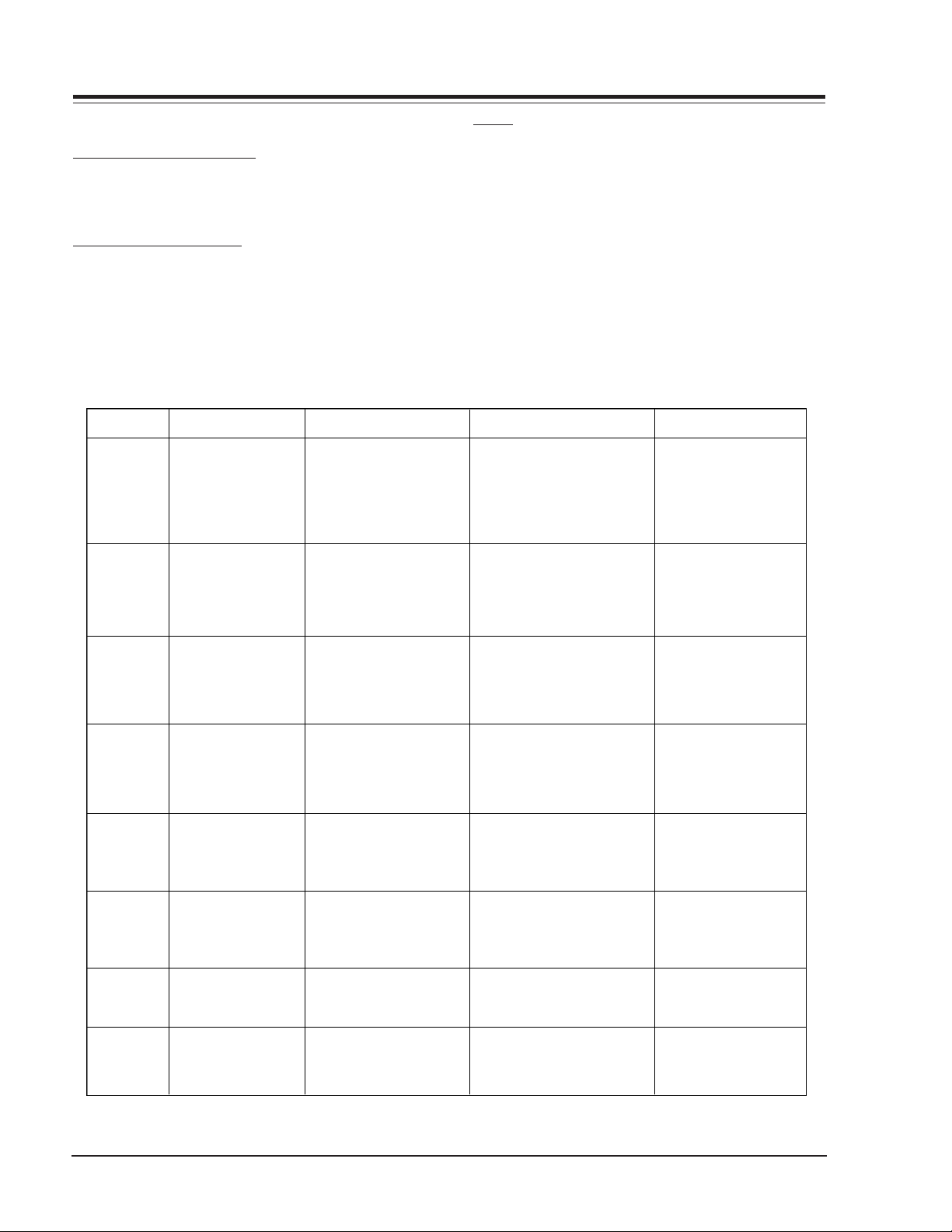

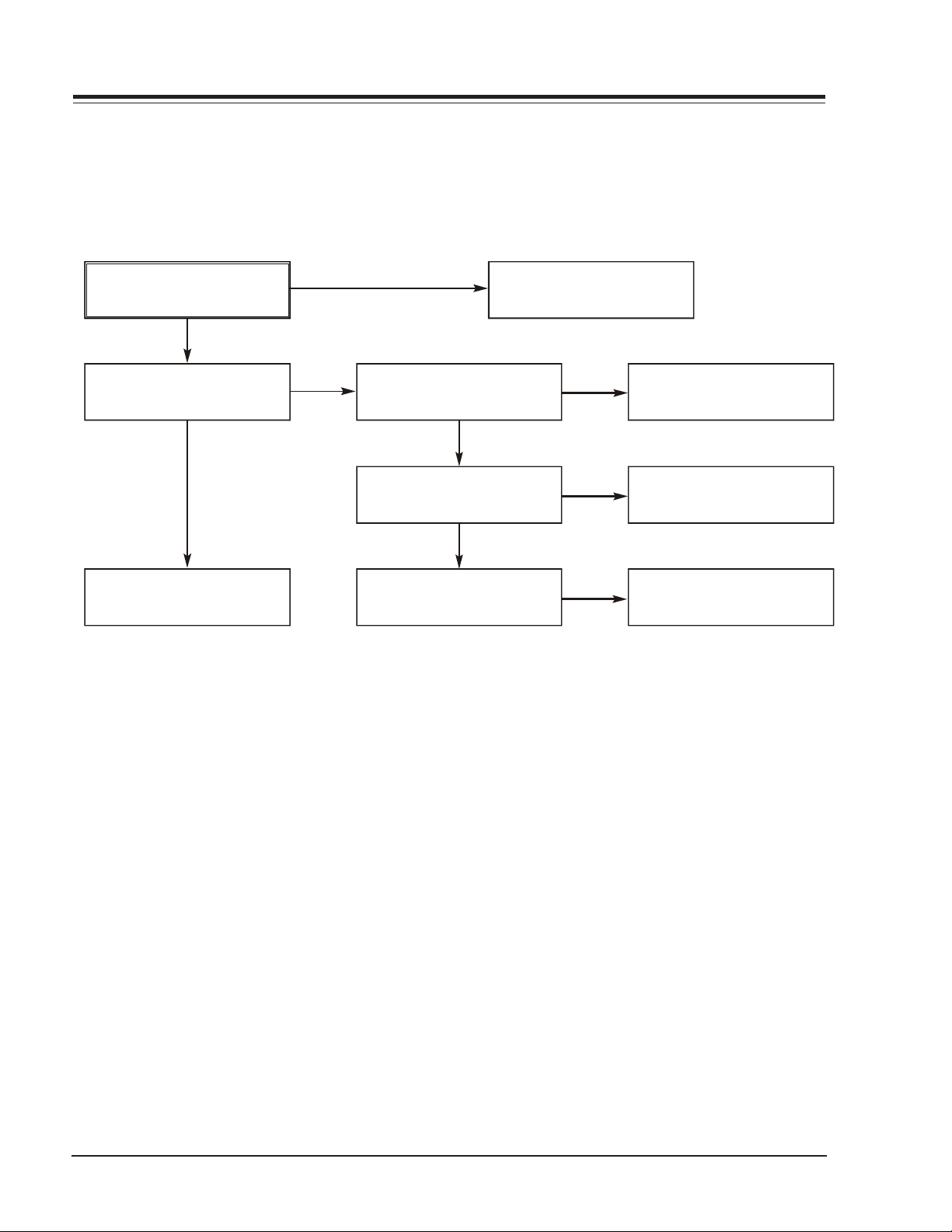

PACKAGE CONTENTS

SUMMARY

BATTERY

REMOCON

PACKING

CABLE SET ASS'Y

RF CABLE

PHONO CORD 1WAY

PHONO CORD 2WAY

OWNER'S MANUAL

PAC KIN G S HE ET

PAC KI NG

BOX CARTON

OPTIONAL PARTS

VR168 - 923-03485 1-4 D35E COMBO - SUMMARY

Page 9

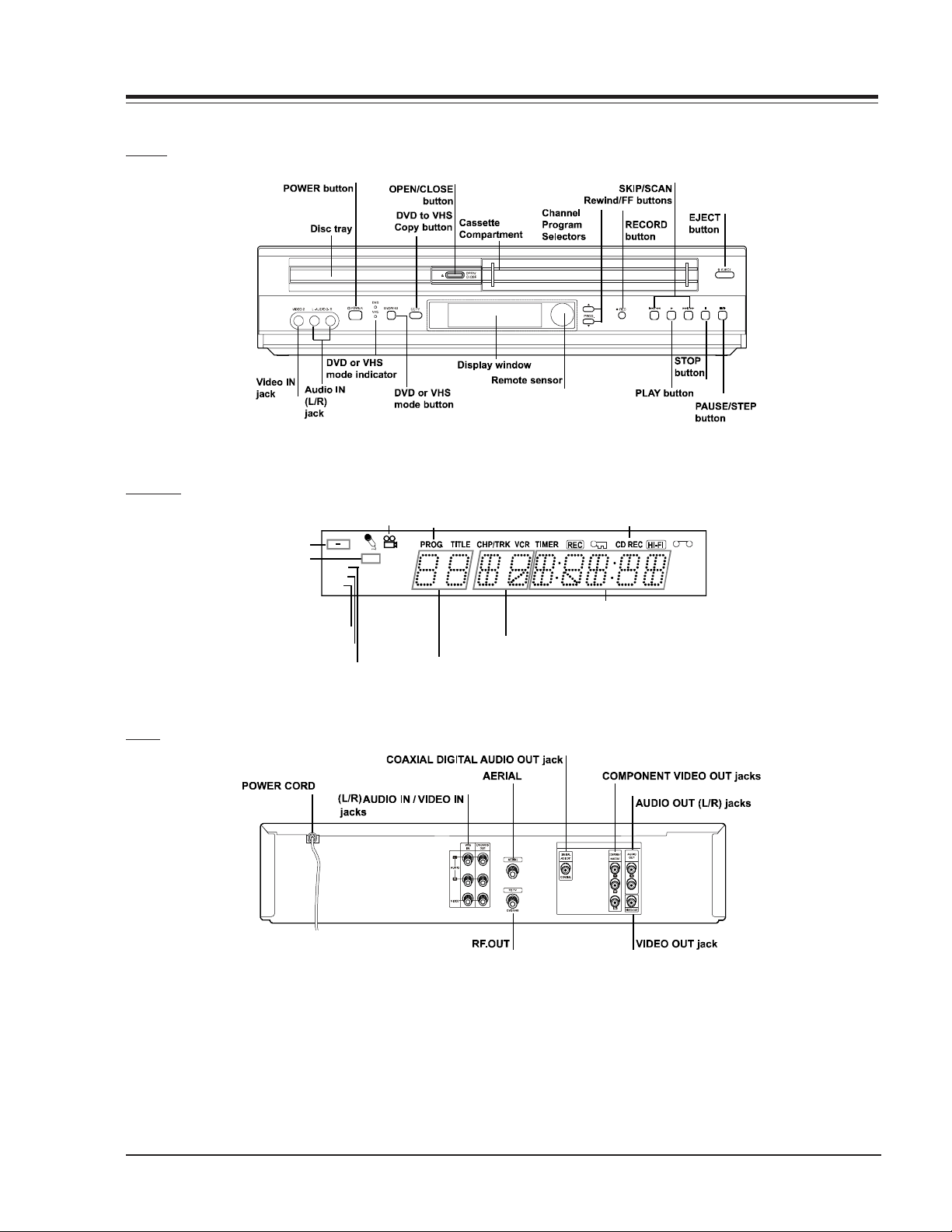

section 2 CHASSIS

Angle icon indi

s

CABINET

FRONT

DISPLAY

CHASSIS

BACK

Repeat playback

mode indicators

Stereo indicator

DVD indicator

Video CD indicator

AB

VCD

DVD

ST

ALL MP3

-R W

BIL PR

SAP CH

cator

PROGRAM indicator

Title number indicator

CD REC indicator

AM

SP

LP

EP

Total playing time/elapsed time indicator

Chapter/Track number indicator

EXPLODED DIAGRAM

See page 6-1 for a detailed exploded view.

VR168 - 923-03485 2-1 D35E COMBO - CHASSIS

Page 10

CHASSIS

SELF DIAGNOSTICS

SELF DIAGNOSTIC OVERVIEW

Provides service personnel a convenient service aid by a

visual display of error codes generated by the

microcomputer and displayed on the digitron.

OPERATIONAL PROCEDURE

With the remote control, press and hold the “MENU” key

until the word MENU appears in the display. Then press

4, 3, 2, 1 and then “ENTER”. The self diagnostic procedure

will sequence through the 8 step procedure. If an error

is detected, a code number will flash approximately 5

times and then return to its initial mode of operation.

DISPLAY

“D1”

“D2”

DESCRIPTION INPUT SIGNAL CIRCUIT STATUS SERVICE POINTS

•Tape Loading

Error

•Tape Loading

Error

•Mode SW

Pos. S1, S2, S3, S4

Pins: 25, 24, 23, 22

•Load Motor

Pins: 60 (+)

Pins: 59 (-)

•Mode SW

Pos. S1, S2, S3, S4

Pins: 25, 24, 23, 22

•Load Motor

Pins: 60

NOTES

1. Error codes will not be stored. The program must be

re-initialized as described in the preceding step.

2. Pin numbers refer to IC501 microcomputer, unless

otherwise stated.

•Mode SW Position not

changed within 6 seconds

after cassette loading

attempt.

•Mode SW Position not

changed within 6 seconds

after cassette loading

attempt.

•Loading motor,

mech problems,

gears, timing

•Mode SW Position

•Mode SW Contacts

“D3”

“D4”

“D5”

“D6”

“D7”

“F1”

•CST Loading

Error

•CST Loading

Error

•DRUM Motor

Error

•Reel Rotational

Error

•Capstan Motor

Error

•Tuner Signal

Input

•Mode SW

Pos. S1, S2, S3, S4

Pins: 25, 24, 23, 22

•Load Motor

Pins: 60

•Mode SW

Pos. S1, S2, S3, S4

Pins: 25, 24, 23, 22

•Load Motor

Pins: 60

•Head SW(30Hz)

Pulses Pin18

•Supply Take-up Reel

Pulses, Pins 79, 80

•Capstan FG Pulses

•CVin Pin 56

•Mode SW Position not

changed within 6 seconds after cassette

loading attempt.

•CST SW must be activated within 3 seconds, otherwise unit shut down will

occur.

•Drum Motor (Slow Start)

•Motor must be up to

speed within 3 seconds

of operation

•CFG Signal present, but

take-up pulses are missing.

(Capstan motor running)

•No CFG Signal

•Composite Sync not

detected, RF or Video

Signal loss.

•Mode SW Contacts

•CST SW or

Connector Contacts

•Drum Motor and

Control Circuits

•Capstan belt

•Idler and reel gears

damaged

•ST/U Sensors

•Capstan control ckt.

•Motor assy.

•IC501 Ckt.

•Loss of C-sync

Tuner Line

Video Path

VCR should be in PB mode for D5, D6 and D7. Stop mode for F1, cassette loading D3, D4 and tape loading D1 and D2.

VR168 - 923-03485 2-2 D35E COMBO - CHASSIS

Page 11

CHASSIS

CABINET DISASSEMBLY

CAUTION BEFORE SERVICING

Electronic parts are susceptible to static electricity and

may easily be damaged. Follow proper grounding

procedures.

Many screws are used inside the unit. To prevent missing,

dropping, etc. of the screws, always use a magnetized

screw driver in servicing. Several kinds of screws are used

and some of them need special cautions. That is, take

care of the tapping screws securing molded parts and

fine pitch screws used to secure metal parts. If they are

used improperly, the screw holes will be easily damaged

and the parts can not be fixed.

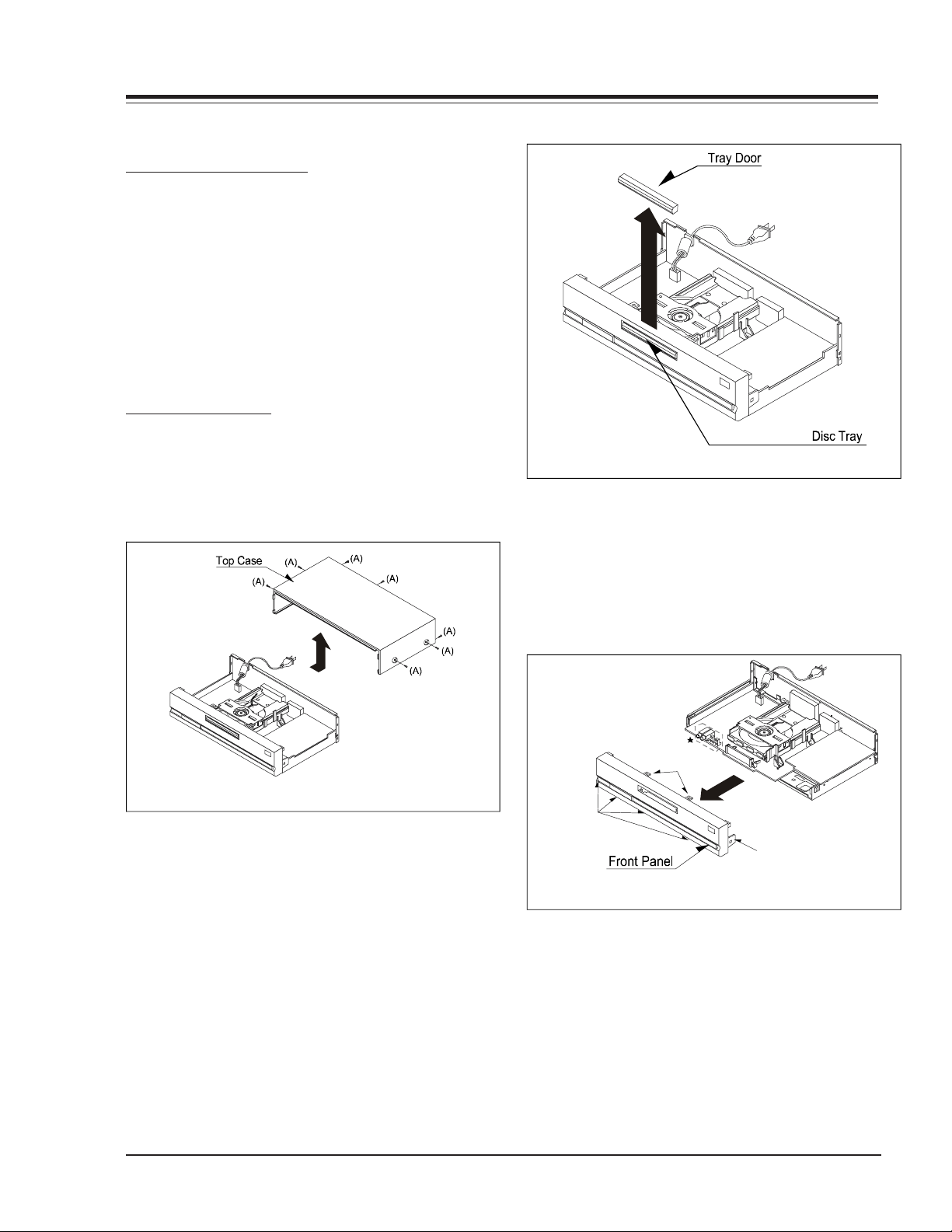

CABINET DISASSEMBLY

TOP CASE

1. Remove 7 screws (A). (See Fig. 2-1)

2. Pull the top case back and up, in the direction of

the arrow, to disengage it from the front panel.

Fig. 2-2

FRONT PANEL

1. Eject the disc tray. (See Fig. 2-2)

2. Remove the tray door. (See Fig. 2-2)

3. Depress the 7 embossed tabs (see fig. 2-3) and

remove the Front panel.

Tabs

Fig. 2-1

Tabs

TRAY DOOR

1. Eject the disc tray.

2. Lift up the tray door in the direction of the arrow.

VR168 - 923-03485 2-3 D35E COMBO - CHASSIS

Fig. 2-3

Tab

Page 12

CHASSIS

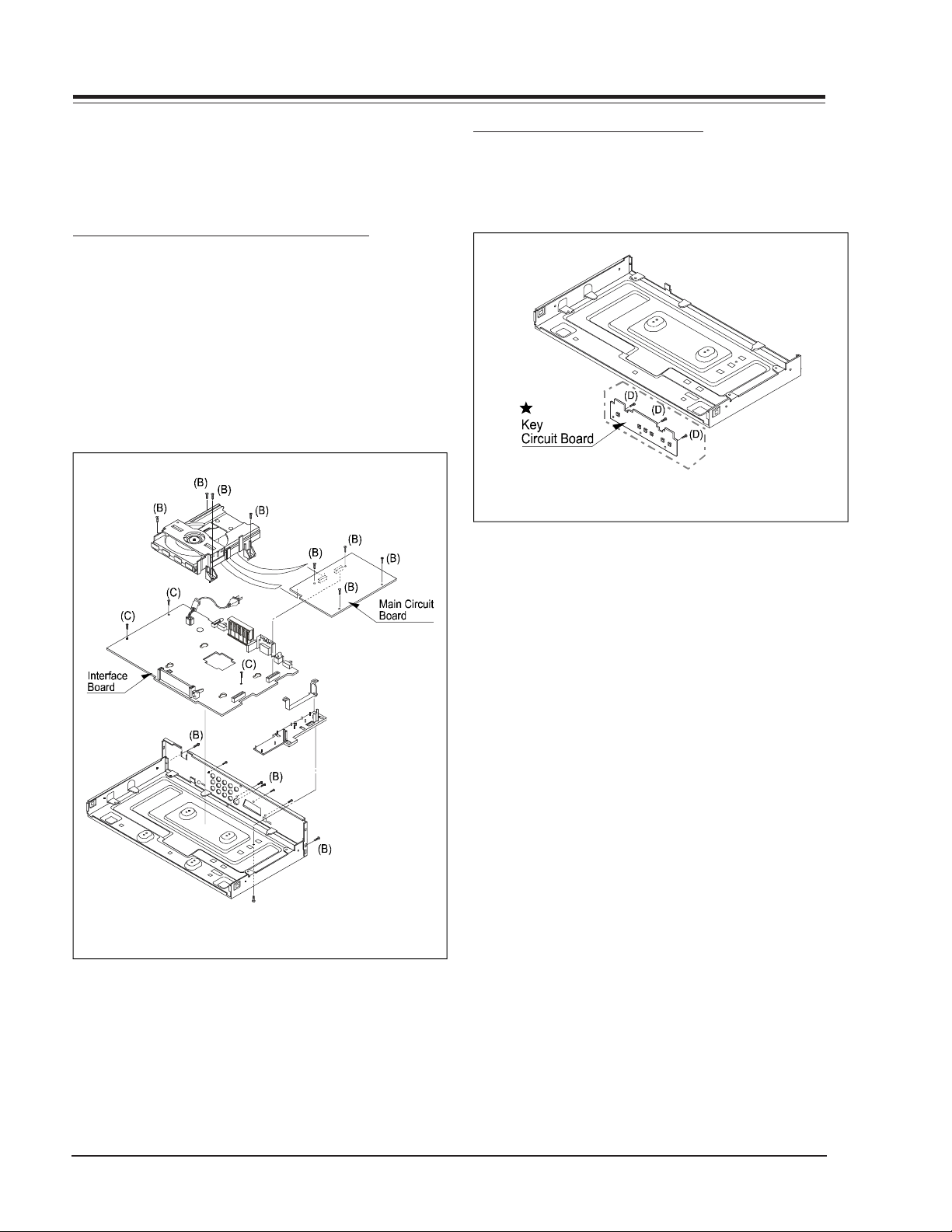

CIRCUIT BOARD DISASSEMBLY

Note: Before removing the main circuit board, be sure

to short circuit the laser diode output land. After

replacing the main circuit board, open the land after

inserting the flexible connector.

MAIN CIRCUIT BOARD AND INTERFACE BOARD

1. Remove the top case. (See Fig. 2-1)

2. Remove 14 screws (B).

3. Remove the Deck from the Main Circuit Board.

4. Remove the Main Circuit Board from the Interface

Board.

5. Remove 2 screws (C).

6. Remove the Interface Board from the chassis.

DIGITRON AND KEY CIRCUIT BOARD

1. Remove the front panel. (See Fig. 2-3)

2. Release 3 screws (D), and remove the digitron circuit board.

Fig. 2-5

Fig. 2-4

VR168 - 923-03485 2-4 D35E COMBO - CHASSIS

Page 13

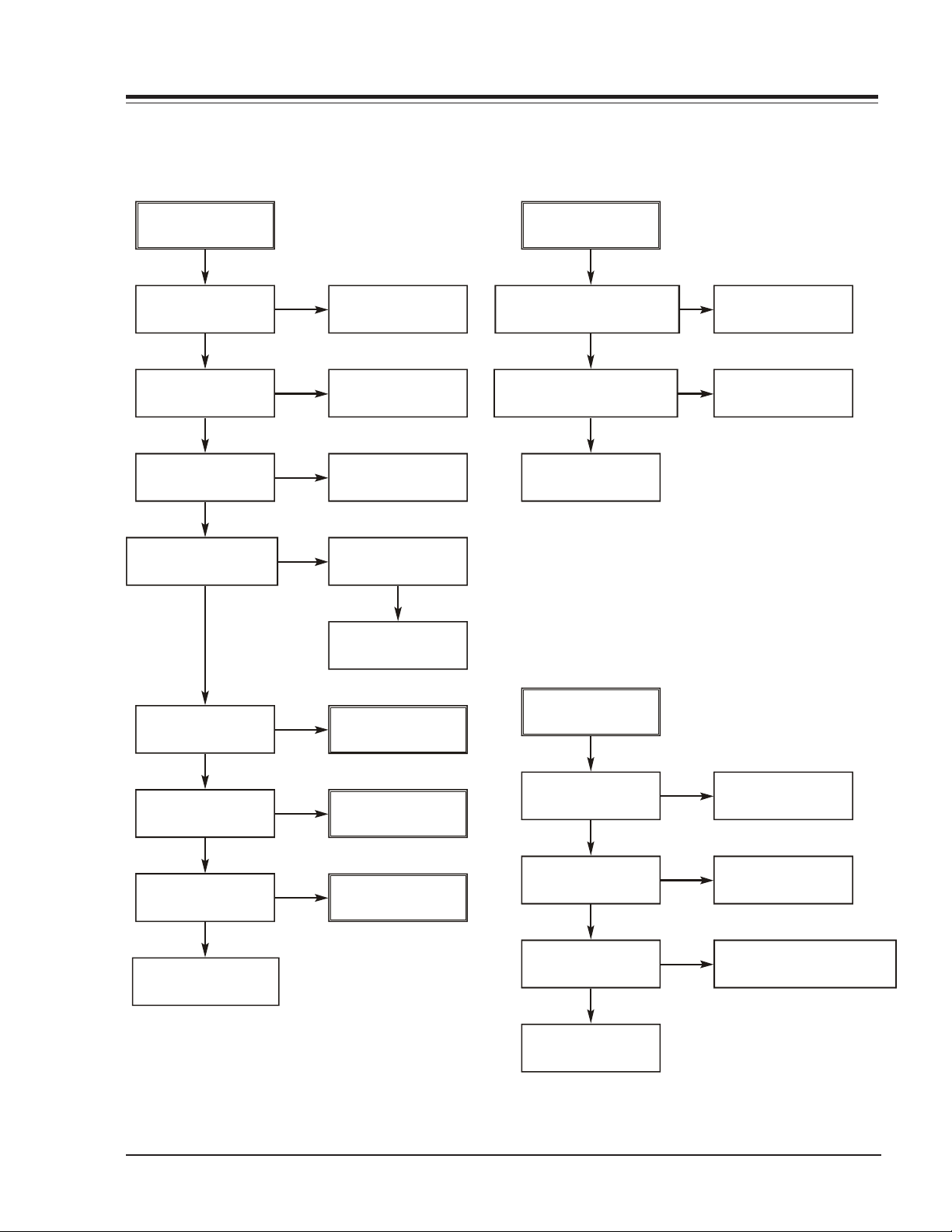

SECTION 3 Electrical

T

TROUBLESHOOTING

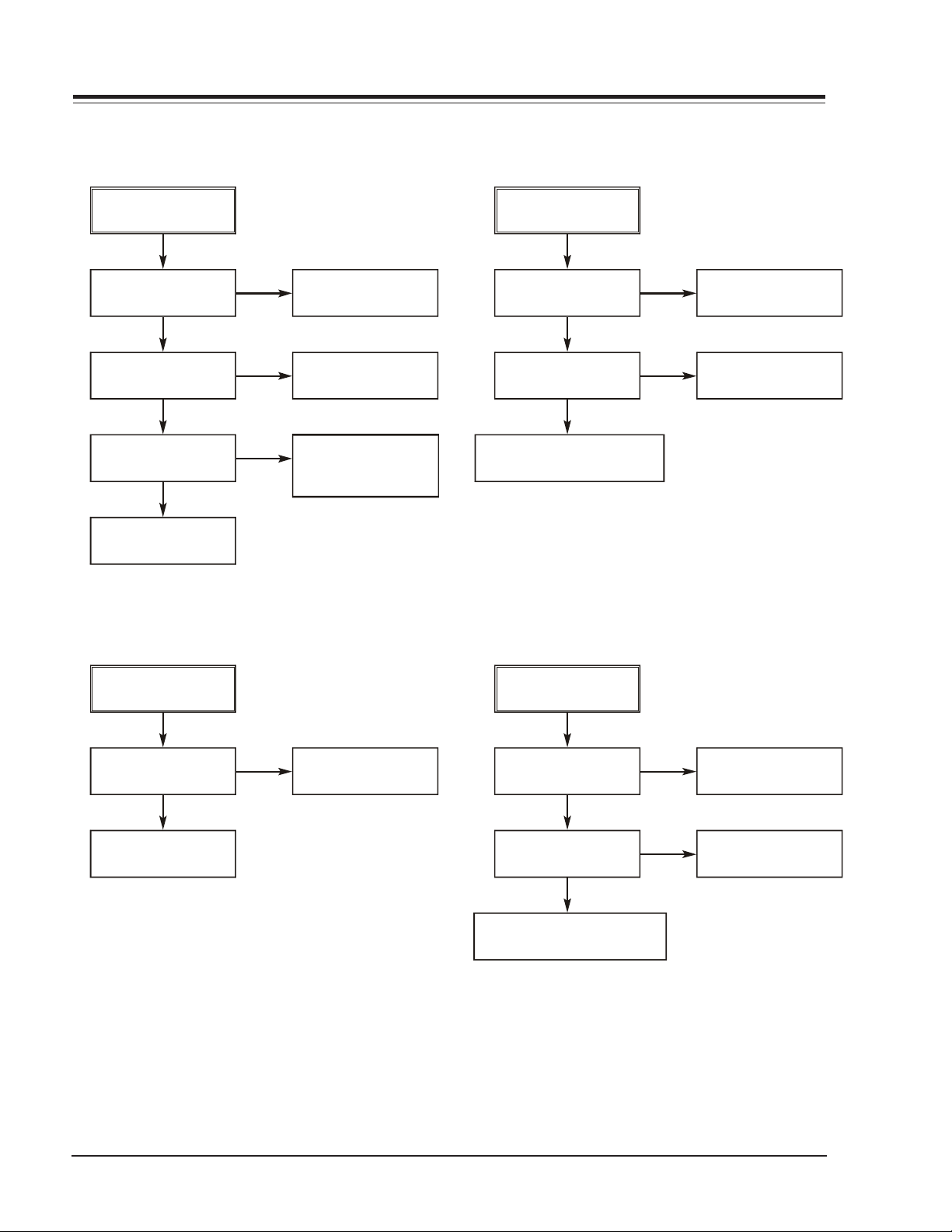

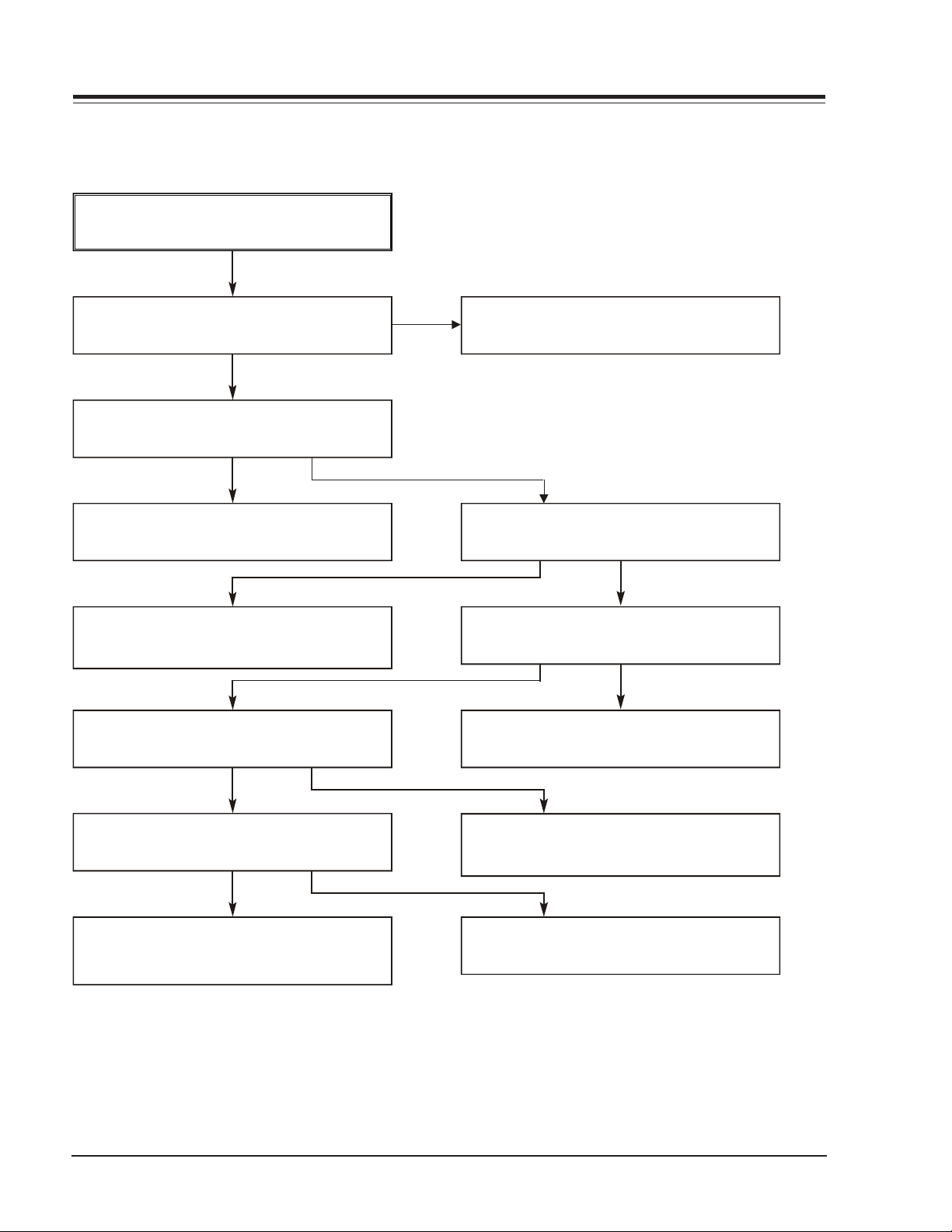

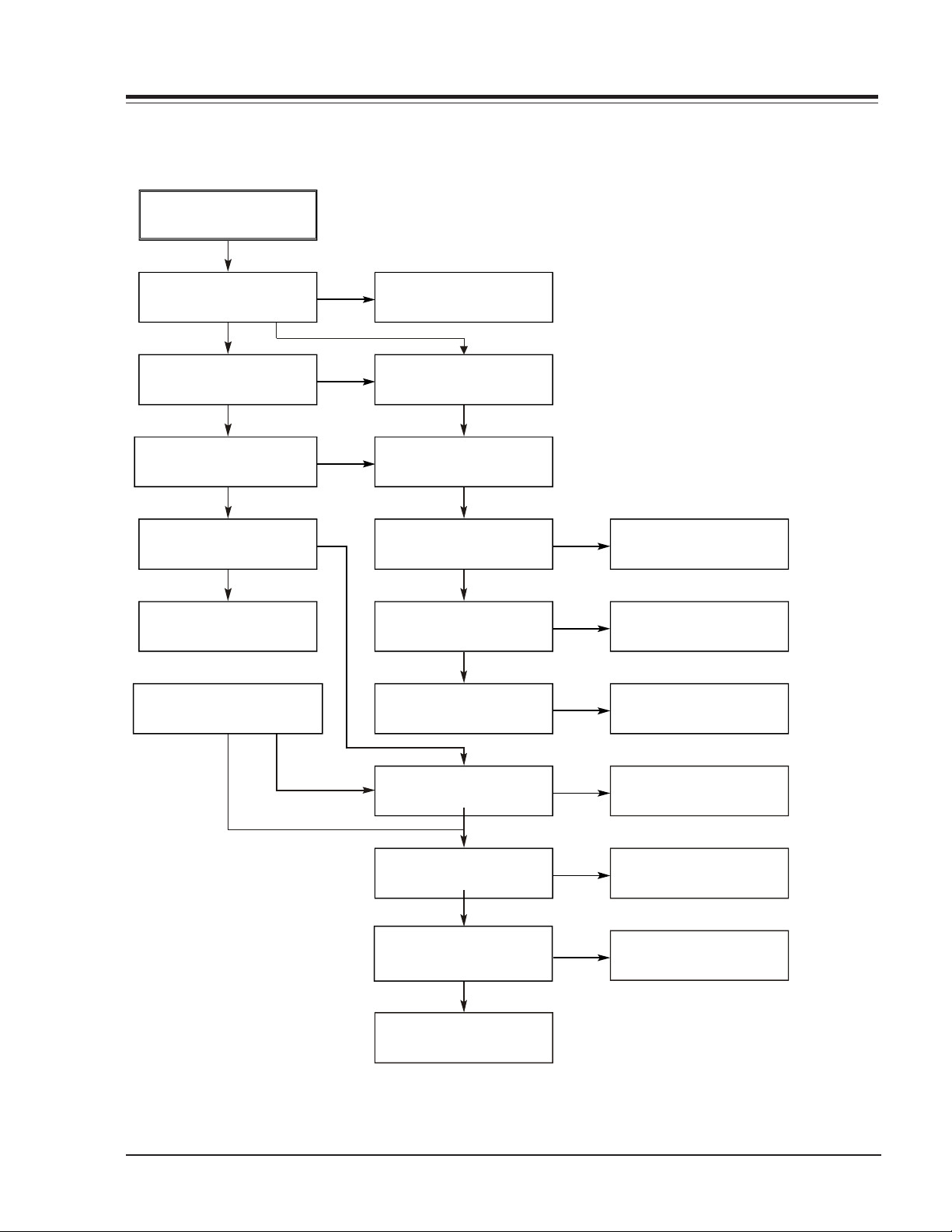

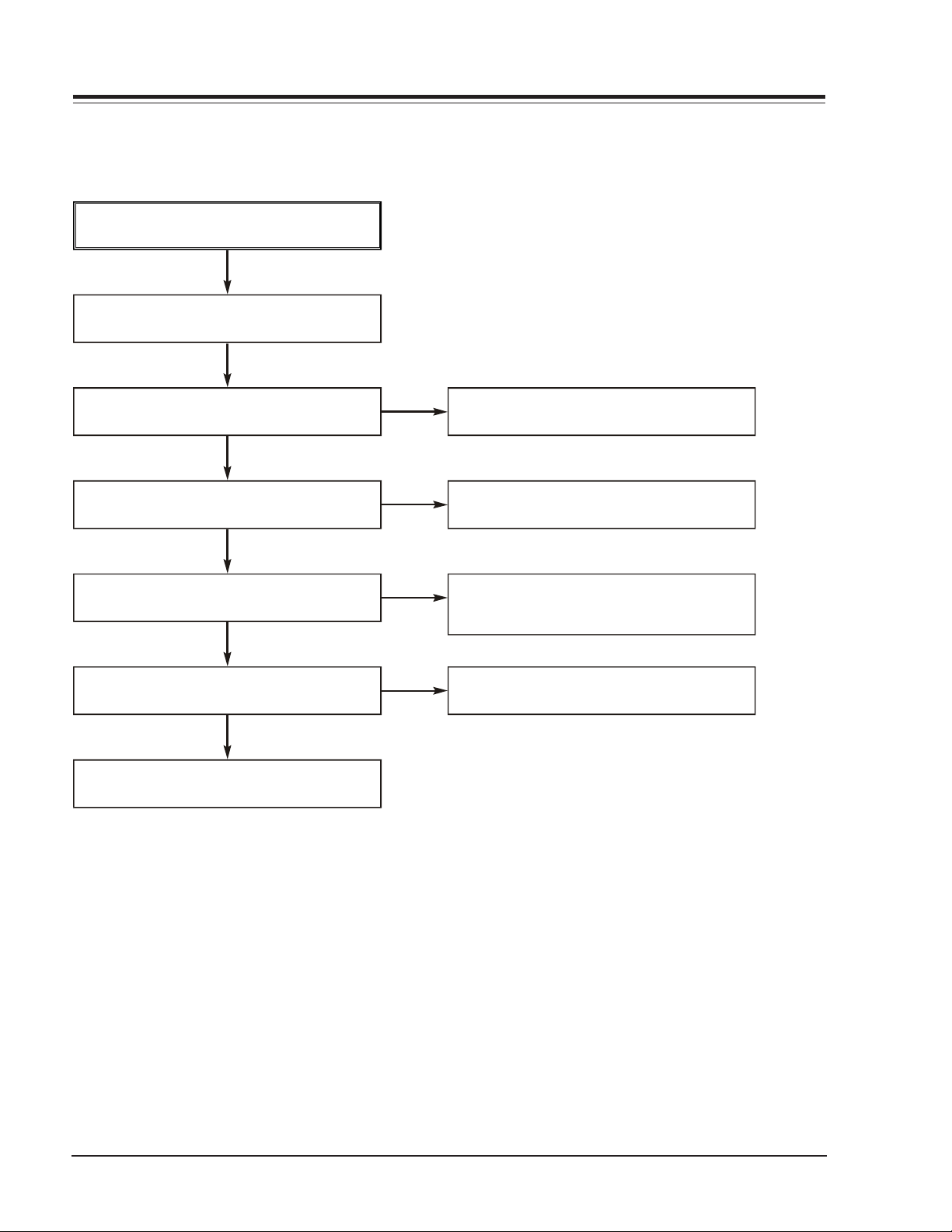

1. Power(SMPS) CIRCUI

ELECTRICAL

(1) No 5.3VA (SYS/Hi-Fi/TUNER)

NO 5.3VA.

YES

Is F101 normal?

YES

Is R101

normal?

YES

Is Bd101

normal?

YES

Is Vcc (8.5~21V)

supplied to IC101 Pin7?

YES

NO

NO

NO

NO

Replace F101.

Replace

BD101.

Replace R101.

Is D102

normal?

N O

(2) No 12VA (TO CAP, DRUM MOTOR)

NO 12VA.

YES

Is the Vcc (13V) supplied to (+)

terminal in D115 and D117?

YES

Is the Vcc (12V) supplied to (-)

terminal in D115 and D117?

YES

Check or Replace

the Motor Vcc.

NO

NO

Check or Replace

D110.

Replace D115,

Is the D112 normal?

YES

Is there about 2.5V

at the IC102 Vref?

YES

Is D110 normal?

YES

Check the Main PCB

5.3VA/5.0V Line short?

Check or Replace

D102.

(3) No 5.2V (SYS/Hi-Fi/TUNER)

N O

N O

N O

Replace D112.

Replace IC102.

Replace the D110.

NO 5.2VA.

YES

Is 5.3VA put into

Q116 Emitter?

YES

Is Q115 Base

“H”?

YES

Is about 5V put into

Q116 Base?

YES

Check or Replace

Q115/Q116

NO

NO

NO

5.3VA Line Check.

Check the Power

Control.

Check or Replace Q115,

R160, R161, R162, D122.

VR168 - 923-03485 3-1 D35E COMBO - ELECTRICAL

Page 14

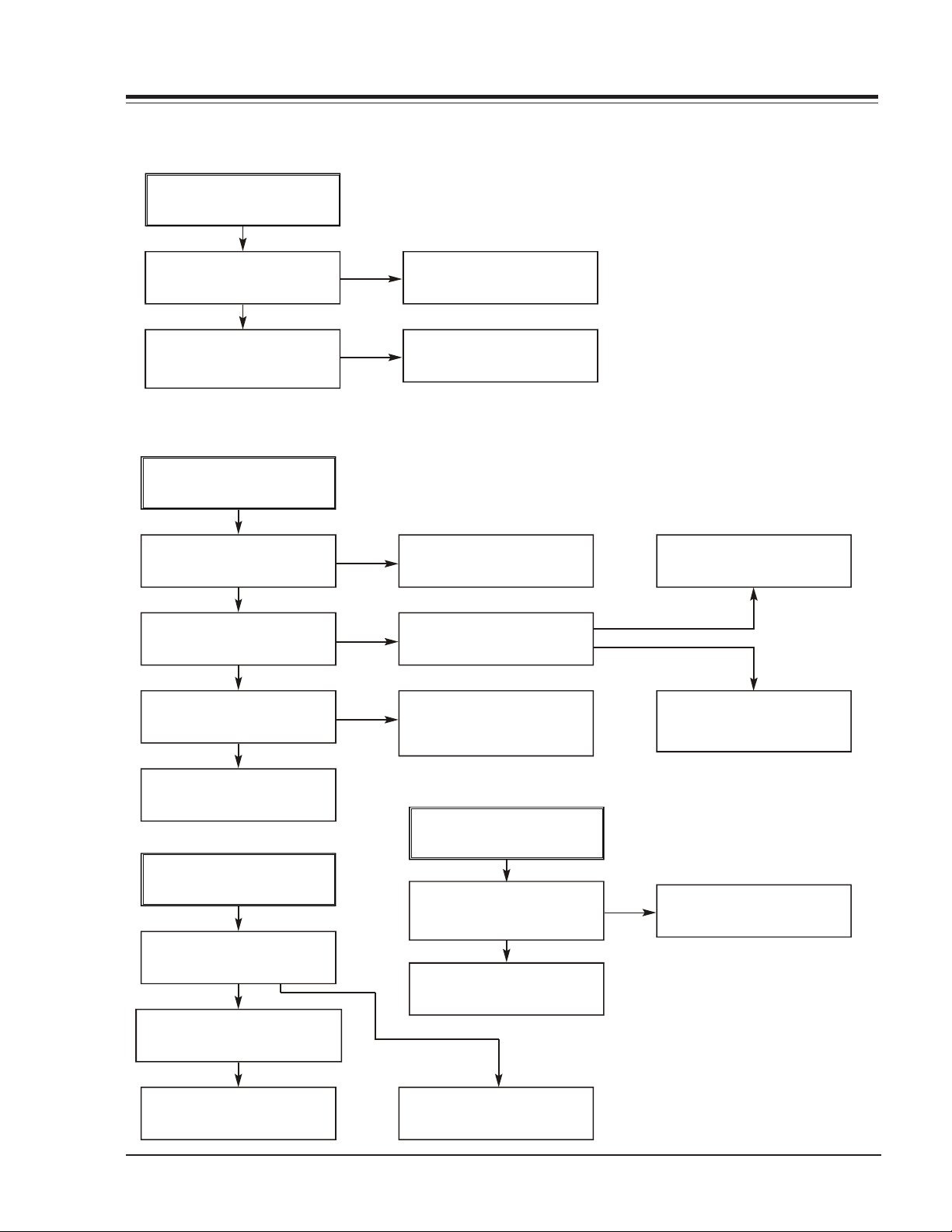

TROUBLESHOOTING (CONTINUED)

ELECTRICAL

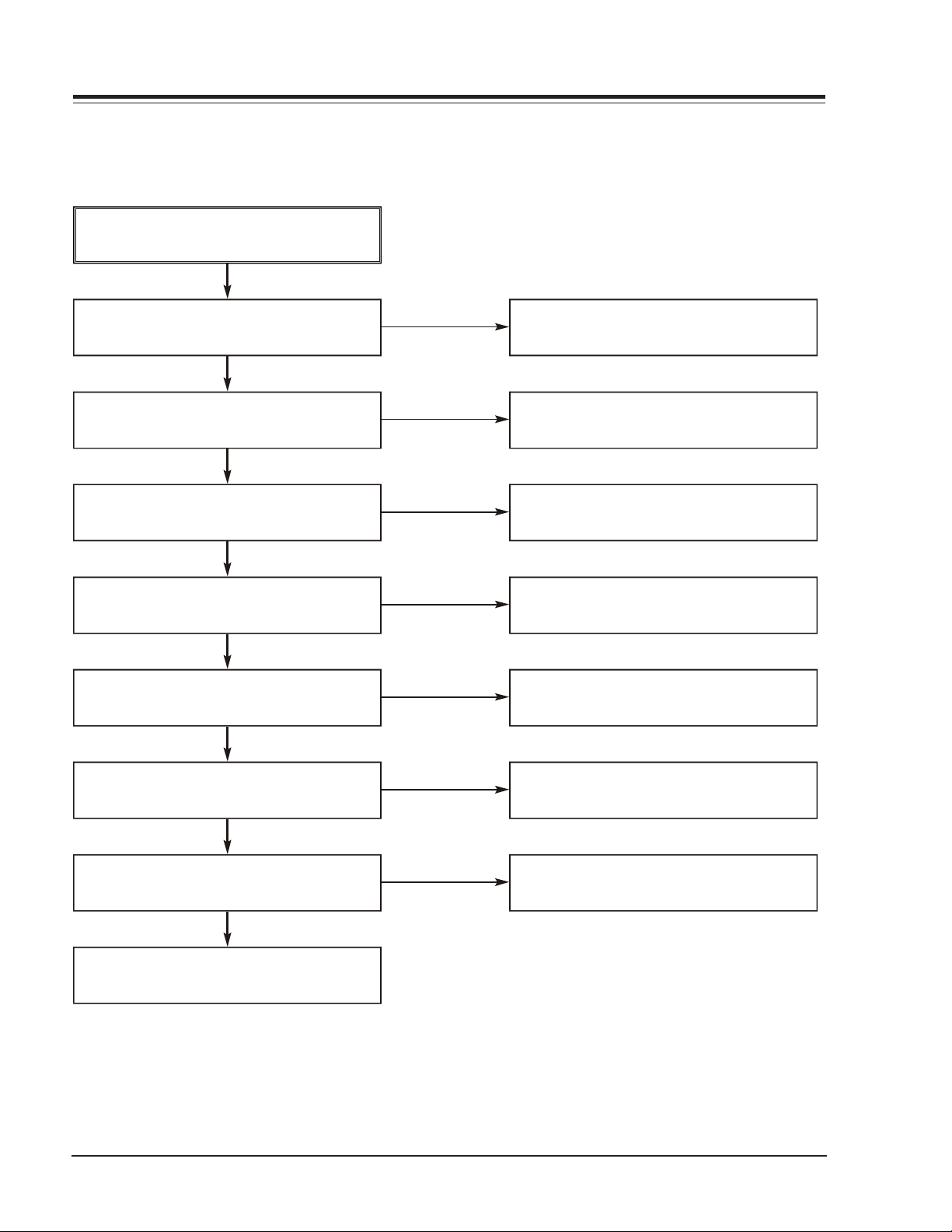

(4) No 5V (TO DVD)

NO 5V.

YES

Is 5.3VA present on

Q113 Emitter?

YES

Is the Q115 Base

“H”?

YES

Is about 5V present on

Q113 Base?

YES

Check or Replace

Q113/Q115

NO

NO

NO

5.3VA Line Check.

Check the Power

Control.

Check or Replace

Q115, R157, R158,

R159, D121.

(5) No REG 5V (AVCP)

No REG 5V.

YES

Is 5.3VA present on

Q117 Collector?

YES

Is 33V present on

Q117 Base?

YES

Check or Replace Q117,

R167, ZD105, C162.

NO

NO

5.3VA Line Check.

Check 33V Line.

(6) No 33V (TUNER)

No 33V.

YES

Is Q115 Base “H”?

YES

Check or Replace

Q114, R154, R155.

(7) No REG 12V

No REG 12V.

YES

N O

Check the Power

Control.

Is 13V present on

Q112 Collector?

YES

Is 33V present on

Q112 Base?

YES

Check or Replace Q112,

ZD103, R153, C151.

NO

NO

Check or Replace

D110.

Check 33V Line.

VR168 - 923-03485 3-2 D35E COMBO - ELECTRICAL

Page 15

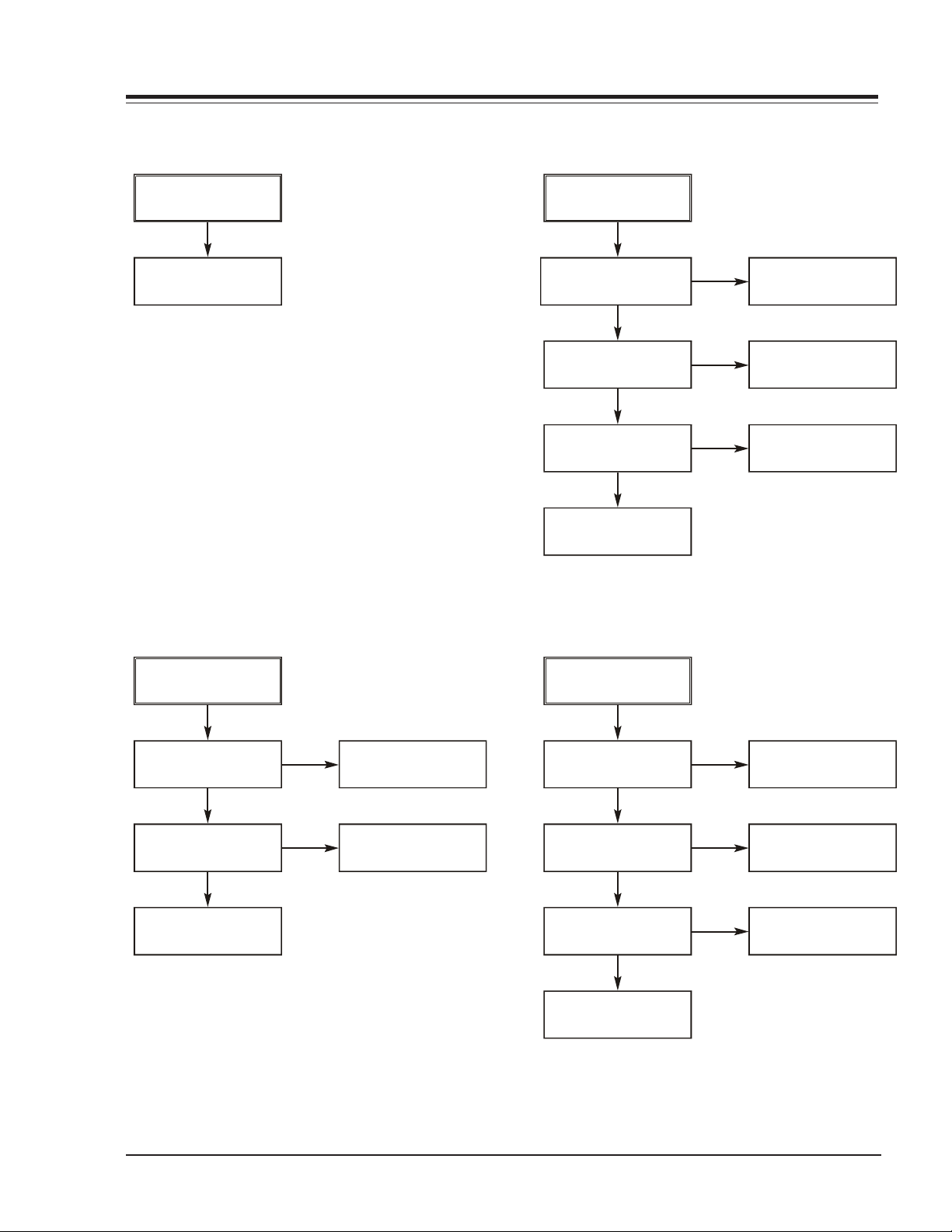

(8)

TROUBLESHOOTING (CONTINUED)

No -29VA.

ELECTRICAL

(9) No 8VA

No -29VA.

YES

Check or Replace

D108.

(10) No 3.3VA

NO 8VA.

YES

Is Vcc (13V) supplied to

(+) terminal in D114?

YES

Is Vcc (12V) supplied

to IC106 Pin1?

YES

Is Q115 Base

“H”?

YES

Check or Replace

IC106, R170, C154.

(11) No 2.5V

NO

NO

NO

Check or Replace

D110.

Check or Replace

D114.

Check the Power

Control.

No 3.3V

YES

Is Vcc (4V) supplied

to IC103 Pin1?

YES

Is the Q115 Base

“H”?

YES

Check or Replace

IC103, R156, C153.

NO 2.5VA.

YES

N O

N O

Check or Replace

D111.

Check the Power

Control.

Is Vcc (4V) supplied

to IC104 Pin1?

YES

Is the Q115 Base

“H”?

YES

Is Vcc (3.3V) supplied

to IC104 Pin2?

YES

Check or Replace

D119, C159.

NO

NO

NO

Check or Replace

D111.

Check the Power

Control.

Check or Replace

Ic104.

VR168 - 923-03485 3-3 D35E COMBO - ELECTRICAL

Page 16

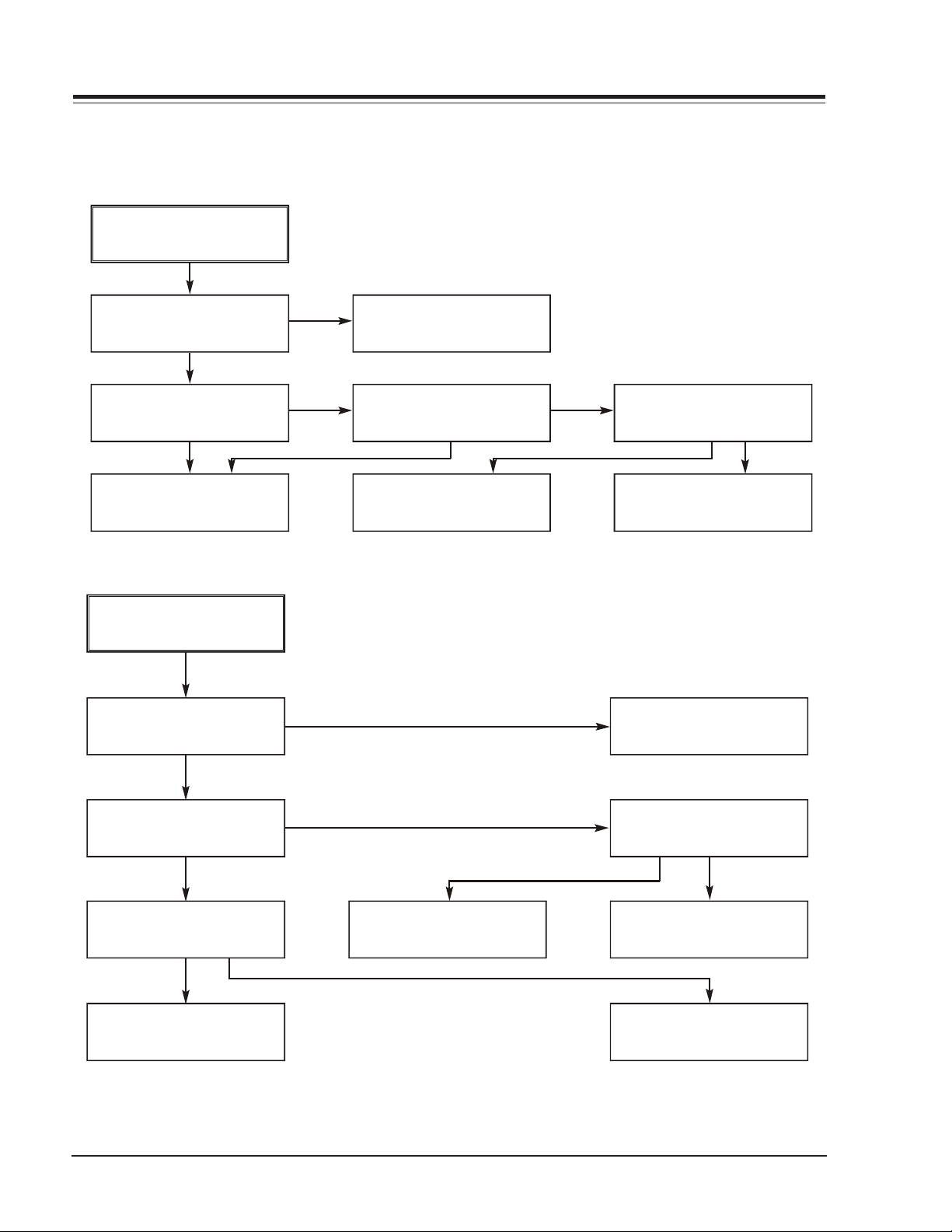

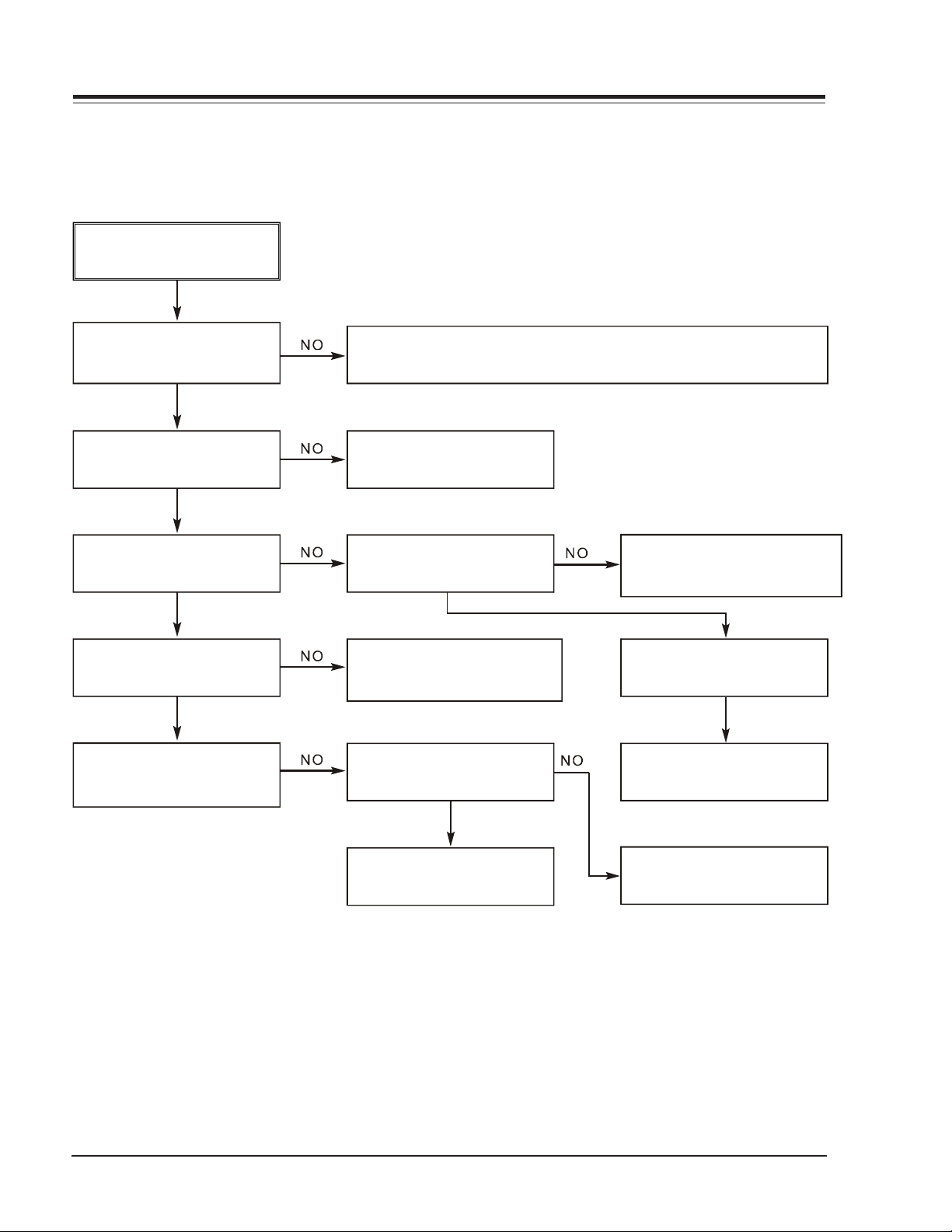

TROUBLESHOOTING (CONTINUED)

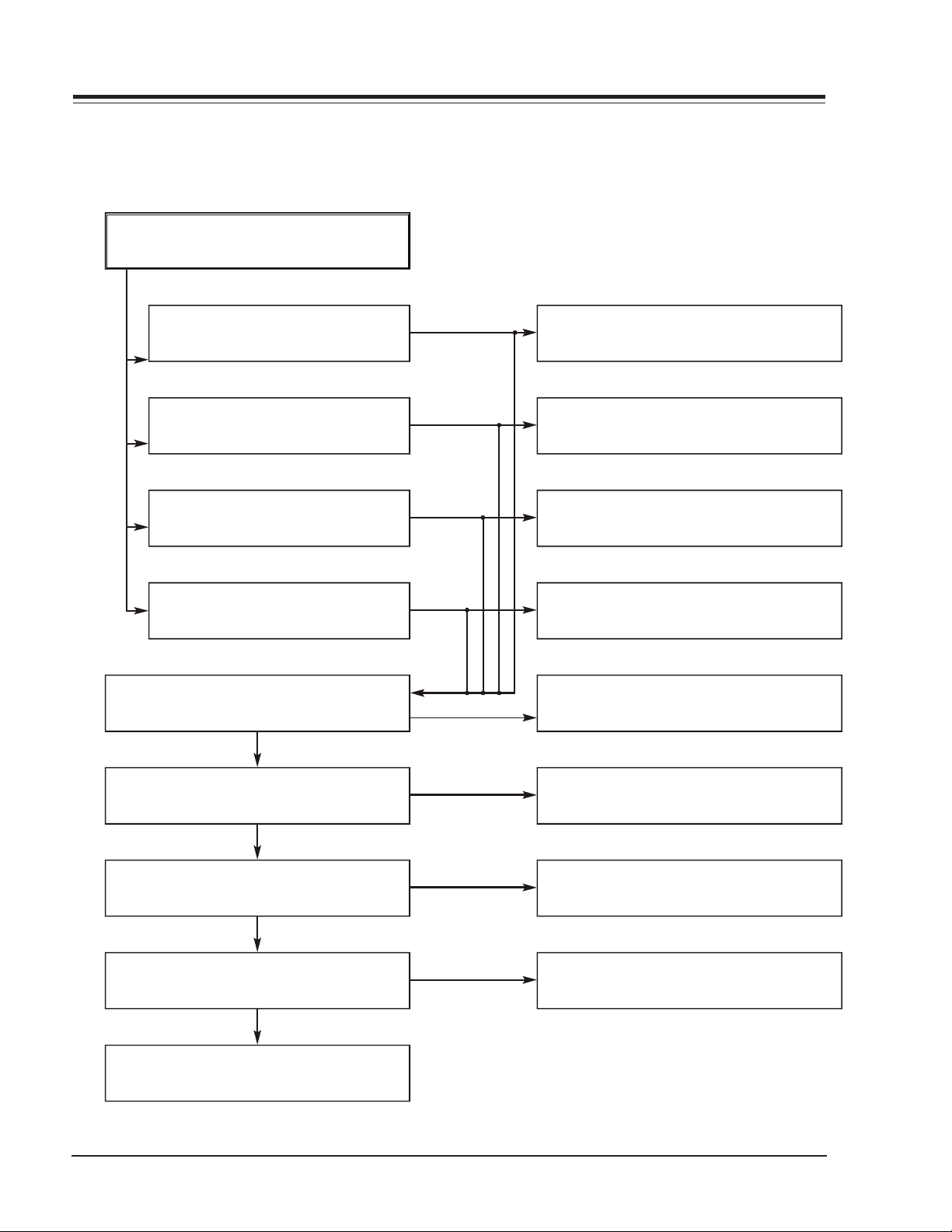

2. SYSTEM/KEY CIRCUIT

(1) AUTO STOP

Auto Stop

YES

ELECTRICAL

Does the SW30 waveform

appear at IC501

Pin24?

YES

Do the T-UP Reel Pulses

appear at IC501 Pin4?

YES

Replace Ic501.

(2) The unstable loading of a Cassette tape

The unstable loading of a

Cassette tape

YES

Is 12V applied to

PMC01 Pin8?

YES

NO

NO NO

O

N

Check the Drum Motor

signal.

Do T/UP Reel Pulses

appear at Q514

Base terminal ?

YES YES

Replace the T/UP Reel

Sensor (RS501).

12 Volt Trouble Shooting”.

Does 5.2V appear at

RS501?

NO

Check the Q116 Power

Circuit.

Refer to “SMPS DRUM

Does the “H” signal appear

at Ic501 Pin57 during

inserting the CST ?

YES

Does the “L” signal appear

at Ic501 Pin19 during

inserting the CST?

YES

Check the Deck

Mechanism.

Caution: Auto stop can occur because Grease or Oil is dried up

VR168 - 923-03485 3-4 D35E COMBO - ELECTRICAL

O

NO

N

Check the CST SW and

the peripheral circuitry.

Is 5.3V applied to

R544 ?

YES

Refer to SMPS 5.3VA

troubleshooting.

Check IC501

Pins74, 75, 76, 77.

NO

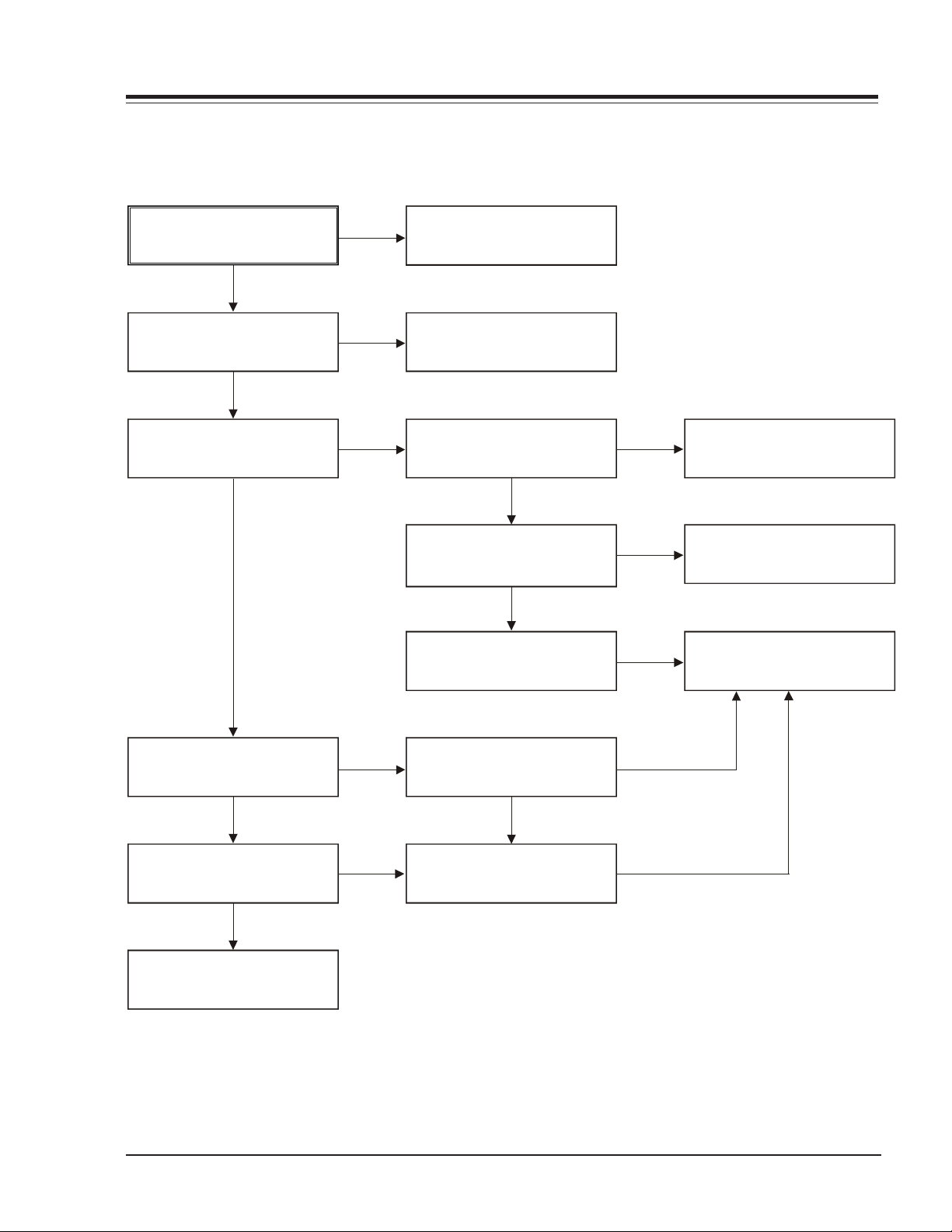

Page 17

TROUBLESHOOTING (CONTINUED)

3. SERVO CIRCUIT

(1) Unstable Video in PB MODE

Unstable Video in

PB Mode.

YES

Does the Noise level of the

screen change periodically?

YES

ELECTRICAL

Do the CTL pulses appear

at IC501 Pin37?

Does the CFG waveform

appear at IC501

On tracking do the CTL

pulses move?

Does the Video Envelope

waveform appear at

IC501 Pin12?

Replace 501.IC

(2) When the Drum Motor

doesn’t run.(2)

When the Drum Motor

Does 12V appear at

PMC01 Pin8?

Does 2.8V appear at

PMC01 Pin12?

Check the connector

(PMC01) and the Drum

Motor Ass’y.

YES

Pin40?

YES

YES

YES

doesn’t run,

YES

YES

NO

NO

NO

O

O

Is the adjustment height of

the CTL Head accurate?

Replace 501.IC

Refer to “When the Y signal

doesn’t appear on the

screen in PB Mode”.

Refer to “(2)

No 12VA of Power section”

Do the Drum PWM Pulses

appear at 501

Are the foil patterns and

the Components between

IC501 Pin26 and PMC01

Pin12 short?

Do the DFG Pulses appear

at the IC501 Pin38?

N

Do the Drum PWM Pulses

appear at 501

N

IC

Pin26?

YES

YES

IC

Pin26?

YES

NO

NO

NO

NO

Readjust the height of the

CTL Head

Do the DFG Pulses appear

at PMC01 Pin11?

YES

NO

Replace the Cap M.

Aren’t the foil patterns and

the Components between

IC501 Pin 38 and PMC01

Pin11 short?

Replace 501.IC

Are the connecting patterns and the Components

between IC501 Pin26 and PMC01 Pin11 short?

VR168 - 923-03485 3-5 D35E COMBO - ELECTRICAL

Page 18

TROUBLESHOOTING (CONTINUED)

(3) When the Capstan Motor doesn’t run

When the Capstan Motor doesn’t run,

ELECTRICAL

Does 12VA appear at PMC01?

YES

Does 2.8V appear at PMC01?

YES

Check PMC01 and the Capstan

Motor Ass’y.

Are the foil patterns and Components

between IC501 Pin25 and PMC01

Pin9 short?

Does the CFG signal come into

IC501 Pin40?

NO

NO

YES

YES

Refer to “SMPS (CAPSTAN/12Volt)

Trouble Shooting”.

Does the PWM signal appear at

IC501 Pin25?

NO

Does the CFG signal appear at

PMC01 Pin1?

NO

Check the Capstan Motor Ass’y.

N O

YES

Does the Capstan PWM signal appear at

IC501 Pin25?

N O

YES

Are the foil patterns and Components

between IC501 Pin 25 and PMC01

Pin9 short?

VR168 - 923-03485 3-6 D35E COMBO - ELECTRICAL

Are the foil patterns and component

between IC501 Pin40 and PMC01

Pin1 short?

Replace IC501.

Page 19

TROUBLESHOOTING (CONTINUED)

KEY doesn't work.

(3)

KEY doesn’t work.

ELECTRICAL

Is 5V applied to

IC501 Pin 15?

YES

Does LED or FLD change

when a function button is

pressed?

4. OSD CIRCUIT

1) No OSD display.

No OSD display.

Is 5.3V applied to

IC501 Pin 42?

YES

Does oscillation occur at

IC501 Pins 52, 53?

YES

Does oscillation occur at

IC501 Pins 50, 51?

YES

Replace IC501.

NO

NO

NO

NO

O

Refer to “SMPS 5.3VA

Trouble Shooting”.

Replace the defective

Refer to “SMPS 5.3VA

Trouble Shooting”.

Is the oscillation input to

Q501 base?

Check or Replace the

Peripheral Circuitry. (L506,

R517, C519, C518, R518)

N

(3) I2C BUS CHECK

switches.

NO

YES

Check whether X301

oscillates

Check or Replace the

Peripheral Circuitry. (L506,

R517, C519, C518, R518)

The I2C waves don’t

2) No F.OSD display.

No F.OSD display.

Refer to “(1) No OSD

display”.

YES

Does the C.SYNC signal

appear at IC501 Pin87?

YES

Replace IC501.

VR168 - 923-03485 3-7 D35E COMBO - ELECTRICAL

O

N

Refer to “AVCP. C. Sync.

come out.

Does Power appear at

the Pull up impedence

Replace IC501.

Trouble shooting”.

(R508, R510)?

YES

NO

Refer to “SMPS 5.3VA

Trouble Shooting”.

Page 20

DVD TROUBLESHOOTING (CONTINUED)

5. Y/C CIRCUIT

(1) No Video in EE Mode

No Video in EE Mode

ELECTRICAL

Does the Video signal

appear at IC301

Pins28, 30, 31?

YES

Is 5.2V applied to IC301

Pins12, 36, 61, 67, 90, 96?

YES

Does the Video signal

appear at IC301 Pin 52?

YES

Does the Video signal

appear at IC501 Pin 45?

YES

Does the Video signal

appear at the Emitter

terminal of Q801?

Check DVD Video Input (IC802, Pin29), Tuner Video Input

(TU701 Pin24), Line Video Input (JK801), respectively.

Check the REG 5V Line.

(Power Circuit)

Is I2C BUS signal applied to

IC301 Pins 62, 63?

YES

Check the path of the signal

between Ic301 Pin

52 and IC501 Pins 43, 45.

Is there 12V on the plus

terminal of C822?

YES

Check the System Circuit.

(Refer to ‘SYSTEM I2C BUS

CHECK Trouble Shooting’)

Check C330. (AGC)

Replace IC301.

YES

Replace Q801.

VR168 - 923-03485 3-8 D35E COMBO - ELECTRICAL

Check the REG 12V Line.

(Power Circuit)

Page 21

ELECTRICAL

DVD TROUBLESHOOTING (CONTINUED)

(2) When the Y(Luminance) signal doesn’t appear on the screen in PB Mode

Is 5V applied to IC301

Pins 12, 36, 61, 67, 90, 96?

YES

Is the I2C Bus signal applied

to IC301 Pins 62, 63?

YES

Does the normal RF signal

appear at the IC301 Pin79?

YES

NO

NO

NO

Check the line of the REG

5V Line. (Power Circuit)

Refer to ‘SYSTEM I2C BUS

CHECK Trouble Shooting’.

Is the V.H.S/W signal

applied to IC301 Pin81?

YES

Does the Rectangular

waveform (5V) appear at

IC301 Pin81(V.H.S/W)

YES

Clean the Drum.

NO

NO

NO

Check the System Circuit.

(IC501 Pin24)

Check the V.H.S/W level.

Replace IC301.

Does the Y(Luminance)

signal appear at IC301

Pin18?

YES

Is the Y(Luminance) Video

waveform showed up at

IC301 Pin39?

YES

Replace IC301.

VR168 - 923-03485 3-9 D35E COMBO - ELECTRICAL

N O

N O

Check the path of the

Y(Luminance) signal.

Check the path of the

Y(Luminance) signal.

YES

YES

Page 22

ELECTRICAL

Y/C

T

TROUBLESHOOTING (CONTINUED)

CIRCUI

(3) When the C(Color) signal doesn’t appear on the screen in PB Mode,

Is 5V applied to IC301

Pins 12, 36, 61, 67, 90, 96?

YES

Does Color signal appear

at the IC301 Pins 58, 60?

YES

Replace IC301.

NO

NO

Check the line of the REG

Does X301(3.58MHZ)

oscillate?

Does the Color signal

appear at IC301 Pin55?

Check the circuit of

IC301 Pins 60, 58, 35.

5V Line. (Power Circuit)

NO

NO

YES

Replace X301.

Check the Color Pass.

(Check C341)

Replace IC301.

VR168 - 923-03485 3-10 D35E COMBO - ELECTRICAL

Page 23

ELECTRICAL

(4)

TROUBLESHOOTING (CONTINUED)

When the Video signal doesn’t appear on the screen in REC Mode,

REC mode

YES

Is EE mode normal?

YES

Is brightness ?

YES

Is the brightness signal

supplied to IC301 Pins 13,14?

YES

Check the power of Pins 12,

36, 61, 67, 90, 96.

YES

Check the REG 5V power

Does the brightness signal

appear at IC301 Pins 21, 26?

YE SNO

NO

YES

NO

NO

NO

Check the EE mode

Is color?

Is color?

NO

Does signal appear at

IC301 Pins 58, 60?

YES

Is 5V supplied to IC301

Pins 12, 36, 61, 90, 96?

YES

Is I2C Bus applied to

IC301 Pins 62, 63?

Do X301, 302 and X-TAL

YES

oscillate?

NO

NO

NO

Check the 5V power

Check system part

Check X301, 302

Is I2C Bus applied to IC301

Pins 62, 63?

YES

Is V.H SW supplied to

IC301 Pin81?

YES

Does the FM signal appear

at IC301 Pins 87, 88(SP)/

92, 93(EP)?

YES

Check the drum

VR168 - 923-03485 3-11 D35E COMBO - ELECTRICAL

NO

NO

NO

Check system part

Check system part

(V.H/SW)

Replace IC301.

*OPTION

Pins86, 87, 88, 89(SP)

Pins91, 92, 93, 94(EP)

Page 24

CIRC

TROUBLESHOOTING (CONTINUED)

6. Hi-Fi

(A) No Sound(EE Mode)

UIT

No Sound.

YES

ELECTRICAL

Check the TU Audio of IC801

Pins 1, 3

Check the DVD Audio of IC801

Pins 4, 5.

Check the AV1 Audio of IC801

Pins 6, 7.

Check the AV2 Audio of IC801

Pins 10, 11.

Check the Vcc of IC801 Pins 34, 40,

IC802 Pin 4.

YES

NO

NO

NO

NO

YES

N O

Check IC751 Pins 30, 31.

Check the DVD MODULE.

(P8D01 Pins 3, 5).

Check the Rear Jack.

(JK801 Audio in).

Check the front Jack.

(PM401 Pins 1, 2).

Check the Power 5.2V, 12V.

Check the IIC Clock and DATA at

IC801 Pins 42, 43, IC802 Pins 32, 33.

N O

Check IC501 Pins 90, 91.

YES

N O

Check the Audio of IC801 Pins 16, 17.

Replace IC801.

YES

Check the Audio of IC802 Pins 22, 26.

N O

Replace IC802.

YES

Check JK801.

VR168 - 923-03485 3-12 D35E COMBO - ELECTRICAL

Page 25

TROUBLESHOOTING (CONTINUED)

3. Y/C CIRCUIT

(B) Hi-Fi Playback

PB mode

YES

No Sound.

YES

ELECTRICAL

Check the Vcc of IC801

(Pins 34, 40)

YES

Check the Hi-Fi Selection switch.

(IC801 Pin 41) and the Tape quality.

YES

Is the RF Envelope at

IC801 Pin 44 over 2Vp-p?

YES

Check IC801 Pin42(Data),

Pin 43(Clock)

YES

Do Audio Signals appear at

IC801 Pin16(L-CH), 17(R-CH)?

YES

Do Audio Signals appear at

IC802 Pin10(L-CH), 16(R-CH)?

YES

NO

NO

NO

NO

Check Power.

Check IC501 Pin23

(A.H/SW)

Check the parts of µ-COM

(IC501 Pins90, 91)

N O

N O

Check the Connection at

P3D01 Pins 7, 9.

Check the A.IN line of

IC802 (C828, C829)

Do Audio Signals appear at

IC802 Pins 22, 26?

YES

Do Audio Signals appear at

JK801?

N O

Check the Vcc of IC802

Pin 4.

YE S YES

Replace IC802.

N O

Check Jack(JK801)

NO

Check Power.

YES

Do Audio Signals appear at

TU701 Pin 2 (MOD A.IN)?

VR168 - 923-03485 3-13 D35E COMBO - ELECTRICAL

N O

Check IC405.

Page 26

(C)

TROUBLESHOOTING (CONTINUED)

Hi-Fi REC.

YES

It is impossible to record Hi-Fi Audio

signal.

YES

ELECTRICAL

Check Vcc of IC801.(Pins34, 40)

YES

Check IC801 Pin42(Data), Pin43(CLOCK).

YES

Do Audio signals appear at IC801

Pins16, 17?

YES

Do FM Audio signals appear at IC801

Pin36?

YES

Check the Contact Point of Drum

Connector if good then Replace the Drum.

NO

NO

NO

Check Power.

Check ports of µ-CPM.

Check Audio input signal of IC801

Pins2, 3(TU.A.), 4, 5(DVD.A.),

6, 7(AVI.A.), 10, 11(AV2.A.)

N O

Replace IC801.

VR168 - 923-03485 3-14 D35E COMBO - ELECTRICAL

Page 27

TROUBLESHOOTING (CONTINUED)

7. Tuner/IF CIRCUIT

(A) No Picture on the TV screen

No picture on the TV

screen

YES

ELECTRICAL

Is the Video signal at

the TU701 Pin 24.

YES

Is +33V applied to TU701

Pin16?

YES

Is +5V applied to TU701

Pin13?

YES

Does the Clock signal

appear at TU701 Pin 11?

YES

Does the data signal

appear at TU701 Pin 12?

YES

Replace Tuner.

Check 33V line.

Check 5V line.

Check the lIC .Clock Signal

of µ-COM Pin90

Check the lIC Data Signal

of µ-COM Pin91.

Does Sync appear at

IC501 Pin 87.

Check the signal flow from

TU701 Pin24 to IC301 Pin 31.

YES

Does the Video signal at

IC501 Pin 45.

Check the signal from IC301

Pin52 to IC501 Pin 43.

YES

Does the Video signal at

IC802 Pin 30.

Check the signal from IC501

Pin45 to IC802 Pin 1.

YES

Check the signal flow from IC802

Pin 30 to JK801 Pin Video out.

VR168 - 923-03485 3-15 D35E COMBO - ELECTRICAL

Page 28

(B)

TROUBLESHOOTING (CONTINUED)

No Sound

No Sound.

YES

ELECTRICAL

Check the Vcc of IC751 Pins1,

11, 19, 22, 33.

YES

Check the Tuner SiF signal at

IC751Pin2.

YES

Check the oscillator of IC751 Pins 5, 6.

YES

Check the Audio of IC751 Pins30, 31.

YES

Check the Audio of IC801 Pins 2, 3.

YES

NO

NO

NO

NO

Check 5.2V Line.

Check the Tuner SIF of TU701 Pin22.

Replace X751

Check the IIC Clock and Data at IC751

Pins 12, 13.

N O

Check the signal flow from IC751

Pins30, 31 to IC801 Pins 2, 3.

Check the Audio of IC801 Pins 16, 17.

N O

Check the IIC Clock and Data at IC801

Pins42, 43.

YES

N O

Check the Audio of IC802 Pins 22, 26.

Check the signal flow from IC801

Pins16, 17 to IC802 Pins 10, 16.

YES

Check the Signal flow from IC802 Pins22,

26, JK801 Audio out(L), (R)

VR168 - 923-03485 3-16 D35E COMBO - ELECTRICAL

Page 29

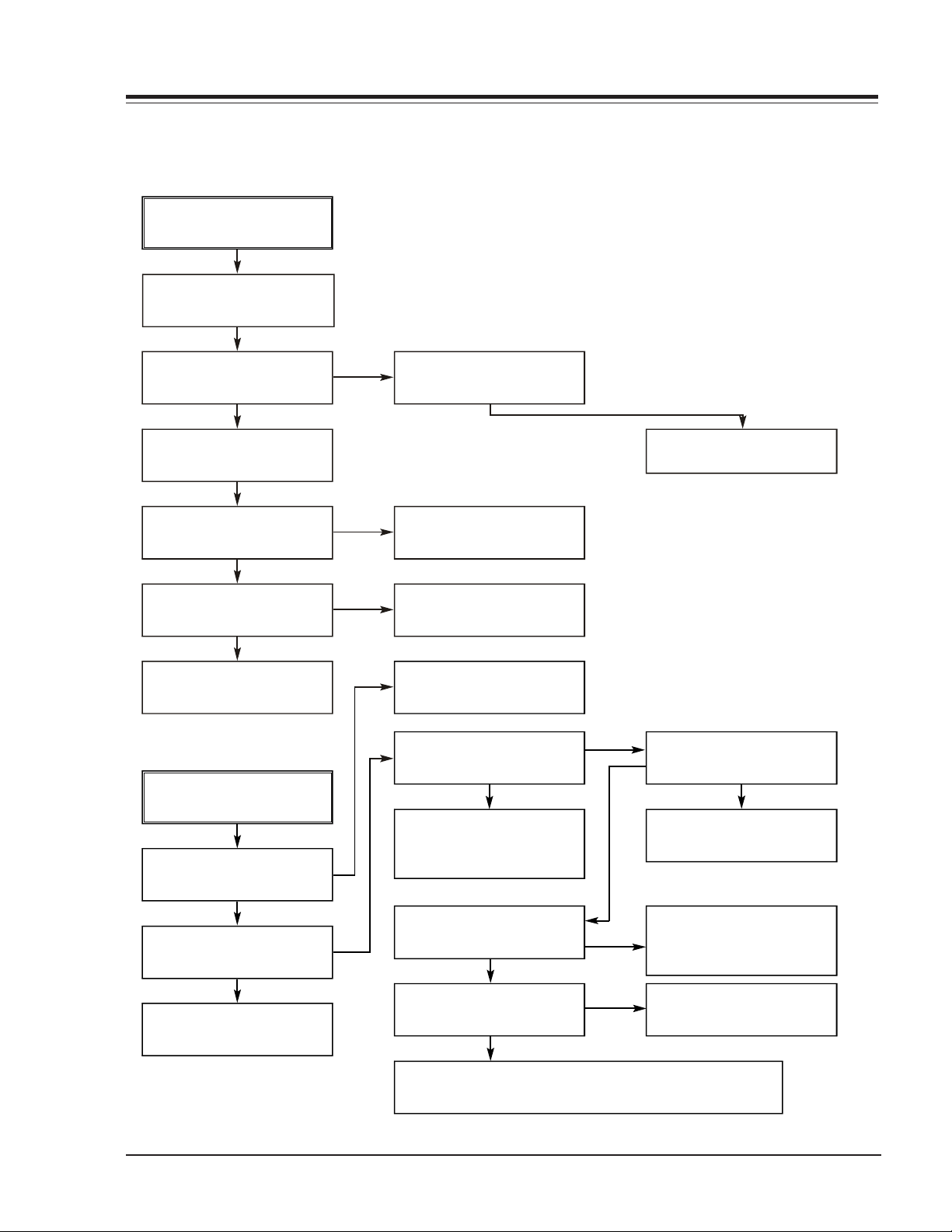

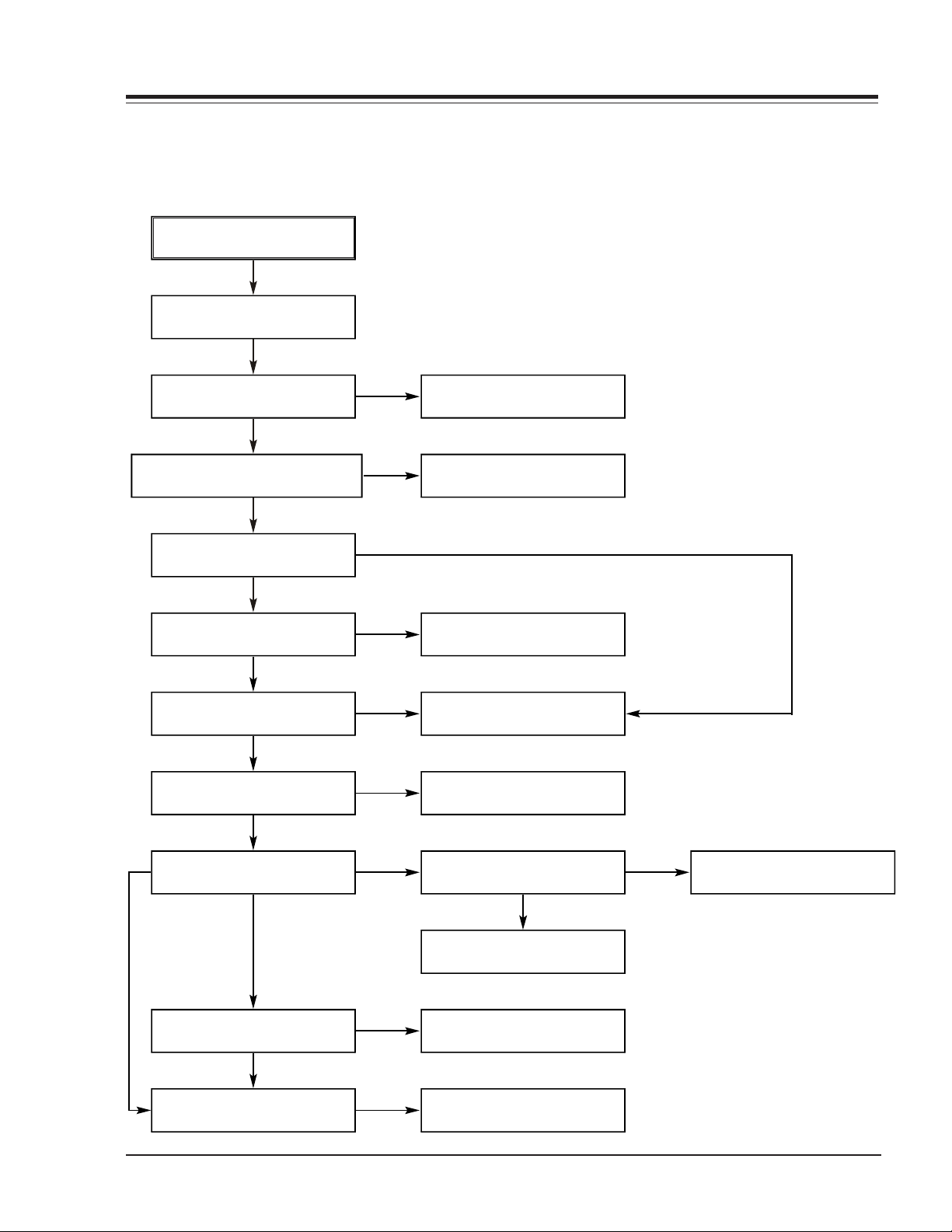

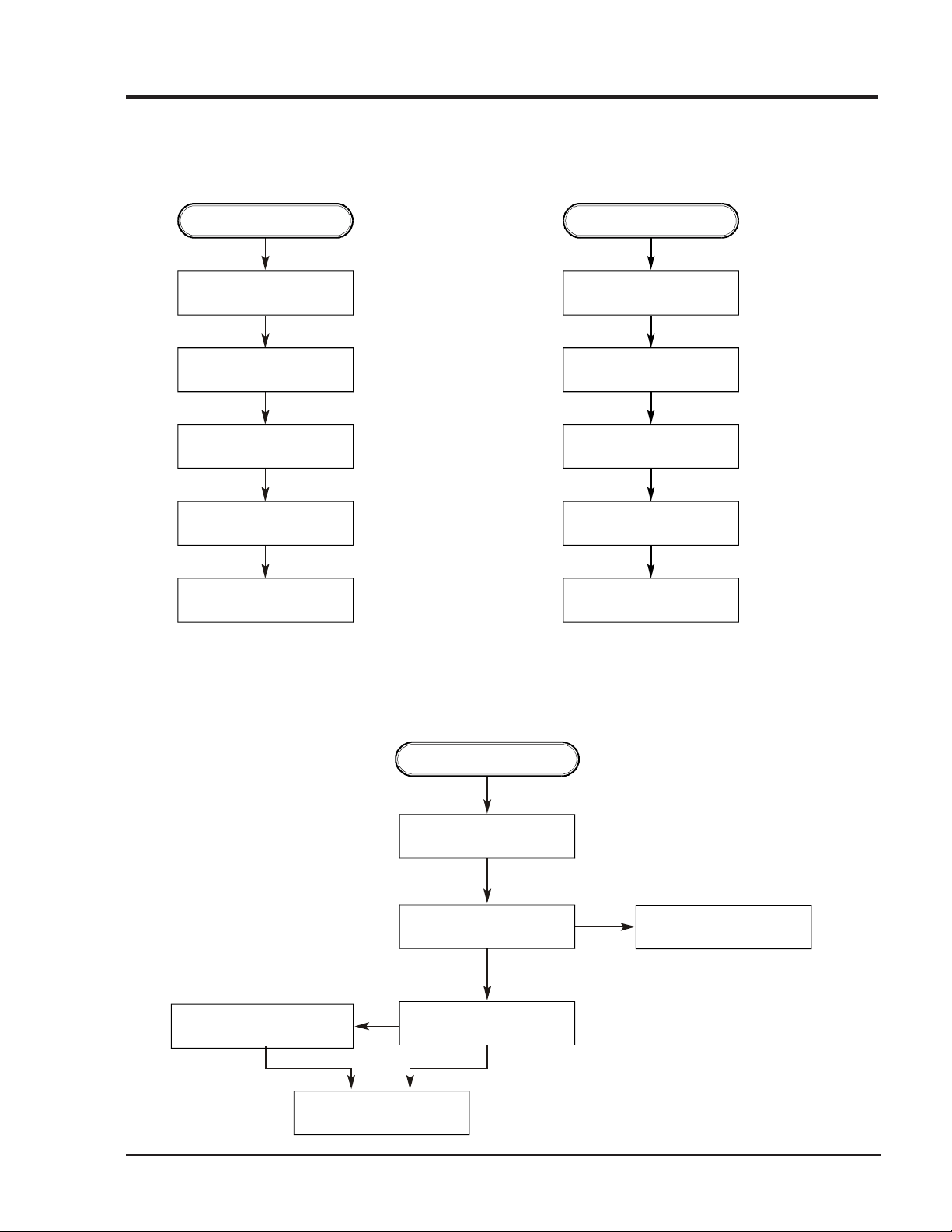

1

COM Ci

TROUBLESHOOTING

ELECTRICAL

. µ-

A. Audio abnormal

rcuit

AUDIO ABNORMAL

Check Audio jack.

Check MPEG_CLK Signal

of MPEG part.

Refer to Audio part.

Refer to MPEG part.

Replace B/D.

YES

YES

YES

YES

(If OK)

(If OK)

(If OK)

(If OK)

B. Video abnormal

VIDEO ABNORMAL

Check Video jack.

Refer to Video part.

Refer to Encoder part.

Refer to MPEG part.

Replace B/D.

YES

YES

YES

YES

(If OK)

(If OK)

(If OK)

(If OK)

C. Open/Close abnormal

Check the connection of MD.

YES

OPEN/CLOSE ABNORMAL

connection of PMD03.

NO

Check IC501 Pins 13, 14.

Refer to SERVO part.

Check Front.

YES

Check the

YES

YES

(If OK)

NO

Reconnect it.

VR168 - 923-03485 3-17 D35E COMBO - ELECTRICAL

Page 30

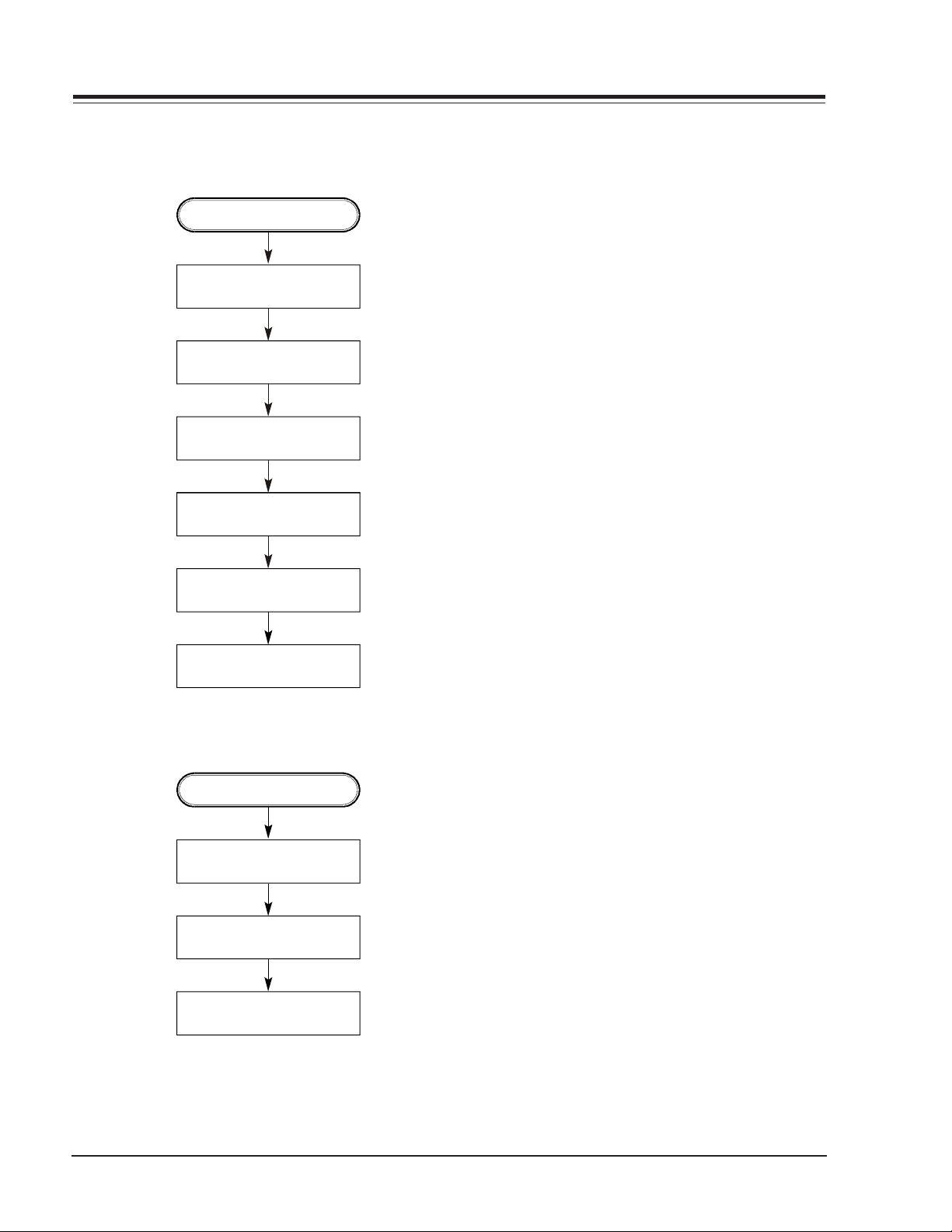

DVD TROUBLESHOOTING (CONTINUED)

D. Picture abnormal

PICTURE ABNORMAL

Check the disc.

Refer to Servo part

If OK

Check MPEG_CLK Signal

of MPEG part

YES

Check DSP

ELECTRICAL

(If OK)

E. Disc Error

Refer to Servo part

YES

Check MPEG

YES

Replace B/D

DISC ERROR

Check Disc

YES

YES

(If OK)

(If OK)

(If OK)

(If OK)

Replace B/D

VR168 - 923-03485 3-18 D35E COMBO - ELECTRICAL

Page 31

2

TROUBLESHOOTING (CONTINUED)

. MPEG Circuit

Power is on

ELECTRICAL

Check power & clock.

Does Logo appear

on the screen?

YES

Does the

moving picture of the DVD Disc

play on the screen

normally?

YES

NO

NO

YES

Check power & clock.

YES

Is MPEG data

signal normal?

YES

Is error signal normal?

NO

OK

NO

Check CD/DVD DSP

output signal.

OK

Check MPEG Decoder

input signal.

Check CD/DVD DSP

output signal.

OK

Check MPEG Decoder

input signal.

Does the

moving picture of the video

CD play on the screen

normally?

YES

Does the audio sound

output normally?

YES

END

VR168 - 923-03485 3-19 D35E COMBO - ELECTRICAL

NO

NO

Is MPEG data

signal normal?

YES

Is Clock normal?

YES

Does the audio

sound output from MPEG

decoder?

YES

NO

NO

Check CD/DVD DSP

output signal.

OK

Check MPEG Decoder

input signal.

Check clock signal

Check clock signal

Page 32

TROUBLESHOOTING (CONTINUED)

3. RF/Servo Circuit

A.

CHECK POINT(General)

ELECTRICAL

Does signal go "High"

to IC201 Pin194 when

power is on?

YES

Does signal pulse

input to IC201 Pins 58, 59

when power is on?

YES

Does

TTL pulse output to

IC201 Pins 140, 142?

Is IC201

Pins 83, 84, 88, 89 voltage

about 2.2V?

YES

NO

NO

NO NO

NO

Check "2.µ-COM Part".

Does

33.8688MHz clock input

to IC201 Pin 63?

YESYES

Replace IC201

(IC206 soldering or IC defect).

Check power circuit.

Replace X301 or IC304

(30MHz clock defect)

END

VR168 - 923-03485 3-20 D35E COMBO - ELECTRICAL

Page 33

TROUBLESHOOTING (CONTINUED)

No disc

B.

No disc

ELECTRICAL

Power on

Does tray open or close?

YES

NO

Check loading Part.

Push Pick-up to inner

track to the end by hand.

Does PMD03 Pin 13

change high to low?

YES

Pressing the open/close key,

check the voltage of IC2M1

Pins 22 change 0V to 5V

YES

Does the voltage change at

PMD03 Pins 1, 3 more than

2V on the basis of 3.8V?

YES

NO

NO

NO

DECK assembly is

defective. (Limit sw)

check µ-COM Part.

Replace IC2M1.

DECK assembly is defective

Does the pick-up slide

inner or outer track?

YES

Does the pick-up lens

move up and down?

YES

Slide the pick-up to

inner track.

END

VR168 - 923-03485 3-21 D35E COMBO - ELECTRICAL

NO

NO

Check SLED Driver output.

IC201 Pin 88 IC2M1 Pins 35, 36.

Check Focus Driver output.

(IC201 Pin 83, IC2M1 Pins 32, 33)

IC201 Pin 88 no output : IC201 is defective

IC2M1 Pin 19 no output : IC2M1 is defective

IC201 Pin 83 no output : IC201 is defective

IC2M1 Pins 24, 41 no output : IC2M1 is defective

Page 34

TROUBLESHOOTING (CONTINUED)

C

.

DISC IN

DISC IN

OPEN/CLOSE

FOCUS ON?

YES

NO

ELECTRICAL

Check the focus error

movingthe lens up and

down. (IC2A1 Pin 42)

YES

Fig.3. FOCUS ERROR waveform

NO

Check IC2A1 Pin 11,12,13,14

in DVD Mode

IC201 no output : Pick-up is defective.

Does the disc turn?

YES

IC201 Pin169 is "High"?

YES

Is OK the track jump.

Does the TTL level change

at IC201 Pin 78 and 132

moving the lens?

YES

Replace µ-COM or IC201.

Check IC2M1 Pin 18, PMD03

NO

Pin 6 turn when the IC2M1

Pin 21 is less than 2.2V.

NO

NO NO

Check A

NO

Check IC201 and IC2M1 when PMD03 Pin 6 is abnormal

Replace IC201.

Does the signal

pulse appear at IC2A1

Pins 39, 29?

IC2A1 is defective.

YES YES

Does the screen appear?

NO

YES

END

VR168 - 923-03485 3-22 D35E COMBO - ELECTRICAL

Video Part is defective.

Check "5.MPEG Circuit."

Check "7.OSD/Video Circuit."

Replace µ-COM part.

Page 35

TROUBLESHOOTING (CONTINUED)

CHECK A

ELECTRICAL

Check RF Eye-Pattern.

RF : 1.5-1.6V(IC2A1 Pin 57)

YES

Is the eye-pattern vivid?

YES YES YES

NO

Check IC2A1 Pins 5, 6, 7, 8.

NO NO N O

Does the

sawtooth waveform emit

at IC2A1 Pin 41?

Replace IC201.

No signal: Pick-up is defective

Does the 1.6V emit?

Check IC201 Pin84.

No signal at IC201 : IC201 is defective

Replace IC2A1.

• Check IC201 Pin 162.

• Check the clock at the IC201 Pins 28, 30.

END

VR168 - 923-03485 3-23 D35E COMBO - ELECTRICAL

• Both are normal : IC201 is defective

Page 36

- 3-24 -

Page 37

SECTION 4 Mechanical

VCR DECK MECHANISM

PART LOCATIONS

Top View

MECHANISM - VCR

2

7

10

1

31

14

15

8

Bottom View

6

3

4

9

5

11

18

16

17

19

19

12

33

13

15

T: Top, B:Bot

NOTES:

• When reassembling, perform the procedure in the

reverse order.

• When reassembling, confirm Mechanism and Mode

Switch Alignment Position (refer to Page 4-14)

VR168 - 923-03485 4-1 D35E COMBO - SERVICING

Page 38

MECHANISM - VCR

DRUM ASSEMBLY

1) Unplug the Drum FPC Connector.

2) Remove three Screws (S1) on the bottom side and

separate the Drum assembly.

3) Unhook (H1), (H2) and separate the Holder FPC and

Cap FPC. Also see figure (B1).

DRUM MOTOR

1) Remove two Screws (S2) and disassemble the Stator of the Drum Motor.

2) Remove two Screws (S3) and separate the Rotor of

the Drum Motor from the Drum Sub assembly.

NOTE: When reassembling, check to ascertain that Carbon

Brush is in position.

(S2)

(S2)

(S3)

(S3)

Fig.

Stator

Drum Motor

Rotor

B-1

Holder FPC

FPC

Drum

Reversed Direction

Cap

FPC

Carbon Brus h

Drum Sub Assembly

(A)

Drum FPC

(S1)

(S1)

(S1)

H2

H1

Holder FPC

Fig. A-1

VR168 - 923-03485 4-2 D35E COMBO - SERVICING

Page 39

MECHANISM - VCR

PLATE TOP (FIG. A-2-1)

1)To Remove, use a screwdriver to carefully free the

tabs at each end (B and B’ in the figure at right).

Rotate the plate upwards to free the slotted hooks

from the studs (C and C’ in the figure).

2) To replace, slide the hooks into position on the

studs (C and C’) and snap the Plate Top down into

place.

(B')

(C')

(C)

(B)

(H8)

(B')

Plate Top

Arm Assembly F/L

Lever Assembly S/W

Spring Lever S/W

(Fig. A-2-1)

(B)

A-2-6)

(Fig.

(Fig.

A-2-7)

Brackert Assembly L/D Motor

(C)

Holder Assembly CST

(E)

(C1)

(Fig.

A-2-2)

(C')

(D)

Chassis

Gear Assembly Rack F/L

(E')

Opener Door

(H6)

(A)

(Fig. A-2-3)

(B)

(Fig. A-2-5)

Fig. A-2

VR168 - 923-03485 4-3 D35E COMBO - SERVICING

Page 40

MECHANISM - VCR

HOLDER ASSEMBLY CST (FIG. A-2-2)

1) Move the Holder assembly CST in direction of arrow

and lift the left side through slot (D) .

2) Pull the right side of the Holder assembly CST from

the guided holes in the Chassis.

Gear Rack F/L

Holder assembly CST

(D)

Chassis

GUIDE CST (FIG.A-2-3)

BRACKET ASSEMBLY L/D MOTOR(FIG. A-2-4)

1) Unplug the Connector (C1).

2) Unhook three Hooks (H3,H4,H5) on the bottom of

the Chassis, lift up the Bracket assembly L/M and

disassemble the Bracket assembly L/D Motor.

(H4)

(H3)

(H5)

Bracket assemb ly L/M

Gear Drive

ARM ASSEMBLY F/L (FIG. A-2-6)

1) Rotate the Arm assembly F/L in the direction of the

arrow and remove the left side first.

2) Pull the Arm assembly F/L from the guided holes in

the Chassis.

LEVER ASSEMBLY S/W (FIG. A-2-7)

1) Hook the Spring Lever S/W on the Hook (H7) first

as shown below.

2) Unhook Hook (H8) in the left side of the Chassis

and remove the Lever assembly S/W.

Chassis

(H8)

(H7)

Spring Lever S/W

GEAR ASSEMBLY RACK F/L (FIG. A-2-5)

1) Move the Gear Assembly Rack F/L in the direction of

the arrow (A) and unhook Hook (H6), pulling back

in front.

2) Separate the Rear Rack F/L in the direction of the

arrow (B).

NOTE: When reassembling, align the Gear part of the Gear

Assembly Rack F/L with the Gear Drive as shown

in the following figure.

VR168 - 923-03485 4-4 D35E COMBO - SERVICING

Page 41

MECHANISM - VCR

ARM ASSEMBLY CLEANER (FIG. A-3-1)

1) Carefully pry tab “A” (see Fig. A-3-1) to clear the

embossed tab on the chassis. Turn the Arm Assembly Cleaner clockwise and lift it from the chassis.

HEAD F/E (FIG. A-3-2)

1) Carefully pry tab “A” (see Fig. A-3-2) to clear the

embossed tab on the chassis. Turn the Arm Assembly Cleaner counter-clockwise and lift it from the

chassis.

BASE ASSEMBLY A/C HEAD (FIG. A-3-3)

1) Remove Screw (S4) and lift the Base assembly A/C

Head up.

Arm Assembly

Cleaner

(Fig. A-3-1)

(A)

(S4)

Head F/E

(Fig.

A-3-2)

(A)

Chassis

Fig. A-3

Base Assembly A/C Head

A-3-3)

*(Fig.

VR168 - 923-03485 4-5 D35E COMBO - SERVICING

Page 42

Arm Assembly Tension

(Fig.

A-4-3)

Spring Tension

(H11)

MECHANISM - VCR

Reel S

A-4-4)

(Fig.

Spring TB

Brake Assembl y T

(Fig. A-4-1)

(Fig.

Spring RS

Reel T

A-4-4)

Brake Assembly RS

A-4-2)

(Fig.

(H12)

Base Tension

Chassis

BRAKE ASSEMBLY T (FIG. A-4-1)

1) Unhook Spring TB from Hook (H9) of the chassis.

2) Lift Brake assembly T.

BRAKE ASSEMBLY RS (FIG. A-4-2)

1) Unhook Spring RS from Hook (H10) of the

chassis.

2) Lift Brake assembly RS.

ARM ASSEMBLY TENSION (FIG. A-4-3)

1) Unhook the Spring Tension from Hook (H11) of the

Arm Assembly Tension.

2) Unhook Hook (H12) of the Base Tension and lift the

Arm Assembly Tension.

(H9)

(H10)

Fig. A-4

Spring Identification Chart

Spring TB

Spring RS

Spring Tension

REEL S / REEL T (FIG. A-4-4)

Reel S Reel T

VR168 - 923-03485 4-6 D35E COMBO - SERVICING

Page 43

MECHANISM - VCR

Opener Lid

(B)

(Fig. A-5-2)

Base Assembly P4

A-5-1)

(Fig.

(A)

(B)

Assembly

(Fig.

(C)

Arm

Pinch

A-5-3)

(C)

Arm T/up

(Fig.

A-5-5)

Lever T/up

(Fig.

A-5-4)

(H13)

(H13)

Chassis

Fig. A-5

BASE ASSEMBLY P4 (FIG. A-5-1)

1) Carefully pry up Tab (A) to clear the embossed tab on

the chassis.

2) Turn the Base assembly P4 counterclockwise and lift

it up.

17. OPENER LID (FIG. A-5-2)

1) Carefully pry up Tab (B) to clear the embossed tab on

the chassis.

2) Turn the Opener Lid clockwise and lift it up.

18. ARM ASSEMBLY PINCH (FIG. A-5-3)

Lift the Arm assembly Pinch up.

VR168 - 923-03485 4-7 D35E COMBO - SERVICING

LEVER T/UP (FIG. A-5-4)

ARM T/UP (FIG. A-5-5)

1) Unhook the Hook (H13) of the bottom Chassis and

lift the Lever T/up.

2) Lift the Arm T/up.

NOTE: When reassembling, confirm that the (C) portion

of the Arm assembly Pinch is inserted to the Chassis

Hole correctly as Fig. Place the Mechanism upsidedown.

Page 44

MECHANISM - VCR

BELT & MOTOR CAPSTAN (FIG. A-6-1/2)

1) Remove the Belt Capstan.

2) Remove the three Screws (S5) from the bottom of

the Chassis and lift the Motor Capstan.

LEVER F/R (FIG. A-6-3)

Unlock the Locking Tab (L1) as in Fig. A-6-3 and

lift the Lever F/R.

Brake Assembly Capstan

A-6-5)

(Fig.

(L1)

CLUTCH ASSEMBLY D35 (FIG. A-6-4)

BRAKE ASSEMBLY CAPSTAN (FIG. A-6-5)

Belt Capstan

(Fig. A-6-1)

Motor Capstan

A-6-2)

(Fig.

(L1)

Remove Washer (W1) and lift the Clutch assembly

D35.

Pull the Locking Tab (L2) back in the direction of

the arrow and lift it up.

Washer(W1)

Clutch Assembly D35

(Fig.

A-6-4)

(L2)

Lever F/R

(Fig.

A-6-3)

Chassis

(S5)

Fig. A-6

VR168 - 923-03485 4-8 D35E COMBO - SERVICING

Page 45

MECHANISM - VCR

GEAR DRIVE & CAM (FIG. A-7-1/2)

1) Remove Washer (W2) and lift the Gear Drive.

2) Unhook Hook (H14) of the Gear Cam and lift the

Gear Cam.

NOTE: When reassembling, align the Gear Drive Hole(A)

and the Gear Cam Hole(B) in a straight line after

the Gear Drive Hole(C) is aligned with the Chassis

Hole. (See Inset)

GEAR SECTOR (FIG. A-7-3)

Unhook Hook (H15) of the Base Loading fron the

bottom of the Chassis and lift the Gear Sector.

(H14)

Gear Cam Hole(B)

Gear Drive Hole(A)

(Fig.

PLATE SLIDER (FIG. A-7-4)

Lift the Plate Slider.

LEVER TENSION (FIG. A-7-5)

1) Unhook the (A) portion of the Lever Tension from

Hook (H16) of the Chassis.

2) Turn the Lever Tension counterclockwise and lift.

LEVER SPRING (FIG. A-7-6)

Unlock Locking Tab (L3) from the bottom of the

Chassis and lift the Lever Spring.

Gear Cam

A-7-2)

Washer (W2)

Gear Drive

A-7-1)

(Fig.

Gear Sector

A-7-3)

(Fig.

Plate Slider

(Fig. A-7-4)

Gear Drive Hole(C)

Fig. A-7

Chassis

(H15)

(H16 )

(A)

(L3)

Lever Tension

(Fig.

A-7-5)

Lever spring

(Fig.

A-7-6)

Base Loading

VR168 - 923-03485 4-9 D35E COMBO - SERVICING

Page 46

MECHANISM - VCR

GEAR ASSEMBLY P2/P3 (FIG. A-8-1/2)

1) Lift the Gear assembly P2.

2) Lift the Gear assembly P3.

NOTE: When reassembling, align the two Holes of the

Gear assembly P2 and P3 after aligning the Gear

Sector Hole(A) with the Plate Slider Hole(B) (see

the inset below).

BASE ASSEMBLY P2/P3 (FIG. A-8-3/4)

1) Move Base assembly P2 in the direction of the arrow

(A) along the slot in the Chassis and disassemble it

from the bottom side.

Gear assembly P2 Hole

Gear assembly P3 Hole

2) Move Base assembly P3 in the direction of the arrow

(B) along the slot in the Chassis and disassemble it

from the bottom side. Place the Mechanism face

down, or return to original position.

Gear Assembly P3

A-8-2)

(Fig.

Lever spring Boss

Gear sector Hole(A)

Plate sl ider Hole(B)

(B)

Chassis

Base Assembly P3

(Fig.

A-8-4)

Fig. A-8

Base Assembly P2

(Fig.

A-8-3)

Gear Assembly P2

(Fig. A-8-1)

(A)

VR168 - 923-03485 4-10 D35E COMBO - SERVICING

Page 47

MECHANISM - VCR

BASE LOADING (FIG. A-9-1)

1) Remove the Screw (S7).

2) Lift the Base Loading.

BASE TENSION (FIG. A-9-2)

1) Carefully pry up Tab (A) to clear the embossed tab on

the chassis.

2) Turn the Base Tension counterclockwise and lift.

Base Tension

(Fig.

A-9-2)

(A)

(S7)

Base Loading

(Fig. A-9-1)

(B) (C)

ARM ASSEMBLY IDLER (FIG. A-9-3)

Pinch (B) and (C) as shown in Fig. A-9-3, and lift.

NOTE: When disassembling, be careful not to catch part

(D) on the Chassis (See the Inset).

Arm Assembly Idler Jog

A-9-3)

(Fig.

(D)

Chassis

Fig. A-9

VR168 - 923-03485 4-11 D35E COMBO - SERVICING

Page 48

TOOLS NEEDED FOR SERVICE

MECHANISM - VCR

1. Cassette Torque meter

1. SRK-VHT-303(Not

SVC part)

4. Torque gauge adapto r

2.

Alignment tape

5. Post height adjusting driver 6. + Type driver

3. Torque gauge

3. 600g.Cm ATG

3.

VR168 - 923-03485 4-12 D35E COMBO - SERVICING

Page 49

VCR ALIGNMENT

ALIGNMENT POSITION CHECK

MECHANISM - VCR

Mechanism

Purpose: To determine if the Mechanism is in the correct Position when a Tape is ejected.

Test Equipment/ Fixture

1) Turn the Power S/W on and eject the Cassette by press-

the Eject Button.

ing

Remove the To p Cover and Plate Assembly Top, visual-

2)

check if the Gear Cam Hole is aligned with the

ly

Chassis

not, rotate the Shaft of the Loading Motor to either

3)

Clockwise

IF

below Fig. C-2.

as

Alignment Position Check

Test Conditions (Mechanism

Blank tape

Hole as below Fig. C-2.

Counterclockwise until the Alignment is

or

Condition)

Remove the Screw which holds the Deck Mechanism and

4)

Main Frame and confirm That the Gear Cam is aligned

with the Gear Drive as below in Fig. C-1(B).

5) Confirm that the Mode S/W on the Main P.C.Board is

aligned as below in Fig.C-1(B).

6) Remount the Deck Mechanism on the Main P.C.Board

and

check each operation.

Check Point

CHECK

DIAGRAM

Gear Cam

(C)

(B)

Mode S/W

TOM VIEW

BOT

TOP VIEW

Gear Drive

Gear Cam (o) and Gear Drive (o) groove alignment

Fig. C-1

Fig. C-2

VR168 - 923-03485 4-13 D35E COMBO - SERVICING

Page 50

MECHANISM - VCR

PREPARATION FOR ADJUSTMENT

(To set the Deck Mechanism to the Loading state with-

out inserting a Cassette Tape).

1) Unplug the Power Cord from the AC Outlet.

2) Disassemble the Top Cover and Plate Assembly Top.

3) Plug the Power Cord into the AC Outlet.

4) Turn the Power S/W on and push the Lever Stopper

of the Holder Assembly CST to the back for Loading

the Cassette without Tape.

CHECKING TORQUE

Purpose: To insure smooth Transport of the Tape during each Mode of Operation.

If

the Tape Transport is abnormal, then check the Torque as indicated by the chart below.

Cover the Holes of the End Sensors at both sides of

the Bracket Side (L) and Bracket Assembly Door to

prevent a light leak. Then the Deck Mechanism drives

to the Stop Mode. In this case, The Deck Mechanism can accept inputs of each mode, however the

Rewind and Review Operation can not be performed

for more than a few seconds because the Take-up

Reel Table is in the Stop State and the reel pulses

can not be detected.

Test Equipment/ Fixture

Torque Gauge (600g/cm ATG)

Torque Gauge Adaptor

Cassette To rq ue Meter

NOTE:

The

Values are measured by using a

Torque Gauge Adaptor with the

Cassette

Torque Meter

Test Conditions

(Mechanism

Play (FF) or Review (REW) Mode

Torque Gauge and

Torque Gauge a ffixed.

Condition)

Checking Method

Perform each Deck Mechanism Mode without

inserting

Preparation for Adjustment).

Read the Measurement of the Ta k e -u p or Supply

Reels

Attach the To r qu e Gauge Adaptor to the To r qu e

Gauge

Cassette Tape (Refer to above No.2

a

the Cassette To rq ue Meter(Fig. C-3-2).

on

and then read the Val ue

(Fig. C-3-1).

NOTE:

The

Torque reading to measure occurs when the Ta pe

abruptly

Mode,

changes direction from Fast Forward of Rewind

when quick bracking is applied to both Reels.

Torque Gauge (600g.cm ATG)

Torque Gauge

Torq ue

Gauge

Adaptor

Tab le

Reel

Fig. C-3-2

VR168 - 923-03485 4-14 D35E COMBO - SERVICING

Fig. C-3-1

Page 51

MECHANISM - VCR

GUIDE ROLLER HEIGHT ADJUSTMENT

Purpose: To regulate the Height of the Tape so that

the Bottom of the Tape runs along the Tape Guide Line

on the Lower Drum.

PRELIMINARY ADJUSTMENT

Test Equipment/ Fixture

Post Height Adjusting Driver

Play or Review Mode

Adjustment Procedure

1) Confirm that the Tape runs along the Tape Guide Line of

the Lower Drum.

2) If the Ta pe runs at the bottom of the Guide Line, turn the

Guide Roller Height Adjustment screw clockwise.

3) If it runs at the top, turn it counterclockwise.

4) Adjust the Height of the Guide Roller to be guided to the

Guide

Point

Line of the Lower Drum from the Starting and Ending

the Drum.

of

PRECISE ADJUSTMENT

Test Equipment/Fixture

Oscilloscope

Alignment

Post Height Adjusting

Driver

Ta p e

CH-1:PB RF Envelope

CH-2:NTSC: SW 30Hz

PAL: SW 25Hz

Head Switching Output

Point

Envelope Output

Point

RF

Adjustment Procedure

1 )Play an Alignment

Oscilloscope

Switching Output

Head

Trac kin g Control(in PB Mode) : Center Position(When

2

Adjustment is performed after the Drum Assembly

this

has

been replaced, set the

)

Output is Maximum).

RF

4

urn(Move) the

3 ) H e i g h t A d j u s t m e n t S c r e w : F l a t t e n t h e R F W a v e f o r m

Clockwise

( F i g . C - 4 - 2

)Check that any Drop of RF Output is uniform at the

5

) T

and End of the

Sta rt

NOTE

Ta p e after connecting the Probe of the

the RF Envelope Output

Te s t Point.

Test Point and

to

Tracking Control so that the

)

Tracking Control(in PB Mode)

and Counterclockwise.(Fig. C-4-3)

Waveform.

ADJUSTMENT DIAGRAM

Play an Alignment Ta p e

Waveform

.

Tracking

Diagrams

POST

P2

ADJUSTMENT

P3 POST

ADJUSTMENT

control at center

Connection Diagram

Adjustment Point

Guide Roller Height Adjustment

screws

Guide

the Supply and Ta ke -U p

on

Rollers.

Guide

Adjustment screw

Upper Flange

Guide

Retaining

Fig. C-4-1

Adjustment Point

Guide Roller Height

Adjustment

Tur n

the Roller Guide Height

Adjustment

to

flatten the waveform.

Fig. C-4-2

Tur n(M ove )

control

C-4-3

Fig.

Roller Height

Roller

Screw

Screws

Screw slightly

both directions

the tracking

to

OSCILLO SCOPE

w i l l

I f t h e a d j u s t m e n t i s e x c e s s i v e o r i n s u f f i c i e n t t h e t a p e

j a m o r f o l d

VR168 - 923-03485 4-15 D35E COMBO - SERVICING

.

RF ENVELOPE OUTPUT TEST POINT

HEAD SWITCHING OUTPUT TEST

POINT

Page 52

MECHANISM - VCR

AUDIO/CONTROL (A/C) HEAD ADJUSTMENT

Purpose: To insure that the Tape passes accurately over

the Audio and Control Tracks in exact Alignment in

both the Record and Playback Modes.

PRELIMINARY ADJUSTMENT

(Height and Tilt Adjustment)

Perform the Preliminary Adjustment when there is no

Audio Output Signal with the Alignment Tape.

Test Equipment/ Fixture

Blank Tape

Screw Driver(+) Type 5mm

Play the blank tape

Adjustment Procedure/Diagrams

1) Initially adjust the Base Assembly A/C Head as shown

Fig.

C-5-1 by using the Height Adjustment Screw (B).

2) Play

3) If

Blank Tape and observe if the Tape passes accu-

a

over the A/C Head without Ta pe Curling or Folding.

rately

Folding or Curling is occured then adjust the Tilt

Adjustment

ble

Fig. C-5-3.

Screw(C) while the Tape is running to resem-

Head Base

A/C

Fig. C-5-1

4) Reconfirm

onds.

NOTE

Ideal