Zenith P42W46XH Service Manual

SERVICE MANUAL

Product Type: PLASMA

Chassis: RF-043A

Manual Series:

Manual Part #:

Model Line:

Product Year: 2004

P42W46X

P42W46XH

Model Series:

CONTENTS

Description of Controls .................................................4

Product Specifications..................................................7

Adjustment Instructions ................................................8

Diagrams ...................................................................23

Parts List ...................................................................27

Schematics ....................................................................

Published Oct. 2003

by Technical Publications

LG Electronics USA, Inc.

201 James Record Road,

Huntsville, Alabama 35824-1513

Copyright © 2003 by Zenith Electronics Corporation

Printed in Korea

http//www.zenithservice.com

All manuals and user guides at all-guides.com

all-guides.com

- 2 -

IMPORTANT SAFETY NOTICE

This manual was prepared for use only by properly trained audio-visual service

technicians.

When servicing this product, under no circumstances should the original design

be modified or altered without permission from Zenith Electronics Corporation.

All components should be replaced only with types identical to those in the

original circuit and their physical location, wiring and lead dress must conform

to original layout upon completion of repairs.

CAUTION: Do not attempt to modify this product in any way.

Never perform customized installations without manufacturer’s

approval.

Unauthorized modifications will not only void the warranty, but may

lead to property damage or user injury.

Service work should be performed only after you are thoroughly familiar with

these safety checks and servicing guidelines.

GRAPHIC SYMBOLS

The exclamation point within an equilateral triangle is intended to

alert the service personnel to important safety information in the

service literature.

The lightning flash with arrowhead symbol within an equilateral

triangle is intended to alert the service personnel to the presence

of noninsulated “dangerous voltage” that may be of sufficient

magnitude to constitute a risk of electric shock.

The pictorial representation of a fuse and its rating within an

equilateral triangle is intended to convey to the service personnel

the following fuse replacement caution notice:

CAUTION: FOR CONTINUED PROTECTION AGAINST RISK

OF FIRE, REPLACE ALL FUSES WITH THE SAME TYPE AND

RATING AS MARKED NEAR EACH FUSE.

SERVICE INFORMATION

While servicing, use an isolation transformer for protection from AC line shock.

After the original service problem has been corrected, make a check of the

following:

FIRE AND SHOCK HAZARD

1. Be sure that all components are positioned to avoid a possibility of adjacent

component shorts. This is especially important on items transported to and

from the repair shop.

2. Verify that all protective devices such as insulators, barriers, covers, shields,

strain reliefs, power supply cords, and other hardware have been reinstalled

per the original design. Be sure that the safety purpose of the polarized line

plug has not been defeated.

3. Soldering must be inspected to discover possible cold solder joints, solder

splashes, or sharp solder points. Be certain to remove all loose foreign particles.

4. Check for physical evidence of damage or deterioration to parts and

components, for frayed leads or damaged insulation (including the AC cord),

and replace if necessary.

5. No lead or component should touch a receiving tube or a resistor rated at 1

watt or more. Lead tension around protruding metal surfaces must be avoided.

6. After reassembly of the set, always perform an AC leakage test on all

exposed metallic parts of the cabinet (the channel selector knobs, antenna

terminals, handle and screws) to be sure that set is safe to operate without

danger of electrical shock. DO NOT USE A LINE ISOLATION

TRANSFORMER DURING THIS TEST. Use an AC voltmeter having 5000

ohms per volt or more sensitivity in the following manner: Connect a 1500

ohm, 10 watt resistor, paralleled by a .15 mfd 150V AC type capacitor

between a known good earth ground water pipe, conduit, etc.) and the

exposed metallic parts, one at a time.

Measure the AC voltage across the combination of 1500 ohm resistor and

.15 mfd capacitor. Reverse the AC plug by using a non-polarized adaptor

and repeat AC voltage measurements for each exposed metallic part.

Voltage measured must not exceed 0.75 volts RMS. This corresponds to 0.5

milliamp AC. Any value exceeding this limit constitutes a potential shock

hazard and must be corrected immediately.

TIPS ON PROPER INSTALLATION

1. Never install any receiver in a closed-in recess, cubbyhole, or closely fitting

shelf space over, or close to, a heat duct, or in the path of heated air flow.

2. Avoid conditions of high humidity such as: outdoor patio installations where

dew is a factor, near steam radiators where steam leakage is a factor, etc.

3. Avoid placement where draperies may obstruct venting. The customer

should also avoid the use of decorative scarves or other coverings that might

obstruct ventilation.

4. Wall- and shelf-mounted installations using a commercial mounting kit must

follow the factory-approved mounting instructions. A product mounted to a

shelf or platform must retain its original feet (or the equivalent thickness in

spacers) to provide adequate air flow across the bottom. Bolts or screws

used for fasteners must not touch any parts or wiring. Perform leakage tests

on customized installations.

5. Caution customers against mounting a product on a sloping shelf or in a tilted

position, unless the receiver is properly secured.

6. A product on a roll-about cart should be stable in its mounting to the cart.

Caution the customer on the hazards of trying to roll a cart with small casters

across thresholds or deep pile carpets.

7. Caution customers against using a cart or stand that has not been listed by

Underwriters Laboratories, Inc. for use with its specific model of television

receiver or generically approved for use with TVs of the same or larger screen

size.

8. Caution customers against using extension cords. Explain that a forest of

extensions, sprouting from a single outlet, can lead to disastrous

consequences to home and family.

AV

PRODUCT SAFETY GUIDELINES

All manuals and user guides at all-guides.com

- 3 -

DESCRIPTION OF CONTROLS...........................................4

SPECIFICATIONS.................................................................7

ADJUSTMENT INSTRUCTIONS ..........................................8

TROUBLE SHOOTING GUIDE...........................................12

BLOCK DIAGRAM...............................................................23

EXPLODED VIEW...............................................................26

EXPLODED VIEW PARTS LIST.........................................27

REPLACEMENT PARTS LIST............................................28

SCHEMATIC DIAGRAM..........................................................

PRINTED CIRCUIT BOARD ...................................................

TABLE OF CONTENTS

All manuals and user guides at all-guides.com

- 4 -

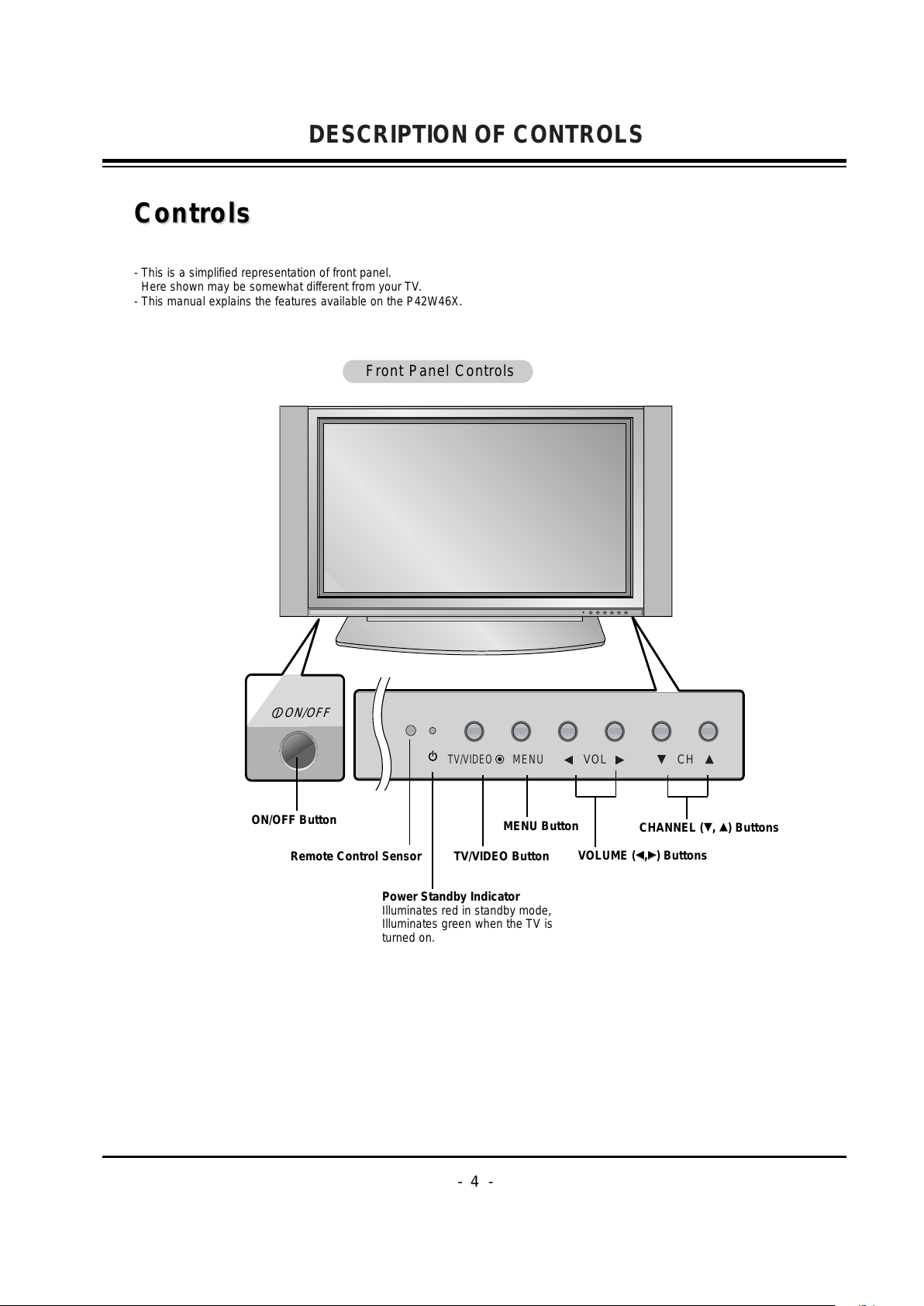

Controls

Controls

ON/OFF

TV/VIDEO

MENU

VOL CH

ON/OFF Button

- This is a simplified representation of front panel.

Here shown may be somewhat different from your TV.

- This manual explains the features available on the P42W46X.

Front Panel Controls

Front Panel Controls

Remote Control Sensor

VOLUME (

FF,GG

) Buttons

Power Standby Indicator

Illuminates red in standby mode,

Illuminates green when the TV is

turned on.

CHANNEL (EE, DD) Buttons

MENU Button

TV/VIDEO Button

DESCRIPTION OF CONTROLS

All manuals and user guides at all-guides.com

- 5 -

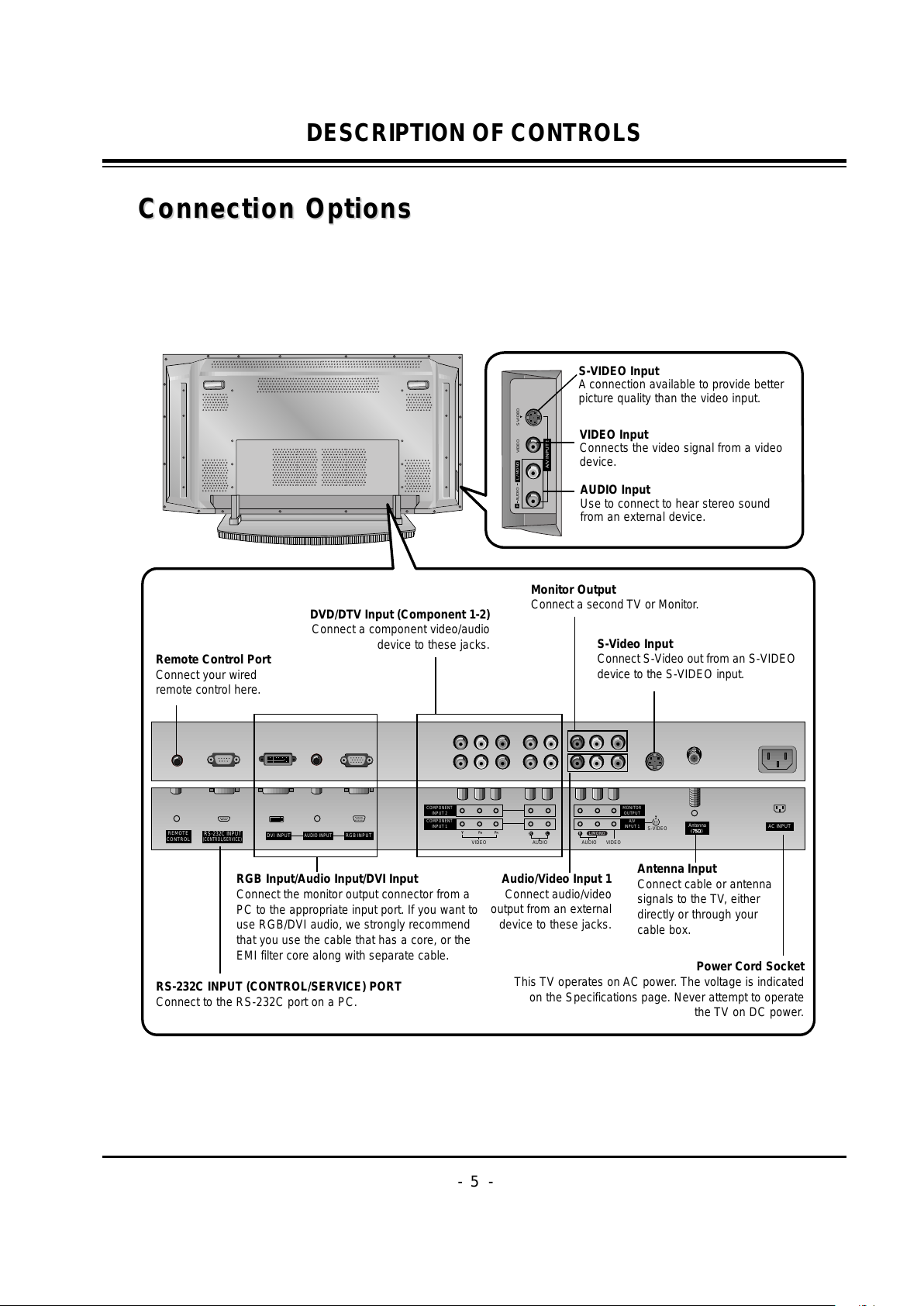

Connection Options

Connection Options

RGB INPUT

Antenna

AUDIO INPUT

DVI INPUT

S-VIDEO

REMOTE

CONTROL

AC INPUT

AUDIOVIDEO

COMPONENT

INPUT 2

COMPONENT

INPUT 1

MONITOR

OUTPUT

A/V

INPUT 1

R L

AUDIO VIDEO

R

RS-232C INPUT

(CONTROL/SERVICE)

L/MONO

R

S-VIDEO VIDEO

L / MONO

AUDIO

A/V INPUT2

Antenna Input

Connect cable or antenna

signals to the TV, either

directly or through your

cable box.

RGB Input/Audio Input/DVI Input

Connect the monitor output connector from a

PC to the appropriate input port. If you want to

use RGB/DVI audio, we strongly recommend

that you use the cable that has a core, or the

EMI filter core along with separate cable.

Audio/Video Input 1

Connect audio/video

output from an external

device to these jacks.

DVD/DTV Input (Component 1-2)

Connect a component video/audio

device to these jacks.

Monitor Output

Connect a second TV or Monitor.

Remote Control Port

Connect your wired

remote control here.

S-Video Input

Connect S-Video out from an S-VIDEO

device to the S-VIDEO input.

Power Cord Socket

This TV operates on AC power. The voltage is indicated

on the Specifications page. Never attempt to operate

the TV on DC power.

RS-232C INPUT (CONTROL/SERVICE) PORT

Connect to the RS-232C port on a PC.

S-VIDEO Input

A connection available to provide better

picture quality than the video input.

VIDEO Input

Connects the video signal from a video

device.

AUDIO Input

Use to connect to hear stereo sound

from an external device.

DESCRIPTION OF CONTROLS

All manuals and user guides at all-guides.com

- 6 -

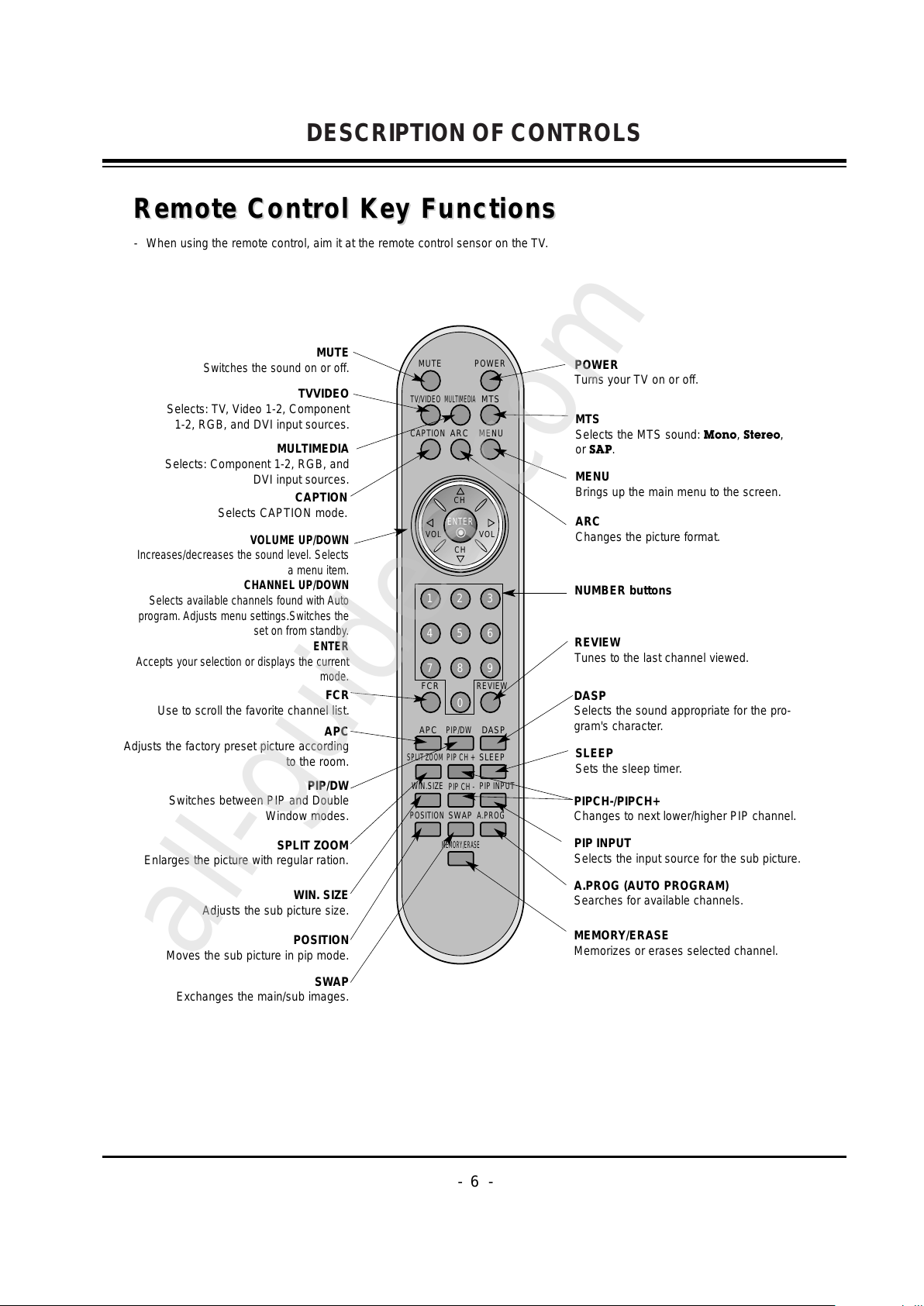

- When using the remote control, aim it at the remote control sensor on the TV.

POWERMUTE

TV/VIDEO

MULTIMEDIA

MTS

CAPTION

CH

CH

VOL

ENTER

1 2 3

4 5 6

7 8 9

0

VOL

ARC

MENU

FCR

PIP/DW

APC DASP

REVIEW

SPLIT ZOOM

PIP CH +

SLEEP

PIP CH -

PIP INPUTWIN.SIZE

SWAP

MEMORY/ERASE

A.PROGPOSITION

MUTE

Switches the sound on or off.

TVVIDEO

Selects: TV, Video 1-2, Component

1-2, RGB, and DVI input sources.

MULTIMEDIA

Selects: Component 1-2, RGB, and

DVI input sources.

CAPTION

Selects CAPTION mode.

VOLUME UP/DOWN

Increases/decreases the sound level. Selects

a menu item.

CHANNEL UP/DOWN

Selects available channels found with Auto

program. Adjusts menu settings.Switches the

set on from standby.

ENTER

Accepts your selection or displays the current

mode.

POWER

Turns your TV on or off.

MTS

Selects the MTS sound: Mono, Stereo,

or SAP.

MENU

Brings up the main menu to the screen.

REVIEW

Tunes to the last channel viewed.

NUMBER buttons

ARC

Changes the picture format.

PIP INPUT

Selects the input source for the sub picture.

SWAP

Exchanges the main/sub images.

PIP/DW

Switches between PIP and Double

Window modes.

PIPCH-/PIPCH+

Changes to next lower/higher PIP channel.

POSITION

Moves the sub picture in pip mode.

SLEEP

Sets the sleep timer.

FCR

Use to scroll the favorite channel list.

MEMORY/ERASE

Memorizes or erases selected channel.

A.PROG (AUTO PROGRAM)

Searches for available channels.

SPLIT ZOOM

Enlarges the picture with regular ration.

Remote Control Key Functions

Remote Control Key Functions

WIN. SIZE

Adjusts the sub picture size.

APC

Adjusts the factory preset picture according

to the room.

DASP

Selects the sound appropriate for the pro-

gram's character.

DESCRIPTION OF CONTROLS

All manuals and user guides at all-guides.com

all-guides.com

- 7 -

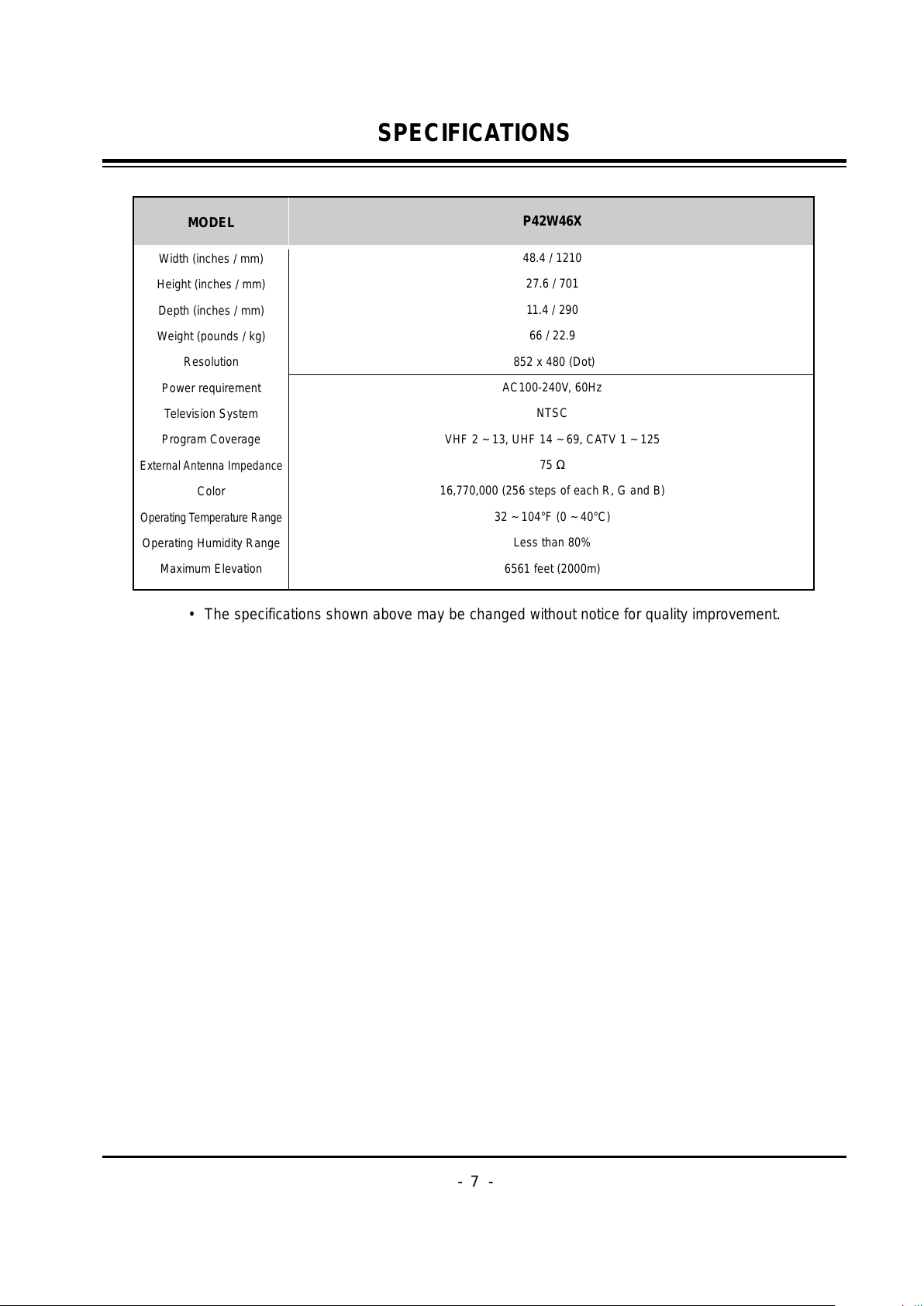

• The specifications shown above may be changed without notice for quality improvement.

MODEL

P42W46X

48.4 / 1210

27.6 / 701

11.4 / 290

66 / 22.9

852 x 480 (Dot)

AC100-240V, 60Hz

NTSC

VHF 2 ~ 13, UHF 14 ~ 69, CATV 1 ~ 125

75 Ω

16,770,000 (256 steps of each R, G and B)

32 ~ 104°F (0 ~ 40°C)

Less than 80%

6561 feet (2000m)

Width (inches / mm)

Height (inches / mm)

Depth (inches / mm)

Weight (pounds / kg)

Resolution

Power requirement

Television System

Program Coverage

External Antenna Impedance

Color

Operating Temperature Range

Operating Humidity Range

Maximum Elevation

SPECIFICATIONS

All manuals and user guides at all-guides.com

- 8 -

ADJUSTMENT INSTRUCTIONS

1. Application Object

These instructions apply to the RF-043A Chassis.

2. Specification

(1) Because this is not a hot chassis, it is not necessary to

use an isolation transformer. However, the use of isolation

transformer will help protect test instrument.

(2) Adjustment must be done in the correct order.

(3) The adjustment must be performed in the circumstance of

25±5°C of temperature and 65±10% of relative humidity if

there is no specific designation.

(4) The input voltage of the receiver must keep 100~220V,

50/60Hz.

(5) The receiver must be operated for about 15 minutes prior

to the adjustment.

O After RGB Full white HEAT-RUN Mode, the receiver must

be operated prior to adjustment.

O Enter into HEAT-RUN MODE

1) Press the POWER ON KEY on R/C for adjustment.

2) OSD display and screen display 100% full WHITE

PATTERN.

[ Set is activated HEAT-RUN without signal generator in

this mode.

[ Single color pattern(RED/BLUE/GREEN) of HEAT-RUN

mode uses to check PANEL.

Caution) If you turn on a still screen more than 20 minutes

(Especially digital pattern, cross hatch pattern), a after

image may be occur in the black level part of the

screen

.

3. Channel memory

3-1. Setting up the G-prove

(1) Install the GProve. (GProve4.4.0.2.exe)

(2) After installing the Gprobe, [Option -> Connection Setup]

or click the icon indicated in the picture and then setup as

below the picture.

(In case of the port (second one), set to the serial port

of the connected PC.

The other only have to be set as below the picture.)

(3) After finishing inputs, click the button [OK] to complete the

connection setup.

3-2. Confirming the G-prove

(1) Connect Rs232 cable and then turn on the power.

If communication is correct, the message is showed like in

the left output terminal.

(2) If the message is not showed, push the [INSTART] button

of the adjust remocon twice, and change the right selection

of the [System Control -> RS-232 Host] from GProbe to

PC.

** If it is impossible to check the OSD, push the [TILT]

button of the adjust remocon.

Then, the message which is “Starting Gprove...”

comes up. From this time, communication is operated

correctly.

However, you have to push the [TILT] button again

in case of turning on Main Power.

** If you want to check again whether commnunication is

on or not, input “test” and push the Enter key on the

right input terminal. If communication is on, the

message of “Test passed.” will come up

3-3. Channel memory method

(1) Click [Command -> Batch].

(2) When the window of [Batch] is showed, enter the text file

(Ch_Memory-RZ_PX10.txt) in the right blank of the File.

(3) Click the button [OK] to write CH information in the

EEPROM.

(4) It means the completion of the CH memory download that

the message of right output terminal is showed as below.

(Fig 2)

(Fig 1)

All manuals and user guides at all-guides.com

- 9 -

ADJUSTMENT INSTRUCTIONS

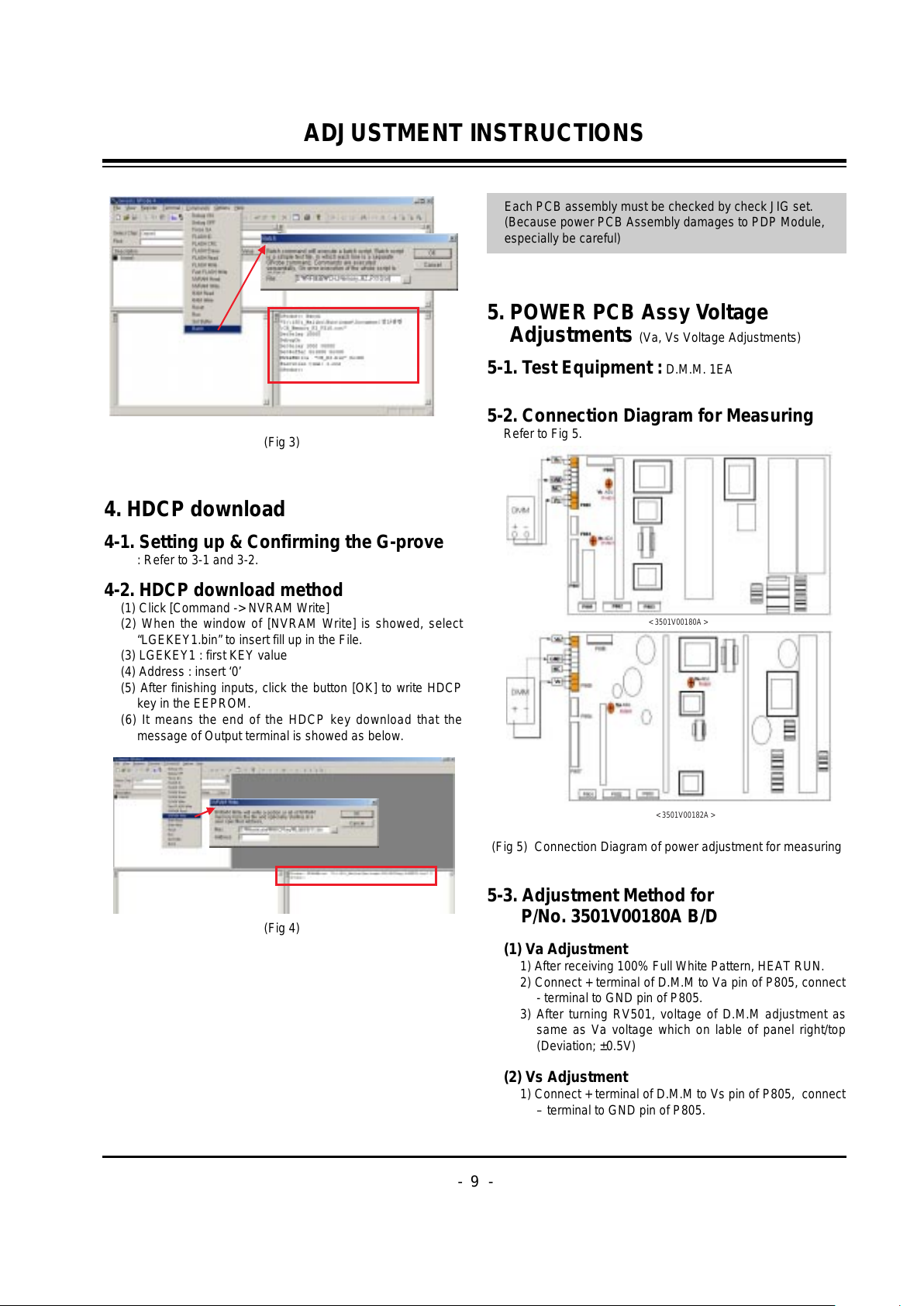

4. HDCP download

4-1. Setting up & Confirming the G-prove

: Refer to 3-1 and 3-2.

4-2. HDCP download method

(1) Click [Command -> NVRAM Write]

(2) When the window of [NVRAM Write] is showed, select

“LGEKEY1.bin” to insert fill up in the File.

(3) LGEKEY1 : first KEY value

(4) Address : insert ‘0’

(5) After finishing inputs, click the button [OK] to write HDCP

key in the EEPROM.

(6) It means the end of the HDCP key download that the

message of Output terminal is showed as below.

5. POWER PCB Assy Voltage

Adjustments

(Va, Vs Voltage Adjustments)

5-1. Test Equipment : D.M.M. 1EA

5-2. Connection Diagram for Measuring

Refer to Fig 5.

5-3. Adjustment Method for

P/No. 3501V00180A B/D

(1) Va Adjustment

1) After receiving 100% Full White Pattern, HEAT RUN.

2) Connect + terminal of D.M.M to Va pin of P805, connect

- terminal to GND pin of P805.

3) After turning RV501, voltage of D.M.M adjustment as

same as Va voltage which on lable of panel right/top

(Deviation; ±0.5V)

(2) Vs Adjustment

1) Connect + terminal of D.M.M to Vs pin of P805, connect

– terminal to GND pin of P805.

< 3501V00180A >

< 3501V00182A >

(Fig 5) Connection Diagram of power adjustment for measuring

(Fig 4)

(Fig 3)

Each PCB assembly must be checked by check JIG set.

(Because power PCB Assembly damages to PDP Module,

especially be careful)

All manuals and user guides at all-guides.com

- 10 -

2) After turning RV401, voltage of D.M.M adjustment as

same as Va voltage which on label of panel right/top.

(Deviation; ±0.5V)

5-4. Adjustment Method for

P/No. 3501V00182A B/D

(1) Va Adjustment

1) After receiving 100% Full White Pattern, HEAT RUN.

2) Connect + terminal of D.M.M to Va pin of P805, connect

- terminal to GND pin of P805.

3) After turning RV601, voltage of D.M.M adjustment as

same as Va voltage which on lable of panel right/top

(Deviation; ±0.5V)

(2) Vs Adjustment

1) Connect + terminal of D.M.M to Vs pin of P805, connect

– terminal to GND pin of P805.

2) After turning RV401, voltage of D.M.M adjustment as

same as Va voltage which on label of panel right/top.

(Deviation; ±0.5V)

6. Adjustment of White Balance

6-1. Required Equipment

Color Analyzer (CA-100 or same product)

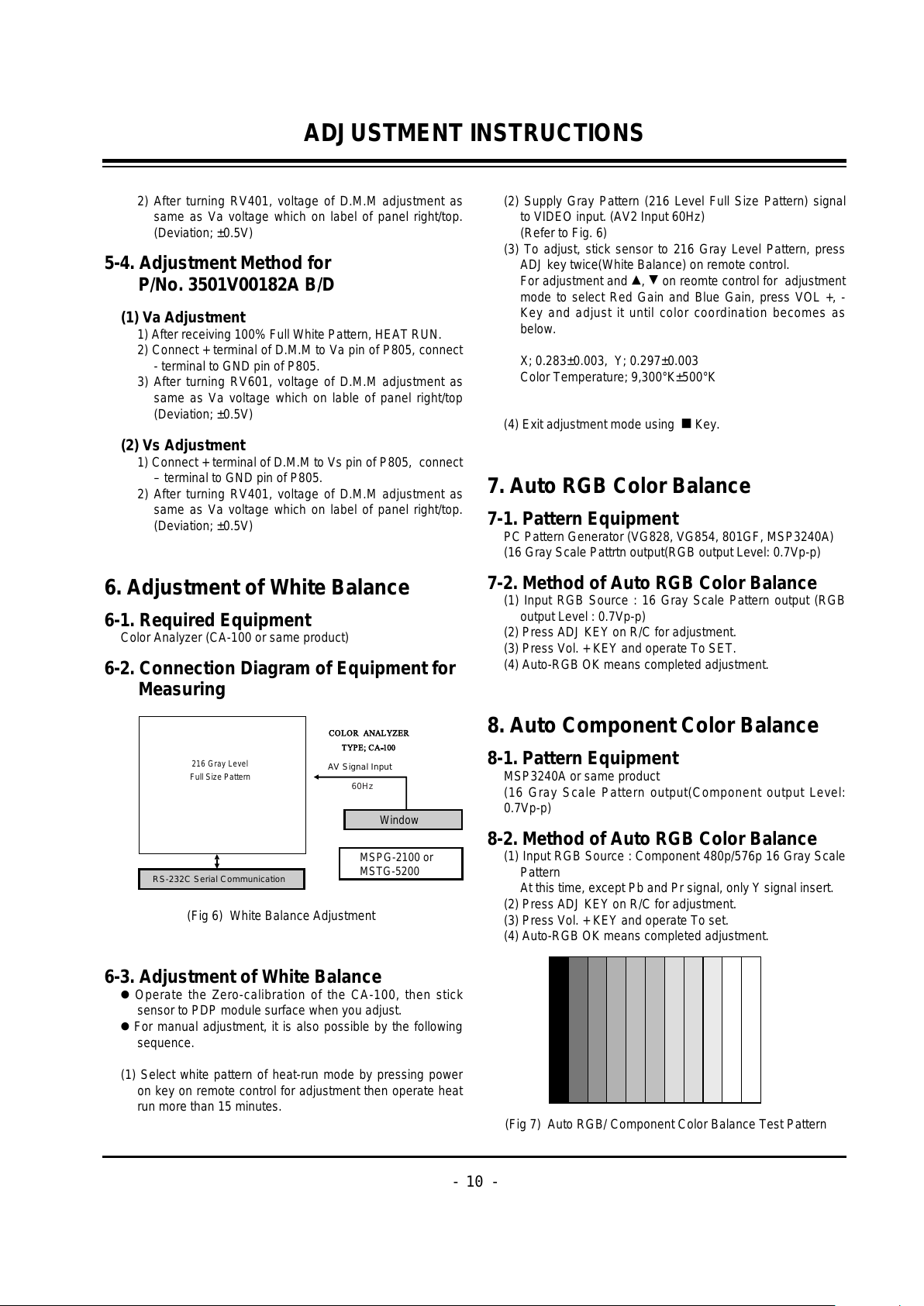

6-2. Connection Diagram of Equipment for

Measuring

6-3. Adjustment of White Balance

O Operate the Zero-calibration of the CA-100, then stick

sensor to PDP module surface when you adjust.

O For manual adjustment, it is also possible by the following

sequence.

(1) Select white pattern of heat-run mode by pressing power

on key on remote control for adjustment then operate heat

run more than 15 minutes.

(2) Supply Gray Pattern (216 Level Full Size Pattern) signal

to VIDEO input. (AV2 Input 60Hz)

(Refer to Fig. 6)

(3) To adjust, stick sensor to 216 Gray Level Pattern, press

ADJ key twice(White Balance) on remote control.

For adjustment and

D, E on reomte control for adjustment

mode to select Red Gain and Blue Gain, press VOL +, -

Key and adjust it until color coordination becomes as

below.

X; 0.283±0.003, Y; 0.297±0.003

Color Temperature; 9,300°K±500°K

(4) Exit adjustment mode using

A Key.

7. Auto RGB Color Balance

7-1. Pattern Equipment

PC Pattern Generator (VG828, VG854, 801GF, MSP3240A)

(16 Gray Scale Pattrtn output(RGB output Level: 0.7Vp-p)

7-2. Method of Auto RGB Color Balance

(1) Input RGB Source : 16 Gray Scale Pattern output (RGB

output Level : 0.7Vp-p)

(2) Press ADJ KEY on R/C for adjustment.

(3) Press Vol. + KEY and operate To SET.

(4) Auto-RGB OK means completed adjustment.

8. Auto Component Color Balance

8-1. Pattern Equipment

MSP3240A or same product

(16 Gray Scale Pattern output(Component output Level:

0.7Vp-p)

8-2. Method of Auto RGB Color Balance

(1) Input RGB Source : Component 480p/576p 16 Gray Scale

Pattern

At this time, except Pb and Pr signal, only Y signal insert.

(2) Press ADJ KEY on R/C for adjustment.

(3) Press Vol. + KEY and operate To set.

(4) Auto-RGB OK means completed adjustment.

Window

MSPG-2100 or

MSTG-5200

AV Signal Input

Full Size Pattern

216 Gray Level

RS-232C Serial Communication

60Hz

(Fig 6) White Balance Adjustment

ADJUSTMENT INSTRUCTIONS

(Fig 7) Auto RGB/ Component Color Balance Test Pattern

All manuals and user guides at all-guides.com

- 11 -

ADJUSTMENT INSTRUCTIONS

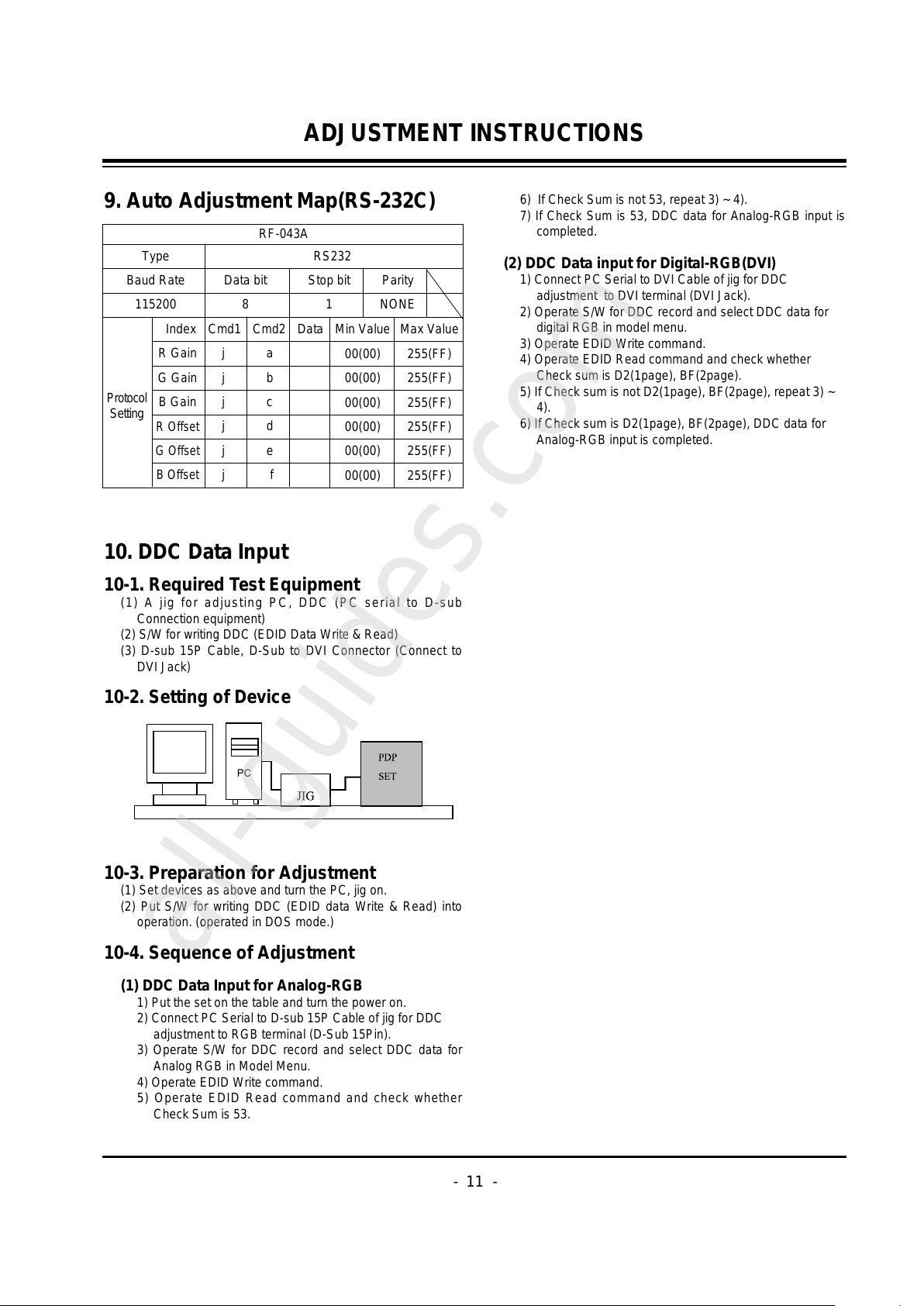

9. Auto Adjustment Map(RS-232C)

10. DDC Data Input

10-1. Required Test Equipment

(1) A jig for adjusting PC, DDC (PC serial to D-sub

Connection equipment)

(2) S/W for writing DDC (EDID Data Write & Read)

(3) D-sub 15P Cable, D-Sub to DVI Connector (Connect to

DVI Jack)

10-2. Setting of Device

10-3. Preparation for Adjustment

(1) Set devices as above and turn the PC, jig on.

(2) Put S/W for writing DDC (EDID data Write & Read) into

operation. (operated in DOS mode.)

10-4. Sequence of Adjustment

(1) DDC Data Input for Analog-RGB

1) Put the set on the table and turn the power on.

2) Connect PC Serial to D-sub 15P Cable of jig for DDC

adjustment to RGB terminal (D-Sub 15Pin).

3) Operate S/W for DDC record and select DDC data for

Analog RGB in Model Menu.

4) Operate EDID Write command.

5) Operate EDID Read command and check whether

Check Sum is 53.

6) If Check Sum is not 53, repeat 3) ~ 4).

7) If Check Sum is 53, DDC data for Analog-RGB input is

completed.

(2) DDC Data input for Digital-RGB(DVI)

1) Connect PC Serial to DVI Cable of jig for DDC

adjustment to DVI terminal (DVI Jack).

2) Operate S/W for DDC record and select DDC data for

digital RGB in model menu.

3) Operate EDID Write command.

4) Operate EDID Read command and check whether

Check sum is D2(1page), BF(2page).

5) If Check sum is not D2(1page), BF(2page), repeat 3) ~

4).

6) If Check sum is D2(1page), BF(2page), DDC data for

Analog-RGB input is completed.

Type

Baud Rate

115200

Index

R Gain

G Gain

B Gain

R Offset

G Offset

B Offset

Data bit

8

Cmd1 Cmd2

j a

j b

j c

j d

j e

j f

Stop bit1Parity

NONE

RF-043A

Protocol

Setting

Data Min Value

00(00)

00(00)

00(00)

00(00)

00(00)

00(00)

Max Value

255(FF)

255(FF)

255(FF)

255(FF)

255(FF)

255(FF)

RS232

All manuals and user guides at all-guides.com

all-guides.com

- 12 -

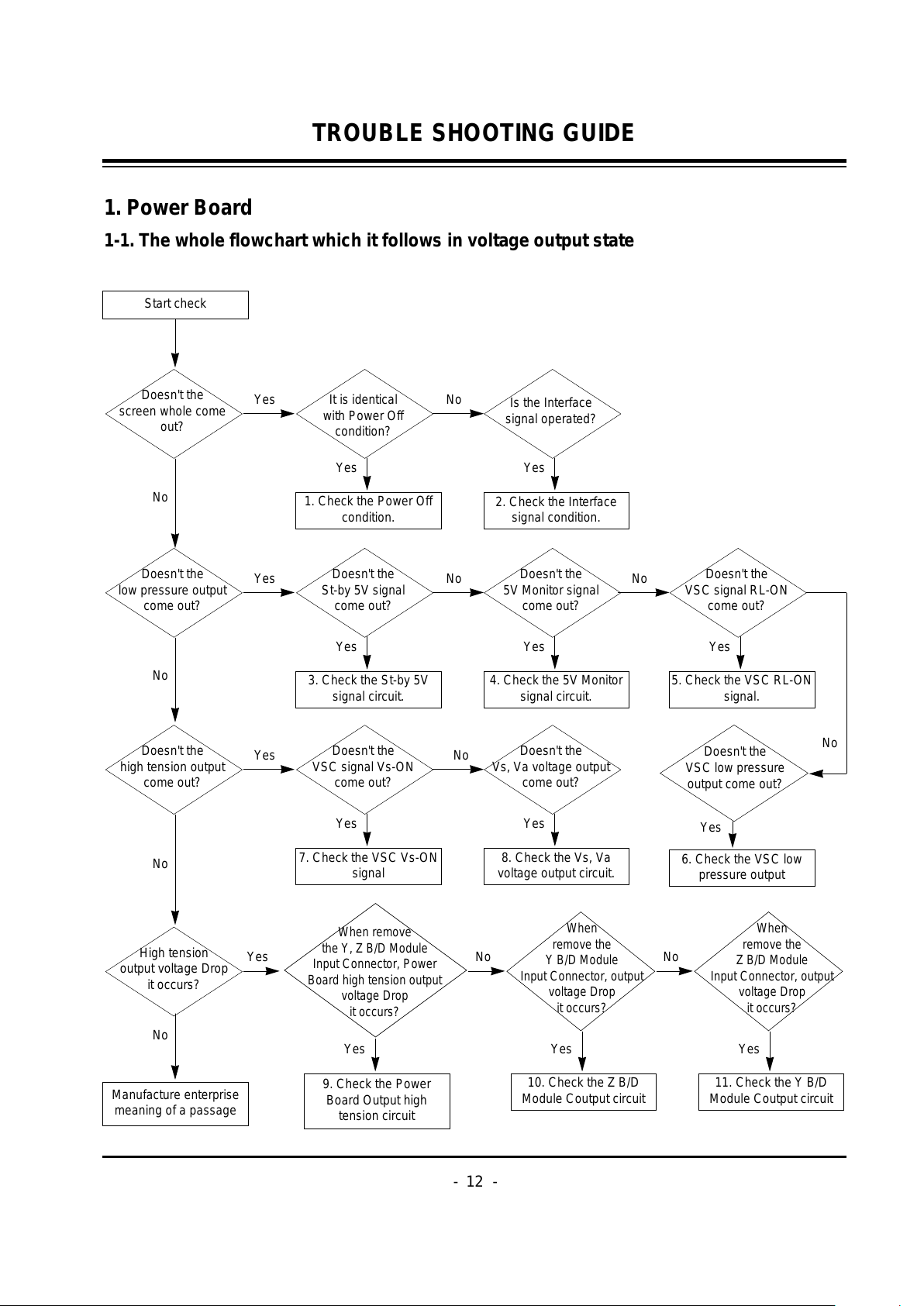

TROUBLE SHOOTING GUIDE

1. Power Board

1-1. The whole flowchart which it follows in voltage output state

Start check

Manufacture enterprise

meaning of a passage

1. Check the Power Off

condition.

Doesn't the

screen whole come

out?

It is identical

with Power Off

condition?

Yes

Yes

No

No

No

No

No

2. Check the Interface

signal condition.

Is the Interface

signal operated?

Yes

3. Check the St-by 5V

signal circuit.

Doesn't the

low pressure output

come out?

Doesn't the

St-by 5V signal

come out?

Yes

Yes

No

4. Check the 5V Monitor

signal circuit.

Doesn't the

5V Monitor signal

come out?

Yes

7. Check the VSC Vs-ON

signal

Doesn't the

high tension output

come out?

Doesn't the

VSC signal Vs-ON

come out?

Yes

Yes

High tension

output voltage Drop

it occurs?

When

remove the

Y B/D Module

Input Connector, output

voltage Drop

it occurs?

When remove

the Y, Z B/D Module

Input Connector, Power

Board high tension output

voltage Drop

it occurs?

Yes No No

9. Check the Power

Board Output high

tension circuit

Yes

10. Check the Z B/D

Module Coutput circuit

Yes

When

remove the

Z B/D Module

Input Connector, output

voltage Drop

it occurs?

11. Check the Y B/D

Module Coutput circuit

Yes

No

8. Check the Vs, Va

voltage output circuit.

Doesn't the

Vs, Va voltage output

come out?

Yes

No

No

5. Check the VSC RL-ON

signal.

Doesn't the

VSC signal RL-ON

come out?

Yes

6. Check the VSC low

pressure output

Doesn't the

VSC low pressure

output come out?

Yes

All manuals and user guides at all-guides.com

- 13 -

TROUBLE SHOOTING GUIDE

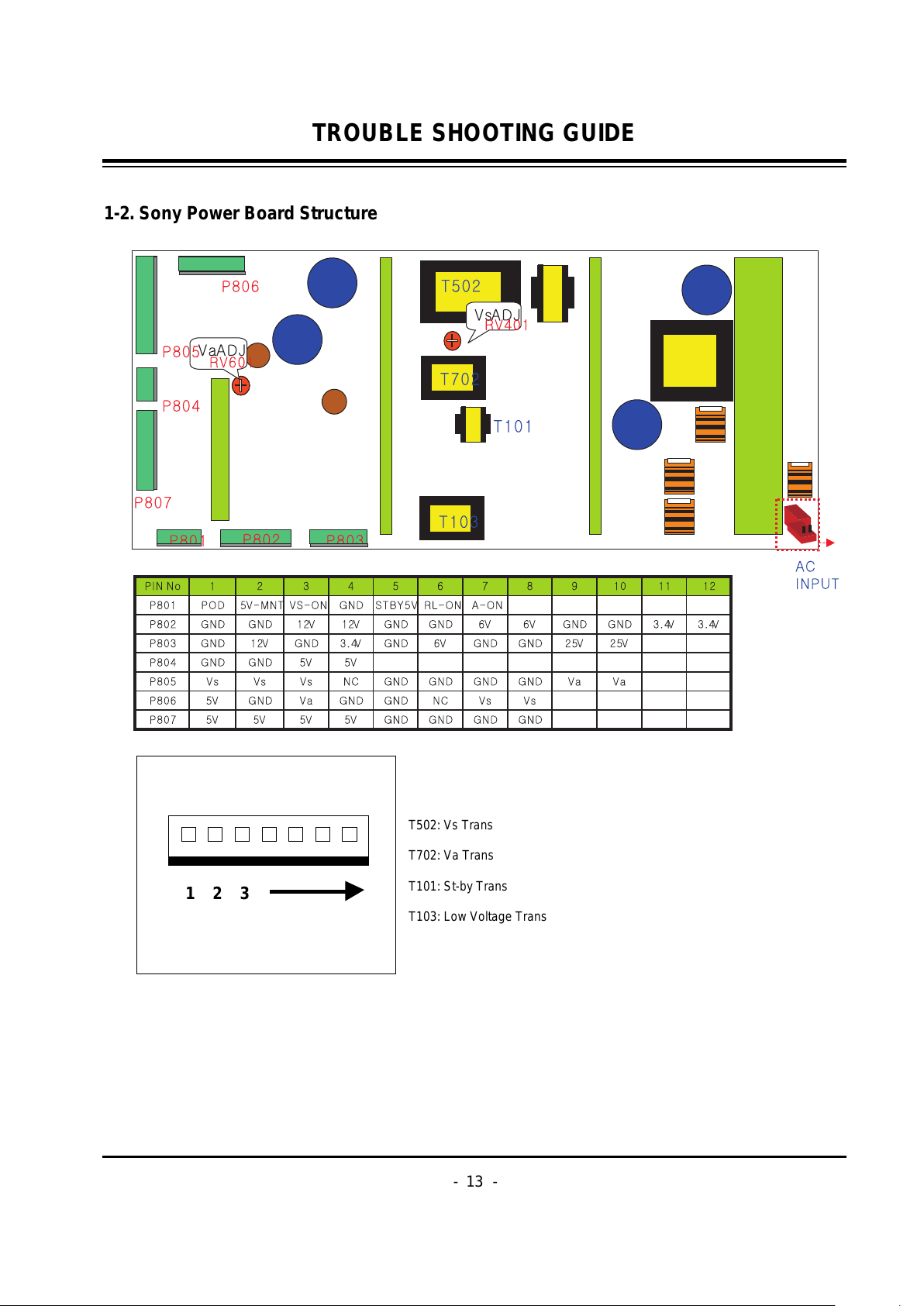

1-2. Sony Power Board Structure

T502: Vs Trans

T702: Va Trans

T101: St-by Trans

T103: Low Voltage Trans

1 2 3

All manuals and user guides at all-guides.com

Loading...

Loading...