Page 1

- 7 -

1. Application Object

These instructions are applied to all of the PDP monitor, NP00LE.

2. Notes

(1) Because this is not a hot chassis, it is not necessary to use

an isolation transformer. However, the use of isolation

transformer will help protect test instrument.

(2) Adjustment must be done in the correct order.

(3) The adjustment must be performed in the circumstance of

25±5¡C of temperature and 65±10% of relative humidity if

there is no specific designation.

(4) The input voltage of the receiver must keep 110~240V,

50/60Hz in adjusting.

(5) The receiver must be operated for about 15 minutes prior

to the adjustment.

¤ After receiving 100% white pattern(06CH), the receiver

must be operate prior to adjustment.(Or white condition

in HEAT-RUN mode)

¤ŁEnter into HEAT-RUN mode

- Select the HEAT-RUN OFF by pressing ADJ button on

Remote Control for adjustment.

- Press the VOL + button in HEAT-RUN OFF.

(OSD display HEAT-RUN WHITE and screen display

100% full WHITE PATTERN)

¤ØSet is activated HEAT-RUN without SET TOP BOX or

signal generator in this mode.

[ Single color pattern of HEAT-RUN mode uses to check

PANEL.(RED/BLUE/GREEN)

[Caution] If you turn on a still screen more than 20 minutes, a

afterinage may be occur in the black level part of the

screen.

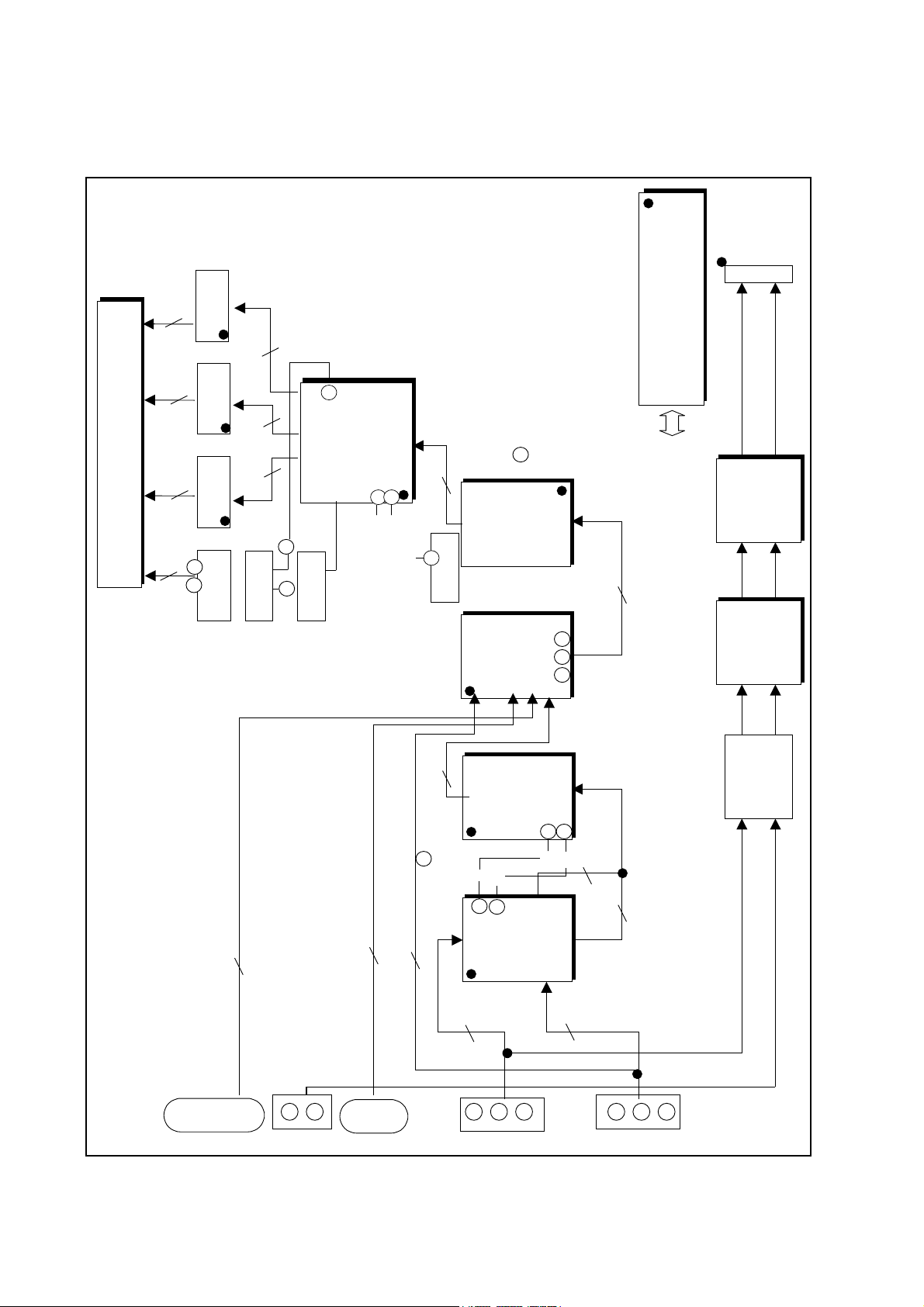

3. POWER PCB Assy Voltage Adjustment

[ Replace PDP Module or Power Board, adjust certainly Power

PCB Assy Voltage.

3-1. Test Equipment

D.M.M 1EA

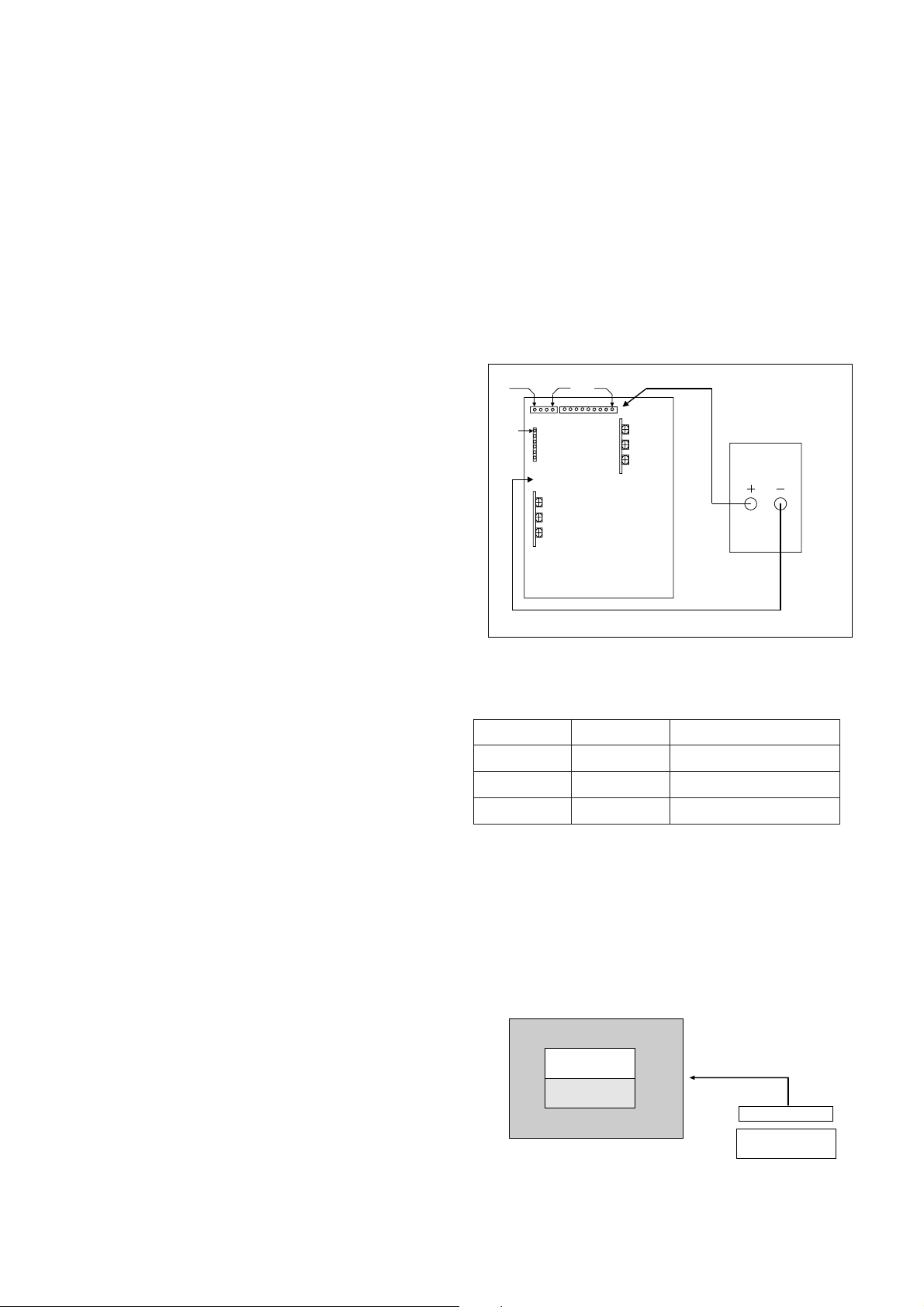

3-2. Connection Diagram for Measuring

Refer to Fig 1.

3-3. Adjustment Method

(1) Va Adjusment(Address Voltage Adjusment)

¤ Connect pin 1 of P814 to (+) jack of D.M.M.

¤ŁAfter turning the VR803(Va Adj), voltage of D.M.M

adjustment as same as Va voltage which on label of

panel right/bottom.(Deviation : ±0.5V)

(2) Vs Adjustment

¤ Connect pin of P803 to (+) jack of D.M.M.

¤ŁAfter turning the VR804(Vs Adj), voltage of D.M.M

adjust as same as Vs voltage which indicated on label

of panel right/bottom.(Deviation : ±0.5V)

(3) VSC Adjustment

¤ Connect pin 4 of P802 to (+) jack of D.M.M.

¤ŁAfter turning the VR806(VSC Adj), voltage of D.M.M

adjust as same as Vs voltage which indicated on label

of panel right/bottom.(Deviation : ±0.5V)

(4) VSETUP Adjustment

¤ Connect pin 1 of P802 to (+) jack of D.M.M.

¤ŁAfter turning the VR805(VSETUP Adj),voltage of D.M.M

adjust as same as Vs voltage which indicated on label

of panel right/bottom.(Deviation : ±0.5V)

4. Adjustment of RGB Cut-off and

White Balance

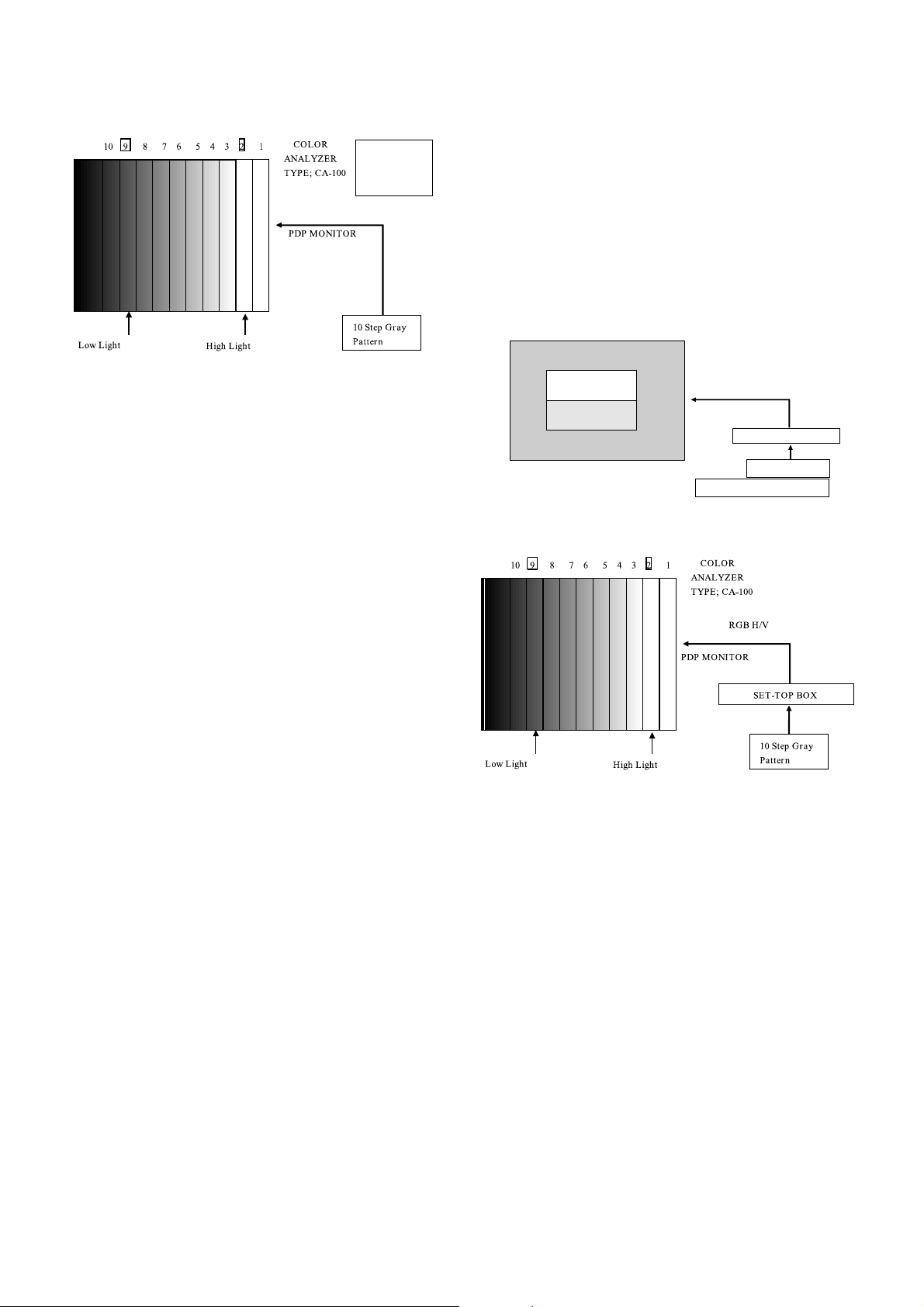

4-1. Required Equipment

Color analyzer(CA-100 or same production)

4-2. Connection Diagram of Equipment for

Measuring

ADJUSTMENT INSTRUCTIONS

VSETUP

VR806

VR805

VR804

DMM

VSC

VA

VSC CTL

V

A CTL

P814

VR803

GND

V

SETUP CTL

V

S CTL

V

S

<Fig 1> Connection Diagram of Power Adjustment for Measuring

Refer to Typical Voltage

Va

Vs

Vsc

Vsetup

75V

188V

90V

230V

Address Voltage

Sustain Voltage

Scan Voltage

Setup Voltage

COLOR

ANALYZER

TYPE; CA-100

Window Pattern

CVBS Signal Input

High Light

120±4cd/m2

Low Light

6±1cd/m2

PDP MONITOR

MSPG-2100 or

MSTG-5200

<Fig 2> Connection Diagram of Automatic Adjustment

Page 2

- 8 -

4-3. Adjustment of RGB CUT OFF

(1) Select RGB cut-off(adjustment 1) by pressing ADJ button

on Remote Control for adjustment. (If it enter to adjustment

mode, it is selected RF 13CH automatically)

(2) Press the VOL + or VOL - button.

(3) It displayed all of the black on the screen and then

adjustment is started.

(4) If adjustment is finished, exit from adjustment mode by

pressing enter button.

4-4. Adjustment of White Balance

¥ White Balance should be done after RGB cut-off become

adjustment.

¥ Operate the Zero-calibration of the CAÑ100, then stick

sensor to PDP module surface when you adjust.

(1) Select WHITE PATTERN of HEAT RUN mode by pressing

ADJ button on Remote Control for adjustment then operate

HEAT RUN more than 15 minute.

(2) Supply 10 step gray scale bar signal or window pattern in

pattern generater. (When using the STB, input RF 13CH, it

does not use, input AV.)

[ When adjustment is operated manually, perate process (3)

to (6) regular sequence, when adjustment is operated

automatically perate process (1) to (2).

(3) To adjust Low Light, stick sensor to 9th pattern(Dark),

select the R cut(adjustment 8)/B cut(adjustment 10) by

pressing ADJ button on Remote Control for adjustment

and adjust it until color coordination becomes

X=0.280±0.003, Y=0.310±0.003 and color temperature

becomes 8.800

cK ± 500cK by pressing VOL+, - button. (G-

cut fixation)

(4) To adjust High Light, stick sensor to 2th pattern(White).

Select the R Gain(adjustment 5)/G Gain(adjustment 6) by

pressing ADJ button on Remote Control for adjustment

and adjust R Gain/G Gain until color coordination becomes

X=0.280±0.003, Y=0.310±0.003 and color temperature

becomes 8.800cK ± 500cK.(B-Gain fixation)

(5) Confirm the result of the High Light adjustment.

If the deviation of High Light occur, operate the adjustment

of Low Light and High Light again.

(6) Exit adjustment mode using Enter button.

5. Color Temperature of STB

White Balance Adjustment

5-1. Required Equipment

Color Analyzer(CA-110, CA-100 or same production)

5-2. Connection diagram of equipment for

measuring

(1) To adjust the deviation of the STB signal output.

(2) Use regular PDP Monitor(JIG).

5-3. Adjustment Method

¥ Connect the STB to regular PDP Monitor.

¥ Operate the zero-calibration of the CA-100, then stick

sensor to surface of PDP module when you adjust.

(1) Select ITE PATTERN of HEAT RUN mode by pressing

ADJ button on Remote Control for adjustment, then

operate HEAT RUN more than 15 minute.

(Operate the HEAT RUN to adjust the STB at first, then if

OFF hour donÕt keep more than 3 minutes, operate next

adjustment of the STB without HEAT RUN.)

(2) Supply 10 step gray scale bar signal or window pattern in

pattern generator(RF 13CH or AV1)

[ When adjustment is operated manually, perate process (3)

to (7) regular sequence, when adjustment is operated

automatically perate process (1) to (2).

CVBS Signal Input

CVBS

Signal Input

Adjustment Adjustment

<Fig 3> Connection Diagram of Manual Adjustment

COLOR

ANALYZER

TYPE; CA-100

CVBS Signal Input

PDP MONITOR

SETTOP BOX

Window Pattern

MSPG-2100 or MSTG-5200

High Light

120±4cd/m2

Low Light

6±1cd/m2

<Fig 4> Connection Diagram of STB Automatic Adjustment

Signal Input

Adjustment Adjustment

<Fig 5> Connection Diagram of STB Manual Adjustment

Page 3

(3) Select CXA2101 ADJ STB(CH+/- button) by pressing

INSTART button on Remote Control for adjustment.

Select adjustment mode with VOL+ or VOL-.(Adjustment

0~4)

(4) To adjust Low Light, stick sensor to 9th pattern(Dark).

Select the B Cut(adjustment 0)/R Cut(adjustment 1), then

adjust the B Cut/R Cut until color coordination becomes

X=0.280±0.003, Y=0.310±0.003 and color temperature

becomes 8.800cK ± 500cK by pressing VOL+, - button.

(5) To adjust High Light, stick sensor to 2th pattern(White).

Select the R Gain(adjustment 2)/G Gain(adjustment 3),

then adjust the R Gain/G Gain until color coordination

becomes X=0.280±0.003, Y=0.310±0.003 and color

temperature becomes 8.800cK ±500cK. (B-Gain fixation)

(6) Confirm the result of the High Light adjustment.

If the deviation of High Light occur, operate the adjustment

of Low Light and High Light again.

(7) Exit adjustment mode using Enter button.

- 9 -

Page 4

- 10 -

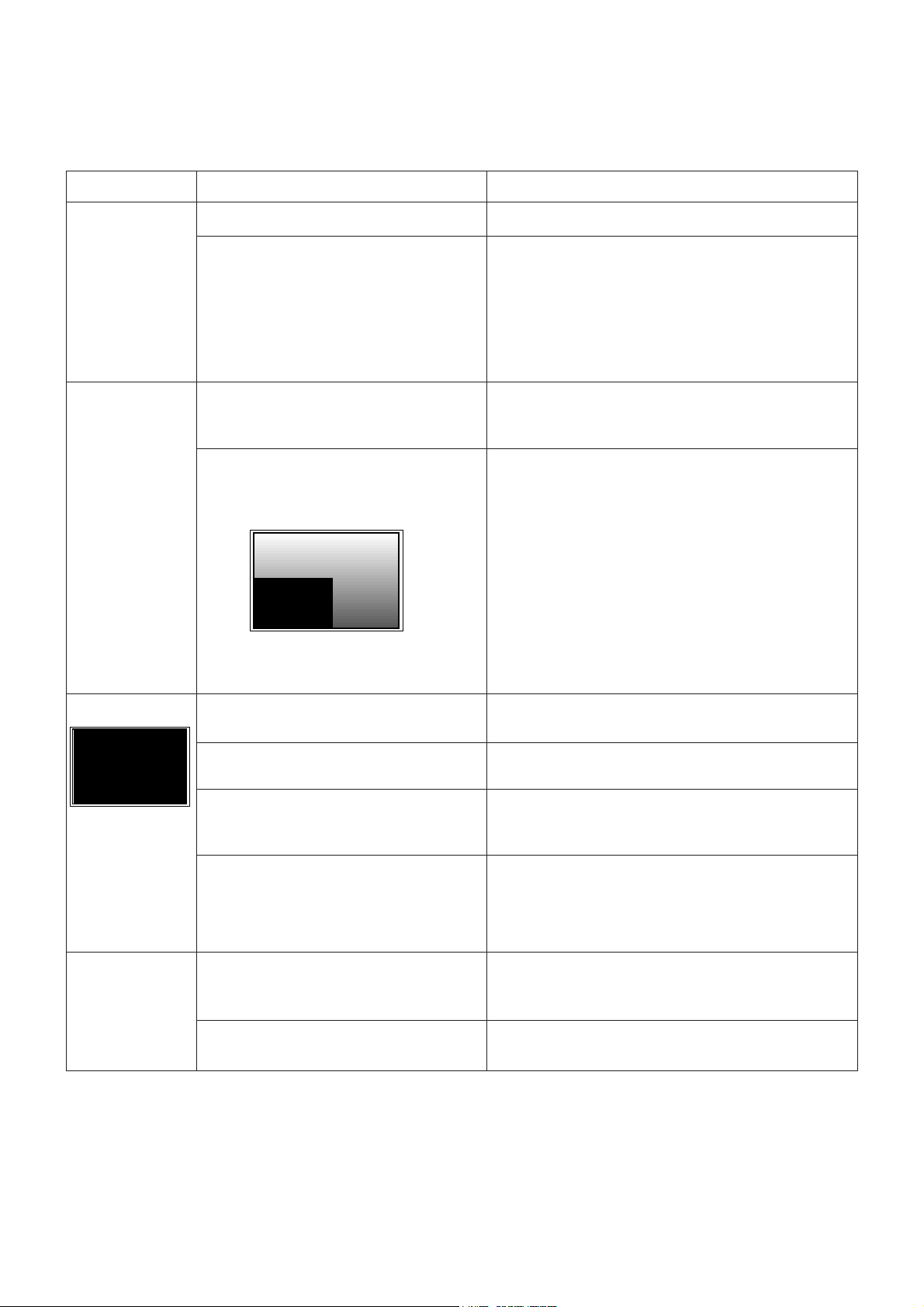

TROUBLESHOOTING

Phenomenon

No Power

No Raster

Abnormal Picture

An example of

abnormal picture.

No Sound

PSU(Power Supply Unit) is dead.

PSU operates protect mode, when the power

lines of the boards of module or VSC(Video

Scan Converter) is short.

When the connecters of Y_board or z_board

are not inserted in a wafer or electrically

opened, the picture of monitor is very dim.

When the connecters of X_boards are not

inserted in a wafer or electrically opened,

three tenths or two tenths of picture of monitor

is not present.

In case of the connecter of

Left_Bottom_X_board is open.

PSU 12V power line is short. Or the VSC 12V

power line short.

The 41p connecter assembly(PD501), from

VSC to control board of Module, is open.

The regulators of VSC Board are wrong

condition.

In case of the clocks of Scaler(MX88L284,

IC401) or AD Converter(THS8083, IC301) are

not present.

In case of one of two connecters(P006A and

P007A) is not connected with a proper wafer,

or opened.

The regulator of VSC Board is wrong

condition.

Replace PSU.

1) Remove all connecter assemblies from PSU to X_board,

Y_board & Z_board.

2) Turn on power.

3) If PSU repeatedly operates protect mode, then replace

VSC board.

4) Otherwise, check the power lines of Module.

5) Power lines of Module are short, replace the board of

module or module.

Find the connecters, insert into a wafer or replace the

connecter.

Find the connecters, insert into a wafer or replace the

connecter.

Replace PSU. Or replace VSC board.

Check the 41p connecter assembly.

If the 41p connecter assembly is internally open, replace.

Check the regulators of VSC(IC201, 202, 205, 301, 302, 404

and 406). If these are wrong inserted or shorted to GND,

then replace.

Check clock output pin of each IC.

If output is not present,

1) Check Power line of the IC.

2) Check Crystals(X301, X401).

3) Replace IC.

Check P006A & P007A.

If it is internally open, then replace.

Check the regulator of VSC(IC601).

If these are wrong inserted or shorted to GND, then replace.

Root Cause/Responsibility Solution

Page 5

- 11 -

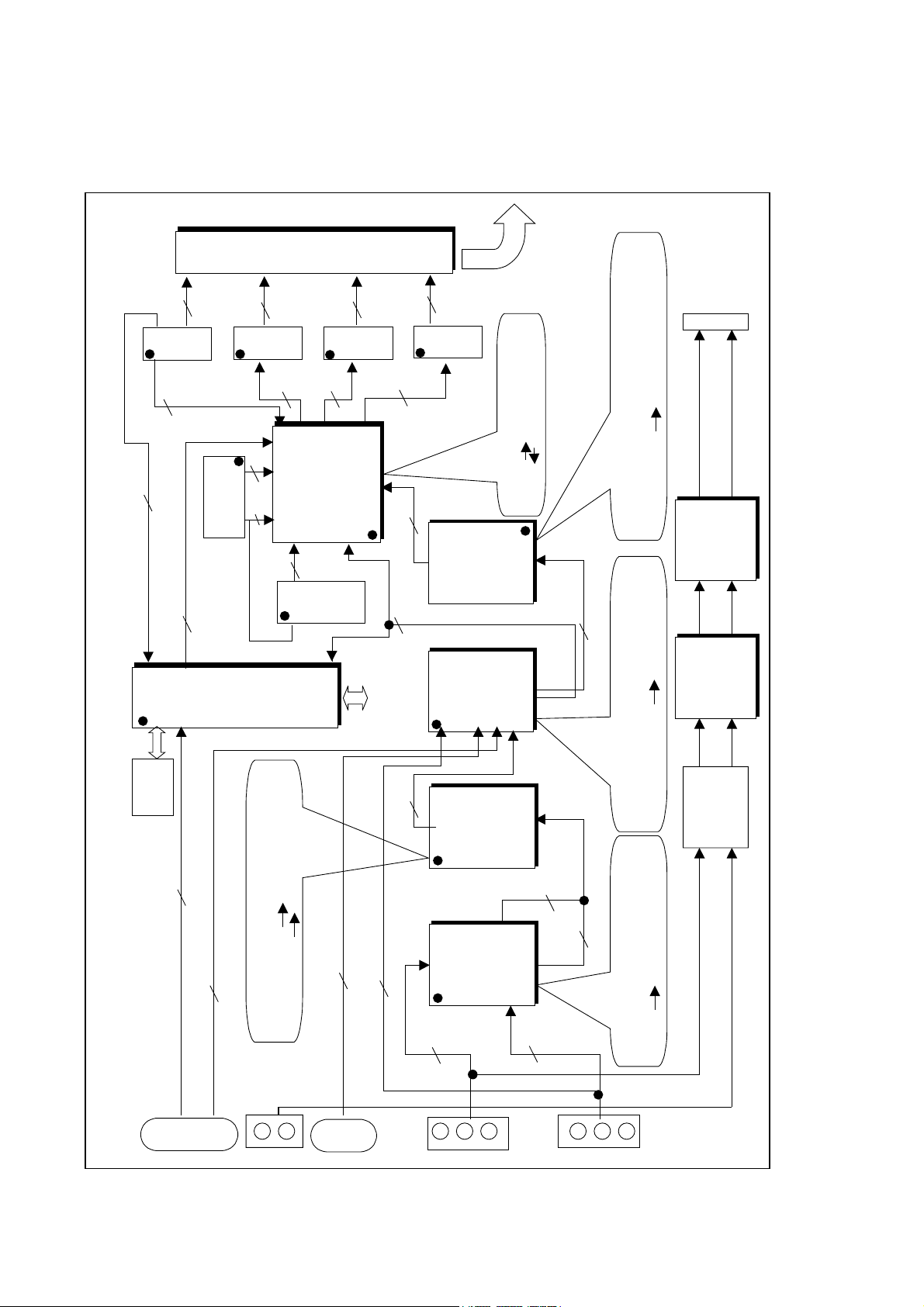

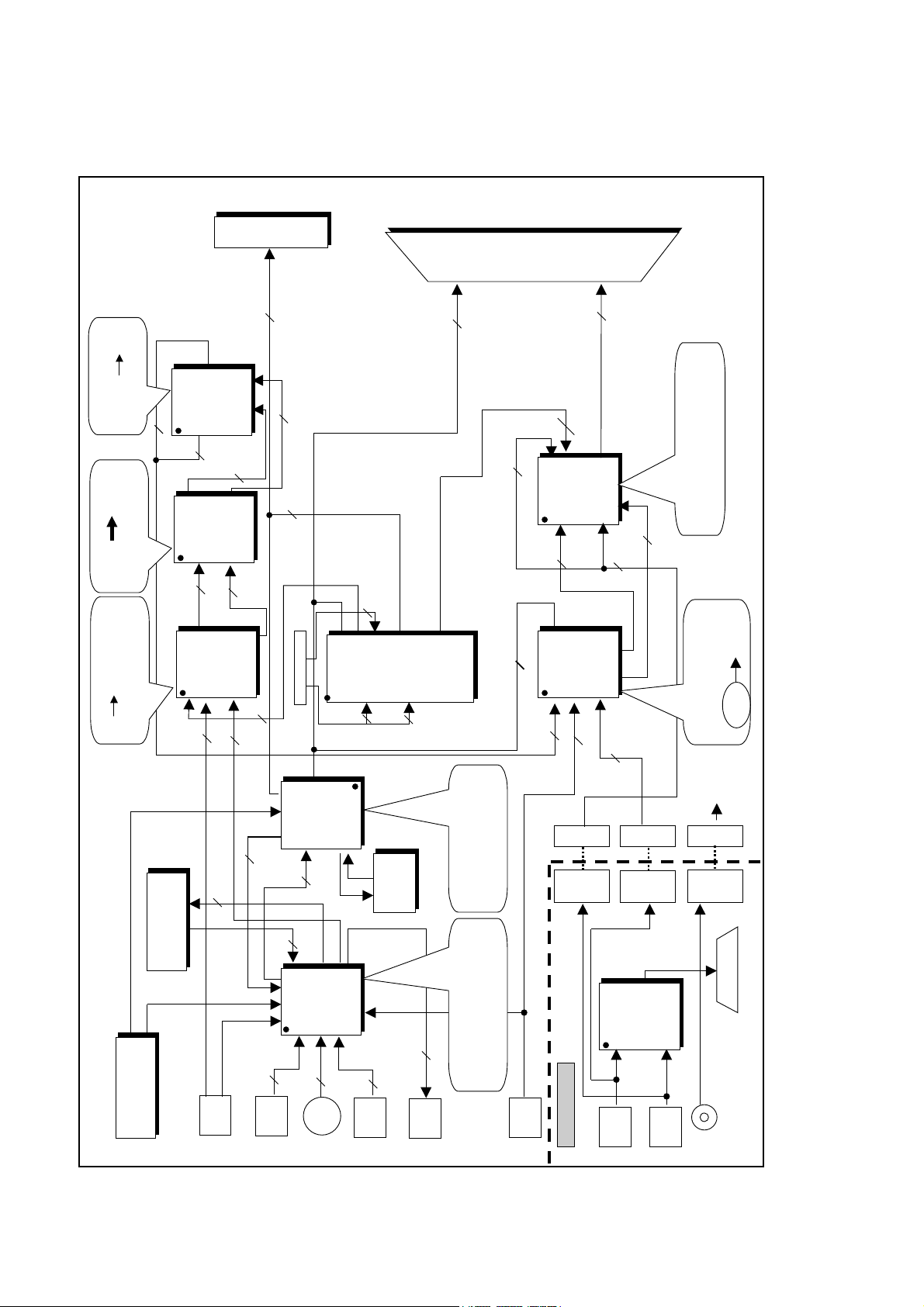

BLOCK DIAGRAM

1. VSC Board

Chip for flat panel display application

VGA SVGA scale up/down

Triple 8Bit, 80MSPS, 3.3V Video&Graphic Digitizer

with Digital PLL

Analog R/G/B 3X8 Digital R/G/B

Display Processor & Scan Rate Converter

(Format Converter)

Interlace

Progressive

15KHz 31KHz(2H X 1V)

Comb Filter Video Process

TV CVBS(Composite Video Baseband

Signal) Y/C(Y,U,V)

P101

V/R/L

P102

DVD

DS102

DS101

IC203

VPC3230

Decoder

80Pin

IC203

VPC3230

Decoder

80Pin

3

Y,Cb,Cr

CVBS

(A)

1

IC204

SDA9410

Deinterlace &

D/A

100Pin

IC204

SDA9410

Deinterlace &

D/A

100Pin

8 LU0-7

8

CHR0-7

IC303

CXA2101AQ

Video&

80Pin

IC303

CXA2101AQ

Video & Chroma

80Pin

STB-R/G/B/HS/VS(A )

5

PC-R/G/B/HS/VS(A)

5

DTV-Y/ Pb/Pr (A)

3

TV-Y/U/ V/ HVs

(A)

4

IC304

THS8083

100Pin

IC304

THS8083

100Pin

3 CXA-R/G/B(A )

IC401

MX88L284

3X2M

Scan converter

208Pin

IC401

MX88L284

3X2M

Scan converter

208Pin

IC001

M37270

EEPROM

IC001

M37280

EEPROM

Micro-Com

IC403

2M

SDRAM

IC402

2M SDRAM

(R/G/B)(D)

CAX-HS/VS

2

2

16

D0-16

A0-10

D16-31

11

16

OSD_R/G/B/YS

4

IC501

74F541

IC502

74F541

IC503

74F541

IC504

74F541

OSD_HS/VS

2

HS/VS_OUT

2

8

DOR0-7

8

DOG0-7

8

DOB0-7

STB-POWER

(A) : Analog Signal

(D) : Digital Signal

VSC DET/POWER

HDSTB_DET

STB_SCL/SDA

ANA_STB_DET

7

PVS/PHS_OUT

2

PAR0-7

8

PAG0-7

8

PAB0-7

8

PD501

(41Pin)

PDP Module

(D)

3X8

Multi-Component Processor

(Baseband Video Signal Processor)

STB, PC, DTV, TV Analog R/G/B

D-sub

25

D-sub

15

IC604

LA7222

(Audio S/W)

(A)

P601

L/R

STB/PC/DTV1

AV/DVD/DTV2

IC602

CXA2022S

(Tone Control)

IC602

CXA2022S

(Tone Control)

IC603

TDA2616

Audio Amp.

(12Wx2)

IC603

LA4282

Audio Amp.

(12Wx2)

Lout

Rout

P007A

(Spk. Jack)

I C Bus

IC002

24C08

Page 6

- 12 -

2. VSC Signal Flow(R/G/B-H/V)

P101

V/R/L

P102

DVD

DS102

DS101

IC203

VPC3230

Decoder

80Pin

IC203

VPC3230

Decoder

80Pin

3

Y,Cb,Cr

CVBS

C236

C209

C210

C211

(A)

1

IC204

SDA9410

Deinterlace

D/A

100Pin

IC204

SDA9410

Deinterlace &

D/A

100Pin

8 LU0-7

C646

C650

C645

C651

8

CHR0-7

IC303

CXA2101AQ

Video&

80Pin

IC303

CXA2101AQ

Video &Chroma

80Pin

STB-R/G/B/HS/VS( : C323~319 A)

5

PC-R/G/B/HS/VS ( : C317~319A)

5

DTV-Y/ Pb/Pr ( : C382~384

R220

A)

3

IC304

THS8083

100Pin

IC304

THS8083

100Pin

3 CXA-R (A )

IC401

MX88L284

3X2M

Scan converter

208Pin

IC401

MX88L284

3X2M

Scan converter

208Pin

Vout

(R/G/B)(D)

(D)

3X8

IC501

74F54

1

IC502

74F541

IC503

74F541

IC504

74F541

8

DOR0-7

8

DOG0-7

8

DOB0-7

PVS/PHS_OUT

2

PAR0-7

8

PAG0-7

8

PAB0-7

8

PD501

(41Pin)

D-sub

25

D-sub

15

IC604

LA7222M

(Audio S/W)

(A)

P601

L/R

STB/PC

AV/DVD/DTV

IC602

CXA2022S

(Tone Control)

IC602

CXA2022S

(Tone Control)

IC603

TDA2616

Audio Amp.

(12Wx2)

IC603

LA4282 Pin7

Pin11

C619

C610

Audio Amp.

(12Wx2)

Lout

Rout

P007A

(Spk. Jack)

IC001

M37270

EEPROM

Micro-Co

IC001

M37270

EEPROM

Micro-Com

I2C Bus

TV-Y/U/ V/ HVs

(A)

4

57

26

35 37 39

27

56

Hs:R208

Vs

Hs

Vs

H:R212

V:R213

H:R301

V:R302

Y:C305

G

B

R G B

H:R319

V:R318

R:C362

G:C366

B:C370( )

H:R345

V:R344

IC405

PLL-H:R355

6

THS-CLP

H

V

203

100

204

BA407

Vs

Hs

H

V

13

15

BA408

OSD-R/G/B/YS

Page 7

- 13 -

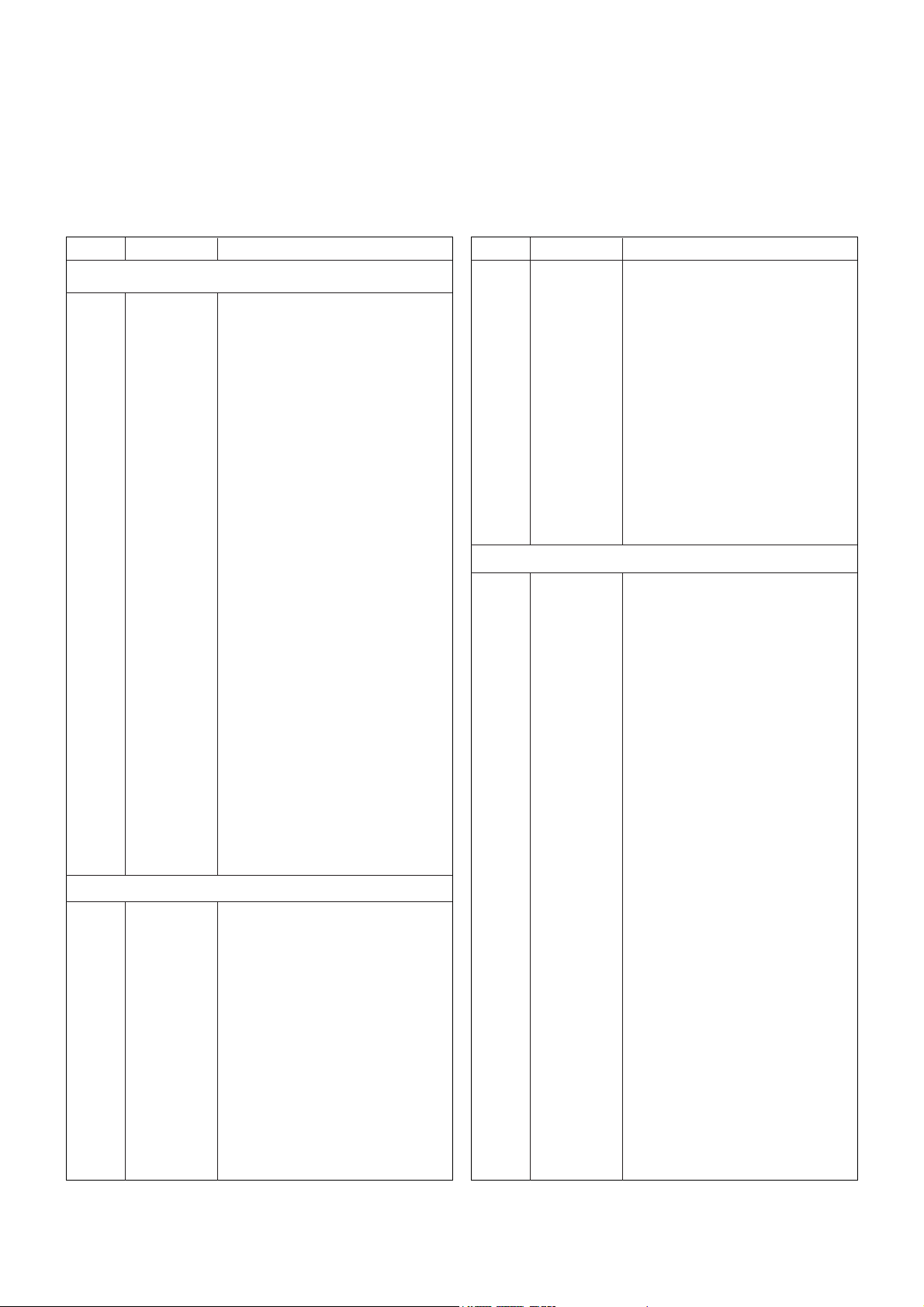

3. STB Main

Single chip multi-standard

sound processors

MONO/STEREO/Bilingual

A/V 1

SVHS

A/V 2

MNT

OUT

DTV2

in

IC 201

CXA2069Q

64pin

IC 201

CXA2069Q

64pin

3 (VRL)

2(Y/C)

3

3

MNT-L/R/V

TUNER

TUNER

IC 601

MSP3401

80pin

IC 601

MSP3401

80pin

DCF(3D)

DCF(3D)

(Digital Comb Filter)

TV Signal

(CVBS)

2

TV-L/R

2

AV-L/R

2

DCF-C/Y

1

DCF-V

IN

IC 301

VPC3230

80pin

IC 301

VPC3230

80pin

IC 701

LGTV1001

64pin

IC 701

LGTV1001

64pin

IC 302

SDA9410

100pin

IC 302

SDA9410

100pin

IC 001

M37272

u-COM

IC 001

M37272

u-COM

KEY-1

DVD

in

3

Y/U/V

IC 401

CXA2101AQ

80pin

IC 401

CXA2101AQ

80pin

IC 402

BA7657

24pin

IC 402

BA7657

24pin

P003

3

OSD R/G/B/YS

3 SCL_A, SDA_B

PC/DTV

1 S-MUTE

3

W/F-OUT(OPT)

OUT-L

OUT-R

3

K

IN

K

OUT

3

5

SDA-HS/VS/U/V/Y

3

SDA Y/V/U

2

SDA-

HS/VS

8

CHROMA0-7

8

LUMA0-7

8 C0-7

8

Y0-7

2

SCL-A

SDL-A

3

CXA R/G/B

2

CXA HS/VS

1

CXA-PC

5

R/G/B/HS/VS

P401

P402

P403

PC

R/G/B

HS/VS

DTV

R/G/B

HS/VS

PC

DTV

PC-R/L

ICX 001

BA7657F

ICX 001

BA7657F

DTV 1

IN

PC IN

PC

RGB/HV

PC/DTV-OUT

5

DTV-R/G/B

HS/VS

3

PC-R/G/B

2

PC-HS/VS

IS 501

(25Pin

Cable)

Input select switch for high

definition display

Internal broadband RGB s/w

2

Y/C

3

(

DTV 2)Y/U/V

PDP MODUL E

Interface Board

TV Audio(SIF)

(VRL)

(Y,Cb,Cr)

(R,L)

IC 602/3/4

SRS block

(option)

IC 602/3/4

SRS block

(option)

7input/3output

wideband video Amp(20MHz,-3dB)

Y/C mix circuit

A/V switch featuring I

2

C BUS

DTV2

(R,L)

(Y,Pb,Pr)

SCL-A

SDL-A

2

CXA2069Q

(pin 23/25)

R/L

PC Audio(Stereo)

DTV

RGB/HV

(R,L)

Comb filter video processor

TV Digital Y/Cr/Cb

Multi-standard color decoder

A/D converter

8bit UVin 8bit UVout

8bit Yin 8bit Yout

Image

Format converter

Interlace

Progressive

Multi-Component Processor

Analog R/G/B

R/G/B

R/G/B

Y/U/V

Page 8

- 14 -

4. STB Signal Flow(R/G/B-H/V)

IC 201

CXA2069Q

64pin

IC 201

CXA2069Q

64pin

3

MNT-L/R/V

TUNER

TUNER

IC 601

MSP3401

80pin

IC 601

MSP3401

80pin

DCF(3D)

(Digital Comb Fil ter)

DCF(3D)

(Digital Comb Fil ter)

2

TV-L/R

2

AV-L/R

IC 301

VPC3230

80pin

IC 301

VPC3230

80pin

IC 701

LGTV1001

64pin

IC 701

LGTV1001

64pin

IC 302

SDA9410

100pin

IC 302

SDA9410

100pin

IC 001

M37272

u-COM

IC 001

M37272

u-COM

KEY-1

IC 401

CXA2101AQ

80pin

IC 401

CXA2101AQ

80pin

IC 402

BA7657

24pin

IC 402

BA7657

24pin

P003

OSD R/G/B/

3 SCL_A, SDA_B

PC/DTV

1 S-MUTE

3

W/F-OUT

OUT-L

OUT-R

3

K

IN

K

OUT

3

5

SDA-Hs/Vs/V/U/Y

8

CHROMA0-7

8

LUMA0-7

8 C0-7

8

Y0-7

2

SCL-A

SDL-A

3

CXA R/G/B

P401

P402

P403

PC

R/G/B

HS/VS

DTV

R/G/B

HS/VS

PC

DTV

PC-R/L

ICX 001

BA7657F

ICX 001

BA7657F

DTV 1

IN

PC IN

PC

RGB/HV

PC/DTV-OUT

5

DTV-R/G/B

HS/VS

IS 501

(25Pin

Cable)

PDP MODULE

Interface Board

IC 602/3/4

SRS block

(option)

IC 602/3/4

SRS block

(option)

DTV2

(R,L)

SCL-A

SDL-A

2

CXA2069Q

(pin 23/25)

R/L

PC Audio(Stereo)

DTV

RGB/HV

4

5

SCL:R101

SDA:R102

4

Video:R108

C225

C-out: R228 Y-out: R225

1103

5

9

Vin:C231

Cout:R241

Yout:R237

SDA:R242

SCL:R243

72

63 58 56

71

Yin:C329

Cin:C328

1 2 3

1314

SCL:R304

SDA:R305

57

Vs:R308

23 25

27

SDA:R704

SCL:R705

Ho:R706

4

5

Ho:R321

Vo:R322

24252627

SDA:R323

SCL:R324

Vi:R321

Hi:R322

84

90

V:R417

U:R418

C407/408/409/410/411

28 29

35

37 39

R:R431

G:R432

B:R433

IC501

OPA3682

16pin

IC501

OPA3682

16pin

135

12

14

15

19

21

22

24

C460/461/462

Vs-in

Hs-in

R:L452

G:L453

B:L454

Hs-out

Vs-out

25

8

R:C501

G:C502

B:C503

1412

10

R:C513

G:C514

B:C515

Page 9

EXPLODED VIEW(MU-40PA10)

300

301

303

304

302

200

202

201

203

204

205

207

211

210

206

209

208

400

540

401

550

551

530

570

520

560

Page 10

EXPLODED VIEW PARTS LIST

200 6348Q-A001A 40” 4:3 640*480 DOU PDP

201 6871VSN168A X RIGHT TOP B/D ASSY

202 6871VSN168B X LEFT TOP B/D ASSY

203 6871VSN168C ZCNT TOP B/D ASSY

204 6871VSN168D ZSUS B/D ASSY

205 6871VSN168E ZCNT BOTTOM B/D ASSY

206 6871VSN168F X LEFT BOTTOM B/D ASSY

207 6871VSN168G X RIGHT BOTTOM B/D ASSY

208 6871VSN168H YDRV B/D ASSY

209 6871VSN168J YSUS B/D ASSY

210 6871VSN168K CTRL B/D ASSY

211 4980V00164B Vertical

300 3091V00288B CABINET ASSY

301 3210V00061B FRAME,TOP

302 3210V00062B FRAME,BOTTOM

303 3210V00063A FRAME,SIDE

304 3210B00063B FRAME,SIDE

400 3809V00212A BACK COVER ASSY

401 3301V00005A PLATE ASSY,REAR A/V

520 6871VMM602A PCB ASSY,MAIN NP-00LA MN-40PA10 VSC BOARD

530 3501V00028A BOARD ASSY,PDP POWER LINE FILTER

540 6871VSM689A PCB ASSY,CONT NP-00LA MN-40PA10 CONT

550 6871VSM690A PCB ASSY,PSW NP-00LA MN-40PA10 POWER S/W

551 5020V00445A BUTTON,POWER

560 6871VSM691A PCB ASSY,SPK NP-00LA MN-40PA10 SPK

570 3501V00027C BOARD ASSY,PDP POWER

No.

Part No.

Description

Page 11

REPLACEMENT PARTS LIST

LOCA. NO PART NO DESCRIPTION

Q107

Q108

Q109

Q110

Q111

Q112

Q201

Q202

Q301

Q302

Q303

Q305

Q306

Q307

Q601

D001

D002

D003

D004

D005

D006

D009

D010

D011

D012

D013

D014

D101

D102

D103

D104

D105

D106

D107

D108

D201

D202

D203

D301

D302

D401

D402

D601

D602

D603

D604

LD001

0TR387500AA

0TR387500AA

0TR387500AA

0TR387500AA

0TR387500AA

0TR150400BA

0TR150400BA

0TR150400BA

0TR150400BA

0TR150400BA

0TR150400BA

0TR102009AG

0TR102009AG

0TR102009AG

0TR150400BA

0DD226239AA

0DD226239AA

0DD226239AA

0DD226239AA

0DD226239AA

0DD226239AA

0DD226239AA

0DD226239AA

0DD226239AA

0DD226239AA

0DD226239AA

0DD184009AA

0DD226239AA

0DD226239AA

0DD226239AA

0DD226239AA

0DD226239AA

0DD226239AA

0DD226239AA

0DD226239AA

0DD226239AA

0DD226239AA

0DD226239AA

0DD226239AA

0DD226239AA

0DD226239AA

0DD226239AA

0DD226239AA

0DD184009AA

0DD184009AA

0DD181009AB

0DL200000CA

CHIP 2SC3875S(ALY) KEC

CHIP 2SC3875S(ALY) KEC

CHIP 2SC3875S(ALY) KEC

CHIP 2SC3875S(ALY) KEC

CHIP 2SC3875S(ALY) KEC

CHIP 2SA1504S(ASY) KEC

CHIP 2SA1504S(ASY) KEC

CHIP 2SA1504S(ASY) KEC

CHIP 2SA1504S(ASY) KEC

CHIP 2SA1504S(ASY) KEC

CHIP 2SA1504S(ASY) KEC

CHIP KRC102S SOT-23 TP KEC

CHIP KRC102S SOT-23 TP KEC

CHIP KRC102S SOT-23 TP KEC

CHIP 2SA1504S(ASY) KEC

CHIP KDS226 SOT-23

CHIP KDS226 SOT-23

CHIP KDS226 SOT-23

CHIP KDS226 SOT-23

CHIP KDS226 SOT-23

CHIP KDS226 SOT-23

CHIP KDS226 SOT-23

CHIP KDS226 SOT-23

CHIP KDS226 SOT-23

CHIP KDS226 SOT-23

CHIP KDS226 SOT-23

KDS184S CHIP 85V 300MA KEC TP

CHIP KDS226 SOT-23

CHIP KDS226 SOT-23

CHIP KDS226 SOT-23

CHIP KDS226 SOT-23

CHIP KDS226 SOT-23

CHIP KDS226 SOT-23

CHIP KDS226 SOT-23

CHIP KDS226 SOT-23

CHIP KDS226 SOT-23

CHIP KDS226 SOT-23

CHIP KDS226 SOT-23

CHIP KDS226 SOT-23

CHIP KDS226 SOT-23

CHIP KDS226 SOT-23

CHIP KDS226 SOT-23

CHIP KDS226 SOT-23

KDS184S CHIP 85V 300MA KEC TP

KDS184S CHIP 85V 300MA KEC TP

CHIP KDS181 85V 300MA KEC

LED,SAM5670(DL-2LRG) BK Y-GREEN -

LOCA. NO PART NO DESCRIPTION

IC001

IC002

IC003

IC004

IC101

IC102

IC103

IC201

IC202

IC203

IC204

IC205

IC301

IC302

IC303

IC304

IC401

IC402

IC403

IC404

IC405

IC406

IC501

IC502

IC503

IC504

IC601

IC602

IC603

IC604

IC804

IC005

IC006

Q001

Q001

Q002

Q020

Q021

Q022

Q101

Q102

Q103

Q104

Q105

Q106

0IZZVA0022B

0IAL240800A

0IFA753307A

0IFA754207A

0IPH827150A

0IFA754207A

0IFA754207A

0ISH323422A

0ISH323422A

0IIT323000D

0ISM941000A

0ISH323422A

0ISH092100B

0ISH323422A

0ISO210100B

0ITI808300B

0IMR882840B

0IEB121616A

0IEB121616A

0ISH323422A

0IPH748600D

0ISH323422A

0IPH745410A

0IPH745410A

0IPH745410A

0IPH745410A

0ISH092100B

0ISO202200A

0ISA428200A

0ISA722200A

0IKE780500Q

0TR830009BA

0TR830009BA

0TR319809AA

0TR387500AA

0TR319809AA

0TR387500AA

0TR387500AA

0TR387500AA

0TR387500AA

0TR387500AA

0TR387500AA

0TR387500AA

0TR387500AA

0TR387500AA

M37280MFSP 64PIN BK EXP

AT24C08 8D EEPROM(8K,IIC)

KA75330ZTA(KA7533ZTA) 3P,TO-92

KA75420ZTA(KA7542ZTA) 3P,TO-92

P82B715T 8SOP R/TP IIC EXTENDE

KA75420ZTA(KA7542ZTA) 3P,TO-92

KA75420ZTA(KA7542ZTA) 3P,TO-92

PQ3RF23 4P(TO-220) 3.3V REGUL

PQ3RF23 4P(TO-220) 3.3V REGUL

VPC3230D QA B4 80P QFP TRAY SO

SDA9410 100QFP BK SCAN CONVERT

PQ3RF23 4P(TO-220) 3.3V REGUL

PQ09RD21 4SIP ST REGULATOR

PQ3RF23 4P(TO-220) 3.3V REGUL

CXA2101AQ 80P,QFP BK VIDEO SIG

THS8083 100QFP BK ADC IC PD-40

MX88L284-V 208QFP BK SCALE MF0

M12L16161A-7T 50P TSOP ST 16M(

M12L16161A-7T 50P TSOP ST 16M(

PQ3RF23 4P(TO-220) 3.3V REGUL

74HC86 SOIC-14 TP QUAD 2-INPUT

PQ3RF23 4P(TO-220) 3.3V REGUL

74F541 20P SOT BK BUFFER MXIC

74F541 20P SOT BK BUFFER MXIC

74F541 20P SOT BK BUFFER MXIC

74F541 20P SOT BK BUFFER MXIC

PQ09RD21 4SIP ST REGULATOR

CXA2022S 30P SDIP ST TONE CONT

LA4282 12S 2CHX10W AUDIO AMP

LA7222 (1280 AUDIO)

KIA7805API 3P TO-220 ST REGULA

BSS83 TP PHILIPS NON N-CHANNEL

BSS83 TP PHILIPS NON N-CHANNEL

KTC3198-TP-Y (KTC1815)KEC

CHIP 2SC3875S(ALY) KEC

KTC3198-TP-Y (KTC1815)KEC

CHIP 2SC3875S(ALY) KEC

CHIP 2SC3875S(ALY) KEC

CHIP 2SC3875S(ALY) KEC

CHIP 2SC3875S(ALY) KEC

CHIP 2SC3875S(ALY) KEC

CHIP 2SC3875S(ALY) KEC

CHIP 2SC3875S(ALY) KEC

CHIP 2SC3875S(ALY) KEC

CHIP 2SC3875S(ALY) KEC

IC

TRANSISTOR

- 18 -

RUN DATE : 2001.6.8

MU-40PA10

DIODE

Page 12

- 19 -

LOCA. NO PART NO DESCRIPTION

LED001

LED002

LED003

ZD001

ZD101

ZD102

ZD103

ZD104

ZD105

ZD106

ZD201

C001

C002

C003

C008

C011

C016

C022

C026

C031

C038

C041

C050

C051

C105

C107

C109

C111

C112

C115

C118

C124

C201

C203

C206

C207

C212

C225

C229

C231

C233

C235

C238

C240

C241

C242

C243

C244

C245

C306

0DL112100AA

0DL112100AA

0DL112100AB

0DZ511109AA

0DZ511109AA

0DZ511109AA

0DZ511109AA

0DZ511109AA

0DZ511109AA

0DZ511109AA

0DZ511109AA

0CN1040K949

0CE476DD618

0CE477BF618

0CE108DF618

0CE108DF618

0CE108DF618

0CE107DD618

0CE107DD618

0CE107DD618

0CE107DD618

0CE107DD618

0CE105CK636

0CE105DK618

0CE107DD618

0CE107DD618

0CE476SF6DC

0CE476DF618

0CE476SF6DC

0CE476SF6DC

0CE476SF6DC

0CQ3331N509

0CE107DD618

0CE107DD618

0CE107DD618

0CE107DD618

0CK224DF56A

0CE107DD618

0CE476DF618

0CE107DD618

0CE107DD618

0CE476DF618

0CE107DD618

0CE107DD618

0CE107DD618

0CE107DD618

0CE107DD618

0CE107DD618

0CE107DD618

0CE476DF618

LED,SR3411(DL-11S2RN1) BK RED -

LED,SR3411(DL-11S2RN1) BK RED -

LED,SM3411(DL-11S2GN1) BK Y-GREEN

ZENER,DTZ5.1BTT11(CHIP) TP ROHM

ZENER,DTZ5.1BTT11(CHIP) TP ROHM

ZENER,DTZ5.1BTT11(CHIP) TP ROHM

ZENER,DTZ5.1BTT11(CHIP) TP ROHM

ZENER,DTZ5.1BTT11(CHIP) TP ROHM

ZENER,DTZ5.1BTT11(CHIP) TP ROHM

ZENER,DTZ5.1BTT11(CHIP) TP ROHM

ZENER,DTZ5.1BTT11(CHIP) TP ROHM

0.1M 50V Z

47UF STD 10V 20%

470UF KME 16V M

1000UF STD 16V M

1000UF STD 16V M

1000UF STD 16V M

100UF STD 10V M

100UF STD 10V M

100UF STD 10V M

100UF STD 10V M

100UF STD 10V M

1UF SHL,SD 50V M

1UF STD 50V M

100UF STD 10V M

100UF STD 10V M

47UF MVG 16V M

47UF STD 16V M

47UF MVG 16V M

47UF MVG 16V M

47UF MVG 16V M

0.033U 100V K

100UF STD 10V M

100UF STD 10V M

100UF STD 10V M

100UF STD 10V M

220000PF 2012 16V 10%

100UF STD 10V M

47UF STD 16V M

100UF STD 10V M

100UF STD 10V M

47UF STD 16V M

100UF STD 10V M

100UF STD 10V M

100UF STD 10V M

100UF STD 10V M

100UF STD 10V M

100UF STD 10V M

100UF STD 10V M

47UF STD 16V M

LOCA. NO PART NO DESCRIPTION

C318

C325

C326

C330

C338

C340

C343

C347

C349

C351

C353

C355

C357

C360

C401

C412

C414

C415

C418

C420

C424

C433

C445

C453

C457

C459

C502

C601

C602

C603

C604

C605

C606

C607

C608

C609

C610

C611

C612

C613

C614

C615

C616

C617

C618

C619

C620

C621

C622

C623

C624

C625

0CE105DK618

0CE107DF618

0CE477BF618

0CE476DF618

0CE106DF618

0CE106DF618

0CE476DF618

0CE107DD618

0CE107DD618

0CE477BF618

0CE106SF6DC

0CE106SF6DC

0CE107DD618

0CE107DD618

0CE107DD618

0CE476DF618

0CE107DD618

0CE107DD618

0CE477BF618

0CE107DD618

0CE107DD618

0CE107DD618

0CE107DD618

0CE107DD618

0CE477BF618

0CE107DD618

0CE107DD618

0CE106DF618

0CE106DF618

0CQ1042K439

0CQ4721N509

0CE475DK618

0CE475DK618

0CE475DK618

0CE475DK618

0CE475DK618

0CE106DF618

0CQ4721N509

0CE106DF618

0CQ1042K439

0CE475DK618

0CQ1042K439

0CQ2231N509

0CQ4721N509

0CQ8221N519

0CE106DF618

0CE475DK618

0CQ8221N519

0CQ1042K439

0CE476DF618

0CQ4721N509

0CQ1042K439

1UF STD 50V M

100UF STD 16V M

470UF KME 16V M

47UF STD 16V M

10UF STD 16V M

10UF STD 16V M

47UF STD 16V M

100UF STD 10V M

100UF STD 10V M

470UF KME 16V M

10UF MVG 16V 20%

10UF MVG 16V 20%

100UF STD 10V M

100UF STD 10V M

100UF STD 10V M

47UF STD 16V M

100UF STD 10V M

100UF STD 10V M

470UF KME 16V M

100UF STD 10V M

100UF STD 10V M

100UF STD 10V M

100UF STD 10V M

100UF STD 10V M

470UF KME 16V M

100UF STD 10V M

100UF STD 10V M

10UF STD 16V M

10UF STD 16V M

0.1UF S 50V J

0.0047U 100V K

4.7UF STD 50V 20%

4.7UF STD 50V 20%

4.7UF STD 50V 20%

4.7UF STD 50V 20%

4.7UF STD 50V 20%

10UF STD 16V M

0.0047U 100V K

10UF STD 16V M

0.1000UF S 50V J

4.7UF STD 50V 20%

0.1UF S 50V J

0.022U 100V K

0.0047U 100V K

0.0082U 100V K

10UF STD 16V M

4.7UF STD 50V 20%

0.0082U 100V K

0.1UF S 50V J

47UF STD 16V M

0.0047U 100V K

0.1UF S 50V J

CAPACITOR

For Capacitor & Resistors,

the charactors at 2nd and 3rd

digit in the P/No. means as

follows;

CC, CX, CK, CN : Ceramic

CQ : Polyestor

CE : Electrolytic

RD : Carbon Film

RS : Metal Oxide Film

RN : Metal Film

RF : Fusible

Page 13

- 20 -

LOCA. NO PART NO DESCRIPTION

C626

C630

C631

C635

C641

C643

C644

C645

C646

C647

C650

C651

C653

C654

C655

C656

C659

C659

C660

C660

C661

JP1

P101

P102

P601

L001

L110

L112

L113

L115

L214

DS101

DS102

R001

R002

R003

R006

R007

R225

R226

R618

R619

R655

R656

0CE107DF618

0CE108DF618

0CE106DK618

0CE476DF618

0CE106DK618

0CE477DK618

0CE477DK618

0CE106DF618

0CE106DF618

0CE476DF618

0CE106DF618

0CE106DF618

0CE477DK618

0CE477DK618

0CE477DK618

0CE477DK618

0CE107DH618

181-120K

0CE107DH618

181-120K

0CE107DH618

6612VLH002A

380-389N

380-389P

6612VJH018A

0LA0102K119

0LC18000A02

0LC18000A02

0LC18000A02

6140VB0006A

0LA0102K119

6630VGA002B

6630VGA001C

0RD3302F609

0RD1002F609

0RD3001F609

0RD4700F609

0RD5100F609

0RN5602F409

0RN2202F409

0RD0331H609

0RD0331H609

0RD4700H609

0RD4700H609

100UF STD 16V M

1000UF STD 16V M

10UF STD 50V M

47UF STD 16V M

10UF STD 50V M

470UF STD 50V 20%

470UF STD 50V 20%

10UF STD 16V M

10UF STD 16V M

47UF STD 16V M

10UF STD 16V M

10UF STD 16V M

470UF STD 50V 20%

470UF STD 50V 20%

470UF STD 50V 20%

470UF STD 50V 20%

100UF STD 25V M

2200PF 4KV M

100UF STD 25V M

2200PF 4KV M

100UF STD 25V M

JACK,RCA SP026B 4P RD/BK/BK/R

JACK,RCA S-456S-N A/V 3P RD-W

JACK,RCA S-456S-P A/V 3P GR-B

JACK,RCA PJ6058C-A A/V 2P MON

INDUCTOR,10UH K

INDUCTOR,CHIP CERATECH R/TP

INDUCTOR,CHIP CERATECH R/TP

INDUCTOR,CHIP CERATECH R/TP

COIL,CHOKE 12UH 0.3PHY,PHY 15.5TURN SB804

INDUCTOR,10UH K

CONNECTOR (CIRC),D-SUB 25PIN

CONNECTOR (CIRC),D-SUB 15PIN 2.29MM

33K OHM 1/6 W 5.00%

10K OHM 1/6 W 5.00%

3K OHM 1/6 W 5.00%

470 OHM 1/6 W 5.00%

510 OHM 1/6 W 5.00%

56K OHM 1/6 W 1.00%

22K OHM 1/6 W 1.00%

3.3 OHM 1/2 W 5.00%

3.3 OHM 1/2 W 5.00%

470 OHM 1/2 W 5.00%

470 OHM 1/2 W 5.00%

LOCA. NO PART NO DESCRIPTION

SW001

SW002

SW003

SW004

BA301

BA302

BA303

BA304

BA305

BA306

BA407

BA408

BA409

BA410

BA411

BA412

BA413

BA414

BA415

BA416

BA417

BA418

BA419

BA420

BA421

BA422

BA423

BA424

F601

F602

L001

L002

L104

L105

L106

L107

L108

L201

L202

L203

L204

L205

L206

L207

L208

L209

L210

6600VM2006A

140-315A

140-315A

140-315A

140-315A

6210VC0004A

6210VC0004A

6210VC0004A

6210VC0004A

6210VC0004A

6210VC0004A

6210VC0004A

6210VC0004A

6210VC0004A

6210VC0004A

6210VC0004A

6210VC0004A

6210VC0004A

6210VC0004A

6210VC0004A

6210VC0004A

6210VC0004A

6210VC0004A

6210VC0004A

6210VC0004A

6210VC0004A

6210VC0004A

6210VC0004A

6210VC0004A

6200VJS001A

6200VJS001A

6210VC0006A

6210VC0006A

6210VC0006A

6210VC0005A

6210VC0005A

6210VC0005A

6210VC0006A

6210VC0006A

6210VC0006A

6210VC0005A

6210VC0005A

6210VC0005A

6210VC0006A

6210VC0006A

6210VC0006A

6210VC0006A

6210VC0006A

SWITCH,PUSH SDDF3PATP011

SWITCH,TACT SKHV17910B NON 12V

SWITCH,TACT SKHV17910B NON 12V

SWITCH,TACT SKHV17910B NON 12V

SWITCH,TACT SKHV17910B NON 12V

FILTER(CIRC),EMC BK3216 4S600

FILTER(CIRC),EMC BK3216 4S600

FILTER(CIRC),EMC BK3216 4S600

FILTER(CIRC),EMC BK3216 4S600

FILTER(CIRC),EMC BK3216 4S600

FILTER(CIRC),EMC BK3216 4S600

FILTER(CIRC),EMC BK3216 4S600

FILTER(CIRC),EMC BK3216 4S600

FILTER(CIRC),EMC BK3216 4S600

FILTER(CIRC),EMC BK3216 4S600

FILTER(CIRC),EMC BK3216 4S600

FILTER(CIRC),EMC BK3216 4S600

FILTER(CIRC),EMC BK3216 4S600

FILTER(CIRC),EMC BK3216 4S600

FILTER(CIRC),EMC BK3216 4S600

FILTER(CIRC),EMC BK3216 4S600

FILTER(CIRC),EMC BK3216 4S600

FILTER(CIRC),EMC BK3216 4S600

FILTER(CIRC),EMC BK3216 4S600

FILTER(CIRC),EMC BK3216 4S600

FILTER(CIRC),EMC BK3216 4S600

FILTER(CIRC),EMC BK3216 4S600

FILTER(CIRC),EMC BK3216 4S600

FILTER(CIRC),EMC BK3216 4S600

FILTER(CIRC),EMI ZJY51R5-4P TDK DC 50VOLT 2A

FILTER(CIRC),EMI ZJY51R5-4P TDK DC 50VOLT 2A

FILTER(CIRC),EMC FBMH3216 HM501NT

FILTER(CIRC),EMC FBMH3216 HM501NT

FILTER(CIRC),EMC FBMH3216 HM501NT

FILTER(CIRC),EMC BK2125 HS 750

FILTER(CIRC),EMC BK2125 HS 750

FILTER(CIRC),EMC BK2125 HS 750

FILTER(CIRC),EMC FBMH3216 HM501NT

FILTER(CIRC),EMC FBMH3216 HM501NT

FILTER(CIRC),EMC FBMH3216 HM501NT

FILTER(CIRC),EMC BK2125 HS 750

FILTER(CIRC),EMC BK2125 HS 750

FILTER(CIRC),EMC BK2125 HS 750

FILTER(CIRC),EMC FBMH3216 HM501NT

FILTER(CIRC),EMC FBMH3216 HM501NT

FILTER(CIRC),EMC FBMH3216 HM501NT

FILTER(CIRC),EMC FBMH3216 HM501NT

FILTER(CIRC),EMC FBMH3216 HM501NT

JACK

COIL

CONNECTOR

RESISTOR

SWITCH

FILTER

For Capacitor & Resistors,

the charactors at 2nd and 3rd

digit in the P/No. means as

follows;

CC, CX, CK, CN : Ceramic

CQ : Polyestor

CE : Electrolytic

RD : Carbon Film

RS : Metal Oxide Film

RN : Metal Film

RF : Fusible

Page 14

- 21 -

LOCA. NO PART NO DESCRIPTION

L211

L213

L301

L302

L303

L304

L305

L306

L401

L402

L403

L404

L405

L407

L408

L409

L501

L502

L601

L602

L603

PA001

X001

X201

X301

X401

A1

A2

A3

6210VC0005A

6210VC0005A

6210VC0006A

6210VC0006A

6210VC0006A

6210VC0006A

6210VC0006A

6210VC0006A

6210VC0006A

6210VC0006A

6210VC0006A

6210VC0005A

6210VC0006A

6210VC0006A

6210VC0006A

6210VC0006A

6210VC0006A

6210VC0005A

6210VC0006A

150-F09A

6210VC0006A

3890V01035A

3920V00255A

6726VH0001A

156-A01P

6202VDB007B

6202VDT002B

6202VDT002B

3828VA0254E

6710V00042G

6866VA9001B

FILTER(CIRC),EMC BK2125 HS 750

FILTER(CIRC),EMC BK2125 HS 750

FILTER(CIRC),EMC FBMH3216 HM501NT

FILTER(CIRC),EMC FBMH3216 HM501NT

FILTER(CIRC),EMC FBMH3216 HM501NT

FILTER(CIRC),EMC FBMH3216 HM501NT

FILTER(CIRC),EMC FBMH3216 HM501NT

FILTER(CIRC),EMC FBMH3216 HM501NT

FILTER(CIRC),EMC FBMH3216 HM501NT

FILTER(CIRC),EMC FBMH3216 HM501NT

FILTER(CIRC),EMC FBMH3216 HM501NT

FILTER(CIRC),EMC BK2125 HS 750

FILTER(CIRC),EMC FBMH3216 HM501NT

FILTER(CIRC),EMC FBMH3216 HM501NT

FILTER(CIRC),EMC FBMH3216 HM501NT

FILTER(CIRC),EMC FBMH3216 HM501NT

FILTER(CIRC),EMC FBMH3216 HM501NT

FILTER(CIRC),EMC BK2125 HS 750

FILTER(CIRC),EMC FBMH3216 HM501NT

FILTER(CIRC),EMC SQE2222 7-14MH 0.37PHY 48TURN

FILTER(CIRC),EMC FBMH3216 HM501NT TAIYOYUDEN 3

BOX,MU-40PA10.AAMZMZ 40Ó

PACKING,MN-40PA10(PD-40X3) TOP/BOT 1KG

REMOTE CONTROLLER RECEIVER,TSOP1238RF1 38KHZ

RESONATOR,CRYSTAL HC49U 8.000MHZ

30

RESONATOR,CRYSTAL HC49U 20.250MHZ 3

RESONATOR,CRYSTAL SX-1SMD 14.318MHZ

RESONATOR,CRYSTAL SX-1SMD 14.318MHZ

MANUAL,OWNERS NP00LE MU-40PA10 ZENITH

REMOTE CONTROLLER,MONITOR ONLY

SIGNAL CABLE,2990-9C UL 1161 AWG 26 TWI 700

LOCA. NO PART NO DESCRIPTION

MISCELLANEOUS

ACCESSORIES

For Capacitor & Resistors,

the charactors at 2nd and 3rd

digit in the P/No. means as

follows;

CC, CX, CK, CN : Ceramic

CQ : Polyestor

CE : Electrolytic

RD : Carbon Film

RS : Metal Oxide Film

RN : Metal Film

RF : Fusible

Page 15

Page 16

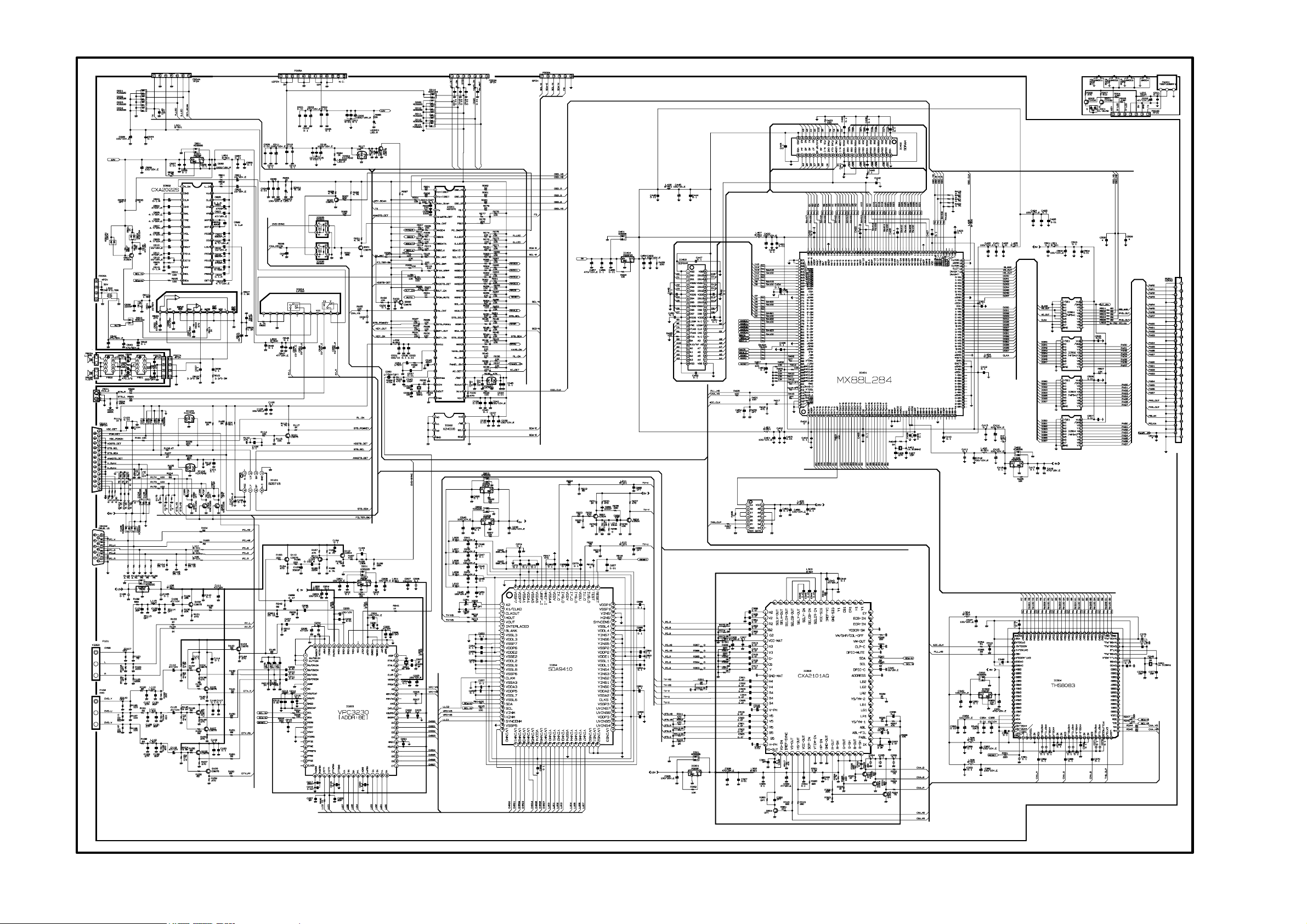

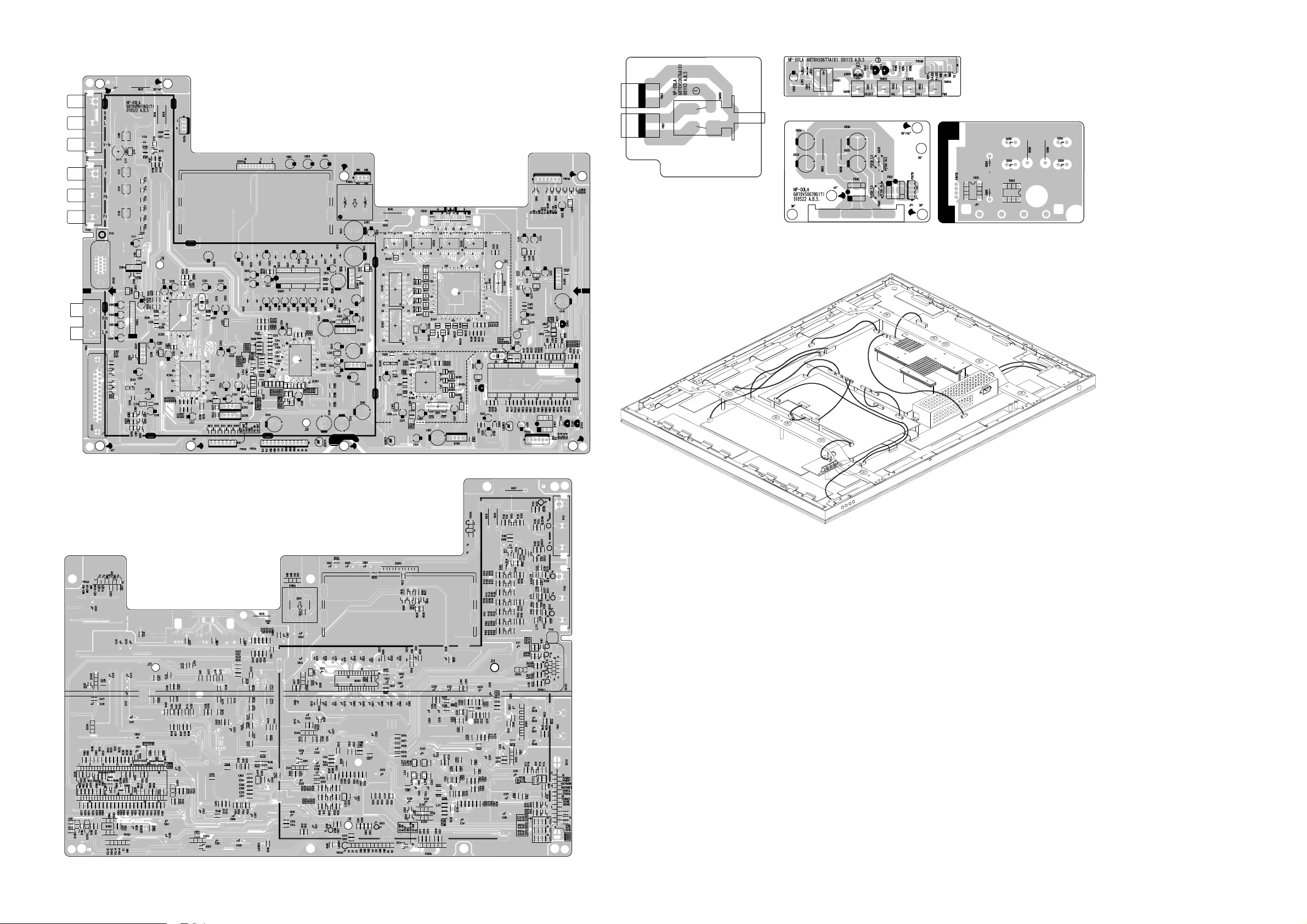

PRINTED CIRCUIT BOARD

MAIN(TOP)

MAIN(BOTTOM)

WIRING DIAGRAM

POWER S/W CONTROL

SPK(TOP) SPK(BOTTOM)

P15

P004B

P004A

P14

PD501

P100

P802

P803

P802

P801

P006A

P810

P811

P806

P801

P809

P815

P005A

P003A

P304

P007B

P007A

P302

P301

P303

P807

P805

P804

P102

Loading...

Loading...