Page 1

SET-TOP BOX

SERVICE MANUAL

MODEL : LST-3100A

MODEL : LST-3100A

SERVICE MANUAL

P/NO : 3829RVN006Q

AUGUST, 2003

Printed in Korea

CAUTION

BEFORE SERVICING THE UNIT, READ THE “SAFETY PRECAUTIONS”

IN THIS MANUAL.

Page 2

CONTENTS

SECTION 1 . . . .SUMMARY

SECTION 2 . . . .CABINET & MAIN CHASSIS

SECTION 3 . . . .ELECTRICAL

SECTION 4 . . . .REPLACEMENT PARTS LIST

Page 3

SECTION 1

SUMMARY

CONTENTS

PRODUCT SAFETY SERVICING GUIDELINES FOR VIDEO PRODUCTS ......... 1-3

SERVICING PRECAUTIONS .................................................................................. 1-4

• General Servicing Precautions

• Insulation Checking Prodedure

• Electrostatically Sensitive Devices

SPECIFICATIONS ................................................................................................... 1-5

Page 4

1-3

CAUTION : DO NOT ATTEMPT TO MODIFY THIS PRODUCT IN ANY WAY,

NEVER PERFORM CUSTOMIZED INSTALLATIONS WITHOUT MANUFACTURER’S APPROVAL. UNAUTHORIZED MODIFICATIONS WILL NOT ONLY

VOID THE WARRANTY, BUT MAY LEAD TO YOUR BEING LIABLE FOR ANY

RESULTING PROPERTY DAMAGE OR USER INJURY.

SERVICE WORK SHOULD BE PERFORMED ONLY AFTER YOU ARE

THOROUGHLY FAMILIAR WITH ALL OF THE FOLLOWING SAFETY

CHECKS AND SERVICING GUIDELINES. TO DO OTHERWISE,

INCREASES THE RISK OF POTENTIAL HAZARDS AND INJURY TO THE

USER.

WHILE SERVICING, USE AN ISOLATION TRANSFORMER FOR PROTECTION FROM A.C. LINE SHOCK.

SAFETY CHECKS

AFTER THE ORIGINAL SERVICE PROBLEM HAS BEEN CORRCTED. A

CHECK SHOULD BE MADE OF THE FOLLOWING.

SUBJECT : FIRE & SHOCK HAZARD

1. BE SURE THAT ALL COMPONENTS ARE POSITIONED IN SUCH A WAY

AS TO AVOID POSSIBILITY OF ADJACENT COMPONENT SHORTS.

THIS IS ESPECIALLY IMPORTANT ON THOSE MODULES WHICH ARE

TRANSPORTED TO AND FROM THE REPAIR SHOP.

2. NEVER RELEASE A REPAIR UNLESS ALL PROTECTIVE DEVICES

SUCH AS INSULATORS, BARRIERS, COVERS, SHIELDS, STRAIN

RELIEFS, POWER SUPPLY CORDS, AND OTHER HARDWARE HAVE

BEEN REINSTALLED PER ORIGINAL DESIGN. BE SURE THAT THE

SAFETY PURPOSE OF THE POLARIZED LINE PLUG HAS NOT BEEN

DEFEATED.

3. SOLDERING MUST BE INSPECTED TO DISCOVER POSSIBLE COLD

SOLDER JOINTS, SOLDER SPLASHES OR SHARP SOLDER POINTS.

BE CERTAIN TO REMOVE ALL LOOSE FOREIGN PARTICLES.

4. CHECK FOR PHYSICAL EVIDENCE OF DAMAGE OR DETERIORATION

TO PARTS AND COMPONENTS. FOR FRAYED LEADS, DAMAGED

INSULATION (INCLUDING A.C. CORD). AND REPLACE IF NECESSARY

FOLLOW ORIGINAL LAYOUT, LEAD LENGTH AND DRESS.

5. NO LEAD OR COMPONENT SHOULD TOUCH A RECIVING TUBE OR

A RESISTOR RATED AT 1 WATT OR MORE. LEAD TENSION AROUND

PROTRUNING METAL SURFACES MUST BE AVOIDED.

6. ALL CRITICAL COMPONENTS SUCH AS FUSES, FLAMEPROOF

RESISTORS, CAPACITORS, ETC. MUST BE REPLACED WITH EXACT

FACTORY TYPES, DO NOT USE REPLACEMENT COMPONENTS

OTHER THAN THOSE SPECIFIED OR MAKE UNRECOMMENDED CIRCUIT MODIFICATIONS.

7. AFTER RE-ASSEMBLY OF THE SET ALWAYS PERFORM AN A.C.

LEAKAGE TEST ON ALL EXPOSED METALLIC PARTS OF THE CABINET, (THE CHANNEL SELECTOR KNOB, ANTENNA TERMINALS. HANDLE AND SCREWS) TO BE SURE THE SET IS SAFE TO OPERATE

WITHOUT DANGER OF ELECTRICAL SHOCK. DO NOT USE A LINE

ISOLATION TRANSFORMER DURING THIS TEST USE AN A.C. VOLTMETER, HAVING 5000 OHMS PER VOLT OR MORE SENSITIVITY, IN

THE FOLLOWING MANNER; CONNECT A 1500 OHM 10 WATT RESISTOR, PARALLELED BY A .15 MFD. 150.V A.C TYPE CAPACITOR

BETWEEN A KNOWN GOOD EARTH GROUND (WATER PIPE, CONDUIT, ETC.) AND THE EXPOSED METALLIC PARTS, ONE AT A TIME.

MEASURE THE A.C. VOLTAGE ACROSS THE COMBINATION OF 1500

OHM RESISTOR AND .15 MFD CAPACITOR. REVERSE THE A.C. PLUG

AND REPEAT A.C. VOLTAGE MEASUREMENTS FOR EACH EXPOSED

METALLIC PART. VOLTAGE MEASURED MUST NOT EXCEED 75

VOLTS R.M.S. THIS CORRESPONDS TO 0.5 MILLIAMP A.C ANY

VALUE EXCEEDING THIS LIMIT CONSTITUTES A POTENTIAL SHOCK

HAZARD AND MUST BE CORRECTED IMMEDIATELY.

SUBJECT: GRAPHIC SYMBOLS

THE LIGHTNING FLASH WITH APROWHEAD SYMBOL. WITHIN

AN EQUILATERAL TRIANGLE, IS INTENDED TO ALERT THE

SERVICE PERSONNEL TO THE PRESENCE OF UNINSULATED

“DANGEROUS VOLTAGE” THAT MAY BE OF SUFFICIENT MAG-

NITUDE TO CONSTITUTE A RISK OF ELECTRIC SHOCK.

THE EXCLAMATION POINT WITHIN AN EQUILATERAL TRIANGLE IS INTENDED TO ALERT THE SERVICE PERSONNEL TO

THE PRESENCE OF IMPORTANT SAFETY INFORMATION IN

SERVICE LITERATURE.

SUBJECT : X-RADIATION

1. BE SURE PROCEDURES AND INSTRUCTIONS TO ALL SERVICE PERSONNEL COVER THE SUBJECT OF X-RADIATION. THE ONLY POTENTIAL SOURCE OF X-RAYS IN CURRENT T.V. RECEIVERS IS THE PICTURE TUBE. HOWEVER, THIS TUBE DOES NOT EMIT X-RAYS WHEN

THE HIGH VOLTAGE IS AT THE FACTORY SPECIFIED LEVEL. THE

PROPER VALUE IS GIVEN IN THE APPLICABLE SCHEMATIC. OPERATION AT HIGHER VOLTAGES MAY CAUSE A FAILURE OF THE PICTURE TUBE OR HIGH VOLTAGE SUPPLY AND, UNDER CERTAIN CIRCUMSTANCES, MAY PRODUCE RADIATION IN EXCESS OF DESIRABLE LEVELS.

2. ONLY FACTORY SPECIFIED C.R.T. ANODE CONNECTORS MUST BE

USED. DEGAUSSING SHIELDS ALSO SERVE AS X-RAY SHIELD IN

COLOR SETS, ALWAYS RE-INSTALL THEM.

3. IT IS ESSNTIAL THAT SERVICE PERSONNEL HAVE AVAILABLE AN

ACCURATE AND RELIABLE HIGH VOLTAGE METER. THE CALIBRA

TION OF THE METER SHOULD BE CHECKED PERIODICALLY

AGAINST A REFERENCE STANDARD, SUCH AS THE ONE AVAILABLE

AT YOUR DISTRIBUTOR.

4. WHEN THE HIGH VOLTAGE CIRCUITRY IS OPERATING PROPERLY

THERE IS NO POSSIBILITY OF AN X-RADIATION PROBLEM. EVERY

TIME A COLOR CHASSIS IS SERVICED. THE BRIGHTNESS SHOULD

BE RUN UP AND DOWN WHILE MONITORING THE HIGH VOLTAGE

WITH A METER TO BE CERTAIN THAT THE HIGH VOLTAGE DOES

NOT EXCEED THE SPECIFIED VALUE AND THAT IT IS REGULATING

CORRECTLY, WE SUGGEST THAT YOU AND YOUR SERVICE ORGANIZATION REVIEW TEST PROCEDURES SO THAT VOLTAGE REGULATION IS ALWAYS CHECKED AS A STANDARD SERVICING PROCEDURE. AND THAT THE HIGH VOLTAGE READING BE RECORDER ON

EACH CUSTOMER’S INVOICE.

5. WHEN TROUBLESHOOTING AND MAKING TEST MEASUREMENTS IN

A PRODUCT WITH A PROBLEM OF EXCESSIVE HIGH VOLTAGE,

AVOID BEING UNNECESSARILY CLOSE TO THE PICTURE TUBE AND

THE HIGH VOLTAGE SUPPLY. DO NOT OPERATE THE PRODUCT

LONGER THAN IS NECESSARY TO LOCATE THE CAUSE OF EXCES

SIVE VOLTAGE.

6. REFER TO HV. B+ AND SHUTDOWN ADJUSTMENT PROCEDURES

DESCRIBED IN THE APPROPRIATE SCHEMATIC AND DIAGRAMS

(WHERE USED).

SUBJECT: IMPLOSION

1. ALL DIRECT VIEWED PICTURE TUBES ARE EQUIPPED WITH AN INTE

GRAL IMPLOSION PROTECTION SYSTEM, BUT CARE SHOULD BE

TAKEN TO AVOID DAMAGE DURING INSTALLATION, AVOID

SCRATCHING THE TUBE. IF SCRATCHED REPLACE IT.

2. USE ONLY RECOMMENDED FACTORY REPLACEMENT TUBES.

SUBJECT : TIPS ON PROPER INSTALLATION

1. NEVER INSTALL ANY PRODUCT IN A CLOSED-IN RECESS, CUBBYHOLE OR CLOSELY FITTING SHELF SPACE. OVER OR CLOSE TO

HEAT DUCT, OR IN THE PATH OF HEATED AIR FLOW.

2. AVOID CONDITIONS OF HIGH HUMIDITY SUCH AS: OUTDOOR PATIO

INSTALLATIONS WHERE DEW IS A FACTOR, NEAR STEAM RADIATORS WHERE STEAM LEAKAGE IS A FACTOR, ETC.

3. AVOID PALCEMENT WHERE DRAPERIES MAY OBSTRUCT REAR

VENTING. THE CUSTOMER SHOULD ALSO AVOID THE USE OF DECORATIVE SCARVES OR OTHER COVERINGS WHICH MIGHT

OBSTRUCT VENTILATION.

4. WALL AND SHELF MOUNTED INSTALLATIONS USING A COMMERCIAL MOUNTING KIT. MUST FOLLOW THE FACTORY APPROVED

MOUNTING INSTRUCTIONS A PRODUCT MOUNTED TO A SHELF OR

PLATFORM MUST RETAIN ITS ORIGINAL FEET (OR THE EQUIVALENT

THICKNESS IN SPACERS) TO PROVIDE ADEQUATE AIR FLOW

ACROSS THE BOTTOM, BOLTS OR SCREWS USED FOR FASTENERS

MUST NOT TOUCH ANY PARTS OR WIRING. PERFORM LEAKAGE

TEST ON CUSTOMIZED INSTALLATIONS.

5. CAUTION CUSTOMERS AGAINST THE MOUNTING OF A PRODUCT ON

SLOPING SHELF OR A TILTED POSITION, UNLESS THE PRODUCT IS

PROPERLY SECURED.

6. A PRODUCT ON A ROLL-ABOUT CART SHOULD BE STABLE ON ITS

MOUNTING TO THE CART. CAUTION THE CUSTOMER ON THE HAZARDS OF TRYING TO ROLL A CART WITH SMALL CASTERS ACROSS

THRESHOLDS OR DEEP PILE CARPETS.

7. CAUTION CUSTOMERS AGAINST THE USE OF A CART OR STAND

WHICH HAS NOT BEEN LISTED BY UNDERWRITERS LABORATORIES,

INC. FOR USE WITH THEIR SPECIFIC MODEL OF TELEVISION

RECEIVER OR GENERICALLY APPROVED FOR USE WITH T.V.’S OF

THE SAME OR LARGER SCREEN SIZE.

8. CAUTION CUSTOMERS AGAINST THE USE OF EXTENSION CORDS,

EXPLAIN THAT A FOREST OF EXTENSIONS SPROUTING FROM A SINGLE OUTLET CAN LEAD TO DISASTROUS CONSEQUENCES TO

HOME AND FAMILY.

PRODUCT SAFETY SERVICING GUIDELINES FOR VIDEO PRODUCTS

A.C. VOLTMETER

GOOD EARTH GROUND

SUCH AS THE WATER

PIPE. CONDUIT. ETC

PLACE THIS PROBE

ON EACH EXPOSED

METAL PART

Page 5

1-4

SERVICING PRECAUTIONS

CAUTION : Before servicing the STB covered by this service

data and its supplements and addends, read and follow the

SAFETY PRECAUTIONS. NOTE : if unforeseen circumstances create conflict between the following servicing precautions and any of the safety precautions in this publications, always follow the safety precautions.

Remembers Safety First:

General Servicing Precautions

1. Always unplug the STB AC power cord from the AC

power source before:

(1) Removing or reinstalling any component, circuit board,

module, or any other assembly.

(2) Disconnection or reconnecting any internal electrical

plug or other electrical connection.

(3) Connecting a test substitute in parallel with an elec-

trolytic capacitor.

Caution : A wrong part substitution or incorrect

polarity installation of electrolytic capacitors may result

in an explosion hazard.

2. Do not spray chemicals on or near this STB or any of

its assemblies.

3. Unless specified otherwise in this service data, clean

electrical contacts by applying an appropriate contact

cleaning solution to the contacts with a pipe cleaner,

cotton-tipped swab, or comparable soft applicator.

Unless specified otherwise in this service data, lubrication

of contacts is not required.

4. Do not defeat any plug/socket B+ voltage interlocks with

whitch instruments covered by this service manual might

be equipped.

5. Do not apply AC power to this STB and/or any of its

electrical assemblies unless all solid-state device heat

sinks are cerrectly installed.

6. Always connect test instrument ground lead to the

appropriate ground before connection the test instrument

positive lead. Always remove the test instrument ground

lead last.

Insulation Checking Procedure

Disconnect the attachment plug from the AC outlet and turn

the power on. Connect an insulation resistance meter(500V)

to the blades of the attachment plug. The insulation resistance between each blade of the attachment plug and accessible conductive parts (Note 1) should be more than 1Mohm.

Note 1 : Accessible Conductive Parts including Metal panels, Input terminals, Earphone jacks, etc.

Electrostatically Sensitive (ES) Devices

Some semiconductor (solid state) devices can be damaged

easily by static electricity. Such components commonly are

called Electrostatically Sensitive (ES) Devices. Examples of

typical ES devices are integrated circuits and some field

effect transistors and semiconductor chip components.

The following techniques should be used to help reduce the

incidence of component damage caused by static electricity.

1. Immediately before handling any semiconductor component or semiconductor-equipped assembly, drain off any

electrostatic charge on your body by touching a known

earth ground. Alternatively, obtain and wear a commercially available discharging wrist strap device, which

should be removed for potential shock reasons prior to

applying power to the unit under test.

2. After removing an electrical assembly equipped with ES

devices, place the assembly on a conductive surface such

as aluminum foil, to prevent electrostatic charge buildup or

exposure of the assembly.

3. Use only a grouned-tip soldering iron to solder or unsolder

ES devices.

4. Use only an anti-static solder removal device. Some

solder removal devices not classified a “anti-static” can

generate electrical charges sufficient to damage ES

devices.

5. Do not use freon-propelled chemicals. These can

generate electrical charge sufficient to damage ES

devices.

6. Do not remove a replacement ES device from its protec

tive package until immediately before you are ready to

install it. (Most replacement ES devices are packaged with

leads electrically shorted together by conductive foam,

aluminum foil, or comparable conductive material).

7. Immediately before removing the protective material from

the leads of a replacement ES device, touch the protective

material to the chassis or circuit assembly into which the

device will be installed.

Caution : Be sure no power is applied to the chassis or

circuit, and observe all other safety precautions.

8. Minimize bodily motions when handling unpackaged

replacement ES devices. (Normally harmless motion such

as the brushing together of your clothes fabric or the lifting

of your foot from a carpeted floor can generate static electricity sufficient to damage an ES device.)

Page 6

1-5

SPECIFICATIONS

Television System NTSC, DTV standard (1080i, 720p, 480p, 480i)

Channel Coverage Terrestrial: 2-69, Cable: 1-135

Input/Output

ATSC ANT Input ANT IN (1) (ATSC-8VSB over Terrestrial or QAM over cable)

ANT Loop Out Out To TV (1)

DVI Output DVI-HDTV Out (1), DVI-D Single Link connector

1080i, 720p, 480p digital RGB

Component Video Output Component Out (1 Set), Typical RCA type Jack connectors

1080i, 720p, 480p, 480i YPbPr

RGB Output RGB Out (1), 15-pin connector

1080i, 720p, 480p RGB

S-Video Output S-Video Out (1), 4-pin Mini-DIN

480i Y/C

Video Output Video Out (1), Typical RCA type Jack connector

480i Composite

Digital Audio Output Coaxial, Optical (Dolby Digital output)

Analog Audio Output Audio Out (2) (Variable Output Level)

Authorized Service Port 9-pin Serial Port (1)

Dimension (W x H X D) 14.2 x 2.4 x 10.4 inches (360 x 60 x 265 mm)

Weight 7.7 lbs (3.5 kg)

Power Requirements AC 120V, 60Hz

Power Consumption 15W

Environment

Humidity 0 to 99 percent non condensing

Storage Temperature -20 to 60 degrees Celsius (-4 to 140 degrees Fahrenheit)

Operating Temperature 0 to 40 degrees Celsius (32 to 104 degrees Fahrenheit)

Accessories

RF cable . . . . . . . . . . . . . . . . . . . . .1

Video cable . . . . . . . . . . . . . . . . . . .1

Audio (L/R) cable . . . . . . . . . . . . . . .1

Component (YPbPr) cable . . . . . . . .1

Remote Control . . . . . . . . . . . . . . . .1

Batteries (size AA) . . . . . . . . . . . . . .2

Page 7

2-1

SECTION 2

CABINET & MAIN CHASSIS

CONTENTS

EXPLODED VIEWS .....................................................................................................................2-2

1. Cabinet and Main Frame Section ...........................................................................................2-2

2. Packing Accessory Section....................................................................................................2-3

Page 8

2-2

EXPLODED VIEWS

1. Cabinet and Main Frame Section

300

A47

463

463

463

463

250

A46

463

463

A43

A44

A49

280

452

452

260

320

466

457

465

466

469

470

457

A

5

4

3

2

1

BCD

Page 9

2-3

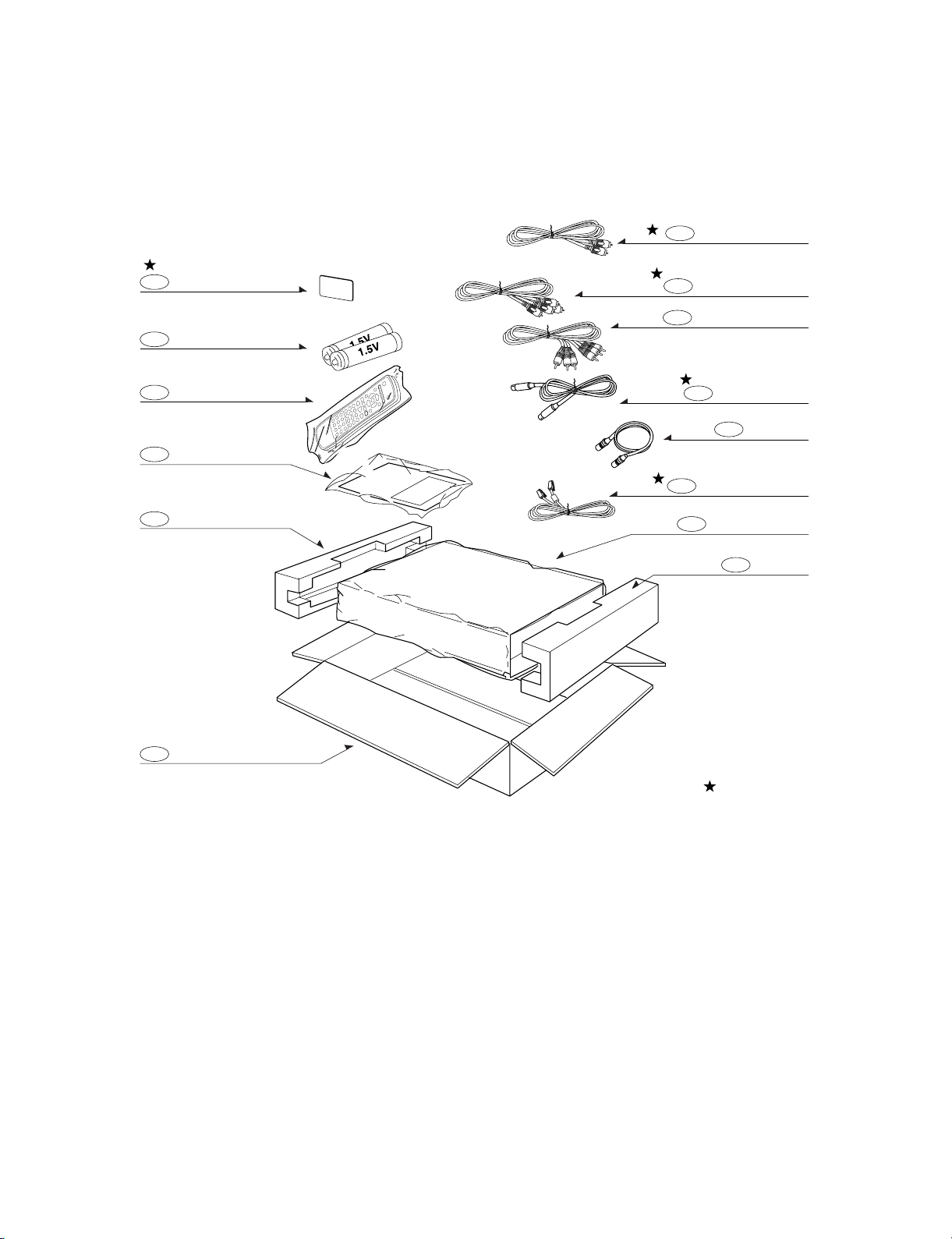

2. Packing Accessory Section

808

804

803

801

900

802

803

813

S-VIDEO CABLE

806

RF CABLE

823

TELEPHONE LINE

820

PLUG ASS'Y(3WAY)

PACKING SHEET

PACKING

BATTERY

822

SMART CARD

REMOCON

BOX CARTONX

PACKING

OWNER'S MANUAL

OPTIONAL PARTS

811

812

PLUG ASS'Y 1WAY

PLUG ASS'Y 2WAY

Page 10

3-1

SECTION 3

ELECTRICAL

CONTENTS

SOFTWARE CORRUPTION PROBLEM.....................................................................................................3-2

ELECTRICAL TROUBLESHOOTING GUIDE............................................................................................3-5

1. POWER(SMPS) CIRCUIT.........................................................................................................................3-5

2. AUDIO CIRCUIT .......................................................................................................................................3-7

1) NO ATSC AUDIO.....................................................................................................................................3-7

2) NO OPTICAL OUTPUT AUDIO...............................................................................................................3-11

3) NO COAXIAL OUTPUT AUDIO ..............................................................................................................3-12

3. CPU (SYSTEM CONTROL) TROUBLESHOOTING ..............................................................................3-14

4. VIDEO TROUBLESHOOTING FLOW ....................................................................................................3-21

5. ATSC/ QAM FRONT- END TROUBLESHOOTING FLOW ....................................................................3-31

6. FRONT PANEL TROUBLESHOOTING FLOW......................................................................................3-32

OVERALL BLOCK DIAGRAM.........................................................................................................................3-34

1. OVERALL BLOCK DIAGRAM 1 ............................................................................................................3-34

2. OVERALL BLOCK DIAGRAM 2 ............................................................................................................3-36

3. OVERALL BLOCK DIAGRAM 3 ............................................................................................................3-38

BLOCK DIAGRAM & SIGNAL FLOW.............................................................................................................3-40

1. POWER(SMPS) BLOCK DIAGRAM ......................................................................................................3-40

2. SYSTEM CONTRL BLOCK DIAGRAM..................................................................................................3-42

3. AUDIO PROCESSING BLOCK DIAGRAM............................................................................................3-44

4. VIDEO PROCESSING BLOCK DIAGRAM ............................................................................................3-46

CIRCUIT DIAGRAM .........................................................................................................................................3-48

1. POWER(SMPS) CIRCUIT DIAGRAM ....................................................................................................3-48

2. CPU, AUDIO, POWER CIRCUIT DIAGRAM..........................................................................................3-50

3. HD2, TUNER, DVI CIRCUIT DIAGRAM.................................................................................................3-52

4. ATSCII-STB CIRCUIT DIAGRAM...........................................................................................................3-54

5. FRONT CIRCUIT DIAGRAM ..................................................................................................................3-56

PRINTED CIRCUIT DIAGRAMS......................................................................................................................3-58

1. DIGITAL MAIN P.C.BOARD(BOTTOM)..................................................................................................3-58

2. DIGITAL MAIN P.C.BOARD(TOP)..........................................................................................................3-60

3. FRONT P.C.BOARD ...............................................................................................................................3-62

4. POWER P.C.BOARD ..............................................................................................................................3-62

Page 11

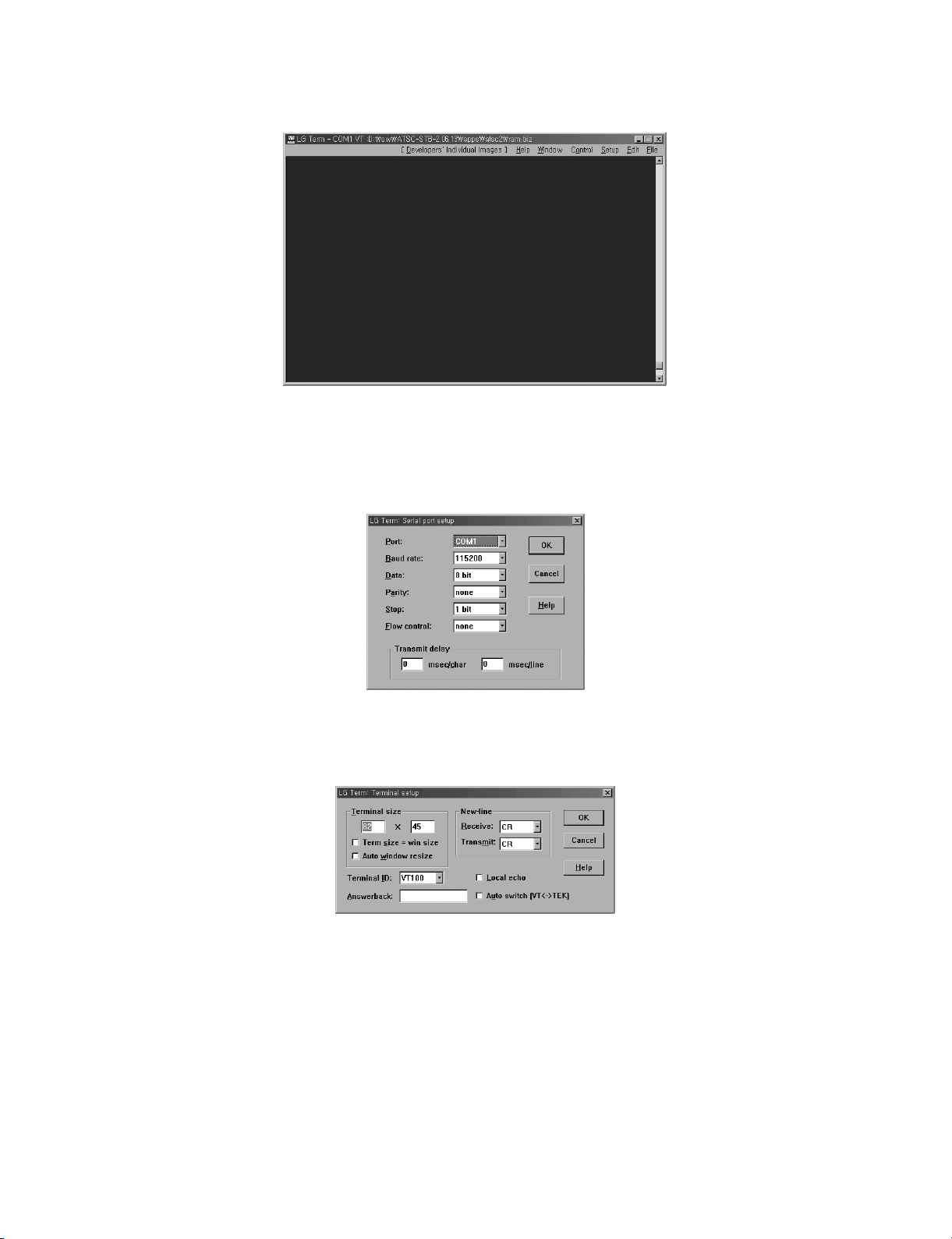

SOFTWARE CORRUPTION PROBLEM

3-2

1. Open window display for Serial Communication like above.

- You can use almost kinds of serial communication programs, but we send the terminal

(LG Term) which is now used on our side.

2. Create “Setup-> Serial Port” like the display. (However, the port depends upon the user

environment so that you need to create properly.)

3. Create “Setup-> Terminal” like the above display.

Page 12

3-3

4. After completing all set-up process, press d key in the terminal and impress STB power.

At this time, you should pull up the plug and then pull into the socket again.

- You have another choice. When activating, please enter “klLST3100”, “ENTER” and

then “F10” keys in sequence. Once the command mode is up, you can download it

even in your “Reset” command.

5. When above display shows up, you can download applications. You can input keys at the

prompt.

6. Press Enter Key several times to input new command. Input serial download command

as “sto ser” like above example and then press Enter key.

7. This is the condition you can download application program from STB.

Page 13

3-4

8. In the downloadable condition, select °∞File->Send File°±. You can watch one more dis-

play like above. You should find °∞ram.biz°∞ file in this new display and open it to start

downloading.

9. You can see the downloading process from display and it takes about 2 minutes to complete. After downloading, the message °∞Please write data into the Flash ROM°± would

show up. (You may experience errors of downloading. Then, follow from No. 6 again.

10. Above message shows that you succeed to write application program into the Flash.

Restart the power source, or input °∞b flash°± in this display to activate properly.

(If you have no response, please input command again.)

Page 14

3-5

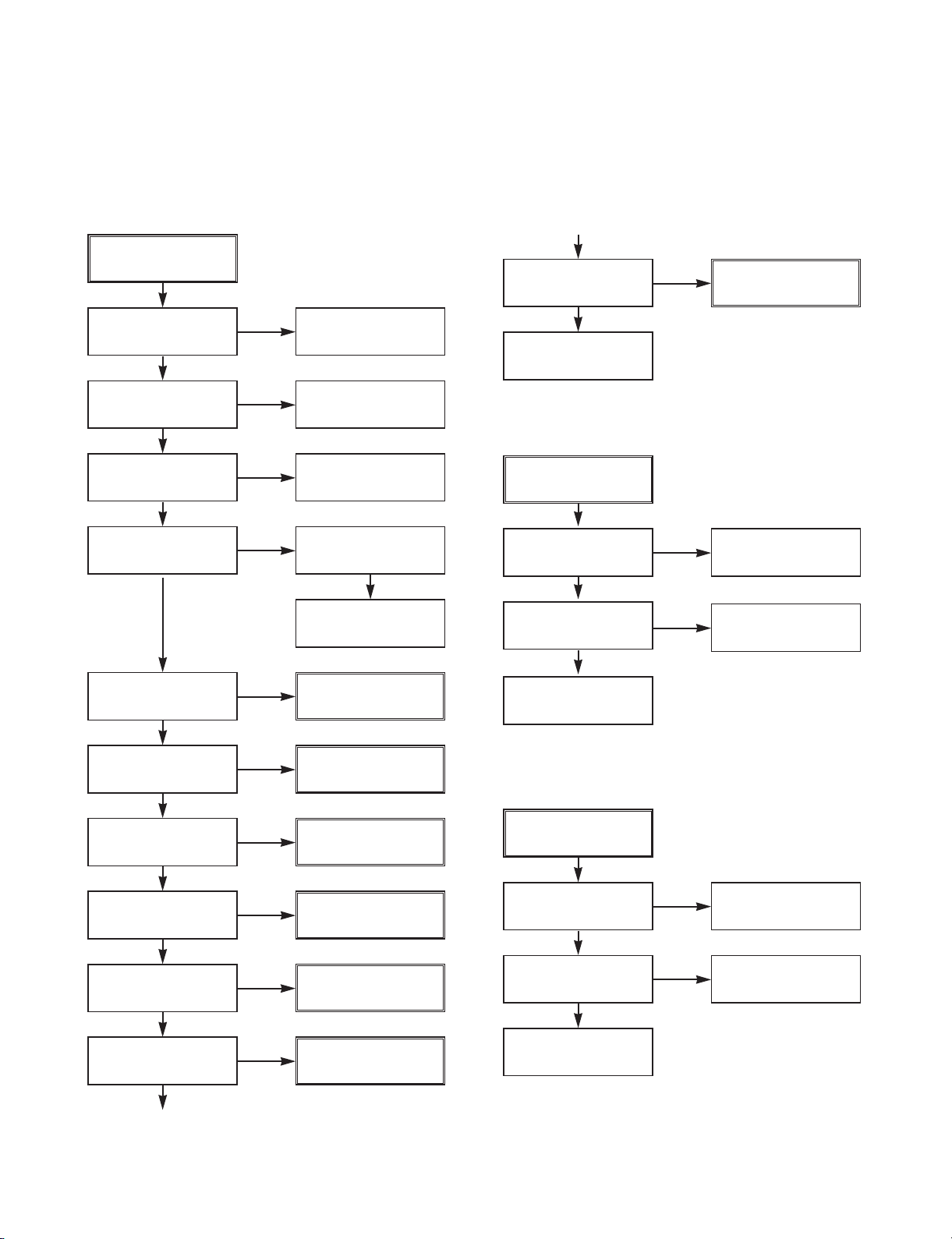

ELECTRICAL TROUBLESHOOTING GUIDE

1. Power(SMPS) CIRCUIT

NO

NO

NO

NO

NO

NO

NO

NO

NO

YES

YES

YES

YES YES

YES

NO

YES

YES

YES

YES

YES

YES

YES

YES

YES

(1) No 5.0VA

Check or Replace

the D106

Check the ‘PWR CTL

“H”’ signal from µ-com

NO

NO

(2) No 5.0V

NO

(3) No 3.3V

No 5.0VA

Is the F101 normal?

Is the R105

Normal?

Is the BD101

normal?

Is Vcc (13V - 16V) supplied to IC101 Pin7?

Are the D106

normal?

Is there about 2.5V

at the IC103 Pin1?

Is the D105

normal?

Is the D109

normal?

Replace the F101.

(Use the same Fuse)

Replace the

BD101.

Replace the R105.

Is the D103

normal?

Check or Replace

the D106.

Replace the

D106.

Replace the IC103.

Replace the

D105.

Replace the

D109.

Replace the

D110.

No 3.3V

Is there about 3.8V

at the IC153 pin1?

Is there about 3.3V~

5V at the IC153 pin4?

YES

Check the IC153

and Replace

Check or Replace

the D105

NO

Check the ‘PWR CTL

“H”’ signal from µ-com

Is there about 5.4V

at the IC152 pin1?

Is there about 3.3V~5V

at the IC152 pin4?

YES

Check the IC152

and Replace

Is the D110

normal?

NO

Replace the

D108.

Is the D108

Normal?

NO 5.0V

YES

YES

Power Line of Main

PCB is short

NO

Replace the

D107.

Is the D107

Normal?

Page 15

3-6

YES

YES

NO

(4) No 12VA

Is there about 13V

at the IC155 pin1?

Is there about 3.3V~5V

at the IC155 pin4?

Check the IC155

and Replace

Check or Replace

the D109

NO

Check the ‘PWR CTL

“H”’ signal from µ-com

YES

YES

YES

YES

NO

NO

NO

(6) No VFD

No VFD

Is The R123

Normal?

Is The D107

Normal?

Is The ZD102

Normal?

Check and

Replace the D108

Replace the R123

Replace the R107

Replace the ZD102

YES

YES

NO

(5) No 30VA

No 30VA

Is The ZD110

Normal?

Check and

Replace the D110

Replace the ZD101

Page 16

3-7

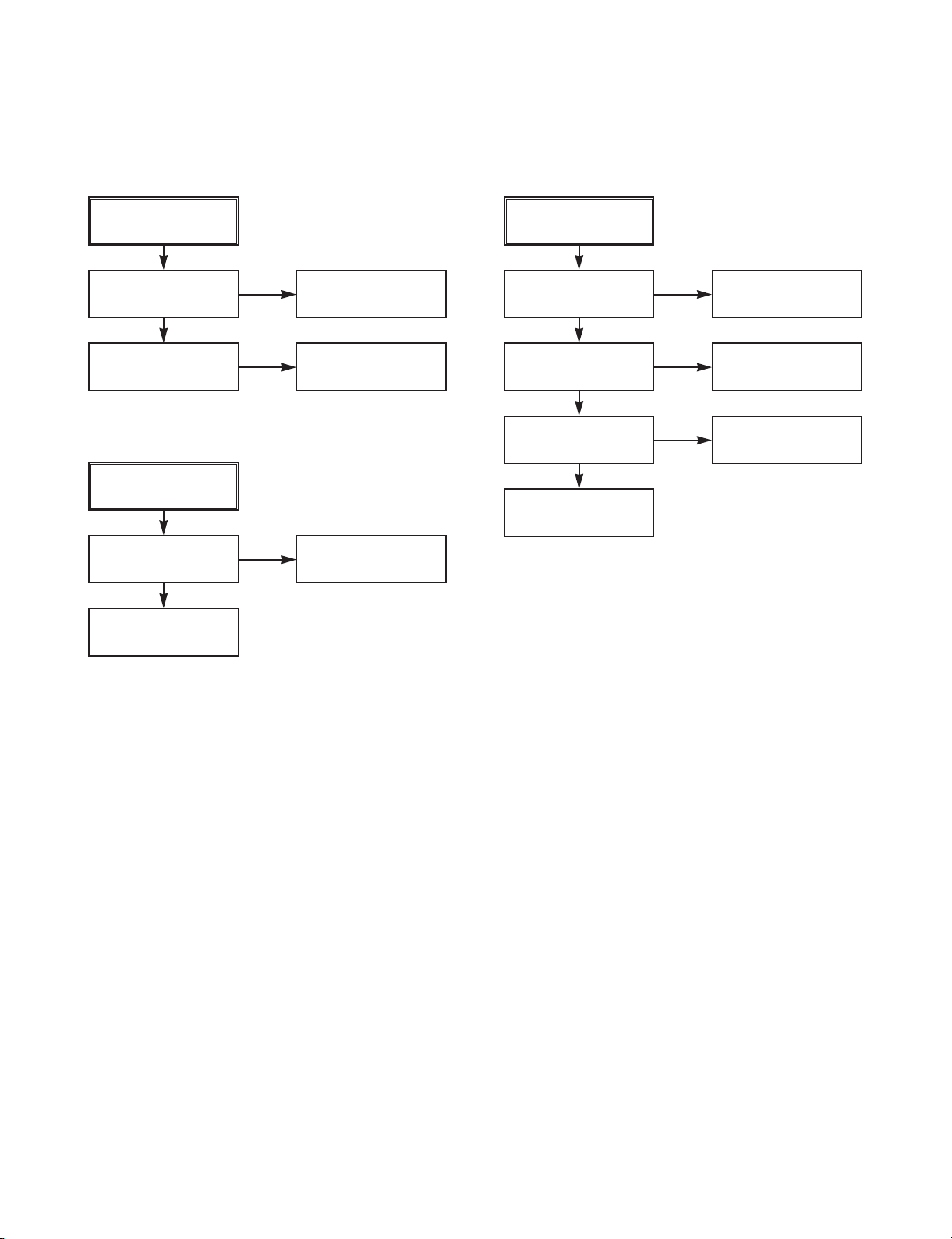

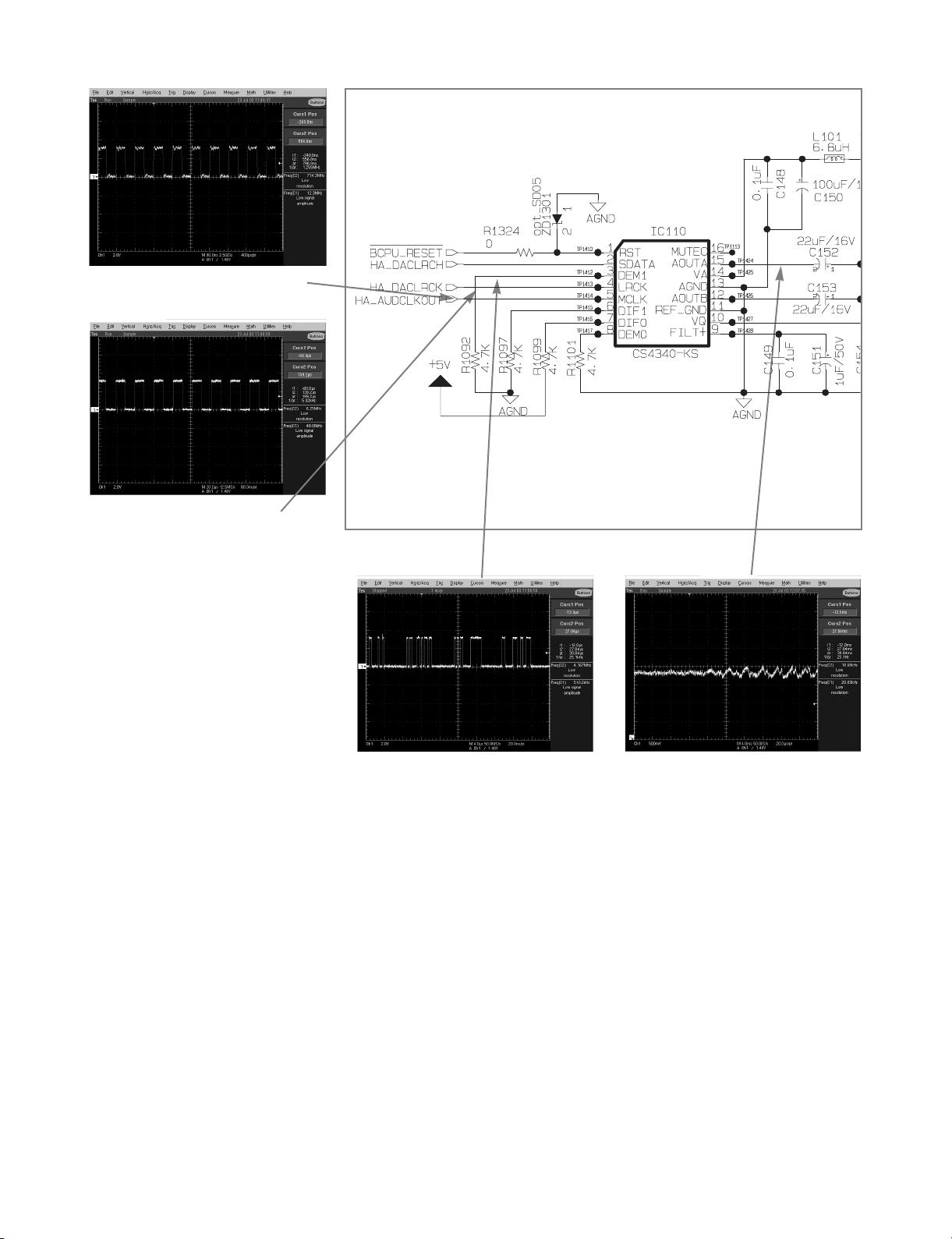

2. AUDIO CIRCUIT

1) NO ATSC AUDIO

NO

NO

NO

NO

NO

YES

YES

YES

YES

(1) Check IC110 and Surroundings

5V is supplied to IC110(14)?

12.2880MHz clock is input to IC110

(5)? Fig. 01

IC110(13) is grounded?

48KHz clock is output from IC110

(4)? Fig. 02

Data Signal is input to IC110(2)?

Fig. 03

YES

Analog Audio Signal from IC110

(12,15)? Fig. 04

Check the Power Supply Part.

Check 12.2880MHz Clock output at

IC200(H5).

Check 48KHz Clock ouput at IC200

(G5)

Check soldering.

Check Data Signal at IC200(G3)

Page 17

3-8

Fig. 01 12.2880MHz clock

Fig. 02 48KHz clock

Fig. 04 Analog Audio SignalFig. 03 Data Signal

Page 18

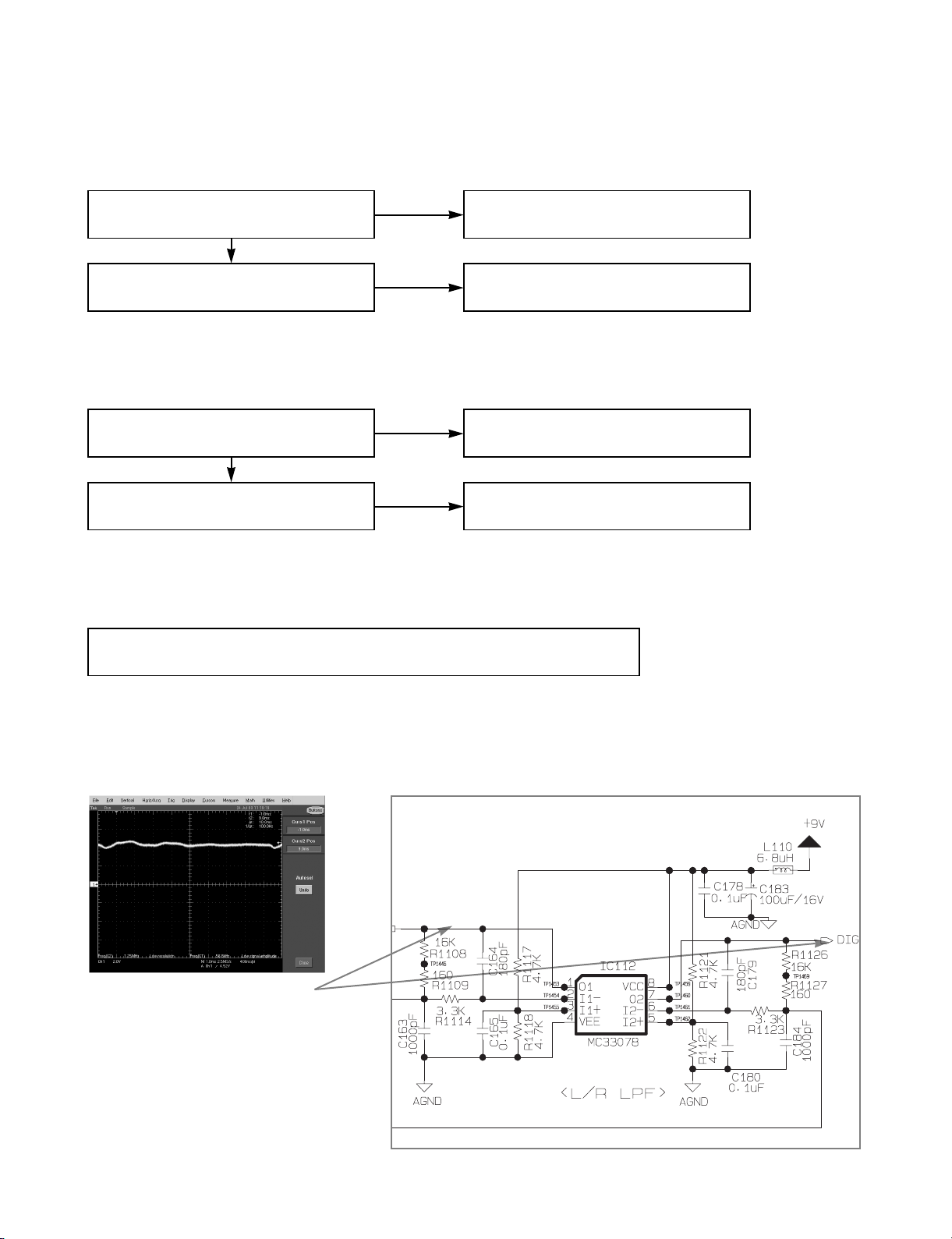

3-9

Fig. 05 Analog Audio Signal

NO

NO

NO

YES

YES

(2) Check IC112 and Surroundings

(3) Check Q102, Q103, Q109, Q110 and Surroundings

(4) Check Output Jack and Surroundings

59V is supplied to IC112(8)?

Analog audio signal is output from

IC112(1, 7)? Fig. 05

Analog audio signal is output from

Q102, Q103, Q109, Q110(1)? Fig. 06

9V is supplied to Q102, Q103,

Q109,Q110(3)?

Check CN300(VARIABLE_ L, VARIABLE_ R, MONITOR_ L, MONITOR_ R)

And their surroundings

Check Power Supply Part

Check IC112 and surroundings

NO

Check Power Supply Part

Check Q102, Q103, Q109, Q110 and

surroundings

Page 19

3-10

Fig. 06 Analog Audio Signal

Page 20

3-11

2) NO OPTICAL OUTPUT AUDIO

NO

YES

SPDIF pulse is output from IC200

(F3)? Fig. 07

Check CN103 and surrounding

Check IC200 and surroundings

Page 21

3-12

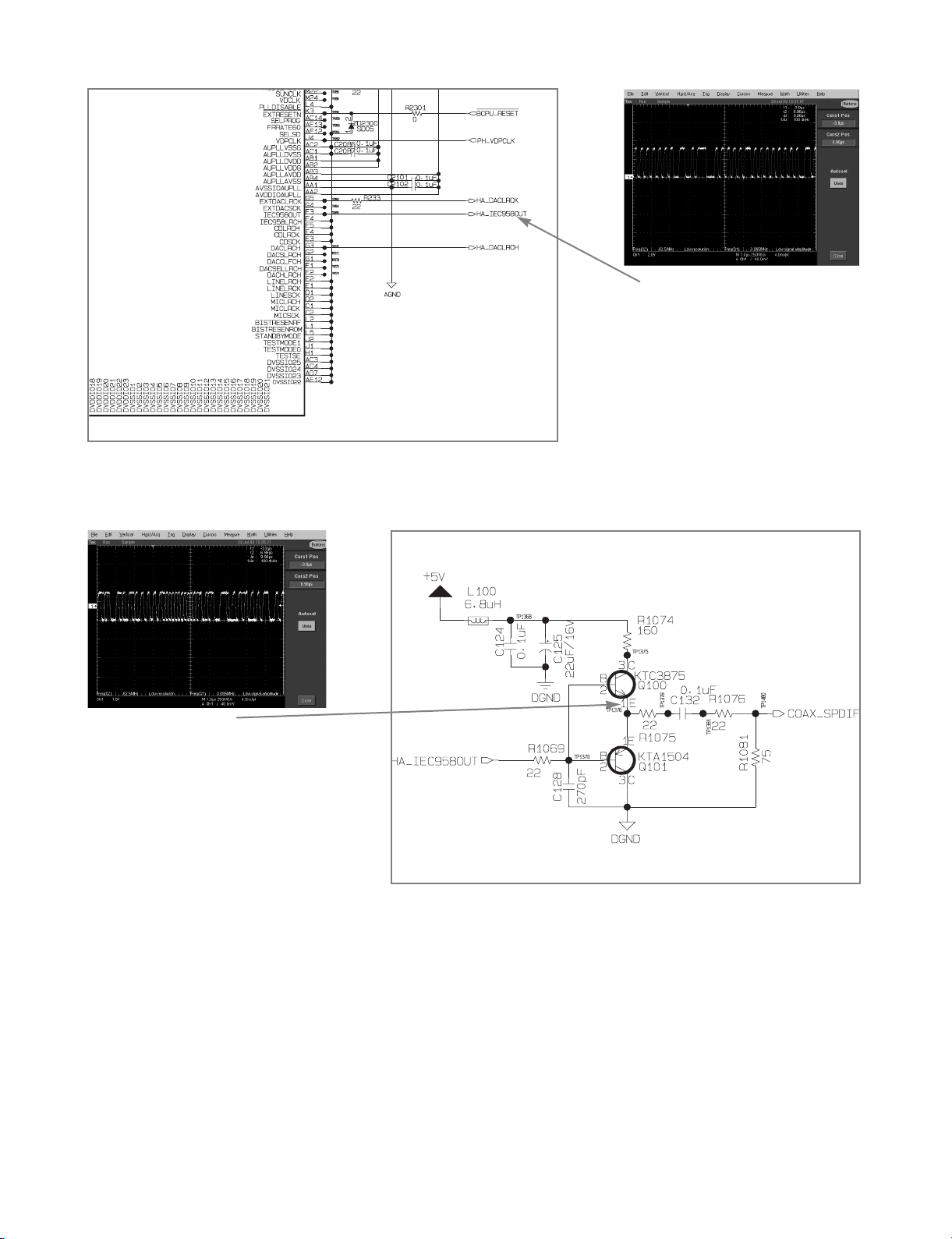

3) NO COAXIAL OUTPUT AUDIO

NO

NO

NO

YES

YES

YES

5V is supplied to Q100(3)?

SPDIF pulse is output from IC200(F3)?

Fig. 07

SPDIF pulse is output from Q100(1)?

Fig. 08

Check CN300(S6, G6) and their

surroundings

Check Power Supply Part

Check IC200 and surroundings

Check Q100, Q101 and surroundings

Page 22

3-13

Fig. 07 ,Digital Audio Signal

Fig. 08

Coaxial Digital Audio Signal

Page 23

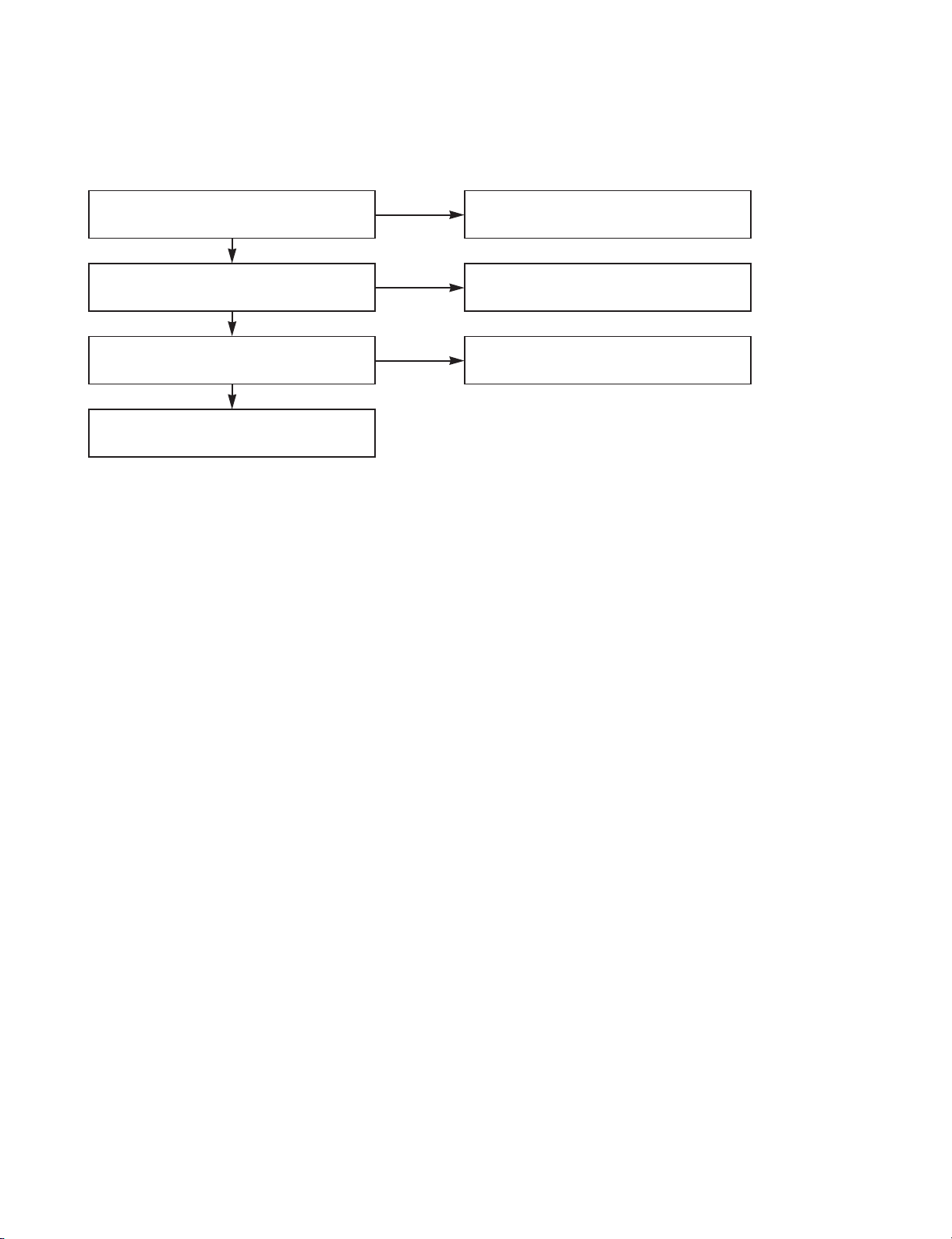

3. CPU (System Control) Troubleshooting

NO

YES

YES

Start

Is Power supplied normally?

Is each clock OK?

YES

Is each reset OK at the time of

power- on reset?

YES

Is each chip selection OK?

YES

Is each I2C channel OK?

YES

Are messages output through

RS- 232C port on PC terminal?

YES

End

Check Power : Refer to (A)

NO

NO

NO

NO

NO

Check each clock : Refer to (B)

Check reset circuit : Refer to (C)

Check each chip selection : Refer to (D)

Check each I2C channel : Refer to (E)

Check RS- 232C circuit : Refer to (G)

3-14

Page 24

3-15

NO

YES

YES

(A)

Is 2.5V supplied to the pin 21 of IC109

and 3.3V to the pin 9 of IC109 ?

Is 3.3V supplied to the pin 37 of IC100,

101 and the pin 1 of IC106, 107 ?

YES

Check IC100, 101, 106, 107, 109

Power Supply Check

IC113 : 2.5V IC111 : 3.3V

NO

Power Supply Check

IC111 : 3.3V

Page 25

3-16

Fig. 02Fig. 01

NO

YES

YES

(B)

Is 10MHz clock output from X101 ?

Fig. 01

Is 60MHz clock output from the pin 28

of IC109? Fig. 02

Check X101

NO

Check IC109

Page 26

3-17

Fig. 04Fig. 03

NO

YES

YES

(C)

Is the pin 3 of IC103 reset ?

Is the pin 4 of IC104 reset ? Fig. 03

YES

Is the pin 93 of IC109 reset ?

YES

Is the pin 10 of IC104 reset at the

time of power- button on? Fig. 04

IC103 Check

NO

NO

NO

IC104 Check

IC109 Check

IC104 Check

Page 27

3-18

Fig. 05

NO

YES

YES

(D)

Is logic low pulse seen at R1060?

Is logic low pulse seen at R1054?

Fig. 05

YES

Is logic low pulse seen at R1061?

Check IC109, 100, 101

NO

NO

Check IC109, 106, 107

Check IC109, 200

Page 28

3-19

Fig. 07Fig. 06

NO

YES

YES

(E)

Are IIC SCL and SDA signals output from

the pin 60, 61 of IC109 ? Fig. 06 & Fig. 07

A re IIC SCL and SDA signal input to

the pin 1, 2 of IC108 from IC109 ?

YES

Are IIC SCL and SDA signals output

from the pin 6, 7 of IC108?

Check IC109

NO

NO

Check IC108, IC109

Check IC108, 105,

Page 29

3-20

Fig. 08

NO

YES

YES

(F)

Is RS- 232C port setup OK?

(Baudrate, Parity, Data Bit, Stop Bit)

Is the pin 11 of IC102 OK?

(TxD signal) Fig. 08

YES

Is the pin 12 of IC102 OK?

(RxD signal)

Modify RS- 232C port setup

NO

NO

Check IC109, IC102

Check IC109, IC102

Page 30

3-21

4. VIDEO Troubleshooting Flow

NO

YES

YES

START

No HV sync OUT?

Any problem in OSD ?

Any problem in main picture?

Any problem in AV out?

End

YES

YES

YES

(A)

NO

NO

NO

NO

(B)

(C)

(D)

(E)

Page 31

3-23

FIG. 04 V- sync signal

FIG. 03 H- sync signal

Page 32

3-24

YES

NO

(C)

Check input stream existence.

Any problem?

Any problem in selecting ATSC?

Any decoding problem?

End

NO

NO

check VSB(IC203 ) block. FIG. 05

YES

YES

OK

Check voltage of IC203(23) => 3.3V

Check signal strength. If OK, check

system clock 27MHz. IC300(9)

Check HD 2 chip Interrupt FIG. 06

YES

NO

(B)

Check whether analog mute ON?

Check analog buffers. IC303 for 480i, IC302

for component YPbPr or RGB analog

Jump to (A) flow

OK

No OSD is not a problem.

Check DVI output.

YES

Check whether +A12V is supplied.

Page 33

3-25

FIG. 05

Input Stream to IC203

FIG. 06

Interrupt Signal

Page 34

3-26

Page 35

3-27

Page 36

3-28

YES

(D)

Check analog buffers.

IC303 for 480i

Jump to (A) flow

Page 37

3-29

NO

YES

START

Is DVI cable connected?

Is Display Format front pane DVI side?

Is The emitter of Q201 high volt ?

Is IC206(11) high volt ?

YES

YES

Is 480P picture OK?

YES

Are 720P & 1080I picture OK?

END

YES

YES

Connect DVI cable

NO

NO

NO

NO

NO

Change to DVI side

Use other DVI cable or Turn on the monitor that is connected with DVI cable.

Change the DVI chip

Check IC206(57(IDCK+), 2(DE),

4(HSYNC), 5(VSYNC)) The IDCK_

clock shall be 27MHz. Refer to Fig. 1

Check IC206(57(IDCK+), 2(DE), 4(HSYNC),

5(VSYNC)) The IDCK_ clock shall be

74.25MHz. Refer to Fig2, Fig3 and Fig4.

Page 38

3-30

FIG. 01

DVI output at 480p

FIG. 04

DVI output at 1080i odd field

FIG. 03

DVI output at 1080i even field

FIG. 02

DVI output at 720p

Page 39

3-31

5. ATSC/ QAM Front- End Troubleshooting Flow

YES

YES

START

Is Power supplied normally?

Is RF signal detected?

(using Spectrum Analyzer)

Check IC203’s output signals of

DATA( Fig. 01 ) (AR200,AR201),

packet valid signal( Fig. 02 )(AR202

or the pin 27 of IC203) and Byte

clock(the pin 30 of CN2301)

( Fig. 03 )

YES

YES

Check the power lines referring

the circuit diagram

Change channel with DTV signal

Check the status of connection on PCB.

Check Error flag LED. (LD200)

OFF: normal, ON: Error

END

YES

Check the NIM Tuner(IC203) and

peripheral parts

FIG. 03FIG. 02FIG. 01

Page 40

3-32

6. FRONT PANEL Troubleshooting Flow

NO

NO

NO

NO

NO

YES

YES

1) If front panel board is not working

START

The IC 5V power is supplied normally?

The IC -28, -24, -21.5V powers are

supplied normally?

The clock #1 operates normally?

The signal #2 operates normally?

YES

YES

Check IC100(13), IC100(43),

IR100(2) voltage : 5V

Check Connector P101(3), P101(2),

P101(1) voltage : -28, -24, -21.5V

Check IC100(5) clock waveform

: See FIG. 01

Check IC100(8) clock waveform

: See FIG. 02

The signal #3 operates normally?

END

YES

Check IC100(42) clock waveform

: See FIG. 03

Page 41

3-33

FIG. 03

IC100(42) VFD Chip Grid1 Pulse

FIG. 02

IC100(8) VFD Control Clock Signal

FIG. 01

IC100(5) VFD Chip Clock

Page 42

3-34 3-35

OVERALL BLOCK DIAGRAM

1. OVERALL BLOCK DIAGRAM 1

Board-to-Board Connection

FRONT Board

MAIN Board

SMPS

Board

15FD(+)/-21.5V15

14FD(-)/-24V14

13GND13

12-28V12

11GND11

103.3V10

93.3V9

85V8

75V7

6GND6

59V5

412V4

3GND3

230V2

1PW R_CTRL1

12

1110

9

87

6

54

3

21

GND

IR_DATA

DATA_RD

DATA_WR

CLK

CS

5

V

GND

GND

-

28

V

FD(-)/-

24

V

FD(+)/-

21

.

5

V

12

1110

9

87

6

54

3

21

AC120V

Page 43

3-36 3-37

2. OVERALL BLOCK DIAGRAM 2

RF IN

Loop

Through

Tuner

5V I2C

ATSC NIM TUNER

CPU

(S3C44B0X)

60MHz

SDRAM

(4Mx16bx2)

Flash ROM

(512Kx16bx2)

EEPROM

(32Kx8b)

CPU I/F

3V I2C

CPU CLK

RS232

Driver

(MAX232)

UART

Sys Reset

(KIA7029 &

74HC14)

RS-232C

10 MHz

X-tal

YPbPr Video Out

AMP

(LMH6683)

Line Driver

(74HC540)

RGB

Hs/Vs

RGB Video Out

TP Demux

Video Decoder

Audio Decoder

Format Converter

VDP

(LGDT1102A

: HD-II)

LPF

(TOKO 25M)

X 3

Main PW M

Main VDP Clock

Clock Gen.

(CY24206)

NT2CLK

SYSCLK

DVI

Transmitter

(Sil170)

TMDS CH0,1,2

TMDS CLK +-

I2C Ext.

(82B715)

5V I2C

DVI Out

Digital RGB

Hs, Vs

3V I2C

SDRAM

(2Mx32bx2)

ATSC TP

Digital

Audio Out

2CH L/R

Audio Out

LPF

(MC33078)

Digital Audio

Optical Out

DAC

(CS4340)

Digital Audio

Coaxial Out

AC120V

+30V

+12V

+9V

+5V

+5V_Alive

+3.3V

-28V

-24V

-21.5V

SMPS

Power Control

Variable

Audio Out X2

I2C Hub

I2CI2C

5V I2C

VCR Out

S-Video Out

VCR out (Comp.)

VCR out (Y/C)

AMP

(LMH6683)

RGB

DVI 5V I2C

Sil 170

+5V_Alive

3.3V

Regulator

+3.3V_Alive

2.5V

Regulator

+2.5V_Alive

+3.3V

1.8V

Regulator

+1.8V

VFD

Controller

Front Panel

VFD

Key Scan

Key Block

IR

Receiver

VCXO IC

(CY24212)

IC203

IC105

IC108

IC103, IC104

IC102

IC109

IC100, IC101 IC106, IC107

IC111

IC113

IC114

IC110 IC112

X101

X3300

27 MHz

X-tal

IC200

IC201, IC202

IC206

IC207

IC205

Buffer

(74LCX157)

Mute Control

IC2300

IC3300

IC300

IC302

IC303

FL300~302

Page 44

3-38 3-39

3. OVERALL BLOCK DIAGRAM 3

RF IN

Loop

Through

Tuner

5V I2C

ATSC NIM TUNER

CPU

(S3C44B0X)

60MHz

SDRAM

(4Mx16bx2)

Flash ROM

(512Kx16bx2)

EEPROM

(32Kx8b)

CPU I/F

3V I2C

CPU CLK

RS232

Driver

(MAX232)

UART

Sys Reset

(KIA7029 &

74HC14)

RS-232C

10 MHz

X-tal

YPbPr Video Out

AMP

(LMH6683)

Line Driver

(74HC540)

RGB

Hs/Vs

RGB Video Out

TP Demux

Video Decoder

Audio Decoder

Format Converter

VDP

(LGDT1102A

: HD-II)

LPF

(TOKO 25M)

X 3

Main PW M

Main VDP Clock

Clock Gen.

(CY24206)

NT2CLK

SYSCLK

DVI

Transmitter

(Sil170)

TMDS CH0,1,2

TMDS CLK +-

I2C Ext.

(82B715)

5V I2C

DVI Out

Digital RGB

Hs, Vs

3V I2C

SDRAM

(2Mx32bx2)

ATSC TP

Digital

Audio Out

2CH L/R

Audio Out

LPF

(MC33078)

Digital Audio

Optical Out

DAC

(CS4340)

Digital Audio

Coaxial Out

AC120V

+30V

+12V

+9V

+5V

+5V_Alive

+3.3V

-28V

-24V

-21.5V

SMPS

Power Control

Variable

Audio Out X2

I2C Hub

I2CI2C

5V I2C

VCR Out

S-Video Out

VCR out (Comp.)

VCR out (Y/C)

AMP

(LMH6683)

RGB

DVI 5V I2C

Sil 170

+5V_Alive

3.3V

Regulator

+3.3V_Alive

2.5V

Regulator

+2.5V_Alive

+3.3V

1.8V

Regulator

+1.8V

VFD

Controller

Front Panel

VFD

Key Scan

Key Block

IR

Receiver

VCXO IC

(CY24212)

IC203

IC105

IC108

IC103, IC104

IC102

IC109

IC100, IC101 IC106, IC107

IC111

IC113

IC114

IC110 IC112

X101

X3300

27 MHz

X-tal

IC200

IC201, IC202

IC206

IC207

IC205

Buffer

(74LCX157)

Mute Control

IC2300

IC3300

IC300

IC302

IC303

FL300~302

: Video Signal

: Audio Signal

: Digital Video Signal

: Digital Audio Signal

Page 45

3-40 3-41

PHOTO COUPLER

(IC102)

T101

TRANS

RECTIFIER &

SMOOTING BLOCK

(D107,C126)

P. CTL ëHí

30VA

9VA

ERROR

AMP

(IC103)

13

12

10

7

11

14

15

FEED-BACK

BLOCK

R116,R117,

C114,R118.

R119.R120

R121)

RECTIFIER &

SMOOTING BLOCK

(D108,C124,L106,C125)

RECTIFIER &

SMOOTING BLOCK

(D110,C122)

RECTIFIER &

SMOOTING BLOCK

(D105,C118,

L104,C119)

RECTIFIER &

SMOOTING BLOCK

(D109,C120)

RECTIFIER &

SMOOTING BLOCK

(D106,C116,

L103,C117)

5V

5VA

TO Main

(P101)

8

9

9V REG & S/W

BLOCK

(IC154,C154,R154)

12V REG & S/W

BLOCK

(IC155,C155,R151)

3.3V REG & S/W

BLOCK

(IC153,C153,R152)

5.0VA REG

BLOCK

(IC156,C156)

5.0V REG & S/W

BLOCK

(IC152,C152,R153)

FD(+)

FD(-)

-29VA

FUSE

(F101)

NOISE FILTER

BLOCK

(C101,L101,

C102)

SNUBBER

BLOCK

(D102,C105

C106,R104)

DRIVE & S/W BLOCK

(IC101, D103, R103,

C111, C109 , R101,

R102,R106,BC101)

BD101

R105

1

3

5

6

Y-CAP

C113

Y-CAP

C112

+

BR BL

(BK)(WH)

C103

!

!

!

!

!

!

3.3V

12VA

BLOCK DIAGRAM & SIGNAL FLOW

1. POWER(SMPS) BLOCK DIAGRAM

Page 46

3-42 3-43

2. SYSTEM CONTRL BLOCK DIAGRAM

CPU

DATA BUS[16-31]

DATA BUS[0-15]

FLASH ROM

(512Kx16b)

FLASH ROM

(512Kx16b)

A[2-20]

A[2-20]

SDRAM

(8Mx16b)

SDRAM

(8Mx16b)

ADDRESS BUS[1-23]

HD2

Addr[23,22,13-2]

Addr[23,22,13-2]

OE

WE

GCS0

GCS1

OEWE

OEWE

GCS6/SCS0

DQM0/DQM1/WE/CA

S/RAS/CLK/CKE

DQM0/DQM1/WE/CA

S/RAS/CLK/CKE

ST

B

WE

WE

CS

READYWAIT

IC200IC109

IC101

IC100

IC106

IC107

DQM0/DQM1/WE/CA

S/RAS/CLK/CKE

Front Panel I/F

PCA9516

SC

L

SDA

SC

L

SDA

I2C1

SC

L

SDA

I2C2

I2C3

I2C4

I2C Ext.

(82B715)

EEPROM

(25LC256)

TUNER PLL

SCL

SDA

SCL

SDA

TUNER VSB IC

DVI Transmitter

(Sil 170)

CS, CLK, DATA_WR,

DATA_RD, IR_DATA

RS232 Driver

(MAX232)

RX, TX

RS-232C

RX, TX

Sys Reset

(KIA7029 &

74HC14)

IC103, IC104

IC108

NIM TUNER

IC207

IC105

IC206

IC203

IC102

DMA control

Page 47

3-44 3-45

3. AUDIO PROCESSING BLOCK DIAGRAM

AUDIO DAC

(CS4340)

IC110

HA_DACLRCH

HA_DACLRCK

HA_AUDCLKOUT

Low Pass

Filter

(MC33078)

IC112

Left Audio Out

Right Audio Out

TR

Buffer

Left Audio Out Right Audio Out

Q102, Q103, Q109, Q110

AUDIO_MUTE_CTRL

Digital Audio

Optical Out

Digital Audio

Coaxial Out

Variable

Audio Out

Variable

Audio Out

HA_IEC958OUT

TR

Buffer

Q100, Q101

HD2

(LGDT

1102A)

IC200

CPU

(S3C44B0X)

IC109

Page 48

3-46 3-47

4. VIDEO PROCESSING BLOCK DIAGRAM

HD2

(LGDT

1102A)

YPbPr Video Out

AMP

(LMH6683)

Line Driver

(74HC540)

RGB

HSYNC_OUT, VSYNC_OUT

RGB Video Out

LPF

(TOKO 25M)

X 3

DVI

Transmitter

(Sil170)

TMDS CH0,1,2+-

(TX0, TX1, TX2)

TMDS CLK +-

(TXC)

I2C Ext.

(82B715)

DVI Out

Digital R(8bit)G(8bit)B(8bit)

3V I2C

VCR Out

S-Video Out

HP_CVBS_OUT

HP_SVIDEO_Y

HP_SVIDEO_C

AMP

(LMH6683)

RGB

IC206

IC207

IC205

IC302

IC303

FL300~302

IC200

DOUTHACTIVE

DOUT_CLK

Buffer

(74LCX157)

DVI_CLK

5V I2C

HP_HSYNC,

HP_VSYNC

HP_G, HP_B, HP_R

Buffer

TR

YPbPr

Q313~Q318

BYPBPR_MUTE_CTRL

BRGB_MUTE_CTRL

MUTE

control

TR

BVCR_MUTE_CTRL

I2C HUB.

(PCA9516)

Q320~Q322

Page 49

3-48 3-49

CIRCUIT DIAGRAM

1. POWER(SMPS) CIRCUIT DIAGRAM

No Power

BD101,R105 are Defective

No Power

D102 is Defective

Switching Error

IC102,IC103 is Defective

No Digitron appeared

D107,R123,ZD102 are Defective

-29VA No Power

D128 is Defective

30VA No Power

D110 is Defective

12V No Power

D125 is Defective

3.3V No Power

D105 is Defective

Switching Error

IC101 is Defective

F101 is Defective

No Power

5VA No Power

D106 is Defective

Page 50

3-50 3-51

2. CPU, AUDIO, POWER CIRCUIT DIAGRAM

Page 51

3-52 3-53

3. HD2, TUNER, DVI CIRCUIT DIAGRAM

Page 52

3-54 3-55

4. ATSCII-STB CIRCUIT DIAGRAM

Page 53

3-56 3-57

5. FRONT CIRCUIT DIAGRAM

Page 54

3-58 3-59

PRINTED CIRCUIT DIAGRAMS

1. DIGITAL MAIN P.C.BOARD(BOTTOM)

LOCATION GUIDE

Page 55

3-60 3-61

2. DIGITAL MAIN P.C.BOARD(TOP)

Page 56

3-62 3-63

3. FRONT P.C.BOARD

4. POWER P.C.BOARD

LOCATION GUIDE

Page 57

Page 58

4-1

SECTION 4 REPLACEMENT PARTS LIST

MODEL : LST-3100A AA1UZL(ZENITH) NSP : Not avallable as service parts.

RUN DATE :13-AUGUST-03

S AL LOCA. NO. LG PART NO. DESCRIPTION SPECIFICATION REMARKS

*** INDIVIDUAL PARTS ***

250 3110R-P020A CASE VCR LSS-2300 TOP(SKYLIFE STB)

300 6410RAHK02D POWER CORD KJ-10W/NISPT-2(ST-HS:80MM) WIT

463 353-051G SCREW,DRAWING + 2 D3.0 L8.0 MSWR3/FN TB ROUN

465 353-046K SCREW SPECIAL (3X10 B.K)

466 1BK-0512391 BOLT,HEXAGON SOCKET HEAD D5.1 L7.0 STS 430

469 1NHD8220060 NUT,HEXAGON 4 D3/8"-16 NO RULE BSP/BN,BSW/

470 1WSV1200084 WASHER,SPRING LOCK NO RULE D12.0 SUS 304

*** PACKING ACCESSORY ***

801 3835RS0061D INSTRUCTION ASSEMBLY VCR LST-3100A AA1UZL

802 3890R-H824W BOX LST-3100A AA1UZL SWM3-A 1.316

803 3921R-0133W PACKING ASSEMBLY LST-3100A AA1UZL STB

804 3880R-H003B BAG HDPE 340 225 0.03 USE O/M ASSY NSP

806 6850R-CAEX1 CABLE,COAXIAL FREE OF HAZARDOUS RF - CABLE N

808 6910R-AB02A BATTERY,ALKALINE LR06 STC ALKALINE 1.5V .MA/H A

811 6611R1G003A PLUG ASSEMBLY 1WAY YL 1.8M GLOBAL

812 6611R2G003A PLUG ASSEMBLY 2WAY RED/WHITE 1.8M GLOBAL

820 6611R3G001B PLUG ASSEMBLY 3WAY 3WAY RD/BL/GR COMPONENT F

*** REMOTE CONTROLLER ***

900 6711R1N141A REMOTE CONTROLLER ASSEMBLY D5 LST-3100 LG

*** CHASSIS ASSEMBLY ***

A44 3141R-0065D CHASSIS ASSEMBLY LSS-3100A AA1UZL NSP

260 3140R-0055B CHASSIS MAIN(LST-3100Z) PRESS

320 3720R-D080C PANEL,VIDEO VCR LST-3100A AA1UZL PRESS

457 353-046N SCREW,DRAWING SPECIAL(3X8 BK.)

*** PANEL ASSEMBLY , FRONT ***

A43 3501R-4548A BOARD ASSEMBLY VCR LST-3100A FRONT ASSY

280 3721R-F720A PANEL ASSEMBLY,FRONT VCR LST-3100A STB NSP

452 353-051A SCREW SPECIAL

A49 6871R-4548A PWB(PCB) ASSEMBLY,TOTAL LST-3100Z TIMER TOTAL

C100 0CN1040K948 CAPACITOR,FIXED TUBULAR(High d 0.1UF D 50V 80%,-20% F(Y5V) TA

C101 0CN1040K948 CAPACITOR,FIXED TUBULAR(High d 0.1UF D 50V 80%,-20% F(Y5V) TA

C102 0CX2200K408 CAPACITOR TUBULA(T.C) 22P 50V J SL TP26

C103 0CE2264K638 CAPACITOR,ELECTROLYTIC 22M SRA 50V M FM5 TP(5)

C104 0CE2264K638 CAPACITOR,ELECTROLYTIC 22M SRA 50V M FM5 TP(5)

C105 0CE2264K638 CAPACITOR,ELECTROLYTIC 22M SRA 50V M FM5 TP(5)

C106 0CN1040K948 CAPACITOR,FIXED TUBULAR(High d 0.1UF D 50V 80%,-20% F(Y5V) TA

C107 0CE4764F638 CAPACITOR,ELECTROLYTIC 47M SRA/SS 16V M FM5 TP(5)

C108 0CN1040K948 CAPACITOR,FIXED TUBULAR(High d 0.1UF D 50V 80%,-20% F(Y5V) TA

C109 0CX2200K408 CAPACITOR TUBULA(T.C) 22P 50V J SL TP26

C110 0CX2200K408 CAPACITOR TUBULA(T.C) 22P 50V J SL TP26

C111 0CX2200K408 CAPACITOR TUBULA(T.C) 22P 50V J SL TP26

C112 0CN1040K948 CAPACITOR,FIXED TUBULAR(High d 0.1UF D 50V 80%,-20% F(Y5V) TA

NOTES) Warning

NOTES) Parts that are shaded are critical

NOTES) With respect to risk of fire or

NOTES) electricial shock.

Page 59

4-2

S AL LOCA. NO. LG PART NO. DESCRIPTION SPECIFICATION REMARKS

C113 0CN1040K948 CAPACITOR,FIXED TUBULAR(High d 0.1UF D 50V 80%,-20% F(Y5V) TA

C114 0CN1040K948 CAPACITOR,FIXED TUBULAR(High d 0.1UF D 50V 80%,-20% F(Y5V) TA

C115 0CN2210K518 CAPACITOR TUBULA(HIGH DIELE) 220P 50V K B TA26

C116 0CN2210K518 CAPACITOR TUBULA(HIGH DIELE) 220P 50V K B TA26

C117 0CE4764F638 CAPACITOR,ELECTROLYTIC 47M SRA/SS 16V M FM5 TP(5)

D101 0DD133009AA DIODE,SWITCHING 1SS133 DETECT,SW TP

D103 0DD133009AA DIODE,SWITCHING 1SS133 DETECT,SW TP

D104 0DD133009AA DIODE,SWITCHING 1SS133 DETECT,SW TP

D105 0DD133009AA DIODE,SWITCHING 1SS133 DETECT,SW TP

D106 0DD133009AA DIODE,SWITCHING 1SS133 DETECT,SW TP

D107 0DD133009AA DIODE,SWITCHING 1SS133 DETECT,SW TP

D108 0DD133009AA DIODE,SWITCHING 1SS133 DETECT,SW TP

D109 0DD133009AA DIODE,SWITCHING 1SS133 DETECT,SW TP

D110 0DD133009AA DIODE,SWITCHING 1SS133 DETECT,SW TP

D111 0DD133009AA DIODE,SWITCHING 1SS133 DETECT,SW TP

DIG101 6302R-V210A DIGITRON HNR-11SS53T SSSDI SEG VFD LSS-

IC100 0IPRPNE001A IC,PERIPHERALS UPD16315GB-3BS NEC 44 QFP BK F

IR100 6712R0838GA REMOTE CONTROLLER RECEIVER TSOP1238UQ1 VISHAY(TEMIC) 37-9

L100 0LR0102K035 INDUCTOR RADIAL LEAD 10M K 6X6 L5 TP

P100 561-716L CONNECTOR (CIRC),WAFER GIL-G-12P-S3L2-E LG CABLE 12PI

R100 0RD8202F608 RESISTOR,FIXED CARBON FILM 82K OHM 1/6 W 5% TA26

R101 0RD2200F608 RESISTOR,FIXED CARBON FILM 220 OHM 1/6 W 5% TA26

R102 0RD1002F608 RESISTOR,FIXED CARBON FILM 10K OHM 1/6 W 5% TA26

R103 0RD1002F608 RESISTOR,FIXED CARBON FILM 10K OHM 1/6 W 5% TA26

R104 0RD1002F608 RESISTOR,FIXED CARBON FILM 10K OHM 1/6 W 5% TA26

R105 0RD0102F608 RESISTOR,FIXED CARBON FILM 10 OHM 1/6 W 5% TA26

SW101 556-282C SWITCH,TACT SKQNQED ALPS DC 12 V 50 MA TA

SW103 556-282C SWITCH,TACT SKQNQED ALPS DC 12 V 50 MA TA

SW104 556-282C SWITCH,TACT SKQNQED ALPS DC 12 V 50 MA TA

SW105 556-282C SWITCH,TACT SKQNQED ALPS DC 12 V 50 MA TA

SW106 556-282C SWITCH,TACT SKQNQED ALPS DC 12 V 50 MA TA

SW107 556-282C SWITCH,TACT SKQNQED ALPS DC 12 V 50 MA TA

SW108 556-282C SWITCH,TACT SKQNQED ALPS DC 12 V 50 MA TA

SW109 556-282C SWITCH,TACT SKQNQED ALPS DC 12 V 50 MA TA

SW110 556-282C SWITCH,TACT SKQNQED ALPS DC 12 V 50 MA TA

*** BOARD ASSEMBLY , TOTAL POWER ***

A47 3501R-2253C BOARD ASSEMBLY LST-3100Z SMPS SECOND AFSTB

BC101 636-004C FILTER(CIRC),EMC BEAD CORE BFS3550R2FD8,R T/P

BD101 0DD160000DA DIODE S1WBA60(1A 600V) SHIDENKEN

C101 624-088F CAPACITOR,DRAWING PCX2 275V 0.1UF,M (PILKO)

C102 624-088F CAPACITOR,DRAWING PCX2 275V 0.1UF,M (PILKO)

C103 0CE157CR610 CAPACITOR,AL.ELECTROLYTIC 150UF SHL,SD 250V M FL BULK

C105 0CQ1031Y519 CAPACITOR,POLYESTER 0.01UF D 630V K PE NI TP

C106 624-087G CAPACITOR HIGH-VOL 68PF/1KV SMPS SAMHWA

C107 0CE1054K638 CAPACITOR,ELECTROLYTIC 1.0M SRA/SS50V M FM5 TP(5)

C109 0CE336BH638 CAPACITOR,ELECTROLYTIC 33UF KME 25V M FM5 TP5

C111 0CN223AK948 CAPACITOR,TUBULAR(HIGH DIELEC) 0.022UF 50V Z F TA26 S

C112 0CG2220U630 CAPACITOR,SEMI CERAMIC 2200 PF 400V M E R (NK,AD,SD)

C113 0CG1020U630 CAPACITOR,SEMI CERAMIC 1000PF 400V M E(Z5U) R

C114 0CE1054K638 CAPACITOR,ELECTROLYTIC 1.0M SRA/SS50V M FM5 TP(5)

C116 0CE108EF630 CAPACITOR,FIXED ELECTROLYTIC 1000UF KMG 16V 20% FM5 BULK

C117 624-082H CAPACITOR CE 1000UF/10V SHL(10*12.5)T/P

C118 0CE108EF630 CAPACITOR,FIXED ELECTROLYTIC 1000UF KMG 16V 20% FM5 BULK

C119 0CE3376D638 CAPACITOR,ELECTROLYTIC 330UF SMS 10V M FM5 TP5

Page 60

4-3

S AL LOCA. NO. LG PART NO. DESCRIPTION SPECIFICATION REMARKS

C120 0CE477BH630 CAPACITOR,AL.ELECTROLYTIC 470UF KME TYPE 25V M FM5 BULK

C122 624-085D CAPACITOR CE 47UF/50V KME (SMPS)

C123 624-085D CAPACITOR CE 47UF/50V KME (SMPS)

C124 624-085D CAPACITOR CE 47UF/50V KME (SMPS)

C125 624-085D CAPACITOR CE 47UF/50V KME (SMPS)

C126 0CE2276F638 CAPACITOR,ELECTROLYTIC 220U SMS 16V M FM5 TP(5)

C152 0CE1074F638 CAPACITOR,ELECTROLYTIC 100U SRA 16V M FM5 TP(5)

C153 0CE1074F638 CAPACITOR,ELECTROLYTIC 100U SRA 16V M FM5 TP(5)

C154 0CE1074F638 CAPACITOR,ELECTROLYTIC 100U SRA 16V M FM5 TP(5)

C155 0CE1074F638 CAPACITOR,ELECTROLYTIC 100U SRA 16V M FM5 TP(5)

C156 0CE1074F638 CAPACITOR,ELECTROLYTIC 100U SRA 16V M FM5 TP(5)

D102 0DD221009AA DIODE,RECTIFIERS ERA22-10 KFLB,TP ,R T/P,FUJI

D103 0DD010009AC DIODE EU01W(R-FORM) TP SANKEN

D105 0DR104510AA DIODE,RECTIFIERS B10A45V1 BK KEC TO220 45V 10A

D106 0DR104510AA DIODE,RECTIFIERS B10A45V1 BK KEC TO220 45V 10A

D107 0DD010009AC DIODE EU01W(R-FORM) TP SANKEN

D108 0DD010009AC DIODE EU01W(R-FORM) TP SANKEN

D109 0DR202000AB DIODE,RECTIFIER HER202 BK RECTRON NON 100V 2A

D110 0DD010009AC DIODE EU01W(R-FORM) TP SANKEN

F101 0FS1601B51B FUSE,SLOW BLOW 1600MA 250 V 5.2X20 CY/GL KS /

FH01 586-008B HOLDER FUSE CLIP TP SINSUNG

FH02 586-008B HOLDER FUSE CLIP TP SINSUNG

IC101 0IPMGFF001A IC,POWER MANAGEMENT ICE2B265 INFINEON 8 DIP ST SMP

IC102 657-063A SENSOR LTV-817B,PHOTO COUPLER(LITEON)

IC103 0ISS431000A IC,SAMSUNG ELECTRONICS KA431AZ (LM431AZ)

IC103 0IKE431000A IC,KEC KIA431 3 PIN TP

IC152 0IPMGFA032A IC,POWER MANAGEMENT KA78R05TSTU FAIRCHILD 4P TO-22

IC153 0IPMGFA046A IC,POWER MANAGEMENT KA278R33TSTU FAIRCHILD 4PIN TO

IC154 0IPMGFA034A IC,POWER MANAGEMENT KA78R09TSTU FAIRCHILD 4P TO-22

IC155 0IPMGSH010A IC,POWER MANAGEMENT PQ12RD1L SHARP 4PIN TO-220 ST

IC155 0IPMGFA017A IC,POWER MANAGEMENT KA78R12TSTU FAIRCHILD 4P TO-22

IC156 0IPMGFA032A IC,POWER MANAGEMENT KA78R05TSTU FAIRCHILD 4P TO-22

L101 616-145H FILTER(CIRC) SHT LFS2020V4-04350

L103 633-088G COIL,CHOKE CHOCK(22MH) 5MM TOKO TP

L104 633-088G COIL,CHOKE CHOCK(22MH) 5MM TOKO TP

L106 0LR1000K035 INDUCTOR RADIAL LEAD 100M K 6X6 L5 TP

P101 561-7150 CONNECTOR (CIRC),WAFER GIL-G-15P-S3T2-E LG CABLE 15P

PW101 561-292B CONNECTOR GP390 LGC 3P 3.96 STRAIGHT SN

R100 0RD1504H632 RESISTOR,FIXED CARBON FILM 1.5M OHM 1/2 W 5.00% MF10

R101 0RD2203F608 RESISTOR,FIXED CARBON FILM 220K OHM 1/6 W 5% TA26

R102 0RD2203F608 RESISTOR,FIXED CARBON FILM 220K OHM 1/6 W 5% TA26

R103 0RD0102F608 RESISTOR,FIXED CARBON FILM 10 OHM 1/6 W 5% TA26

R104 0RS5602K619 RESISTOR,FIXED METAL OXIDE FIL 56K OHM 2 W 5.00% TR

R105 614-007A RESISTOR 2.7/2W CEMENT SMPS V

R106 0RD0222F608 RESISTOR,FIXED CARBON FILM 22 OHM 1/6 W 5% TA26

R109 0RS0350K619 RESISTOR,FIXED METAL OXIDE FIL 0.35 OHM 2 W 5.00% TR

R110 0RD1003F608 RESISTOR,FIXED CARBON FILM 100K OHM 1/6 W 5% TA26

R111 0RD1003F608 RESISTOR,FIXED CARBON FILM 100K OHM 1/6 W 5% TA26

R112 0RD0222F608 RESISTOR,FIXED CARBON FILM 22 OHM 1/6 W 5% TA26

R113 0RD0222F608 RESISTOR,FIXED CARBON FILM 22 OHM 1/6 W 5% TA26

R116 0RD2200F608 RESISTOR,FIXED CARBON FILM 220 OHM 1/6 W 5% TA26

R117 0RD2201F608 RESISTOR,FIXED CARBON FILM 2.2K OHM 1/6 W 5% TA26

R118 0RD1001F608 RESISTOR,FIXED CARBON FILM 1K OHM 1/6 W 5% TA26

R119 0RN3301F408 RESISTOR,FIXED METAL FILM 3.3K OHM 1/6 W 1% TA26

Page 61

4-4

S AL LOCA. NO. LG PART NO. DESCRIPTION SPECIFICATION REMARKS

R120 0RN2701F408 RESISTOR,FIXED METAL FILM 2.7K OHM 1/6 W 1% TA26

R121 0RD1000F608 RESISTOR,FIXED CARBON FILM 100 OHM 1/6 W 5% TA26

R123 0RF0200F708 RESISTOR,VARIABLE[CARBON FILM] 0.2 OHM 1/6 W 10% TA26

R127 0RD3300F608 RESISTOR,FIXED CARBON FILM 330 OHM 1/6 W 5% TA26

R129 0RD1003F608 RESISTOR,FIXED CARBON FILM 100K OHM 1/6 W 5% TA26

R130 0RD1201F608 RESISTOR,FIXED CARBON FILM 1.2K OHM 1/6 W 5% TA26

R131 0RD1201F608 RESISTOR,FIXED CARBON FILM 1.2K OHM 1/6 W 5% TA26

R151 0RD1002F608 RESISTOR,FIXED CARBON FILM 10K OHM 1/6 W 5% TA26

R152 0RD1002F608 RESISTOR,FIXED CARBON FILM 10K OHM 1/6 W 5% TA26

R153 0RD1002F608 RESISTOR,FIXED CARBON FILM 10K OHM 1/6 W 5% TA26

R154 0RD1002F608 RESISTOR,FIXED CARBON FILM 10K OHM 1/6 W 5% TA26

T101 6170RNGW15G TRANSFORMER,SMPS[COIL] EER2828 SOOJUNG LSS-3100Z

V101 656-004C VARISTOR,DRAWING SVC681D-10A SAMHWA 4.O CUT

ZD101 0DZ332609BA DIODE,ZENER UZ-33BSB 26MM TP PYUNG CHANG D

ZD102 0DZ332609FA DIODE,ZENER UZ-3.3BSB 26MM TP PYUNG CHANG

ZD102 0DZ330009CD DIODE,ZENER MTZJ3.3B TP ROHM-K DO34 0.5W 3

ZD102 0DZ337729AA DIODE,ZENERS MTZ3.3B,T-77(26MMTP) TP ROHM -

ZD102 0DZ330009BF DIODE,ZENER GDZJ3.3B TP GRANDE DO34 0.5W 3

*** BOARD ASSEMBLY(MAIN) ***

A46 6871R-9238A PWB(PCB) ASSEMBLY,TOTAL LST-3100Z ATSC2 MAIN

AR100 0RRZVTA001J RESISTOR,DRAWING 4.7K OHM 1 / 16 W 3216 5% R/TP

AR101 0RRZVTA001L RESISTOR,DRAWING 22 OHM 1 / 10 W 1608 4P 5% R/T

AR102 0RRZVTA001L RESISTOR,DRAWING 22 OHM 1 / 10 W 1608 4P 5% R/T

AR103 0RRZVTA001L RESISTOR,DRAWING 22 OHM 1 / 10 W 1608 4P 5% R/T

AR104 0RRZVTA001L RESISTOR,DRAWING 22 OHM 1 / 10 W 1608 4P 5% R/T

AR105 0RRZVTA001L RESISTOR,DRAWING 22 OHM 1 / 10 W 1608 4P 5% R/T

AR106 0RRZVTA001L RESISTOR,DRAWING 22 OHM 1 / 10 W 1608 4P 5% R/T

AR107 0RRZVTA001L RESISTOR,DRAWING 22 OHM 1 / 10 W 1608 4P 5% R/T

AR108 0RRZVTA001L RESISTOR,DRAWING 22 OHM 1 / 10 W 1608 4P 5% R/T

AR109 0RRZVTA001L RESISTOR,DRAWING 22 OHM 1 / 10 W 1608 4P 5% R/T

AR110 0RRZVTA001L RESISTOR,DRAWING 22 OHM 1 / 10 W 1608 4P 5% R/T

AR111 0RRZVTA001L RESISTOR,DRAWING 22 OHM 1 / 10 W 1608 4P 5% R/T

AR112 0RRZVTA001L RESISTOR,DRAWING 22 OHM 1 / 10 W 1608 4P 5% R/T

AR113 0RRZVTA001L RESISTOR,DRAWING 22 OHM 1 / 10 W 1608 4P 5% R/T

AR114 0RRZVTA001J RESISTOR,DRAWING 4.7K OHM 1 / 16 W 3216 5% R/TP

AR115 0RRZVTA001L RESISTOR,DRAWING 22 OHM 1 / 10 W 1608 4P 5% R/T

AR200 0RRZVTA001L RESISTOR,DRAWING 22 OHM 1 / 10 W 1608 4P 5% R/T

AR201 0RRZVTA001L RESISTOR,DRAWING 22 OHM 1 / 10 W 1608 4P 5% R/T

AR202 0RRZVTA001L RESISTOR,DRAWING 22 OHM 1 / 10 W 1608 4P 5% R/T

AR203 0RRZVTA001L RESISTOR,DRAWING 22 OHM 1 / 10 W 1608 4P 5% R/T

AR204 0RRZVTA001L RESISTOR,DRAWING 22 OHM 1 / 10 W 1608 4P 5% R/T

AR205 0RRZVTA001L RESISTOR,DRAWING 22 OHM 1 / 10 W 1608 4P 5% R/T

AR206 0RRZVTA001L RESISTOR,DRAWING 22 OHM 1 / 10 W 1608 4P 5% R/T

AR207 0RRZVTA001L RESISTOR,DRAWING 22 OHM 1 / 10 W 1608 4P 5% R/T

AR208 0RRZVTA001L RESISTOR,DRAWING 22 OHM 1 / 10 W 1608 4P 5% R/T

C100 0CH1104K512 CAPACITOR,FIXED CERAMIC(Temp.c 0.1UF 50V 10% B(5YP) 1608 R/TP

C101 0CH1104K512 CAPACITOR,FIXED CERAMIC(Temp.c 0.1UF 50V 10% B(5YP) 1608 R/TP

C102 0CH1104K512 CAPACITOR,FIXED CERAMIC(Temp.c 0.1UF 50V 10% B(5YP) 1608 R/TP

C103 0CH1104K512 CAPACITOR,FIXED CERAMIC(Temp.c 0.1UF 50V 10% B(5YP) 1608 R/TP

C104 0CH1104K512 CAPACITOR,FIXED CERAMIC(Temp.c 0.1UF 50V 10% B(5YP) 1608 R/TP

C105 0CH8106F611 CAPACITOR,CHIP[AL. ELECTROLYTI 10UF 16V M 85STD(CYL) R/TP

C106 0CH8106F611 CAPACITOR,CHIP[AL. ELECTROLYTI 10UF 16V M 85STD(CYL) R/TP

C107 0CH1104K512 CAPACITOR,FIXED CERAMIC(Temp.c 0.1UF 50V 10% B(5YP) 1608 R/TP

C108 0CH1104K512 CAPACITOR,FIXED CERAMIC(Temp.c 0.1UF 50V 10% B(5YP) 1608 R/TP

Page 62

4-5

S AL LOCA. NO. LG PART NO. DESCRIPTION SPECIFICATION REMARKS

C109 0CH1104K512 CAPACITOR,FIXED CERAMIC(Temp.c 0.1UF 50V 10% B(5YP) 1608 R/TP

C110 0CH1104K512 CAPACITOR,FIXED CERAMIC(Temp.c 0.1UF 50V 10% B(5YP) 1608 R/TP

C111 0CH1104K512 CAPACITOR,FIXED CERAMIC(Temp.c 0.1UF 50V 10% B(5YP) 1608 R/TP

C112 0CH4220K412 CAPA,CHIP CERAMIC M/L T.C F/S 22P 50V J COG 1.6X0.8 R/TP

C113 0CH1104K512 CAPACITOR,FIXED CERAMIC(Temp.c 0.1UF 50V 10% B(5YP) 1608 R/TP

C114 0CH1104K512 CAPACITOR,FIXED CERAMIC(Temp.c 0.1UF 50V 10% B(5YP) 1608 R/TP

C115 0CH1104K512 CAPACITOR,FIXED CERAMIC(Temp.c 0.1UF 50V 10% B(5YP) 1608 R/TP

C116 0CH1104K512 CAPACITOR,FIXED CERAMIC(Temp.c 0.1UF 50V 10% B(5YP) 1608 R/TP

C117 0CH1104K512 CAPACITOR,FIXED CERAMIC(Temp.c 0.1UF 50V 10% B(5YP) 1608 R/TP

C118 0CH1104K512 CAPACITOR,FIXED CERAMIC(Temp.c 0.1UF 50V 10% B(5YP) 1608 R/TP

C119 0CH1104K512 CAPACITOR,FIXED CERAMIC(Temp.c 0.1UF 50V 10% B(5YP) 1608 R/TP

C120 0CH1104K512 CAPACITOR,FIXED CERAMIC(Temp.c 0.1UF 50V 10% B(5YP) 1608 R/TP

C121 0CH1104K512 CAPACITOR,FIXED CERAMIC(Temp.c 0.1UF 50V 10% B(5YP) 1608 R/TP

C122 0CH1104K512 CAPACITOR,FIXED CERAMIC(Temp.c 0.1UF 50V 10% B(5YP) 1608 R/TP

C123 0CH1104K512 CAPACITOR,FIXED CERAMIC(Temp.c 0.1UF 50V 10% B(5YP) 1608 R/TP

C124 0CH1104K512 CAPACITOR,FIXED CERAMIC(Temp.c 0.1UF 50V 10% B(5YP) 1608 R/TP

C125 0CH8226F611 CAPACITOR,CHIP[AL. ELECTROLYTI 22UF 16V M 85STD(CYL) R/TP

C126 0CH1104K512 CAPACITOR,FIXED CERAMIC(Temp.c 0.1UF 50V 10% B(5YP) 1608 R/TP

C127 0CH1104K512 CAPACITOR,FIXED CERAMIC(Temp.c 0.1UF 50V 10% B(5YP) 1608 R/TP

C128 0CH4271K412 CAPACITOR,FIXED CERAMIC(HIGH D 270PF 50V 5% NP0 1608 R/TP

C129 0CH1103K562 CAPACITOR,FIXED CERAMIC(Temp.c 0.01UF 50V 10% X7R(X) 1608 R/T

C130 0CH1103K562 CAPACITOR,FIXED CERAMIC(Temp.c 0.01UF 50V 10% X7R(X) 1608 R/T

C1300 0CH8336H611 CAPACITOR,CHIP[AL. ELECTROLYTI 33UF 25V M 85STD(CYL) R/TP

C1301 0CH8336H611 CAPACITOR,CHIP[AL. ELECTROLYTI 33UF 25V M 85STD(CYL) R/TP

C1302 0CH8476F611 CAPACITOR,FIXED ELECTROLYTIC 47UF 16V M 85STD(CYL) R/TP SAM

C1303 0CH8336H611 CAPACITOR,CHIP[AL. ELECTROLYTI 33UF 25V M 85STD(CYL) R/TP

C1304 0CH8336H611 CAPACITOR,CHIP[AL. ELECTROLYTI 33UF 25V M 85STD(CYL) R/TP

C1305 0CH1104K512 CAPACITOR,FIXED CERAMIC(Temp.c 0.1UF 50V 10% B(5YP) 1608 R/TP

C1306 0CH8477F611 CAPACITOR,FIXED ELECTROLYTIC 470UF 16V 20% 85STD (CYL) R/TP

C1307 0CH4220K412 CAPA,CHIP CERAMIC M/L T.C F/S 22P 50V J COG 1.6X0.8 R/TP

C1308 0CH4220K412 CAPA,CHIP CERAMIC M/L T.C F/S 22P 50V J COG 1.6X0.8 R/TP

C1309 0CH4220K412 CAPA,CHIP CERAMIC M/L T.C F/S 22P 50V J COG 1.6X0.8 R/TP

C131 0CH1103K562 CAPACITOR,FIXED CERAMIC(Temp.c 0.01UF 50V 10% X7R(X) 1608 R/T

C1310 0CH4220K412 CAPA,CHIP CERAMIC M/L T.C F/S 22P 50V J COG 1.6X0.8 R/TP

C1311 0CH4220K412 CAPA,CHIP CERAMIC M/L T.C F/S 22P 50V J COG 1.6X0.8 R/TP

C132 0CH1104K512 CAPACITOR,FIXED CERAMIC(Temp.c 0.1UF 50V 10% B(5YP) 1608 R/TP

C133 0CH4220K412 CAPA,CHIP CERAMIC M/L T.C F/S 22P 50V J COG 1.6X0.8 R/TP

C134 0CH4220K412 CAPA,CHIP CERAMIC M/L T.C F/S 22P 50V J COG 1.6X0.8 R/TP

C135 0CH8106J611 CAPACITOR,CHIP[AL. ELECTROLYTI 10UF 35V M 85STD(CYL) R/TP

C136 0CH8106J611 CAPACITOR,CHIP[AL. ELECTROLYTI 10UF 35V M 85STD(CYL) R/TP

C137 0CH1821K562 CAPACITOR,FIXED CERAMIC(Temp.c 820PF 50V 10% X7R(X) 1608 R/TP

C138 0CH1104K512 CAPACITOR,FIXED CERAMIC(Temp.c 0.1UF 50V 10% B(5YP) 1608 R/TP

C139 0CH1104K512 CAPACITOR,FIXED CERAMIC(Temp.c 0.1UF 50V 10% B(5YP) 1608 R/TP

C141 0CH8106J611 CAPACITOR,CHIP[AL. ELECTROLYTI 10UF 35V M 85STD(CYL) R/TP

C142 0CH8106J611 CAPACITOR,CHIP[AL. ELECTROLYTI 10UF 35V M 85STD(CYL) R/TP

C143 0CH8476F611 CAPACITOR,FIXED ELECTROLYTIC 47UF 16V M 85STD(CYL) R/TP SAM

C144 0CH1104K512 CAPACITOR,FIXED CERAMIC(Temp.c 0.1UF 50V 10% B(5YP) 1608 R/TP

C145 0CH1104K512 CAPACITOR,FIXED CERAMIC(Temp.c 0.1UF 50V 10% B(5YP) 1608 R/TP

C146 0CH4220K412 CAPA,CHIP CERAMIC M/L T.C F/S 22P 50V J COG 1.6X0.8 R/TP

C147 0CH4220K412 CAPA,CHIP CERAMIC M/L T.C F/S 22P 50V J COG 1.6X0.8 R/TP

C148 0CH1104K512 CAPACITOR,FIXED CERAMIC(Temp.c 0.1UF 50V 10% B(5YP) 1608 R/TP

C149 0CH1104K512 CAPACITOR,FIXED CERAMIC(Temp.c 0.1UF 50V 10% B(5YP) 1608 R/TP

C150 0CH8107F611 CAPACITOR,CHIP[AL. ELECTROLYTI 100UF 16V M 85STD(CYL) R/TP

C151 0CH8105K611 CAPACITOR,FIXED ELECTROLYTIC 1UF 50V 20% 85STD (CYL) R/TP

Page 63

4-6

S AL LOCA. NO. LG PART NO. DESCRIPTION SPECIFICATION REMARKS

C152 0CH8226F611 CAPACITOR,CHIP[AL. ELECTROLYTI 22UF 16V M 85STD(CYL) R/TP

C153 0CH8226F611 CAPACITOR,CHIP[AL. ELECTROLYTI 22UF 16V M 85STD(CYL) R/TP

C154 0CH1104K512 CAPACITOR,FIXED CERAMIC(Temp.c 0.1UF 50V 10% B(5YP) 1608 R/TP

C155 0CH8105K611 CAPACITOR,FIXED ELECTROLYTIC 1UF 50V 20% 85STD (CYL) R/TP

C156 0CH8477F611 CAPACITOR,FIXED ELECTROLYTIC 470UF 16V 20% 85STD (CYL) R/TP

C157 0CH1104K512 CAPACITOR,FIXED CERAMIC(Temp.c 0.1UF 50V 10% B(5YP) 1608 R/TP

C158 0CH8477F611 CAPACITOR,FIXED ELECTROLYTIC 470UF 16V 20% 85STD (CYL) R/TP

C160 0CH8106J611 CAPACITOR,CHIP[AL. ELECTROLYTI 10UF 35V M 85STD(CYL) R/TP

C161 0CH8106J611 CAPACITOR,CHIP[AL. ELECTROLYTI 10UF 35V M 85STD(CYL) R/TP

C162 0CH1104K512 CAPACITOR,FIXED CERAMIC(Temp.c 0.1UF 50V 10% B(5YP) 1608 R/TP

C163 0CH1102K562 CAPACITOR,FIXED CERAMIC(Temp.c 1000PF 50V 10% X7R(X) 1608 R/T

C164 0CH4181K412 CAPACITOR,CHIP[CERAMIC M/L TC 180P 50V J COG 1.6X0.8 R/TP

C165 0CH1104K512 CAPACITOR,FIXED CERAMIC(Temp.c 0.1UF 50V 10% B(5YP) 1608 R/TP

C166 0CH8106J611 CAPACITOR,CHIP[AL. ELECTROLYTI 10UF 35V M 85STD(CYL) R/TP

C167 0CH8106J611 CAPACITOR,CHIP[AL. ELECTROLYTI 10UF 35V M 85STD(CYL) R/TP

C168 0CH8477F611 CAPACITOR,FIXED ELECTROLYTIC 470UF 16V 20% 85STD (CYL) R/TP

C169 0CH8476F611 CAPACITOR,FIXED ELECTROLYTIC 47UF 16V M 85STD(CYL) R/TP SAM

C170 0CH1104K512 CAPACITOR,FIXED CERAMIC(Temp.c 0.1UF 50V 10% B(5YP) 1608 R/TP

C171 0CH8477F611 CAPACITOR,FIXED ELECTROLYTIC 470UF 16V 20% 85STD (CYL) R/TP

C172 0CH1104K512 CAPACITOR,FIXED CERAMIC(Temp.c 0.1UF 50V 10% B(5YP) 1608 R/TP

C173 0CH1104K512 CAPACITOR,FIXED CERAMIC(Temp.c 0.1UF 50V 10% B(5YP) 1608 R/TP

C174 0CH8477F611 CAPACITOR,FIXED ELECTROLYTIC 470UF 16V 20% 85STD (CYL) R/TP

C175 0CH1104K512 CAPACITOR,FIXED CERAMIC(Temp.c 0.1UF 50V 10% B(5YP) 1608 R/TP

C176 0CH8476F611 CAPACITOR,FIXED ELECTROLYTIC 47UF 16V M 85STD(CYL) R/TP SAM

C177 0CH1104K512 CAPACITOR,FIXED CERAMIC(Temp.c 0.1UF 50V 10% B(5YP) 1608 R/TP

C178 0CH1104K512 CAPACITOR,FIXED CERAMIC(Temp.c 0.1UF 50V 10% B(5YP) 1608 R/TP

C179 0CH4181K412 CAPACITOR,CHIP[CERAMIC M/L TC 180P 50V J COG 1.6X0.8 R/TP

C180 0CH1104K512 CAPACITOR,FIXED CERAMIC(Temp.c 0.1UF 50V 10% B(5YP) 1608 R/TP

C181 0CH1104K512 CAPACITOR,FIXED CERAMIC(Temp.c 0.1UF 50V 10% B(5YP) 1608 R/TP

C182 0CH1104K512 CAPACITOR,FIXED CERAMIC(Temp.c 0.1UF 50V 10% B(5YP) 1608 R/TP

C183 0CH8107F611 CAPACITOR,CHIP[AL. ELECTROLYTI 100UF 16V M 85STD(CYL) R/TP

C184 0CH1102K562 CAPACITOR,FIXED CERAMIC(Temp.c 1000PF 50V 10% X7R(X) 1608 R/T

C185 0CH8476K611 CAPACITOR,CHIP[AL. ELECTROLYTI 47UF 50V M 85STD(CYL) R/TP

C187 0CH1104K512 CAPACITOR,FIXED CERAMIC(Temp.c 0.1UF 50V 10% B(5YP) 1608 R/TP

C188 0CH8477F611 CAPACITOR,FIXED ELECTROLYTIC 470UF 16V 20% 85STD (CYL) R/TP

C189 0CH8477F611 CAPACITOR,FIXED ELECTROLYTIC 470UF 16V 20% 85STD (CYL) R/TP

C190 0CH1104K512 CAPACITOR,FIXED CERAMIC(Temp.c 0.1UF 50V 10% B(5YP) 1608 R/TP

C191 0CH1104K512 CAPACITOR,FIXED CERAMIC(Temp.c 0.1UF 50V 10% B(5YP) 1608 R/TP

C192 0CH1104K512 CAPACITOR,FIXED CERAMIC(Temp.c 0.1UF 50V 10% B(5YP) 1608 R/TP

C193 0CH1104K512 CAPACITOR,FIXED CERAMIC(Temp.c 0.1UF 50V 10% B(5YP) 1608 R/TP

C194 0CH1104K512 CAPACITOR,FIXED CERAMIC(Temp.c 0.1UF 50V 10% B(5YP) 1608 R/TP

C195 0CH8476F611 CAPACITOR,FIXED ELECTROLYTIC 47UF 16V M 85STD(CYL) R/TP SAM

C196 0CH1104K512 CAPACITOR,FIXED CERAMIC(Temp.c 0.1UF 50V 10% B(5YP) 1608 R/TP

C2000 0CH1104K512 CAPACITOR,FIXED CERAMIC(Temp.c 0.1UF 50V 10% B(5YP) 1608 R/TP

C2001 0CH1104K512 CAPACITOR,FIXED CERAMIC(Temp.c 0.1UF 50V 10% B(5YP) 1608 R/TP

C2002 0CH1104K512 CAPACITOR,FIXED CERAMIC(Temp.c 0.1UF 50V 10% B(5YP) 1608 R/TP

C2003 0CH1104K512 CAPACITOR,FIXED CERAMIC(Temp.c 0.1UF 50V 10% B(5YP) 1608 R/TP

C2004 0CH1104K512 CAPACITOR,FIXED CERAMIC(Temp.c 0.1UF 50V 10% B(5YP) 1608 R/TP

C2005 0CH1104K512 CAPACITOR,FIXED CERAMIC(Temp.c 0.1UF 50V 10% B(5YP) 1608 R/TP

C2006 0CH1104K512 CAPACITOR,FIXED CERAMIC(Temp.c 0.1UF 50V 10% B(5YP) 1608 R/TP

C2007 0CH1104K512 CAPACITOR,FIXED CERAMIC(Temp.c 0.1UF 50V 10% B(5YP) 1608 R/TP

C2008 0CH1104K512 CAPACITOR,FIXED CERAMIC(Temp.c 0.1UF 50V 10% B(5YP) 1608 R/TP

C2009 0CH8226F611 CAPACITOR,CHIP[AL. ELECTROLYTI 22UF 16V M 85STD(CYL) R/TP

C2010 0CH4270K412 CAPACITOR,CHIP[CERAMIC M/L TC 27PF 50V J NP0 1608 R/TP

Page 64

4-7

S AL LOCA. NO. LG PART NO. DESCRIPTION SPECIFICATION REMARKS

C2011 0CH4270K412 CAPACITOR,CHIP[CERAMIC M/L TC 27PF 50V J NP0 1608 R/TP

C2012 0CH4270K412 CAPACITOR,CHIP[CERAMIC M/L TC 27PF 50V J NP0 1608 R/TP

C2013 0CH4270K412 CAPACITOR,CHIP[CERAMIC M/L TC 27PF 50V J NP0 1608 R/TP

C2014 0CH8476K611 CAPACITOR,CHIP[AL. ELECTROLYTI 47UF 50V M 85STD(CYL) R/TP

C2015 0CH1104K512 CAPACITOR,FIXED CERAMIC(Temp.c 0.1UF 50V 10% B(5YP) 1608 R/TP

C2016 0CH4270K412 CAPACITOR,CHIP[CERAMIC M/L TC 27PF 50V J NP0 1608 R/TP

C2017 0CH4270K412 CAPACITOR,CHIP[CERAMIC M/L TC 27PF 50V J NP0 1608 R/TP

C2018 0CH1104K512 CAPACITOR,FIXED CERAMIC(Temp.c 0.1UF 50V 10% B(5YP) 1608 R/TP

C2019 0CH1104K512 CAPACITOR,FIXED CERAMIC(Temp.c 0.1UF 50V 10% B(5YP) 1608 R/TP

C2020 0CH4270K412 CAPACITOR,CHIP[CERAMIC M/L TC 27PF 50V J NP0 1608 R/TP

C2021 0CH4270K412 CAPACITOR,CHIP[CERAMIC M/L TC 27PF 50V J NP0 1608 R/TP

C2022 0CH1104K512 CAPACITOR,FIXED CERAMIC(Temp.c 0.1UF 50V 10% B(5YP) 1608 R/TP

C2023 0CH1104K512 CAPACITOR,FIXED CERAMIC(Temp.c 0.1UF 50V 10% B(5YP) 1608 R/TP

C2024 0CH1104K512 CAPACITOR,FIXED CERAMIC(Temp.c 0.1UF 50V 10% B(5YP) 1608 R/TP

C2025 0CH1104K512 CAPACITOR,FIXED CERAMIC(Temp.c 0.1UF 50V 10% B(5YP) 1608 R/TP

C2026 0CH8226F611 CAPACITOR,CHIP[AL. ELECTROLYTI 22UF 16V M 85STD(CYL) R/TP

C2027 0CH1104K512 CAPACITOR,FIXED CERAMIC(Temp.c 0.1UF 50V 10% B(5YP) 1608 R/TP

C2028 0CH1104K512 CAPACITOR,FIXED CERAMIC(Temp.c 0.1UF 50V 10% B(5YP) 1608 R/TP

C2029 0CH1104K512 CAPACITOR,FIXED CERAMIC(Temp.c 0.1UF 50V 10% B(5YP) 1608 R/TP

C2030 0CH1104K512 CAPACITOR,FIXED CERAMIC(Temp.c 0.1UF 50V 10% B(5YP) 1608 R/TP

C2031 0CH1104K512 CAPACITOR,FIXED CERAMIC(Temp.c 0.1UF 50V 10% B(5YP) 1608 R/TP

C2032 0CH1104K512 CAPACITOR,FIXED CERAMIC(Temp.c 0.1UF 50V 10% B(5YP) 1608 R/TP

C2033 0CH8477F611 CAPACITOR,FIXED ELECTROLYTIC 470UF 16V 20% 85STD (CYL) R/TP

C2034 0CH1104K512 CAPACITOR,FIXED CERAMIC(Temp.c 0.1UF 50V 10% B(5YP) 1608 R/TP

C2035 0CH1104K512 CAPACITOR,FIXED CERAMIC(Temp.c 0.1UF 50V 10% B(5YP) 1608 R/TP

C2036 0CH1104K512 CAPACITOR,FIXED CERAMIC(Temp.c 0.1UF 50V 10% B(5YP) 1608 R/TP

C2037 0CH1104K512 CAPACITOR,FIXED CERAMIC(Temp.c 0.1UF 50V 10% B(5YP) 1608 R/TP

C2038 0CH1104K512 CAPACITOR,FIXED CERAMIC(Temp.c 0.1UF 50V 10% B(5YP) 1608 R/TP

C2039 0CH1104K512 CAPACITOR,FIXED CERAMIC(Temp.c 0.1UF 50V 10% B(5YP) 1608 R/TP

C2040 0CH1104K512 CAPACITOR,FIXED CERAMIC(Temp.c 0.1UF 50V 10% B(5YP) 1608 R/TP

C2041 0CH1104K512 CAPACITOR,FIXED CERAMIC(Temp.c 0.1UF 50V 10% B(5YP) 1608 R/TP

C2042 0CH1104K512 CAPACITOR,FIXED CERAMIC(Temp.c 0.1UF 50V 10% B(5YP) 1608 R/TP

C2043 0CH1104K512 CAPACITOR,FIXED CERAMIC(Temp.c 0.1UF 50V 10% B(5YP) 1608 R/TP

C2044 0CH1104K512 CAPACITOR,FIXED CERAMIC(Temp.c 0.1UF 50V 10% B(5YP) 1608 R/TP

C2045 0CH1104K512 CAPACITOR,FIXED CERAMIC(Temp.c 0.1UF 50V 10% B(5YP) 1608 R/TP

C2046 0CH1104K512 CAPACITOR,FIXED CERAMIC(Temp.c 0.1UF 50V 10% B(5YP) 1608 R/TP

C2047 0CH1104K512 CAPACITOR,FIXED CERAMIC(Temp.c 0.1UF 50V 10% B(5YP) 1608 R/TP

C2048 0CH1104K512 CAPACITOR,FIXED CERAMIC(Temp.c 0.1UF 50V 10% B(5YP) 1608 R/TP

C2049 0CH1104K512 CAPACITOR,FIXED CERAMIC(Temp.c 0.1UF 50V 10% B(5YP) 1608 R/TP

C2050 0CH1104K512 CAPACITOR,FIXED CERAMIC(Temp.c 0.1UF 50V 10% B(5YP) 1608 R/TP

C2051 0CH1104K512 CAPACITOR,FIXED CERAMIC(Temp.c 0.1UF 50V 10% B(5YP) 1608 R/TP

C2052 0CH1104K512 CAPACITOR,FIXED CERAMIC(Temp.c 0.1UF 50V 10% B(5YP) 1608 R/TP

C2053 0CH1104K512 CAPACITOR,FIXED CERAMIC(Temp.c 0.1UF 50V 10% B(5YP) 1608 R/TP

C2054 0CH1104K512 CAPACITOR,FIXED CERAMIC(Temp.c 0.1UF 50V 10% B(5YP) 1608 R/TP

C2055 0CH1104K512 CAPACITOR,FIXED CERAMIC(Temp.c 0.1UF 50V 10% B(5YP) 1608 R/TP

C2056 0CH1104K512 CAPACITOR,FIXED CERAMIC(Temp.c 0.1UF 50V 10% B(5YP) 1608 R/TP

C2057 0CH1104K512 CAPACITOR,FIXED CERAMIC(Temp.c 0.1UF 50V 10% B(5YP) 1608 R/TP

C2058 0CH1104K512 CAPACITOR,FIXED CERAMIC(Temp.c 0.1UF 50V 10% B(5YP) 1608 R/TP

C2059 0CH1104K512 CAPACITOR,FIXED CERAMIC(Temp.c 0.1UF 50V 10% B(5YP) 1608 R/TP

C2060 0CH1104K512 CAPACITOR,FIXED CERAMIC(Temp.c 0.1UF 50V 10% B(5YP) 1608 R/TP

C2061 0CH1104K512 CAPACITOR,FIXED CERAMIC(Temp.c 0.1UF 50V 10% B(5YP) 1608 R/TP

C2062 0CH1104K512 CAPACITOR,FIXED CERAMIC(Temp.c 0.1UF 50V 10% B(5YP) 1608 R/TP

C2063 0CH1104K512 CAPACITOR,FIXED CERAMIC(Temp.c 0.1UF 50V 10% B(5YP) 1608 R/TP

C2064 0CH1104K512 CAPACITOR,FIXED CERAMIC(Temp.c 0.1UF 50V 10% B(5YP) 1608 R/TP

Page 65

4-8

S AL LOCA. NO. LG PART NO. DESCRIPTION SPECIFICATION REMARKS

C2065 0CH1104K512 CAPACITOR,FIXED CERAMIC(Temp.c 0.1UF 50V 10% B(5YP) 1608 R/TP

C2066 0CH1104K512 CAPACITOR,FIXED CERAMIC(Temp.c 0.1UF 50V 10% B(5YP) 1608 R/TP

C2067 0CH1104K512 CAPACITOR,FIXED CERAMIC(Temp.c 0.1UF 50V 10% B(5YP) 1608 R/TP

C2068 0CH1104K512 CAPACITOR,FIXED CERAMIC(Temp.c 0.1UF 50V 10% B(5YP) 1608 R/TP

C2069 0CH1104K512 CAPACITOR,FIXED CERAMIC(Temp.c 0.1UF 50V 10% B(5YP) 1608 R/TP

C2070 0CH1104K512 CAPACITOR,FIXED CERAMIC(Temp.c 0.1UF 50V 10% B(5YP) 1608 R/TP

C2071 0CH1104K512 CAPACITOR,FIXED CERAMIC(Temp.c 0.1UF 50V 10% B(5YP) 1608 R/TP

C2072 0CH1104K512 CAPACITOR,FIXED CERAMIC(Temp.c 0.1UF 50V 10% B(5YP) 1608 R/TP

C2073 0CH1104K512 CAPACITOR,FIXED CERAMIC(Temp.c 0.1UF 50V 10% B(5YP) 1608 R/TP

C2074 0CH1104K512 CAPACITOR,FIXED CERAMIC(Temp.c 0.1UF 50V 10% B(5YP) 1608 R/TP

C2075 0CH1104K512 CAPACITOR,FIXED CERAMIC(Temp.c 0.1UF 50V 10% B(5YP) 1608 R/TP

C2076 0CH1104K512 CAPACITOR,FIXED CERAMIC(Temp.c 0.1UF 50V 10% B(5YP) 1608 R/TP

C2077 0CH1104K512 CAPACITOR,FIXED CERAMIC(Temp.c 0.1UF 50V 10% B(5YP) 1608 R/TP

C2078 0CH1104K512 CAPACITOR,FIXED CERAMIC(Temp.c 0.1UF 50V 10% B(5YP) 1608 R/TP

C2079 0CH1104K512 CAPACITOR,FIXED CERAMIC(Temp.c 0.1UF 50V 10% B(5YP) 1608 R/TP

C2080 0CH1103K562 CAPACITOR,FIXED CERAMIC(Temp.c 0.01UF 50V 10% X7R(X) 1608 R/T

C2081 0CH1104K512 CAPACITOR,FIXED CERAMIC(Temp.c 0.1UF 50V 10% B(5YP) 1608 R/TP

C2082 0CH1104K512 CAPACITOR,FIXED CERAMIC(Temp.c 0.1UF 50V 10% B(5YP) 1608 R/TP

C2083 0CH1103K562 CAPACITOR,FIXED CERAMIC(Temp.c 0.01UF 50V 10% X7R(X) 1608 R/T

C2084 0CH1103K562 CAPACITOR,FIXED CERAMIC(Temp.c 0.01UF 50V 10% X7R(X) 1608 R/T

C2085 0CH1104K512 CAPACITOR,FIXED CERAMIC(Temp.c 0.1UF 50V 10% B(5YP) 1608 R/TP

C2086 0CH1104K512 CAPACITOR,FIXED CERAMIC(Temp.c 0.1UF 50V 10% B(5YP) 1608 R/TP

C2087 0CH1104K512 CAPACITOR,FIXED CERAMIC(Temp.c 0.1UF 50V 10% B(5YP) 1608 R/TP

C2088 0CH1104K512 CAPACITOR,FIXED CERAMIC(Temp.c 0.1UF 50V 10% B(5YP) 1608 R/TP

C2089 0CH1104K512 CAPACITOR,FIXED CERAMIC(Temp.c 0.1UF 50V 10% B(5YP) 1608 R/TP

C2090 0CH1104K512 CAPACITOR,FIXED CERAMIC(Temp.c 0.1UF 50V 10% B(5YP) 1608 R/TP

C2091 0CH1104K512 CAPACITOR,FIXED CERAMIC(Temp.c 0.1UF 50V 10% B(5YP) 1608 R/TP

C2092 0CH1104K512 CAPACITOR,FIXED CERAMIC(Temp.c 0.1UF 50V 10% B(5YP) 1608 R/TP

C2093 0CH1103K562 CAPACITOR,FIXED CERAMIC(Temp.c 0.01UF 50V 10% X7R(X) 1608 R/T

C2094 0CH1104K512 CAPACITOR,FIXED CERAMIC(Temp.c 0.1UF 50V 10% B(5YP) 1608 R/TP

C2095 0CH1104K512 CAPACITOR,FIXED CERAMIC(Temp.c 0.1UF 50V 10% B(5YP) 1608 R/TP

C2096 0CH1104K512 CAPACITOR,FIXED CERAMIC(Temp.c 0.1UF 50V 10% B(5YP) 1608 R/TP

C2097 0CH1104K512 CAPACITOR,FIXED CERAMIC(Temp.c 0.1UF 50V 10% B(5YP) 1608 R/TP

C2098 0CH1104K512 CAPACITOR,FIXED CERAMIC(Temp.c 0.1UF 50V 10% B(5YP) 1608 R/TP

C2099 0CH1104K512 CAPACITOR,FIXED CERAMIC(Temp.c 0.1UF 50V 10% B(5YP) 1608 R/TP

C2100 0CH1104K512 CAPACITOR,FIXED CERAMIC(Temp.c 0.1UF 50V 10% B(5YP) 1608 R/TP

C2101 0CH1104K512 CAPACITOR,FIXED CERAMIC(Temp.c 0.1UF 50V 10% B(5YP) 1608 R/TP

C2102 0CH1104K512 CAPACITOR,FIXED CERAMIC(Temp.c 0.1UF 50V 10% B(5YP) 1608 R/TP

C2103 0CH8226F611 CAPACITOR,CHIP[AL. ELECTROLYTI 22UF 16V M 85STD(CYL) R/TP

C2104 0CH1104K512 CAPACITOR,FIXED CERAMIC(Temp.c 0.1UF 50V 10% B(5YP) 1608 R/TP

C2105 0CH1102K562 CAPACITOR,FIXED CERAMIC(Temp.c 1000PF 50V 10% X7R(X) 1608 R/T

C2106 0CH1104K512 CAPACITOR,FIXED CERAMIC(Temp.c 0.1UF 50V 10% B(5YP) 1608 R/TP

C2107 0CH1104K512 CAPACITOR,FIXED CERAMIC(Temp.c 0.1UF 50V 10% B(5YP) 1608 R/TP