Zenith IQC50H94W, IQC60H95W, IQC50H95W ZP94, ZP95 Service Manual

SERVICE MANUAL

Model Series:

Product Type: Projection TV

Chassis:ZP94/ZP95

Manual Series:PV152

Manual Part #:923-03439

Model Line:C

Product Year:2000

General Information.......................................1

Servicing/Troubleshooting..............................2

Circuit Description......................................... 3

Model Parts Lists..........................................4

Exploded Views.............................................5

PCB Layouts

Schematics

................................................

..................................................67

IQC60H94W

IQC50H94W

IQC60H95W

IQC50H95W

CONTENTS

Printed in U.S.A.

ZP DG 4.3k

Published by Technical Publications

Zenith Electronics Corporation

201 James Record Road - Huntsville, Alabama 35824-1513

ÓCopyright July 2000 by Zenith Electronics Corporation

PRODUCT SAFETY SERVICING GUIDELINES FOR AUDIO-VIDEO PRODUCTS

A.C. Voltmeter

10 WATT

Place this probe

on each exposed

IMPORTANT SAFETY NOTICE

This manual was prepared for use only by properly trained audio-visual service

technicians.

When servicing this product, under no circumstances should the original

design be modified or altered without permission from Zenith Electronics

Corporation. All components should be replaced only with types identical to

those in the original circuit and their physical location, wiring and lead dress

must conform to original layout upon completion of repairs.

Special components are also used to prevent x-radiation, shock and fire hazard.

These components are indicated by the letter “x” included in their component

designators and are required to maintain safe performance. No deviations are

allowed without prior approval by Zenith Electronics Corporation.

Circuit diagrams may occasionally differ from the actual circuit used. This way,

implementation of the latest safety and performance improvement changes into

the set is not delayed until the new service literature is printed.

CAUTION: Do not attempt to modify this product in any way. Never perform

customized installations without manufacturer’s approval. Unauthorized

modifications will not only void the warranty, but may lead to property damage

or user injury.

Service work should be performed only after you are thoroughly familiar with

these safety checks and servicing guidelines.

GRAPHIC SYMBOLS

The exclamation point within an equilateral triangle is intended

to alert the service personnel to important safety information in

the service literature.

The lightning flash with arrowhead symbol within an equilateral

triangle is intended to alert the service personnel to the presence

of noninsulated “dangerous voltage” that may be of sufficient

magnitude to constitute a risk of electric shock.

The pictorial representation of a fuse and its rating within an

equilateral triangle is intended to convey to the service personnel

the following fuse replacement caution notice:

CAUTION: FOR CONTINUED PROTECTION AGAINST RISK OF FIRE,

REPLACE ALL FUSES WITH THE SAME TYPE AND RATING AS MARKED

NEAR EAch FUSE.

SERVICE INFORMATION

While servicing, use an isolation transformer for protection from AC line shock.

After the original service problem has been corrected, make a check of the

following:

FIRE AND SHOCK HAZARD

1. Be sure that all components are positioned to avoid a possibility of

adjacent component shorts. This is especially important on items transported to and from the repair shop.

2. Verify that all protective devices such as insulators, barriers, covers,

shields, strain reliefs, power supply cords, and other hardware have been

reinstalled per the original design. Be sure that the safety purpose of the

polarized line plug has not been defeated.

3. Soldering must be inspected to discover possible cold solder joints, solder

splashes, or sharp solder points. Be certain to remove all loose foreign

particles.

4. Check for physical evidence of damage or deterioration to parts and components, for frayed leads or damaged insulation (including the AC cord), and

replace if necessary.

5. No lead or component should touch a receiving tube or a resistor rated at

1 watt or more. Lead tension around protruding metal surfaces must be

avoided.

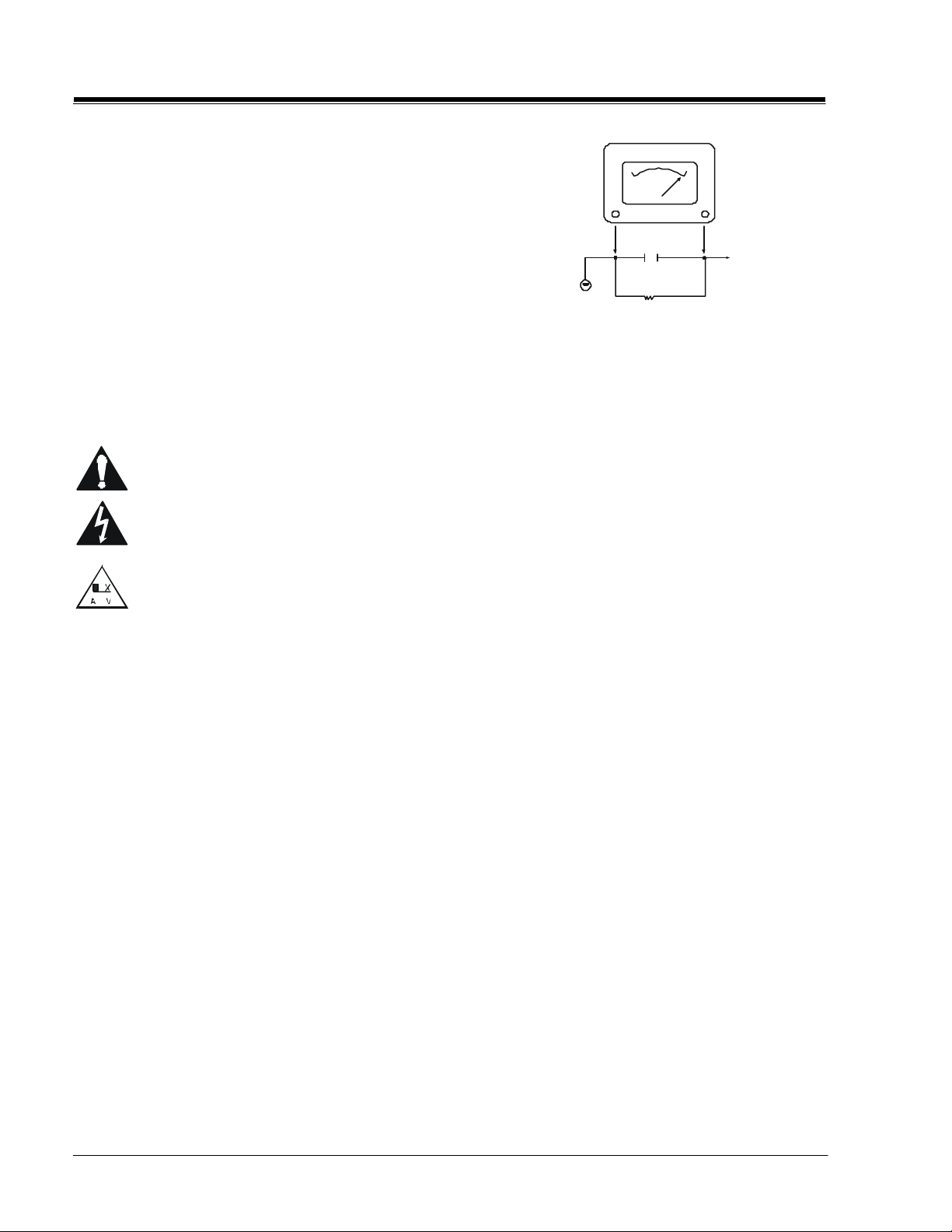

6. After reassembly of the set, always perform an AC leakage test on all exposed

metallic parts of the cabinet (the channel selector knobs, antenna terminals,

handle and screws) to be sure that set is safe to operate without danger of

electrical shock. DO NOT USE A LINE ISOLATION TRANSFORMER DURING THIS

TEST. Use an AC voltmeter having 5000 ohms per volt or more sensitivity in

the following manner: Connect a 1500 ohm, 10 watt resistor, paralleled by

a .15 mfd 150V AC type capacitor between a known good earth ground

water pipe, conduit, etc.) and the exposed metallic parts, one at a time.

Measure the AC voltage across the combination of 1500 ohm resistor and

.15 mfd capacitor. Reverse the AC plug by using a non-polarized adaptor

and repeat AC voltage measurements for each exposed metallic part. Voltage

measured must not exceed 0.75 volts RMS. This corresponds to 0.5 milliamp

AC. Any value exceeding this limit constitutes a potential shock hazard and

must be corrected immediately.

Good Earth Ground

such as the Water

Pipe, Conduit, etc.

X-RADIATION

1. Be sure procedures and instructions to all service personnel cover the

subject of x-radiation. The only potential source of x-rays in current TV

receivers is the picture tube. However, this tube does not emit x-rays when

the HV is at the factory-specified level. The proper value is given in the

applicable schematic. Operation at higher voltages may cause a failure of

the picture tube or high-voltage supply and, under certain circumstances

may produce radiation in excess of desirable levels.

2. Only factory-specified CRT anode connectors must be used.

3. It is essential that the service personnel have available an accurate and

reliable high-voltage meter.

4. When the high-voltage circuitry is operating properly, there is no possibility

of an x-radiation problem. Every time a color Chassis is serviced, the

brightness should be run up and down while monitoring the high voltage

with a meter, to be certain that the high voltage does not exceed the

specified value and that it is regulating correctly.

5. When troubleshooting and making test measurements in a product with a

problem of excessively high voltage, avoid being unnecessarily close to

the picture tube and the high voltage power supply. Do not operate the

product longer than necessary to locate the cause of excessive voltage.

6. Refer to HV, B+, and shutdown adjustment procedures described in the

appropriate schematics and diagrams (where used).

IMPLOSION

1. All direct view picture tubes are equipped with an integral implosion

protection system; take care to avoid damage during installation.

2. Use only the recommended factory replacement tubes.

TIPS ON PROPER INSTALLATION

1. Never install any receiver in a closed-in recess, cubbyhole, or closely

fitting shelf space over, or close to, a heat duct, or in the path of heated

air flow.

2. Avoid conditions of high humidity such as: outdoor patio installations

where dew is a factor, near steam radiators where steam leakage is a factor,

etc.

3. Avoid placement where draperies may obstruct venting. The customer

should also avoid the use of decorative scarves or other coverings that

might obstruct ventilation.

4. Wall- and shelf-mounted installations using a commercial mounting kit

must follow the factory-approved mounting instructions. A product mounted

to a shelf or platform must retain its original feet (or the equivalent

thickness in spacers) to provide adequate air flow across the bottom. Bolts

or screws used for fasteners must not touch any parts or wiring. Perform

leakage tests on customized installations.

5. Caution customers against mounting a product on a sloping shelf or in a

tilted position, unless the receiver is properly secured.

6. A product on a roll-about cart should be stable in its mounting to the cart.

Caution the customer on the hazards of trying to roll a cart with small

casters across thresholds or deep pile carpets.

7. Caution customers against using a cart or stand that has not been listed

by Underwriters Laboratories, Inc. for use with its specific model of

television receiver or generically approved for use with TVs of the same or

larger screen size.

8. Caution customers against using extension cords. Explain that a forest of

extensions, sprouting from a single outlet, can lead to disastrous

consequences to home and family.

0.15uF

1500 OHM

metal part.

PV152 PRO1200 - SAFETY

i

PRODUCT SAFETY SERVICING GUIDELINES FOR AUDIO-VIDEO PRODUCTS

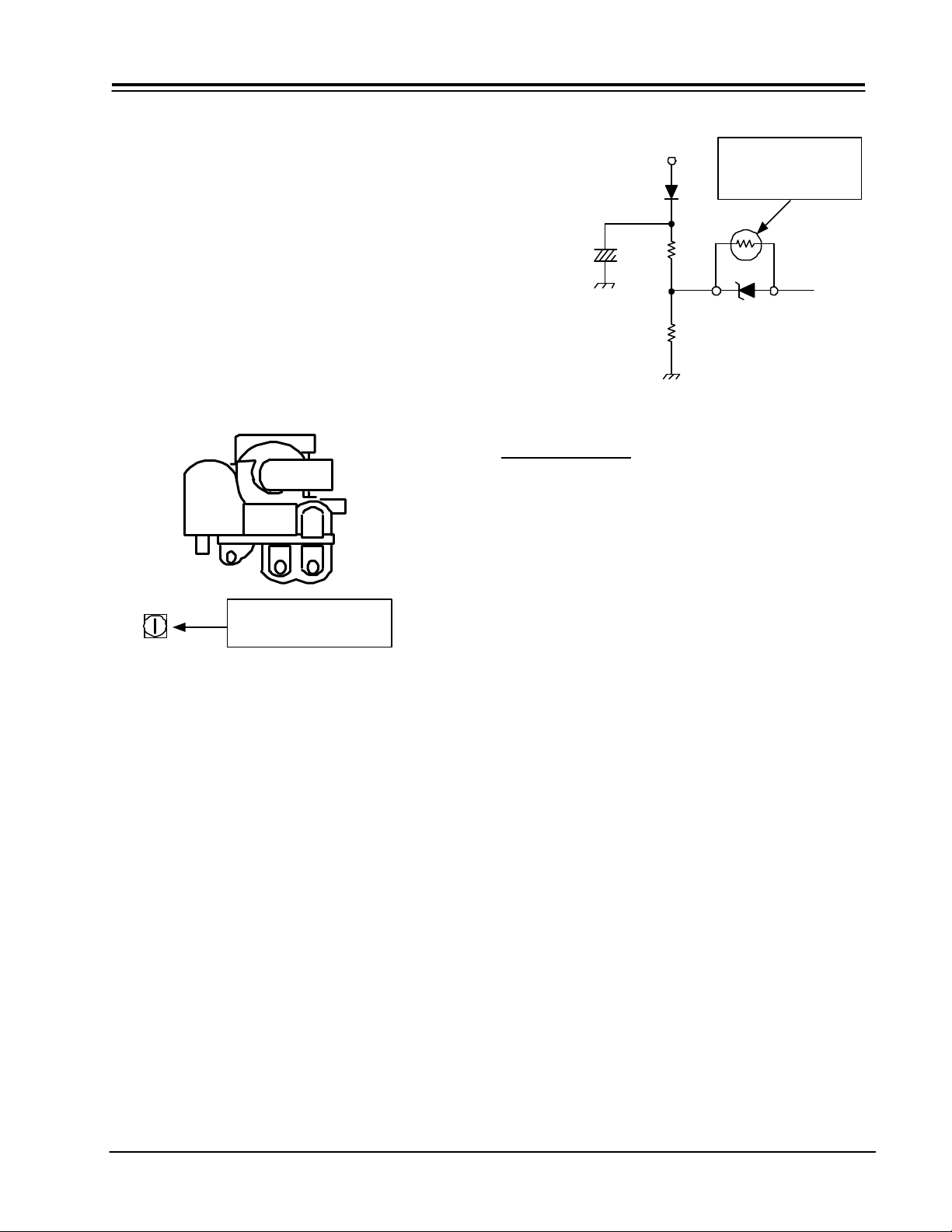

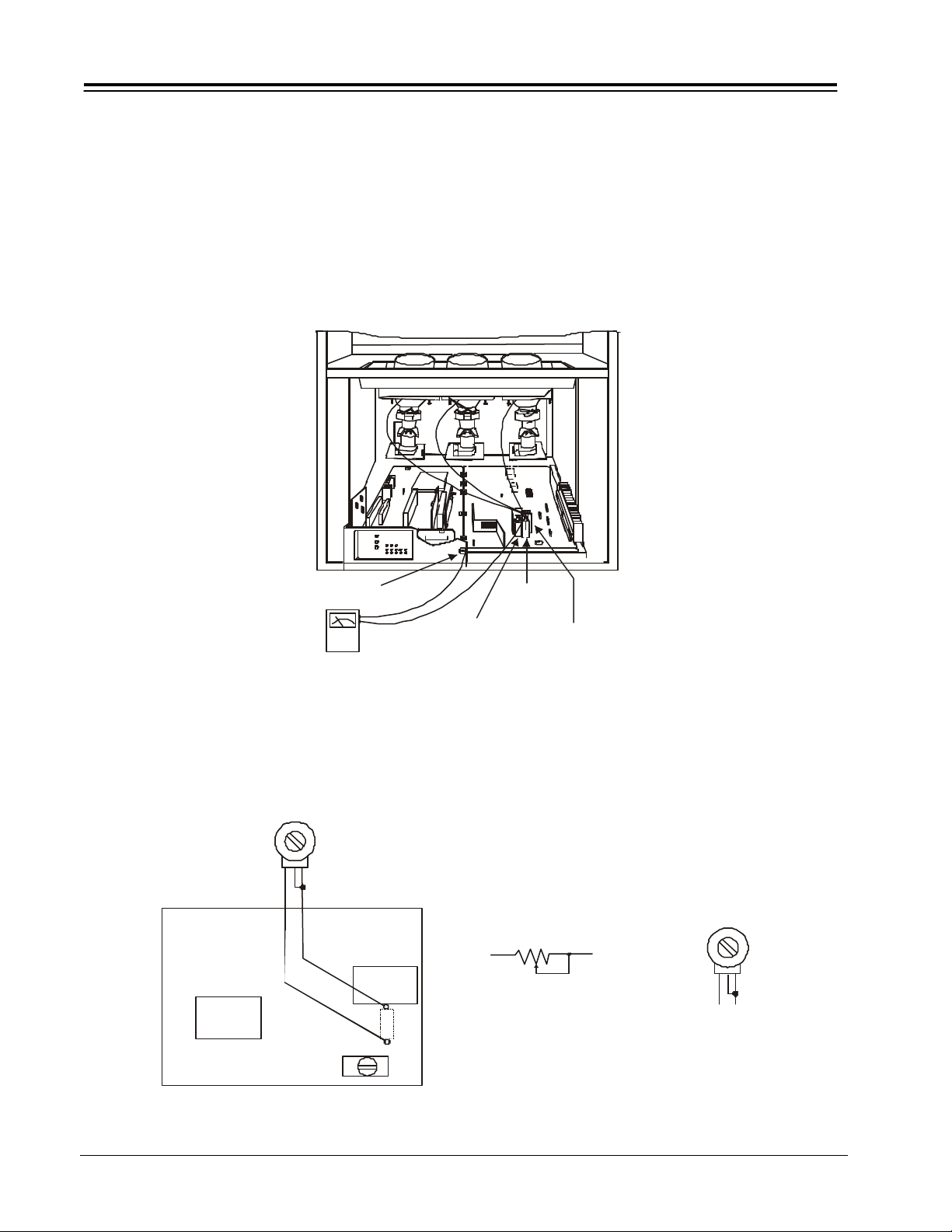

CHASSIS HIGH VOLTAGE ADJUSTMENT PROCEDURE

1. Connect High Voltage meter to FBT High Voltage output. Connect Ground of High Voltage meter to CRT

Ground or FBT Ground.

2. Check that the High Voltage adjustment VR (RH44) is

set to it’s mechanical center on the Deflection PWB.

This VR is located just behind the Flyback transformer

as viewed from the Front of the set. (See diagram below)

3. Receive an NTSC generator signal. (Picture should be

stationary for this adjustment.

4. Video Controls should be set to Factor Settings.

5. Adjust the High Voltage to the following specifications by turning RH44 slowly.

6. Lock Paint the control. If available.

TH01

FBT

RH44

High Voltage ADJ.

+50V Pulse

Add JIG to check Hi

Volt Limit Circuit

JIG = 1k ohm 1/8W

CH30

DH24

RH54

DH31

RH55

Checking Procedure :

1. Check that the picture is turned off and the horizontal deflection circuit stops operation.

After Checking:

1. Unplug set and Remove Jig. Allow set to remain in the

off condition for at least 15 seconds.

2. Apply AC and confirm the set returns to normal operation.

CHASSIS HIGH VOLTAGE LIMITER CHECK

Check Preparation:

1. The set can face any direction.

2. Receive the Cross-Hatch Signal

3. VIDEO CONTROLS: Brightness to Maximum.

4. SCREEN FORMAT: Should be PROGRESSIVE mode.

5. Attach the JIG (1k ohm 1/8W resistor) to both ends

of DH31 as shown in the diagram below. (See Diagram

Below)

CHASSIS FLYBACK PROTECTION CIRCUIT CHECK

Check Preparation:

1. The set can face any direction.

2. Receive the Cross-Hatch Signal

3. VIDEO CONTROLS: Factory Preset.

4. SCREEN FORMAT: Should be PROGRESSIVE mode.

5. Attach a 100 K ohm 1/16W ~ 1/8W resistor between

QP02 base and Gnd. (SD4 connector Pin 4) and check

operation.

After Checking:

1. Unplug set and Remove Jig. Allow set to remain in the

off condition for at least 15 seconds.

2. Apply AC and confirm the set returns to normal operation.

PV151 PROJO

ii

PRODUCT SAFETY SERVICING GUIDELINES FOR AUDIO-VIDEO PRODUCTS

CN04

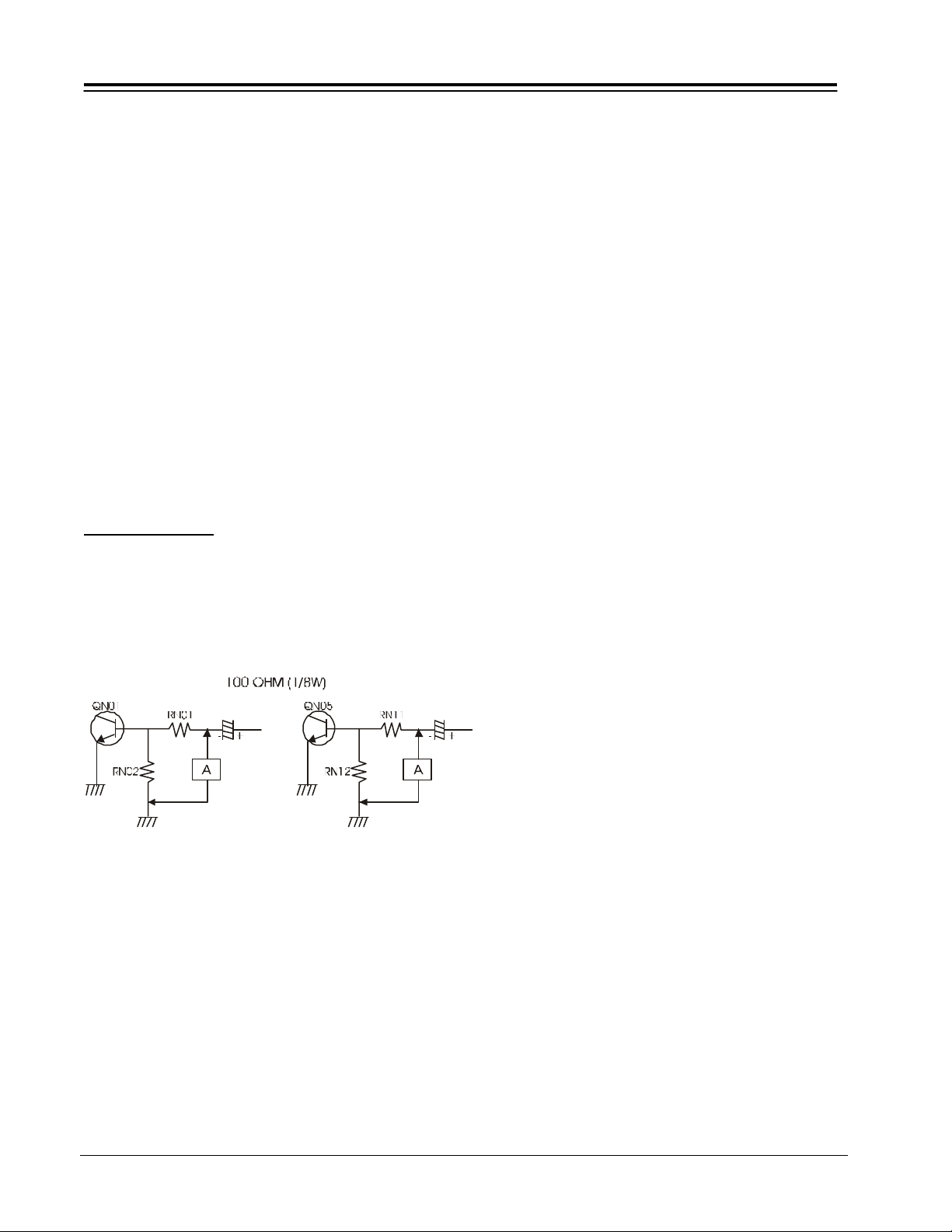

CHASSIS SWEEP LOSS DETECTION CIRCUIT CHECK

Check Preparation:

Check Number (1):

1. The set can face any direction.

2 Receive the Cross-Hatch Signal

3. VIDEO CONTROLS: Factory Preset.

4. SCREEN FORMAT: Should be PROGRESSIVE mode.

5. Attach the JIG (A) (100 ohm 1/8W resistor) to right

hand side of RN01 and to Ground as shown in the

diagram below.

Check Number (2):

1. The set can face any direction.

2. Receive the Cross-Hatch Signal

3. VIDEO CONTROLS: Factory Preset.

4. SCREEN FORMAT: Should be PROGRESSIVE mode.

5. Attach the JIG (B) (100 ohm 1/8W resistor) to right

hand side of RN11 and to Ground as shown in the

diagram below.

Checking Procedure :

1. Check that the picture is turned off in either check.

After Checking:

1. Remove Jig after each check.

2. Confirm the set returns to normal operation.

CN01

PV151 PROJO

iii

TABLE OF CONTENTS

SECTION 1 GENERAL INFO / REMOTE CONTROL

CAUTIONS FOR HV CONNECTOR ................................. 1-1

SPECIFICATIONS .................................................... 1-2

GENERAL INFORMATION ........................................... 1-3

REMOTE ..............................................................1-4

REMOTE CODES ..................................................... 1-5

CUSTOMER AUDIO/VIDEO ADJUSTMENT ........................ 1-7

CUSTOMER CONVERGENCE ADJUSTMENT ....................... 1-9

SECTION 2 SERVICING

SERVICE MENUES .............................................. 2-1

SERVICE ADJUSTMENT ORDER .................................. 2-6

MEMORY INITIALIZATION ........................................ 2-7

PRE HEAT .............................................. 2-7

CUT OFF ADJUSTMENT ............................................ 2-7

PRE FOCUS ADJUSTMENT ........................................ 2-7

DCU PHASE ADJUSTMENT (COARSE) ........................... 2-9

HORIZONTAL PHASE ADJUSTMENT .............................. 2-9

RASTER INCLINATION ............................................. 2-9

BEAM ALIGNMENT .............................................. 2-10

VERT/HORIZ POSITION ADJUSTMENT ........................... 2-10

HORIZONTAL SIZE ADJUSTMENT ................................ 2-11

VERTICAL SIZE ADJUSTMENT .................................... 2-11

BEAM FORM ADJUSTMENT ....................................... 2-11

LENS FOCUS ADJUSTMENT ....................................... 2-12

STATIC FOCUS ADJUSTMENT ..................................... 2-12

BLUE DEFOCUS ADJUSTMENT ................................... 2-12

WHITE BALANCE ADJUSTMENT .................................. 2-13

SUB BRIGHT ADJUSTMENT ....................................... 2-14

HORIZONTAL POSITION ADJUSTMENT (FINE).................. 2-14

DIGITAL CONVERGENCE ADJUSTMENT .......................... 2-14

DIGITAL CONVERGENCE REMOTE ................................ 2-15

CONVERGENCE POINT ADJUSTMENT ............................ 2-16

CONVERGENCE 3X3 ADJUSTMENT ............................... 2-17

CONVERGENCE 7X5 ADJUSTMENT ............................... 2-17

CONVERGENCE 13X9 ADJUSTMENT ............................. 2-17

TROUBLE SHOOTING .............................................. 2-19

ZP 94/95 SIGNAL TOP PCB LAYOUT ............................ 6-3

ZP 94/95 SIGNAL BOTTOM PCB LAYOUT ....................... 6-4

ZP 94/95 SWITCH MODE POWER TOP PCB LAYOUT ........... 6-5

ZP 94/95 SWITCH MODE POWER BOTTOM PCB LAYOUT ..... 6-6

ZP 94/95 CPT TOP PCB LAYOUT ................................. 6-7

ZP 94/95 CPT BOTTOM PCB LAYOUT ........................... 6-8

ZP 94/95 SRS AUDIO TOP PCB LAYOUT ....................... 6-9

ZP 94/95 SRS AUDIO BOTTOM PCB LAYOUT .................. 6-10

ZP 94/95 JACKPACK TOP PCB LAYOUT ......................... 6-11

ZP 94/95 JACKPACK BOTTOM PCB LAYOUT .................... 6-12

ZP 94/95 CONTROL PANEL TOP PCB LAYOUT .................. 6-13

ZP 94/95 CONTROL PANEL BOTTOM PCB LAYOUT ........... 6-14

ZP 94/95 VELOCITY MODULATOR AND SUB TOP

PCB LAYOUT ............................... 6-15

ZP 94/95 VELOCITY MODULATOR AND SUB BOTTOM

PCB LAYOUT ............................... 6-16

ZP 94/95 YC & COMB FILTER TOP PCB LAYOUT ............... 6-17

ZP 94/95 YC & COMB FILTER BOTTOM PCB LAYOUT ......... 6-18

SECTION 7 SCHEMATICS

ZP 94/95 MICRO PWB CIRCUIT .................................. 6-1

ZP 94/95 SIGNAL INTERCONNECT CIRCUIT .................... 6-2

ZP 94/95 TUNER IF CIRCUIT ..................................... 6-3

ZP 94/95 POWER SUPPLY PWB CIRCUIT ....................... 6-4

ZP 94/95 DEFLECTION CIRCUIT ................................. 6-5

ZP 94/95 CONVERGENCE POWER SUPPLY ...................... 6-6

ZP 94/95 REGISTRATION / CONVERGENCE CORRECT PWB ... 6-7

ZP 94/95 JACKPACK / TERMINAL DIAGRAM ................... 6-8

ZP 94/95 2 LINE COMB FILTER CIRCUIT ....................... 6-9

ZP 94/95 CHROMA / LUMMA CIRCUIT ......................... 6-10

ZP 94/95 VELOCITY MODULATOR PWB CIRCUIT ............... 6-11

ZP 94/95 CRT PWB CIRCUIT ..................................... 6-12

ZP 94/95 AUDIO MATRIX / CONTROL PANEL PWB ............ 6-13

SECTION 3 CIRCUIT DESCRIPTION

POWER SUPPLY OPERATION ...................................... 3-1

TURNING ON THE DEFLECTION POWER SUPPLY ............... 3-2

POWER SUPPLY SHUTDOWN EXPLANATION .................... 3-3

ABL CIRCUIT .............................................. 3-4

MICRO PROCESSOR DATA COMMUNICATION ................... 3-5

SECTION 4 PARTS LIST

MODEL PARTS .............................................. 4-1

SECTION 5 DIAGRAMS

ZP 94/95 EXPLODED VIEW....................................... 5-1

ZP 94/95 EXPLODED VIEW FRONT .............................. 5-2

ZP 94/95 EXPLODED BACK ...................................... 5-3

ZP 94/95 INTERCONNECT ........................................ 5-4

ZP 94/95 WIRING DIAGRAM ..................................... 5-5

SECTION 6 PCB LAYOUTS

ZP 94/95 DEFLECTION TOP PCB LAYOUT ...................... 6-1

ZP 94/95 DEFLECTION BOTTOM PCB LAYOUT ................. 6-2

PV152 TOC PROJO

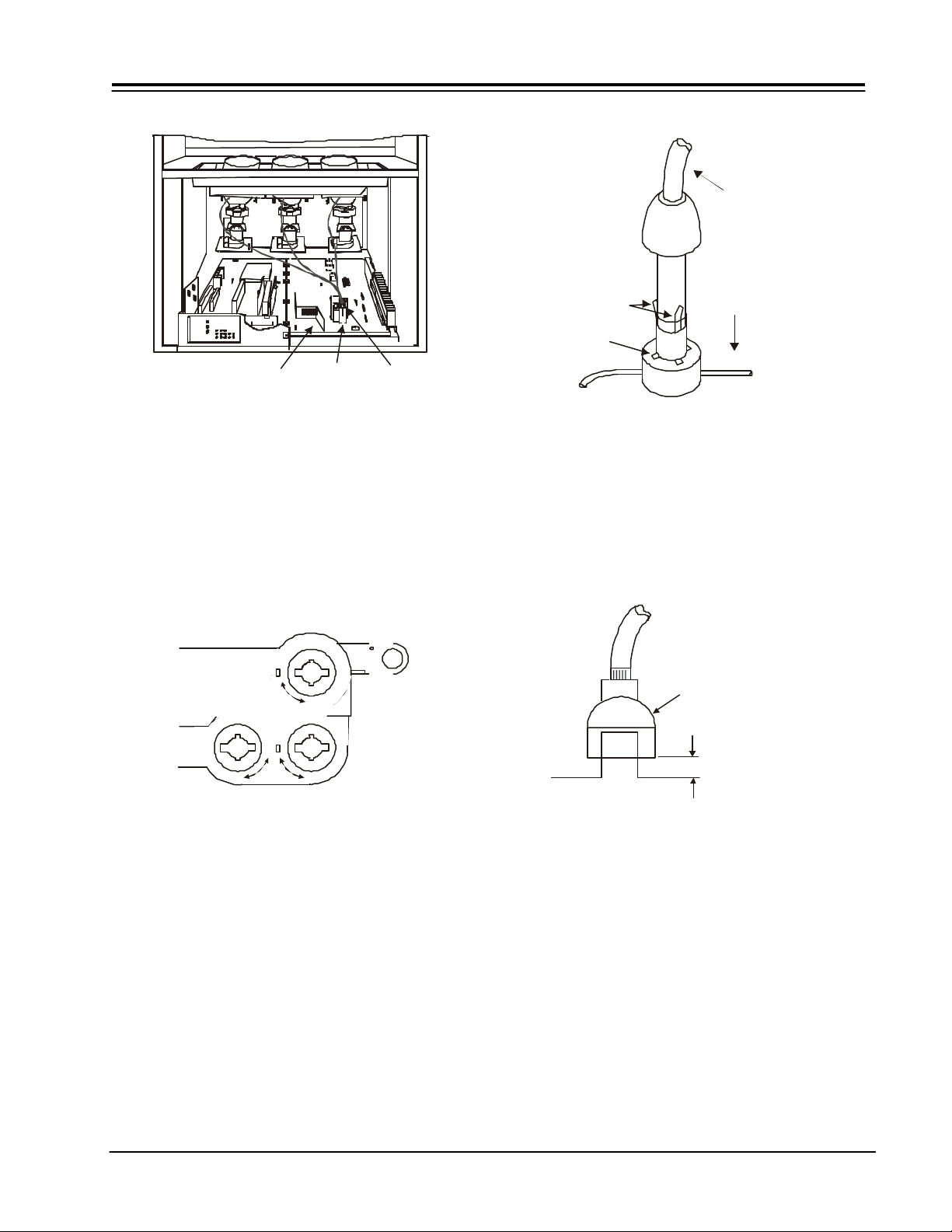

CAUTIONS WHEN CONNECTING / DISCONNECTING THE HV CONNECTOR

FIG. A

HV Cable

POSITION

FIG. B

Boot Assembly

LESS THAN 1mm

DEFLECTION

FBT

ANODE

CONNECTOR

FlybackTAB

P.W.B

Perform the following when the HV connector (anode

connector) is removed or inserted for CPT replacement,

etc.

PUSH

PUSH

During Removal

1. Roll out silicon cover from FBT’s contact area slowly.

2. While turning the connector about 90 degrees following the arrow

(0 position). Push the connector slightly toward the case. (Fig. A)

3. Remove the connector slowly by pulling it away from the case.

HV Cable &

Flyback

During Insertion

1. Please refer to direction for insertion as shown in Fig. B (L position).

Insert connector until “CLICK” sound is heard.

2. Make sure the connector is pressed right in, so that it has a good

contact with the spring.

3. Confirm the contact by pulling the connector slightly. (Don’t pull

hard because it may damage the connector).

4. Cover the high voltage output by carefully pushing silicon boot

onto it. (Don’t turn the connector).

Note: Make sure the silicon boot is covering the high

voltage output.

PV151 1-1 PROJO

TECHNICAL CAUTIONS

SECTION 1

High Voltage

FBT)(TH01

Defelection

H.V. Meter

Remove 80 and connect 50K Ohm jig as shown

High Voltage limiter circuit check

1. Turn off TV and connect jig as shown in Figure 2.

Adjust jig fully counter clockwise for minimun

resistance.

2. Set the AC input to 120V AC and turn on TV.

3. Confirm test pattern on CRT is a usable picture, then

slowly adjust jig until the picture disappears and TV

shuts down.

4. When the limiter circuit is operating properly, Voltage

will be less than 36.5kV at 0.6mA when TV shuts down.

5. Turn off set immediately after checking circuit operations.

6. Unplug set for one minute to reset shutdown circuit.

Remove jig and voltmeter.

TP91

Chassis Ground

High Impedance

Figure 2. Deflection/Power PCB

FBT

RH80

P.W.B.

RH

Connector

50K Ohm VR

JIG

POWER/DEFLECTION PWB

PV151 1-2 PROJO

RH44

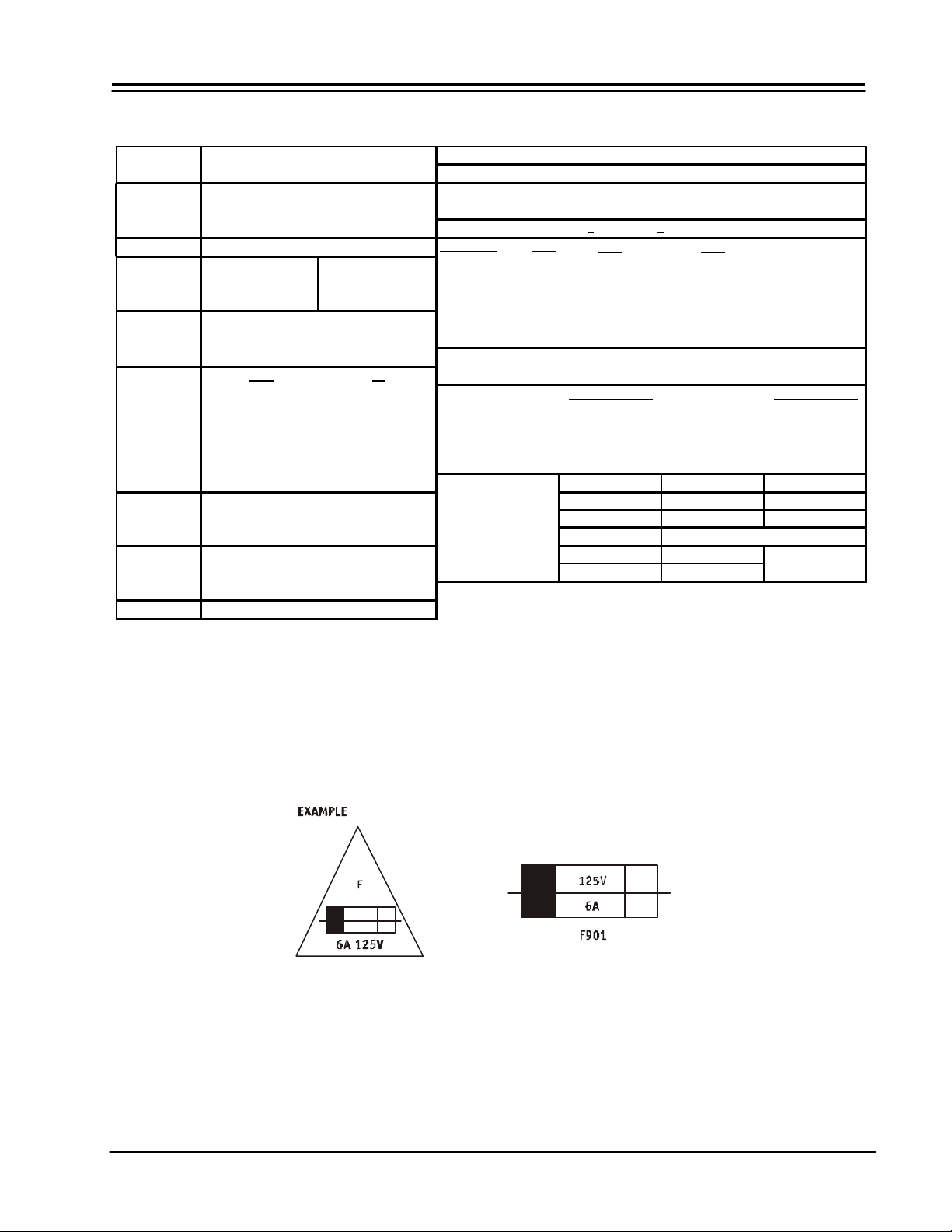

SPECIFICATIONS FOR 94 & 95 SERIES MODELS

ZP94

ZP95

Model:

Cathode-Ray

Tube:

Power Input 120 Volt AC, 6OHz

Power

Consumption:

Antenna

Impedence:

Receiving

Channel:

Intermediate

Frequency:

Video Input:

Video Output: 1 Volt p-p, 75 Ohm

IQC60H95W IQC50H95W Audio Input: 470 mVrms, 47 k Ohm

IQC60H94W IQC50H94W Stereo Audio Output: 470 mVrms, 1 k Ohm

R=P16LFM00RFA(LU) Front- 12 Watt at 10% distortion, 8 Ohm Imp.

G=P16LFM00HHA(LU) Max Output - 15 Watt

B=P16LFM00BMB(EU) Anode Voltage:

224 Watts - Maximum

192 Watts - Operating 206 Watts - Operating

75ohm Unbalanced

VHF / UHF / CATV 2 woofers - 5 Inch

BAND CH (12 cm) Round

VHF 2-13 Dimension: 50" Series Models 60" Series Models

UHF 14-69 Height 52 60 1/2

EXT. Mid (A-5)~(A-1), 4+ Width 43 1/5 51 1/2

CATV Mid A~I Depth 23 1/2 26 1/2

CATV Super J~W Weight

CATV Hyper (W+1) (W+28) Power Supply P.W.B. C.P.T. (B) P.W.B Control P.W.B

Picture I-F Carrier 45.75 MHz VM P.W.B. C.P.T. (G) P.W.B. Sensor Dist. P.W.B.

Sound I-F Carrier 41.25 MHz Surround P.W.B. C.P.T. (R) P.W.B. Sub Deflect. P.W.B

Color Sub Carrier 42.17 MHz Signal P.W.B. Power/Deflection P.W.B.

1 Volt p-p, 75 Ohm Audio Out P.W.B. Control P.W.B.

1 Volt p-p, 75 Ohm (Y) 2H P.W.B. Terminal P.W.B.

07. Volt p-p, 75 Ohm, (Cb, Cr)

Audio Output Power:

30.0 + 1.5kv (1.27 + 0.2ma)

Brightness Size

232 Watts - Maximum Full White 50" 130 130

Brightness Max 60"

Speakers:

Circuit Board

Assemblies:

ZP94 ZP95

100 100

CIRCUIT PROTECTION

CAUTION: Below is an EXAMPLE only. See Replacement Parts List for details. The following symbol near the fuse

indicates fast operation fuse (to be replaces). Fuse ratings appear within the symbol.

The rating of fuse F901 is 6.0A - 125V.

“RISK OF FIRE - REPLACE FUSE AS MARKED”

PV151 1-3 PROJO

Replace with the same type fuse for continued

protection against fire.

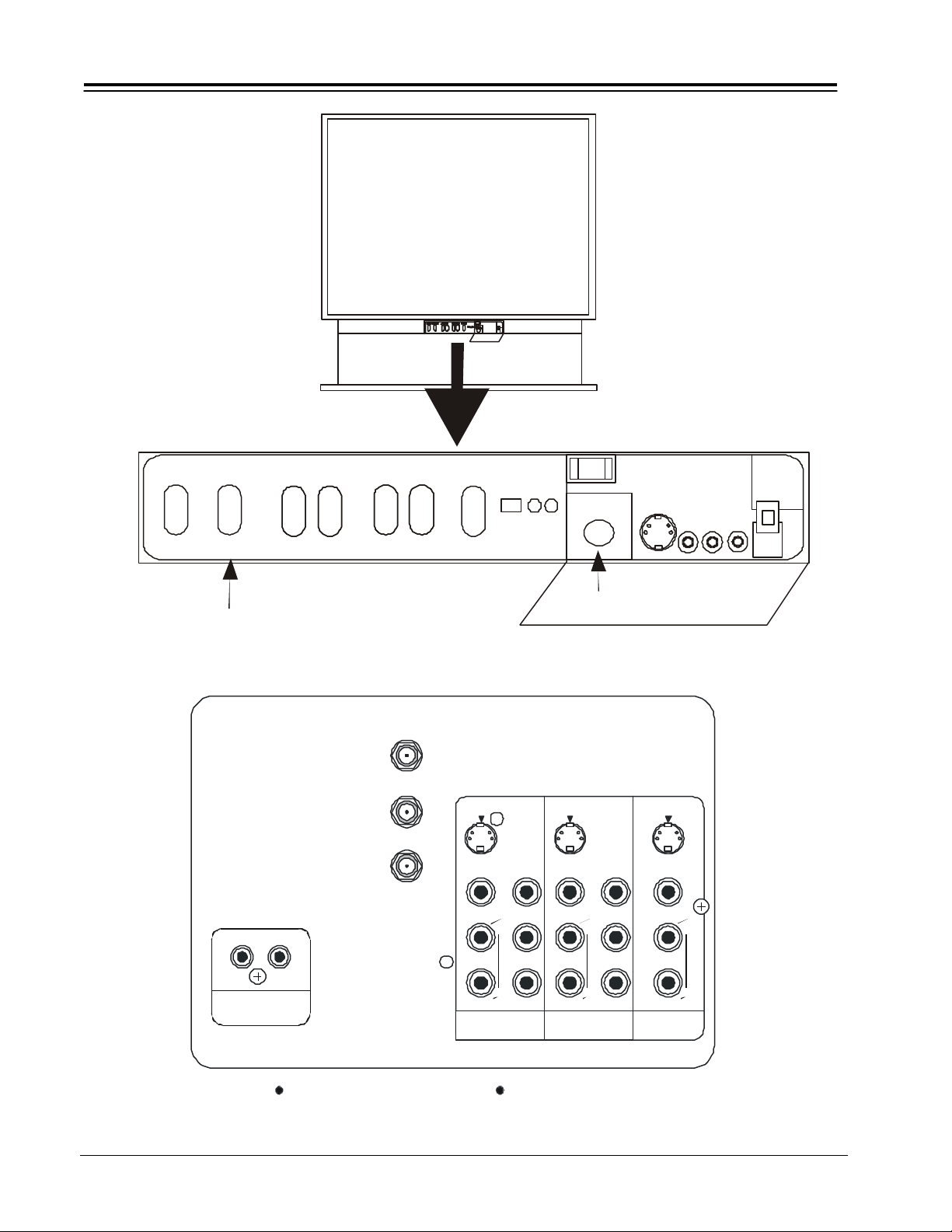

GENERAL INFORMATION

-CHANNEL+

DIGITAL

Source Selector

DIGITAL CONVERGENCE

S-VIDEO

VIDEO

(MONO

)

AUDIOINPUT1INPUT2LRS-VIDEOMONITOROUTY

PBP

R

ANT

B

VIDEO

(MONO

)

AUDIORS-VIDEOVIDE

O

(MONO

)

AUDIOLRS-VIDEOY

PBP

R

MENU

SOURCE

SOURCE

EXIT

TV / VIDEO

-VOLUME+

65

POWER

65

Figure 3. Control Panel

ANT A

To

Converter

SETUP

SETS ONLY

VIDEO

LEFT

AUDIO

RIGHT

AUDIO

PV151 1-4 PROJO

R

A UDIO

TO HI-FI

L

Figure 4. Rear Connection Panel

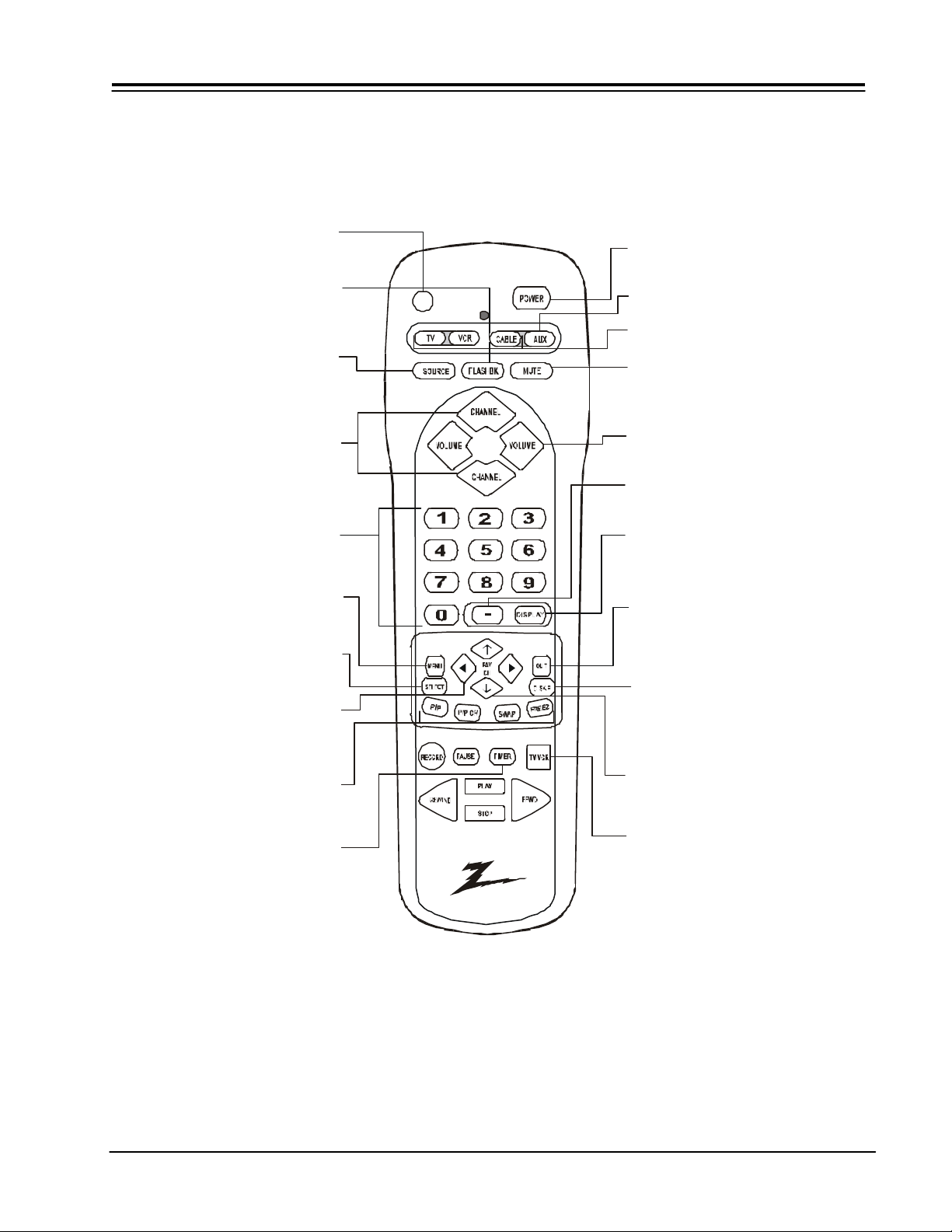

REMOTE CONTROL MODEL MBR3475Z

Selects the remote's mode of operation

Increases / Decreases TV’s sound

level.

QUIT

MBR3475Z

924-10092

C. SKIP

AUX

Auxilliary equipment control

Channel Skip. Tunes Entertainment

Machine to last channel viewed. Tunes

back to original channel after 30, 60,

HELP

PIP MODE

Activates the on-screen help feature.

FLASHBK (Flashback)

Returns to previous Channel.

SOURCE

Signal Source

CHANNEL (Up/Down)

Selects next channel in

TV’s memory. Press

and hold to repeat.

NUMBER PAD

Selects channels directly.

MENU

Displays menus for TV

and other options.

SELECT

POWER

Turns TV On or Off.

MODE

MUTE

Turns sound Off and On

while picture remains.

VOLUME (Left/Right)

Changes PIP Mode

DISPLAY

Shows Channel/Time, enters

channel, or removes any

on-screen menus.

Leaves programming menus

and clear screen of display.

LEFT/RIGHT ARROWS

Chooses and shows the

desired menu option.

PIP KEYS

Special features of some TV’s

TIMER

Press repeatedly to set desired

TV shut-off time.

90, 120, 150, or 180 seconds.

.

UP and DOWN ARROWS

Moves highlighted bar within

menu to select an option.

TV/VCR SOURCE

Steps through source options.

Remote Control Part Number.

PV151 1-5 PROJO

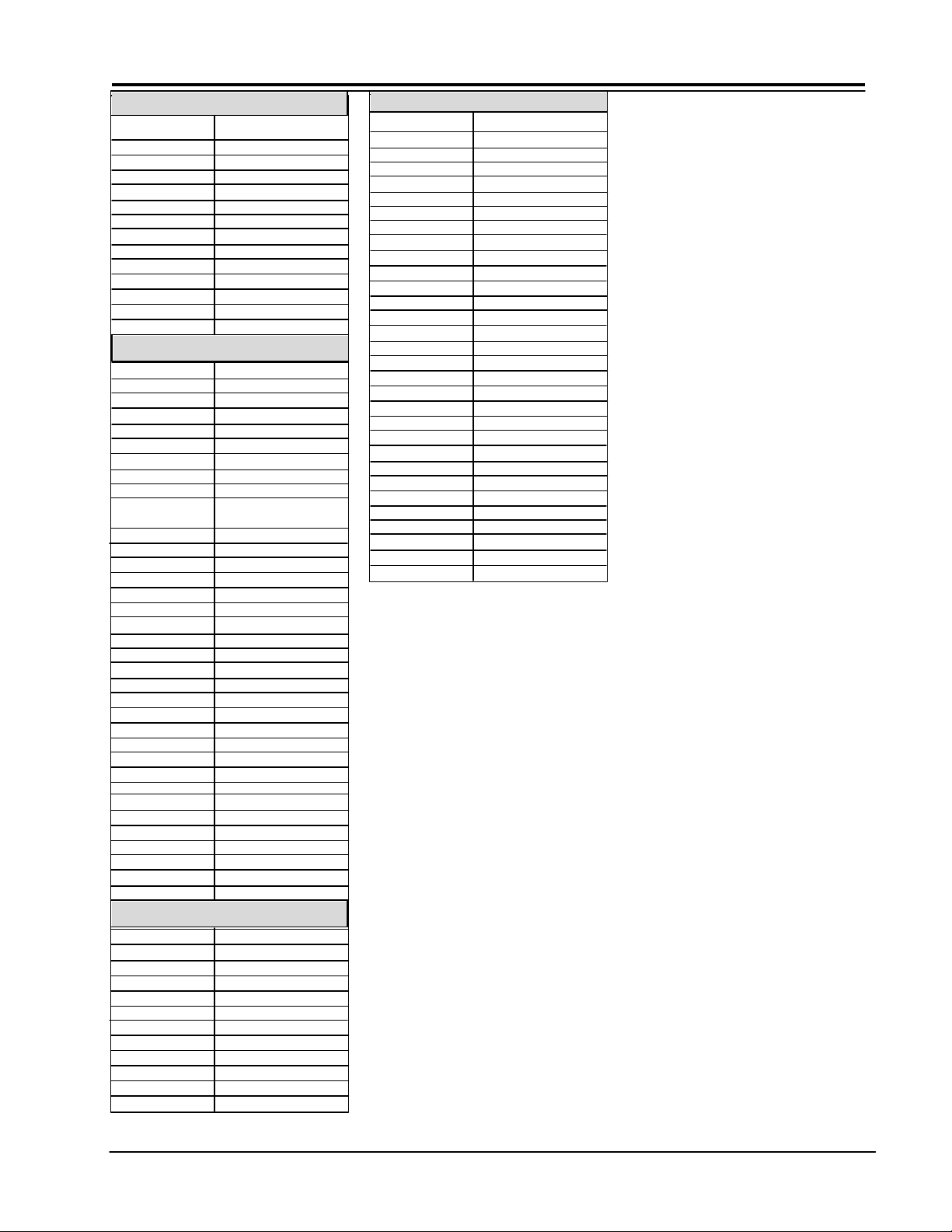

PROGRAMMING CODES

Adventura 00

Aiko 08

Aiwa 00

Akai 01, 48, 49

American High 22

Asha 45

Audiovox 23

Beaumark 45

Bell & Howell 32

Brandt 43

Broksonic 33, 34, 42, 42, 52

Calix 23

Canon 22

Capehart 06

Carver 31

CCE 08, 30

Citizen 08, 23

Colt 30

Craig 18, 23, 30, 45

Curtis Mathis 01, 22, 47

Cybernex 45

Daewoo 06, 08, 16, 38, 50

Daytron 06

Dynatech 00

Electrohome 23

Electrophonic 23

Emerx 07

Emerson 00, 08, 12, 15, 23, 27,

28, 33, 34, 37, 42, 48,

51, 52

Fisher 18, 20, 32, 46

Fuji 09, 22

Funai 00

Garrad 00

General Electric 03, 22, 41, 47

Goldstar 23, 24, 44

Gradiente 00

Harley Davidson 00

Harman / Kardon 24

Harwood 30

Headquarter 17

Hi-Q 18

Hitachi 01, 02, 03, 04

Jensen 01

JVC 01, 13, 26

KEC 08, 23

Kenwood 01, 24, 26

KLH 30

Kodak 22, 23

Lloyd 00

Lloyd’s 27

Logik 30

LXI 23

Magnavox 14, 2, 29, 31, 35

Magin 45

Marantz 22, 3

Marta 23

Matsushita 22

MEI 22

Memorex 00, 14, 17, 18, 19, 22,

23, 32, 45

MGA 15, 48

MGN Tech 45

Minolta 02, 04

Mitsubishi 15, 26, 40, 48, 49

Motorola 19, 22

MTC 00, 45

Multitech 00, 30

VCRS (continued)VCRS

NEC 01, 05, 24, 26, 32

Nikko 23

Noblex 45

Olympus 11, 22

Optimus 19, 23, 32

Orion 51

Panasonic 10, 11, 22, 39, 53

Penny 02, 05, 22, 23, 24, 45,

46

Pentax 02, 03, 04

Philco 22

Philips 20, 29, 31

Pilot 23

Pioneer 26

Portland 06

Protec 30

Pulsar 14

Quarter 17

Quartz 17

Quasar 22

Radio Shack 00, 23

Radix 23

Randex 23

RCA 02, 03, 04, 35, 41, 47

Realistic 00, 17, 18, 19, 20, 22,

23, 32, 45

Ricoh 21

Runco 14

Samsung 16, 45

Sanky 14, 19

Sansui 01, 26

Sanyo 17, 18, 32, 45

Scott 15, 16, 33, 34, 37, 42

Sears 02, 04, 17, 18, 20, 22,

23, 32, 46

Sharp 19

Shintom 30

Shogun 45

Shinger 30

Sony 07, 09, 21, 22

STS 02

Sylvania 00, 15, 22, 29, 31

Symphonic 00

Tatung 01

Teac 00, 01

Technics 22, 39

Teknika 00, 22, 23

Telefunken 43

THK 27, 45

Toshiba 15, 16, 20, 37

Totevision 23, 45

Unitech 45

Vector 16

Vector Research 05, 24

Video Concepts 05, 16, 48

Videosonic 45

Wards 00, 02, 18, 19, 22, 30,

35, 37, 45, 47

XR 1000 00, 22, 30

Yamaha 24

Zenith 09, 14, 21, 55

Cable Satelites

ABC 00, 07, 08, 18, 19, 21,

37, 38, 53

Antronixs 40

Archer 12, 25, 40

Belcor 33

Cable Star 33

Cable Satelites (continued)

Century 12

Citizen 12

Colour Voice 31, 45

Contronics 26, 29

Contec 22

Dae Ryung 21

Eastern 15

Electricord 32

Everquest 56

Focus 57

Garrard 12

GC Electronics 33, 40

Gemini 04, 39, 44, 56

Goldstar 11, 26

General Insturments 00, 13

Hamlin 03, 09, 14, 23, 24

Hitachi 00

Hytex 37

Jasco 12

Jerrold 00, 08, 13, 38, 53, 55,

56

Macom 36

Magnavox 16

Memorex 02

Movie Time 30, 32, 34

NSC 30, 34, 39

Oak 22, 37, 50

Panasonic 02, 10, 49

Paragon 02

Philips 12, 16, 17, 27, 31, 43,

44, 45, 47

Pioneer 06, 11, 20

Popular Mechanics 57

Pulsar 02

RCA 49

Realistic 40

Recoton 57

Regal 03, 09, 23, 35

Regency 15

Rembrandt 00, 39

Runco 02

Samsung 11, 26

Scientific Atlanta 18, 21, 42, 48

Signal 26, 56

Signature 00

SL Marx 26

Sprucer 01, 49

Starcom 38, 53, 56

Stargate 26, 56

Starquest 56

Starsight 58, 59

Sylvania 19

Teleview 26

Texscan 19

Tocom 07, 28, 55

Toshiba 02

Tusa 56

TV 86 30

Unika 12, 40

United Artist 37

United Cable 53

Universal 12, 25, 32, 33, 35, 40

Videoway 51

Viewstar 16, 29, 30, 41

Zenith 16, 29, 30, 41, 64

Zentek 57

Hitachi (SAT) 61

RCA (SAT) 62

Sony (SAT) 63

PV151 1-6 PROJO

PROGRAMMING CODES

DVD Players

Denon 03

Hitachi 06

JVC 00

Kenwood 03

Magnavox 04

Mitsubishi 09

Panasonic 03

Pioneer 02

Philips 05

RCA (ProScan) 08

Sony 01

Toshiba 04

Yamaha 07

Zenith 04, 10

CD Players

Adcom 11

Aiwa 12

California Audio 13

Carver 12

Denon 14

DKK 15

Emerson 11

Fisher 16

Genexxa 17

Hitachi 11, 17, 18, 19, 20,

21, 22

JVC 23

Kenwood 16, 24, 25

Krell 12

Magnavox 12

Marantz 12, 13

MCS 13

Mission 13

NSM 12

Onkyo 26

Optimus 15, 17, 27

Panasonic 13

Philips 12

Pioneer 17, 27

Proton 12

QED 12

Quasar 13

RCA 11, 31

Realistic 11

Rotel 12

SAE 12

Sansui 12

Scott 11

Sony 15, 28

Technics 13, 29, 30

Victor 23

Tape Players

Awia 42, 43

Hitachi 32, 33, 34, 35

Jerrold 44, 45

JVC 36

Kenwood 37

Optimus 38

Panasonic 39

Pioneer 38

Scientific Atlanta 46

Sony 40, 52, 42, 43

Starcom 44

Wards 38

Audio Amplifiers

Aiwa 51, 52

Carver 47, 52, 53, 54

Casio 55

Clarinette 55

Denon 56

Fisher 54, 57

Hitachi 58

JVC 59

Kenwood 60, 61, 63, 64

Lloyd’s 55

Magnavox 57, 63, 55

Marantz 47, 52, 62

MCS 62

Modulaire 55

Onkyo 55

Optimus 49, 50, 57, 61, 66

Panasonic 62

Penney 55

Philips 47, 52

Pioneer 49, 50, 66, 67, 68

Quasar 62

Realistic 55

Sansui 52

Sanyo 57

Sharp 61

Sony 51

Technics 48, 62, 69, 70, 71

Victor 59

Ward 49, 51, 52, 54, 66, 67

Yamaha 61, 72

York 55

PV151 1-7 PROJO

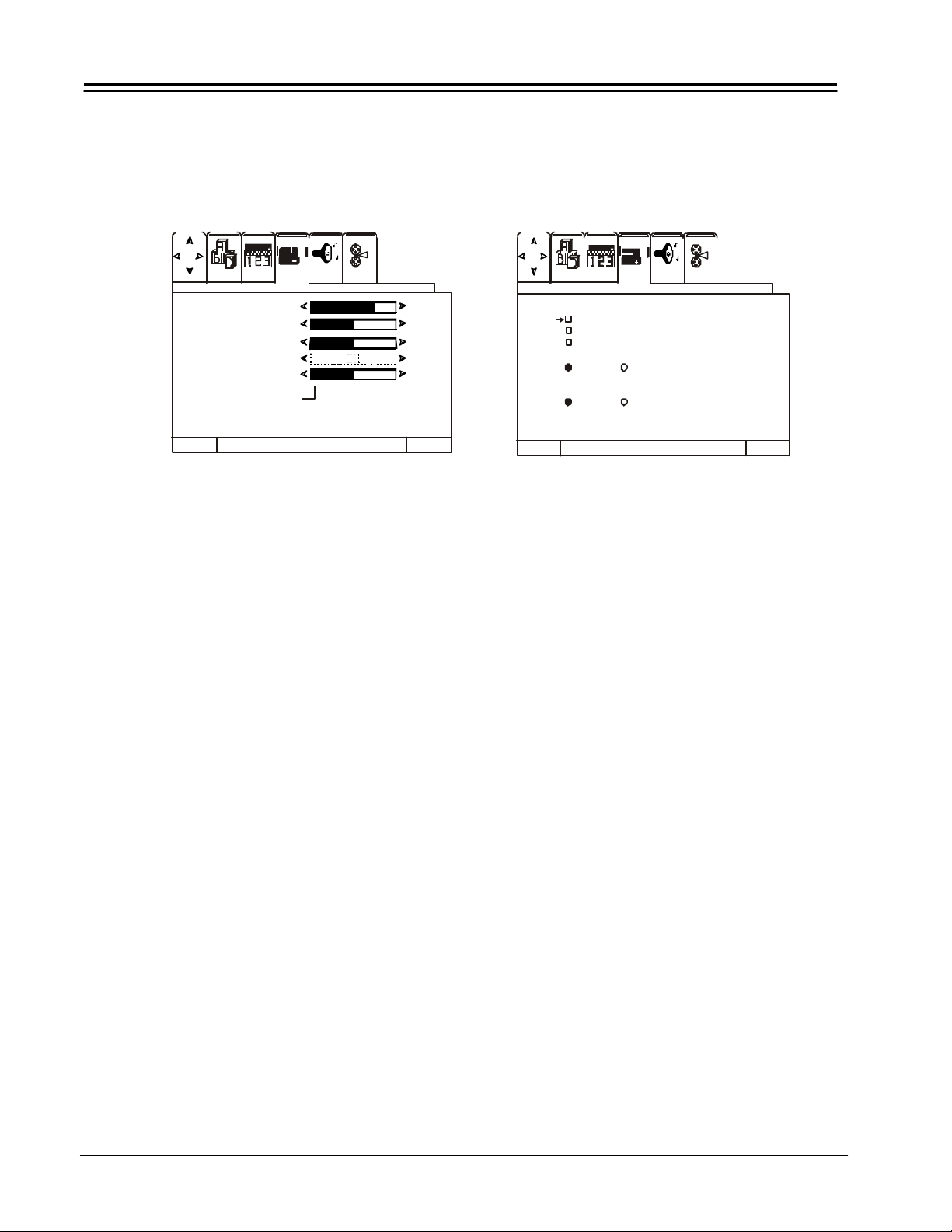

CUSTOMIZED VIDEO AND AUDIO ADJUSTMENTS

THEATER

THEATER

Select VIDEO to adjust picture settings and improve picture quality.

SPECIAL

SETUP

CONTRAST 75 %

BRIGHTNESS 50%

COLOR

TINT

SHARPNESS 50%

RESET

ADVANCED

MENU TO MENU BAR

SETTINGS

VIDEO

AUDIO

TO EXIT

50%

QUIT

Note: If contrast is selected, you are adjusting

CONTRAST. The additional menu items,

BRIGHTNESS, COLOR, TINT, and SHARPNESS

can be adjusted in the same manner.

Contrast and Brightness adjustmens will

effect only the main picture. These

adjustments will not affect the subpicture.

SETUP SPECIAL VIDEO AUDIO

Advanced Settings

View Rite

Auto Flesh

Video

Color Temperature

Cool Warm

Aspect Ratio

4.3 16.9

V. Position +10

MENU TO MENU BAR

TO EXIT

QUIT

Use Cursor Up or Down to highlight the

function to be adjusted.

Press Cursor Left or Right to adjust function.

Press QUIT to exit menu.

CONTRAST

Use this function to change the contrast

between black and white levels in the

picture. This adjustment will only affect the

picture when LIGHT SENTRY is OFF.

BRIGHTNESS

Use this function to adjust overall picture

brightness.

COLOR

Use this function to adjust the color level in

the picture.

TINT

Use this function to adjust flesh tones so they

appear natural. (It may be necessary to adjust

TINT to abtain optimum picture quality when

using the COMPONENT:Y-CbCr Input 2 jacks).

SHARPNESS

Use this function to adjust the amount of

detail in the picture.

RESET

When RESET is selected, press CURSOR RIGHT

to reset video settings to factory preset

conditions.

PV151 1-8 PROJO

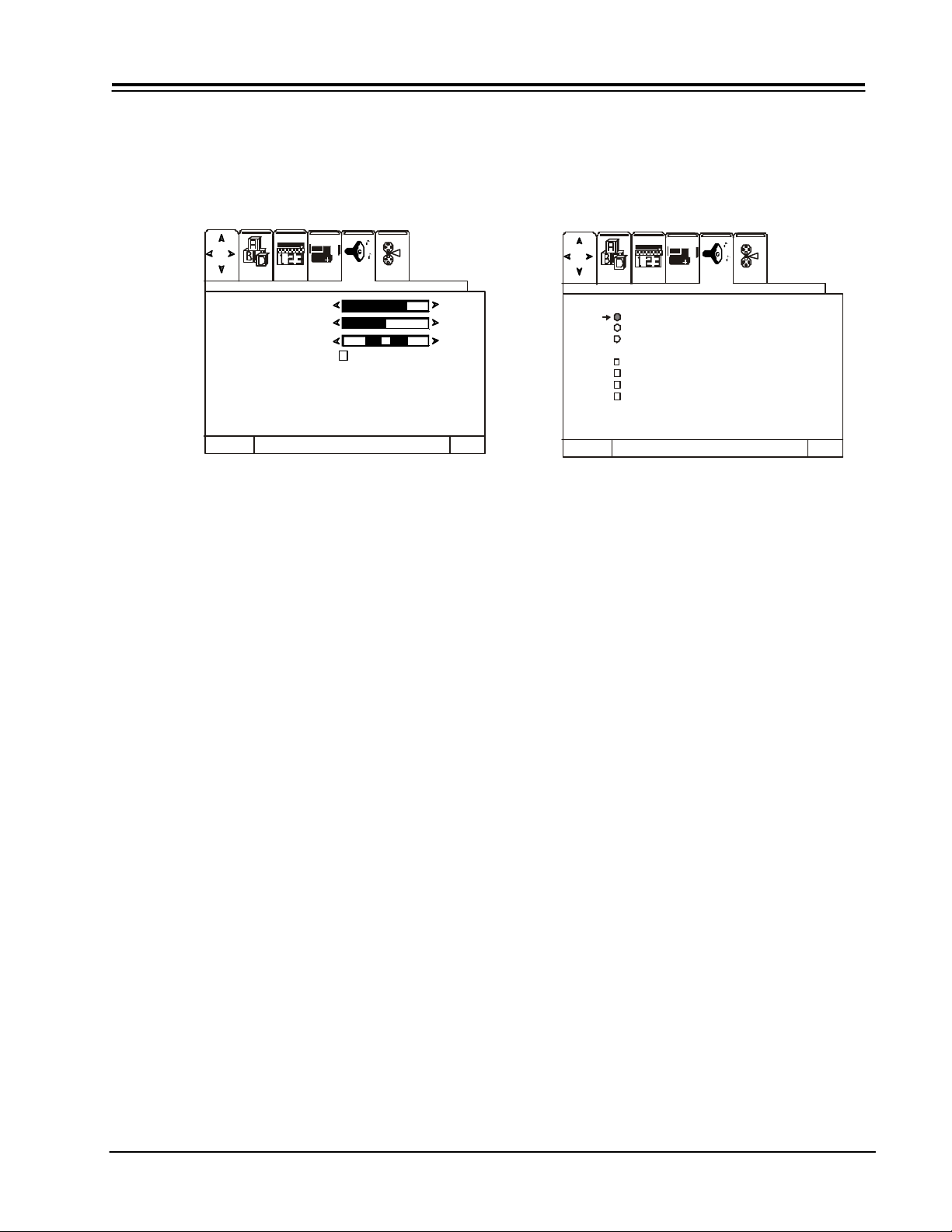

CUSTOMIZED VIDEO AND AUDIO ADJUSTMENTS

THEATER

MENU

TO EXIT

THEATER

MENU

Select AUDIO SETTINGS to adjust the AUDIO to your preference and improve the sound quality.

VIDEO

SETUP SPECIAL

AUDIO

VIDEOSETUP SPECIAL AUDIO

BASS 72 %

TREBLE

BALANCE

RESET

ADVANCED

SETTINGS

TO MENU BAR

50%

QUIT

Note: If BASS is selected you are adjusting BASS.

The additional menu items, TREBLE and

BALANCE can be selected and adjusted in

the same manner

BASS

This function controls the Low Frequency

audio to all speakers.

TREBLE

This function controls the High Frequency

audio to all speakers.

Advanced Settings

Stereo

Mono

Second Audio Programming

Internal Speakers

Auto Noise Control

Loudness

SoundRite

TO MENU BAR TO EXIT QUIT

Use Cursor Up or Down to highlight the

function to be adjusted.

Press Cursor Left or Right to adjust function.

Press QUIT to exit menu.

BALANCE

This function will control the left to right

balance of the TV internal speakers and the

VARIBLE AUDIO OUT output.

RESET

When RESET is selected, press CURSOR RIGHT

to return audio adjustments to factory preset

conditions.

PV151 1-9 PROJO

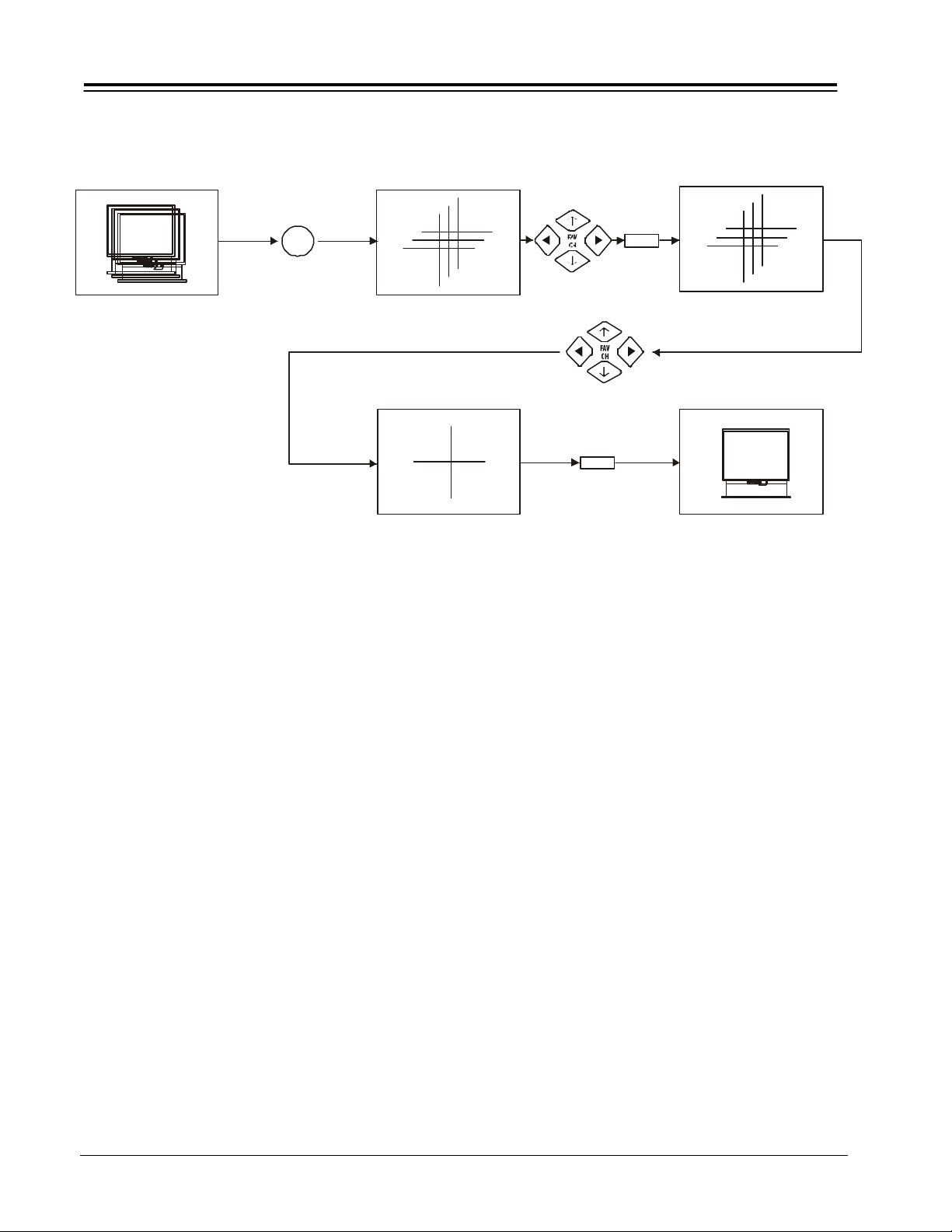

ZP94/95 CUSTOMER CONVERGENCE ADJUSTMENT

Flashes Blue

MENU

Flashes Red

Digital

Setup

MENU

CONVERGENCE ADJUSTMENT (DIGITAL SETUP)

To enter this adjustnment mode, press the front panel

DIGITAL SETUP button.

Press the ARROW buttons on the remote control to move

the displayed color up, down, left, or right. (Press the

QUIT button to toggle between red and blue)

Press MENU on the remote control to change the color

you want to adjust.

Press the front panel DIGITAL SETUP button or the

remote comtrol MENU button when adjustment is done.

This will save your adjustment into memory.

Note:

Only a momentary press of the DGITAL SETUP button is

necessary to enter DIGITAL SETUP convergence adjustment mode.

Do not press the DIGITAL SETUP button for more than

three seconds.

To save your adjustment data into memory, press the

front panel DIGITAL SETUP button or the remote

control MENU button. If you do NOT wish to save your

adjustment data into memory, turn the TV off. When

the TV is ON again, your old convergence data will be

restored.

To exit this function, press DIGITAL SETUP on the front

panel of your Entertainment machine.

PV151 1-10 PROJO

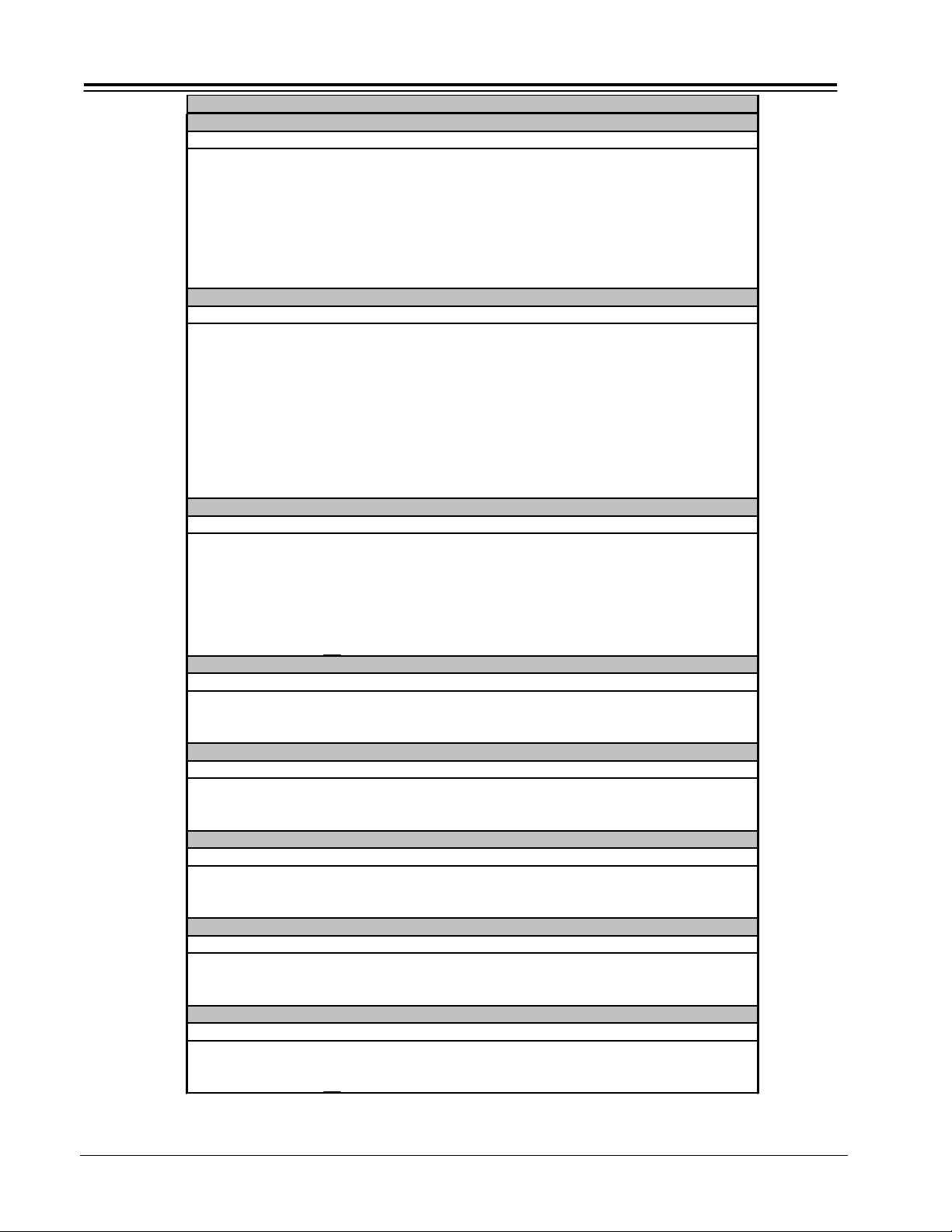

SERVICE MENUES

TA1300 31.5khz Mode

TA1300 33.75khz Mode

ITEM SETTING RANGE DESCRIPTION

P01 ZP94/95 *Non-Adjustable Data

ADJUST MODE Version 704

SUB BRT 3C-C3 Sub Brightness

SERVICE 0 SERVICE

DEF RESET 0

V/P RESET 0

3DYC RESET 0

FLEX RESET 0

DSP RESET 0

CCD RESET 0

FACT RESET 0 Resets Memory

MEMORY INITIAL 0 Resets Memory

P02 ZP94/95

ADJUST MODE

315

H POSI 40 00-7F Horizontal Position

FLEX CONT

VD POS 3F 00-7F Vertical Position

UPD64081

DYGA 09 00-0F Y Motion Detection Gain

DCGA 06 00-0F Chroma Motion Detection Gain

VAPGA 00 00-07 Vertical Aperture Controle Gain

VAPIN 00 00-1F Vertical Aperture Controle Invert

YHCOR 00 00-01 Y Output High Frequency Coring

P02 ZP94/95

ADJUST MODE

3375

H POSI 40 00-7F Horizontal Position

FLEX CONT

VD POS 3F 00-7F Vertical Position

UPD64081

DYGA 09 00-0F Y Motion Detection Gain

DCGA 06 00-0F Chroma Motion Detection Gain

VAPGA 00 00-07 Vertical Aperture Controle Gain

VAPIN 00 00-1F Vertical Aperture Controle Invert

YHCOR 00 00-01 Y Output High Frequency Coring

P03 ZP94/95

ADJUST MODE

TA1270-M

TINT (TV) 3C 00-7F Main NTSC Tint

TOFFO (TV) 00 00-07 Main NTSC TOF fO Peak Frequency Switch

TOFQ (TV) 00 00-07 Main NTSC TOFQ Switch

SUB CNT 0F 00-1F Main NTSC Contrast

SUB CL 1B 00-1F Main NTSC Color

P03 ZP94/95

ADJUST MODE

TA1270-S

TINT (TV) 3C 00-7F Main NTSC Tint

TOFFO (TV) 00 00-07 Main NTSC TOF fO Peak Frequency Switch

TOFQ (TV) 00 00-07 Main NTSC TOFQ Switch

SUB CNT 0F 00-1F Main NTSC Contrast

SUB CLR 1B 00-1F Main NTSC Color

PV152 2-1 PROJO

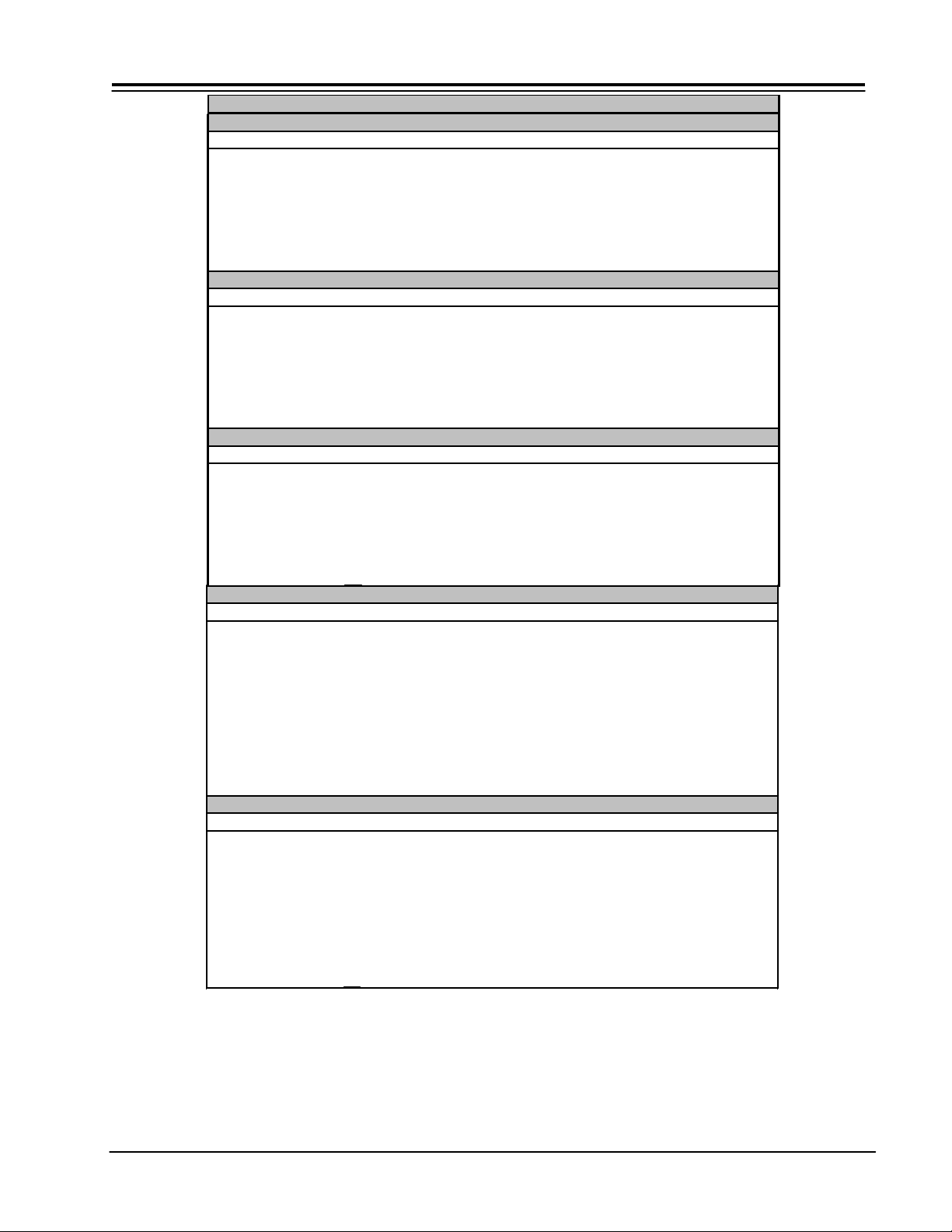

SERVICE MENUES CONT.

ITEM SETTING RANGE DESCRIPTION

P04 ZP94/95 *Non-Adjustable Data

FLEX CONT NTSC

39 HHPF1 00 00-01 Characteristic Switch 0 = Low Frequency, 1 = High Frequency

41 V-CRG 00 00-03 Vertical Enhance Coring

42 H-CRG 00 00-03 Horizontal Enhance Coring

43 V-ENH 00 00-03 Vertical Enhance

44 H-ENH 00 00-03 Horizontal Enhance

96 YVHENH 0B 00-1F Y Vertical & Horizontal Enhance Gain

100 CVHENH 12 00-1F Color Vertical & Horizontal Enhance Gain

P04 ZP94/95

FLEX CONT ATSC (480i, 480p, 1080i, 720p)

39 HHPF1 00 00-01 Characteristic Switch 0 = Low Frequency, 1 = High Frequency

41 V-CRG 00 00-03 Vertical Enhance Coring

42 H-CRG 00 00-03 Horizontal Enhance Coring

43 V-ENH 00 00-03 Vertical Enhance

44 H-ENH 00 00-03 Horizontal Enhance

96 YVHENH (720p) 00 (10) 00-1F Y Vertical & Horizontal Enhance Gain

100 CVHENH 12 00-1F Color Vertical & Horizontal Enhance Gain

P05 ZP94/95

FLEX CONT NTSC

71 YV-ENH 00 00-0F Y Vertical Enhance Gain

79 CV-ENH 00 00-0F Color Vertical Enhance Gain

87 YH-ENH 07 00-0F Y Horizontal Enhance Gain

94 CH-ENH 0F 00-0F Color Horizontal Enhance Gain

66 YV-DSB 00 00-03 Y Vertical Dynamic Shoot Balance Gain

75 CV-DSB 00 00-03 Color Vertical Dynamic Shoot Balance Gain

82 YH-DSB 00 00-03 Y Horizontal Dynamic Shoot Balance Gain

90 CH-DSB 00 00-03 Color Horizontal Dynamic Shoot Balance Gain

69 YV-CLP 00 00-0F Y Vertical Enhance Clip Offset

84 YH-CLP 00 00-0F Y Horizontal Enhance Clip Offset

P05 ZP94/95

FLEX CONT ATSC (480i, 480p, 1080i, 720p)

71 YV-ENH 00 00-0F Y Vertical Enhance Gain

79 CV-ENH 00 00-0F Color Vertical Enhance Gain

87 YH-ENH (1080i) 07 (00) 00-0F Y Horizontal Enhance Gain

94 CH-ENH 0F 00-0F Color Horizontal Enhance Gain

66 YV-DSB 00 00-03 Y Vertical Dynamic Shoot Balance Gain

75 CV-DSB 00 00-03 Color Vertical Dynamic Shoot Balance Gain

82 YH-DSB 00 00-03 Y Horizontal Dynamic Shoot Balance Gain

90 CH-DSB 00 00-03 Color Horizontal Dynamic Shoot Balance Gain

69 YV-CLP 00 00-0F Y Vertical Enhance Clip Offset

84 YH-CLP 00 00-0F Y Horizontal Enhance Clip Offset

P06 ZP94/95

FLEX CONT NTSC

97 YV-NLP 00 00-3F Y Vertical Nonlinear Peaking

98 YH-NLP 0A 00-3F Y Horizontal Nonlinear Peaking

101 Y-LMT FF 00-FF Y Amplitude Limit

83 YH-FRQ 00 00-03 Y Horizontal HPF Peak Frequency Switch

91 CH-FRQ 02 00-03 Color Horizontal HPF Peak Frequency Switch

70 YV-LTI 00 00-01 Y Vertical Enhance Clip 0 = Enhance, 1 = LTI

78 CV-CTI 00 00-01 Color Vertical Enhance Clip 0 = CTI, 1 = Enhance

86 YH-LTI 01 00-01 Y Horizontal Enhance Clip 0 = Enhance, 1 = LTI

93 CH-CTI 01 00-01 Color Horizontal Enhance Clip 0 = CTI, 1 = Enhance

PV152 2-2 PROJO

SERVICE MENUES CONT.

ITEM SETTING RANGE DESCRIPTION

P06 ZP94/95 *Non-Adjustable Data

FLEX CONT ATSC (480i, 480p, 1080i, 720p)

97 YV-NLP 00 00-3F Y Vertical Nonlinear Peaking

98 YH-NLP 0A 00-3F Y Horizontal Nonlinear Peaking

101 Y-LMT FF 00-FF Y Amplitude Limit

83 YH-FRQ 00 00-03 Y Horizontal HPF Peak Frequency Switch

91 CH-FRQ 02 00-03 Color Horizontal HPF Peak Frequency Switch

70 YV-LTI 00 00-01 Y Vertical Enhance Clip 0 = Enhance, 1 = LTI

78 CV-CTI 00 00-01 Color Vertical Enhance Clip 0 = CTI, 1 = Enhance

86 YH-LTI 01 00-01 Y Horizontal Enhance Clip 0 = Enhance, 1 = LTI

93 CH-CTI 01 00-01 Color Horizontal Enhance Clip 0 = CTI, 1 = Enhance

P07 ZP94/95

FLEX CONT NTSC

69 YVDSBC 00 00-07 Y Vertical Dynamic Shoot Balance Coring Amplitude

77 CVDSBC 00 00-07 Color Vertical Dynamic Shoot Balance Coring Amplitude

85 YHDSBC 00 00-07 Y Horizontal Dynamic Shoot Balance Coring Amplitude

92 CHDSBC 00 00-07 Color Horizontal Dynamic Shoot Balance Coring Amplitude

95 Y-CRG 00 00-07 Y Coring Amplitude

99 C-CRG 00 00-07 Color Coring Amplitude

64 YNR-IN 04 00-07 YNR Input Level Gain

73 CNR-IN 04 00-07 CNR Input Level Gain

80 YNRPAS 00 00-07 YNR Passage Level Limit

88 CNRPAS 02 00-07 CNR Passage Level Limit

P07 ZP94/95

FLEX CONT ATSC (480i, 480p, 1080i, 720p)

69 YVDSBC 00 00-07 Y Vertical Dynamic Shoot Balance Coring Amplitude

77 CVDSBC 00 00-07 Color Vertical Dynamic Shoot Balance Coring Amplitude

85 YHDSBC 00 00-07 Y Horizontal Dynamic Shoot Balance Coring Amplitude

92 CHDSBC 00 00-07 Color Horizontal Dynamic Shoot Balance Coring Amplitude

95 Y-CRG 00 00-07 Y Coring Amplitude

99 C-CRG 00 00-07 Color Coring Amplitude

64 YNR-IN 04 00-07 YNR Input Level Gain

73 CNR-IN 04 00-07 CNR Input Level Gain

80 YNRPAS 00 00-07 YNR Passage Level Limit

88 CNRPAS 02 00-07 CNR Passage Level Limit

P08 ZP94/95

FLEX CONT NTSC/ATSC (480i, 480p, 1080i, 720p)

65 YNRRDC 00 00-07 YNR Reducing Gain

74 CNRRDC 00 00-07 CNR Reducing Gain

67 YNR-DC 00 00-03 YNR DC Shift

76 CNR-DC 00 00-03 Color DC Shift

81 YNR-O 00 00-07 YNR 0 Point

89 CNR-O 00 00-0F CNR 0 Point

45 CB-BLK 07 00-0F CB Blanking Level Offset

46 CR-BLK 07 00-0F CR Blanking Level Offset

27 FRMBRT* 60 00-7F Y Frame Bright

102 CLPOUT 7F 00-FF Clamp Output Offset

P09 ZP94/95

FLEX CONT NTSC/ATSC

10 MPLL-S 0F 00-1F Main PLL Vertical Mask Pulse Start Position Offset

17 SPLL-S 0F 00-1F Sub PLL Vertical Mask Pulse Start Position Offset

12 MPLL-E 0F 00-1F Main PLL Vertical Mask Pulse End Position Offset

19 SPLL-E 0F 00-1F Sub PLL Vertical Mask Pulse End Position Offset

11 MVW-PH 05 00-07 Main Vertical Write Input Horizontal Phase Adjustment

18 SVW-PH 05 00-07 Sub Vertical Write Input Horizontal Phase Adjustment

14 MHS-HP 0F 00-1F Main Horizontal Sync Horizontal Phase Offset

21 SHS-HP 0F 00-1F Sub Horizonyal Sync Horizontal Phase Offset

13 MY-CLP 03 00-07 Main Y Clamp Refrence Offset

20 SY-CLP 03 00-07 Sub Y Clamp Refrence Offset

PV152 2-3 PROJO

SERVICE MENUES CONT.

ITEM SETTING RANGE DESCRIPTION

P10 ZP94/95 *Non-Adjustable Data

FLEX CONT NTSC/ATSC (480i, 480p, 1080i, 720p)

23 V-POS 3F 00-3F Wide Vertical Position

24 V-SIZ 7F 00-FF Wide Vertical Size

50 HD-POS 3F 00-7F HD Position Offset

48 VBLK-T 7F 00-FF Vertical Blanking Top Position Offset

49 VBLK-B 7F 00-FF Vertical Blanking Bottom Position Offset

51 HBLK-R 7F 00-FF Horizontal Blanking Right Position Offset

52 HBLK-L 7F 00-FF Horizontal Blanking Left Position Offset

40 READ F 10 00-3F A/D Converter Clock Sampling Phase

P11 ZP94/95

FLEX CONT NTSC/ATSC (480i, 480p, 1080i, 720p)

35 FRMTOP-2 07 00-0F Frame Top Position Offset (2Pix)

FRMTOP-L* 07 00-0F Frame Top Position Offset (Letter)

36 FRMBTM-2 07 00-0F Frame Bottom Position Offset (2Pix)

FRMBTM-L* 07 00-0F Frame Bottom Position Offset (Letter)

37 FRMRGT 07 00-0F Frame Right Position Offset

38 FRMLFT 07 00-0F Frame Left Position Offset

59 BS-TOP 07 00-0F Black Strech Stop Pulse Top Position Offset

60 BS-BTM 07 00-0F Black Strech Stop Pulse Bottom Position Offset

61 BS-RGT 07 00-0F Black Strech Stop Pulse Right Position Offset

62 BS-LFT 07 00-0F Black Strech Stop Pulse Left Position Offset

P12 ZP94/95

FLEX CONT

120 TV/CINE 01 00-01 TV Cinema Detection

121 T/C DET 07 00-0F TV Cinema Detection Vertical Gate Area Start Position

122 T/C UNL 01 00-07 TV Cinema Detection Unlock Protection Count

123 T/C LCK 03 00-0F TV Cinema Detection Lock Protection Count

126 T/C ARE 05 00-FF TV Cinema Detection Motion Area Border Volume Offset

127 T/C CBR 07 00-0F TV Cinema Detection Color 2 Bit Border Volume Offset

128 T/C YBR 07 00-0F TV Cinema Detection Y 2 Bit Border Volume

P13 ZP94/95

TA1298 NTSC

SHARP 0C 00-1F Sharpness (Center Adjustment)

APACON 06 00-07 APACON Peak fO

YNR 00 00-03 YNR

P13 ZP94/95

TA1298 480I

SHARP 0A 00-1F Sharpness (Center Adjustment)

APACON 06 00-07 APACON Peak fO

YNR 00 00-03 YNR

P13 ZP94/95

TA1298 480P

SHARP 0A 00-1F Sharpness (Center Adjustment)

APACON 06 00-07 APACON Peak fO

YNR 00 00-03 YNR

P13 ZP94/95

TA1298 1080I

SHARP 07 00-1F Sharpness (Center Adjustment)

APACON 05 00-07 APACON Peak fO

YNR 00 00-03 YNR

P13 ZP94/95

TA1298 720P

SHARP 0A 00-1F Sharpness (Center Adjustment)

APACON 06 00-07 APACON Peak fO

YNR 00 00-03 YNR

PV152 2-4 PROJO

SERVICE MENUES CONT.

ITEM SETTING RANGE DESCRIPTION

P14 ZP94/95 *Non-Adjustable Data

TA1298 NTSC

COLOR 40 00-7F Color (Center Adjustment)

TINT 45 00-7F Tint (Center Adjustment)

R-Y PH 02 00-03 R-Y Phase

R/B GA 01 00-03 R/B Gain

G-Y PH 00 00-03 G-Y Phase

G/B GA 00 00-03 G/B Gain

COLOR SYSTEM 00 00-07 COLOR SYSTEM

P14 ZP94/95

TA1298 SDTV

COLOR 4F 00-7F Color (Center Adjustment)

TINT 3B 00-7F Tint (Center Adjustment)

R-Y PH 02 00-03 R-Y Phase

R/B GA 02 00-03 R/B Gain

G-Y PH 01 00-03 G-Y Phase

G/B GA 00 00-03 G/B Gain

COLOR SYSTEM 01 00-07 COLOR SYSTEM

P14 ZP94/95

TA1298 HDTV

COLOR 40 00-7F Color (Center Adjustment)

TINT 43 00-7F Tint (Center Adjustment)

R-Y PH 00 00-03 R-Y Phase

R/B GA 02 00-03 R/B Gain

G-Y PH 02 00-03 G-Y Phase

G/B GA 00 00-03 G/B Gain

COLOR SYSTEM 01 00-07 COLOR SYSTEM

P15 ZP94/95

TA1298

RGB BRT 50 00-7F RGB Brightness

RGB CNT 50 00-7F RGB Contrast

G DRV (W) 39 00-7F Green Drive (WARM)

B DRV (W) 2D 00-7F Blue Drive (WARM)

SUB CLR 10 00-1F Sub Color (Demodulator)

SUB CNT 1F 00-1F Main NTSC Contrast

VSM PH 05 00-07 VM Phase

VSM GA 00 00-03 VM Gain

OS ACL 01 00-01 OSD Auto Contrast Limiter Switch

RGB ACL 00 00-01 RGB Auto Contrast Limiter Switch

P16 ZP94/95

TA1298

CLR G 00 00-03 Color G Corection Piont

CLT 00 00-01 Color Limiter Level

YOUT G 00 00-01 Y G (After Contrast) Switch

YG PNT 00 00-01 Y G Point

S TRK 00 00-03 Sharpness Tracking

RGBG 00 00-01 RGB Switch

DC PNT 00 00-07 DC Restoration Point

DC RAT 00 00-07 DC Restoration Rate

DC LMT 00 00-03 DC Restoration Limit Point

PV152 2-5 PROJO

SERVICE MENUES CONT.

ITEM SETTING RANGE DESCRIPTION

P17 ZP94/95 *Non-Adjustable Data

TA1298

BSP 03 00-07 Black Strech Point

APL/BS 00 00-03 APL / Black Strech Point

B COR 01 00-01 Black Level Correction

B GA 00 00-01 Black Strech Gain

B DET 00 00-01 Black Detect Level

DABL PN 00 00-07 Dynamic ABL Detection Point

DABL GA 07 00-07 Dynamic ABL Gain

ABL PN 07 00-07 ABL Detection Point

ABL GA 05 00-07 ABL Gain

P18 ZP94/95

V CHIP RATING

POLLING 0F 00-0F 0

TIMEOUT 05 00-0F 0

STATUS 02 00-0F 0

AFC/CLOCK TEST

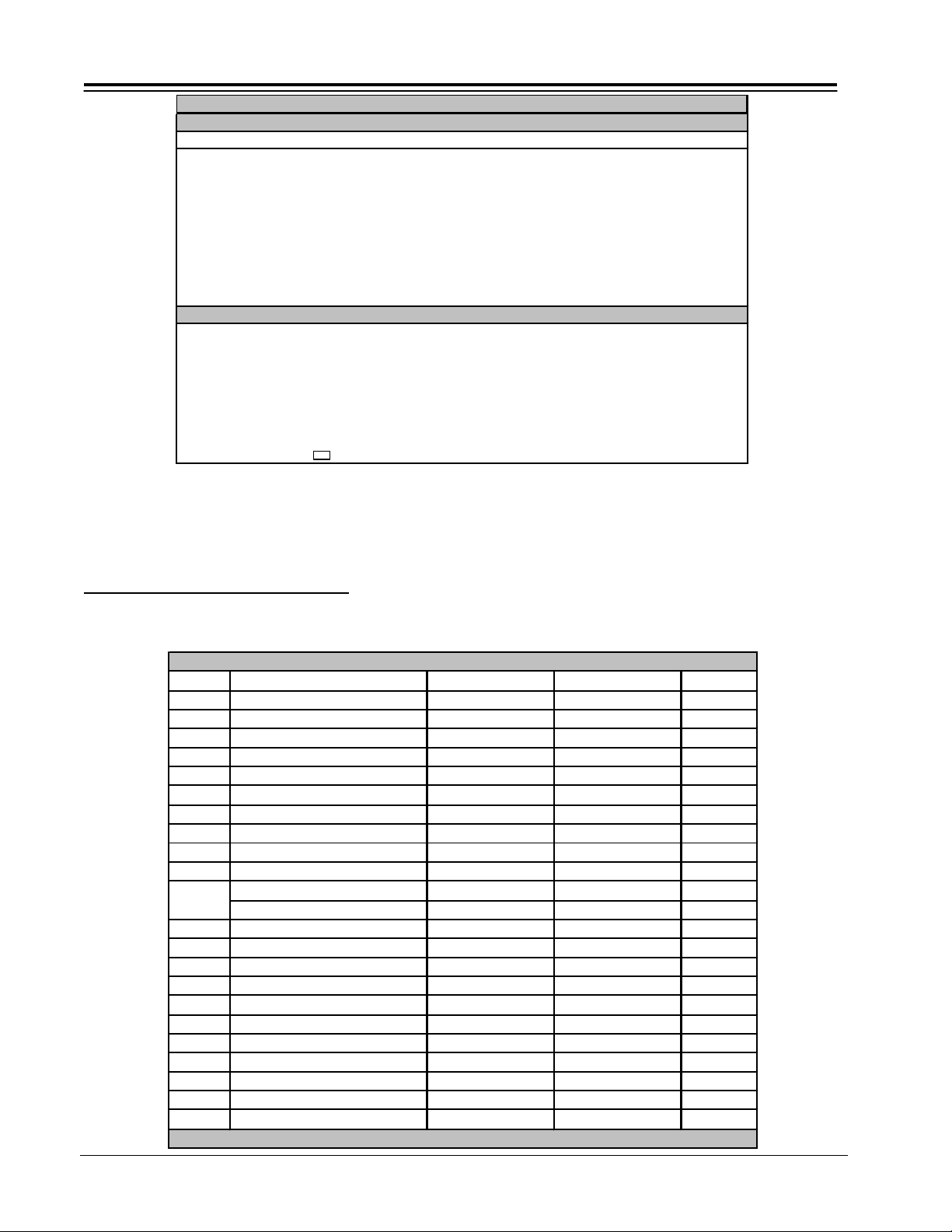

SERVICE ADJUSTMENTS ORDER

SERVICE ADJUSTMENT PROCEDURE ORDER

The following is the suggested order for adjustment

procedures.

ZP 94/95 SERVICE ADJUSTMENT ORDER “PREHEAT BEFORE BEGINNING”

Order Adjustment Item Screen Format Signal DCU Data

Pre HEAT N/A NTSC N/A

1 Cut Off Progressive NTSC

2 Pre Focus Lens and Static Progressive NTSC

3 DCU Phase Data Setting Progressive NTSC

4 DCU Phase Data Setting HD 2.14H

5 Horz. Position Adj. (Coarse) Progressive NTSC

6 Horz. Position Adj. (Coarse) HD 2.14H

7 Raster Tilt Progressive NTSC CLEAR

8 Beam Alignment Progressive NTSC

9 Raster Position Progressive NTSC CLEAR

Horz. Size Adjust Progressive NTSC CLEAR

10

Horz. Size Adjust HD 2.14 CLEAR

11 Vertical Size Adjust Progressive NTSC CLEAR

12 Beam Form Progressive NTSC

13 Lens Focus Adjust Progressive NTSC

14 Static Focus Adjust Progressive NTSC

15 Blue Defocus Progressive NTSC

16 White Balance Adjustment Progressive NTSC

17 Sub Brightness Adjustment Progressive NTSC Color Bar

18 Horz. Position Adjustment Progressive NTSC

19 Horz. Position Adjustment HD 2.14H

20 Convergence Alignment Progressive NTSC

21 Convergence Alignment HD 2.14H

It is necessary to follow the order when performing an alignment on the ZP 94/95 chassis.

CLEAR to start

PV152 2-6 PROJO

Loading...

Loading...