Modular Micro Data Centre Solutions

Installation Manual

zelladc.com

Table of Contents

1. Introduction 3

2. Safety Instructions 4

3. Power Connection 5

4. Access Control 8

5. Single & Dual Cooling System Commissioning Steps 9

6. PDView Access 15

7. Pyrorack Commissioning & User Guide 18

8. Start-up & Ready for Population 23

1. Introduction

A Micro Data Centre is a stand-alone housing unit that replicates

all of the cooling, security and power capabilities of a traditional

data centre on a much smaller, lower cost scale. It miniaturizes the

data centre into the size of an average refrigerator, offering its own

cooling and power capabilities, signicantly reducing operational

and energy costs by 30-60%, and on-premise IT footprint. Moreover,

it allows for portability and can be moved from location to location

and expanded to a set of “modular’’ data centres as business

grows. Micro Data Centres are the perfect solution for companies,

which must house critical infrastructure in a quiet ofce amongst

personnel through to infrastructure-poor remote locations.

This guide needs to be followed according to the steps of

installation to ensure the most effective installation is achieved.

2. Safety Instructions

2.1 Overview

This manual contains instructions relating to safety, installation,

operation, maintenance and warranty of this product and its

components.

Please keep this manual in a safe place for future references.

Handling Safety

Do not lift heavy loads without assistance.

Important safety note

z Caution needs to be taken when removing the

side panels of the Micro Data Centre, in particular

when dealing with the 38U as they are heavy.

We recommend a 2 man lift when removing and

re-installing the side panels.

<18 kg

32–55 kg

18–32 kg

>55 kg

z ALWAYS ENSURE the bottom brackets are locked in

and that the top pins are COMPLETELY slotted in.

z Don’t turn on the cooling system RCD until the

the wiring is completed between the Zella Pro and

external condenser.

3. Power Connection

3.1 Power Supply Requirements

Important note

DEPENDING ON SIZE AND MODEL. Power consumption can vary

from less than 10 amps and up to 60 amps depending on load.

When arranging the on-premise power supply with the landlord

or power company make sure you structure your energy bill

based on power used and not based on a xed power supply.

For security purposes we recommend a hardwired connection

directly into power source rather than a plug.

Max power supply to Zella Pro can either be 10, 32 & 60 amps

(220v – 240v / 50/60hz) depending on the model

WE RECOMMEND THAT INSTALLATION SHOULD ONLY

BE CARRIED OUT BY SUITABLY QUALIFIED ELECTRICAL

CONTRACTOR WITH THE NECESSARY TRAINING.

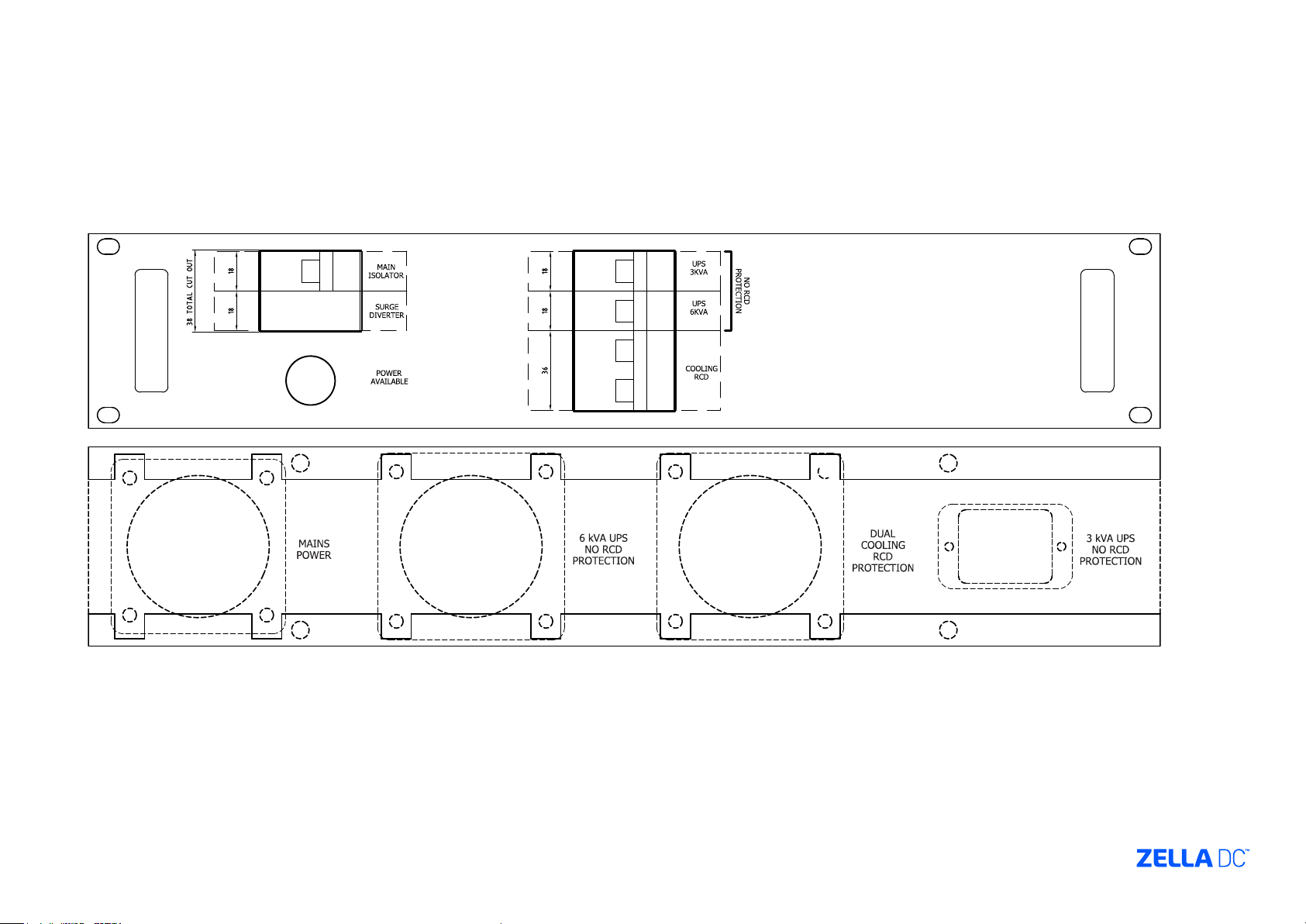

3.2 Switchboard Operation

Following the connection to mains power

DEPENDING ON MODEL THE SWITCHBOARD LAYOUT AND

CONFIGURATION IS DIFFERENT. (SEE LAYOUT DIAGRAMS –

pages 6-9)

Start Up Procedure

z Switch Mains Isolator switch to the ON position

z Very Important - Leave the Cooling System circuit breaker in

the OFF position – Electrical Hazard

z Please Note: If hardwiring 6 or 8KVA UPS – LEAVE IN OFF

POSITION until UPS and switchboard have been connected

by electrician – Electrical Hazard. (See UPS Manual)

z Switch UPS to the ON position once connected

z Important - (Leave the RCD cooling and Cooling system for

the air conditioner contractor – Electrical Hazard)

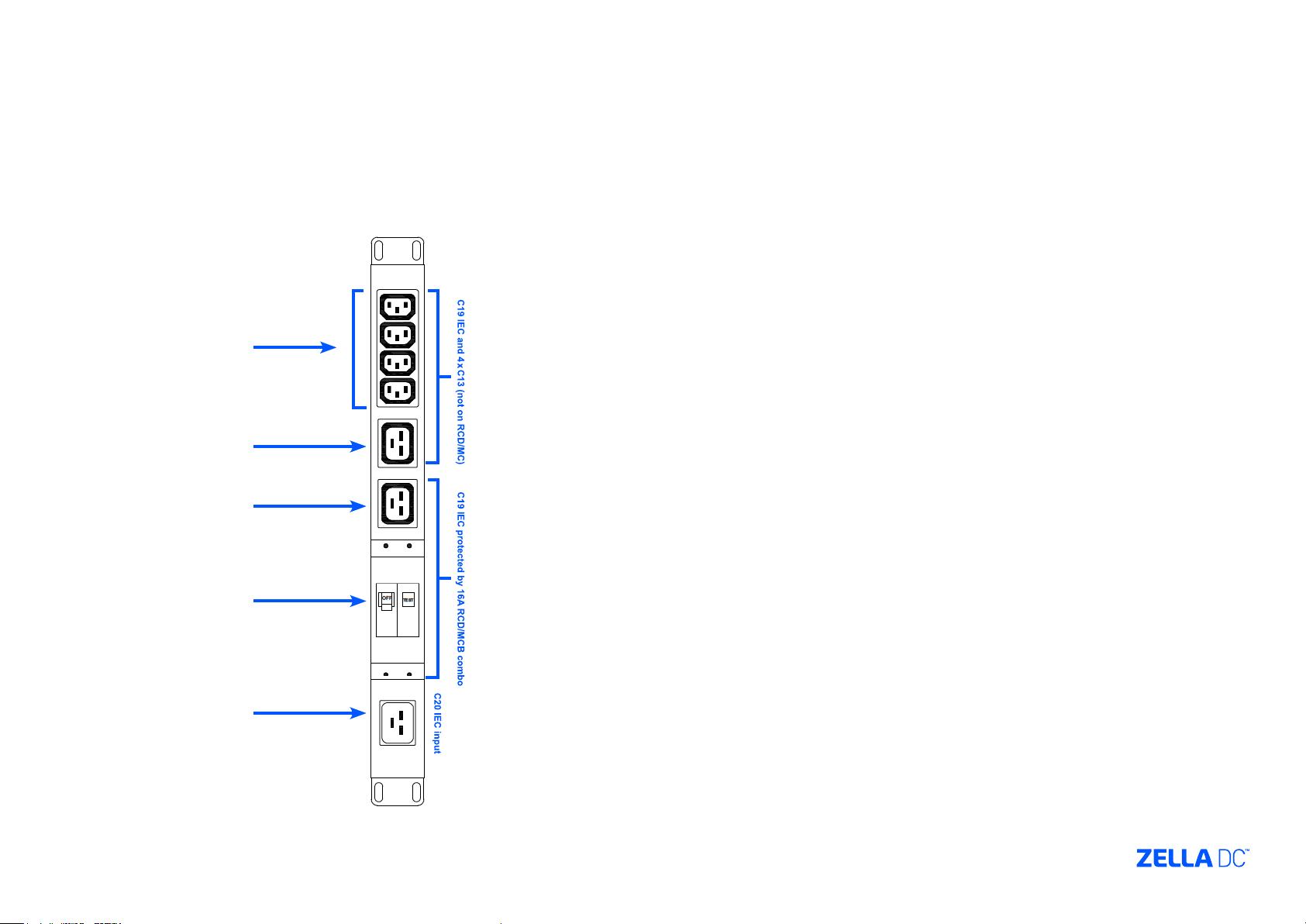

3. Power Connection

3.3 Power Supply diagram to PDU switchboard

Non-monitored sockets

UPS Power

Cooling system

Cooling system

RCD

Mains power

3. Power Connection

3.4 Switchboard layout

Front View

Rear View

4. Access Control

4.1 Metal Key Pad Operation

The default code for the doors are pre-set in the factory

as follows:

z Front door - 2580

z Back door – push button

FOR FURTHER INSTRUCTION TO PROGRAM DOOR

CODES. SEE USER MANUAL

Front panel description

Mode

Indicator

Door

Indicator

Antenna

(AC-Q42 & AC-Q44 only)

3 x 4

Matrix

Keypad

4.2 Biometric / Card Reader

The Zella Pro is supplied with a default card which will

open the front door. The rear door is opened by the push

button located inside the Zella Pro.

See user manual for programming options. Use card

reader until you are ready for biometric access mode.

Card reader

Fingerprint reader

4.3 L.E.D. Key Pad Operation

The default code for the doors are pre-set in the factory

as follows:

z Front door – 2580#

z Back door – push button

FOR FURTHER INSTRUCTION TO PROGRAM DOOR

CODES. SEE USER MANUAL

Key Pad

Card reader

Bell Button

(with BL-D40)

Case Screw

5. Single & Dual Cooling System Commissioning Steps

Important Safety Warning

BEFORE PLUGGING THE EXTERNAL CONDENSER POWER CABLES

(ORANGE AND GREY) TO THE BACK OF THE ZELLA PRO. ENSURE

THE COOLING SYSTEM RCD IS OFF ON THE BASE MOUNTED

SWITCHBOARD

You also have the option to unplug the cooling system/s power

cables from the back of the switchboard during the commissioning

process

PLEASE ENSURE THERE IS POWER TO THE Zella Pro

(SWITCHBOARD) BEFORE COMMISSIONING THE COOLING SYSTEM

5.1 Condenser

Depending on the model and cooling capacity the condenser

maximum distance can vary between 20 and 30 meters. The Zella

Pro is supplied with relevant cable length (3 core orange output

to condenser & 4 core grey cable. The condenser draws its power

from the Zella Pro. The condenser size and weight can also vary

depending on model and cooling capacity. The condenser will be

positioned either on the outer wall of the building or on the roof.

5.3 Wiring

The Zella Pro is supplied with all the cables (orange and grey)

which is pre-coiled and ready to be run with the copper piping

during the commissioning process. The pre-coiled condenser

cables are located inside the Zella Pro.

CONTRACTORS TO ENSURE BOTH ORANGE AND GREY CABLES

ARE LOCKED BY TURNING THE YELLOW DISK ON THE SIDE OF THE

CABLE PLUGS WITH A SCREW DRIVER. THE AIR CONDITIONING

CONTRACTOR MUST SUPPLY THEIR OWN COPPER PIPING.

WIRING TABLE (WHITE CABLE)

1 - Live Red / Brown

2 - Neutral Blue / Black

3 - Signal White

Green / Yellow Earth / Ground

5.2 Commissioning

Once the Zella Pro has been positioned in its proposed location and

connected to power the air conditioning contractor can commission

the cooling system.

Only once the air conditioning contractor has Connected wires to

the condenser and plugged the grey and orange cable into the Zella

Pro, can the cooling be turned on.

ENSURE THE COOLING SYSTEM PLUG IS PLUGGED INTO THE

CORRECT POWER SOCKET ON THE SWITCHBOARD

WIRING TABLE (ORANGE CABLE)

1 - Live Red / Brown

2 - Neutral Blue / Black

Green / Yellow Earth / Ground

5. Single & Dual Cooling System Commissioning Steps

5.3 Wiring cont.

Electrical Hazard – Ensure cooling system is in the OFF position on

Zella Pro base mounted switchboard and orange cooling system

plug is unplugged from rear of switchboard

Grey cable termination in condenser

(supplies power back to the Zella Pro)

(4 core cable)

1 – Brown

2 – Blue

3 – White

- Green / Earth

Orange cable termination in condenser

(supplies power to the external condenser)

(3 core cable)

L – Red

N – Blue

- Green / Earth

5. Single & Dual Cooling System Commissioning Steps

5.3 Wiring cont.

PLEASE NOTE: WHEN PLUGGING THE CABLE CONNECTORS, YOU SHOULD HEAR A CLICK TO CONFIRM CONTACT. AFTER INSERTING THE PLUG ENSURE

BOTH ORANGE AND GREY CABLES ARE LOCKED BY TURNING THE YELLOW DISK ON THE SIDE OF THE CABLE CONNECTOR WITH A SCREW DRIVER.

5. Single & Dual Cooling System Commissioning Steps

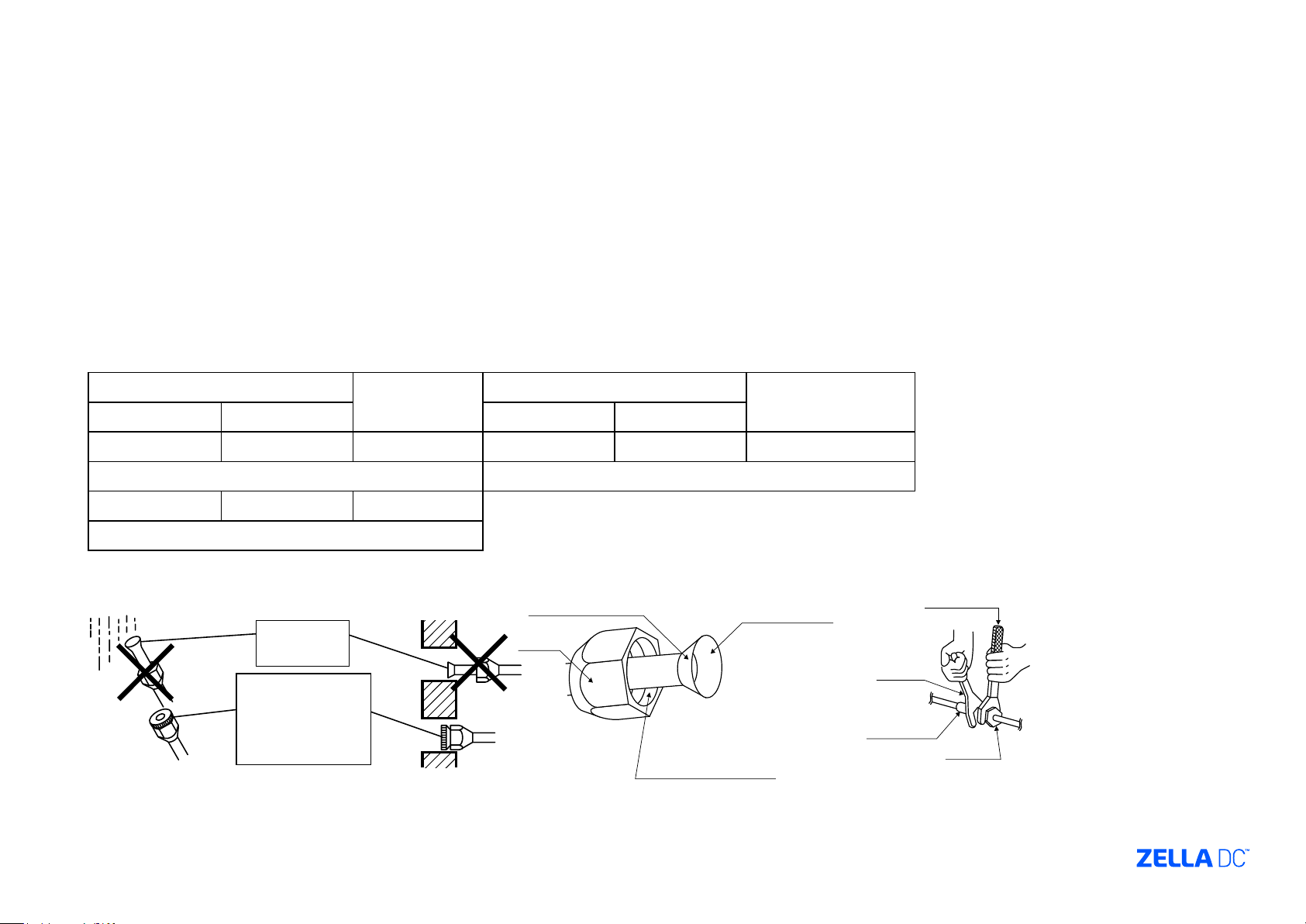

5.4 Copper Piping (refer to handout in Zella Pro)

1. Cut the pipe ends with a pipe cutter

2. Remove burrs with the cut surface facing downwards

so that the chips do not enter the pipe

3. Put the are nuts on pipe

4. Flare the pipe

Gas side

Liquid side

20/25/35 class 46 class 20/25/35 class 46 class

5. Check that the aring is properly made

6. Never use old or pre-used pipes

7. Do not use mineral oil on ared part

8. Incomplete aring may cause gas leakage

9. Use are nut xed to unit

Gas pipe thermal insulation

Liquid pipe thermal

insulation

O.D. 9.5mm O.D. 12.7mm O.D. 6.4mm I.D. 12-15mm I.D. 14-16mm I.D. 8-10mm

Minimum bend radius Thickness 10mm Min.

30mm or more 40mm or more 30mm or more

Thickness 0.8mm (C1220T-O)

Apply Oil Tighten

Rain

Be sure to

place a cap.

If no are cap is

available, cover

the are mouth

with tape to keep

dirt or water out.

Do not apply refrigeration oil

to the outer surface.

Wall

Flare nut

Do not apply refrigeration

oil to the are nut avoid

tightening with over torque.

Apply refrigeration oil to the

inner surface of the are.

10. Use torque wrenches when tightening the are nuts

11. Protect ends from dust

12. Use pipe bender

13. NEVER use pipes thinner than 0.8mm even when it is

available on the market.

Torque wrench

Spanner

Piping union

Flare nut

Please note: Pipe size is 9.5mm for cooling capacity 2kw up to 3.5kw (See enclosed manual with condenser)

5. Single & Dual Cooling System Commissioning Steps

<1+=/">%?;-<@

7-*5%,>139,*-.#*$+''#0-*,#--%0:,64*

J70*-.%,*%11+,-'3-%)02*#3$.*,#$-%)0*%,*

,.)=0*=%-.*311*%-,*5%,>139,*)0*8)'*-.#*

>+'>),#*)8*#@>1303-%)06K

A9B(9,4A:,9%

"CD6+*#$.*%56**&.+

7-*$.30:#,*-.#*-#/>#'3-+'#*,#--%0:64*

A3:#*BL

<1+=/">%?;-<@

7-*5%,>139,*-.#*$+''#0-*,#--%0:,64*

J70*-.%,*%11+,-'3-%)02*#3$.*,#$-%)0*%,*

,.)=0*=%-.*311*%-,*5%,>139,*)0*8)'*-.#*

>+'>),#*)8*#@>1303-%)06K

A9B(9,4A:,9%

"CD6+*#$.*%56**&.+

7-*$.30:#,*-.#*-#/>#'3-+'#*,#--%0:64*

A3:#*BL

P

P

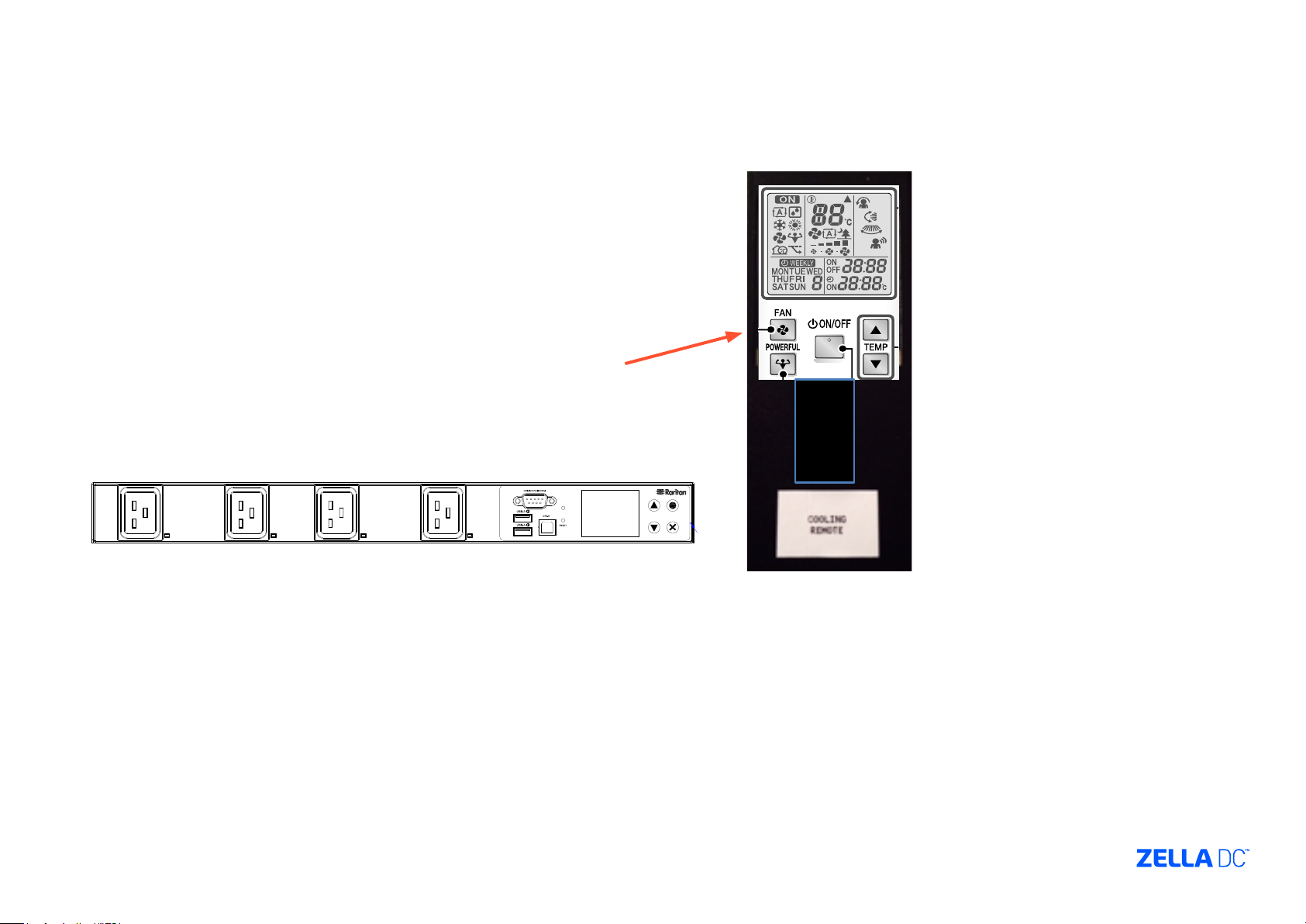

5.5 Start up Procedure – Single Cooling

ONLY once the condenser has been hardwired and copper piping connected can the

cooling system be turned on.

1. Insert cooling system IEC plug (orange cable) into the cooling system socket at

the rear of switchboard labelled (Cooling system).

2. Ensure switchboard is powered and both the Cooling System RCD and Cooling

System are in the ON position.

3. Start-up cooling system on remote located at the back door on left hand side.

4. Press the START button on the cooling system remote.

5. Ensure temperature is set to 23° on cooling mode and FAN STRENGTH is on HIGH.

6. Installation complete

Cooling Remote

Cooling System 1

Cooling System 2

ermanent Supply 1

ermanent Supply 2

5. Single & Dual Cooling System Commissioning Steps

<1+=/">%?;-<@

7-*5%,>139,*-.#*$+''#0-*,#--%0:,64*

J70*-.%,*%11+,-'3-%)02*#3$.*,#$-%)0*%,*

,.)=0*=%-.*311*%-,*5%,>139,*)0*8)'*-.#*

>+'>),#*)8*#@>1303-%)06K

A9B(9,4A:,9%

"CD6+*#$.*%56**&.+

7-*$.30:#,*-.#*-#/>#'3-+'#*,#--%0:64*

A3:#*BL

<1+=/">%?;-<@

7-*5%,>139,*-.#*$+''#0-*,#--%0:,64*

J70*-.%,*%11+,-'3-%)02*#3$.*,#$-%)0*%,*

,.)=0*=%-.*311*%-,*5%,>139,*)0*8)'*-.#*

>+'>),#*)8*#@>1303-%)06K

A9B(9,4A:,9%

"CD6+*#$.*%56**&.+

7-*$.30:#,*-.#*-#/>#'3-+'#*,#--%0:64*

A3:#*BL

5.6 Start up Procedure – Dual Cooling

1. ONLY once the condensers have been hardwired and copper piping been

connected can the cooling system be turned on.

2. Insert cooling system (IEC) plugs (Orange cable) into:

3. Plug Orange Cable (Labelled – Cooling system 1) into Permanent supply 1

4. Plug Orange Cable (Labelled – Cooling system 2) into Permanent supply 2

5. Ensure switchboard is powered and both the Cooling System RCD and Cooling

System are in the ON position

6. Start-up cooling system on remote located at the back door on left hand side.

7. Press the START button on the cooling system remote.

8. Ensure temperature is set to 23° on cooling mode and FAN STRENGTH is on HIGH.

9. Run both system together for 5 minutes – ensure both systems are operating.

10. Pull out both plugs without turning cooling system off from the permanent supply

and plug into Cooling systems 1 & 2 outlets.

11. One system will be operation following this step.

12. Installation complete

Cooling Remote

Cooling System 1

Cooling System 2

ermanent Supply 1

ermanent Supply 2

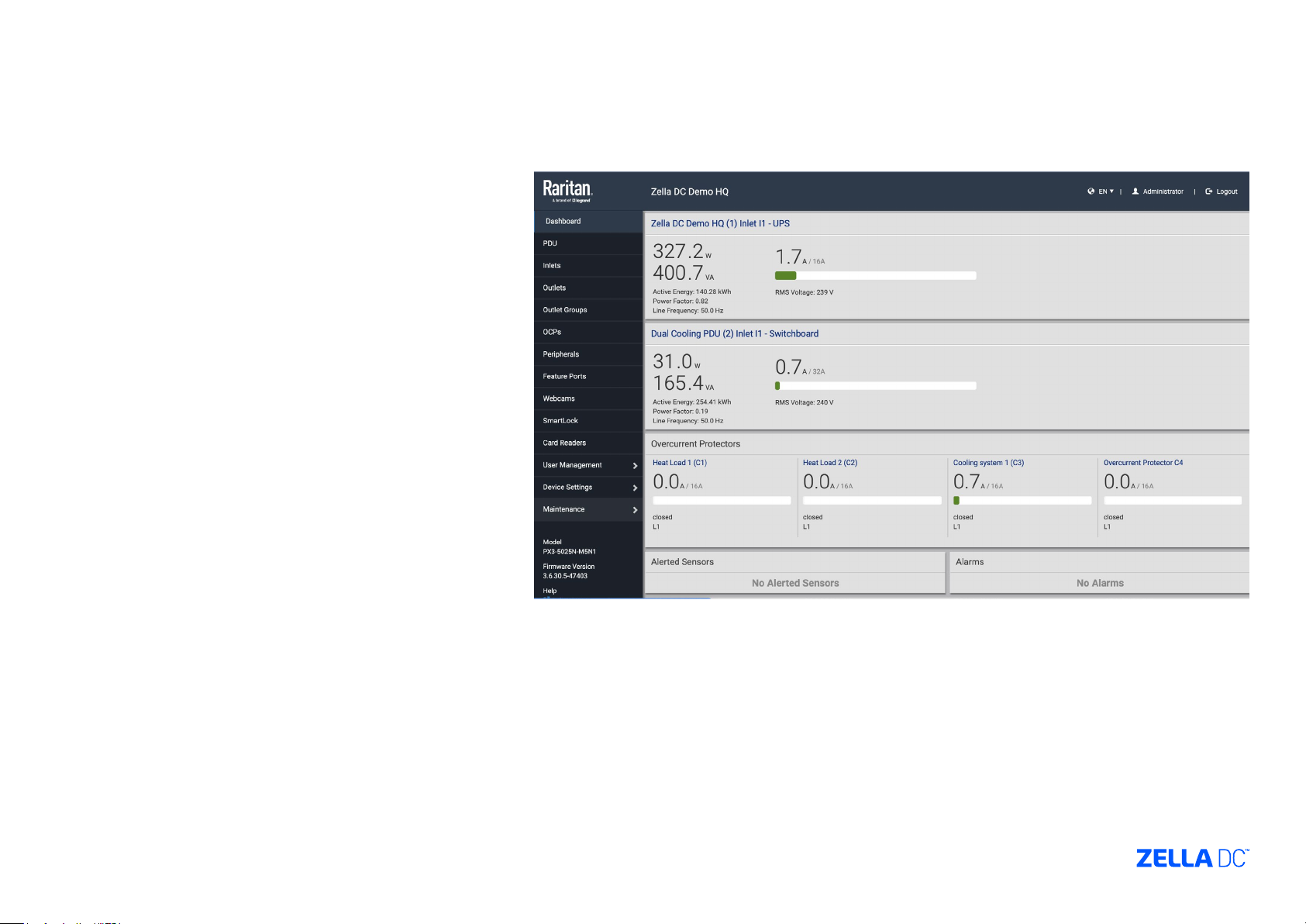

6. PDView Access

Default IP address is 192.168.0.192

Zella Pro PDU Conguration Guide

OPTION 1: To access the Zella Pro PDU using an smart device

(iPhone, iPod, iPad, andriod devise etc.) follow these steps:

1. Download the following App (Raritan PDView) from the Apple App Store,

2. Connect the Apple device with the app installed into the Zella Pro PDU/door

access portal,

3. Use the following to access:

a) Login: admin

b) Password: zellabox

c) Accept the terms of use check box. d) Once connected to the PDU the

following similar image should appear:

4. Access the ‘network’ icon located at the bottom of the screen. If you cannot see the

icon simply click on the nearest icon to the right of the screen and more options

will show.

5. At this point you will be able to locate the IP address for the unit. If you would like

to change the default IP address (192.168.0.1) you can do so at this stage.

6. Change the IP address status to ‘static’.

7. Change the IP address as desired.

8. Remember to save/apply changes at bottom of screen.

6. PDView Access

OPTION 2: To access the Zella Pro PDU using LAN

connections follow these steps:

Plug a CAT cable directly into the PDU and your computer,

Access a web browser,

Type the IP address allocated to the PDU into the web browser. At this

stage if you do not know the IP address go back to ‘OPTION 1’.

Press ‘enter’,

Use the following to access:

Login: admin

Password: zellabox

Accept the terms of use check box.

OPTION 3: To access the Zella Pro PDU through a network /

switch or something similar follow these steps:

Assign the desired IP address to the PDU by referring to ‘OPTION 1’ above,

Plug network cable / switch directly into the PDU,

Access a web browser,

Type the IP address allocated to the PDU into the web browser,

Press ‘enter’,

Use the following to access:

Login: admin

Password: zellabox

Accept the terms of use check box.

6. PDView Access

OPTION 4: To access the Zella Pro PDU through a

network / switch or something similar using DHCP

follow these steps:

Assign the desired IP address to the PDU by referring to

‘OPTION 1’ above,

Plug network cable / switch directly into the PDU,

Access the PDU through local Display,

If you have any questions please contact Zella DC:

Australia: 1300 117 644

International: + 61 8 6311 2814

ONCE YOU HAVE ACCESSED THE PDU VIA WEB BROWSER

THIS IS WHAT YOU SHOULD SEE:

7. Pyrorack Commissioning & User Guide

IMPORTANT

For effective and safe installation follow the steps in the next few slides.

Please note: Accidental discharge will occur if this guide is not followed step by step.

For effective and safe installation follow the steps below See cannister connection quick guide.

Please note: Accidental discharge will occur if this guide is not followed step by step

Please print, laminate & stick near your Zella Pro for all to see the next 2 slides.

7. Pyrorack Commissioning & User Guide

IMPORTANT

For effective and safe installation follow the steps in the next few slides.

Please note: Accidental discharge will occur if this guide is not followed

step by step.

For effective and safe commissioning follow the steps below.

Please note: Accidental discharge will occur if this guide is not followed

step by step.

COMMISSIONING STEPS:

7.1 Preparation 1

Before mounting the Pyrorack into the Zella Pro. Make sure you have the

following ready:

1. Supplied fuses are ready (a pack of fuses should have arrived with

MDC)

2. Ensure keys are in slot at the front of the Pyrorack

3. Star (Phillips screw driver) ( to connect Pyrogen canister)

7.2 Preparation 2

1. Before mounting the Pyrorack, place the Pyrorack upside

2. down on a table.

3. Remove the four screws in the middle – surrounding the

4. string.

5. Remove the Pyrogen canister from the Pyrorack

6. Connect the Pyrogen canister to the Pyrorack by inserting

7. the plug and tightening the washer

8. Reinsert the canister back into the Pyroack

9. Place the Pyrorack into position top of the Zella Pro

10. 7.3 Commissioning Steps

1. Fit the Mains fuse F5 (far right hand side)

2. Insert mains supply cable (C13)

3. Wait 5 seconds

4. Fit the Battery Fuse F4 (middle fuse)

5. Wait 5 seconds

6. Fit the Extinguishing Agent Release Fuse F3. Wait 5 seconds, the

extinguishing agent fault LED goes off

7. Press and hold Test Button and conrm all LEDs are functioning

8. Ensure Key switch is in automatic mode

9. Pyrorack is successfully replaced into service

MAG UNIT

FUSE F3

500mA TL

D-CONN

MALE J2

D-CONN

FEMALE J1

BATTERY

FUSE F4

500mA TL

F5 500mA TL

7.4 Decommissioning Steps

1. Remove Mag fuse F3 from the rear of the Pyrorack (far left)

2. Wait 5 seconds

3. Remove the main fuse F4 (middle fuse)

4. Wait 5 seconds

5. Remove the mains cable

6. Remove the battery fuse F5. The unit shall be powered

7. down at this stage.

8. Remove the Pyrorack from the server cabinet.

7.5 Please print, laminate & stick the next 2 slides near your

Zella Pro for all to see.

MANS

FUSE

Warning

Fire Suppression System Information

z Before working within the Zella Pro ALWAYS ensure you follow these steps:

1. Turn key switch to manual

2. Isolate both zones 1 and 2 by pressing the isolate zones buttons located on the front panel

3. A beeping sound will continue intermittently as a reminder

4. Once you have completed work within the MDC and you are ready to close the doors press

the isolate buttons 1 and 2 once more

5. Turn the key switch back to the automatic position

6. The Pyrorack should return to normal status

7. Pyrorack Commissioning & User Guide

7.6 Pyrorack Canister Replacement

IMPORTANT

Decommission Pyroack rst

1. Remove Mag fuse F3 from the rear of the Pyrorack (far left)

2. Wait 5 seconds

3. Remove the main fuse F4 (middle)

4. Wait 5 seconds

5. Remove the mains cable

6. Remove the battery fuse F5. The unit shall be powered down at this stage.

7. Unplug environmental management cable

8. Remove the Pyrorack from the server cabinet.

9. Place on table upside down.

10. Unscrew the 4 screws in the middle of the Pyrorack.

11. Pull discharged canister out and unscrew cable attachment.

12. Replace with new canister.

13. Follow commissioning steps.

7.7 Important tips.

Before working within the Zella Pro ALWAYS ensure you follow these steps:

1. Turn key switch to manual

2. Isolate both zones 1 and 2 by pressing the isolate zones buttons located on the

front panel

3. A beeping sound will continue intermittently as a reminder

4. Once you have completed work within the MDC and you are ready to close the

doors press the isolate buttons 1 and 2 once more

5. Turn the key switch back to the automatic position

6. The Pyrorack should return to normal status

7. Please note, if you isolate power to the Pyrorack and the fuses are still inserted,

the Pyrorack will still be active as it has 24 hour internal battery backup.

MAG UNIT

FUSE F3

500mA TL

D-CONN

MALE J2

D-CONN

FEMALE J1

BATTERY

FUSE F4

500mA TL

MANS

FUSE

F5 500mA TL

8. Start-up & Ready for Population

The Zella Pro Micro Data Centre is a PLUG N PLAY unit therefore once it has

been installed by a qualied contractor the Micro Data Centre is ready for use!

1. Follow these steps to start up your unit:

z Start-up the switchboard

z Switch Mains Isolator A & B to the ON position

z Switch Cooling System switch to the ON position only when the

cooling system has been commissioned. Leave in the OFF position

until the air con contractor has installed.

z Switch UPS switch to the ON position

z Switch all remaining switches to the ON position

2. Follow Pyrorack Commissioning steps from the installation manual.

3. Populate the Micro Data Centre with your critical equipment and add

equipment labelling in PDView.

NOTE: Ensure adequate gaps are left between the equipment housed within

the Micro Data Centre to ensure an effective air-ow is maintained. The cooling

system will maintain the optimal cooling air-ow between the equipment if this

recommendation is adhered to.

NOTE: DO NOT exceed the cooling system’s recommended BTU/h specications

(listed in the cooling system section) as this will overheat the equipment.

Meet the uptime experts

Over a decade ago Zella DC pioneered the micro data centre. Since then, our nextgeneration server rooms have been proven to work in the harshest environments

on earth. The result is a vendor-agnostic approach to software, hardware

manufactured to global standards, and partners across ve continents.

Summary of solution benet

Uptime and

space usage

Cyber and

physical security

Email info@zelladc.com

Phone +61 (8) 6311 2814

Website zelladc.com

Risk from

human error

Energy and noise

efciency

Self-learning

and autonomy

Data

sovereignty

Scalability

as needed

Local storage/

fast processing

April 2021

Loading...

Loading...