OO

OOIIIILLLL

WW

WWAAAATTTTEEEERRRR

SSSSEEEEPPPPAAAARRRRAAAATTTTOO

OORRRR

TTTTEEEECCCCHHHHNNNNIIIICCCCA

AAALLLLMM

MMAAAANNNNUUUUAAAALLLL

MODELS

OS300 THRU OS2501

COMPRESSED AIR SOLUTIONS

TM

ZEKS Compressed Air Solutions

1302 Goshen Parkway

West Chester, Pennsylvania 19380

610-692-9100 800-888-2323

FAX 610-692-9192

WWW.ZEKS.COM

OS-0604a

TABLE OF CONTENTS PAGE

1. INTRODUCTION 1

2. ABBREVIATED WARRANTY 1

3. OIL/WATER SEPARATOR NOMENCLATURE 1

4. RECEIVING AND INSPECTION 1

5. SAFETY AND OPERATION PRECAUTIONS 2

6. PRINCIPLES OF OPERATION 3

7. INST ALLATION AND INITIAL STAR T-UP 3

8. SCHEDULED MAINTENANCE 4

9. PARTS LIST 5

1. INTRODUCTION

The ZEKS OS Series Oil/Water Separators have been specially developed to separate oil from condensate

extracted from compressed air systems and is effective with all types and makes of compressors, oils and drain

valves. Lubricant carryover in the separated water is 10ppm or lower.

Polyglycol models, indicated by (PG), require a Polyglycol Absorption element for Tower #1. The Carbon

Finishing Element for Tower #2, and the Carbon Finishing Element for the OSEXT, do not change for Polyglycol

applications.

For applications greater than 1250 scfm, the OSEXT can be added to an OS1251 to increase condensate handling capacity up to a 2,500 SCFM system. The OSEXT model can not be utilized as a stand alone oil/water

separator.

2. ABBREVIA

TED WARRANTY

ZEKS OS Series Oil/Water Separators are warranted to be free from defects in material and workmanship for a

period of 12 months from date of start-up but not to exceed 18 months from date of shipment from the factory.

This warranty covers replacement parts. Labor coverage does not apply. Normal maintenance such as drain

cleaning and consumable element replacement are not covered by this warranty.

3. OS OIL/W

ATER SEPARATOR NOMENCLATURE

Model Number Air Compressor Capacity Application

OS300 Up to 300 scfm Mineral, Synthetic, Semi-Synthetic Oils,

Stable Emulsions

OS300PG Up to 300 scfm Polyglycol

OS751 300-750 scfm Mineral, Synthetic, Semi-Synthetic Oils,

Stable Emulsions

OS751PG 300-750 scfm Polyglycol

OS1251 750-1250 scfm Mineral, Synthetic, Semi-Synthetic Oils,

Stable Emulsions

OS1251PG 750-1250 scfm Polyglycol

OS2501 1250-2500 scfm Mineral, Synthetic, Semi-Synthetic Oils,

Stable Emulsions

OS2501PG 1250-2500 scfm Polyglycol

OSEXT* Extends Absorption time

*OSEXT is added to an OS1251 and OS1251PG to increase the handling capacity up to 2500 scfm.

4. RECEIVING

AND INSPECTION

Upon receiving your ZEKS Oil/Water Separator, please inspect the unit closely. If rough handling is detected,

please note it on your delivery receipt, especially if the separator will not be put in to service immediately.

Obtaining the delivery person’s signed agreement to any noted damages will facilitate any incurance claims.

1

5. SAFETY

AND OPERATION PRECAUTIONS

Because components of the Oil Water Separator are connected to pressurized equipment, the same precautions should be observed as with any piece of machinery of this type where carelessness in operation or

maintenance could be hazardous to personnel. In addition to obvious safety rules that should be followed

with this type of machinery, safety precautions as listed below must be observed:

OSHA

Heading Descriptions

1. Only qualified personnel shall be permitted to adjust,

perform maintenance or repair this equipment.

2. Read all instructions completely before operating unit.

3. Do not attempt to remove any parts without first relieving the entire

air system of pressure or isolating unit from

pressure source.

4. Do not attempt to service any part while machine is in an operational mode.

5. Do not operate the separator under conditions in excess of its rating.

6. It is a violation of the Clean Water Act to discharge compressed air condensate into a storm sewer or into a

body of water. Treated compressed air condensate may be legally

discharged into a storm sewer system provided the ppm concentra

tion is within the legal limits of the governing body of that sewer dis

trict. Consult your local sewer authority to determine the maxi

mum acceptalbe ppm limit.

7. Inspect unit daily to observe and correct any unsafe operating conditions.

8. User must comply with all applicable regulations when

disposing of lubricant-contaminated filters or equipment.

NOTICE

“Warning” is used to indicate a

hazardous situation which has

some probability of death or

severe injury. Warning should

not be considered for property

damage accidents unless personal injury risk is present.

NOTICE

“Notice” is used to indicate a

statement of company policy

as the message relates directly

or indirectly to the safety of

personnel or protection of

property. Notice should not be

associated directly with a hazard or hazardous situation and

must not be used in place of

“Danger,” “Warning,” or

“Caution.”

“Caution” is used to indicate a

hazardous situation which may

result in minor or moderate

injury.

The user of any Oil Water Separator sold by ZEKS Compressed Air Solutions, is hereby warned that

failure to follow the above Safety and Operation Precautions may result in personal injury or equipment or environmental damage. However, ZEKS Compressed Air Solutions does not state as fact,

nor does it mean to imply, that the preceding list of Safety and Operating Precautions is all inclusive,

and further, that the observance of this list will prevent all personal injury or equipment damage.

2

CAUTION

6. PRINCIPLES OF OPERATION

Oil-lubricated compressors create lubricant aerosols that combine with the water vapor that is present in the

compressed air. Regulations require that the condensate be separated for safe discharge into surface water,

sanitary sewers and wastewater treatment plants.

ZEKS OS Series Oil/Water Separators collect discharged condensate from the compressed air system.

Condensate enters the unit through the inlet ports and flows through the depressurization chamber where any

air that accompanied the condensate is separated and released to atmosphere. Condensate enters the

Absorption Tower (Tower #1) where the oil is absorbed by the element. The remaining condensate enters the

Carbon Finishing Tower (Tower #2) where any remaining oil residue. Condensate is then released to the

drainage system.

7. INST

ALLATION AND INITIAL

START UP

7.1 UNPACKAGING AND LOCATION SELECTION

Open the packaging for the OS Series Oil/Water Separator and remove the lids from Tower #1 and Tower #2.

Using normal lifting precautions, remove the Absorption Element (large white element) from Tower #1 and the

Carbon Finishing Element from Tower #2. Place lids and elements aside. The OS Series Oil/Water Separators

are designed to easily fit against a wall or in a corner. Select a location where both the condensate drain lines

from the compressed air system and the OS Oil/Water Separator Drain outlet can be conveniently installed

without the possibility of becoming damaged or kinked. Position the unit with the TEST port to the front.

Connect the provided TEST Valve and outlet nipple to the appropriate ports as indicated on the OS

Series unit. Do not over-tighten connections.

7.2 CONNECTION AND ASSEMBLY

Connect the condensate lines to the 1/2” inlet(s) located on top of the unit. Screw plugs (not provided) should

be used to seal the inlet ports that are not going to be utilized.

Connect the 1/2” drain outlet connection to a suitable drain. The drain line needs to be installed without obstruction and in a manner that will allow for unpressurized condensate flow. Testing shows that lubricant carryover in

the separated drain water is less than 10ppm or lower. Check local codes for applicable drainage requirements.

Install the Carbon Finishing Element in to Tower #2. Push the element to the bottom of the vessel and confirm

that the outlet drain port is not obstructed.

Confirm that there is no harmful pressure in the condensate lines from the compressed air system.

WARNING

3

If time permits, the Carbon Finishing Element should be allowed to soak in water for a period of 24

hours prior to installation. Though not necessary, soaking of the Carbon Finishing Element will prevent carbon dusting from occurring within Tower #2 of the unit. Carbon dusting is completely harmless to the OS Series Oil/Water Separator and drainage systems.

NOTICE

Normal lifting precautions need to be observed when servicing the ZEKS OS Series Oil/Water

Separators. Failure to observe lifting precautions may result in personal injury. Elements will be saturated with oil and condensate and therefore will be heavy. Protective clothing and gloves should

always be worn when servicing the units.

WARNING

Remove the foam depressurization pad from from the top of the unit. Pour clean water in to the depressurization chamber until it flows from the outlet drain port of Tower #2. Confirm that there are not any obstructions

with the drain line and the unit is draining properly. During initial filling, dust may rise from the carbon elements;

this is only displaced air and is entirely harmless. ZEKS recommends that carbon elements should be presoaked for 24 hrs. Any carbon dust in the outlet water is harmless. Replace the foam depressurization pad.

Using normal lifting precautions, replace the white Absorption Element in to Tower #1. Push the element completely to the bottom of the tower. Replace the lid to Tower #1.

7.3 INITIAL START-UP AND MONITORING

ZEKS recommends a daily check on the quality of the discharged condensate from the oil/water separator for

the first week of operation. Using the Test bottle provided with the unit, take a sample of condensate from the

TEST port on Tower #2. Fill the bottle as much as possible. The condensate collected should be clear when

viewed through the container. Particulate concentration less than 20ppm is not visible with the human eye.

Therefore, if the condensate appears cloudy, the oil carryover is greater than 20ppm. Within a week of operation, the quality of the condensate should improve. Clean the collection bottle and return it to the holder located

on top of the OS Oil/Water Separator.

8. SCHEDULED MAINTENANCE

8.1 REPLACEMENT OF ELEMENTS:

Under normal operating conditions, ZEKS recommends that the Absorption Element and the Carbon Finishing

Element(s) be replaced simultaneously on a yearly basis. Excessive oil by-pass from the compressed air system will result in shortened element life. Test the quality of the condensate discharge to determine element

effectiveness (Reference Section 7.3).

ABSORPTION ELEMENT (TOWER #1)

Lift the saturated element from Tower #1 using standard heavy lifting precautions. Use caution when lifting

the saturated element from the tower as element will be heavy from retained oil. Allow the element to drain

off excess condensate prior to completely lifting from the tower. Place the saturated element in to a plastic

bag or bucket to allow element to safely continue to drain. Place the new Absorption Element in Tower #1

and push the element completely to the bottom of the tower. Replace the lid to Tower #1. Pour collect condensate from the Absorption Element in to Tower #1. This will ensure that the separation process of the collected condensate is completed prior to disposal.

REPLACEMENT OF CARBON FINISHING ELEMENT

(TOWER #2) AND (TOWER #3 - OS2501 MODEL ONLY)

To prevent dusting, clean water can be poured over the Carbon Finishing Element. Carbon dusting is completely normal with a new element and is completely harmless.

Remove lid from Tower #2. Carefully lift the saturated Carbon Finishing Element from Tower #2 using standard heavy lifting precautions. Allowing the element to drain off excess condensate prior to completely lifting from the tower. Place the saturated element in to a plastic bag or bucket to allow element to safely continue to drain. Place the new Carbon Finishing Element in Tower #2 and push the element completely to

the bottom of the tower. Ensure that the top of the element is below the drain outlet hole. Clean water can

be

Replace lid to Tower #2. Pour collected condensate from Carbon Finishing Element in to Tower #1. This

will ensure that the separation process of the collected condensate is completed prior to the condensate

exiting the unit.

4

All used elements must be properly disposed of in accordance with current regulations

for the disposal of hazardous waste in your area.

WARNING

5

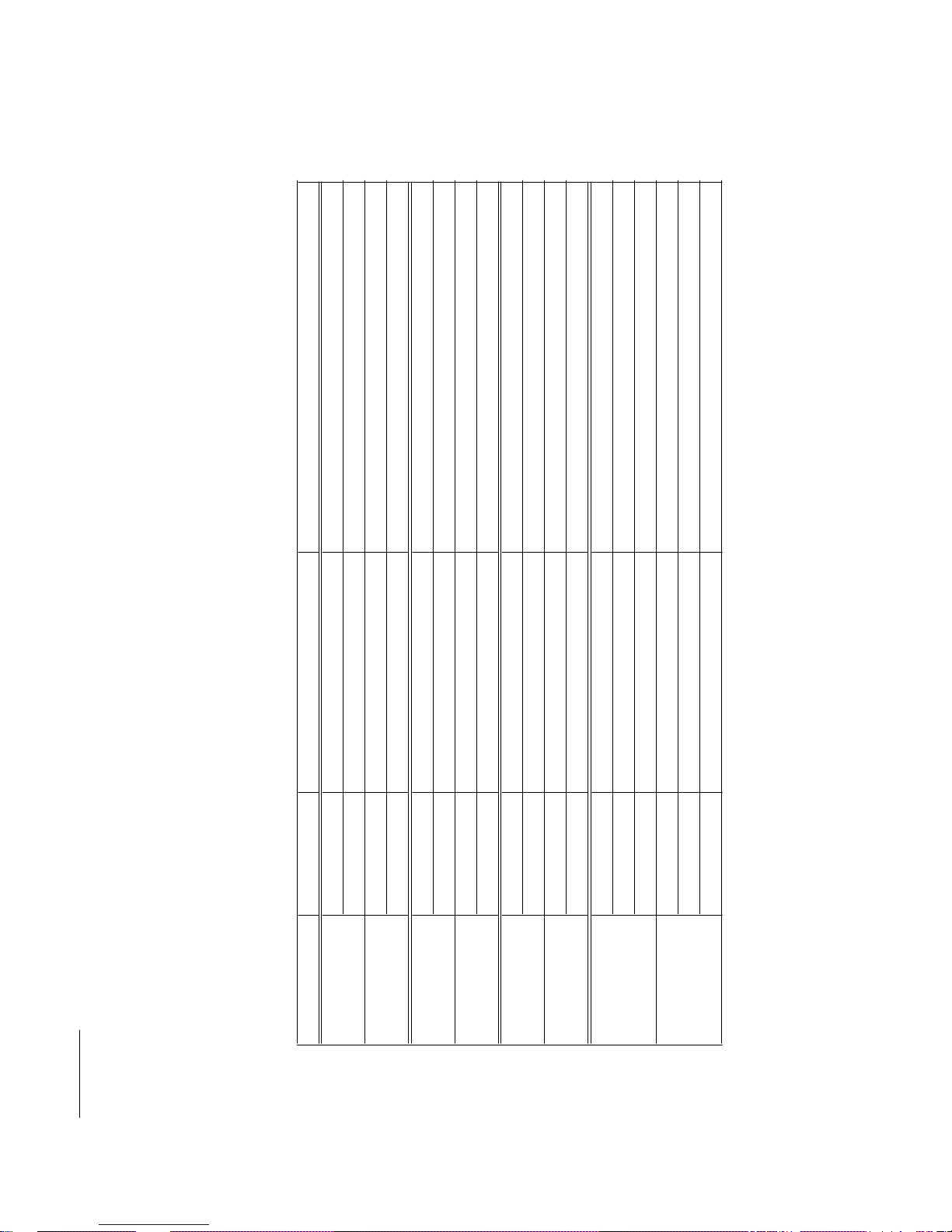

Model Numbe r Part Number Description Ele me nt Application

683535 Absorpt i on (TWR 1) Mi neral Oi l , Sy nthet i c Oi l , S em i -S ynt hei c Oi l

683536 Carbon Finishi ng (TWR 2) Mineral Oi l , S ynt hetic Oi l , S em i -S ynt hei c Oi l

683749 Absorpt i on (TWR 1) Pol ygl ycol

683536 Carbon Finishi ng (TWR 2) Mineral Oi l , S ynt hetic Oi l , S em i -S ynt hei c Oi l

684130 Absorpt i on (TWR 1) Mi neral Oi l , Sy nthet i c Oi l , S em i -S ynt hei c Oi l

684132 Carbon Finishi ng (TWR 2) Mineral Oi l , S ynt hetic Oi l , S em i -S ynt hei c Oi l

684131 Absorpt i on (TWR 1) Pol ygl ycol

684132 Carbon Finishi ng (TWR 2) Mineral Oi l , S ynt hetic Oi l , S em i -S ynt hei c Oi l

683750 Absorpt i on (TWR 1) Mi neral Oi l , Sy nthet i c Oi l , S em i -S ynt hei c Oi l

683752 Carbon Finishi ng (TWR 2) Mineral Oi l , S ynt hetic Oi l , S em i -S ynt hei c Oi l

683751 Absorpt i on (TWR 1) Pol ygl ycol

683752 Carbon Finishi ng (TWR 2) Mineral Oi l , S ynt hetic Oi l , S em i -S ynt hei c Oi l

683750 Absorpt i on (TWR 1) Mi neral Oi l , Sy nthet i c Oi l , S em i -S ynt hei c Oi l

683752 Carbon Finishi ng (TWR 2) Mineral Oi l , S ynt hetic Oi l , S em i -S ynt hei c Oi l

683753 Carbon Finishi ng (TWR 3) Ext ends Carbon Fi nshing Time

683751 Absorpt i on (TWR 1) Pol ygl ycol

683752 Carbon Finishi ng (TWR 2) Mineral Oi l , S ynt hetic Oi l , S em i -S ynt hei c Oi l

683753 Carbon Finishi ng (TWR 3) Ext ends Carbon Fi nshing Time

OS300

OS300PG

OS751

OS751PG

OS1251

OS1251PG

OS2501

OS2501PG

9. PARTS LIST

Loading...

Loading...