TTTTEEEECCCCHHHHNNNNIIIICCCCAAAALLLLMM

MMAAAANNNNUUUUAAAALLLL

ECLIPSE™ DESICCANT DRYERS

ZPA HEATLESS MODELS

TABLE OF CONTENTS PAGE

1. INTRODUCTION 1

2. ABBREVIATED WARRANTY 1

3. HEATLESS DRYER NOMENCLATURE 2

4. RECEIVING AND INSPECTION 3

5. SAFETY AND OPERATION PRECAUTIONS 4

6. PRINCIPLES OF OPERATION 5

7. INSTALLATION / INITIAL START-UP 7

8. SCHEDULED MAINTENANCE 13

9. TROUBLESHOOTING 17

10. PURGE CHARTS 19

A

TTACHMENTS

A. GENERAL ARRANGEMENT DRAWING

B. WIRING DIAGRAM

C. FLOW DIAGRAM

D. SPARE PARTS LIST

E. ENGINEERING SPECIFICATIONS

ZEKS Compressed Air Solutions

1302 Goshen Parkway

West Chester, Pennsylvania 19380

610-692-9100 800-888-2323 FAX 610-692-9192

WWW.ZEKS.COM

COMPRESSED AIR SOLUTIONS

TM

ZPATM 90-5000 V0107

1

1. INTRODUCTION

ZEKS Eclipse™ Heatless Desiccant Dryers are designed to adsorb moisture from

compressed air. The dryers are constructed with two towers, each containing desiccant

beads, that alternate between online (drying) and offline (regenerating) modes, yielding a

continuous stream of dry air at the dryer’s outlet.

During normal operation, wet air passes through the on line tower and water vapor from

the air is adsorbed (collected) on the desiccant beads. While air is being adsorbed in the

online tower, the moisture on the desiccant in the offline tower is removed by a process

called desorption (regeneration). After an initial rapid depressurization, a portion of dried

air from the online tower passes over the desiccant bed and carries the moisture off the

bed and out the dryer’s exhaust.

The continuous, alternating process of adsorption and desorption is controlled using a

timer that switches the towers in a specific timed sequence. Very dry compressed air dew

points are achieved through the continuous switching and operation of this dryer. ZEKS

offers dryers to provide either -40°F, -80°F or -100°F pressure dew point outlet air.

2. ABBREVIA

TED WARRANTY

ZEKS Eclipse™ heatless desiccant dryer products are warranted to be free from defects

in material and workmanship for a period of 12 months from the original date of shipment

from the factory. To allow the warranty to be in effect for 12 months from the date of

equipment start-up, the Warranty Registration Card must be completed and returned to

ZEKS. Alternately, the Warranty Registration Card may be completed online at

www.zeks.com. The total warranty period cannot exceed 18 months from the original date

of shipment from the factory.

Equipment must be installed and operated in accordance with ZEKS’ recommendations.

ZEKS liability is limited to repair of, refund of purchase price paid for, or replacement in

kind at ZEKS’ sole option, during the warranty time period stated above. IN NO EVENT

SHALL ZEKS BE LIABLE OR RESPONSIBLE FOR INCIDENTAL OR CONSEQUENTIAL

DAMAGES, even if the possibility of such incidental or consequential damages has been

made known to ZEKS Compressed Air Solutions. In addition, the usual maintenance and

replacement type products are not covered by this warranty.

The warranties expressed above are in lieu of and exclusive of all other warranties. There

are no other warranties, expressed or implied, except as stated herein. There are no

implied warranties of merchantability or fitness for a particular purpose, which are specifically disclaimed.

Valves – After the Basic Warranty noted above expires the diaphragm valves on the ZPA

heatless dryers are warranted (parts only) for a total of 5 years from the date the dryer is

shipped from the ZEKS factory. The following applies to this warranty:

a. Check valves are excluded

b. Not applicable to dryers provided for -80 and -100 degree F dewpoint applications

c. Valves must be rebuilt every two years. Refer to Section 8. of this manual

d. Control line air filter element must be replaced once per year.

2

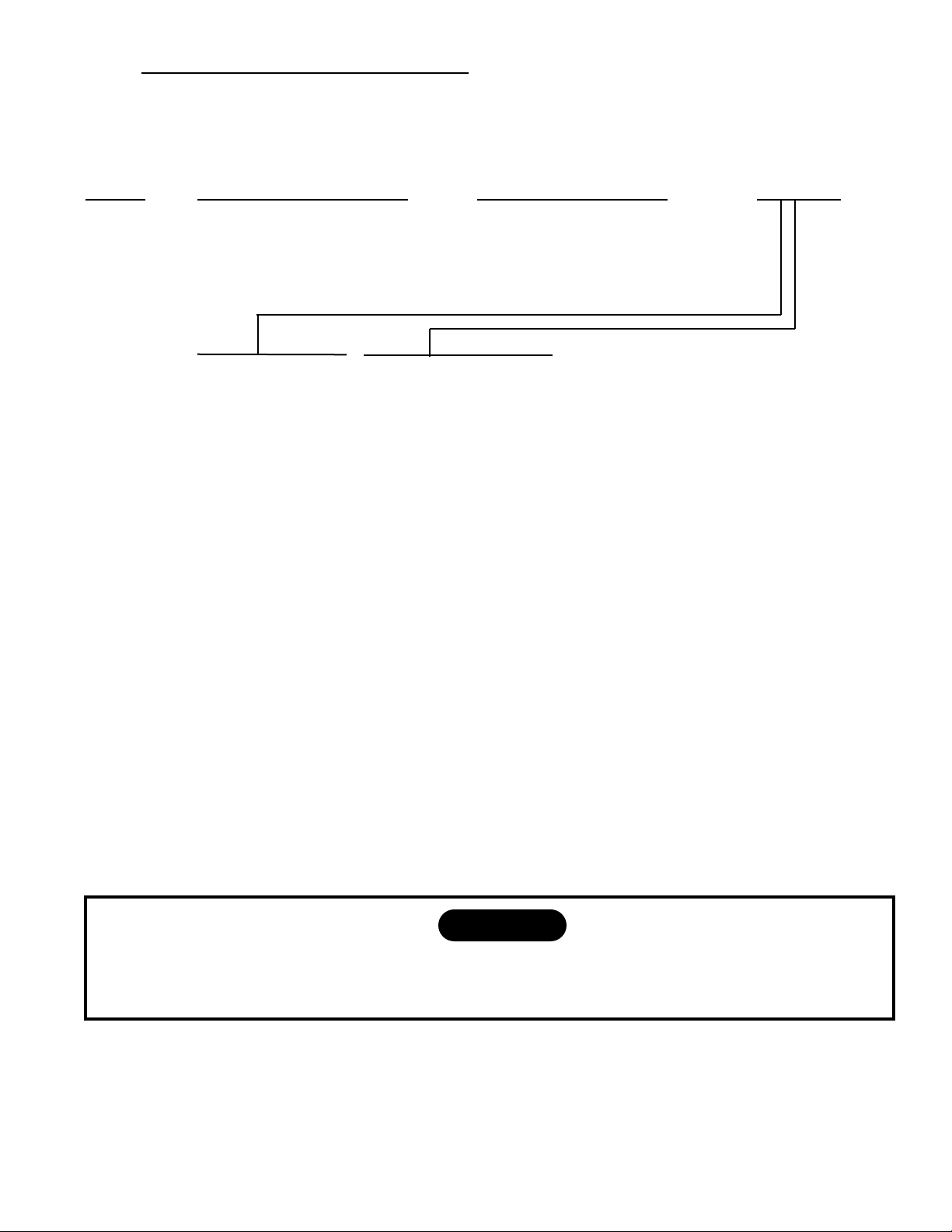

3. HEATLESS DRYER NOMENCLATURE

NOMINAL

FLOW

SCFM*

TYPE / DESIGN SERIES ELECTRICAL POWER OPTIONS

90 ZPA= Pressure Swing 1 = 115-1-60 (-40°F)

120

160

200

250

300

400 0= NEMA 1 0= STANDARD

500 H= NEMA 4 A= FAIL TO SHIFT

600 B= HIGH HUMIDITY

800 C= A + B

1000 M= MOISTURE LOAD

1200 CONTROL + A

1500 N= M + B

1800

2100

2700

3300

4000

5000

* Nominal Flows indicated are for 100°F inlet temperature, 100°F ambient temperature

and 100 psig compressed air pressure..

Nomenclature shown above represents standard price sheet options. Other options are

available, refer to nomenclature insert specific to your dryer for details.

NOTICE

3

4. RECEIVING AND INSPECTION

4.1 INSPECTION

Upon receiving your ZEKS air dryer, please inspect the unit closely. If rough

handling has been noticed, please note it on your delivery receipt, especially if the

dryer will not be immediately uncrated. Obtaining the delivery person’s signed

agreement to any noted damages will facilitate any insurance claims

4.2 UNPACKING AND HANDLING

Refer to labels on the dryer for the appropriate means for lifting or moving the

dryer. For those dryers that indicate lifting via the structural skid, forks should

extend all the way through the skid to reduce unnecessary forces to the dryer

during moving. When lifting the dryer, ensure that no stress is applied to the piping

or valving. Refer to Section 7.2 for locating and mounting of dryer.

NOTICE

Under no circumstances should any person attempt to lift heavy

objects without proper lifting equipment (i.e., crane, hoist, slings or fork

truck). Lifting any unit without proper lifting equipment, can cause

serious injury.

4

5. SAFETY AND OPERATION PRECAUTIONS

Because an air dryer is pressurized and contains mechanical parts, the same precautions

should be observed as with any piece of machinery of this type where carelessness in

operation or maintenance is hazardous to personnel. In addition to the many obvious

safety rules that should be followed with this type of machinery, the safety precautions as

listed below must be observed:

1. Only qualified personnel shall be permitted to adjust, perform

maintenance or repair this air dryer.

OSHA Heading

Description

2. Read all instructions completely before operating unit.

3. Pull main electrical disconnect switch and disconnect

any separate control lines, if used, before attempting to

work or perform maintenance on the unit.

4. Do not attempt to service any part while dryer is in an

operational mode.

5. Do not attempt to remove any parts without first relieving

the entire air system of pressure.

6. Do not operate the dryer at pressures in excess of its

rating.

7. Inspect unit daily to observe and correct any unsafe

operating conditions.

The user of any air dryer manufactured by ZEKS Compressed Air Solutions, is

hereby warned that failure to follow the above Safety and Operation Precautions

can result in personal injuries or equipment damage. However, ZEKS Compressed

Air Solutions does not state as fact, nor does it mean to imply, that the preceding

list of Safety and Operating Precautions is all inclusive, and further, that the

observance of this list will prevent all personal injuries or equipment damage.

NOTICE

“Warning” is used to indicate a

hazardous situation which has

some probability of death or

severe injury. Warning should

not be considered for property

damage accidents unless

personal injury risk is present.

NOTICE

“Notice” is used to indicate a

statement of company policy

as the message relates directly

or indirectly to the safety of

personnel or protection of

property. Notice should not be

associated directly with a

hazard or hazardous situation

and must not be used in place

of “Danger,” “Warning,” or

“Caution.”

CAUTION

“Caution” is used to indicate a

hazardous situation which may

result in minor or moderate

injury.

WARNING

5

6. PRINCIPLES OF OPERATION

6.1 INTRODUCTION

As described in Section 1, water vapor is removed from compressed air by diverting

air flow alternately between two towers filled with desiccant. While one tower

processes the compressed air stream, adsorbing water vapor, the opposite tower is

regenerated by desorbing the water vapor and venting it to atmosphere. Refer to the

Process and Instrumentation Diagram (P&ID) for a visual representation of the drying

and regenerating cycles.

6.2 DRYING CYCLE

Saturated compressed air enters the dryer and is diverted to the appropriate tower

by the Inlet Flow Valves. Referring to the Process and Instrumentation Diagram

(P&ID), the Left Inlet Flow Valve is actuated to a closed position to prevent air flow

from entering the regenerating tower. Simultaneously, the Right Inlet Flow Valve is

actuated to an open position, allowing air flow to the right hand tower. During this

time, the Right Tower Purge Valve is actuated to a closed position, preventing the

compressed air from venting to atmosphere. As the compressed air flows through

the desiccant material at pressure, removal of water vapor from the air stream begins

to occur through adsorption. In the adsorption process, the desiccant material draws

water vapor out of the compressed air and “holds” it until the right tower drying cycle

is complete. Compressed air flows out of the tower for delivery to the process use.

The Outlet Flow Check Valves provide air flow diversion to the outlet air connection

of the dryer. The Right Outlet Flow Check Valve allows air flow through to the outlet

connection of the dryer while The Left Outlet Flow Check Valve checks off to prevent

flow back to the regenerating tower.

6.3 REGENERATION CYCLE

Previously adsorbed moisture, removed from the process stream, gets stripped or

desorbed from the desiccant material in the regeneration process. The first stage of

regeneration is tower depressurization. After the Inlet Flow Valves are switched to

divert air flow away from the regenerating tower, the appropriate Purge Valve will be

opened and the tower will be depressurized. Through rapid depressurization, a

significant portion of the previously adsorbed water vapor is stripped off of the

desiccant material and exhausted to atmosphere.

The second stage of regeneration uses a portion of the dry, compressed air,

expanded to atmospheric pressure to complete the desorption process. As shown on

the P&ID, the compressed air exits the drying tower and a portion of the air flows

through the Purge Adjustment Valve and the Purge Orifice. Once the air has passed

through Purge Orifice, it expands to atmospheric pressure and continues the

regeneration process. Desorption occurs as the desiccant releases water vapor into

the regeneration air and is exhausted through the Purge Muffler.

Eclipse Heatless Dryers may be equipped with an optional Downstream Purge

feature. By adding additional check valves to the upper manifold, a dryer equipped

with the Downstream Purge option is able to use air from a downstream source to

purge the regenerating tower. This optional feature is useful for applications with

downstream (dry) storage tanks, as pulling air from a downstream source can

minimize cycling of the air compressor.

6

6.4 SETTING THE REGENERATION AIR FLOW

Proper setting of the purge is necessary to achieve proper dryer performance.

Setting the purge flow too high will waste compressed air and if set too low, the dryer

will not achieve proper dew point performance.

The purge adjustment manifold consists of the Purge Adjustment Valve, the Purge

Pressure Gauge and the Purge Orifice. When the right tower is the drying tower

(pressurized) and the left tower is depressurized (0 PSIG), manually adjust the

Purge Adjustment Valve until the gauge reading on the purge pressure gauge

matches the Purge Pressure Gauge setting listed on the laminated tag affixed to

the Orifice Plate Assembly.

6.5 TOWER REPRESSURIZATION

Upon completion of tower regeneration, and prior to the Inlet Flow Valves changing

position to switch towers, the regenerated tower must be repressurized.

Repressurization is accomplished by closing the appropriate Purge Valve. Closing

the Purge Valve allows the regeneration air to begin to pressurize the tower. In

addition to the regeneration air, the Repressurization Valve, (standard on -80°F and

-100°F dew point and high pressure dryers; optional on -40°F dew point dryers)

opens allowing some additional air from the outlet of the dryer to ensure adequate

pressurization. During normal tower regeneration, the Repressurization Valve is

held closed so that the only source of air for regeneration passes through the purge

adjustment assembly.

Failure to re-pressurize prior to tower switchover will result in shocking the

desiccant material and cause premature desiccant dusting.

NOTICE

The right tower must be the drying tower for proper purge adjustment setting.

When the left tower is the drying tower, the Purge Adjustment Gauge will read

close to line pressure.

NOTICE

On dryers equipped with the optional NEMA 4 / DPC™ Package or when using the

optional Moisture Load Control feature, the purge valve MUST be set to the factory

set point to insure proper operation of these features.

NOTICE

7

6.6 VALVES

Solenoid valves are used to actuate the Flow Valves, Purge Valves and the optional

Repressurization Valve on Eclipse Heatless Dryers. The Inlet Flow Valves and

optional Repressurization Valve are normally open valves, while the Purge Valves

are connected as nomrally closed valvaes. This arrangement permits air to flow

through the dryer during periods of loss of power.

Outlet Check Valves are single direction check valves that will allow flow in the

direction shown on the P&ID, but not allow flow in the opposite direction.

6.7 TIMING SEQUENCE

All timing functions on NEMA 1 dryers are performed by the Solid State Timer

(SST) and on NEMA 4 dryers by ZEKS DPC™ Controller. Regardless of controller,

the timing of ZEKS -40°F, -80°F and -100°F dryers is as follows:

6.7.1 TIMING CYCLE FOR -40°F DEW POINT DRYERS

The standard timing cycle for -40°F operation switches the Inlet Flow Valve

position every five minutes which alternates the drying tower. At the same

time as a tower Inlet Valve opens, the appropriate tower Purge Valve opens

to depressurize the regenerating tower. Tower regeneration occurs for 4

minutes and 15 seconds, at which time the Purge Valve closes to initiate

repressurization.

6.7.2 TIMING CYCLE FOR AND -80°F and -100°F DEW POINT DRYERS

The standard timing cycle switches for both -80°F and -100°F operation

switches the Inlet Flow Valve position every 2 minutes which alternates the

drying tower. At the same time as a tower Inlet Valve opens, the appropriate

tower Purge Valve opens to depressurize the regenerating tower. Tower

regeneration occurs for 1 minute and 50 seconds, at which time the Purge

Valve closes to initiate repressurization. The Repressurization Valve opens

to assist tower repressurization for the last 10 seconds prior to Inlet Flow

Valve switching.

7. ALARMS

AND INDICATORS

7.1 MOISTURE INDICATOR

The moisture indicator senses a sample of the control air supply which is taken

from the dryer outlet. The indicator provides an indication of dew point deterioration at the outlet of the dryer. Under normal operating conditions, the indicator is

blue. In the event of a dryer malfunction or prolonged dryer shut down, it will turn

gray in the presence of moisture.

7.2 FAILURE TO SHIFT ALARM (Optional)

The Failure to Shift Alarm provides an indication of switching failure in one of the

dryer switching valves. The Fail to Shift Alarm uses a pressure switch to monitor

the pressure in each tower.

8

At “0” PSIG the switches are normally closed which sends a signal to the controller.

When the towers pressurize, the switches open, thus removing the signal to the

controller. The controller anticipates the appropriate open and closed switch

position based on its timing sequence. If either switch is in an incorrect position,

the Failure to Shift Alarm light will illuminate on NEMA 1 dryers. Refer to the NEMA

4 / DPC™ Package Supplement for NEMA 4 dryers equipped with the DPC™

Controller.

7.3 HIGH HUMIDITY ALARM (Optional)

The purpose of the High Humidity Alarm is to provide the operator an indication if

the equipment fails to supply air at its designed dew point. This is accomplished by

passing a sample of dried air from the control line across a sensing element. If the

sensing element is exposed to air with dew point of -10°F or higher (for -40°F

dryers), the sensor sends a signal to the humidistat. On NEMA 1 dryers, power is

then supplied to the red alarm light on the enclosure. This light will remain on until

the problem is corrected and the sensing element has dried out. Refer to the

NEMA 4 / DPC™ Package Supplement for NEMA 4 dryers equipped with the

DPC™ Controller.

7.4 MOISTURE LOAD CONTROL (Optional)

The Moisture Load Control (MLC) feature is designed to minimize the loss of purge

air during low flow or low water loading conditions. On -40 °F units, a sensor

samples the moisture content from the online tower and provides a signal to a

humidistat. As long as the humidistat finds that the air in each tower is dry, it will

not allow the controller to open the Purge Valves. Once the moisture content in

either tower is found to reach the threshold point, the humidistat sends a signal to

the controller and initiates the regeneration cycle. For -80°F & -100°F dryers, a

digital dew point monitor is used in place of the humidistat. For dryers equipped

with the digital dew point monitor, refer to the Dew Point Monitor Addendum. For

NEMA 4 dryers equipped with ZEKS DPC™ Controller, refer to the NEMA 4 /

DPC™ Package Supplement.

9

7. INSTALLATION and START-UP

7.1 APPLICATION and CHECK ANALYSIS

To achieve the best dryer performance, you should carefully check that the design

and installation requirements outlined below are satisfied.

Operating pressure of ZEKS dryers can range from 75 -150 PSIG. Air available for

your usage will vary with operating pressure. The maximum design pressure of the

ZEKS Heatless Dryer is 150 PSIG. For units required for higher operating

pressures, consult your ZEKS representative.

The dryer must never be installed where air and/or ambient temperature exceeds

120°F or drops below +50°F. Locate dryer to avoid extremes of heat and cold from

ambient or other conditions. Avoid locating dryer outside or where it is exposed to

the elements.

7.2 LOCATING and MOUNTING

Lift the dryer only by the lifting points indicated by the lifting labels on the dryer.

Bolt the dryer to the foundation using the bolt holes provided in the base frame.

Anchor bolts should project a minimum of 3.5 inches above the foundation. Refer to

General Arrangement drawing for details.

7.3 PIPING

Pipe the compressed air lines to the inlet and outlet connections. Locate the

prefilters as close as possible to the dryer. Ensure the positioning allows for ease

of servicing. Refer to the General Arrangement drawing.

Note that the wet air inlet is at the dryer’s lower manifold, while the dry air outlet is

at the dryer’s upper manifold. In situations where air supply is required 24 hours a

day (it is undesirable to interrupt the airflow), a three valve by-pass system is

recommended to bypass the dryer. Use the fewest elbows necessary to keep

pressure drop at a minimum.

Once all piping has been connected, all joints including those on the dryer, should

be soap bubble tested at line pressure to ensure no joints have been damaged in

transit and site placement.

The standard dryer is not rated for any gas other than air.

NOTICE

ZEKS recommends that the mufflers be cleaned after initial start-up to remove

any desiccant dust generated during shipment. After running dryer for initial 30

minute period, de-energize / depressurize dryer and remove mufflers.

Disassemble and clean the removable insert inside the muffler core. Reinstall

mufflers prior to operating dryer.

NOTICE

10

7.4 FILTRATION

It is important that a prefilter and an afterfilter be provided in your dryer installation.

Coalescing prefilters, located before the dryer, protect desiccant beds from contamination by oil, entrained water, pipe scale, etc., thereby, extending dryer desiccant

life. Locate prefilters as close to dryer as possible.

It is recommended that a mechanical separator be installed immediately preceding

the prefilter to remove the bulk liquid and entrained water.

Particulate afterfilters, located after the dryer, help eliminate the possibility of

desiccant dusting and carryover into the air system.

7.5 ELECTRICAL CONNECTION

Make all electrical connections to the dryer as shown on the wiring diagram. Care

must be taken in connecting the proper voltages.

Size field connection knock-out for the conduit fitting required by the NEC.

7.6 DESICCANT LEVEL VERIFICATION

Remove desiccant fill port and the top of the desiccant vessel and check desiccant

level. The level should be consistent with the level depicted on the Desiccant Fill

Chart at the end of the manual

All dryers must have proper filtration. A .3 micron coalescing filter with

automatic drain & particulate after filter must be used as a minimum. Failure to

provide proper filtration for dryer will void warranty.

Dryer must be grounded with the full sized ground wire connected to an earth

ground.

Dryer must be fused according to NEC with the size fuse listed on the dryer

serial nameplate, or on specification sheet in technical manual.

NOTICE

NOTICE

NOTICE

11

7.7 START-UP

• Slowly pressurize the dryer. When the dryer reaches full operating pressure,

check the system for air leaks. Soap test all joints and fitting. To maintain desired

dew point, any leaks detected must be fixed, especially those on the outlet side of

the dryer.

• Make sure that the purge adjustment valve is open and air outlet shut off valve (if

equipped) is closed.

• For dryers equipped with a dew point monitor, remove the dew point monitor

sensor from the electrical enclosure and install in the sensing block, located

beside the enclosure and attach the sensor cable to the sensor.

• On dryers equipped with the Moisture Load Control option, verify that the Moisture

Load Control switch is in the OFF position to allow standard cycling at start-up.

• Turn on dryer disconnect switch (supplied by customer) to apply power to the

dryer.

• For the first 30 seconds that the dryer is energized, both purge valves will remain

closed. After 30 seconds, the left tower purge valve will be opened and depressurization of the left tower will occur.

• With a voltmeter, check the power connections for the correct voltage shown on

the dryer serial nameplate.

• Close and secure all electrical panel covers.

• When the dryer is energized, the Power-on Light and Right Tower Drying Light will

be illuminated. When electrical circuit has been energized, the Solid State Timer

will start automatically. See Section 6 for logic operating sequence.

• Following depressurization, adjust purge valve as described in Section 6.4

At initial start-up, check the dryer operation for one or two cycles, especially at

the time of the tower shift. Verify that all systems are operating in their proper

order and sequence. If the dryer is not functioning properly, contact distributor or

ZEKS Technical Service.

NOTICE

For dryers equipped with the optional NEMA 4 / DPC™ Package, refer to the

NEMA 4 / DPC™ Package Technical Manual Supplement prior to starting dryer.

NOTICE

12

• If the dryer has been in storage or off for an extended period of time, the Blue

Moisture Indicator may be gray, the High Humidity Alarm (if equipped) may be

activated and the dew point display (if equipped) may indicate a high dew point.

Depending upon the duration of idle time, it may take anywhere from one to

twelve hours for the alarm condition to go out, the BMI to return to its normal blue

state and the dew point to drop.

• Slowly open the outlet valve to gradually pressurize the down stream piping

• On dryers equipped with Moisture Load Control, the Moisture Load Control switch

may be turned “ON” to save purge air as described in Section 6.11.

When opening the outlet valve, insure drying tower gauge maintains line

pressure. Allowing pressure to drop in the dryer will result in an overflow

condition.

NOTICE

-80° F and -100° F dryers require flow through the dryer to lower the pressure

dew point to design levels. Failure to permit air flow through dryer (deadheading) will result in elevated outlet dew points. Once air is permitted to flow

through the dryer, the pressure dew point will gradually reduce to design levels.

NOTICE

13

8. MAINTENANCE AND SYSTEM CHECK

8.1 SCHEDULED MAINTENANCE

DAILY MAINTENANCE FUNCTIONS:

•Check and record inlet pressure, temperature and flow. Verify that it is

within specifications.

•Check tower pressure gauge readings within operating tolerance.

•Check operation for proper dryer cycling, depressurization and repressurization.

•Check that the prefilter drain is operating properly and that there is no condensate

discharged from purge mufflers.

•Verify that pressure in purging tower is 10 PSIG or less. If higher, muffler replacement is recommended. (Section 8.5)

•Verify that prefilter and afterfilter differential pressure is within operating limits.

Change as required. (Section 8.2)

•Check the Blue Moisture Indicator. Make sure air is bleeding through the indicator.

The indicator will be blue when air is dry.

SEMI-ANNUAL MAINTENANCE FUNCTIONS:

•Check outlet dew point.

•Check pilot air filter element and clean or replace as required.

•Replace prefilter and afterfilter elements and / or cartridges.

ANNUAL MAINTENANCE FUNCTIONS:

•Check desiccant and replace if necessary.

•Inspect and clean pilot air control solenoid valves, check valves and diaphragm

valves. Rebuild and / or replace as required.

•Test lights and switches, replace as necessary.

•Test electrical components, replace as necessary.

EVERY TWO YEARS:

•Replace diaphragm and seal kits on purge and switching diaphragm valves.

EVERY THREE - TO - FIVE YEARS:

•Replace desiccant.

•Rebuild purge and switching diaphragm valves (Preventative)

•Replace Check Valves (Preventative)

14

8.2 Prefilters and Afterfilters

• Prefilters - The cartridges of the prefilter must be changed as often as required to

prevent contamination of the regenerative dryer's desiccant bed.

The prefilter and automatic drain must be checked daily. To prolong filter cartridge

life, it is recommended that a mechanical air / moisture separator be placed

immediately before the prefilter.

• Afterfilters - The purpose of the afterfilter is to remove residual desiccant dust..

Depending upon equipment application and usage, frequency of filter element

change will vary. It is recommended to change filter element every six months as

a minimum.

8.3 Pilot Air Control Solenoid Valves

The length of time the pilot air valves can reliably operate without replacing is

dependent upon the type of dryer and the dryer’s operation. On ZEKS -40°F dew

point dryers, replacing the valves is recommended every 60 months. Given the

difference in cycle times for -80°F and -100°F units, these dryers should have their

pilot valves replaced every 30 months.

8.4 Muffler Changeout Procedure

• Depressurize the dryer turn control power off.

• Replace muffler.

• Follow Start-up procedure described in Section 7.6.

• Turn control power back on.

Should the drying system be overloaded and/or malfunctioning, causing high

pressure drop, afterfilters will prematurely plug. This problem can be avoided

by frequent inspection and proactive replacement of cartridges.

NOTICE

To avoid injury, depressurize dryer before performing any service.

WARNING

15

8.5 Purge and Switching Diaphragm Valves

These valves have two control ports; one on top and the other on the back side.

• Normally Open (N.O.) Valves: For N.O. inlet or repressurization valves, control air

is supplied to the top port. The back side port exhausts out the bottom side of the

diaphragm. If air leaks continuously when control air is supplied to the valve, the

internal seals are leaking and must be replaced.

• Normally Closed (N.C.) Valves: For N.C. purge valves, the top port is plugged.

Control air is supplied to the back port. If air vents out of the back port continuously when the solenoid is de-energized, it will exhaust through the top of the

solenoid. If this condition is observed, the internal seals are leaking and must be

replaced.

8.6 Outlet Check Valves

Outlet check valves sealing can be verified by depressurizing the dryer and slowly

applying pressure to the outlet. The valves should seal and prevent air from

pressurizing the towers. If a tower begins to pressurize, the check valve on that

side requires replacement.

8.7 Desiccant Changeout Procedure

When it becomes necessary to replace the desiccant in the towers, or on units that

are shipped without the desiccant installed, observe the following procedure:

• The standard units are furnished with fill and drain ports on each desiccant tower.

Remove the caps on both ports.

• To assist in getting the desiccant to flow from the tower, insert a small rod in to the

drain port as necessary. This may be required as the desiccant is packed into the

towers which may interfere with the desiccant flow from the towers.

To avoid injury, depressurize dryer before performing any service.

Be sure to wear respiratory protection during the draining and filling process to

minimize inhalation of desiccant, as desiccant will produce dust during this

procedure.

CAUTION

WARNING

16

• Retainer screens, located at the inlet and outlet piping connections of the tower,

are removable on all models. It is suggested that these screens be removed and

cleaned at the time of desiccant changeout. These screens can be accessed by

disconnecting the upper and lower manifolds from the dryer towers.

• After cleaning the retainer screens, replace screens and reattach the outlet port

plug.

• With the fill port plug removed, fill the dryer tower with the appropriate grade and

size desiccant. For those dryers that are shipped without desiccant installed,

using the fill kit provided with the dryer will facilitate filling the desiccant in the

tower. The level of the desiccant should be below the top retainer screen as

shown on the Desiccant Fill Chart below.

• Once the towers have been filled, replace the fill port plug on each tower.

• Any connections disturbed in the desiccant changeout process should be leak

tested prior to re-commissioning the dryer.

DESICCANT

FILL CHART

17

PROBLEM

Elevated dew point

Blue Moisture

Indicator (BMI)

indicates high

moisture level.

Excessive pressure

drop in dryer

Failure to shift

PROBABLE CAUSE

Insufficient purge rate.

Inlet air pressure below

design condition.

Flow rate higher than design

condition.

Inlet temperature above

design condition.(120°F)

Entrained water entering

desiccant bed.

Desiccant contaminated by oil

Elevated dew point

BMI wet

Excessive flowrate.

Inlet pressure below design

condition.

No input power.

Defective solenoid valve.

No pilot air.

Pilot-operated diaphragm

valve seal failure

CORRECTIVE ACTION

Check purge flow settings.

Check purge piping for obstruction.

Clean purge piping and muffler.

Check pressure source and system

for leakage.

Check flowrate and cause for

increased demand. Correct flowrate

condition.

Check aftercooler, clean and service

as necessary,

Check air/moisture separator, prefilter

and drains. Replace dryer desiccant

if necessary.

Install suitable prefilter. Replace dryer

desiccant.

Refer to “Elevated Dew Point” corrective actions above.

Depending on degree of saturation of

the desiccant, the BMI may take a

week or more of continuous use to

switch back to its blue (dry) state.

Check flow rate and cause for

increased air demand.

Check pressure source.

Check power input.

Check solenoid valve.

Check pilot air-line. Check that

control airline filter is clean.

Inspect and replace seals as required.

9. TROUBLESHOOTING

Refer to maintenance descriptions in Section 8 as required for trouble shooting

procedures.

18

CORRECTIVE ACTION

Check that repressurization circuit is

sending control signal.

Check purge valve and its solenoid

valve.

Check purge valve and its solenoid

valve.

Check purge valve and its solenoid

valve. Repair and replace if

necessary.

Check that repressurization circuit is

sending control signal.

Purge muffler is dirty; replace.

Check inlet valve and outlet check

valves. Verify inlet valve is closed to

purging tower (0 psig tower).

Reset when right tower is on line.

PROBLEM

Dryer fails to

pressurize.

Dryer depressurizes

too rapidly.

Dryer fails to purge.

Excessive back

pressure in regenerating tower (above 5

psig)

Right tower

excessively high

pressure at the purge

gauge.

PROBABLE CAUSE

Faulty purge valve.

Purge valve does not close;

dryer repressurizing through

inlet valve.

Purge valve does not open.

Purge valve stuck in closed

position.

Purge muffler does not pass

air.

Purge muffler passes too

much air. Air is leaking

across valve.

Improper calibration.

19

10. PURGE CHARTS

Purge Orifice - 9/64 "

90ZPA Setting - 48 psig @ 14 SCFM

0

2

4

6

8

10

12

14

16

18

0 10203040506070

Purge Meter Setting - psig

Purge Air Flow - SCFM

Purge Orifice - 5/32"

120ZPA Setting - 53 psig @ 19 SCFM

0

2

4

6

8

10

12

14

16

18

20

22

0 10203040506070

Purge Me ter Se tting - psig

Purge Air Flow - SCFM

Purge Ori fic e - 3/16"

160ZPA Setting - 50 psig @ 26 SCFM

0

5

10

15

20

25

30

35

0 10203040506070

Purge Meter Setting - psig

Purge Air Flow - SCFM

Purge Orifice - 7/32"

200ZPA Setting - 42 psig @ 30 SCFM

0

5

10

15

20

25

30

35

40

45

0 10203040506070

Purge Meter Setting - psig

Purge Air Flow - SCFM

Purge Orifice - 1/ 4"

2

50ZPA Setting - 42 psig @ 40 SCFM

0

5

10

15

20

25

30

35

40

45

50

55

60

0 10203040506070

Purge Meter Setti ng - psig

Purge Air Flow - SCFM

Purge Orifice - 9/ 32"

300ZPA

Setting - 40 psig @ 48 SCFM

0

5

10

15

20

25

30

35

40

45

50

55

60

65

70

0 10203040506070

Purge Meter Setting - psig

Purge Air Flow - SCFM

20

Purge Orifice - 5/16"

400ZPA

Setting - 45 psi g @ 65 SCFM

0

10

20

30

40

50

60

70

80

90

0 10203040506070

Purge Meter Setting - psig

Purge Air Flow - SCFM

Purge Ori fice - 3/8"

500ZPA Setting - 35 psi g @ 81 SCFM

0

10

20

30

40

50

60

70

80

90

100

110

120

130

0 10203040506070

Purge Me ter Setting - psig

Purge Air Flow - SCFM

Purge Orifice - 3/8"

600ZPA

Setting - 41 psig @ 93 SCFM

0

10

20

30

40

50

60

70

80

90

100

110

120

130

0 10203040506070

Purge Mete r Setti ng - psig

Purge Air Flow - SCFM

Purge Orifice - 7/16"

800ZPA

Setting - 46 psig @ 130 SCFM

0

20

40

60

80

100

120

140

160

180

0 10203040506070

Purge Meter Setting - psig

Purge Air Flow - SCFM

Purge Orifice - 1/2"

1000ZPA

Setting - 43 ps ig @ 162 SCFM

0

20

40

60

80

100

120

140

160

180

200

220

0 10203040506070

Purge Meter Setting - psig

Purge Air Fl ow - SCFM

Purge Ori fic e - 9/16"

1200ZPA

Setting - 41 psig @ 195 SCFM

0

30

60

90

120

150

180

210

240

270

300

0 10203040506070

Purge Meter Setting - psig

Purge Air Flow - SCFM

Purge Orifice - 5/8"

1500ZPA

Setting - 41 psig @ 243 SCFM

0

30

60

90

120

150

180

210

240

270

300

330

360

0 10203040506070

Purge Meter Setting - psig

Purge Air Flow - SCFM

Purge Orifice - 5/ 8"

1800ZPA

Setting - 51 psig @ 292 SCFM

0

30

60

90

120

150

180

210

240

270

300

330

360

0 10203040506070

Purge Meter Setting - psig

Purge Air Flow - SCFM

Purge Orifice - 3/4"

2100ZPA

Setting - 40 psig @ 340 SCFM

0

50

100

150

200

250

300

350

400

450

500

0 10203040506070

Purge Me ter Se tting - psig

Purge Air Flow - SCFM

Purge Orifice - 3/ 4"

2700ZPA

Setting - 53 psig @ 438 SCFM

0

50

100

150

200

250

300

350

400

450

500

0 10203040506070

Purge Meter Setting - psig

Purge Air Flow - SCFM

Purge Orifi ce - 7/ 8"

3300ZPA

Setting - 47 psig @ 535 SCFM

0

50

100

150

200

250

300

350

400

450

500

550

600

650

700

0 10203040506070

Purge Meter Setting - psig

Purge Air Fl ow - SCFM

Purge Orifice - 1"

4000ZPA

Setting - 44 psig @ 649 SCFM

0

100

200

300

400

500

600

700

800

900

1000

0 10203040506070

Purge Mete r Setti ng - psig

Purge Air Flow - SCFM

21

Purge Ori fice - 1"

5000ZPA

Setting - 56 psig @ 811 SCFM

0

100

200

300

400

500

600

700

800

900

1000

0 10203040506070

Purge Meter Setting - psig

Purge Air Flow - SCFM

22

Loading...

Loading...