Page 1

zebris Medical GmbH

www.zebris.de

Text-Release: 19/01/2016

Specifications

Operating Instructions

and

Page 2

zebris Medical GmbH

FDM Technical Data and Operating Instructions

Page 2/54

Inhalt

1 USER NOTES ................................................................................................................................. 4

1.1 INTRODUCTION .............................................................................................................................. 4

1.2 MANUFACTURER AND SALES .......................................................................................................... 5

1.3 LAYOUT OF THE USER MANUAL FOR THE FDM SYSTEM .................................................................... 5

1.4 CONVENTIONS AND SYMBOLS USED ............................................................................................... 6

2 SCOPE AND SECURITY ................................................................................................................ 7

2.1 INTENDED USE .............................................................................................................................. 7

2.1.1 Indications ................................................................................................................................... 7

2.1.2 Contraindications ........................................................................................................................ 7

2.2 SAFETY ......................................................................................................................................... 8

2.2.1 Environmental conditions ............................................................................................................ 8

2.2.2 Storage and Transport ................................................................................................................ 8

2.2.3 User Obligations .......................................................................................................................... 9

2.2.4 General safety instructions ....................................................................................................... 10

3 PRODUCT DESCRIPTION ........................................................................................................... 11

3.1 SYSTEM COMPONENTS ................................................................................................................ 11

3.2 TECHNICAL SPECIFICATIONS FDM MEASURING SYSTEMS ............................................................... 11

3.2.1 FDM Sensor .............................................................................................................................. 11

3.2.2 FDM platforms for stance and roll over analysis ....................................................................... 12

3.2.3 FDM system for jump analysis .................................................................................................. 13

3.2.4 FDM system for stance and gait analysis ................................................................................. 14

3.2.5 FDM platforms for gait training and rehabilitation applications ................................................. 16

3.3 MEASURING PRINCIPLE ................................................................................................................ 17

3.4 CONTROLS AND CONNECTORS ..................................................................................................... 18

3.5 STATUS INDICATOR LED .............................................................................................................. 18

3.6 ZEBRIS SYNC ............................................................................................................................. 19

3.6.1 Synchronization input (SYNC-IN) ............................................................................................. 20

3.6.2 Synchronization output (SYNC-OUT) ....................................................................................... 21

3.6.3 Synchronizing the FDM Platform with video data (Sync Audio) ............................................... 22

3.6.4 Infrared synchronization with zebris DAB- Bluetooth (EMG) .................................................... 23

3.6.5 Combine two FDM platforms oft he same type ......................................................................... 24

3.7 SPARE PARTS FDM SYSTEM ....................................................................................................... 25

3.8 ACCESSORIES FDM MEASURING SYSTEM .................................................................................... 25

4 VIDEO-MODULE........................................................................................................................... 28

4.1 SYNCCAM ................................................................................................................................. 28

4.2 SYNCLIGHTCAM ........................................................................................................................ 29

4.3 LED VIDEO LIGHTS (SYNCLIGHT / SYNCLIGHT PLUS) ................................................................. 32

4.3.1 SYNCLight ................................................................................................................................ 33

4.3.2 SYNCLight plus ......................................................................................................................... 34

4.3.3 Power Supply Unit SYNCLights ................................................................................................ 35

5 OPERATION OF THE FDM SYSTEM .......................................................................................... 37

5.1 SET UP THE MEASURING SYSTEM ................................................................................................. 37

5.2 HOW TO SWITCH THE PLATFORM ON/OFF ..................................................................................... 37

5.3 ANSCHLUSS DES MESSSYSTEMS AN DAS VERSORGUNGSNETZ ....................................................... 38

5.4 COMPUTER REQUIREMENTS ......................................................................................................... 40

5.5 INSTALLING THE ZEBRIS FDM SOFTWARE ..................................................................................... 40

5.6 CLOSING THE SAFETY LOCK OF THE PLUG TRAY ............................................................................. 41

5.7 SETTING THE SYSTEM OUT OF OPERATION .................................................................................... 41

5.8 RECOMMENDATIONS FOR RECORDING DATA .................................................................................. 42

5.8.1 Walking range ........................................................................................................................... 42

5.8.2 Data recording ........................................................................................................................... 42

5.8.3 Gait velocity ............................................................................................................................... 42

5.8.4 Posture ...................................................................................................................................... 42

5.8.5 Acrosclerosis ............................................................................................................................. 42

Page 3

zebris Medical GmbH

FDM Technical Data and Operating Instructions

Page 3/54

6 CONTROL MEASURES, PREPARATION, DISPOSAL .............................................................. 43

6.1 MANDATORY PERIODIC INSPECTIONS AND STK ............................................................................. 43

6.2 CHECKING THE FDM SENSOR ...................................................................................................... 44

6.2.1 Control measures ...................................................................................................................... 44

6.2.2 Calibration measures ................................................................................................................ 44

6.3 TROUBLESHOOTING ..................................................................................................................... 45

6.4 CLEANING AND DISINFECTION ....................................................................................................... 46

6.4.1 Cleaning .................................................................................................................................... 46

6.4.2 Manuelle Desinfektion ............................................................................................................... 46

6.5 DISPOSAL ................................................................................................................................... 47

6.5.1 Packaging ................................................................................................................................. 47

6.5.2 Disposal of electronics .............................................................................................................. 47

7 SAFETY STANDARDS AND SYSTEM CLASSIFICATION ........................................................ 48

7.1 CLASSIFICATION ACC. TO ANNEX IX OF DIRECTIVE 93/42/EEC ...................................................... 48

7.2 SAFETY OF MEDICAL ELECTRICAL DEVICES .................................................................................... 48

7.2.1 Connecting the FDM-System to other electrical devices .......................................................... 48

7.2.2 Vicinity of the patient / test person ............................................................................................ 49

7.2.3 Use of multiple sockets ............................................................................................................. 50

7.3 ELECTROMAGNETIC COMPATIBILITY GUIDELINE & MANUFACTURER DECLARATION .......................... 51

7.4 DECLARATION OF CONFORMITY MEDICAL PLATFORMS .................................................................... 54

Page 4

zebris Medical GmbH

FDM Technical Data and Operating Instructions

Page 4/54

1 User Notes

1.1 Introduction

Welcome to the User Manual for the zebris FDM measuring system.

This User Manual provides a basic understanding for operating the FDM measuring system.

It provides essential information for the set up of the system and suggests basic principles

for preparing the measuring procedure and data recording.

zebris Medical GmbH does not assume any liability for injury to personnel or patients, nor

damage to the device caused by improper use of the FDM measuring system for gait and

stance analysis.

All data about the measuring system FDM within this user manual has been collected, compiled and checked with the greatest possible care. Nevertheless a User Manual may remain

subject to printing errors, faults and changes. Therefore we should like to point out that

zebris Medical GmbH neither guarantees nor holds the legal responsibility or any liability

whatsoever for consequences occurring due to incorrect data.

Should you become aware of any errors when using this User Manual, or should you find

details that do not conform with your device, please kindly inform us. We shall then correct

any possible errors as quickly as possible.

In the interests of continuous product development, the manufacturer reserves the right to

carry out improvements to this User Manual and the product described therein at any time

and without any further obligation.

Registered trade marks

Several brand names are referred within this User Manual. All these product names are

used only for clarity’s sake or for editorial reasons and are trademarks belonging to the

respective companies. When using the brand names, the trade marks them and also the

rights of the respective proprietors remain protected.

The name zebris is a registered trade mark and FDM identifies a product of the company,

zebris Medical GmbH.

Copyright

This document and extracts taken from it may on no account be duplicated without the ex-

plicit consent of zebris Medical GmbH. The content of this document may on no account be

used for purposes that have not undergone approval by zebris Medical GmbH. Any infringement of the copyright is a punishable offence.

© Copyright zebris Medical GmbH

All rights reserved.

Page 5

zebris Medical GmbH

FDM Technical Data and Operating Instructions

Page 5/54

1.2 Manufacturer and sales

NOTE

Please closely observe the user manuals with initial operation,

use or maintenance as well as transport of the FDM measuring

system.

WARNING

The exact adherence to the instructions in all sections of the operating

Instructions for the measuring system is a precondition for its intended

use.

zebris Medical GmbH

Am Galgenbühl 14 Telephone +49 (0)7562 9726 0

D-88316 Isny im Allgäu Telefax +49 (0)7562 9726 50

Deutschland

Internet: www.zebris.de E-Mail info@zebris.de

1.3 Layout of the user manual for the FDM System

The measuring system FDM consists of the force distribution measuring sensor technology

as well as the corresponding application software including a PC.

Therefore, the user manual of the FDM measuring system consists of several parts:

1. FDM technical specifications and user manual

2. zebris FDM user manual of the application software

3. User manual of the accessories, like e.g. projector or PC

The section FDM technical specifications and user manual primarily contains information on

technical data and the operation of the FDM force distribution measuring sensor technology

as well as on their safe operation.

Page 6

zebris Medical GmbH

FDM Technical Data and Operating Instructions

Page 6/54

1.4 Conventions and Symbols Used

The green markings in the margin of the User Manual denote

new information about the product safety.

“WARNING” symbols indicate a potential hazard to the health

and safety of the users and/or patients. The warnings describe

the risks involved and those can be avoided.

“NOTE” symbols indicate a potential risk which could lead to

damaging of the device. These NOTE symbols describe the risks

involved and how those can be avoided.

The CE mark on the type plate confirms the conformity of the

measuring system with the Directive 73/23/EEC and Directive

89/366/EEC (Low Voltage Directive and EMC Directive).

The CE mark with reference number 0535 of notified body BSI

(formerly EUROCAT) on the type plate confirms the conformity

of the system with the Directive 93/42/EEC for Medical Devices.

Symbol for manufacturer and date of production.

Device of type BF according to DIN EN 60601-1

Symbol for the connection of the external power supply unit

(DC voltage 15-20V with indicated polarity)

USB-Interface

The symbol indicates that in accordance with the Directive

2002/96/EEC (Waste Electronic and Electrical Equipment Directive) and national laws, a product must not be disposed of in

the household waste, and that within Europe it has to be disposed of in a special way.

Carefully read the accompanying documentation, particularly all

information concerning product safety

REF

Item number of the measuring system / accessories

SN

Serial number of the measuring system

Page 7

zebris Medical GmbH

FDM Technical Data and Operating Instructions

Page 7/54

2 Scope and security

2.1 Intended Use

Main function of the force distribution measurement system FDM is the spatially resolved

force distribution measurement under human feet for the analysis of static and dynamic

strains as well as the individual gait parameters.

Operation as well as data evaluation and storage are software-aided by using a computer.

The measuring systems are suitable for the use with patients that are mentally capable of

following the operator’s instructions without limitations in the period of application.

The patient’s weight is limited by the maximum permissible weight of the treadmill. For the

application of the FDM-T with children or patients with severe movement disorders, a fall

stop safety is strongly recommended.

Professional facilities (medical practices, clinics, scientific institutions, rehabilitation centres,

and orthopaedic specialist shops) are specified as application environment.

The application and operation of the system may only be carried out by thoroughly trained

qualified personnel such as clinical doctors, physiotherapists, orthopedics which posses the

ability to evaluate the output data in medical aspects as a aid for the diagnosis, treatment or

patient care and taking into account the clinical history of the patient in the context of other

diagnostic tests.

2.1.1 Indications

Stance and gait analysis of the “normal” as well as the pathological stance and gait.

Diagnosis support with foot malpositions and foot corrections

Diagnosis support and therapy of imbalances / incorrect gait pattern

Detection of inappropriate mechanical stress and overstraining for the prevention of phys-

ical problems and for rehabilitation with disabilities after injury, accidents or surgeries.

Support with the development, adjustment and verification of orthopaedic aids for the

individual patient care

Balance analysis and balance training

Gait training in combination with dynamic visual stimulation (cueing) and feedback train-

ing as therapy/rehabilitation measures after a surgery, stroke, with the Parkinson’s dis-

ease as well as other neurologic and orthopaedic disorders

Success control of therapy/rehabilitation measures

2.1.2 Contraindications

The FDM system must not be applied for a barefoot measurement with patients having

open wounds and/or infections on the feet.

Page 8

zebris Medical GmbH

FDM Technical Data and Operating Instructions

Page 8/54

2.2 Safety

WARNING

FDM systems must NOT be operated in wet zones, wet rooms (swimming pools, saunas) or climatic chambers.

Direct contact with liquids must always be avoided, as the measuring

system is not protected against the entering of liquids. Liquids entering the device can cause fire, electrical shock or other severe accidents.

The FDM system is NOT specified for the operation in vacuum, hyperbaric or altitude chambers.

The measuring systems are not intended for operation in potentially

explosive atmospheres of medically used rooms or oxygen-enriched

atmospheres.

The devices must not be operated in proximity to e.g. engines or

transformers with a high connected load as well as mains current

lines, as electrical or magnetic interference fields can falsify correct

measurements resp. turn them impossible.

2.2.1 Environmental conditions

FDM Measuring Systems are suitable for application in dry interiors with level ground such

as those in hospitals, doctors' surgeries and laboratories.

Temperature range 10°C to 40°C

Relative humidity 30% to 70%

2.2.2 Storage and Transport

Storage and transport of the measuring system are only to be effected in the original packaging provided by zebris.

Storage temperature -20°C to +70°C

Relative humidity 5% to 90%

Air pressure 700 hPa to 1060 hPa

Page 9

zebris Medical GmbH

FDM Technical Data and Operating Instructions

Page 9/54

2.2.3 User Obligations

The relevant, general guidelines and/or national laws, national regulations and technical

rules for the commissioning and the operation of medical products must be applied and

fulfilled corresponding to the indicated purpose of the zebris product. In Germany, operators, device in-charge persons and users are obliged to operate their devices in consideration of the MPG-regulations.

Users are obliged to:

observe all safety guidelines of the user manual.

carry out any inspection and maintenance works on a regular basis as stipulated in

the user manual.

only use work equipment that is free of defects.

check the functional safety and the proper condition of the device before operating.

make all user manuals that are included in delivery and part of the measuring system

accessible to all users at all times and keep the manuals in close proximity of the

measuring system.

protect him-/herself, the patient or third parties against dangers.

avoid a contamination through the product.

When using the system, national legal regulations must be observed, in particular:

the valid industrial safety regulations.

the valid accident prevention.

For the safety, reliability and performance of the components delivered by zebris, respon-

sibility is assumed, if:

assembly, extensions, re-settings, changes or repairs were carried out through zebris

or third parties authorised by zebris, trained technicians or employees of authorised

dealers. Storage and transport are only to be effected in the original packaging delivered by the manufacturer.

the device is operated in accordance with the user manual.

in case of repair, the regulations of the VDE 0751-1 “Recurrent test and test before

commissioning of medical electrical equipment – general regulations” are fully complied with.

the components of information technology provided by the operator correspond to the

technical requirements of hard and software included in this user manual and also

were installed and set up according to the relevant descriptions in this user manual.

the set-up room corresponds to the given environmental conditions of the measuring

the FDM system including accessories is connected to the mains socket with a pro-

exclusively the software provided by zebris as well as the components and accessory

system and the valid installation regulations.

tective grounding conductor and is operated with the correct mains voltage.

parts listed in this user manual are used together with the system.

Page 10

zebris Medical GmbH

FDM Technical Data and Operating Instructions

Page 10/54

2.2.4 General safety instructions

The application and operation of the system and also the evaluation of the measuring

data and their interpretation may only be carried out by trained qualified personnel. The

manufacturer assumes no liability for any injury to persons, damage to property, or loss

of data due to improper use of the software, the device or its component parts.

The patients’ data and measuring data may only be copied, moved, or deleted using the

data-base function provided by the zebris application programs. In the case of data being

changed intentionally without using the database functions, the user alone bears the full

risks involved.

Measurement and analysis results should always be interpreted in the light of the clinical

history of the patient and in the context of other diagnostic tests by a trained person

proven and tested for their relevance.

Should any measures for treatment be taken on the basis of the measuring results, the

measuring system may only be implemented as a supplementary means for evaluation

by an expert. On no account can, or may invasive measures, or measures endangering

the patient be carried out solely on the basis of the measuring results without further

verification of the measuring data by additional methods.

Should there be any detectable damage to the device or component parts, they should

be returned to the manufacturer for a safety check. It is not permissible to continue using

the device or its component parts, as severe damage and serious injuries - even lethal

injuries - may result. The manufacturer or authorized sales partner must always be contacted in all cases of fault or doubt.

If any fluids should penetrate the device, it is mandatory for the device to undergo a tech-

nical, safety test. Damaged plug connections and leads are to be replaced by an authorized service technician. The device must be put out of operation immediately, marked as

"Not working“ and prevented from being used by removing the mains cable.

The measuring system must be checked at regular intervals to make sure it is functioning

properly. More details on this can be found in the section, "Maintenance of the Device" in

this User Manual

Be sure that all the mains and connection cables are laid safely and that they are pro-

tected against stepping on, so that nobody can trip over them. Check all the cables and

the connection plug regularly for any damage. Damaged power Supplys and cables have

to be replaced before further operation

Never try to service the measuring system in any other way as described in the provided

user manual. When removing the covers, you may expose yourself to lethal voltages or

other risks.

We also point out that if any changes are made to this certified device or its accessories

without the prior written consent of zebris, your legal right to operate the device will be

nullified.

Page 11

zebris Medical GmbH

FDM Technical Data and Operating Instructions

Page 11/54

3 Product description

3.1 System components

In its basic configuration the FDM measuring system consists oft he following components:

FDM platform

External power supply unit

USB cable (Type A-A, 3.5 m length)

zebris application software zebris FDM

IBM® compatible computer or notebook

User Manual for platform and software, equipment and zebris FDM Software

3.2 Technical specifications FDM measuring systems

3.2.1 FDM Sensor

The sensors of the different FDM system only vary in size of the measuring area, the number

of single sensors included in the sensor module and the supported sampling frequency. All

other technical data is identical:

Interfaces USB

Synchronization input/output

Video synchronization

Infrared synchronization

Connection Interface box on bottom of housing frame

Measuring principle capacitive force measurement

Operating voltage 16-18V DC

Power consumption max. 60W (depends on type)

Power supply via external power supply unit 100-240V AC / 50-60Hz

Measuring Range 1-120N/cm2

Accuracy of the calibrated measuring range (1-120N/cm2) ±5% (FS)

Mechanical crosstalk -25dB

Pressure threshold 1N/cm²

Page 12

zebris Medical GmbH

FDM Technical Data and Operating Instructions

Page 12/54

3.2.2 FDM platforms for stance and roll over analysis

Type

FDM-SX

REF.-No.

01243005

Outer dimensions

550 x 400 x 21 mm (L x W x H)

Weight

ca. 4,8 kg

Measuring frequency

120 Hz

Number of sensors

40 x 48 / 1920

Sensor surface

400 x 330 mm (L x W)

Resolution

1/3 “ resp. 1,4 sensors/ cm²

Infrared interface

optional

Type

FDM-S

REF.-No.

01243010

Outer dimensions

690 x 400 x 21 mm (L x W x H)

Weight

ca. 6,5 kg

Measuring frequency

100 Hz / optional 240 Hz

Number of sensors

40 x 64 / 2560

Sensor surface

540 x 330 mm (L x W)

Resolution

1/3 “ resp. 1,4 sensors / cm²

Infrared interface

optional

Connector box

at bottom side

Connector box

at bottom side

Page 13

zebris Medical GmbH

FDM Technical Data and Operating Instructions

Page 13/54

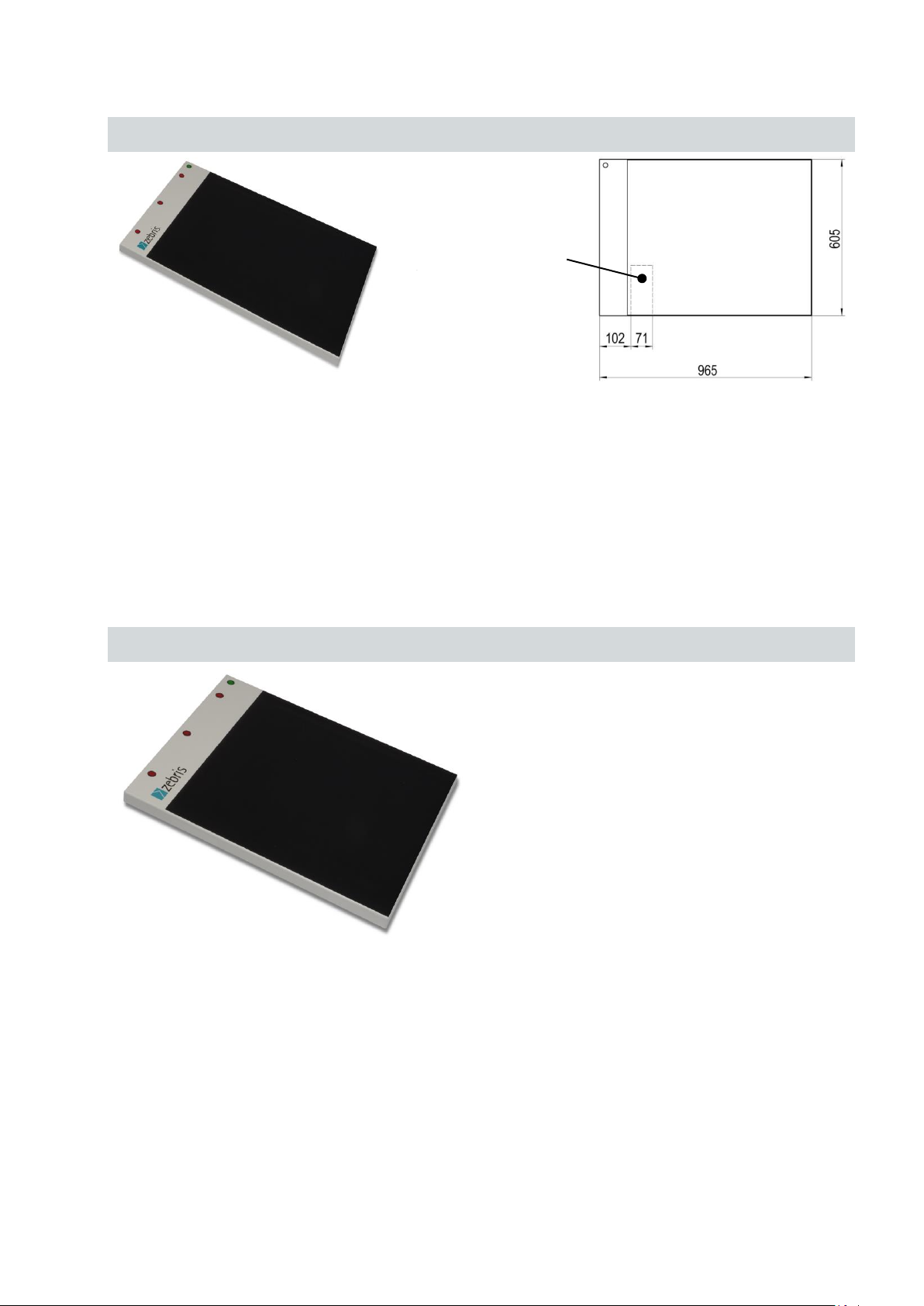

3.2.3 FDM system for jump analysis

Type

FDM-J1.0

REF.-No.

01243200

Outer dimensions

965 x 605 x 21 mm (L x W x H)

Weight

approx.12 kg

Measuring frequency

400 Hz / optional 800 Hz

Number of sensors

60 x 64 / 2560

Sensor surface

810 x 510 mm (L x W)

Resolution

1/2 “ resp. 0.6 sensors / cm²

Infrared interface

integrated

Geben Sie hier eine Formel ein.

Type

FDM-J1.8SQ

REF.-No.

01243210

Outer dimensions

1810 x 1940 x 21 mm (L x W x H)

Weight

approx. 50 kg

Measuring frequency

100 Hz

Number of sensors

96 x 96 / 9216

Sensor surface

1730 x 1730 mm (L x W)

Resolution

3/4 “ approx. 0.3 sensors / cm²

Infrared interface

integrated

Connector box

at bottom side

Page 14

zebris Medical GmbH

FDM Technical Data and Operating Instructions

Page 14/54

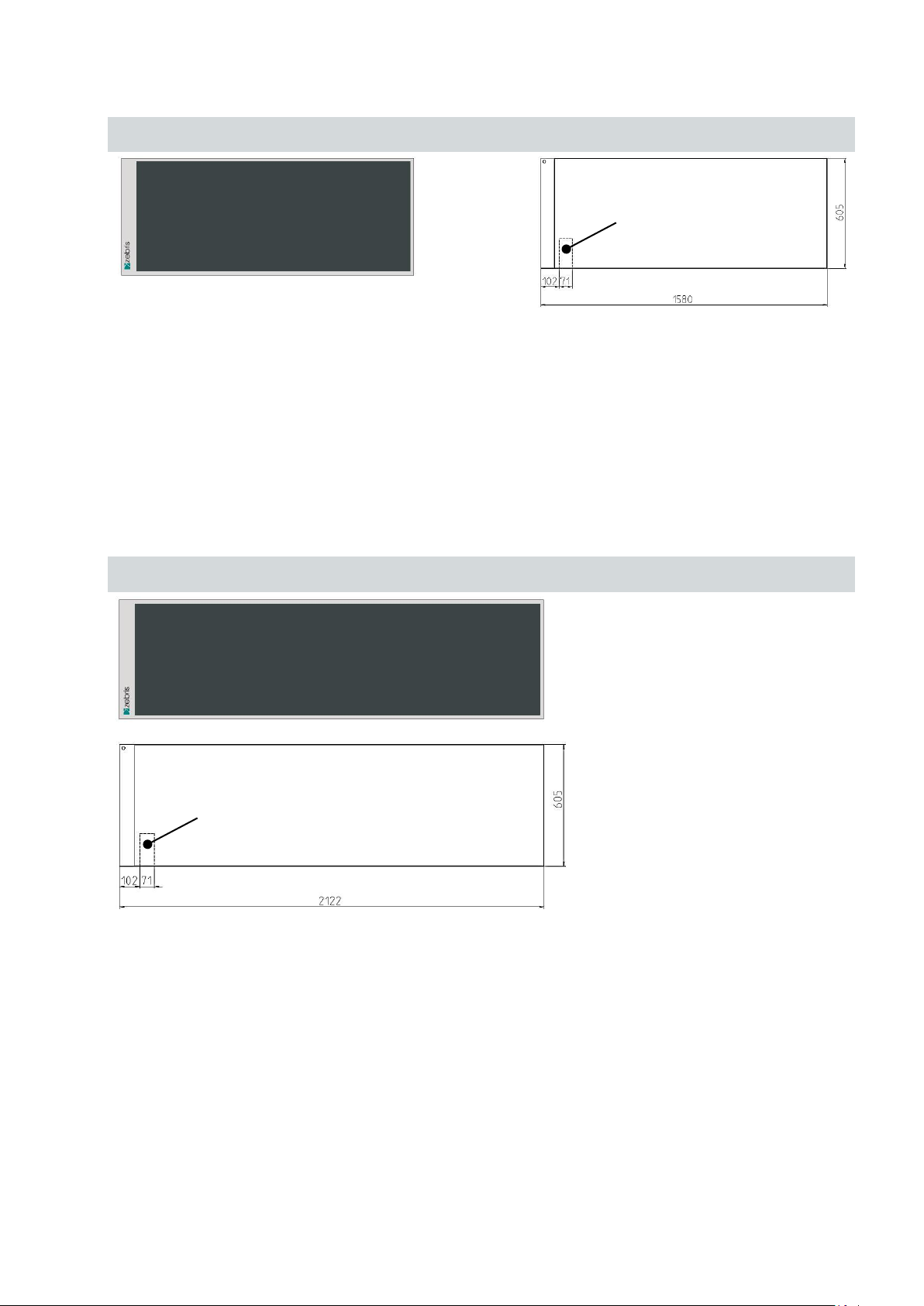

3.2.4 FDM system for stance and gait analysis

Type

FDM-1.5

REF.-No.

01243015

Outer dimensions

1580 x 605 x 21 mm (L x W x H)

Weight

ca. 16,5 kg

Measuring frequency

120 Hz / optional 200 Hz oder 300 Hz

Number of sensors

64 x 176 / 11264

Sensor surface

1440 x 560 mm (L x W)

Resolution

1/3 “ resp. 1,4 sensors / cm²

Infrared interface

integrated

Type

FDM-2

REF.-No.

01243020

Outer dimensions

2122 x 605 x 21 mm (L x W x H)

Weight

approx. 25 kg

Measuring frequency

120 Hz / optional 200 Hz oder 300 Hz

Number of sensors

64 x 240 / 15360

Sensor surface

2030 x 560 mm (L x W)

Resolution

1/3 “ resp. 1,4 sensors / cm²

Infrared interface

integrated

Connector box

at bottom side

Connector box

at bottom side

Page 15

zebris Medical GmbH

FDM Technical Data and Operating Instructions

Page 15/54

Type

FDM-3

REF.-No.

01243030

Outer dimensions

3070 x 605 x 21 mm (L x W x H)

Weight

approx. 35 kg

Measuring frequency

100 Hz

Number of sensors

64 x 352 / 22528

Sensor surface

2980 x 560 mm (L x W)

Resolution

1/3 “ resp. 1,4 sensors / cm²

Infrared interface

integrated

Connector box

at bottom side

Page 16

zebris Medical GmbH

FDM Technical Data and Operating Instructions

Page 16/54

3.2.5 FDM platforms for gait training and rehabilitation applications

Type

FDM-1.7

REF.-No.

01243034

Outer dimensions

1820 x 600 x 21 mm (L x W x H)

Weight

approx. 22 kg

Measuring frequency

100 Hz

Number of sensors

44 x 136 / 5984

Sensor surface

1730 x 560 mm (L x W)

Resolution

1/2 “ resp. 0.6 sensors / cm²

Infrared interface

optional

Type

FDM-2.4

REF.-No.

01243035

Outer dimensions

2510 x 600 x 21 mm (L x W x H)

Weight

approx. 31 kg

Measuring frequency

100 Hz

Number of sensors

44 x 190 / 8360

Sensor surface

2410 x 560 mm (L x W)

Resolution

1/2 “ resp. 0.6 sensors / cm²

Infrared interface

optional

Connector box

at bottom side

Connector box

at bottom side

Ready for installation

in h/p/cosmos parawalk

Page 17

zebris Medical GmbH

FDM Technical Data and Operating Instructions

Page 17/54

3.3 Measuring principle

Kapazitive Meßmatrix

Spaltendekoder

Treiber

Diodenschalter

Schiebe-

register

Diodenschalter

Schiebe-

register

...

Burstgenerator, Ansteuerlogik

Gleichrichter, Verstärker,

8-Bit ADC

Datenbus

Kalibrierdaten

Kalibrier- Flash

RAM

Optokoppler &

Galvanische Trennung mit

Gleichrichter

PC

externes

AC-Netzteil

entspricht

IEC 601

USB

CPU

Programm-

daten

CPU-internes

Flash

Diodenschalter

Schiebe-

register

Diodenschalter

Schiebe-

register

...

The system contains a measuring matrix consisting of capacitive pressure sensors that

are arranged in columns and lines running closely next to each other. For determining the

force distribution over the measuring matrix the capacity proportional to the force exerted

is determined for each individual sensor. To do this, the drive logic generates a number

of sinus burst signals equivalent to the number of columns via the column decoder, and

transmits them to the respective measuring column. The analog signal coupled into the

shift register over the lines is proportional to the pressure-dependent capacity and is

passed on for further processing to the control and signal-processing electronics and

transmitted to the PC from there and shown on the display.

Schematic circuit diagram of the measuring system

Page 18

zebris Medical GmbH

FDM Technical Data and Operating Instructions

Page 18/54

3.4 Controls and Connectors

Status indicator LED

Infrared interface

Measuring area

Connector box

withsafety lock

(bottom side)

All cable connections between platform and PC will be established by the connector box

located at the bottom of the platform.

USB-socket Video-Sync Sync Out/Master Sync In/Slave Powersupply

3.5 Status indicator LED

green flashing The power supply unit is connected to mains and a correct sup-

ply voltage is provided. A USB connection is not established yet

or recognized. The platform is not ready for initialization or

measurement.

green permanent The power supply unit is connected to mains and a correct sup-

orange permanent A measurement is in process.

orange / green flashing A measurement is in process and infrared synchronization sig-

ply voltage is provided. A USB connection is established and

recognized. The platform is ready for initialization or measurement.

nals (from other zebris devices) are received. The orange flashing signalizes that valid synchronization signals are received.

Page 19

zebris Medical GmbH

FDM Technical Data and Operating Instructions

Page 19/54

3.6 zebris SYNC

WARNING

Patient’s safety is guaranteed by means of galvanic separation acc.

to to the provisions of IEC 601-1 when a third party device is synchronized with the FDM system. This allows non medical equipment to be

synchronized with the FDM system as long as such devices are out

of patients reach. Nevertheless the user is completely responsible for

the safety of all third party devices used in combination with the FDM

system.

The correct synchronisation of the measuring data of all coupled systems must be verified before evaluation as soon as a coupling with

devices is carried out, that have not been manufactured by zebris.

zebris does not assume any warranty for the correct functioning and

reliability of the system if the clock signals of external devices do not

correspond to the indicated specifications.

The zebris SYNC serves as a standard solution for the synchronisation of the FDM system

with measuring systems of other manufacturers.

The SYNC-IN and SYNC-OUT sockets provide inputs and outputs for support of „frame by

frame“ In- and Out synchronization. Both sockets are galvanic protected from the platform.

Page 20

zebris Medical GmbH

FDM Technical Data and Operating Instructions

Page 20/54

3.6.1 Synchronization input (SYNC-IN)

View

Front side

Fitting Nut: 30°

Pin assignment

Pin 1 Clk_IN

Pin 2 Activ_IN

Pin 3 GND

View

Solder side

Fitting Nut: 30°

If a third party device is connected to the synchronization input SYNC-IN then depending on

the setting of the configuration window from the application software the measurement will

start/stop or “frame by frame” synchronized by a signal from the third party device. Input is

protected against faulty polarisation and pin 1 is set to +5V ("1") by an internal pull-up- resistor 2.7 k. If this input is set to 0 V ("0") i.e. by a switch or break contact than the SYNCIN is triggered.

Electrical specifications

Input resistance (Pull-Up 5V) 2,7k

VIH (High-Level Input Voltage) ≥ 2,0V

VIL (Low-Level Input Voltage) ≤ 0,8V

Required min. pulse time for triggering 1ms

Built-in LEMO – Jack at Front of ZEBRIS Gauge

Series „00“, 3-pin, fitting Nut 30°

LEMO- Part. No. EPA.00.303.NLN

Respective PlugType of plug for SYNC-IN:

LEMO- Part No. FGA.00 303.CLADxxxx

Page 21

zebris Medical GmbH

FDM Technical Data and Operating Instructions

Page 21/54

3.6.2 Synchronization output (SYNC-OUT)

View

Front side

Fitting Nut: 0°

Pin assignment

Pin 1 +5V

Pin 2 GND

Pin 3 Activ_OUT

Pin 4 Clk_OUT

View

Solder side

Fitting Nut: 0°

If a third party device is connected to the synchronization output SYNC-OUT then depending

on the setting of the configuration window from the application software will trigger a synchronized measurement of the third party device either via start/stop or “frame by frame”

mode.

Electrical specifications

Output resistance 100

High-Level ≥ 2,0V

Low-Level ≤ 0,8V

Respective Plug Type of plug for SYNC-IN

Series „00“, 4-pin , fitting Nut 0°

LEMO- Part. No. EPG.00.304.NLN

Passender Steckertyp für SYNC-OUT

LEMO- Part. No. FGG.00 304.CLADxxxx

Page 22

zebris Medical GmbH

FDM Technical Data and Operating Instructions

Page 22/54

3.6.3 Synchronizing the FDM Platform with video data (Sync Audio)

The Sync-Audio socket serves for synchronizing the platform measurement and recordings

of commercially available video cameras utilizing the external microphone input of the camera.

The synchronization is effected by imprinting a tact signal on the soundtrack of the video

recording. This data is evaluated automatically by the application software WinFDM for synchronizing the platform data and the video signal.

For the connection to the video camera the following synchronization cable is required:

Item No. 01830016 / Video Sync-Control cable,

cable length 7m with amplifier and control LED.

Page 23

zebris Medical GmbH

FDM Technical Data and Operating Instructions

Page 23/54

3.6.4 Infrared synchronization with zebris DAB- Bluetooth (EMG)

FDM-Plattform

USB-interface

Infrared synchronization signal

DAB-Bluetooth

(Infrarotempfänger)

EMG-electrodes

PC

Transmission oft he EMG

signals via Bluetooth interface

Infrared transmitter

For synchronizing the FDM system with the zebris DAB-Bluetooth the optionally available

IR interface which will be integrated within the platform housing is required.

FDM platform and DAB-Bluetooth are synchronized automatically as soon as both devices

have been switched on and a measurement is started.

The following schematic diagram shows the interconnection of the FDM-platform and

the zebris DAB-Bluetooth.

Page 24

zebris Medical GmbH

FDM Technical Data and Operating Instructions

Page 24/54

3.6.5 Combine two FDM platforms oft he same type

NOTE

Be sure to position both platforms as shown below when connecting

them for doubling the walking range.

NOTE

When using the zebris SYNCCam with two combinded plattforms it

must be connected to the “Sync Audio” input of the master platform.

Two FDM platforms of the same type can be combined (Master – Slave) in order to double

usable walking range. To accomplish this task a synchronization cable is required.

Item No. 01830019 / SC-PP Sync. Cable, length 10m

Both platforms have to be connected to separate USB ports of the same PC. By means of

the synchronization cable the „Sync Out“ socket of the master platform has to be connected

to the „Sync In“ socket of the slave platform. The WinFDM software then will recognize the

platform combination automatically and show the corresponding sized measuring area.

Page 25

zebris Medical GmbH

FDM Technical Data and Operating Instructions

Page 25/54

3.7 Spare Parts FDM System

REF- No.

Description

Illustrations

01811513

PS Mascot/2020

Power supply unit 60W/16VDC for FDM

1.5/1.7/2/2.4/3/J

sensors equiv. to EN 60601-1 & UL

01831104

PS MASCOT/2126

Power supply unit 15W/18VDC for FDM

SX/S

sensors equiv. to EN 60601-1 & UL

07200010

zebris FDM Software

for operating system Windows 7 32/64 Bit

79010105

Hardware FDM user manual / english

Printing version is liable to be charged.

Free download of PDF-Files

from zebris Service Center:

79010185

Software zebris FDM user manual / english

Printing version is liable to be charged.

Free download of PDF-Files

from zebris Service Center:

21030071

USB cable A-B, 3 m long

Data connection between

interface box and PC

REF- No.

Description

Illustrations

01540191

SYNCCam

Camera with USB-Cable, synchronizationcable, tripod, inclusive software extension

3.8 Accessories FDM Measuring System

Page 26

zebris Medical GmbH

FDM Technical Data and Operating Instructions

Page 26/54

01540194

SYNCLightCam

Combined solution with Camera and illuminetion, USB-Cable, synchronization cable,

tripod, inclusive software extension

21030321

SYNCCam USB-Cable A-B

USB-Cable for HD-video signal with high

quality plugs, EMC-shielding and ferrites

length 5m

01830016

Video Sync-Control Cable 7.0

Length 7m, both sides phone jack 3,5mm

with amplifier and control-LED

for DV-camcorder

01830041

Video Sync-Control Cable 2.5

Length 2.5m, both sides phone jack 3.5mm,

without amplifier for zebris SYNCCam

21030312

Video Sync-Control Extension Cable

Length 5m, phone jack & socket 3.5mm

01540110

SYNCLight

with 10 power LEDs, power supply unit,

light intensity infinitely variable

VIDEOSYNC, without tripod

01831105

SYNCLight Power Supply Unit

Mains adapter 40W / 24V DC

01540110

SYNCLight Plus

with 10 power LEDs, power supply unit,

light intensity infinitely variable

VIDEO SYNC, PULSE SYNC, zebris SYNC

up to 3 SYNCLight Plus can be combined

into a lighting unit, without tripod.

33102210

SYNCLight plus Power Supply Unit

Mains adapter 110W / 24V DC,

Supports up to 3 SYNC Light plus.

Page 27

zebris Medical GmbH

FDM Technical Data and Operating Instructions

Page 27/54

01850011

SYNCLight plus Adapter Cable

for Master-Slave connection

of up to 3 SYNCLight plus, length 1m

Page 28

zebris Medical GmbH

FDM Technical Data and Operating Instructions

Page 28/54

4 Video-Module

WARNING

The Sync-LEDs are flashing when the camera is disconnected from

the USB port. Therefore it is strongly advised not to look directly into

the camera when it is disconnected in order to avoid dazzling.

NOTE

In order to maintain undisturbed transmission of the video signal it is

mandatory to use high quality USB cables.

Please, only use cables supplied or recommended by zebris for connecting SYNCCam and PC.

USB Socket Typ B

Flash LED‘s

Status-LED

Sync-out

Socket

Sync-in Socket

¼ Inch Tripod-Thread

4.1 SYNCCam

The SYNCCam is an accessory of the FDM-T system and perfectly adapted to be used in

combination with the force distribution measurement. All adjustments of the camera are carried out via hardware setup integrated to the zebris FDM Software. The camera is connected

to the PC by a USB cable of type A-B included within the shipment.

The camera is equipped with ¼ inch tripod threads and can be adapted to zebris tripods as

wells as commercially available camera tripods.

Technical Specifications

REF-No. 01540190

Dimensions 110 x 125 x 15mm (L x W x H)

Weight approx. 190g

Power Supply USB (5V DC / 500mA)

Resolution 1920 x 1080 Pixel (Full-HD) / Autofocus

Frame Rate 30Hz

Synchronization LED-Flash triggered by Sync-IN socket

Mounting ¼ Inch tripod-thread at bottom and back side

Page 29

zebris Medical GmbH

FDM Technical Data and Operating Instructions

Page 29/54

4.2 SYNCLightCam

WARNING

The Sync-LEDs are flashing when the camera is disconnected from

the USB port. Therefore it is strongly advised not to look directly into

the camera when it is disconnected in order to avoid dazzling.

NOTE

In order to ensure failure-free operation of the SYNCLights it is mandatory to keep the black heat sinks at their back side uncovered and

well air circulated at all times.

Power-LEDs

LED-

Heat Sink

¼ Inch Tripod-Thread

Typeplate

The SYNCLightCam is an accessory of the FDM system and perfectly adapted to be used

in combination with the force distribution measurement. All adjustments of the camera are

carried out via hardware setup integrated to the zebris FDM Software. The camera is connected to the PC by a USB cable of type A-B included within the shipment.

The SYNCLightCam is equipped with ¼ inch tripod threads and can be adapted to zebris

tripods as wells as commercially available camera tripods.

Furthermore contains the SYNCLightCam as an integral solution, the LED video illumination.

In order to produce well lighted and tack sharp video captures it is essential to maintain

perfect lighting conditions at the patient’s side. Only with adequate lighting conditions

video cameras can work with shutter times short enough to freeze fast movements and

capture sharp images.

This solution is perfectly matched on the interaction with the FDM system and can be regulated infinitely in its brightness.

The integrated synchronization unit automatically switches the lights on at the start of a

measurement and turns them off again after stopping it.

Page 30

zebris Medical GmbH

FDM Technical Data and Operating Instructions

Page 30/54

Technical Specifications

NOTE

In order to maintain undisturbed transmission of the video signal it is

mandatory to use high quality USB cables.

Please, only use cables supplied or recommended by zebris for connecting SYNCCam and PC.

Status-LED

Light intensityAdjustment

SYNC ModeSwitch

VIDEOSYNC

Sockets (3 mm

Phone Jack) Jack)

Status-LED

Power-

Supply

REF-No. 01540194

Dimensions 220 x 183 x 80mm (B x H x T)

Weight ca. 790g

Power Supply 24V / 36W

Resolution 1920 x 1080 Pixel (Full-HD) / Autofokus

Frame Rate 30Hz

Light Colour / Light Current 6200 K / 1550 Lumen

Synchronization VIDEOSYNC (Ein-/Ausschalten mit der Messung)

SYNC IN Standard zebris Synchronisation

(kompatibel mit SYNC IN/OUT Plattform)

Mounting ¼ Zoll Stativgewinde an der Rückseite

Page 31

zebris Medical GmbH

FDM Technical Data and Operating Instructions

Page 31/54

Interpretation of the STATUS-LED

Modes

Characteristics

Pin Assignment

VIDEO

SYNC IN

ESD - protected, voltage reversal proof input

Input resistance: 38 k (AC)

Signal-Level: AC

Trigger Level: 15 mV

Green Device is ready for use or in operation.

Orange The orange colour indicates when the maximum operation temperature has

been reached. At this point the operation current is reduced automatically

(which results in reduced brightness) in order to prevent the

SYNCLight plus from being damaged by excessive heat.

Power Supply Unit

For operation of the SYNCLight plus a power supply unit needs to be connected.

REF-No. 33102220

Input Output Cable Length

100 – 240 V AC 24 V DC DC-Lead 1.7 m

50 – 60 Hz 40 W Mains Lead Plug Adapter

SYNC-Modus

Page 32

zebris Medical GmbH

FDM Technical Data and Operating Instructions

Page 32/54

4.3 LED Video Lights (SYNCLight / SYNCLight plus)

NOTE

In order ensure failure-free operation of the SYNCLights it is mandatory to keep the black heat sinks at their back side uncovered and well

air circulated all the time.

¼ Inch Tri-

pod-Thread

Type-

plate

Power-LEDs

Lower

Connector Board

Upper

Connector Board

LED-

Heat Sink

In order to produce well lighted and tack sharp video captures it is essential to maintain

perfect lighting conditions at the patient’s side. Only with adequate lighting conditions

video cameras can work with shutters times short enough to freeze fast movements and

capture sharp images.

The LED video lights SYNCLight and SYNCLight plus are accessories of the FDM systems

and perfectly adapted for use in combination with zebris SYNCCam as well as the force

distribution measurement. Their brightness can be adjusted infinitely.

The integrated synchronization unit automatically switches the lights on at the start of a

measurement and turns them off again after stopping it.

Both SYNCLights are equipped with ¼ inch tripod threads and can be adapted to zebris

tripods as well as commercially available camera tripods

Page 33

zebris Medical GmbH

FDM Technical Data and Operating Instructions

Page 33/54

4.3.1 SYNCLight

Status-

LED

Brightness-

Adjustment

SYNC ModeSwitch

VIDEOSYNC

Sockets (3mm Phone

Power-

Supply

If the synchronization signal from the interface box of the FDM-T system is connected to the

VIDEOSYNC socket the SYNCLight will be automatically turned on and off when a measurement is started or stopped.

In order to use the synchronization set the SYNC-Mode switch to position SYNC. At position CONT the SYNCLight plus is switched on permanently. The DIMMER can be used to

adjust the light brightness individually no matter which operation mode is set.

Technical Specifications

REF-No. 01540110

Dimensions / Weight 155 x 210 x 38mm (L x W x H) / approx. 640g

Power Supply 24V DC / 36W

Light Colour / Light Current 6200K / 1550 Lumen

Synchronization VIDEOSYNC (On-/Off with force measurement)

Mounting ¼ Inch tripod thread at back side

Interpretation of the STATUS-LED

Green Device is ready for use or in operation.

Orange The orange colour indicates when the maximum operation temperature has

been reached. At this point the operation current is reduced automatically

(which results in reduced brightness) in order to prevent the

SYNCLight plus from being damaged by excessive heat.

Power Supply Unit

For operation of the SYNCLight a power supply unit needs to be connected.

REF-No. 3310.2220

Input Output Cable Length

100 - 240V AC 24V DC DC-Lead 1.7m

50 - 60Hz 40W Mains Lead Plug Adapter

Page 34

zebris Medical GmbH

FDM Technical Data and Operating Instructions

Page 34/54

4.3.2 SYNCLight plus

Brightness-

Adjustment

SYNC ModeSwitch

VIDEO SYNC

Sockets (3mm Phone Jack)

Power-OUT

PULSE SYNC

(Industrial Camera)

Power-

Supply

Status-

LED

zebris

SYNC IN

The SYNCLight plus supports the zebris VIDEOSYNC as well as more complex synchronization modes that may be required for use of industrial cameras.

In order to use the synchronization modes set the SYNC-Mode switch to position SYNC.

At position CONT the SYNCLight plus is switched on permanently. The DIMMER can be

used to adjust the light brightness individually no matter which operation mode is set.

Up to 3 SYNCLight plus can be combined into a lighting unit. Therefore they have to be

connected with an adapter cable. The adapter cable provides power supply as well as transmission for the synchronization signals.

Technical Specifications

REF-No. 01540120

Dimensions / Weight 155 x 210 x 38mm (L x W x H) / approx. 640g

Power Supply 24V DC / 36W

Light Colour / Light Current 6200K / 1550 Lumen

Synchronization VIDEO SYNC On-/Off with force measurement

PULSE SYNC Shutter Sync. with industrial cameras

SYNC IN Standard zebris synchronization

(Compatible with SYNC IN/OUT platform)

Mounting ¼ Inch tripod thread at back side

Master – Slave Operation off max. 3 SYNCLight plus by adapter cable 185.0011/SL-C1

Interpretation of the STATUS-LED

Green Device is ready for use or in operation.

Orange The orange colour indicates when the maximum operation temperature has

been reached. At this point the operation current is reduced automatically

(which results in reduced brightness) in order to prevent the

SYNCLight plus from being damaged by excessive heat.

Page 35

zebris Medical GmbH

FDM Technical Data and Operating Instructions

Page 35/54

4.3.3 Power Supply Unit SYNCLights

Modes

Characteristics

Pin Assignment

VIDEO

SYNC IN

ESD - protected, voltage reversal proof input

Input resistance: 38K (AC)

Signal-Level: AC

Trigger Level: 15mV

VIDEO

SYNC OUT

ESD - protected, voltage reversal proof input

The signal from the VIDEO SYNC IN is directly

transmitted to VIDEO SYNC OUT and can be

used for control of additional devices.

SYNC IN

ESD - protected, voltage reversal proof input

Input resistance: 38K (Pull-Up)

VIH (High-Level Input Voltage): ≥ 3.7V

VIL (Low-Level Input Voltage): ≤ 3.0V

Both Signals can be used as Trigger input

(“AKTIV” as well as “CLK”) and possess the

same effect.

The signal switches the LED light on to the

brightness level pre-selected by the DIMMER

The SYNC IN is the standard synchronization

tool (zebris SYNC) of all zebris measuring systems and intended to be used to synchronize

the lighting system with the measuring signal of

other zebris measuring systems (e.g. CMS).

In order to use SYNC IN the SYNC mode

switch has to be set to position SYNC.

3-Pin Socket

Pin1: CLK

Pin2: AKTIV

Pin3: GND

Socket Type

LEMO- Part No.

FGA.00 303.CLADxxxx

For operation of the SYNCLight plus a power supply unit needs to be connected.

REF-No. 33102210

Input Output Cable Length

100 - 240V AC 24V DC Mains Lead 1.7m

50 - 60Hz 110W DC-Lead 1.7m

SYNC-Modes

Page 36

zebris Medical GmbH

FDM Technical Data and Operating Instructions

Page 36/54

Modes

Characteristics

Pin Assignment

PULSE

SYNC

ESD - protected, voltage reversal proof input

Input resistance: 2K (Pull-Up)

VIH (High-Level Input Voltage): 2.0V

VIL (Low-Level Input Voltage): 0.8V

Polarity: Lo Active

When mode PULSE SYNC is used LED brightness is set to 150%.

The shutter output of industrial high speed cameras can be used as trigger signal for the PULSE

SYNC.

By utilizing pulsed light optimal lighting conditions

for industrial cameras can be accomplished without being too bright or disturbing for the human

eyesight.

In order to use PULSE SYNC the SYNC mode

switch has to be set to position SYNC.

6-Pin Socket

Pin4: Input

Pin5: GND

Socket Type

HIROSE HR10A-7P-6S

Camera Trigger

Input

Begin of

Illumination

Timing Properties when

switching the Light ON:

should be preset to this Value.

Delay: 50µS

Camera Trigger

End of

Illumination

No Delay!

Timing Properties when

Delay of 50µS

The cameras Trigger-Output

Input

switching the Light OFF:

No Delay (0µS)

No adjustment of

Trigger-Output necessary!

Page 37

zebris Medical GmbH

FDM Technical Data and Operating Instructions

Page 37/54

5 Operation of the FDM System

WARNING

Be sure that all the mains and connection cables are laid safely and that

they are protected against stepping on, so that nobody can trip over

them. Check all the cables and the connection plug regularly for any

damage.

The cables therefore can be laid under a cable protection or fixed to

the floor using a tape if necessary.

5.1 Set up the measuring System

For the commissioning of the FDM platform the suitable power supply, a USB cable type AA as well as the installation CD with the FDM application software are necessary. All components are included in the scope of delivery of the FDM measuring system.

The underground of the set-up location must be plain and horizontal.

The platform must be set up on a slip-proof underlay or installed in a catwalk, so as

to exclude any danger to the test person caused by the platform sliding.

Do not set up the platform near a source of heating or in direct sunlight in front of a

window as a rise in temperature can lead to inaccurate measuring results.

Set-up the measuring system in a way, that the socket for the mains connection is

accessible easily at all times and that the device can be separated from the power

supply.

Once the measuring system is set up safely and horizontally, it can be connected to

the power supply and put into operation.

5.2 How to switch the platform On/Off

The platform is switched on and off by software control as soon as the zebris FDM software

on the PC is started. If the device has been connected correctly, the green LED operating

indicator illuminates on the housing of the platform.

Page 38

zebris Medical GmbH

FDM Technical Data and Operating Instructions

Page 38/54

5.3 Anschluss des Messsystems an das Versorgungsnetz

WARNING

Exclusively use the power plug approved by zebris for the operation

of the FDM platform, which is suitable for the power supply of your

platform.

Input

Output

Cable

Length

100 - 240 V AC

18V DC

AC Cable

---

50 - 60 Hz

15 W

DC Cable

6m

For the connection of the FDM platform with the mains, connect the power supply with the

mains socket and the power socket in the connector compartment.

Power Supply MASCOT/2126 REF-No. 01831104

For the following platforms: FDM-SX

FDM-S

Technical Data

Pin arrangement / polarity

Pin arrangement and polarity is identically to Mascot/2020

Page 39

zebris Medical GmbH

FDM Technical Data and Operating Instructions

Page 39/54

Power Supply Mascot/2020 REF-No. 01811513

Input

Output

Cable

Length

100 - 240 V AC

16V DC

AC Cable

1,7 m

50 - 60 Hz

60 W

DC Cable

5 m

NOTE

Before connecting the measuring system to the mains, compare the

nameplate indications of the power supply and the treadmill in terms

of mains voltage and mains frequency with the local characteristics.

Only connect when they are in accordance.

WARNING

Carry out a visual examination of power supply, mains connection

voltage and socket as well as earthing contacts before connecting

resp. commissioning the measuring system. Damaged power supplies, cables or connection sockets immediately must be replaced by

a person authorised to do so.

„-“Contakt: Outer contact oft

he hollow plug

„+“Contact: Inner contact of

the hollow plug

For the following platforms: FDM-1.5, FDM-2, FDM-3

FDM-1.7, FDM2.4

FDM-J1, FDM-J1.8SQ

Technical Data

Pin arrangement / polarity

Page 40

zebris Medical GmbH

FDM Technical Data and Operating Instructions

Page 40/54

5.4 Computer requirements

WARNING

If the computer is not supplied with the measuring system, the manufacturer shall not be held liable for any damage or malfunctions arising

from a faulty coupling. Should additional hardware be built into the

computer or software installed, the manufacturer shall not be liable for

any malfunctions or damage occurring.

The computer must be CE marked and fulfil the requirements of DIN

EN 60950 resp. DIN EN 60601-1.

WARNING

The FDM measuring system is not designed for the operation within

a network/data network. The connection of the system with a networtk/data network can cause unforeseen risks for patients or third

parties. If the zebris FDM software shall be installed in a network/data

network, the operator is obliged to determine, analyse, evaluate and

control the risks that are connected with doing so – particularly with

regard to the aspects data protection, virus security, updates of the

operating system and regular backups. Risk considerations have to

include subsequent changes of the network/data network, like e.g.

update/upgrade of devices and components that are connected to the

network.

NOTE

Please make absolutely sure that you have installed the zebris

software before connecting the FDM platform to the computer

using the USB cable.

NOTE

How to solve problems with the hardware driver

Should problems with the hardware driver of the FDM platform occur

then disconnect the platform from the PC and restart it. Now proceed

with installing the WinFDM software another time and reconnect the

platform when the installation procedure has been finalized.

As a rule, the measuring system FDM is supplied together with a computer. If the system is

to be operated using other computers or components, the user must then inquire whether

the intended coupling guarantees the necessary safety for the test person, the operator and

the surroundings by consulting the manufacturer, the authorized zebris sales partner or by

asking a specialist.

Please refer to the zebris FDM Software Manual for informations according to PC requirements.

5.5 Installing the zebris FDM software

If your measuring system is delivered without PC/laptop, please install the application software before connecting the measuring system to the computer. Please find information on

the installation in the user manual of the zebris FDM software.

If the platform is connected without installing the software before, problems when installing

the device driver may occur and the system does not work.

Page 41

zebris Medical GmbH

FDM Technical Data and Operating Instructions

Page 41/54

5.6 Closing the safety lock of the plug tray

safety lock

Finally connect the USB socket in the connector compartment and a free USB interface of

your computer by using the provided USB cable. Your measuring system is now ready for

use. The control of a measurement exclusively is carried out via the zebris FDM software.

Therefore, please carefully read the zebris FDM user manual.

If the power supply unit and the USB cable are connected to the sockets of the platform,

please close the lid of the safety lock and fasten it to the housing by means of the four

screws supplied with the platform.

5.7 Setting the system out of operation

In order to set the system out of operation please close the WinFDM software first, then exit

the Windows operating system and shut down the PC. In the next step disconnect the power

supply unit of the FDM sensor and the treadmill from mains supply.

Page 42

zebris Medical GmbH

FDM Technical Data and Operating Instructions

Page 42/54

5.8 Recommendations for recording data

To receive significant data from FDM systems some principle guidelines should be followed.

This chapter describes the ideal conditions for recording measurement data: The following

points refer to the data reception of a person walking and describe the ideal measurement

situation.

5.8.1 Walking range

The best conditions for measurements with platforms of the FDM-S type will be reached by

integration of the system in a walking range. The complete walking range must be plane

with the surrounding floor. This way the test person won’t know the position of the platform

and gives a workaround to the tendency that test persons try to walk exactly on the sensor

area. The width of the stage should be about 1,20m. We recommend a distance of about

4m from start to FDM-S platform and no less than 3m behind. With such a walking stage it

is easier to measure normal walking without acceleration or deceleration.

Of course the same set up can be used to measure with the method of first step. The first

step method is described as follow: The patient stands on one side of the platform in a

distance to reach the platform by the first step. For measurement the patient hits the sensor

area by the first step and moves on. This kind of measurement guaranties reproducible steps

and results. Notice: These results differ more or less from these by normal walking.

5.8.2 Data recording

Please observe the exercise of the patient strictly. Only steps where the complete ground

contact of the foot is located on the sensor area may be used for evaluation. If not the complete foot area was measured by the system (foot did partially not hit the sensor area) the

step can not be evaluated.

5.8.3 Gait velocity

For the measurement a normal (individual) and constant walking velocity is necessary. Ideally an additionally measurement, e.g. by photo sensors, can proof the velocity for notice.

Naturally the patients adapt to the measurement situation within a few minutes. After a few

trials, walking seems normal. A change in velocity of about 5 % is non-effective.

5.8.4 Posture

A visual control of the behaviour pattern of normal gait is recommended. Trials with atypical

behaviour pattern should be deleted from interpretation. The patient has to look straight

ahead and must not be disturbed by paying attention to the platform or monitor. Marks on

the wall in front of the patient can provide orientation to hit the platform.

5.8.5 Acrosclerosis

Different measurements (e.g. P.R. Cavanagh, The Foot (1994) 4, 123-135) show an increase of plantar pressure peaks of about 30 % by acrosclerosis (e.g. weals). The interpretation of measurement data has to include the existence of plantar acrosclerosis.

Page 43

zebris Medical GmbH

FDM Technical Data and Operating Instructions

Page 43/54

6 Control measures, Preparation, Disposal

Scheduled maintenance of the system is essential in order to prevent damage

and guarantees the safety of the device. All methods concerning the system’s

maintenance and disinfection mentioned in this user manual should be carried out on a

regular basis.

Should any malfunctions and/or defects be determined or suspected, the device must be

put out of operation immediately, marked as "Out Of Service" and prevented from being

used by removing the mains cable. In such case be sure to contact the manufacturer or

an authorized sales partner.

The maintenance of the device or its accessories, going beyond the procedures described

in this user manual, must exclusively be carried out by zebris Medical GmbH or a person

who has been explicitly authorized by zebris to do this.

Be sure to switch of the measuring system and disconnect it from mains supply before

starting any maintenance work.

6.1 Mandatory periodic inspections and STK

The zebris Medical GmbH does not stipulate any safety-related control

for the FDM system.

For maintaining the correct state of the electrical equipment, checks and technical

safety inspections have to be carried out repeatedly (e.g. within Germany, acc. to

BGV A3, and accident prevention regulations and technical safety tests according to

the Medical Device Operating Regulations). Here it should be noted that standard

regulations for electrical devices are concerned here and not measures that are specific to zebris.

For safety reasons it is recommended before each use of the measuring system, to

check the correct state of all the connection leads, as well as the mains cable, mains

plug and mains socket. Should certain parts be damaged, these must be replaced

before continuing to use the measuring system.

Immediate maintenance measures are to be carried out if:

a) Fluid enters the device

b) Cable or cable connections habe been damaged

c) Parts of the sensors were damaged

d) Covers habe been damaged

e) A malfunction or a fault is suspected or has been detected

If the type plate or other important labels (warning notices) are damaged or oblite-

rated they have to be replaced by the manufacturer for safety reasons.

Page 44

zebris Medical GmbH

FDM Technical Data and Operating Instructions

Page 44/54

6.2 Checking the FDM Sensor

WARNING

The measuring system must be checked at regular intervals to ensure

that the measuring system is functioning properly.

6.2.1 Control measures

Should any damage to the measuring surface become evident (e.g. something fell hard on

the black measuring surface), no further measurements must be taken. If visible damages

are detected not further measurements are permitted.

After carrying out a baseline measurement, no measuring values may be shown for a condition without any load. In addition, the force distribution images are to be checked regularly

for untypical measuring patterns. These include above all, line or column-shaped measuring

patterns deviating from the surrounding values.

Whenever faults occur or in case of doubt, the manufacturer or sales partner authorized by

zebris must always be contacted.

6.2.2 Calibration measures

The measuring accuracy of the sensors for the force distribution measurement is to be

checked from time to time using a defined application of force.

To do this, the user, knowing the body weight, can stand on the platform on one foot. The

platform must show the approximate body weight, taking the force of gravity, the sensors at

the edges that may not be subject to the full pressure, and the measuring tolerance into

consideration.

In case of deviations larger than > ±5% of max range a recalibration at manufacturers side

is required.

Should the display be incorrect, a recalibration by the manufacturer is required.

Page 45

zebris Medical GmbH

FDM Technical Data and Operating Instructions

Page 45/54

6.3 Troubleshooting

NOTE

Please find further information on error messages and troubleshooting in the user manual of the zebris FDM software.

NOTE

In order to support you the best way possible in case of malfunction

of your FDM measuring system, our service employees need the following information:

Please check the following points if technical malfunctions should occur:

Is the FDM platform properly connected to the mains?

(LED flashes green)

Is the USB connection between platform and the measuring PC properly con-

nected?

(LED flashes green when the USB port and the power supply are connected to the

PC and the device driver has been installed correctly.)

Are all further components of the measuring system (infrared synchronisation with

zebris DAB-Bluetooth, video camera) properly connected?

Checklist for the reception of error messages

Device type + serial number of the FDM platform

Please find the serial number on the left-hand side of the platform close to the connector compartment.

Version of the zebris FDM software

Version of the operating system of your measuring PC

e.g. Windows 7 Professional Servicepack 1

(Call under Windows 7: Windows Start button Control Panel System)

Further components being connected to the measuring system

e.g. Infrared synchronisation (IR) with zebris DAB-Bluetooth, video camera

List of all USB devices that are connected to the measuring PC

e.g. mouse, printer, other measuring systems etc.

Screenshot of the error message, or exact wording

e.g. “EMG adapter not found.”

Precise and detailed description of the procedure that has lead to the error mes-

sage.

e.g. Measurement “Type A” started, then clicked on button “B”, afterwards carried out movement “C”,

switched to function “D”, when switching back, the error message xyz occurred etc.

Page 46

zebris Medical GmbH

FDM Technical Data and Operating Instructions

Page 46/54

6.4 Cleaning and disinfection

NOTE

Do not use any aggressive agents to clean the measuring system.

WARNING

Please be absolutely sure to switch off the device and pull the mains

plug out of the socket before you commence disinfecting and cleaning

WARNING

No spray disinfection!

Spray disinfection can destroy the highly precise

measurement sensors of the platform.

NOTE

If you apply disinfection agent be sure to follow the recommendations

given by the manufacturer of the disinfection agent strictly. Especially

consider the rules concerning the commended application time of the

agent.

WARNING

Due to danger of confusion, chemicals that are necessary for the disinfection or cleansing exclusively must be stored, prepared and provided in containers that are appropriate for this purpose.

NOTE

In order to demonstrate that disinfection was successfully done, it is

recommended to put up a sign on the platform, saying “disinfected”.

6.4.1 Cleaning

The platform and accessories are cleaned with a moist cloth while the device is switched off

and the mains plug taken out.

6.4.2 Manuelle Desinfektion

The platform can be disinfected by wiping over with suitable agents. To clean, wipe the

platform with a cloth soaked in disinfection liquid.

Recommended disinfection agent

Composition approx. 25% ethanol, 35% Propanol

E.g. Mikrozid Liquid / Schülke & Mayr or similar agents

Page 47

zebris Medical GmbH

FDM Technical Data and Operating Instructions

Page 47/54

6.5 Disposal

6.5.1 Packaging

All transport packagings delivered by zebris can be recycled within Germany via the local recycling depots. In order to provide the reuse of the

recyclable material contained in the packagings, the zebris Medical GmbH

takes part in the dual ZENTEK system that takes over the proper disposal

of packagings.

6.5.2 Disposal of electronics

This symbol states that according to the directive on waste electrical

and electronic equipment (2012/19/EEC) the product must not be

disposed by means of the domestic waste system. Within Europe

this device must be forwarded to a specific waste disposal system.

Therefore regular disposal is carried out by the manufacturer. For

this purpose the system should be shipped to the manufacturer and

will be forwarded to regular disposal by zebris.

The improper interaction with electronic waste could lead to negative effects for the environment and the public health because of

potential hazardous materials which are frequently contained within

electric and electronic devices. Additionally with the proper disposal

of this product you will contribute to the effective use of natural resources.

Accumulators and batteries

Accumulators and batteries must not be disposed of with domestic waste! In the interest of

environmental protection, the consumer is legally obliged (battery regulation) to return old

and used batteries. Used accumulators and batteries can be disposed of at the collecting

points of the community or where batteries of the relevant kind are sold. For consumers, the

batteries are taken back free of charge.

Page 48

zebris Medical GmbH

FDM Technical Data and Operating Instructions

Page 48/54

7 Safety standards and system classification