Page 1

User's

Guide

Page 2

Proprietary Statement

This manual contains proprietary information of Zebra Technologies Corporation. It is intended

solely for the information and use of parties operating and maintaining the equipment described herein. Such proprietary information may not be used, reproduced, or disclosed to any

other parties for any other purpose without the expressed written permission of Zebra Technologies Corporation.

Product Improvements

Since continuous product improvement is a policy of Zebra Technologies Corporation, all specifications and signs are subject to change without notice.

FCC Compliance Statement

NOTE: This equipment has been tested and found to comply with the limits for a Class B digital

device, pursuant to Part 15 of FCC Rules. These limits are designed to provide reasonable

protection against harmful interference in a residential installation. This equipment generates,

uses, and can radiate radio frequency energy and, if not installed and used in accordance with

the instructions, may cause harmful interference to radio communications. However, there is

no guarantee that the interference will not occur in a particular installation. If this equipment

does cause harmful interference to radio or television reception, which can be determined by

turning the equipment off and on, the user is encouraged to try and correct the interference by

one ore more of the following measures:

• Reorient or relocate the receiving antenna.

• Increase the separation between the equipment and the receiver

• Connect the equipment into an outlet on a circuit different from that to which the receiver

is connected

• Consult the dealer or an experienced Radio/TV technician for help.

NOTE: This unit was tested with shielded cables on the peripheral devices. Shielded cables

must be used with the unit to insure compliance

“The user is cautioned that any changes or modifications not expressly approved by Zebra

Technologies Corporation could void the user’s authority to operate this equipment.”

Canadian DOC Compliance Statement

This digital apparatus does not exceed the Class A limits for radio noise emissions from digital

apparatus as set out in the radio interference regulations of the Canadian Department of Communications.

Liability Disclaimer

Zebra Technologies takes steps to assure that its published Engineering Specifications and

Manuals are correct; however, errors do occur. Zebra Technologies Corporation reserves the

right to correct any such errors and disclaims liability resulting therefrom.

No Liability for Consequential Damage

In no event shall Zebra Technologies Corporation or anyone else involved in the creation, production, or delivery of the accompanying product (including hardware and software) be liable

for any damages whatsoever (including, without limitation, damages for loss of business profits, business interruption, loss of business information, or other pecuniary loss) arising out of

the use of or the results of use of or inability to use such product, even if Zebra Technologies

Corporation has been advised of the possibility of such damages. Because some states do

not allow the exclusion of liability for consequential or incidental damages, the above limitation

may not apply to you.

Copyrights

The copyrights in this manual and the system described therein are owned by Zebra Technologies Corporation. All rights are reserved. Unauthorized reproduction of this manual or the

software in any of the system modules may result in imprisonment of up to one year and fines

of up to $10,000 (17 U.S.C.506). Copyright violators may be subject to civil liability.

All products and brand names are trademarks of their respective companies. All rights reserved.

©

2001 Zebra Technologies Corporation

Page 3

Page 4

Contents

Introduction ................................................ 7

Unpacking and Inspection ................................................. 7

Reporting Damage .............................................................. 7

Getting Ready to Print................................. 9

Battery ................................................................................. 9

Installing the Battery .................................................................... 9

Charging the Battery.................................................................... 9

Loading the Media ............................................................ 10

Tear-Off Mode ............................................................................ 10

Peel-Off Mode............................................................................ 13

Fanfold Media (optional vibration mount required) .................... 16

Loading the Ribbon (PT SERIES only) ........................... 18

Operator Controls ............................................................. 20

Power Button ............................................................................. 20

Feed Button ............................................................................... 20

Indicator LEDs .................................................................. 21

Power LED ................................................................................. 21

Error LED ................................................................................... 21

Battery Charging LED................................................................ 21

Printing a Test Label ......................................................... 22

Connecting the Printer and Computer............................ 22

Connecting to a Portable Data Terminal ......................... 22

Communicating with the Printer ..................................... 24

Setting the Communication Parameters .................................... 24

IR Communications ................................................................... 24

Setting Up the Software ................................................... 24

Adjusting the Print Width ................................................. 24

Adjusting the Print Darkness .......................................... 25

Adjusting the Printhead Pressure ................................... 25

Adjusting the Strap........................................................... 26

Hand/Shoulder Strap ................................................................. 26

Adjustable Shoulder Strap ......................................................... 27

Calibration ............................................... 28

Auto Calibration ................................................................ 28

Manual Calibration............................................................ 28

Preventive Maintenance ............................ 30

Cleaning............................................................................. 30

Lubrication ........................................................................ 31

4 PA/PT400 & PA/PT 403 User’s Guide

Page 5

Extending Battery Life...................................................... 31

Battery Disposal ........................................................................ 32

Troubleshooting ........................................ 33

Help! The LEDs are On/Off/Flashing) .............................. 33

Resolutions: ......................................................................33

Print Quality Problems ............................................................... 34

Troubleshooting Tests ...................................................... 36

Printing a Configuration Label ................................................... 36

Recalibration .............................................................................. 36

Resetting the Factory Default Values ........................................ 36

Communications Diagnostics .................................................... 37

Feed Button Modes .......................................................... 37

Specifications ........................................... 38

Printing Specifications ..................................................... 38

Ribbon Cartridge Specifications (PT SERIES) ............... 38

Label Specifications ......................................................... 39

Memory/Communications Specifications ...................... 39

Font/Bar Code Specifications.......................................... 40

Physical/Environmental/Electrical Specifications ......... 40

Agency Approvals ............................................................ 41

Options .............................................................................. 41

Adapter Cable Pinouts ..................................................... 42

RJ45 Connector Pin Identification .................................. 42

Null Modem Cable Pinouts .............................................. 42

Index .................................................... 43

PA/PT400 & PA/PT 403 User’s Guide 5

Page 6

6 PA/PT400 & PA/PT 403 User’s Guide

Page 7

Introduction

Thank you for choosing our Zebra Mobile Printer. The PA/PT 400

and PA/PT403 printers are sure to become productive and efficient

additions to your workplace.

• This user’s guide gives you all the information you’ll need to operate your printer.

• There are two basic types of printers in the 400 series: the PA

type which uses direct thermal technology, and the PT type

which uses a thermal transfer film to print.

• There are two models within the 400 series: the cost effective

400 models and the more powerful 403 models with expanded

memory to handle even larger and more complex printing

tasks.

• To create and print label formats, take a look at the

gram Guide

design programming language, better known as “ZPL II.” If one

was not ordered with your printer, simply call your reseller or

Zebra Technologies Corporation or visit the Zebra web site. If

you’d like to use a different label preparation software, contact

your reseller or Zebra for advice and information.

• The

PA400/PT400 Maintenance Manual

tains all the information you’ll need to properly maintain the

printer.

(part #46530L) for information about Zebra’s label

(part #505142L) con-

ZPL II Pro-

Unpacking and Inspection

Inspect the printer for possible shipping damage:

• Check all exterior surfaces for damage.

• Raise the media access door (refer to “Loading the Media” in

the Getting Ready to Print section) and inspect the media compartment for damage.

•Save the carton and all packing material in case you have to

return the printerdue to shipping damage.

Reporting Damage

If you discover shipping damage:

• Immediately notify and file a damage report with the shipping

company. Zebra Technologies Corporation is not responsible

for any damage incurred during shipment of the printer and will

not cover the repair of this damage under its warranty policy.

•Keep the carton and all packing material for inspection.

• Notify your authorized Zebra reseller.

PA/PT400 & PA/PT 403 User’s Guide 7

Page 8

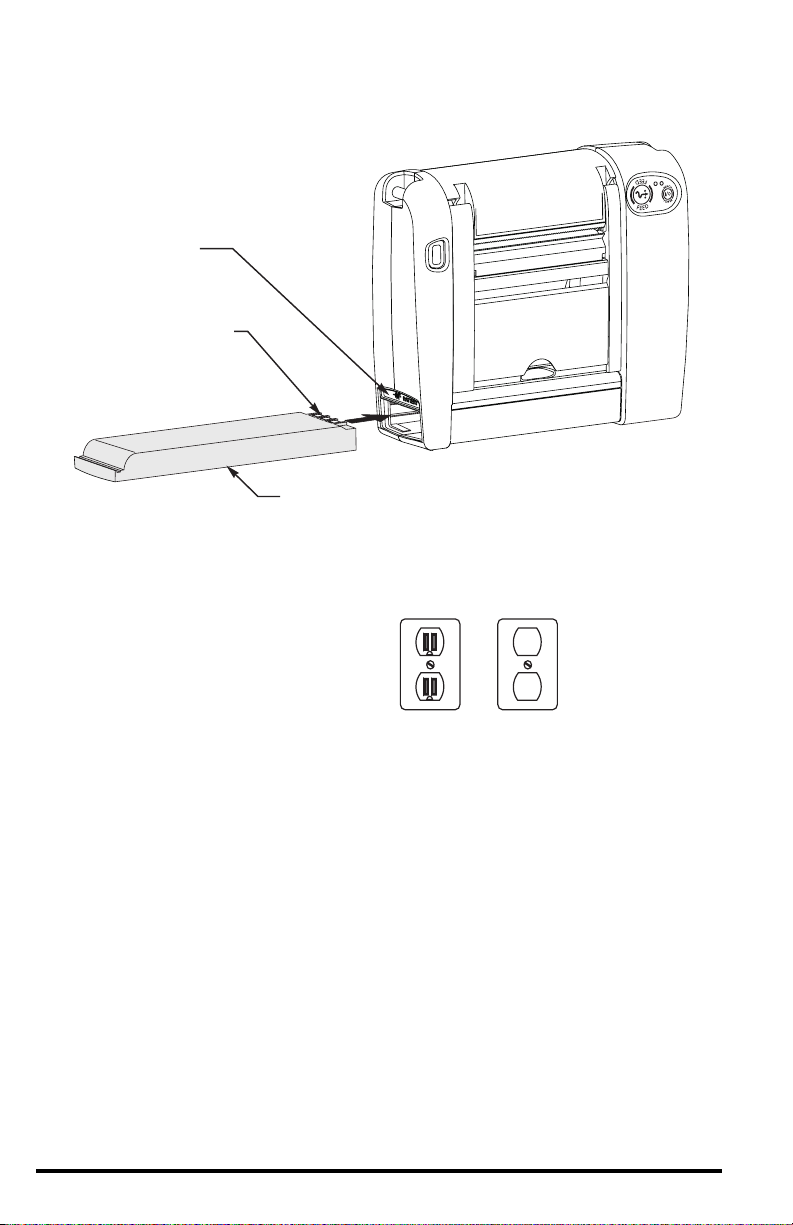

Battery

Compartment

Door

Silver-colored

Contacts

Battery

Battery

F

IGURE

2

8 PA/PT400 & PA/PT 403 User’s Guide

Page 9

Getting Ready to Print

Battery

Installing the Battery

NOTE: Batteries are shipped uncharged.

1. Slide up the battery compartment door.

2. Insert the battery into the printer as shown in Figure 2, with the

silver-colored battery contacts facing up.

3. After the battery is completely inserted, slide down the battery

compartment door.

When the battery is first installed, the Power and Error LEDs will

light approximately two seconds and then go off. If these lights do not

go on the battery is not fully charged (see “Charging the Battery”).

Charging the Battery

Refer to Figure 3 (your battery charger may look slightly different

than the ones illustrated).

1. With the battery installed in the printer, insert the connector of

the battery charger into the receptacle on the side of the printer.

2. If you are using a 120 VAC battery charger: plug the battery

charger into an appropriate 120 VAC electrical outlet.

If you are using a universal battery charger: Make sure the sup-

PA/PT400 & PA/PT 403 User’s Guide 9

Page 10

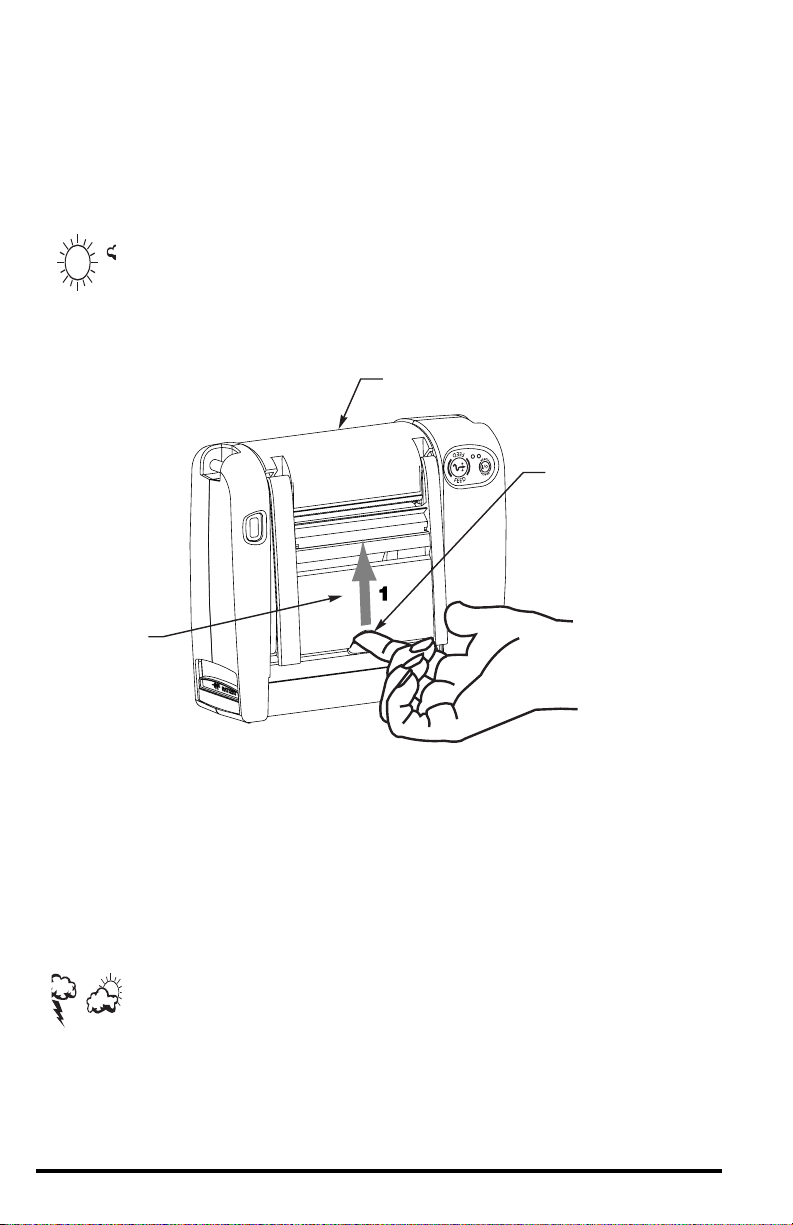

Loading the Media

h

You can operate this printer in one of two different modes: Tear-Off

or Peel-Off. Tear-Off mode allows you to tear off each label (or a strip

of labels) after it is printed. In Peel-Off mode, the backing material is

peeled away from the label as it is printed. After you remove this label, the next one is printed.

Tear-Off Mode

NOTE. If ribbon is loaded (PT models only), remove the

ribbon cartridge before loading the media.

1. Refer to Figure 4. Raise the media access door by lifting at the

notch until it unhooks from the top cover.

Top Cover

Notc

Media

Access

Door

FIG. 4

2. Refer to Figure 5. Swing the media access door open to expose the media compartment.

3. Pivot the top cover to reveal the printhead.

4. Lift the printhead until you feel it “lock” into place. Be careful not

to force the printhead past this position!

WARNING: NEVER touch the thermal print elements on

the underside of the printhead. Under certain conditions,

they can be very hot! Also, dirt or moisture from your

hands can damage the printhead!

10 PA/PT400 & PA/PT 403 User’s Guide

Page 11

5. Refer to Figures 5 and 6. Thread the media into the printer until

it extends approximately 1” (25.4 mm) past the printhead.

6. Separate and hold open the media hangers.

7. Place the media roll onto the media hangers, making sure it is

tightly wound.

8. Release the media hangers so the media locks into the correct

position. Make sure the media is threaded under both media

guides.

PA/PT400 & PA/PT 403 User’s Guide 11

Page 12

9. Refer to Figure 7. If it’s not already in place, install the tear bar

r

in the media access door. Gently lift the tab on the bar to move

it over the protrusion on the door. Make sure the lip of the bar

(inset, Figure 7) faces out of the printer.

If you’re using direct thermal media, continue on with step 10.

However, if you’re using thermal transfer media, you must also

install a ribbon cartridge. Proceed to “Loading the Ribbon “ in

this chapter.

Ta b

Protrusion

Lip

F

IGURE

7

10. Close the printhead and the top cover.

11. Swing up the media access door, ensuring that the media extends over the tear bar (refer to Figure 8).

12. Lift to hook

the top of the

media access

door over the

top cover.

13. Push in the

bottom of the

media access

door to close.

14. Turn on the

printer or press

the Feed button

if the printer is

already on.

12 PA/PT400 & PA/PT 403 User’s Guide

F

IGURE

8

Tear Ba

Page 13

Peel-Off Mode

NOTES.- Your authorized Zebra reseller can recommend

the correct ribbon and peel-off media for your application.

If ribbon is loaded (PT series only), remove the ribbon cartridge before loading the media.

1. Refer to Figure 4. Raise the media access door by lifting at the

notch until it unhooks from the top cover.

2. Refer to Figure 5. Swing the media access door open to expose the media compartment.

3. Pivot the top cover to reveal the printhead.

4. Lift the printhead until you feel it “lock” into place. Use caution

not to force the printhead past this position!

WARNING: NEVER touch the thermal print elements on

the underside of the printhead. Under certain conditions, they can be very hot! Also, dirt or moisture from

your hands can damage the prlnthead!

5. Refer to Figures 5 and 6. Remove approximately 6" (152.4 mm)

of labels from the media roll. Then, thread the media into the

printer until it extends approximately 1" (25.4 mm) past the

printhead.

6. Separate and hold open the media hangers.

7. Place the media roll onto the media hangers, making sure it is

tightly wound.

8. Release the media hangers to lock the media into the correct

position. Ensure that the media is threaded under both media

guides. 9. The tear bar should not be installed in the printer. If it

is, gently lift the tab on the bar to get it over the protrusion on

the door (reverse the procedure shown in Figure 7). Then, pull

the bar out of the printer.

PA/PT400 & PA/PT 403 User’s Guide 13

Page 14

NOTE.- When not in use, the tear bar may be stored on the

g

l

inside of the media access door. Refer to Figure 9. With the

lip of the bar facing the inside of the door, simply align the

notches of the bar with the tabs on the door. Press and slide

the bar toward the door’s hinged end.

Door

Ta b

Door

Ta b

Tear Bar

Notch

Tear Bar

Notch

F

IGURE

9

If you’re using direct thermal media, continue on with step 10.

However, if you’re using a PT series printer with thermal transfer

media, you must also install a ribbon cartridge. Proceed to

“Loading the Ribbon ‘ in this chapter.

10. Close the

printhead and

the top cover.

11. Swing up the

media access

door, ensuring

that the media

liner is threaded through the

Label

wide slot in the

media access

door (refer to

Backin

Materia

Figure 10).

12. Lift to hook

the top of the

media access

door over the

top cover.

Wide Slot

F

IGURE

10

14 PA/PT400 & PA/PT 403 User’s Guide

Page 15

13. Push in the bottom of the media access door to close.

14. Turn on the printer or press the Feed button if the printer is already on.

NOTES. To ensure optimal print quality, make sure that the

backing material is flush against the peel bar (as shown in

Figure 10). If it starts to “loop “ away from the peel bar, gently pull down on the backing material

With certain types of media, it may be necessary to reduce

the print speed to 1.5 “ (38. 1mm) per second to produce

consistent peel operation. Consult your authorized Zebra

reseller for advice and information.

PA/PT400 & PA/PT 403 User’s Guide 15

Page 16

Fanfold Media (optional vibration mount required)

NOTE. If ribbon is loaded (PTseries only), remove the ribbon cartridge before loading the media.

1. Raise the media access door by lifting at the notch until it unhooks from the top cover (refer to Figure 4).

2. Swing the media access door open to expose the media compartment (refer to Figure 5).

3. Pivot the top cover to reveal the printhead.

4. Lift the printhead until you feel it “lock” into place. Be careful not

to force the printhead past this position!

WARNING: NEVER touch the thermal print elements on

the underside of the printhead. Under certain conditions,

they can be very hot! Also, dirt or moisture from your

hands can damage the prlnthead!

5. Separate and hold open the media hangers (refer to Figure

11).

6. Place the plastic media core (refer to Figure 11) onto the media

hangers.

NOTE. The plastic media core can be obtained from an authorized Zebra supplies reseller.

7. Release the media hangers so the plastic media core locks into

the correct position.

8. Place the fanfold media in the fanfold media tray.

F

IGURE

11

16 PA/PT400 & PA/PT 403 User’s Guide

Media

Guides

Media

Hangers

Plastic

Media

Core

Page 17

9. Swing up the media access door. Thread the fanfold media

d

through the slot beneath the notch on the media access door

(refer to Figure 12).

10. Swing open the

media access door.

Continue to insert

the media into the

printer and under

the plastic media

core until it appears

beneath the print-

Notch

head. Make sure the

media is threaded

under both media

guides.

If you’re using direct

thermal media, continue on with step

Slot

Fanfol

Media

11. However, if

you’re using thermal

transfer media, you

must also install a

ribbon cartridge. Proceed to “Loading the Ribbon ‘ in this chapter.

11. Swing up the media access door, ensuring that the media extends over the tear bar (refer to Figure 13).

12. Lift to hook the

top of the media

access door over

the top cover.

13. Push in the bottom of the media

access door to

close.

14. Turn on the printer

or press the Feed

button if the printer

is already on.

PA/PT400 & PA/PT 403 User’s Guide 17

Page 18

Loading the Ribbon (PT400 and 403 only)

1. If the printhead is not already open, lift it until you feel it “lock”

into place.

WARNING: NEVER touch the thermal print elements

on the underside of the printhead. Under certain conditions, they can be very hot! Also, dirt or moisture from

your hands can damage the printhead!

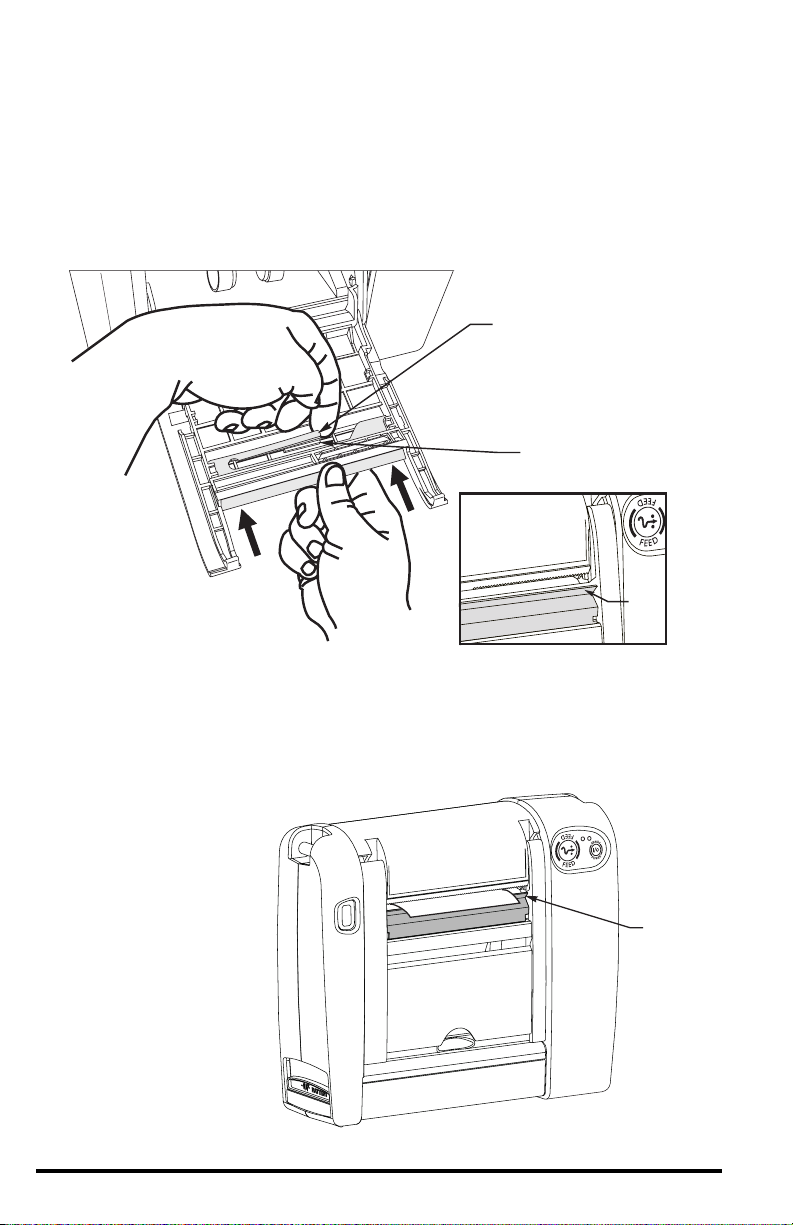

2. Hold the ribbon cartridge as shown in Figure 14. The placement arrows should be visible and pointing toward the back of

the printer.

3. Align the lower protrusions on both sides of the ribbon cartridge with the channels in the left and right frames (refer to

Figure 14).

Channel

Printhead

18 PA/PT400 & PA/PT 403 User’s Guide

Arrows

Ribbon

Page 19

4. Slide the ribbon cartridge past the printhead (refer to Figure

15). It will automatically move into the correct operating position.

5. Close the printhead (refer to Figure 16) and the top cover.

Swing up the

media access

door, ensuring that the

media is properly

extending out of

the printer (see

Figure 8 for TearOff, or Figure 10

for Peel-Off).

6. Lift to hook the top

of the media access door over the

top cover. Push in

the bottom of the

media access door

to close.

7. Turn on the printer or press the Feed button if the printer is already on. To remove the ribbon cartridge, simply lift the printhead and pull the ribbon cartridge from the printer.

PA/PT400 & PA/PT 403 User’s Guide 19

Page 20

Operator Controls

Refer to Figure 17.

Power Button

• Press to turn on the printer.

•To turn off the printer, press and hold until the Power LED

flashes once. (Holding the button for approximately two seconds acts as a safeguard. That way, no data will be lost if the

button is accidentally pressed or bumped.)

CAUTION. The power should be turned off before connecting or disconnecting the communications cable.

Feed Button

•Forces the printer to feed one blank label.

•Takes the printer out of a “pause” condition. (The printer is put

into “pause” by either a software command or an error condition.) See “Troubleshooting”.

• Used for printer setup and status (see “Feed Button Modes” in

“Troubleshooting”).

F

IGURE

Powe r

LED

17

Feed

Button

20 PA/PT400 & PA/PT 403 User’s Guide

Error

LED

Powe r

Button

Page 21

Indicator LEDs

Refer to Figures 17 and 18.

Power LED (Green)

• “On” during normal printer operation.

• Functions as a printer operational/battery status indicator (see

“Help! The LEDs are On/Off/Flashing!” in Troubleshooting).

Error LED (Orange)

• “Off’ during normal printer operation.

• Functions as a printer operational status indicator (see “Help!

The LEDs are On/Off/Flashing!” in “Troubleshooting”).

Battery Charging LED (Yellow)

• Functions as a battery charging status indicator.

• “On” while the battery is fast charging.

• “Flashing” when the printer is preparing the battery for fast

charging or the battery overheats while charging.

• “Off ‘ if the battery is fully charged or the battery charger is not

plugged in.

PA/PT400 & PA/PT 403 User’s Guide 21

Page 22

22 PA/PT400 & PA/PT 403 User’s Guide

Page 23

Adapter

Cable

Null Modem

Cable

Ferrite

Computer

Communications

Por ts

Communications

Cable

PA/PT400 & PA/PT 403 User’s Guide 23

Page 24

Communicating with the Printer

Setting the Communication Parameters

When using the printer’s serial port to transfer data, you will need to

make sure that the printer and the computer have identical communication parameter settings. To initialize the communication parameters

for the printer: Press and hold the Feed button until the Error LED

flashes once, then twice, then three times. Release the button. The

baud rate for the printer will be reset to 9600 baud, 8 bits per character, no parity, and 1 stop bit using software handshaking (XON/

XOFF). Then set the communication parameters on your computer to

match this. Some computer programs use different settings than the

default modes (for example, computers operating in MS-DOS use

hardware handshaking instead of XON/XOFF). To use different settings than the defaults and save these settings permanently, refer to

your label preparation software user’s manual.

IR Communications

Printers equipped with the IR (infrared) option can establish wireless communications between the printer and an IR equipped host

terminal using the industry standard IrDA communications protocol.

IR units can also communicate with a cable as detailed above, however, IR functions are disabled when the cable is plugged in.

IrDA compliant terminals will automatically initiate communications

to the printer. First insure that there is a direct line of sight between

the printer and the terminal that will be sending data. The IR window

on the front of the printer must face the corresponding window on the

terminal and the distance between the communicating units should

not exceed 39” (1 m) to properly send and receive signals (see Figure

21). An IrDA compliant terminal will seek out any linkable devices

and establish communications with them.

Setting Up the Software

In order to create labels, you must decide whether you will use ZPL

II or a commercial label preparation system. To use ZPL II, refer to the

ZPL II Programming Guide. If you choose to use a label preparation

system, follow the installation instructions included in the package.

Adjusting the Print Width

Print width must be calibrated when you are using the printer for the

first time and whenever there is a change in the width of the media

you are using. Print width can be set via the software (consult your

label preparation software user’s manual) or refer to “Feed Button

Modes” in “Troubleshooting”.

24 PA/PT400 & PA/PT 403 User’s Guide

Page 25

Adjusting the Print Darkness

The relative darkness setting is software controlled. Follow the in-

structions in your label preparation software user’s manual.

Adjusting the Printhead Pressure

Adjust printhead pressure if print darkness is inconsistent across

the label.

NOTE: In general, use a higher setting for wide labels and

lower setting for narrow labels.

There are four printhead pressure settings (see Figure 22). Depending on whether you want to increase or decrease the printhead pressure, slide the printhead pressure adjuster toward the back or front of

the printer. Then, print another test label. Repeat this procedure until

you achieve the desired results.

WARNING: NEVER tighten or loosen the two screws

that secure the printhead to the bracket! They are not

used to adjust printhead pressure

Printhead

Pressure Adjuster

Highest

Pressure

Setting

Lowest

Pressure

Setting

Don't tighten or loosen

these screws!

F

IGURE

22

PA/PT400 & PA/PT 403 User’s Guide 25

Page 26

Adjusting the Strap

Hand/Shoulder Strap

To lengthen the strap:

Refer to Figure 23.

1. With the printer in front of you, unwrap the padded handle by

lifting up the loose end of the handle.

2. Unlatch the buckle by squeezing both sides of the fastener.

3. Let the loose end of the strap fall to the side.

4. Pull up the handle.

Handle

(Pull Up)

F

astener

F

IGURE

23

26 PA/PT400 & PA/PT 403 User’s Guide

Buckle

Page 27

To shorten the strap:

Refer to Figure 24.

1. Pull the buckle until the strap is taut.

2. Latch by inserting the fastener into the buckle.

3. Wrap and secure the padded handle around the strap.

Buckle

Fastener

Handle

Adjustable Shoulder Strap

Refer to Figure 25.

Slide the two buckles

toward either the

printer or shoulder pad until

you achieve

the desired

length.

PA/PT400 & PA/PT 403 User’s Guide 27

Page 28

Calibration

Auto Calibration

NOTE., The printer will not auto calibrate when you are using pre-printed labels or pre-printed label backing. If you are

using this type of media, see “Manual Calibration. ‘

By default, this printer automatically sets the sensor levels for, and

determines the length of, the label you are using. To auto calibrate:

1. Load the media according to the instructions in “Loading the

Media” in Getting Ready to Print.

2. Turn on the printer or press the Feed button if the printer is already on.

3. Some blank labels will feed, completing auto calibration.

4. If the Error LED begins flashing, refer to “Manual Calibration.”

Hints:

•Auto calibration only works when you are using non-continuous

media (a gap, notch, or black mark separates each label).

• When auto calibration is selected, it occurs when the printer is

turned on (if the printhead has been opened), whenever an error is cleared, or if the battery (or other power source) has

been removed.

Manual Calibration

A manual calibration should be performed whenever you are using

pre-printed labels (or label backing) or if the printer will not auto calibrate.

1. Turn on the printer power.

2. Remove 4-6" (102-152 mm) of labels from a section of backing

material. Load the media so that only the backing material is

threaded through the printer and under the printhead.

3. Press and hold the Feed button until the Error LED flashes

once, then twice. Release the button.

4. The printer will set the media sensor for the label backing you

are using. After it is done making this adjustment, the roll will

automatically feed until a label is positioned at the printhead.

5. A profile of the media sensor settings will print (similar to the

example in Figure 26). Upon completion, the printer will save

the new settings in memory and the printer is ready for normal

operation.

28 PA/PT400 & PA/PT 403 User’s Guide

Page 29

6. Press the Feed button. One entire blank label should feed. If

this doesn’t happen, try defaulting (refer to “Feed Button

Modes” in the “Troubleshooting” section) and recalibrating the

printer.

NOTES: Performing a manual calibration disables the

auto calibration function. To return to auto calibration,

either default the printer (see “Feed Button Modes” in

“Troubleshooting”) or refer to your label preparation software users manual.

When using non-continuous media, set the appropriate

software command (see your label preparation software

users manual) before you perform a manual calibration.

F

IGURE

26

PA/PT400 & PA/PT 403 User’s Guide 29

Page 30

Preventive Maintenance

WARNING: To avoid possible personal injury or damage

to the printer, never insert any pointed or sharp objects

into the printer.

Cleaning

CAUTION.- Use only the cleaning agents indicated.

Zebra Technologies Corporation will not be responsible

for damage caused by any other cleaning materials

used on this printer.

Area Method Interval

Use 70% isopropyl alcohol on a cotton

swab to clean the print elements from

end to end (the print elements are

Printhead

(Figure 1)

Platen Roller

(Figure 1)

located in the thin gray line on the

printhead). Note: You do not have to

turn off the printer to do this.

If print quality has not improved after

performing this procedure, try cleaning

the printhead with Save-a-Printhead

cleaning film. This specially coated

material removes contamination

buildup without damaging the

printhead. Call your authorized Zebra

reseller for more information.

With the printer turned off, rotate the

platen roller and clean it thoroughly

with 70% isopropyl alcohol and a

cotton swab or lint-free cloth.

After every five

rolls of media or

three ribbon

cartridges (or

more often, if

needed)

With the printer power turned off and

Head open

sensor plate

(Figure 27)

Peel bar

(Figure 1)

Tear bar

(Figure 8)

Exterior

Interior

battery removed, press down on the

top of the printhead. Then, clean the

area beneath the screw with 70%

isopropyl alcohol and a cotton swab.

Caution: Do not turn the screw.

Clean it thoroughly with 70% isopropyl

alcohol and a cotton swab.

Clean it thoroughly with 70% isopropyl

alcohol and a cotton swab.

Water-dampened cloth

Brush/air blow

30 PA/PT400 & PA/PT 403 User’s Guide

As needed

Page 31

Lubrication

CAUTION. No lubricating agents of any kind should be

used on this printer! Some commercially available lubricants, if used, will damage the finish and the mechanical

parts inside the printer.

Extending Battery Life

•Never expose the battery to direct sunlight or temperatures

over 104∞ F (40∞ C).

• Choose the media or ribbon that is easiest to “burn.” An authorized Zebra reseller can help you determine this.

• Make sure you’re using the optimal ribbon/media combination

for your application. An authorized Zebra reseller can help you

determine this.

• If you print the same text or graphic on every label, consider

using a pre-printed label.

• Choose the correct print darkness, print speed, and printhead

pressure for your media and ribbon.

• Use software handshaking (XON/XOFF) whenever possible.

• Select Tear-Off mode whenever possible (Peel-Off mode uses

more power).

• Pull the battery out of the printer if the printer won’t be used for

a day or more and you’re not performing a maintenance

charge.

• Completely discharge the battery before recharging. Wait until

you get a “battery under voltage - level 1 “ indication (Error LED

off and Power LED flashing) before you recharge.

• Consider purchasing an extended life battery, which offers double the life of a standard battery.

PA/PT400 & PA/PT 403 User’s Guide 31

Page 32

Battery Disposal

The EPA certified RBRC® Battery Recycling Seal on the nickel-cadmium (Ni-Cd) battery indicates Zebra Technologies Corporation is voluntarily participating in an industry program to collect and recycle

these batteries at the end of their useful life, when taken out of service in the United States or Canada. The RBRC® program provides a

convenient alternative to placing used Ni-Cd batteries into the trash or

the municipal waste stream, which may be illegal in your area. Please

call 1-800-8-BATTERY for information on Ni-Cd battery recycling and

disposal bans/restrictions in your area. Zebra Technologies Corporation’s involvement in this program is part of our commitment to preserving our environment and conserving our natural resources.

Outside North America, please follow local battery recycling guidelines.

32 PA/PT400 & PA/PT 403 User’s Guide

Page 33

Troubleshooting

Tr y as you may, you can’t seem to get the label to look right. Or, the

LEDs are on or flashing when they’re normally off. This is the section

of the User’s Guide that can help you solve your printer’s problems! If,

after reading this section, you’re still having difficulty getting your

printer to print, contact a qualified Zebra service technician.

Help! The LEDs are On/Off/Flashing)

Error LED Power LED Printer Refer to

(Orange) (Green) Status “Resolutions” #

Off Off Off 1

Flashing On Stopped 2

Double Flashing On Paused 3

On On On 4

On On Stopped 5

Off Flashing On 6

Off Flashing Stopped 7

Alternate Flashing Needs Service 8

Simultaneous Flashing Various 2 and 6

On Flashing On 4 and 6

On Flashing Various 5 and 6

Double Flashing Flashing Yes 3 and 7

Resolutions:

1. The printer is not receiving power.

•Have you turned on the printer power?

• Ensure that the battery is fully charged. Follow the instructions in

“Charging the Battery” in “Getting Ready to Print”.

• Make sure the battery is properly installed. Refer to “Installing the

Battery” in “Getting Ready to Print”.

2. The printhead is open.

• Close the top cover and media access door. Then, press the Feed

button to resume printing.

The media is out.

• Load a roll of media, following the instructions in “Loading the Media”

PA/PT400 & PA/PT 403 User’s Guide 33

Page 34

in “Getting Ready to Print”. Then, press the Feed button to resume

printing.

The ribbon is out (PT SERIES only).

• Load the ribbon, following the instructions in “Loading the Ribbon” in

“Getting Ready to Print”. Then, press the Feed button to resume

printing.

The head open sensor plate is dirty.

• Clean the head open sensor plate according to the instructions in

“Preventive Maintenance”.

3. The printer is paused.

• Press the Feed button to resume printing.

4. The printhead is under temperature.

• Continue printing while the printhead reaches the correct operating

temperature.

5. The printhead is over temperature.

•Printing automatically stops until the printhead cools to an acceptable

printing temperature; the printer then automatically resumes operation.

The battery is over temperature.

•Printing automatically stops until the printer and battery cool to an

acceptable operating temperature; then, the printer automatically

resumes operation.

6. The battery is under voltage (level 1)

•Wait until the current label finishes printing, then plug the battery

charger into the printer (you don’t have to turn off the printer to do

this).

7. The battery is under voltage (level 2).

• The battery may not have enough power to print the next label and

can reset the printer, losing formats in the printer. Plug the battery

charger into the printer (you don’t have to turn off the printer to do

this). After the battery is charged, press the Feed button.

8. FLASH memory is not programmed.

• Return the printer to an authorized Zebra reseller.

Print Quality Problems

No print on the label.

• If you aren’t using ribbon, make sure the correct media (direct

thermal) is loaded. Try this: Quickly rub your nail or a blunt object over

the label surface. If it doesn’t produce dark marks, the wrong media

(thermal transfer) is loaded.

• Are the media and ribbon loaded correctly? Follow the instructions in

“Loading the Media” and “Loading the Ribbon” in “Getting Ready to

Print”.

34 PA/PT400 & PA/PT 403 User’s Guide

Page 35

•You may be trying to use the printer outside of its environmental limits.

The correct operating temperature range for this printer is between

32∞ F and 104∞ F (0∞ to 40∞ C).

The printed image doesn’t look right.

• The printhead is dirty. Clean the printhead according to the

instructions in “Preventive Maintenance”.

•Printhead pressure needs to be adjusted. Follow the steps in

“Adjusting the Printhead Pressure” in “Getting Ready to Print”.

• The print darkness needs to be adjusted. See “Adjusting the Print

Darkness” in “Getting Ready to Print”.

• The print mode may be incompatible with the media you are using. If

your printer is set for thermal transfer mode, you must use thermal

transfer, rather than direct thermal, media and a ribbon cartridge.

• The media being used is incompatible with the printer. Be sure to use

the Zebra-recommended media for your application.

• Battery voltage is low. See “Charging the Battery” in “Getting Ready to

Print”.

There are long tracks of missing print (blank vertical lines) on

several labels.

• The printhead is dirty. Clean the printhead according to the

instructions in “Preventive Maintenance”.

• The printhead elements are damaged. Call a qualified service

technician to replace the printhead.

Mis-registration of labels (the printing does not start at the top of

the label) and misprinting of 1 to 3 labels.

• The media may not be threaded under the media guides. Refer to

“Loading the Media” in “Getting Ready to Print”.

• The printer needs to be calibrated. Refer to “Calibration”.

•Printhead pressure needs to be adjusted. Follow the instructions in

“Adjusting the Printhead Pressure” in “Getting Ready to Print”.

• The correct media sensor may not be activated. In manual calibration,

select the media sensing method for the labels you are using (refer to

your label preparation software user’s manual).

A label format was sent to, but not recognized by, the printer.

• Is the printer in pause mode? If so, press the Feed button.

• If the LEDs are on or flashing, refer to “Help! The LEDs are On/Off/

Flashing!” in “Troubleshooting”.

• Make sure the data cable is installed correctly. Also, make sure you

are using a null modem cable between the printer’s adapter cable and

the computer (see Figure 19), or the appropriate null modem cable.

•A communications problem has occurred. First, make sure that the

PA/PT400 & PA/PT 403 User’s Guide 35

Page 36

correct communications port on the computer is selected. Next, verify

that the same handshaking is in use by both the printer and the

computer. Then, ensure that the communication parameters of the

printer and the computer match. Refer to “Communicating with the

Printer” in “Getting Ready to Print”.

Troubleshooting Tests

Printing a Configuration Label

To print out a listing of the printer’s current configuration (a sample

is shown in Figure 28), refer to “Feed Button Modes” in this chapter.

Recalibration

Recalibrate the printer if it starts to display unusual symptoms, such

as skipping labels. See “Calibration”.

Resetting the Factory Default Values

Resetting the printer to the factory defaults can solve some printer

problems. Follow the instructions in ‘Feed Button Modes” in this chapter.

F

IGURE

28 F

36 PA/PT400 & PA/PT 403 User’s Guide

IGURE

29

Page 37

Communications Diagnostics

If there’s a problem transferring data between the computer and the

printer, try putting the printer in the Communications Diagnostics

mode. The printer will print the ASCII characters and their respective

hexadecimal values for any data received from the host computer

(see Figure 29). To find out how, refer to “Feed Button Modes” in this

chapter.

Feed Button Modes

Power Off Mode (Communications Diagnostics Mode)

With the printer power off, press and hold the Feed button while you turn on the

power. The printer prints out a listing of its current configuration (see Figure 28).

After printing the label, the printer will automatically enter a diagnostic mode in

which the printer prints out a literal representation (see Figure 29) of all data

subsequently received.

Power On Modes

With the printer power on, printhead closed, and Error LED off, press and hold the

Feed button for several seconds. The Error LED will flash a number of times in

sequence. The explanation at the right (Action) shows what happens when you

release the key after the specific number of flashes.

Flash Sequence Action

A configuration label prints.

The media sensor calibrates and a media sensor profile

prints (see Calibration and Figure 25).

The serial communication parameters are reset to 9600

baud, 8 bits per character, no parity, l stop bit, and XON/

XOFF.

Resets the factory defaults, auto calibrates, and saves

settings into memory.

The print width is calibrating. While the Error LED rapidly

flashes, a series of stacking rectangles prints on the label.

When the rectangle prints to the outer edges of the label,

press and release the Feed button. The label width and

current communication parameters will be saved into

memory.

If the Feed button is held down for six flashes and quickly released,

the printer will ignore the button. For additional information, refer to

the maintenance manual.

PA/PT400 & PA/PT 403 User’s Guide 37

Page 38

Specifications

NOTE.- Printer specifications are subject to change without

notice.

Printing Specifications

Print Density 203 dots/inch (8 dots/mm)

Print Width Up to 4.1“ (104 mm)

Print Speed 1.5” or 2” per second (38.1 mm or 50.8 mm

per second), 3” per second on 403 Series

Registration

Tolerance

Distance from

Center Print Element 0.0393” (+/- 1.0 mm)

to Center of Label

Maximum Duty Cycle Up to 60 linear inches of media per batch

Horizontal +/- 0.059"1 (+/- 1.5 mm)

Ver tical +/- 0.0393" 1.0 mm) on media >2” (50.8 mm)

in height

+/- 180"(3.0 mm) on media < 2" (50.8 mm) in

height

unless

they are run without backfeed

Up to 18% black per batch

Up to four batches per hour

Ribbon Cartridge Specifications (PT SERIES)

Ribbon Width 4.33" (1 l 0 mm)

Ribbon Outer Diameter .66" (1 6.8 mm)

38 PA/PT400 & PA/PT 403 User’s Guide

Page 39

Label Specifications

Label/Tag Width 1" to 4.25" (25.4 mm to 108 mm)

Fanfold Width 3.5" to 4.25" (89 mm to 108 mm)

Label/Tag Length 0.5" to 10" (1 2.7 mm to 254 mm) 400 Series;

0.5” to 70” (1 2.7 mm to 1778 mm) 403 Series

Inter-label Gap. 08" to .16" (.12" preferred)

2 mm to 4 mm (3 mm preferred)

Label/Tag Thickness .0030- to .0106- (.076 mm to .269 mm)

Label RollSize:

Max.Diameter 2.1" (53.3 mm)

Inner Core 1" (25.4 mm)

Use Zebra-brand direct thermal or thermal transfer roll

media that is outside wound. Media may be reflective

(black mark) sensing or transmissive sensing, die-cut,

notched, or continuous.

For die-cut labels, use only full auto dies.

Media Requirements Notched media must have a 0.5" (1 2.7 mm) wide x

0.094” (2.4 mm) long cutout located in the center of the

roll. The reflective media black marks must be located in

the center of the roll.

Minimum Black Mark Dimensions:

Mark width: 0.5” (12.7mm) perpendicular to the edge of

the media.

Mark length: 0.094” (2.4 mm) parallel to the edge of the

media.

Memory/Communications Specifications

ROM Memory 1 MB flash (400 Series); 2MB flash (403 Series)

RAM Memory 512 KB DRAM (400 Series); 2 MB DRAM (403 Series)

Communications RS-232 serial port (RJ45 connector)

Configurable Baud rate (from 110 to 19,200 Baud),

parity and data bits.

Software (X-ON/X-OFF) or hardware (DTR/STR)

communication handshake protocols.

Error detection CRC protocol

Optional infrared wireless link (meets IrDA 1.1

specifications) 2,400 to 115,200 Baud rate

PA/PT400 & PA/PT 403 User’s Guide 39

Page 40

Font/Bar Code Specifications

Fonts Available CG Triumvirate Bold Condensed scalable smooth

1D Bar Codes Available EAN 13/JAN 13

2D Bar Codes Available Data Matrix

Zebra fonts A, B, C, D, E, H, GS

Codabar (supports ratios of 2 l to 3: 1)

Code 11

Code 128/USD 8 (supports serialization in all subsets

and UCC Case Codes)

Code 39 (supports ratios of 2:1 to 3: 1)

Code 93

EAN 8/JAN 8

EAN 14/UPCA

lndustrial 2 of 5

Standard 2 of 5

lnterleaved 2 of 5 (supports ratios of 2:1 to 3: l, Modulus

10 Check Digit)

LOGMARS

MSI

Plessey

POSTNET

UPC E

UPC/EAN Extensions

Codablock

Code 49

MaxiCode

MicroPDF417

PDF 417

QR code

Rotation Angles 0∞, 90∞, 180∞, and 270∞

Physical/Environmental/Electrical Specifications

Physical Size (L x W x H) 2.9” x 9.2” x 7.9” [74 mm x 235 mm x 200 mm]

Weight

w/ std. battery & strap, PA400 & 403: 4.0 lbs. (1.8 kg. )

excluding media. PT 400 & 403: 4.2 lbs. (1.9 Kg) Cartridge 1.6 oz. (45 g)

Temperature

Operating 32∞ to 104∞ F (0∞ to 40∞ C)

Storage w/battery -22∞ to 122∞ F (-30∞ to 50∞ C) Range

Storage (w/o battery) -40∞ to 140∞ F (40∞ to 60∞ C) Range

Relative Humidity

Operation 10% to 90% (non-condensing)

Storage 5% to 95% (non-condensing)

Electrical External 120 or 230 VAC battery charger, depending on

40 PA/PT400 & PA/PT 403 User’s Guide

which model you order. Additional custom line cords

may also be available.

Page 41

Agency Approvals

• UL 544 Medical Equipment Standard Part 42.5

• CSA 22.2 number 950 Canadian Safety Standard

• IEC 95O/EN 60950 International Safety Standard

• FCC Part 15 Subpart B Class B Electromagnetic Radiation

Standard

• UL 1950 Domestic Safety Standard

• Canadian DOC Class A

• SOR/88-475 Canadian Electromagnetic Radiation Standard

• EN50082-1 International lmmunity Standard

• EN55022 Class B European Electromagnetic Radiation Standard

Options

• Hand/shoulder strap

• Adjustable shoulder strap

•Weather-resistant protective case

• Vibration mount, U-arm bracket, and media catch tray

• Standard battery

• Extended life battery

• 120 VAC battery charger

• Universal switching battery charger

• Battery eliminator

• Data cables

For details, call your authorized Zebra reseller.

PA/PT400 & PA/PT 403 User’s Guide 41

Page 42

42 PA/PT400 & PA/PT 403 User’s Guide

Page 43

Index

A

Adapter cable 22, 42

Adjusting the strap 26

Adjustments

Print darkness 25

print width 24

Printhead pressure 25

Agency approvals 41

B

Battery, charging 9

Battery Charglng LED 21

Battery disposal 32

Battery, installing 9

Battery life, tips 31

C

Calibration

Automatic 28

Manual 28

Cleaning

Exterior 30

Head open sensor plate 30

Interior 30

Peel bar 30

Platen roller 30

Printhead 30

Tear bar 30

Communication Parameters, setting 24

Communications diagnostics 37

Communications, IR 24

Configuration label 36

D

Damage, shipping 7

Darkness, adjusting 25

Data Terminal Equipment (DTE) 22

Defaulting the printer 37

E

Error LED 21, 33

F

Factory defaults, resetting 36

Fanfold media 16

Feed button 20

Feed button modes 37

H

Handshaking 24

I

Indicator LEDs 21

Inspection 7

L

Loading Media

Tear-Off Mode 10

Loading the Media

Peel-off mode 13

Loading the media

Fanfold media 16

Loading the ribbon 17, 18

Lubrication 31

M

Maintenance Manual 7

Media Loading

Peel-off mode 13

Tear-off mode 10

Media loading

Fanfold media 16

N

Null modem cable 22

pinouts 42

O

Operator controls 20

Options 41

P

Peel-Off Mode 13

Power button 20

Power LED 21, 33

Print Darkness, adjusting 25

Print width, adjusting 24, 37

Printhead pressure, adjusting 25

R

Reporting damage, shipping 7

Ribbon loading 18

RJ45 connector pin identification 42

S

Software 24

Specifications

Font/bar Code 40

Label 39

Memory/communications 39

Physical/Environmental/Electrical 40

printing 38

Ribbon cartridge 38

Strap, adjusting

Adjustable shoulder strap 27

Hand/shoulder strap 26

T

Tear-Off Mode 10

Troubleshooting 33

Troubleshooting tests 36

U

Unpacking 7

Z

ZPL II 7, 24

ZPL II Program Guide, ordering 7

PA/PT400 & PA/PT 403 User’s Guide 43

Page 44

Loading...

Loading...