Page 1

980541-001 Rev. A

Zebra® P640i Card Printer

Card Printer

User Guide

Page 2

© 2004 ZIH Corp.

The copyrights in this guide and the printers described therein are owned by Zebra Technologies Corporation. Unauthorized reproduction of this manual or the software in the label print engine may result in imprisonment of up

to one year and fines of up to $10,000 (17 U.S.C.506). Copyright violators may be subject to civil liability.

Printer Software © ZIH Corp. All rights reserved worldwide.

Windows is a registered trademark of Microsoft Corporation. All other brand names, product names, or trademarks

belong to their respective holders.

Customer Order # 980541-001

Manufacturer Part # 980541-001 Rev. A

Caution labels on P640i Printers

Pinch Hazard • Keep fingers away from printer cover hinges and back of cleaning

cassette

Hot surfaces • Danger of skin burns near laminator components

Advisories used in this Guide

Important • Advises you of important information

Caution• Failure to follow instructions to the letter can cause malfunction, dam-

age to the printer, or personal injury.

ii P640i Card Printer User Guide 980541-001 Rev. A

Page 3

P640i Card Printer User Guide

Caution • The separate Quick Start Guide shows how to

set up the printer using the standard USB interface. If your

printer was configured for the optional Parallel or Ethernet

connections, refer to Technical Note 9 in Section 4 of this

Guide for instructions on driver installation.

980541-001 Rev. A P640i Card Printer User Guide iii

Page 4

WARRANTY INFORMATION

Printers

All Zebra Card Printers are warranted against defects in material or workmanship for twelve (12)

months from the purchase date.

Proof of purchase or shipment date is required to validate the warranty period. The warranty becomes

void if the equipment is modified, improperly installed or used, damaged by accident or neglect, or if

any parts are improperly installed or replaced by the user.

Note: Products must be packaged in the original or comparable packaging and shipping container. In

the event equipment is not so packaged, or if shipping damage is evident, it will not be accepted for

service under warranty. Surface transportation charges for return to customers in the continental United States is paid by Zebra. Otherwise, Zebra pays CPT (carriage paid to) nearest airport, customer

pays customs, duties, taxes and freight from airport to destination. If Zebra determines that the product returned for warranty service or replacement is not defective as herein defined, the customer will

pay all handling and transportation costs.

Printheads

Since printhead wear is part of normal operation, the original printhead is covered by a twelve (12)

month warranty. Warranty period begins on purchase date.

To qualify for this warranty, the printhead must be returned to the factory or to an authorized service

center. Customers are not required to purchase Zebra supplies (media and/or ribbons) for warranty

qualification. However, if it is determined that the use of other manufacturer supplies has caused any

defect in the printhead for which a warranty claim is made, the user is responsible for Zebraís labor

and material charges required to repair the defect. The warranty becomes void if the printhead is

physically worn or damaged; also if it is determined that failure to follow the preventative maintenance

schedule listed in the Userís Guide has caused defect in the thermal printhead for which warranty

claim is made.

Software

Software is warranted to be free of defects in material and workmanship for 30 days from the date of

purchase. In the event of notification within the warranty period of defects, Zebra will replace the defective CD or documentation.

Supplies

Supplies are warranted to be free from defect in material and workmanship for a period of six (6)

months for media and twelve (12) months for ribbon from the date of shipment by Zebra. This is provided the user has complied with storage guidelines, handling, and usage of the supplies in Zebra

printers.

Zebraís sole obligation under these warranties is to furnish parts and labor for the repair or possible

replacement of products found to be defective in material or workmanship during the warranty period.

Zebra may in its discretion issue a credit for any such defective products in such amount as it deems

reasonable.

Spare Parts

All parts, maintenance kits, options kits, and accessories are warranted to be free of defects in material and workmanship for 90 days (except where otherwise denoted) from date of purchase. This warranty becomes void if the item is modified, improperly installed or used, or damaged by accident or

neglect.

iv P640i Card Printer User Guide 980541-001 Rev. A

Page 5

Warranty Exclusions and Conditions

The warranties provided above are the only warranties applicable. No other warranties, expressed or

implied, are given. Zebra does not make any IMPLIED WARRANTY OF MERCHANTABILITY OR

FITNESS FOR A PAR TICULAR PURPOSE in connection with its sale of products or services. While

Zebraís desire is to be responsive to specific needs and questions, Zebra does not assume responsibility for any specific application to which any products are applied including, but not limited to, compatibility with other equipment. All statements, technical information or recommendations relating to

Zebra products are based upon tests believed to be reliable yet do not constitute a guaranty or warranty.

Zebraís maximum liability for warranty claims is limited to the invoice price of the product claimed defective. Zebra does not assume responsibility for delays or replacement or repair of products. Zebra

shall not under any circumstances whatsoever be liable to any party for loss of profits, lost data, diminution of good will, or any other special or consequential damages whatsoever with respect to any

claim made under agreement with Zebra. Specifically for software, Zebra is not liable for any incidental or consequential damages caused by abuse or misapplication of the software or by its use in violation of the U.S. copyright law or international treaty.

980541-001 Rev. A P640i Card Printer User Guide v

Page 6

AGENCY APPROVALS

Product Disposal

Do not dispose of this product in unsorted municipal waste. This product is recyclable.

Please recycle according to your local standards. For more information, please see our

web site at: http://www.zebra.com/recycle

CONTACT INFORMATION

Zebra Technologies • Card Printer Solutions

North America

1001 Flynn Road

Camarillo, CA 93012-8706 USA

Telephone: +1(805) 579 1800

Fax: +1(805) 579 1808

Toll free in the US: 800 452 4056

e-mail: cards@zebra.com

Europe, Middle East and Africa

The Valley Centre, Gordon Road

High Wycombe

Buckinghamshire HP13 6EQ, UK

Telephone: +44 870 241 1527

Fax: +44 870 241 0765

www.zebracard.com

Asia Pacific

16 New Industrial Road

#05-03 Hudson TechnoCentre

Singapore 536204

Telephone: +65 6858 0722

Fax: +65 6885 0836

e-mail: asiasales@zebra.com

Latin America

9800 NW 41St Street, Suite 220

Doral, FL 33178

Telephone: +1(305) 558 3100

Fax: +1(805) 558 8485

vi P640i Card Printer User Guide 980541-001 Rev. A

Page 7

Table of Contents

Table of Contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . vii

1 • Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Photo ID card printing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Printing basics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

What makes the P640i a different kind of printer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

What to expect when you turn on the power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Test card. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Push buttons and Indicator lights. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

PRINT button . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

RIBBON button. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

LAMINATE button. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

INDICATOR LIGHT SUMMARY. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

A typical card production sequence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2 • Media Handling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Loading cards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Hot Loading . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Loading the cleaning cassette. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Why 10 cards is the normal clean frequency . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Loading the color ribbon . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Laminating Station . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Laminate Cassettes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Main components of the laminating system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Removing the cassettes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Loading the cassettes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Installing the cassettes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Clearing the Laminate Channels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Laminating smart cards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

980541-001 Rev. A P640i Card Printer User Guide vii

Page 8

Table of Contents

3 • Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Image Adjustment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Troubleshooting quality problems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Poor color registration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Examples of color mis-registration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Poor color rendering. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Faint, non-uniform image . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Gaps in image at edges and corners . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Continuous white or black stripes on card’s longer dimension. . . . . . . . . . . . . . . . . . 23

Random occurences of white (unprinted) spots . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Image not centered on card . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Image missing at top or bottom of card . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Consistent image defects, card after card . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Random colored patterns on image . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Scratches/dings on long edges of card. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Laminate not centered on card. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Laminate not parallel with card edges . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Laminate wrinkling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Unusual Printer/Lmainator Events . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Color ribbon runs for longer than 2 or 3 seconds when cover is closed (MEDIA

light stays on) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

ALARM light stays ON after error condition is cleared . . . . . . . . . . . . . . . . . . . . . . . . 25

Card has both front and back images printed on same side . . . . . . . . . . . . . . . . . . . 25

MEDIA light ON steady, but no obvious visual problem . . . . . . . . . . . . . . . . . . . . . . . 25

Completely unexpected print results. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

YMC color panels stick to card. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

K (Black) panel sticks to card. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Loud rattling/screeching from card transport . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Brief rattling noise before every print job . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Rattling noise every 10 cards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Unusual events. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Laminator spot check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Additional help . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Error messages. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

viii P640i Card Printer User Guide 980541-001 Rev. A 10/15/2004

Page 9

Table of Contents

4 • Technical Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Technical Note 1 - General Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

P640i Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

ID/Key . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Printer Parameters in the Drivers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Password Protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Technical Note 2 - Card Transport . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

No-slip card transport . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Card transport knob . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Take care of the platen. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Removing the platen. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Truck interlock (arrowed) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Truck home sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Card presence sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Cleaning cassette . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Underside of hopper base molding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Transport Parameters in the Driver . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Avoid These Problems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

TEchnical Note 3 - Magnetic Stripe Encoder . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Mag encoder installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Mag encoder components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Cleaning the read/write head . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Replacing the read/write head . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Magnetic Encoding Functions in the Driver . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Magnetic Encoding Preferences. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Techncial Note 4 - Print Station. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Examples of printhead problems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Cleaning the print head . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Print head attachment hardware . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Replacing the print head . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Print quality tests and adjustments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Print Stati on Parameters in the Driver . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

K (Black) Panel Printing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Technical Note 5 - Flip Station . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

How the flip station works. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Flip station adjustment procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Flip Station Routines in the Driver . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Carrier Motion. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

980541-001 Rev. A 10/15/2004 P640i Card Printer User Guide ix

Page 10

Table of Contents

Techncial Note 6 - Laminator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Laminate position adjustments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Laminator Parameters in the Driver . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Correcting Laminator Problems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Technical Note 7 - ID/Log . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Technical Note 8 - Using the Windows Printer Driver . . . . . . . . . . . . . . . . . . . . . . . . 62

Operator screens . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Printing Preferences . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

What is black extraction? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Printer Properties . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

IDPrint Lite . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

Card Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

Technical Note 9 - Installing the Windows Printer Driver . . . . . . . . . . . . . . . . . . . . . . 73

First things first . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

Driver CD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

Download . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

Uninstalling the printer driver . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

Windows file missing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

Installing the printer driver . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

New Hardware Found Wizard. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

Install using Zebra’s Printer Setup screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

Install using “Add a Printer” . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

Firewall issues . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

Configuring the Ethernet option . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

Technical Note 10 - Printer Pooling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

Set up the Printers individually . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

x P640i Card Printer User Guide 980541-001 Rev. A 10/15/2004

Page 11

1

Introduction

Main cover

Interlock actua-

Card hopper

cover

ID/Key (option-

Card

Hopper

Push

buttons

Indicator

Mag encoder (optional)

Cleaning

station

Print

station

Flip

station

Transfer toggle

Rotate clockwise

to separate trans-

Laminating

station

Card transport

knob

For manual repo-

980541-001 Rev. A P640i Card Printer User Guide 1

Page 12

Introduction

Overview

Overview

The P640i Printer is a complete, fully automatic photo ID card fabricator. It comprises six

functional elements:

• Card hopper

• Magnetic (“mag”) encoder - optional feature

• Cleaning station

• Print station

•Flip station

• Laminator

Because the P640i Printer is fully automa tic, it requires no attention from the ope r ator other

than media loading and an occasional vacuuming.

Although you don’t need a detailed knowledge of the printer to use the printer effectively, an

overall understanding of what goes on can help you troubleshoot effectively.

How you load the cards, color ribbon and laminate is important - see Section 2. Careful

attention to media handling takes care of most problems!

Photo ID card printing

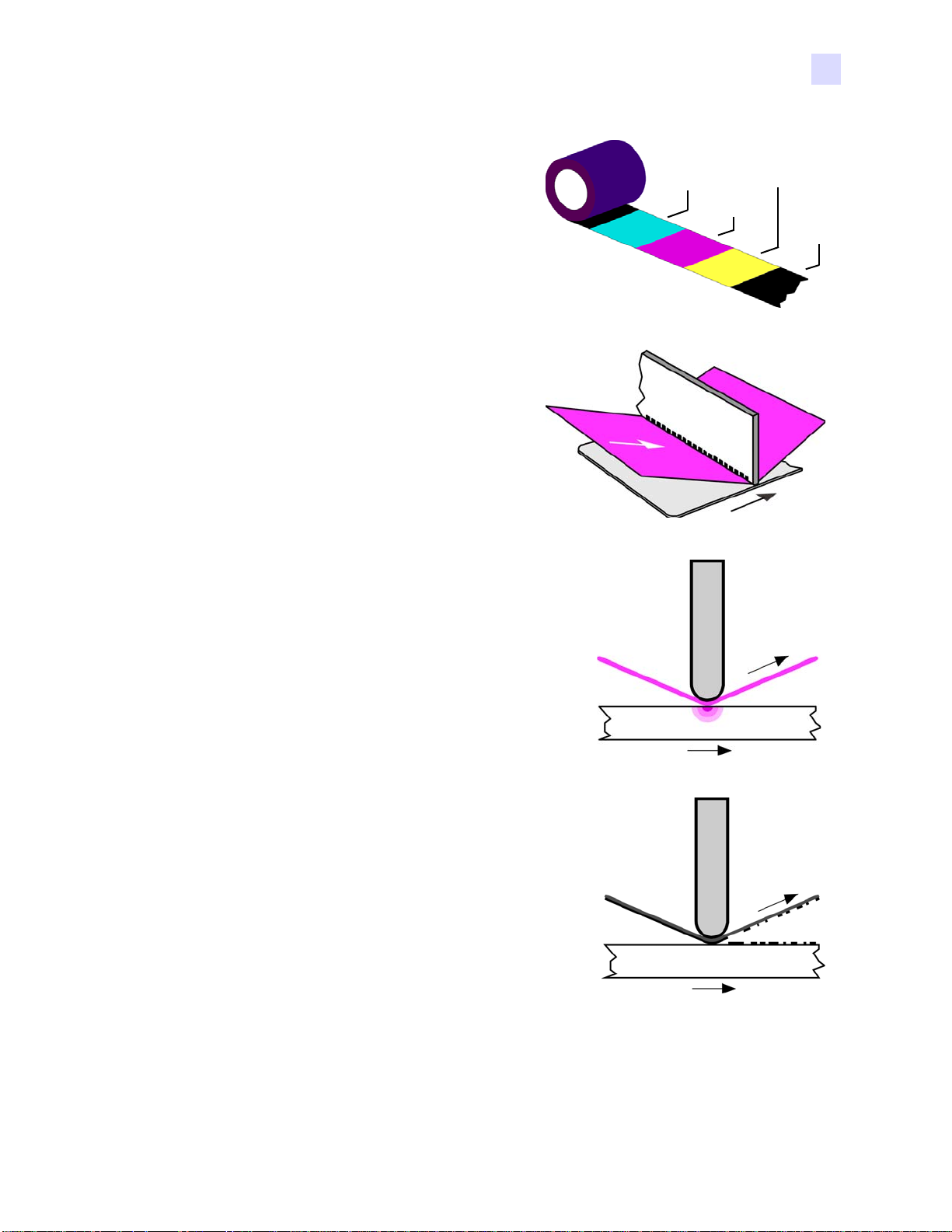

between the print head and the card being printed is the color ribbon, usually a series of

process-color dye panels (Y, M and C) for dye sub, plus a panel of black resin (K) for mass

transfer.

The process used in the P640i Printer is kn own as digital thermal

transfer, a means of printing clean, durable images directly onto the

PVC surface of photo ID cards.

There are two different thermal transfer technologies, both used in the

P640i Printer: dye sublimation (“dye sub”), which uses the three

process colors Yellow/Magenta/Cyan for photos and graphics, and

mass transfer for machine-readable black text and bar codes.

Both types of printing are done with a single print head comprising a

row of tiny heating elements, 300 to the inch, each driven

independently by the printer controller. Sandwiched by spring pressure

2 P640i Card Printer User Guide 980541-001 Rev. A

Page 13

Printing basics

This is the usual pattern for a P640i Printer

ribbon. Y, M and C are the three “dye sub”

process colors. The K panel is for infraredreadable bar codes and other data, usually on

the back of the card. A second K panel

(YMCKK) is sometimes provided to allow

black resin printing on both sides of the card.

Introduction

Printing basics

C

Cyan

Dye

Magen-

ta Dye

Y

Yellow

Dye

M

K

Black

Resin

As the ID card is driven through the print

station, the color ribbon is metered out from

the supply roll at the same speed. Each color

reqires a separate “pass” of the card. The black

dots at the bottom edge of the print head depict

the heating elements - in practice, at 300 to the

inch, they are too small to be seen with the

Card

naked eye.

Color migrates from the dye ribbon onto the ID card,

the spread of the dye depending on the amount of heat

applied by the print head element. Each time it comes to

a dye panel boundary, the print head lifts to allow the

card to back up, then lowers again to print the next

color.

Print

head

Card

Print

head

Print

head

Color

ribbon

The K (black) panel is a resin that “mass transfers”

onto the surface of the card, instead of migrating into

it. With mass transfer the printer has lit tle control over

a pixel’s size or density - it’s either there or it isn’t. K

printing is used for bar codes because it is machine

readable, whereas YMC dyes ar e not.

Card

What makes the P640i a different kind of printer

The print station in the P640i has no pinch rollers that need cleaning to maintain accuracy

980541-001 Rev. A P640i Card Printer User Guide 3

Page 14

Introduction

Printing basics

In the P640i the card is transported on a belt-driven truck that maintains precise registration

Toothed blet

Platen

3. After a few minutes (3 to 5), the READY light will show steady green, indicat in g t hat th e

through the entire process of picking, cleaning, and

multi-pass printing. This means perfect color-to-color

Transport

motor

registration time after time - no slippage, no

deterioration in print quality over time.

What to expect when you turn

Card truck

Card transport

knob

the fan running , and a clicking sound inside the printer (the flip station resetting itself).

Finally;

printer is ready to print.

on the power

1. Nothing happens for two or three seconds, then;

2. The READY light flashes yellow (indicating that

the laminator is warming up), and you will hear

The receiving tray for printed ID cards hooks onto the right side pan el .

Power cord entry and ON-OFF switch are located on the rear

panel.

4 P640i Card Printer User Guide 980541-001 Rev. A

Page 15

Test card

Introduction

Push buttons and Indicator lights

The P640i printer receives data through one

of three types of connector: Ethernet

(optional feature), USB (standard feature) or

Parallel (Centronics type, optional feature).

You may sometimes be asked to print a test

card. This is the pattern stored in the printer’s

memory (it has nothing to do with the

computer). If the printer is functioning

properly, it will be printed when the PRINT

button on the front panel is pressed following

power-up.

Push buttons and Indicator lights

PRINT button

Press the PRINT button to print the image

stored in the printer’s memory. When the

printer is powered up, the memory is loaded

with a checkerboard test pattern, above.

In regular on-line use, the PRINT button

reprints the last image downloaded from the

computer to the buffer memory.

If you press and hold the PRINT button for

more than two seconds, the printer will

continuously reprint the image in the buffer. Stop this action by pressing the button

momentarily while printing is in process.

Note that pressing the PRINT button will have no effect if any of the following applies: 1. An

error condition exists; 2. You have set up the print driver to print color on both sides of the

card, or; 3. The optional hardware lockout key, ID/Key, is missing (but this does not disable

the checkerboard printout available after power-up).

980541-001 Rev. A P640i Card Printer User Guide 5

Page 16

Introduction

Push buttons and Indicator lights

RIBBON button

Figure 1 • Standard YMCK color ribbon

LAMINATE button

If either (or both) of the laminate transfer rollers is not loaded with a laminate patch, then

pressing the LAMINATE button will correct the condition, provided the cassette(s) is not out

of laminate. If both rollers are already loaded, the LAMINATE button has no effect.

This button is used to synchronize the ribbon – in other words,

to position it correctly under the print head.

In typical applications, the ribbon type is YM CK, and th e back

of the card is printed first. In such cases, pressing the RIBBON

button will advance the color ribbon to bring the leading edge

of the next black panel under the print head.

If back side printing is not enabled, the printer will

synchronize on the next yellow panel when the RIBBON

button is pressed.

A typical use of the LAMINATE button is in reloading a transfer rolle r after removin g the first

hand-cut patch of laminate following installation of a fresh roll.

6 P640i Card Printer User Guide 980541-001 Rev. A

Page 17

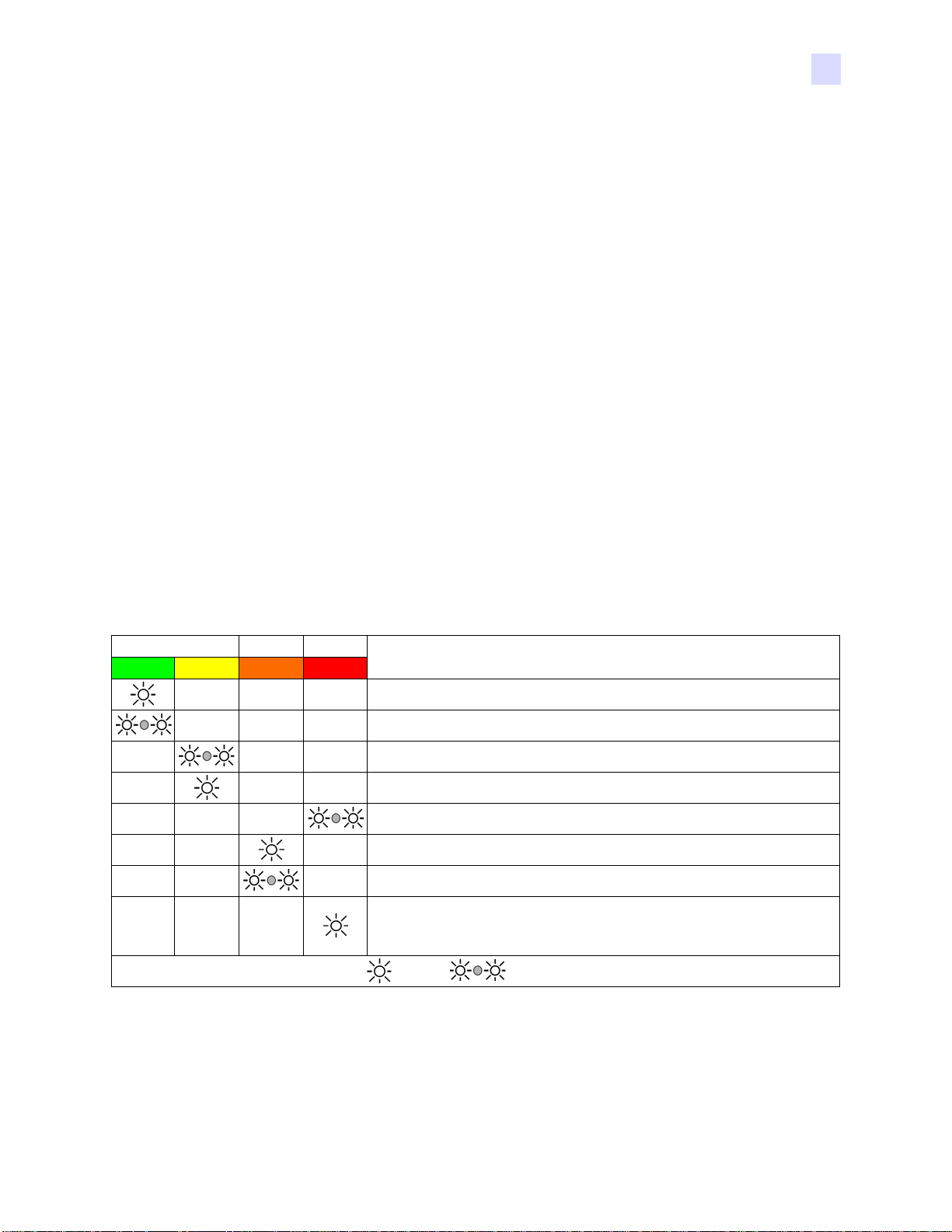

INDICATOR LIGHT SUMMARY

Depending on the condition they are reporti ng, the three indicator l ights, READY, MEDIA and

ALARM, can be in one of three states: Off, On (steady), or Flashing.

The READY indicator is bi-colored. Its two color channels, green and yellow, function

independently.

READY indicator

Green = Ready to print, or printer busy.

Yellow = Laminator not at operating temperature.

MEDIA indicator

Normally Off.

On = Any media outage.

Introduction

INDICATOR LIGHT SUMMARY

ALARM indicator

Normally Off.

READY MEDIA ALARM

GREEN YELLOW ORANGE RED

What the Indicator Lights Tell You

Printer Status

Ready to print

Printer busy

Laminator heating up, but not yet at operating temperature

Laminator heaters in sleep mode (when not in use, the heaters cool at 1oF per minute)

Printhead temperature error.

No cards in magazine, color ribbon out, cleaning tape out, laminator cassette(s) out.

Mag encoding write failure

Serious error conditions, including: MAIN COVER OPEN, Laminator too hot, card

transport stalled, card not seated properly, mag encoding verification error, head lift

failure, ribbon jam, card jam (any location), card missing (any location), no gap between laminator patches.

= light on = light flashing

980541-001 Rev. A P640i Card Printer User Guide 7

Page 18

Introduction

INDICATOR LIGHT SUMMARY

A typical card production sequence

Several variations are possible, such as multi-pass color printing on the back surface (instead

of the black-only printing shown here).

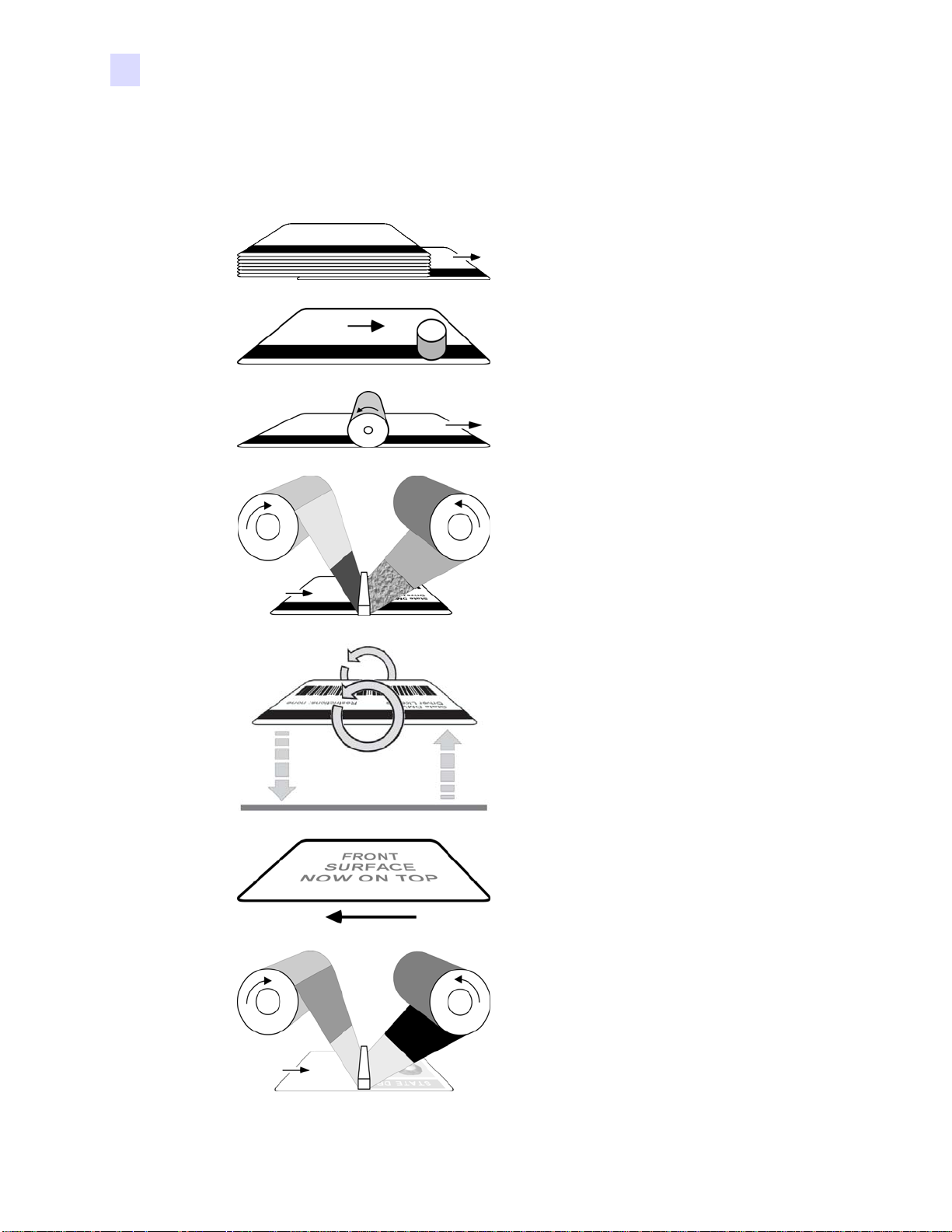

1. Blank cards are loaded face down in the hop-

per, with the mag stripe (if any) toward the

front.

2. The carriage pushes the bottom card out of

the deck, carrying it under the mag encoder.

3. After passing under the encoder, the card sur-

face is cleaned by a tacky roller (which is

itself decontaminated periodically by adhesive tape in the cleaning cassette).

4. The carriage drives the card under the print

head, which transfers black characters and/or

bar code from the K panel onto the back surface of the card.

5. The carriage pushes the back-printed card

into the flip station, which elevates the card

then flips it through 180o.

6. The card, now face up, is returned to the car-

riage, which is then reversed into position for

a second cleaning operation.

7. After its face cleaning the card is driven

under the print head again, this time to p rint a

yellow (Y) dye image - the first of three color

passes.

8 P640i Card Printer User Guide 980541-001 Rev. A

Page 19

8. The carriage reverses the card into position

for the second color pass, magenta (M), followed by another reverse-and-print cycle for

the third color pass, cyan (C).

9. Now fully printed, the card re-enters the flip

station, which this time acts only as an elevator (no flipping) to bring the card up to the

laminator level.

10. An ejector arm propels the card into the laminator infeed rollers, which in turn drive the

card between the two white transfer rollers,

step 11.

Introduction

INDICATOR LIGHT SUMMARY

Upper

cassette

Cutter

11. Each transfer roller is “loaded” with a patch

of laminate, cut from the top and bottom cassettes shortly after the previous card passed

through the laminator.

12. As the card passes between the transfer rollers the laminate patches are rolled into place. They are then permanently bonded to the card by a pair of heated rollers applying pressure to the top and bottom surfaces.

980541-001 Rev. A P640i Card Printer User Guide 9

Page 20

Page 21

Loading cards

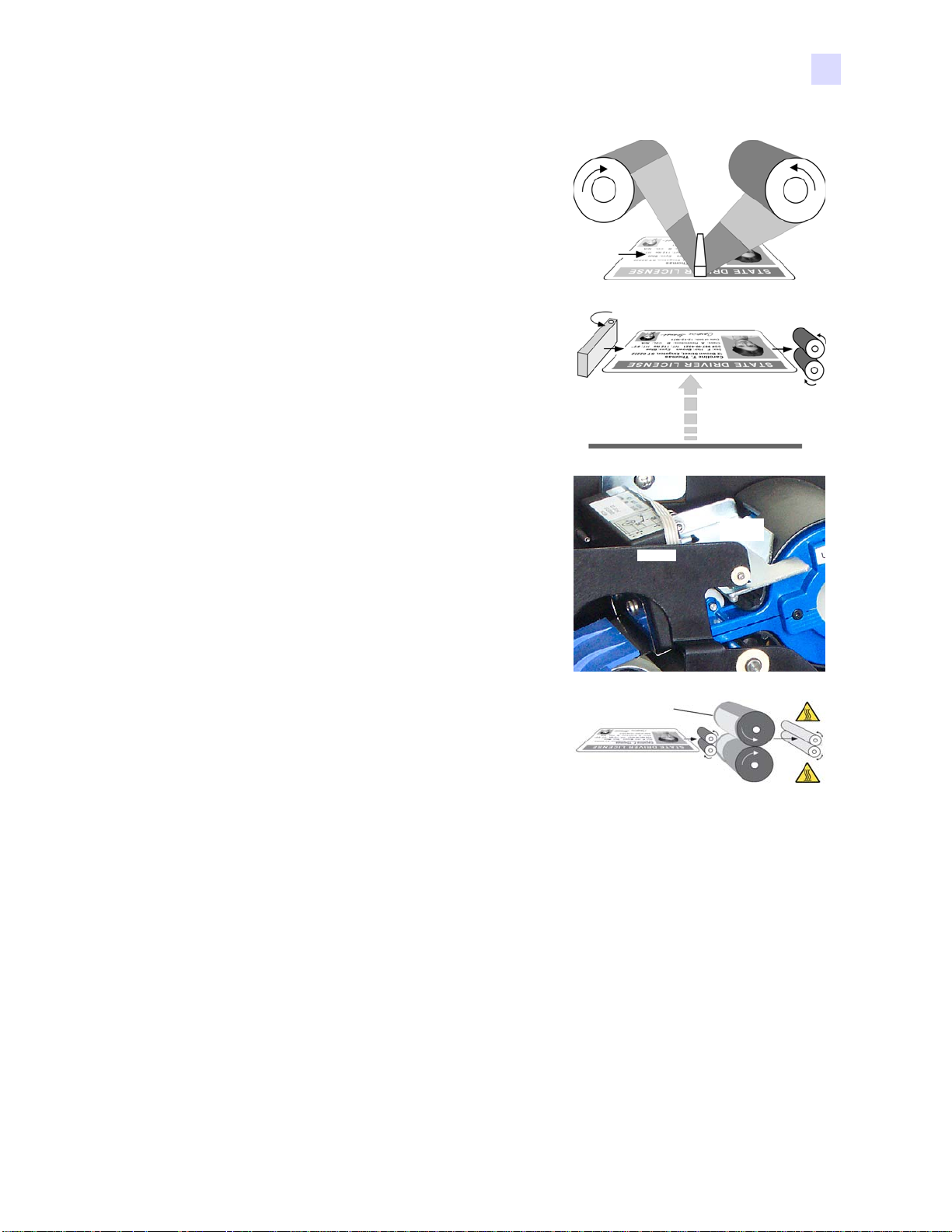

When loading cards, open ONLY the hopper

cover, left. (If you open the main cover, the

interlock switch disables the printer , resu lting

in a start-up delay after the cover is closed.)

2

Media Handling

1. Card orientation in the hopper: the back

side of the card faces up, and the mag

stripe of the card is to the front of the

printer.

Note • If there is no mag stripe, and if th ere is

pre-printed information on the card, your system

administrator will tell you which edge of the

card goes to the front.

2. Load the magazine a few cards at a time, holding the cards by the edges as shown. Don’t try to load an entire pack at one time, because that would mean handling the upper and lower surfaces - see STOP, above right.

Caution • Plastic cards attract dust and dirt.

Keep them clean! Handle them by the edges

and avoid touching the surfaces. Do not use

cards that are dirty or have been dropped on

the floor.

3. Place the weight on top of the card stack.

980541-001 Rev. A P640i Card Printer User Guide 11

Page 22

Media Handling

Loading the cleaning cassette

Hot Loading

You can load cards while the printer is powered up and

operating. If there are no cards left in the hopper, close the

hopper cover then wait until the printer hascompleted its

current print job and returned the truck to its home positon

under the hopper.

Loading the cleaning cassette

Before being printed, each surface of the card is cleaned by a soft tacky roller that is itself

cleaned periodically by adhesive tape in the cleaning cassette. Typically, the roller is cleaned

every 10 cards. The printer driver software allows the card count to be modified.

When the cleaning cassette is exhausted, a warning message appears on the monitor, and the

MEDIA light on the printer turns on.

Note • When the hopper cover is open, the truck

can not drive to its home position.

1. Open the main cover of the printer , then remove the spent cleaning cassette by pulling it toward you.

2. Remove the protective foil from the replacement cleaning cassette.

12 P640i Card Printer User Guide 980541-001 Rev. A

Page 23

3. Install a fresh cleaning cassette by locating the rectangular pin on the cleaning

mechanism in the receptacle on the cassette. Push the cassette gently home,

ensuring that the internal grooves on the

upper spool engage the teeth on the

takeup drive

.

Why 10 cards is the normal clean frequency

If the cleaning system is activated every 10 cards, the cleaning cassette contains suf ficient tape

for 3,000 cards. This matches the other components of the standard Zebra med ia pack (3,000

cards, 3,000 color ribbon images).

Media Handling

Loading the color ribbon

Takeup

drive

Note • In dusty environments, clean the roller more frequently. The driver

allows you to select any frequency from 1 card to 20 cards.

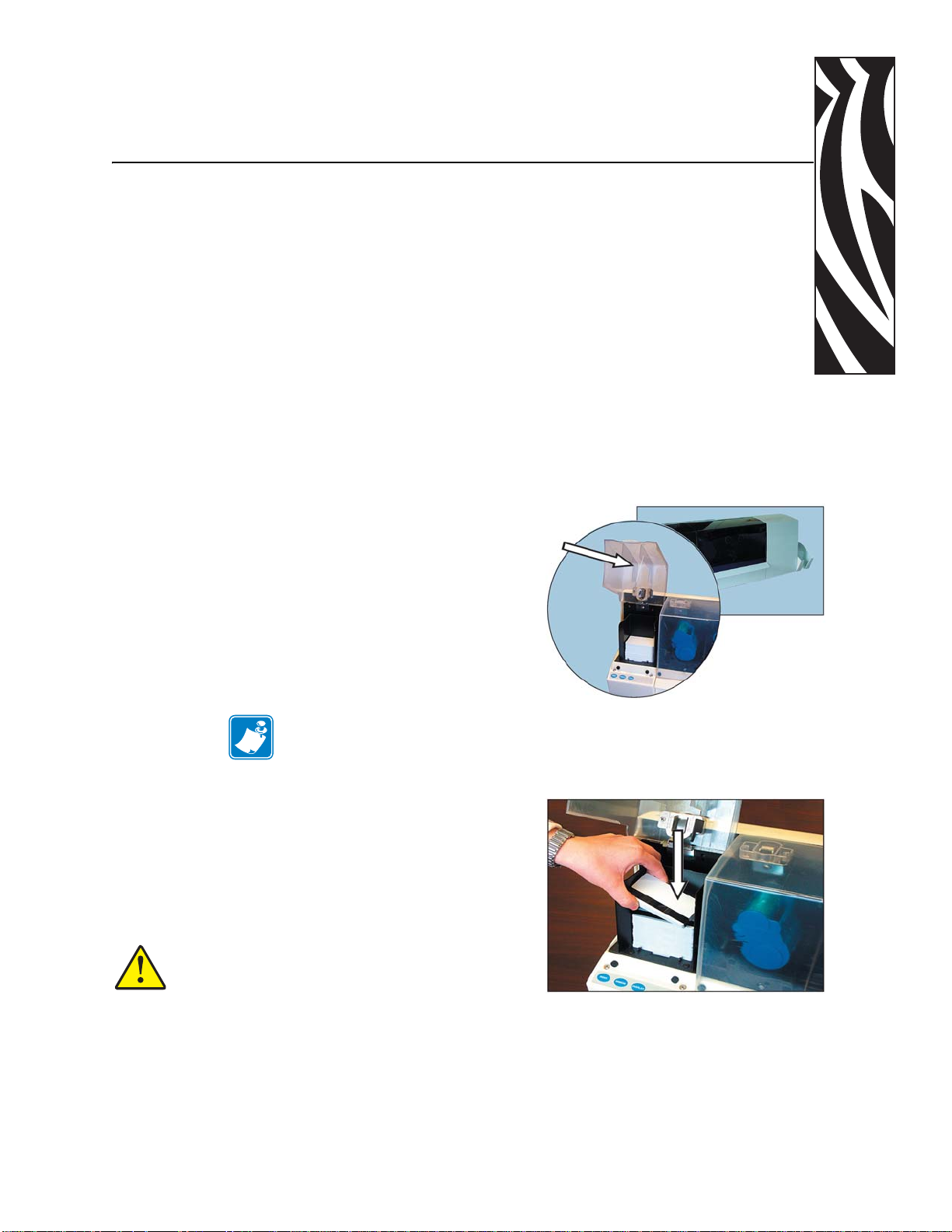

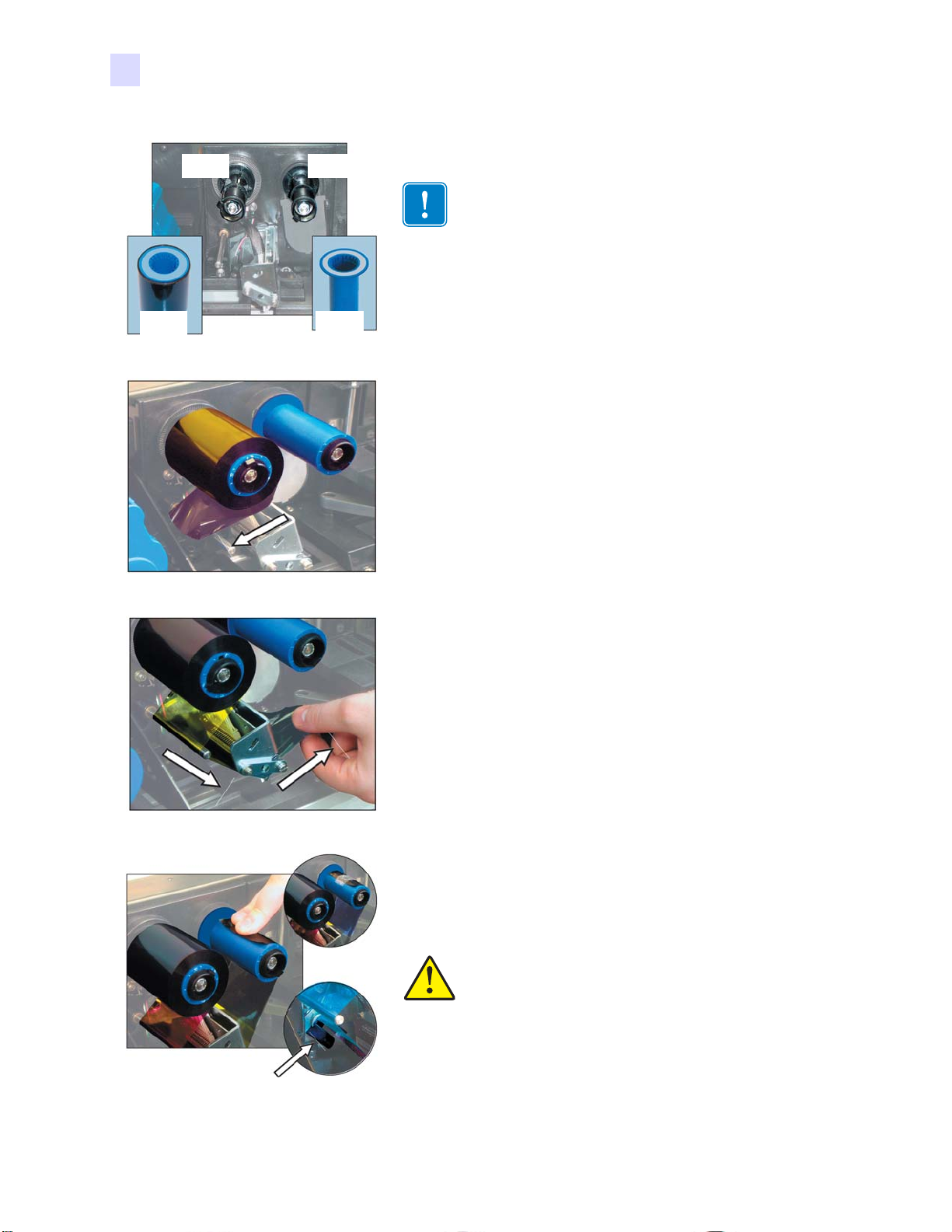

Loading the color ribbon

When the color ribbon is exhausted, a warning message appears on the monitor, and the

MEDIA light on the printer turns on.

Important • Opening of the main cover elevates the printhead

for easy ribbon loading..

980541-001 Rev. A P640i Card Printer User Guide 13

Page 24

Media Handling

Loading the color ribbon

Supply

arbor

Takeup

arbor

P640i color ribbon, left, and empty core, right. The flange end with

internal grooves goes to the back.

Important • Are both the new ribbon and takeup cores

fully home on the arbors, as far back as they will go? You

should hear a click.

Color

ribbon

Empty

core

1. Install an empty ribbon core on the right (takeup) arbor. Push the core back as far as it will go, making sure the internal grooves on the core engage the teeth on the takeup arbor.

2. Pull out more ribbon, then bring the free end of the ribbon u p to the right of the takeup core.

3. With the ribbon centered on t he takeup core, att ach its free end to core with Scotch tape or the adhesive label that came with the fresh roll. Take up slack by reversing the supply roll (don’ t try to rotate the takeup arbor).

Caution • Make sure the ribbon is between the

arms of the ribbon sensor left of the printhead.

14 P640i Card Printer User Guide 980541-001 Rev. A

Page 25

4. Close the printer cover, then press the RIBBON button to initialize the color ribbon. If the MEDIA light fails to go out, check the ribbon sensor.

Caution • Color ribbon wrinkling and “fold-over”

can seriously affect print quality. Unless you are

sure the ribbon is installed properly, proceed to

Step 6

5. Re-open the printer cover to inspect the ribbon path for wrinkles and folds. Correct if necessary, then close the cover.

Laminating Station

Important • When loading or unloading

laminate cassettes, stay away fr om nearby

heated rollers.

When either of the laminate cassettes is empty , a warning message appear s on the monitor, and

the MEDIA light on the printer turns on.

Media Handling

Laminating Station

Overlay laminates come in three widths:

• F or the front (UPPER) of the card,

full width, plain or with special

graphics. Full width

• For the back (LOWER) of the card,

partial width if there is a writable

signature panel or mag stripe,

otherwise full width. Usually, there

are no graphics on lower laminate:

Partial width

(42 mm)

Partial width

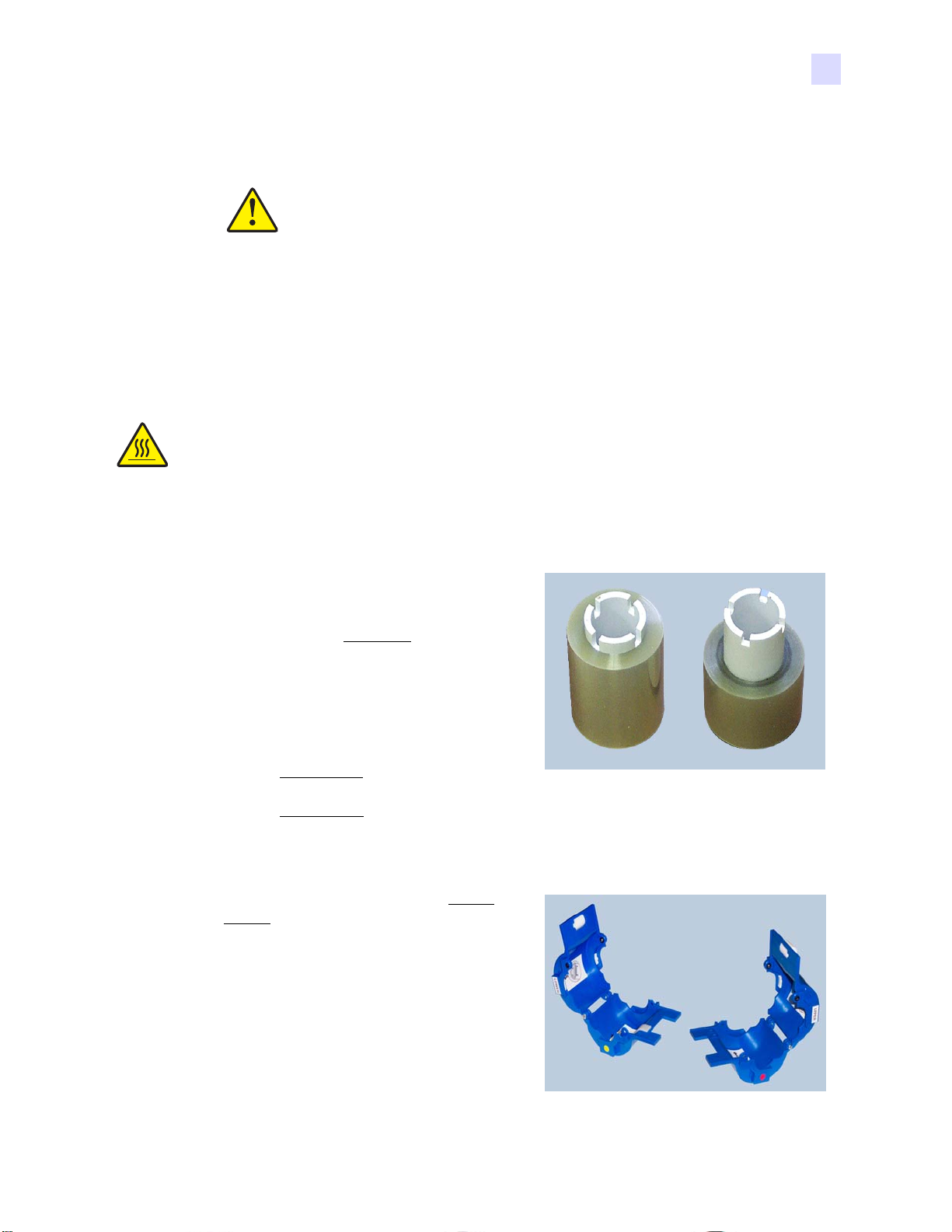

Laminate Cassettes

The upper and lower cassettes are mirror

images, almost identical twins. This can be

confusing if you don’t follow the procedure

outlined in this guide. The cassettes are

differentiated by color-coded dots:Red =

UPPER Yellow = LOWER

= 2” (51 mm)

, signature panel = 1.66”

, mag stripe = 1.3” (33 mm)

980541-001 Rev. A P640i Card Printer User Guide 15

Page 26

Media Handling

Laminating Station

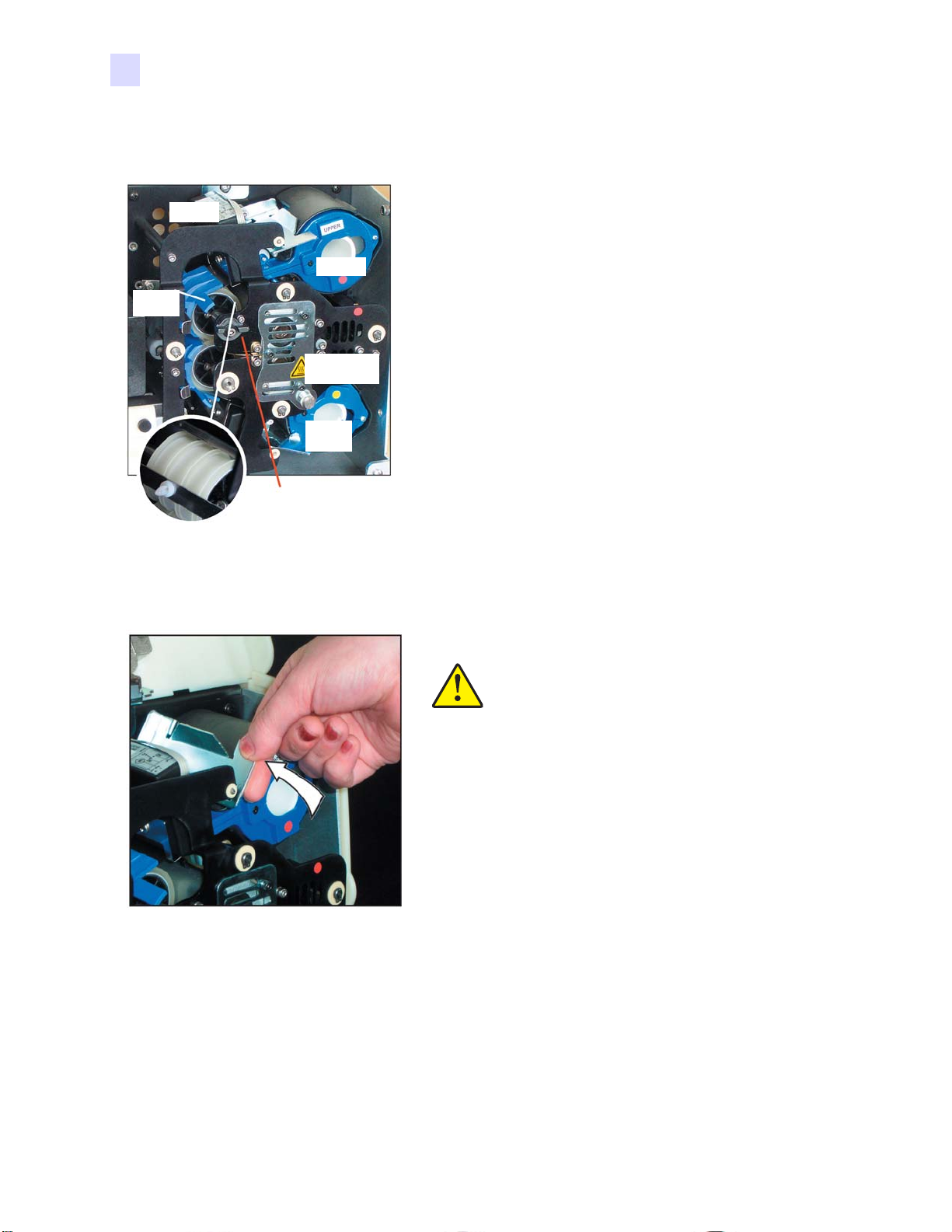

Main components of the laminating system

The laminating system comprises two separate independent

units, one for the front of the card, one for the back.

Laminate

cutter

Upper

Transfer

guide

Heater

compartment

Lower

cassette

Transfer toggle Must be set to

RUN (horizontal) for normal oper-

Transfer

roller

ation. Rotate the toggle to open

the rollers for jam clearance.

Removing the cassettes

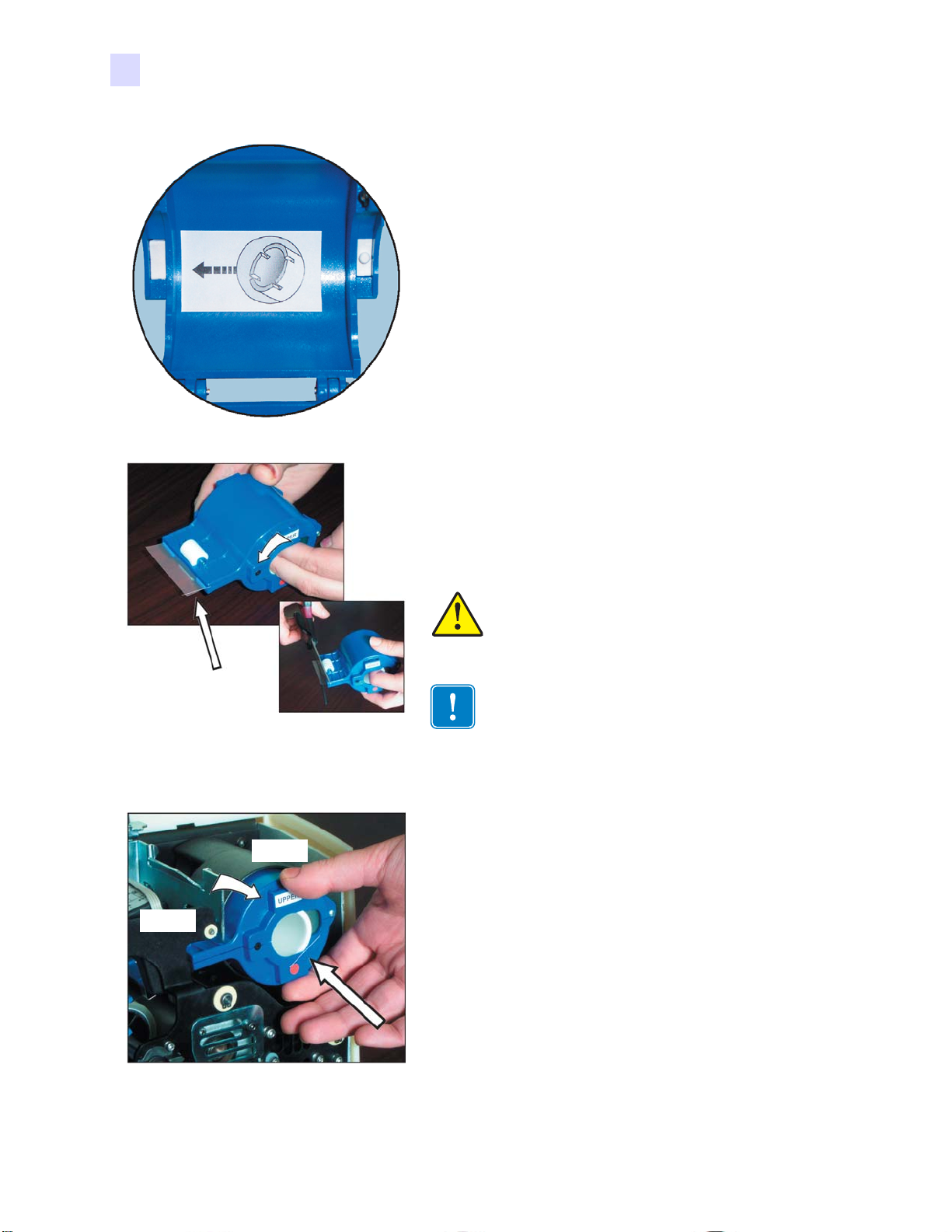

1.Open the latch plate by flipping it to the full vertical position, until you feel some resistance. Turn the UPPER latch

counterclockwise, the LOWER clockwise.

Caution • If either of the latch plates is

opened, even unintentionally, the cassette

affected must be removed and the laminate

reeled in, see page 2-6.

16 P640i Card Printer User Guide 980541-001 Rev. A

Page 27

2. Grasp the cassette and pull it straight toward you, clear of the printer.

Caution • If you feel resistance when

removing the cassette, the laminate has likely

run out, leaving one end attached to the core

and the other end under the cutter. Keep

tugging on cassette, which will come free with

a short tail of laminate.

Caution • Remove the transfer guide to be

sure there are no scraps of laminate

remaining.

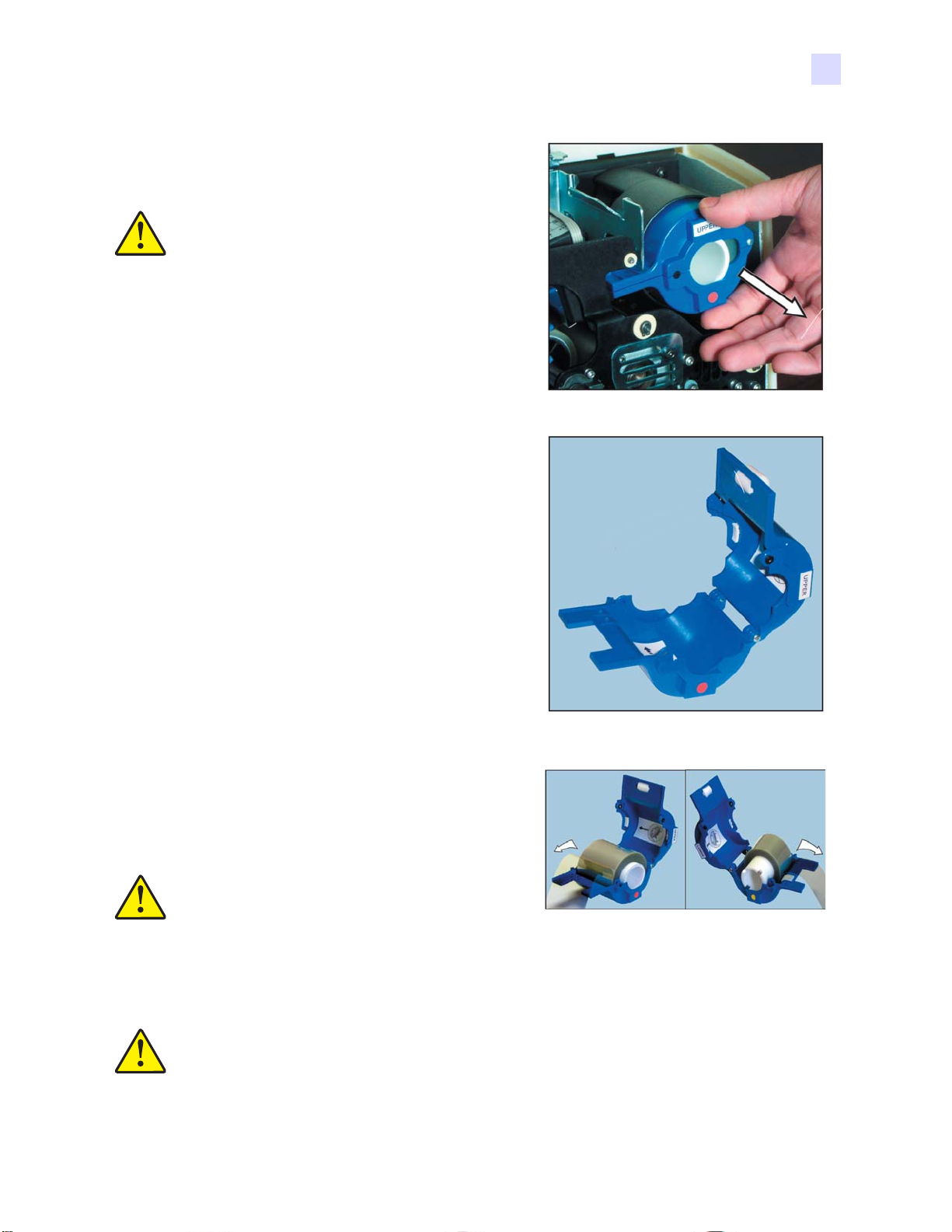

3. Open the cassette, like a clam shell, by separating its two halves. Grasp the two halves firmly with the fingers, then pull. Do NOT use tools to pry it apart.

Media Handling

Laminating Station

Loading the cassettes

1. Discard the spent core. Hold the open cassette with its cavities toward you, white idler wheel to the top.

Caution • You need partial width laminate for

the LOWER cassette if there is a mag stripe

or signature stripe on the card

2. Place a roll of laminate in the cassette so that it feeds from the bottom of the roll, UP and OUT to the front. Pull out an inch or two of laminate.

Caution • If the lower cassette is intended for

partial width laminate, it will have an edge

guide to keep the laminate on track. Make

sure it is in the correct position for the partial

width laminate you are using.

980541-001 Rev. A P640i Card Printer User Guide 17

Page 28

Media Handling

Laminating Station

3. Close the cassette, then pull out a little more laminate. If it

suddenly stops, resisting further pulling, a spring detent on

the cassette, photo below, has snagged a notch on the end

of the core. This means that the core was installed the

wrong way round. If you follow the installation diagram

on the inside of the cassette this won’t happen!

4. With the white roller up and pointing to your left, rotate

the core counter clockwise to reel in the laminate. Stop

when the end of the laminate is even with the lips of the

cassette - no overhang, but make sure it is not clear of the

white roller (otherwise it won’t feed).

Installing the cassettes

Cassette

pocket

Cassette

latch

Caution • If the end of the laminate is crinkled

or uneven, cut it as square as you can with

scissors, then reel it in.

Important • Check for overhang any time th e

cassette latch is opened, or the cassette isremoved.

1. Make sure the laminate is even with the lips of the cassette.

2. Insert the cassette into its black molded pocket, then close

the cassette latch (clockwise for the UPER, counterclockwise for the LOWER).

3. Close the main cover. If there was a laminate error before

you replaced the cassette, laminate will automatically fee d

from the just-loaded cassette, followed by a cutting action

to free a “patch” of laminate onto the transfer roller. If

laminate does not feed automatically, press the LAMINATE button.

18 P640i Card Printer User Guide 980541-001 Rev. A

Page 29

Clearing the Laminate Channels

If your scissor cuts were neat enough to pass for machine-made cuts, continue printing cards in

the usual way. If not, don’t waste a print cycle. Instead, remove the hand-cut patch(es) from

the transfer roller(s) as follows.

Media Handling

Laminating Station

Important • Clearing procedures for the

upper and lower channels are similar. The

upper channel is shown here.

Removal of the Transfer Guide gives access

to the transfer roller.

1. Pull back the retaining spring, at the same time pulling the Transfer Guide straight out toward you.

2. Remove and discard the laminate patch on the transfer roller. Never re-use!

3. Re-install the Transfer Gu ide with its top

edge above the laminate cutter guide.

Laminate cutter guide

It’s easier if you pull back the retaining

spring while re-inserting the guide, then

release the spring as you push the guide

into position (it will click into place, with

its far leg against the back plate of the

laminator). Press the LAMINATE button

to load the transfer roller(s).

980541-001 Rev. A P640i Card Printer User Guide 19

Page 30

Media Handling

Laminating Station

The special laminate for the top cassette is punched with a repeated pattern.

Caution • Improper replacement of the transfer

guide will cause laminate skewing and

misfeeding. Be sure the transfer toggleis set to

RUN. Take care not to damage the transfer

roller ribs when replacing the transfer guide.

Laminating smart cards

The laminating patch on the top surface of a smart card has a

rectangular aperture to expose the card’ s electrical contacts. In

all other respects the laminating process for smart cards is the

same as for ordinary cards.

Cut line in

center of in-

dex hole

Index hole

The smaller hole is an index marker that tells the printer where

to cut the laminate, exactly splitting the inde x hole (t he printer

driver allows adjustment of the cut location).

cutcut

cut

Loading procedure for smart card laminate is exactly the same

as for standard laminate.

20 P640i Card Printer User Guide 980541-001 Rev. A

Page 31

Image Adjustment

Start > Printers (or Printers and Faxes) > Right click Zebra P640i > Printing Preferences >

Image Adjustment

3

Troubleshooting

Brightness

printed image as do similar controls on typical office color printers. Click Reset

default conditions.

Contrast 50

Brightness 25

and Contrast controls on the image Adjustment screen have same effect on the

Contrast 0

Brightness 50

Contrast 25

Brightness 50

Contrast 50

Brightness 75

to restore

Contrast 75

Brightness 50

980541-001 Rev. A P640i Card Printer User Guide 21

Contrast 75

Brightness 50

Contrast 100

Brightness 50

Page 32

Troubleshooting

Troubleshooting quality pr oblems

Troubleshooting quality problems

Poor color registration

• Minor mis-registration of Y, M and C color passes may be due to printhead angle adjust

screw not in firm contact with printhead frame. Reference Technical Note 4

• For gross mis-registration of Y, M and C suspect card not firmly against left hand pick

edge of truck on one or more passes. Spring at left end of platen may be missing or bound

up. Reference Technical Note 2

• C heck printed card for damage on corners or edges. Example: the card may be scraping

along the underside of the hopper base molding. Reference Technical Note 2

• Printhead pressure too light. Reference Technical Note 4

• Printhead may be running hot. Will occur if head resistance incorrectly ente re d in driv er

software. Reference Technical Note 4

• Toothed transport belt pulley may be slipping on drive shaft. Tighten set screws (make

sure the screws bear on flats on the shafts).

Examples of color mis-registration

Left is the test card in the printer’s firmware. Right is an enlargement showing fringing on

process black text generated from Y, M and C.

Adjust in Properties > Device Settings > Color Calibration. Reference Technical Note 4

Faint, non-uniform image

• Printhead pressure too low. Adjust downward. Reference Technical Note 4

• Printhead not pivoting freely. Reference Technical Note 4

Poor color rendering

• Possible source issues - poor quality photos or

graphics, card layout application settings. Isolate

the problem by printing a known image, such as

Portraits.bmp, through IDPrint Lite. Reference

Technical Note 8

• Vary brightness and contrast controls in

Preferences > Image Adjustment (preceding

page). Fine tune if necessary using Contrast

Gaps in image at edges and corners

• Possible de-lamination/wear of platen’s rubber surface.

Try cleaning platen. If unsuccessful, replace platen.

Reference Technical Note 2

• Possible non-uniformity of card thickness, or card surface

defects.

22 P640i Card Printer User Guide 980541-001 Rev. A

Page 33

Troubleshooting

Troubleshooting quality problems

Continuous white or black stripes on card’s longer dimension

• White stripe means blown pixel (nonfunctioning heating element). One or two

blown pixels in isolation may be

acceptable to some. Otherwise replace

printhead. Reference Technical Note 4

• Black stripe means non-functioning

circuit(s) on printhead. If so, replace

printhead, Reference Technical Note 4,

but first check that it is not the result of

an image size change not followed by

power cycling the printer.

• T hese are indep en dent problems, not

necessarily co-located.

Random occurences of white (unprinted) spots

• Possible card quality problem. Run

IDPrint Lite with graytone.bmp on cards

from a different batch. Check platen

surface for specks of debris.

• White spots like these may be caused by

card surface imperfections.

Image not centered on card

• Properties > Device Settings > Printer

Adjustment > Horizontal/Vertical Offset.

• Correct this by increasing horizontal (X)

offset, decreasing vertical (Y) offset.

Image missing at top or bottom of card

• Ribbon folded over at edge. Slacken ribbon by pulling more out of supp ly roll, unfold

edge then press RIBBON button to re-sync. Reference Technical Note 4

• Bottom edge and/or right hand edge of image missing could be card layout application

sending wrong image size (should be 952 x 578 pixels). Select appropriate image size (if

available) in Preferences, or modify layout application.

• Could be on either edge. Almost certainly due to ribbon fold-over, but could be a head

non-pivoting problem, or an image size problem.

980541-001 Rev. A P640i Card Printer User Guide 23

Page 34

Troubleshooting

Troubleshooting quality pr oblems

Consistent image defects, card after card

• Debris on platen, or platen surface not

flat. Clean platen, or replace if

necessary. Reference Technical Note 2

• This gross image artifact was caused

by a tiny scrap of card less than 0.01”

(0.25 mm) thick.

Random colored patterns on image

• Ribbon wrinkling. Reduce takeup torque.

Check printhead pressure. Reference

Technical Note 4

• Too much heat being applied to YMC

panels. Try reducing gain,offset and

preheat separately for each color in the

driver Device Settings > Color

Calibration, Reference Technical Note 4

and Technical Note 5. Typically , the set

of values should be the same for each

color.

• Printhead running too hot. Can happen

after head replacement if head resistance

incorrectly entered through printer

driver. Reference Technical Note 4, Printer Adjustment

• Probably resulting from excessive takeup torque.

Scratches/dings on long edges of card

Look for a narrow band of abrasion up to about 0.1” (2.5 mm) in from either or both of the

long edges.

• Card hopper base set too low. Reference Technical Note 2

Laminate not centered on card

• Vertical offset adjust (mechanical

adjustment). Reference Technical Note 6

• Horizontal

Settings > Printer Adjustment >

Laminate Station Adjust. Reference

Technical Note 6

24 P640i Card Printer User Guide 980541-001 Rev. A

offset: Properties > Device

Page 35

Laminate not parallel with card edges

•Skew adjust (mechanical adjustment). Reference Technical Note 6

• If using partial width laminate, edge guide not properly installed (one of two positons).

Section 2

• Transfer guide not p roperly installed. Section 2

• Laminate patch wrapped around heated roller. Page 3-3

Laminate wrinkling

• Can occur at end of roll. Remove

cassette. If nearly out, discard. Install

fresh roll.

• If not end-of-roll problem, suspect

obstructions in laminate feed path.

Unusual Printer/Lmainator Events

Color ribbon runs for longer than 2 or 3 seconds when cover is closed (MEDIA light stays on)

Troubleshooting

Unusual Printer/Lmainator Events

• Color ribbon not in ribbon sensor. Section 2

• Both ribbon cores not fully engaged on arbors. Section 2

• Ribbon not secured to takeup core. Section 2

• No ribbon type or wrong ribbon type specified in Printer Properties. Reference Technical

Note 8

ALARM light stays ON after error condition is cleared

Note • There is a delay after closing the cover before the ALAR M

light goes out.

• Mai n cover interlock switch may not have actuated when cover closed. Reference

Technical Note 1

• Alarm condition(s) not corrected.

Card has both front and back images printed on same side

• Check selections made in Printing Preferences > Card Setup. Reference Technical Note 8

• Card failed to flip. Run Flip Test 3 to check flip action. Reference Technical Note 5

MEDIA light ON steady, but no obvious visual problem

• Color ribbon not in ribbon sensor. Section 2

• Color ribbon supply and/or takeup cores not engaging properly on arbo rs. Section 2

• Cleaning cassette not engaging properly on the takeup drive. Section 2

• See Laminator sp ot check, page 3-3

980541-001 Rev. A P640i Card Printer User Guide 25

Page 36

Troubleshooting

Unusual Printer/Lmainator Events

Completely unexpected print results

• Color ribbon out, or nearly out. Replace ribbon. Section 2

• Main cover opened during a print job. Open and close main cover, then press RIBBON to

re-sync ribbon. Reprint last job.

• Color ribbon panels out of sync, see previous action.

• Color ribbon not advancing consistently. Color ribbon supply and/or takeup cores not

engaging properly on arbors. Section 2

• Front (color side) of card printed with black. Open and close main cover, then press

RIBBON to re-sync ribbon.

• Inconsistent color, very faint printing. Printhead not pressing on ribbon. Reference

Technical Note 4

• Color ribbon torn, or jamming intermitte ntly. Clear jam. Pull out more from supply roll

and reattach to takeup roll. Section 2

YMC color panels stick to card

• Printhead running too hot. Can happen after head replacement if head resistance

incorrectly entered through printer driver. Reference Technical Note 4, Printer Adjustment

• Check ribbon takeup and supply torques. Reference Technical Note 4

K (Black) panel sticks to card

• Printhead running too hot. Can happen after head replacement if head resistance

incorrectly entered through printer driver. Reference Technical Note 4, Printer Adjustment

• B lack panel density and/or preheat set too high. Reference Technical Note 4, Color

Calibration

• Check ribbon takeup and supply torques. Reference Technical Note 4

Loud rattling/screeching from card transport

• Card(s) has fallen onto truck drive belt, and is jammed at some point. Open cover, remove

all cards from hopper. Remove jammed card if accessible. Look for card(s) in the

transport bed. Using card transport knob, hand-crank truck to push card into one of two

areas for easy removal - under hopper, or under flip station (lift carrier for access, then

push it down again).

Brief rattling noise before every print job

• Make flip station rest position adjust parameter less positive. (But be sure the carrier still

descends to its physical end-stop, otherwise it may fail to pick card off platen.) Reference

Technical Note 5, Flip Station Adjustment

Rattling noise every 10 cards

• Cleaning cassette not firmly engaged. Reference Technical Note 2

26 P640i Card Printer User Guide 980541-001 Rev. A

Page 37

Unusual events

In all of the following cases, and all other unusual events, try power cycling first, then

investigate specific issues:

• Printhead descends before card arrives. Check horizontal offset. Reference Technical Note

4

• Printhead stays down after card has gone away. Check card presence sensor. Reference

Technical Note 2

• Laminate cutter(s) fails to operate. see below, and reference Technical Note 6

• Unusual media light indications.

Laminator spot check

• Make sure the transfer roller toggle is in the operating position, pointing right.

• Up per or lower laminate feed problems: remove, then replace transfer guides, discarding

laminate patches on transfer rollers. Check for laminate where it shouldn’t be. Remove

both laminate cassettes. If out, or nearly out, load fresh laminate. W ind la minate back in to

eliminate overhang. Reinstall cassettes, latching securely. Visually check path from

cassette(s) through feed roller, cutter and transfer guide.

• Check for misfeeding of laminate due to poor engagement of white plastic idler on

cassette with drive roller. Mark the upper core to check that i t rotates (no nee d to mark the

lower core - watch the notches on the laminate core). Feed laminate by pressing the

LAMINATE button.

• Laminate patch may be wrapped around the heated roller, causing card feed problems

and/or poor lamination. Turn printer OFF, allow 10 minutes for cooling, then remove

heated rollers - careful, they will still be HOT. Remove the rogue patch. Do NOT use a

metal knife or any tool that might damage the heated rollers.

• Check upper and lower laminate sensor readings, Reference Technical Note 6, with and

without laminate present (< 20 if present, > 180 if absent - numbers valid only if transfer

guides installed).

Troubleshooting

Error messages

Additional help

For more information on specific printer functions (print station, flip station, laminator, etc.)

refer to the appropriate Tech Note in the separate Tech Note Supplement to this Operator’s

Guide.

Error messages

Most P640i error conditions are identified by the printer itself, and are reported by the

computer as error messages with corrective actions. Error messages are not further described

in this section of the manual, which deals only with fault conditions that are not reported

automatically. On this page are five examples of error messages:

Important • Most problems can be prevented by careful handling of

the media (cards, color ribbon and laminate), see Section 2, Media

Handling.

There is almost no preventative maintenance to do. Dust and debris should be vacuumed out

every 12 months, or more frequently in adverse environments.

980541-001 Rev. A P640i Card Printer User Guide 27

Page 38

Troubleshooting

Error messages

Most of the problems described in the following pages are correctable by the user, but please

note there is the potential for unexpected results if the procedures are not followed carefully. If

in doubt, call for service assistance.

Before calling for technician help, do the following:

• Check all cable connections, including power.

• Check that the power switch is ON.

• Unless you hear noises suggesting a card jam condition, try power

cycling: switch OFF, wait 15 seconds, then switch ON.

• Open the main cover, then look for obvious problems, such as a

card where it shouldn’t be, media outages or misfeeds (color ribbon, laminate, cleaning cassette).

• Check this section, referring if necessary to the relevant T ech Note.

28 P640i Card Printer User Guide 980541-001 Rev. A

Page 39

READY MEDIA ALARM

GREEN YELLOW ORANGE RED

Troubleshooting

Error messages

What the Indicator Lights Tell You

Printer Status

Ready to print

Printer busy

Laminator heating up, but not yet at operating temperature

Laminator heaters in sleep mode (when not in use, the heaters cool at 1oF per minute)

Printhead temperature error.

No cards in magazine, color ribbon out, cleaning tape out, laminator cassette(s) out.

Mag encoding write failure

Serious error conditions, including: MAIN COVER OPEN, Laminator too hot, card

transport stalled, card not seated properly, mag encoding verification error, head lift

failure, ribbon jam, card jam (any location), card missing (any location), no gap between laminator patches.

= light on = light flashing

980541-001 Rev. A P640i Card Printer User Guide 29

Page 40

Page 41

4

Technical Notes

Restore printer configuration

You can return the printer to its previous backup configuration be pressing the

PRINT, RIBBON and LAMINATE buttons on the front panel at the same time as

the printer is powered up. But first, remove the color ribbon! This is termed a

“three button reset,” page TN1-4

Flip station

Any time you open the main cover, for whatever reason, be sure that the flip

station is fully down before the cover is closed. Do this by gently pushing down

at the back of the flip carrier.

Correction to this User Guide

Most fasteners used in the P640i have U.S. standard threads. Printers manufactured after

October 2004 use Torx® socket head screws in locations other than set screws on pulleys and

gears. In addition to a standard set of small hex drivers, you will need the following Torx drivers:

T10, T15, T20 and T25.

Other useful facts

ID/Key is an optional hardware key encoded with a serial number that is compared prior to every

print job with a number in the printer’s NVRAM. If there is a mismatch, the printer is disabled.

ID/Code is a field-alterable password stored by both the printer dirver and the printer itself. It pre-

vents use of the printer with a PC not having the same

to function, and everything else looks fine. Reference Technical Note 8.

Password protection blocks access to some of the lower level printer adjustment screens. Not to be

confused with ID/Code. Reference Technical Note 8.

Interlock “cheating” is not something the operator should do, but as a technician you will need to run

the P640i with the main cover open. Cut a narrow strip of plastic from a used CR-80 card, fold it,

then push it into the interlock slot in the center wall. When the ALARM light goes out, the interlock

switch is closed.

ID/Code. Check the ID/ Code if the printer fails

980541-001 Rev. A P640i Card Printer User Guide 31

Page 42

Technical Note 1 - General Information

Model P640i with card receiver The cover at left gives access only to the card hopper, which

may be “hot loaded” while the printer is powered up and operating (unlike the main cover,

right, opening the card hopper cover does not disable the printer).

Dimensions in inches and (italicized) millimeters

P640i Specifications

Card size: ISO CR-80 (2.125" x 3.385"), 30 mil thick

Card hopper: 150 cards

Throughput: 120 cards/hour (YMC on front, K on back)

Print system: Single printhead, with flip station for front and

back printing. Dye sublimination for YMC colors, and thermal

mass transfer for K and Uv panels (K = opaque black resin,

Uv = clear ultraviole t-visible resin).

Printhead resolution: 300 dpi

Image size (typical): 952 pixels (3.17") x 578 pix els (1.93")

Magnetic stripe encoder (option): Hi-Co type. 3-track,

ISO and AAMVA compatible. Custom formattable through

Windows printer driver.

Cleaning system: Both card faces cleaned by high-tack

roller. Roller is refr eshed a u tom atically by transfer tape at

selectable intervals (typically 10 cards).

Laminating system : Waste-free design with built-in

cutters. Continuous1 mil (0.025 mm) thick polyester film in

reloadable cassettes.

Controls

Print, Ribbon advance, Laminate advance

Indicators : Ready to print, Media outage, Alarm

Data interface : USB, Parallel (option), Ethernet (option)

Windows drivers: Plug-and-Play 2000, XP

Security features ID/Key (option): a hardware lockout

and a printer-to-PC password lockout

Compliances: FCC Class A, UL/IEC/EN 60950-1, CSA

C22.2

Power requirement:

105-125Vac, 60Hz, 3A

190-260Vac, 50Hz, 1.5A

32 P640i Card Printer User Gu ide 980541-001 Rev. A

Page 43

Environment:

Operating: 50° to 95°F (10° to 35°C), 20 to 80% RH non-condensing

Storage: -4° to 158°F (-20° to 70°C), 5 to 90% RH non-condensing

Dimensions : see above drawing

Net weight 35 lb (15.9 kg) net. Shipping weight 43 lb (19.5 kg).

Sensors and interlock switches in the P640i

Y ou cane learn a lot abou t how the P640i functions by spending

a few minutes thinking about its various sensors and interlocks.

These are of several different types, but they have one thing in

common - they tell the printer’s control logic what’s happening

and where, enabling it to continue with the process or, if a

malfunction occurs, to light the appropriate indicator light and

report a specific error condition on the host computer screen.

Printer Parameters in the Drivers

See Tech Note 8 Windows Printer Driver for more information.

ID/Key

Theoptional ID/Key is a hardware “dongle” that is tied to a

specific P640i printer. It is intended to prevent unauthorized

use of the printer.

Like a camera

battery in

appearance, the

ID/Key

alterable memory

containing a

unique 64-bit

serial number that

is compared prior

to each print job

with a serial

number stored in

the printer’s

nonvolatile RAM.

If the serial

numbers fail to

match, or if no

ID/Key is removed during a card printing session, the

the

printer will cease to operate after the current batch of cards is

printed.)

ID/Key is carried in a 2” x ¾” plastic fob that plugs into a

The

receptacle to the right of the card hopper. Typically, at the end

of each work session the

and stored in a secure location such as the key safe.

ID/Key is detected, the printer is disabled. (If

ID/Key is removed from the printer

has a non-

Refer also to other Tech Notes specific to the functional

element in question - Card Transport, Mag Encoder, Print

Station, etc.

Start > Printers (or Printers and Faxes) > Right click Zebra

P640i > Properties > Device Settings > Control > Advanced

Utilites

ID/Code :

Sends an ID/Code (password of your choice) to the printer,

synchronizing the driver-to-printer ID/Code. This prevents use

of the printer with a PC not having the same ID/Code.

Update Backup Config :

Most of the parameters affecting operation of the printer, e.g.,

laminate station adjustments, are set up using the printer driver,

and are then saved in the printer’s flash memory as “current

configuration”. The original factory configuration also resides

in a separate “backup” memory, allowing you to recover the asshipped settings. Update Backup Config

replace the factory configuration with the current

configuration, but DO NOT DO THIS CASUALLY. On the

same lines as System Restore in Windows XP, you can revert to

the backup config as follows: 1. Power OFF; 2.

color ribbon

LAMINATE buttons at the same time as you switch on the

power; 4. Release the three buttons when you see activity in the

printer.

; 3. Press and hold the PRINT, RIBBON and

instructs the printer to

Remove the

Replacing a lost ID/Key:

The recovery procedure requires a special computer file

obtainable only from Zebra product support. This file is

downloaded to the printer , following which the replacement ID/

Key is inserted. The printer is then power cycled, off the n on, at

which point the key’s serial number is recorded in NVRAM.

980541-001 Rev. A P640i Card Printer User Guide 33

Page 44

Password Protection

Not the same as ID/Code. Password Protection blocks access to

various low level printer adjustment screens (including this

one). Check Use Password, then enter a password of your

choice.

Start > Printers (or Printers and Faxes) > Right click Zebra

P640i > Properties > Device Settings > Control > Advanced

Utilites >

Show Sensor data

Sensor Data

Printer Properties

Start

> Printers (or Printers and Faxes) > Right click Zebra

P640i > Properties > General

Table 1: General

Ribbon Panel Detect:

ribbon sensor.

The current reading of the color

Panel Threshold: The current value of the detection

threshold for the color ribbon. Above this value is termed

“black,” below this value is termed “not black.”

Laminate Sensors: Reflective sensor that detect the

presence of laminate on the transfer rollers: below threshold =

laminate present, above threshold = laminate absent.

Card presence Sensor: The reflective sensor to the right

of the card hopper: High = no card, Low = card present

Printhead Voltage: Should be about 24V.

AC Frequency: 50 or 60 Hz

Assumed AC Voltage: 110V assumed for 60 Hz. If

frequency and voltage are not correct, see Laminate Station

Adjust, TN6-5

Printhead Temperatue: Temperature ceiling 70°C (above

that temperature, printing is stopped until the head cools).

Printing Preferences brings up the preferences screen, see Tech

Note 8, Windows Printer Driver.

Print Test Page

Printer Properties

prints the standard Windows test page, cropped as shown here.

Table 1: Color

Management

Start > Printers (or Printers and Faxes) > Right click Zebra

P640i > Properties > Color Management

Controller Board Temperature: Should be about 5°

above ambient.

Heater Temperature: Temperatures at the top and bottom

laminate heater cores.

Not currently supported

Logic States: Summarizes all two-state interlocks and

photosensors - a very useful diagnostic tool.

34 P640i Card Printer User Guide 980541-001 Rev. A

Page 45

Printer Properties

Start > Printers (or Printers and Faxes) > Right click Zebra

P640i > Properties > Sharing

Table 1: Sharing

Printer Properties

Start > Printers (or Printers and Faxes) > Right click Zebra

P640i > Properties > Ports

Table 1: Ports

This is sharing according to the Microsoft Windows definition.

In a network environment, it allows other computers to send

jobs to the printer that’s connected to your computer.

Printer Properties

Start > Printers (or Printers and Faxes) > Right click Zebra

P640i > Properties >

Security

Table 1: Security

Specifies the computer port to which the P640i is connected.

This will have been established at the initial installation of the

printer, and will not normally require attention.

An exception to this is if you wish to use “printer pooling”, the

ability to distribute print jobs to multiple printers. To enable

printer pooling, check the “Enable Printer Pooling” box, then

check multiple ports. Each port should have a single Zebra

printer installed on it, and all printers should be configured

identically (for example: all with YMC front, K back). Now,

when you print to the “main printer” (that is, whichever printer

you right-clicked in Printers and Faxes to get to this screen),

this printer will get print jobs until it has buffered as many jobs

as it can take. Remaining jobs will then “spill over” to other

printers until all printers in the pool are busy.

For more information, see Tech Note TN10.

This is the standard Windows security screen, showing user

access to various printer control options. Both Print and

Manage printers

P640i.

980541-001 Rev. A P640i Card Printer User Guide 35

must be checked for full functionality of the

Page 46

Printer Properties

Start > Printers (or Printers and Faxes) > Right click Zebra

P640i > Properties > Advanced

Determines the spooling (queuing) of print jobs, and how

spooled jobs are handled relative to the most recent job.

Printing Defaults allows the system administrator to establish

default settings such as print quality.

Table 1: Advanced

Print Processor

and Separator Page should be left alone.

36 P640i Card Printer User Guide 980541-001 Rev. A

Page 47

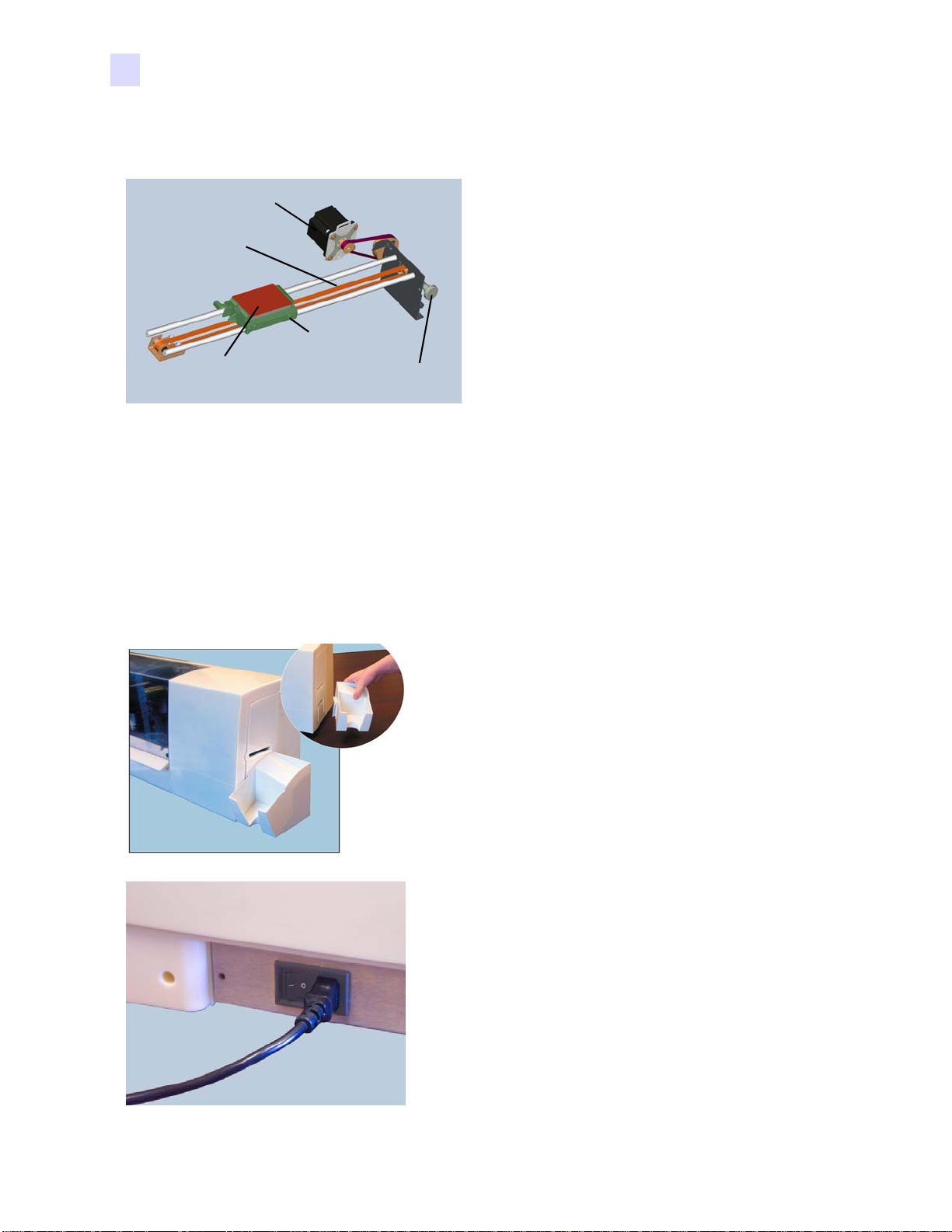

Technical Note 2 - Card Transport

Stepper

Platen

Transport belt

Tru ck

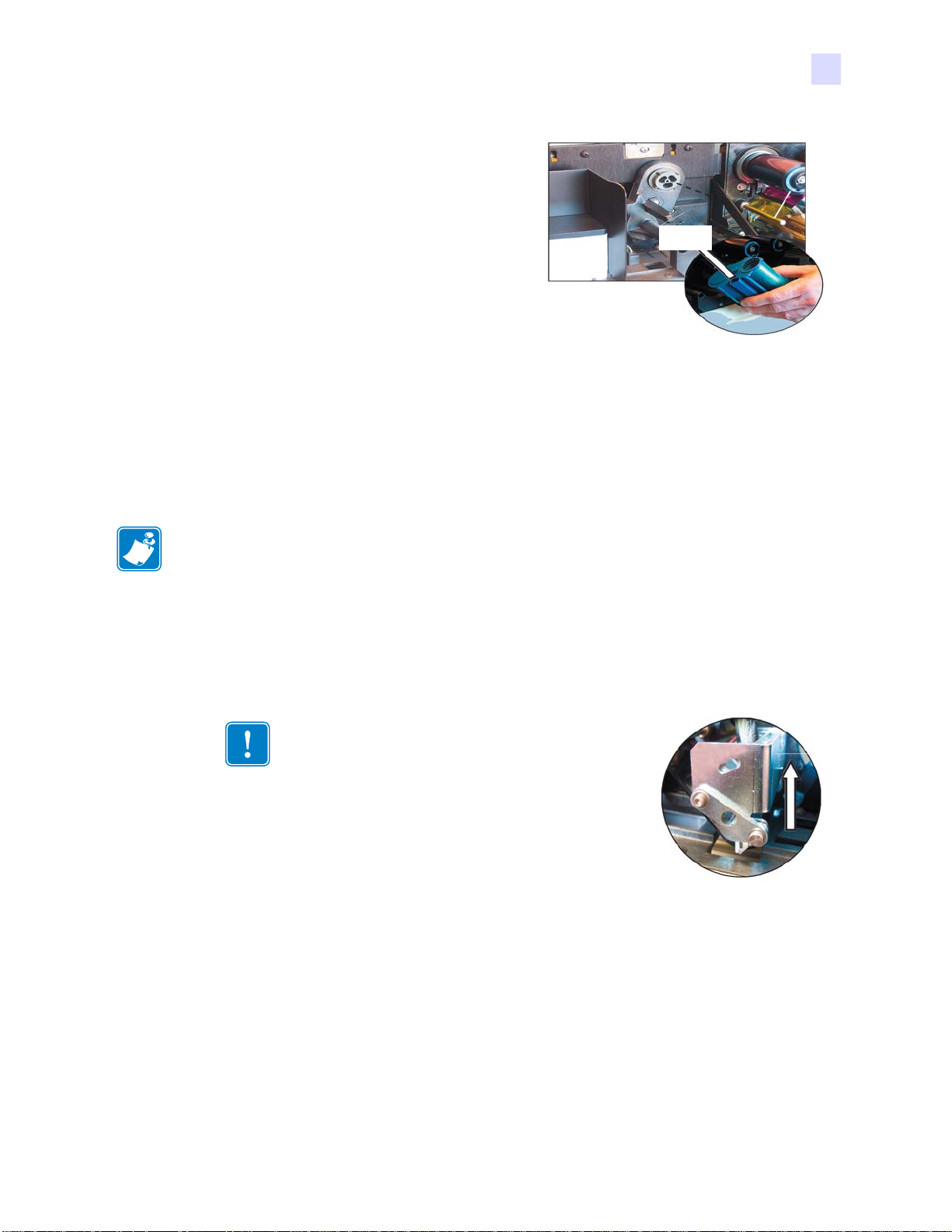

No-slip card transport

The P640 does not rely on friction rollers to drive the

card through the print station. Instead, the entire pick

The platen plays an important part in the printing

process, providing a rigid supporting surface for the

card as it passes under the print head. Because

is important, the platen is surface ground to close

tolerances. Any irregularities in the surface due to

abrasion, dings, or even seemingly unimportant

particles of debris can noticeably degrade printing

performance, see page TN2-3. Regular cleaning of the

platen helps maintain performance.

flatness

and print process is precisely controlled by a belt

driven truck riding on parallel rails.

Card transport knob

Allows you to move the truck to left or right by hand.

When the printer cover is lifted, there is no power

applied to the transport stepper motor.

Take care of the platen

980541-001 Rev. A P640i Card Printer User Guide 37

Removing the platen

Using the card transport knob move the truck back to

its home position, stopping when the right hand edge

of the platen is even with the right hand inner sufrace

of the hopper.

Push the platen to the left against its spring, then pry

the platen out using a CR-80 card.

Page 48

Truck home sensor

Determines the truck’ s end st op position. Activa ted by

a vertical flag on the left edge of the truck, photo

above.

Home sensor flag

Home sensor

Do not lose the spring! It holds the platen tight against

the right hand end of the truck, and is essential for

good print registration.

Truck interlock (arrowed)

If there are no cards present in the hopper, and a hot

load is attempted while the truck is elsewhere, the

cavity under the hopper is exposed and potentially

Card presence sensor

Located behind the mag encoder.

Ta ke -u p

Cassette

motion

Supply