Page 1

980459-001 Rev C

Zebra

®

P330i & P330m

Card Printer User’s Manual

Page 2

Page 3

Foreword

This manual contains installation and operation information for the Zebra P330i and

P330m Card Printers manufactured by Zebra Technologies Corporation, Camarillo,

California.

The only difference between these models is that the P330i supports full-color ribbons

(which may include a protective overcoat panel), and the P330m supports monochrome

color printing only.

In this manual, references that are specific to the P330i or P330m will be identified as

such; references that apply to both models will use the term “the printer.”

Return Materials Authorization

Before returning any equipment to Zebra Technologies Corporation for in-warranty or outof-warranty repair, contact Repair Administration for a Return Materials Authorization

(RMA) number. Repack the equipment in the original packing materia l and mark the RMA

number clearly on the outside. Ship the equipment, freight prepaid, to the address listed

below:

• For USA, Latin America, and Asia / Pacific:

Zebra Technologies Corporation

Zebra Card Printer Solutions

1001 Flynn Road

Camarillo, CA. 93012-8706.USA

Phone: +1 (805) 578-5001

FAX: +1 (805) 579-1808

• For Europe and Middle East:

Zebra Technologies Corporation

Zebra Card Printer Solutions

Pittman Way, Fulwood

Preston, PR2 9ZD

Lancashire, U.K.

Phone: +44 - 1 - 772 - 797555

FAX: +44 - 1 - 772 - 693000

980459-001 Rev C P330i & P330m Card Printer User’s Manual iii

Page 4

Foreword

Copyright Notice

Copyright Notice

© 2004, 2005 ZIH Corp.

This document contains information proprietary to Zebra Technologies Corporation. This

document and the information contained within is Copyrighted by Zebra Technologies

Corporation and may not be duplicated in ful l or in part by any person without written

approval from Zebra. While every effort has been made to keep the information contained

within current and accurate as of the date of publication, no guarantee is given that the

document is error-free or that it is accurate with regard to any specificat ion. Zebra reserves the

right to make changes, for the purpose of product improvement, at any time.

Trademarks

P330i and P330m are trademarks and Zebra is a register ed trademark of Zebra Technologies

Corporation. Windows and MS.DOS are registered trademarks of Microsoft Corp. All other

trademarks or registered trademarks are marks of their respective holders.

Product Disposal

Product Disposal Information • Do not dispose of this product in unsorted municipal

waste. This product is recyclable, and should be recycled ac co rding to your local

standards. For more information, please see our web site at:

http://www.zebra.com/environment

Declarations of Conformity

89/336/EEC

modified by

92/31/EEC and

93/68/EEC

73/23/EEC modified

by 93/68/EEC

1999/5/CE

EMC Directive

EMC Directive

EMC Directive EN55024 (2001)

Low voltage

Directive

R&TTE Directive

EN 55022 (1998) RF Emissions control

EN 301489-3 V1.4.1

EN 60950-1 (2001) Product safety

EN300330-2 V1.1.1 Radio Frequency Interferences

RF Emissions and Immunity for radio

equipment

Immunity to Electro-Magnetic

Disturbances

For a formal certificate, please contact the Compliance Office at Zebra’s Camarillo facility.

iv P330i & P330m Card Printer User’s Manual 980459-001 Rev C

Page 5

EUROPE: Norway Only: This product is also designed for IT power system with phase to phase

voltage 230V. Earth grounding is via the polarized, 3-wire power cord.

FI: “Laite on liitettävä suojamaadoitus koskettimilla varustettuun pistorasiaan”

SE: “Apparaten skall anslutas till jordat uttag”

NO: “Apparatet må tilkoples jordet stikkontakt”

FCC Regulations

Models P330i and P330m has been tested and found to comply with the limits for a Class A

digital device, pursuant to Part 15 of the FCC Rules. These limits are designed to provide

reasonable protection against harmful interference when t he equipment is operated in a

commercial environment. This equipment generates, uses, and can radiate radio frequency

energy and, if not installed and operated in accordance with the P330i and P330m User’s

Manual, may cause harmful interference to radio communications. Operation of this

equipment in a residential area is likely to cause harmful interference in which case the user

will be required to correct the interference at his own expense.

Pursuant to Part 15.21 of the FCC Rules, any changes or modifications to this equipment not

expressly approved by Zebra may cause harmful interference and void the FCC authorization

to operate this equipment.

Foreword

Declarations of Conformity

FCC Radiation Exposure Statement (applicable to 15.247 device only)

This equipment complies with FCC radiation exposure limits set forth for an uncontrolled

environment. This equipment should be installed and operated with minimum 20 cm between

the radiator and your body. This transmitter must no t be collocated or operating i n conjunction

with any other antenna or transmitter unless authorized to do so by the FCC.

Industry Canada Notice

This device complies with Industry Canada ICES-003 class A requirements.

Cet equipement est conforme a l’ICES-003 classe A de la norm Industrielle Canadian.

980459-001 Rev C P330i & P330m Card Printer User’s Manual v

Page 6

Foreword

Declarations of Conformity

Printer Models

The Zebra Product Number tells a story:

Here is a quick review of the Zebra Card Printer Serie s numbering an d letterin g system for the

P330i and P330m Card Printers to help you.

Model numbers include identifiers that specify options using the following lettering

conventions:

Part Number Description

P 3 3 0 i - _ _ _ _ _ - _ _ _

P 3 3 0 m - _ _ _ _ _ - _ _ _

_ _ _ _ _ - 0 _ _ _ _ - _ _ _

_ _ _ _ _ - A _ _ _ _ - _ _ _

_ _ _ _ _ - B _ _ _ _ - _ _ _

_ _ _ _ _ - C _ _ _ _ - _ _ _

_ _ _ _ _ - D _ _ _ _ - _ _ _

_ _ _ _ _ - E _ _ _ _ - _ _ _

_ _ _ _ _ - F _ _ _ _ - _ _ _

_ _ _ _ _ - G _ _ _ _ - _ _ _

_ _ _ _ _ - H _ _ _ _ - _ _ _

Base Printer

P330i Color Card Printer

P330m Monochrome Card Printer

Smart Card Options

None

Contact encoder & MIFARE contactless & HID iCLASS

Contact Encoder

Contact encoder & HID iCLASS

Contact encoder & MIFARE contactless

Contact station

HID iCLASS

MIFARE contactless & HID iCLASS

MIFARE contactless

_ _ _ _ _ - _ 0 _ _ _ - _ _ _

_ _ _ _ _ - _ M _ _ _ - _ _ _

_ _ _ _ _ - _ _ 0 _ _ - _ _ _

_ _ _ _ _ - _ _ 1_ _ _ - _ _ _

_ _ _ _ _ - _ _ 3 _ _ - _ _ _

_ _ _ _ _ - _ _ _ 0 _ - _ _ _

_ _ _ _ _ - _ _ _ _ A - _ _ _

_ _ _ _ _ - _ _ _ _ C - _ _ _

_ _ _ _ _ - _ _ _ _ _ - I _ _

_ _ _ _ _ - _ _ _ _ _ - U _ _

_ _ _ _ _ - _ _ _ _ _ - _ D 0

Magnetic Encoder

None

Yes (select defaults below)

Magnetic Encoder Defaults

None

Stripe Down, HiCo

Stripe Up, HiCo

Memory Expansion

None

Interface

USB Only

USB and Ethernet

Power Cords

U. S. and Europe

U. K. and Australia

Windows Drivers and User Documentation

Windows Drivers and User Documentation included on

one CD (Software & Documentation Package) which

contains Multi-language documentation.

vi P330i & P330m Card Printer User’s Manual 980459-001 Rev C

Page 7

Icons

Foreword

Declarations of Conformity

Throughout this manual, different icons highlight important information, as follows:

Note • Indicates information that emphasizes or supplements important poin ts of the main

text.

Important • Advises you of informatio n that is essential to comple te a task, or point s out the

importance of specific information in the text.

Provides an example or scenario to demonstrate or clarify a section of text.

Electrostatic Discharge Caution • Warns you of the potential for electrostatic

discharge.

Electric Shock Caution • Warns you of a potential electric shock situation.

Caution • Warns you of a situation where excessive heat could cause a burn.

Caution • Advises you that failure to take or avoid a specific action could result in

physical harm to you, or could result in physical damage to the hardware.

980459-001 Rev C P330i & P330m Card Printer User’s Manual vii

Page 8

Foreword

Declarations of Conformity

viii P330i & P330m Card Printer User’s Manual 980459-001 Rev C

Page 9

Contents

• Foreword . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .iii

Return Materials Authorization. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . iii

Copyright Notice. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . iv

Trademarks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . iv

Product Disposal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . iv

Declarations of Conformity. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . iv

1 • Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Controls, Connectors, and Indicators. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

LCD Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2 • Installation and Setup. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

General Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Unpacking the Printer. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Installing the Print Driver Software and Setting Driver Options . . . . . . . . 10

Installing the Print Driver . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Loading a Ribbon. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Installing the Card Cleaning Cartridge. . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Setting the Card Thickness Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Loading Cards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Card Output Hopper. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Connecting the Printer to your Computer. . . . . . . . . . . . . . . . . . . . . . . . . 21

Connecting Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Printing a Test Card . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Packing the Printer for Shipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

980459-001 Rev C P330i & P330m Card Printer User’s Manual 1

Page 10

3 • Printing a Card . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Setting Printer Properties. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Printing a Sample Card . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Feeding One Card at a Time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

4 • Cleaning. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Cleaning the Printer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

When to Clean . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

How to Clean . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Cleaning the Print Head. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Card Cleaning Cartridge. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

When to Replace the Cleaning Roller . . . . . . . . . . . . . . . . . . . . . . . . 32

How To Replace the Cleaning Roller . . . . . . . . . . . . . . . . . . . . . . . . . 32

5 • Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Print Quality Issues . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Troubleshooting the Ethernet Connection and Adapter. . . . . . . . . . . . . . 41

Resetting to Factory Defaults. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Ethernet Adapter Status Indicator . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Network Status/Activity Indicator . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

6 • Technical Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

General Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Ribbon Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Card Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Bar Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Fonts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Card Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Bi-Directional Communications Interfaces . . . . . . . . . . . . . . . . . . . . . . . . 45

Mechanical Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Electrical. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Environmental . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Options. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Appendix A • Magnetic Card Encoder . . . . . . . . . . . . . . . . . . . . . . 47

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Media Loading Orientation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Sample Encoding Program . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Magnetic Encoder Cleaning. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

When to Clean . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

How to Clean . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

ISO Standard Encoding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

2P330i & P330m Card Printer User’s Manual 980459-001 Rev C

Page 11

Appendix B • Smart Card Contact Station . . . . . . . . . . . . . . . . . . . 51

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Media Loading Orientation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Smart Card Contact Station Interface. . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Appendix C • Connecting to a Network . . . . . . . . . . . . . . . . . . . . . 53

Printer Sharing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

External Print Server . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Internal Print Server. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Appendix D • Worldwide Sales & Support. . . . . . . . . . . . . . . . . . . 55

Sales and Support Locations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Website . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

980459-001 Rev C P330i & P330m Card Printer User’s Manual 3

Page 12

4P330i & P330m Card Printer User’s Manual 980459-001 Rev C

Page 13

1

Introduction

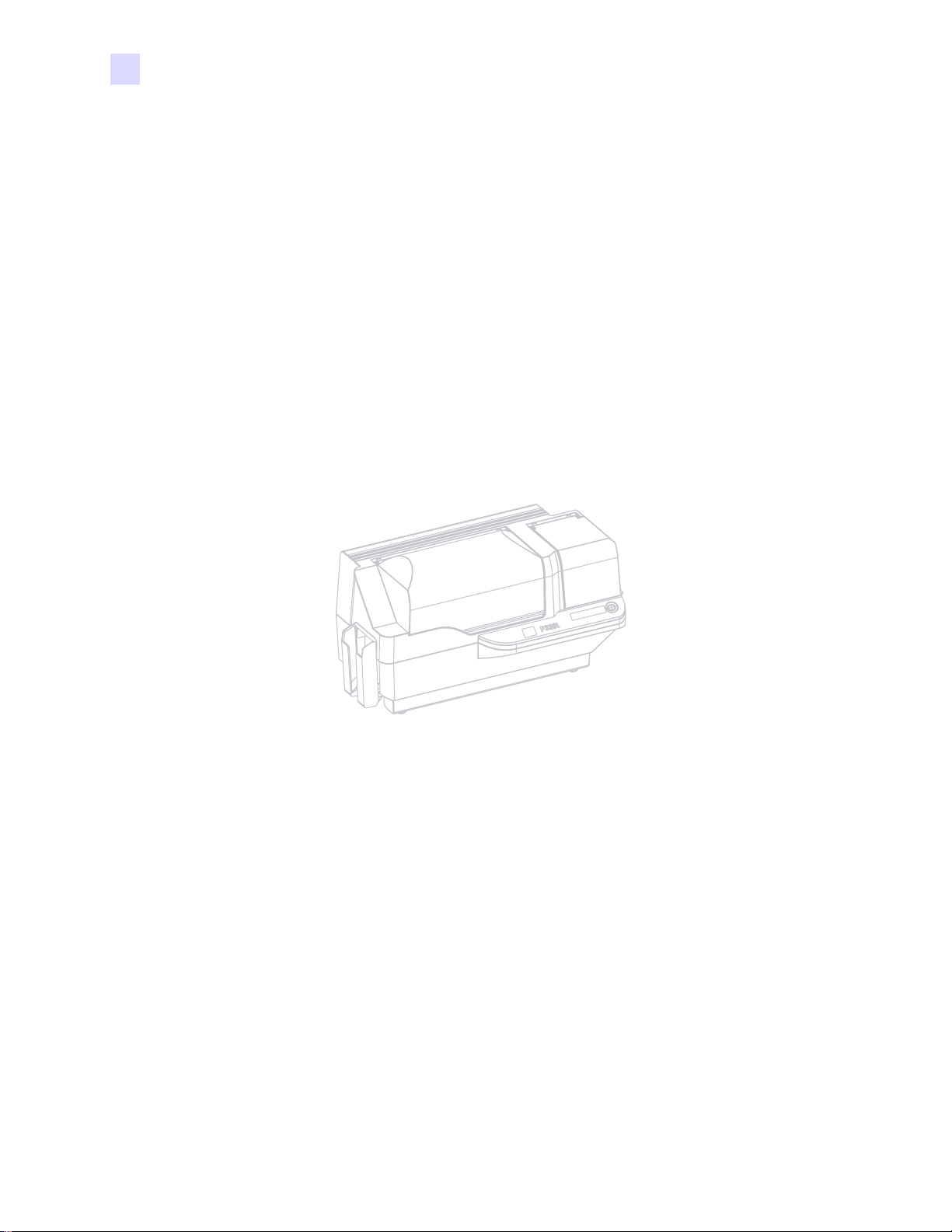

Thank you for choosing the Zebra P330i or P330m Card Printer. This manual guides you to

efficient start up and operation of your new Card Printer.Printer Features.

The only difference between these models is that the P330i supports full-color ribbons (which

may include a protective overcoat panel), and the P330m supports monochrome color prin ting

only.

Print

Head

(Optional)

Magnetic

Encoding

Station

Output

Hopper

(shown in

open

position)

In this manual, references that are specific to the P330i or P330m will be identified as such;

references that apply to both models will use the term “the printer.”

The following shows the main functional features found on your printer.

Main Cover

(shown open)

Ribbon

Take-Up

Spindle

Print Head Carriage

(shown in open

position)

Ribbon

Supply

Spindle

Print Head

Carriage Latch

(Optional)

Smart Card

Contact Station

Card

Feeder

Cover

(shown

open)

Card

Thickness

Control

Card

Cleaning

Cartridge

Panel

Button

LCD Display Panel

980459-001 Rev C P330i & P330m Card Printer User’s Manual 1

Page 14

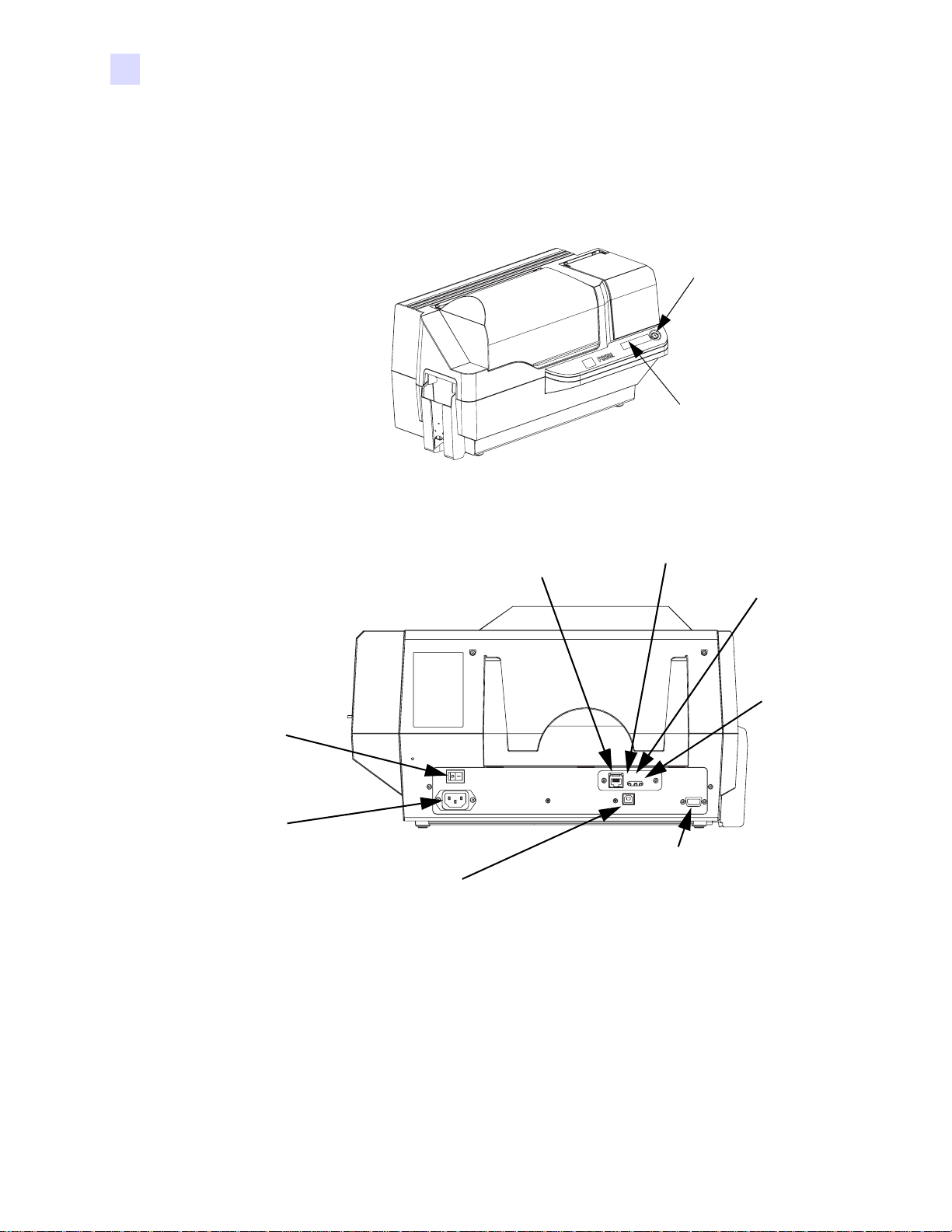

Introduction

Controls, Connectors, and Indicators

Controls, Connectors, and Indicators

Your printer has an LCD Display Panel and a Panel Button on the front and a power connector ,

power switch, and interface connector(s) on the rear panel.

Panel Button

LCD Display

Panel

Power

Switch

Power

Connector

USB Connector

10/100base-T

Connector *

Ethernet Switch *

Optional DB-9

Connector location

for Smart Card

Contact Station

Ethernet

Adapter

Status

LED *

Network

Status /

Activity

LED *

* These

are on the

optional

Ethernet

Adapter.

2P330i & P330m Card Printer User’s Manual 980459-001 Rev C

Page 15

LCD Panel

The LCD Panel can display the following messages:

Introduction

Controls, Connectors, and Indicators

Message Mode

Operational

INITIALIZING Scrolling

READY Fixed

DOWNLOADING DATA Fixed

PRINTING MONO Fixed

MAG ENCODING Fixed

CONTACT ENCODING Fixed

PRINTING CYAN

PRINTING YELLOW

PRINTING MAGENTA

PRINTING BLACK

Fixed (These

Messages do not

apply to the

P330m Printer.)

PRINTING OVERLAY

DOWNLOADING FW Fixed

CLEANING PRINTER Fixed

Warnings

CLEAN PRINTER Scrolling

REMOVE RIBBON THEN CLOSE HEAD Scrolling

EMPTY FEEDER & PRESS BUTTON Scrolling

LOAD CLEANING CARD IN FEEDER Scrolling

PRESS BUTTON TO CONTINUE Scrolling

FEED LONG CLEANING CARD IN EXIT Scrolling

CLEANING PRINTER Scrolling

ENCODING ERROR (printing stops) Blinking

INVALID MAGNETIC DATA

Scrolling

(encoding stops)

REMOVE RIBBON Fixed

Errors (Printer will not operate)

OUT OF RIBBON Blinking

MECHANICAL ERROR Blinking

OUT OF CARDS Blinking

PRINT HEAD OPEN Blinking

980459-001 Rev C P330i & P330m Card Printer User’s Manual 3

Page 16

Introduction

Controls, Connectors, and Indicators

4P330i & P330m Card Printer User’s Manual 980459-001 Rev C

Page 17

Installation and Setup

General Information

This section will guide you through the installation and setup of your P330i or P330m Card

Printer. This consists of the following procedures, which should be performed in the order

presented.

• Unpacking the Printer

• Installing the Print Driver Software and Setting Driver Options

• Loading a Ribbon

• Installing the Card Cleaning Cartridge

• Setting the Card Thickness Control

• Loading Cards

• Connecting the Printer to your Computer

• Connecting Power

• Printing a Test Card to verify printer operation

2

The procedure to be followed for Packing the Printer for Shipment is given at the end of this

section.

The printer should be placed in a location that allows easy access to all sides. The printer

should never be operated while resting on its side or upside down.

Electric Shock Caution • Limit AC power supplied to the printer to 110 ~ 230 volts, 60 ~

50 Hertz. Limit excess current draw to 16 amps or less, using an associated circuit

breaker or other such device. Never operate the printer in a location where operator,

computer, or printer can get wet. Personal injury could result. The printer must be

connected to an earthed electrical power source and properly protected against

electrical surges and grounding faults; the electrical reliability of the printer is based on

the reliability of the mains power source and with the earth connection.

The printer’s power supply is an internal unit that can only be serviced or replaced by

trained and authorized personnel.

980459-001 Rev C P330i & P330m Card Printer User’s Manual 5

Page 18

Installation and Setup

U

Unpacking the Printer

Unpacking the Printer

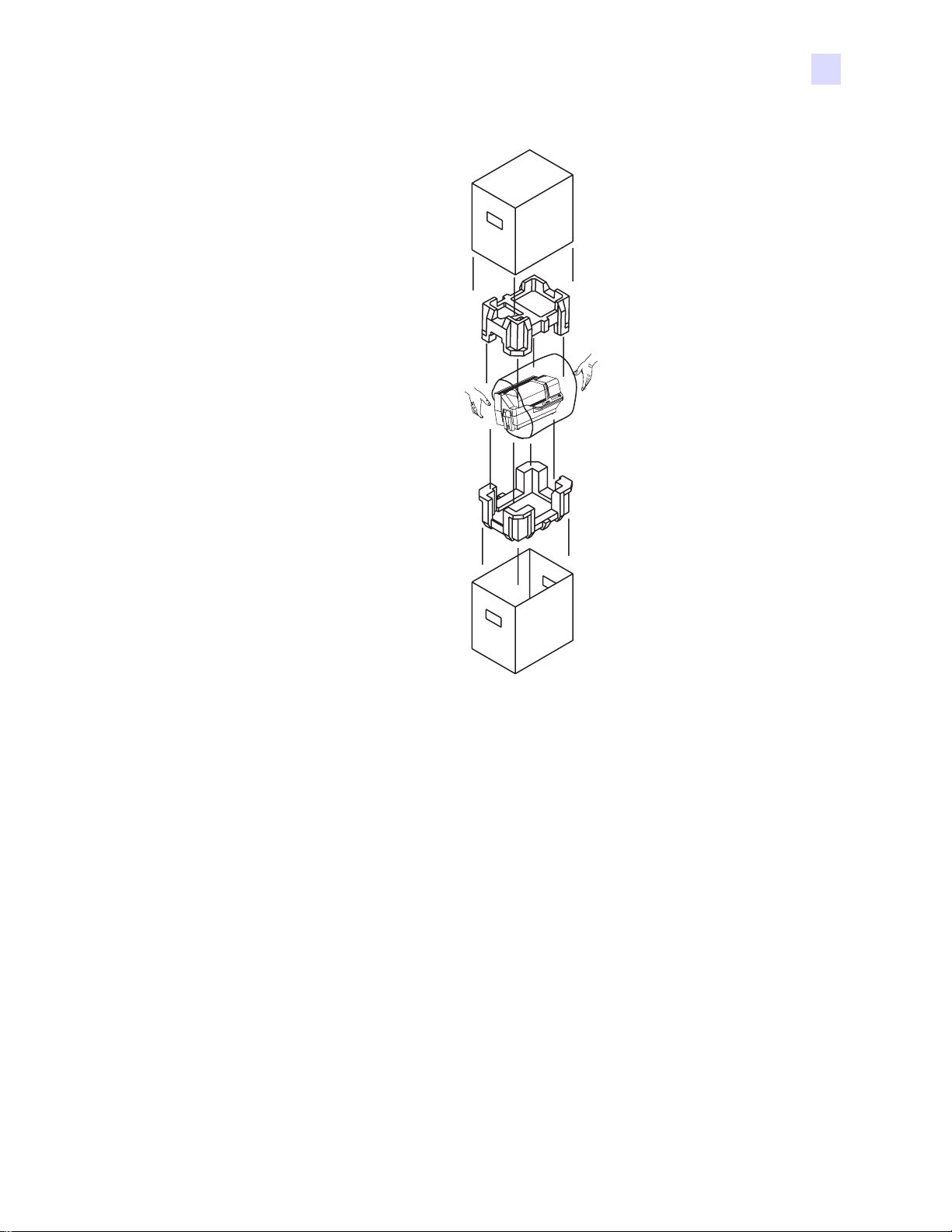

Your Card Printer ships in a carton and protective anti-static bag. Keep all packaging material

in case you need to move or re-ship the printer.

1. Inspect the shipping container to ensure that no damage has occurred during shipment. If

any damage is apparent, file a claim with the shipper.

2. Unlatch and remove the handles on either end of the shipping container, as shown in the

figure below .

P

3. (See the figure on the next page as you perform the following steps.) Lift the upper part of

the shipping container off of the lower part (which will still hold the printer and its

packing material).

4. Remove the packing material around the top of the printer.

6P330i & P330m Card Printer User’s Manual 980459-001 Rev C

Page 19

Installation and Setup

Unpacking the Printer

5. Lift the printer out of the carton by holding it with both hands.

6. Please ensure that you have a clean and nearly dust free environment for proper operation

and storage of the printer.

7. Make sure the following items are included with your printer:

980459-001 Rev C P330i & P330m Card Printer User’s Manual 7

Page 20

Installation and Setup

Unpacking the Printer

CD-ROM with Driver Wizard

and User’s Manual

Power Cables (2)

Card Cleaning Cartridge

USB Cable

Cleaning Kit

If any items are missing, please contact your dealer. To reorder, please refer to

Appendix D of this manual.

8. Remove packing tape securing the printer’s Main Cover and Card Feeder Cover.

9. Your printer ships with warning tape where the Card Cleaning Cartridge will be installed,

and a pad that protects the print head from possible damage in shipment. To remove the

tape and pad, follow the following steps:

a. Open the printer’s main cover by lifting at its lower front lip.

8P330i & P330m Card Printer User’s Manual 980459-001 Rev C

Page 21

Installation and Setup

Unpacking the Printer

b. Locate the Print Head protection pad and the Card Cleaning Cartridge location tape

(see below).

Remove me

A

T

L

S

L

N

I

Print Head

Protection Pad

Card Cleaning Cartridge

Location Tape

c. Release the Print Head Carriage by pushing the Print Head Carriage Latch to the left,

and raise the Print Head Carriage. It will remain open at about a 45

° angle.

Print Head

Carriage

Latch

980459-001 Rev C P330i & P330m Card Printer User’s Manual 9

Page 22

Installation and Setup

Installing the Print Driver Software and Setting Driver Options

d. Remove the print head protection pad. Keep the pad, as well as the other packing

material and the shipping carton, in case the printer is shipped or moved. If the

original material is lost, a replacement Shipping Kit can be ordered from Zebra;

please refer to the Media List on the Windows Drivers and User Documentation CD

supplied with this printer.

Installing the Print Driver Software and Setting Driver

Options

Printing with the P330i or P330m Printer requires the Windows Print Driver and your card

design/issuing software or printer command level programming through the printer interface.

Both models use the same Print Driver.

The printer can be used with any Windows 2000 or Windows XP computer, using the driver

provided on CD with the printer.

This section contains information on the printing of a sample card in color (using the 5-panel

color ribbon YMCKO and the Windows Print Driver).

Note • If updating the printer driver from a previous version, before installing the updated

print driver version, always delete the existing version from yo ur computer.

Installing the Print Driver

To install the Print Driver automatically on all Operating Systems, use the Zebra Install

Wizard.

Note • Ensure that you have administrative priv il ege s to p erform t hi s in sta lla tio n, or contact

your IT department.

The Install Wizard will walk you through the appropriate installation steps. The Wizard will:

• Automatically launch when the driver CD is inserted.

10 P330i & P330m Card Printer User’s Manual 980459-001 Rev C

Page 23

• From the main menu of your documentation CD, select your desired language and then

select “DRIVERS” from the subsequent menu. The Install Wizard will walk you through

the appropriate steps.

• Delete previous versions of the driver and clean up any necessary Registry entries. You

must select “Remove” from the install options to remove any previous driver versions.

Loading a Ribbon

(This paragraph applies only to the P330i, but the ribbon loading steps that follow apply to

both models.) i Series Printers require the use of i Series ribbons for full color printing. The

Resin Thermal Transfer and Dye Sublimination ribbons for P330i are specifically designed for

your P330i Printer.

1. Place the printer power switch in the OFF (0) position.

2. If the printer’s Main Cover is closed:

a. Open the printer’s Main Cover; lift it by the lip at the bottom front as shown in the

figure below left.

Installation and Setup

Loading a Ribbon

Electrostatic Discharge Caution • DO NOT TOUCH the Print Head or the electronic

components on the Print Head Carriage. Discharges of electro-static energy that

accumulate on the human body or other surfaces can damage the Print Head or other

electronic components used in the printer.

Note • Avoid any direct contact with the print head to prevent transfer of oils or

contamination. Outside of normal operation, only the Zebra-approved cleaning materials

should come in contact with the print head.

980459-001 Rev C P330i & P330m Card Printer User’s Manual 11

Page 24

Installation and Setup

Loading a Ribbon

b. Raise the Print Head Carriage by pressing the release latch to the left (toward the

output hopper) and lifting as show n below to about a 45

Carriage will stay in that position, as shown at the right below.

° angle. The Print Head

Ribbon Take-up

Spindle

3. Locate the Ribbon Supply Spindle and the Ribbon Take-up Spindle (see above). Load

Ribbon Supply

Spindle

ribbon onto the supply spindle (under the print head carriage) flange side in, and load the

empty core (with tape attached) onto the take-up spindle. Make sure the ribbon comes off

the top of the supply spindle and feeds to the top of the take-up spindle.

Take-up

Spool

Flange

Supply Spool

12 P330i & P330m Card Printer User’s Manual 980459-001 Rev C

Page 25

Installation and Setup

Loading a Ribbon

Caution • Do not touch the print head if the printer has been in service within the last 10

minutes. It could be very hot and cause a burn.

Electrostatic Discharge Caution • A static discharge is possible if you touch any

exposed metal parts. Use of an anti-st atic wrist strap or comp arable anti-sta tic protection is

required.

4. Gently press the print head carriage down until it is fully lowered, as shown below. Very

little force is neccessary to perform this step.

Note • During normal operation (with power connected and turned on), the ribbon would

automatically synchronize when the Print Head is restored to its fully-down position. The

ribbon would be identified and the corresponding parameters sent to the driver.

Since power is not connected at this point in the Installation and Setup Procedure, nothing

will happen when the Print Head Carriage is closed. The ribbon will synchronize when

power is turned on.

980459-001 Rev C P330i & P330m Card Printer User’s Manual 13

Page 26

Installation and Setup

Installing the Card Cleaning Cartridge

Installing the Card Cleaning Cartridge

The Card Cleaning Cartridge cleans the cards entering the printe r. The Card Cleaning

Cartridge consists of a Cartridge Frame and an Adhesive Roller, which are packed together.

1. Remove the Cartridge Frame and the Adhesive Roller from their packaging. Insert the

Adhesive Roller into the Cartridge Frame, as shown below. To avoid contamination,

always hold the frame and the roller by the ends.

.

2. Peel the protective wrapper from the Adhesive Roller.

3. If the printer’s main cover is closed, open it. Locate the area where the Card Cleaning

Cartridge will be installed (initially, this area was covered by a warning tape).

Card Cleaning

Cartridge Mounting

Location

14 P330i & P330m Card Printer User’s Manual 980459-001 Rev C

Page 27

Installation and Setup

Installing the Card Cleaning Cartridge

4. Locate the slot at the rear of the Card Cleaning Cartridge mounting location; see below.

Card Cleaning

Cartridge

Positioning Slot

5. Hold the Card Cleaning Cartridge by the extended “handle ” (so the l ar ge arrow on the top

is pointing away from you). With the cartridge at about a 30

° angle (pointing downward),

insert the lip of the cartridge into the slot, until the cartridge seats against the back wall.

Then press the front of the cartridge down until it seats all the way down and latches with

an audible “click”. See below.

Slot

Card Cleaning Cartridge in final position

6. Close the printer’s Main Cover.

980459-001 Rev C P330i & P330m Card Printer User’s Manual 15

Page 28

Installation and Setup

Setting the Card Thickness Control

Setting the Card Thickness Control

The Card Thickness Control is set by the user to adjust the gap as cards enter the printer, to

prevent double-feeds (which could cause a jam) or mis-feeds.

Note • Set the Card Thickness Control before loading cards.

1. Open the Card Feeder cover. The cover is hinged; lift it by the lip at the right front corner.

Note • To reduce contamination and ensure better print quality, minimize the time the Card

Feeder cover is open.

2. The Card Thickness Control Lever is at the front of the left-side opening of the Card

Feeder area.

16 P330i & P330m Card Printer User’s Manual 980459-001 Rev C

Page 29

Installation and Setup

Setting the Card Thickness Control

Card Thickness

Control

3. There are four detents to set the position of the Card Thickness Control. Slide the Card

Thickness Control to the position corresp onding to the following:

Detent Position Card Thickness

Highest 50 mil (1.27 mm) to 60 mil (1.52 mm)

3rd position 30 mil (0.76 mm) to 50 mil (1.27 mm)

2nd position 20 mil (0.51 mm) to 40 mil (1.02 mm)

Lowest 10 mil (0.25 mm) to 20 mil (0.51 mm)

Note • The overlap in settings above accomodates variations in environmental conditions

(especially humidity) and cards from different manufacturers. In general, start at the lowest

position and move the lever up until cards feed reliably.

Note • “60 mil” (“1.524 mm”) cards may have a significant variation (over 10%) in the

actual thickness of the cards; do not use these cards unless each card has been measured to

have a thickness less than 66 mil (1.676 mm).

980459-001 Rev C P330i & P330m Card Printer User’s Manual 17

Page 30

Installation and Setup

Loading Cards

Loading Cards

This section shows how to load plastic cards into the P330i or P330m Printer. The printer can

use cards with a range of thickness from 10 mil (0.25 mm) to 60 mil (1.5 mm).

Note • Do not mix cards of different thicknesses!

The printer can also load and print cards fed individually. Information on this is given in the

next chapter.

Note • DO NOT bend cards or touch print surfaces as this can reduce print quality. The

surface of the cards must remain clean and dust free. Always store cards in an en closed

container. Ideally, use cards as soon as possible.

Note • For cards with magnetic stripe, refer to Appendix A for loading instructions.

The plastic cards generally come in decks of 100 cards; the Card Feeder can hold a full deck of

100 30-mil cards. Cards sometimes will stick together; this can cause mis-feeding or doublefeeding. To avoid this, separate the cards before loading, as described in steps 2 through 4

below.

1. If the Card Feeder cover is closed, open it. The cover is hinged; lift it by the lip at the right

front corner.

Note • To reduce contamination and ensure better print quality, minimize the time the Card

Feeder cover is open.

18 P330i & P330m Card Printer User’s Manual 980459-001 Rev C

Page 31

Installation and Setup

Loading Cards

Caution • Do not touch print surfaces of the cards; this can reduce print quality

2. Remove all wrapping from the card deck.

3. Holding the card deck by the sides, hold it vertically against a flat surface such as a

desktop. If the deck is too thick for your hand to hold it comfortably, use about half a deck

at a time.

4. Push the stack back and forth to an angle of about 45° from vertical, so as to separate all of

the cards.

Note • Static charges and edge burrs from the card die-cut ting process can render individual

cards stuck together with significant adhesion force. These cards must be

physically

separated from each other before in serting into the feeder; if not separa ted, feeding or

printing problems may occur.

5. Restore the card stack to its original squared-off condition, and place the cards in the input

hopper.

6. Note that there will be a “gap” in the card stack, with several cards lying flat and the cards

above angled upward, as shown in the exaggerated drawing below. This is normal and

ensures proper feeding.

980459-001 Rev C P330i & P330m Card Printer User’s Manual 19

Page 32

Installation and Setup

Card Output Hopper

Note • Do not try to eliminate the gap by pressing down on the card stack in the input

hopper; this can cause misfeeds.

Card Output Hopper

The card output hopper is normally extended to receive the printed cards. The printer may be

operated with the card output hopper in its closed position; in this case the cards will not be

collected in the output hopper.

1. Pull the card output hopper out to place it in its functional position.

Note • The output hopper is a very snug fit to prevent it from moving during shipping or

operation; firm force is required to change its position.

2. When not using the printer, slide the card output hopper back into its closed position to

protect the printer from dust and protect the output hopper from damage.

3. The output hopper can be completely remo ved from the pr inter i f nec essary by i nserting a

thin, blunt object (such as a pencil) up through the hole in the bottom of the printer

enclosure and pressing (up) to release the hopper while simultaneously pullin g t he h opper

out. To re-install the output hopper, simply slide the output hopper in until it locks in

place.

20 P330i & P330m Card Printer User’s Manual 980459-001 Rev C

Page 33

Connecting the Printer to your Computer

Connecting the Printer to your Computer

The P330i or P330m Printer includes a standard USB interface.

As an option, either printer model can be ordered with a 10/100base-T Ethernet Adapter (in

addition to the USB interface). The Ethernet Adapter can also be ordered as an add-on option

and installed in the field by a Zebra factory certified technician.

1. If using the USB interface, use the supplied USB cable to connect between the USB

connector on the printer and a USB port on the computer, as shown below. (Note that the

figure below shows the optional Ethernet Adapter directly above the USB Connector; this

may not be present on your printer.)

Installation and Setup

Power

Switch

Power

Connector

2. If your printer includes the optional Ethernet Adapter as well as the standard USB

USB Connector

(Optional)

Ethernet

Connector

connection, use either the supplied USB cable or a standard Ethernet cabl e to connect the

printer to a corresponding port on the computer or network.

Important • Do not use both USB and Ethernet connections at the same time!

Important • Intermittent or unpredictable operation may occur from unsecured connectors.

If damaged, the power cable must be replaced by an exact equivalent.

980459-001 Rev C P330i & P330m Card Printer User’s Manual 21

Page 34

Installation and Setup

Connecting Power

Connecting Power

The printer includes an internal AC power supply that accepts nominal input voltage in the

range from 110 to 230 volts at 50 to 60 Hertz. The power source must be grounded.

Depending on specific model number, your printer will include one or two power cords; use

the one that is appropriate for the AC power source connection at your location. If neither has

an appropriate connector, AC power cords may be purchased locally; make sure it is a threewire (grounded) cord.

Power

Switch

Power

Connector

1. Place the Printer’s power switch in the OFF ( O ) position.

2. Depending on your local AC voltage, plug the appropriate power cord into the printer’s

power connector and a grounded AC power source connection.

Caution • If the power cord appears damaged in any way, or if the power cord will not

securely plug into the Printer’s power connector or the AC power source connection,

STOP! Use of a damaged or incorrect power cord could cause equipment damage,

result in an electrical fire, or possibly cause injury.

3. To turn the Printer on, set the Printer’s power switch to the ON ( | ) position.

22 P330i & P330m Card Printer User’s Manual 980459-001 Rev C

Page 35

Printing a Test Card

With ribbon and cards loaded, your printer is ready to print. To check the operation of the

printer, you should print a test card. (Printing a test card does not require that the printer be

connected to your computer or network, but power must be applied.)

1. Set the printer’s power switch (on the back of the printer) to the OFF ( O ) position.

2. While pressing the Printer’s front panel button (next to the LCD display panel), switch the

printer ON (

3. Hold the panel button until the LCD display panel reads “SELF TEST”.

4. Release the panel button, and the test card will print.

This is an example of the test card:

| ).

PLASTIC CARD PRINTER

PRINTER: P330iM

Serial N°: XXXXX

Firmware: XXXXXXX

300 dpi

Installation and Setup

Printing a Test Card

Packing the Printer for Shipment

If the printer is to be shipped, it is important to use the original packing and shipping material

to prevent damage to the Printer . If the original material is lost, a replacement Shipping Kit can

be ordered from Zebra; please refer to the Media List on the Windows Drivers and User

Documentation CD supplied with this printer.

Note • The specifics of the shipment and the printer’s condition may influence which of the

following steps are followed; common sense should prevail.

1. Remove cards in the card feeder:

a. While the printer still has power applied and is turned on, and is still connected to the

host computer, remove cards from the card feeder. The last card may be difficult to

remove. If so, use the Eject Card command available through the driver on the host

computer to eject the last card that is staged in the feeder.

TEST CARD

Head resistance: XXXX

Offset: XXXX-XXXX

Printing counter: XXXXX

EC:XX

Caution • Do not physically pull the last card out of the feeder staging area. This could

damage the printer and void the warranty, as well as damage the card.

b. Close the Card Feeder Cove r.

980459-001 Rev C P330i & P330m Card Printer User’s Manual 23

Page 36

Installation and Setup

Packing the Printer for Shipment

2. If the printer still has power applied and is turned on, and is still connected to the host

computer, set the printer’s power switch (on the back of the printer) to the OFF ( O )

position, and disconnect the interface and power cables to the printer.

3. Open the Main Cover. Open the Print Head Carriage and remove the Ribbon. (If you wish

to save the ribbon for future use, you may want to put it in a plastic bag for storag e.)

4. Insert the print head protection pad, and close the Print Head Carriage. Remove the Card

Cleaning Cartridge and place it in the upper foam insert. Close the Main Cover.

5. Slide the Output Hopper in all the way against the Printer.

6. Place the Printer in its protective plastic bag.

7. Place the lower foam insert in the lower part of the shipping carton.

8. Use both hands to carefully place the Printer into the recess in the lower foam insert.

9. Place the upper foam insert onto the Printer and gently press it down so it makes a snug fit

on the Printer; the top of the upper foam insert should be even with the up per edge of the

lower part of the shipping carton.

10. Slide the upper part of the shipping carton down over the lower part.

11. Insert and close the handles/latches.

24 P330i & P330m Card Printer User’s Manual 980459-001 Rev C

Page 37

3

Printing a Card

Printing with the P330i or P330m Card Printer is similar to printing with any other printer in a

Windows environment.

• The Print Driver Software is installed on your computer (see Chapter 2).

• The printer is connected to the power source and the computer (see Chapter 2).

• The printer is selected by either the Operating System or the appropriate application

software program.

• Printer Properties are set (the factory default values will be appropriate for many

applications).

• Card printing is directed by the appropriate application software program.

Setting Printer Properties

Printer Properties can be set either at the Operating System level or within the application

software program used for printing cards.

Note • In the following description of setting Printer Properties, only those properties

and options that are suitable fo r b ein g set by the User are described. The User should not

make selections or set parameters unless they are specifically described in this section

Preferences settings can configure the printer for Landscape (wide) or Portrait (tall) printing

orientation, and allow the user to verify that the desired ribbon is installed in the printer.

(Monochrome ribbons are selected via the drop-down menu.)

If the printer includes the optional magnetic card stripe encoder, encoding parameters and

coercivity can be set.

Printer cleaning can be initiated from the Tools window (printer cleaning can also be initiated

at the printer; see Chapter 4).

Also from the Tools window, the Test Card can be selected from several pre-loaded styles.

980459-001 Rev C P330i & P330m Card Printer User’s Manual 25

Page 38

Printing a Card

Printing a Sample Card

“Single Feed Options” allows Disabling or Enablin g Single Feed Support.

• If “Disable Single Feed Support” is selected, when the printer runs out of cards in the

feeder, the LCD display will read OUT OF CARDS. To continue, press the panel

button.

• If “Enable Single Feed Support” is selected, when the printer runs out of cards in the

feeder it will wait until a card is inserted in the single-card slot or cards are loaded in

the feeder, and then will automatically continue.

Printing a Sample Card

Sample card designs are installed with the printer driver . Sample cards re quire Microsoft Word

or Microsoft Paint application software. The cards are accessed via the Start menu. Select

Start, select Programs, select Zebra Card Printers, and select a sample card, or follow the

directions below to design a card.

Follow these steps to design and print your first card:

1. Launch Microsoft Word Software. Depending on your computer configuration this may be

done by double-clicking an icon on your desktop, or by cl icking the Windows Start icon,

selecting Programs, and navigating to Microsoft Word

2. Go to the File menu and choose Page Setup.

3. Select the Paper Size tab, choose Card. Under orientation, select Landscape.

4. Select the Margins tab, and set the Top, Bottom, Left, and Right margins to 0 (zero).

5. Click OK to close the Page Setup window.

6. The card appears on the screen.

7. Design a card with both black and colored text and with colored pictures (see example

below).

http://www.zebracard.com

Note • For cards thinner than 20 mils (0.51 mm), the card design must be limited to (1) no

more than two 30 mm x 30 mm areas of full color, (2) black information (text and barcode,

for example) must cover no more than 50% of the card area, and (3) there must be at least a

5mm unprinted border along all edges.

For cards thicker than 40 mils (1.02 mm), the card design must have at least a 5mm unprinted

border along all edges.

For cards with thickness between 20 mils ( 0.51 mm) and 40 mils (1.02 mm), these

restrictions do not apply; full color printing is permitted edge to edge in both directions.

26 P330i & P330m Card Printer User’s Manual 980459-001 Rev C

Page 39

8. Once you are ready to print, go to the File menu and select Print.

9. If the printer was not selected as the default printer, go to the File menu, select Print

Setup and choose Zebra P330i Card Printer (or Zebra P330m Card Printer) from the

printer names list. Then Close the Print Setup dialog box.

10. The printer will feed in a card and start printing (the data download time will vary

depending on the complexity of the card design and the processing speed of your

computer).

11. Once the printing job is complete, the card is ejected from the printer.

Feeding One Card at a Time

A Manual Feed Slot is available below the Card Input Hopper for feeding single cards. The

Card Input Hopper must be empty for single-card feeding to work properly.

1. Open the Card Feeder cover. Verify that there are no cards in the feeder, then close the

Card Feeder cover.

2. Insert a single card into the slot below th e Card Feeder. Do not feed more than one card at

a time.

Printing a Card

Feeding One Card at a Time

Note • If single-card feeding will be the normal mode of operation, you may sele ct that mode

through the driver software. In single-card feed mode, the card will not be printed until the

print job has been sent to the printer and the card to be printed has been inserted into the

single-card feed slot

980459-001 Rev C P330i & P330m Card Printer User’s Manual 27

Page 40

Printing a Card

Feeding One Card at a Time

28 P330i & P330m Card Printer User’s Manual 980459-001 Rev C

Page 41

Cleaning

Caution • PROTECT YOUR FACTORY WARRANTY!

4

The recommended cleaning procedures must be performed to maintain your

factory warranty. Other than the recommended cleaning procedures described in

this manual, allow only Zebra authorized technicians to service the P330i or

P330m Printer.

NEVER loosen, tighten, adjust, bend, etc., any part or cable inside the printer.

NEVER use a high pressure air compressor to remove particles in the printer.

Cleaning the Printer

Clean your printer using Pre-Saturated Cleaning Cards provided. The regular use of these

cards will clean and maintain important parts of y our prin ter that canno t be rea ched, in cludi ng

the Print Head, Transport Rollers, and optional Magnetic Encoder Station.

When to Clean

When the LCD Panel displays the message CLEAN PRINTER.

Approximately every 1000 cards when u sing 5-pa nel c olor ribbon (P330 i o nly), or ev ery 5000

cards when using a monochrome ribbon.

980459-001 Rev C P330i & P330m Card Printer User’s Manual 29

Page 42

Cleaning

Cleaning the Printer

How to Clean

Note • This cleaning procedure uses two cleaning cards. One cleaning card is the size of a

regular plastic card, and is referred to as the “cleaning card.” The other is elongated, with a

wider section at one end; it is referred to as the “lon g cleaning card.”

1. Leave the Printer power on, or turn it on if it was off.

2. Initiate the cleaning process by either of the following methods:

• At the printer, press and hold the panel button for several seconds, until the LCD

• From the computer, en ter the Printer Tools software, and click on the CLEAN button.

3. Open the Main Cover, release the Print Head Carriage, and remove the ribbon. Then close

the Print Head Carriage. (For details, see Chapter 2.) The LCD Panel will display the

message EMPTY FEEDER & PRESS BUTTON.

4. Open the Card Feeder Cover and remove cards from the Card Feeder. The last card is

difficult to remove; leave it in place. Press the Pane l Button on the front of the pri nter. The

card remaining in the feeder will be ejected. The LCD Panel will then displ ay the message

LOAD CLEANING CARD IN FEEDER.

Panel displays the message REMOVE RIBBON THEN CLOSE HEAD.

The LCD Panel will display the message REMOVE RIBBON THEN CLOSE

HEAD.

5. Place a pre-saturated Cleaning Card into the Card Feeder. The Cleaning Card will

automatically feed into the printer and the cleaning process will start (there is a several

second delay after the Cleaning Card feeds before the cleaning movement starts). While

the cleaning process is underway, the LCD Panel will display the message CLEANING

PRINTER.

6. At the conclusion of this part of the cleaning process, the Cleaning Card will be ejected,

and the LCD Panel will display the message PRESS BUTTON TO CONTINUE.

7. After the user presses the panel button, the LCD Panel will display the message FEED

LONG CLEANING CARD IN EXIT. Insert the long end of the long cleaning card into

the card exit (directly above the Output Hopper). If the user inserts a “regular” cleaning

card into the card exit, the LCD Panel will disp lay the message INVALID CARD, PRESS

BUTTON until the user presses the panel button and inserts the long cleaning card into

the card exit.

Note • If the user does nothing at this point (i.e., does not insert the lo ng cleaning card), after

a timeout the LCD Panel display will change to CLEAN PRINTER. The printer will be able

to print, but the LCD Panel will continue to display CLEAN PRINTER.

This limited cleaning does not do a thorough cleaning, but may be performed if no “long

cleaning cards” are available.

To restore the display to READY, you will need to perform a complete cleaning process,

using both short and long cleaning cards, from step 2 above through step 9 below.

30 P330i & P330m Card Printer User’s Manual 980459-001 Rev C

Page 43

8. The long cleaning card will automatically feed into the printer and the printing process

will continue. The LCD Panel will again display the message CLEANING PRINTER.

9. When the cleaning process is completed, the long cleaning card will be ejected and the

LCD Panel will display the message READY, indicating that the printer is re ady to resume

normal printing operations.

10. Discard both cleaning cards after a single use.

Note • Do not use previously used cleaning cards.

Cleaning the Print Head

A cleaning using the Cleaning Ca rds usually suf fices. However, a separate Print Head cleaning

can remove more stubborn deposits when print anomalies persist. To avoid deposits, only use

foam-tipped swabs.

1. Place the printer power switch in the OFF ( O ) position.

Cleaning

Cleaning the Print Head

2. Open the Main Cover, release the Print Head Carriage, and remove the ribbon. Leave the

Print Head Carriage in its raised position. (For details, see Chapter 2.)

3. Clean Print Head by moving an alcohol-moistened swab tip side-to-side across the Print

Head elements. Only use moderate force. T o re -order swabs, please refer to the Media List

on the Windows Drivers and User Documentation CD supplied with this printer.

4. The swabs can also be used in a similar manner to clean the optional magnetic encoding

head.

Caution • Never use a sharp object or any abrasive to scrape deposits from the print

head. Permanent damage to the print head will result.

Caution • Do not touch the print head if the printer has been in service in the last 10

minutes. It could be very hot and cause a burn.

980459-001 Rev C P330i & P330m Card Printer User’s Manual 31

Page 44

Cleaning

Card Cleaning Cartridge

Card Cleaning Cartridge

Y o ur printer includes a Card Cleaning Cartridge. Thi s item cleans the cards entering the printer

through the card feeder. To ensure print quality, the cleaning roller requires periodic

replacement. New cleaning rollers are included with each ribbon or may be purchased

separately. (To reorder, please refer to the Media List on the Windows Drivers and User

Documentation CD supplied with this printer.)

Installation of the Card Cleaning Cartridge is described in Chapter 2 and is not repeated in

detail here.

Note • Before replacing the Card Cleaning Cartridge or its cleaning roller, clean the Printer

using the Cleaning Cards as described earlier in this chapter.

When to Replace the Cleaning Roller

Replace the Cleaning Roller each time you install a new ribbon.

How To Replace the Cleaning Roller

1. Open the main cover and locate the Card Cleaning Cartridge.

2. Gently remove the Card Cleaning Cartridge. Lift the “handle” end, and then pull it away

from the printer.

Card Cleaning

Cartridge

32 P330i & P330m Card Printer User’s Manual 980459-001 Rev C

Page 45

Card Cleaning Cartridge

3. Remove the cleaning roller from the Card Cleaning Cartridge and discard.

Cleaning

4. Install new cleaning roller into the Card Cleaning Cartridge. To avoid contamination,

always hold the cleaning roller by the ends . (For replacement cl eaning rollers, please refer

to the Media List on the Wi ndows Drivers and User Documentat ion CD supplied with this

printer.)

5. Peel protective wrapper from the cleaning roller by gently pulling on the tape.

980459-001 Rev C P330i & P330m Card Printer User’s Manual 33

Page 46

Cleaning

Card Cleaning Cartridge

Note • DO NOT touch the adhesive roller surface that contacts the cards.

6. Replace the Card Cleaning Cartridge into the printer:

7. Close the printer main cover.

Card Cleaning

Cartridge in final

position

34 P330i & P330m Card Printer User’s Manual 980459-001 Rev C

Page 47

5

Troubleshooting

The table on the next page offers causes and solutions to symptoms related to improper

operation. Check the table when experiencing any loss of operation o r print quality.

980459-001 Rev C P330i & P330m Card Printer User’s Manual 35

Page 48

Troubleshooting

Problem / Description Cause / Solution

The LCD Panel displays OUT

OF CARDS message.

The LCD Panel displays OUT

OF RIBBON message.

The LCD Panel displays PRINT

HEAD OPEN message.

The LCD Panel displays

MECHANICAL ERROR

message.

1. Check for cards in the card

feeder. If no cards present, load

cards.

2. Check that Card Thickness

Control lever is properly adjusted

(see Loading Cards in Chapter 2).

3. Press the Panel Button for 1

second. The printing job will

restart.

1. Check ribbon. Replace if

defective or entirely used.

Ribbon will automatically

synchronize and printing will

restart with a new card.

1. Check that Print Head Carriage

is closed and latched. If not, close

and latch it.

1. Check that you are using the

correct card type (see Technical

Specifications).

2. Check that Card Thickness

Control lever is properly adjusted

(see Loading Cards in Chapter 2).

3. If 2 cards are fed into the

printer at the same time:

Open cover and remove Card

Cleaning Cartridge, empty the

Card Feeder, and pull the jammed

cards out. Replace the Card

Cleaning Cartridge.

Remove cards from Card Feeder,

separate them as shown in

Loading Cards in Chapter 2, and

replace.

4. Check that ribbon is loaded

correctly.

The LCD Panel displays

ENCODING ERROR message.

1. Check that you are using the

correct magnetic card type (for

low or high coercivity encoding).

2. Verify command syntax.

3. Contact Zebra technical

support.

The LCD Panel displays

CLEAN PRINTER message.

36 P330i & P330m Card Printer User’s Manual 980459-001 Rev C

1. Printer cleaning required (see

Chapter 4).

Page 49

Print Quality Issues

This section will help you resolve print quality problems. The print quality is dependent on

several factors. The two most important factors that will increase your print quality are

cleanliness and card stock. To diagnose and fix print quality problems, follow the

troubleshooting procedures below:

Example 1 • Small spots appear on the printed card with a non-printed area or a different

color.

Possible Cause:

• Contamination on the card surface.

Solutions:

• Check that cards are stored in a dust free environment.

• Use a different supply of cards.

Troubleshooting

Print Quality Issues

Possible Cause:

• Dust inside the printer and/or dirty Cleaning Roller.

Solutions:

• Perform a Cleaning of the printer (see Chapter 4).

• Replace Cleaning Roller (see Chapter 4).

Example 2 • There are non-printing horizontal lines (white) on the card surfaces.

Possible Cause:

• Ribbon cartridge is not correctly positioned.

Solutions:

• Ensure that the ribbon is properly rolled onto the ribbon cores of the cartridge and that

there are no wrinkles in the ribbon.

• Replace ribbon cassette, making sure it locks in place.

980459-001 Rev C P330i & P330m Card Printer User’s Manual 37

Page 50

Troubleshooting

Print Quality Issues

Possible Cause:

• Print Head is dirty.

Solution:

• Clean the Print Head

Possible Cause:

• Print Head elements are damaged (e.g., scratched or burnt).

Solution:

• Call Zebra Customer Service for Print Head replacement information.

Example 3 • Printing shows very pale, very dark, or inconsistent results

Possible Cause:

• Ribbon has been stored improperly or is damaged.

Solution:

• Change ribbon and print again.

Possible Cause:

• Cards may not meet specifications.

Solution:

• Use a different supply of cards.

Possible Cause:

• Contrast and/or Intensity may be set to incorrect values.

Solution:

• Adjust Contrast and/or Intensity values in software.

Possible Cause:

• Head Settings are too low / high.

Solution:

• Adjust Head Settings higher / lower.

38 P330i & P330m Card Printer User’s Manual 980459-001 Rev C

Page 51

Troubleshooting

Print Quality Issues

Possible Cause:

• Dust or embedded contamination on elements of the Print Head.

Solution:

• Perform a Cleaning of the Print Head (see Chapter 4).

Example 4 • Printing shows blurry printed image.

Possible Cause:

• Ribbon cartridge may not be correctly positioned.

Solution:

• Check that the ribbon is properly rolled onto the ribbon cores of the cartridge.

• Replace ribbon cartridge, making sure it locks in place, and print again.

Possible Cause:

• Ribbon may not be synchronized on the correct co lor panel position (model P330i

only)

Solution:

• Open the Print Head Carriage, then close it. This will cause the ribbon to resynchronize.

Possible Cause:

• Cards may not meet specifications.

Solution:

• Use a different supply of cards.

Possible Cause:

• Dust or embedded contamination inside the printer and/or dirty Cleaning Roller.

Solution:

• Clean the Print Head.

• Replace the Cleaning Roller.

980459-001 Rev C P330i & P330m Card Printer User’s Manual 39

Page 52

Troubleshooting

Print Quality Issues

Example 5 • No printing on the card.

Possible Cause

• Ribbon may not be installed in the printer.

Solution:

• Check for ribbon in the printer.

Possible Cause

• Cards may not meet specifications.

Solution:

• Use a different supply of cards.

Possible Cause

• Print Head elements may be scratched or burnt.

Solution

• Call Service for Print Head replacement information.

Example 6 • Only one panel of a color ribbon prints. (This applies to the P330i only.)

Possible Cause

• Using the wrong type of ribbon.

Solution:

•Use only i Series ribbons for full color printing.

Note • For optimum print quality , always keep the Main Cover and the Card Feeder Cover of

the printer closed.

40 P330i & P330m Card Printer User’s Manual 980459-001 Rev C

Page 53

Troubleshooting

Troubleshooting the Ethernet Connection and Adapter

Troubleshooting the Ethernet Connection and Adapter

Resetting to Factory Defaults

To reset the Ethernet Adapter configuration parameters to the factory defaults, press the

Ethernet Switch

and hold it in while turning the printer power on. Keep the Panel Button pressed until the

Status Indicator light turns green, then release the Ethernet Switch. To print a configuration

card, press and hold the Ethernet Switch until a card starts to print.

Ethernet Adapter Status Indicator

A bi-color Status Indicator displays the operational status of the Ethernet Adapter.The

following conditions might occur:

1. During normal operation, the LED is solid green for more than 30 seconds. This indicates

all the hardware is functioning properly and the Ethernet Adapter has detected the

presence of the network. It does not mean the Ethernet Adapter has an IP address or is

attached to a printer queue.

2. If the LED is rapidly flashing gr een (9 times/sec), the Ethernet Adapter has not detected

the presence of a network cable. To solve the problem:

• Verify that the network cable is appropriate for the network and has an RJ-45

connector.

• Turn the printer power off (O). Remove the network cable from the Ethernet Ada pter.

Plug the network cable back in until you hear a positiv e cl ick . Che ck the o the r end of

the cable in the same manner. Turn the printer power on; if the Ethernet Adapter still

does not detect a cable, continue.

• Connect the Ethernet Adapter to a known good network connection. If t he Et hernet

Adapter is still unable to detect the network cable, contact Technical Support for

assistance.

Important • Cables with a rating higher than CAT-6 have not been tested.

3. If the LED is slowly flashing green (1 time/sec), the Ethernet Adapter is trying to print a

job. If the job does not print, check the following:

• Verify that the printer has media and ribbon. If the printer is showing any error s , it is

unlikely that the Ethernet Adapter can send data to the printer. The LED continues to

blink until the printer malfunction is resolved or until the printer is turned off (O).

• Flashing red indicates the Power On Self Test (POST) is in progress.

4. If the LED is solid red for more than 30 seconds, the Ethernet Adapter has failed the

POST. A failed POST can be caused by any of the following:

• The printer attached to the Ethernet Adapter device is malfunctioning. Turn the

printer power off, wait 10 seconds, then turn the printer back on ( | ).

• If the Ethernet Adapter still fails the POST, the Ethernet Adapter has a hardware

problem that can be fixed only by replacing or returning the unit. Contact Technical

Support for repair or replacement information.

980459-001 Rev C P330i & P330m Card Printer User’s Manual 41

Page 54

Troubleshooting

Troubleshooting the Ethernet Connection and Adapter

5. If the LED is alternately flashing red and green for longer than 2 minutes, the Ethernet

Adapter is in firmware-download mode. This means it is waiting for new firmware data to

be sent before it continues normal functioning. Perform the following:

• If the Ethernet Adapter was purposely put into firmware-download mode, finish the

download with the proper update utility. Contact the Zebra web site at

http://www.zebra.com to download this utility.

• Contact Technical Support for help recovering this unit.

Network Status/Activity Indicator

A bi-color Status/Activity LED indicates network speed, established link, and network

activity.

1. If the LED is off, no link was established.

2. If the LED is solid green, a 100Base link is established.

3. If the LED is flashing green, a 100Base link is established and network activity has been

detected.

4. If the LED is solid orange, a 10Base link is established.

5. If the LED is flashing orange, a 10Base link was established and network activity has

been detected.

Network activity detected by this LED does not mean the activity is data for the print server.

The activity is all activity on the network seen on the Ethernet Adapter.

42 P330i & P330m Card Printer User’s Manual 980459-001 Rev C

Page 55

Technical Specifications

General Specifications

• Full color dye-sublimation card printing

• 25 seconds per card single-sided color printing (YMCKO) (P330i only)

• Monochrome thermal transfer printing

6

Ribbon Specifications

• Patented ribbon core and spindle system

• i Series technology featuring RFID (P330i only)

Note • "i Series" Printers require the use of "i Series" ribbons for full color printing. For

more information about Card Media and Ribbons available from Zebra Technologies Corp.,

please refer to the Media List on the Windows Drivers and User Documentation CD supplied

with this printer. (This applies to P330i only.)

Card Specifications

• Types: PVC or Composite

• Card Width/length ISO CR-80 - ISO 7810, 2.125" (54 mm) x 3.375" (86 mm)

• Option: Magnetic Stripe - ISO 7811

• Card thickness: 10-60 mil (0.25-1.5 mm) ± 10%

• Card feeder capacity: up to 100 cards (30mil) (Optional high-capacity feeder: up

to 220 cards)

• Card output hopper capacity: 100 cards (30mil)

980459-001 Rev C P330i & P330m Card Printer User’s Manual 43

Page 56

Technical Specifications

a

m

Bar Codes

Bar Codes

• Code 39, Code 128 B & C with & without check digit

• 2 of 5 and 2 of 5 interleaved

• UPC-A, EAN8, and EAN13

• PDF-417 2D bar code and other symbologies available via Windows printer driver

Fonts

• Arial and Arial Bold

• True Type fonts av ailable via Windows Driver

Card Dimensions

ISO Standard 7810 Dimensions for Plain Card

2.125 ± 0.002 in

(53.98 ± 0.050 mm)

Radius

0.125 in

(3.18 mm)

3.375 ± 0.01 in

(85.72 ± 0.25 mm)

0.009 ~ 0.033 in

(0.23 ~ 0.84 mm)

ISO Standard 7811 Dimensions for Magnetic Stripe Card

0.623in (15.82mm) min

0.218in (5.54mm) m

0 ~ 0.115in (2.92mm) max

0 ~ 0.115in (2.92m

44 P330i & P330m Card Printer User’s Manual 980459-001 Rev C

Page 57

Technical Specifications

Bi-Directional Communications Interfaces

Contact Location for Smart Card ISO Standard 7816

0.757 in

(19.23 mm)

0.403 in (10.25 mm)

0.782 in (19.87 mm)

1.124 in

(28.55 mm)

Bi-Directional Communications Interfaces

•USB

• Built-in Ethernet (optional)

Mechanical Specifications

• Width: 18.2 in (462 mm)

• Depth: 9.4 in (239 mm)

• Height: 10.1 in (256 mm)

• Weight: 15.5 lbs (7 kg)

Electrical

• 110 ~ 230 Volts AC ± 10% (100 - 254 V), 60 ~ 50 Hz ± 3Hz (47 - 63 Hz)

• FCC Class A, CE, UL, and CUL approved

Environmental

• Operating Temperature: 60°F to 86°F (15°C to 30°C)

• Operating Humidity: 20% to 65% non condensing

• Storage Temperature: 23

• Storage Humidity: 20% to 70% non-condensing

• Ventilation: Reasonably dust free air environment

Options

• Built-in Ethernet network communications

• Three track magnetic stripe encoder (standard and reverse)

• High capacity feeder (220 30-mil cards)

• Contactless encoding (MIFARE and HID iCLASS)

• Contact encoding (Station and encoder)

°F to 158°F (-5°C to 70°C)

980459-001 Rev C P330i & P330m Card Printer User’s Manual 45

Page 58

Technical Specifications

Options

46 P330i & P330m Card Printer User’s Manual 980459-001 Rev C

Page 59

Magnetic Card Encoder

Introduction

APPENDIX A

This Appendix includes operation and maintenance requirements for the P330i or P330m

Printer with the optional magnetic card stripe encoder. (See Chapter 2 for location of the

Magnetic Card Stripe Encoder.)

The magnetic encoder can be set for either high or low coercivity. Use the printer driver to

change the encoder setting.

Media Loading Orientation

The magnetic encoder may be installed with the read/write head positioned below the card

path. Magnetic Card Stripe Encoder upgrade kits are also available.

When loading cards with magnetic stripes into the card feeder, please ensure that the

magnetic stripe is down and nearer to the rear of the printer.

Also available are Printer models with the Magnetic Re ad/W rite he ad positioned above the

card path. When loading cards into one of these models, ensure that the magnetic stripe is

up and nearer to the rear of the printer.

980459-001 Rev C P330i & P330m Card Printer User’s Manual 47

Page 60

Magnetic Card Encoder

Sample Encoding Program

Sample Encoding Program

Refer to the Programmer’s Manual (part number 98001-001).

Note • ONLY USE cards that comply with ISO 7810 and 7811 standards for magnetic stripe

cards. The magnetic stripe must be flush to the surface of the card to work properly. Never

use cards which have taped-on magnetic stripes.

Magnetic Encoder Cleaning

The Magnetic Encoder Read/Write Head is cleaned as part of the prin ter clea ni ng process. If

the frequency of encoding errors increases, the magnetic encoder head may need cleaning.

When to Clean

When the LCD Panel displays the message ENCODING ERROR at an increasing frequency .

How to Clean

1. Leave power on.

2. Press and hold the front panel button for a few seconds.

3. Open the main cover and release the Print Head Carriage latch, raise the Print Head

Carriage, and remove the ribbon. Close the Print Head Carriage.

4. Close the main cover.

5. Open the Card Feeder cover and remove any cards.

6. Insert a Pre-Saturated Cleaning Card (provided) into the slot below the Card Feeder. The

cleaning card will feed into the printer and carry out the cleaning process. Repeat the

process with a new cleaning card if necessary.

7. Additional cleaning of the magnetic head can be accomplished using the alcohol-soaked

swabs provided with the printer. Follow the directions given in Section 4.

48 P330i & P330m Card Printer User’s Manual 980459-001 Rev C

Page 61

ISO Standard Encoding

Magnetic Card Encoder

ISO Standard Encoding

Track #

Field

Separator

1 ^ 210 BPI* Alphanumeric

2 = 75 BPI* Numeric

Track

Density

Valid

Characters

(ASCII 20~95

†)

# of

characters

79

‡

40‡

(ASCII 48~62)

3 = 210 BPI* Numeric

107‡

(ASCII 48~62)

*Bits per inch

†Except the “?” character

‡Including Start, Stop, and LRC characters. Also note that these 3 characters are

automatically managed by the magnetic encoder according to the ISO Standard

Norms.

Note • Refer to the Card Printer Programmer’s Manual for complete programming

information.

980459-001 Rev C P330i & P330m Card Printer User’s Manual 49

Page 62

Magnetic Card Encoder

ISO Standard Encoding

50 P330i & P330m Card Printer User’s Manual 980459-001 Rev C

Page 63

APPENDIX B

Smart Card Contact Station

This section contains information on the addi tional operation s of a P330i or P330m Printer

equipped with the optional Smart Card Contact Station. (See Chapter 2 for location.)

Introduction

Smart Cards can have a built-in microcomputer and/or me mory to store fingerprints, voic e

recognition patterns, medical records, and other such data. The printer may be equipped

with an optional contact station for programming Smart Cards (ISO 7816). This printer

model responds to commands that position the card at the cont act station, where the printer

connects to the contacts on the Smart Card. All other printer operations remain the same as

the standard models.

Media Loading Orientation

Orient the cards with the gold-plated Smart Card cont acts at the top surface of the card and

facing to the left.

980459-001 Rev C P330i & P330m Card Printer User’s Manual 51

Page 64

Smart Card Contact Station

Smart Card Contact Station Interface

Smart Card Contact Station Interface

When a command to the printer interface sends a card to the Smart Card Contact Station, the

printer connects the Smart Card Contact Station to the female DB-9 connector on the rear of

the printer.

An attached external Smart Card Programmer can be used to program Smart Card chips. The

following table shows the Smart Card Contact Points.

DB-9 Connector location for

Smart Card Contact Station

DB-9 Pin Smart Card Contact Points DB-9 Pin Smart Card Contact Points

1

2

3

4

5

C1 (VCC) 6 C6 (Vpp)

C2 (Reset) 7 C7 (I/O)

C3 (Clock) 8 C8 (RFU)

C4 (RFU)

9 (GND when chip is at station)

C5 (GND)