Page 1

®

For the Zebra 400™ and 600™ Printers

SS

Customer order # 44885L

Manufacturer part # 44885LB Rev. 2

User’s

Guide

Page 2

Proprietary Statement

This manual contains proprietary information of Zebra Technologies Corporation. It is

intended solely for the information and use of parties operating and maintaining the

equipment described herein. Such proprietary information may not be used, reproduced, or

disclosed to any other parties for any other purpose without the expressed written

permission of Zebra Technologies Corporation.

Product Improvements

Continuous improvement of products is a policy of Zebra Technologies Corporation. All

specifications and signs are subject to change without notice.

FCC Compliance Statement

NOTE:

This equipment has been tested and found to comply with the limits for a Class B

digital device, pursuant to Part 15 of the FCC Rules. These limits are designed to provide

reasonable protection against harmful interference in a residential installation. This

equipment generates, uses, and can radiate radio frequency energy and, if not installed and

used in accordance with the instructions, may cause harmful interference to radio

communications. However, there is no guarantee that the interference will not occur in a

particular installation. If this equipment does cause harmful interference to radio or

television reception, which can be determined by turning the equipment off and on, the

user is encouraged to try to correct the interference by one or more of the following

measures:

n

Reorient or relocate the receiving antenna.

n

Increase the separation between the equipment and the receiver.

n

Connect the equipment into an outlet on a circuit different than that to which the receiver is

connected.

n

Consult the dealer or an experienced Radio/TV technician for help.

NOTE:

This unit was tested with shielded cables on the peripheral devices. Shielded

cables must be used with the unit to insure compliance.

The user is cautioned that any changes or modifications not expressly approved by Zebra

Technologies Corporation could void the user s authority to operate the equipment.

Canadian DOC Compliance Statement

This digital apparatus does not exceed the Class A limits for radio noise emissions from

digital apparatus as set out in the radio interference regulations of the Canadian

Department of Communications.

Liability Disclaimer

Zebra Technologies Corporation takes steps to assure that its published Engineering

specifications and Manuals are correct; however, errors do occur. Zebra Technologies

Corporation reserves the right to correct any such errors and disclaims liability resulting

therefrom.

No Liability for Consequential Damage

In no event shall Zebra Technologies corporation or anyone else involved in the creation,

production, or delivery of the accompanying product (including hardware and software) be

liable for any damages whatsoever (including, without limitation, damages for loss of

business profits, business interruption, loss of business information, or other pecuniary

loss) arising out of the use of or the results of use of or inability to use such product, even

if Zebra Technologies Corporation has been advised of the possibility of such damages.

Because some states do not allow the exclusion or limitation of liability for consequential

or incidental damages, the above limitation may not apply to you.

Copyrights

This copyrighted manual and the label printer described herein are owned by Zebra

Technologies Corporation. All rights are reserved. Unauthorized reproduction of this

manual or the software in the label printer may result in imprisonment of up to one year

and fines of up to $10,000 (17 U.S.C.506). Copyright violators may be subject to civil

liability.

All products and brand names are trademarks of their respective companies. All rights

reserved.

© 1998 Zebra Technologies Corporation

Page 3

I have determined that the Zebra printers identified as the

Stripe Series

400 and 600SS

manufactured by:

Zebra Technologies Corporation

333 Corporate Woods Parkway

Vernon Hills, Illinois 60061-3109 U.S.A.

have been shown to comply with the applicable technical standards of the FCC

for Home, Office, Commercial, and Industrial use

if no unauthorized change is made in the equipment,

and if the equipment is properly maintained and operated.

Page 4

Page 5

S400 & S600 User’s Guide i

Contents

Introduction

Unpacking ..................................1

Reporting Damage..............................1

Site Requirements ..............................2

Introduction to Printers ...........................2

Tear-Off Mode ..............................2

Peel-Off Mode ..............................3

Cutter Mode ................................3

Printer Overview ..............................4

Getting Ready to Print

AC Power Cable...............................5

Loading the Media .............................7

Tear-Off Mode ..............................7

Roll Media ...............................7

Fanfold Media .............................8

Peel-Off Mode ..............................9

Removing the Label Backing Material ................10

Cutter Mode ...............................11

Loading the Ribbon ............................12

Ribbon Supply Spindle: Normal Position ................12

Ribbon Supply Spindle: Low-Tension Position .............12

Ribbon Loading Instructions ......................13

Ribbon Removal ..............................14

Adjusting the Media Sensor ........................15

Non-Continuous Media .........................15

Continuous Media ............................15

Auto Calibration ..............................16

Operator Controls .............................16

Front Panel Buttons ...........................16

Front Panel LEDs ............................17

AC Power ON/OFF Switch ........................18

Page 6

ii S400 & S600 User’s Guide

Printing a Test Label ............................18

Connecting the Printer and Computer ...................18

RS-232 Interface Requirements .....................18

Parallel Interface Requirements .....................19

Serial and Parallel Cabling Requirements ................19

Communicating with the Printer ......................19

Via the Parallel Port ...........................19

Via the Serial Port ............................19

Defaulting the Printer ..........................19

Autobaud.................................20

^SC Command..............................20

Setting Up the Software ..........................20

Routine Care and Adjustments

Cleaning ..................................21

Cleaning the Exterior ..........................23

Cleaning the Interior ...........................23

Cleaning the Printhead and Platen Roller ................23

Cleaning the Cutter Module .......................24

Lubrication .................................30

AC Power Fuse Replacement .......................30

Mechanical Adjustments ..........................31

Print Quality Adjustments ........................31

Toggle Pressure Adjustment.......................31

Media Rest Position Adjustment ....................33

Top of the Label Position Adjustment..................33

Media Sensor Position Adjustment ...................33

Ribbon Supply Spindle Adjustment ...................33

Backing Rewind Power Roller Adjustment ...............34

Troubleshooting

Troubleshooting Table ...........................37

Printer Status Sensors ...........................43

Manual Calibration.............................45

Resetting Printer Parameters ........................46

Page 7

S400 & S600 User’s Guide iii

Resetting Factory Defaults .......................46

Resetting Communications Parameters .................46

Resetting Ribbon Parameters ......................46

Printer Diagnostics .............................47

Power-On Self Test ...........................47

Additional Printer Self Tests ......................47

CANCEL Key Self Test........................48

PAUSE Key Self Test .........................49

FEED Key Self Test..........................50

MODE Key Self Test .........................51

Specifications

General Specifications ...........................53

Printing Specifications ...........................54

Ribbon Specifications ...........................54

Media Specifications ............................55

Media Handling ..............................55

Options ...................................56

Zebra Programming Language (ZPL II

Bar Codes .................................57

Standard Printer Fonts ...........................57

Optional Printer Fonts ...........................57

®

).................56

Appendix

RS-232 Connector Technical Information .................59

Interconnecting to DTE Devices ....................59

Interconnecting to DCE Devices ....................59

Parallel Interface Technical Information..................61

Storage and Reshipping ..........................62

Glossary

Index

Page 8

iv S400 & S600 User’s Guide

Page 9

S400 & S600 User’s Guide 1

Introduction

Congratulations! You have just purchased a high-quality thermal label

printer manufactured by the industry leader in quality, service, and value.

For over 25 years, Zebra Technologies Corporation has provided customers

with the highest caliber of products and support.

n

This user's guide provides all the information you will need to operate

the printer on a daily basis.

n

ZPL II®is Zebra Technologies Corporation’s Zebra Programming

Language II label design language. ZPL II lets you create a wide variety

of labels from the simple to the very complex, including text, bar codes,

and graphics. To create and print label formats, refer to the ZPL II

Programming Guide (part #46469L). If one was not ordered with your

printer, simply call your distributor or Zebra Technologies Corporation.

n

In addition, label preparation software is available. Contact your

distributor or Zebra Technologies Corporation for further information.

Or, visit our web site for a free demo copy.

n

The S400/S600 Maintenance Manual (part #44895L) contains all the

information you will need to maintain your printer. To order, contact

your distributor or Zebra Technologies Corporation.

Unpacking

Save the carton and all packing materials in case reshipping is required.

Inspect the printer for possible shipping damage.

n

Check all exterior surfaces for damage.

n

Raise the media access cover (refer to Figure 4) and inspect the media

compartment for damage.

Reporting Damage

If you discover shipping damage:

n

Immediately notify and file a damage report with the shipping company.

Zebra Technologies Corporation is not responsible for any damage

incurred during shipment of the printer and will not cover the repair of

this damage under its warranty policy.

n

Keep the carton and all packing material for inspection.

n

Notify your authorized Zebra distributor.

For storage and reshipping information, refer to the Appendix.

Page 10

2 S400 & S600 User’s Guide

Site Requirements

CAUTION: To insure that the printer has proper ventilation and cooling,

do not place any padding or cushioning material under the unit, because

this restricts air flow.

This printer may be installed on any solid, level surface of sufficient size

and strength to accommodate the physical dimensions and weight of the

unit. The area enclosure in which the printer will operate must meet the

environmental conditions specified. Electrical power must be available and in

close proximity to the printer.

Since this printer was designed and is fabricated as an industrial-type unit, it

will function satisfactorily in areas such as warehouses, factory floors, and

office environments that conform to specified environmental and electrical

conditions.

Introduction to Printers

The first thing you want to do is identify your printer. This makes certain

tasks -- such as media loading -- much easier to do!

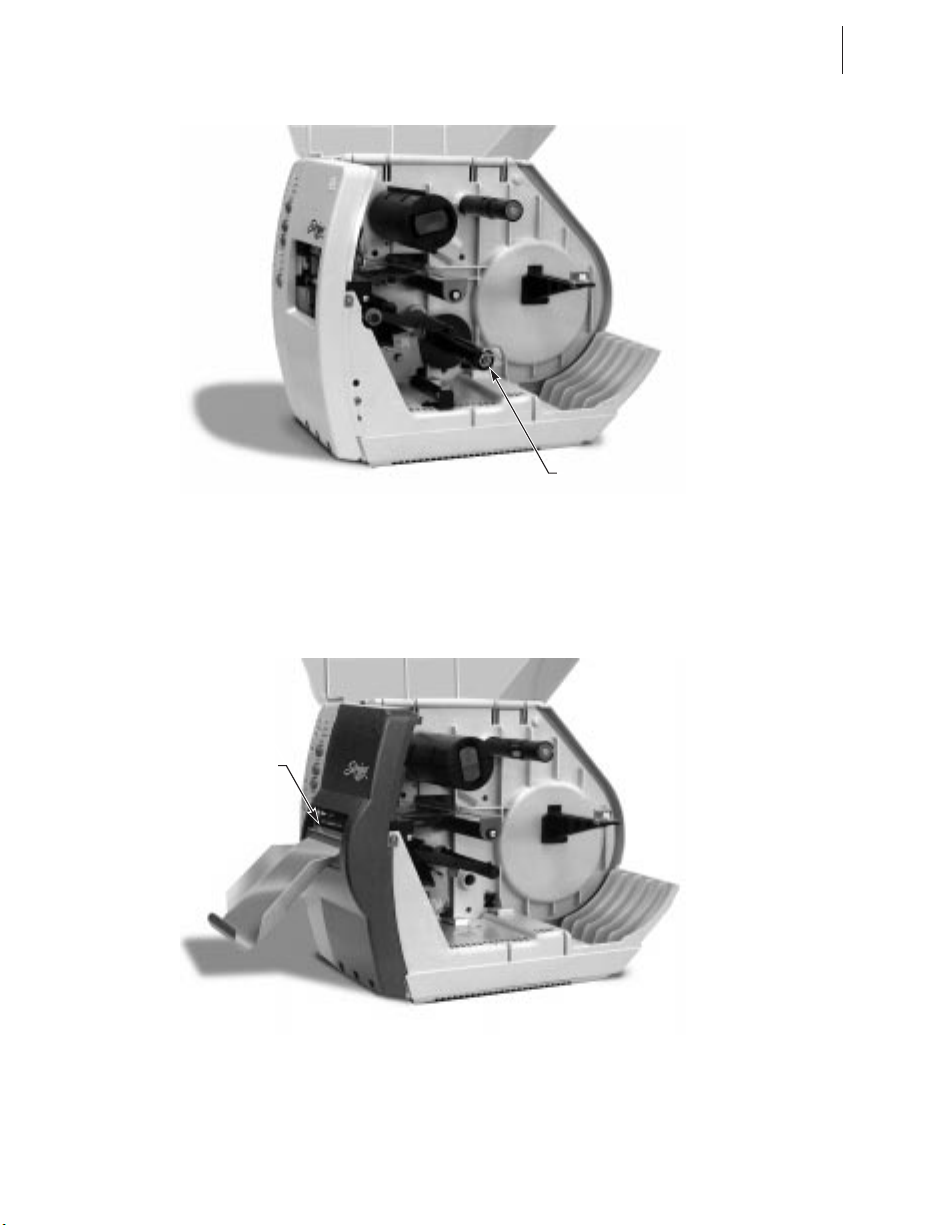

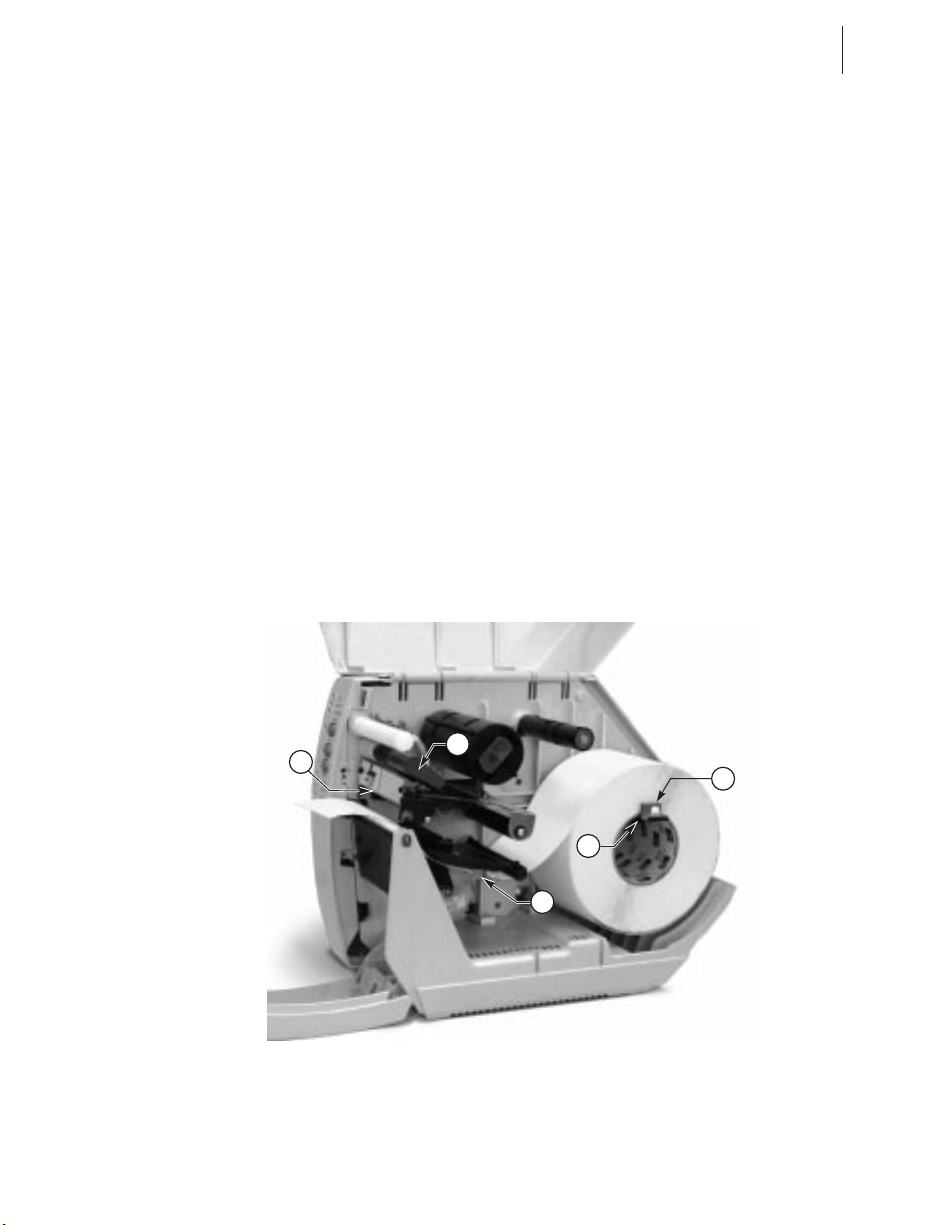

If your printer

looks like this

(Figure 1), it is

set up for

Tear-Off mode.

Tear-Off allows

you to tear away

each label, or a

strip of labels,

after it is

printed.

To load media,

refer to

“Loading the

Media -Tear-Off Mode”

in Getting Ready

to Print.

Figure 1

Page 11

Figure 2

S400 & S600 User’s Guide 3

Backing

Rewind Spindle

This printer

(Figure 2)

operates in

Peel-Off mode.

In Peel-Off,

backing material

is peeled away

from the label as

it is printed.

After this label is

removed from the

printer, the next

one is printed.

To load media,

refer to “Loading

the Media -Peel-Off Mode”

in Getting Ready

to Print.

Cutter

Module

Printers like this

(Figure 3) are

equipped for

Cutter mode.

When in cutter

mode, the printer

automatically

cuts the label

after it is printed.

Then, the cutter

catch tray

“catches” the

label.

To load the

media, refer to

“Loading the

Media -- Cutter

Mode” in Getting

Ready to Print.

Figure 3

Page 12

4 S400 & S600 User’s Guide

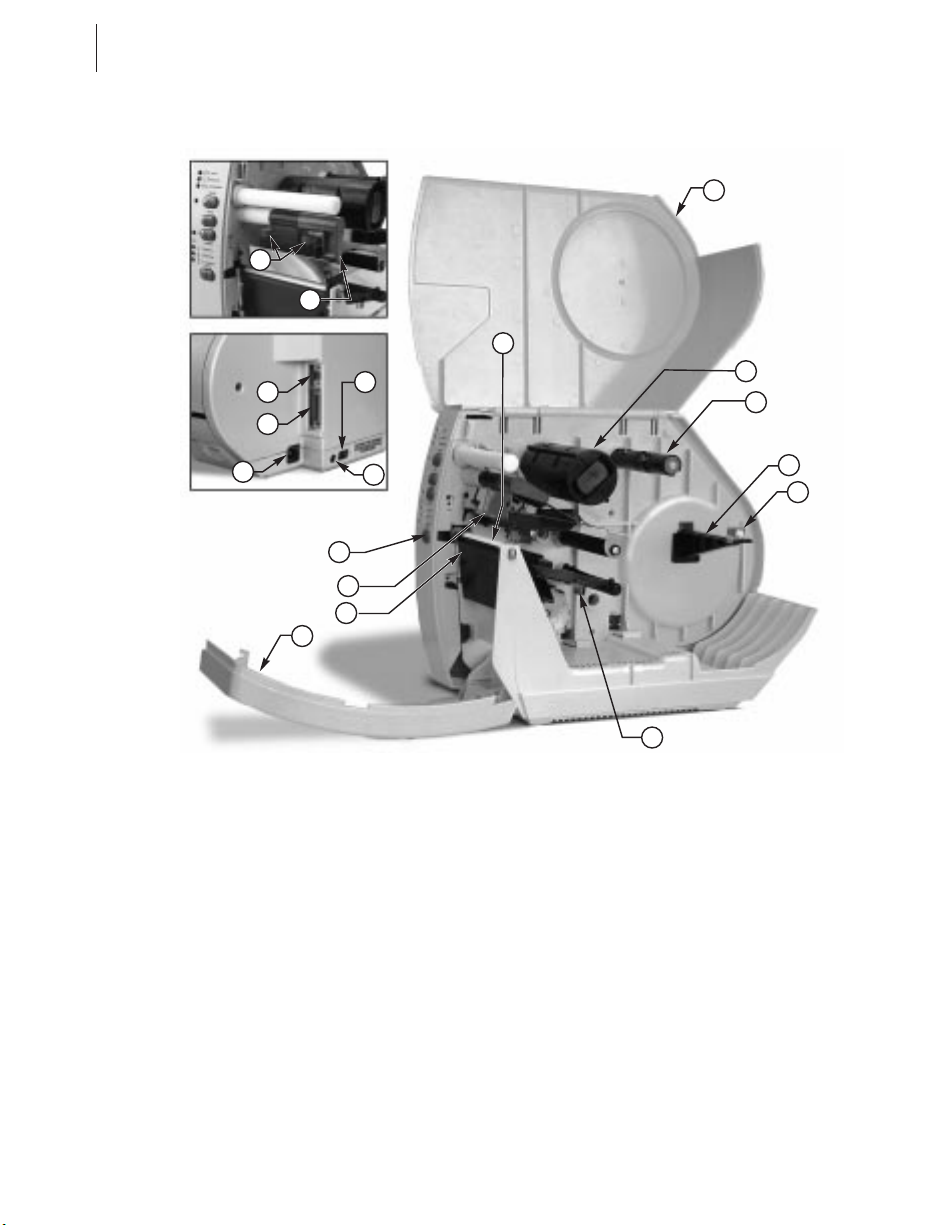

18

14

13

1

17

11

16

2

3

12

7

1

Media Access Cover

Ribbon Take-up Spindle

2

Ribbon Supply Spindle

3

Media Supply Hanger

4

Media Supply Guide

5

Media Guide

6

Front Cover

7

Tear Plate

8

Printhead

9

10

15

9

8

6

10

Control Panel

Platen Roller

11

AC Power Cable Connection

12

Parallel Interface

13

Serial Interface

14

Fuse

15

Power On/Off Switch

16

Head Open Lever

17

Pressure Toggles

18

4

5

Figure 4

Page 13

S400 & S600 User’s Guide 5

Getting Ready to Print

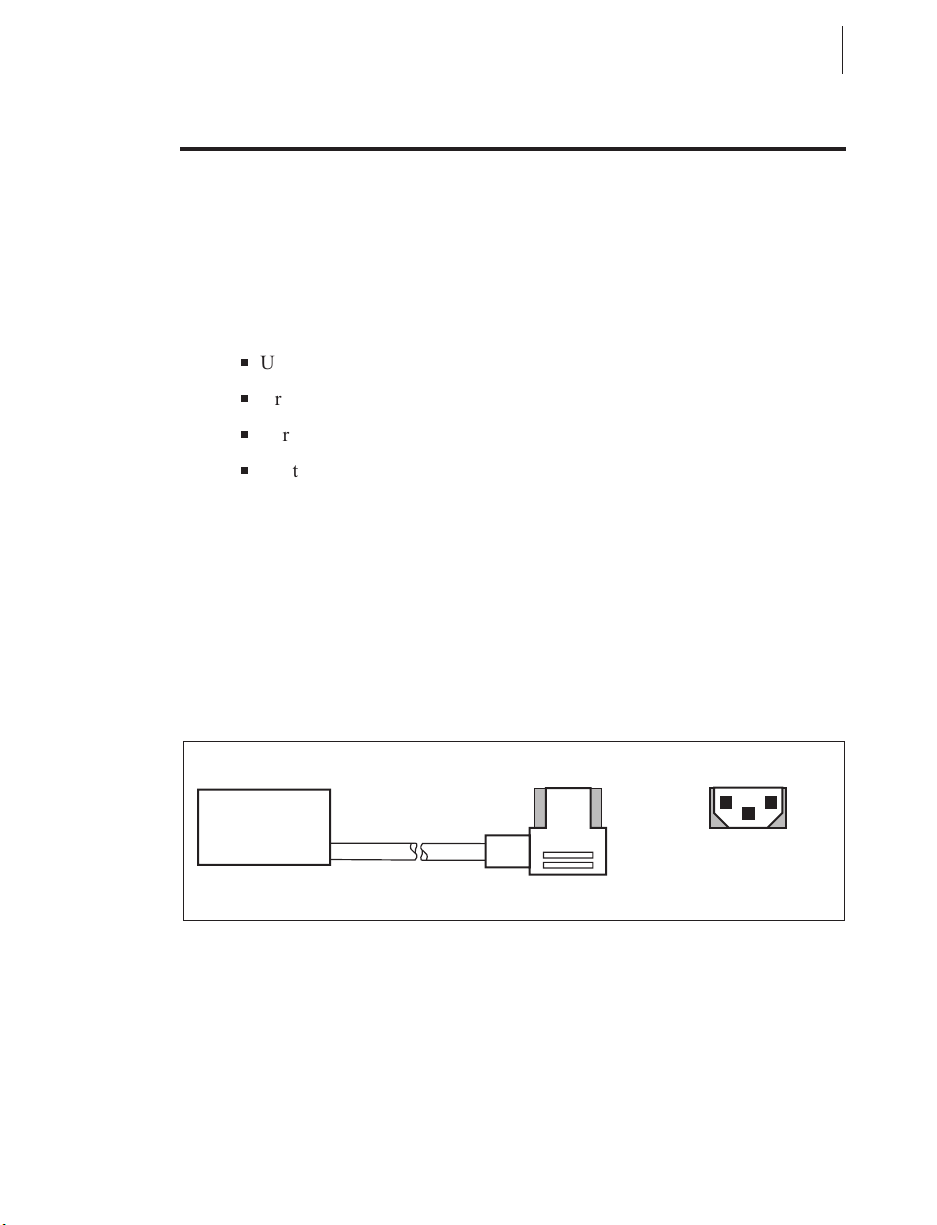

AC Power Cable

The AC power cable has a three-prong female connector on one end (see

Figure 5). This connector must be plugged into the mating connector on the

left side of the printer. See Figure 6.

The connector at the other end of the AC power cable will be one of the

following:

n

US Standard 110 VAC three-prong plug

n

Great Britain Standard 230 VAC three-prong plug

n

European Standard 230 VAC three-prong plug

n

Australian Standard 230 VAC three-prong plug

WARNING!!! For personnel and equipment safety, always use a

three-prong plug with an earth ground connection.

Insure that the AC power on/off switch is in the “off” position before

connecting the AC power cable to a nearby electrical outlet.

AC

POWER

CONNECTOR

3 CONDUCTOR

CABLE

NEUTRAL LIVE

EARTH

Figure 5

Page 14

6 S400 & S600 User’s Guide

RS-232

(Serial)

Interface

Parallel

Interface

Power

On/Off

Switch

Figure 6

Fuse

AC Power Cable

Connection

Page 15

S400 & S600 User’s Guide 7

Loading the Media

Media widths and thicknesses vary between applications. To maintain print

quality from one application to another, refer to “Print Quality

Adjustments” in Routine Care and Adjustments.

NOTE: Zebra recommends using media that is outside wound (you can see

the labels on the outside of the roll).

Tear-Off Mode

1. Refer to Figure 7. Move the head open lever (a) counterclockwise to the

open position to raise the printhead (b).

2. Slide the media guide (c) and the media supply guide (d) as far out from

the printer frame as possible.

If you are loading roll media in Tear-Off mode, follow steps 3-5. For

loading fanfold media in Tear-Off mode, skip to step 6.

3. Place the media roll on the media supply hanger (e), and thread the me-

dia through the printhead assembly as shown.

b

a

d

e

c

Figure 7

Page 16

8 S400 & S600 User’s Guide

4. Adjust the media supply guide and the media guide against the outer

edge of the media. These guides must not cause pressure or excessive

drag on the media.

5. Close the head open lever, and see “Adjusting the Media Sensor” later in

this chapter to adjust the media sensor position.

For loading fanfold media:

6. Refer to Figure 8. Make sure the fanfold media feeds through either the

bottom (e) or rear (f) access slot.

NOTE: When utilizing the bottom access slot, be sure to thread media over

the media supply hanger.

7. Thread the media through the printhead as shown in Figure 8.

8. Adjust the media supply guide and the media guide against the outer

edge of the media. These guides must not cause pressure or excessive

drag on the media.

9. Close the head open lever, and see “Adjusting the Media Sensor” later in

this chapter to adjust the media sensor position.

Figure 8

f

e

Page 17

S400 & S600 User’s Guide 9

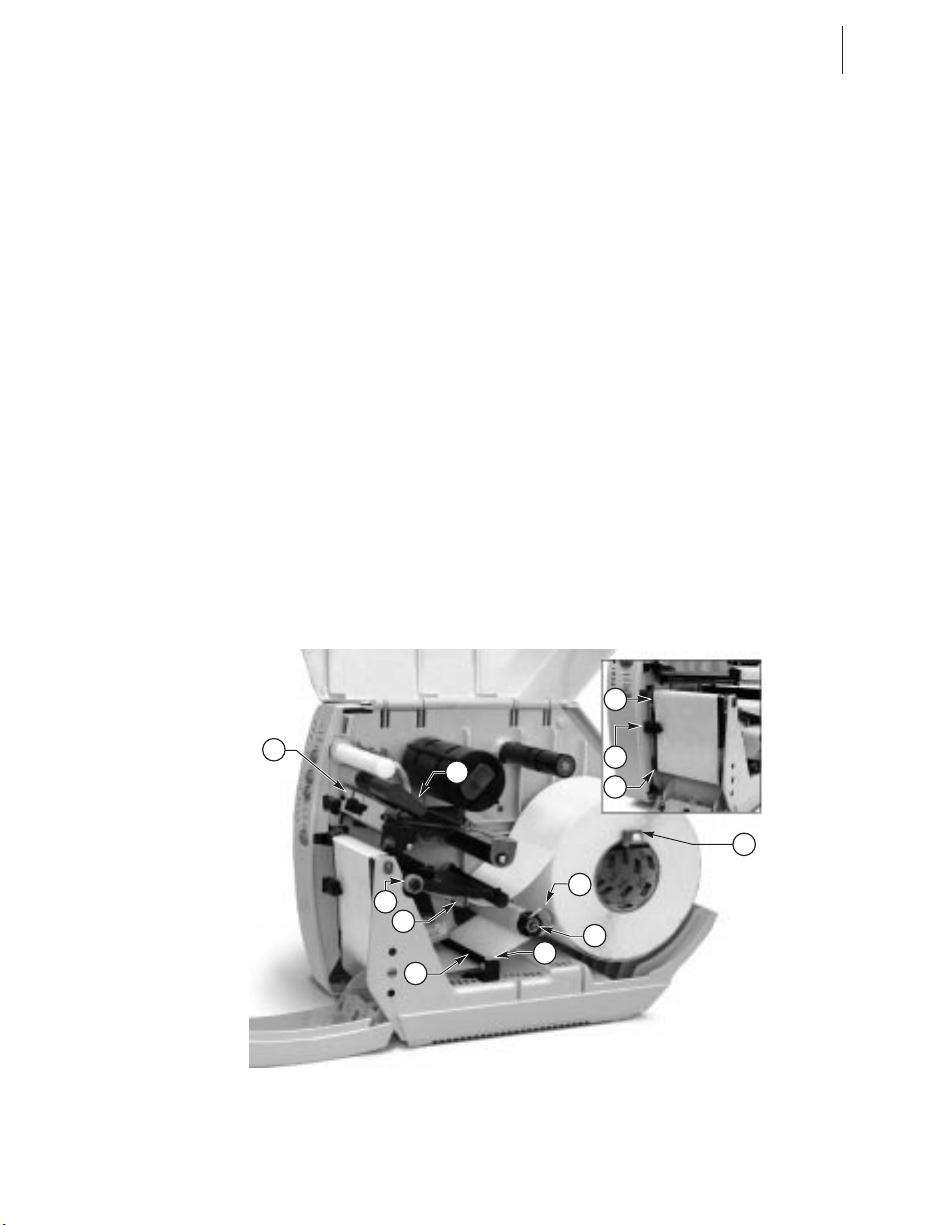

Peel-Off Mode (Optional)

Refer to Figure 9 and follow the procedure below.

1. Slide the media supply guide (a), media guide (b), and the outer edge

guides on both the platen guide rod (c) and the lower guide rod (d) as far

out from the printer frame as possible.

2. Open the head open lever (e) to raise the printhead (f).

3. Remove the hold down hook (g).

4. Thread the media through the printhead as shown in Figure 9.

5. From the front of the printer, pull the media through the printhead until

approximately 24" of media extends out from the printer. Remove the

labels from the backing of the 24" of media that extends from the front

of the printer.

6. Align the inside edge of the media with the edge guide mark (h) near the

left side of the tear-off/peel-off plate, then close the head open lever.

(See Figure 25 for a detailed illustration.)

7. Thread the label backing behind the lower label available sensor (i),

through the slot under the rewind power roller (j), and below the lower

guide rod (k) to the backing rewind spindle (l). Then, wind the backing

material around the backing rewind spindle three or four times in a

counterclockwise direction. To insure proper winding, press the edge of

the backing material against the round plate at the far end of the spindle.

h

f

e

c

b

d

k

Figure 9

i

j

a

g

l

Page 18

10 S400 & S600 User’s Guide

8. To hold the media against the spindle, place the hold down hook over

the backing and insert both ends into the small slots in the round plate at

the far end of the spindle. Again, rotate the backing rewind spindle

counterclockwise to remove any slack in the backing material.

9. Adjust all of the guides:

n

Push the media supply guide inward until it is just touching the outer

side of the media supply roll, then lock the guide in place with its

locking screw. The guide must not cause pressure or excessive drag on

the media supply roll.

n

Adjust the outer edge guides on both the lower guide rod and the platen

guide rod until they just touch the outer edge of the media and backing

without causing the material to buckle.

n

Adjust the media guide until it just touches the outer edge of the media

without causing the material to buckle.

10.See “Adjusting the Media Sensor” later in this chapter to adjust the me-

dia sensor.

NOTE: In the Peel-Off mode, proper media tracking is critical. Refer to

the “Backing Rewind Power Roller Adjustment” in Routine Care and

Adjustments to make sure that the media tracks properly through the

printer.

Removing the Label Backing Material

quired)

(Peel-Off Option Re-

When the amount of backing wound on the backing rewind spindle reaches

full capacity, the backing rewind spindle full sensor activates, the

paper/ribbon light flashes, and printing pauses.

To remove the backing material, follow these steps (you don’t need to

power off the printer for this procedure):

1. Unwind about 24" of backing from the backing rewind spindle and cut it

off at the spindle.

2. Pull out the hold down hook and slide the backing material off of the

spindle and discard.

3. Feed the new starting edge of the backing through the mechanism and

attach it to the backing rewind spindle as described in the loading procedure.

NOTE: While holding the media in position against the tear-off/peel-off

plate, open and close the printhead without disturbing the media position.

The printer is now ready to print more labels.

Page 19

S400 & S600 User’s Guide 11

Cutter Mode (Optional)

To insure proper media loading, follow the directions for the Tear-Off

Mode with the exception that the end of the media must be positioned on

top of the platen roller. See Figure 10.

With the end of the media positioned directly on top of the platen roller (a),

close the head open lever. The printer will automatically calibrate, feed out,

and cut the label when the printer is powered on or the printhead is opened

and closed.

NOTES: The cutter only cuts if the printer is in cutter mode. Refer to the

ZPL II Programming Guide or the label preparation software user’s guide

for instructions.

The cutter will cycle once at power up or reset (even when NOT in cutter

mode).

a

Figure 10

Page 20

12 S400 & S600 User’s Guide

Loading the Ribbon

Before you load the ribbon, make sure the ribbon supply spindle is adjusted

properly.

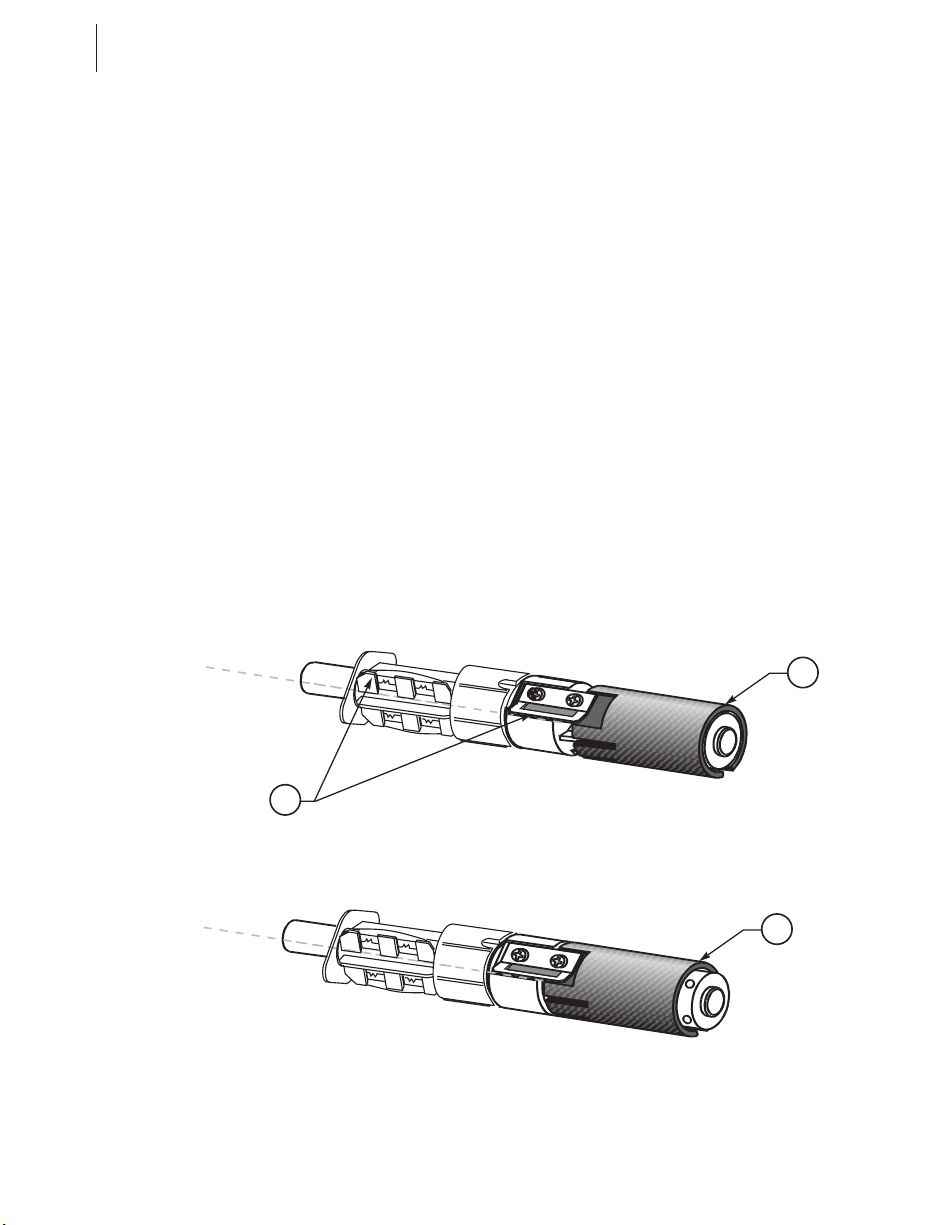

Ribbon Supply Spindle: Normal Position

In the normal position, the “dual-tension” ribbon supply spindle provides

the desired amount of ribbon back tension for different ribbon widths.

To place the spindle in the normal position, firmly pull the spindle end cap

(a) until it clicks into place, as shown in Figure 11.

Ribbon Supply Spindle: Low-Tension Position

Low-tension position is used in limited applications to provide lower ribbon

back tension. Low-tension position is only recommended when normal

tension hampers the ribbon movement (for example, you will see scuffing

or image breakup on the label).

To put the spindle in the low-tension position, firmly push the spindle end

cap (a) until it clicks into place, as shown in Figure 11.

Normal Position

a

b

Low-Tension Position

a

Figure 11

Page 21

S400 & S600 User’s Guide 13

Ribbon Loading Instructions

NOTES:

n

Zebra recommends the use of ribbon that is wider than the media. The

smooth backing of the ribbon protects the printhead from wear and

premature failure due to excessive abrasion. (For the direct thermal

print method, ribbon is not used and should not be loaded in the

printer.)

n

Zebra recommends the use of ribbon that is outside wound (the ink side

is on the outside of the roll).

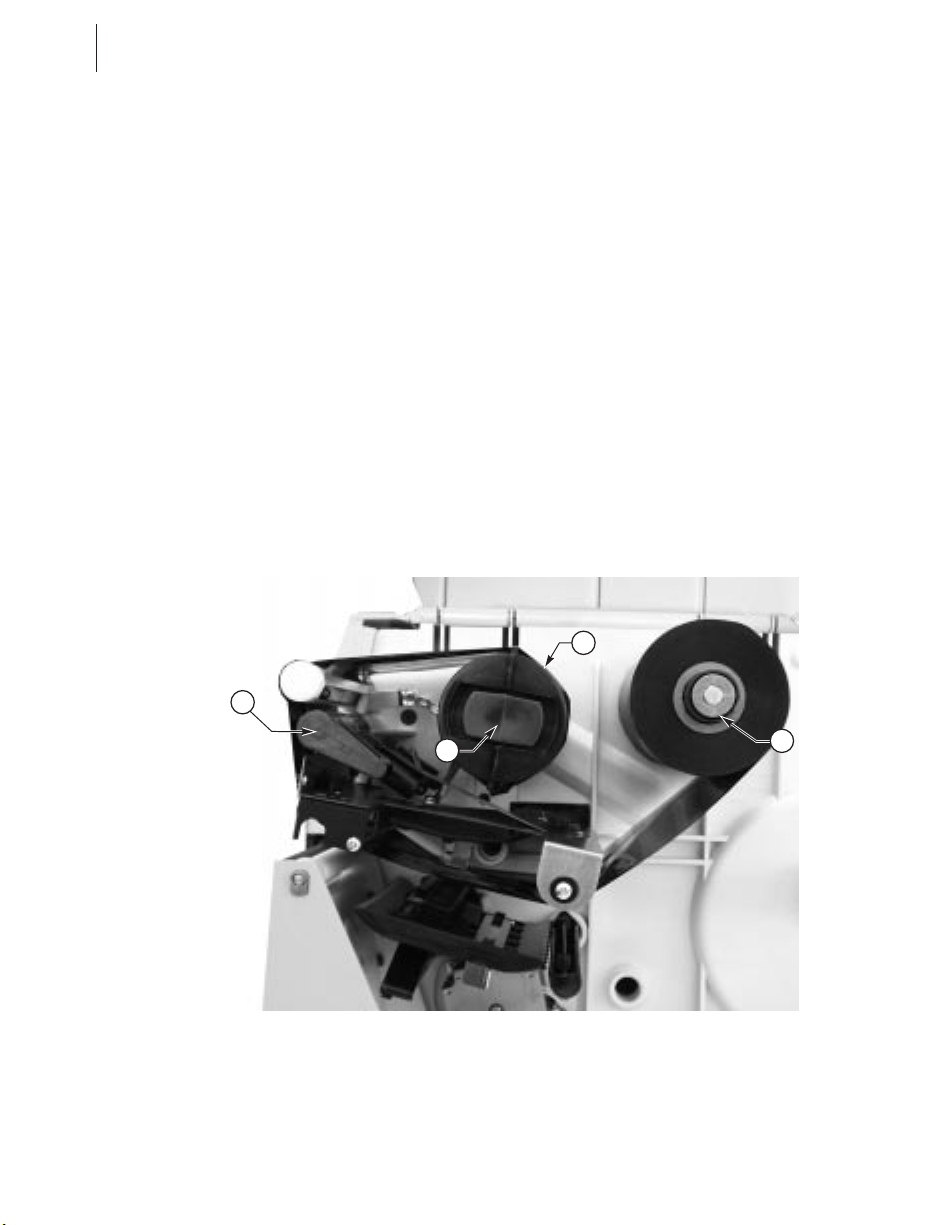

To load ribbon, see Figure 12 and follow the procedure below.

1. Adjust the ribbon supply spindle position for normal or low tension.

2. Align the blades (b) on the two sections of the spindle as shown in

Figure 11. (You do not need to do this if your ribbon width is 2.4"

[60 mm] or less.)

3. Place the ribbon roll on the ribbon supply spindle (a). Make sure the roll

is pushed in to the stop at the end of the spindle.

4. Open the printhead by moving the head open lever (b) counterclockwise

to the open position.

5. Thread the ribbon as shown. Wind the ribbon onto the ribbon takeup

spindle (c) for several turns in a clockwise direction until wrinkles and

creases disappear.

6. Close the printhead by moving the lever clockwise to the closed posi-

tion.

Page 22

14 S400 & S600 User’s Guide

Ribbon Removal

Refer to Figure 12.

When it’s time to change the ribbon, cut the ribbon where it is stretched

between the upper ribbon guide arm and the takeup spindle. To remove

ribbon from the takeup spindle, press the release button (d) and slide the

ribbon off the spindle.

c

b

d

Figure 12

a

Page 23

S400 & S600 User’s Guide 15

Adjusting the Media Sensor

This adjustment aligns the position of the light sensor with the notch or

edge of the label, so the printer can determine the correct label size.

See Figure 13. With the printhead open, look through the side of the print

mechanism and locate the media sensor adjustment lever (a). Reposition

the sensor until the top of the adjustment lever is in line with the notch or

web in the media or the edge of the label. Close the printhead by moving

the head open lever to the closed position.

When continuous media (no notch or opening to sense) is used, position the

media sensor anywhere over the media so that an “out-of-media” condition

will still be sensed.

Non-Continuous Media

This type of media has some type of physical characteristic (web, notch,

perforation, etc.) that indicates the start/end of each label.

The media sensor must be properly positioned to sense these indicators.

See “Adjusting the Media Sensor” (above). Then, turn on the printer. If the

printer will not auto calibrate, press the MODE button three times, and then

the FEED button once, to manually calibrate (a label will print that shows

the sensor profile).

Continuous Media

Since continuous media does not contain label start/end indicators, you

must tell the printer via software how long each label is. If you are using

ZPL or ZPL II, include a Label Length (^LL) instruction in each label

format you send to the printer (refer to your ZPL II Programming Guide).

If you are using other software to operate your printer, refer to the

instructions provided with that software.

a

Figure 13

Page 24

16 S400 & S600 User’s Guide

Auto Calibration

This procedure occurs whenever the printer is turned on or the printhead is

opened and closed. During this procedure, the printer automatically

determines the media type, label length, media and ribbon sensor settings,

and printing method (direct thermal or thermal transfer). This procedure is

set at the factory but may be changed via ZPL II command.

NOTE: If the printer fails to auto calibrate when you are using pre-printed

labels or pre-printed label backing, or if the printer will not auto calibrate,

see “Manual Calibration” in Troubleshooting.

1. Load the media and ribbon (if used).

2. Turn on the printer power.

3. Two or three blank labels will feed, completing auto calibration.

Operator Controls

Front Panel Buttons

Refer to Figure 14.

PAUSE Button

n

Starts and stops the printing process.

n

The first time the button is pressed, any partially printed label is

completed; then, the printing process is stopped.

n

If the printer is idle when the button is pressed, no new print requests are

printed until PAUSE is pressed again.

FEED Button (also referred to as the UP button)

n

Forces the printer to feed one blank label.

n

If the button is pressed when the printer is idle or paused, a blank label

immediately feeds.

n

When the button is pressed while the printer is printing, one blank label

feeds after the completion of the current batch of labels.

n

Once the blank label has been fed, pressing the button again will feed a

second label.

n

When in the configuration mode, functions as the UP button.

CANCEL Button (also referred to as the DOWN button)

n

This button only functions when the printer is paused.

Page 25

n

If the button is pressed, the

label format that is currently

printing is canceled.

n

If pressed when no label format

is printing, then the next format

to be printed is canceled.

n

Press for at least three seconds

to cancel all label formats the

printer has received and return

the printer to an idle state.

n

When in the configuration

mode, functions as the DOWN

button.

S400 & S600 User’s Guide 17

POWER

PRINTHEAD

PAPER/RIBBON

PAUSE

MODE Button

n

Puts the printer into the

configuration mode.

n

Used to change print darkness

and media position, and to

calibrate the printer.

Front Panel LEDs

Refer to Figure 14.

The front panel LEDs give you a

quick indication of the printer’s

current status. During normal

operation, the POWER LED is on

and all other LEDs are off. For all

other conditions, please refer to

Troubleshooting.

Now, you’re ready to turn on the

printer!

FEED

DATA

CANCEL

DARKEN

POSITION

CALIBRATE

MODE

Figure 14

Page 26

18 S400 & S600 User’s Guide

AC Power ON/OFF Switch

This switch is located on the left side of the printer near the AC power cord

and fuse (see Figure 6). The AC power switch should be turned off before

connecting or disconnecting any cables.

Turning the switch on activates the printer and causes it to perform a Power

ON Self Test, which can take up to 30 seconds, as it begins operation.

Turning the printer power on while holding down certain front panel keys

will activate additional printer self tests following the Power ON Self Test.

See Troubleshooting.

External influences, such as lightning storms or unwanted noise on the

power or data cables, may cause erratic printer behavior. Turning the AC

power off and back on may re-establish proper printer operation.

Otherwise, see Troubleshooting.

Printing a Test Label

Before you connect the printer to your computer, make sure that the printer

is in proper working order. You can do this by printing a configuration

label (refer to the “CANCEL Key Self Test” in Troubleshooting.) If you

can’t get this label to print, refer to Troubleshooting.

To make print quality adjustments, refer to “Print Quality Adjustments” in

Routine Care and Adjustments.

Connecting the Printer and Computer

This printer comes with both a nine-pin Electronics Industries Association

(EIA) RS-232 serial data interface and an IEEE 1284 bi-directional parallel

data interface. In either case, you must supply the required interface cable

for your application.

CAUTION: This printer complies with FCC “Rules and Regulations,”

Part 15, for Class B Equipment, using fully shielded six-foot data cables.

Use of longer cables or unshielded cables may increase radiated emissions above the Class B limits.

RS-232 Interface Requirements

Refer to Figure 6.

The required cable must have a 9-pin “D” type (DB-9P) connector (male)

on one end, which is plugged into the mating (DB-9S) connector (female)

located inside the access opening on the left side of the printer.

The other end of the signal interface cable connects to a serial port at the

host computer. This cable will be one of two types -- standard or null

modem -- depending on the specific interface requirements.

Page 27

S400 & S600 User’s Guide 19

For pinout information, as well as information on how to interconnect to

either a DTE or DCE device, refer to the Appendix.

Parallel Interface Requirements

Refer to Figure 6.

An IEEE 1284 compatible bi-directional parallel data cable is required

when this communication method is selected. The required cable must have

a standard 36-pin parallel connector on one end, which is plugged into the

mating connector located inside the access opening on the left side of the

printer. The parallel interface cable is connected using bail clips instead of

screws.

The other end of the parallel interface cable connects to the printer

connector at the host computer.

For pinout information, refer to the Appendix.

Serial and Parallel Cabling Requirements

Data cables must be fully shielded and fitted with metal or metallized

connector shells. Shielded cables and connectors are required to prevent

radiation and reception of electrical noise.

To minimize electrical noise pickup in the cable:

1. Keep data cables as short as possible.

2. Do not bundle the data cables tightly with power cords.

3. Do not tie the data cables to power wire conduits.

Communicating with the Printer

Via the Parallel Port

n

Set the parallel connection on the host computer. For instructions, refer

to your computer’s user’s guide.

Via the Serial Port

n

Set the host computer to the factory defaults of the printer: 9600 baud, 8

bit word length, no parity, 1 stop bit, and XON/XOFF. For instructions,

refer to your computer’s user’s guide.

NOTE: If you can’t reset the host computer communications settings, then

you must establish a temporary parallel connection to send down the Set

Communications (^SC) command that changes the printer’s settings to

match the host settings.

DEFAULTING THE PRINTER: To reset only the communications

parameters on the printer to the factory defaults (9600 baud, 8 bit word

Page 28

20 S400 & S600 User’s Guide

length, no parity, 1 stop bit, and XON/XOFF), press and hold the PAUSE,

FEED, and MODE buttons while turning on the printer, then release the

buttons when the CALIBRATE LED goes out. All of the LEDs will go on,

while the DARKEN, POSITION, and CALIBRATE LEDs will flash. Press

and hold the MODE button until all of the lights go out, then release the

MODE button. The factory defaults have now been reset. Next, set the

communications parameters on your computer to match this.

NOTE: To save the default settings, press the MODE button four times.

Otherwise, the previous settings will be restored the next time the printer is

turned on.

AUTOBAUD: To automatically detect the communications parameters,

press and hold the PAUSE, FEED, and MODE buttons while turning on the

printer, then release the buttons when the CALIBRATE LED goes out. All

of the LEDs will go on, while DARKEN, POSITION, and CALIBRATE

LEDs will flash. Send a label format using the host computer settings. If

the printer accepts the host parameters, all of the LEDs will go off (except

for the POWER LED) and the printer will restart with the host

communication settings. If the printer does not accept the host

communications parameters, the printer will not restart and the LEDs will

flash on and off. If this should happen, turn the printer off and then on, and

try again.

NOTES: Label formats sent to the printer at this time only help the printer

determine the host settings. No label will print until settings are recognized.

In order for autobaud to work, your label must start with either a ^XA or

~XA ZPL II command. If all the LEDs are on, send another label format.

Save the new communication settings by pressing MODE four times.

Autobaud only works for 9600 baud and higher.

^SC: Use the Set Communications (^SC) command to change the

communications settings on the printer. 1) With the host computer set at

the same communications settings as the printer, send the ^SC command to

change the printer to the desired settings. 2) Then, change the host

computer settings to match the printer settings.

Setting Up the Software

In order to create labels, you must decide whether you will use ZPL II or

commercial label preparation software. To use ZPL II, refer to the ZPL II

Programming Guide. If you choose to use a label preparation software,

follow the installation instructions included in the package.

Page 29

S400 & S600 User’s Guide 21

Routine Care and Adjustments

Cleaning

CAUTION: Use only the cleaning agents indicated below. Zebra

Technologies Corporation will not be responsible for any other products being used on this printer. No lubricants are needed.

The following table provides a brief cleaning schedule. Specific cleaning

procedures are provided on the following pages. Cleaning swabs saturated

with 70% isopropyl alcohol are available from your distributor as a

preventive maintenance kit.

Refer to Figure 15 for cleaning locations.

Printhead (a) Alcohol

Platen roller (b) Alcohol

Media sensor (c) Air blow

Media path (d) Alcohol

Ribbon path (e) Air blow

Upper guide rod (f) (Peel-Off) Alcohol

Platen guide rod (g) (Peel-Off) Alcohol

Rewind power roller (h) (Peel-Off) Alcohol

Lower guide rod (i) (Peel-Off) Alcohol

Cutter

Assembly

(j)

(if used)

Tear-Off/Peel-Off plate (k) Alcohol Once a month.

Label available sensor (l) Air blow Once every six months.

Area Method Interval

After every roll of media (or 500

feet of fanfold media) when

printing in the direct thermal

mode.

After every roll of ribbon when

printing in the thermal transfer

mode.

Cutting

continuous,

pressuresensitive media

Cutting tagstock

or label backing

material only

Citrus

based

adhesive

remover

Alcohol and

air blow

After every roll of media or more

often, depending upon your

application and media.

After every 2 or 3 rolls of media.

Page 30

22 S400 & S600 User’s Guide

e

c

d

h

j

g

l

a

b

i

f

k

Figure 15

Page 31

S400 & S600 User’s Guide 23

Cleaning the Exterior

The exterior surfaces of the printer may be cleaned with a lint-free cloth.

Do not use harsh or abrasive cleaning agents or solvents. If necessary, a

mild detergent solution or desktop cleaner may be used sparingly.

Cleaning the Interior

Remove any accumulated dirt and lint from the interior of the printer using

a soft bristle brush and/or vacuum cleaner. Inspect this area after every roll

of media.

Cleaning the Printhead and Platen Roller

Inconsistent print quality, such as voids in the bar code or graphics, may

indicate a dirty printhead. For optimum performance, perform the

following cleaning procedure after every roll of ribbon.

NOTE: It is not necessary to turn the printer off before cleaning the

printhead. If power is turned off, all label formats and images, as well as

any temporarily saved parameter settings stored in the printer’s DRAM

memory, will be lost. When power is turned back on, it will be necessary to

reload these items.

To clean the printhead, refer to Figure 16 and follow these steps:

1. Open the media access cover and the front cover (see Figure 4).

b

c

d

Figure 16

a

Page 32

24 S400 & S600 User’s Guide

2. Open the printhead (a) by moving the head open lever (b) to the open

position.

3. Remove the media and ribbon (if present).

4. With a swab, wipe the print elements (c) from end to end (the print ele-

ments are the grayish/black strip just behind the chrome strip.) Allow a

few seconds for the solvent to evaporate.

5. Rotate the platen roller (d) and clean thoroughly with alcohol.

6. Brush/vacuum any accumulated paper lint and dust away from the roll-

ers and media sensors.

7. Reload ribbon and/or media, close and latch the printhead, close the

front cover and the media access cover, and continue printing.

If print quality has not improved after performing this procedure, try

cleaning the printhead with Save-a-Printhead cleaning film. This specially

coated material removes contamination buildup without damaging the

printhead. Call your authorized Zebra distributor for more information.

Cleaning the Cutter Module (for Printers

Equipped with the Optional Cutter)

The cutter module requires periodic cleaning to remove paper dust and

gummed label residue. The procedure on the following pages should be

performed by the operator according to the cleaning schedule table.

However, depending on your application and media type, you may need to

clean the cutter more or less frequently.

NOTE: In the figures shown, media and ribbon have been removed for

clarity. It is not necessary to remove media or ribbon before performing the

maintenance procedures described.

IMPORTANT: Do not exchange cutter modules between different

printers. The cutter module adjustments are optimized during installation to

work with a particular printer and may not perform correctly if the module

is placed on a different printer.

I. Removing the cutter module from the printer.

1.

Turn off the printer’s AC power.

See Figure 17. Remove the label catch tray (a) by lifting it up and away from

2.

the front of the cutter module (b).

3.

Raise the printer’s media access cover and lower the printer’s front cover.

See Figure 18. Gently pull straight down on the cutter cable connector (a) to

4.

remove it from the mating socket on the cutter module.

Turn the cutter mounting screw (b) with a screwdriver or by hand in a

5.

counterclockwise direction until it is loose.

See Figure 19. Hold the cutter module as shown. Apply gentle upward pressure to

6.

the left and right ends while raising the cutter module up and away from the

mounting posts (a). If necessary, rock the module side to side to loosen it.

Page 33

S400 & S600 User’s Guide 25

b

a

Figure 17

b

a

Figure 18

Page 34

26 S400 & S600 User’s Guide

a

b

Figure 19

a

Figure 20

c

b

a

Page 35

S400 & S600 User’s Guide 27

II. Disassembling the cutter module.

See Figure 20. Hold the cutter module as illustrated. Put your thumbs on the

two wire spring loops (a) and your index fingers on the top of the rear cutter

1.

blade guard (b). It may help to lay the cutter module on a table or other

surface throughout this process.

To remove the rear cutter blade guard, first press down simultaneously on the

two wire spring loops. While pressing down on the loops, press the rear

2.

cutter blade guard back toward you and over the top of the loops. (You’re

trying to tuck the loops underneath the blade guard in this process.)

Continue pressing the rear cutter blade guard toward you and allow the back

edge of the guard to pop up as the guard comes free from its holders. You

3.

may now remove the rear cutter blade guard by lifting it off of the module.

NOTE: The wire springs may flip up out of position during this process.

Springs will be repositioned during reassembly.

Observe the ends of the rear cutter blade guard and note the small metal pins

protruding toward the inside. During the reassembly procedure, these pins

4.

will be mounted into the corresponding mounting slots in the cutter side

panels.

To provide complete access to the area to be cleaned, raise the upper cutter

5.

blade guard (c) as shown in Figure 20.

III. Cleaning the cutter module.

Remove any label material which has adhered to the cutter parts and use a

1.

small brush to remove any paper dust from the cutter module.

If you use pressure-sensitive media, use a lint-free cloth soaked in an adhesive

remover to remove all gum and label residue from the cutting blades and

2.

guards.

If you use tag stock, use alcohol to remove any dirt.

IV. Reassembling the cutter module.

See Figure 21. Position the two wire springs (a) down against the lower cutter

1.

blade.

Place the rear cutter blade guard (b) over the wire springs, perpendicular to its

final position. Place your thumbs on the top (flat) part of the guard.

2.

NOTE: Insure that the ends of the rear cutter blade guard are positioned on the

outside of the cutter side panels.

Press the rear cutter blade guard down and forward, rotating the guard as you

proceed, to lock the mounting pins (c) into position in the cutter side panel

mounting slots (d). Slide the guard forward until the two wire spring loops

3.

pop up on the back side of the Guard.

NOTE: Insure that the wire springs remain positioned under the rear cutter blade

guard when assembly is completed.

Lower the upper cutter blade guard back to its normal position. When

4.

reassembled, the back of the cutter module should look like the one shown in

Figure 22.

Page 36

28 S400 & S600 User’s Guide

a

b

a

b

c

d

a

b

a

CUTTER

SIDE PANEL

Figure 21

Figure 22

CUTTER

SIDE PANEL

Page 37

S400 & S600 User’s Guide 29

V. Reinstalling the cutter module.

See Figure 19. Position the cutter module above the cutter mounting posts (a).

1.

Press down on the cutter module until the mounting slots (b) engage the

mounting posts on the printer.

See Figure 18. Tighten the mounting screw (b) in a clockwise direction to

2.

hold the cutter module in position.

See Figure 18. Position the cutter cable connector (a) so the flat side of the

3.

connector faces away from the printer, then insert it up into the mating

connector on the cutter module.

Replace the cutter catch tray onto the two mounting posts located on the

4.

front of the cutter module.

VI. Testing the Cutter Operation.

If necessary, reload ribbon and label stock into the printer, then close the

printer’s front cover and media access cover.

1.

NOTE: When loading media, make sure the end of the label is positioned on

top of the platen roller, then close the printhead open lever.

When the printer is turned on, the cutter module will cycle through one cutting

2.

operation and be ready to print labels.

OPTIONAL: Hold in the PAUSE button while turning on the printer’s AC power.

When the Power ON Self Test begins (all LEDs on), release the PAUSE button.

3.

When the Power ON Self Test ends, the printer will automatically print test labels

that the cutter module will automatically cut.

End of the cutter cleaning procedure.

Page 38

30 S400 & S600 User’s Guide

Lubrication

No lubricating agents of any kind are required on this printer. Some

commercially available lubricants will damage the finish if used.

AC Power Fuse Replacement

A user-replaceable AC power fuse (see Figure 6) is located just to the left of

the power on/off switch. For use with both voltage ranges, the replacement

fuse is a 5x20 fast blow style rated at 5 Amp/250 VAC.

1. Before replacing the fuse, turn the AC power switch off and unplug the

AC power cable.

2. To replace the fuse, insert the tip of a flathead screwdriver into the slot

in the end of the fuse holder end cap.

3. Press in slightly on the end cap and turn the screwdriver slightly counterclockwise. This will disengage the end cap from the fuse holder and

permit the removal of the fuse.

4. To install a new fuse, reverse the procedure.

Page 39

S400 & S600 User’s Guide 31

Mechanical Adjustments

This printer has been designed with minimal operator adjustments required.

Print Quality Adjustments

When changing from one media/ribbon combination to another, only slight

changes in print darkness or toggle pressure may be required. For these

situations, refer to the toggle pressure adjustment in this chapter.

I. Checking the initial print quality.

Open the media access cover and front cover on the printer (see

1.

Figure 4).

Load the recommended media and ribbon for your application and adjust the

2.

media sensor position.

Send a label format to the printer or activate the PAUSE key self test (see

3.

Troubleshooting), print a few labels, and press the PAUSE button to stop

printing.

Observe the print quality of the test labels. If it is satisfactory, exit the PAUSE

4.

key self test by pressing and holding the CANCEL button until the DATA LED

goes off. Otherwise, continue to step II.

II. Adjusting the print darkness (burn temperature).

Press the MODE button once (DARKEN and PAUSE LEDs turn on) to permit

1.

darkness adjustment.

2.

Press the PAUSE button to begin printing test labels.

While observing the print darkness, repeatedly press the UP (FEED) button to

3.

make the printing darker, or the DOWN (CANCEL) button to make the printing

lighter, until the desired darkness is achieved.

Briefly press the MODE button three times. The MODE LEDs will flash on and

4.

off to indicate that the settings have been saved in memory.

5.

Press the PAUSE button to stop printing.

NOTE: To confirm the change, turn off the printer. Then, turn on the printer

while holding the CANCEL button.

If you are still experiencing poor print quality, perform the following toggle

pressure adjustment. Otherwise, exit the PAUSE key self test by pressing

and holding the CANCEL button until the DATA LED goes off.

Toggle Pressure Adjustment

The toggle assembly presses the printhead against the ribbon (if used), the

media, and the platen.

Page 40

32 S400 & S600 User’s Guide

The pressure applied by the toggle assembly may need to be increased or

reduced when different thicknesses or widths of media are used in the

printer.

NOTE: Before increasing toggle pressure to achieve darker print darkness,

perform the print quality adjustments.

Refer to Figure 23. Turn the two knurled toggle pressure adjust knobs (a)

on top of the toggle assembly to adjust the pressure. Turning clockwise will

increase the pressure, and turning counterclockwise will decrease the

pressure.

Always use the lowest toggle pressure necessary to provide the desired print

darkness on the label.

NOTE: When using media narrower than 4.5" wide (full media width),

reduce the pressure on the right hand toggle until print quality is affected,

then increase pressure just to the point where good print quality is achieved.

This reduces the wear on those areas of the printhead and the platen where

ribbon and media are not present. (For very narrow media, zero pressure

from the right toggle may be required.)

a

Figure 23

Right

Toggle

Page 41

S400 & S600 User’s Guide 33

Media Rest Position Adjustment

This procedure sets the end-of-label position relative to the Tear-Off plate

or cutter. Adjust this if your label is not being torn or cut at the correct

point.

1. Briefly press the MODE button twice. The PAUSE and POSITION

LEDs turn on.

2. Press UP (FEED) or DOWN (CANCEL) to adjust the current setting.

3. Briefly press the MODE button twice. The MODE LEDs will flash on and

off to indicate that the settings have been saved in memory.

4. Press PAUSE to exit the pause mode. The PAUSE LED turns off.

Top of the Label Position Adjustment

This procedure positions the printing on the label relative to the top edge of

the label. Adjust this if your printing is too close or too far away from the

top or bottom edge of the label.

1. Briefly press the MODE button twice, then press and hold it for about

five seconds until the lights change. The PAUSE, DARKEN, and

CALIBRATE LEDs turn on.

2. Press UP (FEED) or DOWN (CANCEL) to adjust the current setting.

3. Briefly press the MODE button twice. The MODE LEDs will flash on

and off to indicate that the settings have been saved in memory.

4. Press PAUSE to exit the pause mode. The PAUSE LED turns off.

Media Sensor Position Adjustment

This procedure is covered in Getting Ready to Print.

Ribbon Supply Spindle Adjustment

This procedure is covered in Getting Ready to Print.

Page 42

34 S400 & S600 User’s Guide

Backing Rewind Power Roller Adjustment

(PEEL-OFF OPTION REQUIRED)

NOTE: This roller is only present on printers with the Peel-Off option.

Zebra presets this roller during manufacture for proper operation with most

applications. Only adjust this roller when necessary.

In the Peel-Off mode, proper media tracking is critical. The rewind power

roller automatically turns along with the movement of media, to insure

continuous rewind of the label backing material. When adjusting this roller,

the operating position may vary due to the type, width, and thickness of the

backing material.

Before performing this adjustment, review the media loading procedure in

Getting Ready to Print. Insure minimal sideways movement during the

printing process by positioning the left edge of the label backing even with

the edge guide mark on the tear-off/peel-off plate. Position the media

guides against the outside (right) edge of the media, but not so tight as to

bind the material.

When the power roller is properly adjusted, the backing material should

have even tension across its entire width and be wrapped snugly around all

guides and rollers. If the tension is not even, the media/backing material

may slide (walk) to the left or to the right as printing occurs. This can cause

print registration problems on the labels.

Left

Edge

Right

Edge

b

d

Figure 24

Up

a

c

Down

e

Page 43

S400 & S600 User’s Guide 35

Figure 24 illustrates an improperly adjusted backing rewind power

roller (a). On the left side, the backing material (b) is not contacting the

power roller. The backing has more tension on the right edge (c) than on

the left edge (d).

Use a coin or screwdriver to turn the power roller adjustment (e). The

adjustment mechanism changes the position of the right end of the roller,

while the left end is stationary. The right end moves up and down for

tension balance.

Turning this adjustment in a counterclockwise direction causes the right end

of the power roller to move down and increases the tension on the right side

of the backing material. (Turning the adjustment in a clockwise direction

moves the right end of the power roller up and decreases the tension on the

right side.)

Balancing the tension increases the reliability of the printer to provide

properly printed labels by preventing the label backing from walking.

Use the FEED key self test (see Troubleshooting) or your own label format

to print several labels to insure tracking is maintained and tension on both

edges of the backing material remains consistent. Remember to remove

each label as it is automatically peeled away from the backing.

Page 44

36 S400 & S600 User’s Guide

Page 45

S400 & S600 User’s Guide 37

Troubleshooting

If the printer operates in an abnormal fashion, consult the troubleshooting

table below. The printer diagnostics following the troubleshooting table

may also help you to determine the problem.

The troubleshooting of some problems may be beyond the abilities of the

operator. In these cases, call a service technician to perform additional

troubleshooting and repair procedures.

Troubleshooting Table

Symptom Diagnosis Action

No LEDs turn on.

Printer locks up with all

LEDs on when running

the Power-on self test.

CALIBRATE LED is off but

all other LEDs are on.

CALIBRATE and

POSITION LEDs off but

all other LEDs on.

CALIBRATE, POSITION,

and DARKEN LEDs off

but all other LEDs on.

CALIBRATE, POSITION,

DARKEN, and DATA

LEDs off but all other

LEDs on.

CALIBRATE, POSITION,

DARKEN, DATA, and

PAUSE LEDs off but all

other LEDs on.

No AC power

applied to the

printer.

Faulty AC power

fuse.

No voltage

available from the

internal power

supply.

Hardware failure. Call a service technician.

Boot-block CRC

error.

DRAM error. Call a service technician.

Firmware

decompression

error.

Firmware error.

Firmware error.

Insure the AC power cable is

connected to a working voltage

source.

Replace the fuse.

Call a service technician.

Call a service technician.

Call a service technician for

instructions on how to download

and install firmware.

Page 46

38 S400 & S600 User’s Guide

Symptom Diagnosis Action

Printer stops, PAUSE LED

and PAPER/RIBBON LED

both on.

Printer stops, PAUSE

LED on and PAPER/

RIBBON LED flashing.

Printer stops, PAUSE

LED on and PRINTHEAD

LED flashing.

Printer stops, PAUSE

LED and PRINTHEAD

LED both on.

Printer will not

successfully perform an

auto calibration.

Printer will not perform a

manual calibration.

Printing continues,

PRINTHEAD LED on.

PAUSE LED flashing.

Media incorrectly

or not loaded.

Cutter error.

Calibration error. Re-calibrate printer.

Misadjusted

media sensor.

Are you using

pre-printed

media?

Ribbon

incorrectly or not

loaded.

Backing rewind

spindle is full.

Malfunctioning

ribbon sensor.

Ribbon not

calibrated.

Printhead is not

fully closed.

Printhead open

sensor not

detecting its

position flag.

Printhead

element is

overheated.

Power supply

over temperature.

Printhead open. Close the printhead.

You’re using

pre-printed

labels.

Media is out.

Media is out of

specification.

Hardware failure. Call a service technician.

Printhead is

under

temperature.

Waiting for user

to peel label.

Load media correctly, then turn the

printer off and on. See Getting

Ready to Print.

Clear jam, then open and close the

printhead.

Check position and sensitivity of

media sensor. See Getting Ready

to Print.

Calibrate the printer. Refer to

Getting Ready to Print.

Load ribbon correctly, then turn the

printer off and on. See Getting Ready

to Print.

Remove label backing from the

spindle.

Call a service technician.

Calibrate the ribbon. Refer to

“Resetting Ribbon Parameters”

later in this chapter.

Close printhead completely, then

turn the printer off and on.

Call a service technician.

Printer resumes printing when the

printhead element cools.

Printer resumes printing when the

power supply cools.

Perform a manual calibration. See

“Manual Calibration” later in this

chapter.

Load media. Ensure that the media

sensor is properly positioned.

Ensusre that the media sensor is

properly positioned. Or, perform a

manual calibration. See “Manual

Calibration” later in this chapter.

Continue printing.

Remove label.

Page 47

Symptom Diagnosis Action

DATA LED is single

flashing.

PAUSE LED and DATA

LED alternately flashing,

but all other LEDs on.

DATA LED is flashing.

DATA LED is slow

flashing.

Dots missing in printed

area of label.

Loss of printing

registration on labels.

For Peel-Off mode:

Excessive vertical drift in

top-of-form registration.

Light vertical lines

approximately .006 wide

running through all

labels.

Light printing or no

printing on the left or

right side of the label.

Short printed lines at 45°

to label edge on left or

right side of label.

CANCEL button

was pressed and

a format was

deleted.

Firmware error.

Printer is

receiving data.

Printer sent a

“stop

transmitting” to

the host

computer.

Dirty printhead.

Printhead

element going

bad. Print quality

problems.

Print width set

incorrectly.

Possible media

sensor problem.

Printer set for

non-continuous

media, but

continuous media

loaded.

Improperly

adjusted media

edge guides or

power roller.

Incorrect media

loading or media

sensor

adjustments.

Dirty head or

ribbon rollers.

Defective printhead

elements.

Printhead needs

balancing.

Too much

printhead

pressure.

No action required.

Call a service technician for

instructions on how to download

and install firmware.

Printing resumes when data is

received.

No action required.

Clean the printhead. See Routine

Care and Adjustments.

Call a service technician.

Default the printer. Refer to

“Resetting Factory Defaults” later in

this chapter.

Adjust media sensor position and

call a service technician if

necessary.

Set printer for correct media. See

Getting Ready to Print.

Refer to Getting Ready to Print and

Routine Care and Adjustments for

proper positioning and

adjustments.

See “Loading the Media” or

“Adjusting the Media Sensor” in

Getting Ready to Print.

See “Printhead Cleaning” in

Routine Care and Adjustments.

Call a service technician.

Adjust balance. See “Toggle

Pressure Adjustment” in Routine

Care and Adjustments.

Reduce the pressure. See “Toggle

Pressure Adjustment” in Routine

Care and Adjustments.

S400 & S600 User’s Guide 39

Page 48

40 S400 & S600 User’s Guide

Symptom Diagnosis Action

Truncated print, no

print, or FEED button

operates incorrectly

while using

non-continuous media.

Fine gray lines on blank

labels at angles.

Long tracks of missing

print on several labels.

Wrinkled ribbon.

In Peel-Off mode,

skewed or stuck labels.

Image is not positioned

correctly and/or misprint

of 1 to 3 labels.

Media or ribbon

improperly

loaded.

Incorrect media

sensor position or

sensitivity.

Wrinkled ribbon. See “Wrinkled Ribbon” in this table.

Wrinkled ribbon. See “Wrinkled Ribbon” in this table.

Print element

damaged.

Ribbon fed

through machine

incorrectly.

Incorrect

darkness setting.

Incorrect

printhead

pressure.

Incorrect

dual-tension

spindle setting.

Media not feeding

properly; it is

walking from side

to side.

Continuing

symptoms.

Glue material

from back of

labels causing

media movement

problems.

Media and

backing not

properly aligned

in printer.

Media was pulled

when motor was

not moving.

Incorrect media

sensor position.

Media or ribbon

improperly

loaded.

Auto calibrate

failed.

See “Loading the Media” and

“Loading the Ribbon” in Getting

Ready to Print.

See “Adjusting the Media Sensor”

in Getting Ready to Print.

Calibrate. See “Auto Calibration” in

Getting Ready to Print.

Call a service technician.

See ribbon loading in Getting

Ready to Print.

Set to the lowest value needed for

good print quality.

See “Toggle Pressure Adjustment”

in Routine Care and Adjustments.

Pull spindle end cap out when

using wide media to obtain normal

(higher) tension. See “Loading the

Ribbon” in Getting Ready to Print.

Make sure the media is snug by

adjusting the media guides.

Call a service technician.

Refer to Routine Care and

Adjustments and perform

maintenance and cleaning of the

printer.

Refer to Getting Ready to Print and

Routine Care and Adjustments;

reload media and adjust the power

roller, if needed.

Open and close the printhead, so it

calibrates to find the label length.

See “Adjusting the Media Sensor

Position” in Getting Ready to Print.

See “Loading the Media” and

“Loading the Ribbon” in Getting

Ready to Print.

Perform a manual calibration. See

“Manual Calibration” later in this

chapter.

Page 49

Symptom Diagnosis Action

Reload the factory defaults (see

“FEED Key and PAUSE Key” later in

this chapter), calibrate the printer,

then cycle the power on/off switch.

Call a service technician.

See “Loading the Ribbon” in

Getting Ready to Print to adjust the

ribbon supply spindle to provide

low tension.

Print configuration label and verify

that the host computer and printer

settings match. If they do, perform

the MODE key self test and check

for format or overrun errors. If

they do not, refer to

“Communicating with the Printer”

in Getting Ready to Print.

Set the characters in the printer to

match the ZPL format.

Check configuration printout for

correct characters.

If problem continues, check the

ZPL format for changed ^CC,

^CT, and ^CD instructions.

Changes in parameter

settings did not take

effect.

When using wide ribbon

(over 2.4"), the image

gets lighter or smears

near the end of the roll

of ribbon. Ribbon

appears to slow down or

stop.

ZPL was sent to printer,

but not recognized. The

DATA LED remains off.

Parameters are set

or saved

incorrectly.

If problem

continues, there

may be a

problem on the

main logic board.

Too much

back-tension on

the ribbon.

Communications

parameters are

set incorrectly.

Prefix and

delimiter

characters set in

printer

configuration do

not match the

ones sent in the

ZPL label formats.

S400 & S600 User’s Guide 41

Page 50

42 S400 & S600 User’s Guide

In cutter mode, skewed,

stuck, improperly cut or

partially cut labels.

The cutter is jamming

up with labels, or labels

are being cut more than

once.

Labels are not being cut

at all.

Printing stops,

PAPER/RIBBON, PAUSE,

and CANCEL LEDs on.

For printers with the

cutter option installed.

Cutter is dirty.

Cutter blades are

dull.

Cutter is dirty.

Label length is

too short.

Cutter option not

enabled.

Connecting cable

not connected to

cutter module.

Out of media. Load media.

Media jammed in

cutter.

Cutter module is

dirty.

End of the media

not positioned

correctly on top of

platen.

If error condition persists after attempting each of the

above solutions, call a service technician.

Follow cutter cleaning procedure in

Routine Care and Adjustments.

Call a service technician.

Follow cutter cleaning procedure in

Routine Care and Adjustments.

Increase label length.

See Routine Care and

Adjustments.

With printer power off, plug cable

into cutter module.

Remove media, clean cutter

module if necessary.

Clean cutter module. See Routine

Care and Adjustments.

Reposition media so that the end is

on top of the platen. See Getting

Ready to Print.

Page 51

S400 & S600 User’s Guide 43

Printer Status Sensors

The printer contains several status sensors. These sensors alert the operator

to various conditions by either stopping the printing or turning on an LED.

Sensor What it Monitors How it Works

Printhead

sensor

Media sensor

(See Getting

Ready to Print

to adjust this

sensor.)

Ribbon sensor

Label available

sensor (PeelOff option

required. See

Figure 25.)

Backing rewind

spindle full

sensor (PeelOff option

required. See

Figure 26.)

Checks the open/ closed

status of the printhead

lever.

Checks for proper

media loading.

If non-continuous media

is used, sets label length

for individual labels.

Monitors the presence

of ribbon.

In Peel-Off mode, it

checks to see if a label

is available.

Senses when the

backing rewind spindle

is full of used backing

material.

If the printhead is open, the

PRINTHEAD LED flashes.

If you run out of paper, the

PAPER/RIBBON LED will turn on.

If you run out of ribbon, the PAPER/

RIBBON LED flashes.

Once a label prints, it will pass

between the two parts of this sensor

and cause the printer to pause.

When the label is removed, printing

resumes.

When the spindle is full, the

PAPER/RIBBON LED flashes.

Page 52

44 S400 & S600 User’s Guide

Label

Available

Sensor

Tear-Off/

Peel-Off

Plate

Edge Guide Mark

Figure 25

Figure 26

Rewind

Spindle Full

Sensor

Page 53

S400 & S600 User’s Guide 45

Manual Calibration

Perform a manual calibration whenever you are using pre-printed

media, if the printer is in manual calibration mode, or when the printer

will not auto calibrate.

During this procedure, the media type, label length, media and ribbon

sensor settings, and printing method are determined. Media type is

determined by sensing either continuous or non-continuous media as blank

labels move through the printer. If non-continuous media is sensed, label

length is also calibrated. If ribbon is sensed, the thermal transfer print

method is configured; otherwise, the direct thermal print method is

configured.

The results of this calibration are stored in the printer’s memory and are

retained even if printer power is removed. These parameters remain in

effect until the next calibration is performed.

NOTES: This procedure should only be done once to put the printer into

manual calibration. After that, press the MODE button three times and the

FEED button once when you change media (a label will print that shows the

sensor profile).

If the printer is in the Peel-Off mode, the operator must “catch” the labels as

they are peeled away from the backing during this procedure.

1. Place the head open lever in the open position.

2. Remove the ribbon.

3. Remove approximately 6” of labels from the media roll, enough so that

only the backing material is threaded under the media sensor when the

media is loaded.

4. Reload the media.

5. Press and hold down the PAUSE, FEED, and CANCEL buttons.

6. Turn on the power switch.

7. After the CALIBRATE LED goes out, release the PAUSE, FEED, and

CANCEL buttons.

8. When the PRINTHEAD LED flashes, reload the ribbon.

9. Make sure the media sensor is properly positioned.

10.Close the printhead.

11.A media and ribbon sensor profile will print.

NOTE: To return to Auto Calibration, press and hold the PAUSE,

CANCEL, and MODE buttons when you turn on the printer.

Page 54

46 S400 & S600 User’s Guide

Resetting Printer Parameters

Resetting Factory Defaults

If it is ever necessary to reset all of the factory default values, press and

hold the FEED and PAUSE buttons while turning on the power.

Permanently save these values in memory by pressing the MODE button

four times; the DARKEN, POSITION, and CALIBRATE LEDs will flash,

indicating the changes have been saved. To return to printing mode, turn

off and then turn on the printer.

Resetting Communications Parameters

Pressing and holding the FEED, PAUSE, and MODE buttons while turning

on the power resets only the communications parameters to 9600 baud, 8 bit

word length, no parity, and 1 stop bit. Permanently save these values in

memory by pressing the MODE button four times; the DARKEN,

POSITION, and CALIBRATE LEDs will flash, indicating the changes have

been saved.

Resetting Ribbon Parameters

If it is ever necessary to reset the ribbon parameters to the factory default

values, follow this procedure:

1. Turn off the printer.

2. Open the printhead and remove the ribbon.

3. Turn on the printer while pressing and holding the FEED, CANCEL,

and MODE buttons.

4. After the PRINTHEAD LED flashes, reload the ribbon.

5. Close the printhead.

NOTE: A label automatically prints, showing the ribbon sensor profile.

6. To save, press the MODE button four times.

Page 55

S400 & S600 User’s Guide 47

Printer Diagnostics

Power-On Self Test

A Power-On Self Test (POST) is performed automatically each time the printer

is turned on. This test checks for proper initialization of various electronic

circuits and establishes starting parameters as those stored in the printer’s

memory. During this test sequence, the front panel lights will turn on and off to

insure proper operation.

At the end of this self test, only the POWER LED will remain lit. If other

LEDs are also lit, refer to the troubleshooting table.

Additional Printer Self Tests

These self tests produce sample labels and provide specific information that

help the operator determine the operating conditions for the printer.

Each self test is enabled by holding in a specific front panel button while

turning the power switch on. Keep the button depressed until the

CALIBRATE LED goes out. When the Power-On Self Test is complete,

the selected printer self test will automatically start. To return to printing

mode, turn off and then turn on the printer.

NOTES:

n

When performing self tests, disconnect all communications interface

cables from the printer.

n

When canceling a self test before its actual completion, always turn the

printer power switch off and back on.

n

When performing these self tests while in the Peel-Off mode, the

operator must remove the labels as they become available.

n

When the cutter option is installed and enabled, the labels printed in

these self tests should be automatically cut as they are printed.

Page 56

48 S400 & S600 User’s Guide

CANCEL Key Self Test

This self test prints the printer’s configuration parameters (for example,