Page 1

Psion Teklogix

WORKABOUT PRO HDK

User Manual

September 12 2007 Part No. 8100057.C

ISO 9001 Certified

Quality Management System

Page 2

© Copyright 2007 by Psion Teklogix Inc., Mississauga, Ontario

This document and the information it contains is the property of Psion Teklogix Inc., is issued in

strict confidence, and is not to be reproduced or copied, in whole or in part, except for the sole

purpose of promoting the sale of Psion Teklogix manufactured goods and services. Furthermore,

this document is not to be used as a basis for design, manufacture, or sub-contract, or in any

manner detrimental to the interests of Psion Teklogix Inc.

Windo ws® and th e Windows Logo are trademarks or registered trademarks of Microsoft Corporation in the United States and/or other countries.

The Bluetooth® word mark and logos a re registered trademarks owned by Bluetooth SIG, Inc.

and any use of such trademarks by Psion Teklogix Inc. is under license.

All trademarks are the pr operty of their respective holders.

Page 3

Return-To-Factory Warr anty

Psion Teklogix Inc. provides a return to factory warranty on this product for a period of twelve

(12) months in accordance with the Statement of Limited Warranty and Limitation of Liability

provided at www .psionteklogix.com/warranty . (If you are not already a member of T eknet and yo u

attempt to view this warranty, you will be asked to register. As a member of Teknet, you will have

access to helpful information about your Psion T eklogix products at no char ge to you .) In some regions, this warranty may exceed this period. Please contact your local Psion Teklogix office for

details. For a list of offices, see Appendix A: “Support Services / Worldwide Offices”. The warranty on Psion Teklogix manufactured equipment does not extend to any product that has been

tampered with, altered, or repaired by any person other than an employee of an authorized Psion

Teklogix service organization. See Psion Teklogix terms and conditions of sale for full details.

W arning: Psion Teklogix warranties take effect on the date of shipment.

Service

Psion Teklogix provides a complete range of product support services to its customers. For detailed information, please refer to Appendix A: “Support Services / Worldwide Offices”. This

section also provides information about accessing support services through the Psion Teklogix

web site.

Waste Electrical and Electronic Equipment (WEEE) Directive 2002/96/EC

This Product, and its accessories, comply with the requirements of the Waste Electrical and Electronic Equipment (WEEE) Directive 2002/96/EC. If your end-of-life Psion Teklogix product or

accessory carries a label as shown here, please contact your local country representative for details

on how to arrange recycling.

For a list of international subsidiaries, please go to:

www.psionteklogix.com/EnvironmentalCompliance

Page 4

Restriction On Hazardous Substances (RoHS) Directive 2002/95/EC

What is RoHS?

The European Union has mandated that high environmental standards be met in the design and

manufacture of electronic and electrical products sold in Europe, to reduce hazardous substances

from entering the environment. The “Restriction on Hazardous Substances Directive (RoHS)” prescribes the maximum trace levels of lead, cadmium, mercury, hexavalent chromium, and flame

retardants PBB and PBDE that may be contained in a product. Only products meeting these high

environmental standards may be “placed on the market” in EU member states after July 1, 2006.

RoHS Logo

Although there is no legal requirement to mark RoHS-compliant products, Psion Teklogix Inc. indicates its compliance with the directive as follows:

The RoHS logo located either on the back of the product or underneath the battery in the battery

compartment (or on a related accessory such as the charger or docking station) signifies that the

product is RoHS-compliant as per the EU directive. Other than as noted below, a Psion Teklogix

product that does not have an accompanying RoHS logo signifies that it was placed on the EU

market prior to July 1, 2006, and is thereby exempt from the directive.

Note: Not all accessories or peripherals will have a RoHS logo due to physical space limitations

or as a result of their exempt status.

Disclaimer

Every effort has been made to make this material complete, accurate, and up-to-date. In additio n,

changes are periodically added to the information herein; these changes will be incorporated into

new editions of the publication.

Psion Teklogix Inc. reserves the right to make improvements and/or changes in the product(s)

and/or the program(s) described in this document without notice, and shall not be responsible for

any damages, including but not limited to consequential damages, caused by reliance on the material presented, including but not limited to typographical errors.

Page 5

TABLE OF CONTENTS

Chapter 1: Introduction

1.1 About This Ma nual.........................................................................................3

1.2 Text Conventions...........................................................................................4

1.3 Contents Of The HDK......................................................................................4

1.3.1 Files In The HDK..................................................................................4

1.4 Obtaining The HDK........................................................................................6

1.5 About the WORKABOUT PRO Hand-Held Computer .....................................................6

1.6 Discontinued Hardware.....................................................................................7

Chapter 2: Hardware

2.1 Overview ......................................................................... .........................11

2.2 Variants Of The WORKABOUT PRO.....................................................................11

2.2.1 Scanner Variants................................................................................. 11

2.2.2 Expansion Card Variants......................................................................... 11

2.3 WORKABOUT PRO C, S, M, ME........................................................................ 11

2.3.1 Main Processor................................................................................... 11

2.3.2 Peripheral Processors............................................................................. 12

2.4 WORKABOUT PRO 2nd. Generation C, S............................................................... 13

2.4.1 Main Processor................................................................................... 13

2.4.2 Peripheral Processors............................................................................. 13

2.5 Identifying Hardware..................................................................................... 15

2.6 The LED ................................................................................................. 1 5

2.7 Connectors ....... ........................................................................................ 15

2.8 Power Management....................................................................................... 15

2.8.1 Batteries..................................................................... ..................... 16

2.9 Switching Th e Backup Battery Power On And Off........................................................ 16

2.10 Connector Locations...................................................................................... 17

Chapter 3: Software

3.1 Overview ......................................................................... ........................ 21

3.2 Windows Drivers......................................................................................... 21

3.2.1 The Peripheral Control (PCO) Driver............................................................. 21

3.2.2 The PCMCIA Driver............................................................................. 21

3.2.3 The Serial Port Driver............................................................................ 21

3.3 Non-PsionTeklogix Drivers .............................................................................. 21

3.3.1 Installation .................................... ................................................... 21

3.3.2 Drivers In Windows Mobile 6.................................................................... 21

3.4 System Initialization...................................................................................... 22

3.5 Registry Keys............................................................................................. 22

3.5.1 Registry Settings For Controlling VGA........................................................... 22

3.5.2 Registry Settings For Serial Po rts................................................................. 22

3.5.3 Registry Settings For PsionTeklogix Device D rivers............................................. 23

3.5.4 Registry Settings For Non-PsionTeklogix Device Drivers........................................ 23

3.5.4.1 Loading Non-PsionTeklogix Device Drivers........................................... 24

Psion Teklogix WORKABOUT PRO HDK User Manual i

Page 6

Contents

3.6 COM Port Assignments................................................................................... 24

3.7 The C++ Application Programming Interface ... ................. ......................................... 25

3.7.1 Installing The Software...........................................................................25

3.7.2 Development Pl atforms...........................................................................26

3.7.3 The Interrupts Namespace........................................................................ 26

3.7.4 The ExpansionW akeup Namespace............................................................... 26

3.7.5 The GPIO Namespace............................................................................ 26

3.7.6 The EEPROM Namespace........................................................................ 26

3.7.7 The ExpansionU SB Namespace..................................................................26

3.7.8 The USBhub Namespace......................................................................... 27

3.7.9 The ScannerPort Namespace ..................................................................... 27

3.7.10 The smBus Namespace...........................................................................27

3.7.11 The PCMCIA Namespace........................................................................ 27

Chapter 4: Mechanical Considerations

4.1 Overview .................................... ............................................................. 31

4.2 HDK Mechanical Files....................................................................................31

4.3 Installation.................................................................... ............................ 33

4.3.1 Endcap-Mounte d Device Inst allation ............................................................. 33

4.3.2 Backplate-Mou nted Device Installation........................................................... 33

4.3.3 Expansion Module Installation.................................................................... 34

4.4 Location And Construction ...............................................................................34

4.4.1 Materials ............... .......................................................................... 34

4.4.2 Backplate-Mou nted Device....................................................................... 35

4.4.3 Expansion Module................................................................................ 35

4.4.3.1 100-Pin Connector .....................................................................35

4.4.3.2 Mounting Frame ....................................................................... 36

4.4.4 Endcap, Card Stop, And Stylus...................................................................36

4.4.5 Bottom Footprint................................................................................. 37

Chapter 5: External Connectors

5.1 Overview Of External Connectors, Cables, And Accessories.............................................. 41

5.2 Extern al Connectors On The WORKABOUT PRO....................................................... 41

5.2.1 WORKABOUT PRO C, S, M, ME............................................................... 41

5.2.2 WORKABOUT PRO 2nd. Generation C, S....................................................... 42

5.3 The LIF Connector........................................................................................ 44

5.3.1 Sensing Device Presence.........................................................................44

5.4 The Tether Connector.....................................................................................44

5.4.1 The WORKABOUT PRO C, S, M, ME Tether Connector........................................ 44

5.4.1.1 COM2: Serial Port..................................................................... 45

5.4.1.2 Sensing Device Presence...............................................................46

5.4.2 The WORKABOUT PRO 2nd. Generation C, S Tether Connector................................ 47

5.4.2.1 Sensing Device Presence...............................................................48

5.4.3 Cables For the Tether Connector..................................................................48

5.5 The WORKABOUT PRO C , S, M, ME Audio Connector.................................................48

5.6 Docking Stations..........................................................................................49

5.6.1 Single Unit Docking Stations..................................................................... 49

5.6.1.1 The USB Host Connector .............................................................. 50

5.6.1.2 The USB Client Con nector.............................................................50

5.6.2 Four Unit Multi-Dock Docking St ation (Quad Docker)...........................................51

ii Psion Teklogix WORKABOUT PRO HDK User Manual

Page 7

Contents

5.7 Vehicle Cradles........................................................................................... 52

5.7.1 The Vehicle Cradle 15-Pin Connector............................................................ 53

5.8 Port Replica tor............................................................................................ 54

5.8.1 The Serial Connectors............................................................................ 56

5.9 Other Cables And Adaptors............................................................................... 56

5.10 Mechanical Considerations ............................................................................... 56

Chapter 6: Internal Connectors

6.1 Overview ......................................................................... ........................ 59

6.2 WORKABOUT PRO 2nd. Generation C, S Audio Connector............................................. 59

6.2.1 Cables................................................................ ............................ 59

6.3 WORKABOUT PRO 2nd. Generation C, S USB Connecto r.............................................. 59

6.3.1 Cables................................................................ ............................ 60

6.4 100-Pin Connector........................................................................................ 60

6.5 Scanner Connector........................................................................................ 60

Chapter 7: 100-Pin Connector

7.1 Overview ......................................................................... ........................ 63

7.1.1 Signals On The 100-Pin Connector............................................................... 63

7.1.2 Connector Type.................................................................................. 63

7.1.3 Connector Position And Orientation.............................................................. 64

7.2 100-Pin Connector Pinout................................................................................. 64

7.3 Power And Ground....................................................................................... 69

7.4 Data And Address Buses.................................................................................. 70

7.5 Serial ..................................................................................................... 70

7.6 USB ............................................................. ......................................... 71

7.7 General-Purpose I/O...................................................................................... 71

7.8 General-Purpose Interrupts................................................................................ 72

7.9 PCMCIA .............................................. ................................................... 72

7.10 Wakeup.............................................................................. ..................... 73

7.11 I2C Device Identification................................................................................. 73

7.11.1 I2C Addresses.................................................................................... 74

7.11.2 Expansion Module EEPROM Fields.............................................................. 75

7.12 Example Expansion Modules............................................................................. 76

7.13 PsionTeklogix Serial Endcaps............................................................................ 77

7.13.1 Serial Port Assignments.......................................................................... 77

7.14 WORKABOUT PRO 2nd. Generation C, S USB Connecto r.............................................. 77

Chapter 8: Scanner Connector

8.1 Overview ......................................................................... ........................ 81

8.2 Scanner Kits.............................................................................................. 82

8.3 Scanner Connector Location.............................................................................. 83

8.4 Scanner Connector Pinout ................................................................................ 83

8.5 The Scanner Flex......................................................................................... 85

8.6 Power And Ground....................................................................................... 85

8.7 Signals To The Scanner Device........................................................................... 86

Psion Teklogix WORKABOUT PRO HDK User Manual iii

Page 8

Contents

Chapter 9: Example: Scanner Converter Board

9.1 Overview .................................... ............................................................. 91

9.2 Example Scan ner Boards..................................................................................91

9.2.1 Serial Sc anner Board............................................................................. 91

9.3 Power And Ground.......................................................................................96

9.4 Signals To The Scanner Module........................................................................... 96

9.4.1 Serial Signals..................................................................................... 96

9.4.2 USB Signals...................................................................................... 97

9.4.3 Control Signals...................................................................................97

Chapter 10: Example: PCMCIA Expansion Module

10.1 Overview .................................... ............................................................ 101

10.2 Installation.................................................................... ...........................101

10.3 Dimensions................................................................................. .............101

10.4 Expansion Module Connectors...........................................................................101

10.5 Electrical ............................................................................ ....................102

10.5.1 PCMCIA Compatibility .........................................................................102

10.5.2 The Card Detect Signals.........................................................................103

10.5.3 The Buffer Enable Signals.......................................................................103

10.5.4 The Slot Power Enable Signal ...................................................................103

10.5.5 Selectab le Card Supply Voltage .................................................................103

10.6 EEPROM Data ..........................................................................................104

Chapter 11: Example: Multi-I/O Expansion Module

11.1 Overview .................................... ............................................................ 107

11.2 Schematics...................... ......................................................................... 108

11.3 Connectors...................... ......................................................................... 108

11.3.1 Main Logic Board 100-Pin Connector (J1).......................................................109

11.3.2 Main Logic Board Scanner Connector (J2).......................................................109

11.3.3 Scanner-Port Serial Connector (J3)..............................................................109

11.3.4 USB Host Port 2 Connector (J4).................................................................1 10

11.3.5 The FF UART Serial Connector (J5).............................................................110

11.3.6 The USB Host 1 Connector (J6).................................................................112

11.3.7 The Power Conne ctor (J7).......................................................................113

11.4 Configuration..... ....................................................................................... 113

11.4.1 Slot Power Control..............................................................................114

11.4.2 EEPROM Write Control.........................................................................114

11.4.3 Voltage Configuration For Stan dard-Power Output..............................................115

11.4.4 Voltage Configuration For High-Power Output..................................................116

11.4.5 Control Signals For FFUART Level Converter ..................................................117

11.4.6 TTL Output Option For Scanner Serial Port ... .......... ........................................118

11.5 Power And Ground......................................................................................118

11.6 EEPROM Data ..........................................................................................119

11.7 Installation.................................................................... ...........................119

iv Psion Teklogix WORKABOUT PRO HDK User Manual

Page 9

Contents

Appendices

Appendix A: Support Services / Worldwide Offices

A.1 Technical Su pport........................................................................................A-1

A.2 Product Repairs..........................................................................................A-1

A.3 Worldwide Offic es.......................................................................................A-2

A.3.1 Company Headquarters..........................................................................A-2

A.3.2 Canadian Service Centre ........................................................................A-2

A.3.3 North American Headquarters And U.S. Service Centre.........................................A-2

A.3.4 International Subsidiaries .......................................................................A-3

Appendix B: Resources

B.1 PsionTeklogix WORKABOUT PRO User Manuals.....................................................B-1

B.2 Other PsionTeklogix Manuals...........................................................................B-1

B.3 PsionTeklogix Downloada ble Software..................................................................B-1

B.4 PsionTeklogix Accessory And Parts Information ........................................................B-1

Appendix C: Specifications WORKABOUT PRO M

C.1 Hand-Held Computer Specifications WORKABOUT PRO M ...........................................C-3

C.2 Radio Specifications..................................................................................... C-4

C.3 Scann er Options.........................................................................................C-5

C.4 Batte ry Specifications....................................................................................C-5

C.4.1 Standard Battery Pack...........................................................................C-5

C.4.2 High-Capacity Battery Pack..................................................................... C-6

Appendix D: Specifications WORKABOUT PRO C, S & ME

D.1 Hand-Held Computer Specifications.....................................................................D-3

D.1.1 Model Variants..................................................................................D-3

D.2 WORKABOUT PRO C Variant..........................................................................D-3

D.3 WORKABOUT PRO S Variant..........................................................................D-4

D.4 WORKABOUT PRO ME Variant .......................................................................D-4

D.5 WORKABOUT PRO C, S, and ME Variants.............................................................D-5

D.6 Radio Option s...........................................................................................D-7

D.7 Scanner Opti ons.........................................................................................D-7

D.8 Battery Opti ons..........................................................................................D-7

Appendix E: WORKABOUT PRO 2nd. Generation

E.1 WORKABOUT PRO Specifications..................................................................... E-3

E.1.1 WORKABOUT PRO C Variant.................................................................E-3

E.1.2 WORKABOUT PRO S Variant................................................................. E-3

E.1.3 WORKABOUT PRO All Variants.............................................................. E-3

E.2 Radio Option s........................................................................................... E-8

E.3 Battery Opti ons.......................................................................................... E-8

E.4 Scanner Opti ons......................................................................................... E-8

E.4.1 Scanner/Imager Model Numbers ................................................................ E-8

Appendix F: Specifications WORKABOUT PRO Radios

F.1 Radio Specifications..................................................................................... F-3

F.2 802.11g Direct Sequence Spread Spectrum (Model RA2040) ............................................ F-3

F.3 802.11b/g Direct Sequ ence Spread Spectrum (DSSS) (Model RA2041).................................. F-3

Psion Teklogix WORKABOUT PRO HDK User Manual v

Page 10

Contents

F.4 GSM/GPRS/EDGE Radio (Model RA3030-G2)......................................................... F-4

F.5 Bluetooth Radio.......................................................................................... F-5

Appendix G: Specifications Scanners And Imagers

G.1 Scanner and Imager Specifications.......................................................................G-3

G.2 Scanner Specifications...................................................................................G-3

G.2.1 SE 1223HP, LR, ALR And SE 955HP Specifications............................................G-3

G.3 Imager Specifications....................................................................................G-6

G.3.1 EV15 Imager Specifications.....................................................................G-6

G.3.2 HHP5180 Imager Specifications.................................................................G-7

G.3.3 SX5393 Imager Specifications ...................................................................G-8

G.3.4 SX5400 Imager Specifications ..................................................................G-1 0

Appendix H: Specifications WORKABOUT PRO Batteries

H.1 Battery Specification s....................................................................................H-3

H.2 Standard Capacity–2000 mAh (Model WA3000-G1).....................................................H-3

H.2.1 Electric al Specifications.........................................................................H-3

H.2.2 Standard Discharge..............................................................................H-4

H.2.3 Environmental Test..............................................................................H-5

H.3 High-Capacity 3000mAh (Model WA3006)..............................................................H-6

H.3.1 Electric al Specifications.........................................................................H-6

H.3.2 Standard Discharge..............................................................................H-7

H.3.3 Safety Data......................................................................................H-8

H.3.4 Safety Lic ense...................................................................................H-8

H.3.5 Environmental Test..............................................................................H-8

H.4 Super High-Capacity (Model WA3010)..................................................................H-9

H.4.1 Electric al Specifications.........................................................................H-9

H.4.2 Standard Discharge.............................................................................H-10

H.4.3 Safety Data.....................................................................................H-1 1

H.4.4 Safety Lic ense..................................................................................H-1 2

H.4.5 Environmental Test.............................................................................H-12

H.5 Maxell ML2032 Rechargeable Coin Battery ............................................................H-13

H.6 WORKABOUT PRO 2nd. Generation (C And S) Internal Battery ......................................H-13

Appendix I: Hardware Developer Kit License Agreement

I.1 HARDWARE DEVELOPER KIT LICENSE AGREEMENT.............................................I-3

I.2 GRANT OF LICENSE ...................................................................................I-3

I.3 DESCRIPTION OF REQUIREMENTS, RESTRICTIONS, RIGHTS AND LIMITATIONS ..............I-3

I.4 HIGH RISK ACTIVITIES. ...............................................................................I-4

I.5 DISCLAIMER OF WARRANTY ........................................................................I-4

I.6 LIMITATION OF LIABILITY............................................................................I-4

I.7 COPYRIGHTS, OWNERSHIP AND PROPRIETARY RIGHTS .........................................I-4

I.8 CONFIDENTIALITY .......................... ..........................................................I-5

I.9 ENDING THIS AG REEMENT...........................................................................I-5

I.10 GENERAL .... ......................................................................... ..................I-5

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . I

vi Psion Teklogix WORKABOUT PRO HDK User Manual

Page 11

INTRODUCTION 1

1.1 About This Manual............................................3

1.2 Text Conventions........................................ .....4

1.3 Contents Of The HDK.................... ...... ...... ...... ... ..4

1.3.1 Files In The HDK..... ...... ... ...... ...... ...... ...... ..4

1.4 Obtaining The HDK........................... ...... ...... .....6

1.5 About the WORKABOUT PRO Hand-Held Computer..........................6

1.6 Discontinued Hardware............................... ...... .....7

Psion Teklogix WORKABOUT PRO HDK User Manual 1

Page 12

Page 13

1.1 About This Manual

This manual is supports developers of customized hardware for all variants of the Psion Teklogix

Inc. WORKABOUT PRO hand-held computer.

Chapter 1: Introduction

is an overview of the WORKABOUT PRO Hand-Held Computer and the

WORKABOUT PRO HDK.

Chapter 2: Hardware

describes, in general terms, the hardware of the WORKABOUT PRO.

Chapter 3: Software

gives an overview of the API for expansion devices, discusses installing

device drivers.

Chapter 5: External Connectors

describes the external connectors on the WORKABOUT PRO, and accessories that

connect to them.

Chapter 4: Mechanical Considerations

describes the space and mounting for expansion module devices.

Chapter 7: 100-Pin Connector

describes the electrical interface between the WORKABOUT PRO and expansion

module devices.

Chapter 1: Introduction

About This Manual

Chapter 8: Scanner Connector

describes the scanner connector .

Chapter 9: Example: Scanner Converter Board

describes the interface between the scanner and the standardized scanner connector.

Chapter 10: Example: PCMCIA Expansion Module

describes an example of an expansion module that has a PCMCIA slot.

Chapter 11: Example: Multi-I/O Expansion Module

describes an example of an expansion module that makes the serial and USB

connections on the 100-pin connector easily available.

Appendix A: Support Services / Worldwide Of fices

provides the helpdesk phone number at Psion Teklogix Inc., Mississauga, Ontario,

Canada office and details the support services available. This appendix also lists

worldwide office addresses and their ph one numbers.

Appendix B: Resources

contains a list of other publications and web sites where related information

is available.

Appendix C: Specifications WORKABOUT PRO M

contains specifications for the WORKABOUT PRO M variant.

Appendix D: Specifications WORKABOUT PRO C, S & ME

contains specifications for the WORKABOUT PRO C, S, and ME variants.

Appendix E: WORKABOUT PRO 2nd. Generation

contains specifications for the WORKABOUT PRO 2nd. Generation C and

Svariants.

Psion Teklogix WORKABOUT PRO HDK User Manual 3

Page 14

Chapter 1: Introduction

Text Conv entions

Appendix F: Specifications WORKABOUT PRO Radios

contains specifications for the WORKABOUT PRO radios.

Appendix G: Specifications Scanners And Imagers

contains specifications for the WORKABOUT PRO internal scanners and image rs.

Appendix H: Specifications WORKABOUT PRO Batteries

contains specifications for the WORKABOUT PRO batteries.

Appendix I: Hardware Developer Kit License Agreement

provides the text of the License Agreement that accompanies the HDK.

1.2 Text Conventions

Note: Notes highlight additional helpful information.

Important: These statements provide important instructions or additional information that is

critical to the operation of the computer or other equipment.

W arning: These statements provide important information that may prevent injury, damage

to the equipment, or loss of data.

An arrow next to field description information (usually in tables) indicates a recommended or

suggested configuration setting.

1.3 Contents Of The HDK

The Hardware Development Kit (HDK) for the WORKABOUT PRO includes the

following items:

•This manual.

• Libraries and sample programs for the APIs for managing expansion cards and scanner

devices. See “The C++ Application Programming Interface” on page 25 for a description of

these files.

• Drawings and engineering models of the backplates and endcaps available for the

WORKABOUT PRO. The models can be customized. See Chapter 4: “Mechanical Consider-

ations” for a description of these models.

• Sample schematics and drawings for expansion modules and scanner converter boards.

1.3.1 Files In The HDK

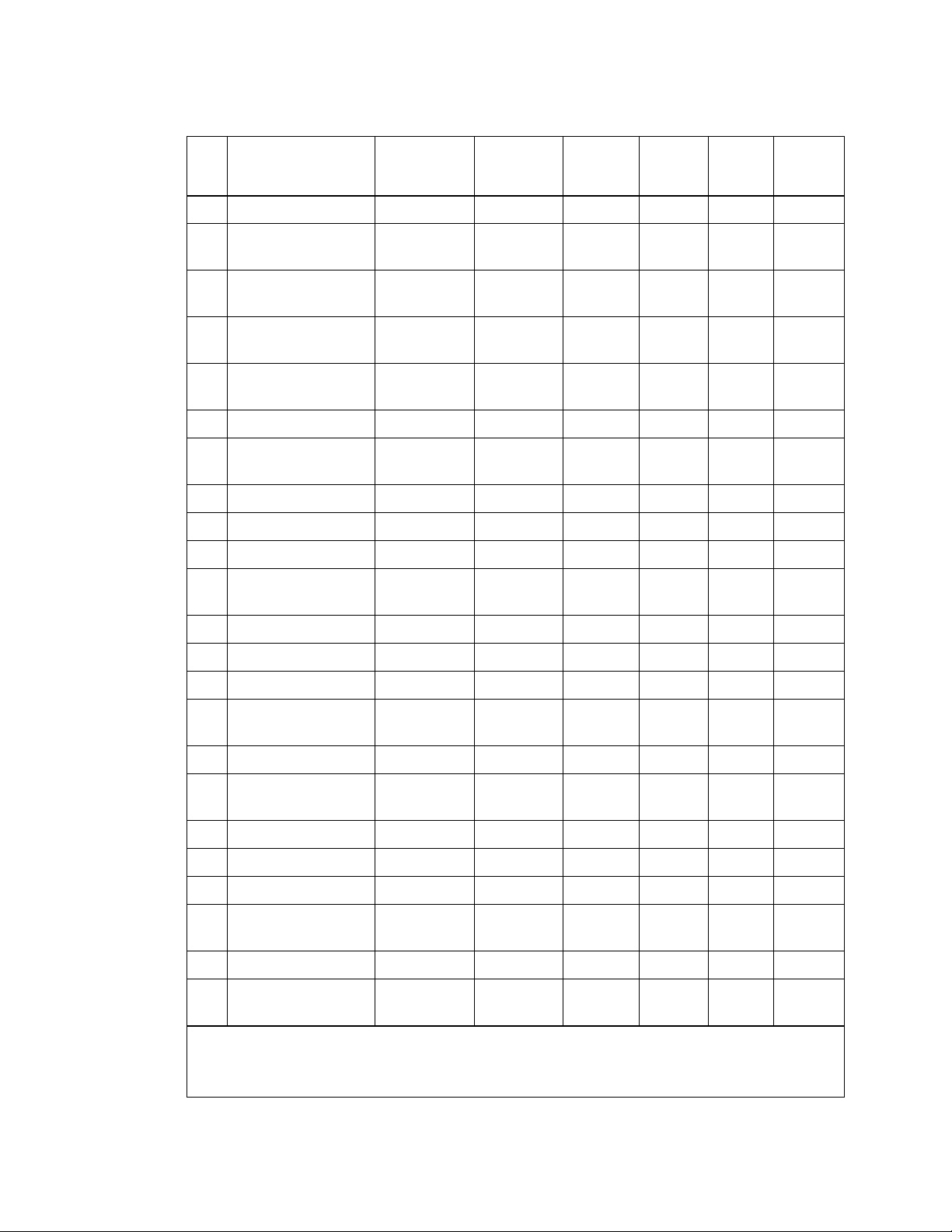

Table 1.1 Files in the HDK

Filename Description

...\Mechanical\WORKABOUTPRO\G2\iges_files

\G2_C_body.igs

...\Mechanical\WORKABOUTPRO\G2\iges_files

\G2_mounting_frame.igs

4 Psion Teklogix WORKABOUTPRO HDK User Manual

Body shell—WORKABOUT PRO 2nd.

Generation—C variant.

Mounting frame—WORKABOUT PRO 2nd.

Generation C, and S variants.

Page 15

Table 1.1 Files in the HDK (Continued)

Filename Description

Chapter 1: Introduction

Files In The HDK

...\Mechanical\WORKABOUTPRO\G2\iges_files

\G2_S_body.igs

...\Mechanical\WORKABOUTPRO\iges_files

\backplate.igs

...\Mechanical\WORKABOUTPRO\iges_files

\colour_mono_terminal.igs

...\Mechanical\WORKABOUTPRO\iges_files

\endcap.igs

...\Mechanical\WORKABOUTPRO\iges_files

\endcap_assembly.igs

...\Mechanical\WORKABOUTPRO\iges_files

\mounting_frame.igs

...\Mechanical\WORKABOUTPRO\iges_files

\pcmcia_xmod.igs

...\Mechanical\WORKABOUTPRO\iges_files

\short_terminal.igs

...\Mechanical\WORKABOUTPRO\iges_files

\stylus_pen.igs

...\Mechanical\WORKABOUTPRO\pdf

\backplate.pdf

Body shell—WORKABOUT PRO 2nd. Generation

S variant.

Backplate—all variants.

Body shell—WORKABOUT PRO C, M, and

ME variants.

Endcap—all variants.

Endcap assembly—all variants.

Mounting frame—WORKABOUT PRO C, M,

ME. and S variants.

Sample expansion card—all variants.

Body shell—WORKABOUT PRO S variant.

Stylus pen—all variants.

2D backplate—all variants.

...\Mechanical\WORKABOUTPRO\pdf

\endcap.pdf

...\Mechanical\WORKABOUTPRO\pdf

\endcap_assembly.pdf

...\Mechanical\WORKABOUTPRO\pdf

\endcap_assembly_ball.pdf

...\Mechanical\WORKABOUTPRO\pdf

\endcap_assembly_ball_holder.pdf

...\Mechanical\WORKABOUTPRO\pdf

\endcap_assembly_ball_spring.pdf

...\Mechanical\WORKABOUTPRO\pdf

\endcap_assembly_stylus_rubber.pdf

...\Mechanical\WORKABOUTPRO\pdf

\housing_body.pdf MISSING

...\Mechanical\WORKABOUTPRO\pdf

\internal_metal_frame.pdf

...\Mechanical\WORKABOUTPR\G2\pdf

\mechanical_stop.pdf ADD TO LIBRARY

...\Mechanical\WORKABOUTPRO\pdf

\stylus_pen.pdf

2D endcap—all variants.

2D endcap assembly —all variants.

2D ball for endcap—all variants.

2D endcap ball holder—all variants.

2D endcap, and ball spring—all variants.

2D stylus gasket for endcap—all variants.

2D body shell—WORKABOUT PRO S variant.

2D internal frame—WORKABOUT PRO C, M,

and ME variants.

2D card stop—WORKABOUT PRO 2nd.

Generation C, and S variants.

2D stylus—all variants.

Psion Teklogix WORKABOUT PRO HDK User Manual 5

Page 16

Chapter 1: Introduction

Obtaining The HDK

Table 1.1 Files in the HDK (Continued)

Filename Description

...\Electrical\WORKABOUTPRO\Samples

\PCMCIAExpansionCard.pdf

...\Electrical\WORKABOUTPRO\Samples

\SerialScannerInterfaceBoard.pdf

...\Electrical\WORKABOUTPRO\Samples

\USBScannerInterfaceBoard.pdf

Sample schematic PCMCIA expansion

module—all variants.

Sample schematic scanner interface board for a

serial scanner—all variants.

Sample schematic scanner interface board for a

USB scanner—all variants.

1.4 Obtaining The HDK

The HDK is available as a download from Psion Teklogix. If you have a Teknet usercode, the

download is available on the Teknet site at:

www .PsionTeklogix.com/downloads

1.5 About the WORKABOUT PRO Hand-Held Computer

The WORKABOUT PRO Hand-Held Computer is an industrial hand-held computer.

The following WORKABOUT PRO variants are available:

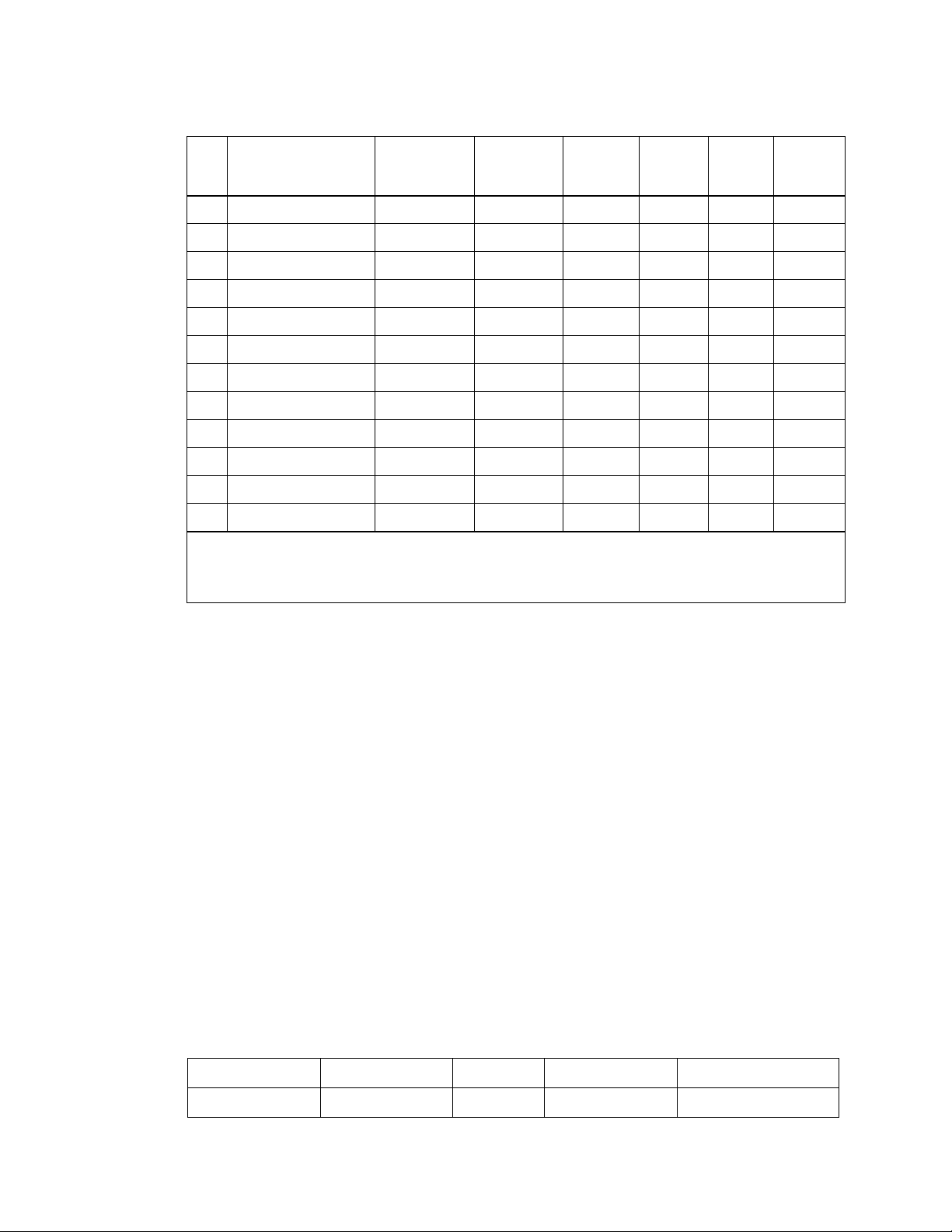

Model Variant Description

WORKABOUT PRO M

(discontinued)

Monochrome screen, full keyboard,

PXA255 processor.

C Colour screen, full keyboard, PXA255 processor.

ME Monochrome enhanced screen, full keyboard,

PXA255 processor.

S Colour screen, short keyboard, PXA255 processor.

WORKABOUT PRO 2nd. Generation C Colour screen, full keyboard, PXA270 processor.

S Colour screen, short keyboard, PXA270 processor.

The specifications for these computers are in the following appendices:

• Appendix C: “Specifications WORKABOUT PRO M”

• Appendix D: “Specifications WORKABOUT PRO C, S & ME”

• Appendix E: “WORKABOUT PRO 2nd. Generation”

For details on the configuration and operation of the WORKABOUT PRO models consult the

user manuals listed in Appendix B: “Resources”.

6 Psion Teklogix WORKABOUTPRO HDK User Manual

Page 17

Chapter 1: Introduction

Discontinued Hardware

The following windows operating systems are available on the WORKABOUT PRO:

• Windows Mobile 2003

• Windows CE .NET 4.2

• Windows Embedded CE 5.0

• Windows Mobile 5

• Windows Mobile 6

Windows operating systems are available on the WORKABOUT PRO as follows:

Model

WORKABOUT PRO M

(discontinued)

WORKABOUT PRO C Yes Yes Yes

WORKABOUT PRO ME Yes Yes Yes

WORKABOUT PRO S Yes Yes Yes

WORKABOUT PRO

2nd. Generation

Yes Yes

1.6 Discontinued Hardware

The WORKABOUT PRO M and some of the peripherals described in this manual are no longer

available for purchase from Psion Teklo gix. They are included in this manual fo r the benefit of developers who are continuing to support them alongside newer hardware. For currently available

hardware consult the Accessories Catalog at www.PsionTeklogix.com/Accessories

Windows Mobile 2003

Windows CE .NET 4.2

Windows Embedded CE 5.0

Yes Yes

Windows Mobile 5

Windows Mobile 6

.

Psion Teklogix WORKABOUT PRO HDK User Manual 7

Page 18

Page 19

HARDWARE 2

2.1 Overview.................................................11

2.2 Variants Of The WORKABOUT PRO................................ .11

2.2.1 Scanner Variants........................................11

2.2.2 Expansion Card Variants....................................11

2.3 WORKABOUT PRO C, S, M, ME...................................11

2.3.1 Main Processor ........................................11

2.3.2 Peripheral Processors.....................................12

2.4 WORKABOUT PRO 2nd. Generation C, S...............................13

2.4.1 Main Processor ........................................13

2.4.2 Peripheral Processors.....................................13

2.5 Identifying Hardware............................. ...... ...... .15

2.6 The LED............................................. ....15

2.7 Connectors....................... ...... ...... ...... ... ....15

2.8 Power Management...........................................15

2.8.1 Batteries . ... ...... ...... ...... ... ...... ...... ...... .16

2.9 Switching The Backup Battery Power On And Off.......................... .16

2.10 Connector Locations .. ...... ...... ...... ... ...... ...... ...... .17

Psion Teklogix WORKABOUT PRO HDK User Manual 9

Page 20

Page 21

2.1 Overview

This chapter gives an overview of the hardware of the WORKABOUT PRO.

2.2 Variants Of The WORKABOUT PRO

There are six variants of the WORKABOUT PRO. The specifications for all the variants are in the

following appendices:

• Appendix C: “Specifications WORKABOUT PRO M”

• Appendix D: “Specifications WORKABOUT PRO C, S & ME”

• Appendix E: “WORKABOUT PRO 2nd. Generation”

For the specifications of the radio, scanner, and battery options see:

• Appendix F: “Specifications WORKABOUT PRO Radios”

• Appendix G: “Specifications Scanners And Imagers”

• Appendix H: “Specifications WORKABOUT PRO Batteries”

For setup, configuration, and operational details consult the user manual for your WORKABOUT

PRO. A list of user manuals is included in Appendix B: “Resources”.

2.2.1 Scanner Variants

Chapter 2: Hardware

Overview

The WORKABOUT PRO comes standard with no scanner. Consult the specifications for the

scanners that are available for each WORKABOUT PRO variant.

The scanners and their housings fasten to the underside of the WORKABOUT PRO, replacing the

backplate. The scanner connects through a flex cable to the scanner connector on the

WORKABOUT PRO main logic board. The scanner may be installed by the end user; for instructions see Psion T eklogix WA9000, W A9005, & WA9006 Scanner Module Installation (Part number

8000030).

Only one internal scanner can be installed in a WORKABOUT PRO. The internal scanner can be

triggered from the trigger switch on the WORKABOUT PRO handgrip (if present), from one of

the [SCAN] buttons on the WORKABOUT PRO keyboard, or from an assigned keyboard key.

2.2.2 Expansion Card V ariants

See the specifications for the WORKABOUT PRO variants for information on the expansion card

slots that are available. Additional card slots can be installed by connecting to the internal 100-pin

connector. Some card slots are accessed by removing the endcap.

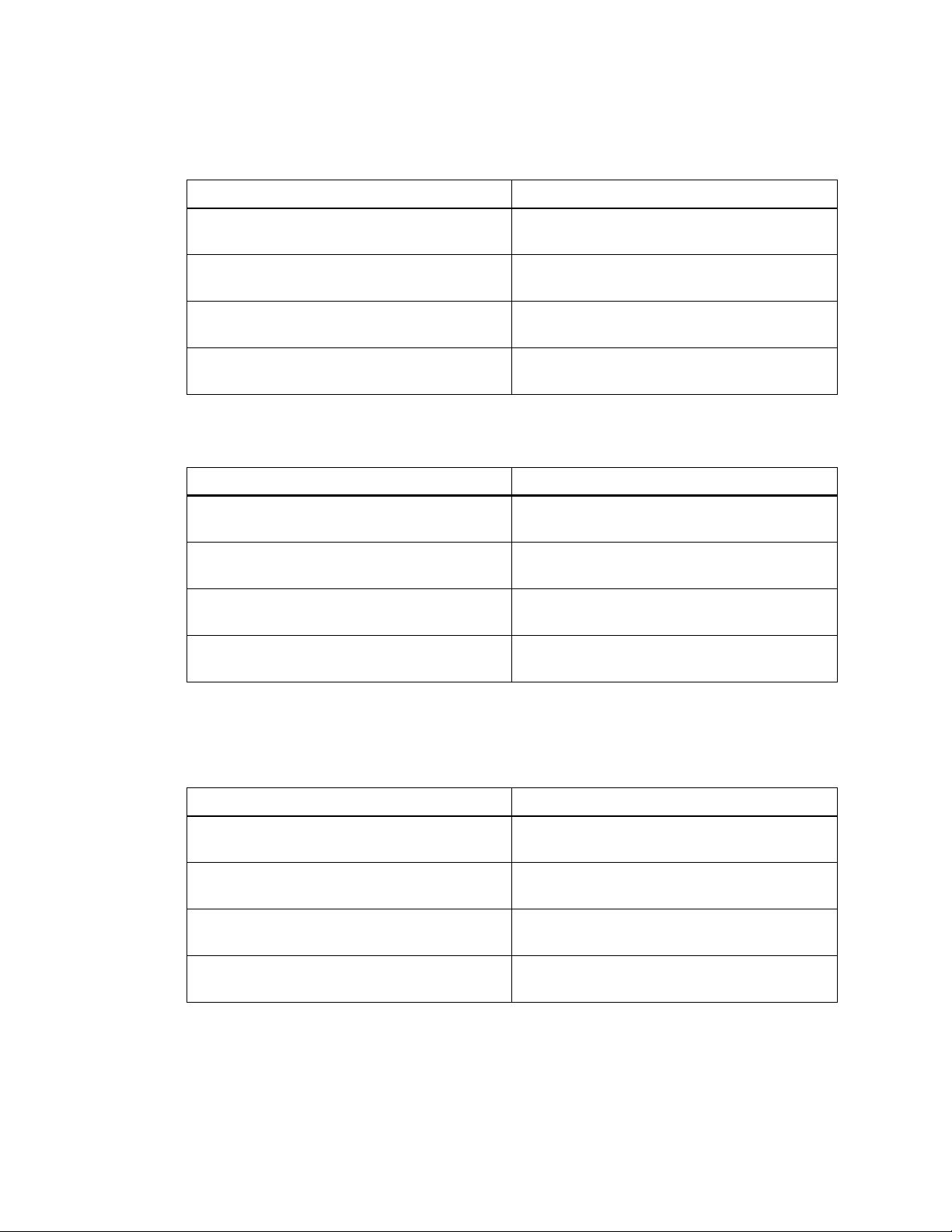

2.3 WORKABOUT PRO C, S, M, ME

See Figure 2.1 on page 12.

2.3.1 Main Processor

The WORKABOUT PRO is built around a 400 MHz Marvell X-Scale PXA255 processor. This

processor can run binaries compiled for the ARMv4 and ARMv4i target processor.

Psion Teklogix WORKABOUT PRO HDK User Manual 11

Page 22

Chapter 2: Hardware

Peripheral Processors

Figure 2.1 WORKABOUT PRO C, S, M, ME Block Diagram

802.11b/g radio

option

Main Logic Board (RMB)

Bluetooth

Antenna

SD Slot

Keyboard Module (RKB) Display Module (RLB)

Microphone

Key Scan

Keyboard

Status

LEDs

Backlight

LEDs

3.3V

SD

Power

SW

Key Scan

Matrix

Connectors

Message

LED

Backlight

Power

Power

Switch

Media

Processor

Bluetooth

Module

BT Uart

Address/Data

CS, etc

EEPROM

RTC

Backlight PWM

V+3.3, V+5,

V+CORE,..

etc.

DC-DC Converter

Circuits

3.3V

BT Power

SW

I2C

CompactFlash

CompactFlash Socket

Socket

3.3V

CF

Buffers

Power

PXA255 CPU

400MHz

USB

SPI

Client

Keyboard & Power

Management MCU

Tether

Detect

Detect

Power

Key

Enable

IRQ

LIF

PCMCIA Adaptor

(Option)

Internal 100-pin Expansion Slot

(Interfaces: I2C, SSP, Full Function UART,

USB host 1)

Address/Data

FF UART /

SSP /

PCMCIA Socket

Select /

USB_H1_PSW

Audio/Touch

AC-Link

Backlight Control (PWM)

Battery Cover

SW

USB

Host Root

BAT_DATA

Controller

FLASH

64MB

SDRAM

64 or 128 MB

Scanbay

Power 5V

I2C

Key Scan

UART

USB Host 2

controller

USB Host 3

USB

Host 1

USB hub

DC_IN

USB Host 1

USB Host 4

Connector

MIC in, SPK out

Touch controls

LCD data

VIN, 5V, 3.3V

5V

Charge

Status

VIN

GSM

Speaker out

PCMCIA card option

e.g. GSM/GPRS radio

VIN

Scanbay Connector

Power MCU

Backup

Battery

Charger

Diodes and

FETs

Speaker

Connector

3.3V

Slide

SW

VBAT

Board-to-Board Connector (50-pin)

VBAT

LCD power

FLEX

Speaker

4-wire Touch

LCD TFT

(1/4 VGA

240x320)

supplies

LED

driver

Internal Scanner

Options:

- 1D Laser Scanner

-2DImager

- 1D Imager

Rechargable Backup

Battery

Panel

LED

Backlight

Audio/Touch

Controller

BT module /

PXA

BT Uart

50-pin Board-to-Board I/O Connector

50-pin Board-to-Board I/O Connector

Connector Board (RCB)

BT TX/RX

USBHost3&Power

Tether

USB

SERIAL

(TX/RX)

Host

Tether Connector

(18-pin)

ID

Detect

Input

DC

2.3.2 Peripheral Processors

MSP430MF133 Keyboard Processor

The WORKABOUT PRO has a keyboard processor , for contro lling and mo nitoring the keyboard

and signal LEDs, and the battery.

12 Psion Teklogix WORKABOUT PRO HDK User Manual

DC_IN

Diodes

Audio Jack

(headphone, mic)

USBHost4&Power

USB Client

(From media processor)

DC

Input

DC_IN

USB

Client

LIF Connector

(12-pin)

Battery Cover

Detect SW

USB

Host

LIF ID

Detect

Charge Status

& Control

Main

Battery

Charger

Circuit

BAT_DATA

VBAT

Li-ion Battery

3.7V nominal

Page 23

Chapter 2: Hardware

WORKABOUT PRO 2nd. Generation C, S

MQ1188 Multimedia Platform Controller

This processor handles connections to the liquid-crystal display module and the SD/MMC card

slot. It also provides the USB host interface to the USB host (through the hub) and

client connections.

ISP1122A USB Host Hub

The ISP1122A USB hub, together with individual current limited load switches, provides USB

data lines and DC power to the USB ports on the following connectors:

• 100-pin expansion connector .

• Scanner connector.

• T ether co nnector.

• LIF connector.

The overcurrent sensing capability and DC power is not provided by the ISP1122A

controller alone.

This controller integrates a Serial Interface Engine (SIE), hub repeater, hub controller, USB data

transceivers, and a configurable number (2 - 5) of downstream ports. It has the following features:

• Complies with USB Specification 1.1.

• Full-speed (12Mbps) fully compliant.

• OHCI register compliant.

• Supports DMA.

WM9705 Audio Controller

The audio controller permits audio recording and playback to the AC97 specification. This chip

also handles the touchscreen digitizing input.

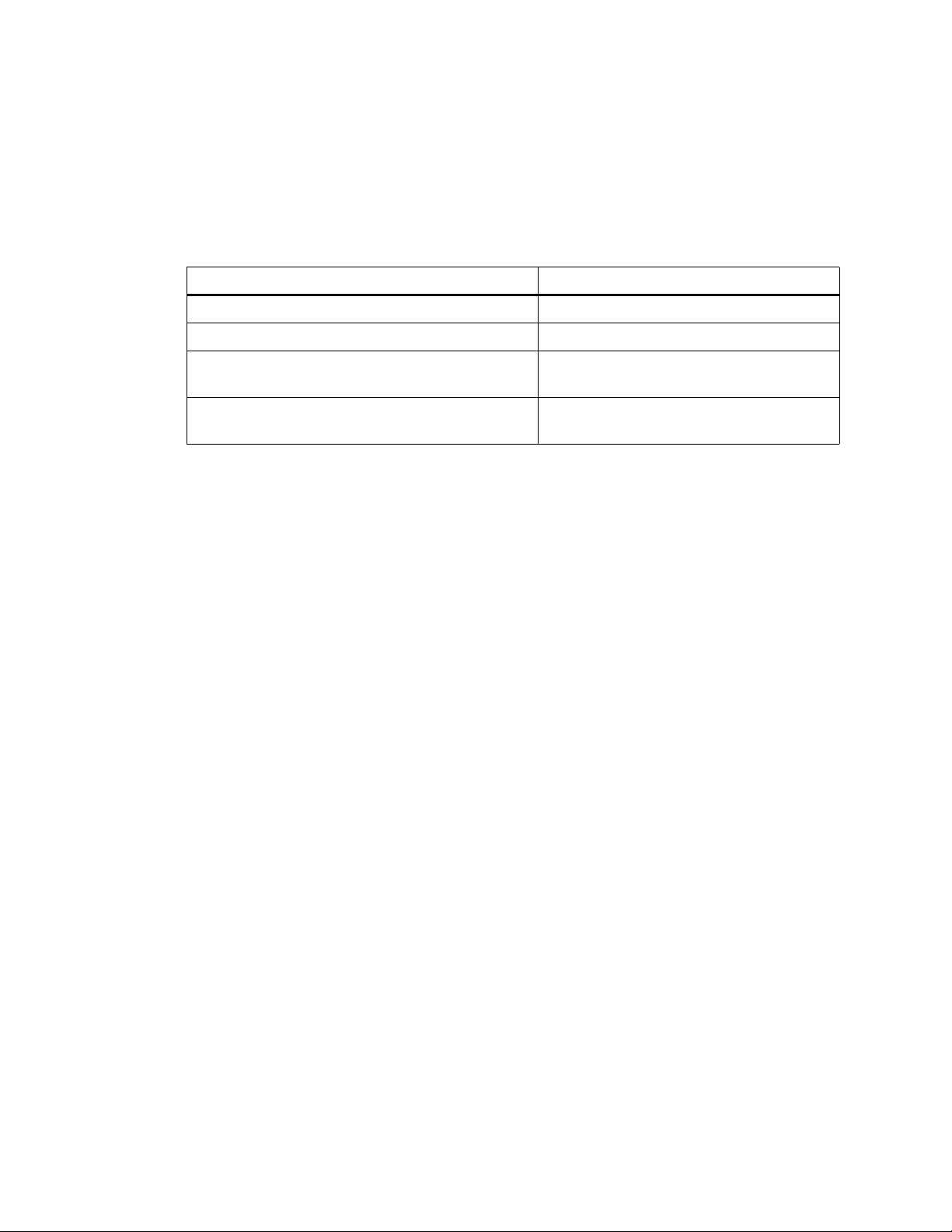

2.4 WORKABOUT PRO 2nd. Generation C, S

See Figure 2.2 on page 14.

2.4.1 Main Processor

The WORKABOUT PRO is built around a 520 MHz Marvell X-Scale PXA270 processor. This

processor can run binaries compiled for the ARMv4 and ARMv4i target processor.

2.4.2 Peripheral Processors

C8051F315 Keyboard Processor

The WORKABOUT PRO has a keyboard processor, for controlling and monitoring the keyboard

and signal LEDs, and the battery.

C8051F312 Microcontroller for P ower Management Control

The C8051F312 controller is used for controlling and monitoring the power state of various components (e.g. Li-ion battery chargers) in the system. It also detects the presence of devices

connected to the LIF port and the tether port.

LC4128ZC CPLD

This CPLD is used for interfacing Compact Flash and PC cards via the internal 100-pin

expansion slot.

Psion Teklogix WORKABOUT PRO HDK User Manual 13

Page 24

Chapter 2: Hardware

Peripheral Processors

Figure 2.2 WORKABOUT PRO 2nd. Generation C, S Block Diagram

802.11b/g radio

option

e.g. RA2041 radio

Main Logic Board (RMB)

Bluetooth

Antenna

Bluetooth

I2C

USB

OTG

&

I2C

Control

Signals

USB OTG

Transceiver

Module

BT Uart

Power I2C

Power MCU

(Regulated DC

outputs for CPU)

Vbus

Power

SW

USB OTG

&Power

BT Uart

Keyboard Module (RKB) Display Module (RLB)

Microphone

Keyboard

Controller

Key Scan Matrix

Keyboard

I2C LED

Dimmer

Power

Switch

Backlight

LEDs

V+3.3 /

VIN

Key

IRQ

Key

Scan

I2C

3-pin Compression

Connector

22-pin Flex Cable

SD Slot

3.3V

SD Power

SW

V+3.3 /

VIN

Key IRQ

Key Scan

2 x Side

Buttons

EEPROM

RTC

BT module /

PXA

PCM

3.3V

BT Power

SW

V+1.8MEM

V+CORE

VCC_PLL

VCC_SRAM

VCC_BAT

VIN

CompactFlash

CompactFlash Socket

Socket

3.3V

CF

CPLD

Power

PXA270 CPU

520MHz

I2C

&

Control

USB

Signals

Client

Management Control

50-pin I/O Connector

AC97

USB Host Root

MCU for Power

Tether

Detect

Detect

PCMCIA Adaptor

(Option)

Internal 100-pin Expansion Slot

(Interfaces: I2C, SSP2, Full Function UART,

USB host 1)

FF UART /

Beeper Output

LIF

SSP2 /

PCMCIA

socket

Select /

USB_H1_PSW

Backlight Control

Power switch

Charge

Status

I2C

Audio/Touch

Controller

GoForce 4000

Media Processor

Key Scan

UART

Scanbay

Power

5V/3.3V

USB Host 2

USB Host 3

DC_IN

USB

Host 1

MDOC 128MB

USB hub

controller

USB Host 4

FLASH

SDRAM

128 MB

5V/3.3V

GSM

Connector

USB Power

USB Host 1

Charge

VINDC_IN

Status

Speaker out

Touch controls

VIN

Supplies

(e.g. 3.3V

and 5V)

PCMCIA card option

e.g. GSM/GPRS radio

Headphone

Jack (J703)

Speaker

Connector

LCD data

Scanbay Connector

Internal

USB

Connector

(CN601)

Backup

Slide

Battery

Charger

5V

System

VIN

Diodes

and FETs

Main

Battery

Charger

Circuit

LCD power

supplies

Charge

Pump

Li-Poly Backup

Li-ion Battery

3.7V nominal

3000mAh /

4000mAh

4-wire Touch

Internal Scanner

Options:

- 1D Laser Scanner

-2DImager

- 1D Imager

Battery

50-pin Flex Cable

FLEX

SW

VBAT

BAT_DATA

VBAT

50-wire Cable

Connector Board (RCB)

USB MCU

(USB / Serial

Interface)

UART

BT Uart

USB OTG & Power

USB

Host 3

50-pin I/O Connector

DC_IN

Power Path

Selector

USB Host 4 & Power

USB Client

(PXA270)

Battery Cover Detect

Switch (To PXA270)

Beeper

Speaker

Panel

LCD TFT

(Full VGA

480x640)

LED

Backlight

SERIAL

USB

OTG

Tether Connector

(18-pin)

ID

Detect

Input

DC

Tether

GoForce 4000 Me dia Processor

This provides the following:

• Video controller.

14 Psion Teklogix WORKABOUT PRO HDK User Manual

DC Input Jack

Input

DC

USB

Client

LIF Connector

(12-pin)

USB

Host

LIF ID

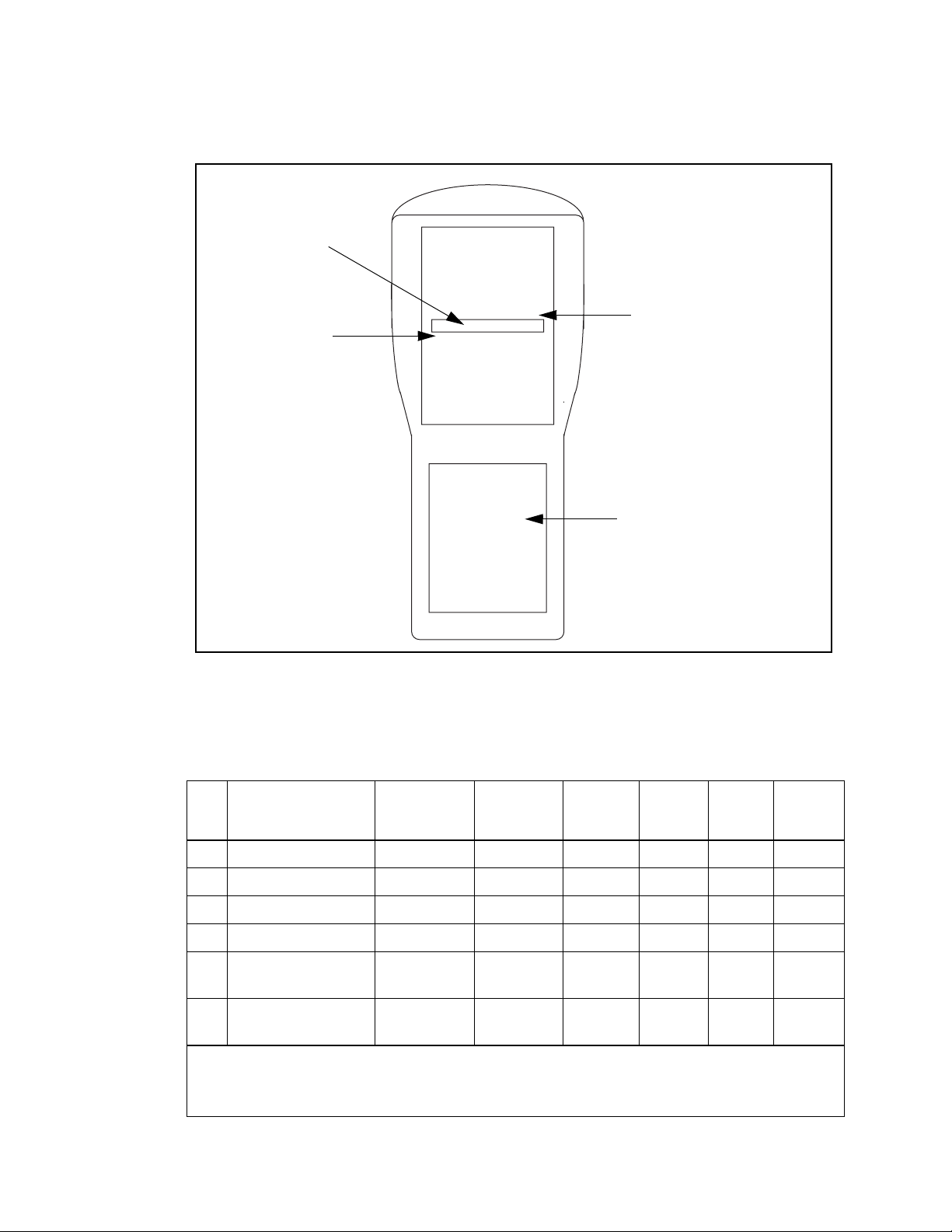

Detect

Page 25

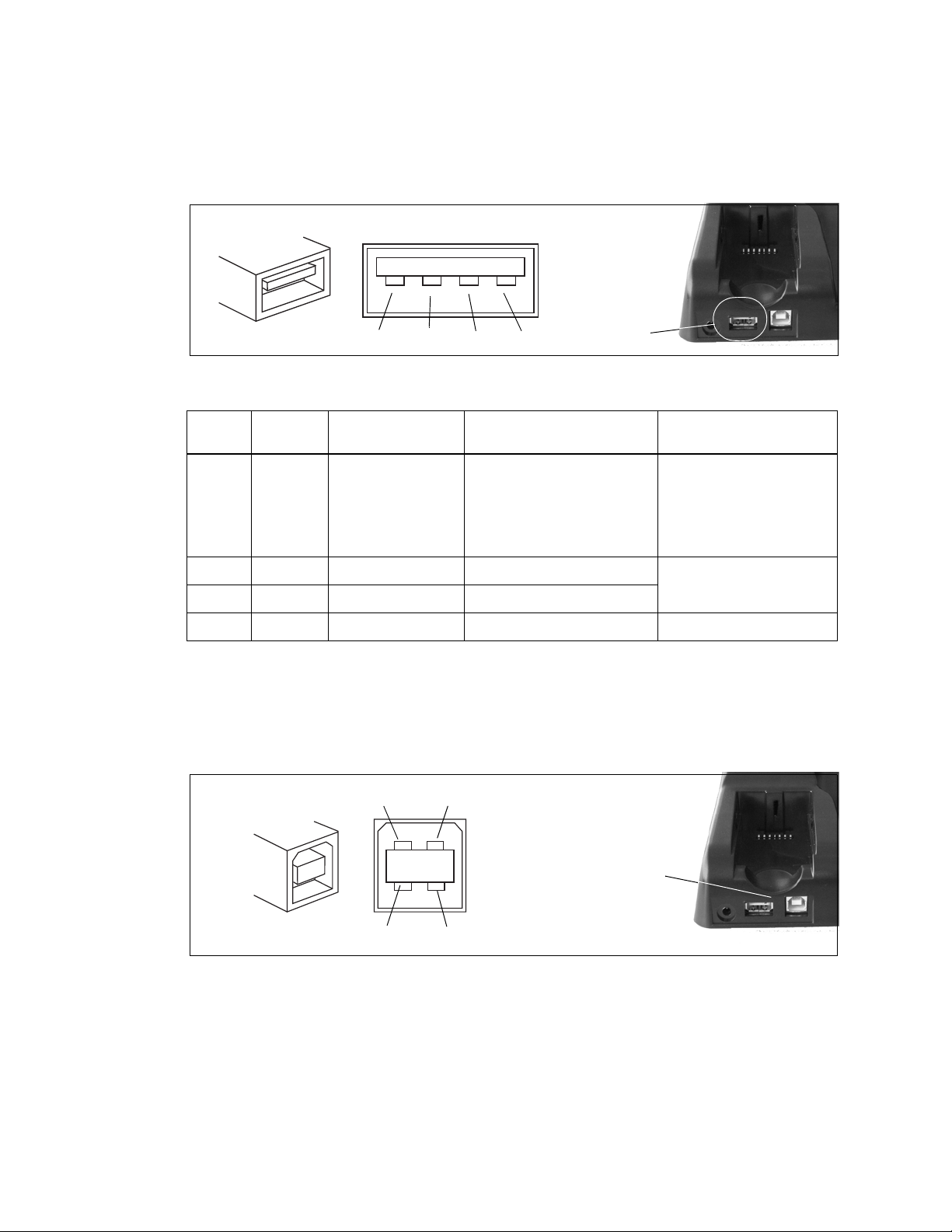

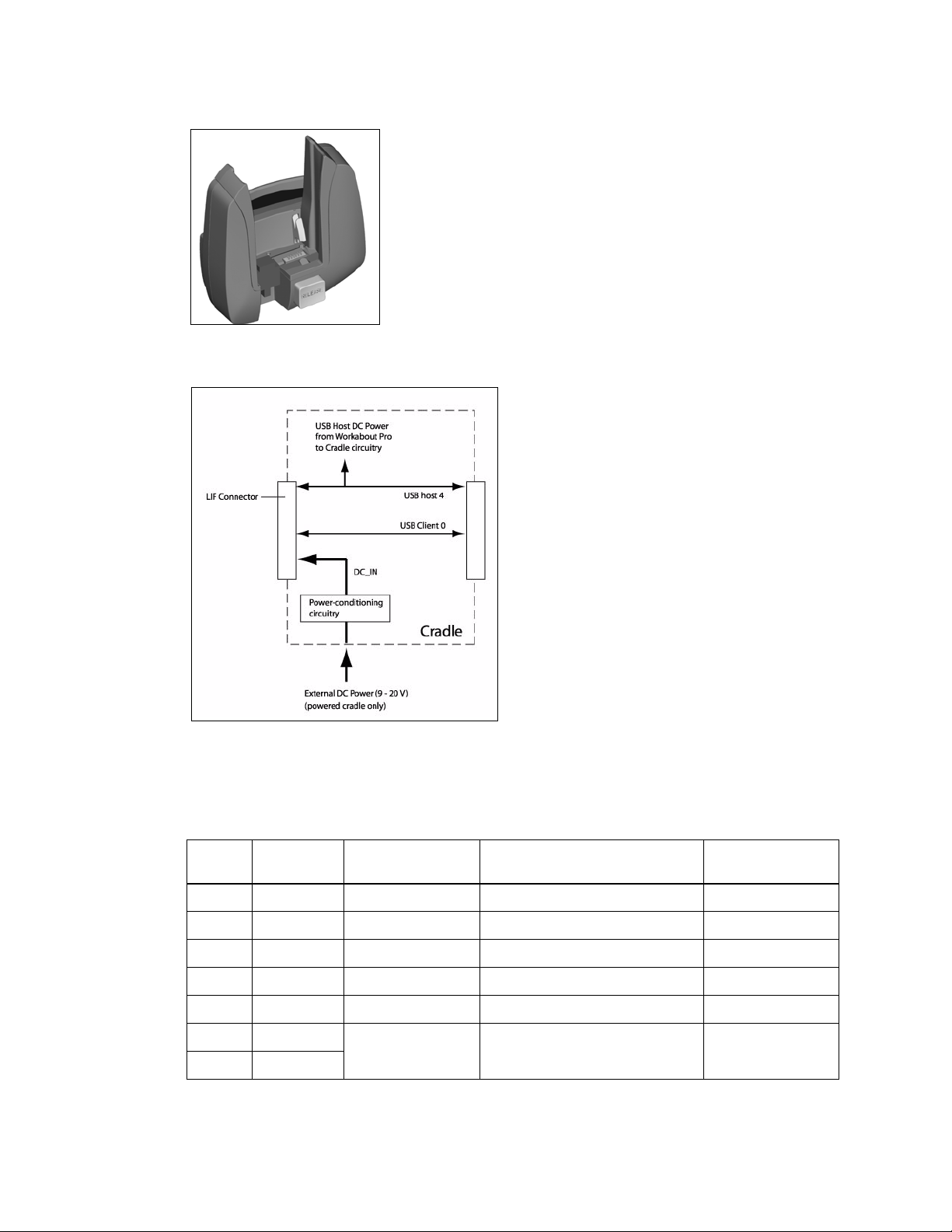

TUSB2046BI USB Hub

The TUSB2046BI USB hub, together with individual current limited load switches, provides USB

data lines and DC power to USB ports on the following connectors:

1. 100-pin expansion connector.

2. Scanner connector.

3. Tether connector.

4. LIF connector.

5. Internal USB connector.

It provides one upstream port and four downstream ports in compliance with the USB 1.1 specifi-

cation. Fully-compliant USB transceivers are integrated for all upstream and downstream ports.

The downstream ports support both full-speed (12 Mbps), and low-speed (1.5 Mbps), devices by

automatically setting the slew rate according to the speed of the device attached to the ports.

WM9713 Audio Controller

The audio controller permits audio recording and playback to the AC97 specification. This chip

also handles the touchscreen digitizing input.

2.5 Identifying Hardware

An overview of the operating system and the installed hardware on the WORKABOUT PRO can

be viewed using the Control Panel. Depending on the version of Windows installed, the Control

Panel program is one of the following:

Chapter 2: Hardware

Identifying Hardware

•System.

• About Device.

2.6 The LED

The WORKABOUT PRO has a two-coloured indicator LED to show power and charging state.

This LED can be controlled by application programs.

2.7 Connectors

For information on the external connectors that are provided on the WORKABOUT PRO, see the

specifications for each of the variants. For pinouts for the external connectors see Chapter 5: “External Connectors”.

For information on connecting devices to the 100-pin internal connector, see Chapter 7: “100-Pin

Connector”, and for connecting devices to the internal scanner connector see Chapter 8: “Scanner

Connector”.

2.8 P ower Management

The WORKABOUT PRO is powered by a lithium-ion rechargeable battery pack. The

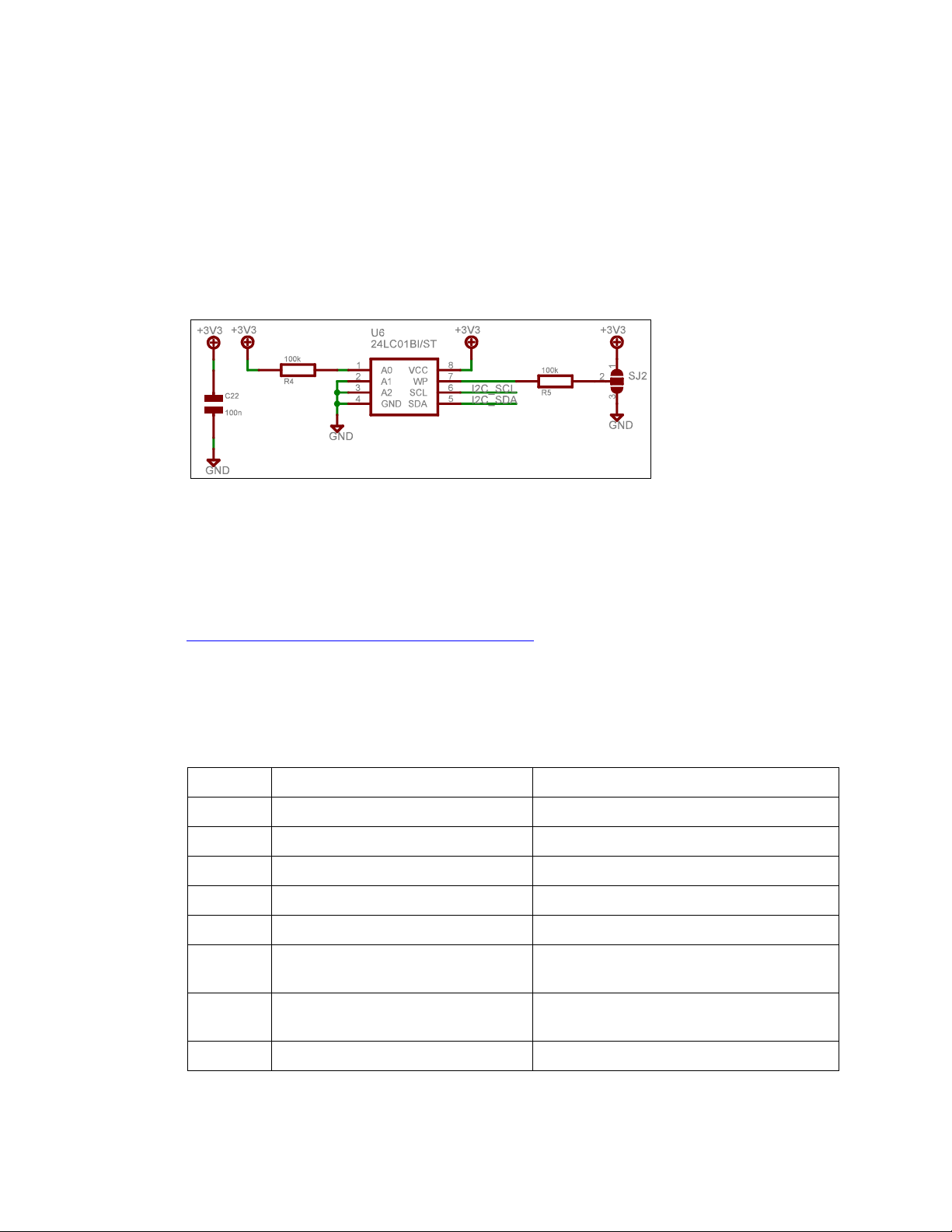

WORKABOUT PRO can be powered from external power. When the WORKABOUT PRO is

powered from external power, the battery pack also charges.

Use only power sources recommended or sold by Psion Teklogix for the WORKABOUT PRO.

Psion Teklogix WORKABOUT PRO HDK User Manual 15

Page 26

Chapter 2: Hardware

Batteries

2.8.1 Batteries

The battery is a single-cell lithium-ion battery , available with capacities between 1700 mAh and

4000 mAh. When the battery charge drops below 2.6 V, the battery shuts down.

When the battery output drops below preset values, the WORKABOUT PRO power management

causes the following:

Table 2.1 Battery Threshold V oltages

Power State

Battery V oltage

WORKABOUT PRO C, S, M, ME WORKABOUT PRO 2nd. Generation C, S

Suspend mode Below 3.41 V Below 3.1 V

Unit shuts down &

Below 2.6 V Below 3.0 V

V_IN switches to 0 V

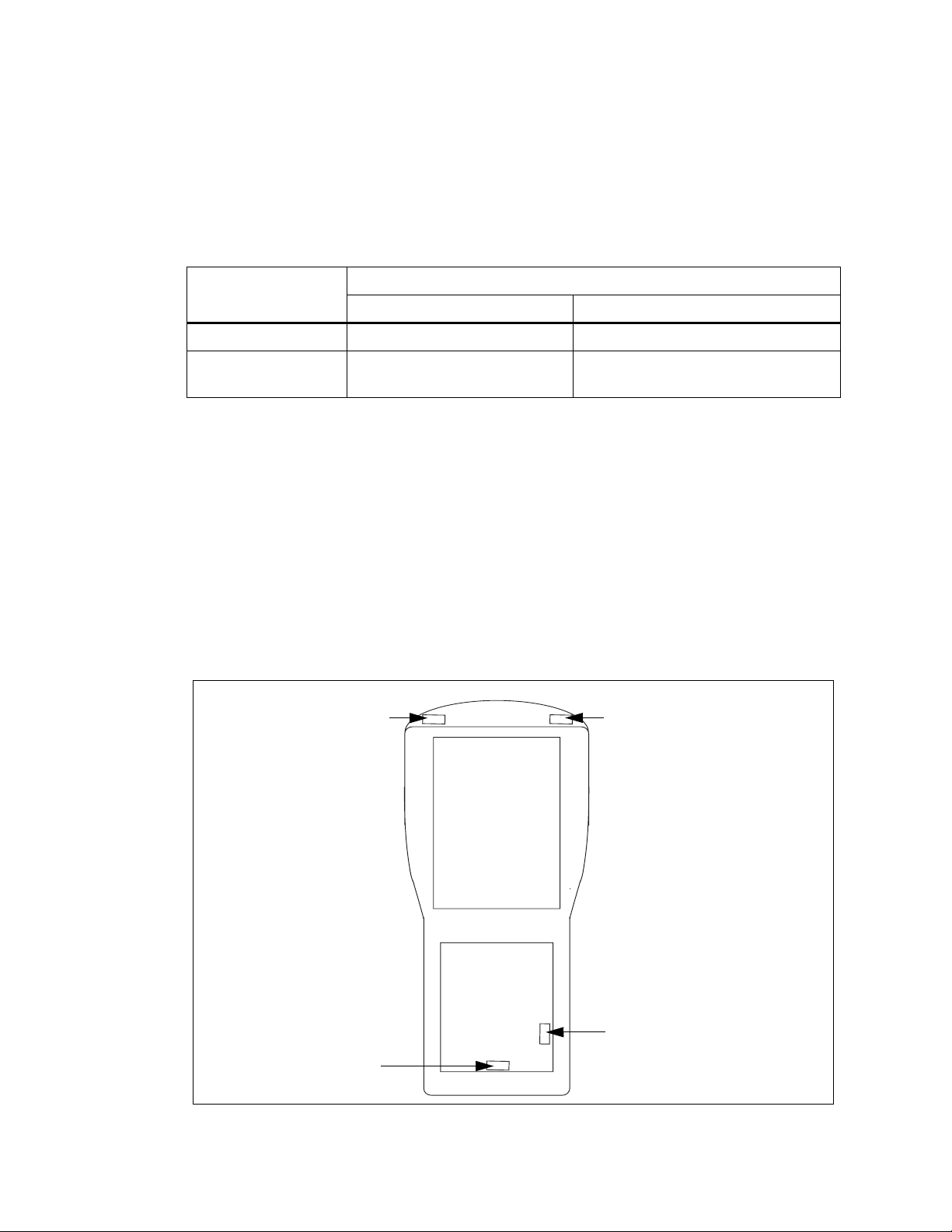

2.9 Switching The Backup Battery P ower On And Off

Power from the backup battery must be switched off before inserting or removing an expansion

module. It must be switched on after the operation is complete. The backup battery switch location

differs between the WORKABOUT PRO variants.

WORKABOUT PRO C, M, ME, and S

T o access the on/of f switch, remove the endcap. See Figure 2.3 on page 16 for the switch position.

WORKABOUT PRO 2nd. Generation C, and S

T o access the on/off switch, remove the battery cover and remove the batteries. See Figure 2.3 on

page 16 for the switch position.

Figure 2.3 WORKABOUT PRO back view showing the positions of the on/off switch

WORKABOUT PRO C, M, ME

variants (SW1401)

WORKABOUT PRO S variant

(SW1401)

WORKABOUT PRO 2nd.

16 Psion Teklogix WORKABOUT PRO HDK User Manual

Back-

Battery

WORKABOUT PRO 2nd.

Generation S variant (SW1502)

Page 27

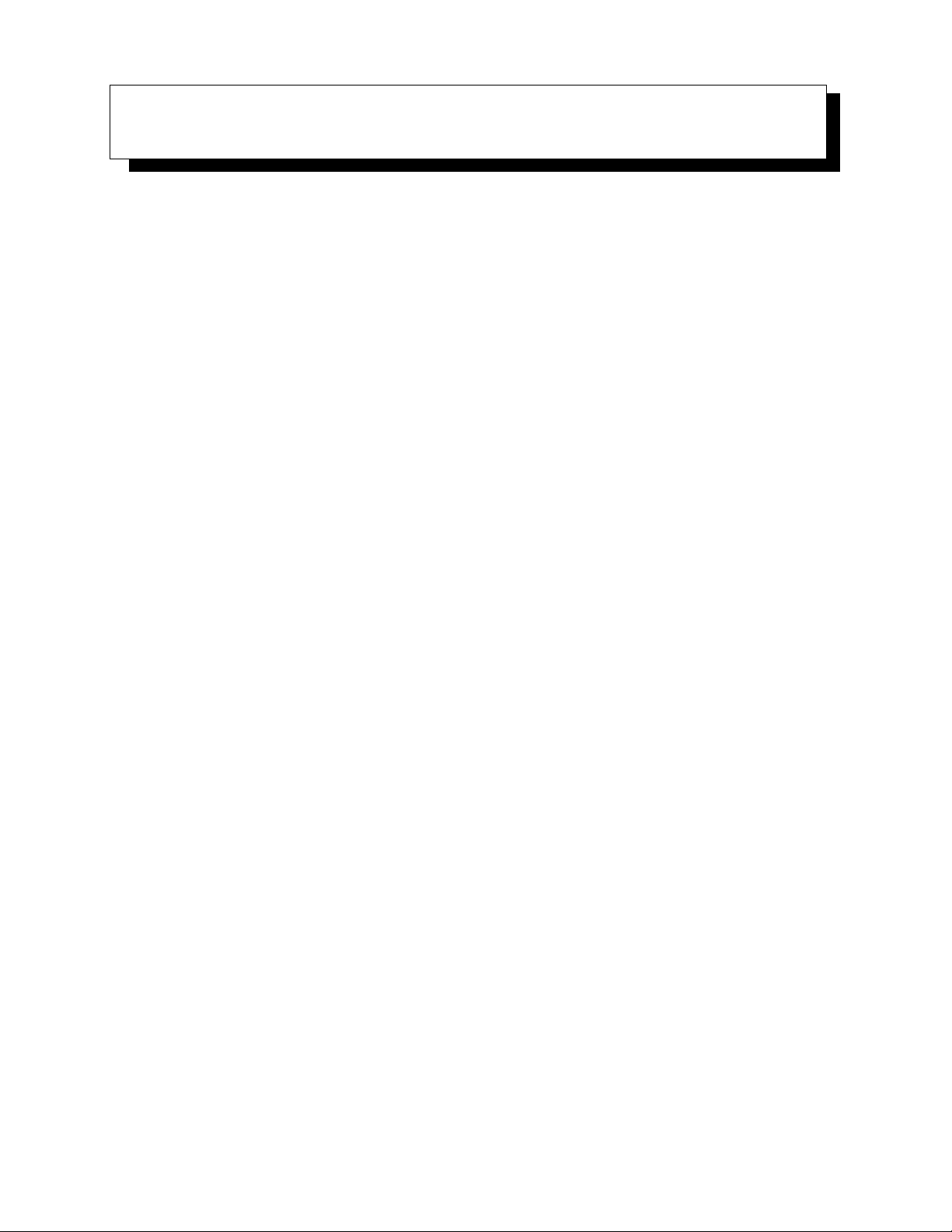

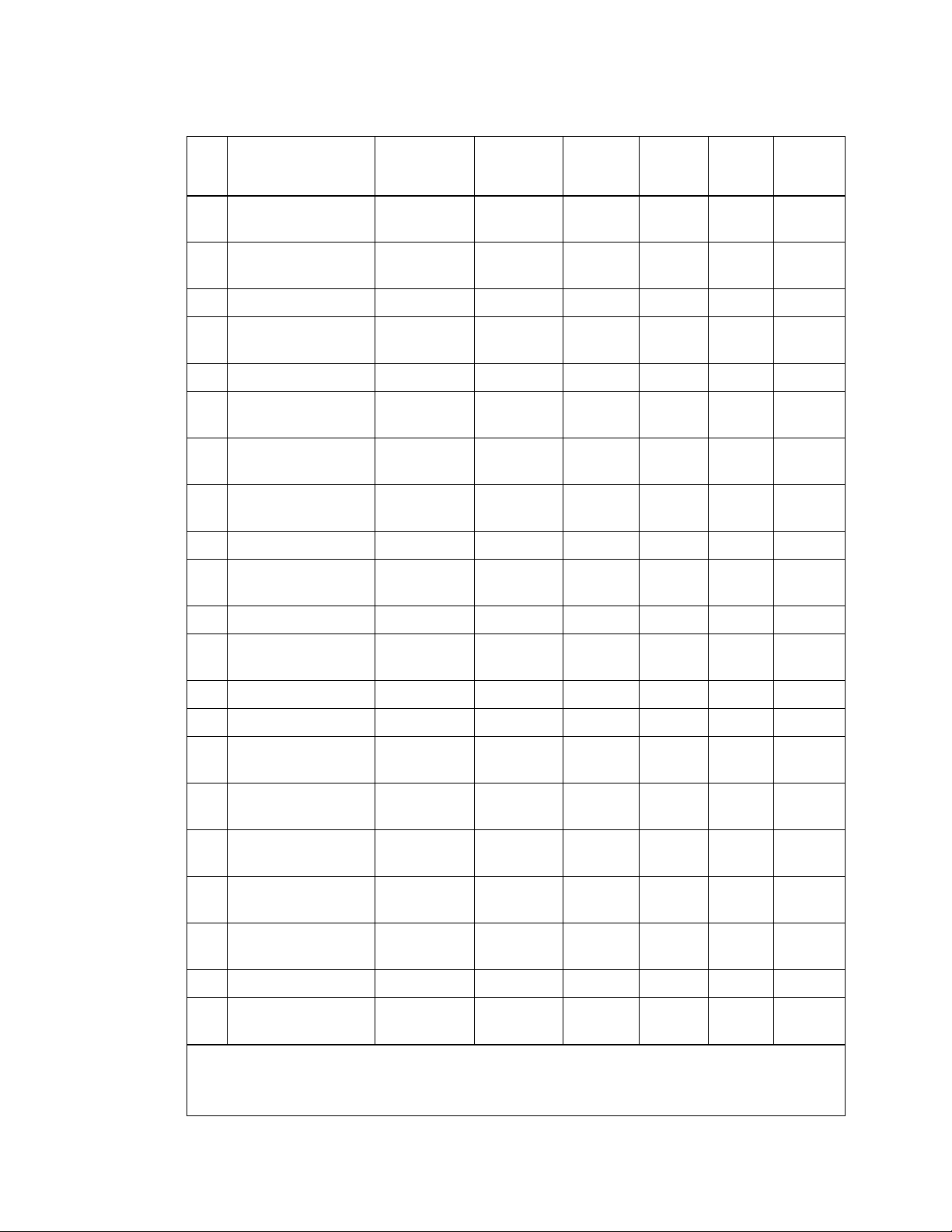

2.10 Connector Locations

The following diagrams show the positions of the electrical connectors on the main logic board for

the WORKABOUT PRO and the WORKABOUT PRO 2nd. Generation computers.

Figure 2.4 Connector Locations On The WORKABOUT PRO C, M, And ME

Chapter 2: Hardware

Connector Locations

100-Pin Connector

Scanner Connector

Figure 2.5 Connector Locations On The WORKABOUT PRO S

Audio Connector

(Not supported in software)

100-Pin Connector

Scanner Connector

Audio Connector

(Not supported in software)

Psion Teklogix WORKABOUT PRO HDK User Manual 17

Page 28

Chapter 2: Hardware

Connector Locations

Figure 2.6 Connector Locations On The WORKABOUT PRO 2nd. Generation C And S

USB Connector

Audio Connector

100-Pin Connector

Audio Connector

(Not supported in software)

Scanner Connector

18 Psion Teklogix WORKABOUT PRO HDK User Manual

Page 29

SOFTWARE 3

3.1 Overview.................................................21

3.2 Windows Drivers ............................................21

3.2.1 The Peripheral Control (PCO) Driver............. ... ...... ...... .21

3.2.2 The PCMCIA Driver .....................................21

3.2.3 The Serial Port Driver.....................................21

3.3 Non-PsionTeklogix Drivers.............. ...... ...... ... ...... ....21

3.3.1 Installation...........................................21

3.3.2 Drivers In Windows Mobile 6........... ...... ...... ...... ... .21

3.4 System Initialization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

3.5 Registry Keys..............................................22

3.5.2 Registry Settings For Serial Ports . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

3.5.3 Registry Settings For Psion Teklogix Device Drivers. . . . . . . . . . . . . . . . . . . . . 23

3.5.4 Registry Settings For Non-Psion Teklogix Device Drivers . . . . . . . . . . . . . . . . . . 23

3.5.4.1 Loading Non-PsionTeklogix Device Drivers....................24

3.6 COM Port Assignments.........................................24

3.7 The C++ Application Programming Interface..............................25

3.7.1 Installing The Software....................................25

3.7.2 Development Platforms........... ...... ...... ...... ...... .26

3.7.3 The Interrupts Namespace............................ ...... .26

3.7.4 The ExpansionWakeup Namespace.................... ...... ....26

3.7.5 The GPIO Namespace.....................................26

3.7.6 The EEPROM Namespace ..................................26

3.7.7 The ExpansionUSB Namespace................................26

3.7.8 The USBhub Namespace...................................27

3.7.9 The ScannerPort Namespace.................................27

3.7.10 The smBus Namespace....................................27

3.7.11 The PCMCIA Namespace...... ...... ...... ...... ... ...... .27

Psion Teklogix WORKABOUT PRO HDK User Manual 19

Page 30

Page 31

3.1 Overview

This chapter describes the software aspects of controlling expansion modules for the

WORKABOUT PRO.

3.2 Windows Drivers

3.2.1 The Peripheral Control (PCO) Driver

Psion Teklogix provides the peripheral control driver (PCO), a driver for the 100-pin expansion

slot. The PCO driver is a Streams driver activated very early at boot up time (it is loaded after the

File devices driver and the I2C driver).

3.2.2 The PCMCIA Driver

Hardware containing a PCMCIA slot may be connected to the 100-pin expansion slot. The PCO

driver determines whether this PCMCIA socket is present and enabled, and controls the loading of

the PCMCIA driver.

The PCMCIA driver handles both the Compact Flash and the PCMCIA socket interfaces. Since

the PCMCIA socket is itself an expansion module, the PCO driver must identify this hardware

prior to activating the PCMCIA driver.

Non-Psion Teklogix d rivers may no t separately activate the PCMCIA socket. You may design interfaces using the PCMCIA memory specification and interface to the hardware using the

predefined PCMCIA memory windows.

Chapter 3: Software

Overview

3.2.3 The Serial Port Driver

The PCO driver also controls the loading of the full-function UART serial port driver.

3.3 Non-Psion Teklogix Drivers

The Psion Teklogix platform loads some standard device drivers. If the expansion module uses

standard drivers such as PCMCIA, serial, or USB, there is no need to load customized drivers. For

information on specifying a Psion Teklogix driv er see “Expansion Mod ule EEPROM Fields” on

page 75.

3.3.1 Installation

All non-Psion Teklogix drivers must be installed in permanent storage—not in RAM. This ensures

that the driver can be activated after a cold reset.

There must be a registry entry for the driver and its parameters. For details see “Registry Keys” on

page 22.

The name of the driver must be set in the Manufacturer/Model field in the expansion module

EEPROM. For details see “Expansion Module EEPROM Fields” on page 75.

3.3.2 Drivers In Windows Mobile 6

The files required for signing drivers in Windows Mobile 6 are included in the HDK pack age.

Psion Teklogix WORKABOUT PRO HDK User Manual 21

Page 32

Chapter 3: Software

System Initialization

3.4 System Initialization

During system startup the following occur:

1. The expansion module EEPROM is initialized and read.

2. If a non-Psion Teklogix device driver is required, it is identified from the EEPROM data

and activated. For details of this process see “Loading Non-Psion Teklogix Device Drivers” on page 24.

3. The PCMCIA/Compact Flash card driver is activated if one of the following

conditions exists:

• The PCMCIA registry key is set. See “Registry Settings For Psion Teklogix Device Driv-

ers” on page 23.

•The Hardware type field in the expansion module EEPROM is set for a PCMCIA device.

See “Expansion Module EEPROM Fields” on page 75.

4. The full-function UART (FFUART) serial port driver is activated if one of the following

conditions exists:

• The FFUART registry key is set. See “Regis try Settings For Psion Teklogix Device Driv-

ers” on page 23.

•The Hardware type field in the expansion module EEPROM is set for a serial device. See

“Expansion Module EEPROM Fields” on page 75.

5. The USB hub is activated if one of the following conditions exists:

• The USB registry key is set. See “Registry Settings For Psion Teklogix Device Drivers” on

page 23.

•The Hardware type field in the expansion module EEPROM is set for a USB device . See

“Expansion Module EEPROM Fields” on page 75.

• A USB scanner is detected on the internal scanner port.

6. If a scanner is detected, the keyboard processor wakeup signals for the scan keys is set.

3.5 Registry Keys

3.5.1 Registry Settings For Controlling VGA

The WORKABOUT PRO VGA settings are located in the following registry subkey:

HKEY_LOCAL_MACHINE\Drivers\Display\NVDDI

Registry V alues

QVGA mode (REG_DWORD)

00 = VGA

non-zero = QVGA

Note: This value is only available for the WORKABOUT PRO 2nd. Generation.

3.5.2 Registry Settings For Serial Ports

The WORKABOUT PRO serial settings are located in the following registry subkey:

HKEY_LOCAL_MACHINE\Drivers\PsionTeklogix\Serial

22 Psion Teklogix WORKABOUT PRO HDK User Manual

Page 33

Registry Settings For Psion Teklogix Device Drivers

Note: These setting are specific to the platform and should be modified with care.

Registry V alues

HardwareFlowBaud (REG_DWORD)

Setting this value enables hardware R TS/CTS on the FFUART of the WORKABOUT PRO

2nd. Generation.

non-zero = the minimum baud rate where hardware flow control is enabled. The maximum rate is

921.6 k baud.

00 = enable all baud rates.

Note: This value is only available for the WORKABOUT PRO 2nd. Generation.

Index

Setting this value moves the COM port to a different location.

3.5.3 Registry Settings For Psion Teklogix Device Drivers

The WORKABOUT PRO device driver settings are located in the following registry subkey:

HKEY_LOCAL_MACHINE\Drivers\PsionTeklogix\Expansion Slot

Chapter 3: Software

Registry V alues

FFUAR T (REG_DWORD)

Setting this value enables hardware RTS/STS on the FF UART of the WORKABOUT PRO 2nd.

Generation. If the key is absent, the FFUAR T COM1: port is not enabled.

1 = enables the full-function UART (FFUART) using the stan dard serial driver as COM1 :.

0 = the FFUAR T COM1: port will not be enabled. (Default)

PCMCIA (REG_DWORD)

1 = enables the PCMCIA socket on the 100-pin connector—socket 1. The PCMCIA pins become

unavailable for other uses. The pins defined for this slot have predefined meanings and must be

adhered to in the hardware design.

0 = the PCMCIA socket is not be enabled. (Default)

USB (REG_DWORD)

1 = enables the USB hub and the 100-pin connector USB power control.

0 = neither the USB hub nor the USB power control signal will be enabled for the100-pin

connector. (Default)

Note: If the USB value is absent or has a value of 0, the expansion module USB power control can

still be controlled by the HDK API library .

3.5.4 Registry Settings For Non-Psion T eklogix Device Drivers

All non-Psion Teklogix device drivers mu st have a regis try entry. These device driver entries are

formatted as follows:

HKEY_LOCAL_MACHINE\Drivers\PsionT eklogix\Expansion Slot\EEPROM

Psion Teklogix WORKABOUT PRO HDK User Manual 23

Page 34

Chapter 3: Software

COM Port Assignments

Where: EEPROM is the name of the device driver. This is the contents of the

Manufacturer/Model field in the expansion module EEPROM. For details see “Expansion

Module EEPROM Fields” on page 75.

3.5.4.1 Loading Non-Psion Teklogix Device Drivers

At system startup the following process is used to load non-Psion Teklogix device drivers:

1. The contents of the Manufacturer/Model field in the expansion module EEPROM are

appended to the registry key

HKEY_LOCAL_MACHINE\Drivers\PsionTeklogix\Expansion Slot\

For example, if the Manufacture/Model field contains:

ACME gizmo

then the following driver is loaded:

HKEY_LOCAL_MACHINE\Drivers\PsionTeklogix\Expansion Slot\ACME gizmo

2. The DriverActivate() function uses this registry key to activate the driver.

No driver is loaded if:

•The Manufacturer/Model field is not valid, or it is empty.

• The derived registry key does not exist.

Note: If multiple device drivers are r equired for the same device, subkeys are defined. Only the

first driver is automatically activated. The application must load and activate all

additional device drivers.

3.6 COM P ort Assignments

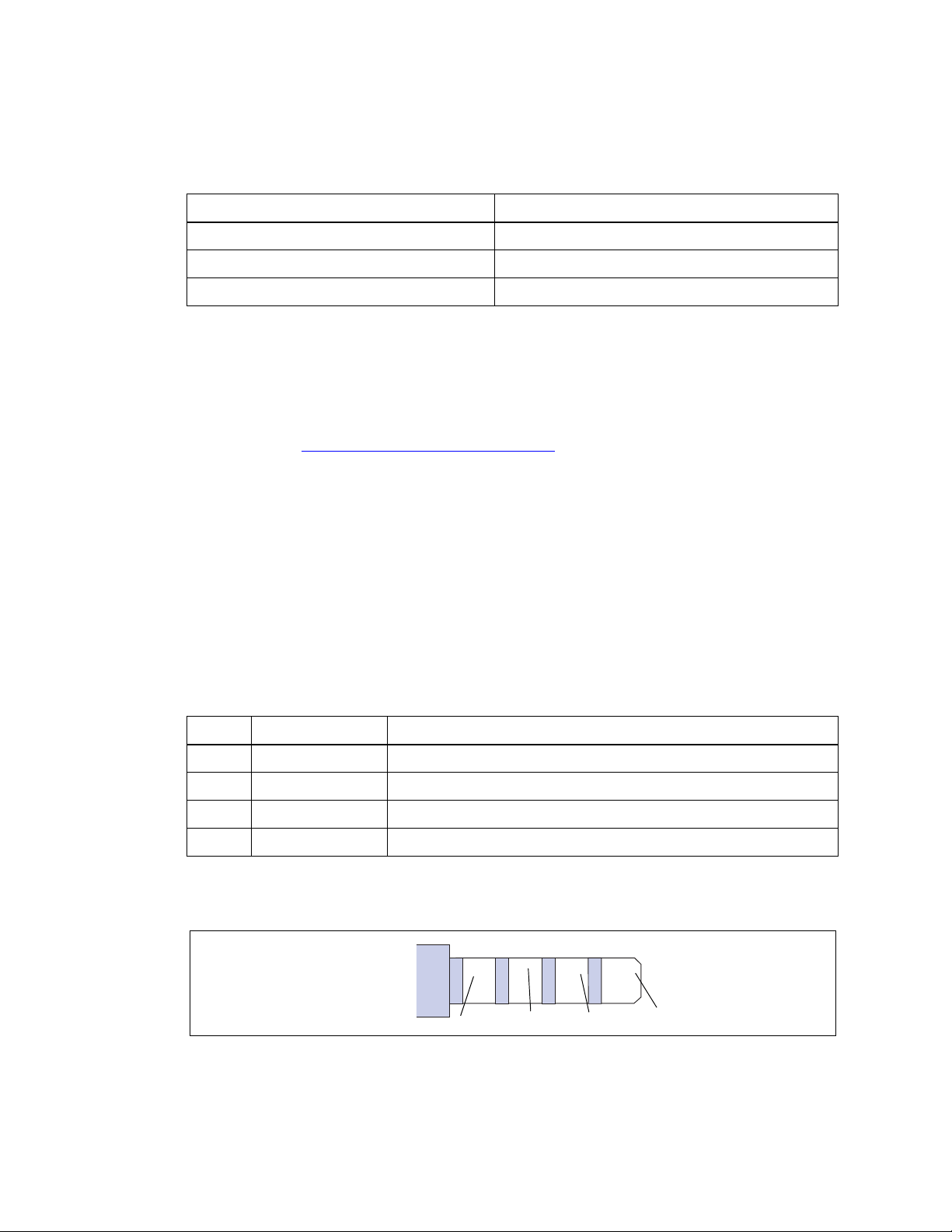

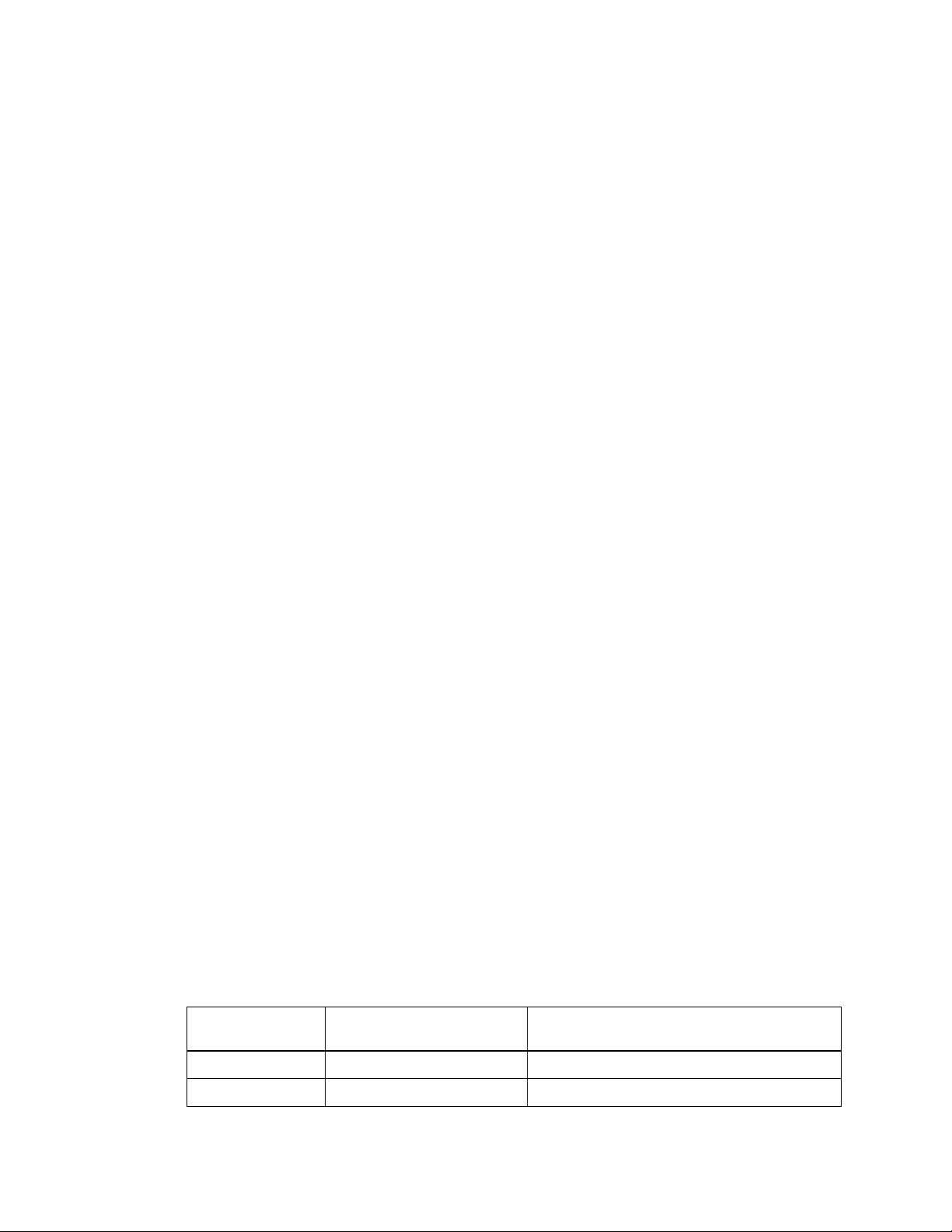

Table 3.1 Default COM-Port Assignment

COM Port

WORKABOUT PRO WORKABOUT PRO 2nd. Generation

COM0:

COM1: On 100-pin expansion connector. On 100-pin expansion connector.

COM2: Cannot be reassigned.

Internal Bluetooth radio. If no Bluetooth is

installed, or Bluetooth is disabled, this port

goes to the serial lines on the tether port.

An adapter is required to use these lines.

COM3: Cannot be reassigned.

Internal scanner or imager.

COM4: Cannot be reassigned.

USB client port—used by ActiveSync.

Default Assignment

Virtual serial port of the tether port. No

adapter is required to use these lines.

Cannot be reassigned.

Internal scanner or imager.

Cannot be reassigned.

USB client port—used by ActiveSync.

COM5: RS-232 port A on port replicator, and serial

port available on USB-to-serial adaptor.

This port is removed in suspend and

restored on resume.

24 Psion Teklogix WORKABOUT PRO HDK User Manual

RS-232 port A on port replicator , and serial

port available on USB-to-serial adaptor.

This port is removed in suspend and

restored on resume.

Page 35

Table 3.1 Default COM-Port Assignment

Chapter 3: Software

The C++ Application Programming Interface

COM Port

WORKABOUT PRO WORKABOUT PRO 2nd. Generation

COM6: RS-232 port B on port replicator.

This port is removed in suspend and

restored on resume.

COM7: RS-232 port C on port replicator.

This port is removed in suspend and

restored on resume.

COM8: Virtual port—for WWAN GSM Virt ual port— for WWAN GSM

COM9: Cannot be reassigned.

IRCOMM port.

COM20 Not available. Cannot be reassigned.

COM21 Not available. Built-in USB-Serial adapter port. This port

Default Assignment

RS-232 port B on port replicator.

This port is removed in suspend and

restored on resume.

RS-232 port C on port replicator.

This port is removed in suspend and

restored on resume.

Cannot be reassigned.

IRCOMM port.

Internal Bluetooth radio.

is removed in suspend and restored

on resume.

All COM ports can be reassigned excep t those marked as Cannot be reassigned. Reassignment is

done either using the Psion Teklogix COM Port Manager Control Panel program, or in th e

windows registry.

Serial ports on computers with user-accessible cards are assigned dynamically—at the lowest

available COM port number—as the cards are inserted and removed.

On the WORKABOUT PRO, the maximum baud rate is 230.4 k. On the WORKABOUT PRO

2nd. Generation, the maximum rate is 921.6 k baud if RTS/CTS hardware flow control is enabled.

Bluetooth

BSP: can be used to add a Bluetooth virtual COM port. For setup instructions see the User Manu al

for your WORKABOUT PRO.

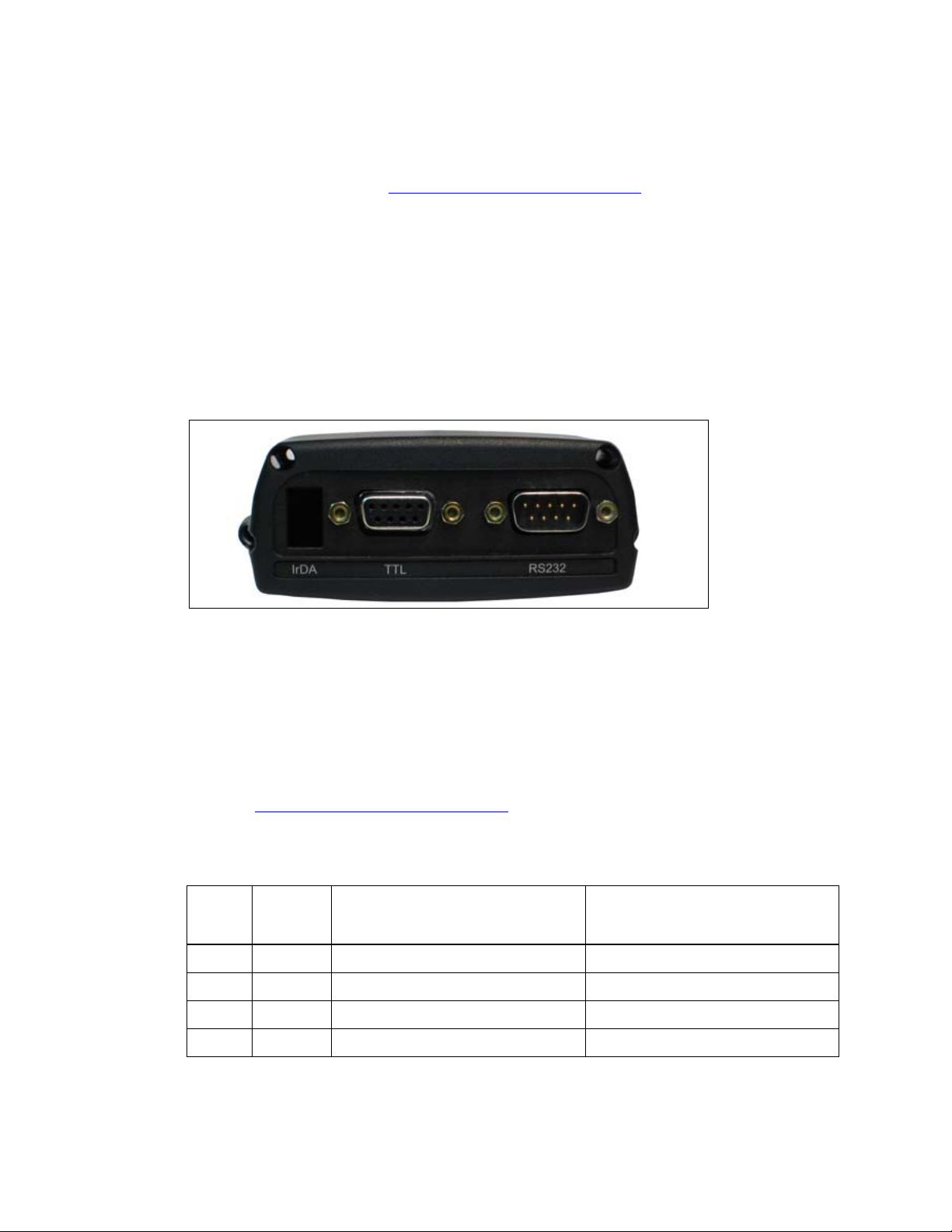

Psion Teklogix Serial Endcaps

Psion Teklogix supplies endcaps with serial ports for the WORKABOUT PRO and for the

WORKABOUT PRO 2nd. Generation computers. These endcaps use the following serial ports:

• IrDA, TTL, and RS-232 serial endcap (BR1000)—COM9:, COM0:, COM1:, and COM8:

• RS-232 serial endcap (BR1001)—COM9: and COM1:

• IrDA serial endcap (BR1002)—COM9: and COM0:

3.7 The C++ Application Programming Interface

The WORKABOUT PRO HDK API library enables application programs to control custom-built

hardware that connects to the 100-pin connector and the scanner connector.

3.7.1 Installing The Software

The WORKABOUT PRO HDK API library is installed as part of the Psion Teklogix Mobile

Devices SDK.

Psion Teklogix WORKABOUT PRO HDK User Manual 25

Page 36

Chapter 3: Software

Development Platforms

3.7.2 Development Platforms

The following development platforms should be used with the WORKABOUT PRO HDK:

Windows Development Environment

Windows Mobile 2003 Microsoft eMbedded Visual C++ 4.0 compiler. It is

Windows CE .NET 4.2

Windows Embedded CE 5.0

Windows Mobile 6

3.7.3 The Interrupts Namespace

This namespace is used to manage interrupts from the expansion module. The expansion module

interrupt pins are also used by the PCMCIA socket.

The following program-accessible interrupt pins are provided on the 100-pin connector:

• InputPin63

• InputPin65

If the PCMCIA driver is in use, these interrupt pins are not available.

If these pins are not used as interrupts, or by PCMCIA, they are available as GPIO.

recommended that eMbedded Visual C++ 4.0 Service Pack 3

(SP3) be installed.

Microsoft Visual Studio 2005.Windows Mobile 5

3.7.4 The ExpansionWakeup Namespace

This namespace manages the wakeup from suspend signal on pin 79 of the 100-pin co nnector . The

wakeup can be enabled or disabled.

This signal is connected to the keyboard controller and is monitored from there. This pin wakes

the processor but does not generate a software-accessible interrupt.

3.7.5 The GPIO Namespace