MP6000

INTEGRATOR GUIDE

MP6000

INTEGRATOR GUIDE

72E-172632-13

Revision A

February 2017

ii MP6000 INTEGRATOR GUIDE

No part of this publication may be reproduced or used in any form, or by any electrical or mechanical means,

without permission in writing from Zebra. This includes electronic or mechanical means, such as photo copying,

recording, or information storage and retrieval systems. The material in this manual is subject to change

without notice.

The software is provided strictly on an “as is” basis. All softwa

a licensed basis. Zebra grants to the user a non-transferable and non-exclusive license to use each software

or firmware program delivered hereunder (licensed program) . Except as n oted below, such licen se may n ot be

assigned, sub-licensed, or otherwise transferred by the user without prior written consent of Zebra. No right to

copy a licensed program in whole or in part is granted, except as permitted under copyright law. The user shall

not modify , merge, or incorporate any for m or portion of a licensed program with other pro gram material, create

a derivative work from a licensed program , or us e a li censed program in a network without written permission

from Zebra. The user agrees to maintain Zebra’s copyright notice on the licensed programs delivered

hereunder , and to include the same on any au thorized copies it m akes, in whole or in part. The user agree s not

to decompile, disassemble, decode, or reverse engineer any licensed program delivered to the user or any

portion thereof.

Zebra reserves the right to make changes

Zebra does not assume any product liability arising out of, or in connection with, the application or use of any

product, circuit, or application described herein.

No license is granted, either expressly or by implicatio

Corporation, intellectual property rights. An implied license only exists for equipment, circuits, and su bsystems

contained in Zebra products.

Zebra Technologies Corporation

Lincolnshire, IL U.S.A.

http://www.zebra.com

to any software or product to improve reliability, function, or design.

n, estoppel, or otherwise under any Zebra Technologies

re, including firmware, furnished to the user is on

Warranty

Subject to the terms of Zebra’s hardware warranty statement, the MP6000 is warranted against defects in

workmanship and materials for a period of 1 (one) year from the date of shipment.

For the complete Zebra hardware product warranty statement, go to:

http://www.zebra.com/warranty

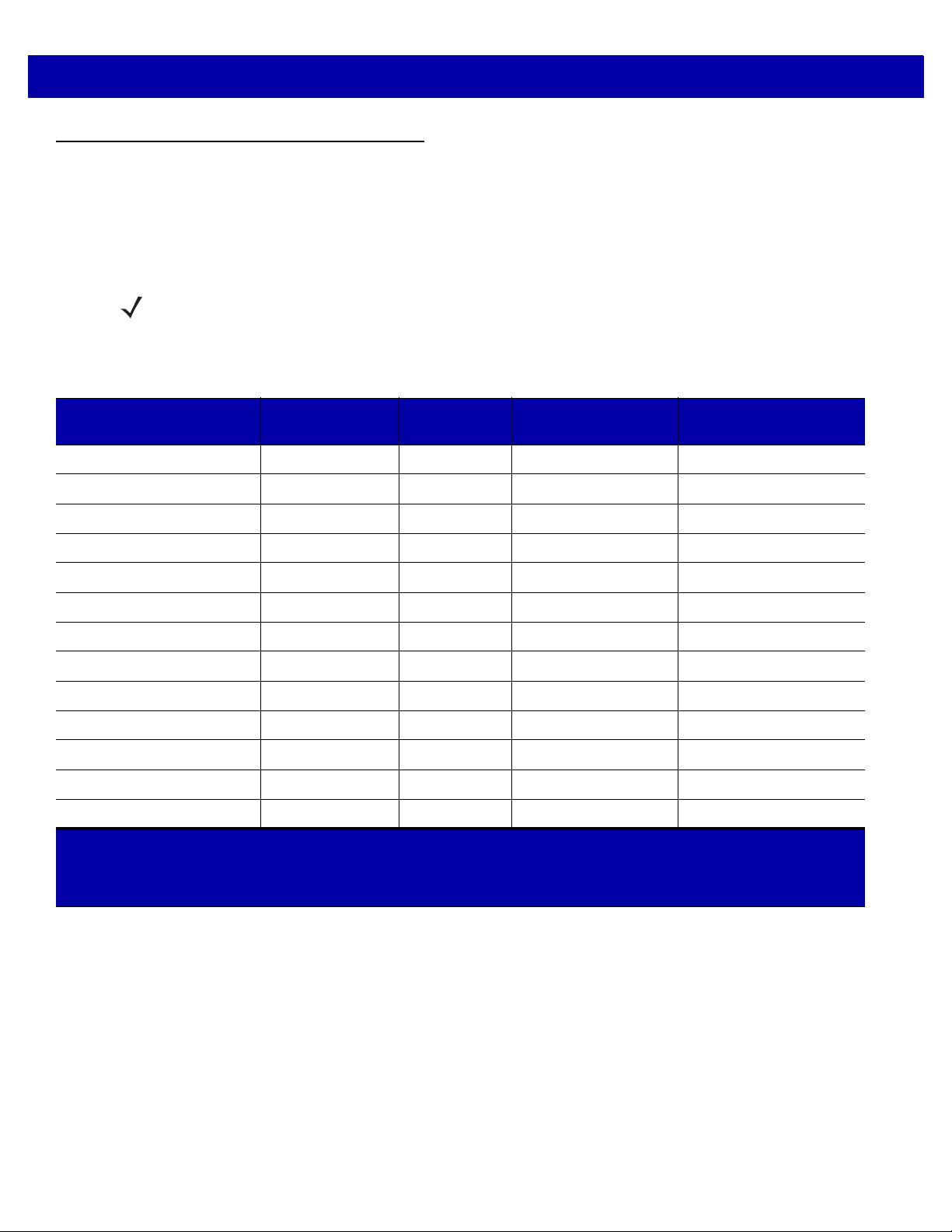

Revision History

T abl e A includes revisions to the guide.

iii

Table A

-01 Rev A 6/2013 Initial Release.

-02 Rev A 6/2013

-03 Rev A 12/2014

Revisions

Change Date Description

Added:

- Figure 3-43, Sensormatic Coil Routing

Updated:

- Figure 1-2, Left Side View

- Figure 3-44, Checkpoint Ante nna Installa tion

- Figure A-2 callouts

- Checkpoint antenna routing color

Added:

- NCR single cable scanner/scale, NCR scanner, Datalogic scanner only, and new

RS-232 bar codes.

- Support for third party hand-held scanners using USB auxiliary ports.

- RS-232 host connection to AUX 2 port (leaves USB host port available for future

e).

us

- Programmable scale initial zero setting range.

- IBM scale 3-byte status support.

- Volume button disable feature.

- Dual cable scale (SASI only).

- Wincor A/B, and RS-232 host interfaces (see

- USB HID keyboard interface.

- Drivers License Parsing (some models).

Updated:

- Host interface ports, and cables.

Table 2-4 on page 2-15

).

-04 Rev A 5/2014

-05 Rev A 7/2014

Added:

- Third Party Scale bar codes.

- Price Computational Scale Interface circuit drawing.

- Mounting frame.

Updated:

- Added information to step 2 on page 4-7.

Updated:

- Table A-1; E18, E25, E27 and E30 errors changed to warnings.

5.0

-From Active Mode

peak.

average, <12W peak to Active Mode

4.65

average, <12W

iv MP6000 INTEGRATOR GUIDE

Table A

-06 Rev A 11/2014

Revisions (Continued)

Change Date Description

Updated:

- Price Computational Scale Interface.

- Connecting the USB Cable.

- Checkpoint Antenna Installation.

- Page 1-3, Table 1-1: added Bahamas and Ecuador to OIML group.

- Figure 3-41; Adjusting Leveling Screws.

- Figure 3-46; Checkpoint Antenna Installation.

- Page 4-3: Updated Step 1 - Electronic Entry into Calibration Mode to include new

mware version calibration.

fir

- Page 5-6: Customer Side Scanner (CSS) - Optional section; second paragraph

phrased.

re

Added:

- Page 1-3: Leek platter diagram, and description.

- Page 2-20: NCR Variant (both scanner only and scanner/scale versions).

- Page 3-18: Speaker Wire Ferrite Placement (step and figure).

- Figures 3-43 and 3-44; installing Sensormatic coils.

- Replace drawing with Figure 3-40; Lowering the Short, Medium, Long MP6000 into

e Counter.

th

- Diagrams for installing Sensormatic Coils.

- Page 4-8: Added the "Important" note regarding newer firmware in the section

Calibra

- Page 4-11: "Important" note about audit tallies.

- Page 5-27, Table 5-1: Added a new row for "Press and hold Scale Zero and

V

- Page A-2: Under sect ion "L ED Display Notes" added "For scale firmware versi on #

1.0

- Appendix E, Com Protocols.

- Zebra Branding.

- Added Ident

times.

tion Mode Exit Conditions.

olume/Tone buttons" with two notes.

4F (for applicable countries)" information.

ifying Firmware Version section, and various notes about new firmware

-07 Rev A 3/2015 - Zebra Rebranding

-08 Rev A 5/2015

-09 Rev A 6/2015 - Error codes U32/U33 were changed to E32/E33.

-10 Rev A 11/2015 - Updated Figure 1-6 (missed Motorola logo).

-11 Rev A 1/2016 - Added Statistics appendix.

-12 Rev A 9/2016 - Added note regarding RS-232 NCR setting; updated 123Scan chapter.

Updated:

- Scale Zero Button section.

- Warning code U12 with zeroing weight limit info

- Note on page 1-8...changed presentation cradle to standard cradle.

- Power consumption information in Tech Specs.

- 123Scan text.

- Symbol Native API (SNAPI) with Ima

Added:

- Warning about checkpoint antenna placement.

- IP Rating (Environmental Sealing) to Tech Specs.

- Warning to the Checkpoint Installation on page 3-27 to note that if the checkpoint

tenna is not sitting completely below its routing features it can cause issues with

an

scale functionality.

ging Interface info in table E-1.

rmation.

v

Table A

-13 Rev A 01/2017 - Added manual scale calibration information.

Revisions (Continued)

Change Date Description

- Added two new entries to table 4-2.

- Added various text throughout guide regarding the calibration switch.

vi MP6000 INTEGRATOR GUIDE

TABLE OF CONTENTS

Warranty ......................................................................................................................................... ii

Revision History.............................................................................................................................. iii

About This Guide

Introduction..................................................................................................................................... v

Chapter Descriptions ...................................................................................................................... v

Notational Conventions................................................................................................................... vi

Related Publications....................................................................................................................... vi

Recommended Services Information.............................................................................................. vii

Chapter 1: PRODUCT OVERVIEW AND FEATURES

Introduction .................................................................................................................................... 1-1

Product Overview ........................................................................................................................... 1-2

Configurations ................................................................................................................................ 1-3

Peripherals ..................................................................................................................................... 1-8

Supported Auxiliary Hand-held Scanner .................................................................................. 1-8

EAS Devices ............................................................................................................................ 1-8

Scale Devices .......................................................................................................................... 1-8

USB Flash Drives ..................................................................................................................... 1-8

Customer Side Scanner (CSS) ................................................................................................ 1-8

Features of the MP6000 ................................................................................................................ 1-9

Optional Leak Platter (European Configurations Only) ............................................................ 1-13

Features Summary .................................................................................................................. 1-13

Chapter 2: HOST INTERFACES AND CABLE PINOUTS

Overview ........................................................................................................................................ 2-1

Interfaces, Components, and Communication ............................................................................... 2-2

POS Interfaces and Host Communication ............................................................................... 2-2

Auxiliary Ports and Peripherals ................................................................................................ 2-2

Programming Management Tools ............................................................................................ 2-3

Application Programming Interfaces ........................................................................................ 2-3

viii MP6000 INTEGRATOR GUIDE

Connecting a USB Interface .......................................................................................................... 2-4

USB Host Parameters ................................................................................................................... 2-6

USB Device Type ..................................................................................................................... 2-6

Connecting an RS-232 Interface ................................................................................................... 2-12

MP6000 Scanner Only or MP6200/6500 Scale with Single Cable Protocol ............................ 2-12

Price Computational Scale Interface Circuit Drawing .............................................................. 2-13

Connect MP6000 to RS-232 Host ............................................................................................ 2-14

MP6000 with a Dual Cable Scanner/Scale .............................................................................. 2-14

RS-232 Parameters ....................................................................................................................... 2-15

RS-232 Host Parameters ............................................................................................................... 2-16

RS-232 Host Types ............................................................................................................. ..... 2-20

RS-232 Host -NCR Variant ................................................................................................ 2-30

RS-232 Host -Datalogic Variant ......................................................................................... 2-32

RS-232 Device Port Configuration ........................................................................................... 2-33

Third Party Scale Parameters .................................................................................................. 2-38

Third Party Scale ............................................................................................................... 2-38

Third Party Scale LED Pin ................................................................................................. 2-40

Third Party Scale Zero Pin ................................................................................................. 2-42

Connecting an IBM RS-485 Interface ............................................................................................ 2-44

IBM RS-485 Host Parameters ....................................................................................................... 2-45

IBM Scale Port Addresses ....................................................................................................... 2-50

Connector Pins .............................................................................................................................. 2-54

RS-232 AUX 1 ................................................................................................................... 2-54

Scale Display Port .............................................................................................................. 2-54

RS-232 AUX 2 ................................................................................................................... 2-55

Checkpoint Interlock .......................................................................................................... 2-55

AUX A-B (Stacked USB) .................................................................................................... 2-55

POS ................................................................................................................................... 2-56

12V DC ............................................................................................................................. 2-56

Chapter 3: SITE PREPARATION AND INSTALLATION

Overview ........................................................................................................................................ 3-1

Site Preparation ............................................................................................................................. 3-2

Ventilation and Spacing Requirements .................................................................................... 3-2

Service Access Requirements ................................................................................................. 3-2

Electrical Power Considerations .............................................................................................. 3-3

Grounding .......................................................................................................................... 3-3

Checkstand Preparation .......................................................................................................... 3-4

Liquid Spills and Moisture .................................................................................................. 3-4

Vertical Clearance .............................................................................................................. 3-4

Tools .................................................................................................................................. 3-4

Counter Cutout ................................................................................................................... 3-5

Ergonomics ........................................................................................................................ 3-5

Installing Components ................................................................................................................... 3-6

Quick Reference Installation Steps .......................................................................................... 3-6

Remove Existing Bioptic Scanner and Accessories ................................................................ 3-7

Unpacking MP6000 Equipment ............................................................................................... 3-7

Pre-Installation Notes ......................................................................................................... 3-8

Assemble the Dual Head Scale Display .................................................................................. 3-9

Required Tools ................................................................................................................... 3-9

Table of Contents ix

Install the Scale Display ........................................................................................................... 3-12

Getting Started ................................................................................................................... 3-14

Installing ............................................................................................................................. 3-15

Cables and Connections .......................................................................................................... 3-15

Install the Customer Side Scanner (MX101) ............................................................................ 3-16

Installing the MX101 on the Customer’s Right Side (Default) of the Tower Cover ............ 3-17

Installing the MX101 on the Customer’s Left Side of the Tower Cover .............................. 3-22

Affixing the Identification Label .......................................................................................... 3-24

Install the MP6000 /Scale ........................................................................................................ 3-25

Checkstand Counter Cutouts and MP6000 Dimensions .................................................... 3-25

Cutout/Dimensions - MP6000 Short ................................................................................... 3-26

Cutout/Dimensions - MP6000 Short (continued) ................................................................ 3-27

Cutout/Dimensions - MP6000 Medium .............................................................................. 3-28

Cutout/Dimensions - MP6000 Long ................................................................................... 3-30

Install Sensormatic Coils .......................................................................................................... 3-34

Install Checkpoint Antenna ...................................................................................................... 3-37

Trim Kit Installation (If Required) ............................................................................................. 3-38

MP6000 Mounting Frame (If Required) ................................................................................... 3-39

Chapter 4: SCALE CALIBRATION (MODELS WITH A SCALE ONLY)

Overview ........................................................................................................................................ 4-1

Scale Calibration Procedure (Scanner/Scale Configurations Only) ............................................... 4-2

Scale Configurations ................................................................................................................ 4-2

Identifying Firmware Version ................................................................................................... 4-2

Step 1 - Electronic Entry into Calibration Mode ....................................................................... 4-3

Firmware Versions Older Than v3.4 .................................................................................. 4-3

Firmware Versions Newer Than v3.4 ................................................................................. 4-3

Step 2 - Manual Entry into Calibration Mode ........................................................................... 4-3

Step 3 - Program Legal Parameters ........................................................................................ 4-4

Legal Scale Units (Unit Selection) - Kilograms or Pounds ................................................. 4-5

Important Notes .................................................................................................................. 4-5

Legal Scale Dampening Filter ............................................................................................ 4-5

Step 4 - Calibration at NO LOAD ............................................................................................. 4-5

Step 5 - Calibration at LOAD ................................................................................................... 4-6

Step 6 - Calibration Success or Failure ................................................................................... 4-8

Calibration Success ........................................................................................................... 4-8

Calibration Failure .............................................................................................................. 4-8

Possible Reasons for a Fail ............................................................................................... 4-8

Calibration Mode Exit Conditions ............................................................................................. 4-10

Verification Test ....................................................................................................................... 4-10

Audit Tallies ............................................................................................................................. 4-13

Scale Configuration Parameters .................................................................................................... 4-15

Legal Scale Units ..................................................................................................................... 4-15

Scale Display Configuration ..................................................................................................... 4-17

Legal Scale Dampening Filter Setting ...................................................................................... 4-19

User Interface Displays and Signals .............................................................................................. 4-23

x MP6000 INTEGRATOR GUIDE

Chapter 5: OPERATING THE SCANNER

Overview ........................................................................................................................................ 5-1

Controls and Indicators .................................................................................................................. 5-2

LED Array Bar .......................................................................................................................... 5-2

Diagnostic LED/7-segment Display ......................................................................................... 5-3

Front Panel Buttons ................................................................................................................. 5-4

The three front panel user interface buttons are backlit for ease of use. ........................... 5-4

Scale Zero Button (Configurations with Scale Only) .......................................................... 5-4

Volume/Tone Control Button .............................................................................................. 5-4

Sensormatic Manual Activation and Sensormatic Status Button ....................................... 5-5

Soft Reset Buttons ............................................................................................................ . 5-5

MP6000 Related Hardware ........................................................................................................... 5-6

Scale Display (Scanner/Scale Configurations Only) ................................................................ 5-6

Scale (Scanner/Scale Configurations Only) ............................................................................. 5-6

Single Interval Range Scales ............................................................................................. 5-6

Dual Interval Range Scales ............................................................................................... 5-6

Calibration Switch .............................................................................................................. 5-6

Customer Side Scanner (CSS) - Optional ............................................................................... 5-6

Platter ....................................................................................................................................... 5-7

Installing/Removing the Short and Medium Non-Scale Platters ........................................ 5-7

Installing/Removing the Long Non-Scale and Medium Scale Platters ............................... 5-7

Installing/Removing the Long Scale Platter ....................................................................... 5-8

Scan Windows ......................................................................................................................... 5-9

Operating Modes ........................................................................................................................... 5-10

Programming the MP6000 ............................................................................................................. 5-10

Programming Management tools ............................................................................................. 5-10

Application Programming Interfaces ........................................................................................ 5-10

Programming Bar Codes ......................................................................................................... 5-11

USB Staging Flash Drive ............................................................................................................... 5-12

MP6000 Menu Structure for the USB Staging Flash Drive ...................................................... 5-12

Manually Staging/Configuring MP6000 Devices ...................................................................... 5-13

Loading Cloning Files ........................................................................................................ 5-14

123Scan Staging Flash Drive Configuration ............................................................................ 5-15

Approved USB Flash Drives for the Flash Drive Well .............................................................. 5-15

Scanning ........................................................................................................................................ 5-16

Weighing Items .............................................................................................................................. 5-17

Electronic Article Surveillance (EAS) ............................................................................................. 5-18

Supported EAS Controllers ...................................................................................................... 5-18

EAS Operating Modes and Settings ........................................................................................ 5-18

Checkpoint Controller .............................................................................................................. 5-19

Sensormatic Controller ............................................................................................................ 5-19

Sensormatic EAS Hard Tags ................................................................................................... 5-19

Sensormatic EAS Soft Tags (Labels) ...................................................................................... 5-20

Beeper and LED Conditions .......................................................................................................... 5-21

Table of Contents xi

Chapter 6: 123SCAN

Introduction .................................................................................................................................... 6-1

123Scan ......................................................................................................................................... 6-1

Communication with 123Scan ................................................................................................. 6-2

123Scan Requirements ........................................................................................................... 6-2

123Scan Information ................................................................................................................ 6-3

Scanner SDK, Other Software Tools, and Videos ................................................................... 6-3

Scanner Control App ...................................................................................................................... 6-4

Advanced Data Formatting (ADF) .................................................................................................. 6-4

Multicode Data Formatting (MDF) .................................................................................................. 6-5

Programming Options .............................................................................................................. 6-5

MDF Terms and Definitions ..................................................................................................... 6-5

Preferred Symbol ........................................................................................................................... 6-6

Programming Options .............................................................................................................. 6-6

Chapter 6:

Appendix A: MAINTENANCE, TROUBLESHOOTING, AND ERROR CODES

Overview ........................................................................................................................................ A-1

Maintenance .................................................................................................................................. A-1

Troubleshooting ............................................................................................................................. A-2

Diagnostic LED 7-segment Display - Error and Warning Codes ............................................. A-2

LED Display Notes ................................................................................................................... A-2

Status Indicator Light ............................................................................................................... A-2

Troubleshooting Assistance ..................................................................................................... A-3

General Error and Warning Codes .......................................................................................... A-5

Scale Warning Codes .............................................................................................................. A-6

Appendix B: TECHNICAL SPECIFICATIONS

Technical Specifications ................................................................................................................ B-1

Appendix C: HOST INTERFACE CHARACTER SETS

Overview ........................................................................................................................................ C-1

RS-232 Character Sets .................................................................................................................. C-2

Appendix D: PARAMETER DEFAULT TABLE

Appendix E: COMMUNICATION PROTOCOLS

Appendix F: STATISTICS

Index

xii MP6000 INTEGRATOR GUIDE

ABOUT THIS GUIDE

Introduction

The MP6000 Integrator Guide provides information on installing, operating, and programming the MP6000.

Chapter Descriptions

Following are brief descriptions of each chapter in this guide.

•

Chapter 1, PRODUCT OVERVIEW AND FEATURES provides an overview of the MP6000 including

configurations, peripherals, and features.

•

Chapter 2, HOST INTERFACES AND CABLE PINOUTS describes the host interfaces supported by the

MP6000, how to connect the MP6000 to a host, setup, and cable pin-outs. It also includ es host inter face bar

codes.

•

Chapter 3, SITE PREPARATION AND INSTALLATION describes how to install the MP6000 into a counter

top.

•

Chapter 4, SCALE CALIBRATION (MODELS WITH A SCALE ONLY) describes how to change weight

measurement, calibrate the scale, verify calibration, and recognize errors.

•

Chapter 5, OPERA TING THE SCANNER descr ibes how to ope rate the MP6000 including bu ttons, switches,

LED indicators, and scanning.

•

Chapter 6, 123SCAN provides information about configuring the MP6000 using the 123Scan utility.

•

Appendix A, MAINTENANCE, TROUBLESHOOTING, AND ERROR CODES provides error/warning codes,

troubleshooting, and maintenance information.

•

Appendix B, TECHNICAL SPECIFICATION S provides technical information about the MP6000.

•

Appendix C, HOST INTERFACE CHARACTER SETS provides ASCII character sets for some host

interfaces.

•

Appendix D, PARAMETER DEFAULT TABLE pro vides a list of defaults for the parameters in this guide. For

all MP6000 programming bar codes, refer to the MP6000 Bar Code Programming Guide (p/n

E-172633-xx).

72

•

Appendix E, COMMUNICATION PROTOCOLS provides a table of MP6000 communication interfaces.

vi MP6000 INTEGRATOR GUIDE

Notational Conventions

This document uses these conventions:

•

“User” refers to anyone operating the device.

•

“Device” refers to the MP6000.

•

Italics are used to highlight specific items in the general text, and to identify chapters and sections in this

and related documents. It also identifies names of windows, menus, menu items, and fields within

windows.

•

Bold identifies buttons, and switches to be tapped or clicked, and bar code names.

•

Bullets (•) indicate:

• lists of alternatives or action items.

• lists of re

•

Numbered lists indicate a set of sequential steps, i.e., those that describe step-by-step procedures.

NOTE This symbol indicates something of special interest to the reader. Failure to read the note will not result in

quired steps that are not necessarily sequential.

physical harm to the bar code reader, equipment or data.

IMPORTANT This symbol indicates something of importance to the reader. Failure to read the note may impair

the equipment or data.

CAUTION This symbol indicates that if this information is ignored, the possibility of data or material damage

may occur.

WARNING! This symbol indicates that if this information is ignored the possibility that serious

personal injury may occur.

Related Publications

Following is a list of documents that provide additional information about configuring the MP6000:

•

MP6000 BAR CODE PROGRAMMING GUIDE,

p/n 72E-172633-xx, provides bar codes for MP6000 configuration.

•

MX101 PRODUCT REFERENCE GUIDE, p/n 72E-171320-xx, provides general instructions for setting

up, operating, maintaining, and troubleshooting the MX101 digital scanner.

•

MP6000 MULTI-PLANE IMAGING SCANNER REGULATORY GUIDE, p/n 72-171321-xx, provides

domestic and international regulatory information.

•

Advanced Data Formatting Programmer Guide, p/n 72E-69680-xx, provides information on ADF, a

means of customizing data before transmission to a host.

For the latest version of this guide an

d all guides, go to: http://www.zebra.com/support

Recommended Services Information

If you have a problem using the equipment, contact your facility's technical or systems support. If there is a

problem with the equipment, they will contact the Zebra Customer Support Center at:

http://www.zebra.com/support

About This Guide vii

When contacting Zebra support, please have the

•

Serial number of the unit

•

Model number or product name

•

Software type and version number (if available).

Zebra responds to calls by e-mail, telephone or fax within the time

If your problem cannot be solved by the Zebra Customer Support Center, you may need to return your

e

quipment for servicing and will be given specific directions, a Field Service Technician from Zebra, or your

authorized service provider may be sent to your loca tion to pe rf or m th e re pa ir, depending on your level of

entitlement set forth in the service agreement. Zebra is not responsible for any damages incurred during

shipment if the approved shipping container is not used. Shipping the units improperly can possibly void the

warranty.

If you purchased your business product from a Zebra business pa

for support.

Zebra recommends the following Service options to kee

throughout its lifecycle:

•

Service from the Start with Advance Exchange Support (available for scanner-only configurations).

•

Service from the Start with On Site System Support (available for scanner-only and scanner/scale

configurations).

following information available:

limits set forth in service agreements.

rtner, please contact that business partner

p the MP6000 operating at peak performance

•

Zebra also offers service support through authorized resellers who qualify as authorized service

partners.

viii MP6000 INTEGRATOR GUIDE

CHAPTER 1 PRODUCT OVERVIEW AND

FEATURES

Introduction

This chapter includes the following topics:

•

Product Overview on page 1-2

•

Configurations on page 1-3

•

Peripherals on page 1-8

•

Features of the MP6000 on page 1-9.

1 - 2 MP6000 INTEGRATOR GUIDE

Product Overview

The MP6000 is a data capture solution that uses a sophisticated optical arrangement to view six sides of an

object as it passes through the scanning area. Bar code data is transmitted to a Point-Of-Sale (POS) host via

USB, RS-232, or RS-485. Auxiliary device support includes USB and RS-232 hand-held scanners, Checkpoint

and Sensormatic Electronic Article Surveillance (EAS), scale and optional Scale Display (varies with the

model), USB staging flash drive (memory stick), as well as an optional Customer Side Scanner (2D imager)

that may be mounted into the tower.

The MP6000 is designed to be embedded in a cutout in the retail checkstand.

Features include:

•

Six sided scanning

• Rea

• Omni-directional symbol orientation.

•

Optional integrated scale (single/dual interval).

•

Optional Checkpoint EAS antenna.

ds top-bottom, left-right, and cashier-customer side bar codes

•

Optional integrated Sensormatic EAS coil antennas.

•

Optional Scale Display (single/dual head) for scale installations.

•

Auxiliary scanner support (USB and RS-232).

•

High swipe speed for increased throughpu t.

•

User interface (LED indicators, touch controls, audio).

•

Aggressive scanning performance on high density, truncated, and poorly printed bar codes.

•

2D scanning (PDF, Aztec etc.) in both vertical and horizontal windows, or all six-sided orientations.

•

Mobile bar code scanning (cell phone) in both vertical and horizontal windows, or all six-sided

orientations.

•

Optional integrated Customer Side Scanner (CSS) [1D/2D support].

•

Scanner Management Service (SMS), and 123Scan² support enables remote configur ation and

monitoring attached peripherals.

Configurations

The MP6000 captures printed or mobile 1D or 2D bar codes. An optional customer-side scanner (CSS) can be

added for bar codes displayed on mobile phones, traditional loyalty cards, or item bar codes. Hand-held

scanner, integrated EAS, and scale support is also available.

This guide covers the configurations listed in Table 1-1.

NOTE 1. All configurations of the MP6000 include a sapphire glass horizontal platter. An optional sapphire

glass horizontal leak platter is also available for EU configurations.

2. New scale configurations are added continually. If you don’t see your country listed, call your

Zebra office.

PRODUCT OVERVIEW AND FEATURES 1 - 3

Table 1-1

MP6000-LN000M010US Multi-plane scanner, long, with Checkpoint, worldwide.

MP6000-LP000M010US Multi-plane scanner, long, with Checkpoint, with DL Parsing, US/CA.

MP6000-MN000M010US Multi-plane scanner, medium, with Checkpoint, worldwide.

MP6000-MP000M010US Multi-plane scanner, medium, with Checkpoint, with DL Parsing, US/CA.

MP6000-SN000M010US Multi-plane scanner, short, with Checkpoint, worldwide.

MP6000-SP000M010US Multi-plane scanner, short, with Checkpoint, with DL Parsing, US/CA.

MP6010-LN000M010US Multi-plane scanner, long, with Checkpoint, with CSS, worldwide.

MP6010-LP000M010US Multi-plane scanner, long, with Checkpoint, with DL

MP6010-MN000M010US Multi-plane scanner, medium, with Checkpoint, with CSS, worldwide.

MP6010-MP000M010US Multi-plane scanner, medium, with Checkpoint, with DL Parsing, US/CA.

MP6010-SN000M010US Multi-plane scanner, short, with Checkp

MP6010-SP000M010US Multi-plane scanner, short, with Checkpoint, with DL Parsing, US/CA.

MP6200-LN000M010AU Multi-plane scanner, long, with sin gle interv

MP6000 Configurations

Configuration Description

Parsing, US/CA.

oint, with CSS, worldwide.

al scale, with Checkpoint, scale for

Australia/NZ/SA.

MP6200-LN000M010CM Multi-plane scanner, long, single interv

Canada-Mexico scale label.

MP6200-LN000M010EU

Notes:

1. EU scales are legally accepted in the following countries:

Austria, Belgium, Bulgaria, Cyprus, Czech Republic, Denmark, Estonia, Finland, France,

Germany, Greece, Hungary, Ireland, Iceland, Italy, Liechtenstein, Lithuania, Luxembourg, Latvia,

Malta, Netherlands, Norway, Poland, Portugal, Romania, Slovak Republic, Spain, Sweden,

Switzerland, United Kingdom

2. OIML scales are legally accepted in the following countries: Bahamas, Barbados, Belize,

Bermuda, Chile, Colombia, Costa Rica, Ecuador, El Salvador, Guatemala, Hong Kong, Jamaica,

Saint Lucia, Philippines, Thailand, Trinidad and Tobago, Vietnam

Multi-plane scanner, long, with single interval scale, with Checkpoint, scale for

EU countries.

al kg scale, no CSS, Checkpoint,

1 - 4 MP6000 INTEGRATOR GUIDE

Table 1-1

MP6200-LN000M010NN Multi-plane scanner, long, with sin gle interv al scale, with Checkpoint, scale for

MP6200-LN000M010US Multi-plane scanner , long, with sin gle inter

MP6200-LN000M01ABE Multi-plane scanner, Long with single interva

MP6200-LN000M01BBE Multi-plane scanner, Long with single interva

MP6200-LN000M01CBE Multi-plane scanner, Long with single interva

MP6200-LP000M010US Multi-plane scanner, long, with single interv

MP6200-MN000M010AU Multi-plane scanner , medium, with single inter val scale, with Checkpoint, scale

MP6200-MN000M010CM Multi-plane scanner, medium, single interva

MP6000 Configurations (Continued)

Configuration Description

OIML countries.

US/Puerto Rico/Guam/USVI/British VI.

Gravity Zone A for Belgium.

Gravity Zone B for Belgium.

Gravity Zone C for Belgium.

parsing, scale for US.

r Australia/NZ/SA.

fo

Canada-Mexico scale label.

val scale, with Checkpoint, scale for

l kg scale, with Checkpoint, scale

l kg scale, with Checkpoint, scale

l kg scale, with Checkpoint, scale

al scale, with Checkpoint, with DL

l kg scale, no CSS, Checkpoint,

MP6200-MN000M010EU Multi-plane scanner , medium, with single inter val scale, with Checkpoint, scale

or EU countries.

f

MP6200-MN000M010NN Multi-plane scan ner , me dium, with single interval sca le, with Checkpoint, scale

r OIML countries.

fo

MP6200-MN000M010US Multi-plane scanner , medium, with single inter val scale, with Checkpoint, scale

or US/Puerto Rico/Guam/USVI/British VI.

f

MP6200-MN000M01ABE Multi-plane scanne r, Medium with single

scale Gravity Zone A for Belgium.

MP6200-MN000M01BBE Multi-plane scanne r, Medium with single

scale Gravity Zone B for Belgium.

MP6200-MN000M01CBE Multi-plane scanner, Medium with single

scale Gravity Zone C for Belgium.

MP6200-MP000M010US Multi-plane scanner, medium, with single inter

DL parsing, scale for US.

MP6210-LN000M010AU Multi-plane scanner, long, with single interval scale, with Checkpoint, with

S, scale for Australia/NZ/SA.

CS

Notes:

1. EU scales are legally accepted in the following countries:

Austria, Belgium, Bulgaria, Cyprus, Czech Republic, Denmark, Estonia, Finland, France,

Germany, Greece, Hungary, Ireland, Iceland, Italy, Liechtenstein, Lithuania, Luxembourg, Latvia,

Malta, Netherlands, Norway, Poland, Portugal, Romania, Slovak Republic, Spain, Sweden,

Switzerland, United Kingdom

interval kg scale, with Checkpoint,

interval kg scale, with Checkpoint,

interval kg scale, with Checkpoint,

val scale, with Checkpoint, with

2. OIML scales are legally accepted in the following countries: Bahamas, Barbados, Belize,

Bermuda, Chile, Colombia, Costa Rica, Ecuador, El Salvador, Guatemala, Hong Kong, Jamaica,

Saint Lucia, Philippines, Thailand, Trinidad and Tobago, Vietnam

PRODUCT OVERVIEW AND FEATURES 1 - 5

Table 1-1

MP6210-LN000M010CM Multi-plane scanner, long, single interval kg scale, with CSS, Checkpoint,

MP6210-LN000M010EU Multi-plane scanner, long, with single interv

MP6210-LN000M010NN Multi-plane scanner, long, with single interv

MP6210-LN000M010US Multi-plane scanner, long, with single interv

MP6210-LN000M01ABE Multi-plane scanner, Long with single interval kg s

MP6210-LN000M01BBE Multi-plane scanner, Long with single interval kg s

MP6210-LN000M01CBE Multi-plane scanner, Long with single interval kg s

MP6210-LP000M010US Multi-plane scanner, long, with single interv

MP6000 Configurations (Continued)

Configuration Description

Canada-Mexico scale label.

al scale, with Checkpoint, with

CSS, scale for EU countries.

al scale, with Checkpoint, with

CSS, scale for OIML countries.

al scale, with Checkpoint, with

CSS, scale for US/Puerto Rico/Guam/USVI/British VI.

cale, with CSS, with

Checkpoint, scale Gravity Zone A for Belgium.

cale, with CSS, with

Checkpoint, scale Gravity B for Belgium.

cale, with CSS, with

Checkpoint, scale Gravity Central C for Belgium.

al scale, with Checkpoint, with

CSS, with DL parsing, scale for US.

MP6210-MN000M010AU Multi-plane scanner, medium, with single inter

CSS, scale for Australia/NZ/SA.

MP6210-MN000M010CM Multi-plane scanner, medium, single interval

Canada-Mexico scale label.

MP6210-MN000M010EU Multi-plane scanner, medium, with single inter

CSS, scale for EU countries.

MP6210-MN000M010NN Multi-plane scan ner , me dium, single interval sc

scale for OIML countries.

MP6210-MN000M010US Multi-plane scanner, medium, with single inter

CSS, scale for US/Puerto Rico/Guam/USVI/British VI.

MP6210-MN000M01ABE Multi-plane scanne r, Medium with single

Checkpoint, scale Gravity Zone A for Belgium.

MP6210-MN000M01BBE Multi-plane scanne r, Medium with single

Checkpoint, scale Gravity Zone B for Belgium.

MP6210-MN000M01CBE Multi-plane scanner, Medium with single

Checkpoint, scale Gravity Zone C for Belgium.

Notes:

1. EU scales are legally accepted in the following countries:

Austria, Belgium, Bulgaria, Cyprus, Czech Republic, Denmark, Estonia, Finland, France,

Germany, Greece, Hungary, Ireland, Iceland, Italy, Liechtenstein, Lithuania, Luxembourg, Latvia,

Malta, Netherlands, Norway, Poland, Portugal, Romania, Slovak Republic, Spain, Sweden,

Switzerland, United Kingdom

val scale, with Checkpoint, with

kg scale, with CSS, Checkpoint,

val scale, with Checkpoint, with

ale, with Checkpoint, with CSS,

val scale, with Checkpoint, with

interval kg scale, with CSS, with

interval kg scale, with CSS, with

interval kg scale, with CSS, with

2. OIML scales are legally accepted in the following countries: Bahamas, Barbados, Belize,

Bermuda, Chile, Colombia, Costa Rica, Ecuador, El Salvador, Guatemala, Hong Kong, Jamaica,

Saint Lucia, Philippines, Thailand, Trinidad and Tobago, Vietnam

1 - 6 MP6000 INTEGRATOR GUIDE

Table 1-1

MP6210-MP000M010US Multi-plane scanner, medium, with single interval scale, with Checkpoint, with

MP6500-LN000M010CM Multi-plane scanner, long, with dual inter

MP6500-LN000M010EU Multi-plane scanner, long, with dual inter

MP6500-LN000M010NN Multi-plane scanner, long, with dual inter

MP6500-LN000M010US Multi-plane scanner, long, with dual inter

MP6500-LP000M010US Multi-plane scanner, long, with dual inter

MP6500-MN000M010CM Multi-plane scanner, medium, with dual int

MP6500-MN000M010EU Multi-plane scanner, long, with dual inter

MP6000 Configurations (Continued)

Configuration Description

CSS, with DL parsing, scale for US.

val scale, with Checkpoint, scale for

Canada/Mexico.

val scale, with Checkpoint, scale for

EU.

val scale, with Checkpoint, scale for

NN.

val scale, with Checkpoint, scale for

US.

val scale, Drivers License Parsing,

with Checkpoint, scale for US.

erval scale, with Checkpoint, scale

for Canada/Mexico.

val scale, with Checkpoint, scale for

EU.

MP6500-MN000M010NN Multi-plane scanner, medium, with dual int

for NN.

MP6500-MN000M010US Multi-plane scanner, medium, with dual int

for US.

MP6500-MP000M010US Multi-plane scanner, medium, with dual inter

with Checkpoint, scale for US.

MP6510-LN000M010CM Multi-plane scanner, long, with dual inter

scale for Canada/Mexico.

MP6510-LN000M010EU Multi-plane scanner, long, with dual inter

scale for EU.

MP6510-LN000M010NN Multi-plane scanner, long, with dual inter

scale for NN.

MP6510-LN000M010US Multi-plane scanner, long, with dual inter

scale for US.

MP6510-LP000M010US Multi-plane scanner, long, with dual inter

with Checkpoint, with CSS, scale for US.

Notes:

1. EU scales are legally accepted in the following countries:

Austria, Belgium, Bulgaria, Cyprus, Czech Republic, Denmark, Estonia, Finland, France,

Germany, Greece, Hungary, Ireland, Iceland, Italy, Liechtenstein, Lithuania, Luxembourg, Latvia,

Malta, Netherlands, Norway, Poland, Portugal, Romania, Slovak Republic, Spain, Sweden,

Switzerland, United Kingdom

erval scale, with Checkpoint, scale

erval scale, with Checkpoint, scale

val scale, Drivers License Parsing,

val scale, with Checkpoint, with CSS,

val scale, with Checkpoint, with CSS,

val scale, with Checkpoint, with CSS,

val scale, with Checkpoint, with CSS,

val scale, Drivers License Parsing,

2. OIML scales are legally accepted in the following countries: Bahamas, Barbados, Belize,

Bermuda, Chile, Colombia, Costa Rica, Ecuador, El Salvador, Guatemala, Hong Kong, Jamaica,

Saint Lucia, Philippines, Thailand, Trinidad and Tobago, Vietnam

PRODUCT OVERVIEW AND FEATURES 1 - 7

Table 1-1

MP6510-MN000M010CM Multi-plane scanner, medium, with dual interval scale, with Checkpoint, with

MP6510-MN000M010EU Multi-plane scanner, medium, with dual int

MP6510-MN000M010NN Multi-plane scanner, med ium, with dual int

MP6510-MN000M010US Multi-plane scanner, medium, with dual int

MP6510-MP000M010US Multi-plane scanner, medium, with dual inter

Notes:

1. EU scales are legally accepted in the following countries:

2. OIML scales are legally accepted in the following countries: Bahamas, Barbados, Belize,

MP6000 Configurations (Continued)

Configuration Description

CSS, scale for Canada/Mexico.

erval scale, with Checkpoint, with

CSS, scale for EU.

erval scale, with Checkpoint, with

CSS, scale for NN.

erval scale, with Checkpoint, with

CSS, scale for US.

val scale, Drivers License Parsing,

with Checkpoint, with CSS, scale for US.

Austria, Belgium, Bulgaria, Cyprus, Czech Republic, Denmark, Estonia, Finland, France,

Germany, Greece, Hungary, Ireland, Iceland, Italy, Liechtenstein, Lithuania, Luxembourg, Latvia,

Malta, Netherlands, Norway, Poland, Portugal, Romania, Slovak Republic, Spain, Sweden,

Switzerland, United Kingdom

Bermuda, Chile, Colombia, Costa Rica, Ecuador, El Salvador, Guatemala, Hong Kong, Jamaica,

Saint Lucia, Philippines, Thailand, Trinidad and Tobago, Vietnam

1 - 8 MP6000 INTEGRATOR GUIDE

Peripherals

The MP6000 supports the peripheral devices listed below.

Supported Auxiliary Hand-held Scanner

The MP6000 provides auxiliary data ports (USB and RS-232) to which a hand-held scanner can be connected.

NOTE An auxiliary cordless scanner, such as the LI4278, LS4278, or DS6878, can be attached to the MP6000. If

a standard cradle is used with any of these scanners, a separate cradle power supply is required.

IMPORTANT The MP6000 scanner does not configure an auxiliary scanner. Auxiliary scanners must be

configured separately, independently of the MP6000 scanner.

EAS Devices

•

Sensormatic AMB-9010 controller (available December 2014)

•

Sensormatic AMB-9010-IPS controller

•

Sensormatic ScanMax-Pro controller

•

Checkpoint controller

•

Checkpoint with interlock controller.

See Electronic Article Surveillance (EAS) on page 5-18 for

Scale Devices

•

OEM standard scale

•

Single/dual head Scale Displays.

•

Mettler-Toledo price computing scale for parts of Europe (available September 2014).

USB Flash Drives

•

Typical USB flash drive with Type A connector. (See USB Staging Flash Drive on page 5-12.)

Customer Side Scanner (CSS)

•

The CSS (MX101) is an optional integrated device that supports 1D and 2D bar code scanning. The CSS

unit replaces the MP6000 tower cover, and can be installed on either side of the MP6000. Refer to the

MX101 PRODUCT REFERENCE GUIDE, p/n 72E-171320-xx, for installation and configuration

information.

detailed information.

Features of the MP6000

Horizontal

Scan

Window

Volume/Tone

Control Button

LED Array Bar

Scale Zero

Button

EAS

Deactivation

Button

(Sensormatic

only)

Vertical Scan

Window

Platter

Optional CSS MP6000

CSS Scan

Window

Scale

(optional)

7-segment

Display

Speaker

The following illustrations of the medium model show the features of the MP6000. See Table 1-2 on page 1-13

for brief descriptions of all features. See Controls and Indicat or s on pa g e 5- 2 for detailed descriptions of each

feature.

NOTE Refer to the MX101 Product Reference Guide (p/n 72E-171320-xx) for information about the optional

Customer Side Scanner (CSS). The CSS is shown in its default (left side) position, but it can be moved to

the other side at any time - no tools required.

PRODUCT OVERVIEW AND FEATURES 1 - 9

Figure 1-1

CSS and MP6000 Front View

1 - 10 MP6000 INTEGRATOR GUIDE

Scale Cable Channel

EAS Cable Channel

(also see Figure 3-46 on page 3-36 for

Sensormatic coil routing)

Drainage/Ventilation Holes

Tower Bezel

Tower

Cover

RS-232

AUX 1

0.0

Scale

Display

RS-232

AUX 2

AUX

A-B

2

POS

12V

DC

CKP

I-LOCK

1

Drainage/Ventilation Holes

1

Checkpoint Interlock Port

2

Auxiliary USB Ports

Strain Relief

Groove (for

cables)

CSS Cable

Channels

Figure 1-2

Left Side View

Figure 1-3

Right Side View/Connector Ports

Optional Scale

(scale is not available in

MP6000 short models)

Staging USB Flash

Drive Cap/Port

PRODUCT OVERVIEW AND FEATURES 1 - 11

4 Leveling Screws (2 screws on opposite side)

1

Leveling Screw Access Holes

(medium and short units only)

NOTE The tower bezel must be

removed, and the Tower

Cover slid backwards to

access the leveling screws.

1

Leveling screws are an

optional accessory.

To use leveling screws, buy

accessory kit

MX301-SR00004ZZWR for

standard-length screws, or

accessory kit

MX302-SR00004ZZWR for 1

in. (25 mm) extra length.

Figure 1-4

Figure 1-5

View Under Platter

Leveling Screws

290

o

290

o

1 - 12 MP6000 INTEGRATOR GUIDE

Figure 1-6

Scale Displays (Some Scanner/Scale Configurations Only) - Single Head (MX201) and Dual Head

(MX202; additional head added during installation)

PRODUCT OVERVIEW AND FEATURES 1 - 13

Leek Bars (lift if flat)

Optional Leak Platter (European Configurations Only)

The optional leak platter is used to weigh very long or round items. The leek bars prevent the items from falling

off the scale.

Figure 1-7

MP6000 with Optional Leak Platter

Features Summary

Table 1-2

Diagnostic LED/7-segment Display

LED Array Bar Provides visual feedback

Scale Zero Button Scale status LED and touch button provides

Volume/Tone Control Button

EAS Deactivation Button (Sensormatic only) Indicates the state

Features on the MP6000

Feature Description Page

Internal display provides detailed status,

troubleshooting information, and scale legal

parameters during calibration.

for system statuses

and alerts.

ale status, and allows user to "zero" the scale.

sc

User selectable settings for audible system

indications. (Status LED and button.)

of the Sensormatic EAS

device, and controls manual deactivation

(optional).

5-3

5-2

5-4

5-4

5-5

Scale (Optional/ Scanner Scale

Configurations Only)

Scales are available for the medium length and

long leng

th configurations.

5-6

1 - 14 MP6000 INTEGRATOR GUIDE

Table 1-2

Features on the MP6000 (Continued)

Feature Description Page

Platter Stainless steel horizontal scanning surface;

5-7

imaging window for processing bar code data,

and placing items on the surface to determine

weight.

CSS (Optional) Modular unit that fits into the MP6000 tower;

for

used

Scale Display Single or dual display option pro

customer scanning.

vides the weight

5-6

5-6

of items on the scale.

Leveling Screws (medium and short models

only)

ews for leveling the MP6000 when shelf

Scr

mounting is required. Leveling screws are an

1-11

optional accessory.

Connectors Connect the MP6000 to peripherals, and

Tab l e 1- 3

POS/host.

Internal USB Cap/Port The internal USB port is available under the

ter.

plat

1-11

EAS Cable Channel Cable routing channel for EAS antennas. 1-

Scale Cable Channel Cable routing channel for the scale cable. 1-10

10

Drainage/Ventilation Holes Outlet for spills. 1-10

CSS Cable Channels Channels for routing CSS cables. 1-10,

3-16

Table 1-3

Description of Connectors

Port Description

RS-232 AUX 1 (J7) See Table 2-3 on page 2-13 for description.

0.0 (J6) Scale Display port.

RS-232 AUX 2 (J5) See Table 2-3 on page 2-13 for description.

CKP I-LOCK (J4) Checkpoint EAS Interlock.

AUX A-B (J3) Dual USB 2.0 full speed ports for auxiliary USB

scanners, CSS, or mass

storage device.

NOTE An additional USB port is available in the front under the platter. All USB

ports can be used for the USB staging flash drive. See Table 2-14 on page

2-55 and USB Staging Flash Drive on page 5-12 for more information.

POS (J2) Point of Sale terminal port.

12V DC (J1) External power input. 12V / 3.33A (not required if powered from terminal).

NOTE If a power supply plug is inserted to the J1 connector, with no voltage to the

power supply, the scanner will not power up.

CHAPTER 2 HOST INTERFACES AND CABLE

PINOUTS

Overview

This chapter describes the host interfaces sup po rt ed by the MP6000, and how to connect the MP6000 to a

host. It also include host interface bar codes. See Figure 1-1 on page 1-9 for locations of the interface

connectors.

OPOS/JAVAPOS settings are outside the scope of this

www.zebra.com/scannersdkforwindows.

NOTE SDK supported functionality by communication protocol is listed in Appendix E, COMMUNICATION

PROTOCOLS.

guide. For the Zebra SDK, go to:

2 - 2 MP6000 INTEGRATOR GUIDE

Interfaces, Components, and Communication

The MP6000 supports the following.

POS Interfaces and Host Communication

IMPORTANT Avoid inserting a POS cable in the AUX 1 or AUX 2 port.

•

USB 2.0 full speed using Zebra USB multi-host cables

•

RS-232 connection using several communication protocols.

•

RS-485 communication protocol.

NOTE SDK supported functionality by communication protocol is listed in Appendix E, COMMUNICATION

PROTOCOLS.

Auxiliary Ports and Peripherals

•

Three USB 2.0 full speed auxiliary ports (see AUX A-B (Stacked USB) on page 2-55).

•

Two RS-232 auxiliary ports (AUX 1/AUX 2; see Figure 1-3 on page 1-10).

The MP6000 can support the following combinations of peripherals:

•

Hand-held scanners supported in USB mode, or RS-2 32 mo de .

•

CSS (CSS is USB only).

NOTE A total of one hand-held scanner plus one CSS is supported.

•

Wireless auxiliary scanner support may be provided via a corded cradle as an auxiliary device.

NOTE An auxiliary cordless scanner, such as the LI4278, LS4278, or DS6878, can be attached to the

MP6000. If a standard cradle is used with the DS6878, a separate cradle power supply is required.

•

Sensormatic controller via the RS-232 auxiliary port.

IMPORTANT Use only Zebra approved cables when connect ing peripherals to the ports on the MP6000.

•

Dual cable scanner/scale: Via RS-232 AUX 1, or RS-232 AUX 2 ports (see Figure 1-3 on page 1-1 0, and

Table 2-3 on page 2-13).

HOST INTERFACES AND CABLE PINOUTS 2 - 3

Programming Management Tools

•

123Scan (see Chapter 6, 123SCAN)

•

SMS

•

Staging flash drive reprogramming (USB memory stick)

NOTE Only Zebra hand-held scanners can be managed via 123Scan (see Chapter 6, 123SCAN), and SMS

through the MP6000 scanner.

Application Programming Interfaces

•

Zebra scanner SDK APIs (CoreScanner APIs)

NOTE SDK supported functionality by communication protocol is listed in Appendix E, COMMUNICATION

PROTOCOLS.

•

Zebra scanner OPOS/JPOS APIs.

For access to these programming interfaces, go to: www.zebra.com/scannersdkforwindows.

NOTE If the MP6000 is powered up with no interface cable present, it reverts to “no host mode.” This is useful for

demonstrations where no host is present.

2 - 4 MP6000 INTEGRATOR GUIDE

AUX

A-B

POS

12V

DC

Connecting a USB Interface

NOTE For a list of supported scanner functionality by communication protocol Appendix E, COMMUNICATION

PROTOCOLS.

The MP6000 connects directly to a USB host. An additional power supply may be required

(PWRS-14000-148R). Only a USB Power Plus host can power the MP6000 using a Zebra Power Plus cable,

without an external power supply.

Figure 2-1

USB Connections

NOTE Interface cables vary depending on configuration.

There are three possible USB connection methods for the MP6000:

•

POS connection using USB Power Plus (12V); requires a CBA-U52-S16PAR cable between POS

equipment (e.g., IBM) and the MP6000 POS RJ-45 connector. The MP6000 is a USB device for this

connection; no power supply is required (the MP6000 draws power from USB cable).

•

POS connection using USB Standard A (5V); requires a CBA- U5 1-S16ZAR cable between POS

equipment (standard device - PC) and MP6000 POS RJ-45 connector. The MP6000 is USB device but

requires an external power supply (MP6000 does NOT draw power from USB cable).

•

AUX scanner connection using a Zebra USB hand-held scanner; requires a Zebra USB type A cable

between the Zebra USB hand-held scanner (RJ-45), and the MP6000 AUX A-B USB port. The MP6000

is the USB host, and the Zebra scanner is the USB device which draws power from 5V cable.

HOST INTERFACES AND CABLE PINOUTS 2 - 5

To set up the MP6000:

1. Connect the RJ-45 modular connector of the USB interface cable to the POS interface port on the

MP6000.

2. Plug the series A connector, or the Power Plus connector in the USB host. If Power Plus is used, the

MP6000 powers up with the POS.

3. If no Power Plus is used, connect a 12V power supply. Co nnecting the 12V power supply immediately

turns the unit on.

4. Select the USB device type by scanning the appropriate bar code (see USB Device Type on page 2-6).

5. To modify any parameter options:

a. Scan the appropriate bar codes in the MP6000 Bar Code Programming Guide, p/n 72E-172633-xx.

or

b. Use 123Scan.

or

c. Use the 123Scan 2D configuration bar code.

or

d. Use a USB staging flash drive (see USB Staging Flash Drive on page 5-12).

2 - 6 MP6000 INTEGRATOR GUIDE

USB Host Parameters

USB Device Type

To select a USB device type, scan one of the ba r co de s lis te d in Table 2-1.

NOTE 1.When changing USB device types, the MP6000 automatically resets and issues the standard startup

beep sequences.

2.Before selecting CDC COM Port Emulation, install

the scanner does not stall during power up (due to a failure to enumerate USB). If the scanner stalls,

recover it by installing the CDC INF file, and reboot the MP6000.

NOTE This guide includes limited parameter bar codes. For ALL MP6000 programming bar codes, refer to the

MP6000 Bar Code Programming Guide (p/n 72E-172633-xx

Table 2-1

USB Device Type

IBM Table-top USB (default)

IBM Hand-held USB

IBM OPOS

(IBM Hand-held USB with Full Scan Disable)

HID Keyboard Emulation

CDC COM Port Emulation

USB Host Parameters

Parameter

the Zebra USB CDC driver on the host to ensure

).

Page

Number

2-7

2-8

2-9

2-10

2-11

USB Device Type (continued)

HOST INTERFACES AND CABLE PINOUTS 2 - 7

* IBM Table-top USB

2 - 8 MP6000 INTEGRATOR GUIDE

USB Device Type (continued)

IBM Hand-held USB

USB Device Type (continued)

HOST INTERFACES AND CABLE PINOUTS 2 - 9

IBM OPOS

(IBM Hand-held USB with Full Scan Disable)

2 - 10 MP6000 INTEGRATOR GUIDE

USB Device Type (continued)

When the HID Keyboard host is selected, and the MP6000 has auxiliary scanners connected, use ADF rules to

program the auxiliary scanners to add a 500 msec pause to the end of the data to prevent the interleaving of bar

code data from multiple scanners. This works with standard RS-232, and SSI over RS-232 (with the Send Raw

Decode Data setting).

HID Keyboard Emulation

USB Device Type (continued)

HOST INTERFACES AND CABLE PINOUTS 2 - 11

CDC COM Port Emulation

2 - 12 MP6000 INTEGRATOR GUIDE

RS-232

AUX 1

RS-232

AUX 2

POS

12V

DC

Connecting an RS-232 Interface

NOTE For a list of supported scanner functionality by communication protocol Appendix E, COMMUNICATION

PROTOCOLS.

MP6000 Scanner Only or MP6200/6500 Scale with Single Cable Protocol

Use the RS-232 interface to connect the MP6000 to POS devices, host computers, or other devices with an

available RS-232 port (e.g., com port).

NOTE The MP6000 uses +/-6V RS-232 signal levels to accommodate long cable lengths, and increased noise

immunity.

Figure 2-2

Table 2-2

Host Connections

RS-232 Connections.

NOTE Interface cables vary depending on configuration.

Port Connection Options

POS Unpowered USB

(p/n CBA-U51-S16ZAR)

Powered USB

(p/n CBA-U52-S16PAR)

RS-232

(p/n CBA-R51-S16ZAR)

RS-485

(p/n CBA-M51-S16PAR)

HOST INTERFACES AND CABLE PINOUTS 2 - 13

J5

R302

XCVR5 TXD

0

4

-

J5

R298

XCVR5 RXD

0

5

-

J5

R303

XCVR5 RTS

AUX RJ45

50 –12100–2975

1-1734580-4

0

6

-

J5

R299

XCVR5 CTS

RTZ 5V0

1206, BLM31P

ZERO 5V0

0

7

-

J5 8

-

J5 9

-

J5 10

-

J5

AUX_12V

AUX_5V

L4

1B

3

-

J5 2

-

J5 1 N/C

5V (500mA)

GROUND

FROM SCALE

TO SCALE

12V (150mA)

NOT USED

SHIELD

-

J5 11

-

J5 12

-

Table 2-3

Auxiliary Connections

RS-232

Connect Device to These Ports

Device Port

Configuration Choices

for the Devices Below

RS-232 auxiliary

scanner, and a

Sensormatic Controller

RS-232 auxiliary

scanner, and a Dual

Cable Scanner/Scale

Dual Cable

Scanner/Scale, and a

Sensormatic Controller

Third-Party-Scale &

Sensormatic-Controller

1

Default setting

2

The Dual Cable Scanner/Scale protocol is 'SASI'

3

In all configurations up to one or two additional USB auxiliary scanners can be connected, but the

Configuration

Value

(see parameter

page 2-33

1246

1

0

3

)

1 Dual Cable

3

2 Sensormatic

3

AUX 1 AUX 2 USB2 USB3

Sensormatic

Controller

RS-232

auxiliary

scanner

RS-232

2

Scanner/Scale

auxiliary

scanner

Dual Cable

Controller

Scanner/Scale

2

4 Third-Party-Scale Sensormatic

Controller

USB auxiliary

3

scanner

3

USB auxiliary

3

scanner

3

USB auxiliary

scanner

3

USB auxiliary

scanner

3

total RS-232 auxiliary scanners plus USB auxiliary scanners cannot exceed two. An auxiliary scanner

is not counted until it is attached.

USB auxiliary

scanner

3

USB auxiliary

scanner

3

USB auxiliary

scanner

3

USB auxiliary

scanner

3

Price Computational Scale Interface Circuit Drawing

Price Computational Scale Interface available on AUX 1. (Also see Third Party Scale on page 2-38.)

Figure 2-3

Price Computational Scale Interface

2 - 14 MP6000 INTEGRATOR GUIDE

Connect MP6000 to RS-232 Host

To connect the MP6000 to an RS-232 host:

1. Connect the modular connector of the RS-232 interface cable to the POS interface port on the MP6000.

2. Connect the other end of the RS-232 interface cable to the serial port on the host.

3. Connect a 12V power supply directly to the MP6000.

4. Select the RS-232 host type by scanning the appropriate bar code (see RS-232 Host Types on page 2-20).

If your host does not appear in the terminal specific tables, refer to the documen tation for the host device to

set communication parameters to match the host.

5. To modify any other parameter options, scan the appropriate bar codes in the MP6000 Bar Code

Programming Guide, p/n 72E-172633-xx.

MP6000 with a Dual Cable Scanner/Scale

Use the RS-232 interface to connect the MP6000 to POS devices, host computers, or other devices with an

available RS-232 port (e.g., com port). Then use a second RS-232 cable (p/n CBA-R51-S16ZAR, and

CBA-R52-S16ZAR) to connect the MP6000 Dual Cable Scanner/Scale AUX port to a scale-only port on the

POS device.

The Dual Cable Scanner/Scale interface supports the industry

communicates with a POS using a 9600 baud rate, 7 data bits, and even parity.

To set up the MP6000 and Dual Cable Scanner/Scale:

1. Attach the RJ-45 modular connector of the RS-232 scanner interface cable to the POS port on the

MP6000. Connect the other end of the RS-232 scanner interface cable to the serial scanner port on the

host.

2. Attach the RJ-45 end of the RS-232 slave interface cable to AUX 2 (see Figure 1-3 on page 1-10) on the

MP6000. Connect the other end of the RS-232 interface cable to the scale-only port on the host.

3. Connect the power supply directly to the MP6000.

4. Select the RS-232 scanner host type by scanning the appropriate bar code (see RS-232 Host Types on

page 2-20). If your host does not appear in the terminal specific tables, refer to the documentation for the

host device to set communication parameters to match the host. To modify any other parameter options,

scan the appropriate bar codes in the MP6000 Bar Code Programming Guide, p/n 72E-172633-xx.

5. The protocol on this Dual Cable Scanner/Scale port is SASI.

6. Select the device port configuration by scanning the appropriate bar code (refer to the MP6000 Bar Code

Programming Guide for RS-232 device port configuration).

7. Cycle power on the MP6000.

standard SASI scale-only protocol, and

RS-232 Parameters

NOTE This guide includes limited parameter bar codes. For ALL MP6000 programming bar codes, refer to the

MP6000 Bar Code Programming Guide (p/n 72E-172633-xx

HOST INTERFACES AND CABLE PINOUTS 2 - 15

).

Table 2-4

RS-232 Host Type

Standard RS-232 (default)

ICL RS-232

Wincor-Nixdorf RS-232 Mode A

Wincor-Nixdorf RS-232 Mode B

Olivetti ORS4500

Omron

OPOS/JPOS

Fujitsu RS-232

CUTE

NCR Variant

Datalogic Variant

RS-232 Device Port Configuration

RS-232 Host Parameters

Parameter

Page

Number

2-21

2-22

2-23

2-24

2-25

2-26

2-27

2-28

2-29

2-31

2-32

AUX 1 Sensormatic and AUX 2 RS-232 Scanner (default) 2-34

Third Party Scale

Disable Third Party Scale (default - Disable) 2-39

Third Party Scale LED Pin (default - Active High) 2-41

Third Party Scale Zero Pin (default - Active High) 2-43

2 - 16 MP6000 INTEGRATOR GUIDE

RS-232 Host Parameters

Various RS-232 hosts use their own parameter default settings. Selecting standard, ICL, Fujitsu,

Wincor-Nixdorf Mode A, Wincor-Nixdorf Mode B, OPOS/JPOS, Olivetti, Omron, Common Use Terminal

Equipment (CUTE-LP/LG bar code readers), NCR, or Datalogic sets the defaults listed in Table 2-5 and Table

2-6.

NOTE All items listed in Table 2-5 and Table 2-6 are for scanner only connections, except for NCR which can

support scanner and scale.

Table 2-5

Terminal Specific RS-232

Parameter ICL Fujitsu

Baud Rate

Parity

Stop Bit Select

ASCII Format

Hardware Handshaking

Software Handshaking

Serial Response Timeout

RTS Line State

Beep On <BEL>

Transmit Code ID

Data Transmission Format

Prefix

Suffix

Wincor-Nixdorf

Mode A