FS10/xS20

Smart Camera

Product Reference Guide

MN-004336-01EN Rev A

ZEBRA and the stylized Zebra head are trademarks of Zebra Technologies Corporation, registered in

many jurisdictions worldwide. All other trademarks are the property of their respective owners.

©2021 Zebra Technologies Corporation and/or its affiliates. All rights reserved.

Information in this document is subject to change without notice. The software described in this document

is furnished under a license agreement or nondisclosure agreement. The software may be used or copied

only in accordance with the terms of those agreements.

For further information regarding legal and proprietary statements, please go to:

SOFTWARE:zebra.com/linkoslegal

COPYRIGHTS:zebra.com/copyright

WARRANTY:zebra.com/warranty

END USER LICENSE AGREEMENT: zebra.com/eula

Terms of Use

Proprietary Statement

This manual contains proprietary information of Zebra Technologies Corporation and its subsidiaries

(“Zebra Technologies”). It is intended solely for the information and use of parties operating and

maintaining the equipment described herein. Such proprietary information may not be used, reproduced,

or disclosed to any other parties for any other purpose without the express, written permission of Zebra

Technologies.

Product Improvements

Continuous improvement of products is a policy of Zebra Technologies. All specifications and designs are

subject to change without notice.

Liability Disclaimer

Zebra Technologies takes steps to ensure that its published Engineering specifications and manuals are

correct; however, errors do occur. Zebra Technologies reserves the right to correct any such errors and

disclaims liability resulting therefrom.

Limitation of Liability

In no event shall Zebra Technologies or anyone else involved in the creation, production, or delivery of the

accompanying product (including hardware and software) be liable for any damages whatsoever

(including, without limitation, consequential damages including loss of business profits, business

interruption, or loss of business information) arising out of the use of, the results of use of, or inability to

use such product, even if Zebra Technologies has been advised of the possibility of such damages. Some

jurisdictions do not allow the exclusion or limitation of incidental or consequential damages, so the above

limitation or exclusion may not apply to you.

i

Contents

Terms of Use .......................................................................................................................... i

Proprietary Statement .......................................................................................................... i

Product Improvements ......................................................................................................... i

Liability Disclaimer ............................................................................................................... i

Limitation of Liability ............................................................................................................. i

Service Information ............................................................................................................... v

Getting Started

Configurations ....................................................................................................................... 1

Accessories ........................................................................................................................... 1

Cables ................................................................................................................................. 1

Power Supplies (xS20 Only) ............................................................................................... 2

FS10 and xS20 Smart Camera Specifications ...................................................................... 3

FS10 Specifications ............................................................................................................ 3

xS20 Specifications ............................................................................................................... 5

Installation

Dimensional Drawings .......................................................................................................... 7

FS10 Dimensional Drawings ............................................................................................... 7

xS20 Dimensional Drawings ............................................................................................... 8

FS10 Connection ................................................................................................................ 9

xS20 Connections ............................................................................................................... 9

Torque Specification ......................................................................................................... 10

Power Sources .................................................................................................................... 11

12 Pin M12 Power Input (xS20 only) ................................................................................ 11

Power Over Ethernet (xS20 Only) .................................................................................... 11

USB Type C (xS10 Only) .................................................................................................. 11

Grounding for Electro-Magnetic Compliance and ESD Safe .............................................. 11

Cable Pin Outs .................................................................................................................... 12

Power and I/O Connector (xS20 Only) ............................................................................. 12

Ethernet Connector (xS20 Only) ....................................................................................... 13

Setting up an FS/VS Smart Camera ................................................................................... 14

Mounting Instructions ........................................................................................................ 14

Mounting the Device Using the L-Bracket Accessory (BRKT-LMNT-U000) ..................... 14

ii

FS10 Mounting Options .............................................................................................. 15

xS20 Mounting Options ............................................................................................... 16

Using the Smart Camera

USB Type C (FS10 Only) .................................................................................................... 18

User Interface ...................................................................................................................... 18

Data Capture ....................................................................................................................... 18

LED and Beeper Indicators ................................................................................................. 20

FS10/xS20 Decode Ranges ................................................................................................ 22

General Purpose Input and Outputs ................................................................................... 23

Optically Coupled GPIO .................................................................................................... 23

Thermal Management ......................................................................................................... 25

Zebra Aurora Software Overview

Human-Machine Interface (HMI) ....................................................................................... 26

Industrial Ethernet Information .......................................................................................... 26

Zebra Aurora Features ........................................................................................................ 26

Device Discovery ................................................................................................................ 27

Network Setup (xS20 only) ............................................................................................... 29

Configuring Device Settings ................................................................................................ 30

Communication Settings ................................................................................................... 31

General Settings ............................................................................................................... 32

GPIO Mapping (xS20 only) ............................................................................................... 33

Building and Deploying Fixed Scanning (FS) Jobs ............................................................. 34

Building and Deploying Vision System (VS) Jobs (xS20 only) ............................................ 35

Using the QuickDraw Tool ................................................................................................ 35

Accessing the Web Human-Machine Interface (HMI) ......................................................... 37

Live Monitoring with the Web HMI .................................................................................... 38

Accessing the Device Using the Web HMI ....................................................................... 39

Factory Reset ...................................................................................................................... 41

Software License Activation Methods ................................................................................. 43

Obtaining a License Key ................................................................................................... 43

Activating a License with Zebra Aurora ............................................................................ 44

Supported Symbologies ...................................................................................................... 44

Contents

Troubleshooting

Communicating with the Device .......................................................................................... 46

Pinging the Device via IP .................................................................................................. 46

Pinging the Device via Hostname ..................................................................................... 46

Device Discovery Troubleshooting Methods ....................................................................... 47

Factory Reset the Device .................................................................................................. 47

Power Cycling the Device ................................................................................................. 47

Security Settings ................................................................................................................. 48

Zebra Aurora Communication Port Usage .......................................................................... 49

iii

Maintenance

Contents

Maintenance ........................................................................................................................ 50

Known Harmful Ingredients ............................................................................................... 50

Approved Cleaning Agents ............................................................................................... 50

Tolerable Industrial Fluids and Chemicals ................................................................................. 51

Cleaning the Device .......................................................................................................... 51

iv

About This Guide

Introduction

The FS/VS Smart Camera Series Product Reference Guide provides general instructions for

integrating, setting up, and programming the device.

IMPORTANT: If you have a problem with your equipment, contact Zebra Global Customer Support for

your region. Contact information is available at: zebra.com/support.

Related Documents and Software

The documentation set provides information for specific user needs, and includes:

• Industrial Ethernet User Guide

For the latest version of this guide and all guides, go to: zebra.com/support

Service Information

If you have a problem with your equipment, contact Zebra Global Customer Support for your region.

Contact information is available at: zebra.com/support.

When contacting support, please have the following information available:

• Serial number of the unit.

• Model number or product name.

• Software type and version number.

Zebra responds to calls by email, telephone or fax within the time limits set forth in support

agreements.

If your problem cannot be solved by Zebra Customer Support, you may need to return your equipment

for servicing and will be given specific directions. Zebra is not responsible for any damages incurred

during shipment if the approved shipping container is not used. Shipping the units improperly can

possibly void the warranty.

If you purchased your Zebra business product from a Zebra business partner, contact that business

partner for support.

v

Getting Started

This section outlines the configurations, accessories, and specifications of the FS/VS Smart Camera

Series.

Configurations

Fixed Industrial Scanning (FS) devices come equipped with a USB or PoE scanner with auto focus, while

Vision System (VS) devices come equipped with a smart PoE Sensor with adjustable focus.

Table 1 FS10/xS20 Configurations

Device Description

FS10 Fixed Industrial USB Scanner, Auto Focus, Standard Range,

1.0MP, Fast 2D Barcode Decoder, Red and White illumination

FS20 Fixed Industrial PoE Scanner, Auto Focus, Standard Range,

1.0MP, Ethernet with PoE, Serial and Industrial Protocols, Red or

White Illumination

VS20 Smart PoE Sensor, Adjustable Focus, Standard Range, 1.0MP,

Sensor Toolset with Fast 2D Decode, Ethernet with PoE, Serial and

Industrial Protocols, Red or White Illumination

Accessories

Supported cables and power supplies for FS10 and xS20 devices are listed below.

Cables

FS10 devices utilize USB-C to C or USB-C to A cables, while xS20 devices utilize X-coded Ethernet and

power, serial, and GPIO cables.

Table 2 Cables

Device Part Number Description

FS10 CBL-USB03000-USC00 Cable, USB 2M, locking USB-C to USB C

CBL-USB04000-USC00 Cable, USB 4M, locking USB-C to USB C

CBL-USB02000-USA00 Cable, USB 2M, locking USB-C to USB A

CBL-USB04000-USA00 Cable, USB 4M, locking USB-C to USB A

1

Table 2 Cables

Device Part Number Description

xS20

CBL-ENT00500-M1200

CBL-ENT01500-M1200

CBL-PWR00500-M1200 Cable, power 5M, 12 Pin M12 to flying leads, standard flex

CBL-PWR01500-M1200 Cable, power 15M, 12 Pin M12 to flying leads, standard flex

Power Supplies (xS20 Only)

The xS20 device supports the use of 24 V power supplies.

Table 3 Power Supply

Part Number Description

PWR-24V03A-0000 Power supply, 24VDC 3AMP, DIN rail mount

PWR-24V05A-0000 Power supply, 24VDC 5AMP, DIN rail mount

PWR-POE30W-0000 Power over Ethernet injector, 30W POE+, AC input

Getting Started

Cable, Ethernet 5M, X-Coded M12 to RJ45, standard flex

Cable, Ethernet 15M, X-Coded M12 to RJ45, standard flex

2

Getting Started

FS10 and xS20 Smart Camera Specifications

The following table outlines the physical characteristics, performance characteristics, user environment,

and regulatory approvals of FS10 and xS20 devices.

FS10 Specifications

Table 4 FS10 Specifications

Item Description

Physical Characteristics

Dimensions

Weight 110 g/3.9 oz

Power USB Type-C, 1A max

Interface Ports (1) USB Type C supports USB 2.0 high speed only

Communication Protocols USB RNDIS, HID, CDC

Performance Characteristics

Image Sensor Monochrome: 1.0 MP (1280x800 pixels) CMOS

Acquisition Rate 60 frames/second

Aimer 617nm Red LED aim dot

Illumination (1) 2700K (Color Temperature) White LED

Imager Field of View 35°(H) x 26°(V)

User Environment

Operating Temperature 0°C - 45°C (32°F to 113°F)

1.0 in. H x 2.0 in. W x 1.92" D

25.4 mm H x 50.8 mm W x 48.9mm D

Sensor with Global Shutter and 3.0 um pixel size

(1) 660nm Red LED

(duty cycle-dependent)

Storage Temperature -40° to 70°C (-40°F to 158°F)

Humidity 5 % to 90 % RH (Non Condensing)

Vibration Resistance EN 60068-2-6, 14 mm @ 2 to 10 Hz, 1.5 mm @ 13 to 55

Hz; 2 g @ 70 to 500 Hz; 2 hours on each axis

Shock Resistance EN 60068-2-27, 30g; 11 ms; 3 shocks on each axis

Sealing IP65 and IP67

Light Immunity Product operates in: Incandescent 450 ft candles, Sunlight

<6000 ft candles, Florescent 450 ft candles, Mercury

Vapor 450 ft candles, Sodium Vapor 450 ft candles, LED

450 ft candles

Electrostatic Discharge ±15kV Air, ±8kV Contact

3

Getting Started

Table 4 FS10 Specifications

Item Description

Trigger Durability Withstand 1,000 cycles of operation with no degradation in

functionality

Regulatory Approvals

Environmental EN 50581:2012

EN IEC 63000:2018

Electrical Safety IEC 62368-1 (Ed.2)

EN 62368-1:2014/A11:2017

LED Safety IEC 62471: 2006 (Ed.1)

EN 62471: 2008

EMI/EMS EN 55032:2015/A11: 2020

EN 55035:2017/A11: 2020

EN 61000-3-2: 2014

EN 61000-3-3: 2013

EN 61000-6-2: 2005 & 2019

FCC 47 CFR Part 15, Subpart B

Canada ICES-003, Issue 7

EU Declaration of Conformity 2014/30/EU; 2014/35/EU; 2011/65/EU

Refer to the Declaration of Conformity (DoC) for details of

compliance to the current standards. The DoC is available

at: zebra.com/doc

4

xS20 Specifications

Table 5 xS20 Specifications

Physical Characteristics

Getting Started

Item Description

Dimensions

Weight 200 g/7.1 oz

Power 10 to 30 VDC external power supply, 7W max at 24V

Configurable IO (4) Four opto-isolated GPIO: 2 dedicated inputs(IN0/IN1),

Interface Ports (1) M12 X-Coded 1000/100/10 Mbps Ethernet

Communication Protocols Ethernet/IP, PROFINET, CC-Link, Modbus TCP, TCP/IP

Performance Characteristics

Image Sensor Monochrome: 1.0 MP (1280x800 pixels) CMOS

Acquisition Rate Up to 60 frames/second

Aimer 617nm Red LED aim dot

Illumination

1.1 in. H x 2.15 in. W x 3.71 in D

28.3 mm H x 54.6 mm W x 94.3 mm D

Class 2 PoE, 7W

2 dedicated outputs (OUT0/OUT1)

(1) M12 12-pin Power/GPIO/Serial

Sensor with Global Shutter and 3.0 um pixel size

(2) 2700K (Color Temperature) White LEDs

or (depending on model)

(2) 660nm Red LEDs

Imager Field of View

User Environment

Operating Temperature 0°C - 45°C (32°F to 113°F)

Storage Temperature -40° to 70°C (-40°F to 158°F)

Humidity 5 % to 90 % RH (Non Condensing)

Vibration Resistance EN 60068-2-6, 14 mm @ 2 to 10 Hz, 1.5 mm @ 13 to 55

Shock Resistance EN 60068-2-27, 30g; 11 ms; 3 shocks on each axis

Sealing IP65 and IP67

Light Immunity Product operates in: Incandescent 450 ft candles, Sunlight

Electrostatic Discharge ±15kV Air, ±8kV Contact

35°(H) x 26°(V)

(duty cycle-dependent)

Hz; 2 g @ 70 to 500 Hz; 2 hours on each axis

<6000 ft candles, Florescent 450 ft candles, Mercury

Vapor 450 ft candles, Sodium Vapor 450 ft candles, LED

450 ft candles

5

Getting Started

Table 5 xS20 Specifications

Item Description

Trigger Durability Withstand 1,000 cycles of operation with no degradation in

functionality

Regulatory Approvals

Environmental EN 50581:2012

EN IEC 63000:2018

Electrical Safety IEC 62368-1 (Ed.2)

EN 62368-1:2014/A11:2017

LED Safety IEC 62471: 2006 (Ed.1)

EN 62471: 2008

EMI/EMS EN 55032:2015/A11: 2020

EN 55035:2017/A11: 2020

EN 61000-3-2: 2014

EN 61000-3-3: 2013

EN 61000-6-2: 2005 & 2019

FCC 47 CFR Part 15, Subpart B

Canada ICES-003, Issue 7

EU Declaration of Conformity 2014/30/EU; 2014/35/EU; 2011/65/EU

Refer to the Declaration of Conformity (DoC) for details of

compliance to the current standards. The DoC is available

at: zebra.com/doc

6

Installation

This section describes the mounting procedure for the FS10/xS20 series.

Dimensional Drawings

The following illustrations display the dimensions and mounting orientation for FS10 and xS20 devices.

Use the guidance provided to mount the device to an L-bracket as shown in Mounting Instructions.

FS10 Dimensional Drawings

Figure 1 FS10 Dimensional Drawings

Optical Axis

15.00

12.80±1.00

For use with a Zebra

USB-C locking cable

2 X 8.83

5.3

19.25±1.00

12.70±1.00

19.25±1.00

50.80±0.60

38.50

Optical Axis

25.40

38.50

4X M3 X 0.50

X 3.75 MAX DEPTH

48.88±0.60

2X 37.21±0.50

2X 3.90

2X 3.90

2X 12.8

25.4

7

2X M3 X 0.50 THD

X 3.75 MAX DEPTH

Optical Axis

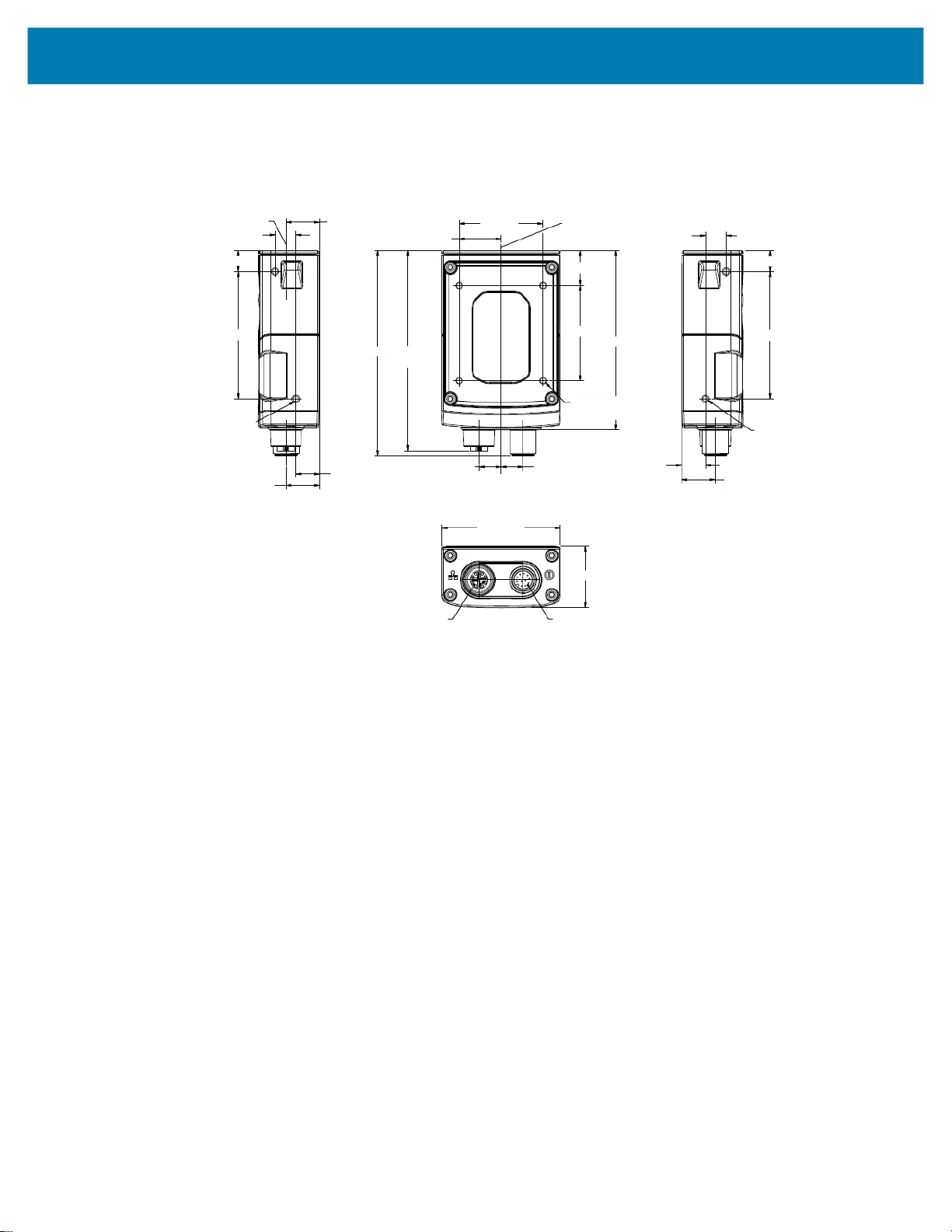

xS20 Dimensional Drawings

Figure 2 xS20 Side Dimensional Drawings

Installation

Optical Axis

9.48

9.66±.50

58.45

2X M3 X 0.50 THD

X 4.5 MAX DEPTH

8 PIN M12

CONNECTOR

15.50

15.51±1.00

Optical Axis

94.23±1.00

11.00

2X19.25±1.00

91.83±1.00

8 PIN M12

CONNECTOR

8 PIN M12

CONNECTOR

10.13

2X 38.50

54.60±1.00

Optical Axis

2X 16.10

2X 43.74

4X M3 X 0.50 THD

X 3.5 MAX DEPTH

10.13

8 PIN M12

CONNECTOR

28.30±1.00

12 PIN M12

CONNECTOR

82.38±1.00

11.00

9.48

9.66±.50

58.45

2X M3 X 0.50 THD

X 4.5 MAX DEPTH

15.50

8 PIN M12

CONNECTOR

8

FS10 Connection

The FS10 supports USB-C connections (USB 2.0 high speed only).

Figure 3 FS10 Connection

1

1 USB-C

Installation

xS20 Connections

The xS20 supports power, serial, GPIO, and Ethernet.

Figure 4 xS20 Connections

1 Power, Serial, and GPIO

2 X-Coded Ethernet

1

2

9

Torque Specification

To guarantee an IP65 or IP67 product specification, Zebra cables and/or connector covers must be

torqued to the following specification:

• Torque for M12 Zebra cables (xS20 only): 24.0 in-lbs

• Torque for USB-C cables (FS10 only): 1 in-lb

• Torque for connector covers (xS20 only): 10.0 in-lbs

Installation

NOTE:

covers must be torqued at installation to guarantee an IP65 or IP67 specification if cables are not used.

To ensure proper connector cover seating, see the figure below for the reference dimension (5.80 mm) of

the connector covers.

Figure 5 Connector Covers Reference Dimension

Connector covers are hand tightened from the factory to allow for easy hand removal. The

5.80 mm

For additional information on Zebra cables, see Cables.

10

Power Sources

FS/VS Smart Camera devices can be powered through an external power supply, Power over Ethernet

(PoE) (xS20 only), or USB Type C (FS10 only) for maximum flexibility. A power priority scheme selects

power from the external power supply over PoE (xS20 only) to ensure the least restrictive power source is

utilized. Changes to the power source trigger a reboot.

12 Pin M12 Power Input (xS20 only)

This power source input powers the xS20 only. There are no external peripherals are powered through the

xS20. As a result, as long as the voltage and currents are met in the specifications table, the xS20 will

operates as expected. A self-resettable fuse prevents the physical overload of the M12 connector and

provides protection from reverse voltage and prevents the voltage from exceeding or falling below the

input specifications.

Power Over Ethernet (xS20 Only)

FS/VS Smart Camera devices support operation from power sourcing equipment meeting the 802.3at

class 4 (30 W) or 802.3af class 3 (15.4W) or 802.3af Class 2 (7W) IEEE Power Over Ethernet (PoE)

standards. These are commonly referred to as PoE+ and PoE respectively by equipment providers.

Installation

USB Type C (xS10 Only)

USB Type C allows for novel and cost-effective installations provided the following constraints are

acceptable:

• Optocoupled GPIO is still functional provided the COMMON_IN and COMMON_OUT are properly

terminated when using the appropriate cable.

CAUTION: For optimal performance, use USB BC1.2 or USB charging ports that can supply up to 1.5A

only.

Grounding for Electro-Magnetic Compliance and ESD Safe

The vision system is designed with a rugged metal chassis connected internally to ground for robust

Electro-Magnetic Compliance (EMC) and ESD Safe operation. Do not mount to any conductive object,

body, structure, or mechanism that may become connected to line voltage or a voltage potential other than

Protected Earth Ground. Chassis grounding via cable shield, mounting screws, or low inductance ground

strap to a local Protected Earth Ground is acceptable.

NOTE: There is no galvanic connection to Earth Ground when the device is powered over an

unshielded Ethernet cable. In this scenario, grounding to local Earth Ground through another cable

shield, mounting screw, or ground strap is required for ESD Safe compliance and best practice for

EMC.

11

Cable Pin Outs

The following sections outline the pin outs for the 12 pin Power and I/O connector and the Ethernet

connector for xS20 devices.

Power and I/O Connector (xS20 Only)

Figure 6 Power and I/O Connector - 12 Pin Diagram

3

2

Installation

Key Position

4

11

5

6

10

12

7

1

9

8

Table 6 Power and I/O Connector - 12 Pin Listing

Pin Color Description

1 Yellow OUT1

2 White / Yellow TXD

3 Brown RXD

4 White / Brown IN1

5 Violet RTS

6 White / Violet COMMON_IN

7 Red DC_IN

8 Black GND

9 Green COMMON_OUT

10 Orange IN0

11 Blue OUT0

12 Grey CTS

SHELL Bare SHIELD

12

Loading...

Loading...