Page 1

2443

Thermal Printer

User’s Manual

User’s Manual No. 980336-001 Rev. A

©2001 Zebra Technologies Corporation

Page 2

ii 980336-001 Rev. A

Page 3

FOREWORD

This manual provides installation and operation information for the LP 2443 series printers, manu

factured by Zebra Technologies Corporation, Camarillo, California.

COPYRIGHT NOTICE

This document contains information proprietary to Zebra Technologies Corporation. This docu

ment and the information contained withiniscopyrightedbyZebraTechnologies Corporation and

may not be duplicated in fullorinpartbyanypersonwithout written approvalfrom Zebra Technol

ogies Corporation. While every efforthas beenmade to keep the information contained withincur

rent and accurate as of the date of publication, no guarantee is given or implied that the document

is error-free or that it is accurate with regard to any specification. Zebra Technologies Corporation

reserves the right to make changes, for the purpose of product improvement, at any time.

TRADEMARKS

LP 2443 is a service mark of Zebra Technologies Corporation. Windows and MS-DOS are regis

tered trademarks of Microsoft Corp. All other marks are trademarks or registered trademarks of

their respective holders.

LP 2443 Thermal Printers

European Council Directive Compliance to Standards

89/336/EEC EMC Directive EN 55022-B 1995 RF Emissions control

-

-

-

-

-

92/31/EE EMC Directive EN 50082-1 1992

Immunity to Electro-

magnetic Disturbances

FCC - DECLARATION OF CONFORMITY:

Model: LP 2443 conforms to the following specification:

FCC Part 15, Subpart B, Section 15.107(a) and Section 15.109(a) Class B

digital device

Supplemental Information:

This device complies with Part 15 of theFCC Rules. Operation is subjectto the following Two Con

ditions: (1) This device may not cause harmful interference , and (2) this device must accept any

interference received, including interference that may cause undesired operation.

INDUSTRY CANADA NOTICE:

This device complies with Industry Canada ICS-003 class B requirements.

Cet equipement est conforme a l’ICS-003 classe B de la norm Industrielle Canadian

-

980336-001 Rev. A iii

Page 4

SHOCK HAZARD WARNING:

The printer and power supply should never be operated in a

location where either one can get wet. Personal injury could

result.

MEDIA WARNING:

Always use high quality, approved labels, tags and transfer

ribbons. If adhesive backed labels areused that DO NOTlay flat

on the backing liner, the exposed edges may stick to the label

guides and rollers inside the printer, causing the label to peel

off from the liner and jam the printer. Approved supplies can be

ordered from your dealer.

RELOADING HINT:

If you should run out of labels while printing, DO NOT turn the

power switch OFF (0) while reloading or data loss may result.

The printer will automaticallyresume printing when a newlabel

roll is loaded.

iv 980336-001 Rev. A

Page 5

TABLE OF CONTENTS

Installation and Operation. . . . . . . . . . . . . . . . . . 1

Unpacking Your Printer . . . . . . . . . . . . . . . . . . . . 2

Getting To Know Your Printer . . . . . . . . . . . . . . . . . 3

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Power Supply . . . . . . . . . . . . . . . . . . . . . . . 4

Interface Cable . . . . . . . . . . . . . . . . . . . . . . 5

Load Labels. . . . . . . . . . . . . . . . . . . . . . . . 6

AutoSense . . . . . . . . . . . . . . . . . . . . . . . . 8

Label Dispeser Option . . . . . . . . . . . . . . . . . . . . . 10

Using Fan Fold Media . . . . . . . . . . . . . . . . . . . . . 11

Install Software . . . . . . . . . . . . . . . . . . . . . . . . 12

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . 13

Serial Interface Cable Wiring. . . . . . . . . . . . . . . . . . 14

Cleaning the Print Head . . . . . . . . . . . . . . . . . . . . 15

Preparing Media, Paper, and Labels Before Loading . . . . . 16

980336-001 Rev. A v

Page 6

vi 980336-001 Rev. A

Page 7

1

Installation and Operation

This section provides information on the

installation and operation of the printer.

The LP 2443 is a low cost, desktop direct thermal printer. This family of printers is specifically

designed for printing labels, tags or continuous

receipts (with or without bar codes) from any

DOS™, Windows™or ASCII-based compatible

computer.

980336-001 Rev. A 1

Page 8

Installation and Operation

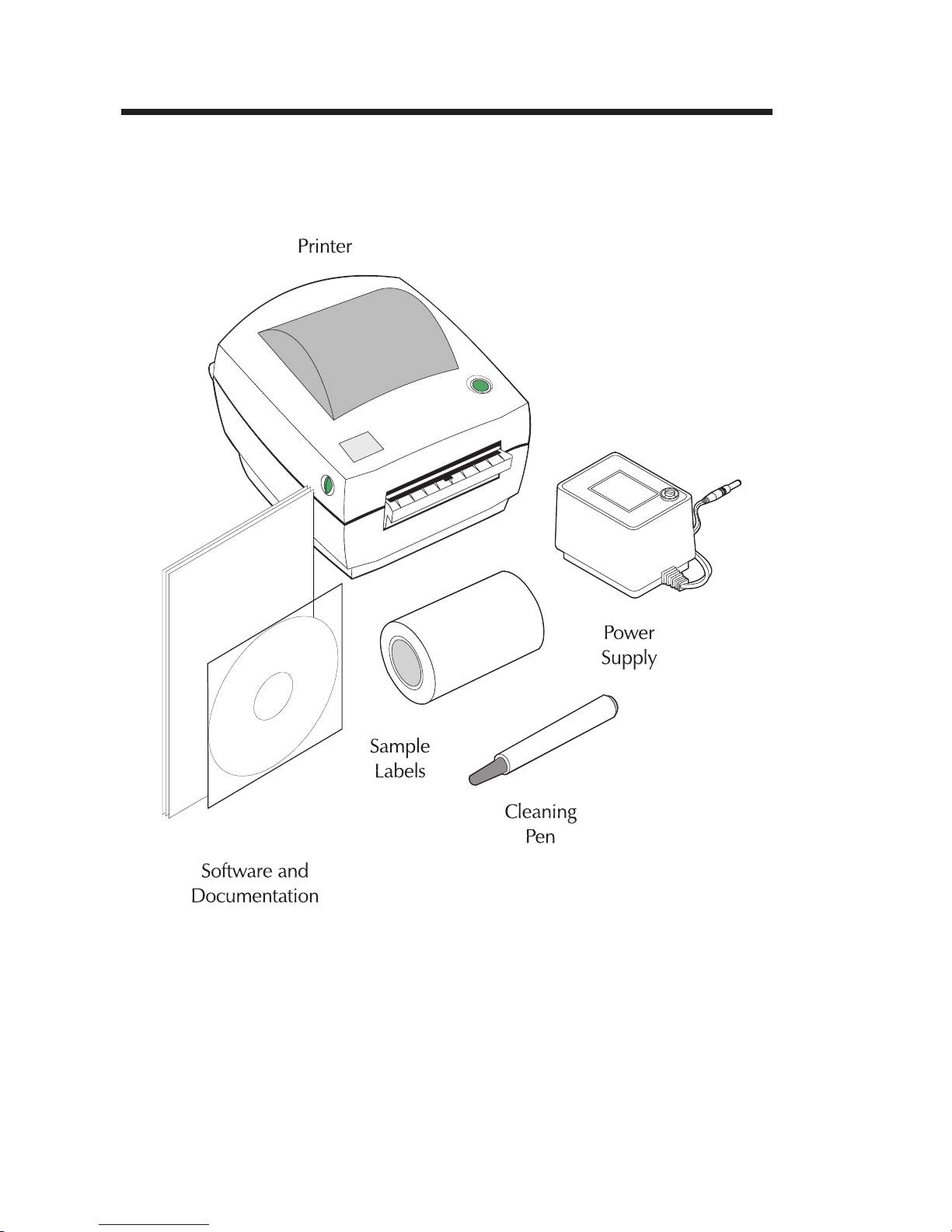

Unpacking Your Printer

2 980336-001 Rev. A

Page 9

Getting To Know

Your Printer

Installation and Operation

980336-001 Rev. A 3

Page 10

Installation and Operation

Installation The following steps will guide you through the

installation of the printer and software.

Step 1 Attach Power Supply To The Printer

Attach the power supply to a suitable AC outlet.

See the SHOCK HAZARD WARNING on page

iv.

4

980336-001 Rev. A

Page 11

Step 2 Attach Interface Cable

Parallel Interface

Serial Interface

For serial cable wiring, refer to Appendix A.

Installation and Operation

Step 3 Open Printer

Open Cover

Open Guides

980336-001 Rev. A 5

Page 12

Installation and Operation

Step 4 Load Media

Remove the outside

length of media

For more infor

mation on media

preparation, refer

to Appendix A.

Install Roll

-

Thread Through

Guides

6 980336-001 Rev. A

Page 13

Load Media - continued

Adjust Guides

Note: When using

linerfree labels,

adjust the guides

to the widest

position.

Close Cover and

Tap Feed Switch

Installation and Operation

980336-001 Rev. A 7

If the indicator fails to light, refer to

Appendix A - Troubleshooting.

Page 14

Installation and Operation

Step 5 AutoSense Gap Sensor Adjustment

Perform this procedure when loading a new

roll. You cannot perform this procedure if using

the printer’s label dispenser option.

Power OFF

Hold

Feed Button

Power ON

8

980336-001 Rev. A

Page 15

Installation and Operation

AutoSense Gap Sensor Adjustment - continued

When Indicator

Flashes, Release

Feed Button

Printer Advances

Media and Prints

Status Summary

Note: Printer is in

diagnostic dump mode

Tap Feed Button

To Begin Normal

Operation

Note: Printer prints

“out of DUMP”

4 MO3351F 16 V3.21

Serial port : 96,N,8,1

Image buffer size:245K

Fmem:000,0K,019.9K avl

Gmem:000K,0241K avl

E

mem:000K,0241K avl

I8,0,001 rY

S2 D10 R016,000 ZT UN

q800 Q1029,025

Option:

04 08 13

now in DUMP

n

o

w

0

in

4

D

0

U

8

O

M

p

1

P

t

3

io

q

n

8

:

0

0

S

Q

2

1

D

0

I

1

2

8

0

9

,0

,0

R

,0

E

0

2

m

0

1

5

1

6

e

,0

m

G

r

0

m

Y

:

0

0

e

0

Z

T

U

N

1

K

a

v

l

K

a

v

l

K

a

v

l

F

m

0

m

K

:

0

e

,0

0

m

2

4

1

.9

5

K

I

0

m

:

K

0

a

,0

0

g

0

e

2

,0

4

b

K

u

S

ffe

,0

1

9

2

4

e

r

r

ia

s

4

l

iz

p

e

:

M

o

O

r

t

3

3

:

5

9

1

6

F

,N

1

,8

6

,1

V

3

.2

1

980336-001 Rev. A 9

If the indicator remains orange or red, see the

troubleshooting steps.

Page 16

Installation and Operation

Label Dispenser Option

Open Door and

Push Switch

I = Dispense

0 = Batch

Remove Several

Labels and Push

Liner Through Slot

Close Door

10 980336-001 Rev. A

Page 17

Using Fan-Fold Media

Insert Media

Installation and Operation

Adjust Guides

Adjust Holders

Tighten Screw

Note: Use a small

Phillips driver (#1)

980336-001 Rev. A 11

Page 18

Installation and Operation

Step 6 Install Software

Start your computer and follow the installation

instructions on the compact disc (CD).

12

980336-001 Rev. A

Page 19

Appendix A - Troubleshooting

Problem Solution or Reason

POWER indicator does not

light GREEN when power

switch is turned to ON (1)

position.

1. Check power connections from A.C.

outlet to power supply to printer.

POWER indicator lights

GREEN, but printer will not

print.

Printer appears to be

working (media is being fed

out), but nothing is printed.

Printing is faded or poor

quality.

Prints only partial label or

skips a label.

Printing stops and POWER

indicator lights ORANGE or

RED.

1. Check interface cable connections from

computer to printer.

1. Verify that the labels are the correct

type (direct thermal).

2. Check that the roll is loaded with the di

rect thermal side facing up.

3. Clean the print head with cleaning pen.

1. Clean the print head with cleaning pen.

2. Adjust print speed/darkness in software.

1. Perform AutoSense gap sensor

adjustment on page 8.

2. Label caught on print head.

3. Print head is not properly latched.

4. Possible software problem. Check the

printer memory configuration. Refer to

the EPL2 Programming manual.

1. Perform AutoSense gap sensor adjust

-

ment on page 8.

2. Possible problem with label stock. Use

only approved labels and tags.

3. Possible label jam.

4. Insufficient memory for label size. Check

the printer memory configuration.

5. Possible software problem. Refer to the

EPL2 Programming manual.

-

980336-001 Rev. A 13

Page 20

Appendix A - Troubleshooting

Serial Interface

Cable Wiring

The figure below displays the cable wiring

required to use the printer's RS-232 serial

interface.

DB-9

Pin #

N/C

RxD

TxD

DTR

GND

DSR

RTS

CTS

RI

Female DB-9 to Male DB-9

Cable P/N 300017-006 (6') or 300017-010 (10')

DB-25

Pin #

N/C

RxD

TxD

DTR

GND

DSR

RTS

CTS

RI

DB-9

Pin #

11

22

33

44

55

66

77

88

99

DB-9

Pin #

18

23

32

420

57

66

74

85

922

PrinterHost

+5 Volts*

TxD

RxD

N/C

GND

RDY

N/C

RDY

N/C

PrinterHost

+5 Volts*

TxD

RxD

N/C

GND

RDY

N/C

RDY

N/C

14

FemaleDB-25toMaleDB-9

Cable P/N 300018-006 (6')

*+5 volts at 150 mA for external device (e.g. KDU or scanner)

980336-001 Rev. A

Page 21

Appendix A - Troubleshooting

Cleaning the

Print Head

Rub Cleaning Pen

Across Dark Area of

the Print Head

Wait One Minute

Before Closing

Printer

Do Not Clean

the Platen

When you load new media, you can also clean

the print head.

980336-001 Rev. A 15

Page 22

Appendix A - Troubleshooting

Preparing Media,

Paper, and Labels

Before Loading

Label Rolls

Find the tape and

pull off both labels

held by the tape

Tag Stock Rolls

During shipment, the outside length of media

may become dirty when handled or dusty when

stored. A preparation before loading media

makes sure both the print head and platen stay

cleaner for more time.

Find the tape

and detach the

bottom tag

You must avoid dragging adhesive or dirty

media between the print head and platen. Such

an occurance damages the print head and is not

covered under your warranty.

16

980336-001 Rev. A

Page 23

980336-001 Rev. A 17

Page 24

Loading...

Loading...