Zebra S-Series

Maintenance Manual

Volume 1: General Maintenance

Zebra Technologies Corporation

333 Corporate Woods Parkway

Vernon Hills, IL, US A 60061-3109

Telephone: +1 (847) 634-6700

Fax: +1 (847) 913-8766

38452L Rev. 3 Copyright 1995 Zebra Technologies Corporation. All rights reserved.

Zebra Technologies Europe Limited

Zebra House

The Valley Cen tre, Gordan R oad

High Wycombe, Buckinghamshire

HP13 6EQ, UK

Telephone: +44 (0) 1494 472872

Fax: +44 (0) 1494 450103

R

Zebra S-Series Printer

Maintenance Manual

(Volume 1, Rev. 3)

Registration Form

ZEBRA TECHNOLOGIES CORPORATION

To receive Maintenance Manual revisions and updates,

complete this form and fax or mail it to Zebra Technologies

at the fax number or address shown below.

Company __________________________________________

Address ____________________________________________

City________________________________________________

State, Zip ___________________________________________

Phone # (_______) __________________________________

Contact: ___________________________________________

Zebra Technologies Corporation

333 Corporate Woods Parkway

Vernon Hills, Illinois, USA 60061-3109

ATTN: Technical Training

FAX Number: +1 (847) 913-8766

R

R

ii 38452L Rev. 3

TABLEOFCONTENTS

ComplianceandCopyrightStatements ..........i

THEZEBRAS-SERIESSYSTEM

Printer Specifications.....................1-1

MediaHandling......................1-1

PrintingConsiderations..................1-2

MediaConsiderations...................1-2

RibbonConsiderations..................1-3

Zebra Programming LanguageII(ZPLII

BarCodes.........................1-3

Standard Printer Fonts...................1-4

Physical Size.......................1-5

ElectricalRequirements..................1-6

CableRequirements....................1-6

115 VAC Applications..................1-6

230VAC Applications..................1-6

Environmental OperatingRange.............1-6

Communication Specifications................1-7

SerialDataCommunications Overview..........1-7

ParallelDataCommunicationsOverview.........1-9

®

).......1-3

GETTINGREADYTOPRINT

Controls andIndicators....................2-2

FrontPanelControls...................2-2

FrontPanelLEDs.....................2-3

MediaLoading........................2-4

RibbonLoading........................2-6

MediaCalibration.......................2-7

AdjustingthePrint Darkness.................2-7

AdjustingtheTear-Off Position................2-8

AdjustingthePosition of theTopof theLabel........2-9

AdjustingtheMediaSensor Positions............2-9

Upper MediaSensor....................2-9

Lower MediaSensor..................2-11

OptionSwitches.......................2-12

Bank 1..........................2-13

Bank 2..........................2-14

38452L Rev.3 iii

PRINTERDIAGNOSTICS

Power ON SelfTest......................3-1

Printer SelfTests.......................3-1

CANCELKeySelf Test..................3-3

PAUSEKeySelfTest...................3-4

FEED KeySelf Test....................3-5

MODE KeySelfTest...................3-6

FEED, PAUSEand CANCEL Keys...........3-6

PAUSEKeyand CANCEL Key.............3-7

FEED Keyand CANCELKey..............3-7

FEED Keyand PAUSEKey...............3-7

ExtendedPrinterDiagnostics.................3-9

PAUSEKeyLoopbackTest................3-9

FEED KeyLoopbackTest...............3-10

PREVENTIVEMAINTENANCE

Field MaintenanceFunctions.................4-1

Tools Required........................4-1

CleaningtheS-Seriesprinter.................4-1

CleaningthePrinthead....................4-2

CleaningtheSnapPlate....................4-2

CleaningtheCutterModule..................4-4

Lubricating theCutterModule................4-4

RecommendedPreventiveMaintenanceSchedule......4-5

CORRECTIVEMAINTENANCE

Tools Required........................5-2

TestEquipment Required...................5-2

105SPrintheadReplacement.................5-3

160SPrintheadReplacement.................5-5

Printhead Adjustments....................5-7

PrintQualityAdjustments.................5-7

Printhead Parallelism Adjustment.............5-8

Wear PlatePositionAdjustment..............5-9

Printhead Position Adjustment.............5-10

Printhead PressureAdjustment.............5-11

StripPlateAdjustment.................5-12

Printhead VoltageAdjustment................5-12

AdjustmentProcedure..................5-13

MediaSensor Position Adjustment.............5-15

ReflectiveSensorAdjustment................5-17

MediaSensor andRibbonSensorSensitivityAdjustment.5-17

TakeLabelSensor Alignment................5-19

iv 38452L Rev.3

MediaTrackingAdjustments................5-20

Rewind Mode......................5-20

Peel-Off Mode......................5-21

SpindleAdjustment and Maintenance...........5-22

TensionMeasurement Procedure............5-22

SpindleTensionAdjustment..............5-22

Removing theAdapterBoard................5-24

InstallingtheAdapterBoard................5-24

Removing theMain LogicandPower SupplyBoards...5-24

InstallingtheMainLogic and PowerSupplyBoards....5-28

EPROMSoftwareInstallation................5-29

MainDriveBelt— Removal, Replacement& Adjustment.5-31

Rewind DriveBelt—Removal,Replacement & Adjustment5-32

AC Power FuseReplacement................5-33

BatteryReplacement....................5-34

CutterAdjustmentsand Replacement Instructiions.....5-34

InternalAccess.....................5-35

CutterMotor Removal andInstallation.........5-35

CutterMechanicalAssemblyRemoval and Installation 5-37

Drive Link AssemblyInstallation............5-38

CutterCircuitBoardRemoval and Installation.....5-38

OpticalSensorRemoval andInstallation........5-39

Lower Drive Arm MechanicalAlignment.......5-39

Upper DriveArmAlignment..............5-40

TROUBLESHOOTING

Troubleshooting........................6-1

Power-ON Troubleshooting................6-1

GeneralTroubleshooting.................6-2

CutterModule Troubleshooting..............6-4

SampleLabels.........................6-5

FactoryAssistance.....................6-11

Returning Equipment....................6-11

105Sand160SMECHANICALDRAWINGSandPARTSLISTS

MechanicalPartsand Assemblies...............7-1

105SeMECHANICALDRAWINGSandPARTSLISTS

MechanicalPartsand Assemblies...............8-1

38452L Rev.3 v

R

vi 38452L Rev. 3

1 TheZebraS-SeriesSystem

Inthissection... Page

PrinterSpecifications.....................................................................1-1

MediaHandling.........................................................................1-1

PrintingConsiderations............................................................1-2

MediaConsiderations...............................................................1-2

RibbonConsiderations.............................................................1-3

ZebraProgrammingLanguageII(ZPLII

BarCodes...................................................................................1-3

StandardPrinterFonts..............................................................1-4

PhysicalSize..............................................................................1-5

ElectricalRequirements...........................................................1-6

CableRequirements..................................................................1-6

115VACApplications..............................................................1-6

230VACApplications..............................................................1-6

EnvironmentalOperatingRange............................................1-6

CommunicationSpecifications.....................................................1-7

SerialDataCommunicationsOverview.................................1-7

ParallelDataCommunicationsOverview.............................1-9

®

).........................1-3

PrinterSpecifications

Media Handling

• Tear-Offmode:Labelsareproducedinstrips.

• Rewindmode: RequiresMediaRewindoption.Labelsarer ewound

• Peel-Offmode: RequiresPeel-OffoptionorMediaRewindoption.

• Cuttermode RequiresCutterModuleoption(105Seonly).Mediaiscut

internallyontoa3"-inner-diametercardboardcore.

Labelsaredispensedandpeeledfromtheliner.The

linercanberewounddirectlyontothespindleusing

the“J”Hookorontoa3"-inner-diametercar dboardcore.

afterprinting;undersoftwarecontrol.

38452L Rev.3 Page1-1

S

-Series Maintenance Manual: Volume 1 TheS-Series System

Ribbon Considerations

Ribbon Specifications 105S/105

Ribbon width

To protect the printhead fromwear, Zebra recommends using

ribbon at least as wide as the media you are using.

Standard

lengths

Roll size Inner diameter of core 1.0" 25.4 mm 1.0" 25.4 mm

2:1 media to ribbon roll ratio 984 ft 300 m 984 ft 300 m

3:1 media to ribbon roll ratio 1476 ft 450 m 1476 ft 450 m

Outside diameter of full ribbon roll 3.2" 81.2 mm 3.2" 81.2 mm

Maximum 4.5" 114 mm 6.89" 175 mm

Minimum 0.75" 19 mm 2.0" 50.8 mm

Se

160

S

Zebra Programming Language II (ZPL II®)

• Downloadable graphic s

(with data compression)

• Bit image data transfer and printing,

including mixing of text and graphics

• Format inversion

• Mirror image printing

• Four-position field rotation

(0, 90, 180, 270 degrees)

• Slew command

• Programmable quantity with print pause

• Communicates in p rintable ASCII

characters

• Controlled via m ainframe, mini, PC,

Zebra-Mate or other data-entry device

• Serialized fields

• In-spec OCR-A and OCR-B

• UPC/EAN at nominal 100% magnification

(6 dot/mm and 12 dot/mm printheads only)

Bar Codes

The following bar codes are available:

• Code 11, Code 49, Code 93

• Code 39 (Supports ratios of 2:1, 3:1, 5:2,

and 7:3)

• Code 128 (Supports serialization in subsets B

and C and UCC Case C C o d es )

• CODABAR (Supports ratios of 2:1, 3:1 and

5:2)

• Interleaved 2 of 5 (Supports ratios of 2:1,

3:1 and 5:2; also supports Modulus 10

Check Digit)

• Industrial 2 of 5, Standard 2 of 5

• Plessey

• MSI

• CODABLOCK and MAXICODE

• E/EAN-8, E/EAN-13, EAN EXTENSIONS

• UPC-A, UPC-E, UPC EXTENSIONS

• PDF 417 and POSTNET

• Data Matrix

38452L Rev. 3 Page 1-3

TheS-Series System

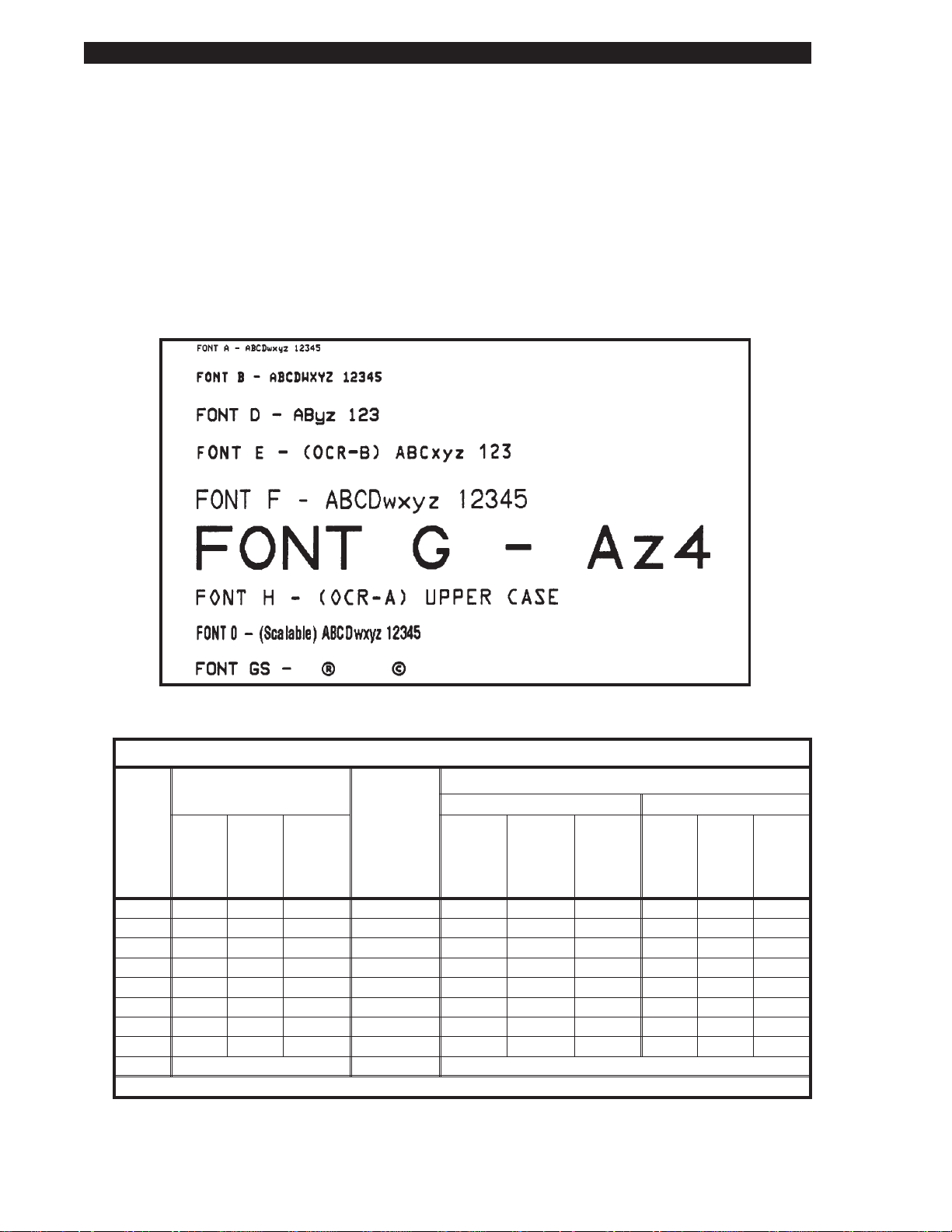

Standard Printer Fonts

Fonts A, B, C, D, E, F, G, H, and GS are expandable up to 10 times, height- and

width-independent. However, fonts E and H (OCR-A and OCR-B) are not

considered “in-spec” when expanded.

The scal able smooth font Ø (CG Triumvirate™ Bold Condensed) is expandable

on a dot-by-dot basis, height- and-width independent, while maintaining smooth

edges. Maximum character size depends on the available memory.

IBM Code Page 850 international character sets are available in fonts A, B, C,

D, E, F, G, and Ø through software control.

S

-Series Maintenance Manual: Volume 1

Figure 1.1 Sample of Default Fonts

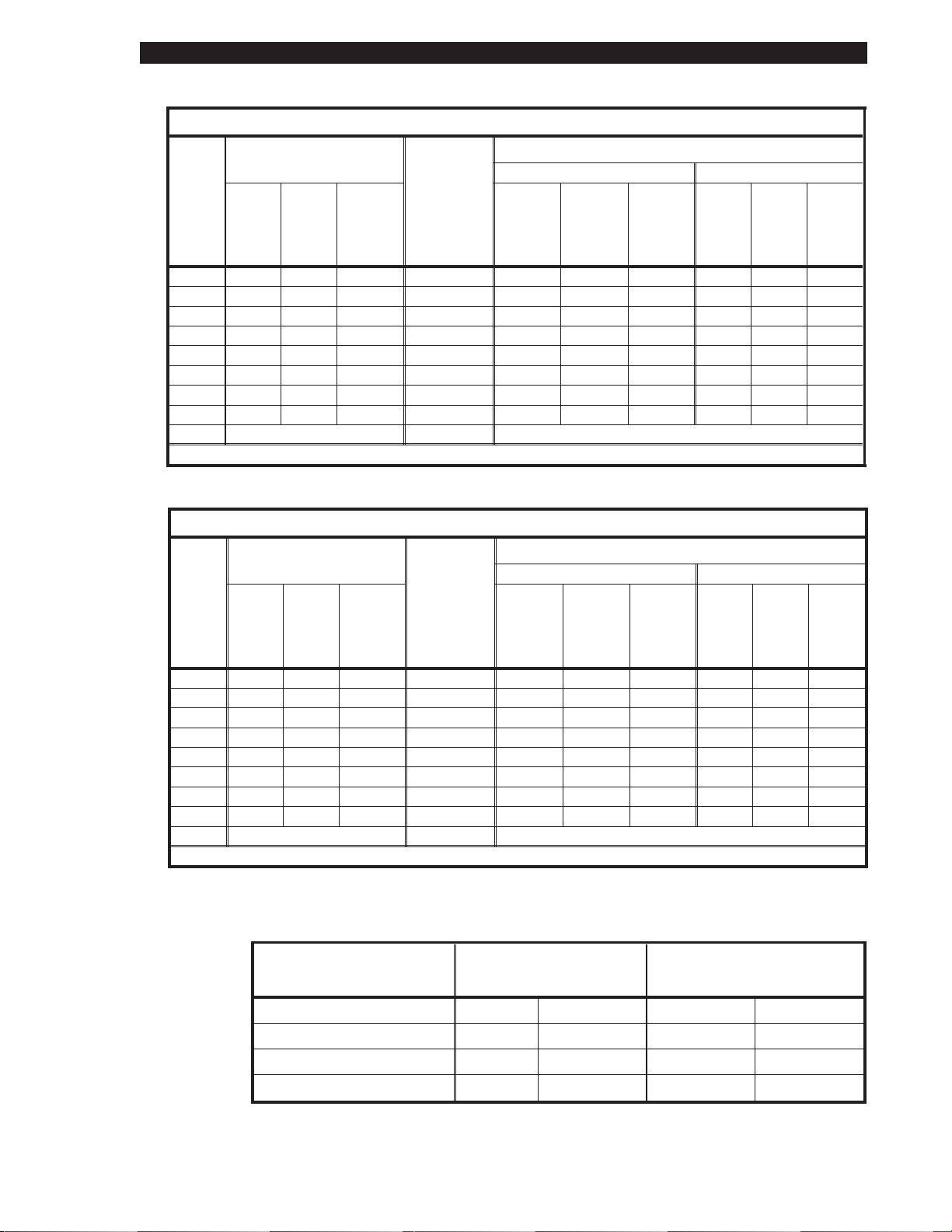

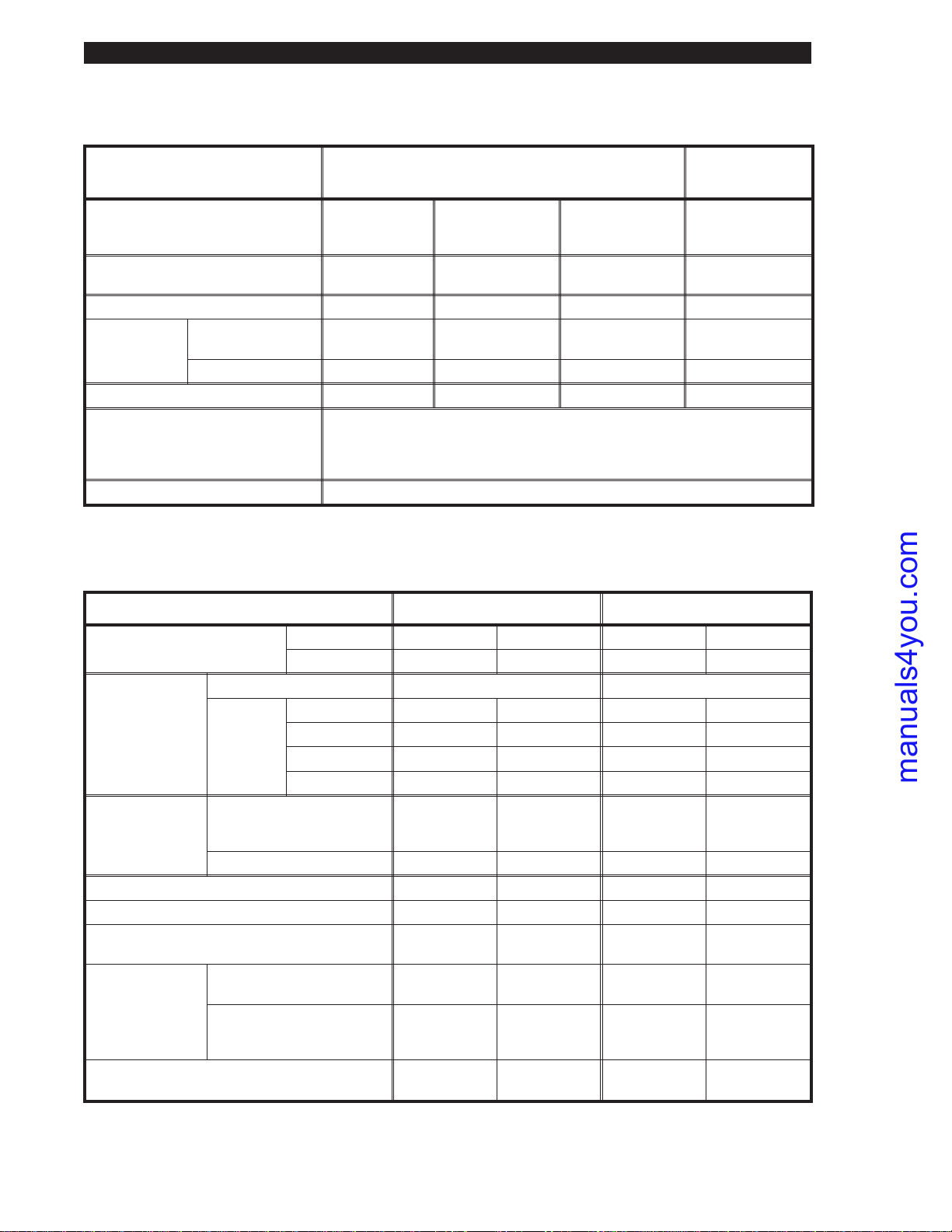

Font Matrices for 6 dots/mm Printhead (105S/105Seonly)

Font Matrix Type* Character Size

Inches Millimeters

gap

Height

A 9 5 1 U-L-D 0.059 0.039 25.40 1.50 1.00 1.00

B 11 7 2 U 0.072 0.059 16.93 1.83 1.50 0.67

C, D 18 10 2 U-L-D 0.118 0.079 12.70 3.00 2.00 0.50

E 21 10 3 OCR-B 0.138 0.085 11.72 3.50 2.17 0.46

F 26 13 3 U-L-D 0.171 0.105 9.53 4.33 2.67 0.38

G 60 40 8 U-L-D 0.394 0.315 3.18 10.00 8.00 0.13

H 17 11 4 OCR-A 0.112 0.098 10.16 2.83 2.50 0.40

GS 24 24 0 SYMBOL 0.157 0.157 6.35 4.00 4.00 0.25

Ø Default: 15 x 12 U-L-D Scalable

* U = Uppercase, L = Lowercase, D = Descenders

Page 1-4 38452L Rev. 3

Width

Inter-

character

Height

Width

Char./inch

Height

Width

Char./mm

S

-Series Maintenance Manual: Volume 1 TheS-Series System

Font Matrices for 8 dots/mm Printhead (105S, 105Seand 160S)

Font Matrix Type* Character Size

Inches Millimeters

gap

Height

A 9 5 1 U-L-D 0.044 0.029 33.90 1.13 0.75 1.33

B 11 7 2 U 0.054 0.044 22.60 1.38 1.13 0.89

C, D 18 10 2 U-L-D 0.088 0.059 16.95 2.25 1.50 0.67

E 28 15 5 OCR-B 0.138 0.098 10.17 3.50 2.50 0.40

F 26 13 3 U-L-D 0.128 0.079 12.71 3.25 2.00 0.50

G 60 40 8 U-L-D 0.295 0.236 4.24 7.50 6.00 0.17

H 21 13 6 OCR-A 0.103 0.093 10.71 2.63 2.38 0.42

GS 24 24 0 SYMBOL 0.118 0.118 8.48 3.00 3.00 0.33

Ø Default: 15 x 12 U-L-D Scalable

* U = Uppercase, L = Lowercase, D = Descenders

Width

Inter-

character

Height

Width

Char./inch

Height

Width

Char./mm

Font Matrices for 12 dots/mm Printhead (105S/105Se)

Font Matrix Type* Character Size

Inches Millimeters

gap

Height

A 9 5 1 U-L-D 0.029 0.016 50.80 0.73 0.40 2.00

B 11 7 2 U 0.036 0.023 33.86 0.91 0.58 1.34

C, D 18 10 2 U-L-D 0.059 0.033 25.40 1.49 0.83 1.00

E 42 20 6 OCR-B 0.138 0.066 23.44 3.50 1.67 0.92

F 26 13 3 U-L-D 0.185 0.042 19.06 2.15 1.06 0.76

G 60 40 8 U-L-D 0.198 0.132 6.36 5.02 3.35 0.26

H 34 22 8 OCR-A 0.112 0.072 20.32 2.84 1.82 0.80

GS 24 24 0 SYMBOL 0.079 0.079 12.70 2.00 2.00 0.50

Ø Default: 15 x 12 U-L-D Scalable

* U = Uppercase, L = Lowercase, D = Descenders

Width

Inter-

character

Height

Width

Char./ inch

Height

Physical Size

Physical

Characteristics 105

S

/105

Se

160S

Width

Char./mm

Height 15.4" 391 mm 15.4" 391 mm

Width 10.5" 267 mm 13.1" 333 mm

Depth 18.9" 480 mm 18.9" 480 mm

Weight (without options) 43 lbs. 19.5 kg 55 lbs. 24.9 kg

38452L Rev. 3 Page 1-5

TheS-Series System

Electrical Requirements

• 115VAC+15%/−20%or230VAC+15%/−15%,48-62Hz

• 5Amps@115V,3Amps@230V

• UL1950Listed-Certifiedt oCAN/CSA- C22.2No.950-M89

• ClassifiedtoIEC950andComplieswithFCCandCanadianDOCclass“A”rules

• CarriestheCEmarkofcompliance

Cable Requirements

TheACPowerCordhasathree-prongfemaleconnectorononeend.This

connectormustbepluggedintothematingcon nectorattherearoftheS-Seri es

printer.

115 VAC Applications

AStandardUS-style,three-pronggroundedmaleplugisattachedtotheother

endoftheACPowerCord.Thisconnectormustbepluggedintoanearby

electricaloutlet.

S

-Series Maintenance Manual: Volume 1

230 VAC Applications

AnACPowerCordmayormaynotbeincludedwiththeprinter.Forthose

locationsthatcannotuseeitherofthethreepowercordslistedbelow,aproper

groundedACPowerCordmustbeobtainedandinstalledbytheuser(SeeFigure

1.2).Thecablemustthenbepluggedintoanearbyelectricaloutlet.

Part Number ACPowerCableDescription

44618 Detachable Power Cord(US Standard 3-prongplug -115VAC)

44629 Detachable Power Cord(ContinentalEurope3-prongplug-230VAC)

44637 Detachable Power Cord(British 3-prongplug- 230VAC)

Figure1.2ACPowerCable

Environmental Ranges

Operating +41°Fto +104°F(+5°C to +40°C)

Temperature

Non-condensing

relativehumidity

Page1-6 38452L Rev.3

Storage -40°Fto +158°F(-40°Cto +70°C)

Operating 20%to 85%

Storage 20%to 85%

S

-Series Maintenance Manual: Volume 1 TheS-Series System

Communication Specifications

Both serial and parallel dat a communication interfaces are available for the

S-Series printers. The S-Series printer sends and receives standard ASCII

(American Standard Code for Information Interchange) data characters.

With ZPL II

communications. Refer to the user’s gui de for further information.

Serial Data Communications Overview

The S-S eries printers have a D ata Terminal Equipment (DTE) port that supports

RS-232 serial data communications. The RS-232 interf ace has a standard 25-pin

DB25-S connector located at the rear of the printer. For all RS-232 input and

output signals, the S-Series printer follows the EIA RS-232 and CCITT V.24

specifications for signal levels.

The baud rate, number of data bits, and parity are user-selectable via DIP

switches at the rear of the printer. Parity only applies to data transmitted by the

printer. The parity associated with received data is ignored. Further information

on the settings of these switches is contained in the printer’s user ’s guide.

®

, the Error Det ection Protocol feature provides virtually error-free

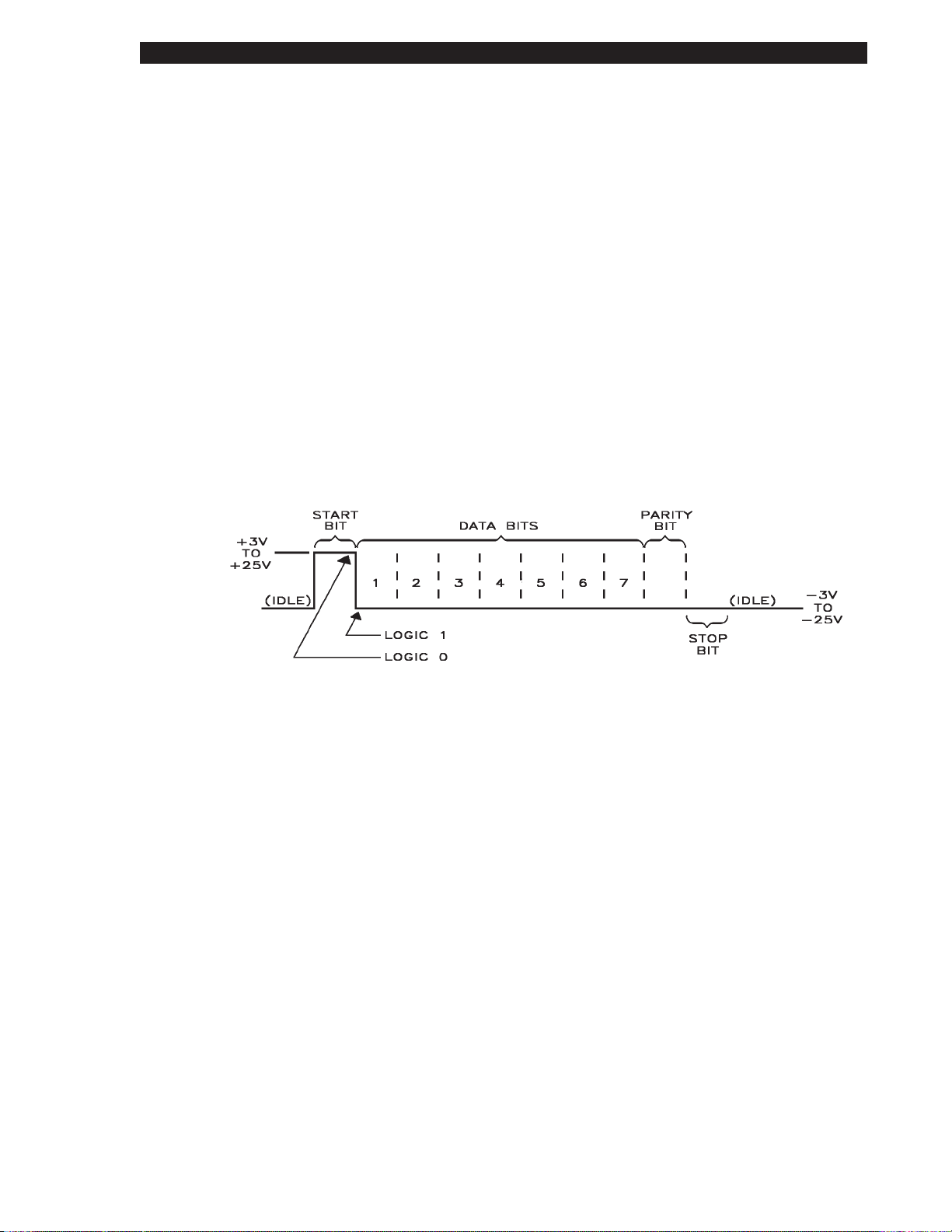

Figure 1.3 RS-232 Signal/ASCII Code Data Conditions

Serial Data Signal Levels

Serial data signals are defined as either MARK or SPACE, while control signals

are either ON or OFF. The output levels for the S-S eries printers are as follow s:

MARK or OFF = - 7 to - 10 Volts

SPACE or ON = +7 to +10 Volts

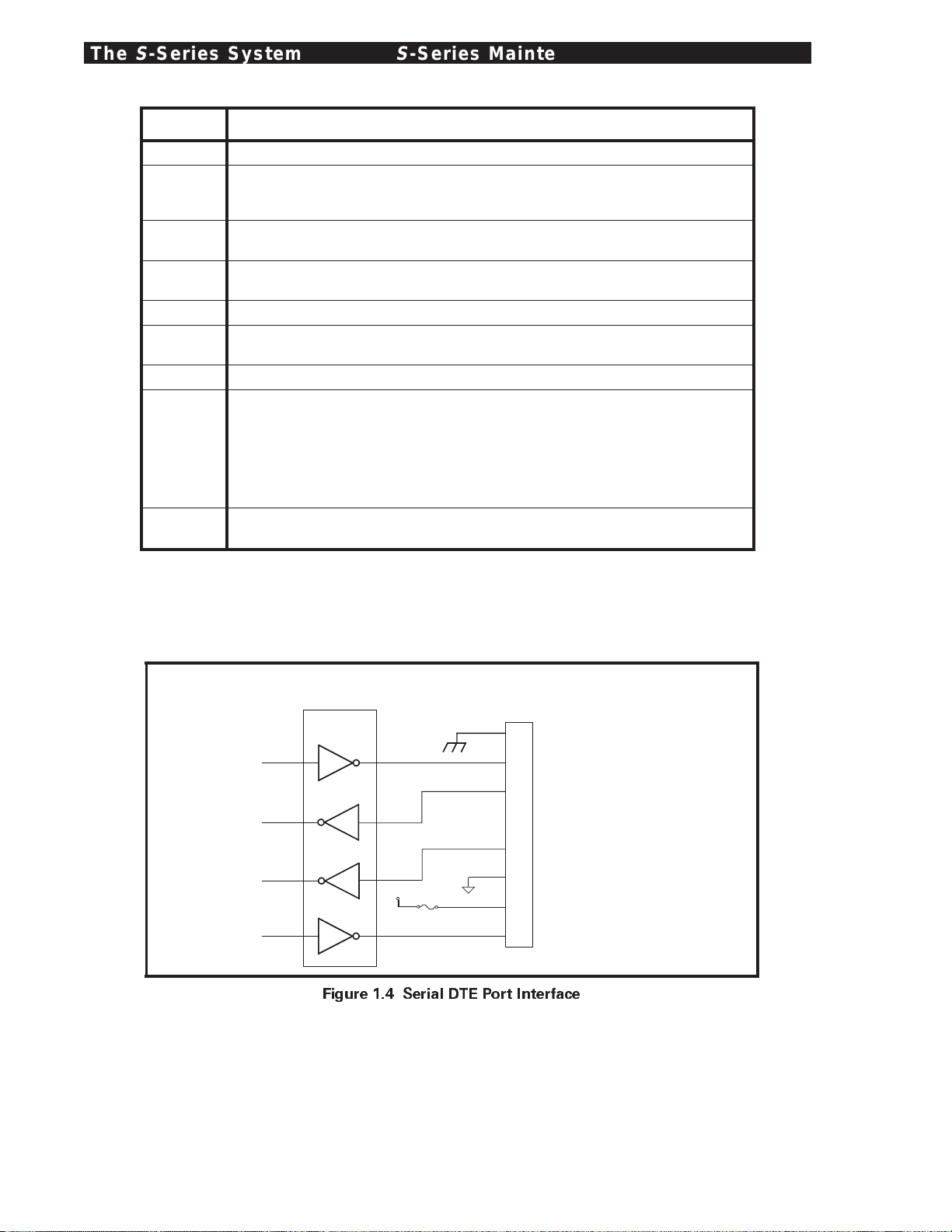

Serial Interface Connector Pinout and Description

A D B25-S connector is located at the rear of the Zebra S-Series printer and

provides serial data communications to a host using RS-232 signaling.

The pinout s and signal descriptions for the DTE port are as follows:

38452L Rev. 3 Page 1-7

TheS-Series System

Pin No. Serial Data Port Signal Description

1 Frame Ground

2 Transmit Data: TXD is the serial data output of the Zebra S-Series printer.

It is on this lead that printer status information is transmitted

to the host.

3 Receive Data: RXD is the serial data input to the Zebra S-Series printer from

the host.

4 Request ToSend: RTS is an output from the Zebra S-Series printer.

It is a constantly active output to the host computer.

6 Data Set Ready: DSR is an input to the Zebra S-Series printer from the host.

7 Signal Ground: Tied to logic ground. This lead serves as the voltage

reference between the two communicating devices.

9 Reserved: For Future Use.

20 Data Terminal Ready: DTR is an output from the Zebra S-Series printer

and is the control line between the printer and the host. When the DTR

control line from the printer is in the ON condition, the host is allowed to

send data to the printer. When DTR is in the OFF condition, the host is not

allowed to send data. This condition occurs when the printer is configured

for DTR/DSR data flow control and the communication buffer is within

512 characters of its capacity.

5, 8, 10-19,

21-25

Unterminated: These leads are not used.

S

-Series Maintenance Manual: Volume 1

COMM PORT

MAX232

11

12

9

10

14

13

8

+5 V

7

4

F

1 Amp

Figure 1.4 Serial DTE Port Interface

RS-232

J7

1

2

3

4

6

7

9

20

Frame Ground

RS-23 2

RS-23 2

Request To Send

Data Set Ready

Signal Ground

Reserved for

Future Use

Data Terminal

Ready

Transmit

Receive

Page 1-8 38452L Rev. 3

S

-SeriesMaintenanceManual:Volume1 TheS-Series System

Parallel Data Communications Overview

TheS-Seriesprintermayhaveaparalleldatacommunicationsportinsteadofthe

previouslymentionedserialdataport.TheParallelInterfacehasastandard

36-pinconnectorlocatedattherearoftheprinter.Inthisdatacommunica tion

method,thebitsofdatawhichmakeupeachcharacteraresentallatonetime

overseveralwiresinthecable,onebitperwire.

ParallelDataSignalLevels

ParalleldatasignalsaredefinedaseitherHIGHorLOW,whileControlSignals

areeitherActiveorInactive.ThedistinctionisduetothefactthatsomeControl

SignalsareactiveHIGHwhileothersareactiveLOW.Thevoltagelevelswhich

representtheseconditionsare:

DataSignal Voltage Level

HIGH +5VDC

LOW 00 VDC

ParallelInterfaceConnectorPinoutandDescription

Thefollowingchartprovidesadesc riptionofeachofthepinsintheparallel

connector.Astandardparalleldatacablewillprovidetherequired

interconnectionbetweenthehostandtheS-Seriesprinter.

Pin No. ParallelDataPort Signal Description

1 The

STROBEprinter input has internal3.3kÙpull-upresistorsto 5V (IOL=1.5mA) and is

designed to receive a signaldriven opencollector V

<=0.8V.This pin is a signalfromthe

OL

host computer.Its LOW goingedge willlatch the dataat theeight DATA inputs.Datais

non-transparentlylatched soas to avoid hold time requirementsonthe DATA signals. The

STROBEinput isdebounced torequirean activewidthgreaterthan 0.5µsecbefore datais

latched.

Ù

2-9 DATAinputshave TTL input characteristicswith internal3.3k

pullups andrepresent

1TTLunit load orless.The DATAinputs arepositivelogicwith a HIGHvoltagelevel

corresponding toa logic1.Pin 2throughPin 9= D0throughD7respectively.

10 The

ACKoutput is a 12microsecondactiveLOWpulse indicating thatthe printer is readyto

accept data. The active LOW state precedesBUSY by7 microseconds.

Ù

collector with a 3.3k

internalpull-up.The output sinks 7 mA to a VOL<=0.4V.

ACKis driven open

11 The BUSY output is active HIGHwheneverthe printercannotaccept datadueto any

normalorabnormal condition,includingBufferOverflow,Head Open,Over Temperature,

and Media Error conditions.BUSYis driven opencollector with a 3.3k

The output sinks 7mAto a V

OL

<=0.4V.

Ù

internalpull-up.

12 ThePAPEROUTsignalisactiveHIGHwhenevertheprinterisoutofmediaorribbon.

13 The SELECT signal function is determined byanadditional configuration option which

becomes active when the portispresent. Inthe default condition,SELECT is active HIGH

whenever theparallel portis powered upand the parallelportis enabled.Inthe non-default

condition, SELECT willgoactive LOW whenever the printeris printing.

18 +5VDC Supplyprovidesan output of +5VDCat a maximum currentrating of 50mA.

(InternalFuse Protected)

32 The

ERROROutput (Pin 15)is active LOW whenever anyerrorconditionis present.

ERRORis driven opencollector witha 3.0kÙinternalpull-up. The output sinks 7mAto a

<=0.4V.

V

OL

Ù

35 +5VDC Pull-Up provides an output of +5VDC throughan internal 3.0k

16,17,19-

SIGNALGROUNDSaretheLogicGroundsandReturnsforallInputandOutpu tsignals.

resistor.

30,33

14,15,31,

NOT USED-Theseleadsshouldbe left unconnected.

34,36

38452L Rev.3 Page1-9

TheS-Series System

S

-Series Maintenance Manual: Volume 1

R

Page 1-10 38452L Rev. 3

2 GettingReadytoPrint

Inthissection... Page

ControlsandIndicators..................................................................2-2

FrontPanelControls.................................................................2-2

FrontPanelLEDs......................................................................2-3

MediaLoading.................................................................................2-4

RibbonLoading...............................................................................2-6

MediaCalibration...........................................................................2-7

AdjustingthePrintDarkness........................................................2-7

AdjustingtheTear-OffPosition....................................................2-8

AdjustingthePositionoftheTopoftheLabel..........................2-9

AdjustingtheMediaSensorPositions.........................................2-9

UpperMediaSensor.................................................................2-9

LowerMediaSensor.................................................................2-11

OptionSwitches..............................................................................2-12

Bank1.........................................................................................2-13

Bank2.........................................................................................2-14

ThissectionofthemanualisintendedtosupplementtheUser’sGuideby

providingadditionalinformationtoaidtheservicetechnicianin

troubleshootingandmaintainingtheprinter.

38452L Rev.3 Page2-1

Getting Ready to Print

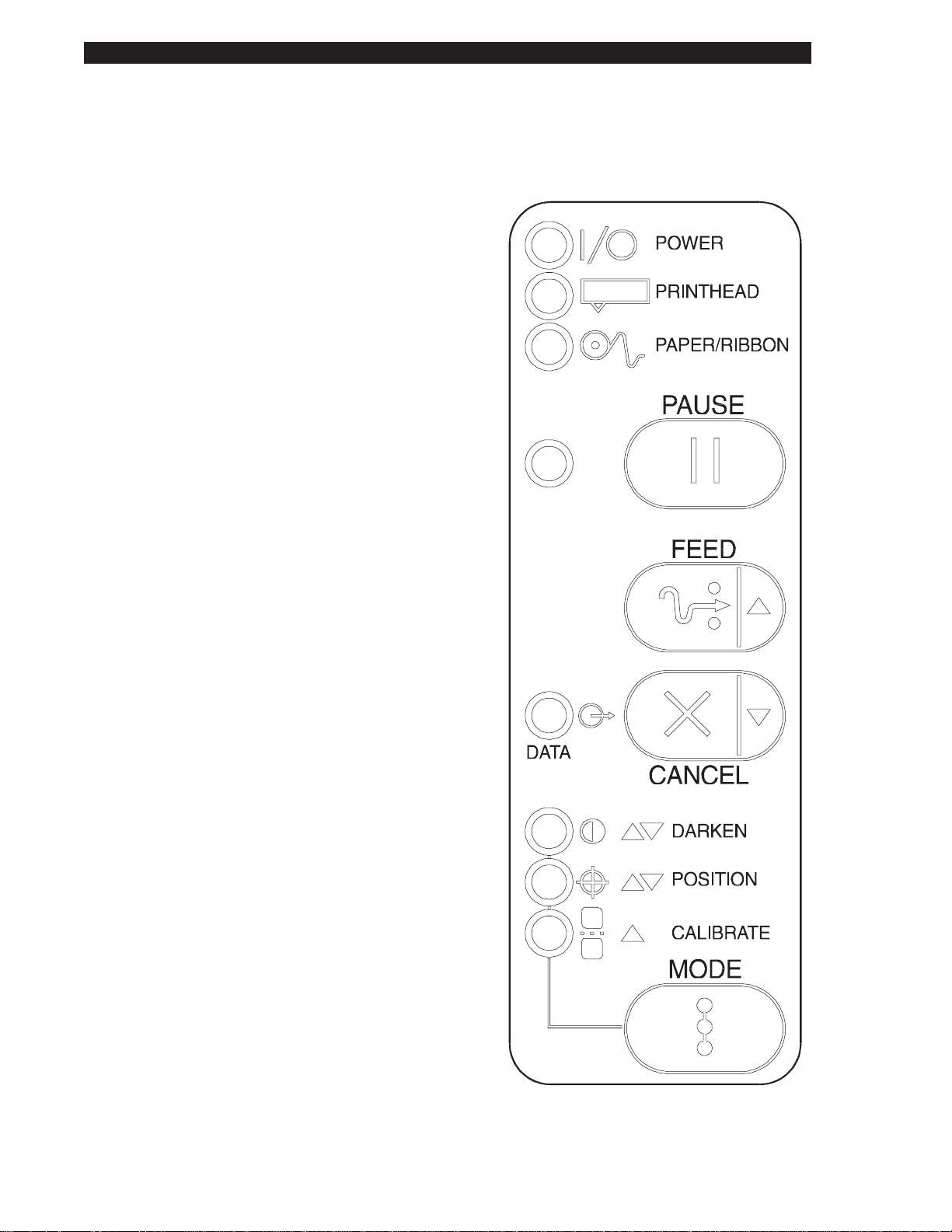

Controls and Indicators

All of the printer controls and indicators are located on the front of the unit except for the

Power ON/OFF Switch,whichis located at the rear of the printer.

Front Panel Controls

AC Power ON/OFF Switch

Controls appli cation of AC Power t o

the printer. When powered ON, the

printer will perform a Power ON Self

Test as it begins operation. Turning the

printer ON while holding down certain

front panel keys will cause additional

printer self tests to occur once the

Power ON Self Test is complete. The

AC Power Switch should be turned

OFF prior to connecting or

disconnecting any cables.

PAUSE Key

The PAUSE Ke y stops and restarts the

printing process. If the printer is idle

(not printing) when the PAUSE Key is

pressed, no printing can take place. If

the PAUSE Key is pressed while

printing is in progress, the printing

stops onc e the current label is

completed.

S

-Series Maintenance Manual: Volume 1

FEED Key

CANCEL Key

Pressing the PAUSE Key a second time

resumes the printing process.

The FEED Key forces the printer to

feed one blank label. If the printer is

idle (not pri nting) or if the PAUSE

function is active when the FEED Key

is pressed, one blank label feeds from

the pri nter immediately. If the printer

is printing, one blank label feeds out

after completion of the current batch of

labels. After one blank label is fed out,

pressing the FEED Key again will

provide a second blank label.

The CANCEL Key is only recognized

when the PAUSE function is active.

Press the CANCEL Key and the current

label format will be canceled. If no

format is printing, the next one to be

printed will be cancel ed. If there are no

formats in the printer, the CANCEL

Key is ignored. If the CANCEL Key is

pressed f or an extended period of time

(3 seconds), the printer will perform a

“Cancel All Formats” operation.

Figure 2.1 Front Panel Controls

Page 2-2 38452L Rev. 3

S

-SeriesMaintenanceManual:Volume1 GettingReadytoPrint

MODEKey

TheMODEKeycausestheprintertoentertheConfigurationMode.Inthis

Mode,thePrintDarkness,MediaTear-OffPosition,andLabelTopPosition

settingscanbeadjusted.

TheMediaCalibrationprocedureisalsoactivatedbytheMODEkey.

Refertotheuser’sguidefordetailsontheConfigurationModeandtheMedia

Calibrationprocedures.

Front Panel LEDs

RefertoFigure2.1forthelocationoftheLEDs.

NOTE:IfanoperatingconditionwhichcausesanLEDtobeONconstantlyand

onewhichcausesthesameLEDtoflashoccuratthesametime,theLEDwill

flash.

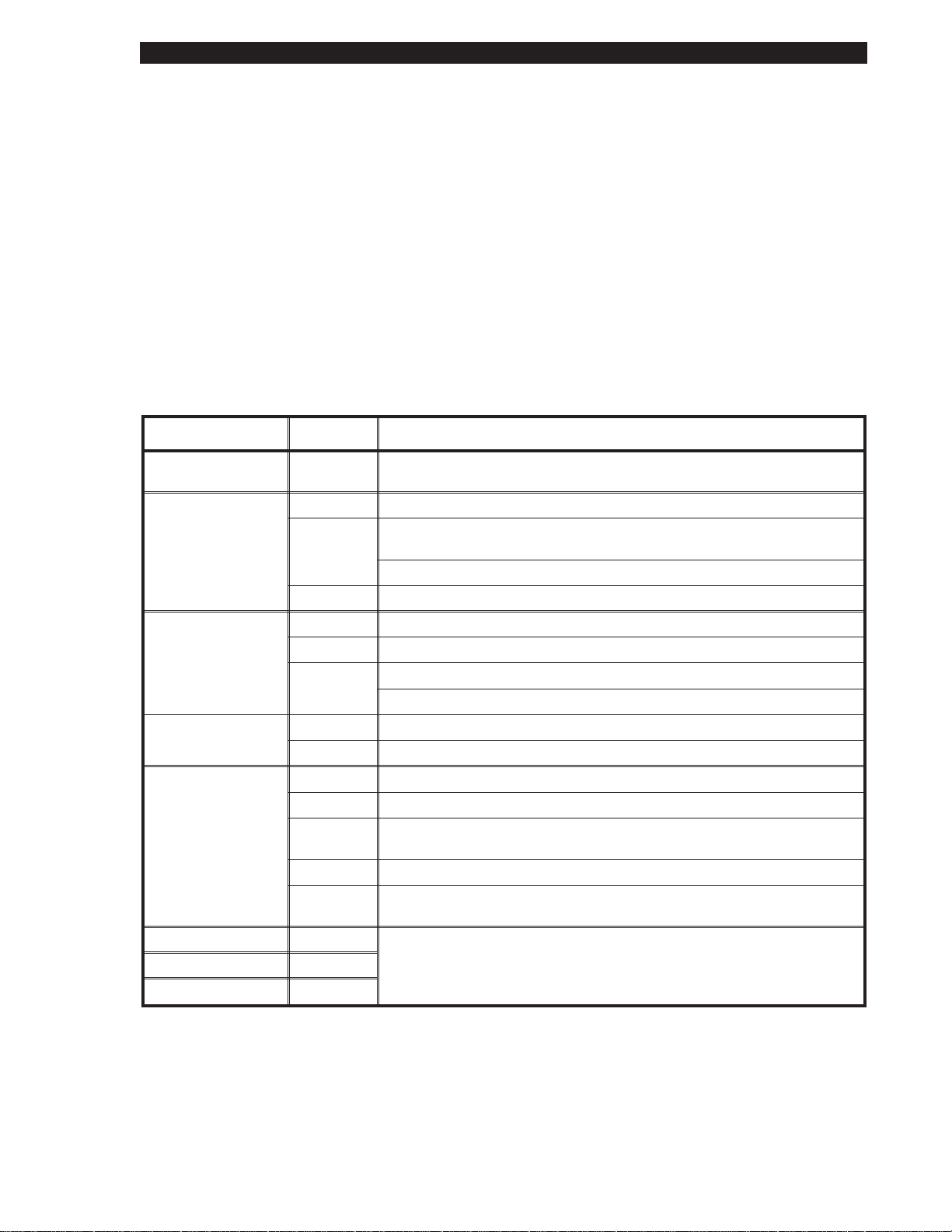

LED Name Status Indication

POWER ON Printer isON.The AC Power ON/OFF Switch isintheONposition

and the powercord is connected.

PRINTHEAD OFF Normaloperation.

ON PrintheadOverTemperature condition.Printing stops untilthe

printheadcools down.Printingresumes automatically.

PrintheadUnderTemperature condition.Printingcontinues.

Flashing PrintheadOpen.

PAPER/

RIBBON

PAUSE OFF Normaloperation.

DATA OFF Idle, nodatabeing received.

DARKEN ON

POSITION ON

CALIBRATE ON

OFF Mediaandribbon (if used) are properlyloaded.

ON Paper out.

Flashing 1.InThermal TransferMode: Ribbon is out.

2.InDirectThermalMode: Ribbon is in the printer.

ON Printer has stopped allprintingoperations.

ON Labelsareprinting.

Single

flash

Flashing Receiving datafromhost computer.

Slow

flashing

TheCANCELkeywas pressed and a format was successfully

deleted fromthe print queue.

Printer senta “stoptransmitting data”(X-OFF)commandtothehost

computer.

Printer isintheConfiguration Mode.See theModeKeyoperation

for moreinformation.

38452L Rev.3 Page2-3

GettingReadytoPrint

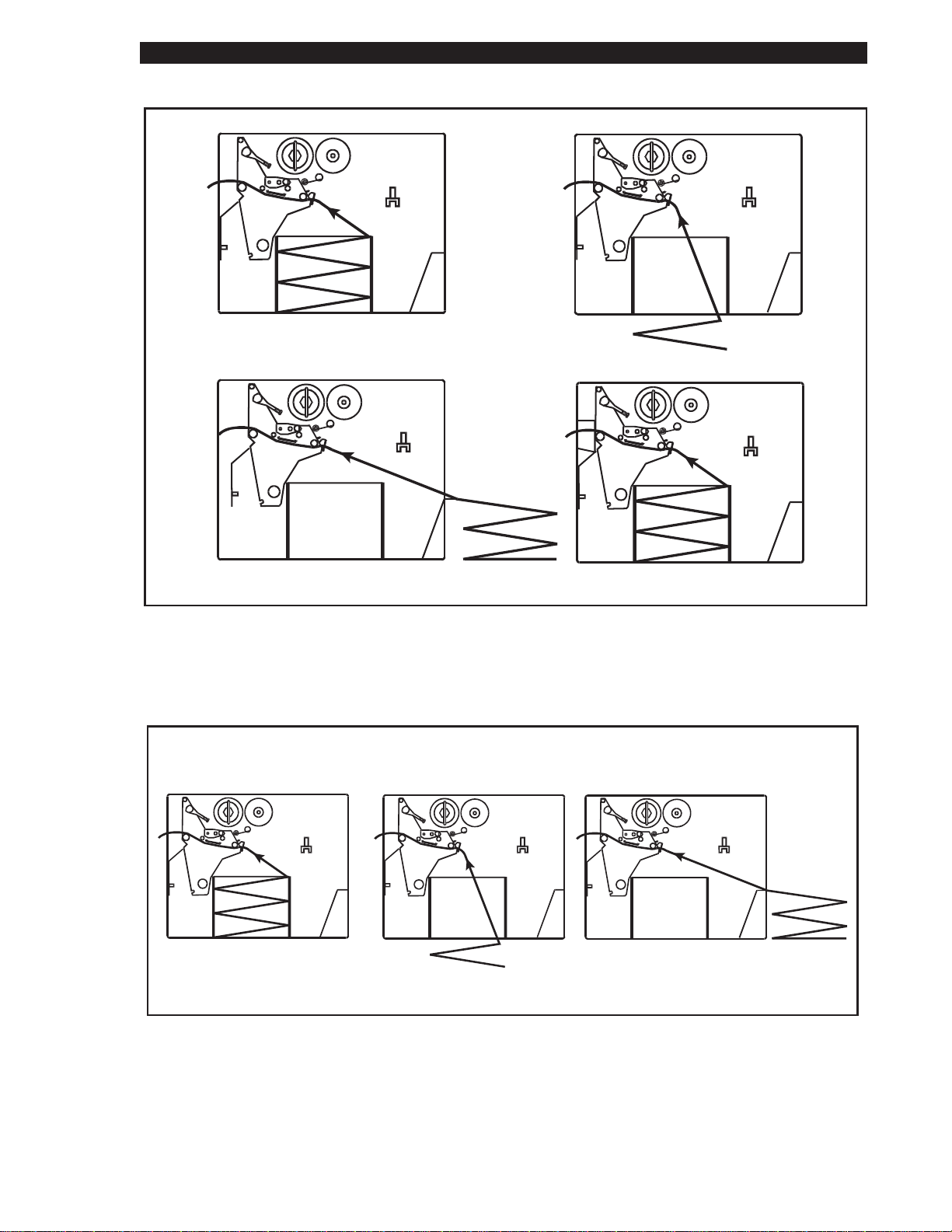

MediaLoading

S

-Series Maintenance Manual: Volume 1

TEAR-OFF

Figure2.2 RollMedia Loading

PEEL-OFF

105Se

TEAR-OFF PEEL-OFF

REWIND CUTTER

REWIND

160S

Figure 2.3 RollMedia LoadingDiagrams

Page2-4 38452L Rev.3

S

-SeriesMaintenanceManual:Volume1 GettingReadytoPrint

TEAR-OFF

REARSUPPLY

BOTTOMSUPPLY

CUTTER

INTERNALSUPPLY

105Se

Figure2.4 Fanfold MediaLoadingDiagrams

BOTTOMSUPPLY

Figure 2.5 FanfoldMedia LoadingDiagrams (160S)

REARSUPPLY

38452L Rev.3 Page2-5

GettingReadytoPrint

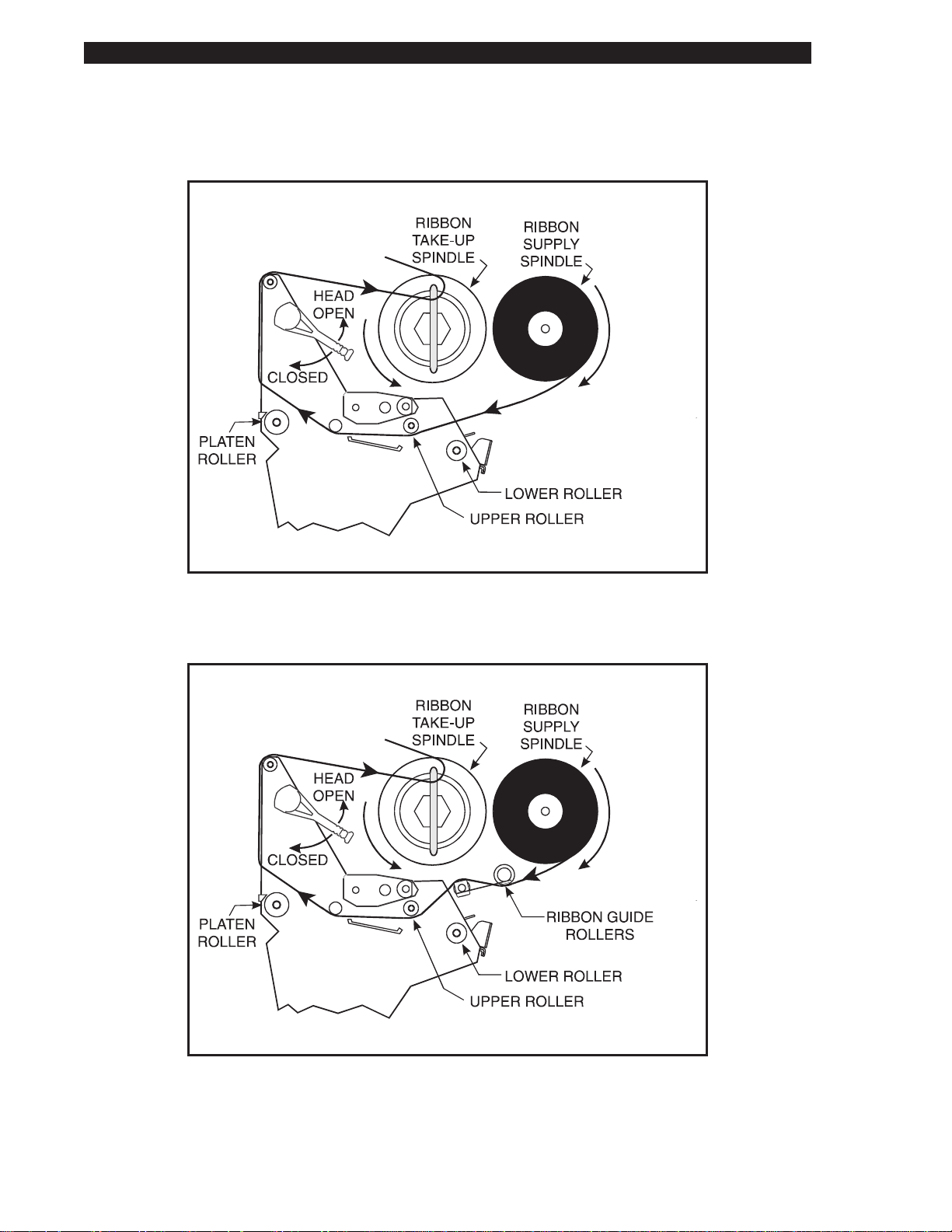

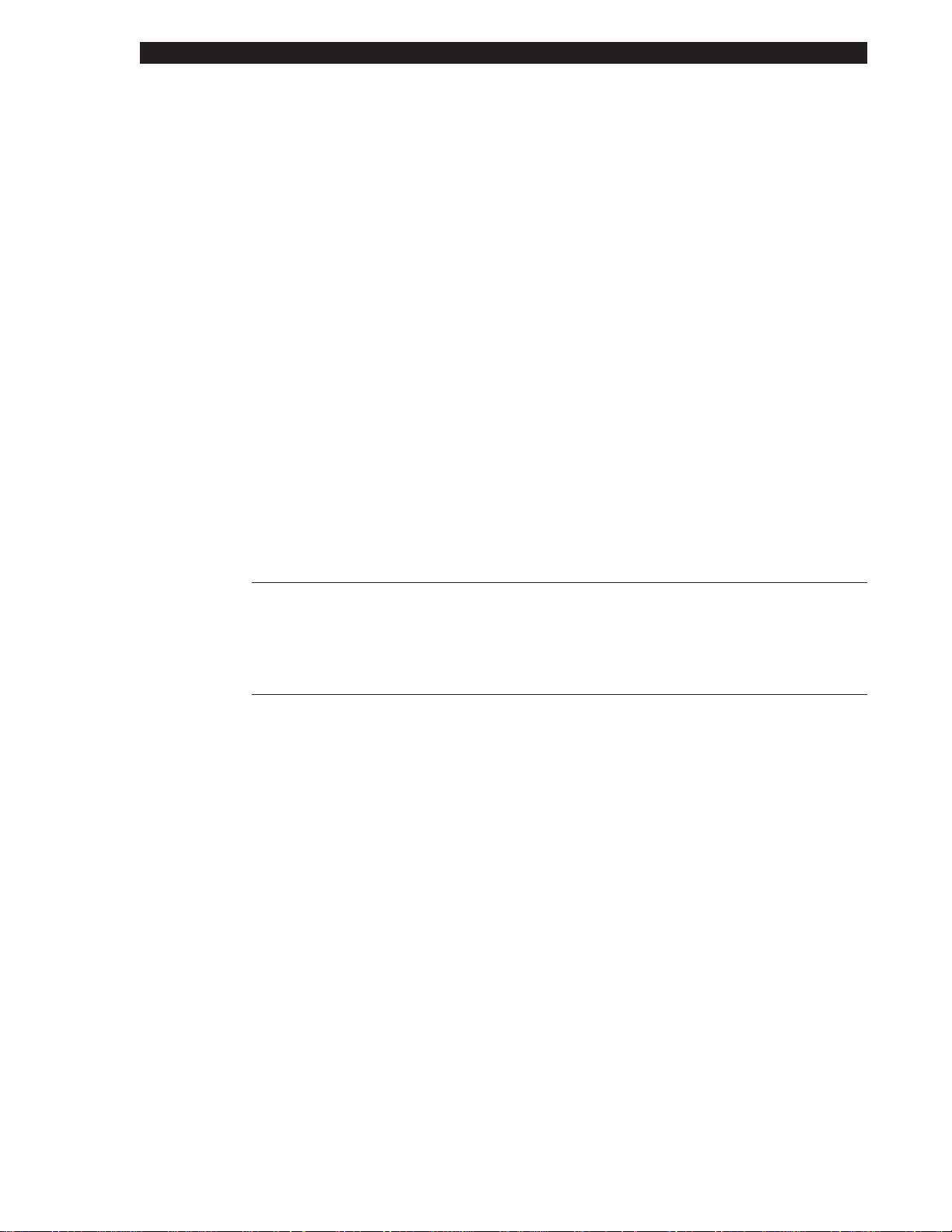

RibbonLoading

S

-Series Maintenance Manual: Volume 1

Figure 2.6 105Se RibbonLoadingDiagram

Figure 2.7160S RibbonLoadingDiagram

Page2-6 38452L Rev.3

S

-SeriesMaintenanceManual:Volume1 GettingReadytoPrint

MediaCalibration

IMPORTANT:Performthemediacalibrationprocedurew henmediais

firstinstalledorwhenadifferenttypeofmediaorribbonisinstalled.

Duringthisprocedure,theprinterautomaticallydeterminesthemediatype,label

length,mediaandribbonsensorsettings,andprintingmethod.

NOTE:Makesurethatthemediaandribbonrollsarepositionedagainstthe

innerspindlestops.

1. PresstheMODEkeythreetimes.ThePAUSEandCALIBRATElightsturn

on.

2. PressFEEDtocalibrate.Theprinterfeedssomemedia.TheMODElights

willflashonandofftoindicatethatthesettingshavebeensavedinmemory.

3. PressPAUSEtoexitPAUSEmode;thePAUSElightturnsoff.

AdjustingthePrintDarkness

Duetodifferencesintypesofmedia/ribbonandthewearontheprinthead,it

maybenecesarytoadjustthedarknesssetting(burntemperature)ofthe

S-Seriesprintheadtoachieveproperprinting.Usethefollowingprocedureto

adjustthedarkness;turningtheprinterOFFisnotrequiredforthenewsettingto

takeeffect.

CAUTION

Setthedarknesstothelowestpossibleforthedesiredprint

quality.Darknesssettoohighforagivenribbonmaycause

printheaddamage,inksmearing,ribbonwrin kle,and/orburning

throughoftheribbon.

1. Beginprintingabatchoflabels.Useaselftestlabel(seePrinter

Diagnostics)orpreferably,oneofyourownformats.

2. PausetheprintingbypressingthePAUSEkey.

3. PresstheMODEkeyoncetoplacetheprinterin“DarknessAdjustMode.”

TheDARKENlightturnson.

4. PresstheUPorDOWNkeytoadjustthecurrentsetting.

5. PressPAUSEtoressumeprinting;checkthenewsetting.

6. Repeatsteps2through5forfurtheradjustment.

7. Whendarknessiscorrect,pressPAUSEonceandMODEthreetimes.The

MODElightswillflashonandofftoindicatethatthesettingshavebeen

savedinmemory.

8. PressPAUSEtoresumeprinting.Monitorthenewsetting,adjustingif

necessary.

38452L Rev.3 Page2-7

TheS-Series System

Printing C onsiderations

S

-Series Maintenance Manual: Volume 1

Specification 105S/105

Resolution (thermal transfer

or direct thermal)

Dot size (square) 0.00492"

Maximum print width 4.09" (104 mm) 4.09" (104 mm) 4.09" (104 mm) 6.30" (160 mm)

Standard 512 KB

Maximum

print length

Bar code modulus (“X”) dimension 5 mil to 50 mil 6.6 mil to 66 mil 3.33 mil to 33.3 mil 5 mil to 50 mil

Programmable constant

printing speeds

Thin film printhead with Energy Control

memory

With 1 MG memory 39" (991 mm) 39" (991 mm) 18" (457 mm) 25" (635 mm)

203 dots per inch

(8 dots per mm)

(0.125 mm)

15" (381 mm) 26" (660 mm) N/A 9.5" (241mm)

2" (51 mm), 3" (76 mm), 4" (102 mm), 5" (127 mm), or 6" (152 mm) per second.

The 105S and 105Se with optional 300 dots/inch resolution support

2.4" (61 mm), 3" (76 mm), and 4" (102 mm) per second.

Optional

152 dots per inch

(6 dots per mm)

0.00656"

(0.167 mm)

Se

Optional

300 dots per inch

(12 dots per mm)

0.0033" x 0.0039"

(0.083 x 0.100 mm)

160

203 dots per inch

(8 dots per mm)

0.00492"

(0.125 mm)

Media Considerations

Media Specifications 105S/105

Se

160

S

S

Total media width Maximum 4.5" 114.3 mm 7.2" 182.9 mm

Minimum 0.75" 19.05 mm 2.0" 50.8 mm

Maximum 39" (991 mm) 25" (635 mm)

Tear-Off 0.63" 16.00 mm 0.63" 16.00 mm

Label length

Minimum

Peel-Off 0.50" 12.8 mm 0.50" 12.8 mm

Rewind 0.50" 12.8 mm 0.50" 12.8 mm

Cutter 1.25" 31.75 mm N/A N/A

Total thickness

(includes liner)

Maximum

position may need adjustment

if thickness is above 0.01")

(Printhead

0.012" 0.304 mm 0.012" 0.304 mm

Minimum 0.0023" 0.058 mm 0.0023" 0.058 mm

Core size 3.0" 76.2 mm 3.0" 76.2 mm

Maximum roll diameter 8.0" 203 mm 8.0" 203 mm

Interlabel gap

(0.115"/3 mm preferred)

Minimum mark length

Black mark

sensing

(thickness)

Minimum mark width

0.079" -

0.157"

2 mm - 4 mm 0.079" -

0.157"

2 mm - 4 mm

.118” 3 mm .118” 3 mm

.393” 10 mm .393” 10 mm

(extending in from the liner

or tag stock edge)

Maximum internal fanfold media

pack size (L x W x H)

8.0" x 4.5"

x 6.2"

203 x 114

x 158 mm

8.0" x 7.2"

x 6.2"

203 x 183

x 158 mm

Page 1-2 38452L Rev. 3

Getting Ready to Print

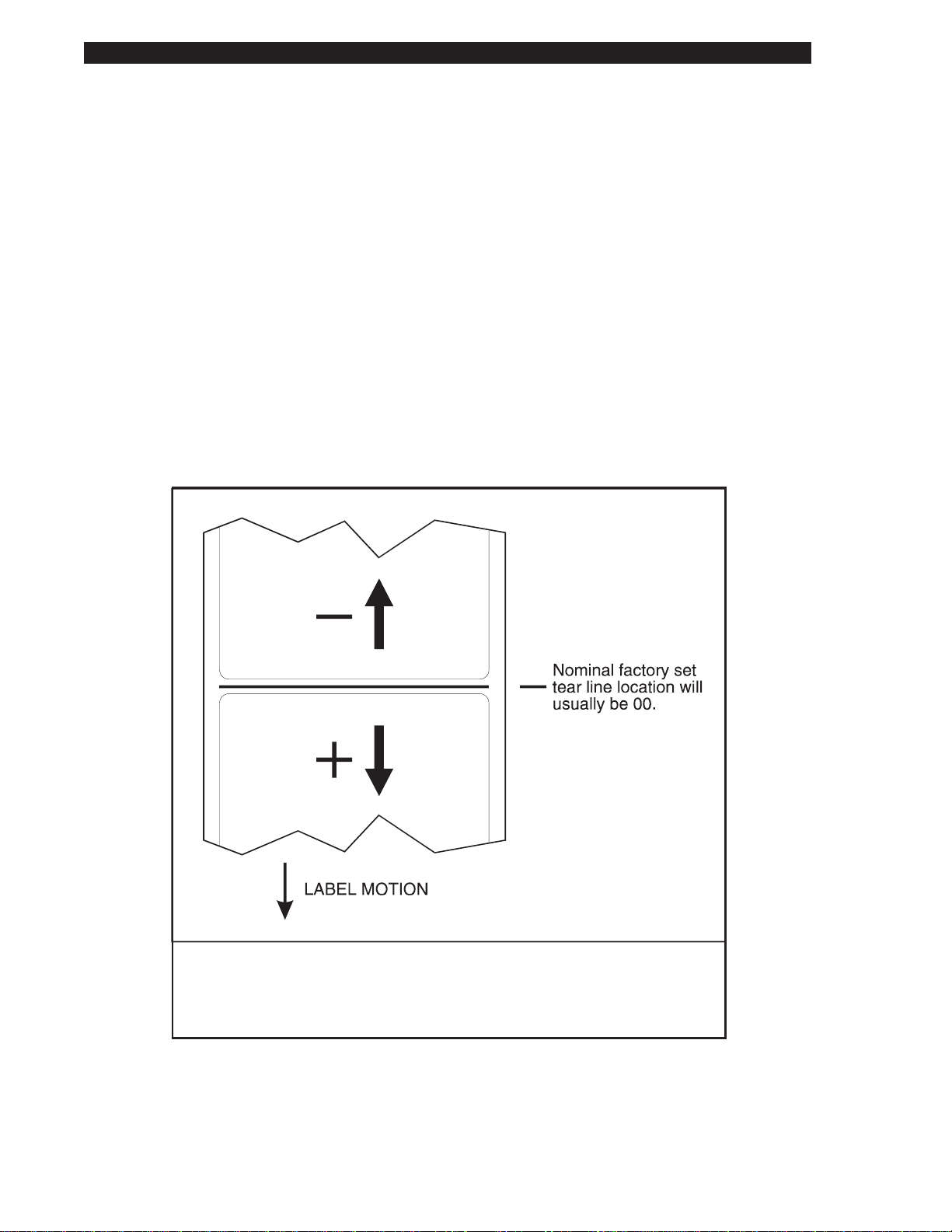

Adjusting the Tear-Off Position

This procedure sets the rest position of the media over the Tear Bar after

printing. The possible adjustment range is approximately plus or minus 80 dot

rows. Power need not be turned off to reset this parameter.

NOTE: The printer configura tion label reports the actual number of dot rows,

not the number of presses of the buttons used for adjustment.

1. Press the MODE key twice. The PAUSE and POSITION lights turn on.

2. Press the UP or DOWN key to adjust the current setting.

3. Press the MODE key twice. The MODE lights will flast on and off to

indicate that the settings have been saved in memory.

4. Press PAUSE to exit the PAUSE mode; the PAUSE light turns off.

S

-Series Maintenance Manual: Volume 1

This illustration shows how higher values move the label further out from

the printer (moves the tear line closer to the leading edge of the next label)

while lower values move the label into the printer (moves the tear line

closer to the edge of the printed label).

Figure 2.8 Tear-Off Position Adjustment

Page 2-8 38452L Rev. 3

S

-SeriesMaintenanceManual:Volume1 GettingReadytoPrint

AdjustingthePositionoftheTopoftheLabel

1. PresstheMODEkeytwice,thenpressandholdt heMODEkeyforabout

fiveseconds,untilthelightsc hange.PAUSE,D ARKEN,andCAL IBRATE

lightsturnon.

2. PresstheUPorDOWNkeytoadjustthecurrentsetting.

3. PresstheMODEkeytwice.TheMODElightswillflashonandoffto

indicatethatthesettingshavebeensavedinmemory.

4. PressPAUSEtoexitthePAUSEmode;thePAUSElightturnsoff.

AdjustingtheMediaSensorPositions

ThissensorisnotusedifBlackMarksens ingisselected.

NOTE:Ifyou’reusingcontinuousmedi a,donotperformt hisadjustment.

Leavethemediasensoratthefactory-setposition.

Non-continuousmediahasanotchoropeningbetweeneachlabel.Tomonitor

labelmovementyouneedtoalignthemediasensorwiththisnotchoropening.

Themediasensorconsistsoftwopartsthatmustbeproperlyalignedwiththe

notchoredgeofthelabel.Thefactory-setpositionshouldbesufficientformost

applications.Ifnot,performtheappropriateadjustments.

Adjusting the Upper Media Sensor

Toadjustfortheinsidehalfofthemedia:

1. Removetheribbon.Locatetheuppermediasensor(Figure2.9-A).

2. Loosen,butdonotremove,thePhillipsheadscrew.

3. Slidetheuppersensoralongtheslottoanypositionalongtheweb,except

wheretheroundedcornersofthelabelaredetected.Whenusingtagstock,

positiontheuppersensordirectlyovertheholeornotch.

4. Tightenthescrew.

38452L Rev.3 Page2-9

Getting Ready to Print

To adjust for the outside half of the media (160S ONLY):

1. R emove the ribbon. Locate the upper media sensor (Figure 2.9-A).

2. R emove the printer’s left side panel and reroute the media sensor cable to

provide a dditional slack.

3. R emove the Phillips head screw to release the upper section of the sensor

and wire cover.

4. Lift the upper media sensor assembly and move the sensor and the wire

cover to the outside half. Carefully pull the wires through the tie wrap.

You may need to set aside the sensor wire cover if the adj ustment is far to

the outside.

5. Replace and tighten the Phillips head screw.

6. Make sure the wires are routed back into the g roove of the media sensor

bracket.

7. Replace the printer ’s left side panel.

S

-Series Maintenance Manual: Volume 1

Figure 2.9 Upper Media Sensor

A

Page 2-10 38452L Rev. 3

S

-Series Maintenance Manual: Volume 1 Getting Ready to Print

Lower Media Sensor Adjustment

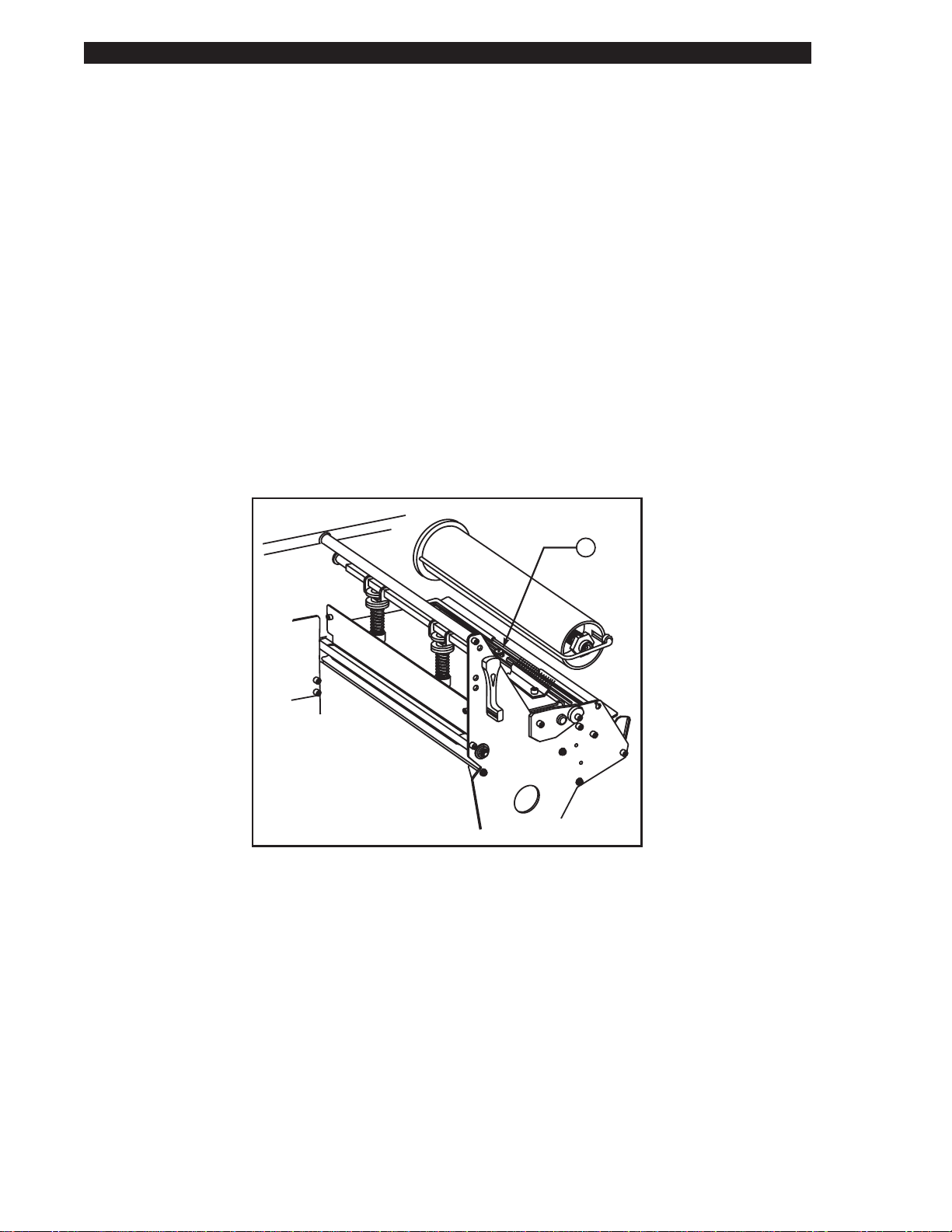

1. Locate the lower media sensor assembly under the rear idler roller

(Figure 2.10-A). (It is a spring clip holding a circuit boa rd.)

2. Slide the sensor until the two brass-colored infrared emitters are under the

upper medi a sensor. Gently pull wires out as needed (wires should have a

little slack).

3. NOTE: If the sensor is being moved inward and a large loop of wire

develops, remove the cover from the electronics side of the printer and

gently pull the wires through. Clamp the wires so that they do not rub any

belts.

A

Figure 2.10 Lower Media Sensor

38452L Rev. 3 Page 2-11

Getting Ready to Print

Option Switches

These switches are located above the signal interface cable connector. See

Figure 2.11.

In the following tables, “R” means the switch is in the right position, while “L”

means the switch is in the left position. Refer to Figure 2.12.

S

-Series Maintenance Manual: Volume 1

BANK 2BANK 2

BANK 1

(ONLY ON

SERIAL UNITS)

SIGNAL INTERFACE

CABLE CONNECTION

105 and 160

Se S

PARALLEL

Figure 2.11 Option Switch Locations

105 and 160

Se S

SERIAL

(L)(R)

1 2 3 4 5 6 7 8

Figure 2.12 Option Switches

Page 2-12 38452L Rev. 3

S

-Series Maintenance Manual: Volume 1 Getting Ready to Print

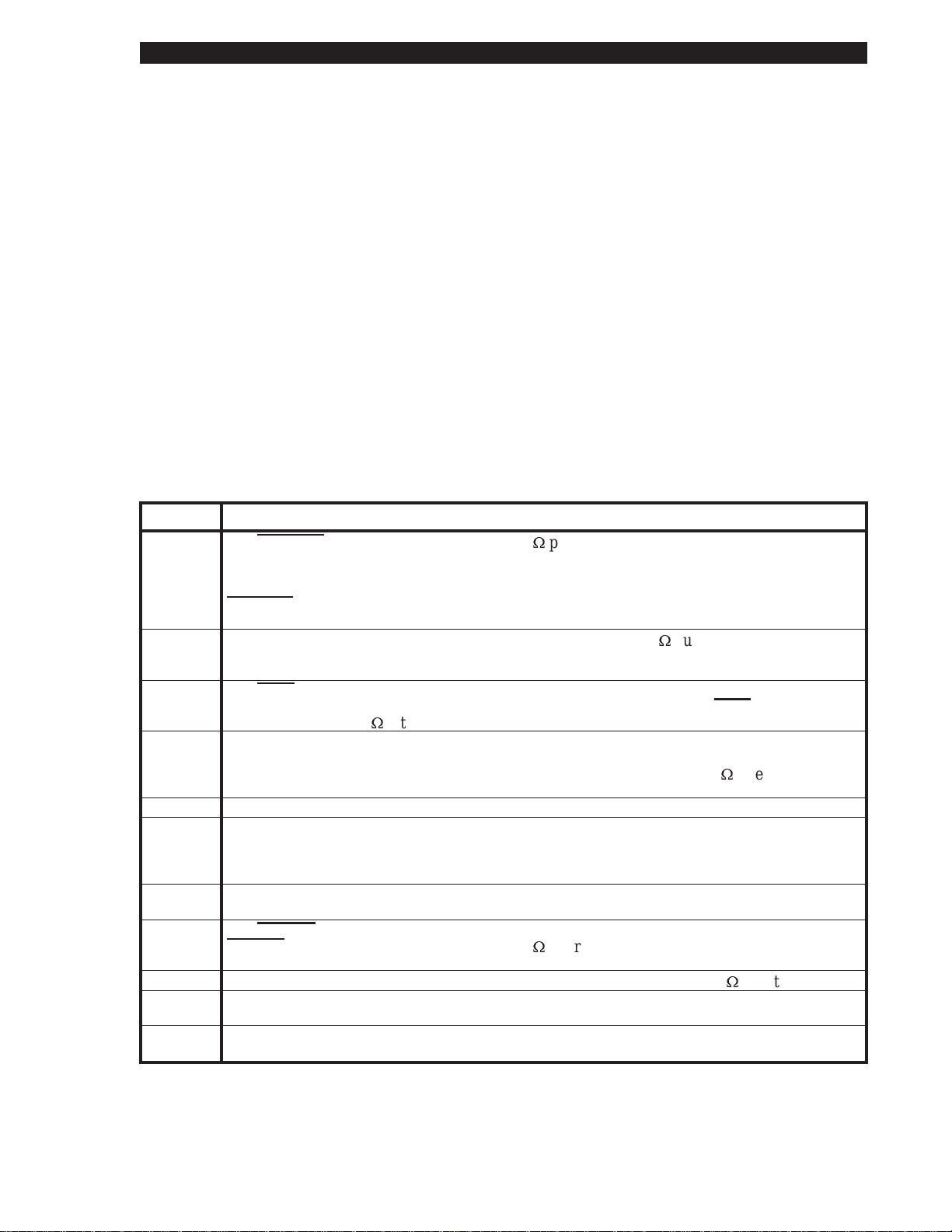

Bank 1 (Serial interface printers only)

NOTE: Parallel interf ace printers do not have Bank 1 switches since they are

not required. Bank 1 switches must be properly positioned to establish serial

data communications with the host computer. Once communications are

established, do not change the position of th ese switches.

Bank 1

Switch

321

R R R 9600

R R L 19200

R L R 110

R L L 300

L R R 600

L R L 1200

L L R 2400

L L L 4800

Switch

4

R7

L8

Switch

6 5 Parity

R R Even parity

R L Parity disabled

L R Odd parity

L L Parity disabled

Switch

7 Communication Handshake Control

R XON/XOFF control

L DTR/DSR control

Switch

8 Error Detection Protocol

R No error detection

L Error detection active

(Must be set to 8 data bits for Code Page 850)

Baud Rate

Data Bits

38452L Rev. 3 Page 2-13

Getting Ready to Print

Bank 2

These switches can manually override any ZPL commands that affect print

mode, media mode, and media type. They can also override settings established

during the calibration procedure.

If you do not want to override ZPL or the calibration settings, disable one or

more of the options by setting switches 1, 4, and/or 7 to t he “R” position and

turn the power on. With these disabled, the printer will requi re ZPL commands

to set print mode, media mode, and/or media type.

To override, set the switches to one of the modes shown in the table. If you a re

in the process of printing, this change takes affect on the next label printed. If

you change the switches from active to disabled after printer power-up, the

printer remains in the current mode until a ZPL command changes the mode.

Switch

321

R R L Cutter

R L L Tear Off

L R L Peel Off

L L L Rewind

- - R Disabled

Switch

6 5 4 Media Mode

R R L Non-continuous mark sense

R L L Non-continuous web sense

L L L Continuous

- - R Disabled

Switch

8 7 Media Type

R L Thermal transfer

L L Direct thermal

- - R Disabled

S

-Series Maintenance Manual: Volume 1

Bank 2

Print Mode

Page 2-14 38452L Rev. 3

3 PrinterDiagnostics

Inthissection... Page

PowerONSelfTest........................................................................3-1

PrinterSelfTests.............................................................................3-1

CANCELKeySelfTest...........................................................3-3

PAUSEKeySelfTest...............................................................3-4

FEEDKeySelfTest..................................................................3-5

MODEKeySelfTest................................................................3-6

FEED,PAUSEandCANCELKeys.......................................3-6

PAUSEKeyandCANCELKey..............................................3-7

FEEDKeyandCANCELKey................................................3-7

FEEDKeyandPAUSEKey....................................................3-7

ExtendedPrinterDiagnostics........................................................3-9

PAUSEKeyLoopbackTest.....................................................3-9

FEEDKeyLoopbackTest.......................................................3-10

BuiltintotheZebraS-SeriesPrintersa retestroutinestoaidthetechnicianin

diagnosingfaults.

Power ONSelfTest

APowerONSelfTest(POST)isperformedeachtimetheprinteristurnedON.

Thistestchecksforproperinitializationofvariouselectroniccircuitsand

establishesstartingparametersasthosestoredintheprinter’smemory.During

thistestsequence,thefrontpanelLEDswillturnONandOFFtoinsureproper

operation.

Attheendofthisselftest,onlythePOWERLEDwillremainlit.IfotherLEDs

remainlit,refertoTroubleshootinginthismanual.

PrinterSelf Tests

Theseselftestsproducesamplelabelsandprovidespecificinformationwhich

helpsdeterminetheoperatingconditionsfortheprinter.

Eachselftestisenabledwhenafr ontpanelkeyispressedwhilethepri nter’s

ACPowerSwitchisturnedON.KeepthekeypresseduntilthefrontpanelLEDs

turnON.

WhenthePowerOnSelfTestiscompleted,theselectedprinterselftestwill

startautomatically.

38452L Rev.3 Page3-1

Printer Diagnostics

NOTES: It is r ecommended that full width media be used when performing

these t ests. Labels less than full w idth in size will lose printing on the right side.

Label length will determine the amount of pr inting starting at the top of th e label.

When performi ng these self tests while in the Peel-Off Mode, the operator must

remove t he labels as they become available.

When canceling a self test prior to its actual completion, always turn the printer

power O FF and then back ON to reset the printer.

Some of the printer self tests produce labels at varying print speeds. These

speeds may be referred to as “inches per second,” “millimeters per second,” or

by alphabetic letter designation (i.e., “A,” “B,” “C,” etc.). The following chart

shows the relationships between the different speeds.

S

-Series Maintenance Manual: Volume 1

Letter

Designation

A* 2" 51 mm

B3"76mm

C 4" 102 mm

D 6" 152 mm

* S peed “A” for the 105S and 105Se with the optional 300 dots-per-inch

printhead is 2.4" (61 mm).

Inches

per Second

5" 127 mm

Millimeters

per Second

Page 3-2 38452L Rev. 3

S

-SeriesMaintenanceManual:Volume1 PrinterDiagnostics

CANCEL Key Self Test

Thisselftestprintsasinglelabelwhichcontainsalistingoftheprinter’scurrent

configurationparametersstoredinConfiguration(EEPROM)Memory.Pressthe

CANCELKeywhileturningtheACPowerSwitchON.Asamplelabelisshown

inFigure3.1.

Theprinterconfigurationmaybechangedtemporarilyforspecificlabelformats

orribbonandlabelstock,orpermanentlybysavingthenewparametersin

EEPROMMemory.Savingnewparametersoccurswheneveraprinter

configurationprocedureisperformed.RefertoGettingReadytoPrintfor

furtherdetailsonthePrinterConfigurationprocedure.

Figure 3.1 CANCELKey Self Test Label

38452L Rev.3 Page3-3

PrinterDiagnostics

PAUSE Key Self Test

EnterthisselftestmodebypressingthePAUSEKeywhileturningtheAC

powerON.

Thisselftestconsistsofeightseparatetestsequences,printinglabelsatboth

Speed“A”andSpeed“D”(“C”forthe300-dpi105Sand105Se).Duringthe

firstfourtestsequences,theprintersimulatesthe“Tear-Off”modeand

backfeedsthemediapriortoprintingeachlabel.Duringthelastfourtest

sequences,theprintersimulatesthe“Rewind”modeanddoesnotbackfeedthe

media.

Thisselftestcanbeusedtoprintthetestlabelsrequiredwhenmaking

adjustmentstotheprinter’smechanicalassemblies.Thesetestlabelscanalso

beprintedwhenrequiredduringtheConfigurationandCalibrationprocesses

describedinGettingReadytoPrint.SeethelabelexampleinFigure3.2.

NOTE:IftheTakeLabelSensorpairismountedonthefrontoftheprinter,

“PEELOPTIONINSTALLED”willbeprintedonthefirstlabel.Duringthefirst

fourtestsequences,eachlabelmustbemanuallyremovedfromthesensorpath

beforethenextlabelwillprint.Duringtestsequencesfivethrougheight,the

TakeLabelSensorpairisnotenabledandcontinuousprintingoccurs.

S

-Series Maintenance Manual: Volume 1

Tobypassthefirstfoursequences,pressthePAUSEKey;thentearoffthefirst

printedlabel.Oncethelabelisremoved,theprinterwillenterthePAUSEmode.

PresstheCANCELKeyfourtimesandmakesuretheDataLEDflashesonce

eachtime.PressthePAUSEKeyoncetostarttestsequencefive.

1. Theinitialtestsequenceprints15labelsatspeed“A”thenautomatically

PAUSEStheprinter.Another15la belsequencewillstartifthePA USEKey

ispressedtopermitprinting .

2. WhiletheprinterisPAUSED,presstheCANCELKeyoncetoselectthe

secondselftestsequence.NoweachtimethePAUSEKeyispressed,the

printerprints15labelsatspeed“D”(“C”forthe300-dpi105Sand105Se).

Another15labelsequencewillstartifthePAUSEKeyispressedtopermit

printing.

3. WhiletheprinterisPAUSED,presstheCANCELKeyoncetoselectthe

thirdselftestsequence.NoweachtimethePAUSEKeyispressed,the

printerprints50labelsatspeed“A”.Another50labelsequencewillstartif

thePAUSEKeyispressedtopermitprinting.

4. WhiletheprinterisPAUSED,presstheCANCELKeyoncetoselectthe

fourthselftestsequence.NoweachtimethePAUSEKeyispressed,the

printerprints50labelsatspeed“D”(“C”forthe300-dpi105Sand105Se).

Another50labelsequencewillstartifthePAUSEKeyispressedtopermit

printing.

5. SelfTestsequencesfivethrougheightarethesameassequencesone

throughfourbutsimulatethe“Rewind”modeofoperationbynot

backfeedingatthebeginningofeachlabel.Inaddition,theTakeLabel

Sensorpairisdisabledduringthesetestsequencessolabelsdonotneedto

beremovedindividually.

Page3-4 38452L Rev.3

S

-Series Maintenance Manual: Volume 1 Printer Diagnostics

Figure 3.2 PAUSE Key Self Test Label

FEED Key Self Test

The CANCEL Key Self Test should be performed prior to this Self Test.

Information on the printed “Configuration” Label (CANCEL Key Self Test) will

be used with the results of this self test to determine the best Darkness Setting

for a specific media/ribbon combination.

The FEED Key Self Test Label will print out at various PLUS or MINUS

darkness settings relative to the darkness value shown on the configuration

label. Inspect these labels and determine which one has the best darkness setting

for t he application. See the example in Figure 3.3.

Figure 3.3 FEED Key Self Test Label

38452L Rev. 3 Page 3-5

PrinterDiagnostics

Thevalueprintedonthatlabelisaddedto(plus)orsubtractedfrom(minus)the

“Darkness”valuespecifiedontheConfigurationLabel.

Theresultingnumericvalue(0to30)ist hebestdarknessvalueforthatspec ific

media/ribboncombination.

ThevalueselectedcanbeenteredwhileperformingaMediaDarkness

Adjustment.ThePLUSvaluecanbeenteredbypressingtheUP(FEED)Key,

whiletheMINUSvalueisenteredbypressingtheDOWN(CANCEL)Keythe

appropriatenumberoftimes.RefertotheCalibrationprocessesdescribedin

GettingReadytoPrint.

Optionally,therequiredrelativedarknessvaluecanbeprogrammedintothe

ZPLIIlabelformatssenttotheprinter.

MODE Key Self Test

ThisselftestplacestheprinterintheCommunicationsDiagnosticsMode.

PresstheMODEKeywhileturningtheACpowerswitchON,thensendalabel

formattotheprinter.Inthismode,theprinterprintstheASCIIcharactersand

theircorrespondinghexadecimalvaluesforanydatareceivedfromthehost

computer.SeetheexampleinFigure3.4.

S

-Series Maintenance Manual: Volume 1

NOTE:Turntheprinter’spowerOFFtoexitthisselftest.

Figure3.4MODEKeySelfTestLabel

FEED, PAUSE, and CANCEL Keys

Ifthesethreekeysarehelddepressedatthesametimeandthepoweristurned

ON,theprinterwillentertheMediaSensorandR ibbonSensorSensi tivity

AdjustmentMode.SeeCorrectiveMaintenancefortheseadjustments.

Page3-6 38452L Rev.3

S

-SeriesMaintenanceManual:Volume1 PrinterDiagnostics

PAUSE Key and CANCEL Key

Thisselftestcanbeusedtoverifyproperprinteroperationafterpartshavebeen

replacedoradjusted.Whenactivated,theprinterprintsamaximumof500Head

TestLabels.Eachlabelbackfeedspriortoprintingandfeedsforwardtotherest

positionafterprinting.Aserializednumberwillprintoneachlabel.Pressthe

PAUSEKeyorturntheprinterp owerOFFtostopprint ing.RefertoFigure3 .6.

FEED Key and CANCEL Key

Thisselftestisnormallyperformedduringthemanufacturingprocessoraftera

majoroverhaulofthemechanicalassemblies.Thistestprintsseven

pre-programmedlabelformats,firstatSpeed“D,”thenthesameformatsat

Speed“A.”Theprinterwillautomaticallypauseaftereachformat.Thesequence

oflabelformatsisshownbelow.RefertoFigures3.7through3.13.

FORMAT PRINTING TEST FUNCTION

1 20atSpeed D LeftRibbonWrinkle Test

2 20atSpeed D RightRibbon WrinkleTest

3 20atSpeed D Bar CodeWrinkleTest(Code-39)

4 20atSpeed A LeftRibbonWrinkle Test

5 20atSpeed A RightRibbon WrinkleTest

6 20atSpeed A Bar CodeWrinkleTest(Code-39)

7 10atSpeed D UsableArea Test

8 10atSpeed D Head TemperatureTest

9 10atSpeed D UpperSmear Test

10 10atSpeed D Lower SmearTest

11 10atSpeed A UsableArea Test

12 10atSpeed A Head TemperatureTest

13 10atSpeed A UpperSmear Test

14 10atSpeed A Lower SmearTest

FEED Key and PAUSE Key

Pressingthesetwokeysatthesametime,whileturningthepowerON,

temporarilyresetstheprinterconfigurationtothefactorydefaultvalues.These

valueswillbeactiveuntilpoweristurnedOFF.Ifthefactorydefaultconditions

aretobeusedonapermanentbasis,savethembypressingtheMODEKeyfour

times-MODELEDscycleONthenOFF.AMediaCalibrationprocedure

mustbeperformedafterfactorydefaultvalu esaresaved.Figure3.5

indicateswhichprinterfunctioncontrolseachoftheconfigurationparameters.

38452L Rev.3 Page3-7

Printer Diagnostics

Parameter Controlled By

Darkness Front Panel Adjustment or ZPL II

Tear Off Adjust Front Panel Adjustment

Web Sensor Front Panel Calibrate or ZPL II

Media Sensor Front Panel Calibrate or ZPL II

Ribbon Sensor Front Panel Calibrate or ZPL II

Mark Media Sensor DIP Switches or ZPL II

Mark Sensor Front Panel Calibrate or ZPL II

Media LED Front Panel Calibrate or ZPL II

Ribbon LED Front Panel Calibrate or ZPL II

Mark LED Front Panel Calibrate or ZPL II

Label Length Front Panel Calibrate or ZPL II

Max Label Length ZPL II Controlled

Print Width ZPL II Controlled

Print Mode DIP Switches or ZPL II Controlled

Media Type Front Panel Calibrate, DIP Switches or ZPL II

Print Method Front Panel Calibrate, DIP Switches or ZPL II

Host Port Firmware Controlled

Network Port Firmware Controlled

Baud DIP Switches

Data Bits DIP Switches

Parity DIP Switches

Stop Bits Firmware Controlled

Handshake Dip Switches

Protocol Dip Switches

Delimiter ZPL II Controlled

Format Prefix ZPL II Controlled

Control Prefix ZPL II Controlled

Network ID ZPL II Controlled

Modes Enabled ZPL II Controlled

Modes Disabled ZPL II Controlled

Resolution ZPL II Controlled

Backfeed ZPL II Controlled

Label Top Front Panel Calibrate or ZPL II

Left Position ZPL II Controlled

Socket 1 ID EPROM

Socket 2 ID EPROM

Firmware Firmware Controlled

Configuration Firmware Controlled

Memory Functioning Memory

B: Memory Firmware Controlled

Media Power Up ZPL II Controlled

Media Head Close ZPL II Controlled

S

-Series Maintenance Manual: Volume 1

Figure 3.5 Configuration Parameter Controls

Page 3-8 38452L Rev. 3

S

-Series Maintenance Manual: Volume 1 Printer Diagnostics

Extended Printer Diagnostics

Additional diagnostic tests are available for printhead assembly adjustments.

These diagnost ics tests are only accessible when the data interface cable is

disconnected fr om the printer and a Loopback Connector i s attached in its place.

The Serial Loopback Connector is a 25-pin “D” type (DB25P-Male ) style with

the following pins tied together.

• pins 2 and 3

• pins 6 and 20

• pins 13 and 14

• pins 16 and 19

The Par allel Loopback Connector is a standard 36-pin parallel connector

mounted to a small circuit board. This connector is available from Zebra

Technologies as Part # 44680.

For each of these diagnostic tests, the printer will “transmit” the test label

format out of the Data Interface Connector to the Loopback Connector. The

Loopback C onnector passes the test label format back to the printer as “receive”

Data and the test label is printed.

PAUSE Key Loopback Test

This test demonstrates the media movement capabilities of the printer and

provides a t est label to view while making print quality adjustments.

With the Loopback Connector in place, press the PAUSE Key while turning the

AC Power Switch ON.

After the Power On Self Test, the printer will print 500 Head Test label s. Each

label will backfeed prior to printing and feed to the rest position after printing.

A s erialized number will print on each label for label comparison purposes if

required. See the example in Figure 3.6.

The PAUSE Key can be used to stop and restart the printing operation.

Figure 3.6 PAUSE Key Loopback Test Label

38452L Rev. 3 Page 3-9

Printer Diagnostics

FEED Key Loopback Test

With the Loopback Connector in place, press the F EED Key while turning the

AC Power Switch ON.

After the POST, the printer will begin printing a series of label formats as shown

in the chart below. The printer will PAUSE at the end of each printed format.

Press the PAUSE Key to begin printing the next format. R efer to the label

examples in Figures 3.7 through 3.13.

The PAUSE Key can be used to stop and restart the printing operation. When the

printer is p aused, the CANCEL Key can be used to move to the next label format.

FORMAT PRINTING TEST FUNCTION

1 20 at Speed D* Left Ribbon Wrinkle Test

2 20 at Speed D* Right Ribbon Wrinkle Test

3 20 at Speed D* Bar Code Wrinkle Test (Code-39)

4 20 at Speed A Left Ribbon Wrinkle Test

5 20 at Speed A Right Ribbon Wrinkle Test

6 20 at Speed A Bar Code Wrinkle Test (Code-39)

7 10 at Speed D* Usable Area Test

8 10 at Speed D* Head Temp Test

9 10 at Speed D* Upper Smear Test

10 10 at Speed D* Lower Smear Test

11 10 at Speed A Usable Area Test

12 10 at Speed A Head Temp Test

13 10 at Speed A Upper Smear Test

14 10 at Speed A Lower Smear Test

S

-Series Maintenance Manual: Volume 1

* “C ” for the 105S and 105Se with the 300 dots/inch printhead

Figure 3.7 Format 1 (8) Test Label

Page 3-10 38452L Rev. 3

S

-Series Maintenance Manual: Volume 1 Printer Diagnostics

Figure 3.8 Format 2 (9) Test Label

Figure 3.9 Format 3 (10) Test Label

Figure 3.10 Format 4 (11) Test Label

38452L Rev. 3 Page 3-11

Printer Diagnostics

S

-Series Maintenance Manual: Volume 1

Figure 3.11 Format 5 (12) Test Label

Figure 3.12 Format 6 (13) Test Label

Figure 3.13 Format 7 (14) Test Label

Page 3-12 38452L Rev. 3

4 PreventiveMaintenance

Inthissection... Page

FieldMaintenanceFunctions........................................................4-1

ToolsRequired.................................................................................4-1

CleaningtheS-SeriesPrinter........................................................4-1

CleaningthePrinthead...................................................................4-2

CleaningtheSnapPlate.................................................................4-2

CleaningtheCutterModule..........................................................4-4

LubricatingtheCutterModule......................................................4-4

RecommendedPreventiveMaintenanceSchedule.....................4-5

FieldMaintenanceFunctions

FieldmaintenancefunctionsfortheZebraS-Seriesprintercanbedivide dinto

twobasiccategories.

• Thissectionofthemanualcontainspreventivemaintenanceproceduresand

operatorcareinstructions.Preventivemaintenanceconsistsofavisual

inspectionandgeneralcleaningoftheinteriorandexterioroftheunitand

printhead.Theseproceduresmaybeperformedbytheoperatorandshould

beperformedonaregularbasis.

• Correctivemaintenance,describedinCorrectiveMaintenance,provides

detailedstepsforresolvingfaults.Repairsareaccomplishedbyreplacement

ofcomponentsormodulesorbyadjustments.

ToolsRequired

Toproperlyperformthepreventivemaintenancetasks,theservicetechnician

shouldbeequippedwiththefoll owing:

• Applicators

• 70%isopropylalcohol

• Citrus-basedcleaner

Unlessindicatedotherwise,turnpowerOFFbefore

performingmaintenanceprocedures.

CleaningtheS-SeriesPrinter

EXTERIOR—TheexteriorsurfacesoftheS-Seriesprintermaybecl eaned

withalint-freecloth.DONOTusesolventsorharshcleaningagents.Iftheunit

isexcessivelydirty,amilddetergentsolutionordesktopcleanermaybeused

sparingly.

WARNING

38452L Rev.3 Page4-1

PreventiveMaintenance

INTERIOR—Asrequired,removeanydirt/lintaccumulatedintheinteriorof

theprinterusingasoftbristlebrushand/orvacuumcleaner.Itisagoodpractice

toinspecttheseareasaftereveryfourthrollofmedia.

CleaningthePrinthead

Inconsistentprintqualitysuchasblankareasinthebarcodesorgraphicsmay

indicateadirtyprinthead.Foroptimumperformance,theprintheadshouldbe

cleanedregularly.Whenprintingindirectthermalmode,performthefollowing

cleaningprocedureaftereveryrollofmedia(or500feetoffanfoldmedia).

Whenprintinginthethermaltransfermode,cleanaftereveryrollofribbon.

NOTE:ItisnotnecessarytoturntheprinterOFFpriortocleaning.Alllabel

formats,images,andparametersettingsstoredintheprinter’smemorywillbe

lostiftheprinteristurnedOFF.IftheprinteristurnedOFF,itmaybenecessary

toreloadsomeitemsintotheprinter’smemory.

1. OpentheprintheadbymovingtheLatchingLevertotheOPENposition.

2. Removethemediaandribbon(ifpresent).

3. Useanapplicatormoistenedwith70%isopropylalcoholtowipetheprint

elementsfromendtoend.(RefertoFigure4.1.Theprintelementsarethe

brownstripjustbehindthechromestrip.)Allowafewsecondsforthe

solventtoevaporate.

4. RotatethePlatenRollerandcleanthoroughlywithisopropylalcohol.

5. Brushorvacuumanyaccumulatedpaperlintanddustawayfromtherollers

andtheMediaandRibbonSensors.

6. Reloadribbonand/ormedia,closeandlatchtheprinthead,andcontinue

printing.

S

-Series Maintenance Manual: Volume 1

CleaningtheSnapPlate

Intheeventofalabeljam,theMediaGuidePlate(SnapPlate)canberemoved

andcleaned.RefertoFigure4.2andfollowthesesteps.

1. OpenthePrintheadtoitsfullyopenpositionbyrotatingtheLatchingLever

counterclockwise.ThePrintheadpivotstoanalmostverticalposition.

2. Fromthefrontoftheprinter,po pupthefrontedgeo ftheSnapPlateusing

yourfingernailoraflat-bladescrewdriver.

3. LiftthefrontedgeoftheSnapPlatewhilepullingitupandoutoftheprint

mechanism.

4. CleantheSnapPlate,includingtheraisedareadirectlybelowtheribbon

sensor.Removeanystucklabelsanduseacitrus-basedcleanertoremove

anybuilt-upadhesive.

IncorrectinstallationoftheSnapPlatecandisablethe

5. ReplacetheSnapPlatebyplacingthebacklegsintheopeningsintheMain

MediaGuidewhileslidingittotherearoftheopeningsandsnappingit

downintoplace.RefertoFigure4.2.

CAUTION

RibbonSensororcauseheadpressureimbalance.

Page4-2 38452L Rev.3

S

-SeriesMaintenanceManual:Volume1 PreventiveMaintenance

PRINTHEAD

RIBBON

SENSOR

LABEL

AVAILABLE

SENSORS

PLATEN

ROLLER

Figure4.1PrintheadCleaning

PEEL/TEAR

BAR

SNAP

PLATE

Figure4.2SnapPlateCleaning

38452L Rev.3 Page4-3

Preventive Maintenance

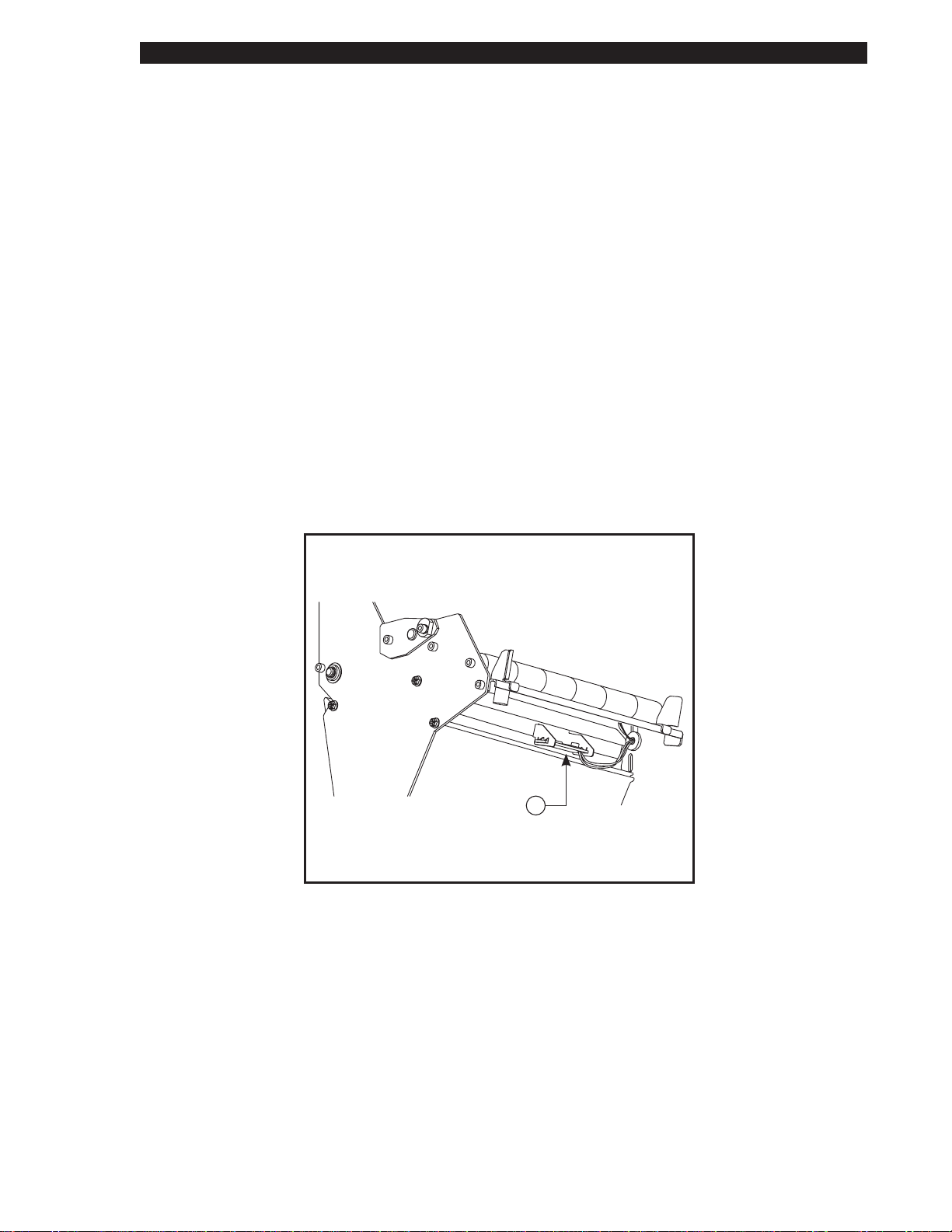

Cleaning the Cutter Module

Periodically, the Cutter Module should be cleaned to remove paper dust and

label residue. Refer to Figure 4.3.

Clean the stationary cutter blade with a cotton swab moistened with a

citrus-based cleaner when it becomes gummed up with label adhesive or paper

debris. After cleaning, apply a small amount of petroleum lubricating grease to

the moving cutter parts.

S

-Series Maintenance Manual: Volume 1

Figure 4.3 Cutter Blade Cleaning

Lubricating the Cutter Module

Certain applications or types of label stock may cause the cutter blades to

eventually st art to squeak. This commonly occurs when less-than-full width

media is being used.

To eli minate the squeak and prolong cutter life, first turn off the printer. Next,

clean the lower cutter blade by following the above procedure. Then, coat a

cotton swab with a small amount of petroleum lubricating grease and wipe the

swab along the top of the lower cutter blade and on the surface of the ring at the

end of the rotary blade (refer to Figure 4.4).

DETAIL

Figure 4.4 Cutter Module Lubrication

Page 4-4 38452L Rev. 3

S

-SeriesMaintenanceManual:Volume1 PreventiveMaintenance

RecommendedPreventiveMaintenanceSchedule

AREA METHOD INTERVAL

PRINTHEAD Isopropyl alcohol When printinginthedirect

PLATEN ROLLER Isopropyl alcohol

MEDIASENSOR Airblow

MEDIA PATH Isopropyl alcoholandcloth

RIBBON SENSOR Airblow

PEELROLLER Isopropyl alcohol Once per month

LABELAVAILABLE

SENSOR

RIBBONFEEDING PATH Visual Once per three months

DRIVE BELTS Visual Six monthsor500rolls

CUTTER BLADES Citrus-based cleanerand/or air

Formalpreventivemaintenance is not required onthese

spindles. Spindletension should notbe adjustedunless

the printer ismalfunctioning(i.e.,spindlesnot rotating

MEDIA TAKE UPSPINDLE

smoothly).Therecommendedtensionsandadjustment

procedures are provided inCorrectiveMaintenance.

Airblow Once per six months

blow

thermalmode:after everyroll

ofmedia (or500feet of

fanfold media).

When printinginthethermal

transfer mode:after everyroll

ofribbon.

As needed

RIBBONSUPPLY SPINDLE

RIBBONTAKE UPSPINDLE

105Sand105Seprinters:Thespindles should be taken

apart and the felt pads replaced with new ones presoaked in

silicone oil (new feltpads and silicone oil are availablein

kit #01688-140)per the followingschedule:

Media SupplyandTake-Up Spindles - once per yearor

after500media rollsof media

Ribbon Supplyand Ribbon Take-Up Spindles-once per

yearorafter 200rolls of ribbon.

160Sprinter:

Thesespindles should onlybe disassembled andcleaned with

alcoholiftheyfail torotate smoothly.

DONOTlubricatethesespindles.

38452L Rev.3 Page4-5

Preventive Maintenance

S

-Series Maintenance Manual: Volume 1

R

Page 4-6 38452L Rev. 3

5 CorrectiveMaintenance

Inthissection... Page

ToolsRequired.................................................................................5-2

TestEquipmentRequired...............................................................5-2

105Sand105SePrintheadReplacement.....................................5-3

160SPrintheadReplacement.........................................................5-5

PrintheadAdjustments...................................................................5-7

PrintheadVoltageAdjustment.......................................................5-12

MediaSensorPositionAdjustment..............................................5-15

MediaSensorandRibbonSensorSensitivityAdjustment.......5-17

TakeLabelSensorAlignment.......................................................5-19

MediaTrackingAdjustments........................................................5-20

RewindMode.............................................................................5-20

Peel-OffMode...........................................................................5-21

SpindleAdjustmentandMaintenance.........................................5-22

TensionMeasurementProcedure............................................5-22

SpindleTensionAdjustment...................................................5-22

RemovingtheAdapterBoard........................................................5-24

InstallingtheAdapterBoard.........................................................5-24

RemovingtheMainLogicandPowerSupplyBoards..............5-24

InstallingtheMainLogicandPowerSupplyBoards................5-28

EPROMSoftwareInstallation.......................................................5-29

MainDriveBelt-Removal,ReplacementandAdjustment.....5-31

RewindDriveBelt-Removal,ReplacementandAdjustment.....5-32

ACPowerFuseReplacement........................................................5-33

BatteryReplacement.......................................................................5-34

CutterAdjustmentsandReplacementInstructions....................5-34

PrinterDisassembly..................................................................5-34

InternalAccess..........................................................................5-35

CutterMotorRemoval..............................................................5-35

CutterMotorInstallation.........................................................5-35

CutterMechanicalAssemblyRemoval..................................5-37

CutterMechanicalAssemblyInstallation.............................5-37

DriveLinkAssemblyInstallation..........................................5-38

CutterCircuitBoardRemoval................................................5-38

CutterCircuitBoardInstallation............................................5-38

OpticalSensorRemoval...........................................................5-39

OpticalSensorInstallation......................................................5-39

LowerDriveArmMechanicalAlignment.............................5-39

UpperDriveArmAlignment...................................................5-40

38452L Rev.3 Page5-1

Corrective Maintena nce

When a problem is encountered with the S-Ser ies printer, the service technician

should first insure the unit is being used properly, then exercise i t to localize the

fault. Onc e localized, refer to the appr opriate replacement or adjustment

procedure t o correct the fault.

Tools Required

Screwdriver, flat blade, 1/4", 1/8" x 8", and 3/16" x 3"

Screwdriver, Phillips #1, #1 extended r each, and #2

Pliers, long-nose, small needle nose, utility, snap ring

Set of inch combination (open end/box end) w renches (must include a 7/16")

Set of inch Allen wrenches (1/ 16", 3/32", 5/64", 7/64", 9/64" )

Allen bit socket 5/32"

Allen hex key, 5/64"

Torque wrench calibrated in inch-pounds (drive size to fit 5/32" Allen bit socket)

Nut driver, 5/16"

Hex head drivers, 0.35", 1/16", 1/16" ball point, 3/32", 5/32", 5/64", 7/64", 7/6 4"

extended r each (minimum 10" shaft), 7/64" ball point, 9/64"

Metric hex head drivers, 1.5 mm, 2 mm, 3 mm, and 5 mm

Metric hex key set

0–1,000gSpringScale

0-2.25 Kg Spring Scale

Clip to clip (jumper) lead

Wire cutters

Soldering iron, 20-35W

Potentiometer adjustment tool

File

Metric/English ruler, metal scale

Fuse, 5 Amp, Slo Blo, 250V 3AG (115 VAC installations)

Fuse, 3 Amp, Slo Blo, 250V 3AG (230 VAC installations)

Spindle Torque Adjustment Kit, Part # 01773

Digital Voltmeter w ith Clip-On Leads

S

-Series Maintenance Manual: Volume 1

Test Equipment Required

Multimeter and test leads.

Anti-static mat and anti-static wrist strap (used when removing electronic

circuit boards or updating firmware).

WARNING

Unless indicated otherwise, turn printer power

OFF before performing main tenance procedures.

CAUTION

To prevent possible damage to EPR OMs or the Main Logic

Board, please disconnect ALL communications cables before

performing maintenance procedures.

Page 5-2 38452L Rev. 3

S

-SeriesMaintenanceManual:Volume1 CorrectiveMaintenance

105Sand 105

RefertoFigure5.1whileperformingthefollowingprocedure.

1. TurntheprinterOFFandremovethePowerCord.

2. Removemediaandribbon.

3. Properlyconnectyourselftoananti-staticprotectionsystem.

4. RemovethePrintheadPressurePlateandtheStaticRemovalBrushby

5. Notethelocationofthegroundingstrap,andcarefullyholdtheprinthead

6. Holdingtheprintheadstable,removetheelectricalconnectormountedat

7. Removetheoldprinthead.

8. Priortoinstallingthenewprinthead,notetheresistancevalueshown

9. Reconnecttheelectricalconnectortothenewprinthead.

10.Fitthenewprintheadintothemountingbracket.

Se

Printhead Replacement

CAUTION

Observeproperelectrostaticsafetyprecautionswhenremoving,

handling,andreplacingthePrinthead.

removingthesix(6)Allenheadmountingscrews.(Someprintersmay

requiretheremovaloftwoadditionalscrewsthatmounttheStaticRemoval

Brush.)

andremovethefourPhillipsscrewsthatholdittotheMountingBracket.

thebackoftheprinthead.

onthelabellocatedunderthenewprint head.

CAUTION

Ensurethatthegroundingstrapisreattachedbytheprinthead

mountingscrew.

11.LooselyinstallthefourPhillipsscrewsthroughthePrintheadBracketand

thePrinthead’saluminumbody.

12.AfterverifyingthePrintheadisseatedproperly(PrintheadBracketGuide

Pinsarefittedintotheguideholesonthe12dots/mmPrinthead),tighten

thePhillipsheadmountingscrews.

13.ReinstallthePressurePlateandStaticRemovalBrushwiththemounting

screws.

14.UsethePreventiveMaintenanceKittocleanthenewprintheadthoroughly.

15.Reinstallmediaandribbon.

16.ConnecttheACPowerCordandturntheprinterpowerON.

17.AftertheprintercompletesthePowerOnSelfTest,refertothePrinthead

Resistancevalue(notedinStep8above)andperformthePrintheadVoltage

Adjustmentonpages5-12through5-14.

18.PressthePAUSEKeywhileturningtheprinterpowerON,andcheckthe

printqualityofthetestlabels.

38452L Rev.3 Page5-3

Corrective Maintena nce

PRESSURE

PLATE

MOUNTING

SCREWS

PRINTHEAD

PRESSURE

PLATE

GROUNDING

STRAP

PRINTHEAD

MOUNTING

SCREWS

S

-Series Maintenance Manual: Volume 1

STATIC

REMOVAL

BRUSH

PRINTHEAD

BRACKET

GUIDE PINS

(12 DOT/MM ONLY)

PRINTHEAD

GUIDE HOLES

PEM STUDS

(6 DOT/MM

8 DOT/MM ONLY)

&

Figure 5.1 105S/105Se Printhead Replacement

Page 5-4 38452L Rev. 3

S

-SeriesMaintenanceManual:Volume1 CorrectiveMaintenance

160SPrintheadReplacement

RefertoFigure5.2whileperformingthefollowingprocedure.

CAUTION

ObserveproperElectrostaticSafetyPrecautionswhenremoving,

handlingandreplacingthePrinthead.

1. TurntheprinterOFFandremovethePowerCord.

2. OpenthePrintheadAssemblyandremovethemediaandribbon;thenclose

thePrintheadAssembly.

3. Properlyconnectyourselftoananti-staticprotectionsystem.

4. LocatetheSpring-loadedPrintheadMountingScrewontopofthePrintheadAssembly.

5. LoosentheMountingScrewuntilitdisengagesfr omthePrinthead.

CAUTION

Usecaretominimizeanyphysicaldamagetothe

Printheadduringtheremainderofthisprocedure.

6. SlowlyopenthePrintheadAssembly.ThePrintheadwillberestingonthe

PlatenwhiletherestoftheAssemblypivotsback.

7. SpreadaparttheholdingtabsonthesidesofthePrintheadDataConnectors

toreleasetheDataCables.

8. GrasptheoutsideedgesofthePrintheadPowerCableConnectorandpress

downonthePowerCableLockingTab.

9. Whilemaintainingpressureonthelockingtab,disconnectthePrinthead

PowerCableandremovethePrintheadthroughthefrontoftheprinter.

10.Priortoinstallingthenewprinthead,notetheresistancevalueshown

onthelabellocatedunderthenewprint head.

11.ConnectthePrintheadPowerCabletotheappropriateconnector.

12.Spreadaparttheholdingtabsonthesidesofthetwodataconnectorsand

presstheappropriatePr intheadDataCableint oeachconnector.T he

HoldingTabsmust“snap”intoplacearoundthecableconnectors.Dress

cablescompletelybehindtheprint head.

13.CarefullypositionthealignmentslotsinthenewPrintheadoverthe

alignmentpostsontheundersideofthemountingbracket(referto

Figure5.2).

14.AfterensuringthatnocablesarebetweenthePrintheadandthePrinthead

BracketandverifyingthePrintheadisseatedproperly,carefullytightenthe

mountingscrew.(Ifanyproblemsoccurduringthisinstallationprocess,contact

ourTechnicalSupportgroup.)

15.RefertoFigure4.1.Use70%isopropylalcoholtothoroughlycleantheprint

element(brownarea)ofthenewPrinthead.

16.Reinstallmediaandribbon.

17.ConnecttheACPowerCordandturntheprinterpowerON.

38452L Rev.3 Page5-5

Corrective Maintena nce

PRINTHEAD

MECHANISM

ASSEMBLY

PRINTHEAD

MOUNTING

SCREW

S

-Series Maintenance Manual: Volume 1

DO NOT LOOSEN

THESE SCREWS!!

PRINTHEAD

DATA

CONNECTORS

PRINTHEAD

ALIGNMENT

SLOTS

PRINTHEAD

PRINTHEAD

ALIGNMENT

POSTS

POWER CABLE

LOCKING TAB

PRINTHEAD

POWER

CONNECTOR

Figure 5.2 160S Printhead Replacement

Page 5-6 38452L Rev. 3

S

-SeriesMaintenanceManual:Volume1 CorrectiveMaintenance

18.AftercompletingthePowerONSelfTest,refertothePrintheadResistance

value(notedinStep11above)andperformthePrintheadVoltage

Adjustmentonpages5-12through5-14.

19.Afteradjustingtheprintheadvoltage,activatethePAUSEKeySelfTestby

pressingthePAUSEKeywhileturningtheprinterpoweron.Checkprint

quality.

20.Theprintershouldbereadyforoperation.Ifproblemsarise,referto

Troubleshooting.

PrintheadAdjustments

Print Quality Adjustments

Therearefiveinterrelatedadjustmentsthatleadtooptimumprintqualitywith

increasedPrintheadlife:

• PrintheadParallelism

• WearPlate(Balance)Position

• PrintheadPosition

• PrintheadPressure

• StripPlatePositioning