Page 1

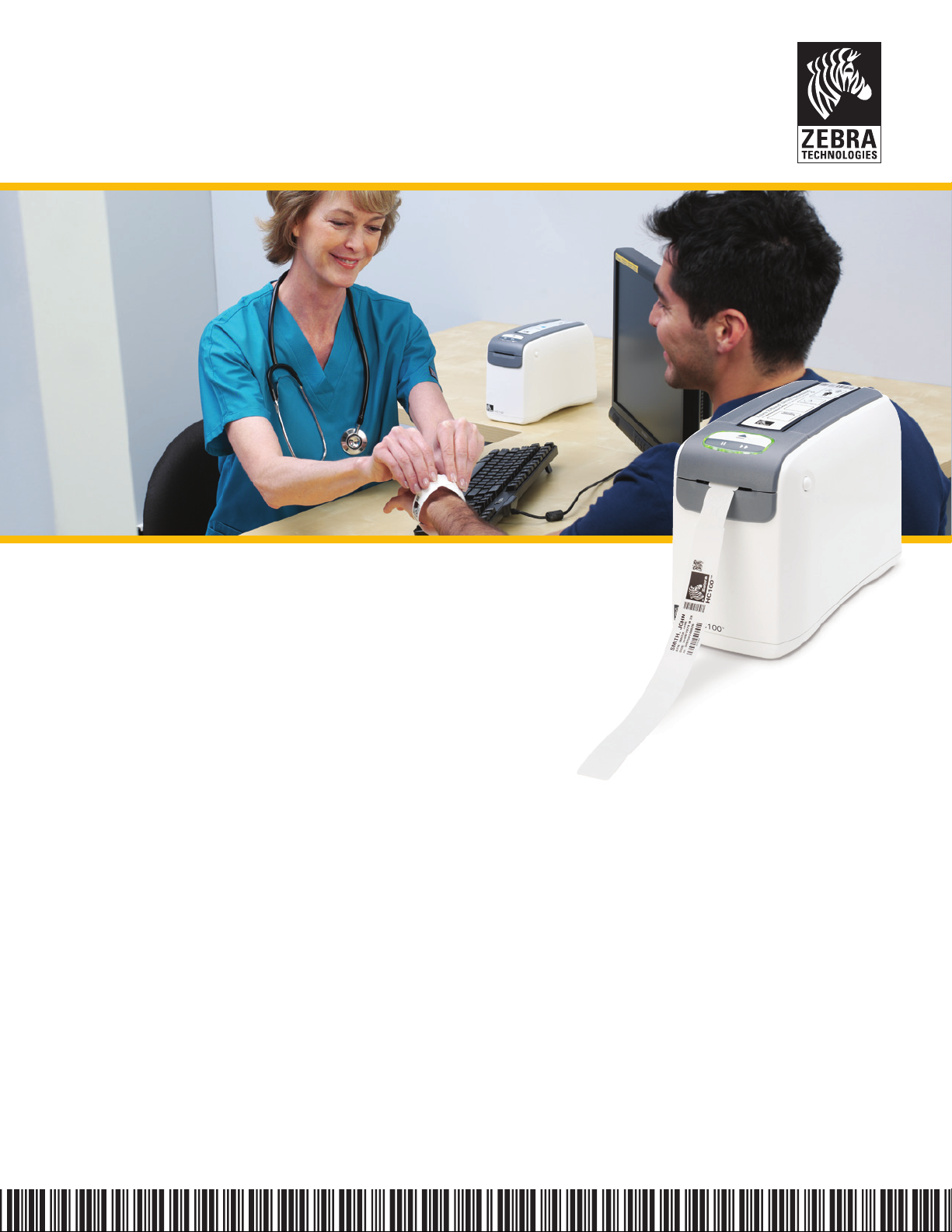

HC100™

Patient I.D. Solution

Have You Thought About What Laser Wristband Printing Is

Really Costing You?

At first glance, laser may seem like an adequate print technology for

wristbands. But, in reality, the hidden costs as well as staff

inefficiencies and frustrations add up fast:

• With laser, the adhesive backing on the wristband and label

forms can ooze and cause performance problems for the

printer. This leads to increased help desk calls and higher

maintenance costs.

• Laser toner is expensive, and more toner is used to print

high-density bar codes than plain text.

• Laser wristband printing can be time consuming and labor

intensive. With some laser bands, the staff must load forms into a

special tray, print labels, apply a label to the band, and then fold a

laminate coating over the band to protect the bar code image.

• Many laser forms include extra wristbands and labels that are not

needed and must be destroyed under HIPAA guidelines.

Zebra’s new HC100 Patient I.D. Solution overcomes all of these

obstacles. Now your hospital staff can produce and attach a longlasting, antimicrobial-coated thermal wristband in just two steps. No

wasted time with the cumbersome wristband assembly many laser

solutions require. No jammed laser printers. No toner. No ribbon. It’s

that simple.

All-in-One Wristband Solution

• Remarkably easy to use

• Accommodates Zebra’s entire line of

Z-Band® wristbands

• Bar codes on Z-Band wristbands remain

scannable for longer than the average

patient stay

• Small footprint fits well in crowded

workstations

Page 2

Bar Coded Wristband Printing Made Easy

A Zebra Technologies White Paper

Laboratory Testing of Zebra’s Z-Band

®

Direct Thermal Antimicrobial Wristbands

and Cost-Effective

Introducing the HC100 Patient I.D. Solution: an Easy and

Cost-Effective Way to Improve Patient Safety

This all-in-one print solution combines the reliable HC100 direct thermal

printer with easy-to-load cartridges containing the only antimicrobial-coated

wristbands on the market—Zebra’s Z-Band® wristbands.

There’s minimal training required! Pop the wristband cartridge into the

printer and the HC100 automatically detects the wristband size, immediately

calibrates, and prints. You get long-lasting wristbands with bar codes

that remain scannable for longer than the average patient stay. When the

cartridges are empty, return them for recycling.

For optimal printing quality and proper printer performance, the HC100

printer is designed to work only with cartridges of genuine Zebra™ Z-Band

wristbands.

Zebra partners with the leading Admissions Discharge Transfer (ADT)

software providers to enable hospitals’ easy integration of our wristband

print solutions.

For added peace of mind and a cost-effective way to plan

for your annual maintenance expenditures, protect

your investment with a ZebraCare™ service

agreement.

Count on Zebra

Zebra is a global leader

in on-demand specialty

printing solutions, and is a

proven pioneer in bringing

their benefits to hospitals

and other healthcare

facilities worldwide.

You can trust us and our

authorized partners for

unparalleled bar coding

expertise, just as many

other leading healthcare

providers do. In addition,

we serve many Global

2000 companies and 90

percent of the

Fortune 500.

Learn More About Zebra's Antimicrobial Wristbands

Download our free white paper, Laboratory Testing of Zebra's Z-Band Direct Thermal

Antimicrobial Wristbands, by visiting www.zebra.com/healthcare.

Page 3

Patient Safety Starts at the Wrist

Zebra’s HC100 Patient I.D. Solution accommodates

our entire line of white and color Z-Band

wristbands—including soft, flexible Z-Band

Comfort with superior resistance to hand sanitizers

and an adhesive tab, and Z-Band QuickClip™

with clip closure—in infant, pediatric and adult

sizes. Bar codes on Z-Band wristbands are proven

to withstand water, soaps, foams, alcohol and

other common solvents found in a healthcare

environment and remain scannable for longer than

the average patient stay.

Z-Band wristbands are the only bands on the

market to feature our patent-pending antimicrobial

coating that protects the wristband.

Z-Band additionally meets the patient I.D.

guidelines of the American Hospital Association,

the Joint Commission and the Health Insurance

Portability and Accountability Act (HIPAA).

Zebra's Z-Band wristbands also were tested

by an independent MRI testing company and

were determined “MR-Safe” (MR Safe—an

item that poses no known hazards in all MRI

environments) according to the terminology

specified in the American Society for Testing

and Materials (ASTM) International, Designation:

F2503-08: Standard Practice for Marking Medical

Devices and Other Items for Safety in the Magnetic

Resonance Environment. These wristbands do not

appear to present an additional hazard or risk to a

patient undergoing an MRI procedure.

Choose the HC100 Patient I.D.

Solution for a Lower Total Cost of

Ownership Than Laser

The HC100 Patient I.D. Solution uses thermal print

technology, which in the long run saves time and

money over laser printing.

• Avoid the wasted wristbands and labels that come with laser

printing. With the HC100, you print wristbands as needed. And

the HC100 automatically calibrates to the wristband size.

• Laser printing requires expensive toner, and printing bar codes

uses more toner than printing plain text. With the direct thermal

HC100, there’s no toner and no ribbons.

• Wristbanding with the thermal HC100 Patient I.D. Solution is

considerably less labor intensive than with most laser wristband

solutions. Zebra’s solution requires two simple steps—print

the wristband and place it on the patient. Many laser solutions

require six or seven steps to print and assemble the bands.

• With laser, the adhesive backing on the wristband and label

forms can ooze and cause performance problems for the

printer. This leads to increased help desk calls and higher

maintenance costs.

Purchase the HC100 off a

GPO Contract

The HC100 Patient I.D. Solution is available

through these GPO contracts: Amerinet, MAGNET,

MedAssets, and MHA.

With better connectivity options

and a smaller footprint than any laser

printer, the HC100 printer works with your

network and fits your workspaces

Page 4

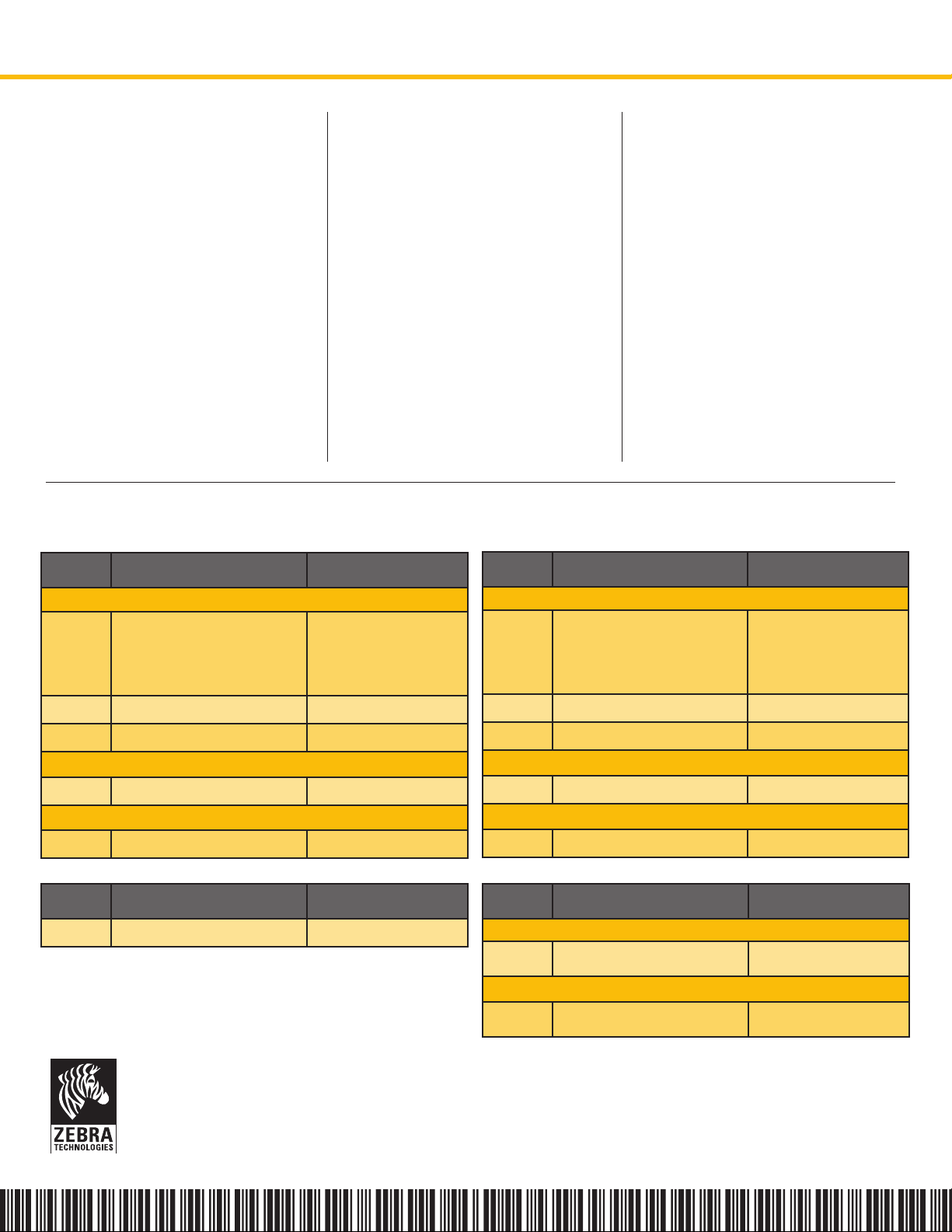

Specifications at a Glance*

Standard Features

• Quick & easy media cartridge loading

• Automatic media loading—no user contact with the

media during loading or removal

• 300 dpi print resolution (12 dots/mm)

• Prints at 2"/51 mm per second

• Direct thermal printing of bar codes, text, and

graphics

• Dual-wall frame, impact resistant plastic

• ZPL® or ZPL II® programming language

• 32 bit RISC processor

• 16 MB Std SDRAM memory (4 MB available to user)

• 8 MB Std Flash memory (2 MB available to user)

• Zebra E3™ Printhead Energy Control

• Dual communications interface: Serial & USB

• Odometer for print length tracking

• Illuminated Media Low/Media Out indicator

• Tool-less printhead and platen replacement

• Unicode™ compliant for multi-language printing

• XML-Enabled printing—allows XML communications

from information systems

• Instant media calibration—no wasted media

• 16 resident expandable bitmap fonts

• One resident scalable font

• Standard tear-off mode feature

Printer Specifications

Resolution

300 dpi/12 dots per mm

Memory

• 16 MB Std SDRAM memory (4 MB available to user)

• 8 MB Std Flash memory (2 MB available to user)

• 64 MB (58 MB user available) Flash memory

(Factory installed option)

Maximum print length

22.0"/558 mm

Minimum print length

3" (76 mm )

3 media widths

0.75"/19.05 mm, 1"/25.4 mm, 1.1875"/30.16 mm

Print speed

2"/51mm per second

Media sensors

Head-up, Media low, and Media out sensors

Media Characteristics

Wristbands feature patent-pending silver antimicrobial coating to protect the wristbands.

Z-Band Comfort—Adhesive Closure (Scannable up to 7 days)

Part

Number

Adult

10010951K

(White)

10011952K 0.75" x 11" (19.05 mm x 279.4 mm) White

Size Color

10010951-1K (Red)

10010951-2K (Blue)

1" x 11" (25.4 mm x 279.4 mm)

10010951-3K (Green)

10010951-4K (Purple)

10010951-5K (Pink)

10010951-6K (Orange)

Networking Options

Ethernet—ZebraNet® 10/100 Internal Print Server

Factory installed only, offered in combination with

serial and USB interfaces

Wireless 802.11b/g

Factory installed only, offered in combination with

serial and USB interfaces. Advanced wireless

security—including WPA and WPA2

Agency Approvals

Emissions

FCC Part 15, Subpart B, VCCI, C-Tick

Emissions and Susceptibility

(CE): EN55022 Class-B, and EN55024

Safety

CB Scheme IEC 60950-1:2001, TUV NRTL

Power Supply

IEC 60601-1:1995

Z-Band Direct—Adhesive Closure (Scannable up to 14 days)

Part

Number

Adult

10006995K

(White)

10006997K 0.75" x 11" (19.05 mm x 279.4 mm) White

Size Color

10006995-1K (Red)

10006995-2K (Blue)

1" x 11" (25.4 mm x 279.4 mm)

10006995-3K (Green)

10006995-4K (Purple)

10006995-5K (Pink)

10006995-6K (Orange)

10011963K 1.1875" x 11" (30.16 mm x 279.4 mm) White

Pediatric

10011954K 1" x 7" (25.4 mm x 177.8 mm) White

Infant

10011953K 1" x 6" (25.4 mm x 152.4 mm) White

Soft Infant Z-Band Direct

Part

Number

10007746K 1" x 7.6875" (25.4 mm x 195.3 mm) White

Size Color

*Specifications subject to change without notice.

©2011 ZIH Corp. All product names and numbers are Zebra trademarks, and Zebra, the Zebra head graphic,

Z-Band, ZPL, ZPL II and ZebraNet are registered trademarks of ZIH Corp. All rights reserved. Unicode is a

trademark of Unicode, Inc. All other trademarks are the property of their respective owners.

Corporate Headquarters Asia-Pacific Headquarters EMEA Headquarters Latin America Headquarters

+1 800 423 0442 +65 6858 0722 +44 (0)1628 556000 +1 847 955 2283

E-mail: inquiry4@zebra.com E-mail: apacchannelmarketing@zebra.com E-mail: mseurope@zebra.com E-mail: inquiry4@zebra.com

Locations

USA: California, Georgia, Rhode Island, Texas, Wisconsin Europe: France, Germany, Italy, Netherlands, Poland, Russia, Spain, Sweden

Asia Pacific: Australia, China, India, Japan, South Korea Latin America: Brazil, Florida (USA), Mexico Africa/Middle East: South Africa,

www.zebra.com

United Arab Emirates

10006996K 1.1875" x 11" (30.16 mm x 279.4 mm) White

Pediatric

10006999K 1" x 7" (25.4 mm x 177.8 mm) White

Infant

10006998K 1" x 6" (25.4 mm x 152.4 mm) White

Z-Band QuickClip™ Wristbands

Part

Number

Adult

10007000K 1.1875" x 11" (30.16 mm x 279.4 mm)

Infant

10007003K 1" x 7" (25.4 mm x 177.8 mm)

Size Color

Red, Blue, Yellow, Green,

Pink, and Purple clips

Red, Blue, Yellow, Green,

Pink, and Purple clips

GSA#: GS-35F-0268N

P1016341 Rev. 4 (2/11)

Loading...

Loading...