Manufacturing Test Suite

Model No.: XG-880M

Libertas™ 802.11g Client Card

Evaluation Tool User Guide

Doc. No. MV-S101517-00, Rev. –

August 5, 2003

802.11g Client Card Evaluation Tool User Guide

Document Status

Adv an ced

Information

Preliminary

Information

Fi nal

Information

Revision Code:

Proprietary Technical Publication:

This document contains design specifications for initial product development. Specifications may

change without notice. Contact Marvell Field Application Engineers for more information.

This document contains preliminary data, and a revision of this document will be published at a

later date. Specifications may change without notice. Contact Marvell Field Application Engineers

for more information.

This document contains specifications on a product that is in final release. Specifications may

change without notice. Contact Marvell Field Application Engineers for more information.

Proprietary Information

This document provides preliminary information about the products described, and such information should not be used for purpose of final design. Visit the Marvell® web

site at www.marvell.com or call 1-866-674-7253 for the latest information on Marvell products.

Disclaimer

No part of this document may be reproduced or transmitted in any form or by any means, electronic or mechanical, including photocopying and recording, for any purpose,

without the express written permission of Marvell. Marvell retains the right to make changes to this document at any time, without notice. Marvell makes no warranty of any

kind, expressed or implied, with regard to any information contained in this document, including, but not limited to, the implied warranties of merchantability or fitness for

any particular purpose. Further, Marvell does not warrant the accuracy or completeness of the information, text, graphics, or other items contained within this document.

Marvell makes no commitment either to update or to keep current the information contained in this document. Marvell products are not designed for use in life-support

equipment or applications that would cause a life-threatening situation if any such products failed. Do not use Marvell products in these types of equipment or applications.

The user should contact Marvell to obtain the latest specifications before finalizing a product design. Marvell assumes no responsibility, either for use of these products or

for any infringements of patents and trademarks, or other rights of third parties resulting from its use. No license is granted under any patents, patent rights, or trademarks

of Marvell.These products may include one or more optional functions. The user has the choice of implementing any particular optional function. Should the user choose to

implement any of these optional functions, it is possible that the use could be subject to third party intellectual property rights. Marvell recommends that the user investigate

whether third party intellectual property rights are relevant to the intended use of these products and obtain licenses as appropriate under relevant intellectual property

rights.

Marvell comprises Marvell Technology Group Ltd. (MTGL) and its subsidiaries, Marvell International Ltd. (MIL), Marvell Semiconductor, Inc. (MSI), Marvell Asia Pte Ltd.

(MAPL), Marvell Japan K.K. (MJKK), Marvell Semiconductor Israel Ltd. (MSIL), SysKonnect GmbH, and Radlan Computer Communications, Ltd.

Export Controls. With respect to any of Marvell’s Information, the user or recipient, in the absence of appropriate U.S. government authorization, agrees: 1) not to re-export

or release any such information consisting of technology, software or source code controlled for national security reasons by the U.S. Export Control Regulations ("EAR"),

to a national of EAR Country Groups D:1 or E:2; 2) not to export the direct product of such technology or such software, to EAR Country Groups D:1 or E:2, if such technology or software and direct products thereof are controlled for national security reasons by the EAR; and, 3) in the case of technology controlled for national security reasons

under the EAR where the direct product of the technology is a complete plant or component of a plant, not to export to EAR Country Groups D:1 or E:2 the direct product of

the plant or major component thereof, if such direct product is controlled for national security reasons by the EAR, or is subject to controls under the U.S. Munitions List

("USML"). At all times hereunder, the recipient of any such information agrees that they shall be deemed to have manually signed this document in connection with their

receipt of any such information.

Copyright © 2003. Marvell. All rights reserved. Marvell, the Marvell logo, Moving Forward Faster, Alaska, and GalNet are registered trademarks of Marvell. Discovery,

Fastwriter, GalTis, Horizon, Libertas, Link Street, NetGX, PHY Advantage, Prestera, Raising The Technology Bar, UniMAC, Virtual Cable Tester, and Yukon are trademarks

of Marvell. All other trademarks are the property of their respective owners.

Marvell

700 First Avenue

Sunnyvale, CA 94089

Phone: (408) 222 2500

Sales Fax: (408) 752 9029

Email: commsales@marvell.com

Doc. No. MV-S101517-00 Rev. –

CONFIDENTIAL

Copyright © 2003 Marvell

Page 2 Document Classification: Proprietary Information August 5, 2003, Proprietary

Table of Contents

Table of Contents

Section 1. Getting Started .................................................................................................... 5

1.1 Overview ................................................................................................................................... 5

1.2 Equipment .................................................................................................................................5

1.2.1 Test Setup...................................................................................................................................5

1.2.2 Calibration ...................................................................................................................................6

1.3 System Requirements............................................................................................................... 6

Section 2. Software Requirements ....................................................................................... 7

2.1 Manufacturing Test Software Suite Contents............................................................................ 7

2.2 Software Installation..................................................................................................................7

2.3 Windows Driver Installation....................................................................................................... 8

2.3.1 Driver Installation Procedure .......................................................................................................8

2.3.2 Programming Configuration Information .....................................................................................9

Section 3. Command Line Interface ................................................................................... 11

3.1 Using the Manual Test Module ...............................................................................................11

3.1.1 DUT Interface ............................................................................................................................11

3.1.2 Golden Unit Interface ................................................................................................................12

3.1.3 Additional Menu Interface..........................................................................................................13

3.1.4 Before Getting Started...............................................................................................................15

3.2 Receiver Sensitivity Test......................................................................................................... 16

3.2.1 Overview ...................................................................................................................................16

3.2.2 Test Procedure..........................................................................................................................16

3.3 Transmitter Tests .................................................................................................................... 17

3.4 Command Descriptions...........................................................................................................18

3.4.1 RF Commands ..........................................................................................................................18

3.4.2 FER Commands........................................................................................................................22

3.4.3 Configuration Information Access Commands ..........................................................................24

3.4.4 SPI/Flash Access Commands...................................................................................................25

3.4.5 Device Specific Commands ......................................................................................................27

3.4.6 Exit Test Command...................................................................................................................28

Appendix A.Sample CalDataFile.txt...................................................................................... 29

Section 4. Index.................................................................................................................. 33

Section 5. Revision History................................................................................................. 35

Copyright © 2003 Marvell

August 5, 2003, Preliminary Document Classification: Preliminary Information Page 3

CONFIDENTIAL

Doc. No. MV-S101517-00 Rev. –

802.11g Client Card Evaluation Tool User Guide

This page is intentionally left blank.

Doc. No. MV-S101517-00 Rev. –

Page 4 Document Classification: Preliminary Information August 5, 2003, Preliminary

CONFIDENTIAL

Copyright © 2003 Marvell

Getting Started

Overview

Section 1. Getting Started

1.1 Overview

This document explains how to use the software command line interface for the following Libertas™ Wireless LAN

(WLAN) client cards:

• Marvell® CB-32 802.11g WLAN CardBus Card

• Marvell® MB-31 802.11g WLAN Mini PCI Card

These cards include the highly integrated Libertas™ IEEE 802.11g two-chip solutions for client applications. The

chipset consists of the 88W8000G Radio Frequency Transceiver and the 88W8310 WLAN Client device.

1.2 Equipment

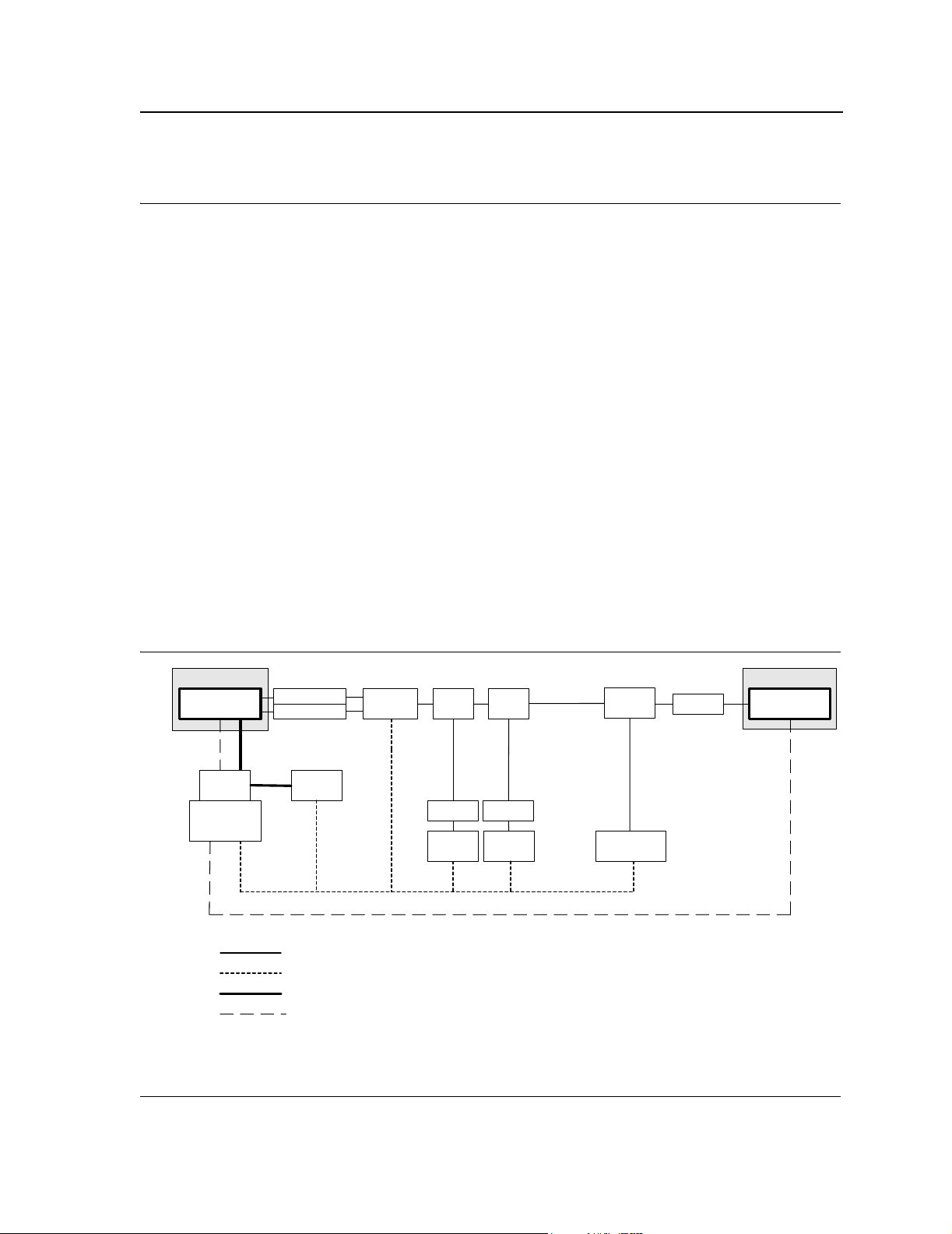

The overall setup for testing the capabilities and performance of the Libertas™ family of WLAN chipset solutions is

shown in Figure 1. The setup shows the equipment required to test the transmit/receive chains and throughput

between a DUT and a golden source. Proper shielding is required for both the DUT and the golden source.

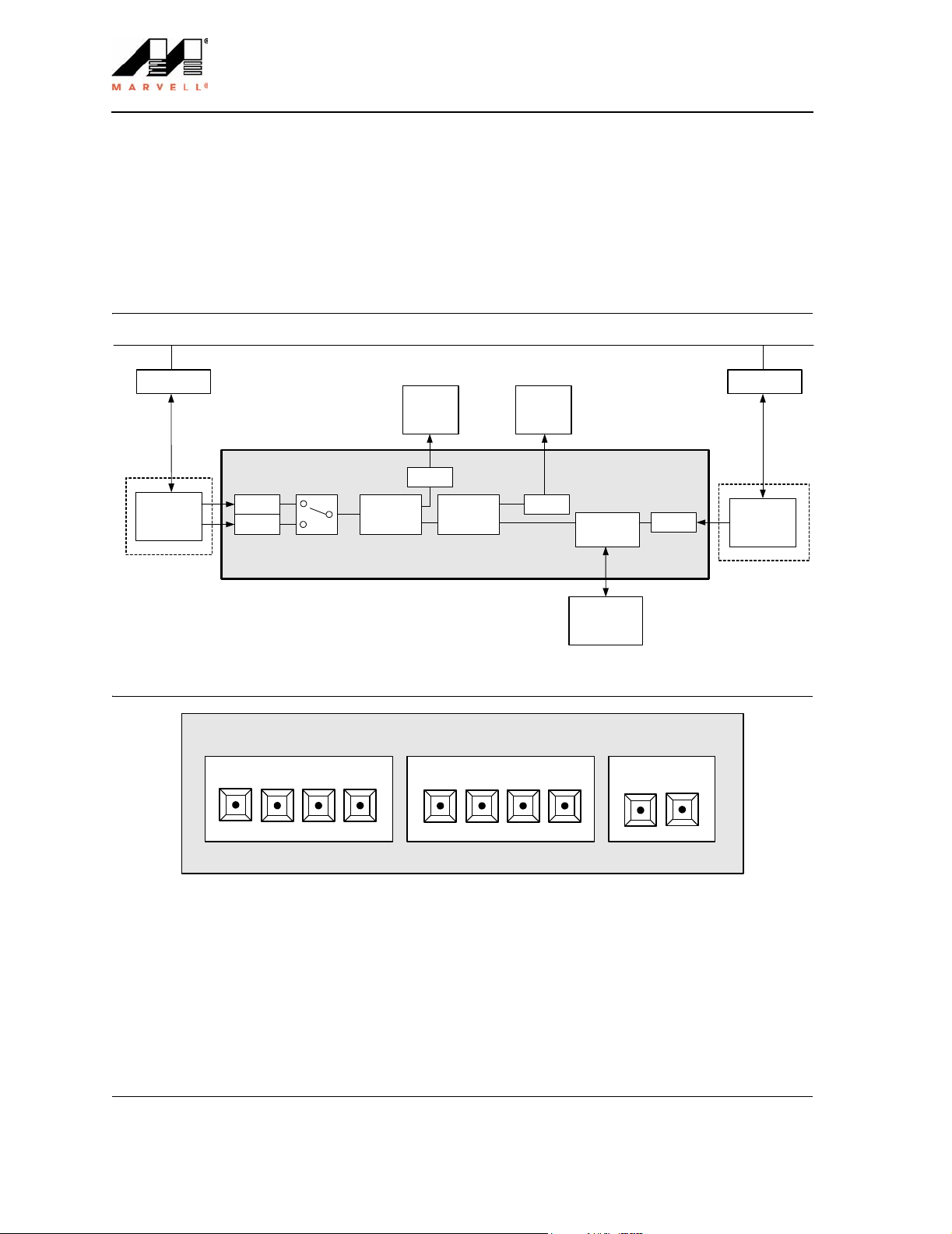

1.2.1 Test Setup

Figure 1: Test Setup

Shielding Box

Attenuator

Attenuator

Power

Supply

RF Cable

GPIB

Power

Fast Ethernet/ Host Interface (control and data)

Host Interface

(control and data)

Test Controller

DUT Switch

PCB

PC

GPIB

optional

Splitter

Attenuator Attenuator

Spectrum

Analyzer

Fast Ethernet

Splitter

Power

Meter

Variable

Attenuator

Attenuator/

Switch Driver

Attenuator

Shielding Box

Golden Source

Copyright © 2003 Marvell

CONFIDENTIAL

Doc. No. MV-S101517-00 Rev. –

August 5, 2003, Preliminary Document Classification: Preliminary Information Page 5

Libertas™ 802.11g Client Card

Evaluation Tool User Guide

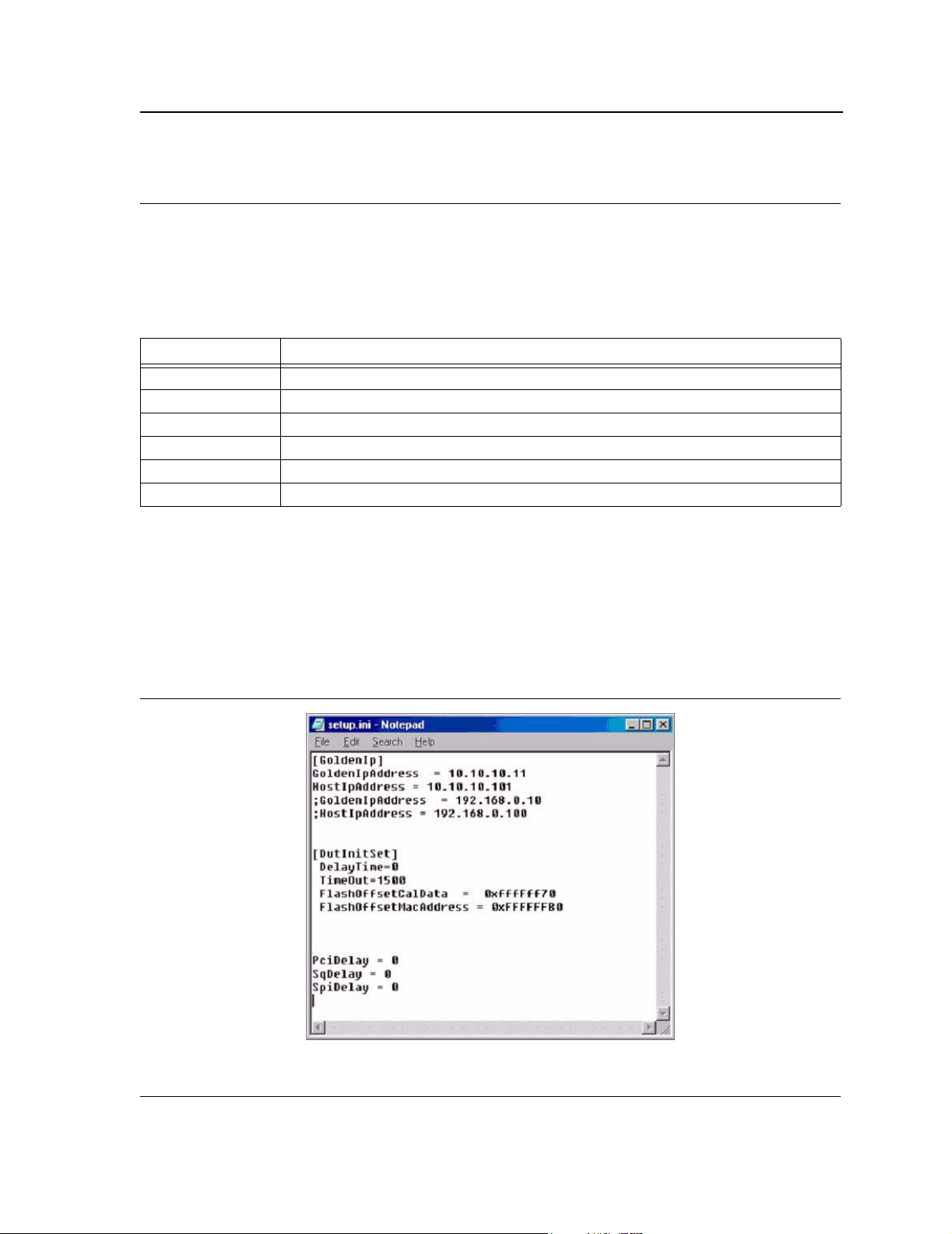

1.2.2 Calibration

It is critical to obtain accurate measurements of the path loss (due to cables, connectors, etc.) from the DUT to the

Golden Unit and from the DUT to the power meter. For path loss measurements, sum the loss of each individual

component along the path. Figure 2 shows the RF path loss for calibration. Figure 3 shows the switch settings for

the programmable attenuator.

Figure 2: RF Path

LAN

Master PC

8493A 11636B11636B

Attenuator

DUT

6 dB

Attenuator

6 dB

Agilent WLAN Test Set

Antenna 1 (2) to ESA = 18dB

Antenna 1 (2) to PM = 24dB

Antenna 1 (2) to Golden = 24dB

Golden to PM = 18dB

Figure 3: Switch Driver

Agilent 11713A Attenuator/Switch Driver

Attenuator X

1234

1 dB 2 dB 4 dB 4 dB

8762B

Divider

6 dB

ESA

Attenuator

6 dB

Divider

6 dB

Power

Meter

Attenuator

Attenuator Y

5

678

10 dB 20 dB 40 dB 40 dB

6 dB

8494H/8496H

Programmable

Attenuator

Attenuator/

Switch Driver

Attenuator

6 dB

Switches

90

Slave PC

Golden

Unit

1.3 System Requirements

• 300 MHz or faster CPU

• Windows® 2000 or 98SE (Second Edition)

• Marvell Libertas™ Client Card (CardBus or Mini PCI)

Doc. No. MV-S101517-00 Rev. –

CONFIDENTIAL

Page 6 Document Classification: Preliminary Information August 5, 2003, Preliminary

Copyright © 2003 Marvell

Software Requirements

Manufacturing Test Software Suite Contents

Section 2. Software Requirements

2.1 Manufacturing Test Software Suite Contents

Table 1: Manufacturing Test Software

Filename Description

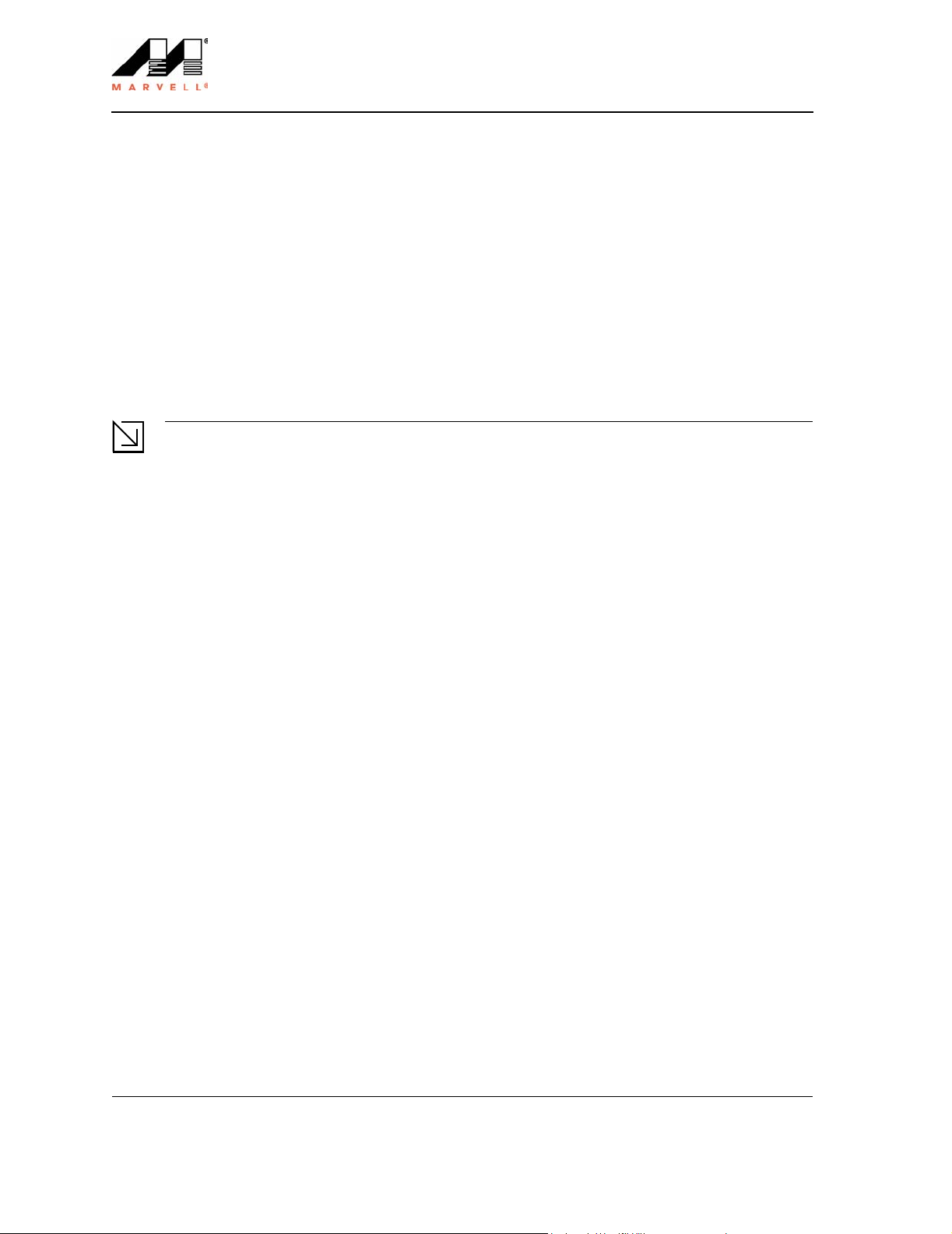

SetUp.ini Setup file. See Figure 4.

DutApi98Dll.dll DLL file for DUT.

DutApiPci98_G.exe Manual test module executable for client card.

GoldenAP.exe Manual test module executable for AP golden unit.

CalDataFile.txt Example manufacturing calibration data file. See Appendix A. "Sample CalDataFile.txt" .

Spi.hex Hexadecimal file to program SPI (see command 35).

2.2 Software Installation

1. Copy the manufacturing test software files to a directory on the C: drive. DutApiPci98_G.exe, DutApi98Dll.dll,

and SetUp.ini must be in the same directory.

2. Open the Setup.ini file with a text editor. When running both the DutApiPci98_G.exe and GoldenAP.exe test

files, the Setup.ini should contain the Golden Unit IP addresses and DUT and Golden setup information:

Figure 4: Setup File

Copyright © 2003 Marvell

August 5, 2003, Preliminary Document Classification: Preliminary Information Page 7

CONFIDENTIAL

Doc. No. MV-S101517-00 Rev. –

Libertas™ 802.11g Client Card

Evaluation Tool User Guide

2.3 Windows Driver Installation

Installation of the driver will allow the user to access hardware memory space. The following files are required:

• MWLAN_G.inf

• windrvr.vxd

• DutApiPci98_G.exe

• wdreg.exe

2.3.1 Driver Installation Procedure

Windows explorer may not show *.Vxd file on the folder. At the MS-DOS command prompt, use the directory (DIR)

command to check the entire contents of the installation disk.

Notes

• In some of the commands below you are asked to type a text string enclosed in double quotes. Do not

type the quotes, they are just there for clarity.

• Commands that you type in are in bold.

• Pressing the Enter key after typing in a text string is assumed.

1. Copy windrvr.vxd from the installation disk to c:\windows\system\vmm32 directory.

2. Create an application directory (for example, “mkdir c:\mactest”).

3. Copy DutApiPci98_G.exe and wdreg.exe from the installation disk to the application directory.

4. Insert the Marvell card and Windows 98SE will run the device installation wizard.

Use the INF file (a:\MWLAN_G.inf) on the installation disk to install the device.

5. Open the MS-DOS command prompt window and change the directory to the application directory

(for example, “cd c:\mactest”).

6. Type “WDREG.EXE -VXD install” to run the registration program. This is CASE-SENSITIVE.

The following messages should appear:

Creating driver entry... OK

Starting driver entry.… OK

7. Open the MS-DOS command prompt window:

a) Change the directory to the application directory (for example, “cd c:\mactest”).

b) Type “DutApiPci98_G.exe” to run the test program.

Doc. No. MV-S101517-00 Rev. –

Page 8 Document Classification: Preliminary Information August 5, 2003, Preliminary

CONFIDENTIAL

Copyright © 2003 Marvell

Software Requirements

Windows Driver Installation

2.3.2 Programming Configuration Information

The configuration information (MAC address, calibration data, CIS table, etc.) are saved in EEPROM and are

accessed through the SPI interface. The image can be also programmed through the PCI interface. There are two

ways to program the image (build-in SPI or with a hex file). Although the build-in image is more stable, loading the

image from a hex file allows access to more recent information and allows more flexibility.

To program build-in image:

1. Type the command 37.

2. Type 38 to verify the image against the build-in image. There should be no errors reported.

3. Type 48.

This command programs the sub-PID and sub-VID for the Marvell Mini PCI card (47 for the CardBus).

To program the image from the file:

1. Type 39.

The current file name is displayed in brackets. The default is Spi.hex.

When prompted for filename, either press Enter or type Spi.hex.

If there is no change to the configuration, press Enter. If there is a change, the configuration information from

the file name entered is retained for this execution (replaces the information in the default file).

2. Type 40.

This command will verify the image against the given file.

3. Type 48.

This command programs the sub-PID and sub-VID for the Marvell Mini PCI card (47 for the CardBus).

After downloading the image, or if the image already exists, the MAC address is programmed as follows:

1. Type “46 xx.xx.xx.xx.xx.xx”.

This command writes the MAC address (xx.xx.xx.xx.xx.xx). Use command 45 to view the MAC address currently programmed.

a) Use hexadecimal values in the following format: xx.xx.xx.xx.xx.xx for the MAC address.

b) Enter the values with a period (.) in between number pairs.

2. Type 99 to exit.

Notes

• To view the these commands, run the DutApiPci98_G.exe file as follows: “DutApiPci98_G.exe -m”.

The space is required between DutApiPci98_G.exe and -m.

See 3.1.3 "Additional Menu Interface" on page 13.

• Command 37 can be used to download the build-in Spi.hex file. However, when a new Spi.hex is

available, use command 39. When using command 37, use command

Copyright © 2003 Marvell

August 5, 2003, Preliminary Document Classification: Preliminary Information Page 9

CONFIDENTIAL

48 to program PID/VID.

Doc. No. MV-S101517-00 Rev. –

Libertas™ 802.11g Client Card

Evaluation Tool User Guide

This page is intentionally left blank.

Doc. No. MV-S101517-00 Rev. –

Page 10 Document Classification: Preliminary Information August 5, 2003, Preliminary

CONFIDENTIAL

Copyright © 2003 Marvell

Command Line Interface

Using the Manual Test Module

Section 3. Command Line Interface

3.1 Using the Manual Test Module

The manual test module runs through a simple menu-driven interface. Two executable files are needed for the

test. The Setup.ini file must be located in the same directory as the executable files.

• DutApiPci98_G.exe. Controls the CardBus and Mini PCI cards.

• GoldenAP.exe. Controls the Golden unit. Needed for Rx Sensitivity tests (unless a signal generator is used).

• Setup.ini

Run both the DutApiPci98_G.exe and GoldenAP.exe files to launch the tool. Each command is numbered, and

some commands accept input parameters. For example, to retrieve the current channel setting, type 11 and press

Enter. This command returns the current channel. To set the channel to 6, type “12 6” and press Enter, where 12

is the command and 6 is the input parameter.

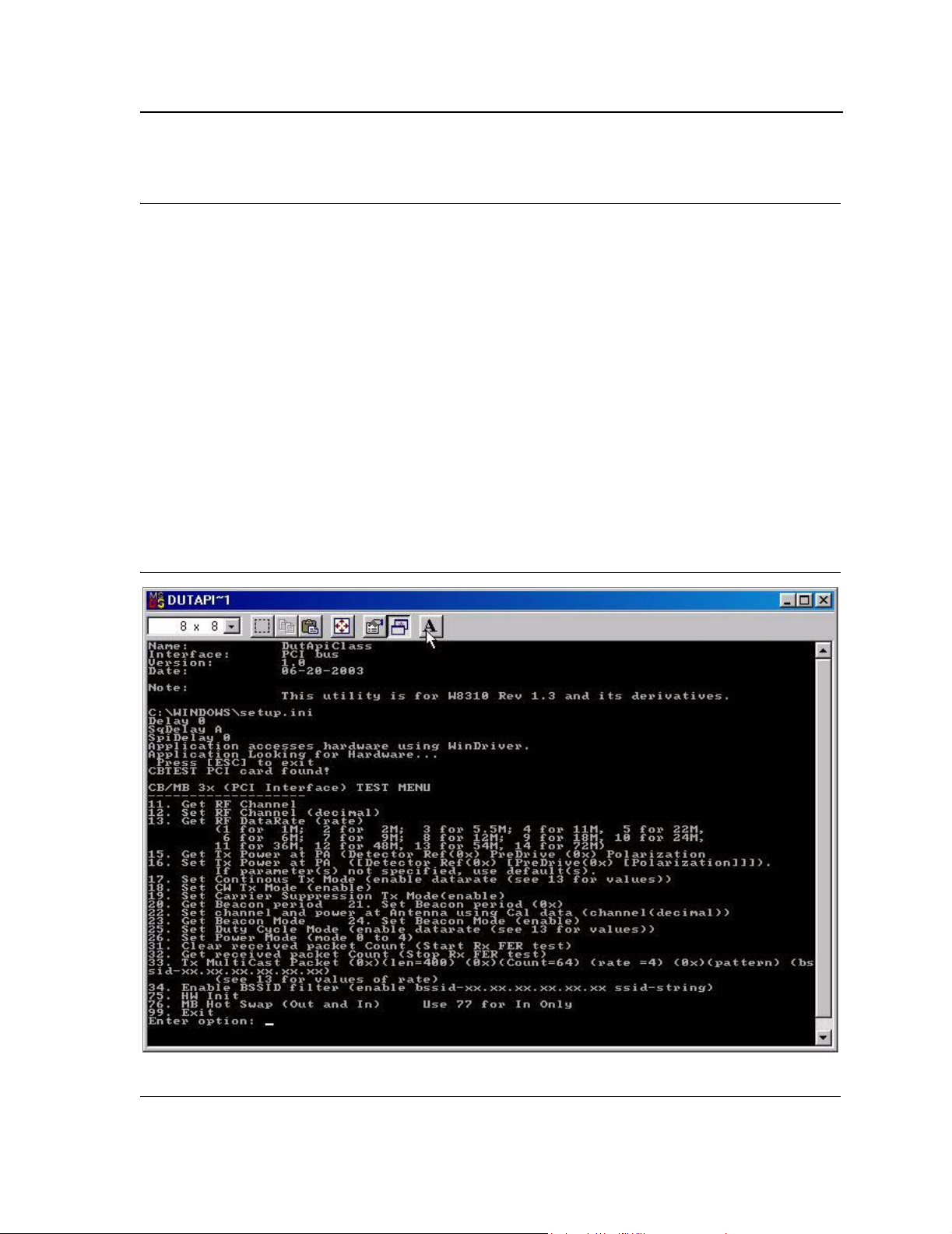

3.1.1 DUT Interface

Figure 5: PCI Interface Test Menu (DutApiPci98_G.exe)

Copyright © 2003 Marvell

August 5, 2003, Preliminary Document Classification: Preliminary Information Page 11

CONFIDENTIAL

Doc. No. MV-S101517-00 Rev. –

Libertas™ 802.11g Client Card

Evaluation Tool User Guide

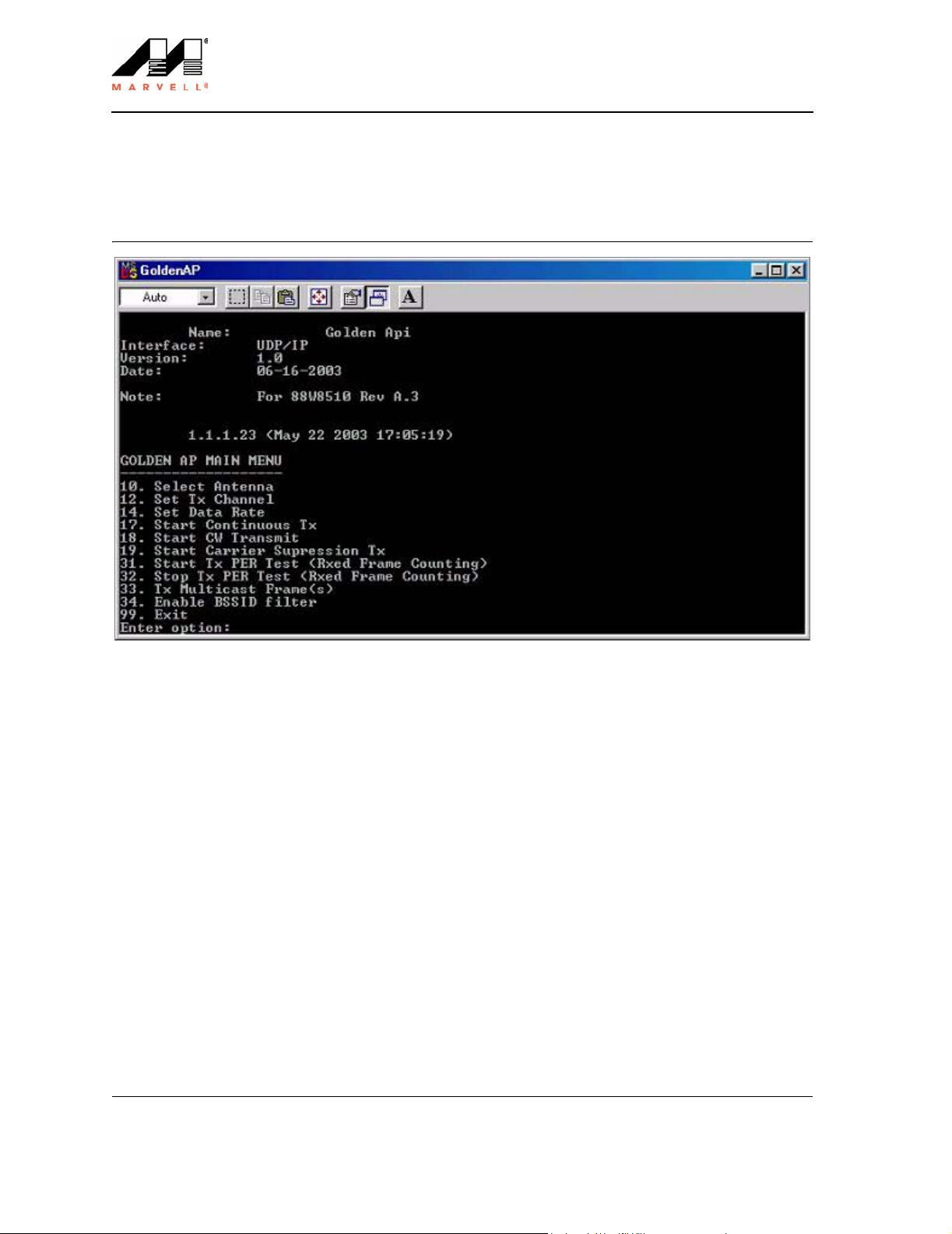

3.1.2 Golden Unit Interface

Figure 6: Golden AP Main Menu (GoldenAP.exe)

Doc. No. MV-S101517-00 Rev. –

Page 12 Document Classification: Preliminary Information August 5, 2003, Preliminary

CONFIDENTIAL

Copyright © 2003 Marvell

Command Line Interface

Using the Manual Test Module

3.1.3 Additional Menu Interface

There is also an additional menu of commands available. To open the menu, add a “-m” argument in the target line

after typing the file name. Figure 7 shows how to create a shortcut for the additional menu interface.

Figure 7: Additional Menu Shortcut

Copyright © 2003 Marvell

August 5, 2003, Preliminary Document Classification: Preliminary Information Page 13

CONFIDENTIAL

Doc. No. MV-S101517-00 Rev. –

Libertas™ 802.11g Client Card

Evaluation Tool User Guide

Figure 8: PCI Interface Test Menu (DutApiPci98_G.exe -m)

Doc. No. MV-S101517-00 Rev. –

Page 14 Document Classification: Preliminary Information August 5, 2003, Preliminary

CONFIDENTIAL

Copyright © 2003 Marvell

Command Line Interface

Using the Manual Test Module

3.1.4 Before Getting Started

Initialize the device after launching the manual test module. Enter command 75 before running any RF tests.

Figure 9: Initialize Device (Command 75)

Copyright © 2003 Marvell

August 5, 2003, Preliminary Document Classification: Preliminary Information Page 15

CONFIDENTIAL

Doc. No. MV-S101517-00 Rev. –

Libertas™ 802.11g Client Card

Evaluation Tool User Guide

3.2 Receiver Sensitivity Test

3.2.1 Overview

The receiver sensitivity test is based on frame error rate (FER). The test will send a known number of frames,

count the number of frames received on the DUT, and calculate the frame error rate. According to the IEEE specification, sensitivity is the lowest input power level needed to achieve a FER less than 8% for 802.11b data rates,

and 10% for 802.11g data rates.

For the manufacturing test, the Golden Unit is used to transmit packets.

3.2.2 Test Procedure

1. Launch the GoldenAP.exe and DutApiPci98_G.exe files.

2. Type 75 to initialize the DUT (in the DutApiPci98_G.exe menu).

3. Type “12 x” (where “x” is the channel number) to set the desired channel on the DUT.

4. Type 31 to clear the received packet counter.

5. OPTIONAL: Type “34 1 11.22.33.44.55.66” to filter on BSSID.

In this example, only frames with BSSID = 11.22.33.44.55.66 will be counted.

6. Set the channel for the Golden Unit (in the GoldenAP.exe menu).

Type 33. The user is prompted to enter the length, count, data rate, pattern, and BSSID as parameters.

7. Type 32 to read the received packet counter. The DUT will report the number of frames received correctly (for

example, no CRC error), the number of multicast frames received correctly, and the number of frames

received with CRC errors. Calculate the FER based on the number of frames sent by the Golden Unit.

8. If necessary, adjust the settings on the programmable attenuators to achieve the desired FER.

Note

To verify the DUT is properly shielded, clear the received packet counter, wait a few seconds, and read

the packet counter. The packet counter should read 0.

Doc. No. MV-S101517-00 Rev. –

Page 16 Document Classification: Preliminary Information August 5, 2003, Preliminary

CONFIDENTIAL

Copyright © 2003 Marvell

Command Line Interface

Transmitter Tests

3.3 Transmitter Tests

As an example, this section describes how to use the manual test module to set the DUT to Tx mode.

1. Connect antenna port 1 to the spectrum analyzer and power meter.

2. Start the manual test module.

3. Type 75 to initialize the DUT.

4. Type “12 x” (where “x” is the channel number) to set the desired channel on the DUT.

5. Type “17 1 13” to enable continuous transmission at the 54 Mbps data rate. The device will output a continu-

ous modulated signal.

6. Type “17 0” to disable continuous transmission.

7. Type “18 1” to enable carrier wave continuous transmission.

8. Type “18 0” to disable carrier wave continuous transmission.

9. Type “33 400 64 13 AAAAAAAA xx.xx.xx.xx.xx.xx” (where AA’s are the frame pattern and xx’s are the BSSID)

to transmit 100 1 KB data packets at a 54 Mbps data rate.

Notes

• The default register values provided by Marvell are the settings used to achieve the highest output

power while still meeting the IEEE specification requirements.

• If the measured EVM is higher than specified in the IEEE specification, please contact your Marvell

Field Applications Engineer.

Copyright © 2003 Marvell

August 5, 2003, Preliminary Document Classification: Preliminary Information Page 17

CONFIDENTIAL

Doc. No. MV-S101517-00 Rev. –

Libertas™ 802.11g Client Card

Evaluation Tool User Guide

3.4 Command Descriptions

This section describes each command in detail.

3.4.1 RF Commands

3.4.1.1 Get RF Channel

Command Number 11

Name Get RF Channel.

Parameters none

Description Returns current RF channel number.

Example n/a

3.4.1.2 Set RF Channel

Command Number 12

Name Set RF Channel

Parameters Channel (1 through 14)

Description Sets the RF channel.

Example “12 11” sets the channel to 11.

3.4.1.3 Get RF Data Rate

Command Number 13

Name Get RF data rate

Parameters none

Description Returns the current data rate:

1 = 1 Mbps

2 = 2 Mbps

3 = 5.5 Mbps

4 = 11 Mbps

5 = 22 Mbps (Marvell proprietary)

6 = 6 Mbps

7 = 9 Mbps

8 = 12 Mbps

9 = 18 Mbps

10 =24 Mbps

11 = 3 6 Mb p s

12 = 48 Mbps

13 = 54 Mbps

14 = 72 Mbps (Marvell proprietary)

Example n/a

Negative Number Unable to be detected when MAC/BBP controls data rate through frame informa-

tion. The data rate is unable to be detected.

Doc. No. MV-S101517-00 Rev. –

Page 18 Document Classification: Preliminary Information August 5, 2003, Preliminary

CONFIDENTIAL

Copyright © 2003 Marvell

3.4.1.4 Get Tx Power at PA

Command Number 15

Name Get Tx Power at PA

Parameters None

Description Returns the RF power settings.

(RF power detector reference; predrive and polarization values).

Example n/a

3.4.1.5 Set Tx Power at PA

Command Number 16

Name Set Tx Power at PA

16 [RefDac [predriver [externalPApolarization]]

Parameters Detector Reference

Predrive

Polarization

Description Sets the RF power.

Example “16 [DetRef] [Predrive] [Polarization]”

Command Line Interface

Command Descriptions

3.4.1.6 Set Continuous Modulated Waveform Mode

Command Number 17 [enable_dataRate]

Name Set Continuous Modulated Waveform Mode

Parameters Enable (1 = enable, 0 = disable) data rate

Description Sets the device for continuous transmission of a modulated waveform.

Example “17 1 13” sets the device for continuous transmission at the 54 Mbps data rate.

“17 0” disables continuous transmission.

3.4.1.7 Set Continuous Waveform Transmission Mode

Command Number 18

Name Set Continuous Waveform Transmission Mode

Parameters Enable (1 = enable, 0 = disable)

Description Sets the device to continuously transmit a carrier waveform.

Example “18 1” sets the device to continuously transmit a carrier waveform.

“18 0” disables this mode.

3.4.1.8 Set Carrier Suppression Mode

Command Number 19

Name Set Carrier Suppression Transmission Mode

Parameters Enable (1 = enable, 0 = disable)

Description Sets the device for Carrier Suppression Transmission Mode.

Example “19 1” sets the device for Carrier Suppression Transmission Mode.

3.4.1.9 Set Channel and Power at Antenna with Calibration Data

Command Number 22

Name Set channel and RF power at antenna with calibration data for the channel

Copyright © 2003 Marvell

August 5, 2003, Preliminary Document Classification: Preliminary Information Page 19

CONFIDENTIAL

Doc. No. MV-S101517-00 Rev. –

Libertas™ 802.11g Client Card

Evaluation Tool User Guide

Parameters Channel 1 through 14:

1 = Channel 1

2 = Channel 2

3 = Channel 3

4 = Channel 4

5 = Channel 5

6 = Channel 6

7 = Channel 7

8 = Channel 8

9 = Channel 9

10 = Channel 10

11 = Channel 11

12 = Channel 12

13 = Channel 13

14 = Channel 14

Description Sets the power using calibration data.

Example “22 6” sets the channel to 6 and RF power using calibration data for channel 6.

Doc. No. MV-S101517-00 Rev. –

Page 20 Document Classification: Preliminary Information August 5, 2003, Preliminary

CONFIDENTIAL

Copyright © 2003 Marvell

Command Line Interface

Command Descriptions

3.4.1.10 Set Duty Cycle Transmission Mode

Command Number 25

Name Set duty cycle transmission mode

Parameters Enable (1 = enable, 0 = disable)

Data rate:

1 = 1 Mbps

2 = 2 Mbps

3 = 5.5 Mbps

4 = 11 Mbps

5 = 22 Mbps (Marvell proprietary)

6 = 6 Mbps

7 = 9 Mbps

8 = 12 Mbps

9 = 18 Mbps

10 =24 Mbps

11 = 36 Mbps

12 = 48 Mbps

13 = 54 Mbps

14 = 72 Mbps (Marvell proprietary)

Description Sets the device to duty cycle transmit. The duty cycle is about 50% for lower date

rates and decreases as the data rate increases.

Example “25 1 13” sets device to duty cycle transmit at 54 Mbps.

3.4.1.11 Set Power Mode (Not Implemented)

Command Number 26

Name Set power mode

Parameters Power mode:

0 = active

1 = standby long

2 = power down

3 = deep sleep

4 = standby short

Description Sets the power mode of the device. This command is not implemented yet.

Example “26 0” sets device to active power mode.

Copyright © 2003 Marvell

August 5, 2003, Preliminary Document Classification: Preliminary Information Page 21

CONFIDENTIAL

Doc. No. MV-S101517-00 Rev. –

Libertas™ 802.11g Client Card

Evaluation Tool User Guide

3.4.2 FER Commands

3.4.2.1 Clear Received Packet Counter

Command Number 31

Name Clear Received packet counter

Parameters none

Description Clears the received packet counter.

Example n/a

3.4.2.2 Get Received Packet Counter

Command Number 32

Name Get received packet counter

Parameters none

Description Returns the following values:

GetRxPckt: Number of correctly received packets (no CRC error), including

unicast and multicast.

GetRxMultiCPkt: Number of correctly received multicast packets (a subset of the

first number).

GetRxErrPckt: Number of received packets with CRC errors. Frame error rate

based on detected packets [GetRxErrPckt/(GetRxPckt +

GetRxErrPckt)].

Example n/a

Note

Because of the timing difference in Reading the counters, if you are in an environment that has continuous

traffic, MultiCPckt count could be larger than RxPckt count.

Doc. No. MV-S101517-00 Rev. –

Page 22 Document Classification: Preliminary Information August 5, 2003, Preliminary

CONFIDENTIAL

Copyright © 2003 Marvell

Command Line Interface

Command Descriptions

3.4.2.3 Transmit Multicast Frames

Command Number 33

Name Transmit Multicast Frames

Parameters Frame Length, in bytes (hex)

Frame Count (hex)

Data rate (hex):

1 = 1 Mbps

2 = 2 Mbps

3 = 5.5 Mbps

4 = 11 Mbps

5 = 22 (Marvell proprietary)

6 = 6 Mbps

7 = 9 Mbps

8 = 12 Mbps

9 = 18 Mbps

A =24 Mbps

B = 36 Mbps

C = 48 Mbps

D = 54 Mbps

E = 72 Mbps (Marvell proprietary)

BSSID (xx.xx.xx.xx.xx.xx) - BSSID field

Description Transmits specified number of frames of specified length, at specified data rate,

with BSSID set to specified value.

Example “33 400 64 13 AAAAAAAA 00.11.22.33.44.55” sends 100 1 KB packets at the 54

Mbps data rate, with BSSID set to 00.11.22.33.44.55 (0x400 = 1024 decimal,

0x64 = 100 decimal).

3.4.2.4 Enable BSSID Filter

Command Number 34

Name Enable BSSID filter

Parameters Enable (1 = enable, 0 = disable)

BSSID (xx.xx.xx.xx.xx.xx)

Description Sets the received packets counter to include only frames that have the specified

BSSID field.

Example “34 1 00.11.22.33.44.55” sets the filter to be BSSID = 00.11.22.33.44.55.

“34 0” disables the filter.

Copyright © 2003 Marvell

August 5, 2003, Preliminary Document Classification: Preliminary Information Page 23

CONFIDENTIAL

Doc. No. MV-S101517-00 Rev. –

Libertas™ 802.11g Client Card

Evaluation Tool User Guide

3.4.3 Configuration Information Access Commands

Figure 10: PCI Command Line Interface

3.4.3.1 SPI Build-In Header Download

Command Number 37

Name SPI Build-In Header Download

Parameters None

Description Programs SPI header into EEPROM. Use command 39 with a hex file.

Example 37

3.4.3.2 SPI Header Verify

Command Number 38

Name SPI Header Verify

Parameters None

Description Compares SPI built-in header with SPI header in EEPROM. Returns the error

count and value of mismatched double words.

Example 38

Doc. No. MV-S101517-00 Rev. –

Page 24 Document Classification: Preliminary Information August 5, 2003, Preliminary

CONFIDENTIAL

Copyright © 2003 Marvell

Command Line Interface

Command Descriptions

3.4.3.3 SPI Download

Command Number 39

Name SPI Download from Hexadecimal File

Parameters None

Description Programs the SPI header using a hex file. The command will prompt the user for

the filename (Spi.hex is default).

Example 39

3.4.3.4 SPI Verify

Command Number 40

Name SPI Verify from Hexadecimal File

Parameters None

Description Compares SPI built-in header with hex file. Returns the error count and value of

mismatched double words.

Example 40

3.4.3.5 Display SPI EEPROM Content

Command Number 41

Name Display SPI EEPROM Content

Parameters (0x)(0x)(startAddress)(Length)

Description Displays the SPI EEPROM.

Example “41 0 20” will display 32 DWORDS starting from offset 0.

3.4.4 SPI/Flash Access Commands

3.4.4.1 Read MAC Address

Command Number 45

Name Read MAC Address

Parameters None

Description Returns the MAC address programmed in the EEPROM.

Example 45

Copyright © 2003 Marvell

August 5, 2003, Preliminary Document Classification: Preliminary Information Page 25

CONFIDENTIAL

Doc. No. MV-S101517-00 Rev. –

Libertas™ 802.11g Client Card

Evaluation Tool User Guide

3.4.4.2 Write MAC Address

Command Number 46

Name Write MAC Address into EEPROM/Flash

Parameters xx.xx.xx.xx.xx.xx

Description Writes the MAC address.

Example “46 10.22.33.44.55.66”

3.4.4.3 Set sub-PID sub-VID Class ID for Marvell CardBus Card

Command Number 47

Name Set sub-PID sub-VID Class ID for Marvell CardBus Card

Parameters None

Description Writes the Product ID and Vendor ID for CardBus.

Example 47

3.4.4.4 Set sub-PID sub-VID Class ID for Marvell Mini PCI Card

Command Number 48

Name Set sub-PID sub-VID Class ID for Marvell Mini PCI Card

Parameters None

Description Writes the Product ID and Vendor ID for Mini PCI.

Example 48

3.4.4.5 Set sub-PID sub-VID Class ID (Customized)

Command Number 49

Name Set sub-PID sub-VID Class ID (Customized)

Parameters Will read back current IDs then prompt for new IDs.

Description Programs a customized ID.

Example 49

3.4.4.6 Get PID VID Class ID

Command Number 50

Name Get PID VID Class ID

Parameters None

Description Returns the PID and VID.

Example 50

Doc. No. MV-S101517-00 Rev. –

Page 26 Document Classification: Preliminary Information August 5, 2003, Preliminary

CONFIDENTIAL

Copyright © 2003 Marvell

Command Line Interface

Command Descriptions

3.4.4.7 Erase Flash

Command Number 51

Name Erase Flash

Parameters (0x)(section)

Description Erases Flash memory. This command is only supported for large EEPROM sizes

(1 Mbit) and will not erase small EEPROM.

Example n/a

3.4.4.8 Write Calibration Table

Command Number 53

Name Write Calibration Table

Parameters none

Description Writes calibration table data from the file CalDataFile.txt.

Example 53 <<Given sample file here>>

3.4.4.9 Read Calibration Table

Command Number 54

Name Read Calibration Table

Parameters None

Description Returns the calibration table data.

Example 54

3.4.4.10 Get SPI Protection

Command Number 55

Name Get SPI Protection

Parameters None

Description Retrieves setting of SPI protection status bit.

Example 55

3.4.4.11 Set SPI Protection

Command Number 56

Name Set SPI Protection

Parameters 1 = enables protection

0 = disables protection

Description Sets SPI protection.

Example “56 1” enables protection.

“56 0” disables protection.

Note: Each write action from this program will set SPI protection mode to enable to prvent accidental crash-

ing of the image.

3.4.5 Device Specific Commands

3.4.5.1 Client Hardware Initialization

Command Number 75

Name HW Init

Copyright © 2003 Marvell

August 5, 2003, Preliminary Document Classification: Preliminary Information Page 27

CONFIDENTIAL

Doc. No. MV-S101517-00 Rev. –

Libertas™ 802.11g Client Card

Evaluation Tool User Guide

Parameters none

Description Hardware initialization. This command must be used before starting the RF tests.

Example n/a

3.4.5.2 Mini PCI Hot Swap (Out and In)

Command Number 76

Name Mini PCI Hot Swap (Out and In)

Parameters none

Description Prompts you to put in a new card. After the new card is replaced, press Enter

twice. This command must be followed by command 75 (HW Init) to use the new

card.

Example n/a

3.4.5.3 Mini PCI Hot Swap (In Only)

Command Number 77

Name Mini PCI Hot Swap (In Only)

Parameters none

Description Prompts you to put in a new card. After the new card is replaced, press Enter

twice. This command must be followed by command 75 (HW Init) to use the new

card.

Example n/a

3.4.6 Exit Test Command

3.4.6.1 Exit Test

Command Number 99

Name Exit

Parameters none

Description Exits the program.

Example n/a

Doc. No. MV-S101517-00 Rev. –

Page 28 Document Classification: Preliminary Information August 5, 2003, Preliminary

CONFIDENTIAL

Copyright © 2003 Marvell

Appendix A. Sample CalDataFile.txt

[Configuration]

Board = MB31-001

StructRev = 1

Pa_External = 3

AntHw =0x0a

[LED]

Led0 = 0xFF

Led1 = 0xFF

Led2 = 0xFF

Led3 = 0xFF

Sample CalDataFile.txt

[CC]

CC_primary = 0x10

CC_secondary = 0xFF

[CCA1]

CCA_0 = 0xff

CCA_1 = 0xff

CCA_2 = 0xff

CCA_3 = 0xff

[CCA2]

CCA_0 = 0xff

CCA_1 = 0xff

CCA_2 = 0xff

CCA_3 = 0xff

[Cus]

Cus_0 = 0xff

Cus_1 = 0xff

Copyright © 2003 Marvell

August 5, 2003, Preliminary Document Classification: Preliminary Information Page 29

CONFIDENTIAL

Doc. No. MV-S101517-00 Rev. –

Libertas™ 802.11g Client Card

Evaluation Tool User Guide

[CalData]

CalTableOption =1

ant2NotCaled = 1

ExtPaPolar_neg = 0

ExterPA_PartId = 0x3

ExterPA_PreDriv = 0x4

Xosc =1635

;Channel1_Ant2Adjust =0

;Channel1_Loss = 4

;Channel1_Tune = 4

Channel1_PDref = 0x60

Channel2_PDref = 0x5e

Channel3_PDref = 0x5c

Channel4_PDref = 0x58

Channel5_PDref = 0x58

Channel6_PDref = 0x56

Channel7_PDref = 0x54

Channel8_PDref = 0x53

Channel9_PDref = 0x53

Channel10_PDref = 0x54

Channel11_PDref = 0x56

Channel12_PDref = 0x56

Channel13_PDref = 0x56

Channel14_PDref = 0x56

Channel1_Pa1 = 0xFF

Channel1_Pa2 = 0xFF

Channel2_Pa1 = 0xFF

Channel2_Pa2 = 0xFF

Channel3_Pa1 = 0xFF

Doc. No. MV-S101517-00 Rev. –

Page 30 Document Classification: Preliminary Information August 5, 2003, Preliminary

CONFIDENTIAL

Copyright © 2003 Marvell

Channel3_Pa2 = 0xFF

Channel4_Pa1 = 0xFF

Channel4_Pa2 = 0xFF

Channel5_Pa1 = 0xFF

Channel5_Pa2 = 0xFF

Channel6_Pa1 = 0xFF

Channel6_Pa2 = 0xFF

Channel7_Pa1 = 0xFF

Channel7_Pa2 = 0xFF

Sample CalDataFile.txt

Channel8_Pa1 = 0xFF

Channel8_Pa2 = 0xFF

Channel9_Pa1 = 0xFF

Channel9_Pa2 = 0xFF

Channel10_Pa1 = 0xFF

Channel10_Pa2 = 0xFF

Channel11_Pa1 = 0xFF

Channel11_Pa2 = 0xFF

Channel12_Pa1 = 0xFF

Channel12_Pa2 = 0xFF

Channel13_Pa1 = 0xFF

Channel13_Pa2 = 0xFF

Channel14_Pa1 = 0xFF

Channel14_Pa2 = 0xFF

Copyright © 2003 Marvell

August 5, 2003, Preliminary Document Classification: Preliminary Information Page 31

CONFIDENTIAL

Doc. No. MV-S101517-00 Rev. –

Libertas™ 802.11g Client Card

Evaluation Tool User Guide

This page is intentionally left blank.

Doc. No. MV-S101517-00 Rev. –

Page 32 Document Classification: Preliminary Information August 5, 2003, Preliminary

CONFIDENTIAL

Copyright © 2003 Marvell

Section 4. Index

Index

A

Additional Menu Interface 13

Additional Menu Shortcut 13

B

Before Getting Started 15

C

CalDataFile.txt 7

Calibration 6

Clear Received Packet Counter 22

Client Hardware Initialization 27

Command 75 15

Command Descriptions 18

Command Line Interface 11

Configuration Information Access Commands 24

D

Device Specific Commands 27

Display SPI EEPROM Content 25

Driver Installation Procedure 8

DUT Interface 11

DutApi98Dll.dll 7

DutApiPci98_G.exe 7, 8, 11, 14

E

Enable BSSID Filter 23

Equipment 5

Erase Flash 27

Exit Test 28

Exit Test Command 28

F

FER Commands 22

G

Get PID VID Class ID 26

Get Received Packet Counter 22

Get RF Channel 18

Get RF Data Rate 18

Get SPI Protection 27

Get Tx Power at PA 19

Getting Started 5

Golden AP Main Menu 12

Golden Unit Interface 12

GoldenAP.exe 7, 12

I

Initialize Device 15

M

Manufacturing Test Software 7

Manufacturing Test Software Suite Contents 7

Mini PCI Hot Swap 28

MWLAN_G.inf 8

P

PCI Command Line Interface 24

PCI Interface Test Menu 11, 14

Programming Configuration Information 9

R

Read Calibration Table 27

Read MAC Address 25

Receiver Sensitivity Test 16

RF Commands 18

RF Path 6

S

Set Carrier Suppression Mode 19

Set Channel and Power at Antenna with Calibration

Data 19

Set Continuous Modulated Waveform Mode 19

Set Continuous Waveform Transmission Mode 19

Set Duty Cycle Transmission Mode 21

Set Power Mode 21

Set RF Channel 18

Set SPI Protection 27

Set sub-PID sub-VID Class ID 26

Set sub-PID sub-VID Class ID for Marvell CardBus Card

26

Set sub-PID sub-VID Class ID for Marvell Mini PCI Card

Copyright © 2003 Marvell

August 5, 2003, Preliminary Document Classification: Preliminary Information Page 33

CONFIDENTIAL

Not Approved by Document Control

Doc. No. MV-S101516-00 Rev. –

Libertas™ 802.11g Client Card

Evaluation Tool User Guide

26

Set Tx Power at PA 19

Setup File 7

SetUp.ini 7

Software Installation 7

Software Requirements 7

SPI Build-In Header Download 24

SPI Download 25

SPI Header Verify 24

SPI Verify 25

Spi.hex 7

SPI/Flash Access Commands 25

Switch Driver 6

System Requirements 6

T

Test Setup 5

Transmit Multicast Frames 23

Transmitter Tests 17

U

Using the Manual Test Module 11

W

wdreg.exe 8

Windows Driver Installation 8

windrvr.vxd 8

Write Calibration Table 27

Write MAC Address 26

Doc. No. MV-S101516-00 Rev. –

Page 34 Document Classification: Preliminary Information August 5, 2003, Preliminary

CONFIDENTIAL

Not Approved by Document Control

Copyright © 2003 Marvell

Section 5. Revision History

Table 2: Revision History

Document Revision Document Change

Rev. - First release.

Revision History

Copyright © 2003 Marvell

August 5, 2003, Preliminary Document Classification: Preliminary Information Page 35

CONFIDENTIAL

Doc. No. MV-S101517-00 Rev. –

Marvell Semiconductor, Inc.

700 First Avenue

Sunnyvale, CA 94089

Phone 408.222.2500

Fax 408.752.9028

www.marvell.com

US and Worldwide Offices

Marvell Semiconductor, Inc.

700 First Avenue

Sunnyvale, CA 94089

Tel: 1.408.222.2500

Fax: 1.408.752.9028

Marvell Asia Pte, Ltd.

151 Lorong Chuan, #02-05

New Tech Park

Singapore 556741

Tel: 65.6756.1600

Fax: 65.6756.7600

Marvell Japan K.K.

Shinjuku Center Bldg. 50F

1-25-1, Nishi-Shinjuku, Shinjuku-ku

Tokyo 163-0650

Tel: 81.(0).3.5324.0355

Fax: 81.(0).3.5324.0354

Marvell Semiconductor Israel, Ltd.

Moshav Manof

D.N. Misgav 20184

Israel

Tel: 972.4.995.1000

Fax: 972.4.995.1001

Worldwide Sales Offices

Western US Sales Office

Marvell

700 First Avenue

Sunnyvale, CA 94089

Tel: 1.408.222.2500

Fax: 1.408.752.9028

Sales Fax: 1.408.752.9029

Central US Sales Office

Marvell

11709 Boulder Lane, Ste. #220

Austin, TX 78726

Tel: 1.512.336.1551

Fax: 1.512.336.1552

Eastern US/Canada Sales Office

Marvell

Knox Trail Office Bldg.

2352 Main Street

Concord, MA 01742

Tel: 1.978.461.0563

Tel: 1.978.461.1406

Fax: 1.978.461.1405

Europe Sales Office

Marvell

3 Clifton Court

Corner Hall

Hemel Hempstead

Hertfordshire, HP3 9XY

United Kingdom

Tel: 44.(0).1442.211668

Fax: 44.(0).1442.211543

Marvell

Fagerstagatan 4

163 08 Spanga

Stockholm, Sweden

Tel: 46.16.146348

Fax: 46.16.482425

Marvell

5 Rue Poincare

56400 Le Bono

France

Tel: 33.297.579697

Fax: 33.297.578933

Israel Sales Office

Marvell

Ofek Center Bldg. 2, Floor 2

Northern Industrial Zone

LOD 71293

Israel

Tel: 972.8.914.1300

Fax: 972.8.914.1301

China Sales Office

Marvell

5J, 1800 Zhong Shan West Road

Shanghai, China 200233

Tel: 86.21.6440.1350

Fax: 86.21.6440.0799

Japan Sales Office

Marvell

Helios Kannai Bldg. 12F

3-21-2 Motohama-cho, Naka-ku

Yokohama, Kanagawa

Japan 231-0004

Tel: 81.45.222.8811

Fax: 81.45.222.8812

Taiwan Sales Office

Marvell

2Fl., No. 1, Alley 20, Lane 407

Ti-Ding Blvd., Nei Fu District

Taipei, Taiwan 114, R. O. C

Tel: (886-2).7720.5700

FAX: (886-2).7720.5707

For more information, visit our website at: www.marvell.com

Copyright © 2003 Marvell. All rights reserved. Marvell, the Marvell logo, Moving Forward Faster, Alaska, and GalNet are registered trademarks of Marvell.

Discovery, Fastwriter, GalTis, Horizon, Libertas, Link Street, NetGX, PHY Advantage, Prestera, Raise The Technology Bar, UniMAC, Virtual Cable Tester,

and Yukon are trademarks of Marvell. All other trademarks are the property of their respective owners.

Federal Communication Commission Interference Statement

This equipment has been tested and found to comply with the limits for a Class B digital device,

pursuant to Part 15 of the FCC Rules. These limits are designed to provide reasonabl e

protection against harmful interference in a residential installation. This equipment generates,

uses and can radiate radio frequency energy and, if not installed and used in accordance with

the instructions, may cause harmful interference to radio communications. However, there

is no guarantee that interference will not occur in a particular installation. If this equipment

does cause harmful interference to radio or television reception, which can be determined by

turning the equipment off and on, the user is encouraged to try to correct the interfer ence by one of

the following measures:

- Reorient or relocate the receiving antenna.

- Increase the separation between the equipm ent and receiver.

- Connect the equipment into an outlet on a circuit different from that to which the receiver is

connected.

- Consult the dealer or an experienced radio/TV technician for help.

This device complies with Part 15 of the FCC Rules. Operation is subject to the

following two conditions: (1) This device may not cause harmful interference, and (2) this

device must accept any interference received, including interference that may cause

undesired operation.

FCC Caution: Any changes or modifications not expressly approved by the party

responsible for compliance could void the user's authority to operate this equipment.

This transmitter must not be co-located or operating in conjunction with any other antenna

or transmitter.

IMPORTANT NOTE:

FCC Radiation Exposure Statement:

This equipment complies with FCC radiation exposure limits set forth for an uncontrolled

environment. This equipment should be installed and operated with minimum distance 20cm

between the radiator & your body.

This transmitter must not be co-located or operating in conjunction with any other antenna or

transmitter.

This device is intended only for OEM integrators under the following conditions:

1) The antenna must be installed such that 20 cm is maintained between the antenna and users,

and

2) The transmitter module may not be co-located with any other transmitter or antenna.

As long as 2 conditions above are met, further transmitter test will not be required. However,

theOEM integrator is still responsible for testing their end-product for any additional

compliance requirements required with this module installed (for example, digital device

emissions, PC peripheral requirements, etc.).

IMPORTANT NOTE: In the event that these conditions can not be met (for example certain

laptop configurations or co-location with another transmitter), then the FCC authorization is no

longer considered valid and the FCC ID can not be used on the final product. In these

circumstances, the OEM integrator will be responsible for re-evaluating the end product

(including the transmitter) and obtaining a separate FCC authorization.

End Product Labeling

This transmitter module is authorized only for use in device where the antenna may be installed

such that 20 cm may be maintained between the antenna and users. The final end product must

be labeled in a visible area with the following:“Contains TX FCC ID: M4Y-0XG880M”.

Manual Information That Must be Included

The users manual for OEM integrators must include the following information in a prominent

location “ IMPORTANT NOTE: To comply with FCC RF exposure compliance requirements,

theantenna used for this transmitter must be installed to provide a separation distance of at lea st

20cm from all persons and must not be co-located or operating in conjunction with any other

antenna or transmitter.

Loading...

Loading...