Page 1

Assembl y

and usage instructions

www.zarges.de

Z200 / Z300

mobile scaffold towers

Z200-300-AA-RC4_EN.indd 1Z200-300-AA-RC4_EN.indd 1 28.02.2008 10:20:4328.02.2008 10:20:43

Page 2

Page 3

Operating and assembly instructions

Z200 / Z300

3

Z200 / Z300

Table of contents

1. General information 4

1.1. Introduction 4

1.2. Manufacturer 4

1.3. Construction type approval 4

1.4. Warranty 4

1.5. Date of issue 5

1.6. Industrial property and trademark rights 5

1.7. Proper usage 5

1.8. Improper usage 5

2. Design 6

2.1. Safety provisions 6

2.2. Behaviour for work on electrical systems with the scaffold 8

2.3. Further applicable safety instructions 8

2.4. Technical specifi cations 8

2.5. General assembly specifi cations 9

2.6. Basic measurements 12

2.7. Identifi cation 13

2.8. Parts list incl. ballasting (see also 5.2) 14

2.9. Position of the individual parts 15

2.10. Assembly drawings 16

3. Note about disassembly of the scaffold 20

4. Usage rules and regulations 20

5. Stability specifi cations 21

5.1. General information 21

5.2. Fastening the ballasting 21

5.3. Maintenance, repair, storage and cleaning 21

5.4. Inspections of the scaffold components 22

6. Spare parts 23

7. Accessories 26

Notes 28

Page 4

Operating and assembly instructions

Z200 / Z300

4

1. General information

1.1. Introduction

The present operating and assembly instructions are only valid for the scaffolds described in

these operating and assembly instructions.

The instructions provided in these operating and assembly instructions for safety as well as

the rules and regulations f or the handling of scaffolds are in the area of application of the scaffolds

mentioned in this documentation.

The operator must on his own responsibility:

• bear responsibility for adherence to local, regional and national regulations,

• adhere to the regulations (laws, ordinances, guidelines, etc.) listed for safe handling,

• ensure that the operating and assembly instructions are available to operating

personnel and that all details such as instructions, warnings and safety pro visions ar e

followed completely.

1.2. Manufacturer

The manufacturer of the scaffolds described in this documentation is:

ZARGES GmbH Tel.: +49 8 81 / 68 71 00

Lift technology branch Fax: +49 8 81 / 68 72 95

PO Box 16 30 E-mail: zarges@zarges.de

82360 Weilheim Internet: http://www.zarges.de

1.3. Construction type approval

The scaffolds addressed below were inspected by.

1.4. Warranty

The scope, period and form of the warranty are established in the manufacturer's sales and

delivery conditions. Authoritative for warranty claims which arise fr om insuffi cient documentation

is always the operating and assembly instructions valid at the time of delivery (see section 1.5).

Beyond the sales and delivery conditions, it applies that: There is no warranty assumed for

damage to the delivered scaffolds which arises due to one or several of the following reasons:

• lack of knowledge or disregarding of these operating and assembly instructions

• insuffi ciently-qualifi ed or trained operating personnel

• use of other than original spare parts

The operator must ensure on his own responsibility:

• that the safety provisions according to section 5 are adhered to,

• that an improper use (see section 1.8) and faulty setting up and impermissible use are

excluded and thus

• that in addition, proper use (see section 1.7) is guaranteed and that the scaffolds are

operated according to the contractually agreed-upon conditions of use.

Z200-300-AA-RC4_EN.indd 4Z200-300-AA-RC4_EN.indd 4 28.02.2008 10:20:4528.02.2008 10:20:45

Page 5

Operating and assembly instructions

Z200 / Z300

5

Z200 / Z300

1.5. Date of issue

The date of issue of these German-language operating and assembly instructions

is 1 October 2006.

1.6. Industrial property and trademark rights

• The trademark right for these operating and assembly instructions remains with

the manufacturer.

• Furthermore, all rights are reserved, especially for the case of the granting of

a patent or utility patent registration.

• Violations which contradict the details above are subject to punitive damages!

1.7. Proper usage

The scaffolds listed in these operating and assembly instructions may only be used as scaffolds

according to the r egulations of EN 1004 and the version o verview of these operating and assembl y

instructions.

1.8. Improper usage

A use other than for the purposes intended – that is, a deviation from the details provided in

section 1.7 of the scaffolds documented in these operating and assembly ins tructions – counts as

improper usage in the sense of ProdSG (s tatus as of 1.8.1997). This also applies for the disregarding

of the standards and guidelines listed in these operating and assembly instructions.

Z200-300-AA-RC4_EN.indd 5Z200-300-AA-RC4_EN.indd 5 28.02.2008 10:20:4628.02.2008 10:20:46

Page 6

Operating and assembly instructions

Z200 / Z300

6

2. Design

2.1. Safety provisions

1. For the stability, installation and usage of the scaff olds mentioned above, the regulations

of EN 1004 "Mobile access and w orking to w er s" apply.

2. The scaffolds may only be assembled and used by people who are familiar with these

operating and assembly instructions.

3. For the assembly and disassembly of the scaffold, at leas t two people are required.

4. Only undamaged and faultless original spare parts of the

manufacturer's scaffold system, which refers to the inspection

certifi cate, may be used. Before using the unit, inspect all c omponents

for proper assembly and functionality.

5.

According to EN 1004, the maximum platform heights are

limited to 8 m outdoors and 12 m in entirely closed-in spaces.

For the scaffolds described in these operating and assembly

instructions, the maximum platform height in entirely closedin spaces is 10 m.

6. The use of lifts on the scaffold is not permitted.

7. The fi rst platform may be at a height of max. 4.40 m above the ground. The distance

between the other platforms may be at most 4 m. The platforms must be at l east 1.70 m

apart.

8. During the assembly and disas sembl y of the scaffold, platf orms or scaffold planks mus t

be laid out completely at a distance of 2 m as assembly aids. With the use of scaffold

planks, these must extend 500 mm beyond the scaffold on each side. It is forbidden to

use railings and braces as a place to st and, also not f or as sembly and disassembly.

9. The assembly of the scaffold is only permitted

perpendicular on a horizontally-level subsurface

with suffi cient carrying capacity. If necessary, load-

distributing bases must be used.

10. For information about the use of chassis beams, ballast weights, stabilisers and wall

spacers to guarantee stability, see these operating and assembly instructions.

11. Work on the working platform is only permitted with complete 3-part side protection,

that is, railing frames, knee protection and surrounding toe boards. The intermediate

platforms do not have to have toe boards.

12. Work on several working platf orms simultaneously is not permitted.

Z200-300-AA-RC4_EN.indd 6Z200-300-AA-RC4_EN.indd 6 28.02.2008 10:20:4628.02.2008 10:20:46

Page 7

Operating and assembly instructions

Z200 / Z300

7

Z200 / Z300

13. For wall-side assembly of the scaffold, wall spacers can also be used for ballasting

(accessory, order no. 44461).

14. The permissible load capacity of the scaffold with e venly-distributed load is 2.0 kN/ m²

(according to EN 1004 - scaffolding group 3).

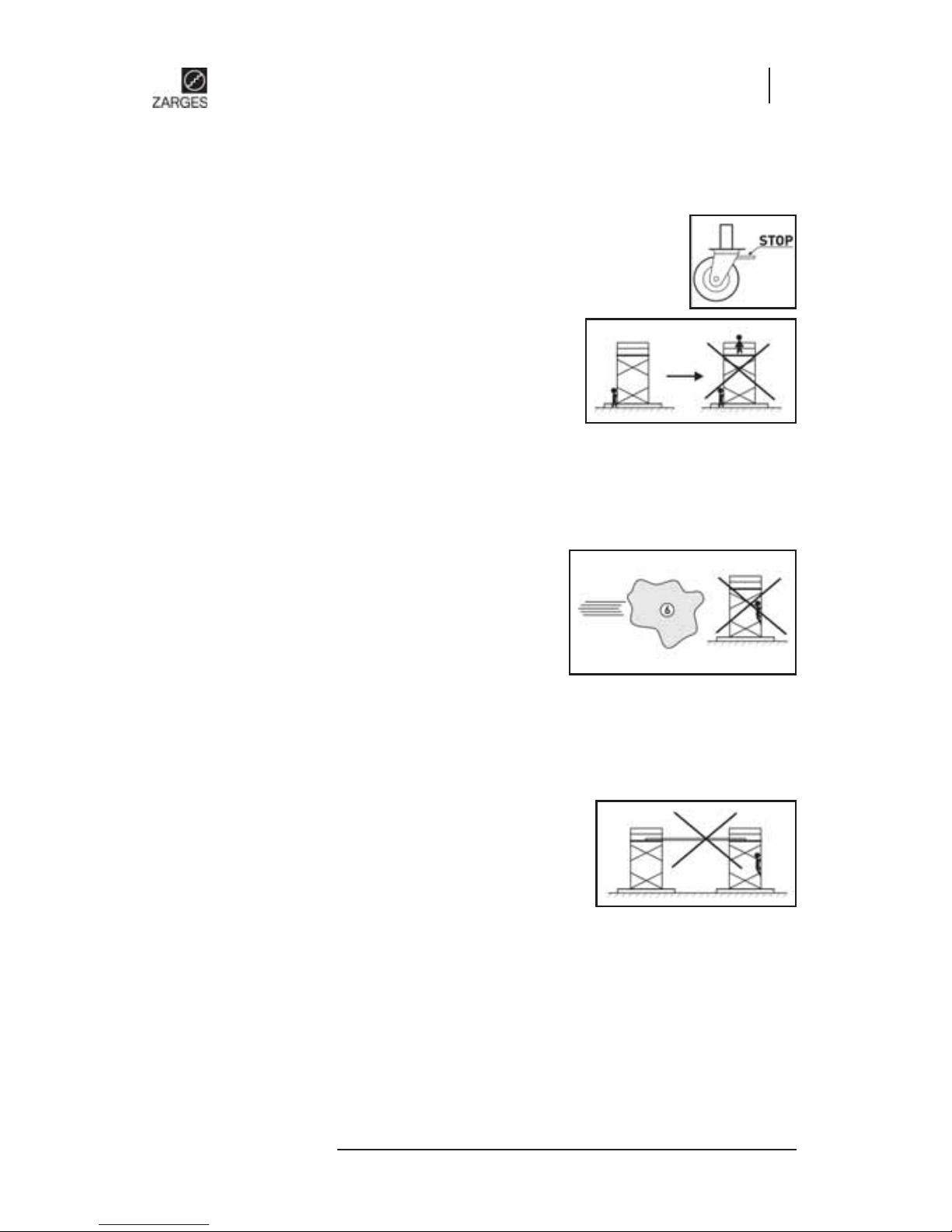

15. All swivel castors must be fi xed by pressing down the brake lever.

The brake lever may only be released for moving.

16. When moving the scaffold, neither people nor material

or tools may be on the platform. Avoid all collisions.

Move the scaffold only by hand in the lengthwise or

diagonal direction on solid, level and obstacle-free

surfaces. When moving, normal walking speed may

not be exceeded.

17. Moving the scaffold with the assistance of vehicles (e.g. fork lifts) is forbidden.

The scaffold may not be lifted or pulled or pushed with the fork lift.

18. The area on which the scaffold is moved must be able to accommodate its weight.

19. For use outdoors or in open buildings, the scaffold

must be moved into a wind-protected area if

there are wind strengths above 6 (according

to the Beaufort scale), in case of an oncoming

storm and when work is complete and protected

against tipping with other suitable measures

(e.g. anchoring). The exceeding of the wind

strength 6 (12 m/s) can be detected with a palpable drag when walking.

20. With the use of anchors in connection with anchor fi tting connections, the information

in the "Bulletin for the attachment of dowels to anchors of facade scaffolds" (can be

ordered from Carl Heymanns Verlag KG, Luxemburger Straße 449 in 50939 Cologneorder no. ZH 1/500) must be heeded.

21. The bridging of scaffolds to buildings with planks

is not permitted. The scaffold may not be used as a

stair tower in order to reach other constructions from

there.

22. Before using the scaffold, the vertical alignment of the scaffold must be checked and

corrected if neces sary . F urthermore, the scaff old must be checked to ensur e compl ete

assembly according to section 2.8.

23. With the use of stabilisers, these must always be attached under a frame. The antitwist devices of the stabilisers must always be attached.

Z200-300-AA-RC4_EN.indd 7Z200-300-AA-RC4_EN.indd 7 28.02.2008 10:20:4728.02.2008 10:20:47

Page 8

Operating and assembly instructions

Z200 / Z300

8

2.2. Behaviour for work on electrical systems with the scaffold

Work on or in the proximity of unprotected live systems, may not be carried out using

the scaffold if

• the system component is not disconnected,

• the system component is not secured against switching on,

• if there is voltage in the system component,

• the system component is not short-circuited with an earthing rail,

• the system component is not isolated against adjacent live parts.

2.3. Further applicable safety instructions

For the inspection, assembly and usage of the scaffold, the following provisions are applicable:

• BGI 663 " Instructions for action for handling work and protective scaffolds"

For the use of electrical de vices on the scaffold, the pr ovisions of BGR 165 and BGI 594 (pre viously

ZH 1/228) "Safety rules for the use of electrical equipment with increased electrical hazard"

apply.

2.4. Technical specifi cations

Z200 folding scaffold 0.7 m × 1.5 m

Approved according to EN 1004 Scaffold group 3

Permissible load according to scaffold group 3 200 kg/m²

Total load of the scaffold (maximum) 210 kg

Load of the platform (maximum) 210 kg

Maximum platform height 6.60 m

Z200 mobile scaffold tower 0.7 m × 1.5 m

Approved according to EN 1004 Scaffold group 3

Permissible load according to scaffold group 3 200 kg/m²

Total load of the scaffold (maximum) 210 kg

Load of the platform (maximum) 210 kg

Maximum platform height 6.85 m

Z300 folding scaffold 0.7 m × 2.0 m

Approved according to EN 1004 Scaffold group 3

Permissible load according to scaffold group 3 200 kg/m²

Total load of the scaffold (maximum) 280 kg

Load of the platform (maximum) 280 kg

Maximum platform height 9.60 m

Z300 mobile scaffold tower 0.7 m × 2.0 m

Approved according to EN 1004 Scaffold group 3

Permissible load according to scaffold group 3 200 kg/m²

Total load of the scaffold (maximum) 280 kg

Load of the platform (maximum) 280 kg

Maximum platform height 9.85 m

Z200-300-AA-RC4_EN.indd 8Z200-300-AA-RC4_EN.indd 8 28.02.2008 10:20:4728.02.2008 10:20:47

Page 9

Operating and assembly instructions

Z200 / Z300

9

Z200 / Z300

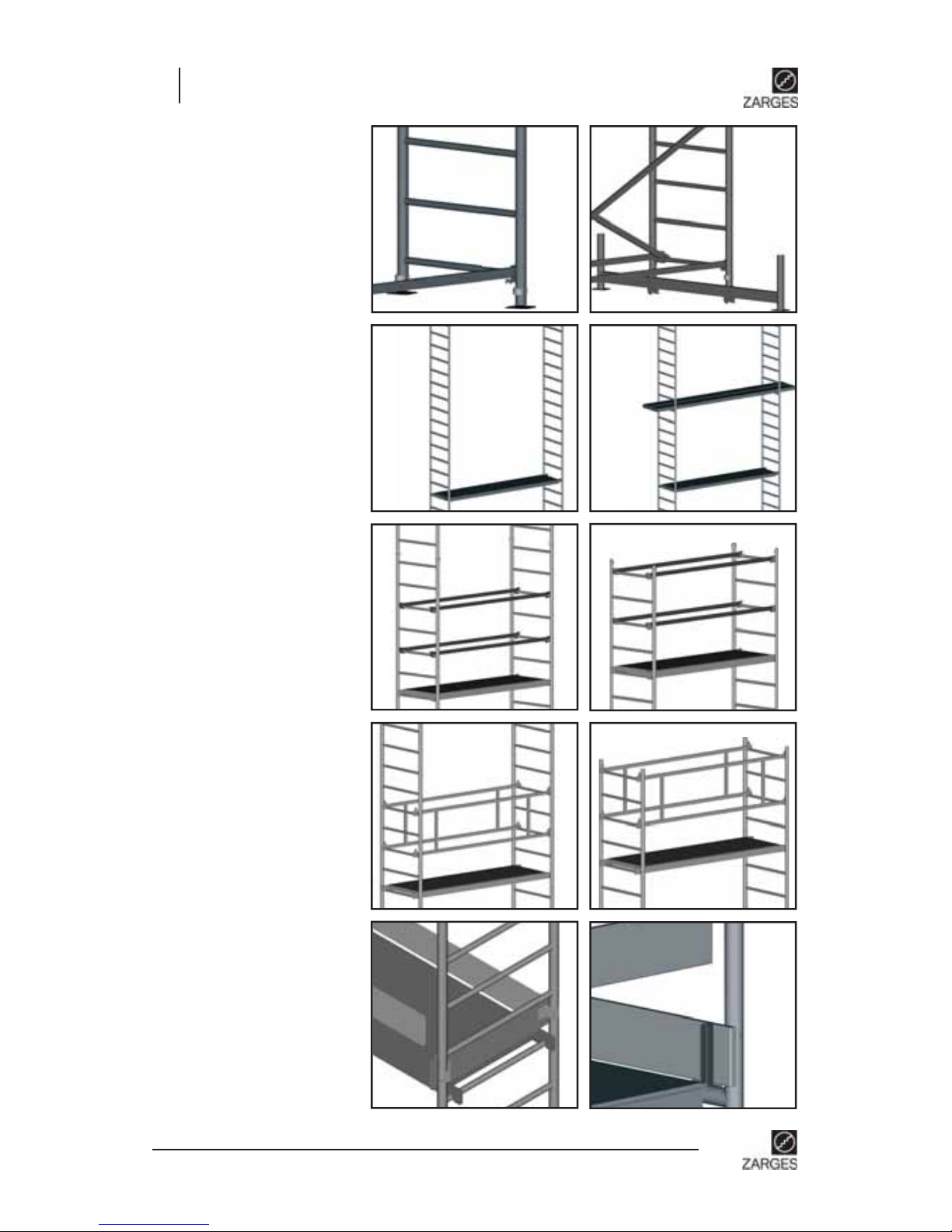

2. Assembly of slip-in frame

on chassis beams

Fig. 3. Fig. 4.

3. Assembly of swivel castor s,

with pivots on the chassis

beams

(base plates are included in the

basic package)

Fig. 5. Fig. 6.

4. Assembly of swivel castor s,

with shafts on the chassis

beams

(base plates are included in the

basic package)

Fig. 7. Fig. 8.

5. Assembly of diagonal

braces

The fi rst diagonals always be-

gin on the 1st rung from the

bottom!!! After that, the diagonals run zig-zag up the long

side of the scaffold.

Fig. 9. Fig. 10.

Ð

Ð

Ô

Î

Í

Ï

1.

2.

Ô

1.

2.

Ï

Ð

2.5. General design specifi ca-

tions

1. Preparatory work for

assembly

Fig. 1. Fig. 2.

1.

2.

Ô

Page 10

Operating and assembly instructions

Z200 / Z300

10

7. Assembly of platform

Scaffold planks or platforms

must be installed as assembly

aids. The platform serves as a

place to stand for the further

assembly (cf. section 2.1 no. 7).

After the scaffold is complete,

all assembly aids (scaffold

planks, etc.) must be removed.

Fig. 13. Fig. 14.

ÐÐ

1. 2.

3.

max.

0.5m

Ò

Fig. 19. Fig. 20.

10. Assembly of toe boards

(lengthwise board, crosswise

board)

1.

2.

Ô

Ð

Ð

8.1 Assembly of railings Z200

For Fig. 15:

Railings for intermediate

platform

For Fig. 16:

Railings for working platform

(uppermost platform)

Fig. 15. Fig. 16.

Ï

Ð

Ô

Ô

8.2 Assembly of railings Z300

For Fig. 17:

Railings for intermediate

platform

For Fig. 18:

Railings for working platform

(uppermost platform)

Fig. 17. Fig. 18.

Ï

Ð

Ô

Ô

6. Assembly of diagonal

braces

Fig. 11.

Ð

Ð

Ð

Fig. 12.

Z200-300-AA-RC4_EN.indd 10Z200-300-AA-RC4_EN.indd 10 28.02.2008 10:20:5428.02.2008 10:20:54

Page 11

Operating and assembly instructions

Z200 / Z300

11

Z200 / Z300

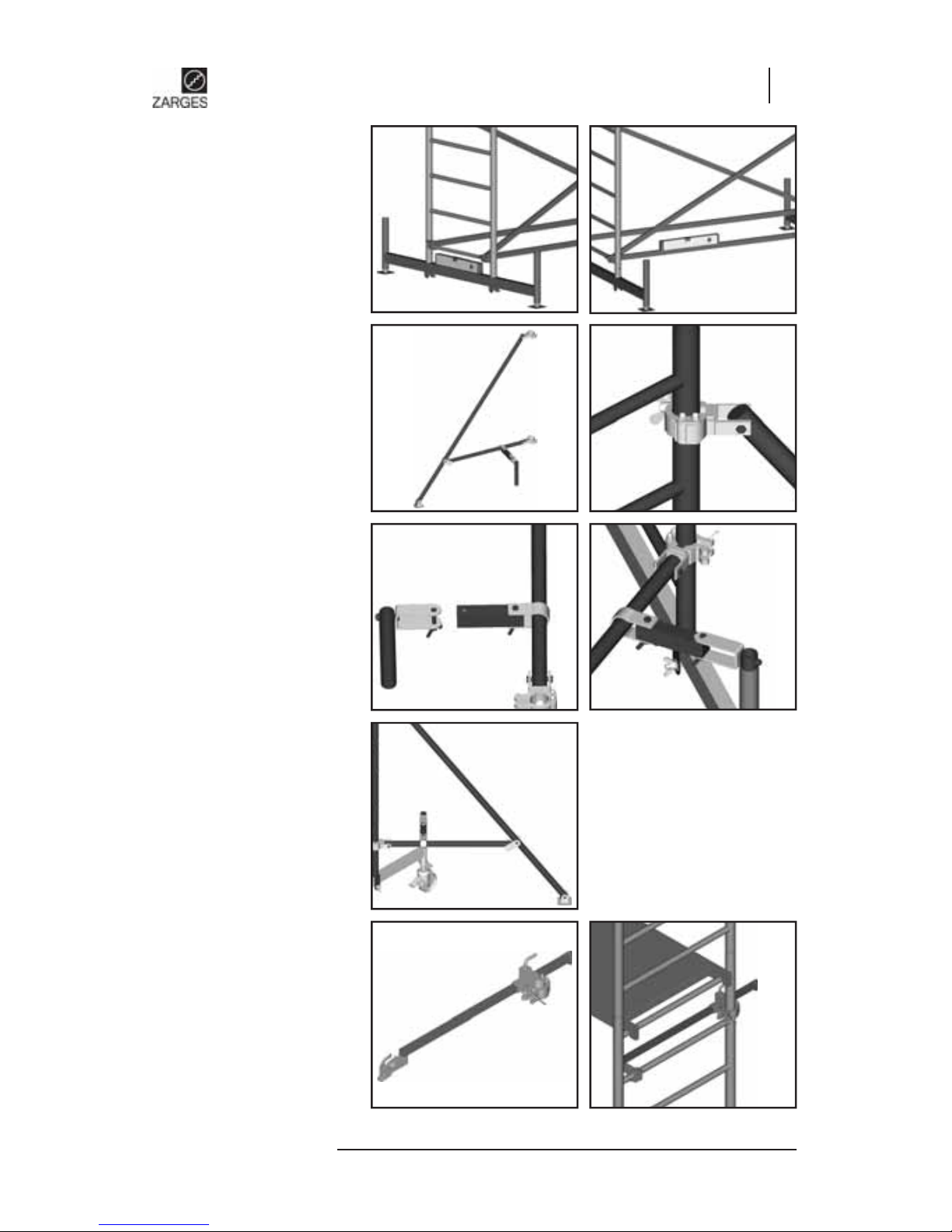

12. Assembly of stabilisers

Only for mobile scaffold towers with stabilisers (D and E

module).

Fig. 23. Fig. 24.

Fig. 25. Fig. 26.

1.

2.

Ñ

Ô

11. Aligning the scaffold

After the scaffold has been assembled, it must be aligned using a spirit level. If the scaffold

should be moved to its usage

location only after assembly,

its alignment must absolutely

be checked again on location.

Fig. 21.

Fig. 22.

13. Assembly of wall anchor

Fig. 28. Fig. 29.

3.

4.

Fig. 27.

Z200-300-AA-RC4_EN.indd 11Z200-300-AA-RC4_EN.indd 11 28.02.2008 10:20:5728.02.2008 10:20:57

Page 12

Operating and assembly instructions

Z200 / Z300

12

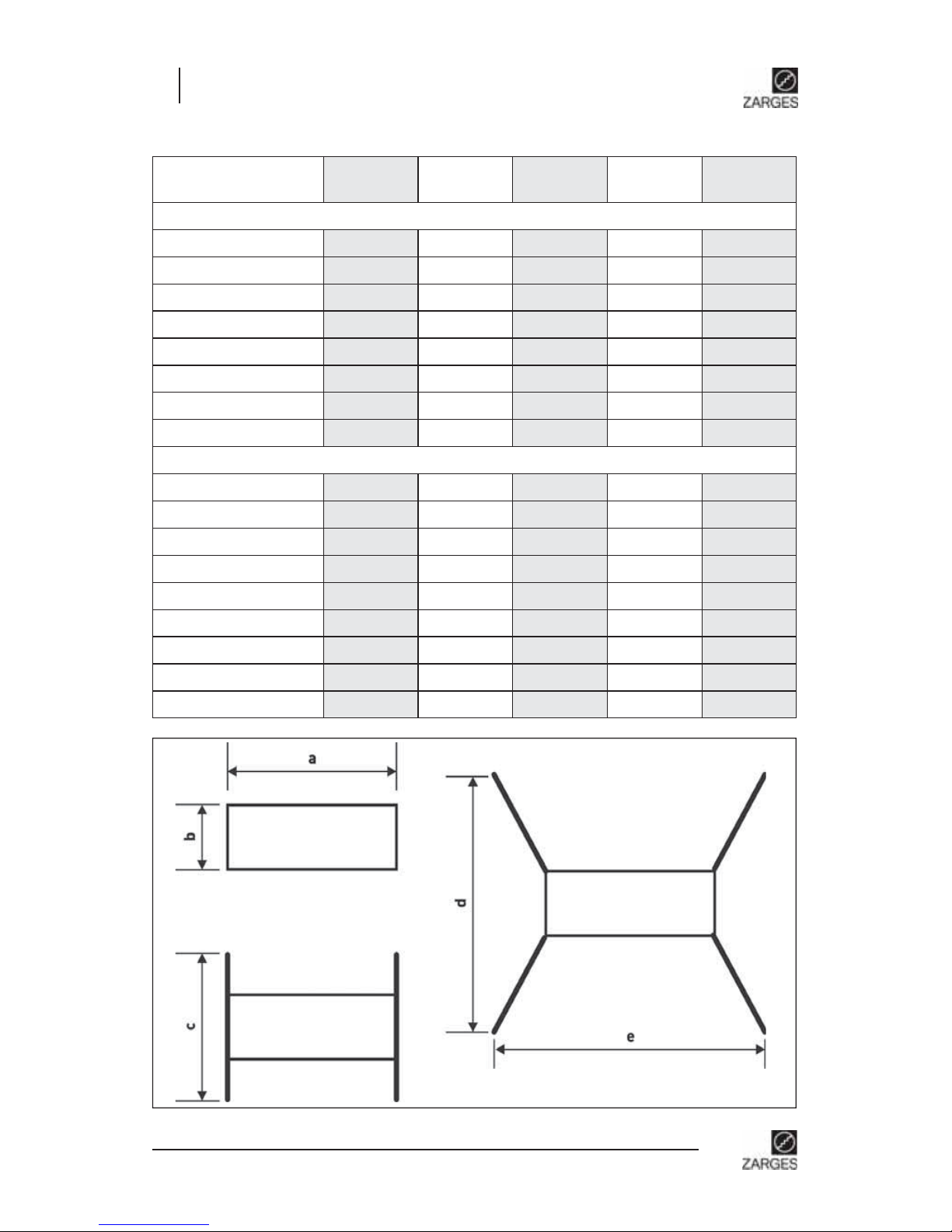

2.6. Basic measurements

Module / dimensions

[mm]

abcde

Z200 0.7 m × 1.5 m

A

1500 700 - - -

A+B

1500 700 1500 - -

A+B+C

1500 700 1500 - -

A+B+C+D

1500 700 1500 3000 2800

K

1500 700 - - -

K+B

1500 700 1500 - -

K+B+C

1500 700 1500 - -

K+B+C+D

1500 700 1500 3000 2800

Z300 0.7 m × 2.0 m

A

2000 700 - - -

A+B

2000 700 1650 - -

A+B+C

2000 700 1650 - -

A+B+C+D

2000 700 1650 3000 3300

A+B+C+D+E

2000 700 1650 3000 3300

K

2000 700 - - -

K+B

2000 700 1650 - -

K+B+C

2000 700 1650 - -

K+B+C+D

2000 700 1650 3000 3300

Z200-300-AA-RC4_EN.indd 12Z200-300-AA-RC4_EN.indd 12 28.02.2008 10:20:5828.02.2008 10:20:58

Page 13

Operating and assembly instructions

Z200 / Z300

13

Z200 / Z300

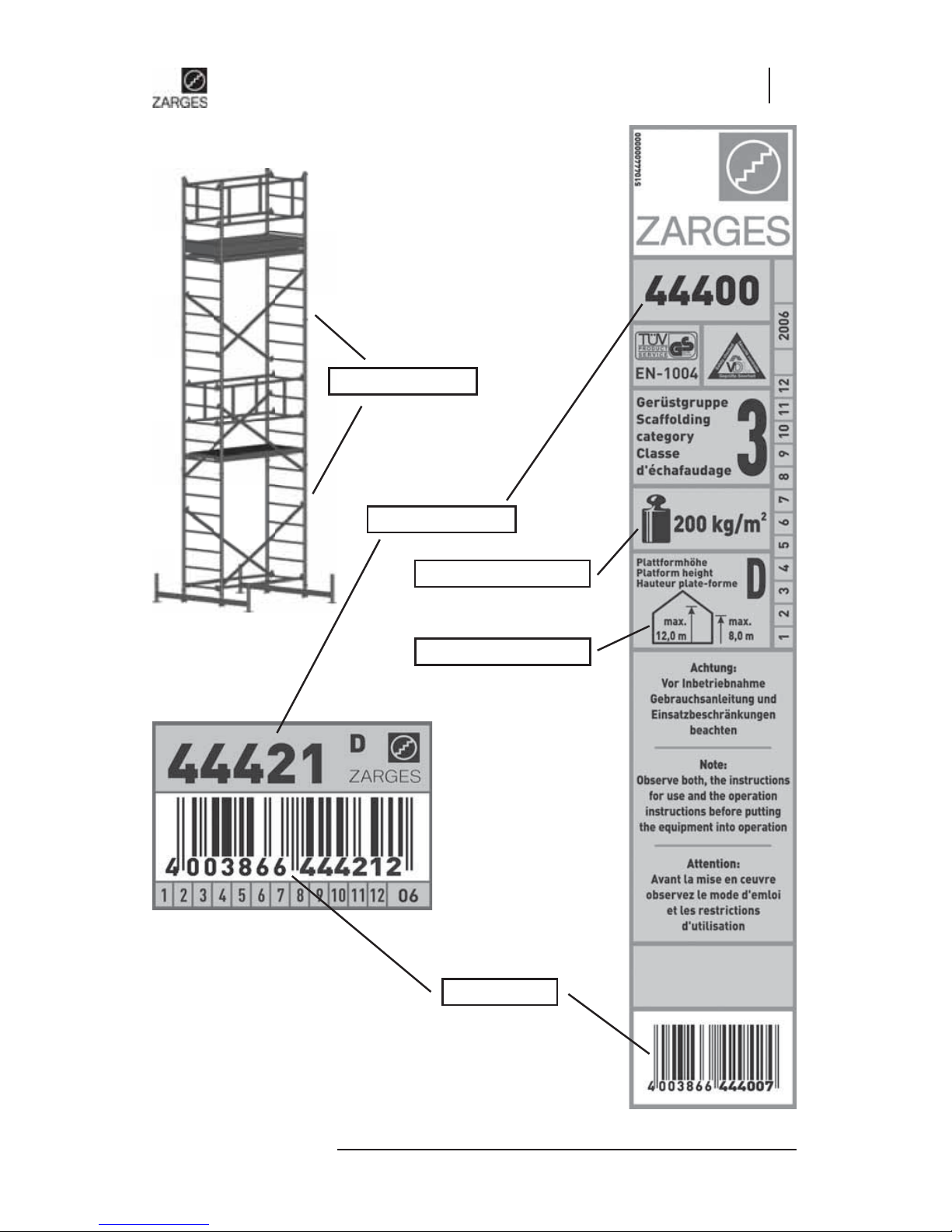

2.7. Identifi cation

Item no.

Type plate

Max. platform height

Load max.

EAN code

Z200-300-AA-RC4_EN.indd 13Z200-300-AA-RC4_EN.indd 13 28.02.2008 10:20:5928.02.2008 10:20:59

Page 14

Operating and assembly instructions

Z200 / Z300

14

2.8. Parts list incl. ballasting (see also 5.2)

The parts list includes the designation of the individual parts, their associated weights, the item

no. of the individual parts which are included in the complete scaffold and the item no. of the

complete scaffold. The necessary ballasting per scaffold is also listed.

Z200 / Z300 mobile scaffold towers

Scaffold size

Working height

1)

Parts list

Basic frame 1.75 m

Folding unit

Slip-in frame 1 m

Slip-in frame 2 m

Railings 2)Platform with fl ap

Crosswise board

Lengthwise board

Diagonal brace

Horizontal brace

Chassis beams

3)

Stabilisers

Base plates

Ballasting

Interior

usage

Outdoor

usage

centre erection

side erection

2)

centre erection

side erection

2)

approx. [m]

Order

no.

44400

44468

44407

44405-44435

44445

44440

44420

44410

44450

44455

44459

Z200 0.7 × 1.5

2.55 48409

-1-- 1---1--4

Number of ballast weights over each swivel cas-

tor

0000

2.80 48400

2--- 1--11--4 0000

5.00 48401

--21 -22252-- 33/333/3

7.00 48402

---2 1--34--- 57/757/7

9.00 48403

---2 ---2--4- 22/222/2

approx. [m]

Order

no.

44400

44404

44407

44405

44413

44436

44445

44441

44421

44411

44451

44455

44459

44460

4)

Z300 0.7 × 2.0

2.55 44509

-1---1---1--4 0000

2.80 44500

2----1--11--4 0000

5.00 44501

--212-22212-- 11/211/2

7.00 44502

---221--3---- 33/543/5

9.00 44503

---2----2--4- 00/020/0

12.00 44504

---321--2---- 22/222/2

1)

With footplates; when swivel castors 44 454 are used = 22 cm to max. 33 cm; 44 453 = +16 cm (at an extr a cost). Ballast w eights

not included in the scope of delivery.

2)

Is replaced with 2 horizontal braces.

3)

Length of the chassis beams for the Z300: 1.65 m of galvanised steel; for the Z200: 1.50 m of aluminium.

4)

In the case of side erection, sometimes more ballast weights are located on the side facing away from the wall.

(Example: 3/5 = 3 weights on the side facing the wall and 5 ballast weights on the side facing away from the wall)

With more than 4 ballast weights per swivel castor, additional slip-in pipes (44449) must be used.

Pay attention to the ballasting specifi cations in the operating and assembly instructions!

Z200-300-AA-RC4_EN.indd 14Z200-300-AA-RC4_EN.indd 14 28.02.2008 10:21:0128.02.2008 10:21:01

Page 15

Operating and assembly instructions

Z200 / Z300

15

Z200 / Z300

2.9. Position of the individual parts

Slip-in frame 2.00 m

Slip-in frame 1.00 m

Folding unit

Platform with access way

Crosswise toe board

Lengthwise toe board

Diagonal brace

Horizontal brace

Stabilisers

Chassis beams

Railings

Z200-300-AA-RC4_EN.indd 15Z200-300-AA-RC4_EN.indd 15 28.02.2008 10:21:0228.02.2008 10:21:02

Page 16

16

Operating and assembly instructions

Z200 / Z300

Scaffold comb.

Module

A

Working height

approx. 2.90 m

Scaffold height

1.75 m

Platform

height

0.90 m

Weight

23.1 kg

Order no.

48400

Scaffold comb.

Module

A+B

Working height

approx. 4.85 m

Scaffold height

3.95 m

Platform

height

2.85 m

Weight

83.1 kg

Order no.

48540

Scaffold comb.

Module

A+B+C

Working height

approx. 6.85 m

Scaffold height

5.95 m

Platform

height

4.85m

Weight

111.2 kg

Order no.

48541

Scaffold comb.

Module

A+B+C+D

Working height

approx. 8.85 m

Scaffold height

7.95 m

Platform

height

6.85 m

Weight

152.2 kg

Order no.

48542

2.10. Assembly drawings

Z200 Mobile scaffold tower, 0.7 m × 1.5 m

Z200-300-AA-RC4_EN.indd 16Z200-300-AA-RC4_EN.indd 16 28.02.2008 10:21:0428.02.2008 10:21:04

Page 17

Z200 / Z300

17

Operating and assembly instructions

Z200 / Z300

Scaffold comb.

Module

K

Working height

approx. 2.70 m

Scaffold height

1.50 m

Platform

height

0.70 m

Weight

24.9 kg

Order no.

48409

Scaffold comb.

Module

K+B

Working height

approx. 4.60 m

Scaffold height

3.70 m

Platform

height

2.60 m

Weight

84.9 kg

Order no.

48590

Scaffold comb.

Module

K+B+C

Working height

approx. 6.60 m

Scaffold height

5.70 m

Platform

height

4.60 m

Weight

113.0 kg

Order no.

48591

Scaffold comb.

Module

K+B+C+D

Working height

approx. 8.60 m

Scaffold height

7.70 m

Platform

height

6.60 m

Weight

154.0 kg

Order no.

48592

Z200 Folding scaffold, 0.7 × 1.5

Z200-300-AA-RC4_EN.indd 17Z200-300-AA-RC4_EN.indd 17 28.02.2008 10:21:1528.02.2008 10:21:15

Page 18

18

Operating and assembly instructions

Z200 / Z300

Scaffold comb.

Module

A+B+C+D

Working

height

approx. 8.85 m

Scaffold

height

7.95 m

Platform

height

6.85 m

Weight

156.1 kg

Order no.

44542

Scaffold comb.

Module

A+B+C+D+E

Working

height

approx. 11.85

m

Scaffold

height

10.95 m

Platform

height

9.85 m

Weight

197.7 kg

Order no.

44543

Z300 Mobile scaffold tower, 0.7 × 2.0

Scaffold comb. Platform height

Module

A

0.90 m

Working height Weight

approx. 2.90 m 27.1 kg

Scaffold height Order no.

1.75 m 44500

Scaffold comb. Platform height

Module

A+B

2.85 m

Working height Weight

approx. 4.85 m 79.6 kg

Scaffold height Order no.

3.95 m 44540

Scaffold comb. Platform height

Module

A+B+C

4.85m

Working height Weight

approx. 6.85 m 114.3 kg

Scaffold height Order no.

5.95 m 44541

Z200-300-AA-RC4_EN.indd 18Z200-300-AA-RC4_EN.indd 18 28.02.2008 10:21:2628.02.2008 10:21:26

Page 19

Z200 / Z300

19

Operating and assembly instructions

Z200 / Z300

Z300 Folding scaffold, 0.7 × 2.0

Scaffold comb.

Module

A+B+C+D

Working

height

approx. 8.60 m

Scaffold

height

7.70 m

Platform

height

6.60 m

Weight

160.1 kg

Order no.

44592

Scaffold comb.

Module

A+B+C+D+E

Working

height

approx. 11.60

m

Scaffold

height

10.70 m

Platform

height

9.60 m

Weight

201.7 kg

Order no.

44593

Scaffold comb. Platform height

Module

A

0.70 m

Working height Weight

approx. 2.70 m 31.1 kg

Scaffold height Order no.

1.50 m 44509

Scaffold comb. Platform height

Module

A+B

2.60 m

Working height Weight

approx. 4.60 m 83.6 kg

Scaffold height Order no.

3.70 m 44590

Scaffold comb. Platform height

Module

A+B+C

4.60 m

Working height Weight

approx. 6.60 m 118.3 kg

Scaffold height Order no.

5.70 m 44591

Z200-300-AA-RC4_EN.indd 19Z200-300-AA-RC4_EN.indd 19 28.02.2008 10:21:3828.02.2008 10:21:38

Page 20

Operating and assembly instructions

Z200 / Z300

20

3. Note about disassembly of the scaffold

Disassembly of the erected scaffold occurs in the reverse order of assembly. Here it must be

noted that the platforms or scaffold planks necessary for the assembly personnel must be

laid out in advance as places to stand and thereby laid out completely. In no case may parts of

the scaffold (braces, platforms, etc.) be disassembled before the levels above them have been

disassembled completely.

4. Usage rules and regulations

1. Ascent to the working platform may only occur from the

inside.

2. It is not permitted to lean against the side protector while

working.

3. It is not permitted to jump on the panel coverings.

4. No horizontal loads may be generated, e.g. due to work on adjacent

constructions which could cause the scaffold to tip.

5. While using scaffolds in passageway buildings, on uncovered buildings or building corners,

special attention must be paid to the wind situation in order to prevent the scaffold from

tipping over.

6. It is forbidden to extend the platform height by using ladders, crates or other equipment.

7. Tools and materials may onl y be handed upwards. Her e, the w eight of the tools and materials

must always be taken into acc ount in order not to overload the w orking platf orm. The per son

lifting the load may only l et go when the person acc epting the load has it secur el y in his or her

hands.

8. Scaffolds with swivel castors can be moved to their later location after assembly (fl oor slant

may not be more than 3%). Avoid all collisions. After moving, the alignment of the scaffold

must be checked again.

9. When moving the scaffold, always pay attention that no live system components are

touched.

10. Electrical devices (drills, etc.) may only be operated on the scaffold with protection low

voltage (48 V), with protective isolation (separation transformer) or if they are connected to a

residual current oper ated devic e with a r esidual current of 30 mA. The regulations of BGI 594

(previously ZH 1/228) must be applied.

11. Tools and materials must be stored on the working platform so that 20 cm on the side of

the working platform remains free as a passageway.

Z200-300-AA-RC4_EN.indd 20Z200-300-AA-RC4_EN.indd 20 28.02.2008 10:21:5028.02.2008 10:21:50

Page 21

Operating and assembly instructions

Z200 / Z300

21

Z200 / Z300

Extension pipe

Order no.: 44449

Ballast weights

Order no.: 44460

5.3. Maintenance, repair, storage and cleaning

Clean the scaffold with water and commercial cleansers. If paint gets on the scaffold, it can be

removed with turpentine. Cl eansers may not penetrate the soil; used cleanser s must be disposed

of in accordance with the applicable environmental regulations.

Greasing the moving parts

Grease all moving parts (spindle, swivel castor bearing, catches) with commercial oil. For use

in the winter, use low viscosity oil. Wipe off excess oil, the oil may not reach the treads - danger

of slipping. Dispose of cleaning rags soiled with grease in accordance with the applicable

environmental regulations.

Storage

Storage must be in a manner such that damage to the unit is excluded. The scaffold c omponents

must be stored so that they are protected against the effects of weather. During transport to

or from the storage location, the scaffold components must be secured against slipping and

bumping as well as falling down. When loading, the scaffold components may not be thrown.

5. Stability specifi cations

5.1. General information

Chassis beams and stabilisers are responsible for the stability of the scaffold. However, these

must also be ballasted according to the area of deployment (indoors / outdoors). For the correct

ballasting, please see the parts lists (packet 2.8).

5.2. Fastening the ballasting

The attachment location and the quantity of the ballast weights depend on the type of assembly

and platform height of the scaffold. For the pr ecise quantity of the ballasting, pl ease see the parts

lists in section 2.8 (lower portion of the tables).

Attach ballast weights over the supports on the swivel castors, see Fig. below. For scaffolds for

which a larger number of ballast weights are required, the supports on the chassis beams can

be lengthened with slip-in pipes (accessory, order no. 44449).

Z200-300-AA-RC4_EN.indd 21Z200-300-AA-RC4_EN.indd 21 28.02.2008 10:21:5128.02.2008 10:21:51

Page 22

Operating and assembly instructions

Z200 / Z300

22

5.4. Inspections of the scaffold components

If a defect is discovered, the affected part may not be used any longer.

Slip-in frame / chassis beams

• Check for deformation, crushing and crack formation.

Braces (diagonal / railings)

• Check for deformation, crushing, crack formation and function of the catches.

Platform

• Check for deformation, crushing, crack formation and function of the catches.

• Check state of the wood.

• Check pass-through fl ap for function.

Toe boards

• Check state of the wood.

• Check toe boards for crack formation.

Swivel castors

• Check rolling capacity of the castor and function of the brake on rolling and

basic frame.

• For swivel castors with spindle, also check that spindle can move freely.

• Check fail safe (thumb screw, plug) on the chassis beams and and basic frame.

Safety springs

• Check for deformation, crushing, crack formation and tight fi t.

If you would like information or if you have special

problems that are not treated in suffi cient detail in these

operating and assembly instructions, you can request

the required information directly from the manufacturer

(see section 1.2).

Furthermore, we hereby notify you that the content of

these operating and assembly instructions is not part of an

earlier existing agreement, covenant or a legal relationship

nor should it change these. All obligations arise from

the respective purchase contract, which also contains

the complete and solely-valid warranty regulation (see also

section 1.4). These contractual warranty regulations are

neither extended nor limited by the details of these operating

and assembly instructions.

The propagation and duplication of these documents,

the exploitation and communication of their content are only

permissible with the expr ess permission of the manufacturer .

Violations which contradict the details above are subject to

punitive damages.

Z200-300-AA-RC4_EN.indd 22Z200-300-AA-RC4_EN.indd 22 28.02.2008 10:21:5128.02.2008 10:21:51

Page 23

Operating and assembly instructions

Z200 / Z300

23

Z200 / Z300

6. Spare parts

Platform with fl ap

1.5 m 44435

2.0 m 44436

Railings Z300

2.0 m 44413

Folding unit

1.5 m 44468

2.0 m 44404

Slip-in frame

1.0 m 44407

2.0 m 44405

Basic frame

1.75 m 44400

Z200-300-AA-RC4_EN.indd 23Z200-300-AA-RC4_EN.indd 23 28.02.2008 10:21:5228.02.2008 10:21:52

Page 24

Operating and assembly instructions

Z200 / Z300

24

Crosswise board

0.70 m 44445

Lengthwise board

1.5 m 44440

2.0 m 44441

Diagonal brace

1.5 m 44420

2.0 m 44421

Horizontal brace

1.5 m 44410

2.0 m 44411

Chassis beams

1.50 m (alu) 44450

1.65 m (steel) 44451

Z200-300-AA-RC4_EN.indd 24Z200-300-AA-RC4_EN.indd 24 28.02.2008 10:21:5228.02.2008 10:21:52

Page 25

Operating and assembly instructions

Z200 / Z300

25

Z200 / Z300

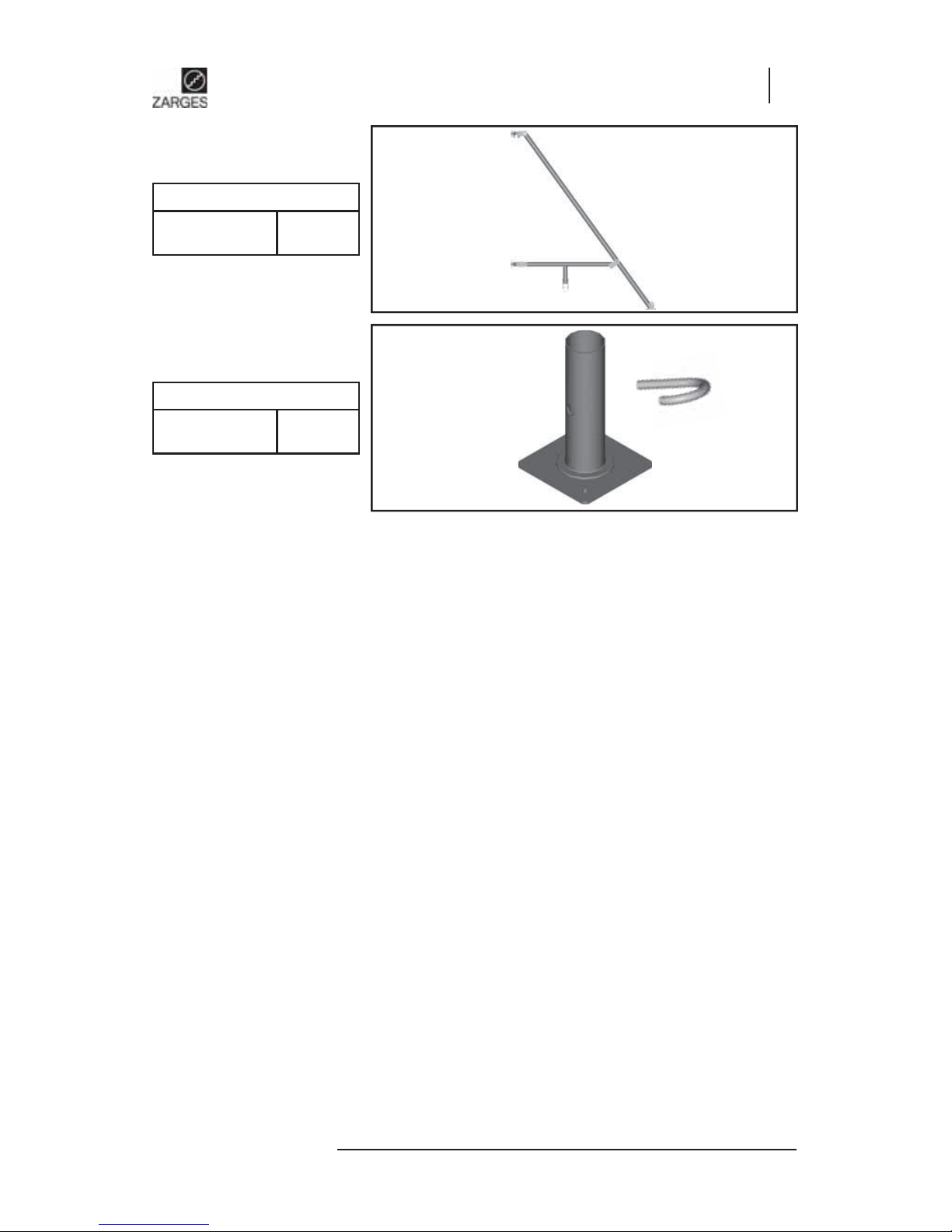

Stabilisers

2.2 m 44455

Base plates

0.30 m 44459

Z200-300-AA-RC4_EN.indd 25Z200-300-AA-RC4_EN.indd 25 28.02.2008 10:21:5328.02.2008 10:21:53

Page 26

Operating and assembly instructions

Z200 / Z300

26

7. Accessories

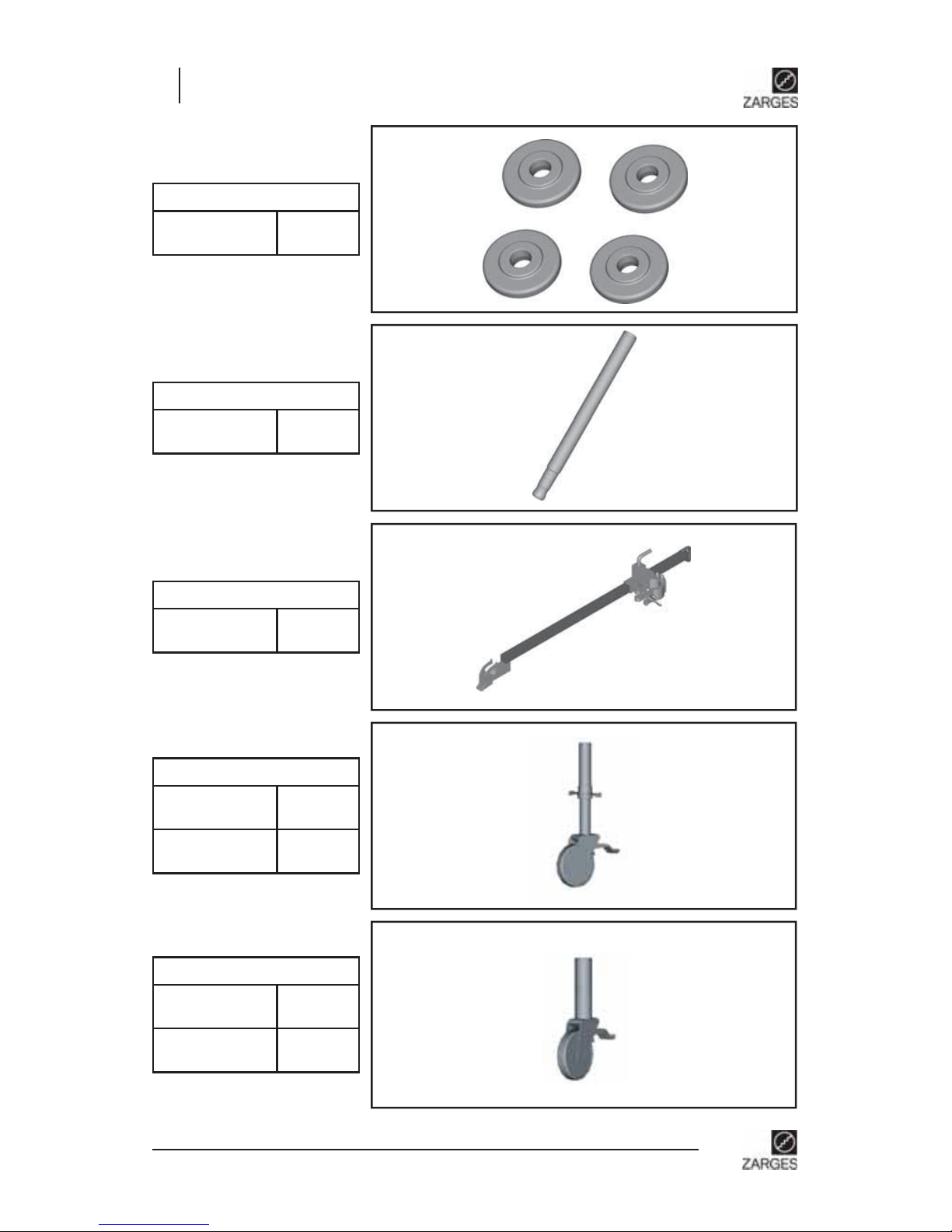

Ballast weight (disk)

10.0 kg 44460

Swivel castors 150 mm

No. pieces 44454

VE (4 pcs.) 44444

Slip-in pipe of alu

0.6 m 44449

Wall anchor

1.0 m 44461

Swivel castors 125 mm

No. pieces 44453

VE (4 pcs.) 44433

Z200-300-AA-RC4_EN.indd 26Z200-300-AA-RC4_EN.indd 26 28.02.2008 10:21:5328.02.2008 10:21:53

Page 27

Operating and assembly instructions

Z200 / Z300

27

Z200 / Z300

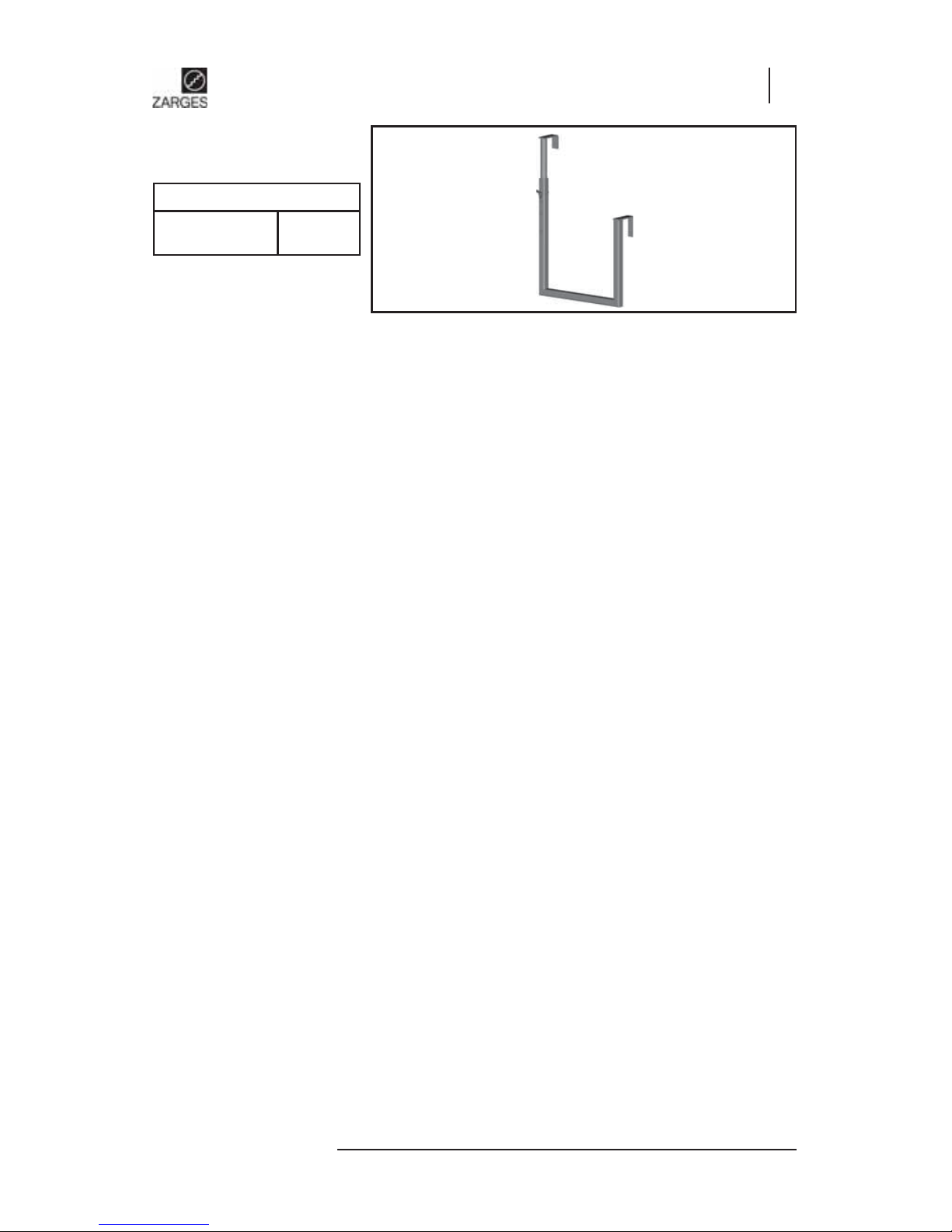

Entry arm (steel)

0.3 m 44456

Z200-300-AA-RC4_EN.indd 27Z200-300-AA-RC4_EN.indd 27 28.02.2008 10:21:5428.02.2008 10:21:54

Page 28

Operating and assembly instructions

Z200 / Z300

28

NOTES

Z200-300-AA-RC4_EN.indd 28Z200-300-AA-RC4_EN.indd 28 28.02.2008 10:21:5428.02.2008 10:21:54

Page 29

Operating and assembly instructions

Z200 / Z300

29

Z200 / Z300

NOTES

Z200-300-AA-RC4_EN.indd 29Z200-300-AA-RC4_EN.indd 29 28.02.2008 10:21:5528.02.2008 10:21:55

Page 30

Operating and assembly instructions

Z200 / Z300

30

NOTES

Z200-300-AA-RC4_EN.indd 30Z200-300-AA-RC4_EN.indd 30 28.02.2008 10:21:5528.02.2008 10:21:55

Page 31

Operating and assembly instructions

Z200 / Z300

31

Z200 / Z300

NOTES

Z200-300-AA-RC4_EN.indd 31Z200-300-AA-RC4_EN.indd 31 28.02.2008 10:21:5528.02.2008 10:21:55

Page 32

Operating and assembly instructions

Z200 / Z300

32

NOTES

Z200-300-AA-RC4_EN.indd 32Z200-300-AA-RC4_EN.indd 32 28.02.2008 10:21:5528.02.2008 10:21:55

Page 33

Operating and assembly instructions

Z200 / Z300

33

Z200 / Z300

NOTES

Z200-300-AA-RC4_EN.indd 33Z200-300-AA-RC4_EN.indd 33 28.02.2008 10:21:5628.02.2008 10:21:56

Page 34

Operating and assembly instructions

Z200 / Z300

34

NOTES

Z200-300-AA-RC4_EN.indd 34Z200-300-AA-RC4_EN.indd 34 28.02.2008 10:21:5628.02.2008 10:21:56

Page 35

Z200-300-AA-RC4_EN.indd 35Z200-300-AA-RC4_EN.indd 35 28.02.2008 10:21:5628.02.2008 10:21:56

Page 36

No291291 EN

N

o

540291291000

Z200-300-AA-RC4_EN.indd 36Z200-300-AA-RC4_EN.indd 36 28.02.2008 10:21:5628.02.2008 10:21:56

Loading...

Loading...