Zanussi ZHC590X/GB User Manual [de]

User

Manual

Bedienungsanlei-

tung

Gebruiksaanwi-

jzing

Manual de

instrucciones

Manual de

Instruções

Model ZHC590

For the User

Important Safety Information

Y our Appliance

Operating Instructions

Cooker Hood Controls

To Operate

Recirculation

Extraction

Maintenance and Cleaning

External Cleaning

Metal Grease Filters

Charcoal Filters

To Remove/Replace Charcoal Filter

Changing the Halogen Light

Something Not Working

Service and Spare Parts

Guarantee Conditions

For the Installer

Technical Information

Electrical Connections

Electrical Requirements

Electrical Connection

Installing the Cooker Hood

Installation Requirements

Unpacking

Fitting the Wall Brackets

Fitting the Canopy Hood

Venting

Recirculation

Fitting the Chimney Stack

Welcome to the world of Electrolux

Thank you for choosing a first class product from

Electrolux, which hopefully will provide you with lots of

pleasure in the future. The Electrolux ambition is to offer

a wide variety of quality products that make your life

more comfortable. You fi nd some examples on the cover

in this manual. Please take a few minutes to study this

manual so that you can take advantage of the benefi ts

of your new machine. We promise that it will provide a

superior User Experience delivering Ease-of-Mind.

Good luck!

Guide to use the instruction book

The following Symbols will be found in the text to guide you through the instruction book

Safety instructions Step by step instructions

GB 2

IMPORTANT SAFETY INFORMATION

These warnings are provided in the interests of your safety. Ensure that you understand them all before

installing or using this appliance. Your safety is of paramount importance. If you are unsure about any of the

meanings of these warnings contact the Customer Services Department.

Installation

• Any installation work must be undertaken by a qualifi ed electrician or a competent person.

• This hood must be installed in accordance with the

installation instructions and all measurements must

be adhered to.

• If the cooker hood is installed for use above a gas

appliance then the provision for ventilation must be

in accordance with the Gas Safety Codes of Practice

BS.6172, BS.5440 and BS.6891 (Natural Gas) and

BS.5482 (LP Gas) 1994, the Gas Safety (Installation

& Use) Regulations, the Building Regulations issued

by the Department of the Environment, the Building

standards (Scotland) (Consolidated) Regulations

issued by the Scottish Development Department.

• The fan motor of this cooker hood incorporates a

cut-out device which will operate if the cooker hood

is installed below the minimum height recommended

under section ‘Clearance Height’, or if the motor becomes overheated. If the cut-out device is activated,

switch off the fan motor and allow the cooker hood to

cool. The cut-out device will reset itself when the fan

motor has cooled signifi cantly.

• It is dangerous to alter the specifi cations or modify

this product in any way.

• When installed between adjoining wall cabinets the

wall cabinets must not overhang the hob.

• If the room where the hood is to be used contains

a fuel burning appliance such as a central heating

boiler then its fl ue must be of the room sealed or

balanced fl ue type.

Child Safety

• This appliance is designed to be operated by adults.

Children should not be allowed to tamper with the

controls or play with the appliance.

During Use

• This product is for domestic use only.

• Never leave frying pans unattended during use as

over-heated fats and oils might catch fi re.

• Never do fl ambé cooking under this cooker hood.

• Do not leave naked fl ames under the hood.

• This cooker hood is designed to extract unpleasant

odours from the kitchen, it will not extract steam.

Maintenance and Service

• This appliance can be a hazard if the synthetic paper

and charcoal fi lters are not replaced as recommen-

ded.

• Under no circumstances should you attempt to

repair the appliance yourself. Repairs carried out

by inexperienced persons may cause injury or more

serious malfunction. Refer to your local Zanussi Service Force Centre. Always insist on genuine spare

parts.

• If other types of fl ue or appliances are fi tted ensure

that there is an adequate supply of air to the room.

• The ducting system for this appliance must not be

connected to any existing ventilation system which is

being used for any other purpose.

• Do not install above a cooker with a high level grill.

GB 3

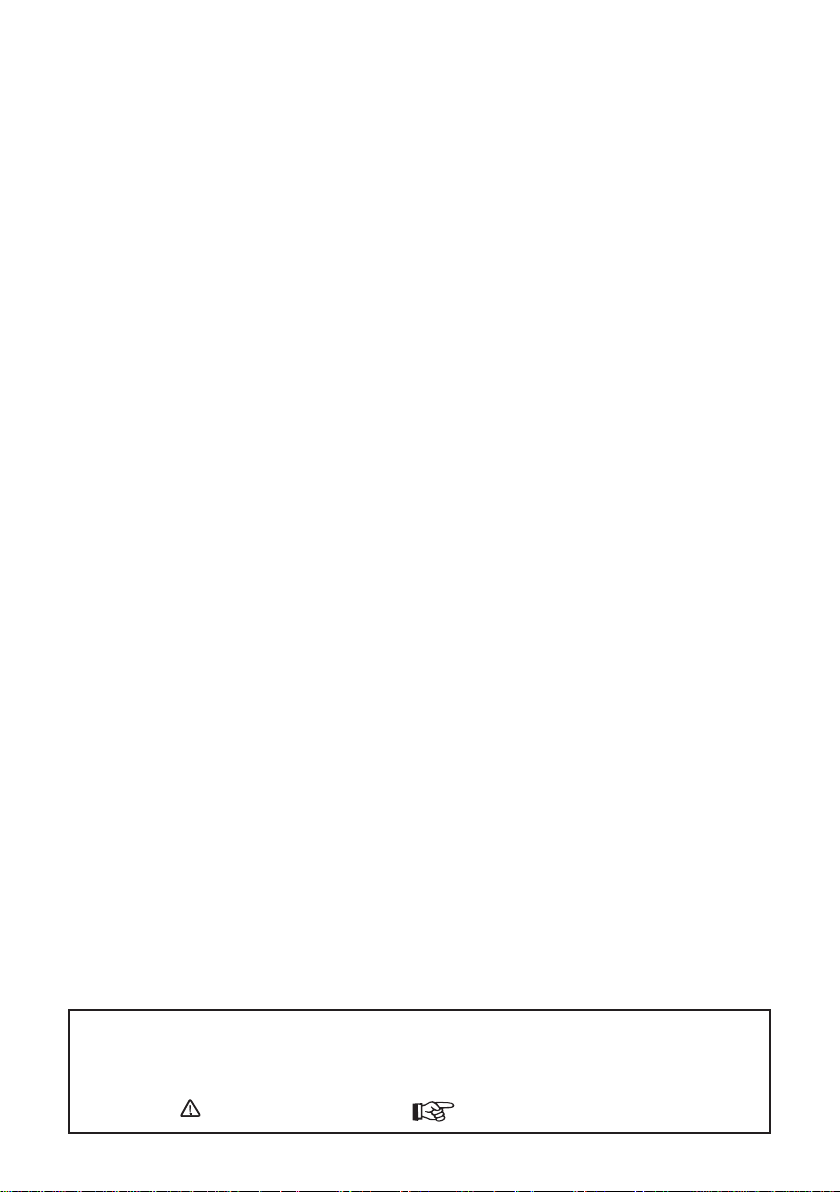

YOUR APPLIANCE

*

**

* Dimensions of the hood in ducting version.

** Dimensions of the hood in recycling version.

GB 4

OPERATING INSTRUCTIONS

The cooker hood is designed to extract unpleasant odours from the kitchen, it will not extract steam.

The appliance can be installed to recirculate or extract contaminated air.

Control Panel

The hood can be switched on pushing directly onto the requested speed without fi rstly having to select 0/1 but-

ton.

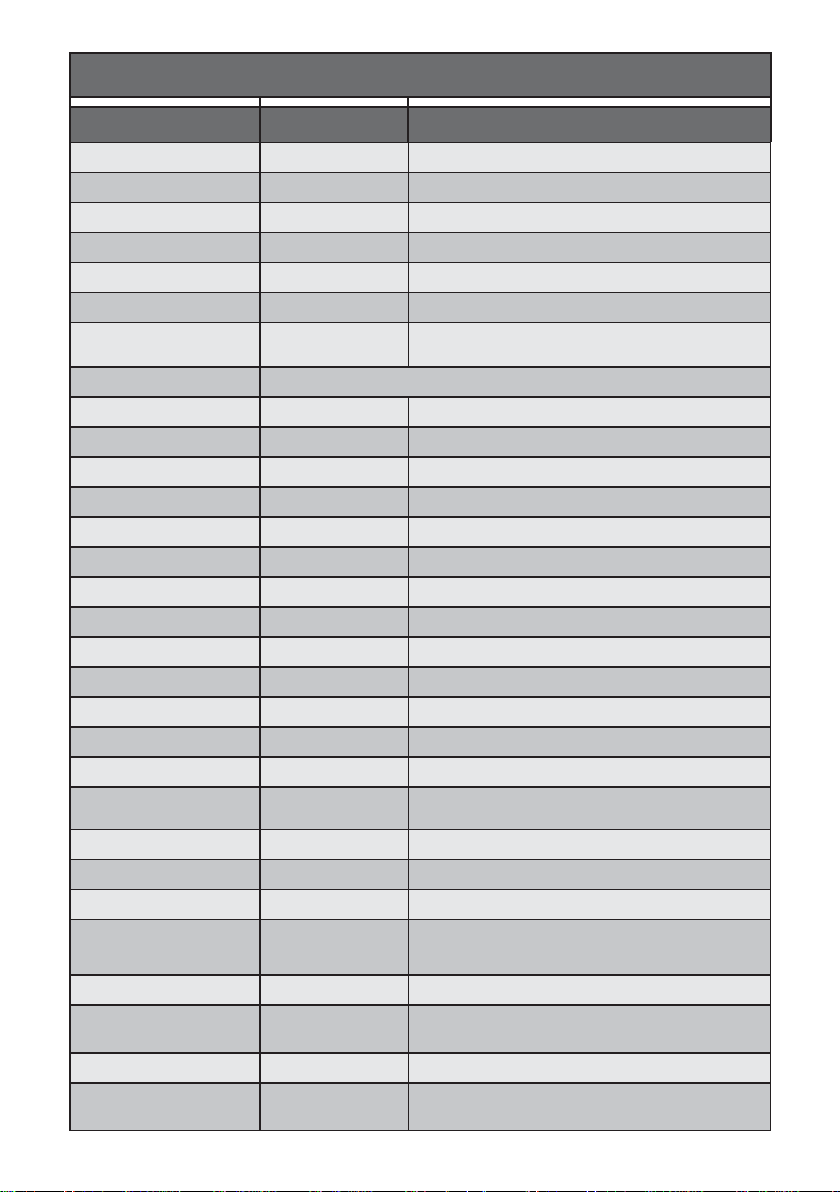

KEY LED FUNCTIONS

L 0/1 Light Turns lighting on and off.

T1 0/1 Motor on First speed.

When pressed for about 1 seconds the

motor is switched off.

T2 Speed on Second speed.

T3 Speed on Third speed.

T4 Speed Fixed Max. speed

Flashing Intensive speed.

Suitable for the strongest cooking vapours

and odours. The function becomes active

when the button is pushed for about 2

seconds. After 10 minutes of functioning

it turns off automatically . This function can

be interrupted by means of pressing any

of the buttons.

S1 Led Fixed Indicates that the Metal grease fi lters

saturation alarm has been triggered, and

the fi lters need to be washed. The alarm is

triggered after 100 working hours. (Reset;

check the Maintenance-paragraph)

Flashing indicates that the activated charcoal odour

fi lter saturation alarm has been triggered,

and the fi lter has to be replaced; the metal

grease fi lters must also be washed. The

activated charcoal odour fi lter is triggered

after 200 working hours. (Activation

and Reset; check the Maintenanceparagraph)

L

T1

T2

T3

T4

S1

GB 5

OPERATING INSTRUCTIONS

To Operate

Select the required fan speed and light if required.

Recirculation

In the recirculation mode the contaminated air enters

the cooker hood through the grease fi lters. The air is

cleaned by passing through the charcoal fi lters before

being passed back into the kitchen through the grilles in

either side of the chimney stack.

Extraction

In the extraction mode the contaminated air enters the

cooker hood passing through the grease fi lters and is

passed out through the ducting into the atmosphere.

To obtain the best performance when cooking it is advisable to switch the cooker hood on for a few minutes

before you start cooking and leave it running for about

15 minutes after fi nishing.

When used in the ducting mode the charcoal

fi lters are not required.

Never do fl ambé cooking under this cooker hood.

Never leave frying pans unattended during use,

as over-heated fats and oils can catch fi re.

Do not leave naked fl ames under the cooker

hood.

Ensure heating areas on your hob are covered

with pots and pans when using the hob and

cooker hood simultaneously.

GB 6

MAINTENANCE AND CLEANING

Before carrying out any maintenance or clean-

ing isolate the cooker hood from the mains

supply.

The cooker hood must be kept clean, as a build

up of grease or fat can be a fi re hazard.

External Cleaning

Wipe the cooker hood frequently with warm

soapy water using a mild detergent.

Never use scouring pads or abrasive cleaners.

Never use excessive amounts of water when

cleaning particularly around the control panel.

Metal Grease Filters

The fi lters are washable and must be cleaned when the

Led S1 lights up or at least every 2 months of operation, or more frequently for particularly heavy usage.

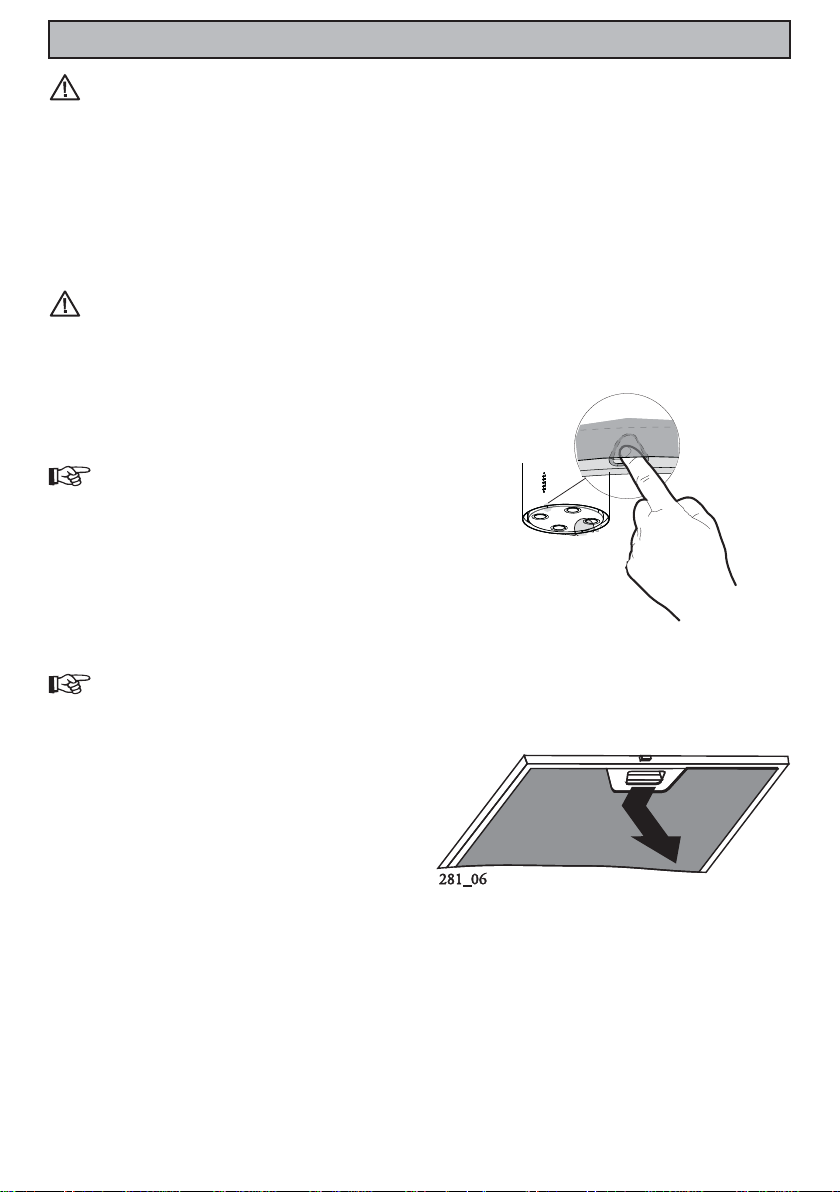

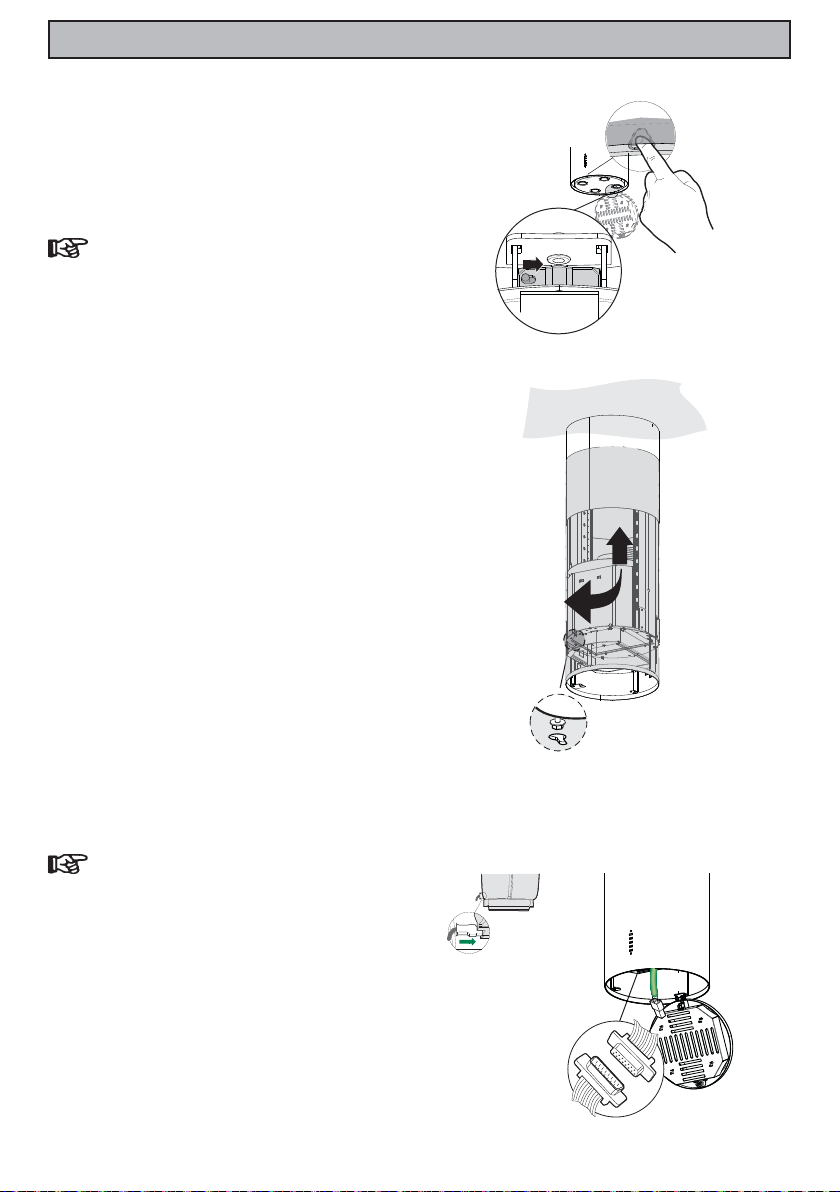

Remove the metal grease

fi lters one at a time by:

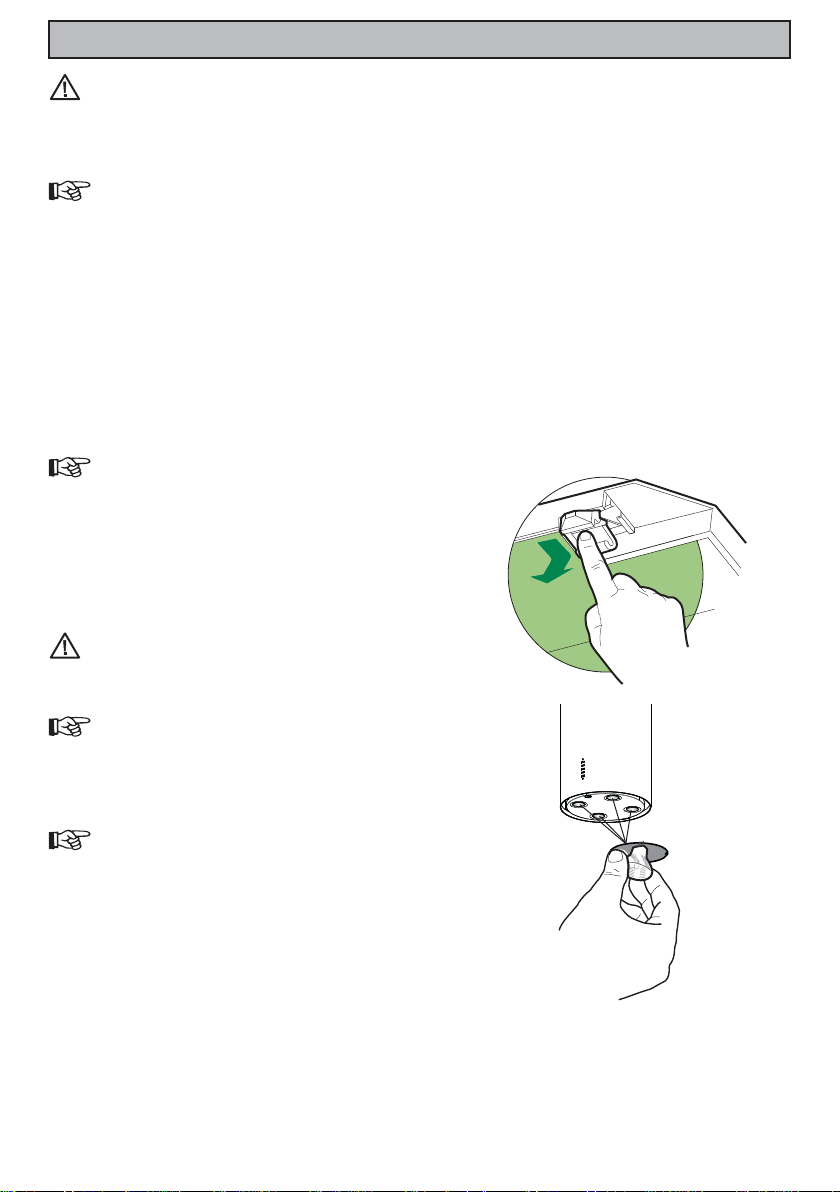

• Open the lighting unit by pulling on the notch.

• Releasing the catches on the fi lters, the fi lters can

be removed.

The metal grease fi lters should be washed, by

hand, in mild soapy water or in a dishwasher. Allow

to dry completely before replacing.

Alarm signal reset

Switch off the lights and extractor motor.

Press Button T3 for at least 3 seconds, until

the leds start to fl ash.

GB 7

MAINTENANCE AND CLEANING

Before carrying out any maintenance or cleaning isolate the cooker hood from the mains supply.

Charcoal Filters

In the recirculation mode the charcoal fi lters absorb smells and unwanted odours.

Enabling the alarm signal

• In Recirculation version Hoods, the Filter saturation alarm can be enabled on installation or at a later date.

• Turn the Lights and the suction Motor off.

• Disconnect the Hood using the Main switch or the double-pole switch on the mains power supply.

• Restore the connection by pressing and holding T1.

• Release the button. All fi ve LEDs are turned on

• Within 3 seconds press T1 until LEDs T1 and T4 fl ash in confi rmation:

• LED fl ashes twice - Activated charcoal fi lter saturation alarm ENABLED

• LED fl ashes once - Activated charcoal fi lter saturation alarm DISABLED

The fi lter is not washable and cannot be regenerated. It must be replaced when led S1 fl ashes or at least every

4 months. The alarm signal will only light up when the extractor motor is switched on.

To Remove/Replace the Charcoal Filters

• Open the lighting unit by pulling on the notch.

• Remove the metal grease fi lters

• Remove the saturated activated carbon fi lter by

releasing the fi xing hooks

• Fit the new fi lter by hooking it into its seating

• Replace the metal grease fi lters.

This appliance can be a possible fi re

hazard if the grease and charcoal fi lters

are not cleaned and replaced as recommended.

Alarm signal reset

• Switch off the lights and extractor motor.

• Press button T3 for at least 3 seconds, until the

leds start to fl ash.

Changing the halogen light

• Remove the halogen lamp from the lamp holder by

pulling gently.

• Replace the lamp with a new one of the same type,

making sure that you insert the two pins properly

into the housings on the lamp holder.

Replacement fi lters and halogen light can be obtained from your local Service Force Centre.

GB 8

SOMETHING NOT WORKING

If, having followed these instructions carefully, your cooker hood fails to work properly please carry out

the following checks.

Symptom

The cooker hood will not start

The cooker hood is not working effectively

The cooker hood has switched off during opera-

tion

If after all these checks, the fault persists, contact your

local Service Force Centre, quoting the model and

serial number.

Please note that it will be necessary to provide proof of

purchase for any in-guarantee service calls.

Solution

• Check the hood is connected to the electricity

supply.

• Make sure the switch is in the ‘ON’ position.

• The fan speed is set high enough for the task

• The grease fi lter is clean.

• The kitchen is adequately vented to allow the

entry of fresh air.

• If set up for recirculation, check that the charcoal

fi lter is still effective.

• If set up for extraction, check that the ducting and

outlets are not blocked.

• The safety cut-out device has been tripped.

• Tum off the hob and then wait for the device to

reset.

In-guarantee customers should ensure that the

above checks have been made as the engineer will

make a charge if the fault is not a mechanical or

electrical breakdown.

GB 9

GUARANTEE / CUSTOMER SERVICE

Standard guarantee conditions

We, Electrolux, undertake that if within

12 months of the date of the purchase

this Electrolux appliance or any part thereof is proved

to be defective by reason only of faulty workmanship

or materials, we will, at our option repair or replace

the same FREE OF CHARGE for labour, materials or

carriage on condition that:

• The appliance has been correctly installed and used

only on the electricity supply stated on the rating

plate.

• The appliance has been used for normal domestic

purposes only, and in accordance with the manufacturer’s instructions.

• The appliance has not been serviced, maintained,

repaired, taken apart or tampered with by any person

not authorised by us.

• Electrolux Service Force Centre must undertake all

service work under this guarantee

• Any appliance or defective part replaced shall become

the Company’s property.

• This guarantee is in addition to your statutory and

other legal rights.

Exclusions

• Damage or calls resulting from transportation, improper use or neglect, the replacement of any light

bulbs or removable parts of glass or plastic.

• Costs incurred for calls to put right an appliance

which is improperly installed or calls to appliances

outside the United Kingdom.

• Appliances found to be in use within a commercial

environment, plus those which are subject to rental

agreements.

• Products of Electrolux manufacturer that are not

marketed by Electrolux

0870 5 929 929

Your telephone call will be automatically routed to the

Service Force Centre covering your postcode area.

For the address of your local Service Force Centre

and further information about Service Force, please

visit the website at

www.serviceforce.co.uk

Before calling out an engineer, please ensure you

have read the details under the heading “Something

not working”

When you contact the Service Force Centre you will

need to give the following details:

1. Your name, address and postcode.

2. Your telephone number.

3. Clear concise details of the fault.

4. The model and Serial number of the

5. The purchase date.

Please note a valid purchase receipt or

guarantee documentation is required for in guarantee

service calls.

appliance (found on the rating plate).

Service and Spare Parts

In the event of your appliance requiring

service, or if you wish to purchase spare parts, please

contact your local Service

Force Centre by telephoning

GB 10

GUARANTEE CONDITIONS

Customer Care

For general enquiries concerning your

Electrolux appliance, or for further information on

Electrolux products please contact our Customer Care

Department by letter or telephone at the address below

or visit our website at www.electrolux.co.uk

Customer Care Department

Electrolux Major Appliances

Addington Way

Luton

Bedfordshire, LU4 9QQ

Tel: 08705 950 950 (*)

(*) Calls may be recorded for training

purposes

European Guarantee

This appliance is guaranteed by Electrolux in each of

the countries listed at the back of this user manual,

for the period specifi ed in the appliance guarantee

or otherwise by law. If you move from one of these

countries to another of the countries listed below the

appliance guarantee will move with you subject to the

following qualifi cations:-

• The appliance guarantee starts from the date you

• The appliance guarantee is for the same period

• The appliance guarantee is personal to the ori-

• The appliance is installed and used in accordance

• The appliance is installed in accordance with all

fi rst purchased the appliance which will be evidenced by production of a valid purchase document

issued by the seller of the appliance.

and to the same extent for labour and parts as

exists in your new country of residence for this

particular model or range of appliances.

ginal purchaser of the appliance and cannot be

transferred to another user.

with instructions issued by Electrolux and is only

used within the home, i.e. is not used for commercial purposes.

relevant regulations in force within your new country

of residence.

The provisions of this European Guarantee do not

affect any of the rights granted to you by law.

GB 11

www.electrolux.com

à

Albania +35 5 4 261 450 Rr. Pjeter Bogdani Nr. 7 Tirane

Belgique/België/Belgien +32 2 363 04 44 Bergensesteenweg 719, 1502 Lembeek

Česká republika +420 2 61 12 61 12 Budějovická 3, Praha 4, 140 21

Danmark +45 70 11 74 00 Sjællandsgade 2, 7000 Fredericia

Deutschland +49 180 32 26 622 Muggenhofer Str. 135, 90429 Nürnberg

Eesti +37 2 66 50 030 Mustamäe tee 24, 10621 Tallinn

España +34 902 11 63 88 Carretera M-300, Km. 29,900 Alcalá de Henares Madrid

France www.electrolux.fr

Great Britain +44 8705 929 929 Addington Way, Luton, Bedfordshire LU4 9QQ

Hellas +30 23 10 56 19 70 4, Limnou Str., 54627 Thessaloniki

Hrvatska +385 1 63 23 338 Slavonska avenija 3, 10000 Zagreb

Ireland +353 1 40 90 753 Long Mile Road Dublin 12

Italia +39 (0) 434 558500 C.so Lino Zanussi, 26 - 33080 Porcia (PN)

Latvija +37 17 84 59 34 Kr. Barona iela 130/2, LV-1012, Riga

Lietuva +370 5 2780609 Verkių 29, LT-09108 Vilnius

Luxembourg +35 2 42 43 13 01 Rue de Bitbourg, 7, L-1273 Hamm

Magyarország +36 1 252 1773 H-1142 Budapest XIV, Erzsébet királyné útja 87

Nederland +31 17 24 68 300 Vennootsweg 1, 2404 CG - Alphen aan den Rijn

Norge +47 81 5 30 222 Risløkkvn. 2 , 0508 Oslo

Österreich +43 18 66 400 Herziggasse 9, 1230 Wien

Polska +48 22 43 47 300 ul. Kolejowa 5/7, Warsaw

Portugal +35 12 14 40 39 39

Romania +40 21 451 20 30 Str. Garii Progresului 2, S4, 040671 RO

Schweiz - Suisse - Svizzera +41 62 88 99 111 Industriestrasse 10, CH-5506 Mägenwil

Slovenija +38 61 24 25 731 Tržaška 132, 1000 Ljubljana

Slovensko +421 2 43 33 43 22

Suomi +35 8 26 22 33 00 Konepajanranta 4, 28100 Pori

Sverige +46 (0)771 76 76 76

Türkiye +90 21 22 93 10 25 Tarlabaşı caddesi no : 35 Taksim İstanbul

Россия +7 095 937 7837

Quinta da Fonte - Edifi cio Gonçalves Zarco - Q 35 -2774-

518 Paço de Arcos

Electrolux Slovakia s.r.o., Electrolux Domáce spotrebiče SK,

Seberíniho 1, 821 03 Bratislava

Electrolux Service, S:t Göransgatan 143, S-105 45 Stockholm

129090 Москва, Олимпийский проспект, 16, БЦ

“Олимпик”

GB 12

INSTALLATION INSTRUCTIONS

It is dangerous to alter the specifi cations or attempt to modify this product in any way.

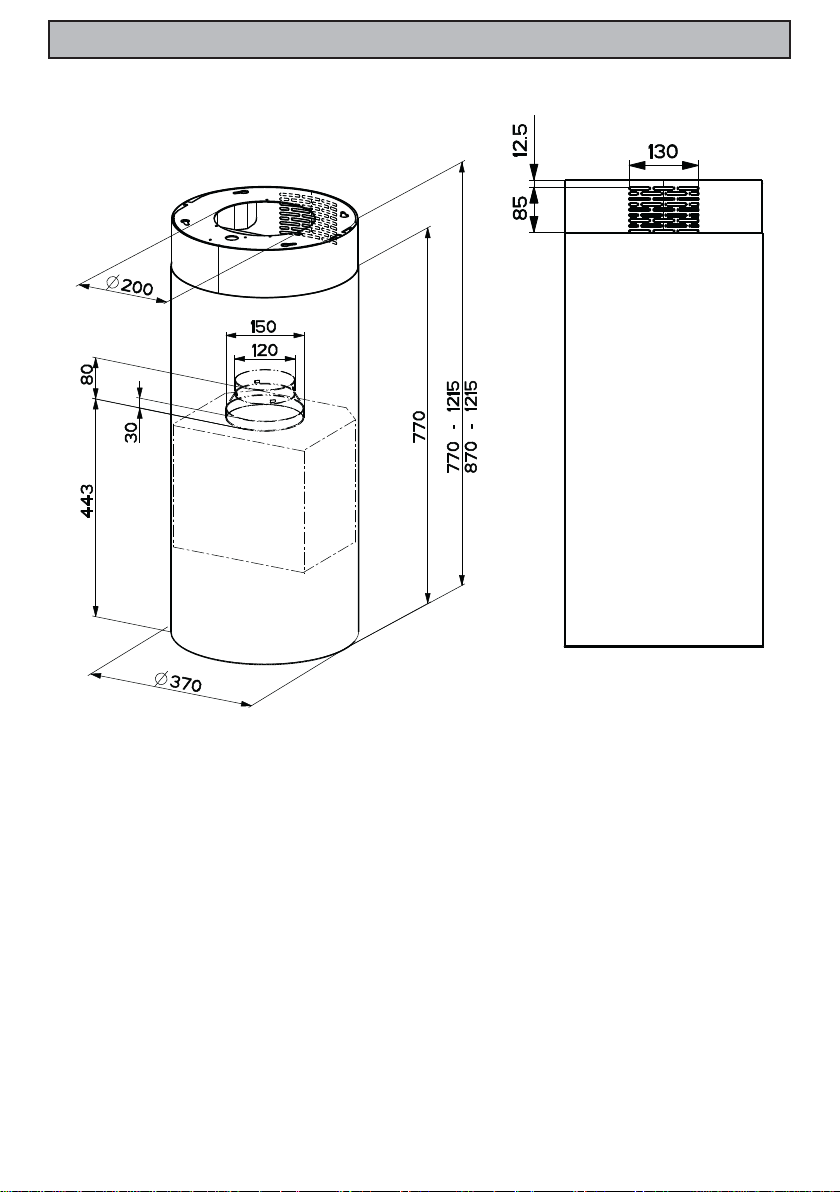

Technical Information

DIMENSIONS HEIGHT OF CANOPY: 935 mm

HEIGHT OF CHIMNEY: (UPPER SECTION) 290 mm

(LOWER SECTION) 935 mm

WIDTH OF CANOPY : 370 mm

DEPTH OF CANOPY: 370 mm

ELECTRICAL SUPPLY: VOLTAGE: 220-240 V 50Hz

POWER CONSUMPTION: 410 W

FAN MOTOR: 330 W

LAMPS : (4 x 20 W) 80 W

Note: CE Marking certifi es that this appliance complies with the requirements

laid down in EEC directive 89:336. (Electromagnetic compatibility) and

subsequent modifi cations and Low Voltage directive 72/23/E.

The symbol on the product or on its packaging indicates that this product may not be treated as household waste. Instead it shall be handed

over to the applicable collection point for the recycling of electrical and electronic equipment. By ensuring this product is disposed of correctly,

you will help prevent potential negative consequences for the environment and human health, which could otherwise be caused by inappropriate

waste handling of this product. For more detailed information about recycling of this product, please contact your local city offi ce, your household

waste disposal service or the shop where you purchased the product.

ELECTRICAL CONNECTIONS

THIS APPLIANCE MUST BE EARTHED

Electrical Requirements

Any permanent electrical installation must comply with

the latest I.E.E. Regulations and local Electricity Board

regulations. For your own safety this should be undertaken by a qualifi ed electrician e.g. your local Electricity

Board, or a contractor who is on the roll of the National

Inspection Council for Electrical Installation Contracting

(NICEIC).

Electrical Connection

Before connecting to the mains supply ensure that the

mains voltage corresponds to the voltage on the rating

plate inside the cooker hood.

GB 13

This appliance is fi tted with a 3 core mains cable and

must be permanently connected to the electricity supply

via a double-pole switch having 3mm minimum contact

gap on each pole. A Switched Fuse Connection Unit to

BS1363 Part 4, fi tted with a 3 Amp fuse, is a recom-

mended mains supply connection accessory to ensure

compliance with the Safety Requirements applicable to

fi xed wiring instructions.

This appliance conforms to BS 800: 1988 and EEC

Directive No. 78 308 regarding suppression of radio and

television interference.

INSTALLING THE COOKER HOOD

Please ensure that when the appliance is installed it is easily accessible to an engineer in the event of a

breakdown.

All installations must comply with the local authorities requirements for the discharge of exhaust air.

Incorrect installation may affect the safety of this cooker hood.

Installation Requirements

Before installation check the wall to which the cooker hood is to be fi tted for electric cables, water pipes or

gas.

This cooker hood is designed to be fi xed to any orizontal surface over a cooking area, and can be used in the

extraction (ducted to the outside) or recirculation mode.

The installation work must be undertaken by a qualifi ed and competent person.

The manufacturer disclaims any responsibility for damage due to incorrect installation of the cooker hood or if the

hood is not installed in compliance with relevant regulations controlling this type of installation.

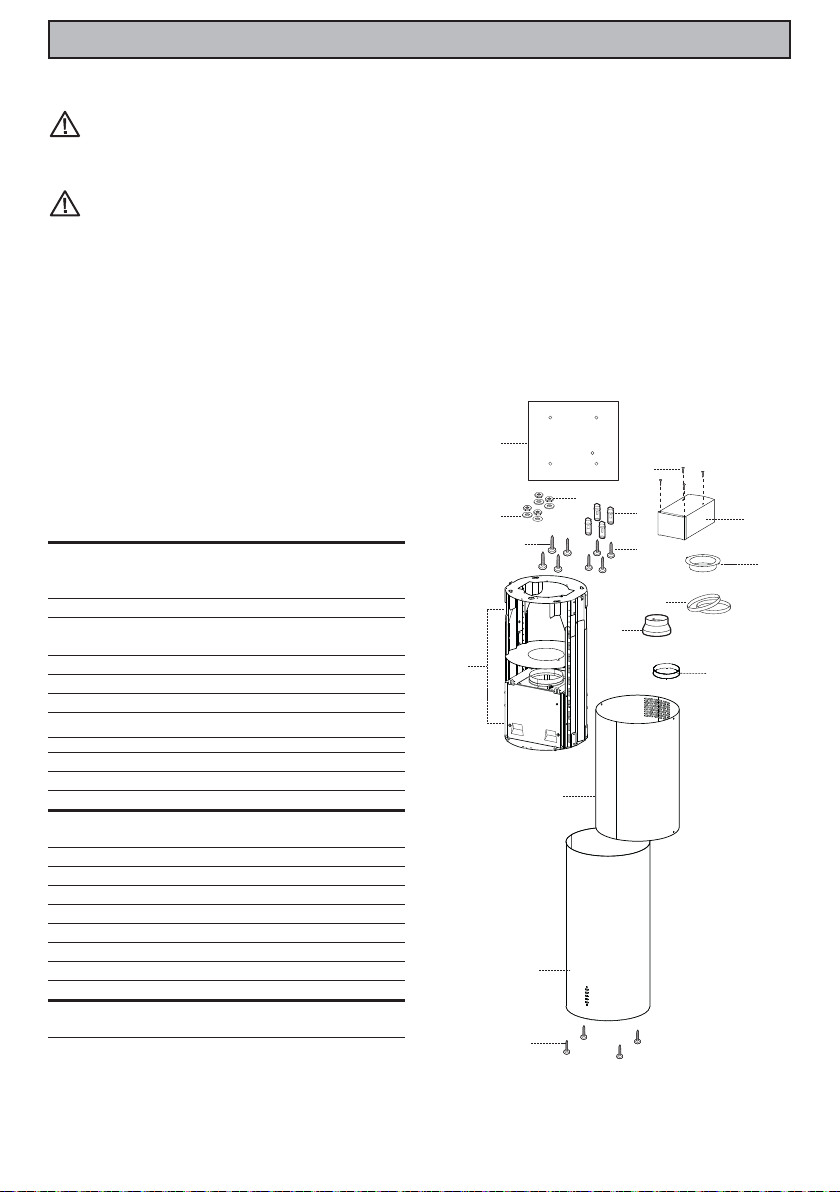

Unpacking

Before unpacking the cooker hood position the carton

with the arrows pointing upwards as illustrated on the

carton.

The cooker hood is made up of the following components:

Components

Ref. Q.ty Product Components

1 1 Hood Body, complete with: Controls, Light, Blower,

2 1 Chimney Upper

7.1 1 Telescopic frame complete with extractor, consisting

7.1a 1 Upper frame

7.1b 1 Lower frame

9 1 Reducer Flange ø 150-120 mm

9a 1

10 1 Flange ø 120 mm

15 1 Recirculation Air Outlet Connection

25 2 Pipe clamps

Filters

of:

Ø120-125mm collar

7.1a

7.1

7.1b

21

12c

22

23

12g

2

12h

11

25

9

15

10

9a

Ref. Q.ty Installation Components

11 4 Wall Plugs ø 10

12c 4 Screws 2,9 x 6,5

12f 4 Screws M6 x 10

12g 4 Screws M6 x 80

12h 4 Screws 5,2 x 70

21 1 Drilling template

22 4 6.4 mm int. dia washers

23 4 M6 nuts

1

Q.ty Documentation

1 Instruction Manual

12f

GB 14

INSTALLING THE COOKER HOOD

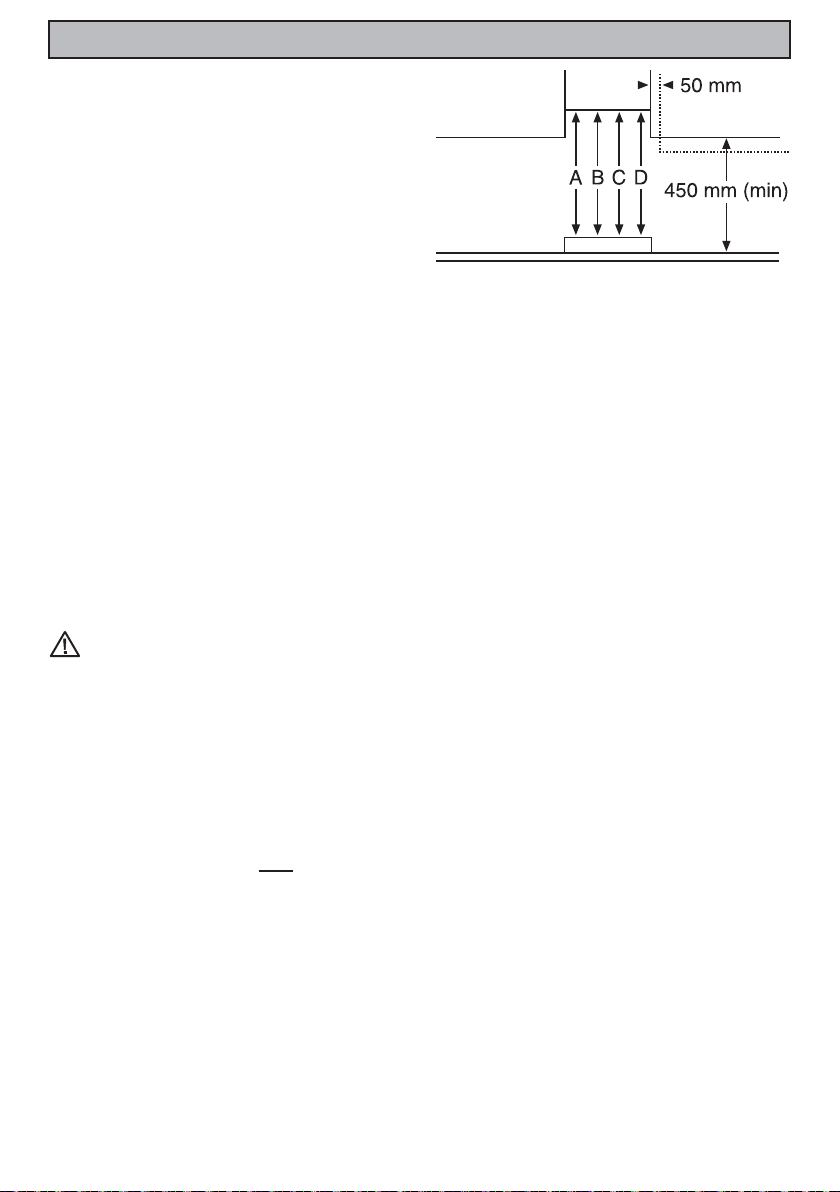

Clearance Height

The cooker hood is designed to be fi tted over a cook-

ing appliance at the clearance heights stated, providing

the maximum output of the appliance beneath does not

exceed the maximums quoted in the Technical Specifi cations.

If the output of the appliance below the cooker hood

exceeds the maximum outputs quoted, please refer to

the cooker manufacturer’s installation instructions.

A clearance height of 650mm (25 1/2 ”) is required when

installed above a built-in electric hob, or 700mm

when installed above a built-in gas hob.

A clearance height of 685mm (27”) is required when

installed above a slot-in electric cooker, or 787mm

(30 1/2 ”) when installed above a slot-in gas cooker.

When installed between adjoining wall cabinets, the wall

cabinets must not overhang the hob and the distance

between the underside of the cabinet and the worktop

must be 450mm. If the height of the wall cabinet is

less than 450mm, a gap of 50mm must be maintained

either side of the hob.

This cooker hood must not be installed above a

cooking appliance with a high level grill.

The hood can be installed above these heights but

for optimum performance it should be installed at the

distances quoted for the appropriate heat source.

This appliance can be used in either extraction mode

(ducting) or recycling mode (fi ltering).

The hood is supplied suitable for recirculation with the

charcoal fi lters fi tted.

When used in the extraction mode (ducting) the charcoal fi lters are not required and must be removed and

destroyed.

(27 1/2”)

A: Built-in Electric Hob: 650mm clearance

B: Built-in Gas hob: 700mm clearance

C: Slot-in Electric Cooker: 685mm clearance

D: Slot-in Gas Cooker: 787mm clearance

Hob

GB 15

INSTALLING THE COOKER HOOD

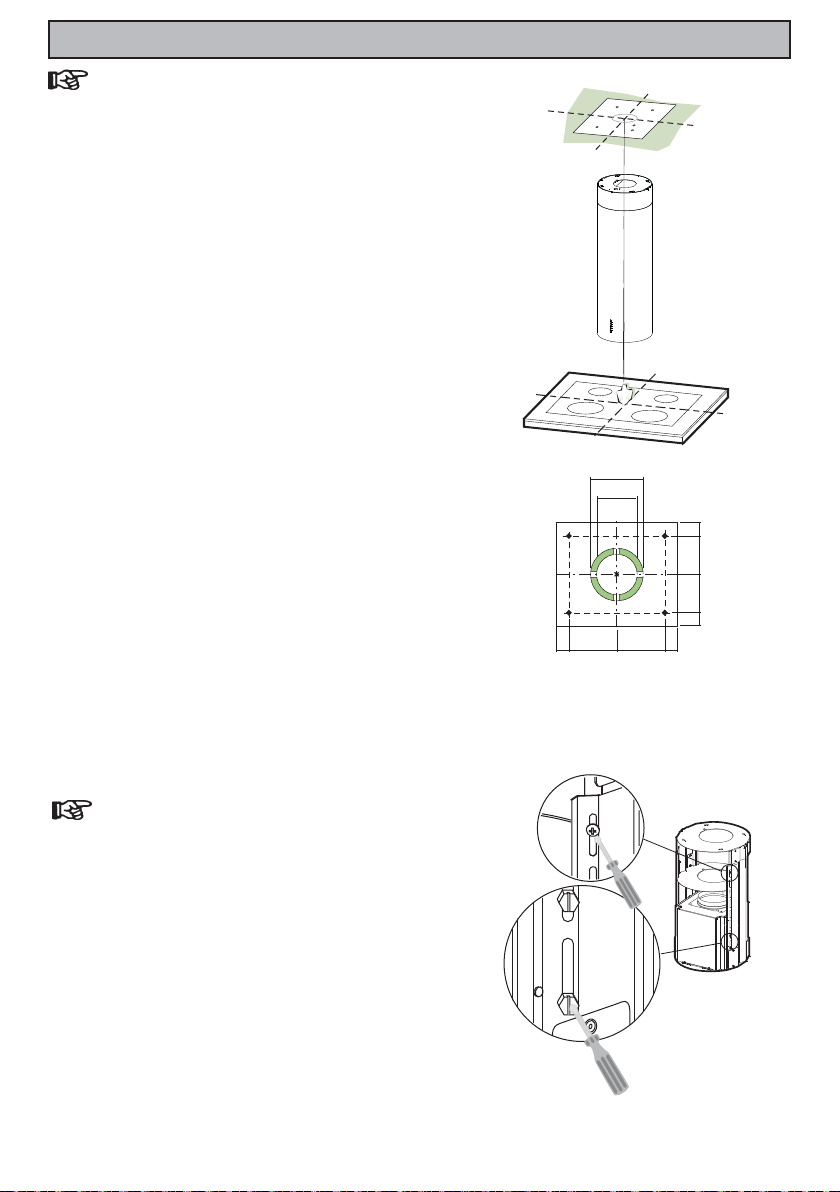

Drilling the Ceiling/Support

Shelf

• Use a plumb line to mark the centre of the hob on

the ceiling/support shelf.

• Place the drilling template 21 provided on the ceiling/

support shelf, making sure that the template is in the

correct position by lining up the axes of the template

with those of the hob.

• Mark the centres of the holes in the template.

• Drill the holes at the points marked:

• For concrete ceilings, drill for plugs appropriate to

the screw size.

• For hollow brick ceilings with wall thickness of 20

mm: drill ø 10 mm (immediately insert the Dowels

not provided).

• For wooden beam ceilings, drill according to the

wood screws used.

• For wooden shelf, drill ø 7 mm.

• For the power supply cable feed, drill ø 10 mm.

• For the air outlet (Ducted Version), drill according

to the diameter of the external air exhaust duct

connection.

• Insert two screws of the following type, crossing them

and leaving 4-5 mm from the ceiling:

• For concrete ceilings, use the appropriate plugs

for the screw size (not provided).

• For Cavity ceiling with inner space, with wall thi-

ckness of approx. 20 mm, Screws not provided.

• For wooden beam ceilings, use 4 wood screws

(not provided).

• For wooden shelf, use 4 screws with washers and

nuts (not provided).

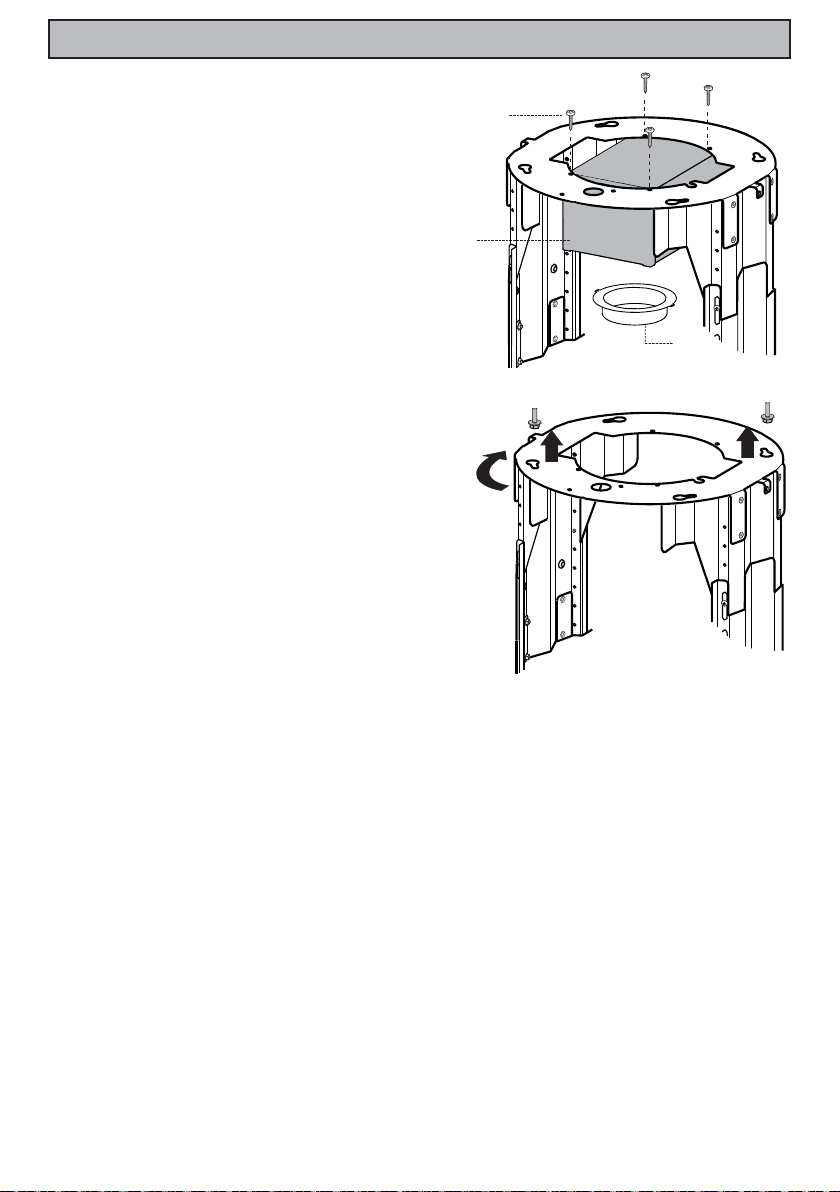

Fixing the Frame

A

In case the hood is used in recycling version it is

necessary to prepare the frame with all the necessary

connection pieces. In order to make the installation

easier it is necessary to lengthen the frame:

• Unscrew the two screws 2.1 fi xing the upper chimney

to the frame and pull the chimney out.

• Unscrew the four safety screws placed at the top in

the frame separation area. (A).

• Unscrew the eight metric screws connecting the two

columns, placed on both sides of the frame (B).

GB 16

B

INSTALLING THE COOKER HOOD

Installation of components in recycling version:

• Fix the recycling air outlet piece 15 to the upper part

of the frame using four 12c screws supplied with the

hood.

• Fix the fl ange (ø120) 10 to the lower part of the recycling

air outlet 15.

• Put the reducer fl ange 9 on the hood body outlet.

• At this point, join the fl anges with a pipe. In order to

calculate the height of the pipe it is necessary to estimate

the height of the hood (mm) and subtract 615 mm. (H

pipe = H hood-615).

• Lengthen the frame so that the pipe can be inserted.

Place the pipe between the two fl anges and block it. Make

sure that the height of the frame is correct considering

the height of the cooker hood (H frame = H hood – 184).

Adjust the height of the frame and tighten again the earlier

removed screws. Tighten again the safety screws in order

to give more stability to the structure.

• Fix the pipe with the pipe clamps 25 supplied with the

hood.

• Lift the frame up, making sure that the index over the

frame plate is turned backwards.

• Fit the frame slots onto the two screws inserted in the

ceiling as above, and turn until reaching the centre of

the adjustment slot.

• Tighten the two screws and fasten the other two screws

provided; before locking the screws completely, it is

possible to adjust the frame by turning it, making sure

that the screws do not come out of their housing in the

adjustment slot.

• The Frame must be securely fastened so as to support both the weight of the Hood and the stress

caused by occasional axial pressure against the fi tted Appliance. After fi xing, make sure that the base

is stable even when the Frame is subjected to lateral stress.

• If the Ceiling is not strong enough in the area where the hood is to be fi xed, the Installer must strengthen

the area using suitable plates and counterplates anchored to resistant structures.

Extraction

The cooker hood is more effective when used in the extraction mode (ducted to the outside).

Venting kits may be purchased through your retailer or DIY store, and must be ducted to an outside vent

of Ø125mm (5”) or Ø150mm (6”).

For the best performance use the shortest possible duct run and the minimum number of bends.

Where fl exible ducting is fi tted it should not be turned through very tight bends as this may impair the perform-

ance of the hood.

It is recommended a maximum length of 3 metres with one bend, to be installed, to be reduced metre for each

90o bend.

If a distance is greater than 3 metres the effi ciency of the hood could be impaired.

The ducting used must be manufactured from fi re retardent material conforming to the relevant British Standard

or DIN 4102-B1.

When the cooker hood is ducted to the outside the charcoal fi lter must be removed.

15

2

12c

10

1

1

GB 17

INSTALLING THE COOKER HOOD

Ducting Connection

Connect the ducting chosen to:

• the Ø150mm ducting spigot on top of the motor

housing, or the Ø150-120mm ducting spigot item 9

and secure using the jubilee clips item 25.

• A Ø120-125mm collar item 9a is provided to fi t over

the Ø120mm ducting spigot when 125mm ducting is

fi tted.

If the room where the cooker hood is to be used

contains a fuel burning appliance such as a central

heating boiler, then its fl ue must be of the room

sealed or balanced fl ue type.

If other types of fl ue or appliances are fi tted sure

that there is an adequate supply of air to the

room.

The cooker ducting (extraction mode) must never

be connected to central heating fl ues, radiators or

water heaters etc.

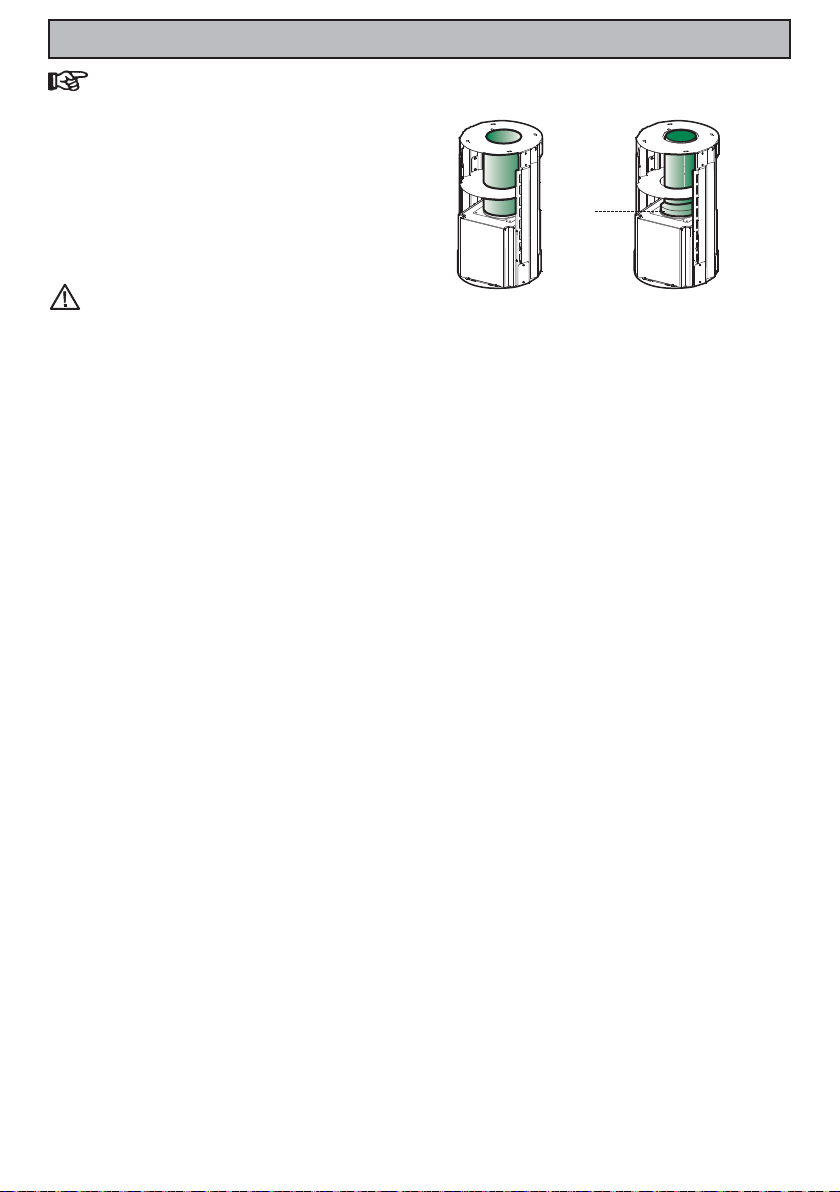

Recirculation

The cooker hood is supplied specifi ed for use in the

recirculation mode, with the charcoal fi lter fi tted.

In the recirculation mode contaminated air is passed

through the charcoal fi lter to be purifi ed and recirculated

into the kitchen through the grille outlets on either side

of the chimney.

9 + 9a

ø 125ø 150

Recirculation Connection

• Insert reducer fl ange 9 on the extractor outlet.

• Push fi t connector 15 onto the reducer fl ange.

• Insert extension piece 14.2 sideways into connector

15 making sure that the outlet corresponds with the

mouth of the chimney

GB 18

INSTALLING THE COOKER HOOD

Chimney Stack

The chimney consists of two sections.

The lower chimney measures (with the Hood body and

recirculation grilles) 935 mm and the upper chimney

measures 290 mm. The overall installed measurement

is min. 935 - max 1215 mm.

Fitting the Upper Chimney and

the Hood Body

When the hood is installed in recycling version the

chimney has to be positioned with the slots upwards.

When the hood is installed in ducting version it has to

be positioned in the opposite way.

• Place the chimney on the frame and fi x it to the

upper part of it with the earlier removed screws.

When installing the hood in recycling version make

sure that the slots correspond to the air outlet of the

recycling air outlet piece 15.

• Open the lighting unit by slightly pulling the notch.

Remove the unit from the hood by sliding the fi xing

pivot.

• Remove the fi lter pushing it towards the back side of

the hood unit and simultaneously pulling downwards.

• Remove possible charcoal fi lters.

• In order to fi x the hood body to the frame insert the

4 screws 12f in their seats. It is necessary to leave

at least 4-5 mm gap between the screw heads and

the frame plate.

• Hook the hood canopy to the frame and turn it to

the left until it reaches the stop, then lock the screws

immediately to prevent the hood canopy from falling

out accidentally.

1

2

Electrical Connection

• Ensure that the supply cable connector is properly

inserted into the Suction device socket

• Hook up the Commands connector Cmd.

• Hook up the Spotlights connector Lux to the socket

provided behind the lighting unit cover.

• For the recirculation version, fi t the activated carbon

odour fi lter.

• Replace the grease fi lters.

• Replace the lighting unit.

Lux

Cmd

GB 19

Gebruiksaanwijzing

INHOUDSOPGAVE

ADVIEZEN EN SUGGESTIES .................................................................................................................................................21

EIGENSCHAPPEN ..................................................................................................................................................................22

INSTALLATIE ...........................................................................................................................................................................24

GEBRUIK .................................................................................................................................................................................28

ONDERHOUD .........................................................................................................................................................................29

NL 20

Loading...

Loading...