Page 1

EINBAU-BACKOFEN MIT

DAMPFGARENRICHTUNG

FOUR À VAPEUR

STOOMOVEN

BUILT-IN STEAM OVEN

ZBS 862

GEBRAUCHSANLEITUNG

NOTICE D'UTILISATION

GEBRUIKSAANWIJZING

INSTRUCTION BOOKLET

Page 2

ENGLISH

Warning

☛

These warnings are provided in the interest of safety. You MUST read them carefully before

installing or using the appliance.

It is most important that this instruction book should be retained with the appliance for future

reference. Should the appliance be sold or transferred, always ensure that the book is left with

the appliance in order that the new owner can get to know the functions of the appliance and

the relevant warnings.

For Y our Safety

☛

During Operation

• This appliance has been designed to be operated by

adults and children under supervision. Young children

MUST NOT be allowed to tamper with the controls or

play near or with the oven.

• This appliance has been designed for cooking

edible foodstuff only and MUST NOT be used for any

other purposes.

• It is dangerous to alter the specification in any way.

• For hygiene and safety reasons, this appliance should

be kept clean at all times. A build-up of fats or other

foodstuff could result in a fire.

• Accessible parts of this appliance may become hot

when it is in use. Children should be KEPT AWAY until

it has cooled.

• Under no circumstances should you attempt to repair

the appliance yourself. Repairs carried out by

unexperienced persons may cause injury or serious

malfunctioning. Refer to your local Zanussi Service

Centre. Always insist on genuine Zanussi spare

parts.

• Ensure that all control knobs are in the OFF position

when not in use.

• Should you connect any electrical tool to a plug near

this cooking appliance, ensure that electric cables

are not in contact with it and keep them far enough

from the heated parts of this appliance.

• If the appliance is out of order, disconnect it from the

electric supply.

• Do not leave untensils containing foodstuffs, e. g. fat

or oil in or on the appliance. This could cause

damage in case the appliance is inadvertently

switched on.

MANUFACTURER:

ELECTROLUX ZANUSSI S.p.A.

Viale Bologna 298 - 47100 FORLI’ (Italia)

About Installation, Cleaning

and Manteinance

• It is mandatory that all operations required for the

installation are carried out by a qualified or competent

person, in accordance with existing rules and

regulations.

• Disconnect the appliance from the electrical supply,

before carrying out any cleaning or manteinance

work.

• Once you removed all packaging from the appliance,

ensure that it is not damaged and the electric cable

is in perfect conditions. Otherwise, contact your

dealer before proceeding with the installation.

• The manufacturer disclaims any responsability

should all the safety measures not be carried

out.

This appliance complies with the following

E.E.C. Directives:

- 73/23 - 90/683 (Low Voltage Directive);

- 89/336

- 93/68 (General Directives)

and subsequent modifications.

OVEN DOOR PROTECTION DEVICE

All our appliances comply with the European Safety

Standards. Nevertheless, in order to ensure the

highest safety level, and avoid little children to be

exposed to the heat when the appliance is operated,

it is possible to fit a special protection device to the

oven door. This device can be purchased in our

Service Force Centres, specifying the relevant code

(35791) and the Product No. shown on the rating

plate. Fitting instructions are provided with the kit

package.

(Electromagnetical Compatibility Directive);

61

Page 3

Contents

For Your Safety .........................................61

Description of the appliance.....................63

Oven Control Knobs.................................64

Oven Function Control Knob............................. 64

Thermostat Control Knob..................................64

Thermostat Control Light ..................................64

End of cooking programmer.............................. 65

The Safety Thermostat...................................... 65

The Cooling Fan for the Controls......................65

When the oven is first installed.................66

Safety when cooking ................................66

Water tank pilot lamps..............................67

How to set the oven ready for a steam

cooking.....................................................67

Hints and tips about steam cooking .........68

Cooking with steam..................................68

Accessories for steam cooking ................69

Steam cooking chart ................................70

Technical Data..........................................78

Installation ................................................78

Building In ......................................................... 78

Securing the Oven to the Cabinet.....................79

Electric Connection ........................................... 79

Terminal block ................................................... 79

Traditional, fan and grill cookings .............71

Conventional cooking........................................ 71

The Fan Oven ...................................................71

Defrosting.......................................................... 71

Grilling...............................................................71

Hints and Tips on Cooking Fish and Meat ........71

Hints and Tips on baking...................................71

Hints and Tips on grilling................................... 71

Cooking charts (traditional and fan oven,

grill) ..........................................................72

Cleaning and maintenance ......................73

Cleaning the steam generator..................74

Cleaning the water tank .................................... 74

Cleaning the exhaust pipe.................................75

Using different water types................................75

What happens if something goes wrong..76

Guarantee ................................................77

Techical Assistance and Spare Parts.......77

62

Page 4

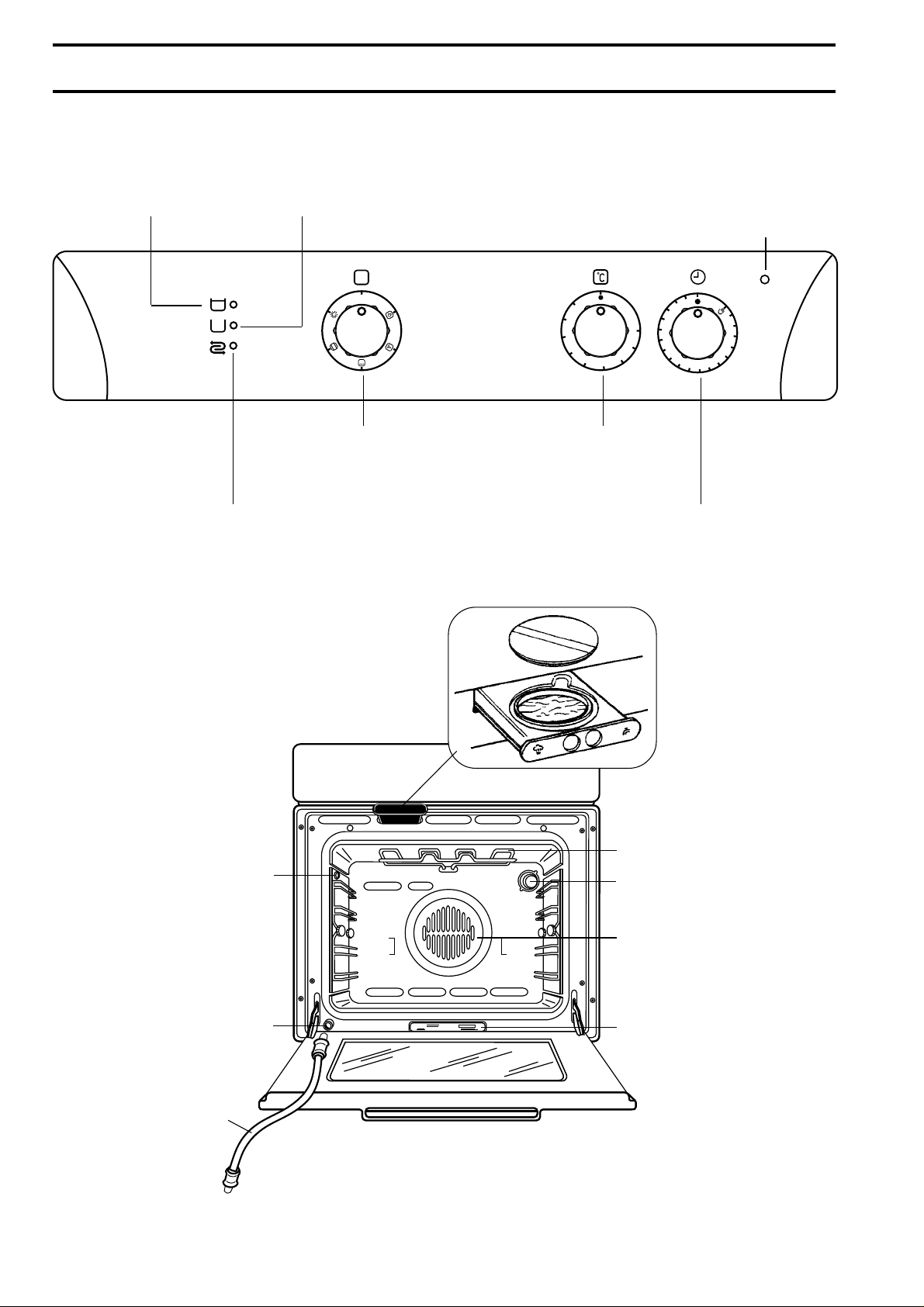

Description of the appliance

GREEN PILOT

LIGHT

(FULL TANK)

RED PILOT LIGHT

(CLEANING

RED PILOT LIGHT

(TANK OUT OF

WATER)

NEEDED)

0

COOKING

FUNCTION

CONTROL KNOB

50

100

MAX

200

150

THERMOSTAT

CONTROL KNOB

END OF COOKING

PROGRAMMER

THERMOSTAT

5

10

15

30

60

45

CONTROL

LIGHT

90

75

INJECTOR

WATER TANK

EXHAUST-VALVE

WATER TANK

EXHAUST-PIPE

WATER TANK

FEEDING

DRAWER

GRILLELEMENT

STEAM

OVEN LAMP

FAN

RATING

PLATE

63

Page 5

0

Oven Control Knobs

Your new steam oven allows you to cook your

favourite dishes without losing any nutrition property

and keeping their original taste.

You can choose both the traditional cooking systems

or the steam cooking system. To obtain the best

cooking results, it is necessary to get familiar with the

oven controls.

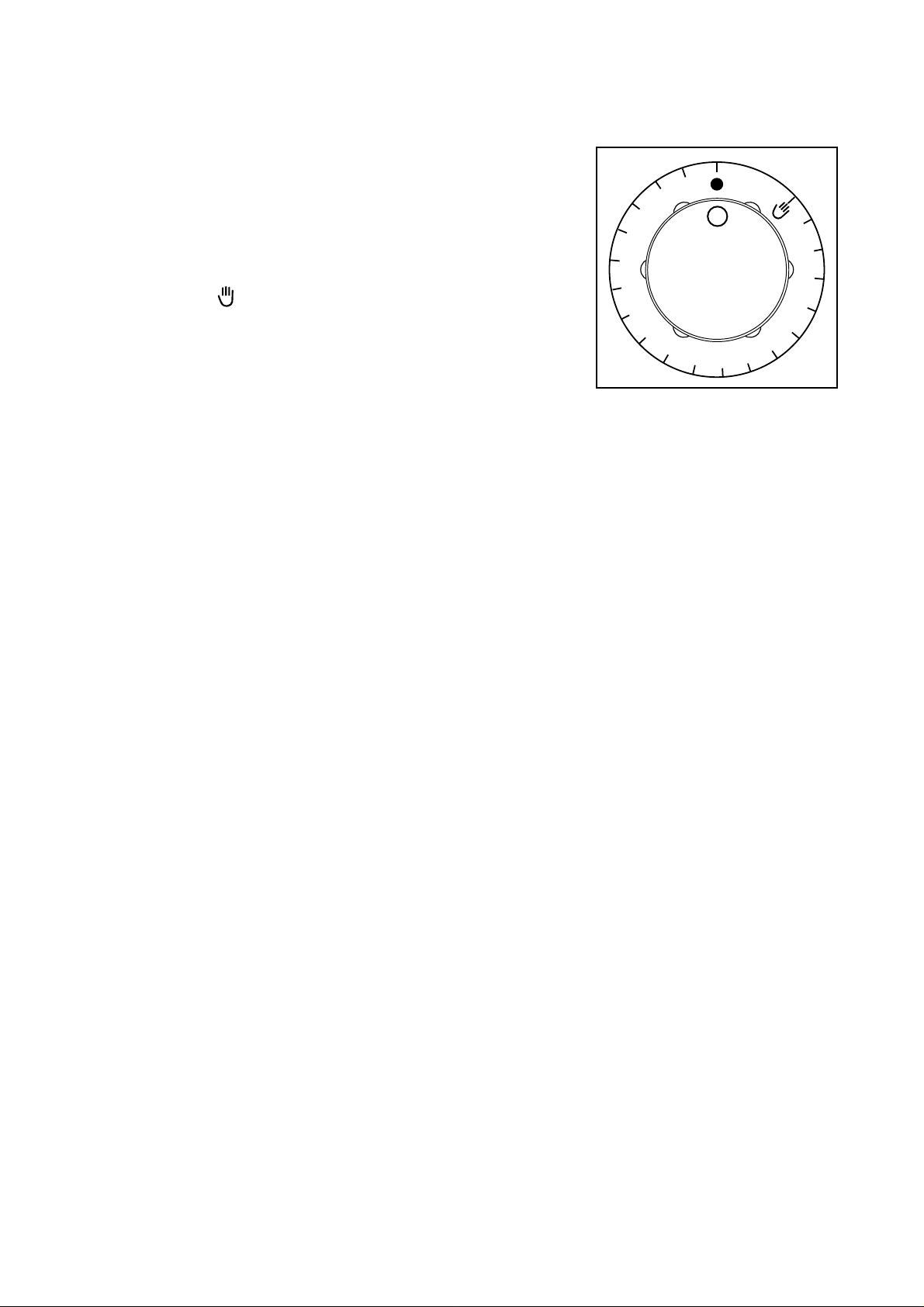

Oven Function Control Knob (Fig. 1)

Here you can find the symbols appearing on the Oven

Function Control Knob and their meaning.

Oven Light - The oven light will be on without any

cooking function

Conventional cooking - The heat comes from both

the top and bottom element, ensuring even

heating inside the oven.

Fan cooking - This allows you to roast or roast

and bake simoultaneously using any shelf,

without flavour transference.

Grill - The grill element will be on.

Steam cooking - The steam cooking function will

be on (see the following pages for the correct

use of this cooking function).

Fig. 1

You can choose the function you need by turning the

knob on the relevant symbol.

Thermostat Control Knob (Fig. 2)

By turning the oven control knob clockwise, you can

select cooking temperatures, from 50° C up to 250° C

(MAX).

Thermostat Control Light

Once the oven temperature has been selected, the

temperature light will come on and remain on until the

oven has reached the correct setting; after that, it will go

on and off with the thermostat, showing how the temperature is being maintained.

50

MAX

100

200

150

Fig. 2

64

Page 6

End of cooking programmer (Fig. 3)

This device allows you to make the oven switch off

automatically once the preset time is over. An acousitic

signal will be heard when the cooking is completed.

The cooking duration can be set up to 90 minutes

maximum.

Turn the timer knob on to set the oven on manual

operation.

Turn the timer knob clockwise to set the required

cooking time. Then place food in the oven and turn the

oven function control knob and the thermostat control

knob on the required settings. When the cooking time

is over, an acoustic alarm will sound and the oven will

switch off automatically.

The Safety Thermostat

This oven is provided with a safety thermostat. In case

of malfunctioning of the main thermostat, and consequent

over-heating, the safety device will stop the power

supply to the appliance. If this happens, call your local

Zanussi Service Centre. Under no circumstances should

you attempt to repair the appliance yourself.

Fig. 3

15

30

10

5

45

90

75

60

The Cooling Fan for the Controls

This oven is provided with a cooling fan, meant to keep

the front panel, the knobs and the oven door handle

cool. This fan may run on after the oven or grill is

switched off, until a normal temperature is reached.

65

Page 7

When the oven is first installed

Once the oven has been installed:

☞

a) set the thermostat knob to MAX;

b) switch the oven function control knob to

conventional cooking ( );

c) allow the oven to run empty for approximately

45 minutes;

d) open a window for ventilation.

During this time, an unpleasant odour may be emitted.

This is absolutely normal, and is caused by residues of

manufacturing.

Once this operation is carried out, let the oven cool

down, then clean the oven cavity with a soft cloth soaked

in warm soapy water.

Before cooking for the first time, carefully wash the shelf

and the dripping pan.

FO 2196

To open the oven door, always catch

the handle in its central part (Fig. 4).

Fig. 4

Safety when cooking

Always cook with the oven door

closed

• Always use oven gloves to remove and replace food

in the oven.

• The temperatures inside the oven can reach 250°C.

Always ensure that you are using oven proof baking

trays, oven dishes, etc.

• Do not place pans, biscuit pans or aluminium foil

directly on the base of the oven. This could cause a

heat build-up which could affect the performance of

the oven and damage the oven enamel.

• Carefully supervise cookings with fats or oil, since

these types of foodstuff can result in a fire, if overheated.

For the same reason, be careful when placing or

removing food in the oven, not to let any fat or oil fall

on the oven base. If this happens, carefully clean the

oven to avoid unpleasant smells or smoke.

66

Page 8

Water tank pilot lamps

0

Red pilot lamp (full water tank)

It indicates that the oven is ready to be used for a steam

cooking.

Red pilot lamp (tank out of water)

It indicates that the oven cannot be used for a steam

cooking and water should be poured into the water tank.

Cleaning cycle pilot lamp

It indicates that the water tank cleaning procedure sould

be carried out or that the steam injector is obstructed.

How to set the oven ready for a steam cooking

Before using the oven for a steam cooking, the

water tank must be filled.

To fill the water tank, open the oven door, pull out the

water tank drawer, unscrew the drawer cap and pour in

water using a graduated vessel, until the red pilot light

"FULL WATER TANK" comes on. Consider that not more

than one liter of water can be poured into the water tank.

Then refit the drawer cap and push in the water tank

drawer. Your oven is now ready for a steam cooking.

If too much water happens to be poured into

the water tank, the exceed water will flow into

the oven cavity through a safety opening.

Immediately wipe the oven cavity dry with a

sponge or a soft cloth (Fig. 6).

Fig. 5

Fig. 6

67

Page 9

Cooking with steam

☞

1 - Before any steam cooking, fill the water tank

as described in the previous chapter. One liter

of water allows about 1 hour of steam cooking.

2 - Place the food in suitable ovenproof pans or

pots and place them on the oven shelf (Fig. 7).

Set the shelf level according to the cooking

table. The second shelf level from the bottom

usually gives the best cooking results.

3 - Turn the oven function control knob on the

"STEAM COOKING" function (symbol ) .

4 -Turn the thermostat control knob on the

required temperature between 140° and

220°C. Consider that a temperature above

220°C will not give good cooking results.

Hints and tips about steam cooking

Fig. 7

● Don't cover the pans or pots. This would not

i

Steam can condense and produce water droplets

on the oven door glass. This is quite normal and

is not caused by fault of the oven. We recommend

you to wipe away condensation after all

cookings.

allow steam to come in contact with the food.

● You can also place food directly on the oven

shelf, as shown in Fig. 8. In that case, always

place the dripping pan at the lowest level, with

some water in it, to avoid smoke and

unpleasant smells.

● If you need to open the oven door and check

the food, always remember to switch off the

steam cooking function by turning the function

control knob on symbol . After having

checked it, turn back the function control knob

on symbol to make the steam function

operate again.

Fig. 8

68

Page 10

Accessories for steam cooking

A special accessory kit is available at your retailer's

shop. This is meant to allow a wider range of steam

cookings, especially for fish, vegetables, etc.

The accessory kit includes:

- a diet cooking double dish, provided with a special

mould to allow a steam injector to be fitted to the dish

(Fig. 9);

- a small shelf meant to be inserted inside the double

dish to prevent food to lay on the dish surface;

- two different steam injectors, to be used as shown in

figures 9 and 10 after being fitted to the exhaust pipe

which is supplied with the appliance.

The diet cooking double dish (Fig. 9) is particularly

recommended to cook vegetables, as it allows you to

keep their original taste and nutrition properties.

The direct steam cooking system (Fig. 10) will give

the best results with poultry. The long steam injector

provided with holes on its surface must be inserted

inside the joint and makes steam cook the internal

part, while the outside is gently browned by the

traditional heating elements. The injector holes must

not be covered: for this reason the injector must be

inserted into the empty cavity inside the joint, as

shown in Figure 10.

Fig. 9

Fig. 10

69

Page 11

Steam cooking chart

Weight

in

gr.

Cakes

Whipped up kneading

Leavened kneading

Creme caramel 2 150 40 ~ 60

Butter-milk cheese cake 2 150 40 ~ 60

Apple cake 2 175 30 ~ 45

Strudel 2 150 45 ~ 60

800 Mixed cooked fruit 2 150 30 ~ 40 Sliced

1000 Cooker apples - pears 2 175 45 ~ 60 Whole

500 White bread 2 200 45 ~ 65 2 pieces

500 Bread rolls 2 200 25 ~ 35 6 rolls

1200 Beef 2 175 60 ~ 90

1000 Pork 2 175 60 ~ 90

1000 Veal 2 175 60 ~ 90

1000 Mutton 1 o 2 175 120 ~ 150

800 Guinea-fowl 2 175 60 ~ 90 Whole

1200 Lamb 1 o 2 150 120 ~ 150

1200 Chicken 2 175 60 ~ 90 Whole

1000 Pigeons 2 175 60 ~ 80 3 pieces

800 Quails 2 175 40 ~ 60 6 pieces

1000 Boar 2 150 120 ~ 140 Chops

4000 Turkey 1 o 2 175 150 ~ 180 Whole

1500 Duck 2 150 90 ~ 120 Whole

3000 Goose 2 150 120 ~ 150 Whole

1200 Rabbitt 2 175 90 ~ 120 Chops

1000 Stockfish 2 150 35 ~ 45 Sliced

800 Sea-bream 2 175 30 ~ 40 2 fishes

1000 Hake 2 150 20 ~ 30 Filets

1000 Gilthead 2 175 30 ~ 40 Whole

1500 Salmon 2 175 30 ~ 40 Sliced

1000 Sole 2 175 20 ~ 30 Whole

1200 Tunny 2 175 Sliced

1500 Trout 2 150 30 ~ 45 4 fishes

1000 Squill 2 175 25 ~ 35 Whole

1000 Prawn 2 175 25 ~ 35 Whole

1200 Lobster 2 150 30 ~ 40 2 lobsters

1000 Tomatoes 2 200 20 ~ 30 Half cut

1000 Potatoes 2 175 30 ~ 40 Sliced

1000 Roasted potatoes 2 150 45 ~ 60 Sliced

1200

1500 Stuffed peppers 2 175 45 ~ 60 Half cut

1000 Courgettes 2 175 30 ~ 40 Half cut

1000 Fennels 2 150 45 ~ 60 Sliced

800 Cauliflower 2 175 35 ~ 45

800 Stuffed mushrooms 2 175 25 ~ 35 9 mushrooms

800 Onions 2 150 35 ~ 45

600 Celery 2 150 35 ~ 45 Chopped

Jam-tart 2 175 30 ~ 45

Small cakes 2 175 15 ~ 25 6 pieces

Bread and Pizza

Pizza 2 175 15 ~ 35

Flans

Pasta flan 2 175 30 ~ 40

Quiche 2 175 35 ~ 45

Lasagne 2 175 35 ~ 45

Vegetable flan 2 175 35 ~ 45

Meat

Fish

Vegetables

Aubergines

Food

Steam cooking

4

3

Level

2 150 30 ~ 45

2 160 30 ~ 45

2 175 30 ~ 45

temp.

2

1

°C

Cooking

duration

minutes

Notes

70

Page 12

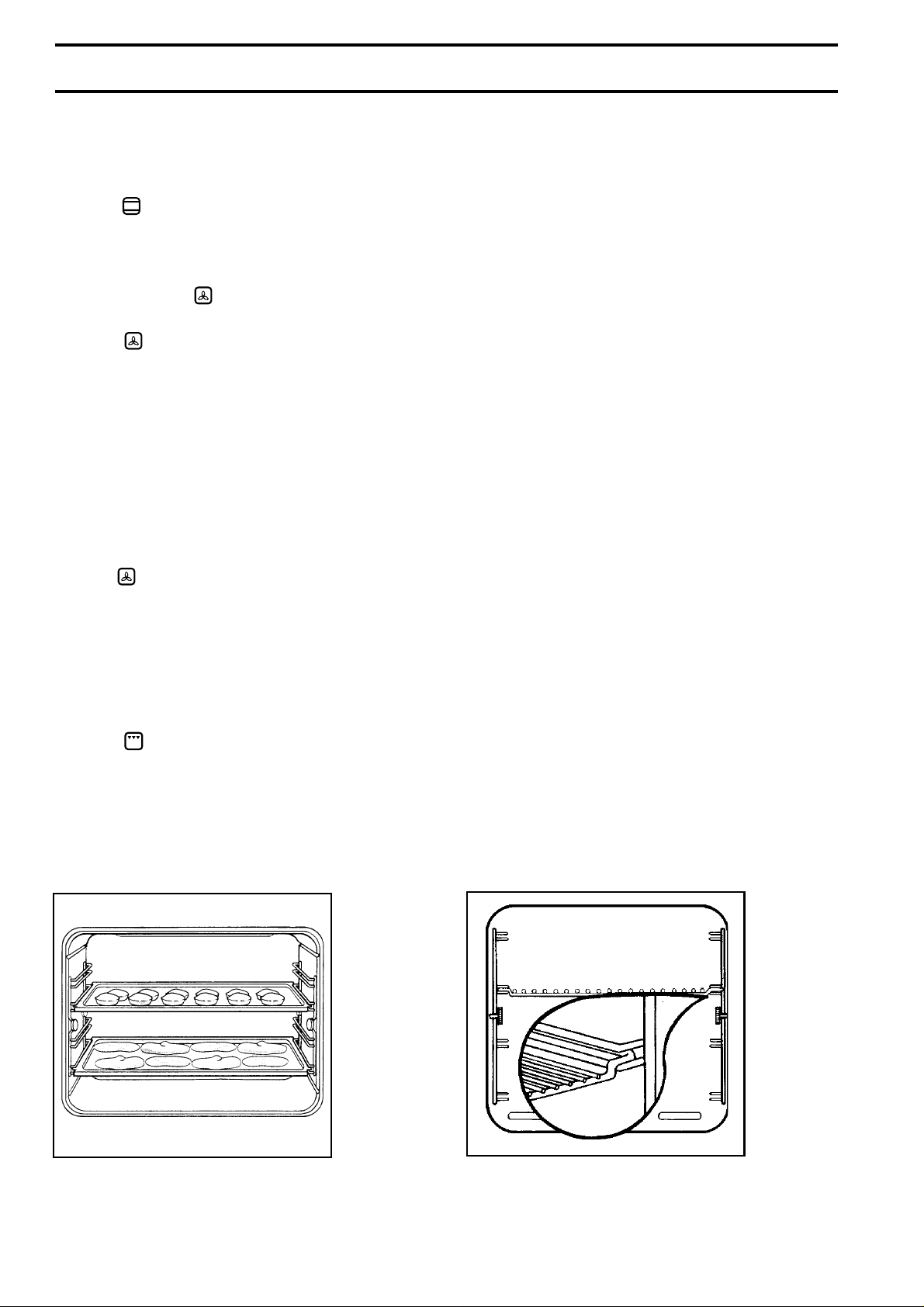

Traditional, fan and grill cookings

Conventional cooking

Turn the oven function control knob to the relevant

symbol ( ) and set the thermostat knob on the

required temperature.

If your dish need more heat from the top or from the

bottom adjust the shelf level as required (see Fig. 11).

The Fan Oven ( )

Turn the oven function control knob to the relevant

symbol ( ) and set the thermostat knob on the

required temperature.

The fan situated behind the back panel circulates heated

air into the oven.

If you need to cook more than one dish in the fan oven

at the same time, place the shelves on the first and third

position from the bottom (See Fig. 11).

If you are cooking only one dish in the fan oven, use the

lower positions, as this will give you better results.

Defrosting

Turn the oven function control knob to the relevant

symbol ( ) and set the thermostat knob on the OFF

position (symbol : ●).

The oven fan operates without heat and circulates the

air, at room temperature, inside the oven. This increases

the rate at which defrosting takes place.

Grilling

Turn the oven function control knob to the relevant

symbol ( ) and set the thermostat knob on the

required temperature.

Hints and Tips on Cooking Fish and Meat

You can place meat in oven proof dishes, or directly on

the oven shelf. In this case, remember to place the

dripping pan in the first position from the bottom (see

Fig. 7) with some water in it. The dripping pan will avoid

the falling of melted fat on the oven base.

White meat, poultry and fish in general, need a medium

temperature cooking (between 150 and 175 ° C). If you

need to cook red meat (slightly browned on the outside

and more gently cooked in the inside), a higher temperature (between 200 and 250 ° C) for a short time is

recommended.

Hints and Tips on baking

Cakes usually need a medium temperature cooking,

between 150 and 200 °C.

A short oven pre-heating (about 10 minutes) is

recommeded when cooking cakes or baking. Once the

cooking has been started, keep the oven door closed

during all the cooking time, and check the cooking

results through the oven door glass.

Hints and Tips on grilling

If you need to grill meat or fish, place them directly on the

shelf after spreading a little oil on them.

In the grill function, heat comes only from the top

element. Therefore, you need to adjust the cooking level

depending on meat or fish's thickness.

Always remember to place the dripping pan in the lower

position with some water in it.

Place the oven shelf as shown in Fig. 12.

FO 0285

Fig.11

Fig.12

71

Page 13

Cooking charts (traditional and fan oven, grill)

TRADITIONAL COOKING AND FAN DUCTED COOKING

WEIGHT

(GR.)

1000 White bread 1 200 2 175 45 ~ 60 1 piece

500 Rye bread 2 200 2 175 30 ~ 45 In bread pan

500 Bread rolls 2 200 2 (1 and 3)* 175 20 ~ 35 8 rolls

250 Pizza 1 220 2 (1 and 3)* 200 20 ~ 35 In baking pan

1000 Beef 2 200 2 175 50 ~ 70 On grid

1200 Pork 2 200 2 175 100 ~ 130 On grid

1000 Veal 2 200 2 175 90 ~ 120 On grid

1500

1200 Lamb 2 200 2 175 110 ~ 130 Leg

1000 Chicken 2 200 2 175 60 ~ 80 Whole

4000 Turkey 2 200 2 175 210 ~ 240 Whole

1500 Duck 2 175 2 160 120 ~ 150 Whole

3000 Goose 2 175 2 160 150 ~ 200 Whole

1200 Hare 2 200 2 175 60 ~ 80 Cut in pieces

1000 Whole 2 200 2 (1 and 3)* 175 40 ~ 60 2 fishes

800 Fillets 2 200 2 (1 and 3)* 175 30 ~ 40 4 fillets

TYPE OF DISH

Level

Cakes

Whipped up kneading

Leavened kneading

Shortbread dough

Butter-milk cheese cake 1 175 2 150 60 ~ 80

Apple cake 1 180 2 (1 and 3)* 160 40 ~ 60

Strudel 2 175 2 (1 and 3)* 150 60 ~ 80

Jam-tart 2 180 2 (1 and 3)* 160 45 ~ 60

Small cakes 2 180 2 (1 and 3)* 160 15 ~ 25

Biscuits 2 180 2 (1 and 3)* 160 10 ~ 20

Meringues 2 100 2 (1 and 3)* 100 90 ~ 120

Bread and Pizza

Flans

Pasta flan 2 200 2 (1 and 3)* 175 40 ~ 50

Vegetable flan 2 200 2 (1 and 3)* 175 45 ~ 60

Quiches 2 200 2 (1 and 3)* 175 35 ~ 45

Lasagne 2 200 2 175 45 ~ 60

Meat

English roast beef

Fish

4

3

temp.

2

1

2 180 2 (1 and 3)* 160 45 ~ 60

2 180 2 (1 and 3)* 160 20 ~ 35

2 180 2 (1 and 3)* 160 20 ~ 30

2 220 2 200 50 ~ 70 On grid

°C

Level

Fan OvenTraditional Cooking

4

3

temp.

2

1

°C

Cooking

time

minutes

NOTES

NOTE:

Cooking times do not include pre-heating time. We

reccomend a short oven pre-heating (about 10

minutes) before baking or cooking pizza.

GRILLING

Quantity

TYPE OF DISH

PIECES WEIGHT

Steaks

Chops

Sausages 8 500 4 max 10 6

Chicken (cut in pieces)

Kebabs 4 700 4 max 12 10

Chicken (breast) 4 400 4 max 13 10

Tomatoes 8 500 4 max 12 —

Fish (fillets) 4 400 4 max 8 6

Sandwiches 4 — 4 max 8 —

Toast 4 — 4 max 2~3 1

4 800 4 max 10 8

4 600 4 max 12 8

6 800 3 max 30 20

72

(*) If you need to cook more than one dish at the same

time, we recommend you to place them on the levels

quoted between brackets.

Cooking time

(minutes)

Upper

side

Lower

side

Level

Grilling

4

3

2

1

temp.

°C

Page 14

Cleaning and maintenance

General Cleaning

Before cleaning, always allow the oven to

cool down.

The correct operation of the oven is ensured by a gasket

placed round the edge of the oven cavity.

When using spray cleaning products, be

careful not to spread them on the heating

elements or on the thermostat sensor.

Never use harsh abrasives, steel wool or

cleaners with bleach, as they could damage

the enamel and the oven door glass.

The Oven Cavity

The enamelled oven cavity is best cleaned whilst the

oven is still warm. It is advisable to wipe the oven over

with a soft cloth soaked in warm soapy water after each

use. However, from time to time, it will be necessary to

do a more complete cleaning, using a proper oven

cleaner.

In case of particularly tough stains, you can use some

warm vinegar.

• If cooking fruits, some over-heated natual acids

can squeeze and settle on the oven enamel, causing

stains quite difficult to remove. This could affect the

enamel brightness, but it will have no consequence on

the oven performances. To avoid these stains to be

burnt out during the next cooking, carefully clean the

oven cavity after all fruits cookings.

Periodically check the condition of this gasket.

If necessary, clean it without using abrasive

cleaning products.

If the gasket shows to be damaged, call you

local Zanussi Service Centre. Do not use the

oven until it has been repaired.

The Oven Door and its gasket

Before cleaning the oven door, we recommend you to

remove it from the oven.

Proceed as follows:

☞

a) open the oven door completely;

b) find the hinges linking the door to the oven (fig

6);

c) unlock and turn the small levers located on the

two hinges (fig. 13);

d) handle the door by its left- and right-hand

sides, then slowly turn it towards the oven until

it is half-closed;

e) gently pull the oven door off its site (fig. 14);

f) place it on a steady plan;

g) unscrew the two screws marked with lett. A

fig.14;

h) pull up the oven door glass and take it away

from the oven door.

Clean the oven door glass with warm water and a softh

cloth only.

Once the cleaning is carried out, refit the oven door,

following the procedure in reverse.

FO 0288

Fig. 13

FO 0027

Fig. 14

73

Page 15

Replacing the Oven Light

Ensure the electricity supply is switched off

before carrying out this operation.

The oven bulb has to comply to these features:

a) resistant to temperatures of 300 °C;

b) electric rate: 230 V - 50 Hz;

c) electric power rate: 15 W.;

d) connection type: E 14.

To replace the bulb, proceed as follows (Fig. 15):

a) push in and turn the glass lid anticlockwise;

☞

b) remove tha faulty bulb;

c) replace it with a new one;

d) refit the glass lid;

e) switch on the electricity supply.

Cleaning the steam generator

FO 0287

Fig. 15

Cleaning the water tank

Just like in any appliance fed with water (e.g. the iron),

is it absoluitely normal that limestone residues form in

the water tank.

After having used the oven for steam cooking several

times, the limestone residues that settle inside the water

tank can cause a reduction of the steam.

If the red pilot light that indicates the need of a cleaning

cycle comes on, this means that a certain quantity of

limestone has settled in the water tank and that a

thorough cleaning of the steam generator is necessary.

In that case proceed as follows:

- Set the water tank exhaust-pipe ready for use.

☞

Fit the connector with hexagonal nut (Figure

16, letter "A") to one of the edges of the pipe.

- Open the oven door (Fig. 17) and fit the

connector (A) into the exhaust-valve (C)

located in the lower left hand corner of the

oven cavity frame.

Fig. 16

- Place the free edge of the pipe into a vessel,

then turn the pipe connector "A" anticlockwise

to open the exhaust-valve. Water will flow out

the water tank.

74

Fig. 17

Page 16

- When water stops flowing out the water tank,

turn the pipe connector clockwise to close the

exhaust-valve.

Warning! - The connector "A" has not a block fitting.

Take care this connector doesn't slip off the pipe during

the water tank exhaust procedure.

- After the water tank has been drained, melt

two spoonful of citric acid (about 50-60 grams)

into 800 cc. of water.

Citric acid is a natural substance, which

i

looks like white small grains of sugar. It is

normally used in food industry and can be

purchased in drugstores, wine shops or

chemist's shops.

- Pour the citic acid and water solution into the

water tank drawer, as explained in chapter 5,

page 8.

- Fit the connector "B" to one of the edges of the

exhaust-pipe, then insert the connector "B"

into the steam injector (Figure 18, letter "D").

Place the free pipe edge in a vessel, to collect

the limestone residues.

- Let the citric acid and water solution stay into

the water tank for about 60 minutes, with the

oven cooled down.

- After 60 minutes, switch on the oven by turning

the function control knob on the "STEAM

COOKING" function (symbol: ) and set the

thermostat knob on 140° C.

- After about 20-25 minutes, turn the knobs off.

- Allow the oven to cool down, then drain the

water tank following the procedure previuosly

explained.

- When the procedure is carried out, rinse the

water tank by pouring water into the tank

drawer and letting the water flow out through

the exhaust pipe, until you see clear water

without limestone residues coming out.

While carrying out this procedure, a lemon flavour will

be smelt in the room.

Fig. 18

Cleaning the exhaust pipe

When a cleaning procedure has been cariied out,

carefully wash the exhaust pipe in warm soapy water.

Don't use acids, spray cleaners or abrasives to clean the

exhaust pipe and connectors, this could damage them.

Using different water types

If you use bottled mineral water or water with low

limestone content, the need of cleaning the water tank

will be reduced (e.g., every 150-200 cookings). If a

water conditioner or a water softener has been installed

in your house, then the main water supply of your house

can be normally used.

If you foresee not to use the steam oven for 2-3 weeks,

we recommend to drain the water tank.

Using hard waters (that is, waters with high

i

limestone content) will make the necessity

of cleaning procedures more frequent, but

this will not affect in any way the oven

operation.

75

Page 17

What happens if something goes wrong

If the appliance is not working correctly, please carry out the following checks, before contacting your local

Zanussi Service Centre.

SYMPTOM

■ THE OVEN DOES NOT WORK

■ THE "TANK OUT OF WATER" LIGHT COMES ON

■ THE "CLEANING CYCLE" LIGHT COMES ON

■ THE "FULL TANK" GREEN LIGHT GOES OFF

SOLUTION

◆Check the control knobs are correctly set for a cooking

function and follow the instructions given in this book

or

◆Check the appliance is wired in properly, and the socket

switch or the switch from the mains supply to the oven are

ON.

◆Fill the water tank

◆Carry out a complete cleaning cycle as described in the

relevant chapter

or

◆If you already carried out a cleaning cycle but the pilot light

does not go off, repeat the procedure and allow the citric

acid and water solution to stay in the tank several hours.

or

◆The steam injector can be obstructed. Remove the

limestone residues from the steam injector.

◆Fill. the water tank. If the green light does not come on after

having poured more than 1 liter of water, call the nearest

Service Centre.

■ THE "STEAM COOKING FUNCTION" DOES NOT

WORK

■ THE OVEN LAMP DOES NOT COME ON

■ THERE IS WATER IN THE OVEN CAVITY

■ IT TAKES TOO MUCH TIME TO FINISH THE

DISHES, OR THEY ARE COOKED TOO FAST.

■ CONDENSATION SETTLES ON THE FOOD AND

THE OVEN CAVITY.

◆Check the oven function control knob is set on the "Steam

Cooking" function, that is on symbol .

or

◆Carefully close the oven door

or

◆Fill the water tank

◆Buy a new oven light bulb, asking for it to your local Zanussi

Service Centre and replace it by following the instruction

provided in this booklet.

◆Too much water has been poured into the oven tank. Turn

the control knobs on the "OFF" position, then wipe the oven

cavity dry with a sponge or a soft cloth.

◆Refer to the contents of this booklet, especially to the

chapter "Using the Oven".

◆Leave dishes inside the oven no longer than 15-20 minutes

after the cooking is completed.

76

Page 18

SER. NO.

Mod.

PROD. NO.

SER. NO.

MOD.

PROD. NO.

TYPE

Techical Assistance and Spare Parts

If after the checks listed in the previous chapter, the

appliance still does not work correctly, contact your

locals Zanussi Service Centre, specifying the type of

malfunctioning, the appliance model (Mod.), the

product number (Prod. No.) and the serial number

(Ser. No.) marked on the identification plate.

This plate is placed on the oven cavity frame, as

indicated in Fig. 19.

Original spareparts,

certified by the product

manufacturer and

carrying this symbol are

only available at our

Service Centre and

authorized spareparts

shops.

Fig. 19

Guarantee

Your new appliance is under guarantee. You will find

attached here the guarantee certificate. If it is missing,

ask for it to your retailer, stating the date of purchase,

the model number and the serial number marked on

the appliance's identification plate.

Keep the guarantee certificate with the proof of

purchase, and show them at the request of our

technical personnel, otherwise they will have to make

a charge.

The Zanussi Service Force, through its numerous

authorized centres, provides assistance to the most

important brands of electrical domestic appliances. If

necessary, contact the nearest Centre by consulting the

telephone directory under the name Zanussi, or the

yellow pages in the section Electrical Domestic

Appliances / Repair.

77

Page 19

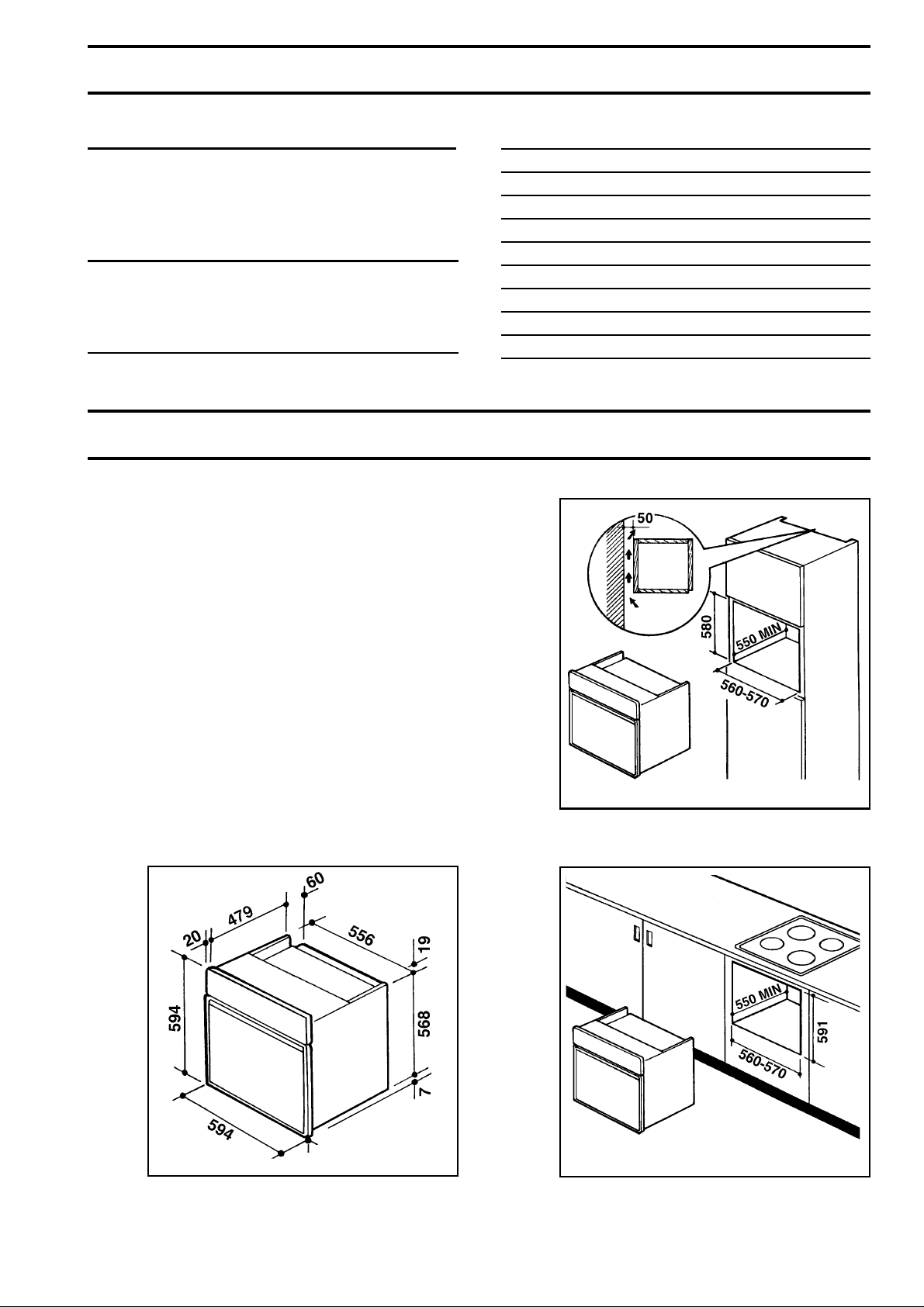

Technical Data

Recess

dimensions height

width 560 mm

depth 550 mm

Internal height 325 mm

oven width 440 mm

dimensions depth 390 mm

oven capacity 53 l.

in coloumn: 580 mm

{

undertop: 591 mm

Installation

Building In

Oven ratings

Top + Bottom heating elements 1800 W

Grill element 1750 W

Fan oven element 2000 W

Steam generator 735 W

Oven light 25 W

Cooling fan 20 W

Convection fan 30 W

Total rating 2800 W

Voltage tension (50Hz) 230 V

It is important that the dimensions and materials of the

surround or cabinet into which the oven will be built are

correct and will withstand a temperature increase.

A correct installation will have to ensure a proper

protection against contact with electric parts or merely

functionally isolated parts.

All the units meant to ensure protection have to be fitted

not to be taken away without using any tool.

We recommed not to install the appliance near

refrigerators or freezer, since the heat could affect the

performance of these appliances.

FO 0290

Fig. 20 - Oven Dimensions

FO 0414

Fig. 20 - Coloumn Built-in Recess Dimlensions

78

FO 0292

Fig. 22 - Undertop Built-in Recess Dimensions

Page 20

Securing the Oven to the Cabinet

Fit the appliance into the cabinet recess.

Open teh oven door and secure the oven to the kitchen

cabinet with four wood screws, which fit the holes

provided in the oven frame (Fig. 23-24).

When installing an electric plate hob over the oven, the

hob's electrical connection and the oven's one have to

be carried out separately, for security reasons and to let

the oven be taken off the unit easier, if necessary.

Electric Connection

Before the appliance is connected:

1) check that the main fuse and the domestic

☞

This appliance is supplied without connection cable . A

suitable one must be fitted to the appliance and a proper

plug, able to carry the load specified on the rating plate,

must be fitted on the connection cable. The connection

cable must be a three-wired cable, with the earth wire

marked yellow-green. The cable type must be one of the

following:

— H07 RN-F

— H05 RN-F

— H07 RR-F

— H05 VV-F

The plug has to be fitted in a proper socket.

If connecting the appliance directly to the electric system,

a double pole switch must be installed between the

appliance and the electricity supply, with a minimum

gap of 3 mm. between the switch contacts and of a type

suitable for the required load in compliance with the

current rules. The earth wire must not be interrupted by

the double switch pole.

The connection cable has to be placed in order that, in

each part, it cannot reach a temperature 50 °C higher

than the room temperature.

After the connection is carried out, test the heating

elements for about 3 minutes.

installation can support the load;

2) check that the power supply is properly earthed

in compliance with the current rules;

3) check the socket or the double pole switch

used for the electrical connection can be

easily reached with the appliance built in the

forniture unit.

FO 0039

Fig. 23

FO 0986

Fig. 24

Terminal block

The oven has an easily accessible terminal block,

which is meant to work with an electric single-phase

rate of 220-230 V.

(Fig. 25)

The manufacturer disclaims any

responsability should all the

safety measures not be carried

out.

FO 0279

Fig. 25

79

Loading...

Loading...