Page 1

TUMBLE DRYER

DOOR

OPEN

COTTON

SYNTHETICS

STORE DRY

Spun at rpm

kg 5

kg 2.5

IRON DRY

800 / 900 1000 / 1200

90' -110' 85' -105'

60' - 75' 55' - 70'

Spun at rpm

650

30' - 40'

25' - 35'

kg 2

kg 1

800 / 900 1000 / 1200

75' - 95' 65' - 90'

45' - 60' 40' - 55'

IMPORTANT: PLEASE READ THE INSTRUCTION BOOK BEFORE USING THIS APPLIANCE

STORE DRYSTORE DRY

AUTOREVERSE

DRYING

TIME

TC 481W

TC 482 W

125994190

INSTRUCTION BOOKLET

Page 2

Important Safety Information

It is most important that this instruction book should be retained with the appliance for

future reference. Should the appliance be sold or transferred to another owner, or should

you move house and leave the appliance, always ensure that the book is supplied with the

appliance in order that the new owner can get to know the functioning of the appliance

and the relevant warnings.

These warnings have been provided in the interest of safety. You MUST read them carefully

before installing or using the appliance.

Installation

●

This appliance is heavy. Care should be taken

when moving it.

●

It is dangerous to alter the specifications or

attempt to modify this product in any way.

●

Any electrical work required to install this

appliance should be carried out by a qualified

electrician or competent person.

●

Care must be taken to ensure that the appliance

does not stand on the electrical supply cable.

●

If the machine is situated on a carpeted floor,

please adjust the feet in order to allow air to

circulate freely.

●

If the tumble dryer is placed on top of a washing

machine, it is compulsory to use the stacking kit

(optional accessory).

Child Safety

●

This appliance is designed to be operated by

adults. Children should not be allowed to tamper

with the controls or play with the product.

●

Pets and children have been known to climb into

tumble dryers. Please check your drum before

use.

Keep all packaging well away for children.

●

Use

●

Do not overload the appliance (see programme

chart).

●

Clothes which are dripping wet should not be

placed in the dryer.

●

As some bulky items such as duvets and

eiderdowns should be dried in large commercial

machines because of their bulk, check with the

manufacturer of the item if it is suitable for drying

in a domestic machine, even if the dry weight of

the item is within the limit advised.

●

Do not dry canvas shoes or sports shoes, as they

could get stuck between the door and the drum,

thus blocking this latter.

●

Please make sure that no gas lighters have

accidentally been left in pockets of garments to be

loaded into appliance.

●

Danger of explosion: Never tumble dry items

that have been in contact with inflammable

solvents (petrol, methylated spirits, dry cleaning

fluid and the like). As these substance are volatile,

they could cause an explosion. Tumble dry only

items washed with water.

●

In order to avoid danger of fires caused by

excessive drying, do not use appliance to dry the

following items:

●

Cushions, quilts and the like (these items

accumulate heat).

●

Items containing rubber foam or materials similar

to rubber foam.

●

Leave the door slightly ajar when the appliance is

not being used. This will allow the seal to be

preserved.

●

Clean fluff filter after using tumble dryer. To

prevent fire risks, do not use the appliance if the

fluff filter is damaged or without filter.

●

Under no circumstances should you attempt to

repair the machine yourself. Repairs carried out

by inexperienced persons may cause injury or

serious malfunctioning. Contact your local

Zanussi Service Centre. Always insist on genuine

Zanussi spare parts.

2

Page 3

Contents

For the User

Important Safety Information

●

Installation 2

●

Child Safety 2

●

Use 2

Your New Tumble Dryer

Description of the Appliance

The Control Panel

●

Water full indicator light 5

●

Mains-on light 5

●

Time selector dial/ON-OFF switch 5

Programme Chart

Operating Sequence

●

Load the laundry 7

●

Select the drying time 7

●

When drying is completed 7

Hints & Tips on Drying

For the Installer

2

Installation Instructions

Technical Specifications

■

Positioning 15

■

Stacking kit (optional accessory) 15

■

4

4

5

6

7

8

Door reversal 16

■

Electrical connection 17

14

14

Maintenance and Cleaning

●

External cleaning 9

●

Cleaning fluff filter 9

●

Cleaning the condenser unit 9

●

Emptying the water reservoir 9

Something Not Working

Service and Spare Parts

Customer Care

Guarantee Conditions

Zanussi Service Force

12-13

Guide to use the Instruction Book

The following symbols will be found in the text to guide you throughout the instructions:

9

10

10

10

11

Safety instructions

Hints and tips

Environmental information

3

Page 4

Your New Tumble Dryer

12345

6

7

8

9

10

11

12

13

This tumble dryer will give your wash that soft, relaxed feel whatever

the weather.

Extremely high quality standards both during development and

manufacturing guarantee a long service life for your appliance.

Maximum economy in the operation of your dryer is achieved through

very frugal electricity consumption and short drying times.

Energy saving tips

To save energy we recommend that you follow these

hints:

●

Try to load the maximum capacity of the machine

as small loads are uneconomical.

●

Always load well spun laundry. The higher the

spin speed, the lower the electricity consumption

and the shorter the drying times.

●

Do not over-dry laundry, this avoids creasing and

saves energy.

●

Clean the filter regularly to avoid excessive

drying times and high electricity consumption.

●

Ventilate the room well. The room temperature

should not exceed +35°C during drying.

In the interest

of the environment

●

Materials marked with the symbol are

recyclable.

●

Check with your local Council or Environmental

Health Office to see if there are facilities in your

area for re-cycling this appliance.

●

When the appliance is to be scrapped, cut off the

power supply cable and make the door closing

device unusable to prevent young children from

being trapped inside.

●

Help to keep your country tidy - use authorised

disposal sites for your old appliance.

How do we help to protect the

environment? We use recycled paper!

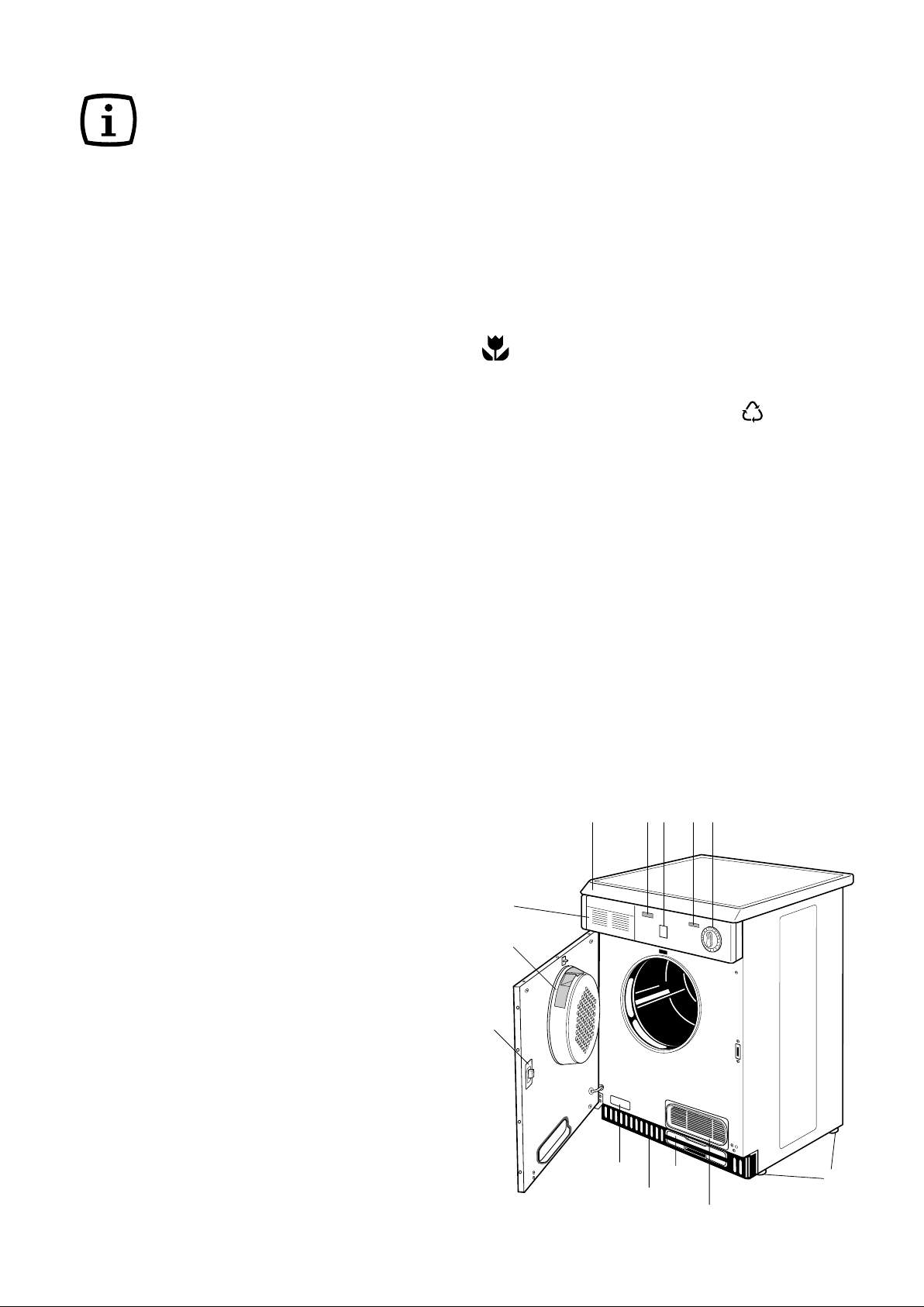

Description of the Appliance

1 Worktop

2 Reservoir Full Indicator Light

3 Door Open Button

4 Mains-On Light

5 Time Selector Dial-ON/OFF switch

6 Programme Chart

7 Fluff Filter

8 Door Catch

9 Rating Plate

10 Ventilation Grille

11 Water Reservoir

12 Condenser Unit

13 Adjustable Feet

4

Page 5

COTTON

SYNTHETICS

STORE DRY

Spun at rpm

kg 5

kg 2.5

IRON DRY

800 / 900 1000 / 1200

90' -110' 85' -105'

60' - 75' 55' - 70'

Spun at rpm

650

65' - 75'

30' - 40'

kg 2.5

kg 1

800 / 900 1000 / 1200

75' - 95' 65' - 90'

45' - 60' 40' - 55'

IMPORTANT: PLEASE READ THE INSTRUCTION BOOK BEFORE USING THIS APPLIANCE

STORE DRYSTORE DRY

AUTOREVERSE

DRYING

TIME

DOOR

OPEN

123 45

TC 482W

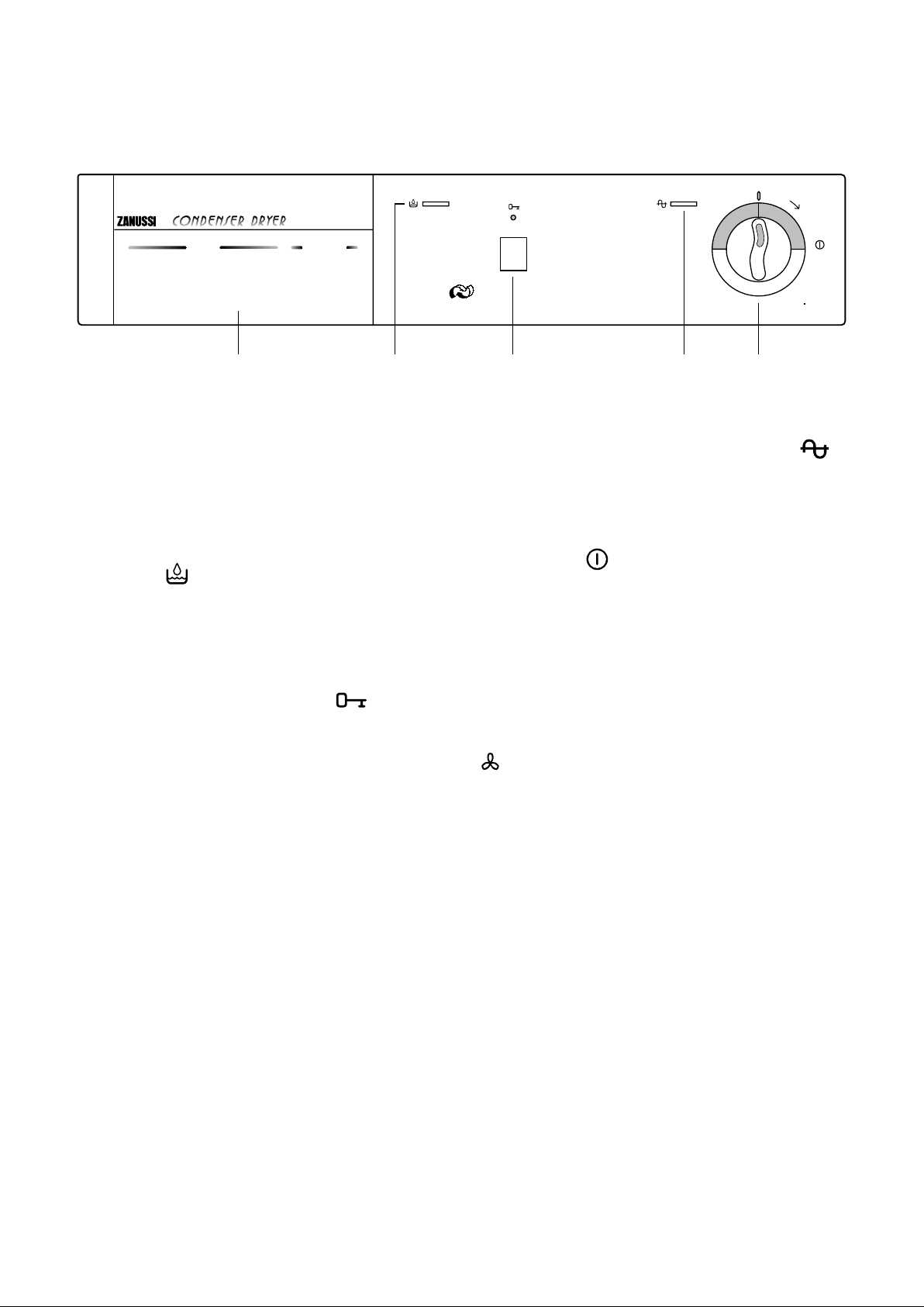

The Control Panel

1 Programme Chart

This will help you to select the correct time for

drying.

2 Water Full Indicator Light

(red)

This light illuminates when the reservoir is full or

improperly fitted.

The programme will be interrupted.

3 Door Open Button

Depress this button to open the door.

The door of the machine can be opened at any time

during the programme if you want to feel the dryness

of the fabrics.

4 Mains-On Light (orange)

This light indicates operating status.

5 Time Selector Dial-On/Off

Switch

Turn the dial clockwise (to the right) to select the

time for drying (see Chart page 6). At the same time

the machine is switched on and the programme starts.

This dryer has two drying cycles of up to 120 and 80

minutes, giving a high or low heat temperature

according to the type of fabric.

When selecting the drying time you should remember

that it includes a 12 minute cooling phase (position

on the dial).

This phase should not be shortened, stopped or

avoided, as this could cause skin burns or damages to

the laundry.

5

Page 6

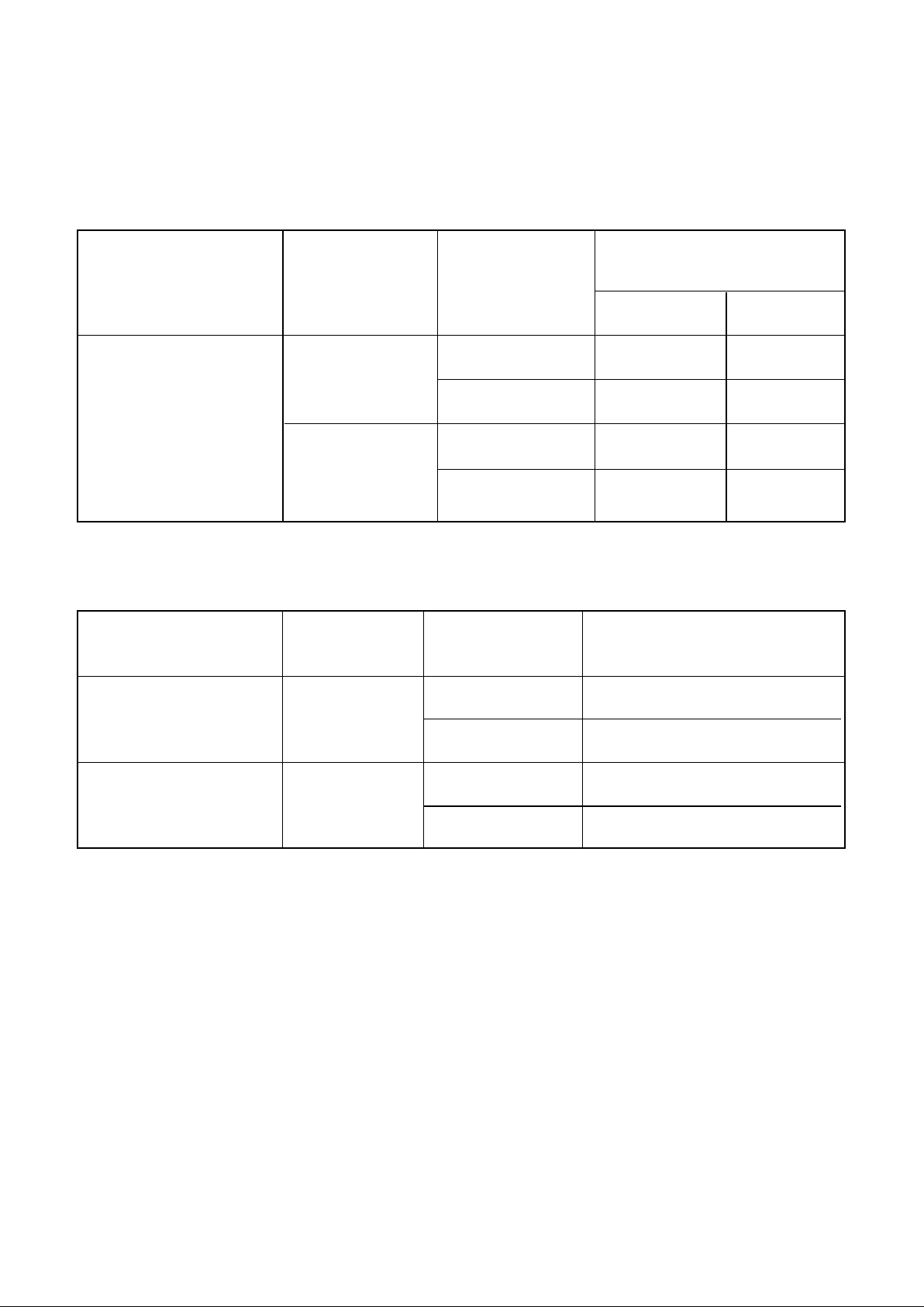

Programme Chart

Cotton and linen

Selector dial up to 120 minutes (high temperature section)

Type of laundry:

Cotton

Towelling

Shirts

Sheets

Hand towels

Tablecloths

Table napkins

Degree of drying

Store dry

(wardrobe dry)

Iron dry

(not completely dry;

suitable for ironing)

Synthetics

Selector dial up to 80 minutes (low temperature section)

Type of laundry:

Synthetics or mixed fabrics

which do not require

ironing.

Degree of drying

Store dry

Amount of laundry

Amount

of laundry

in kg

5

2.5

5

2.5

in kg

2.5 65-75

1

Drying time in minutes for

laundry spun at

800/900 rpm 1000/1200 rpm

90-110

60-75

75-95

45-60

Drying time in minutes for laundry

spun at a minimum speed of 650 rpm

85-105

55-70

65-90

40-55

30-40

Synthetics or mixed fabrics

which have to be ironed.

(Please see labels on items)

ATTENTION! Please follow the instructions on labels when drying mixed fabrics.

Iron dry

2.5

1

55-65

20-30

6

Page 7

Operating Sequence

P0871

P0486S

100

Before using your tumble dryer for the first time, we

recommend to place a few damp cloths inside the

appliance and dry for approximately 20 minutes.

There may be dust inside a brand new tumble dryer.

1. Load the laundry

Open the door by pressing the relevant button.

Load the items one at a time, shaking them out

loosely and close the door.

Please check the laundry does not get caught between

the door and filter.

2. Select the drying time

Turn the selector dial clockwise to the desired time

(in the high or low temperature section, according to

the fabric).

The mains-on light illuminates and the programme

starts.

3. When drying is completed

The machine stops automatically and the mains-on

light goes out.

Open the door and take out the laundry.

Clean the filter after every drying programme.

A clean filter ensures correct functioning of the

appliance.

7

Page 8

Hints & Tips on Drying

Before placing articles of laundry in your tumble

dryer, check the care labels to ensure they are

recommended for tumble drying.

Care Labels you may find on your laundry

normal drying (high temperature)

delicate drying (low temperature)

may be tumble dried

do not tumble dry

Do not overload the appliance.

Here is a list of the approximate weight of some

common laundry items.

Sheet 700 to 1000 g

Pillowcase 100 to 200 g

Tablecloth 400 to 500 g

Table Napkin 50 to 100 g

Kitchen Towel 70 to 120 g

Linen Hand Towel 100 to 150 g

Hand Towel 150 to 250 g

Bath Towel 700 to 1000 g

Bathrobe 1000 to 1500 g

Shirt 200 to 300 g

Apron 150 to 200 g

●

Always load well spun laundry. The higher the

spin speed the lower the electricity consumption

and the shorter the drying time.

●

DO NOT load dripping wet laundry into the

dryer. Roll the article in a towel or spin to remove

excess water.

●

Close poppers and zips and fasten any buttons.

●

Sort the laundry. Separate synthetics from

cotton/linens, and dry separately.

●

Remove the laundry immediately after the

programme has finished.

●

Use a fabric conditioning sheet to reduce static.

We recommend the sheet is pinned to an article of

laundry (using a safety pin).

●

Mix the load i.e. large and small articles.

●

When drying large items such as sheets, we

recommend you periodically stop the dryer to

redistribute the load.

DO NOT use the tumble dryer to dry the

following:

●

Articles contaminated with inflammable

substances e.g. petrol, cleaning solvents, cooking

oil, fats or hair lacquer.

●

Woollen and synthetic/wool mixtures unless the

item is labelled as suitable for tumble drying.

●

Very delicate articles such as silk.

●

Very large and bulky items such as duvets or

sleeping bags.

8

Page 9

P0638

P0637

P0639

P0636

Maintenance and Cleaning

You must disconnect the appliance from the

electricity supply, before you can carry out any

cleaning or maintenance work.

External cleaning

Use only soap and water and then dry thoroughly.

From time to time, apply a little wax furniture cream

with a soft cloth.

Important: do not use methylated spirit, diluents or

similar products.

Cleaning the filter

The tumble dryer cannot operate efficiently with a

clogged filter. The filter collects all the fluff which

forms during drying and it is therefore essential to

remove and clean this filter after each drying

programme.

Cleaning the condenser unit

Clean the air condenser periodically, 3 or 4 times a

year depending on how frequently the dryer is used.

Pull out the condenser, holding it at the top, and

remove all fluff. Clean it with a brush and rinse it

under the shower if necessary.

Also clean the outside, removing all fluff.

Clean the rubber seal round the porthole door and the

seal of the condenser in the inner door with a damp

cloth.

Emptying the water reservoir

You should not be alarmed by the amount of fluff

which collects on the filter; this is due to normal

wearing of the fabrics dried and not to incorrect

operation of your machine. Rubbing of the fibres

during normal wear and washing forms fluff. If

laundry is dried on a line, this fluff simply flies away,

whereas inside the tumble dryer it collects together

and swells considerably as a result of the drying

action.

Water extracted from the laundry condenses inside

the machine and is collected in a reservoir.

The reservoir must be emptied after each drying

cycle to ensure efficient operation when the machine

is next used.

If this is not done a safety device trips: pilot light

on the control panel comes on and the programme

stops, leaving the laundry damp.

The reservoir can be emptied even in the middle of a

programme.

The reservoir must be re-inserted correctly.

Handy tip: The condensed water may be used in a

steam iron or to top up a battery, etc. In this case it

must be filtered (e.g. through a coffee filter).

9

Page 10

Something Not Working

Certain problems are due to lack of simple maintenance or oversights, which can be solved easily without

calling out an engineer. Before contacting your local Service Centre, please carry out the checks listed below.

IMPORTANT: if you call out an engineer to a fault listed below, or to repair a fault caused by incorrect

use or installation, a charge will be made even if the appliance is under guarantee.

Symptom Possible causes

●

The tumble dryer does not start

The door has not been closed.

●

The plug is not properly inserted in the power

socket.

●

There is no current at the socket

●

The main fuse or the fuse in the plug has blown.

●

A drying time has not been selected.

●

The water reservoir is full or not properly

inserted (the pilot light is on).

Drying takes too long or laundry is not

dry enough.

Service & Spare Parts

In the event of your appliance requiring service, or if

you wish to purchase spare parts, please contact your

local Zanussi Service Force Centre by telephoning:

0870 5 929929

Your telephone call will be automatically routed to

the Service Force Centre covering your post code

area.

The addresses are listed on the following pages.

Before calling out an engineer, please ensure you

have read the details under the heading “Something

Not Working”.

When you contact the Service Force Centre you will

need to give the following details:

1. Your name, address and post code

2. Your telephone number

3. Clear and concise details of fault

4. The model and serial number of the appliance

(found on the rating plate - see picture page 4).

5. The purchase date

●

The laundry has not been spun properly.

●

The filter and/or air condenser are clogged up.

●

The room temperature is too high.

●

The selected time or section was not suitable for

the laundry

●

There is too much laundry inside the appliance.

●

The dryer is not correctly installed.

Customer Care

For general enquiries concerning your Zanussi

appliance or for further information on Zanussi

products, please contact our Customer Care

Department by letter or telephone as follows:

Customer Care Department

Zanussi

55-77 High Street

Slough

Berkshire

SL1 1DZ

Tel 08705 727727*

or visit our website at www.zanussi.co.uk

* calls to this number may be recorded for training

purposes.

10

Page 11

Guarantee Conditions

Standard guarantee conditions

We, Zanussi undertake that if, within 12 months of

the date of the purchase, this Zanussi appliance or

any part thereof is proved to be defective by reason

only of faulty workmanship or materials, we will, at

our option, repair or replace the same FREE OF

ANY CHARGE for labour, materials or carriage on

condition that:

●

The appliance has been correctly installed and

used only on the electricity supply stated on the

rating plate.

●

The appliance has been used for normal domestic

purposes only, and in accordance with the

manufacturer’s instructions.

●

The appliance has not been serviced, maintained,

repaired, taken apart or tampered with, by any

person not authorised by us.

All service work under this guarantee must be

undertaken by a Zanussi Service Force Centre.

Any appliance or defective part replaced shall

become the Company’s property.

This guarantee is in addition to your statutory and

other legal rights.

Home visits are made between 8.30am and 5.30pm

Monday to Friday. Visits may be available outside

these hours in which case a premium will be

charged.

Exclusions

This guarantee does not cover:

●

Damage or calls resulting from transportation,

improper use or neglect, the replacement of any

light bulbs or removable parts of glass or plastic.

●

Costs incurred for calls to put right an appliance

which is improperly installed or calls to

appliances outside the United Kingdom.

●

Appliances found to be in use within a

commercial environment, plus those which are

subject to rental agreements.

●

Products of Zanussi manufacture which are NOT

marketed by Zanussi.

European guarantee

If you should move to another country within Europe

then your guarantee moves with you to your new

home subject to the following qualifications:

The guarantee starts from the date you first

●

purchased your product.

The guarantee is for the same period and to the

●

same extent for labour and parts as exists in the

new country of use for this brand or range of

products.

The guarantee relates to you and cannot be

●

transferred to another user.

Your new home is within the European

●

Community (EC) or European Free Trade Area.

The product is installed and used in accordance

●

with our instructions and is only used

domestically, i.e. a normal household.

The product is installed taking into account

●

regulations in your new country.

Before you move please contact your nearest

Customer Care Centre, listed below, to give them

details of your new home. They will then ensure that

the local Service Organisation is aware of your move

and able to look after you and your appliances.

France Senlis +33 (0)344 62 22 22

Germany Nurnberg +49 (0)911 323 2600

Italy Pordenone +39 (0)1678 47053

Sweden Stockholm +46 (0)8 738 79 50

UK Slough +44 (0)1753 219897

11

Page 12

Zanussi Service Force

To contact your local Zanussi Service Force Centre telephone 08705 929 929

CHANNEL ISLANDS

GUERNSEY Guernsey Electricity

PO Box 4

Vale, Guernsey

Channel Islands

JERSEY Jersey Electricity Company

PO Box 45

Queens Road

St Helier

Jersey

Channel Islands JE4 8NY

SCOTLAND

ABERDEEN 54 Claremont Street

(M05) Aberdeen AB10 6RA

AUCHTERMUCHY 33a Burnside

(M03) Auchtermuchy

Fife KY14 7AJ

BLANTYRE Unit 5

(M07) Block 2

Auchenraith Ind. Estate

Rosendale Way

Blantyre G72 0NJ

DUMFRIES 93 Irish Street

(M01) Dumfries

Scotland DG1 2 PQ

DUNOON Brair Hill

(M67) 7 Hill Street

Dunoon

Argyll PA23 7AL

GLASGOW 20 Cunningham Road

(M04) Clyde Estate

Rutherglen

Glasgow G73 1PP

INVERNESS Unit 3B

(M06) Smithton Ind. Estate

Smithton

Inverness IV1 AJ

ISLE OF ARRAN Arran Domestics

Unit 4 The Douglas Centre

Brodick

(OWN SALES) Isle of Arran KA27 8AJ

ISLE OF BARRA J Zerfah

244 Bruernish

Isle of Barra

(OWN SALES) Western Islands HS9 5QY

ISLES OF BUTE Walker Engineering

Glenmhor

Upper Serpentine Road

Rothesay

Isle of Bute PA20 9EH

ISLE OF LEWIS ND Macleod

16 James Street

Stornoway

Isle of Lewis PA87 2QW

KELSO 2-8 Wood Market

(M08) Kelso

Borders TD5 7AX

ORKNEY Corsie Domestics

(M65) 7 King Street

Kirkwall

Orkney KW15

PERTH Hydro Electrical

Inveralmond House

Ruthervenfield Road

Perth PH1 3AQ

PERTH Graham Begg

Unit 4

Airport Ind Est ate

(OWN SALES) Wick KW1 4QS

SHETLAND Tait Electronic S ystems Ltd

Holmsgarth Road

Lerwick

(OWN SALES) Shetland ZE1 0PW

SHETLAND Bolts Shetland Ltd.

26 North Road

Lerwick

(OWN SALES) Shetland ZE1 0PE

WHALSAY Leask Electrical

Harisdale

Symbister, Whalsay

(OWN SALES) Shetland ZE2 9AA

NORTHERN IRELAND

BELFAST Owenmore House

(M27) Kilwee Business Park

Upper Dunmur y Lane

Belfast

BT17 0HD

WALES

CARDIFF Guardian Industrial Estate

(M28) Clydesmuir Road

Tremorfa

Cardiff

CF2 2QS

CLYWD Unit 6-7 Coed – Parc

(M14) Abergele Road

Rhuddlan

Clwyd

Wales

LL18 5UG

DYFED Maes Y Coed

(M77) High Mead

Llanyb ydder

Carmarthenshire

SA40 9UL

HAVERFORDWEST Cromlech Lodge

(M75) Ambleston

Haverfordwest

Pembrokeshire

SA62 5DS

OSWESTRY Plas Ffynnon

(M17) Warehouse

Middleton Road

Oswestry

SY11 2PP

NORTH EAST

GATESHEAD Unit 356a

(M39) Dukesway Court

Dukesway

Team Valley

Gateshead NE11 0BH

GRIMSBY 15 Hainton Avenue

(M42) Grimsby

South Humberside

DN32 9AS

HULL Unit 1

(M41) Boulevard Industrial Estate

Hull

HU3 4AY

LEEDS 64-66 Cross Gates Road

(M37) Leeds

LS15 7NN

NEWTON AYCLIFFE Unit 16

(M45) Gurney Way

Aycliffe Industrial Estate

Newton Aycliffe

DL5 6UJ

SHEFFIELD Pennine House

(M38) Roman Ridge Ind.

Roman Ridge Road

Sheffield S9 1GB

NORTH WEST

BIRKENHEAD 1 Kelvin Park

(M11) Dock Road

Birkenhead

L41 1LT

CARLISLE Unit 7

(M10) James Street Workshops

James Street

Carlisle

Cumbria CA2 5AH

ISLE O F MAN South Quay Ind. Estate

(M64) Douglas

Isle of Man

IM1 5AT

LIVERPOOL Unit 1

(M15) Honeys Green Precinct

Honeys Green Lane

Liverpool

L12 9JH

MANCHESTER Unit B

(M09) Central Industrial Estate

St Marks Street

Bolton

BL3 6NR

PRESTON Unit 250

(M13) Dawson Place

Walton Summit

Bamber Bridge

Preston

Lancashire PR5 8AL

STOCKPORT Unit 20 Haigh Park

(M16) Haigh Avenue

Stockport

SK4 1QR

12

Page 13

Zanussi Service Force

To contact your local Zanussi Service Force Centre telephone 08705 929 929

MIDLANDS

BIRMINGHAM 66 Birch Road East

(M18) Wyrley Road Ind. Estate

Witton

Birmingham

B6 6DB

BOURNE Manning Road Ind. Estate

(M44) Pinfold Road

Bourne

PE10 9HT

BRIDGNORTH 68 St. Mary’s Street

(M72) Bridgnorth

Shropshire

WV16 4DR

GLOUCESTER 101 Rycroft Street

(M23) Gloucester

GL1 4NB

HEREFORD Unit 3

(M31) Bank Buildings

Cattle market

Hareford

HE4 9HX

HIGHAM FERRERS 30 High Street

(M51) Higham Ferrers

Northants

NN10 8BB

ILKESTON Unit 2

(M43) Furnace Road

Ilkeston DE7 5EP

LEICESTER Unit 7

(M22) Oaks Ind. Estate

Coventry Road

Narborough

Leicestershire

LE0 5GF

LINCOLN Unit 8

(M40) Stonefield Park

Clifton Street

Lincoln

LN5 8AA

NEWCASTLE 18-21 Croft Road

UNDER LYME Brampton Ind. Estate

(M12) Newcastle under Lyme

Staffordshire

ST5 0TW

REDDITCH 13 Thornhill Road

(M20) North Moon s Moat

Redditch

Worcestershire

B98 9ND

TAMWORTH Unit 3

(M19) Sterling Park

Claymore

Tamworth

B77 5DO

WORCESTER Units 1 & 2

(M73) Northbroo k Close

Gregorys Mill Ind. Estate

Worcester

WR3 8BP

LONDON & EAST ANGLIA

BECKENHAM 11a Gardener Ind. Estate

(M79) Kent House Lane

Beckenham

Kent BR3 1QZ

CHELMSFORD Hanbury Road

(M47) Widford Ind. Estate

Chelmsford

Essex

CM12 3AE

COLINDALE Unit 14

(M53) Capitol Park

Capitol Way

Colindale

London NW9 0EQ

ELTHAM 194 Court Road

(M78) Mottingham

Eltham

London SE9 4EW

ENFIELD 284 Alma Road

(M49) Enfield

London

EN3 7BB

GRAVESEND Unit B4

(M57) Imperial Business Estate

Gravesend

Kent

DA11 0DL

HARPENDEN Unit 4

(M46) Riverside Estate

Coldharbour Lane

Harpenden

AL5 4UN

LETCHWORTH 16-17 Woodside Ind. Estate

(M50) Works Road

Letchworth

Herts

SG6 1LA

LONDON 2/4 Royal Lane

(M76) Yiewsley

West Drayton

Middlesex

UB7 8DL

MAIDENHEAD Reform Road

(M60) Maidenhead

Berkshire

SL6 8BY

MOLESEY 10 Island Farm Avenue

(M61) West Molesey

Surrey

KT8 2UZ

NEWBURY 9 Pipers Court

(M24) Berkshire Drive

Thatcham

Berkshire

RG19 4ER

IPSWICH Unit 6C

(M48) Elton Park Business Centre

Hadleigh Road

Ipswich

IP2 0DD

NORWICH 2b Trafalgar Street

(M52) Norwich

NR1 3HN

SUNBURY Unit 1a

(M63) The Summit

Hanworth Road

Hanworth Ind. Estate

Sunbury on Thames

TW16 5D

SOUTH EAST

ASHFORD Unit 2

(M58) Bridge Road Business Est.

Bridge Road

Ashford

Kent TN2 1BB

FLEET Unit 1

(M59) Redsfield Ind. Estate

Church Crookham

Fleet

Hampshire GU13 0RD

HAYWARDS 21-25 Bridge Road

HEATH Haywards Heath

(M55) Sussex RH16 1UA

SOUTH WEST

BARNSTAPLE Main Road

(M30) Fremington

Barnstaple

North Devon EX31 2NT

BOURNEMOUTH 63-65 Curzon Road

(M26) Bournemouth

Dorset

BH1 4PW

BRIDGEWATER 6 Hamp Ind. Estate

(M35) Bridgewater

Somerset TA6 3NT

BRISTOL 11 Eldon Way

(M25) Eldonwall Trading

Bristol

Avon BS4 3QQ

EMSWORTH 266 Main Road

(M33) Southbourne

Emsworth

PO10 8JL

ISLE OF WIGHT Unit 8

(M34) Enterprise Court

Ryde Business Park

Ryde

Isle of Wight PO3 3 1DB

NEWTON ABBOT Unit 2

(M29) Zealley Ind. Estate

Kingsteignton

Newton Abbot

S. Devon

TQ12 3TD

REDRUTH Unit 7D

(M36) Pool Ind. Estate

Wilson Way

Redruth

Cornwall TR15 3QW

13

Page 14

Installation Instructions

It is dangerous to alter the specifications or

attempt to modify this product in any way.

Care must be taken to ensure that the appliance

does not stand on the electrical supply cable.

Any electrical work required to install this

appliance should be carried out by a qualified

electrician or competent person.

Technical Specifications

DIMENSIONS Height 85 cm (33.5”)

Width 60 cm (23.6”)

Depth 60 cm (23.6”)

POWER SUPPLY VOLTAGE 230-240 V/50 Hz

TOTAL POWER ABSORBED 2700 W (13A)

MAXIMUM RECOMMENDED LOAD Cotton, linen 5 kg (11 lbs)

Synthetics, delicates 2.5 kg (5 lbs)

DRUM VOLUME 108 l

This appliance complies with the following E.E.C. Directives:

- 73/23 EEC of 19.2.73 (Low Voltage Directive) and subsequent modifications;

- 89/336 EEC of 3.5.89 (Electromagnetic Compatibility Directive) and subsequent modifications.

14

Page 15

Positioning

P1044

P0046

It is recommended that, for your convenience, the

dryer is positioned close to your washing machine.

The tumble dryer must be installed in a clean place,

where dirt does not build up.

Air must be able to circulate freely all round the

appliance. Do not obstruct the front ventilation grille

or the air intake grilles in the back of the machine.

To keep vibration and noise to a minimum when the

dryer is in use, it should be placed on a firm, level

surface.

Once in its permanent operating position, check that

the dryer is absolutely level with the aid of a spirit

level. If it is not, raise or lower the four adjustable

feet until it is.

The feet must never be removed.

Do not restrict the floor clearance through deeppile carpets, strips of wood or similar. This might

cause heat build-up which would interfere with

the operation of the appliance.

Important

When operating the tumble dryer, the room

temperature must not exceed 35°C, as it may affect

the performance of the appliance.

Stacking kit

A special stacking kit is available through your

dealer, to enable the mounting of the dryer on top of

your washing machine.

15

Page 16

Door Reversal Instructions

D

b

c

E

B

A

d

F

1

1

2

C

P0866

a

C

A

B

F

A

C

P0865

c

d

B

The appliance is supplied with the door opening from

right to left. If you wish to change the opening

direction, proceed as follows (see picture A):

1. Unhook door stopper «A» from its seat «a» and

loosen from hole «b» by a 90° rotation.

2. Remove the plastic plug from hole «c» by a 90°

rotation and re-fix in hole «b».

3. Unscrew hinge «B» (loosen the 2 screws, holding

the door securely) and lower the door from the

top pivot.

4. Re-insert pin «F» from the door above and below

on opposite sides respectively.

5. Loosen door catch «C» by pressing both lugs

together (see small illustration).

6. Loosen opposite plastic part «D» as in step 5

(you may need to use a screwdriver to assist in

both steps 5 and 6 ).

7. Interchange and insert parts «C» and «D».

8. Remove screws «E» and refit on the opposite

side. Fix hinge «B» on the right handside.

Do not fully tighten the screws.

9. To mount door, see picture B:

■

First locate into upper right hand hole with upper

pin «F».

■

Then place lower pin into the hinge «B» at the

bottom of the door.

■

Align door before tightening hinge.

■

Tighten hinge.

10. Remove the plug from hole «d» and refix in

hole«a» (Fig. A).

11. Fix door stopper «A» in hole «c» by 90° rotation.

12. Hook door stopper «A» into hole «d».

16

Page 17

Electrical connection

GREEN & YELLOW

BROWN

CORD CLAMP

BLUE

13A

P1041

E

N

L

Any electrical work required to install this appliance

should be carried out by a qualified electrician or

competent person.

WARNING: THIS APPLIANCE MUST BE

EARTHED.

The manufacturer declines any liability

should this safety measure not be observed.

Before switching on, make sure the electricity supply

voltage is the same as that indicated on the

appliance’s rating plate. (See picture page 4).

The appliance is supplied with a 13amp plug fitted.

In the event of having to change the fuse in the plug

supplied, a 13amp ASTA approved (BS1363A) fuse

must be used.

Should the plug need to be replaced for any reason,

proceed as described below.

The wires in the mains lead are coloured in

accordance with the following code:

Green and Yellow - Earth

Blue - Neutral

Brown - Live

The wire coloured green and yellow must be

connected to the terminal marked with the letter «E»

or by the earth symbol or coloured green and

yellow.

The wire coloured blue must be connected to the

terminal «N» or coloured black.

The wire coloured brown must be connected to the

terminal marked «L» or coloured red.

Upon completion there must be no cut, or stray

strands of wire present and the cord clamp must be

secure over the outer sheath.

WARNING:

A cut off plug inserted into a 13 amp socket

is a serious safety (shock) hazard.

Ensure that the cut off plug is disposed of

safely.

Permanent connection

In the case of permanent connection it is necessary

that you install a double pole switch between the

appliance and the electricity supply (mains), with a

minimum gap of 3mm between the switch contacts

and of a type suitable for the required load in

compliance with the current electrical regulations.

The switch must not break the yellow and green earth

cable at any point.

17

Page 18

From the Electrolux Group.

The Electrolux Group is the world's largest producer of powered appliances for kitchen, cleaning and outdoor

use. More than 55 million Electrolux Group products (such as refrigerators, cookers, washing machines,

vacuum cleaners, chain saws and lawn mowers) are sold each year to a value of approx. USD 14 billion in

more than 150 countries around the world.

The world’s No. 1 choice

.

© Electrolux Household Appliances Limited 2000

Loading...

Loading...