Page 1

Hobs

ZANUSSI

OPERATING AND INSTALLATION MANUAL

2

Page 2

CONTENTS

Technical characteristics Pag. 3

General warnings Pag. 4

Instructions for user Pag. 5

Use Pag. 6

Maintenance and cleaning Pag. 7

Instructions for installer Pag. 7

Gas connection Pag. 8

Electrical connection Pag. 9

Adaption of hob burners to different types of gas Pag. 10

Insertion in kitchen units Pag. 12

Technical assistance and spareparts Pag. 15

TECHNICAL DATA

Power of gas burners

Rapid burner (large) 10,00 MJ/h

Semi-rapid burner (medium) 6,12 MJ/h

Auxiliary burner (small) 3,60 MJ/h

Appliance operation Natural Gas

L.P.G. Gas

Appliance caliber Natural Gas 1,0 kPa 25,84 MJ/h

Conversion to use with L.P.G. 2,75 kPa 25,56 MJ/h

Gas entry connection G1/2

Voltage tension 240 V 50 Hz

MANUFACTURER: ELECTROLUX ZANUSSI ELETTRODOMESTICI S.p.A.

Viale Bologna, 298

47100 FORLÌ (Italy)

3

Page 3

WARNINGS - GAS HOBS

It is most important that this instruction brochure should be kept together with the

appliance for future consultation. If the appliance is sold or transferred to another person,

ascertain that the brochure is also given, in order that the new user can be aware of the

correct use of the machine and the relative warnings.

THESE WARNINGS HAVE BEEN PREPARED FOR YOUR SAFETY AND FOR THAT

OF OTHERS, WE THEREFORE REQUEST YOU TO READ THEM CAREFULLY

BEFORE INSTALLING AND USING THE APPLIANCE.

● This appliance has been designed for use by

adults. Take care, therefore, that children do

not attempt to play with it.

● This appliance has been designed for

cooking purposes only. It must not be used

for any other purposes, or be destined to

professional or industrial use.

● Where this appliance is installed in marine

craft or in caravans, it shall not be used as a

space heater.

● The work of installation must be carried out

by competent and qualified installers

according to the regulations in force.

● The appliance must be installed at a

minimum distance of 50 cm. from curtains

or other combustible material.

● Any modifications to the domestic electrical

mains which may be necessary for the

installation of the appliance should only be

carried out by competent personnel.

● In case of repairs contact an authorized

Technical Assistance Centre and insist on

original spareparts.

● It is dangerous to modify, or attempt to modify,

the characteristics of this appliance.

● Unstable or deformed pans should not be

placed on the burners or plates in order to avoid

accidents caused by upsetting or boiling over.

● Particular care should be taken when cooking

with oil or fat.

● Burners, plates, grills and pans remain hot for

a long time after being switched off. Supervise

children at all times when in use paying

attention that they do not touch surfaces or

remain in the vicinity of the appliance when in

use or when not completely cooled.

● If the appliance is fitted with a cover, its

function is to protect the surface from dust

when closed and to accumulate splashes of

grease when open. Do not use for other

purposes.

4

● Always clean the cover before closing and

allow the burners and/or plates to cool before

closing.

● Always check that the switch is in the « »

position when the appliance is not in use.

● Ensure that air can circulate around the gas

appliance. Poor ventilation can produce a lack

of oxygen.

● Supply the appliance with the type of gas

stamped on the relevant adhesive label situated

in the immediate vicinity of the gas connection

tube.

● Before maintenance or cleaning disconnect the

appliance and allow to cool.

● Do not spray areosols in the vicinity of this

appliance while it is in operation.

● To facilitate ignition, light the burner before

placing the pan on the grill.

● After having lit the burner check that the flame

is regular.

● Always lower the flame or turn it off before

removing the pan.

● In case of repairs, do not atempt to correct

yourself. Repairs carried out by unqualified

persons can cause damage. Contact the nearest

Assistance Centre and use only original

spareparts.

The use of a gas cooking appliance

produces heat and humidity in the room in

which it is installed. Ensure good

ventilation of the room by keeping natural

ventilation openings clear or installing an

extractor hood with a discharge tube.

A prolonged and intensive use of the

appliance may necessitate supplementary

ventilation, for example the opening of a

window or a more efficient ventilation by

increasing the power of mechanical

extraction, if existing.

Page 4

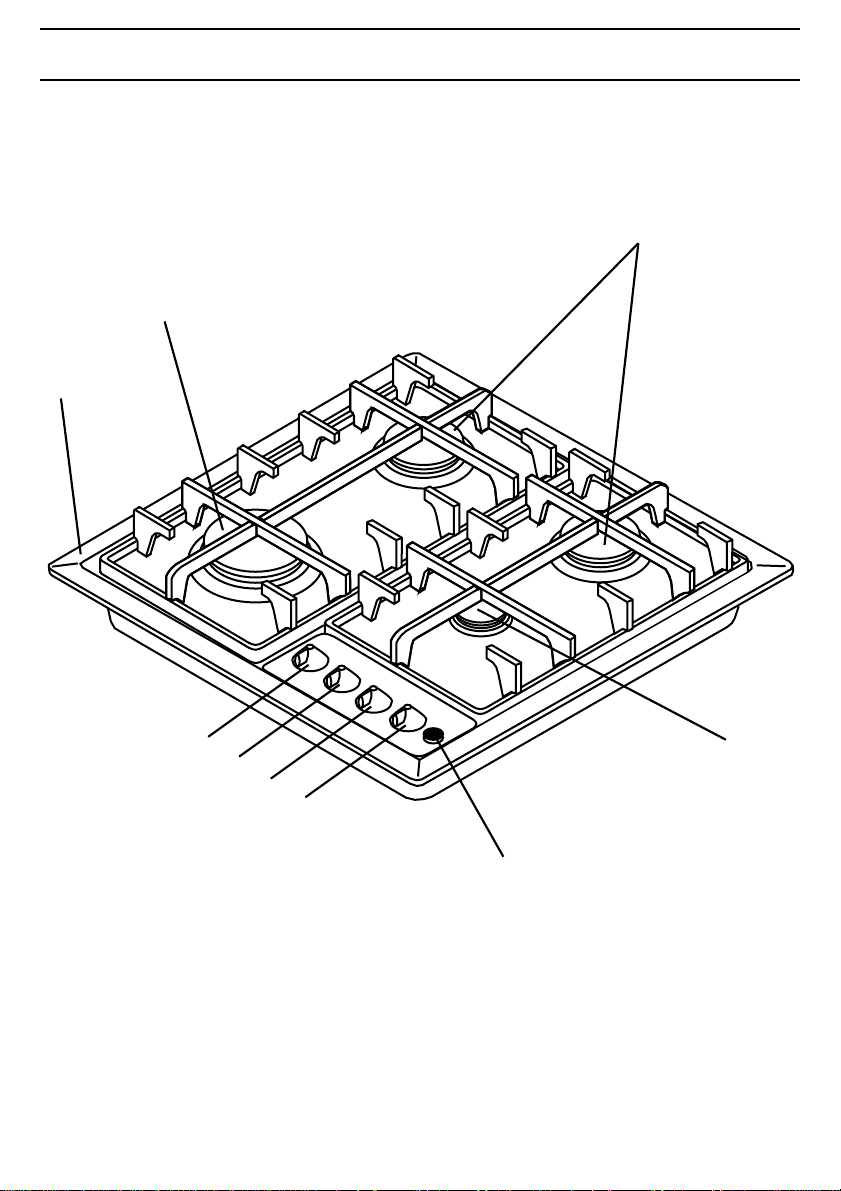

INSTRUCTIONS FOR THE USER

2

1

3

6

7

8

9

1. Hob Top

2. Rapid Burner

3. Semirapid Burners

4. Auxiliary Burner

5. Control Panel

6. Control knob for back left burner

7. Control knob for front left burner

8. Control knob for front right burner

9. Control knob for back right burner

4

5

5

Page 5

INSTRUCTIONS FOR USER

INSTALLATION

All operations relating to installation, regulation and adaption to the type of gas supplied, must be

carried out by qualified personnel, according to the regulations in force.

Specific instructions are contained in the notices reserved for the installer.

USE

Hob control switch

The switches for the gas burners of the hob are

situated on the control panel. The regulating

switch of the burners can only be turned in an

anti-clockwise direction to the small flame sign

and vice-versa in the opposite direction.

no emission of gas

maximum emission of gas

minimum emission of gas

Ignition of burners

To ignite a burner, before positioning the

saucepan, approach with a flame, push the

corresponding switch in completely and turn in an

anti-clockwise direction to the maximum position.

Then regulate the flame as required.

In models having automatic ignition work the

appropriate button, marked by a small spark, and

then open the tap completely.

In models having a security device turn the

corresponding switch in an anti-clockwise

direction to the maximum position, press in fully

and keep pressed for approximately 5 seconds

until the security valve automatically maintains

the flame alight.

IMPORTANT

If after a few attempts the burner does not ignite,

check that the baffle and its cap are correctly

positioned.

To interrupt the supply of gas, turn the switch in a

clockwise direction to the position « ».

For a minor consumption of gas and a better

efficiency it is advisable to use pans having a

diameter suitable to the burners, as shown in the

table. It is also advisable that, as soon as a liquid

starts to boil you should lower the flame

sufficiently to maintain simmering point. In case

the burner flame accidentally goes out, close the

command switch and try to ignite again after not

less than 1 minute.

During cooking, when using fats or oils, take

particular care as they can, when over-heated,

self-ignite.

Minimum and maximum diametres of recipients

which can be placed on the burners.

Burner Min. diam. Max. diam.

Rapid (large) 160 mm 240 mm

FO 0252

6

Semi-rapid (medium) 120 mm 220 mm

Auxiliary (small) 80 mm 160 mm

Page 6

MAINTENANCE AND CLEANING

Before each operation electrically disconnect the

appliance.

Wash the enamelled parts with warm water and

detergent, do not use abrasive products which

could damage them; frequently wash the baffles

of the burners with boiling water and detergent,

taking care to remove all encrustrations; the parts

in stainless steel should be rinsed well with water

after use and dried with a soft cloth.

The hob’s enamelled grills can also be washed in

the dishwasher. For persistent marks use normal,

non-abrasive detergents or specific products

which can easily be found in commerce.

It is never advisable to use wire pads, steel wool

or acids for cleaning.

For hobs having automatic ignition periodically

carry out an accurate cleaning of the ignitor

(ceramic or electrode) to avoid ignition

difficulties, furthermore check that the baffle

holes are not obstructed.

Clean the plates with a damp cloth and lightly

grease with vegetable oil or sewing machine oil

whilst still warm.

Periodic oiling of the taps must be carried

out by qualified personnel who should also

be contacted if a fault in the functioning of

the appliance occurs.

INSTRUCTIONS FOR THE INSTALLER

ATTENTION: This appliance must be installed and used only in rooms which are permanently

The following instructions relating to installation and regulation must be carried out by qualified

personnel. The appliance must be installed correctly in conformity with the rules and regulations in

force. All interventions must be carried out with the appliance electrically disconnected.

THE MANUFACTURER DECLINES ALL RESPONSIBILITY FOR ANY DAMAGES

DERIVING FROM AN INSTALLATION WHICH DOES NOT CONFORM WITH THE

SITE OF INSTALLATION

For a good operation of the gas appliance it is

indispensable that the air necessary for gas

combustion can circulate in the room in a natural

manner. (The installer must follow the regulations

in force.)

ventilated according to the regulations in force.

REGULATIONS IN FORCE.

● The appliance must be installed at a

minimum distance of 50 cm. from curtains

or other combustible material.

7

Page 7

CONNECTION TO THE GAS SUPPLY

CONNECTION

Gas connection must be carried out in conformity

with the regulations in force. The appliance

leaves the factory tested and regulated for the

type of gas indicated on the plate which is

situated in the lower position near the gas

connection tube. Ascertain that the type of gas

with which the appliance will be supplied is the

same as that indicated on the plate.

If different carry out all the operations according

to the indications cited in the paragraph “adaption

to different types of gas”.

For a maximum output and minimum

consumption ascertain that the pressure of the gas

used has the values indicated in the table of

“burner characteristics”.

If the pressure of the gas used is different (or

variable) from that foreseen it is necessary to

install a suitable pressure regulator on the inlet

tube.

The use of pressure regulators for liquid gas

(GPL) is permitted as long as these conform to

the regulations in force.

The joint is mounted on the intake area of the

pipe, fitted with a filleted nut GJ 1/2, between the

sealing components as shown in Fig. 1. Screw the

parts without forcing, turn the joint in the

direction required and then tighten everything.

A) Intake pipe with nut

B) Seal

C) Adjustable joint

Carry out the connection to the gas plant only by

means of a rigid metallic tube conforming to the

regulations in force.

The joint for the entry of gas into the appliance is

threaded GJ 1/2".

Carry out the connection avoiding any type of

stress on the appliance.

The adjustable joint permits the location of the

supply tube in the appropriate site situated on the

side of the protection box of the hob itself (Fig.

2).

This system permits the total encumbrance of the

hob plus the gas supply tube to be contained to a

depth of 30 mm.

A) Intake pipe with nut

B) Adjustable joint

C) Rigid metallic gas supply tube

FO 0265

Fig. 2

IMPORTANT

Upon completion of installation, always check:

● that all the joints are completely sealed by

using a soapy solution, never a flame;

Fig. 1

● that the automatic ignition system is

operating satisfactory on all burners, both

individually and in combination.

8

Page 8

ELECTRICAL

CONNECTION

The appliance is predisposed to function with a

230V monophase voltage tension. Connection

must be carried out in conformity with the

regulations and dispositions of the laws in force.

Before connecting ensure that:

- The limiter valve and the electrical mains can

support the voltage of the appliance (see

registration plate).

- The power supply is correctly earthed according

to the regulations in force.

- The plug or omnipolar interrupter used can be

easily reached once the appliance has been

installed.

Fit the cable with a plug suitable to the voltage

and connect to an appropriate security socket.

If a direct connection to the mains is required, an

omnipolar interrupter with a minimum opening of

3mm between contacts, dimensioned to the

voltage and corresponding to the regulations in

force, should be interposed between the appliance

and the supply. The yellow/green earth cable must

not be interrupted by the interrupter. The brown

coloured phase cable (situated at terminal “L” of

the terminal box) must always be connected to the

network phase. The voltage cable must always be

positioned in such a manner that it at no point

reaches a temperature of 50∞C above room

temperature. An example of the best routing is

shown in fig. 3. The cable is guided by use of

clamps fixed laterally to the unit in such a way as

to avoid any contact with the appliance under the

hob.

CLAMPS

Openings

in the

{

Forniture

Unit

FO 0238-EN

YES

RIGID METALLIC TUBE

OR FLEXIBLE STAINLESS

STEEL TUBE

REAR VIEW

NO

REAR VIEW

Fig. 3

FO 0073-EN

Fig. 4

In case of substitution of the voltage cable use

cable type H05 RRF having a section suited to the

charge, it is furthermore necessary that the

yellow/green earth wire be approximately 2cm

longer than the phase and neutral wires (Fig. 4).

After connection try out the heating elements

allowing them to function for approximately 3

minutes.

The manufacturer declines all responsibility

in case the prevention of accidents regulations

are not respected.

9

Page 9

ADAPTATION TO DIFFERENT TYPES OF GAS

SUBSTITUTION OF THE

NOZZLES

Remove the grills:

Remove the caps and baffles from the burners:

With a tubular spanner no. 7 unscrew and remove

(fig. 5) the nozzles substituting them with those

corresponding to the type of gas used (see tab):

Remount the parts carrying out the operations

described in reverse. Then substitute the caliber

plate (positioned near the gas supply connection)

with the one corresponding to the new type of

gas. This can be found in the injector bag

supplied.

If the pressure of gas used is different (or

variable) from that foreseen an appropriate

pressure regulator should be installed on the entry

tube.

In case pressure regulators for GPL are used these

should conform to the regulations in force.

REGULATION OF THE

MINIMUM

Fig. 5

To regulate the minimum bring the tap to the

minimum flame position.

Extract the knob.

If the tap is of a type with the pin by-pass inside

the bar (Fig. 6-8), it is sufficient to screw or

unscrew according to the type of gas as indicated

in the following paragraph.

If the tap is of a type with a lateral by-pass (Fig.

8) it is necessary to detach the command panel by

applying pressure to the lateral projection (Fig. 7),

then insert a screwdriver through the hole until

the pin is reached.

When transforming from methane gas to GPL gas

fully screw down the by-pass pin.

Finally check that by quickly turning the tap from

the maximum position to the minimum position

the burner is not extinguished; remount the parts

carrying out the operations described in reverse.

The above-described adaption operations can be

easily carried out whatever the positioning or

fixture of the hob to the kitchen unit.

10

Fig. 6

FO 0254

Fig. 7

TAP

Burner Ø By-pass

Auxiliary 28

Semi-rapid 35

Rapid 45

of tap

1/100 mm

Page 10

Fig. 8

a) minimum

regulation

screw

b) normal tap

c) valvular tap

FO 1045

Fig. 9

TYPE TYPE NOZZLE NOMINAL REDUCED

OF GAS OF BURNER MARKS THERMAL THERMAL

1/100 mm CAPACITY CAPACITY kPa

MJ/h MJ/h

NATURAL

GAS

(methane)

L.P.G.

GAS

Rapid (large) 140 10,00 2,34

Semi-rapid (medium) 111 6,12 1,51 1,0

Auxiliary (small) 89 3,60 0,90

Rapid (large) 88 9,72 2,34

Semi-rapid (medium) 71 6,12 1,51 2,75

Auxiliary (small) 55 3,60 0,90

MAINTENANCE

Periodically control the state of conservation and

efficiency of the gas tube and, if present, the

pressure regulator; in case of irregularity do not

attempt to repair, but substitute the damaged part.

To guarantee good functioning and security the

gas regulation taps should be periodically

greased.

The periodic lubrification of the taps must

be carried out by qualified personnel who

should also be contacted in case

irregularities are encountered in the

functioning of the apparatus.

NOMINAL

PRESSURE

11

Page 11

INSTALLATION IN THE KITCHEN UNITS

DIMENSIONS

Height (overall): 74 mm. (see drawing)

Depth: 510 mm.

Width: 580 mm.

Thickness: 30 mm.

Automatic Taps

Ignition Switches: YES

Gas Hob Burners: 1 Rapid Burner (front left)

1 Auxiliary Burner (front right)

2 Semirapid Burners (back)

12

30

SR

554

SR

A

R

13

13

510

16,5

477

CUT OUT DIMENSIONS

Height: 72 mm.

Depth: 480 mm.

Width: 560 mm.

Weight: 9 Kg.

74

510

480

580

560

580

FO 0767

Fig. 10

A = Auxiliary Burner

SR = Semirapid Burner

R = Rapid Burner

12

16,5

FO 0697

Fig. 11

Page 12

INSERTION AND ASSEMBLY

The hobs can be installed in a unit having an

opening for installation of the dimensions

illustrated in fig. 11.

The fixture of the hob to the unit must be carried

out as follows:

position the appropriate sealings, supplied, on the

edge of the opening predisposed taking care that

the edges meet without overlapping;

place the hob in the opening of the unit taking

care in centring;

fix the hob to the unit by means of the appropriate

clips (see fig. 12). The traction of the screws is

sufficient to trace the seal, whose excess can thus

be removed. The edge of the hob forms a double

labyrinth seal which provides a total guarantee

against the infiltration of liquids.

POSSIBILITY FOR INSERTION

Kitchen unit with door

Suitable precautions should be taken in the

construction of the unit in order to avoid possible

contact with the hot surround of the hob when in use.

This could occur if the hob surround is affected by a

depression or pressure following the opening or

closing of the door. The solution recommended to

avoid this inconvenience is illustrated in Fig. 14.

The panel under the hob should be easily removable

in order to permit blocking and unblocking of the hob

for technical assistance purposes.

The opening for insertion must be distant from the

base and the side, of a minimum of 55 millimetres for

the rear fig. 18.

60

Fig. 14

a) Seal

Fig. 13

30

Fig. 12

480

30

a

20 min

b

a) Panel of

380

dismantled

591

140

unit

b) Possible

space

useful for

FO 1013

connections

FO 1038

Fig. 15

13

Page 13

Kitchen unit with oven

The opening should have the dimensions shown in figs. 13-14 and be provided with supports to permit

an efficient ventilation. To avoid excessive overheating it is advisable to carry out installation as (figs.

16-17). The electrical connection of the hob and that of the oven must be carried out separately, both for

electrical reasons and to facilitate the frontal extraction of the oven.

2

120 cm

2

50 cm

FO 0939

180 cm

2

Fig. 16 Fig. 17

FO 0938

360 cm

2

MINIMUM DISTANCE TO BE RESPECTED

(in millimetres)

55 MIN.

650 mm

FO 0805

Fig. 18

FO 0479

Fig. 19

In case of a right or left side having a height exceeding that of the hob, this should be situated at a

minimum of 100mm from the top opening. Cupboards or extractor fans should be situated at a minimum

of 650mm from the hob (Fig. 19).

14

Page 14

TECHNICAL ASSIST ANCE AND SP ARE P ARTS

Before leaving the factory this appliance was

tested and controlled by expert and specialized

personnel in order to give the best working

results. All repairs or controls which may be

necessary should be undertaken with maximum

care and attention.

For this reason we recommend you always

contact the Retailer who sold it or our nearest

Assistance Centre, specifying the type of problem

and the model of the appliance in your

possession.

The Manufacturer is not responsible for possible inaccuracies, caused by printing or

transcription errors, contained in the present manual. It reserves the right to make any

modifications to its products which it deems necessary or useful, even in the interest of the

user, without prejudizing essential operating and security characteristics.

Important!

This appliance is easy to use. Nonetheless,

to obtain the best results it is important that

this brochure be read carefully and all the

instructions followed before using for the

first time.

The brochure provides the correct

indications for installation, use and

maintenance as well as providing useful

advice.

15

Loading...

Loading...