Zanussi FCZ102GAD, 237513, FCZ102GAG, 237503 User Manual

RANGE

COMPOSITION

ZANUSSI Professional easySteamPlus

blends tradition with the latest technological

research in order to satisfy the creativity and

working requirements of today's professional

kitchen. The easySteamPlus range offers a

choice of different models available in two

levels of operation, providing a high degree

of automation and an extensive range of

accessories. The easySteamPlus combis are

designed to form complete cook&chill

systems together with air-o-chill blast

chillers/freezers, therefore, any installation

can be tailored to meet the needs of the

caterer.

The easySteamPlus combis detailed are 10

GN 2/1 gas models.

FUNCTIONAL AND

CONSTRUCTION

FEATURES

� Convection cycle (max. 300ºC): ideal for

meat to be cooked without humidity and "au

gratin". In conjunction with the half-power

function for all kinds of pastry cooking. The

humidity generated by the food itself can be

controlled by Lambda sensor for a natural

cooking.

� Steam cycle (max. 130ºC): for products

that can be cooked in water. Steam cooking

respects the original properties of food and

reduces weight loss.

� Combi cycle (max. 250ºC): ideal for most

kinds of cooking. Impressive reduction of

cooking times and food shrinkage. The

humidity generated by the food and the

steam generator can be controlled by

Lambda sensor for consistent results

independent from the food load.

� easySteamPlus ovens can cook by

controlling either the cooking time or the

product's core temperature through a

6-sensor probe.

� Regeneration cycle: it produces the best

humidity conditions for quickly heating the

products to be regenerated (max. 250ºC) on

the plate.

easySteamPlus OVENS

COMBI LW 10 GN 2/1-GAS

TECHNICAL DATA

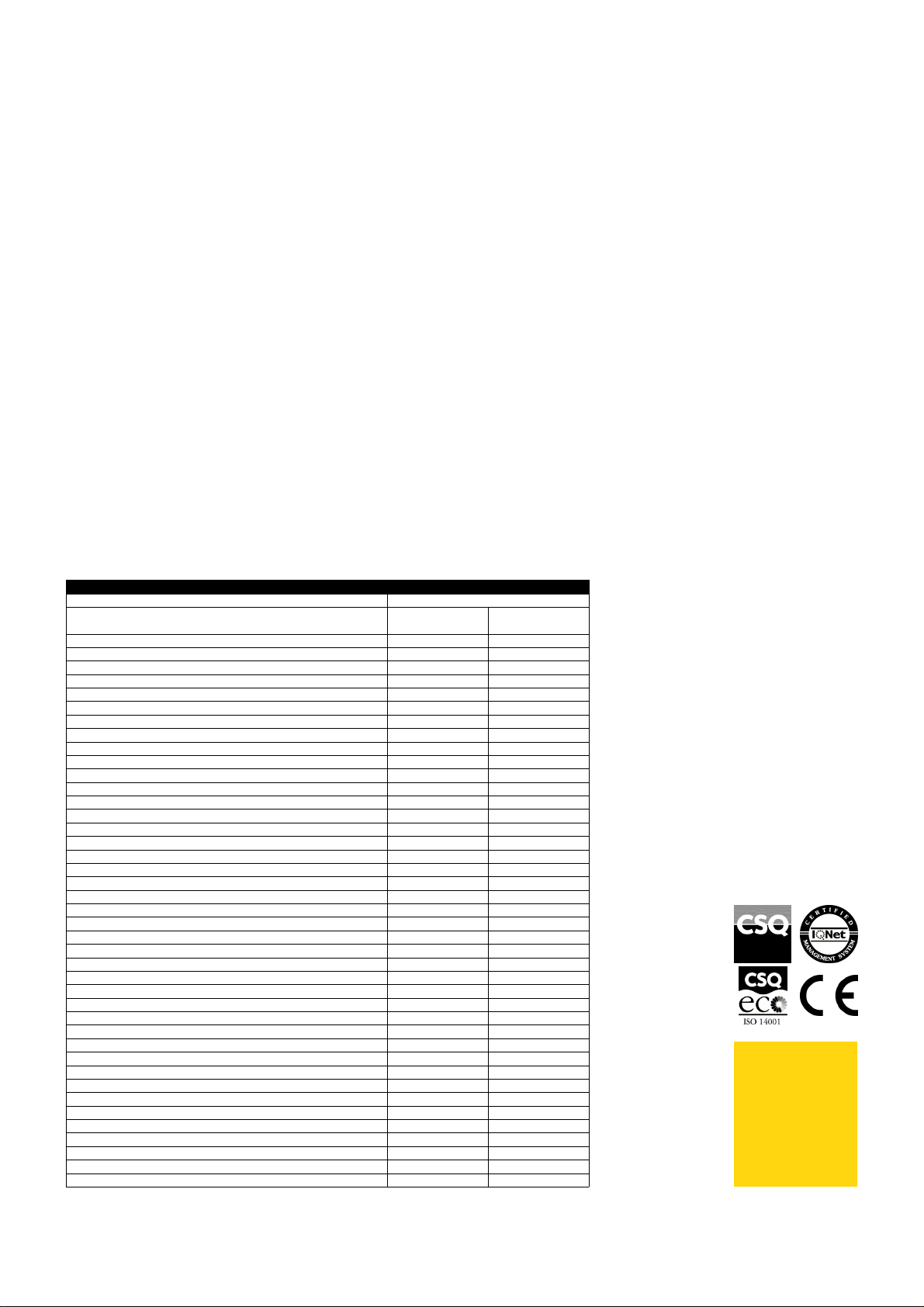

CHARACTERISTICS MODELS

Power supply Gas Gas

Gas Natural Gas LPG

Number of grids 10 10;

Runners pitch - mm 65 65

Cooking cycles - °C

air-convection 300 300

steam 130 130

combi 250 250

Humidity control l l

Two-speed fan l l

Multi Point Probe l l

Automatic cleaning system l l

N° of programs 100 100

External dimensions - mm

width 1208 1208

depth 1065 1065

height 1058 1058

Internal dimensions - mm

width 640 640

depth 855 855

height 736 736

Power - kW

boiler 25 25

auxiliary 1 1

cooking chamber 27 27

electric 1 1

gas 45 45

Net weight - kg. 203 203

Supply voltage 230 V, 1N, 50/60 230 V, 1N, 50/60

ZANUSSI

P R O F E S S I O N A L

FCZ102GAG

237503

FCZ102GAD

237513

COMBI LW 10 GN 2/1-GAS

easySteamPlus OVENS

� Fan speeds: full, half speed (for delicate

cooking such as for baking cakes) and HOLD

(pulse ventilation for baking and low

temperature cooking). The "HOLD utility" is

also perfect for keeping food warm at the end

of the cooking cycle.

� Low power cycle: for delicate cooking

such as for baking cakes.

� Eco-delta: the temperature inside the

cooking cell is higher than the temperature of

the food and rises accordingly.

� Low Temperature Cooking (LTC,

automatic cycle): indicated for large pieces of

meat, automatically selects the cooking

parameters to achieve the lowest weight

loss. It features ARTE (Algorithm for

Remaining Time Estimation).

� Exhaust valve electronically controlled to

evacuate the humidity excess.

� Break phase: set a time to delay the start

of cooking programs or to program a break

between two cooking cycles (for example to

allow rising).

� 20 pre-set programs and 100 7-step free

cooking programs.

� Automatic cleaning system: 4 different

pre-set cycles to clean the cooking cell,

OPTIONAL ACCESSORIES

ACCESSORIES MODELS

1 GRID GN1/1 FOR 8 WHOLE CHICKENS(1.2KG) 922266 922266

2 FRYING BASKETS FOR OVENS 922239 922239

2 GRIDS GN 1/1 FOR CHICKENS (8 PER GRID) 922036 922036

AUTOMATIC WATER SOFTENER FOR OVENS 921305 921305

BANQUET RACK-51PLATES-75MM PITCH-10GN2/1 922052 922052

BASKET F. DETERGENT TANK ON SUPPORT 10GN 922212 922212

CONTROL PANEL FILTER-10 GN2/1 OVENS-LW 922247 922247

CUPB. BASE+TRAY SUPP-10 GN 2/1 OVENS LW 922254 922254

DOUBLE-CLICK CLOSING CATCH FOR OVEN DOOR 922265 922265

DRAIN KIT (D=50MM) OVENS 6&10 GN 1/1-2/1 922283 922283

EXHAUST HOOD WITH FAN FOR 10 GN2/1-LW 640794 640794

EXHAUST HOOD WITHOUT FAN FOR 10GN2/1-LW 640793 640793

EXTERNAL SIDE SPRAY UNIT 922171 922171

FAT FILTER FOR OVENS 10X1/1-2/1 922178 922178

FLUE CONDENSER FOR GAS OVENS-LW 922235 922235

FRYING GRIDDLE GN 1/1 FOR OVENS 922215 922215

FRYING GRIDDLE GN 2/3 FOR OVENS 922284 922284

HEAT SHIELD FOR 10 GN 2/1 OVENS 922252 922252

HOT CUPB.BASE+TRAY SUPP-10 GN 2/1 LW 922256 922256

KIT 4 ADJUSTABLE FEET 922012 922012

KIT HACCP EKIS 922166 922166

KIT INTEGRATED HACCP FOR OVENS 922275 922275

KIT TO CONVERT FROM LPG TO NATURAL GAS 922278

KIT TO CONVERT FROM NATURAL GAS TO LPG 922277

NON-STICK U-PAN GN 1/1 H=20 MM 922090 922090

NON-STICK U-PAN GN 1/1 H=40 MM 922091 922091

NON-STICK U-PAN GN 1/1 H=65 MM 922092 922092

NON-STICK U-PAN GN 2/3 H=20 MM 922285 922285

OPEN BASE+TRAY SUPPORT FOR 10GN2/1 LW 922198 922198

OVEN GRILL (ALUMINIUM) GN 1/1 922093 922093

PAIR OF 1/1GN AISI 304 S/S GRIDS 922017 922017

PAIR OF 2/1 GN AISI 304 S/S GRIDS 922175 922175

PASTRY(400X600)RACK+WHEELS-80MM,10 2/1LW 922067 922067

RESIN SANITIZER FOR WATER SOFTENER 921306 921306

SLIDE-IN RACK WITH HANDLE-10 GN 2/1-LW 922047 922047

THERMAL COVER FOR 10 GN 2/1-LW 922048 922048

TRAY RACK+WHEELS 10 GN 2/1,65MM PITCH-LW 922043 922043

TRAY RACK+WHEELS 8 GN 2/1,80MM PITCH-LW 922045 922045

TRAY SUPPORT FOR OVEN BASE 10 GN 2/1-LW 922041 922041

TROLLEY FOR SLIDE-IN RACK 10 GN 2/1-LW 922042 922042

WATER FILTER FOR OVENS 0.8 L/MIN. 922186 922186

LCAB30 2009-09-21 The Company reserves the right to alter technical specifications without prior notice.

according to the actual requirements. The

cleaning system is built-in (no need for

add-ons).

� Quick cooling: useful when passing to a

type of cooking that requires a lower

temperature than the previous one. It works

automatically and manually.

� Manual injection of water in the cell.

� Built-in retractable hand shower for

countertop models.

� Automatic steam generator water draining

with an automatic scale diagnosis system.

� HACCP management as standard: it

allows the recording of the cooking

programme according to H.A.C.C.P.

standard (Hazard Analysis and Critical

Control Points).

� Humidity control: controls and displays the

exact (single degree of accuracy) humidity

degree of the oven atmosphere in hot air,

combi and regeneration cycles. The Lambda

sensor measures physically the real humidity

level inside the cooking cell and acts

consequently according to the set value. With

hot air cycles, it also manages to exhaust the

excess humidity generated from the food.

� Perfect eveness: blows fresh air from

FCZ102GAG

237503

FCZ102GAD

237513

outside through the bi-functional fan, which

pulls the air in from the backside of the oven,

after it is pre-heated and therefore

guaranteeing the evenness of the cooking

process.

� Multi-sensor food probe: 6 sensors, ½ ºC

accuracy.

� The cell and steam generator gas burners:

GASTEC certification on high efficiency and

low emissions. High efficiency cell and steam

generator heat exchangers.

� Stainless steel 304 throughout, with

seamless joints in the cooking cell.

� Height adjustable legs.

� Double thermo-glazed door equipped with

drip pans to catch condensate and prevent

slippery floor for maximum security and four

holding positions allowing easier loading and

unloading manoeuvres.

� Halogen lighting in the cooking cell.

� Access to main components from the front

panel.

� Automatic scale diagnosis system in the

steam generator to detect the presence of

scale build-up.

� IPX5 water protection.

� Air-o-steam ovens meet GASTEC safety

requirements.

ZANUSSI

P R O F E S S I O N A L

www.zanussiprofessional.com

Loading...

Loading...