Zanussi easySteamPlus FCZ201EAH, easySteamPlus 237014, easySteamPlus FCZ201EAN, easySteamPlus FCZ201ETA, 237204 Brochure & Specs

...

ZANUSSI

P R O F E S S I O N A L

COMBI LW 20 GN 1/1-ELECTRIC

easySteamPlus OVENS

237204

TROLLEY TRAY RACK 20X1/1GN,63MM PITCH-LW 1 1

TROLLEY TRAY RACK 16X1/1GN,80MM PITCH-LW 1

DOOR SHIELD 20 1/1-PRE-HEAT W/O TROLLEY 1 1 1

CONTROL PANEL FILTER-20 GN1/1 OVENS-LW 1 1

INCLUDED ACCESSORIES

Supply voltage 400 V, 3N, 50/60 400 V, 3N, 50/60 230 V, 3, 50/60

Net weight - kg. 284 284 284

electric 34.5 34.5 34.5

cooking chamber 34 34 34

auxiliary 0.8 0.8 0.8

boiler 24 24 20

Power - kW

height 1450 1450 1450

depth 715 715 715

width 460 460 460

Internal dimensions - mm

height 1795 1795 1795

depth 957 957 957

width 993 993 993

External dimensions - mm

N° of programs 1000 1000 1000

Automatic cleaning system l l l

Multi Point Probe l l l

Two-speed fan l l l

Low temp steaming l l l

Regeneration l l l

Humidity control l l l

Convection/steaming l l l

Steaming l l l

Convection l l l

combi 250 250 250

steam 130 130 130

air-convection 300 300 300

Cooking cycles - °C

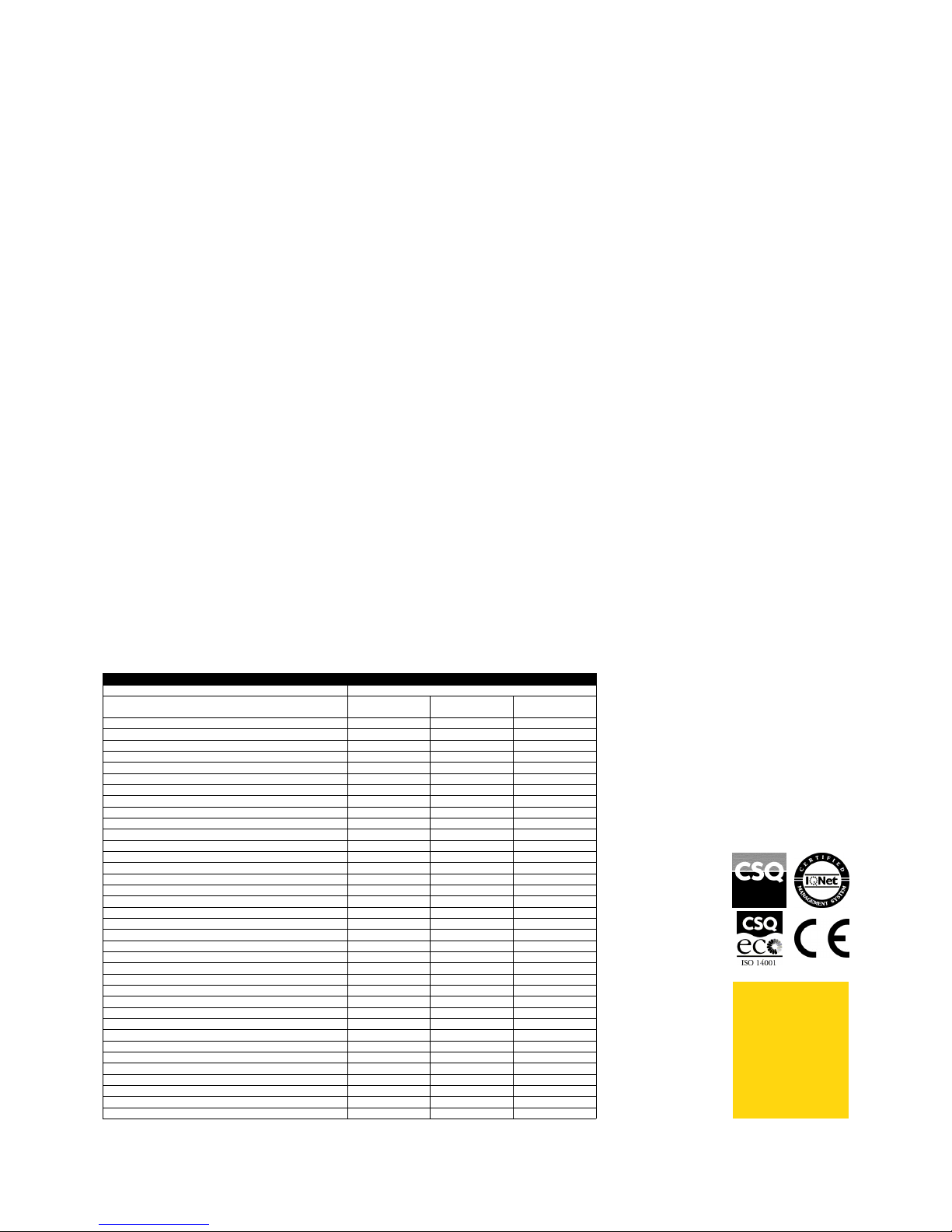

Runners pitch - mm 63 80 63

Number of grids 20 16 20

Power supply Electric Electric Electric

FCZ201ETA

237204

FCZ201ETH

237214

FCZ201ETN

237224

CHARACTERISTICS MODELS

TECHNICAL DATA

RANGE

COMPOSITION

ZANUSSI Professional easySteamPlus

blends tradition with the latest technological

research in order to satisfy the creativity and

working requirements of today's professional

kitchen and simplify the usage of the control

panel. The easySteamPlus range offers a

choice of different models available in two

levels of operation, providing a high degree

of automation as well as an extensive range

of accessories. The easySteamPlus combis

are designed to form complete cook&chill

systems together with the easyChill blast

chillers/freezers, therefore, any installation

can be tailored to meet the needs of the

caterer.

The easySteamPlus combis detailed are 20

GN 1/1 electric models.

FUNCTIONAL AND

CONSTRUCTION

FEATURES

� Selection window with three cooking

modes (Automatic, Manual and Programs),

cleaning cycles and setting mode.

� Automatic mode: just select the family and

food type and the oven will do the rest.

Temperature, cooking climate and time are

managed by the oven to achive a perfect

result, regardless of the food load. The

automatic mode is ideal for less skilled

operators.

3 Special automatic cycles:

- Low Temperature Cooking (LTC, automatic

cycle): indicated for meat and fish,

automatically selects the cooking parameters

to achieve the lowest weight loss and the

maximum quality.

- Reheating cycle: the best humidity

conditions are managed to quickly reheat the

products.

- Proofing cycle: thanks to the Lambda

sensor it’s possible to create a perfect

ambient for proofing.

� Programs mode: the recepies can be

stored up to a maximum of 1000, 16-step

cooking programs available.

� Manual Mode: the traditional way of

cooking by selecting the cooking cycle,

temperature, time and advanced features.

COMBI LW 20 GN 1/1-ELECTRIC

easySteamPlus OVENS

LCAA40 2011-11-29 The Company reserves the right to alter technical specifications without prior notice.

www.zanussiprofessional.com

ZANUSSI

P R O F E S S I O N A L

WATER FILTER FOR OVENS 0.8 L/MIN. 922186 922186 922186

WATER FILTER FOR 20 2/1 OVENS 1.8 L/MIN. 922104 922104 922104

TROLLEY TRAY RACK 20X1/1GN,63MM PITCH-LW 922007 922007 922007

TROLLEY TRAY RACK 16X1/1GN,80MM PITCH-LW 922010 922010 922010

TRAY(400X600X38)5 ROWS-PERF.ALUM/SILICON 922189 922189 922189

THERMAL COVER FOR 20X1/1GN-LW 922014 922014 922014

RETRACT. SPRAY UNIT-20 GN1/1& 2/1 OVENS 922263 922263 922263

RESIN SANITIZER FOR WATER SOFTENER 921306 921306 921306

PASTRY TROLLEY 16(400X600)80MM-20 1/1 LW 922068 922068 922068

PAIR OF 1/1GN AISI 304 S/S GRIDS 922017 922017 922017

OVEN GRILL (ALUMINIUM) GN 1/1 922289 922289 922289

NON-STICK U-PAN GN 2/3 H=20 MM 922285 922285 922285

NON-STICK U-PAN GN 1/1 H=60 MM 922092 922092 922092

NON-STICK U-PAN GN 1/1 H=40 MM 922091 922091 922091

NON-STICK U-PAN GN 1/1 H=20 MM 922090 922090 922090

KIT INTEGRATED HACCP FOR OVENS 922275 922275 922275

KIT HACCP EKIS 922166 922166 922166

HEAT SHIELD FOR 20 GN 1/1 OVENS 922243 922243 922243

FRYING GRIDDLE GN 2/3 FOR OVENS 922284 922284 922284

FRYING GRIDDLE GN 1/1 FOR OVENS 922215 922215 922215

EXTERNAL SIDE SPRAY UNIT 922171 922171 922171

EGG FRYER FOR 8 EGGS - GN 1/1 922290 922290 922290

DOOR SHIELD 20 1/1-PRE-HEAT W/O TROLLEY 922094 922094 922094

CONTROL PANEL FILTER-20 GN1/1 OVENS-LW 922248 922248 922248

BASKET FOR DETERGENT TANK-WALL MOUNTED 922209 922209 922209

BANQ.TROLLEY-54PLATES-74MM PITCH-20GN1/1 922016 922016 922016

BANQ.TROLLEY-45PLATES-90MM PITCH-20GN1/1 922072 922072 922072

BAKING TRAY(400X600X20)4 EDGES-PERF.ALUM 922190 922190 922190

BAKING TRAY(400X600X20)4 EDGES-ALUMINIUM 922191 922191 922191

BAKING TRAY FOR BAGUETTE GN 1/1 922288 922288 922288

AUTOMATIC WATER SOFTENER FOR OVENS 921305 921305 921305

2 GRIDS GN 1/1 FOR CHICKENS (8 PER GRID) 922036 922036 922036

2 FRYING BASKETS FOR OVENS 922239 922239 922239

2 FAT FILTERS FOR 20X1/1 & 2/1 OVEN 922179 922179 922179

1 GRID GN1/2 FOR 4 WHOLE CHICKENS(1.2KG) 922086 922086 922086

1 GRID GN1/1 FOR 8 WHOLE CHICKENS(1.2KG) 922266 922266 922266

FCZ201ETA

237204

FCZ201ETH

237214

FCZ201ETN

237224

ACCESSORIES MODELS

OPTIONAL ACCESSORIES

� Automatic steam generator water draining with

an automatic scale diagnosis system.

� Traditional cooking cycles:

- Convection cycle (max. 300 ºC): ideal for

products that should be cooked without humidity.

Humidity generated by the food itself can be

controlled thanks to the Lambda sensor, for a

natural cooking.

- Steam cycle (max. 130 ºC): for products that

can be cooked in water. It can be used as Low

temperature Steam (25-99°C), Steam (100°C) or

High temperature steam (100-130°C).

- Combi cycle (max. 250ºC): combining

convected heat and steam to obtain a

humidity-controlled cooking environment (thanks

to the Lambda sensor), reducing cooking times

and food shrinkage.

� Humidity control with Lambda sensor: controls

and displays the exact (single degree of

accuracy) amount of humidity contained in the

hot air which circulates in the oven atmosphere

during the combi and regeneration cycles. The

Lambda sensor measures physically the real

humidity level inside the cooking cell and acts

consequently according to the set value. With hot

air cycles, it also manages to exhaust the excess

humidity generated from the food.

� Perfect eveness: blows fresh air from the

outside through the bi-functional fan, which

pushes the air that has been preheated in the

meantime, into the cooking chamber,

guaranteeing the evenness of the cooking

process.

� Automatic cleaning system: 4 different pre-set

cycles to clean the cooking cell, according to the

actual requirements. The cleaning system is

built-in (no need for add-ons).

� Integrated Automatic Intensive Cleaning

System: the new cleaning parameters and the

improved design of the wash arms allow to

optimize the use of detergent, rinse aid and water

and to obtain superior cleaning results.

� Multi-sensor food probe: 6 sensors, ½ ºC

accuracy.

� Sous-vide USB Probe, available as optional

accessory, ensures excellent cooking results

even with vacuum-packed products.

� Fan speeds: full, half speed (for delicate

cooking such as for baking cakes) and pulse

(pulse ventilation for baking and low temperature

cooking).

� Low power cycle: for delicate cooking such as

for baking cakes.

� Eco-delta: the temperature inside the cooking

cell is higher than the temperature of the food

itself and rises accordingly.

� Quick cooling: useful when switching to a type

of cooking that requires a lower temperature than

the previous one. It works automatically and

manually.

� Guided descaling function guides operator

during the boiler descaling phase (from "Setting"

mode).

� MultiTimer: function that manages a sequence

of different cooking cycles to improve flexibility

and ensure perfect cooking results. Up to 14

timers can be set and an alarm warns the

operator when cooking time is reached.

� Holding phase allows the food to be kept at a

set temperature at the end of the cooking cycle

(accessible from the "Manual" mode).

� Make-it-Mine feature allows the operator to

personalize all main user interfaces in the

"Setting" mode according to his needs and to

block the editing or deleting of stored programs.

� Manual injection of water in the cell.

� Food Safe control: automatic monitoring and

validation of the cooking process in accordance

with HACCP standards, with regards to

microbiological safety of process.

� HACCP management available upon request:

it allows the recording of the cooking programme

according to H.A.C.C.P. standard (Hazard

Analysis and Critical Control Points).

� USB connection available to download Food

Safe Control and HACCP Log.

� Stainless steel 304 throughout, with seamless

joints in the cooking cell.

� Double thermo-glazed door equipped with drip

pans to catch condensation and prevent

drippings on the floor, for maximum security. Four

holding positions allowing easier loading and

unloading.

� Halogen lighting in the cooking cell.

� IPX5 water protection.

� easySteamPlus ovens meet IMQ safety

requirements.

Loading...

Loading...