Page 1

INSTRUCTION BOOKLET

822 90 11-21

DISHWASHER

DCS 14 W

DCS 14 S

Page 2

- 2 -

For the user

Important safety information 3

Description of the appliance 4-5

- Rinse aid dispenser

- Spray arm

- Coarse strainer

- Fine filter

- Detergent dispenser

- Water softener

- Water softener plug

The control panel and programmes 6

Using your appliance 7

How to load the dishwasher 8-9

-Instruction for verification tests

Maintenance and cleaning 10

- Important

- General cleaning

- Cleaning the filters

- Cleaning the cabinet

- Moving the machine

- Protecting the machine against freezing

If the machine is not working 11

Service 12

- Service and spare parts

- Customer care

Guarantee Conditions 13

Zanussi Service Force 14-15

For the installer

Technical specifications 16

Unpacking the machine 17

- If the machine is damaged

- Accossories

- Identification of materials

Installation 18-19

- Water inlet

- Water drainage

- Power supply

Guide to use the instruction book

The following symbols will be found in the text to guide you throughout the instructions:

Safety instructions

Step by step instructions

Hints and tips

Environmental information

Contents

Page 3

- 3 -

822 90 11-21

Before installing and first using the dishwasher, read the instruction booklet carefully, including

its hints and warnings. Doing so will ensure that your machine will perform properly and to best

advantage. Anyone using the machine should be thoroughly familiar with its instructions for use

and safety features. Save these instructions and make sure they remain with the machine if it is

moved or sold, so that everyone using it through its life can be properly informed on appliance

use and safety.

Installation

■ All installation work and other work done on the product

must be carried out by a qualified technician. Work

performed by persons with inadequate know ledge

may adversely affect the satisfactory functioning of

the product and may cause personal injury or damage.

■ This appliance is heavy. Care should be taken when

moving it.

■ Make sure that the power cord is not nipped or other-

wise damaged and that its hoses do not get crushed

or kinked when moving the dishwasher in connection

with installation or cleaning etc.

Child Safety

■ This appliance is designed to be operated by adults.

Children should not be allowed to tamper with the

controls or play with the product.

■ Keep all packaging well away for children.

■ Keep all detergents in safe place out of children´s

reach.

During Use

■ This dishwasher is designed solely for washing house-

hold utensils suitable for machine washing and only

in accordance with these instructions. Using it for

other purposes could lead to physical injury or damage

to property.

■ Items that are contaminated by petrol, paint.steel or

iron debris, corrosive, acidic or alkaline chemicals

must not be washed in this dishwasher.

■ Avoid opening the door while the machine is running.

■ If you take any dishes out of the machine before the

end of the dishwashing cycle, it is extremely important

to rinse them thoroughly under running water to remove

any remaining detergent.

■ Only use detergent specifically designed for use in

dishwashers.

■ Long bladed knives stored in an upright position are

a potential hazard.

■ Long and/or sharp items of cutlery such as carving

knives must be positioned horizontally in the basket.

■ When finishing loading or unloading close the door,

as an open door can be a hazard.

■ Make sure that the machine is disconnected from the

power supply during cleaning and maintenance work.

■ After using the machine, turn off its water supply and

disconnect it from the power supply. When removing

the electrical plug, grip the plug, not the lead.

■ Servicing and repairs must be carried out by a service

company authorised by the supplier. Use only spare

parts supplied by these. Never try to repair the machine

yourself.

Conservation

In the interest of the environment:

■ At the end of the machine's useful life, disconnect

the electrical plug from the power supply, then cut

the electrical lead at the point where it enters the

machine. Make quite sure that children will not be

able to play with the severed lead and plug.

Important safety information

Page 4

- 4 -

Description of the appliance

1

2

3

4

5

6

1. Rinse aid dispenser

2. Spray arm

3. Coarse strainer

4. Fine filter

5. Detergent dispenser

6. Water softener

Page 5

- 5 -

Rinse aid dispenser

Use of rinse aid will result in faster drying of the load and

gives the dishes a shiny finish. It may be necessary to adjust

the quantity of rinse aid dispensed if you live in either a very

hard water or a very soft water area. More is needed for

hard water and less for soft water. Leave the dispenser in

its preset position when you first use the dishwasher and

only adjust if, after a few cycles, you notice the following:

• Crockery remaining dull looking and/or showing

occasional round spots. If this happens, increase the

quantity of rinse aid by turning the red dial below the

filter trough clockwise.

• Crockery feeling sticky or showing whitish spots. If this

happens, decrease the quantity of rinse aid by turning

the red dial below the filler trough anti-clockwise.

The dispenser holds about 140 ml. This is enough for 4070 wash cycles, depending on the dosage setting. When

the rinse aid level is approaching the bottom of the scale it

is time to refill the dispenser. Swivel out the filler trough and

carefully fill up with rinse aid until the level reaches up to the

red mark on the level indicator tube. Do not overfill and

carefully wipe off any spillage to prevent sudsing problems.

Don’t forget to close the filler trough afterwards.

Do not fill the rinse aid dispenser with liquid

detergent.

Spray arm

It is important to keep all the holes in the spray arm clear.

If the spray arm becomes blocked this will affect washing

efficiency. If the spray arm needs cleaning, unscrew the

nut clockwise (left-hand thread) and lift off the spray arm.

Clear the holes and shake out any food particles.

Coarse strainer

The purpose of the coarse strainer is to catch large objects,

such as toothpicks and pieces of eggshell. Make sure that

the strainer is always clean. Lift it out and rinse it under

running water whenever necessary.

Fine filter

It is just as important to keep this filter clean. A dirty or

clogged filter will impair washing efficiency. The fine filter

can easily be lifted out for cleaning when you have removed

the coarse strainer.

Detergent dispenser

Only use detergents specially designed for dishwashers.

Open the detergent compartment on the inside of the door

by pushing the lid catch sideways. Pour the detergent into

the compartment, for a normal load pour about 15g.

Close the lid firmly. The detergent will be automatically

dispensed at the right time. Pre-wash detergent is not

generally needed, but if the dishes ar heavily soiled add

an extra 5g anywhere on the inside of the door.

Since not all detergents are the same, you should also

consult the instructions on the packet. Using the correct

amount of detergent also contributes to reducing pollution.

Zanussi recommends the use of Finish dishwasher detergent and Rinse Aid.

Water softener

This dishwasher is equipped with a water softener for hard

(chalky) water, therefore the rinse aid dispenser should

be set for a low dosage.

The lime (chalk) in hard water causes white deposits to

occur on dishes and the interior of the dishwasher.

To prevent this, the water has to pass through a special

container where its hardness is removed. Since the water

softener consumes coarse dishwasher salt, you will have

to replenish the salt container after a certain number of

dishwashing cycles. When the indicator lamp on the

control panel lights up, it is time to fill up with salt.

Proceed as follows:

1. Unscrew the salt container filler cap.

2. Fill up salt container with water (only the first

time).

3. Fill the container with coarse salt. Use the funnel

supplied with the machine.

Ordinary domestic salt will affect the effiency of

the water softener and damage it.

4. Remove the funnel and wipe off any spillage.

5. Screw the filler cap back in place.

The salt container holds about 1 litre, which is enough for

about 20 - 30 dishwashing cycles. Always ensure that

there is water in the salt container before filling salt.

Only fill with salt just before starting one of the

complete washing programmes. This will prevent

any grains of salt or salty water, which may have

been spilled, remaining in the bottom of the

machine for any period of time, this could cause

corrosion.

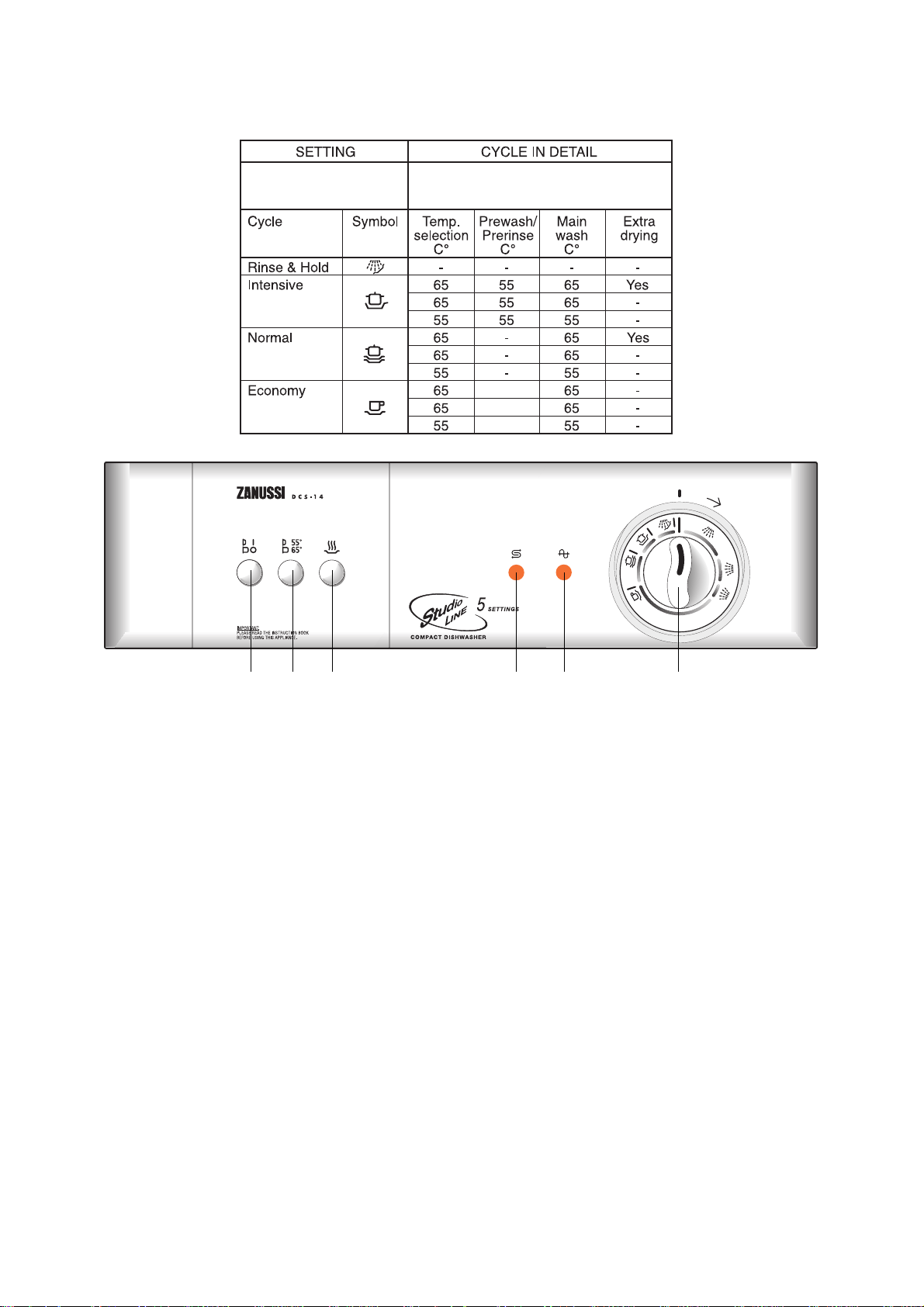

Water softener plug

As supplied from the factory,

the water softener is set for

a water hardness of up to

20°dH. If your water is harder

than this, you can increase

the capacity of the water

softener by pulling out the

rubber plug at the rear of the

dishwasher on the left hand

side viewed from the back.

See illustration.

Contact your local Water Authority to find the exact water

hardness level for your area.

Never run the dishwasher without salt in the container as

this may damage the water softener. If the damage is slight,

the water-softener function can be partially restored by

filling the container with salt and then running the Normal

cycle 4-5 times.

Page 6

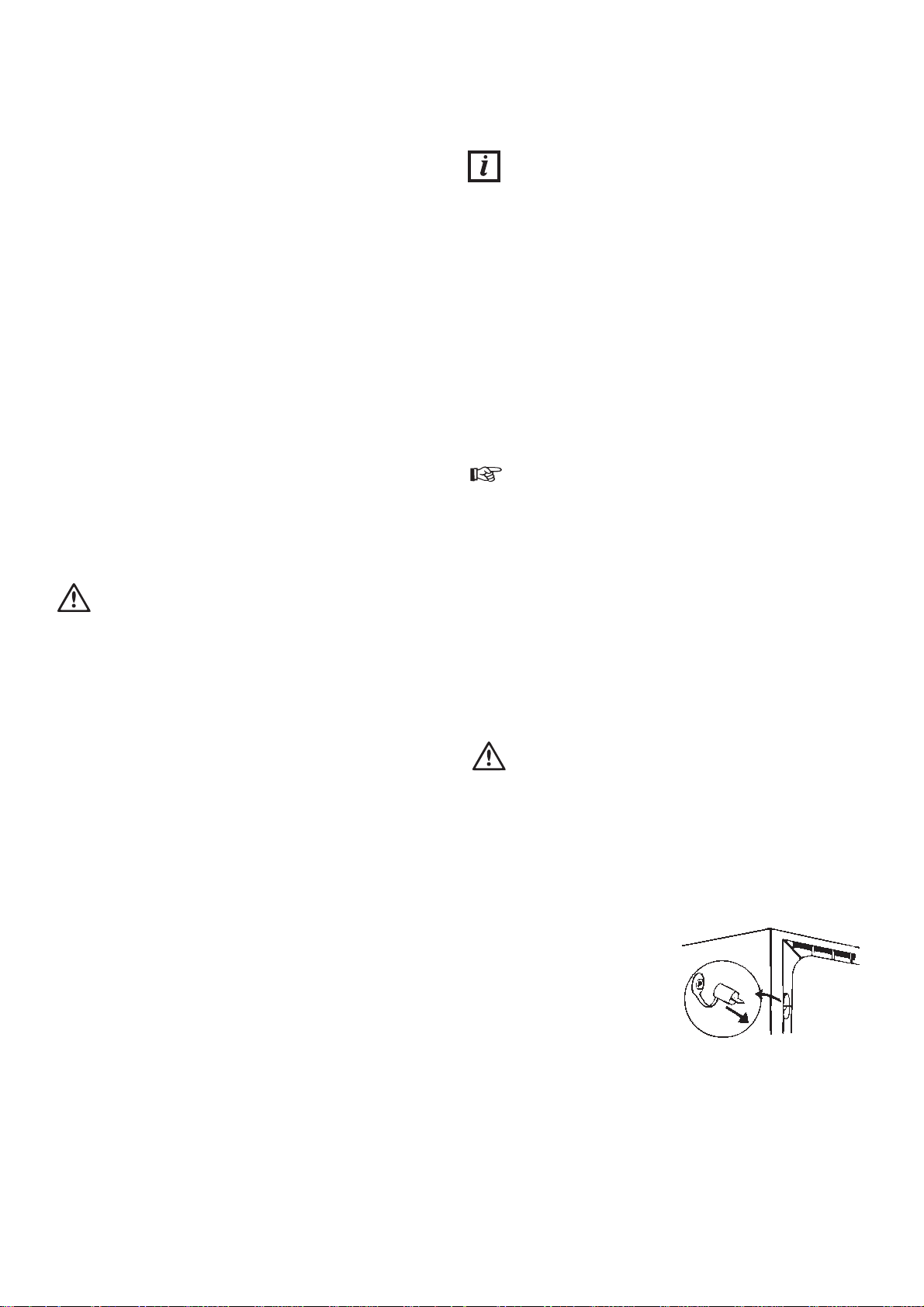

The control panel and programmes

- 6 -

123 6 5 4

1 On/Off-button

Press the button in order to start the required

programme.

2 Temperature selector

55° - Button in

65° - Button out

3 Extra drying effect

If the button is pressed in the temperature of the

final rinse water will be higher and the drying effect

will be improved.

4 Programme selector

Turn the programme selector clockwise to the

programme required and press in the On/Off button.

To isolate the dishwasher from the mains completely,

unplug it from the wall socket.

5 Indicator lamp

While the programme is in progress, the operating

lamp is lit and it goes out when the programme is ready.

6 Salt indicator lamp

The operating lamp indicates when the salt needs to be

replenished. The lamp may remain lit for one or more

programmes after replenishment, which is fully normal.

Door lock

Press the handle down and open the door. Avoid opening

the door while the machine is running. If the door is opened

and is put standing ajar after a completed programme the

dishes will dry faster.

Programmes

Rinse & Hold is used if you want to wait until you have

a full load. This cycle rinses the load and keeps it moist,

making the main wash easier later on.

No detergent should be used. It does not matter which

temperature you select.

Intensive for loads which have heavily dried-on food

remnants and for those which are heavily soiled.

Normal for normal soiled loads. Replaces the pre wash

with one rinse without heating.

Economy is used for lightly soiled loads which do not

need any rinse off, such as cups, saucers and glasses.

Page 7

Using your appliance

- 7 -

Proceed as follows:

1. Scrape off solid food remnants.

2. Load the dishwasher.

(See page 8: “How to load the dishwasher”).

Pour aprox 15 g detergent into the detergent

dispenser and cloce the dispenser lid.

If the dishes are heavily soiled add an extra

5 g anywhere on the inside of the door.

3. Close the door.

4. Select a suitable programme.

5. Select the required temperature and eventually

the option for extra drying. The programme gets

started when the On/Off button is pressed in.

6. Check the strainers to see whether they need

cleaning when the dishwasher has finished

the wash.

1

2

3

4

5

6

Page 8

How to load the dishwasher

- 8 -

The illustration to next page shows the machine loaded

with five standard place settings. Your own dishes are

not likely to be identical to this load, but if you follow the

advice below we are sure you will be pleased with the

results.

• Always place glasses, cups and bowls upside down.

• Incline deep dishes (soup plates etc.) so that the

water can run off when drying.

• Make sure that the dishes do not rest against each

other. This is particularly important in regard to the

cutlery basket - nested spoons, etc. simply cannot be

properly washed. MAKE SURE THAT THE WATER

CAN GET AT ALL THE SOILED SURFACES.

• Make sure that cutlery with slender handles and other

items do not protrude through the openings in the

basket and prevent the spray arm from rotating.

• Never put silver and stainless steel objects together.

When these metals come into contact with each other

a chemical reaction occurs which stains the silver.

• China with a pattern applied on top of the glaze may

not be suitable for machine washing as the colours

may fade and lose their lustre. The same applies to

cutlery with wooden or plastic handles.

Always buy articles that are machine washable

in future.

• Not all plastic articles are machine washable. If you

are in doubt as to whether your plastic-ware can be

washed in the machine, we suggest you check by

washing a single item or else wash them by hand.

• Aluminium becomes dull and tarnished when machine

washed. The machine gets it clean, but at the expense

of its appearance.

• When washing delicate items, select the lower wash

temperature.

• Substances such as ketchup containing strong

colouring agents can cause temporary discoloration

in the machine.

Rack and basket

Cutlery basket

Dish rack

Page 9

- 9 -

Detergent recommendations

For best results we recommend the use of Finish detergents, rinse aid and salt.

A complimentary sample pack is included in your new dishwasher.

1

Instruction for verification tests.

Test standard: EN 50242

Rated capacity: 5 place settings

Loading of rack: According to figure 1

Test program: Normal 65° C (+ Extra Drying)

Detergent (IEC type B): 15 gram in the dispenser

Rinse aid (typ III): Setting medium

Feed water pressure: Minimum 0,8 bar, maximum 10 bar

Waste water outlet: Install according to figure 2

The salt container and rinse aid dispenser shall be filled in accordance with the instruction manual. Before conducting

the measurements the dishwasher shall be operated for one or two complete cycles using detergent and a clean load.

2

Page 10

Important

Make sure that the machine is unplugged and the water

turned off before undertaking any kind of maintenance.

General cleaning

Inspect the filters and spray arm nozzle before re-loading

the machine and remove any food scraps. Wipe round

the rubber gasket at the bottom of the door to remove

grease which tends to collect there.

Cleaning the filters

There are two filters, a coarse one and a fine one which

should be cleaned after every wash. Lift out these filters

which are in the base of the dishwasher and wash under

running water.

The dishwasher must not be used without the

filters. Incorrect repositioning of the filters will

produce poor washing results.

Cleaning of the filters is vital to ensure correct

operation of the machine.

Cleaning the spray arm nozzle

The holes in the spray arm nozzle must be kept free of

scraps for the efficiency of the washing action.

Inspect the spray arm regularly. When thorough cleaning

is necessary, remove the spray arm by unscrewing the

nut clockwise (it has a left-handed thread) and lift off the

spray arm.

Wash the spray arm with hot soapy water using a stiff

saucepan brush if necessary to remove scraps.

Re-assemble carefully, making sure the nut is secure.

Cleaning the cabinet

Wipe the outside of the cabinet and control panel regularly

with a soft damp cloth. When necessary, use liquid kitchen

or household cleaner to remove stubborn marks, rinse with

a damp cloth and rub up with a soft duster.

Never use abrasive cleaners which could damage the

surface, ie: scouring pads or solvents (acetone, trichloriethylene, etc).

If the machine is not going to be used for some time, take

the folllowing precautions:

1. Unplug the machine and turn off the water supply.

2. Fill up the rinse aid container.

3. Make sure the tub is clean by carrying out a wash

programme (without any crockery) using Finish

Dishwasher cleaner, then dry the inside thoroughly.

4. Leave the door ajar.

Moving the machine

If you have to move the machine (you are moving

house, etc):

1. Unplug it.

2. Turn off the water tap.

3. Remove the water inlet and discharge hoses.

Avoid tilting the machine during transportation.

Protecting the machine against freezing

If the machine is kept in a place where the temperature

may sometimes fall below 0°C, there is a risk that the

small amount of water which remains inside parts of the

machine after normal use will freeze and damage it.

To prevent this you should:

1. Turn off the water supply to the machine and

disconnect the water intake hose from the

supply pipe.

2. Select a wash programme, start the machine

and let the programme run for a short time.

- 10 -

Maintenance and cleaning

Page 11

- 11 -

If the machine is not working

The machine will not start.

The machine is not filling with water.

The machine will not drain.

The dishes are not clean (poor wash).

Visible lime deposits or white film on

the dishes.

The machine is noisy.

The dishes are not quite dry.

■ Have you pressed the ON/OFF button?

■ Has the machine no power supply?

■ Check circuit-breakers/fuses (start with fuse in electrical plug).

■ Is the door closed properly?

■ Have you set the programme control knob properly?

■ Is the machine's water tap turned on?

■ Is the machine's water tap turned on?

■ Has your domestic water supply been cut off temporarily?

■ Is the water intake hose kinked or blocked?

■ Is the filter inside the intake hose blocked?

■ Is the water pressure too low?

■ Is the drain hose kinked?

■ Is the sink drain blocked?

■ Is the drain hose extension not correct?

■ Is there no air vent in the end of the drain hose?

■ Are the baskets too full?

■ Have the dishes not been arranged properly?

■ Does the spray arm not rotate?

■ Are the spray arm holes clogged?

■ Are the filters clogged?

■ Are the filters not in position?

■ Not enough detergent has been used or is it unsuitable?

■ Is the detergent old or has gone hard?

■ Is the salt container cap not properly closed?

■ Is the washing programme selected too gentle?

■ Is the end of the drain hose submersed in waste water

(in the sink?)

■ Is there no salt or has the softener not been adjusted to the

hardness of the water?

■ Has the rinse aid run out or is too little being used?

■ Are the dishes rattling against each other?

■ Is the spray arm knocking against the dishes?

■ Have the dishes been left too long inside the machine?

Symptom Check

The door is difficult to close.

■ Is the dishwasher not level?

Certain problems are due to lack of simple maintenance or oversights, which can be solved easily without calling out

an engineer. Before contacting your local Service Force Centre, please carry out the checks listed below.

Never attempt to repair the dishwasher yourself.

Repairs carried out by unauthorised or inexperienced

persons can cause injury or serious malfunctioning.

Page 12

- 12 -

Service and spare parts

If you require an engineer or you wish to purchase spare parts

contact your local Zanussi Service Force Centre by telephoning:

0870 5 929929

Your call be routed to the service centre covering your post code

area. Before calling an engineer please read the checklist under

the heading ‘If the machine is not working’, as you may be able

resolve the problem yourself.

In-guarantee customers should ensure that the checks have

been made as the engineer will make a charge if the fault

is not a mechanical or electrical breakdown.

Please note that proof of purchase is required for any in-guarantee

service calls.

When you contact the Service Centre you will need to give the

following details:

1. Your name, address and post code

2. Your telephone number

3. Clear and concise details of the fault

4. The model and serial number of the appliance

(found on the rating plate)

5. The purchase date

Customer Care

For general enquiries or for further information on Zanussi

products, please contact our Customer Care Department at:

Zanussi

55-77 High Street

Slough

Berkshire

SL1 1DZ

Tel: 08705 727727 *

Site: www.zanussi.co.uk

* call to this number may be recorded for training purposes.

Service

Page 13

- 13 -

Guarantee Conditions

Standard guarantee conditions

We, Zanussi, undertake that if within 12 months of the date of the purchase this Zanussi appliance or any part thereof

is proved to be defective by reason only of faulty workmanship or materials, we will, at our option repair or replace the

same FREE OF CHARGE for labour, materials or carriage on condition that:

• The appliance has been correctly installed and used only on the electricity supply stated on the rating plate

• The appliance has been used for normal domestic purposes only, and in accordance with the manufacturer’s

instructions

• The appliance has not been serviced, maintained repaired, taken apart or tampered with by any person not

authorised by us

• All service work under this guarantee must be undertaken by a Zanussi Service Force Centre

• Any appliance or defective part replaced shall become the Company’s property

• This guarantee is in addition to your statutory and other legal rights

Home visits are made between 8.30am and 5.30pm Monday to Friday. Visits may be available outside these hours in

which case a premium will be charged.

Exclusions

This guarantee does not cover:

• Damage or calls resulting from transportation, improper use or neglect, the replacement of any light bulbs or

removable parts of glass or plastic

• Costs incurred for calls to put right an appliance which is improperly installed or calls to appliances outside the

United Kingdom

• Appliances found to be in use within a commercial environment, plus those which are the subject to rental

agreements

• Products of Zanussi manufacture which are not marketed by Zanussi

European Guarantee

If you should move to another country within Europe then your guarantee moves with you to your new home subject

to the following qualifications:

• The guarantee starts from the date you first purchased your product

• The guarantee is for the same period and to the same extent for labour and parts as exists in the new country

of use for this brand or range of products

• This guarantee relates to you and cannot be transferred to another user

• Your new home is within the European Community (EC) or European Free Trade Area

• The product is installed and used in accordance with our instructions and is only used domestically, i.e. a

normal household

• The product is installed taking into account regulations in your new country

Before you move please contact your nearest Customer Care centre, listed below, to give them details of your new

home. They will then ensure that the local Service Organisation is aware of your move and able to look after you and

your appliances.

France Senlis +33 (0)3 44 62 29 99

Germany Nurnberg +49 (0)911 323 2600

Italy Pordenone +39 (0)1678 47053

Sweden Stockholm +46 (0)8 738 79 50

UK Slough +44 (0)1753 219897

Page 14

- 14 -

Zanussi Service Force

To contact your local Zanussi Service Force Centre telephone 08705 929 929

CHANNEL ISLANDS

GUERNSEY Guernsey Electricity

PO Box 4

Vale, Guernsey

Channel Islands

JERSEY Jersey Electricity Company

PO Box 45

Queens Road

St Helier

Jersey

Channel Islands JE4 8NY

SCOTLAND

ABERDEEN 54 Claremont Street

(M05) Aberdeen AB10 6RA

AUCHTERMUCHY 33a Burnside

(M03) Auchtermuchy

Fife KY14 7AJ

BLANTYRE Unit 5

(M07) Block 2

Auchenraith Ind Estate

Rosendale Way

Blantyre G72 0NJ

DUMFRIES 93 Irish Street

(M01) Dumfries

Scotland DG1 2PQ

DUNOON Brair Hill

(M67) 7 Hill Street,

Dunoon

Argyll PA23 7AL

GLASGOW 20 Cunningham Road

(M04) Clyde Estate

Rutherglen

Glasgow G73 1PP

INVERNESS Unit 3B

(M06) Smithton Ind. Estate

Smithton

Inverness IV1 AJ

ISLE OF ARRAN Arran Domestics

Unit 4 The Douglas Centre

Brodick

(OWN SALES) Isle of Arran KA27 8AJ

ISLE OF BARRA J Zerfah

244 Bruernish

Isle of Barra

(OWN SALES) Western Islands HS9 5QY

ISLE OF BUTE Walker Engineering

Glenmhor

Upper Serpentine Road

Rothesay

Isle of Bute PA20 9EH

ISLE OF LEWIS ND Macleod

16 James Street

Stornoway

Isle of Lewis PA87 2QW

KELSO 2-8 Wood market

(M08) Kelso

Borders TD5 7AX

ORKNEY Corsie Domestics

(M65) 7 King Street

Kirkwall

Orkney KW15

PERTH Hydro Electrical

Inveralmond House

Ruthervenfield Road

Perth PH1 3AQ

PERTH Graham Begg

Unit 4

Airport Ind. Estate

(OWN SALES) Wick KW1 4QS

SHETLAND Tait Electronic Systems Ltd.

Holmsgarth Road

Lerwick

(OWN SALES) Shetland ZE1 0PW

SHETLAND Bolts Shetland Ltd.

26 North Road

Lerwick

(OWN SALES) Shetland ZE1 0PE

WHALSAY Leask Electrical

Harisdale

Symbister, Whalsay

(OWN SALES) Shetland ZE2 9AA

NORTHERN IRELAND

BELFAST Owenmore House

(M27) Kilwee Business Park

Upper Dunmury Lane

Belfast BT17 0HD

WALES

CARDIFF Guardian Industrial Estate

(M28) Clydesmuir Road

Tremorfa

Cardiff CF2 2QS

CLYWD Unit 6-7 Coed - Parc

(M14) Abergele Road

Rhuddlan

Clwyd

Wales LL18 5UG

DYFED Maes Y Coed

(M77) High Mead

Llanybydder

Carmarthenshire

SA40 9UL

HAVERFORDWEST Cromlech Lodge

(M75) Ambleston

Haverfordwest

Pembrokeshire

SA62 5DS

OSWESTRY Plas Ffynnon Warehouse

(M17) Middleton Road

Oswestry SY11 2PP

NORTH EAST

GATESHEAD Unit 356a

(M39) Dukesway Court

Dukesway

Team Valley

Gateshead NE11 0BH

GRIMSBY 15 Hainton Avenue

(M42) Grimsby

South Humberside

DN32 9AS

HULL Unit 1

(M41) Boulevard Ind. Estate

Hull

HU3 4AY

LEEDS 64-66 Cross Gates Road

(M37) Leeds

LS15 7NN

NEWTON AYCLIFFE Unit 16

(M45) Gurney Way

Aycliffe Ind. Estate

Newton Aycliffe

DL5 6UJ

SHEFFIELD Pennine House

(M38) Roman Ridge Ind.

Roman Ridge Road

Sheffield S9 1GB

NORTH WEST

BIRKENHEAD 1 Kelvin Park

(M11) Dock Road

Birkenhead

L41 1LT

CARLISLE Unit 7

(M10) James Street Workshops

James Street

Carlisle

Cumbria CA2 5AH

ISLE OF MAN South Quay Ind. Estate

(M64) Douglas

Isle of Man IM1 5AT

LIVERPOOL Unit 1

(M15) Honeys Green Precinct

Honeys Green Lane

Liverpool L12 9JH

MANCHESTER Unit B

(M09) Central Ind. Estate

St Marks Street

Bolton BL3 6NR

PRESTON Unit 250

(M13) Dawson Place

Walton Summit

Bamber Bridge

Preston

Lancashire PR5 8AL

STOCKPORT Unit 20 Haigh Park

(M16) Haigh Avenue

Stockport SK4 1QR

Page 15

- 15 -

Zanussi Service Force

To contact your local Zanussi Service Force Centre telephone 08705 929 929

MIDLANDS

BIRMINGHAM 66 Birch Road East

(M18) Wyrley Road Ind. Estate

Witton

Birmingham B6 6DB

BOURNE Manning Road Ind. Estate

(M44) Pinfold Road

Bourne PE10 9HT

BRIDGNORTH 68 St. Mary’s Street

(M72) Bridgnorth

Shropshire WV16 4DR

GLOUCESTER 101 Rycroft Street

(M23) Gloucester GL1 4NB

HEREFORD Unit 3

(M31) Bank Buildings

Cattle Market

Hereford HE4 9HX

HIGHAM FERRERS 30 High Street

(M51) Higham Ferrers

Northants NN10 8BB

ILKESTON Unit 2

(M43) Furnace Road

Ilkeston DE7 5EP

LEICESTER Unit 7

(M22) Oaks Industrial Estate

Coventry Road

Narborough

Leicestershire LE0 5GF

LINCOLN Unit 8

(M40) Stonefield Park

Clifton Street

Lincoln LN5 8AA

NEWCASTLE 18-21 Croft Road

UNDER LYME Brampton Ind. Estate

(M12) Newcastle under Lyme

Staffordshire ST5 0TW

REDDITCH 13 Thornhill Road

(M20) North Moons Moat

Redditch

Worcestershire B98 9ND

TAMWORTH Unit 3

(M19) Sterling Park

Claymore

Tamworth B77 5DO

WORCESTER Unit 1 & 2

(M73) Northbrook Close

Gregorys Mill Ind. Estate

Worcester WR3 8BP

LONDON & EAST ANGLIA

BECKENHAM 11A Gardener Ind. Estate

(M79) Kent House Lane

Beckenham

Kent BR3 1QZ

CHELMSFORD Hanbury Road

(M47) Widford Ind. Estate

Chelmsford

Essex CM12 3AE

COLINDALE Unit 14

(M53) Capitol park

Capitol Way

Colindale

London NW9 0EQ

ELTHAM 194 Court Road

(M78) Mottingham

Eltham

London SE9 4EW

ENFIELD 284 Alma Road

(M49) Enfield

London EN3 7BB

GRAVESEND Unit B4

(M57) Imperial Business Estate

Gravesend

Kent DA11 0DL

HARPENDEN Unit 4

(M46) Riverside Estate

Coldharbour Lane

Harpenden AL5 4UN

LETCHWORTH 16-17 Woodside Ind. Estate

(M50) Works Road

Letchworth

Herts SG6 1LA

LONDON 2/4 Royal Lane

(M76) Yiewsley

West Drayton

Middlesex UB7 8DL

MAIDENHEAD Reform Road

(M60) Maidenhead

Berkshire SL6 8BY

MOLESEY 10 Island Farm Avenue

(M61) West Molesey

Surrey KT8 2UZ

NEWBURY 9 Pipers Court

(M24) Berkshire Drive

Thatcham

Berkshire RG19 4ER

IPSWICH Unit 6C

(M48) Elton Park Business Centre

Hadleigh Road

Ipswich IP2 0DD

NORWICH 2b Trafalgar Street

(M52) Norwich NR1 3HN

SUNBURY Unit 1a

(M63) The Summit

Hanworth Road

Hanworth Ind. Estate

Sunbury on Thames

TW16 5D

SOUTH EAST

ASHFORD Unit 2

(M58) Bridge Road Business Est.

Bridge Road

Ashford

Kent TN2 1BB

FLEET Unit 1

(M59) Redfields Ind. Estate

Church Crookham

Fleet

Hampshire GU13 0RD

HAYWARDS HEATH 21-25 Bridge Road

(M55) Haywards Heath

Sussex RH16 1UA

SOUTH WEST

BARNSTAPLE Main Road

(M30) Fremington

Barnstaple

North Devon EX31 2NT

BOURNEMOUTH 63-65 Curzon Road

(M26) Bournemouth

Dorset BH1 4PW

BRIDGEWATER 6 Hamp Ind. Estate

(M35) Bridgewater

Somerset TA6 3NT

BRISTOL 11 Eldon Way

(M25) Eldonwall Trading

Bristol

Avon BS4 3QQ

EMSWORTH 266 Main Road

(M33) Southbourne

Emsworth PO10 8JL

ISLE OF WIGHT Unit 8

(M34) Enterprise Court

Ryde Business Park

Ryde

Isle of Wight PO33 1DB

NEWTON ABBOT Unit 2

(M29) Zealley Ind. Estate

Kingsteignton

Newton Abbot

S. Devon TQ12 3TD

REDRUTH Unit 7D

(M36) Pool Ind. Estate

Wilson Way

Redruth

Cornwall TR15 3QW

Page 16

Installation instructions

Any electrical work required to install this

appliance should be carried out by a qualified

electrician or competent person.

Any plumbing work required to install this

appliance should be carried out by a qualified

plumber or competent person.

Technical specifications

This appliance complies with E.E.C. directive Np. 87/308 of 2.6.87 relative to radio interference suppression.

DIMENSIONS Height 460 mm

Width 450 mm

Depth 480 mm

WEIGHT (net) 17 kg

(gross) 20 kg

CAPACITY 5 (standard IEC place settings)

WATER PRESSURES Minimum 50 kPa (0.5 bar)

Maximum 1000 kPa (10 bar)

ELECTRICAL DATA Power supply 230 V - 50 Hz

Fuse 13 A

Heating element 1200 W

Power rating 1280 W

- 16 -

Page 17

Unpacking the machine

If the machine is damaged

If the machine has been damaged during transportation,

you should immediately notify the company responsible

for delivering it.

Check that the dishwasher is undamaged. If you discover

any damage, faults or that anything is missing, you should

notify the seller immediately.

Never leave packaging material in a place where children

may play with it.

Accossories

• Discharge hose (1)

• A funnel for filling with salt (2)

• Elbow for discharge hose (3)

• Hose clip (2x) for discharge hose

and the rubber nozzle (4)

• Washer/filter for inlet hose (5)

• A rubber nozzle for the discharge hose (6)

Identification of materials

All materials used in packaging this machine are

environmentally-friendly. The various plastics used

are identified and can be recycled:

• PE stands for polyethylene, which is used for the bag

around the machine and the bag in which these

instructions were supplied.

• PS stands for polystyrene (moulded), which is used for

the sections of packaging needed to cushion the machine.

The cardboard components of the packaging are made

from recyclable paper and should be taken to a collection

point for recycling.

The machine contains plastic and rubber components.

These have identifying marks to show what they are

made from, so they can be recycled or disposed of

properly at the end of the machine's life.

The materials are identified according to international

standards.

2

3

4

5

6

1

- 17 -

Page 18

Installation

The dishwasher is intended for installation on a

kitchen sink or worktop. It is important to ensure

the dishwasher is level to avoid any difficulty

opening and closing the door. Its height can be

adjusted with the adjustable feet (8 mm each) in

each corner of the dishwasher.

Water inlet

The dishwasher should be permanently plumbed

into a separate cold water supply.

The water pressure must be within the limits given

in the technical specifications, as it will not function

correctly if pressure is outside these specifications.

Your local Water Authority will advise you on the

average mains pressure in your area. Where the

water is supplied from a cold water cistern you can

work out the pressure yourself by measuring the

vertical distance (or ‘Head’) between the machine’s

inlet hose and the outlet from the cold water storage

cistern; allowing .86 psi for every 2 feet under normal

conditions.

We would advise you to have a shut-off valve or

stopcock in the water supply pipe close to the dishwasher and accessible for easy use. This should

be turned off when the appliance is not in use.

Insert the combination rubber washer/filter and

connect the inlet hose to a tap with a 3/4” pipe

thread.

The inlet hose (1) must not be joined onto any form

of extension hose. If it is too short, the entire hose

must be replaced with a longer high-pressure hose,

specially designed for the purpose.

The machine end of this hose can be turned in any

direction. Loosen the retaining nut, turn the hose,

then retighten the nut.

- 18 -

1

Page 19

Water drainage

The grey discharge hose should be permanently

plumbed in. If this is not possible, it can be placed

in the sink to drain. Don’t forget that the water will

come out with some force, so position the pipe so

that the force of the water will not push the hose out

of the sink, use the elbow supplied which should be

fitted over the pipe to support it. Ensure the sink

outlet is not blocked.

Connect the discharge hose to the pipe stub at the

rear of the dishwasher, using the hose clip supplied.

It is important to push the discharge hose (2) onto

the pipe stub as far as it will go and tighten the hose

clip (3) as hard as possible. Make sure that the hose

clip is pushed as far towards the cabinet as possible

in order that it is covering both pipes completely.

The discharge hose must not at any point rise higher

than the top of the dishwasher. If it runs higher, operation of the dishwasher might be impaired. It is also

important to ensure that the inside diameter of the

hose is not less than 13 mm at any point.

If the discharge hose is too long it can easily be cut

to the right length.

1. Cut the hose to a suitable length, using a

sharp knife.

2. Fit the elbow supplied onto the end of the

hose.

Do not extend the hose under any circumstances as

this could affect the operation of the dishwasher.

Power supply

The dishwasher is supplied with a lead and electrical

plug for connection to a 230 V, 13 A earthed wall

socket. Before any work is carried out on the machine,

it must be isolated from the electric mains supply, for

example by removing the plug from the wall socket.

Permanent electrical installation must be

carried out by an authorised electrician.

- 19 -

2

3

Page 20

© Electrolux Household Appliances Limited 2000

Loading...

Loading...