Page 1

Revision History

Revision

Date

Notes

Released By

01

05/04/2014

Initial Release

Owen Carlson

02

05/24/2015

Updated Release

Owen Carlson

Basic 7in and 9in

Bluetooth Keyboard

Page 2

Page 3

Table of Contents

1. General Specification ............................................................................................................................... 6

2. Mechanical Specification ......................................................................................................................... 8

2.1. Characteristics of Material ................................................................................................................... 8

2.2. Packed – Including Packaging............................................................................................................... 8

2.3. Detachability of Cable Pull Out ............................................................................................................ 9

2.4. Key module configuration .................................................................................................................... 9

2.5. Key Board Specification ..................................................................................................................... 10

2.6. Life Test ............................................................................................................................................. 10

2.7. Specification of Rubber Switch .......................................................................................................... 10

2.8. Max Keycap Depressing Force............................................................................................................ 11

2.9. Keyboard Height ................................................................................................................................ 11

2.10.Keycap Strength ............................................................................................................................... 11

2.11.Keycap Spacing and Alignment ......................................................................................................... 11

2.12.Key in Test Spec On The 4 Corners Of The Key Cap ........................................................................... 12

2.13.Characteristics of Switches ............................................................................................................... 12

2.14.Slide Switch ...................................................................................................................................... 12

2.15.Tact Switch ...................................................................................................................................... 13

2.16.Sleep Magnet Function .................................................................................................................... 13

2.17.Snap force and life test .................................................................................................................... 13

3. Electrical Specification ........................................................................................................................... 13

3.1. Electrical Characteristics .................................................................................................................... 13

3.2. Feature: ............................................................................................................................................. 13

3.3. Power Rating ..................................................................................................................................... 13

3.4. LED Indicator behavior....................................................................................................................... 14

3.5. RF Specifications ................................................................................................................................ 15

3.6. Bluetooth Module Block Diagram ...................................................................................................... 16

3.7. Sleep mode ....................................................................................................................................... 17

3.8. Keyboard layout ................................................................................................................................ 17

3.9. 7 Inch Key frame ................................................................................................................................ 17

3.10. .............................................................................................................. Fn Combination Key Function

Descriptions ...................................................................................................................................... 19

Page 4

3.10.1. 7in Non backlight Alcatel Android 5.0 US ..................................... Error! Bookmark not defined.

3.10.2. 7in Non backlite LG E8 Android 5.0 US ........................................ Error! Bookmark not defined.

3.11.Bluetooth 3.0 9 inch Keyboard Key Matrix for Apple ........................................................................ 20

3.12.Schematic Circuit ............................................................................................................................. 21

3.13.Pseudo N-Key Rollover Capability ..................................................................................................... 22

3.14.Free From Illegal Ghost key .............................................................................................................. 22

3.15.Compatibility ................................................................................................................................... 22

3.16.Charging Specification ...................................................................................................................... 22

3.17.Keyboard Module ............................................................................................................................ 22

3.18.Key Functional Test .......................................................................................................................... 22

3.19.Bluetooth RF Power & Frequency Test ............................................................................................. 22

3.20.EMI Test ........................................................................................................................................... 22

3.21.ESD TEST .......................................................................................................................................... 23

3.22.EFT Test ........................................................................................................................................... 23

4. Environmental and Reliability Specifications .......................................................................................... 24

4.1. Acoustic Noise ................................................................................................................................... 24

4.2. Temperature and Humidity Test ........................................................................................................ 24

4.3. Heat Treatment Impact Test .............................................................................................................. 25

4.4. Vibration Test .................................................................................................................................... 25

4.5. Bare Unit Drop Test ........................................................................................................................... 26

4.6. Packaged Box Drop Test .................................................................................................................... 26

4.7. Life Test ............................................................................................................................................. 27

4.8. UV Test .............................................................................................................................................. 27

4.9. Spillage Test ...................................................................................................................................... 28

4.10.Endurance Test ................................................................................................................................ 29

4.11.Physical / Software compatibility check ............................................................................................ 30

4.12.PLP – Product Liability Program ....................................................................................................... 30

4.13.Abrasion Test – Legend (1X key silk-screen printing) ......................................................................... 30

4.14.Abrasion Test - Logo/ Icon ................................................................................................................ 31

4.15.Abrasion Test – Painting (Outlook parts printing) ............................................................................. 31

4.16.Chemical Resistance Test ................................................................................................................. 31

4.17.Adhesion Test .................................................................................................................................. 31

Page 5

4.18.Keycap Texture Endurance Test........................................................................................................ 32

4.19.Compression Test-Type 1A ............................................................................................................... 32

4.20.Corrugated Box (Carton) Compression Test ...................................................................................... 32

4.21.Compliance ...................................................................................................................................... 32

4.22.Safety Standard ................................................................................................................................ 33

4.23.Environment Specification Items ...................................................................................................... 33

4.24.Appearance Specification ................................................................................................................. 34

5. Patent ................................................................................................................................................... 34

6. View Angle ............................................................................................................................................ 34

6.1. Angle Specifications ........................................................................................................................... 34

7. Keyboard Layout for different Languages .............................................................................................. 35

7.1. 7in Non backlight Alcatel Android 5.0 US ................................................ Error! Bookmark not defined.

7.2. 7in Non backlite LG E8 Android 5.0 US .................................................... Error! Bookmark not defined.

8. Cable ..................................................................................................................................................... 35

8.1. Micro USB Charge Cable .................................................................................................................... 35

Page 6

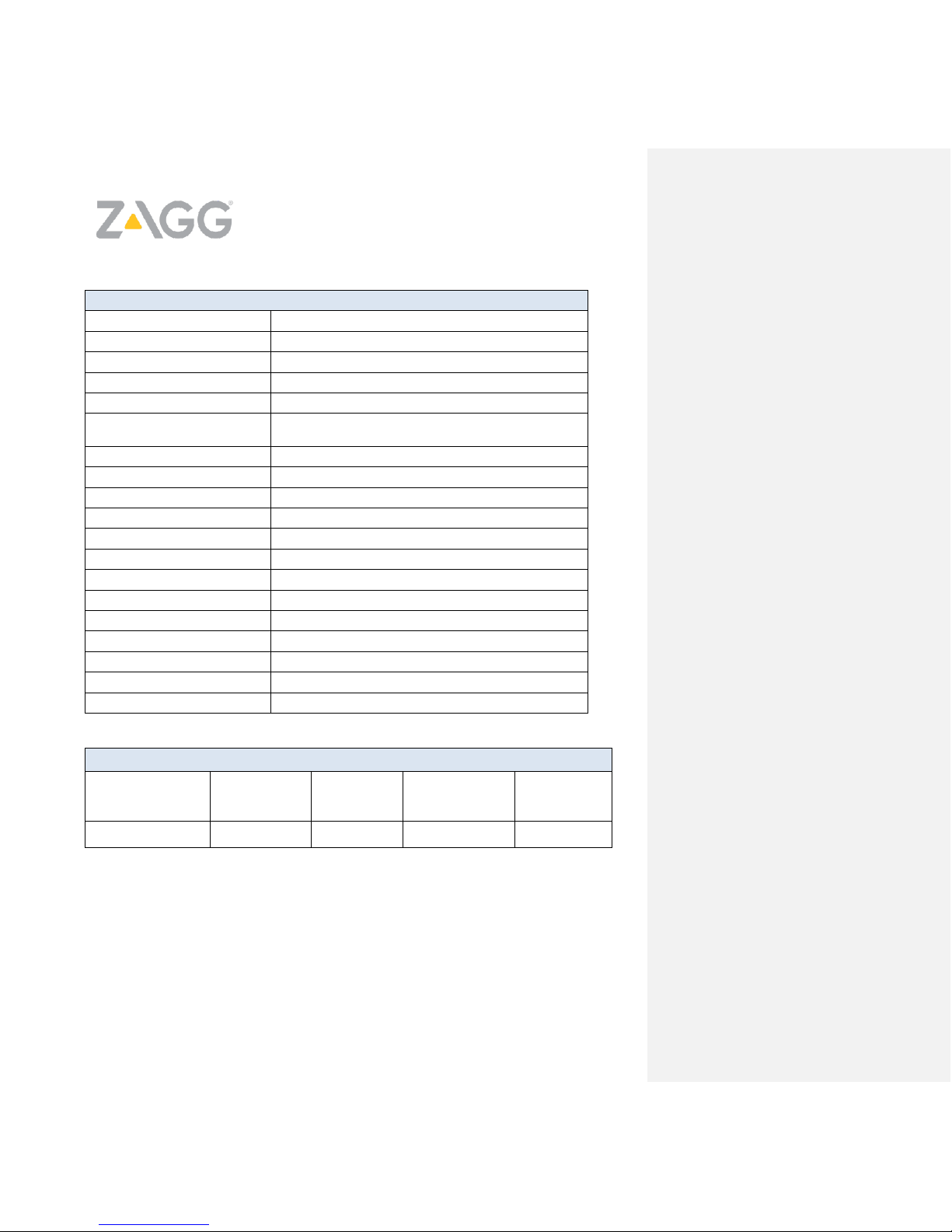

General Product Information

Product Type

ZAGG Folio Keyboard

Connection Type

Bluetooth Wireless

Keypad Features

Slim

Wireless Protocol

Bluetooth 3.0

Wireless Range

10M

Software Support (at

release)

As needed per device

OS Support (at release)

As needed per device

Indicator Lights (LED)

Under Caps Lock, Under Power (for Pairing too)

Backlight

None

Battery Details

450mAh, 3.7V

Battery Life

365 days one hour per day use

Power Charge

Micro USB cable ( TPE coated cable)

Power On Function

Power key on key frame will power on

Hinge Angle

0~135 +/- 3 Degrees

Hinge Life

5000 cycles on opening and closing

Hinge Torque

N/A

Opening Force (Free Stop)

N/A

Closed Mode

Magnet assist closure and retention

Book Mode

Magnet assist retention

Product Dimensions

Product

component

Width

( No Fabric)

Depth

(No Fabric)

Height

(Tablet

Dependent)

Weight

Keyboard

246 mm

178.5 mm

6.2mm

XXX grams

1. General Specification

This specification is applied to the Bluetooth wireless keyboard folio for Windows iPad series.

Page 7

Page 8

Product Dimensions Tolerance: +/- 3 mm

Package Spec.

Qty

Width

Length

Height

Weight

Gift box with handle

1

TBD

TBD

TBD

TBD

Carton (Inner)

5

TBD

TBD

TBD

TBD

Carton (Outer)

10

TBD

TBD

TBD

TBD

Parts

Material

Color

Texture

Bezel, Key Surround

PC/ABS

(70/30)

White/Black/

Purple and as

needed

MT11010

Keys, HF-3201GS

ABS

White/Black

Texture MT 11005 Semi-Gloss Paint

Fabric Cover, Interior

Synthetic

Suede

Black

TBD

Fabric Cover, Exterior

Weave/

Knit

Black/

Purple/ Red

TBD

Side Hooks

PC

White/Black/

Purple etc

TBD

Cradle

PC

White/Black/

Purple etc

TBD

Base

PC

White/Black/

Purple etc

TBD

Top Hooks

PC

White/Black/

Purple etc

TBD

V type hook

PC

Black

TBD

Cradle Slim

PC

Black

TBD

Bottom Board

PC

Black

TBD

Cradle Slim Cover

PC

Black

TBD

2. Mechanical Specification

2.1. Characteristics of Material

2.2. Packed – Including Packaging

Page 9

2.3. Detachability of Cable Pull Out

General Product Information

Product Type

Key module

Output Pin

28 Pin

Travel

1.5 mm

Total Height

3.9 mm

Weight

N/A

Size

198.4 X 96.5 mm (main rectangular foot-print)

Click Ratio

35 ~ 55

Indicator Lights (LED)

RGB

Key life

Standard key and long key: 3 M, Small key: 5 M

Color

Define by Customer

Key layout

Define by Customer

Name

Material

Flaming

UL

Key Cap

ABS

94 HB

Scissor EXT

POM

94 HB

Scissor INT

POM

94 HB

Rubber Dome

Rubber

94 HB

Plate

0.3 SECC

5VA

Membrane

PET

94 HB

The cable entrance for corded devices can meet product specification. Function test will be performed

before and after this test. Refer to the definition of related standard.

USB Implementers Forum. 2007-01-04. Micro USB connector mating force is less than 30N, un-mating

force is 8+/-1N. Life test is 5000 cycles in this device.

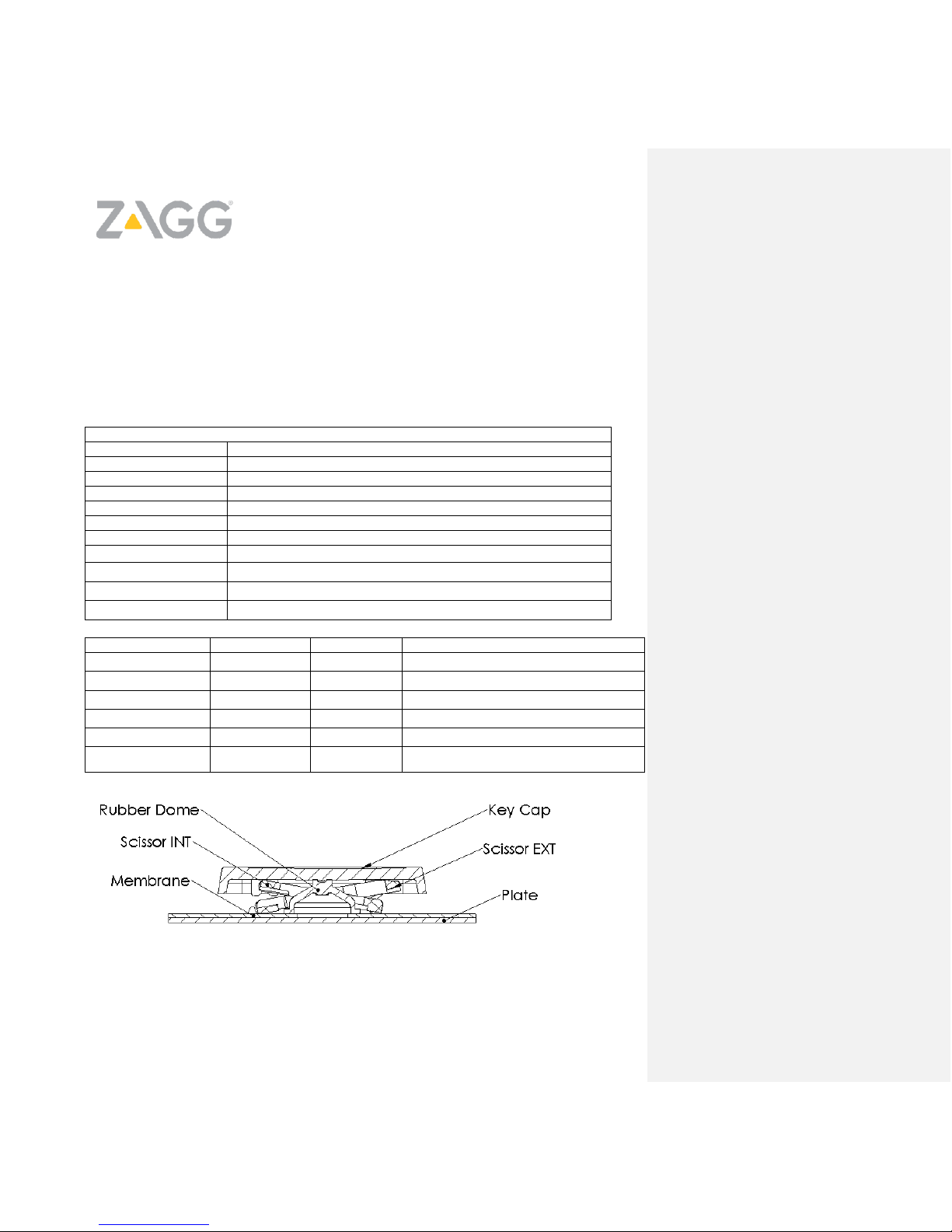

2.4. Key module configuration

This specification is applied to the 7” key module.

Page 10

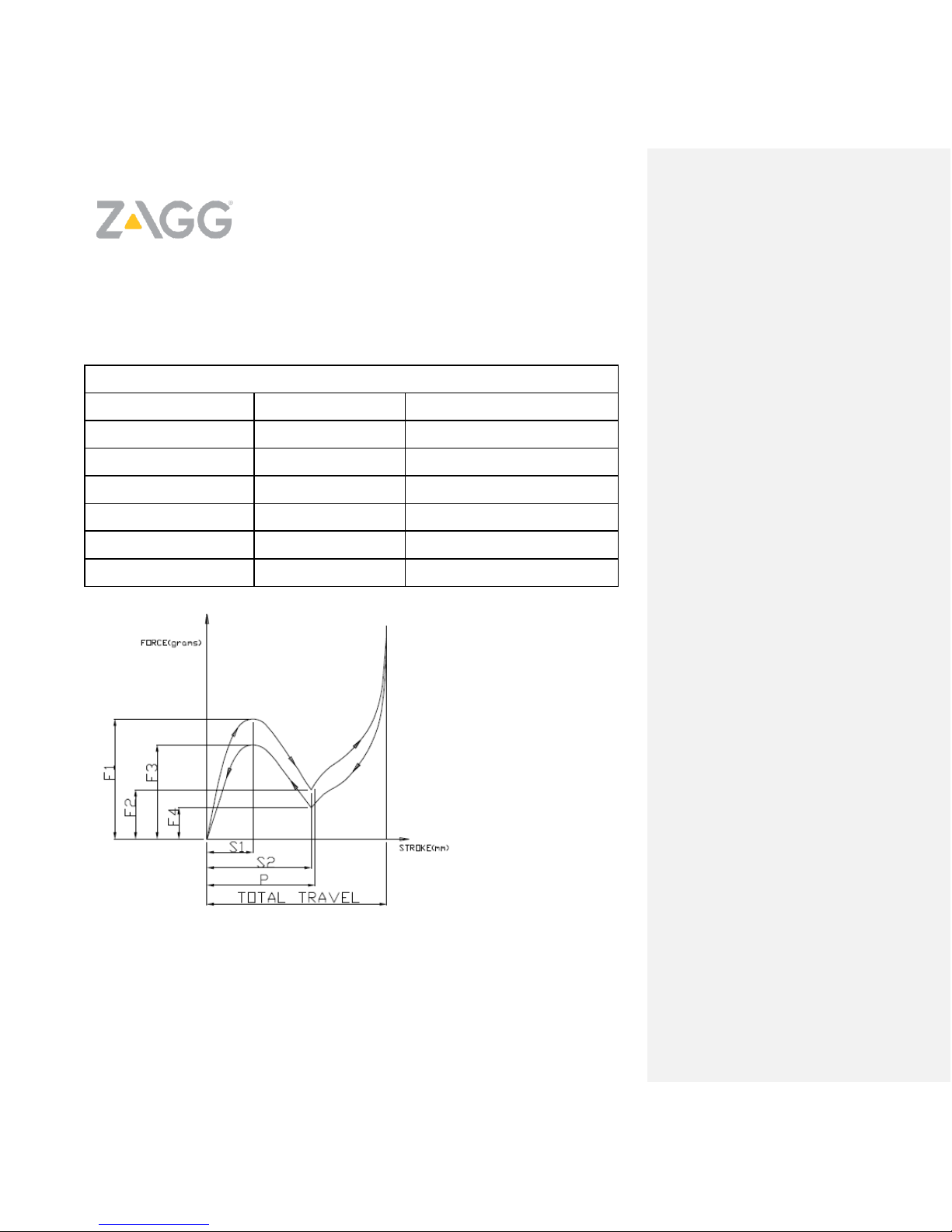

2.5. Key Board Specification

Normal And Function Key Rubber Dome Key Characteristic

Point

Stroke

Force

P1

0.5 ± 0.2 mm

60 ± 15 gf

P2

0.8 ± 0.2mm

15~48 gf

P3

1.5 ± 0.2 mm

Maximum 120 gf

P4 Maximum 15 gf

Pre-Loading

0 ~ 0.2 mm

Click ratio:

35 – 55 %

P3

P1

P2

2.6. Life Test

Standard key is 5 million cycles and Function key is 3 million cycles.

( 4 times/second, 100 ± 20 gf ).

2.7. Specification of Rubber Switch

Figure 1 Standard key curve of force response

Travel

Operating Travel: 1.5±0.30mm

Full Travel: 1.5±0.30mm (force at 110g)

Page 11

Keycap Pull Off Force

500gf minimums with equal load applied to all 4 corners of the keycap

150gf minimums at any one corner or side of a given keycap

2.8. Max Keycap Depressing Force

To act on the center of the keycap with stand 5Kgf force for 1 minute.

2.9. Keyboard Height

3.90±0.20mm(normal key)

3.90±0.20mm(space bar)

2.10. Keycap Strength

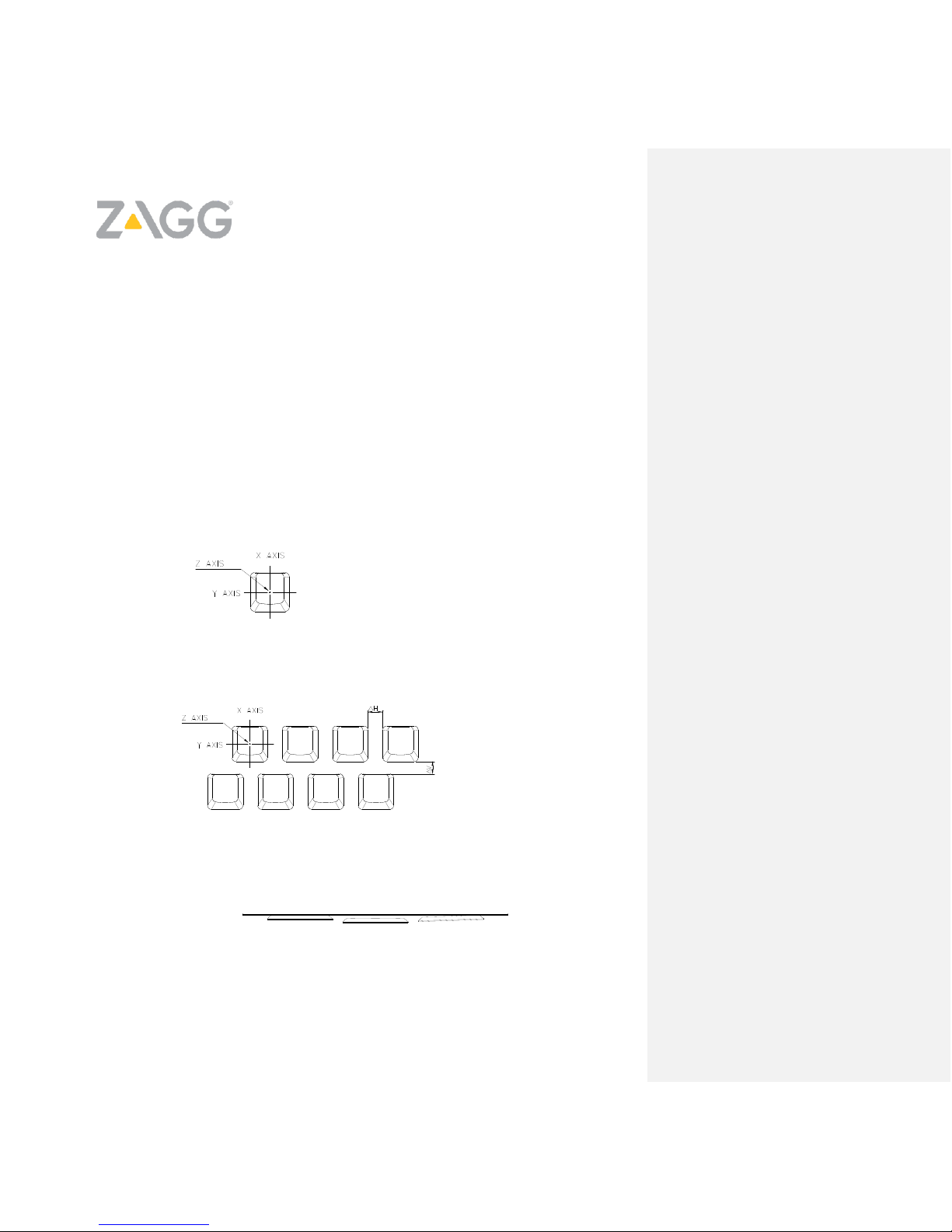

To act at “X” and “Y” axis with stand 1Kgf force for 5 sec.

2.11. Keycap Spacing and Alignment

Clearance between keycaps (standard keycaps): ΔH (ΔV) -- ± 0.30 mm

Alignment (keycap to keycap): Neighbor 0.4 mm max, In a row 0.4 mm max

Height alignment (keycap to keycap): Neighbor 0.4 mm max In a row 0.4 mm max

Key slant (keycap to keycap): 0.6 mm max

Key X, Y Movement: Shall be ≦0.5mm for full amplitude on both X and y directions.

Key twisting: Normal key ±0.4mm

Fn Key ±0.3mm

Page 12

Space key ±0.4mm

Long Key ±0.4mm

2.12. Key in Test Spec On The 4 Corners Of The Key Cap

Unit: mm (All Types)

A. Standard Key

B. Space Bar

C. Long Types Key

D. Small Key

Key in Force (Center) ≥ 80g

2.13. Characteristics of Switches

2.13.1. Slide Switch

No slide switch

Page 13

2.13.2. Tact Switch

Items

Specifications

1

Operation Voltage:

Voltage supplied to device: 3.0VDC ~ 4.2VDC

2

Active Power consumption

0.65mA Avg

Commented [OC1]:

No tact switch

2.14. Sleep Magnet Function

Act magnet switch in 1.1mm height from top surface of KB cover.

2.15. Snap force and life test

Snap in force between tablet and keyboard cover is (TBD)15N +/- 20% in handle and snap out force is

(TBD)25N +/- 20%.

Snap life is (TBD) 5,000 times.

3. Electrical Specification

3.1. Electrical Characteristics

3.2. Feature:

Bluetooth V 3.0 specification.

Bluetooth HID profile V 1.1 compliant.

Frequency Range: 2.400G ~ 2.480GHz

Peak Power consumption: 0.66 mA Max

Built-in 3.7V, 450mAh Li-Polymer Battery, can be rechargeable.

Sleep mode Power consumption: 0.033 mA Max

Security Encryption: 64 bits

Support AFH (Adaptive Frequency Hopping).

Support Language: US, Europe, Asia

Compatibility with necessary OS

FCC, CE, BQB, R&TTE, RoHS

Active Range: around 10 meter

Build-in Power on/off Switch.

RGB LED indicators for Battery Low alert , Recharge and Bluetooth Connectivity

Debounce: No double characters

Key buffering: 2 seconds

Wakup Time: 1.9 seconds

Auto-pair Requirement: 1.5 seconds

BQB Requirement: 10m or 30ft

3.3. Power Rating

Page 14

Battery Voltage

Percentage

Battery

Level

LED Colour

Remark

3.71V ~ 4.2V

50% ~ 100%

Full

Green

Flash 3 times. Each time

flash 1 sec, stop 1 sec.

3.5V ~ 3.71V

25% ~ 49%

Low

Yellow

Flash 3 times. Each time

flash 1 sec, stop 1 sec.

3.4V ~ 3.5V

12% ~ 24%

Charge

Red

Flash 3 times. Each time

flash 1 sec, stop 1 sec.

3.0V ~ 3.4V

0% ~ 11%

Critical

Red

Flash 3 times. Each time

flash 1 sec, stop 1 sec.

Function

LED Colour

Remark

Power On

Green LED under

power key

The GREEN LED will turn ON instantly when

power key is pressed. The LED will turn ON for 2

seconds then turn OFF and the keyboard will

automatically reconnect with the tablet. If

pressed again GREEN LED will turn on 2 seconds

then off indicating it is still ON.

Power Off

Red LED under

power key

The RED LED will blink twice then turn OFF

indicating the keyboard is OFF when the power

key is pressed and held down for 3 second.

When power is turned OFF the keyboard with

disconnect BT.

Charging

Red LED under

power key

RED LED stay ON until Battery cell is full Charged.

Low power

Red LED under

power key

When battery reaches a Charge level (12%~24%)

the back lightning will be disabled and when

3

Standby Mode current

0.25mA Avg

4

Hibernation mode current

0.033mA Avg

5

Bluetooth disconnect

Bluetooth keyboard will disconnect communication

after 20 minutes. The keyboard will always stay

paired so when coming out of hibernation it will

automatically allow keyboard to work with tablet

with limited time delay.

3.4. LED Indicator behavior

Press Fn + Right Control Key will indicate battery status by LEDs.

Battery status description:

Power On, Charging, & Pairing:

Page 15

Critical Level is achieved (0%~11%) a RED LED

will flash three times, one flash sequence every 5

minute. (1 Hz Flash 50% Duty)

Bluetooth Pairing

Blue LED under

power key

Push and hold Pairing key for 3 seconds for

pairing. A BLUE LED under power key will Flash

when pairing. Flash will stop flashing when

paired. Pairing times out after 60 sec.

Function

LED Colour

Remark

Caps Lock ON

Blue LED under

Caps Lock Key

LED Stay on until key is pressed again

Function

Name

Remark

Display in Bluetooth

settings

ZAGG Basic Folio

Zagg Basic will show in the display of Bluetooth

devices the tablet detects

Modulation:

FHSS

Caps Lock ON:

Blue light

Voltage (Supply):

3.0V

Transmitter Output Power:

2.66 dBm

Receiver Sensitivity:

- 86.14 dBm

Range:

>= 10m (in no interference environment)

Auto paring:

Device starts auto pairing mode after power on,

and leaves after 60 seconds.

Caps Lock:

Tablet Bluetooth Display

Note: Now the turning ON and OFF of the keyboard through the key frame is really only

toggling between Hibernation Mode and Active Mode and disconnecting Bluetooth

connection when in Hibernation Mode.

To perform a HARD RESET, a micro USB cable needs to be plugged into a 5V power source

and then plugged into the keyboard. A GREEN LED under the power key will come on for 2

seconds then changes to RED indicating the PCBA has been reset.

For all flashing of LED’s a flash cycle time 1 Hz Flash 50% Cycle will be used.

3.5. RF Specifications

Simple data transmitter operation at 2.4GHz range

Page 16

RF IC Model for keyboard: Broadcom BT3GMD-B47P is a Bluetooth Human Interface Device

(HID) module based on the Broadcom BCM20730 Bluetooth 3.0 specification basic rate-compliant stand

baseband processor with an integrated 2.4GHz transceiver or equivalent performance chip.

3.6. Bluetooth Module Block Diagram

Page 17

3.7. Sleep mode

Auto sleep if no typing for 20 minutes.

3.8. Keyboard layout

3.8.1. 7 Inch Key frame

3.8.1.1. 7in Non backlit Key Frame US Apple Layout

3.8.2. 9 Inch Key frame

3.8.2.1. 9in Non backlit Key Frame US Apple Layout

Page 18

Page 19

3.9. Fn Combination Key Function Descriptions

Item #

Keystroke

Description

01

Fn +

Battery Level

01

Page 20

Item #

Keystroke

Description

01

Fn +

Battery Level

02

Fn +

Search

03

Fn +

Show / Hide Keyboard

01

02

03

3.10. Bluetooth 3.0 9 inch Keyboard Key Matrix for Apple

Page 21

3.11. Schematic Circuit

Page 22

3.12. Pseudo N-Key Rollover Capability

‘N’ key roller is the numbers of keys that may be held depressed simultaneously and have the

keyboard generate the appropriate code for each pressed and released key without keyboard

interruption. The keyboard is capable of at least a pseudo 6-key rollover. All combinations of

Ctrl, Alt and Shift keys are not ghost keys.

3.13. Free From Illegal Ghost key

Key matrix layout has been properly managed such that no ghost key occurs for any 3-key

combination. The ghost key is defined as 3-key combination where a valid third key falls in the

‘#’ pattern in the key matrix, formed by the proceeding valid 2-key combination. Normally in

this case, the third key will be masked without sending any code because the third key and

fourth key in this ‘#’ pattern are confusing the microprocessor of three keyboard.

3.14. Compatibility

Operation System: Windows OS

Bluetooth 3.0 LE specification compliant.

Bluetooth HID profile V 1.1 compliant

VID/PID in firmware is 0a5c/8502 (Default Broadcom)

3.15. Charging Specification

Charging current: 180mA

3.16. Keyboard Module

Key matrix traces with switch contact fingers are laid out and routed on a 3 layers membrane

sheet and scissor keycap as a key module. The contact resistance is less than 1000 ohm.

3.17. Key Functional Test

Refer to Key Layout and to use Bluetooth test program & fixture.

3.18. Bluetooth RF Power & Frequency Test

RF Power Range: -35dBm ~ -5 dBm

Frequency tolerance: +/- 75 KHz

Low Frequency: 2402 MHz

Middle Frequency: 2441 MHz

High Frequency: 2448 MHz

3.19. EMI Test

European Standard EN 55022: 2006 Class B.

FCC/CFR 47 : Part 15 Class B

Frequency Range of Test: from 30MHz to 1000 MHz

Page 23

3.20. ESD TEST

Basic standard: IEC 61000-4-2

Generic standard: EN 55024:1998 + A1:2001 + A2:2003

Performance Criteria: B

Level: 2 for Contact discharge

Tested Voltage: ± 8V for Air discharge, ± 4 KV for Contact discharge

Temperature: 15-23 ºC

Relative Humidity: 30-60 % RH

Test Condition : Air ±8Kv, ±15Kv ESD

Judgment Standard:

o ±8Kv No malfunction

o ±15Kv No deviation or destruction of component

3.21. EFT Test

Basic standard: IEC 61000-4-4

Generic standard: EN 50 082-1

Performance Criteria: B

Level: on Power Supply 3

Test Voltage: on Power Supply ± 1 KV

Temperature:15-35ºC

Relative Humidity: 30-60 % RH

Page 24

Test Item

Specification

Test Equipment

Acoustic noise

Keyboard : Normal key

Max: 50dBA,

Space bar: Max:55dBA

Mouse: Max:55dBA

Sound level meter: Point microphone

toward the center-line of the

spacebar on keyboard.

A

C

D

B

4. Environmental and Reliability Specifications

4.1. Acoustic Noise

A = 38 +/- 13mm

B = 750 +/-13mm

C = 260 +/-13mm

D = 330 +/-13mm

4.2. Temperature and Humidity Test

Page 25

Test Item

Specification

Test Equipment

High Temp

High Humidity

Test

1. Sample size: 5 pieces

2. Test Condition: 50°C /95%, 120 hours

3. Judgment Standard:

No malfunction

No decay inside of the product

Chamber

Storing in Low

Temperature

1. Sample size: 5 pieces

2. Test Condition: -20°C, 96 hours

3. Judgment Standard:

- No malfunction

Chamber

Test Item

Specification

Test Equipment

Heat Treatment

Impact Test

1. Sample size: 5 pieces

2. Test Condition: -40°C ~ 85°C, 2 hours /cycle,

30cycle

3. Judgment Standard:

No malfunction

No decay or color change of PBA Soldering

& component

No crack, dent, or change

Chamber

Test Item

Specification

Test Equipment

Vibration

1. Sample size: 5 pieces

2. Condition: Sine sweep: 10HZ~ 500HZ~ 10HZ;

3. Sweep speed: 0.5 Octave/minute

4. Acceleration: 2G

5. Duration: 30 minutes per face.

6. Judgment Standard:

i) The mechanical appearance and inner

structure should not be damaged after test.

ii) No functional failure should be found during

and after the test.

Vibration machine

4.3. Heat Treatment Impact Test

4.4. Vibration Test

Page 26

4.5. Bare Unit Drop Test

Test Item

Specification

Test Equipment

Bare unit drop test

1. Sample size: 2 pieces

2. Test Condition : Drop at 91.44 cm ( 36in ) on

wood surface, 5 times on each face and 5

times on the top and bottom ( Total 30 times

without device) NAC and Mahindra Testing

3. Judgment Standard

I. No malfunction (button, mechanical or

electrical)

II. No deviation or destruction of component

(No major cracks in plastic housing)

Drop machine

Test Item

Specification

Test Equipment

Master Carton

packaged box drop

test

10 drops (One corner, Three edges, Six surfaces ) from

36 inches (91.44cm) to concrete surface, No damage

product, Product function OK

Drop test machine

4.6. Packaged Box Drop Test

Page 27

Test Item

Specification

Test Equipment

Keycap

Spec: Keyboard normal keys: 5 M cycles

Function key: 3 M cycles

Life tester machine

On/Off Button

N/A On Key Frame

Pairing Button

N/A On Key Frame

Snap Life Test

Magnetic force between tablet and keyboard is snap

in force 6N +/- 20% and snap out force is 6.5N +/20%. Snap life is 5,000 times

1. Judgment Standard

No Cracks

Still connects and hold tablet and

Test by Hand or Machine

Hinge Cycle Test

5000 cycles of hinge with tablet installed. No wear to

tablet and torque of hinge cannot change.

Test Item

Specification

Test Equipment

UV Test

1. Test Standard: ISO4892-3:2006; Method B, 72

Hrs; 0.76 Watts per square meter at 340 nm

wavelength, Ambient temperature of 50°C

3°C, Lamp type 1B (UVA-340), Humidity is not

controlled.

2. Judgment Standard

No crack / dent / color change and ETC.

4.7. Life Test

4.8. UV Test

Page 28

Test Item

Specification

Test Equipment

4.9. Spillage Test

Page 29

Spillage test

Unit shall be ON.

The keyboard shall be functional after performing the

liquid spill tests:

Pour the liquid from a funneled system from a height

of 3.0" above the keyboard over between the G, B, and

H keys. The funnel should accurately dispense all the

liquid at a rate of approximately 4 Oz (116 cc) per

minute of elapsed time. The Keyboard shall remain idle

for 60 seconds and then the keyboard shall be tilted to

drain the liquid. Liquid for test:

(1) 8.0 fluid oz. of hot coffee mixture (65C±5C)

(Coffee mixture shall be prepared by adding 4.0

gm. of sugar and 2.0 gm. of non-dairy creamer

to an 8.0 oz. cup of hot coffee.).

(2) 1.0 fluid oz. of cold sugared Cola (15C ±5C)

(3) 350cc of water (24±2°C):Don’t shake keyboard

after complete spilling water, Pour out water.

Pass Criteria

All keys on the keyboard are functional

Liquid effectively drains from the specific

keyboard liquid drain hole(s) Fail Criteria

Liquid does not pass through keyboard and

into the drain hole(s) and out the bottom of

the keyboard

Spontaneous characters appearing on the

screen.

Repeating keys (a repeating key is a key cap

that is depressed and release once but

continues to scroll the character more than

once)

Non-Functioning keys

Test Item

Specification

Test Equipment

4.10. Endurance Test

Page 30

Endurance test

Hinge endurance: There shall be no damage,

when a load of 25N is applied in pressure

direction for 15 seconds.

Rubber pad endurance: Rubber pad does not peel

off when a load of 10N is applied on its surface.

Breakage test (25N force applied to top of case.)

Pull gauge.

Test Item

Specification

Test Equipment

Physical / Software

compatibility check

Physical / Software Compatibility Test

Window Surface Tablet

Test Item

Specification

Test Equipment

PLP Electronic, Physical PL review, Manual/Package safe

clause review

Test Item

Specification

Test Equipment

4.11. Physical / Software compatibility check

4.12. PLP – Product Liability Program

4.13. Abrasion Test – Legend (1X key silk-screen printing)

Page 31

Abrasion testlegend

1,250 cycles, 450g , CS-10F eraser, 50% legend line

width missing or damaged

Fixture

Test Item

Specification

Test Equipment

Abrasion testLogo/Icon

200 cycles, 450g, CS-10F , 50% legend line width

missing or damaged

Fixture

Test Item

Specification

Test Equipment

Abrasion testpainting

500 cycles, 1 kg, CS-10 abrasive wheel, substrate is first

visible through the painted surface.

Abrasion machine

Test Item

Specification

Test Equipment

Chemical resistance

test

Supplier product spec. 12 chemicals per unit, room

temperature exposure followed by 60°C/65% RH, 12

chemicals are Oil of Olay; Vaseline with 6.5% Alpha

hydroxyl ; Jergen’s Lotion; Eternity Body Lotion;

Perfume; 99% Isopropyl Alcohol; 409 Spray Cleaner;

Ammonia (Windex); Vegetable Oil, Artificial sweat;

Coffee and Coke.

Test Item

Specification

Test Equipment

Adhesion test

Per ASTM D-3359.

must not exhibit paint flaking, peeling, or

degradation

4.14. Abrasion Test - Logo/ Icon

4.15. Abrasion Test – Painting (Outlook parts printing)

4.16. Chemical Resistance Test

4.17. Adhesion Test

Page 32

4.18. Keycap Texture Endurance Test

Test Item

Specification

Test Equipment

Keycap texture

endurance test

250,000 cycles, 200gm, CS-5 wear eraser, no visual

change to surface finish

Abrasion test machine

Test Item

Specification

Test Equipment

Compression

Test-Type 1A

Test 1Min load

L = M x Jx(H-h)/ h x F

Compression test

machine

Test Item

Specification

Test Equipment

Corrugated box

(Carton)

compression test

Minimum compression strength = ((BW x N)

+ EPW)) x SF

BW = Individual Box Weight

N = number of boxes in a column above the bottom

box

EPW = Empty Pallet Weight

SF = Safety Factor = 5

Compression test

machine

Items

Specifications

1

USB

Compliance of USB compliance program

4.19. Compression Test-Type 1A

4.20. Corrugated Box (Carton) Compression Test

4.21. Compliance

Page 33

4.22. Safety Standard

Items

Specifications

1

Regulation

(Safety/EMC)

Safety / EMC

Country

Standard

CE

U.S.A

EN301489, EN300328, IEC 60950-1

FCC

U.S.A

FCC Part15 Subpart B / C, Class B

RoHS

U.S.A

Folio

UL

U.S.A

On Battery

UN38.3

U.S.A

On Battery

CEC

California

CEC-400 Battery

WERC

U.S.A

Battery

Bluetooth SIG

U.S.A

Bluetooth Module

Bluetooth Qualification

Body

U.S.A

PCBA

MSDS

U.S.A

Battery

WEEE

U.S.A

ALL Electrical (Mainly Euro)

NAC or Mahindra

U.S.A

Complete Folio (ZAGG Performs)

Items

Specifications

1

Compliance to

law regulation/

public

standards

To be reflected in Product safety (environment) evaluation list To clarify the

regulations to correspond to “Law/regulation control standard (product)”

appendix “Regulation compliance list” and attach to product planning

document or/and product specification document.

2

Environmental

label

To be reflected in environmental label check sheet

Destination

If compliance

is required or

not

Subject

Name

WW □ Main unit

<Place to show logo>

International Energy

Star program

Europe

■

Main unit

RoHS

3

Compliance to customer’s

internal regulation etc. other

than above

□Required ■Not required

4.23. Environment Specification Items

Page 34

4.24. Appearance Specification

Opening angle of folio

Viewing angle is infinitely variable but must be

balanced at 133 degrees from flat surface.

Items

Requirement

1

General

There is no infringing of other company patent in worldwide.

133 degree

Appearance specification: Refer to SIP standard.

Corrosively: It is not seen the rust part to the appearance part. (Edge of sheet metal is included.)

5. Patent

6. View Angle

Angle is 133 +- 3 from the table

6.1. Angle Specifications

Page 35

7. Keyboard Layout for different Languages

8. Cable

8.1. Micro USB Charge Cable

Page 36

FCC WARNING

This device complies with Part 15 of the FCC Rules. Operation is subject to the following two

conditions:

(1) This device may not cause harmful interference, and

(2) this device must accept any interference received, including interference that may cause

undesired operation.

NOTE 1: Any changes or modifications to this unit not expressly approved by the party

responsible for compliance could void the user's authority to operate the equipment.

Loading...

Loading...