Instruction Manual

10GPROUDA-W-ABO

YS-TR-520FDS

-590FDS

(PROUD)

W-Cylinder UT

Ⅱ

Ⅱ

- Thank you very much for purchasing Yuyama Full Auto Tablet Packer

YS-TR-520FDS

-Read this manual carefully and use YS-TR-520FDS

-Store this manual at hand with the guarantee card.

/590FDS

Ⅱ

Read Pages 3 to 5 “Safety Precautions” carefully

Ⅱ

.

/590FDS

Ⅱ

before use.

properly.

Ⅱ

Table of Contents

Introduction

Safety instructions ......................................3

Accessories ................................................7

Names of Each Section..............................8

Machine appearance• .........................8

Inside the machine• .............................9

W-Cylinder Interior • ...........................10

Touch panel ..............................................11

Key button• ........................................12

Displaying the prescription •

Information and the status of the

packing machine ..............................13

How to use (Basic)

Turning on the power ................................14

Unlocking the upper door .........................16

•

Refilling tablets

[Refill information entry] 02................... •

When all tablets have been •

dispensed during dispensing ...........22

When all tablets have been •

dispensed during dispensing

[Call Cassette]• ..................................24

[Call Drug]• ........................................25

[Search]• ............................................26

Details of DTA filling• .........................27

Turning off the power ................................30

.................................17

Maintenance

DTA unit....................................................62

Last hopper...............................................68

Large hopper ............................................71

Revolver unit.............................................73

Sash unit...................................................78

Printer head ..............................................81

Heater roller ..............................................82

Tablet feed pipe........................................83

Box unit.....................................................90

Standby valve unit ...................................101

Procedure for replacing the prefilter........104

Others

Consumables ..........................................114

Troubleshooting ......................................115

Warning errors ........................................116

Speci fi cation ...........................................122

Inspection and

Maintenance Record Table .....................123

32. )ytpme si ettessac puorg eht nehw(

How to use (Speci

Pausing dispensing ..................................32

Aborting dispensing ..................................33

Emergency stop........................................34

Issuing using only packing machine .........35

Maintenance mode ...................................38

[Move cleaning position], [Complete •

Cleaning] .........................................39

[DTA collect]• .....................................40

[User Setting]• ...................................41

[Register Group Cassette] 44............... •

[Close Lock]• .....................................46

Turning the cylinder manually ...................47

fic)

Replacement of consumables

Packing paper...........................................48

Ink ribbon ..................................................57

はじめに

Safety instructions

Degrees of dangers and damages caused by wrong usage ignoring ■

instructions are categorized and explained in the following symbols.

WARNING

CAUTION

Be sure to use the machine following the Instruction Manual and obey •

This symbol indicates that failure to obey this instruction

may result in serious injury or death.

This symbol indicates that failure to obey this instruction

may result in injury or only property damage.

This symbol is used to “promote awareness.”

This symbol is used to indicate “prohibited” actions.

This symbol is used to indicate “forced” actions.

instructions thereof for safe operation.

WARNING

Do not operate switches with

Fear of an electric shock or an injury

wet hands.

Do not plug or unplug the

Fear of an electric shock or an injury

power with wet hands.

Earth leakage due to problems such as a failure

Earth the machine securely.

Do not disassemble, repair

or modify the machine.

may result in an electric shock. Be sure to ask

specialists to earth the machine.

Failure to obey this instruction may cause a fi re

or a malfunction, resulting in injury. Personnel

other than service personnel are not allowed

to disassemble or repair the machine. Do not

modify the machine.

3

WARNING

ᅠഥ

Prohibited

Prohibited

ᅠഥ

ᅠഥ

Prohibited

ᅠഥ

Prohibited

ᅠഥ

Prohibited

Do not move your fi ngers

close to the cutter blade.

Do not move your fi ngers

close to the heater roller

during paper feed.

Do not touch the heater

roller during heating or right

after the power is turned off.

CAUTION

Do not apply strong

vibrations or impacts on the

body.

Do not place the machine in

places specifi ed in the right

column.

Sharp blades are used for the machine. Do not

move your fi ngers close to the cutter blades.

Failure to obey this instruction may result in injury.

Failure to obey this instruction may result in burn

injury or injury.

Failure to obey this may result in burn injury.

This machine contains refi ned electronic parts.

Therefore, strong vibrations and impacts on the

machine will result in malfunctions. Ensure that

the machine is not contaminated with pieces of

paper and metals.

Unstable places•

Places that cannot burden the weight of the •

machine

Humid or dusty places•

Places that are exposed to direct sunlight•

Failure to obey this instruction may result in

machine failures.

ᅠഥ

Prohibited

ᅠഥ

Prohibited

ᅠഥ

Prohibited

4

Do not insert your hands and

fi ngers into the DTA cells

while the tablet set plate is

operating.

Do not touch the conveyor

or place anything near the

conveyor.

Do not use the machine

when it is wet.

Failure to obey this instruction may result in injury.

Do not touch the operating conveyor. Failure to

obey this instruction may result in injury.

Accumulated packed items or items near the

conveyor may be caught by the conveyor, resulting

in machine failures.

If the machine gets wet by fl ood damage or any

other reasons, do not use the machine but contact

with a nearby dealer immediately.

Be sure to use the genuine

power outlet.

CAUTION

Use of an outlet with an inapplicable voltage and

electric capacitance may result in heat generation

and fi re. In addition, lack of the power capacity

and rapid voltage fl uctuations may result in

malfunctions. Be sure to use the genuine power

outlet.

Disconnect the power cord

and plug in case of abnormal

conditions.

Clean the passage for drugs

securely.

Be sure to use YUYAMA’s

genuine paper.

Observe the temperature

and humidity ranges.

Damaged power cord/plug, loosen outlet or piled

dust may cause an electric shock, heat generation

and fi re. If any abnormality is detected, stop

operation and disconnect the power plug.

Clean the passage for drugs securely to prevent

remaining drugs from mixing with other drugs.

To avoid wrong drug dispensing, be sure to follow

the instructions in this Instruction Manual for

packing paper attachment and use YUYAMA’s

genuine paper.

Use the machine under the following environment.

Temperature range: 10 to 35 degrees C

Humidity range: 15% to 85% (No condensation is

allowed)

However, use the machine at humidity of 48% or

less when the temperature is 35 degrees C and

at temperature of 28 degrees C or less when the

humidity is 85% .

Stop the machine

immediately in case of

operational abnormality.

Perform a periodic inspection

once a year.

Before moving the machine,

be sure to unplug the power.

If the machine is not to be

used for a long time, turn the

breaker [OFF].

In case of abnormality such as malfunction, stop

the machine immediately.

To use the machine safely, it is recommended to

inspect all parts at least once a year besides daily

maintenance.

Moving the machine with the power plugged may

damage the power plug.

Turn the breaker OFF for safety.

5

FCC Part15.19

This device complies with Part 15 of the FCC Rules. Operation is subject to the following

two conditions: (1) this device may not cause harmful interference, and (2) this device

must accept any interference received, including interference that may cause undesired

operation.

FCC Part.15.105(b)

This equipment has been tested and found to comply with the limits for a Class B digital

device, pursuant to Part 15 of the FCC Rules. These limits are designed to provide reasonable

protection against harmful interference in a residential installation. This equipment

generates, uses and can radiate radio frequency energy and, if not installed and used in

accordance with the instructions, may cause harmful interference to radio communications.

However, there is no guarantee that interference will not occur in a particular installation.

If this equipment does cause harmful interference to radio or television reception, which

can be determined by turning the equipment o and on, the user is encouraged to try to

correct the interference by one or more of the following measures:

-- Reorient or relocate the receiving antenna.

-- Increase the separation between the equipment and receiver.

-- Connect the equipment into an outlet on a circuit di erent

from that to which the receiver is connected.

-- Consult the dealer or an experienced radio/TV technician for help.

FCC Part.15.21

You are cautioned that changes or modi cations not expressly approved by the party

responsible for compliance could void your authority to operate the equipment

This device complies with FCC RF radiation exposure limits set forth for an uncontrolled

environment. The antenna used for this transmitter must be installed to provide a

separation distance of at least 20 cm from all persons and must not be co-located or

operating in conjunction with any other antenna or transmitter

ICES-003

This Class B digital apparatus complies with Canadian ICES-003.

Cet appareil numèrique de la classe B est conforme à la norme NMB-003 du Canada.

RSS-Gen 7.1.5

Operation is subject to the following two conditions: (1) this device may not cause

interference, and (2) this device must accept any interference , including interference that

may cause undesired operation of the device.

6

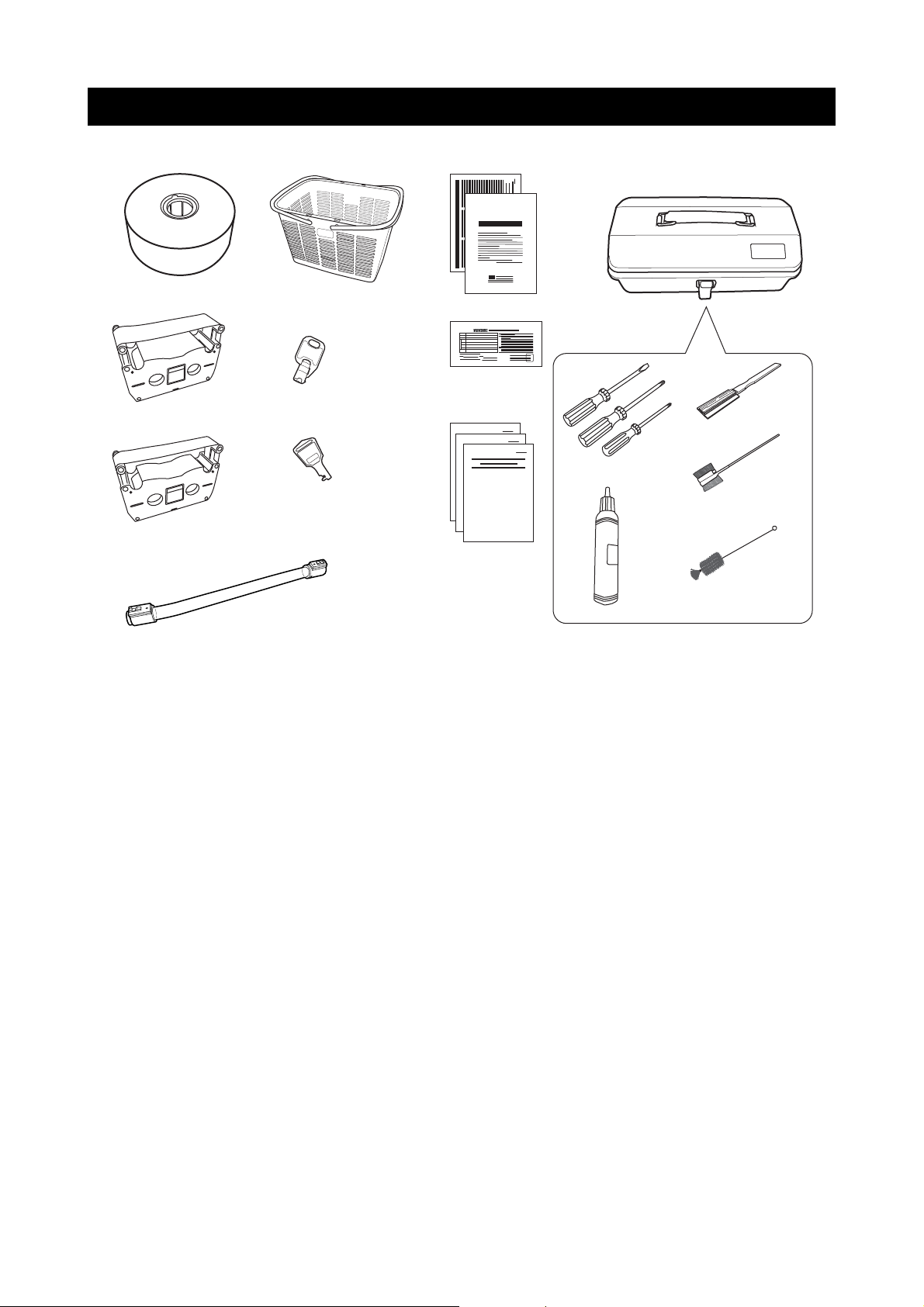

Accessories

(1)

ae k

bf

(16)

p

(4) (7) (10)

(5) )8()2(

(6) )

g

h

i

(11) (13)

ln

9

()3(

jc

(12)

m

(14)

o

(15)

p

(1) Packing paper (10) Tool box

(2) Ink ribbon (black or color) * (11) Phillips screwdriver (large and small)

(3) Half type ink ribbon (black) *

(4) Drug basket

(5) Key (for upper door) x 2

(6) Key (for the sides of the packing machine) x 2

(7) Request for packing paper and list of sales offi ces

(8) Warranty

(9) Instruction Manual (for each type)

*Any of the inks with a * mark will be provided.

- Do not store the packing paper in a place that is exposed to direct sunlight or with high humidity.

- Contact with your dealer or your nearest Yuyama’s sales offi ce (in the separate sheet) when you need to purchase

accessories.

and straight slot screwdriver

(12) Wax

(13) Printer head cleaner

(14) Heater roller cleaning brush

(15) Cleaning brush

(16) Tablet feed pipe

7

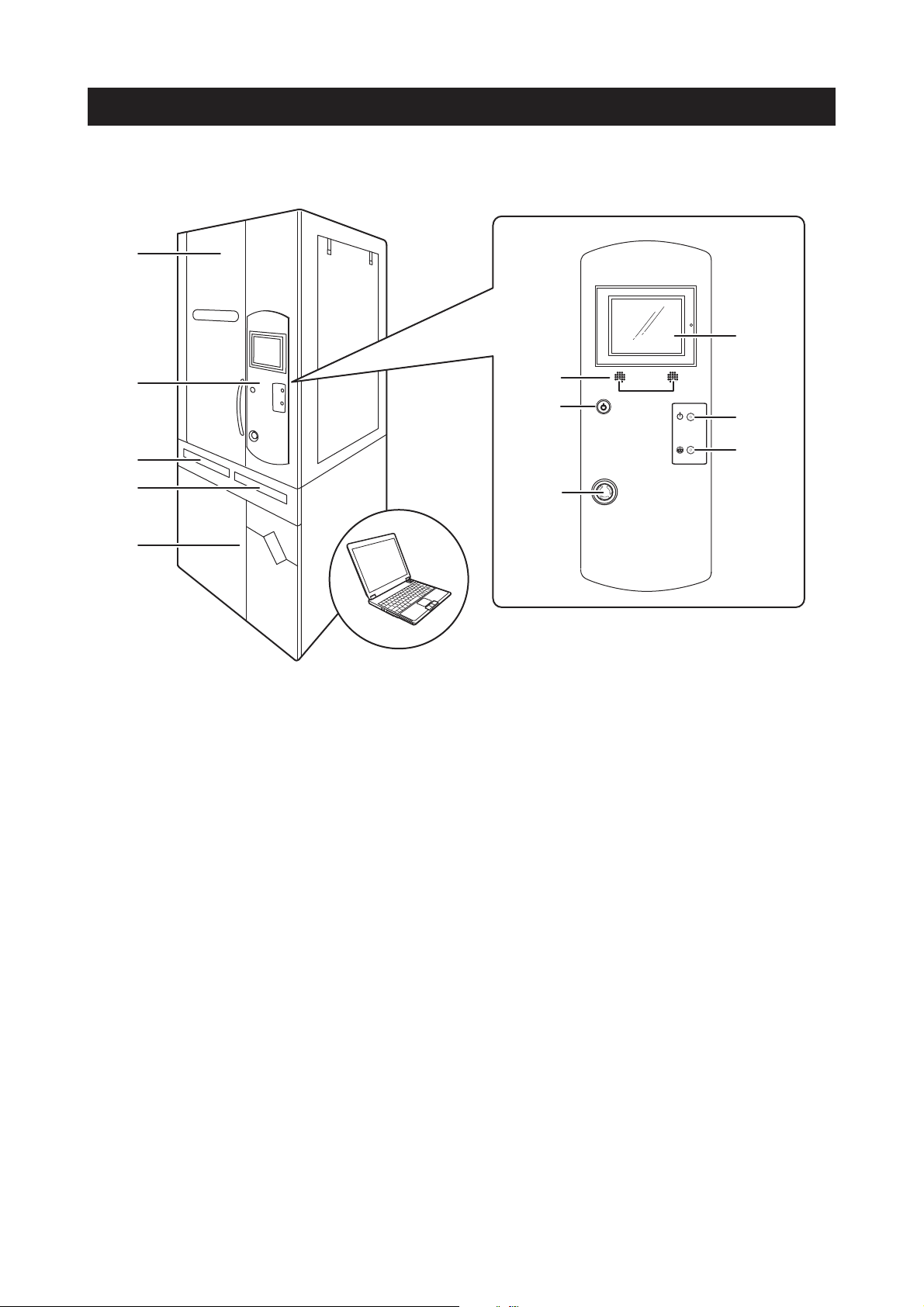

Names of Each Section

Machine Appearance

■

a

g

b

c

d

e

Upper door

①

Operation panel

②

DTA tray

③

Adaptive table

④

Lower doors

⑤

PC (notebook PC or desktop PC)

⑥

Touch panel

⑦

[Power] switch

⑧

[Cutter] switch

⑨

Loudspeaker

⑩

Door key

⑪

[Emergency] switch

⑫

f

j

k

l

POWER

CUTTER

h

i

8

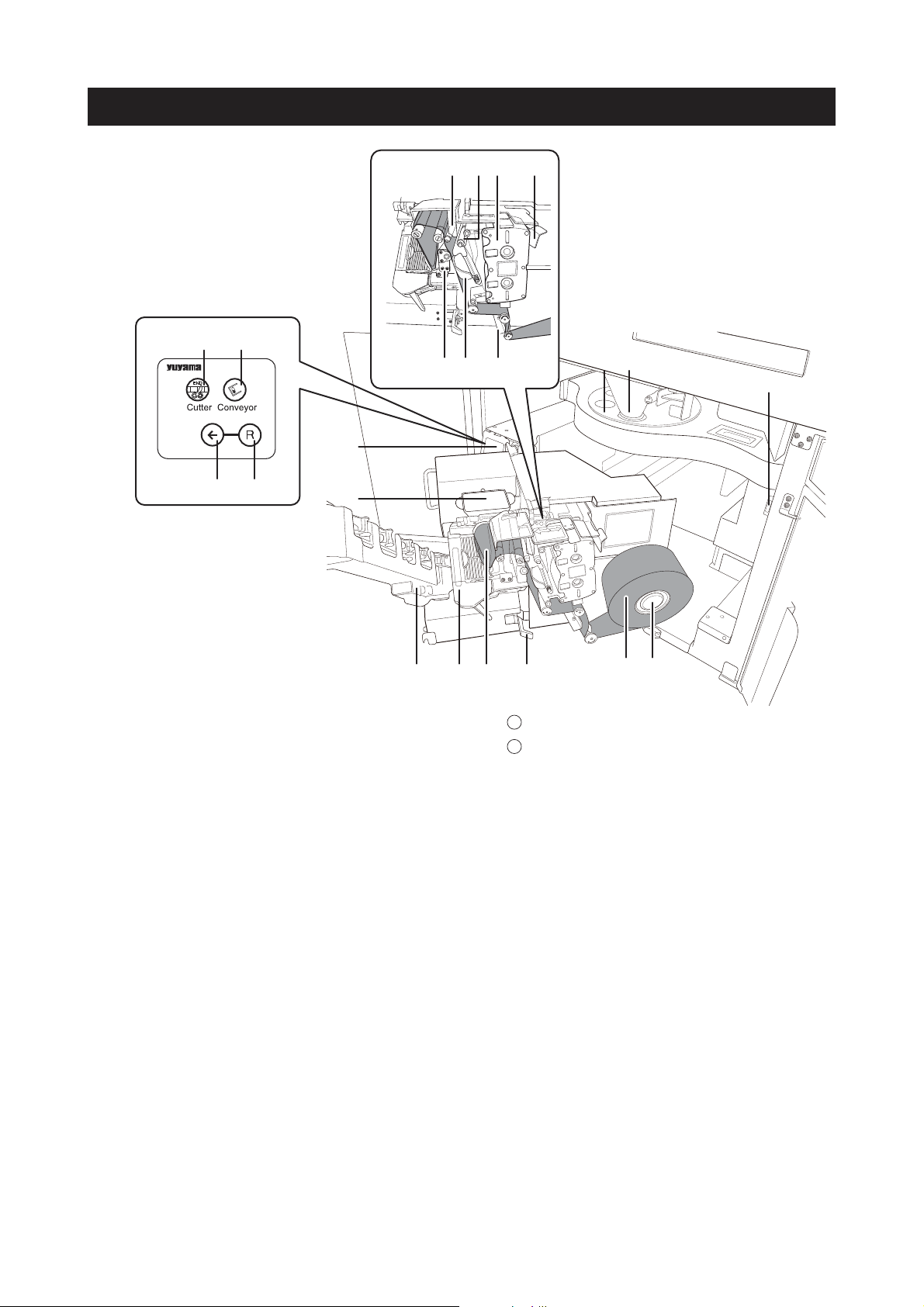

■

Inside the machine

o

n

lm

st

r

q

p

ab

c

Roller

uv

Revolver unit

①

Major hopper

②

Circuit breaker

③

Paper tube shaft

④

Packing paper

⑤

Packaging section opening/closing lever

⑥

Paper guide

⑦

Heater roller

⑧

Conveyor

⑨

Final hopper

⑩

Lower section operation panel

⑪

Paper guide pin

⑫

Ribbon tension bar

⑬

Ink ribbon

⑭

Printer head release lever

⑮

Paper end sensor

⑯

Ribbon guide

⑰

Platen roller

⑱

[Cutter] switch

⑲

[Conveyor] switch

⑳

k

j

i

e

f

gh

21

[Heater Roller Backward] switch

22

[Heater Roller Forward] switch

d

9

■

W-Cylinder Interior

ab

c

d

Upper door

①

Operation panel

②

Door key

③

Lower door

④

Tablet route unit

⑤

Standby unit

⑥

f

e

10

Touch panel

(1) (2)

POWER

CUTTER

(3) (4)

(1) Message display Displays the status and operation of the packing machine.

(2) Key button Used to operate the packing machine.

(3) Display of prescription information

and status of the packing machine

(4) Display and setting of details Displays the detail of prescription.

Displays the prescription information for the drug that is now being dispensed (or

is to be dispensed) and the status of the packing machine.

Also used to operate the packing machine such as to call a cassette.

(P12)

(P13)

11

Key button ■

(1) (2)

(3)

(4)

)7()6()5(

)9()8(

(10) (11) (12) (13)

(1) Switches the mode to the one where dispensing is issued only by the packing machine.

Restarts dispensing when the machine is temporarily stopped.

(2) Stops dispensing temporarily.

(3) Opens/closes the DTA tray.

(4) Sets the DTA.

(Cannot set the DTA when [Number of DTAs: 2].

(5) Switches the screen to the [Call Cassette] screen.

(6) Switches the screen to the [Call Drug] screen.

(7) Exits the maintenance mode or the special mode.

(8) Unlock the drug rack door.

(9) Returns to the previous page.

(10) Switches to screen to the [Maintenance] screen.

(11) Cancels the prescription.

(12) Displays the content of the next prescription.

(13) Goes to the next screen.

Displayed key buttons vary depending on the status of the packing machine.*

12

■

Displaying the prescription Information and the status of the packing machine

(1)

(2)

(3)

(4)

(12)

(11)

(5)

(6)

(7)

(8)

(9)

(10)

(1) Number of

pouches

(2) Patient ID Displays the patient ID during dispensing.

(3) Name of patient Displays the name of the patient during dispensing.

(4) Ticket number Displays the ticket number of the drug that is currently being dispensed.

(5) Number of days Displays the number of days for the drug to be dispensed.

(6) Pk. Order Displays the packing order (dispenses drug according to the usage [Continuation] or by the

(7) Form of tablet Displays the form of the drug to be used for dispensing (cassette or DTA).

(8) Paper Displays the remaining paper amount by 5 levels.

(9) DTA STATUS Displays the number of reserved DTA.

(10) Communication Displays the status of communication between the personal computer and the packing

(11) Temperature Displays the temperature of the heater roller.

(12) Number of

pouches

Displays the number of fi nished pouches and the number of the remaining pouches during

dispensing.

day [Repeat])

machine.

Displays the number of pouches (the number of doses for a day) for the dispensing data.

13

使いかた(基本)

Turning on the power

Press the power switch,turns on the power of packaging machine.

Even when the packing machine has been turned ON, do not start operation until the eating

of the heater roller is completed.

*Operate the breaker before installing the packing machine or cleaning the printer head.

1. Connect the power plug to the

outlet.

Be sure to use an AC100V outlet •

with the 3P earth.

Do not use a multi-outlet extension •

cord from a device such as a table tap.

CAUTION

Be sure to connect earth to avoid power-supply

noises and electric shocks. Lack of the power

capacity and rapid voltage fl uctuations may result

in malfunctions.

2. Open the lower door.

Push [PUSH] on the acrylic door •

and open it while folding it.

14

Unhook to open the door •

on the conveyor side.

POWER

CUTTER

3. Turn [ON] the breaker.

After the breaker has been turned •

on, close the lower door.

4. Packaging machine power switch on.

Wait for a while until packing is ready •

as the heater roller is heated.

You can start dispensing when •

[Ready to dispense] is displayed.

15

Unlocking the upper door

You are required to input a password to open the upper door. Open the door after entering the

password.

Once the password has been entered, you can set the machine so that you can open the door

without entering the password or you are required to enter the password every time you open

the door.

Once the power is turned off, you are required to enter the password again.

Entering a password is required only for the packing machine whose upper door has a *

lock.

1. Touch [RELEASE].

The screen is switched to the •

password entry screen.

Select [Operator].•

(When [Operator] is touched, the list of •

registered operators appears. Select a

desired operator’s name from the list.)

After the password has been •

entered, press [ENT].

The upper door is unlocked, so •

that you can open the door.

16

Refilling tablets

The following describes how to refilling tablets.

The cassette varies depending on the size and shape of the tablets. Be sure to refill the *

tablets speci fied on the cassette.

1. Touch [CAN FIND].

The screen is switched to the •

[Call Cassette] screen.

After touching a shelf number, •

please search for touch.

•

The

called cassette moves to

the front.

2. Open the upper door.

holding its handle.

elihw rood reppu eht nepO •

17

3. Remove the cassette.

Remove the cassette by pressing the lock •

of the cassette until it makes a click sound.

4. Put tablets in the cassette.

Replace the desiccant in the •

cassette periodically.

CAUTION

Note the following points when re filling tablets.

Note that foreign materials are not mixed.•

Do not put too many tablets.•

Make sure that tablets are not put in the backside of •

the cassette (the part where the tablets are ejected).

5. Touch [QTY].

Touch the frame of [QTY] to open •

the numeric keypad screen.

.]TNE[ hcuot ,ytitnauq eht gniretne retfA •

.]YTQ[ ni deyalpsid si rebmun deretne ehT •

18

.]LLIFER[ hcuoT •

er retfA filling, touch [RETURN] to •

return to the original screen.

[+] and [-] are alternatively displayed •

by touching the code next to [QTY].

by touching [REFILL] with [-].

tnuoma yrotnevni eht ecuder nac uoY •

6. Install the cassette.

Insert the cassette all the way.•

7. Close the upper door.

Close the upper door while •

holding its handle.

19

[Re fill information entry] ■

You can go to the re fill information entry screen by reading the drug name

by its barcode and clicking the displayed drug name while the re fill screen is

displayed.

1. Read the drug name using its

barcode and click the displayed

drug name.

2. Enter the manufacturing number

(up to 20 alphanumeric

characters).

Touch the manufacturing number •

display item and enter alphanumeric

characters using the numeric keypad.

1 Repeat of 1→@→1

2 Repeat of 2→A→B→C→2

3 Repeat of 3→D→E→F→3

4 Repeat of 4→G→H→I→4

5 Repeat of 5→J→K→L→5

6 Repeat of 6→M→N→O→6

7 Repeat of 7→P→Q→R→S→7

8 Repeat of 8→T→U→V→8

9 Repeat of 9→W→X→Y→Z→9

0 0

→ Enter

(Move the cursor in the right direction.)

Clear Backspace

20

3. The manufacturing number is

displayed. Enter the expiration

date (2-digit Christian era and

4-digit month and day or 2-digit

Christian era and 2-digit month).

Touch the expiration date display •

item and enter a numeric figure

using the numeric keypad.

Enter of either the manufacturing number •

or the expiration date is acceptable.

4. The expiration date is displayed.

Touch [ENTER].

5. You can return to the refill screen.

“ i ”

The mark is displayed next

to the drug name (barcode).

“ i ”

This mark is displayed when

the manufacturing number and

the expiration date have been

acquired from the RSS barcode or

when the manufacturing number

and the expiration date have been

entered in the re fill information

entry screen.

21

When all tablets have been dispensed during dispensing ■

Dispensing stops when all tablets have been dispensed.

After re fill of tablets is completed ([REFILL] is touched), dispensing

automatically resumes.

1. [Cassette empty warning] is

displayed on the touch panel and

an alarm is issued. (The detail of

the short drug is displayed.)

2. Touch [MUTE] to stop the alarm.

3. Re fill tablets in the cassette and

touch [REFILL].

[Cassette empty warning] is released •

and dispensing resumes.

22

When all tablets have been dispensed during dispensing (when the ■

group cassette is empty)

This page describes the case when tablets registered in the group cassette

are short during dispensing.

1. When the drug for the group

cassette is short, the [Next Cass]

button is displayed.

Touch [MUTE] to stop the alarm.•

Press the [Next Cass] button.•

The location number (MB#) of the •

displayed cassette is changed.

The next location number moves

to the front by cylinder rotation by

pressing the [SEARCH] button.

si nottub ]ssaC txeN[ eht emit yrevE •

pressed, the location number where empty

cassettes are attached is displayed in the

ascendant order. The displayed location

number is called by pressing [SEARCH].

When [Next Cass] is pressed *

when the largest location number

is displayed, the smallest

location number is displayed.

23

[Call Cassette] ■

You can call a desired cassette using its cassette number.

When the cassette is placed on the re filling table on the [Call Cassette]

screen, the location number where the cassette was attached to is

displayed.

1. Touch [CAN FIND].

Enter the cassette number and •

then touch [SEARCH].

The called cassette moves to •

the front of the tablet rack.

er nehT fill the drug. •

24

[Call Drug] ■

You can call a desired cassette using a drug name.

1. Touch [CAN FIND].

The screen is switched to the •

[Call Cassette] screen.

Then touch [Call Drug]. (The screen is •

switched to the [Call Drug] screen.)

eht fo rettel latipac eht hcuoT •

drug to be called. (1)

latipac detceles eht htiw sgurD •

letter are displayed in a list. Touch

a desired drug in the list. (2)

.]HCRAES[ hcuoT •

ot sevom ettessac dellac ehT •

the front of the tablet rack.

er nehT fill the drug. •

25

]hcraeS[■

You can search places where any cassette is not attached (used).

The cassette condition is displayed by placing the cassette on the re fill table

on the [Search] screen.

1. Touch [CAN FIND].

The screen is switched to the •

[Call Cassette] screen.

2. Touch [SEARCH].

The screen is switched to •

the [Search] screen.

3. Search

Select the condition of the cassette to •

be searched and then touch [SEARCH].

(The cassette size display varies

depending on the packing machine type.)

The place that fits the condition moves •

to the front of the tablet rack.

26

Details of DTA filling ■

Filling of the drug selected on the DTA drug list screen is displayed.

1. The DTA set wait screen is

displayed at the time of issuing

a DTA prescription or when the

second filling is to be performed

after the DTA set. (Up to 13 drugs

are displayed at one time.)

,erom ro sgurd 41 era ereht fI •

press [NEXT PAGE].

Other drugs are displayed. You can return •

to the previous screen displaying the 13

drugs by pressing [NEXT PAGE] again.

(The [NEXT PAGE] button is displayed

only when there are 14 drugs or more.)

27

2. Touch the drug name.

3. You go to the DTA drug list screen.

4. Touch the drug name you want

to display. Press the [DETAILS]

button while the drug name is

displayed within the black frame.

5. How to fill the drug selected in the

DTA drug list is displayed.

Press [NEXT PAGE].•

28

6. How to fill the unfilled drug that is

next to the currently displayed

drug is displayed.

When unequal tablets are to be set, •

a caution message is displayed.

Press [RETURN].•

7. If you return to this screen by

pressing [RETURN] on the DTA

details screen, you will notice that

the background color for the drug

name displaying the filling details

have been changed, indicating

that the drug has been already

browsed.

Set DTA and press [RETURN].•

8. Dispensing starts and DTA starts

delivering.

29

Loading...

Loading...