Yuh Dak SIC-A User Manual

Date: Feb, 2006

Version: V1.0 (English)

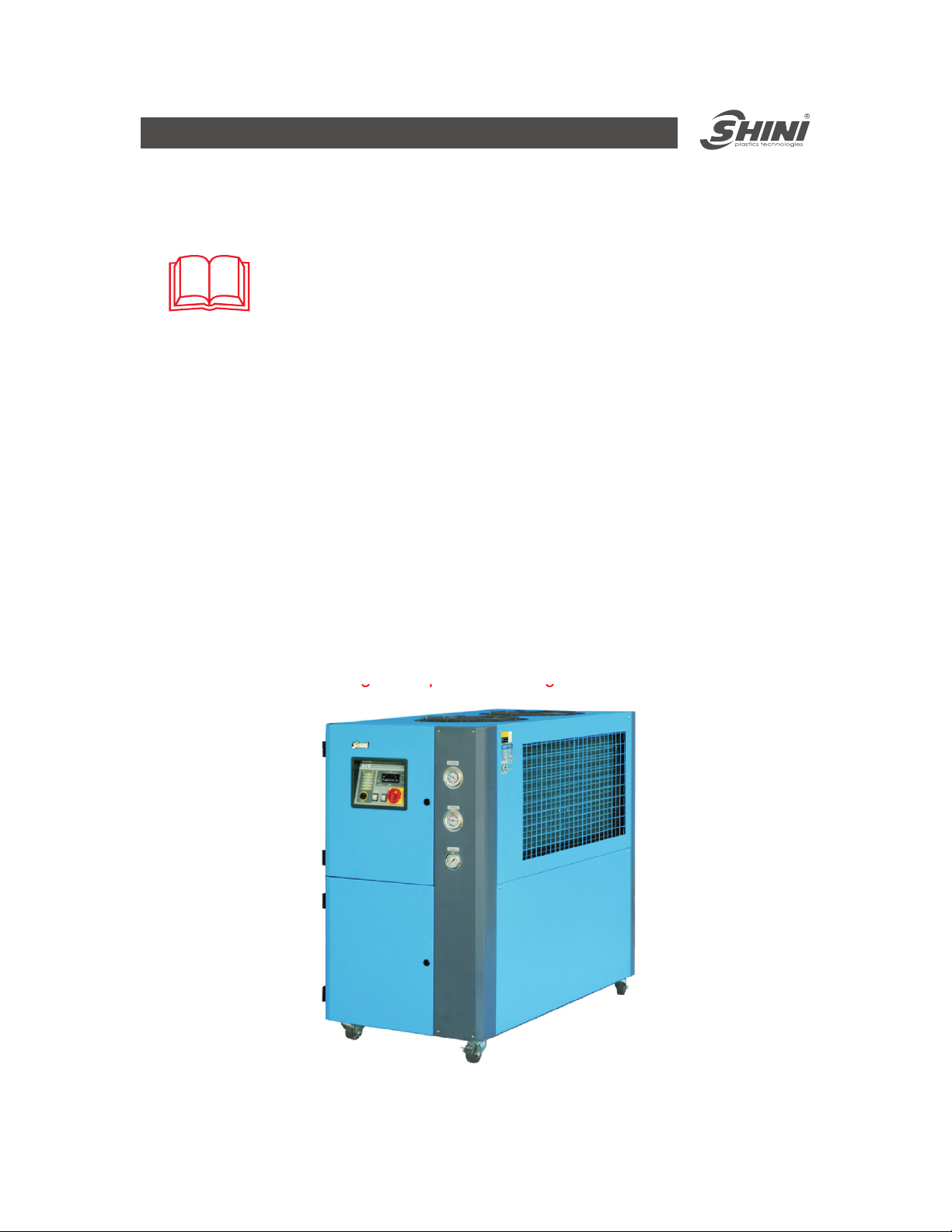

Air-cooled Water Chillers

SIC-A series

Contents

1. General Description

2. Technical Specifications

IC A Series Outer Dimensions 2.1 S -

2.2 SIC-A Series Specification List

3. Main Functions

3.1 Working Principle

4. Safety Regulations

5. Installation

5.1 Installation Instructions

5.2 Installation Space

5.3 Schematic Drawing of Installation

6. Operation Guide

6.1 Control Panel

1-1

2-1

2-1

2-7

3-1

3-1

4-1

5-1

5-1

5-2

5-3

6-1

6-1

6.2 System Startup

6.3 System Shut Off

6.4 Temperature Controller

7. Service & Maintenance

7.1 Refrigerant Filling

7.2 Parts Service

7.3

The useful life of the key parts of the product

8. Trouble Shooting

9. Assembly Drawing

9.1 IC-A Series Assembly Drawing

S

6-3

6-4

6-4

7-1

7-1

7-3

7-4

8-1

9-1

9-2

Contents

9.2 IC-A Series Parts List

9.3 Main Components Functions

S

10. Electrical Circuit Diagram

10.1 IC-3A/4A/5A-P Electrical Circuit Diagram

10. IC-3A/4A/5A-P Electrical Components List

10.3 IC-8A/10A/12.5A/15A-P Electrical Circuit Diagram

10.4 IC-8A/10A/12.5A/15A-P Electrical Components List

10. IC- Electrical Circuit Diagram

10. IC- A Electrical Components List

10. IC- Electrical Circuit Diagram

10. IC- A Electrical Components List

10. IC- Electrical Circuit Diagram

10. IC- A Electrical Components List

10. IC- Electrical Circuit Diagram

S

2 S

S

S

5 S 20A/25A-P

6 S 20A/25 -P

7 S 30A-P

8 S 30 -P

9 S 40A-P

10 S 40 -P

11 S 45A-P

9-3

9-11

10-1

10-1

10-4

10-7

10-10

10-14

10-16

10-18

10-20

10-21

10-24

10-25

12 S 45 -P

10. IC- A Electrical Components List

13 S 50A-P

10. IC- Electrical Circuit Diagram

14 S 50 -P

10. IC- A Electrical Components List

15 Main Electrical Components Description

10.

Mainten

11. ance Schedule

11.1 General Machine Information

11.2 Check after Installation

11.3 Daily Checking

11.4 Weekly Checking

11.5 Monthly Checking

11.5 Half-yearly Checking

10-28

10-29

10-32

10-33

11-1

11-1

11-1

11-2

11-5

11-8

11-10

1. General Descriptoin

1. General Description

Please read through this operation manual before using and

installation to avoid damage of the machine and personal injuries.

The SIC series of air-cooled water chillers use a single closed-loop design for

pressurised refrigerant. All models are equipped with compressor and motor

overload protection, phase shortage and reversal alarms, anti-freeze

thermostat, pressure gauges, etc. They feature excellent performance and a

long lifespan. Working under the basic principle of heat exchange, they are

mostly used with industrial processes that require flow of precisely controlled

chilled water. Water chillers are considered as indispensable equipment to

modern industry.

The SIC series of water-cooled water chillers are intended for plastic industry.

The precision temperature control is required when cooling mould to achieve

higher quality of the product surface finish lower cycle time. The compact and

moveable characteristics are best for machine side cooling. Besides, the selfcontain chiller are designed to provide cooling water for all industry application.

1-1

1-2

1. General Descriptoin

o

1. Cooling capacity from 7 to 35 C.

2. Stainless insulated water tank.

3. Equipped with anti-freeze thermostat.

5. Refrigeration loop controlled by high and low pressure switches.

6. Compressor and pump overload relays.

7. Tube-fin condenser design for excellent heat transfer and rapid cooling.

8. Tube-in-shell evaporator for excellent cooling. Can be used in environments

with relatively high ambient temperature.

o

9. Italian made temperature control accurate to 1 C.

10. Compact design, easy to operate and maintain.

4. Environment-friendly R407C refrigerant used as standard for efficient

cooling.

Main Features:

Our company provides excellent after-sales service. Should you have any

problem during using the machine, please contact the company or the local

vendor.

2. Technical Specifications

2. Technical Specifications

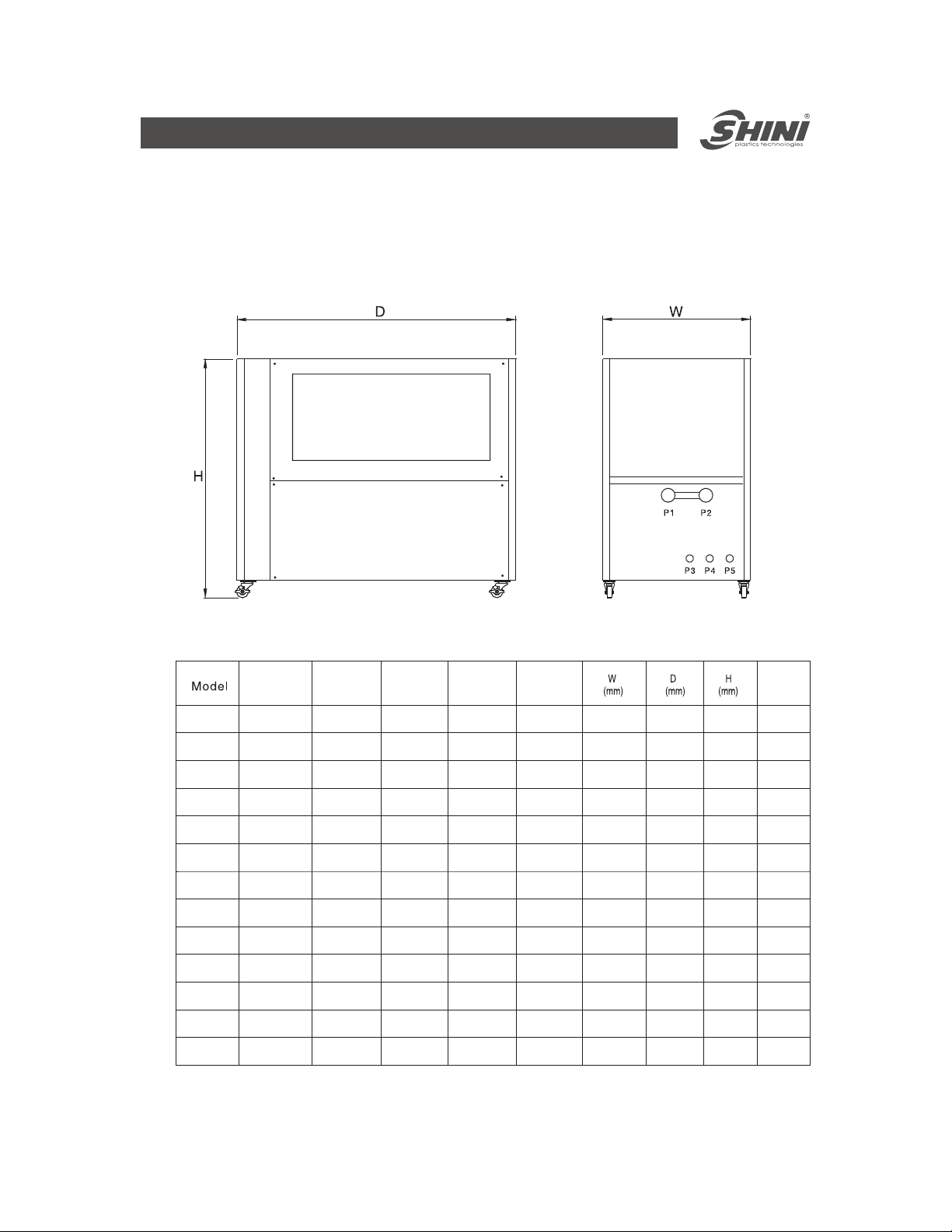

2.1 SIC-A Series Outer Dimensions

SIC-3A-P

SIC-4A-P

SIC-5A-P

SIC-8A-P

SIC-10A-P

SIC-12.5A-P

SIC-15A-P

SIC-20A-P

SIC-25A-P

SIC-30A-P

SIC-40A-P

SIC-45A-P

SIC-50A-P

P1

process water

inlet

1''

1''

1

1 ' '

1

1 / ''

2

1

1 / ''

2

2''

2''

2''

2''

1

2 / ''

2

1

2 / ''

2

1

2 / ''

2

1

2 / ''

2

P2

process water

outlet

1''

1''

1''

1

1 / ''

2

1

1 / ''

2

2''

2''

2''

2''

1

2 / ''

2

1

2 / ''

2

1

2 / ''

2

1

2 / ''

2

P3

water tank

refill port

1/2''

1/2''

1/2''

1/2''

1/2''

1/2''

1/2''

1/2''

1/2''

1/2''

1/2''

1/2''

1/2''

P4

water tank

outlet port

1/2''

1/2''

1/2''

1/2''

1/2''

1/2''

1/2''

1/2''

1/2''

1/2''

1/2''

1/2''

1/2''

2-1

P5

water tank

overflow port

1/2''

1/2''

1/2''

1/2''

1/2''

1/2''

1/2''

1/2''

1/2''

1/2''

1/2''

1/2''

1/2''

740

740

740

740

740

900

900

1100

1100

1100

1300

1300

1300

1300

1300

1300

1582

1582

1780

1780

2800

2800

2800

3390

3390

3390

1400

1400

1400

1350

1350

1520

1520

1940

1940

1940

1940

1940

1940

Weight

(kg)

250

280

310

426

423

630

670

1050

1100

1220

1500

1850

2100

2. Technical Specifications

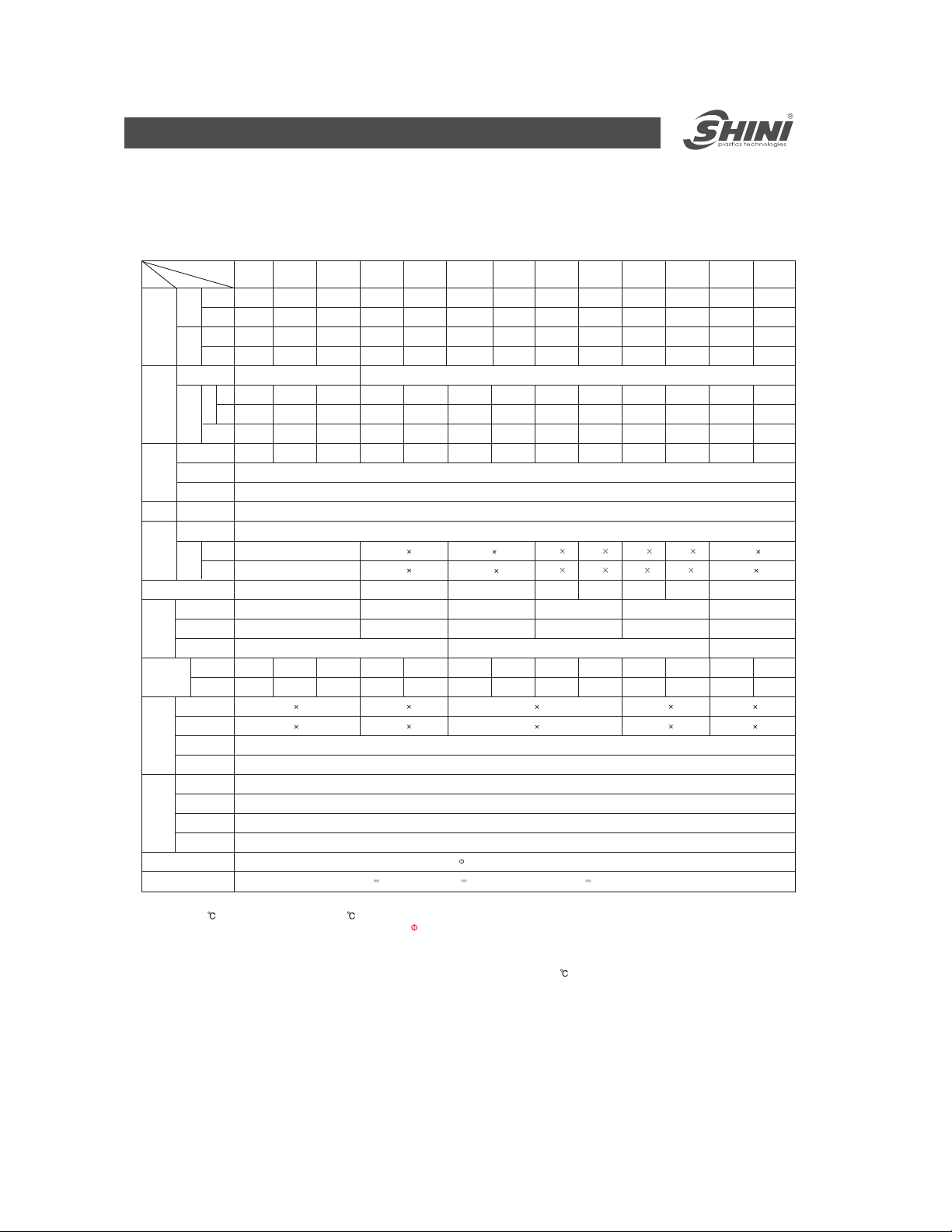

2.2 SIC-A Series Specification List

Model

Type

Type

Type

Type

Pump

KW

50Hz

60Hz

50Hz

60Hz

50Hz

60Hz

Hp

(3)

50Hz

60Hz

50Hz

60Hz

2

SIC-3A-P

7.69 10.71

6612 9208

2.2

2.6

3

2.7

3.25

Item

Parameter

KW

(1)

Refrigeration

capacity

Kcal/hr

Compressor

Power

Weight (kg)

Refrigerant

Control unit

Evaporator

Condenser

Blower

(kw)

Water tank (L)

Power (KW)

(50/60Hz)

(4)

Pump flow (L/Min)

Pump

(50/60Hz)

Working pressure (kg/cm)

Total power kw( )

Cooling water outlet

Cooling water inlet

Pipe

coupling

Drainage port

(inch)

of water tank

Overflow port

of water tank

Compressor

Protections

Refrigerant circuit

Cooling water circuit

Power supply

Measures exchange

Note: 1) Refrigeration capacity is tested under the condition that cold water outlet temperature

is at 12 and ambient temperature at 30 .

2) A piston type compressor is used when power supply is 3 , 230V. (SIC-3A-P ~ SIC-5A-P)

3) Medium-high pressure pump (Model denotes "P" , such as SIC-5A-P) is used as standard,

and high pressure pump (Model denotes "HP" , such as SIC-5A-HP) is optional.

4) Demands on special voltage of power supply could be satisfied.

5) Air-cooled chillers are best to be used in the environment with ambient temperature under 30

6) Noise level LP =55 dB max .

SIC-5A-P SIC-10A-P SIC-12.5A-P SIC-15A-P SIC-20A-P SIC-25A-P

SIC-4A-P

13.5

SIC-8A-P

19.08

25.56

31.41

38.79

16.2 37.6 46.5

16405

11607 21976

13928 26371 32407

(2)

3

3.6

4

3.6 7

5.5

3.7

6.6

4.4

5

8

4.3

7.5

9.0

10

8

33352

27006

40022 52731 64815 80043

10

11

12

13.2

12.5

15

13

11

Thermostatic expansion valve

R407C

Tube-in-shell style

Tube-fin style

0.3 0.18 2

0.36

50

0.75 / 0.75

55 / 50

0.22 2

90

1.35 / 1.35

100 / 90

0.3 2

0.36 2

140

2.0 / 1.85

150 / 140

2.5

4.05

4.7

1" 1

1" 1

4.75

7.2

10.8 48.7 52.9

8.4

5.5

1

1 / "21

1

1 /2" 1

12.6

14.6

13.6

15.8

9.3

1/ 2"

1/ 2"

Overload relay

Overload relay

High and low pressure switch / anti-freezing switch

Water level switch / by-pass valve

3 , 400V, 50/60Hz

1 KW 8 60 Kca l/hr 1 RT 3 024 Kc al/hr 10000 Btu/h r 2 520 Kc al/hr

0.55 2 0.65 2 0.75 2

0.66 2 0.78 2 0.9 2

2" 1

2" 1

SIC-30A-P

SIC-40A-P

51.12

62.82

77.58

61.2 75.3 93.1 122.49.12 12.8 22.8 30.6

43943

54013

66703

Scroll Scroll

15

19.8

18 23.8

20

18

22

26.4

30

25

26

22

0.75 3

180 200 270 400

2.6 / 2.6

190 / 210

4.0 / 3.7

300 / 280

3

18.7

21.9

23.7

28.0

27.5

31.9

1

2 / "21

1

2 /2" 1

SIC-45A-P

SIC-50A-P

113.94

102.24

87906

136.6

97956

125.64

150.7

108026

1054877838 11008 19686 117547 129831

30

34

37.5

36

40.8 45

45

40

34

50

34 34

0.75 3

0.9 3

0.9 3

400

5.2 / 5.2

380 / 380

3.2

41.45

36.25

45.0

42.43.7

3" 1

3" 1

2-2

3. Main Functions

3. Main Functions

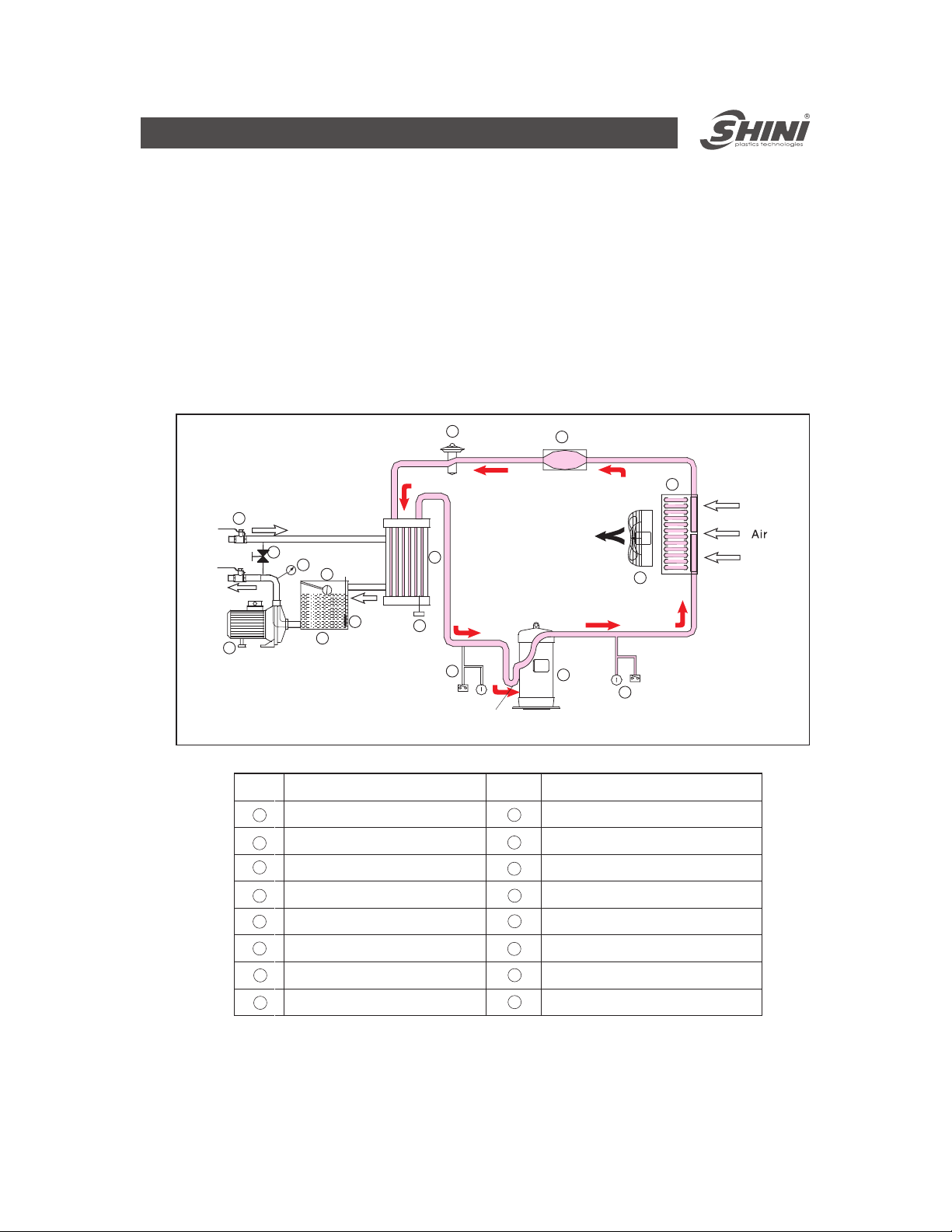

3.1 Working Principle

SIC-A air-cooled water chillers include compressor, condenser, thermostatic

expansion valve, and evaporator four main components. The system adopts

a single closed-loop design for refrigeration system. Refrigerant is

alternatively changed from gaseous to liquid state to absorb or release heat

thus a cooling effect is achieved.

6

12

1

2

3

4

5

6

7

8

Process water

13

11

E

8

9

10

Name No.

Compressor

Condenser

Dry filter

Thermostatic valve

Evaporator

Ball valve

Anti-freezing switch

Level sensor

4

D

5

7

14

Direction of refrigerant

3

C

A

1

9

10

11

12

13

14

15

16

2

16

B

15

Name No.

Temp. sensor

Water tank

Pump pressure gauge

Pump

By-pass valve

Low pressure switch

High pressure switch

Blower

3-1

3. Main Functions

When the machine is started, compressor (1) starts working. Refrigerant is

compressed into high pressure and high temperature gas in the process from

A to B. In the process from B to C and D, this high pressure and high temp.

gas is cooled when it is passing through the condenser (2) and changed into

liquid. Heat is taken away by the cooling water. In the process from D to E,

the pressure of liquid refrigerant is reduced by expansion valve (4) and a part

of the refrigerant is changed from liquid to gaseous state. In the process from

E to A, refrigerant absorbs the heat of process water in the evaporator (5) and

returns back to the compressor. This heat exchange process repeats until

process water is cooled down to required temperature.

3-2

4. Safety Regulations

4. Safety Regulations

4. Safety Regulations

Operation should be carried out according to the safety regulations

this manual to avoid damage of the machine and personal injuries.

Abide by the following regulations during operation.

Electrical installation should done by qualified electricians.

Main switch and control should be turned before service and

maintenance.

Warning High voltage!

This sign is attached to the cover of control box!

Warning Be careful!

Pay more attentions at the places where this sign is attached

4-14-1

4. Safety Regulations

4-2

Transportation and storage of the machine

Transportation

1) SIC-A series are packed in crates or plywood cases with wooden pallet at

the bottom, suitable for quick positioning by fork lift.

2) After unpacked, castors equipped on the machine can be used for ease of

movement.

3) Do not rotate the machine and avoid collision with other objects during

transportation to prevent improper functioning.

4)The structure of the machine is well-balanced, although it should also be

handled with care when lifting the machine for fear of falling down.

5) The machine and its attached parts can be kept at a temperature from

-25 to +55 for long distance transportation and for a short distance,

it can be transported with temperature under +70 .

Storage

O

1) SIC-A series should be stored indoors with temperature kept from 5 C to

O

40 C and humidity below 80%.

2) Disconnect all power supply and turn off main switch and control switch.

3) Keep the whole machine, especially the electrical components away from

water to avoid potential troubles caused by the water.

4) Plastic film should be used to protect the machine from dust and rains.

Working environment

The machine should be operated:

1) Indoors in a dry environment with max. temperature +45 and humidity no

more than 80%.

Do not use the machine:

1) if it is with a damaged cord.

2) on a wet floor or when it is exposed to rain to avoid electrical shock.

3) if it has been dropped or damaged until it is checked or fixed by a

qualified serviceman.

4. Safety Regulations

4) This equipment works normally in the environment with altitude within 3000m.

5) At least a clearance of 1m surrounding the equipment is required during

operation. Keep this equipment away from flammable sources at least two

meters.

6) Avoid vibration, magnetic disturbance at the operation area.

Rejected parts disposal

When the equipment has run out its life time and can not be used any more,

unplug the power supply and dispose of it properly according to local code.

Fire hazard

In case of fire, Co dry powder fire extinguisher should be applied.

2

4-3

5. Installation

5. Installation

Read this chapter before installation. Install the machine according to

following steps

Air-cooled water chillers should be installed in an environment that has good

ventilation, such as draughty area against the window. Ambient temperature

should not be more than 35 if it is installed indoors. Use exhaust pipe to

conduct the hot air produced by the chiller to the outside. If the chiller is

installed outdoors, protective cover should be used.

5.1 Installation Instructions

1). Make sure that the voltage and frequency corresponds with the

requirements on manufacturer's name plate.

2). Connect the machine with electrical wires and negative wire according to

local code.

3). Use independent electrical wires and switch. Diameter of electrical wire

should not be smaller than that of the electric wire which is used for the

electrical control box.

4). Wiring connections should be firmly fixed.

5). The chillers use three phase & five core wire. Connect wire N to negative

wire, PE to earth wire, and others to live wire.

6). Power supply:

Voltage deviation: 10%

Frequency deviation: 2%

7). Piping system should be installed according to the schematic drawing of

installation. Use insulated material to protect the cold water pipe.

8). Circulation pipe diameter of the pump should not less than that of

condenser inlet pipe. Circulation pipe with larger diameter should be used

for long distance transportation of process water.

9). Automatic exhaust tap should be installed at the top of circulation pipe,

and at the lowest part drainage valve should be installed.

10). Water filter should used in the process water and cooling water circulation

pipe if water quality and surroundings of cooling tower is bad.

11). After the installation is completed, check if there are leakages in the

circulation system. Cold water circulation pipe should be covered with a

layer of insulated material to avoid temperature increasing and water

drops forming on the surface of circulation pipe.

Electrical wire connection of water chiller should be done by qualified

electrician! Electrical wiring circuit should not be modified unless

authorized by our company. We shall not be reliable for machine

damages caused by unauthorized modification.

5-1

5. Installation

5.2 Installation Space

5

00

mm

5

00

mm

During installation of the machine, keep at least 500mm installation space

around the machine as shown by the picture. Do not install the machine in

a position crowded with other objects. This would cause inconvenience to

operation, maintenance and repair.

Do not sit on the machine.

Make sure the machine is in an environment with good air convection.

5-2

5. Installation

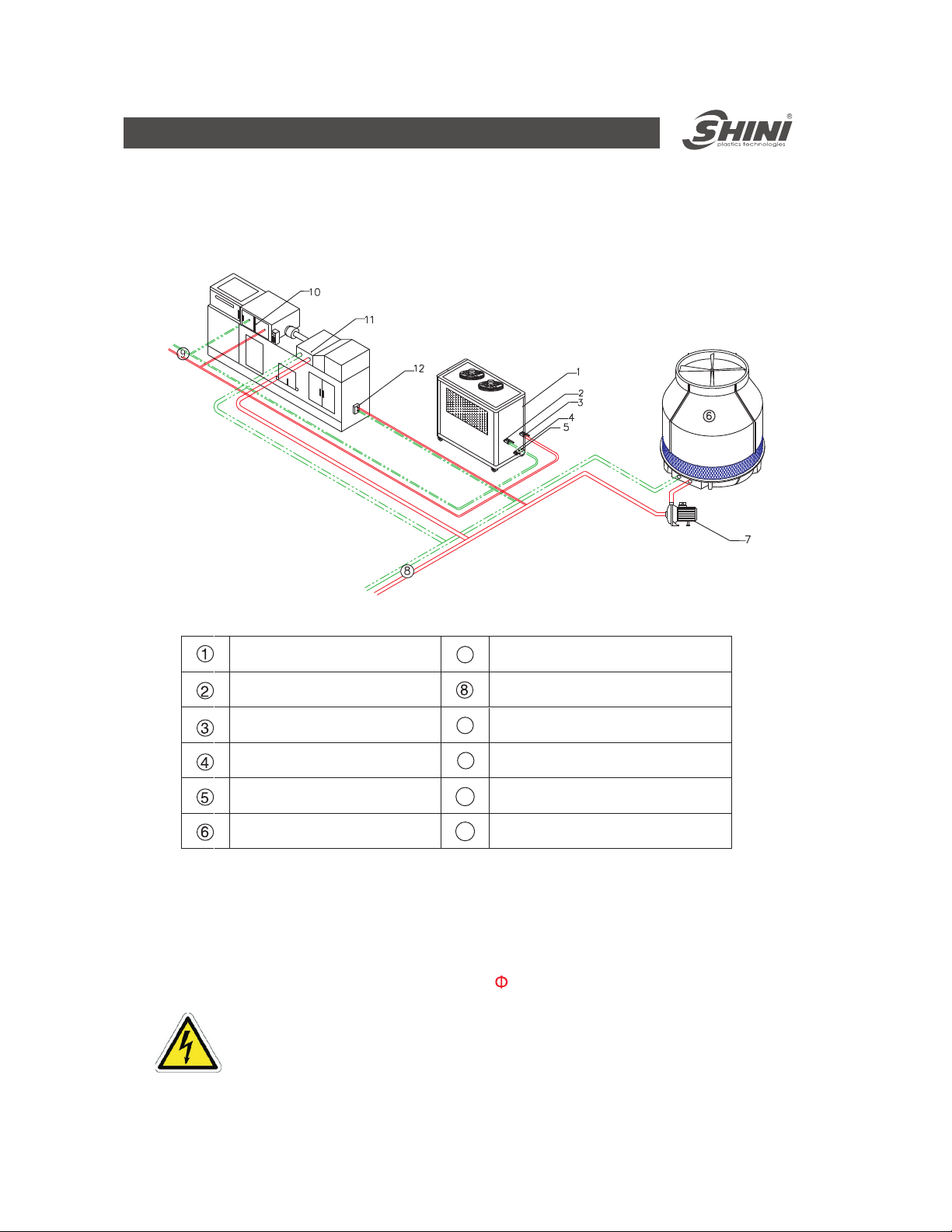

5.3 Schematic Drawing of Installation

Water chiller

Process water outlet

Process water inlet

Water discharge port

7

9

10

Water refill port

Cooling tower

11

12

Cooling water pump

Cooling water circulation

Cold water circulation

Mould cooling

Cooling chamber

Hydraulic oil cooling

5.4 Power Supply

Make sure that power supply is the same as required before installation.

SIC-A series should be connected with 3 400V power supply and earth wire.

Before connecting the machine with power supply, please make sure

that main switch is turned off!

5-3

6. Operation Guide

6. Operation Guide

6-1

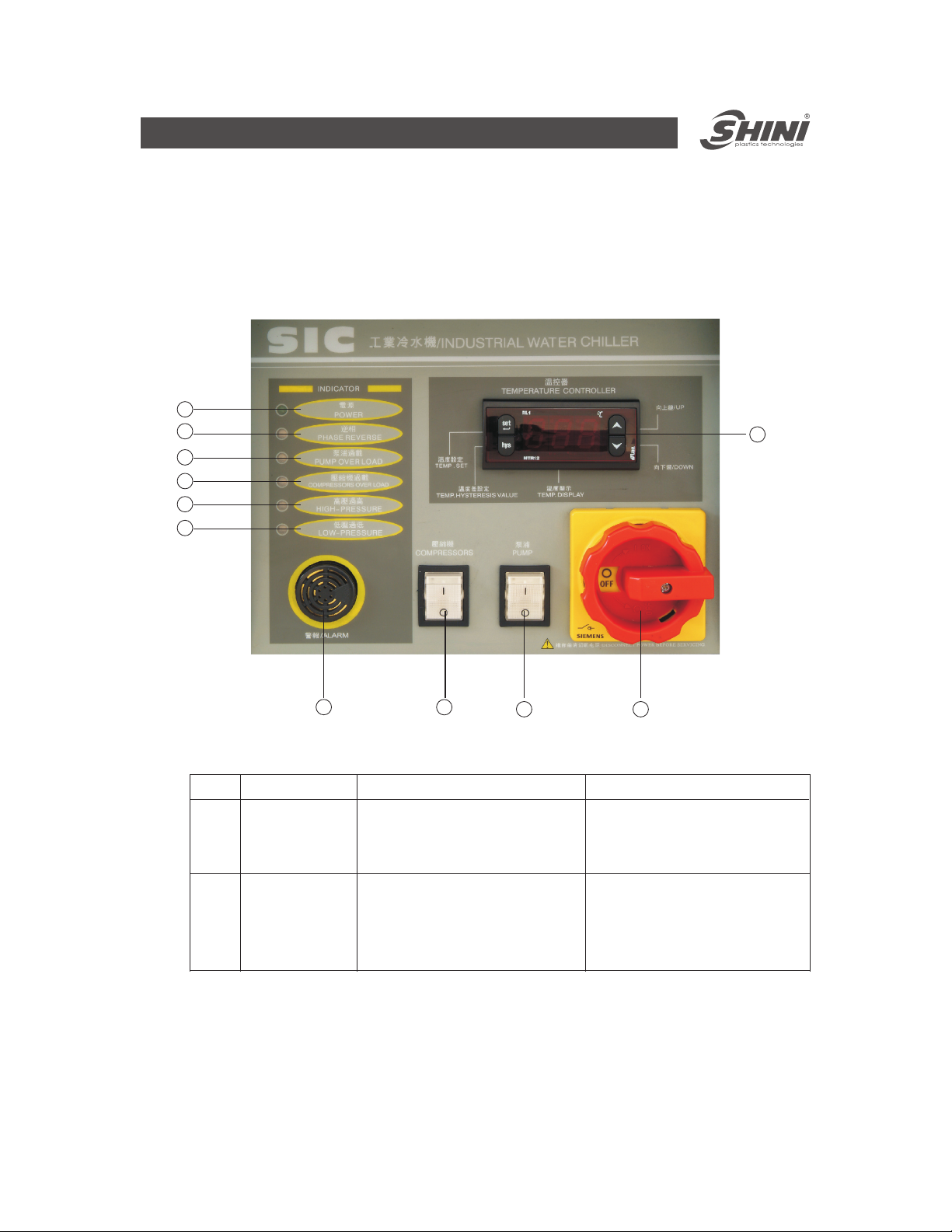

6.1 Control Panel

1

2

3

4

5

6

10

7

8

9

11

No. Name Functions Remarks

1 Power indicator Connect through power supply and

turn on the main switch, the

indicator will becomes bright.

Note! Do not disassemble any

electrical components or terminals

in case of electrical shock.

2 Anti-phase

indicator

It is used to indicate phase

reversal or phase shortage. The

buzzer sounds and system stops

working.

Check the power supply and

exchange two of the live wires to

reset the alarm.

Low pressure

alarm

9

Pump switch

10

Main switch

Turn on/off main power.

11

Temperature

controller

Temperature setting and control.

The start & stop of the compressor.

High-pressure switch setting value

should be correctly set as 25 bar.

When the inlet pressure of

compressor is lower than setting

value of low-pressure switch, the

alarm will be raised. The buzzer

sounds and system stops working.

Low-pressure switch should be

correctly set as 2 bar.

The buzzer makes audible alarm

when problems is detected.

Note! Before turning on the

compressor, turn on the pump first.

Please refer to page 6-4 for details.

6. Operation Guide

No. Name Functions Remarks

3 Pump overload

indicator

4 Compressor

overload alarm

5 High pressure

alarm

6

When pump current exceeds the

limits, this indicator becomes

bright. The buzzer sounds and

system stops working.

If working current of the

compressor is above the setting

current of overhear relay, the

alarm will be raised. The buzzer

sounds and system stops working.

When the outlet pressure of the

compressor is higher than setting

value of high-pressure switch, the

alarm will be raised. The buzzer

sounds and system stops working.

Check if the motor is blocked or

the bearing is broken. If motor

works normally, please check if

the setting current of the overload

relay in the control box is set too

low. After the above measures

are taken, wait for about 1 minute,

then press the blue "reset"

button to reset the alarm.

Check if the setting current of

overheat relay is correct. Setting

current of overheat relay should

be bigger than the rated current

of the compressor.

7 Buzzer

8

Compressor switch

The start & stop of the pump.

6-2

Pump rotating direction should

be correct.

Note!

Pump rotating direction should be correct.

Note!

Before starting the system, make sure that cooling water pump is

turned on. Check the water tank of the chiller, do not start the machine

when there is no water left in water tank. We shall not be liable for

any damages caused by this reason.

Note!

In order to reduce the possibilities of machine damage and prolong

the life, start the machine with correct methods.

Note!

Temperature setting value should not be lower than 5 . Temperature

of anti-freezing switch and high and low pressure switch is already

set before delivery. We shall not be liable for any damage caused by

unauthorized change of the setting.

6-3

6. Operation Guide

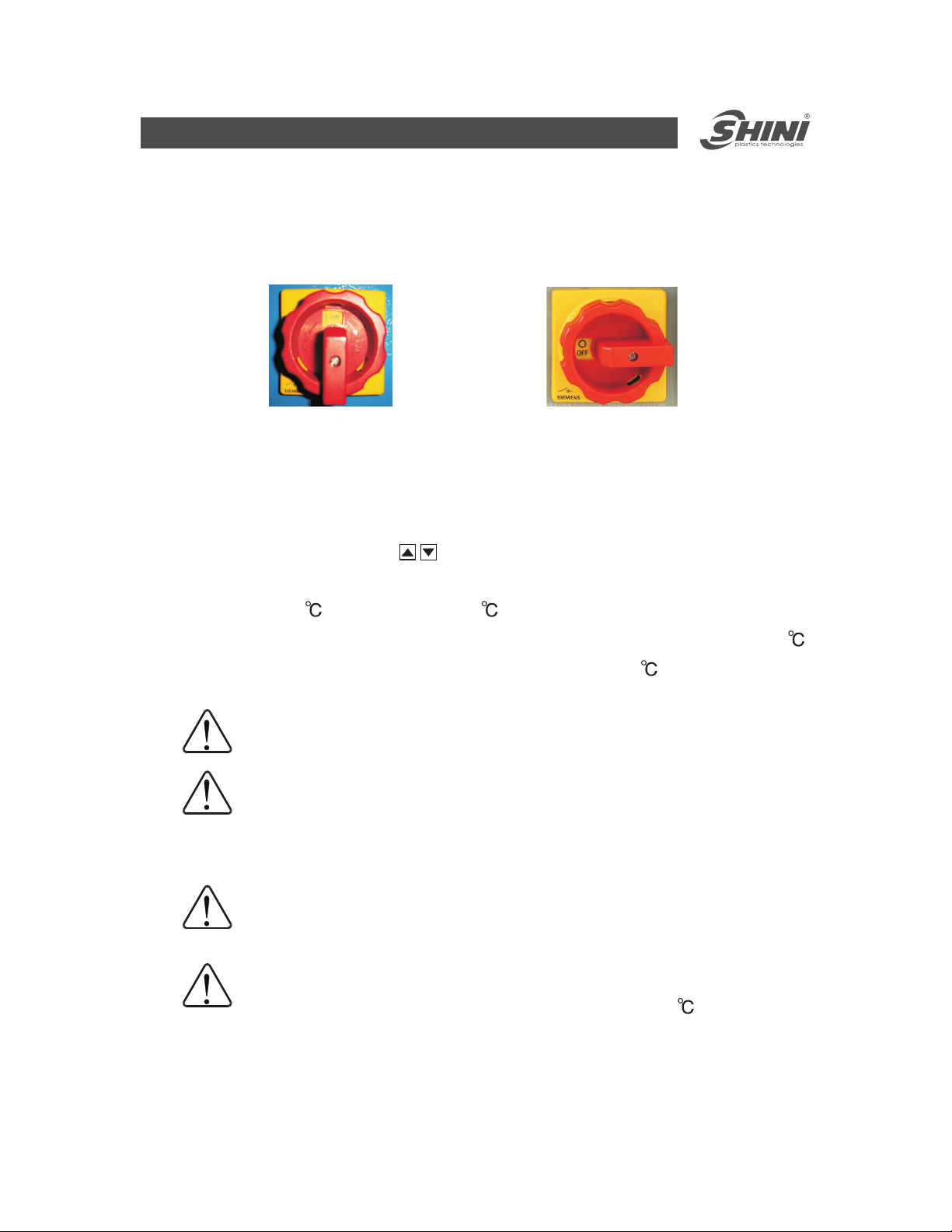

6.2 System Startup

1) Turn on the main switch.

2) Turn on the pump.

3) Turn on the compressor.

4) Set process water temperature (Neglect this step if temperature is

already set). Press to increase or decrease water temperature.

For this series of water chillers, process water temperature should be

set as 7 (never set below 5 ).

5) Anti-freezing setting: anti-freezing switch equipped (setting value 5 ).

ON OFF

When process water temperature is lower than 5 , the compressor

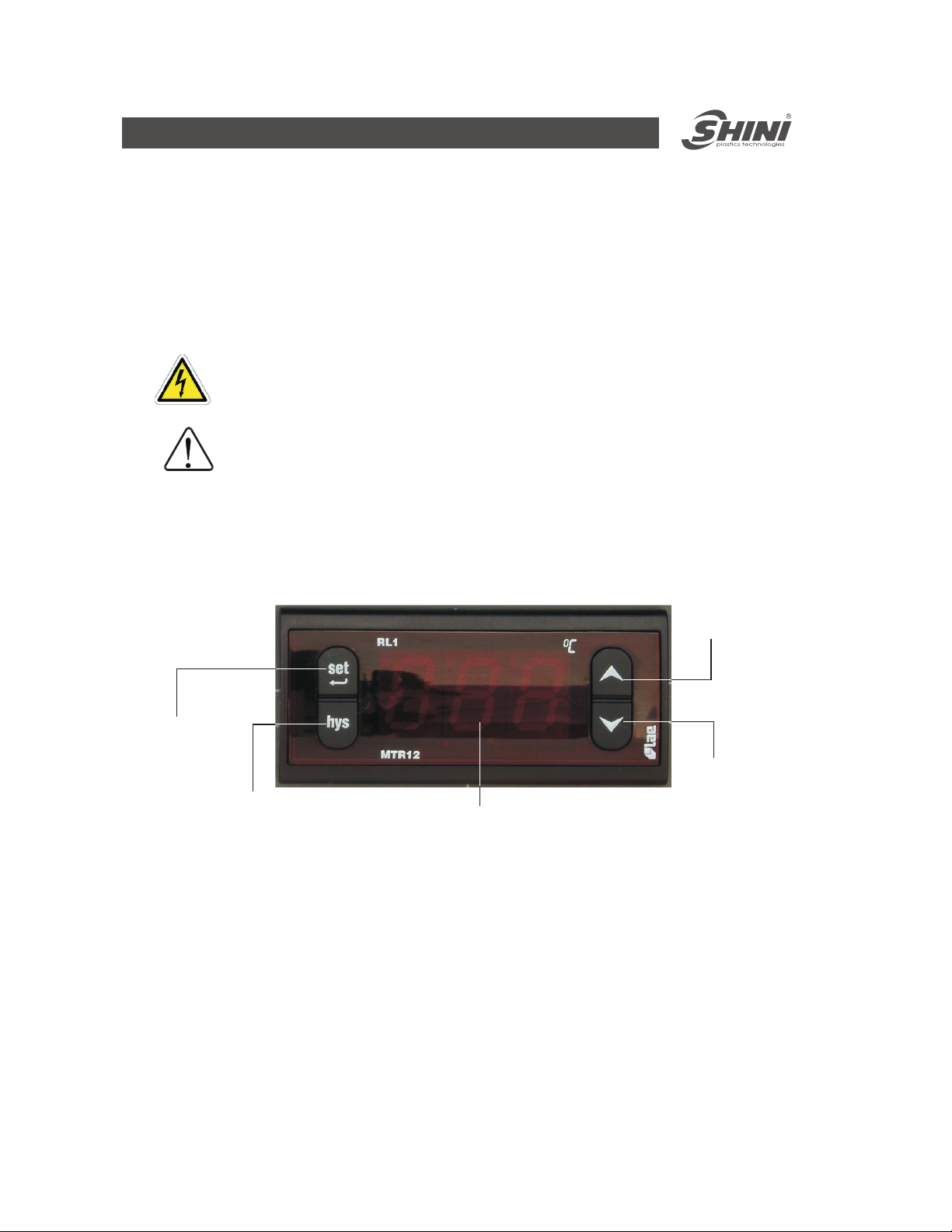

will stop working.

Temperature

setting

Temperature hysteresis

value

Increase value

Decrease value

Temperature display

6.4.1 Functions of temperature controller

There are two kinds of different control output for this controller. The

setting points of the two control mode are on and off, the differences

are that the actual value is lower than the setting value in the cooling

control mode, that is to say, keeps off sate; however in the heating

control mode the control output is turned to on state.

6. Operation Guide

6.3 Machine Shut Off

1) Turn off the compressor.

2) Turn off the pump.

3) Turn off the main switch.

6.4 Temperature Controller

Note!

Avoid electrical shock when main switch is turned on.

Note!

In order to reduce the possibilities of machine damage and prolong

the life, shut off the machine with correct methods.

6-4

6-5

6. Operation Guide

key Display the delay time value. Press key to display "HY1",

display the setting value two seconds later. Positive value is cooling

control, negative value is heating control. The delay time is the

difference between On and Off. When MRT is On, the indicator light

beside RL1 is on. For example (1) L1=+25 Celsius degree; HY1=-03

Celsius degree, the output control is heating mode. Show that RTL1 is

off when the temperature is 25 Celsius degree; RTL1 is on when the

temperature is 22 Celsius degree. For example (1) L1= 10 Celsius

degree; HY1=+02 Celsius degree, the output control is cooling mode.

Show that RTL1 is off when the temperature is 10 Celsius degree;

RTL1 is on when the temperature is 8 Celsius degree.

4) If the coupling end of the probe head of temperature control instrument

is open circuit or out of the range, display "PFA", RL1 output will work

according to the permanent setting value of SETUP.

The setting of MTR is completed by

changing the control parameters. The parameter setting can be completed

by the following produces.

1) Turn off the temperature control instrument, at the same time press

the key and hold up, turn on the power supply, then display "PAR",

press and key repeatedly to choose the setting items of parameters,

after displaying value press key to change the value, and then press to

save the value.There is no necessary to display the value from one

parameter to another parameter to press key directly, also can choose

certain specs parameter and set the parameter according to the

arrangement plan.

key Press or to increase or decrease the values of

parameters. Press and hold up to change the parameter values at a

quick. The biggest and smallest values have been set in the "SETUP".

Change it according to the first part of 6.4.2 and the following

instruction.

2) key When the MTR works normally, press key, the screen

display"L1", display the setting value two seconds later. If "L1" achieve

the settingvalue, the control output RL1 changes from On to Off. If press

key when set the parameters, the parameters can be saved, and

switch to control mode. Return to control mode automatically six

seconds later without pressing any key.

6.4.2 The parameter setting of temperature control instrument.

6. Operation Guide

2). Parameter instruction

SP The lowest setting value(-50 C~+5 0 C) ;(0~100%)

v

SP The highest setting value( SP~+150 C) ;( SP~100%)

O O

v v

O

rt1 The lowest turn off time of Rl1. The lowest time interval of

setting turn on and turn offRL1can be adjusted between zero and

ten minutes.

Pf1 The time of probe head malfunction, the working stage of

RL1 On/Off

ADj The compensate value of the input value. Allow range

(-20 +20)

hy1 The range of daily time determines the turning on and

turning off of Rl1,Choose the output mode of +or +controlRL1.

+ is cooling, - is heating.(-25 +25)

After carrying out the setting, turn of the temperature control

instrument. When turn on again, the temperature control instrument

will work according to the new settings.

Note! The parameters of temperature controller is already set before

delivery. Do not reset the parameters except for special reasons.

6-6

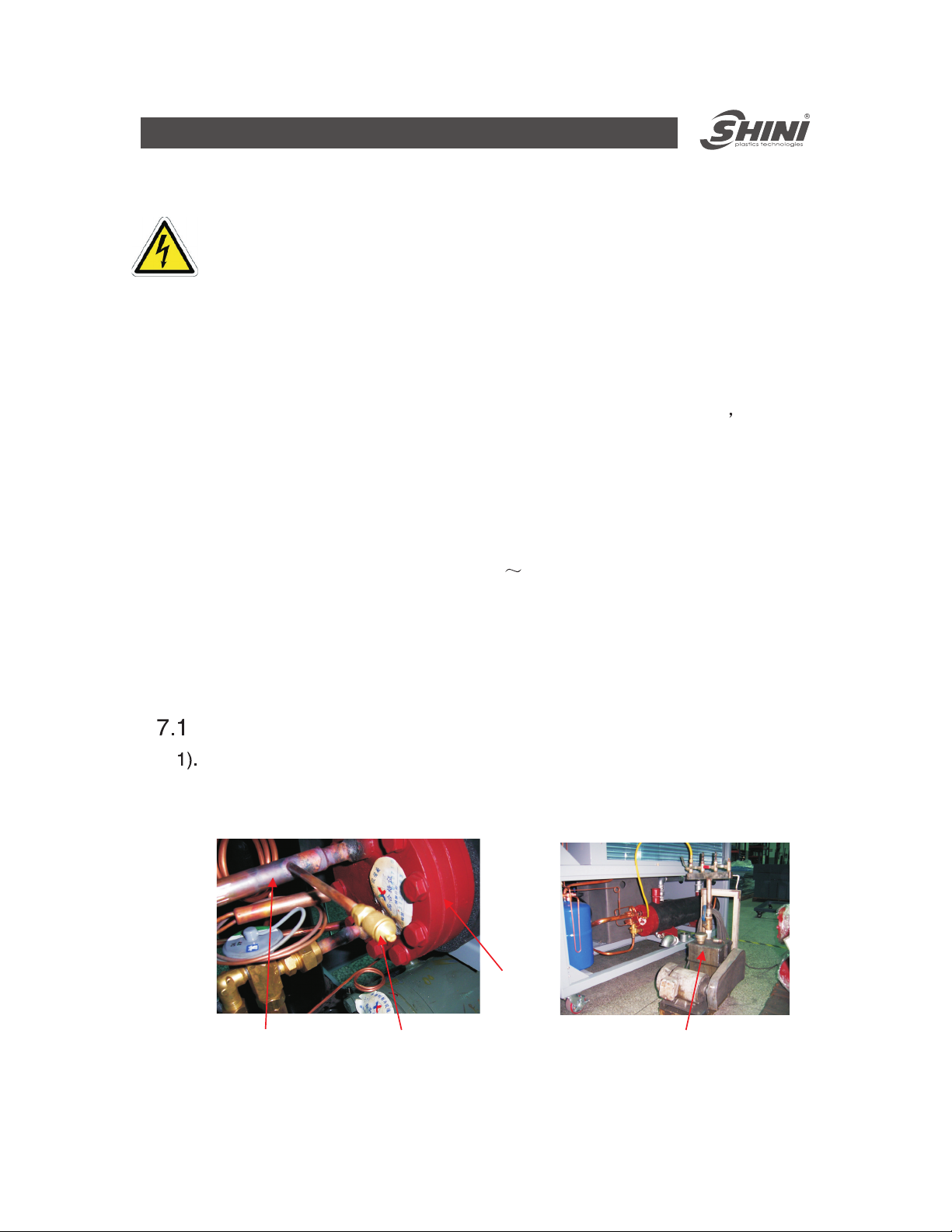

7. Service & Maintenance

The end cap of the

liquid filling thimble valve

The

evaporation

The air return pipe

The vacuum pump

7. Service & Maintenance

All repair work should be done by qualified personnel only to avoid damage

the machine or personnel injury.to

In order to operate the machine rightly and safely, please caution the matter

follows:

1) Do not turn off the main power switch to stop the machine,except emergency

situation.

2) When failures set in and the machine stop work with buzzer sound, first press

down

the main power switch of the machine (alarm indicator will die) then go

to check

the reason of the failures, do not force the machine on before remove

the failures.

3) please check periodicaly to prolong the life of the machine and prevent the

safety

accident to appear.

4) water supply should be processed, because the high PH can corrode the copper

pipe acute. This must reduce the life of the heating and cooling implement, PH

of the

water supply must be between 7.0 8.5.

5) keep the machine room dry,clean and vent.

6) the operation and service of the machine should be done by qualified technician

only.

Please take notice that the disassembly and the inspection of the machines are

(

hazardous when the machines are running

as

!)

suction pipe of the vacuum pump to the liquid filling thimble valve to take the

vacuum pumping, and this process may take one to two hours.

Fill in the refrigerant

Screw off the end cap of the liquid filling thimble valve, and connect the air

7-1

7-2

After the vacuum pumping, connect the air pipe of the refrigerant

tank to the liquid filling thimble valve, and fill the refrigerant into the air

return pipe. Watch the change of the weight displayed by the electronic

scale, and stop filling the refrigerant immediately when receiving the

schedule weight.

In the condition of the starting up, the shown pressure of the high

pressure gage should be about 13 to 15 bar; and shown pressure of the

low pressure gage should be about 3 to 5 bar. Note: the temperature of

the environment should be and the temperature of the frozen water

should be

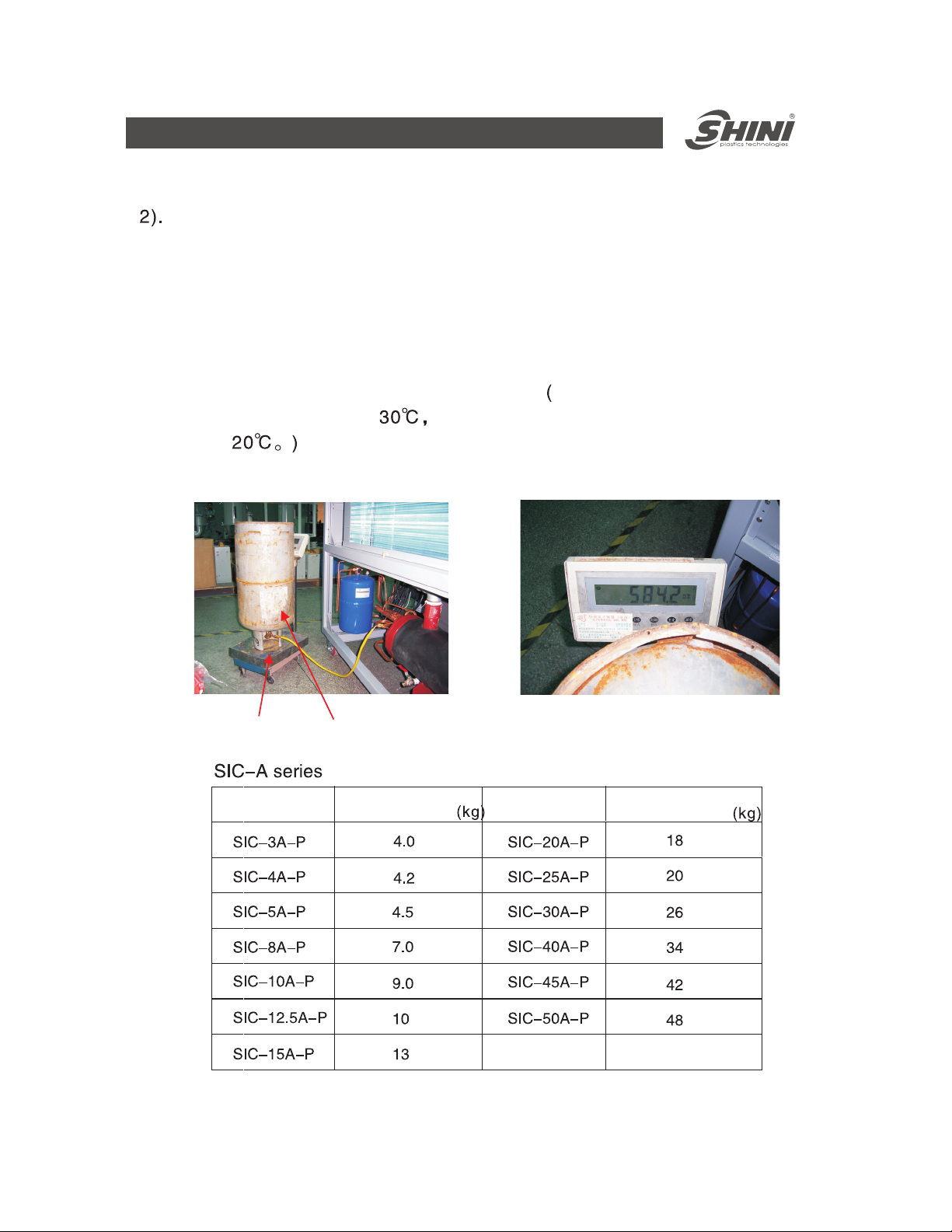

The filled weight

of the refrigerant

The model

of the machine

The model

of the machine

The electronic scale

The coolants tank

filled weight

7. Service & Maintenance

The filled weight

of the refrigerant

7. Service & Maintenance

Note: Drain the water inside the evaporator and the condenser away,

O

when the machine stop running under 0 C.

7.2 Maintenance of the subassemblies

7.2.1 Condenser

SIC-A series water chillers use the air cooled condenser with ferrule

installed openly, in the using time, it hard to avoid any dust and

sundries ,which will influence the heat emission effect, so it is

necessary to clean the condenser at fixed periods in order to keep its

working performance. Use brush, dust catcher or compressed air to

clean the wings and copper pipe. Then use the low pressure water to

cascade the tray pipe. Note: do not let the water to cascade on the

surface of the fan motor.

Note: do the cleaning work every half-year in the environment with little

dust, but you must do the work every month in the environment with a

great deal of dusts, and under the scurviness environment you had

see the situation to do the work. better

7.2.2 The evaporator

The inner flank of the heat emission pipe will pile up a great deal of

water incrustation after a long time use of the evaporator, which will

influence the heat emission effect, so it is necessary to clean the

evaporator at fixed periods in order to keep its working performance.

Open the pollution discharge porthole on the bottom of the

evaporator1,and spray rinse the heat emission pipe from the outer

flank to the innerflank, the water incrustation will be discharged from

the pollution discharge porthole.

7-3

7. Service & Maintenance

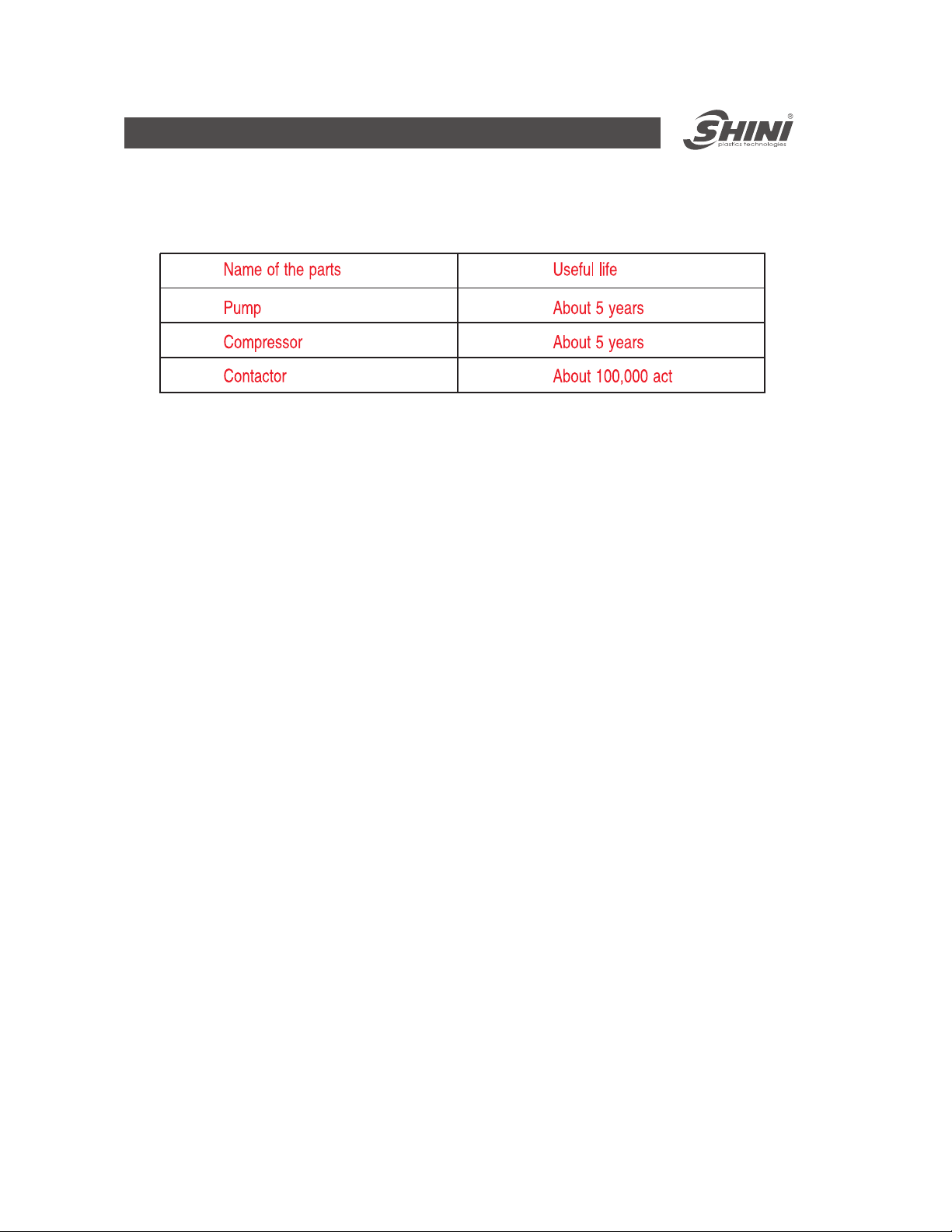

7.3 The useful life of the key parts of the product

7-4

Loading...

Loading...