Page 1

YSI 2900 Ser ies

Biochemistry Analyzers

Operations and Maintenance Manual

Page 2

Table of Content s

Introduction .................................................................................................................................... 5

1.

Description ................................................................................................................................. 5 1.1

User Features ............................................................................................................................ 5 1.2

Models ....................................................................................................................................... 5 1.3

2900 Series General Specifications .......................................................................................... 6 1.4

2960 Online Monitor Specifications ........................................................................................... 6 1.5

Monitor ................................................................................................................................ 6

1.5.1

1.5.2 Analog/Control .................................................................................................................... 7

2. Safety ............................................................................................................................................... 7

Important Safety Instructions ..................................................................................................... 7 2.1

Explanation of Symbols ............................................................................................................. 8 2.2

Getting Started ............................................................................................................................... 9

3.

Unpacking .................................................................................................................................. 9 3.1

Warranty Card ......................................................................................................................... 10 3.2

What You Need ....................................................................................................................... 10 3.3

Major Components .................................................................................................................. 10 3.4

Basic Setup ................................................................................................................................... 12

4.

Install Bottle Racks .................................................................................................................. 13 4.1

Right Side .......................................................................................................................... 13

4.1.1

4.1.2 Left Side (2950 models only) ............................................................................................ 14

Connect Printer ........................................................................................................................ 15 4.2

Connect AC Power .................................................................................................................. 15 4.3

Connect 2960 Online Monitor .................................................................................................. 16 4.4

Align Sipper ............................................................................................................................. 16 4.5

Configure Instrument Chemistries ........................................................................................... 19 4.6

Assign Chemistries to Probes ........................................................................................... 19

4.6.1

4.6.2 Assign Reagents ............................................................................................................... 22

Prepare and Install Buffer Solutions ........................................................................................ 24 4.7

Prepare Buffer ................................................................................................................... 25

4.7.1

4.7.2 Install Buffer Solution(s) .................................................................................................... 25

Install Calibrator Solution(s) .................................................................................................... 25 4.8

Install Membranes and ISEs .................................................................................................... 26 4.9

Enzyme Membranes ......................................................................................................... 26

4.9.1

4.9.2 Ion Selective Electrodes.................................................................................................... 27

Prime the Fluid System ........................................................................................................... 29 4.10

Check Probe Currents ............................................................................................................. 30 4.11

Biosensor Probes ....................................................................................................... 30

4.11.1

4.11.2 ISE Probes.................................................................................................................. 30

Enable 21 CFR Part 11 Mode ................................................................................................. 30 4.12

Running the Instrument ............................................................................................................... 30

5.

Perform Daily Operational Checks .......................................................................................... 30 5.1

Enzyme Membrane Integrity Test ..................................................................................... 31

5.1.1

5.1.2 Linearity Test ..................................................................................................................... 33

5.1.3 Results .............................................................................................................................. 33

Sample Preparation ................................................................................................................. 35 5.2

Run Batch ................................................................................................................................ 35 5.3

1

Page 3

5.3.1

Create Batches ................................................................................................................. 35

5.3.2 Load Samples ................................................................................................................... 37

5.3.3 Start ................................................................................................................................... 39

5.3.4 Status ................................................................................................................................ 39

Run Stat ................................................................................................................................... 39 5.4

Results ..................................................................................................................................... 42 5.5

Online Monitor and Control......................................................................................................... 42

6.

2960 Installation....................................................................................................................... 43 6.1

Align Sipper ............................................................................................................................. 46 6.2

Sample Interface...................................................................................................................... 46 6.3

Sterilization ........................................................................................................................ 47

6.3.1

Electrical Interface ................................................................................................................... 47 6.4

Analog Outputs ................................................................................................................. 47

6.4.1

6.4.2 Pump Control Outputs....................................................................................................... 48

6.4.3 Auxiliary Connector / Signal List ....................................................................................... 48

Monitor Setup .......................................................................................................................... 48 6.5

Name ................................................................................................................................. 49

6.5.1

6.5.2 Flow Rate and Purge Time ............................................................................................... 50

6.5.3 Antiseptic ........................................................................................................................... 50

6.5.4 Filtrate Pump ..................................................................................................................... 51

6.5.5 Module............................................................................................................................... 51

Start Monitor ............................................................................................................................ 56 6.6

Manual Sample during Monitor Sess ion ........................................................................... 57

6.6.1

Stop Monitor ............................................................................................................................ 58 6.7

Control Setup ........................................................................................................................... 58 6.8

Control Type ...................................................................................................................... 58

6.8.1

Print Monitor Configuration ...................................................................................................... 67 6.9

System Configuration .................................................................................................................. 68

7.

Settings .................................................................................................................................... 68 7.1

System .............................................................................................................................. 68

7.1.1

7.1.2 Fluid Detection (Bottles) .................................................................................................... 70

7.1.3 Display............................................................................................................................... 71

7.1.4 Auto-Cal Settings .............................................................................................................. 73

7.1.5 Scheduler .......................................................................................................................... 74

7.1.6 21 CFR Part 11 ................................................................................................................. 76

7.1.7 Date/Time .......................................................................................................................... 81

Service ..................................................................................................................................... 82 7.2

Sipper ................................................................................................................................ 82

7.2.1

7.2.2 Pumps ............................................................................................................................... 85

7.2.3 Modules ............................................................................................................................. 86

7.2.4 Stirbar ................................................................................................................................ 87

7.2.5 Monitor .............................................................................................................................. 89

Data ......................................................................................................................................... 90 7.3

Plate .................................................................................................................................. 90

7.3.1

7.3.2 Monitor .............................................................................................................................. 92

7.3.3 Calibration ......................................................................................................................... 94

Help ......................................................................................................................................... 95 7.4

About ................................................................................................................................. 95

7.4.1

7.4.2 Software ............................................................................................................................ 96

7.4.3 FAQ ................................................................................................................................... 97

7.4.4 Training ............................................................................................................................. 97

2

Page 4

Ethernet Port ............................................................................................................................ 98 7.5

LAN (Shared Network Connection) ................................................................................... 98

7.5.1

7.5.2 Router (Private Network Connection) ............................................................................... 98

7.5.3 Accessing Stored Data...................................................................................................... 99

8. Chemistry Setup ......................................................................................................................... 101

Sample Volume ..................................................................................................................... 101 8.1

Measurement Parameter Information .................................................................................... 101 8.2

Choline ............................................................................................................................ 102

8.2.1

8.2.2 Ethanol/Ethanol-HC ........................................................................................................ 103

8.2.3 Galactose ........................................................................................................................ 104

8.2.4 D-Glucose (Dextrose) ..................................................................................................... 105

8.2.5 L-Glutamate (L-Glutamic Acid) ....................................................................................... 106

8.2.6 L-Glutamine ..................................................................................................................... 107

8.2.7 Glycerol ........................................................................................................................... 108

8.2.8 Hydrogen Peroxide ......................................................................................................... 109

8.2.9 L-Lactate ......................................................................................................................... 110

8.2.10 Lactose ..................................................................................................................... 111

8.2.11 Methanol ................................................................................................................... 112

8.2.12 Sucrose ..................................................................................................................... 113

8.2.13 Xylose ....................................................................................................................... 114

8.2.14 Simultaneous Ammonium and Potassium ................................................................ 115

8.2.15 Simultaneous Glucose and L-Lactate ...................................................................... 116

8.2.16 Simultaneous Glucose and Sucrose ........................................................................ 117

8.2.17 Simultaneous Glucose and Xylose ........................................................................... 118

8.2.18 Simultaneous L-Glutamate and L-Glutamine ........................................................... 119

9. Operational Checks and Maintenance ..................................................................................... 119

Cleaning, Disinfecting, and Dec ontaminating ........................................................................ 119 9.1

Touch Panel .................................................................................................................... 119

9.1.1

9.1.2 Decontamination Procedures .......................................................................................... 119

Daily Maintenance ................................................................................................................. 120 9.2

Empty the Waste Bottle(s) .............................................................................................. 120

9.2.1

9.2.2 Check the Calibrator Bottle(s) ......................................................................................... 120

9.2.3 Check the Buffer Bottle(s) ............................................................................................... 120

9.2.4 Check for Leaks .............................................................................................................. 120

9.2.5 Clean up Spills ................................................................................................................ 120

9.2.6 Daily Operational Checks................................................................................................ 120

Monthly Maintenance ............................................................................................................ 120 9.3

Calibration Pumping System Maintenance ..................................................................... 120

9.3.1

Preventive Maintenance – 6 months or 1000 Hours ............................................................. 121 9.4

Sample Module Cleaning ................................................................................................ 121

9.4.1

9.4.2 Waste Module Cleaning .................................................................................................. 122

9.4.3 Enzyme Probe Cleaning ................................................................................................. 122

9.4.4 ISE Cleaning ................................................................................................................... 123

9.4.5 Sipper pump Seal Replacement ..................................................................................... 123

9.4.6 Bottle Tubing ................................................................................................................... 125

9.4.7 Pump Tubing Replacement ............................................................................................ 127

9.4.8 Install Waste Modules ..................................................................................................... 130

9.4.9 Waste Tubing .................................................................................................................. 130

9.4.10 Install Sample Modules ............................................................................................ 131

9.4.11 Sipper Replacement ................................................................................................. 131

9.4.12 Calibrate Sipper ........................................................................................................ 132

9.4.13 Install Bottles ............................................................................................................ 132

9.4.14 Install Membranes and ISEs..................................................................................... 132

9.4.15 Prime Fluid System .................................................................................................. 132

3

Page 5

Fuse Replacement................................................................................................................. 133 9.5

Fuse Requirements ......................................................................................................... 133

9.5.1

2960 Maintenance ................................................................................................................. 133 9.6

Tubing Replacement ....................................................................................................... 133

9.6.1

9.6.2 Monitor Sample Cup ....................................................................................................... 135

10. Storage ........................................................................................................................................ 136

Instrument Storage ................................................................................................................ 136 10.1

Enzyme Membrane Storage .................................................................................................. 136 10.2

ISE Storage ........................................................................................................................... 136 10.3

Reference ISE .......................................................................................................... 136

10.3.1

10.3.2 Ammonium/Potassium ISE ....................................................................................... 136

Instrument Handling/Transport .............................................................................................. 136 10.4

Troubleshooting ......................................................................................................................... 136

11.

Printout Information ............................................................................................................... 138 11.1

Enzyme Sensors ...................................................................................................... 138

11.1.1

11.1.2 Ion Selective Electr odes ........................................................................................... 140

Troubleshooting Chart ........................................................................................................... 143 11.2

2960 Online Monitor ................................................................................................. 147

11.2.1

12. Principles of Operation .............................................................................................................. 149

Enzyme Sensor Technology .................................................................................................. 149 12.1

Ion Selective Electrode .......................................................................................................... 150 12.2

Measurement Methodology ................................................................................................... 150 12.3

Baseline Stability ................................................................................................................... 151 12.4

Calibration .............................................................................................................................. 151 12.5

Linearity ................................................................................................................................. 151 12.6

Temperature Compensation .................................................................................................. 152 12.7

Level Sensing ........................................................................................................................ 152 12.8

Warranty and Repair .................................................................................................................. 152

13.

Limitation of Warranty ............................................................................................................ 152 13.1

Shipping Instructions ................................................................................................ 152

13.1.1

13.1.2 Cleaning Instructions ................................................................................................ 153

YSI Factory Authorized Service C ent ers ............................................................................... 154 13.2

Notices ........................................................................................................................................ 155

14.

Declaration of Conformity ...................................................................................................... 155 14.1

Declaration of Conformity - Australian and New Zealand Electromagnetic Compatibility .... 156 14.2

Radio and Television Interference Notice ............................................................................. 157 14.3

Appendix A – Software Flowchart ............................................................................................ 158

15.

16. Appendix B – Concentration Unit Conversion ........................................................................ 159

Linearity Test. Concentration Unit Conversion ...................................................................... 160 16.1

FCN Membrane Integrity Test. Concentration Unit Conversion ............................................ 161 16.2

Appendix C - Line Power Cord and Plug Wiring ..................................................................... 162

17.

18. Appendix D - Reagents and Accessori es ................................................................................ 163

4

Page 6

1. Introduction

Ammonium

D-Glucose (Dextrose)

Potassium

Hydrogen Peroxide1

L-Lactate

Sucrose

L-Glutamate

Ethanol

L-Glutamine

Glycerol

Ethanol-HC

Methanol

Xylose

Galactose1

Choline

Lactose

Slim modular design

Easily expand analytes or chemistries

Proprietary enzyme electrode

Fast, accurate, and analyte-specific results

Uses biological separation technology

No hazardous chromatography solvents to dispose

Icon-driven user interface with touchscreen

Easy to learn

Data download options

Save data on a USB drive, send it over the network,

Onboard training videos

Minimizes operator learning curve

21 CFR Part 11

Regulatory compliance

Description 1.1

The 2900 Series Biochemistry Analyzer is a laboratory instrument intended for use in research, food-processing and

bioprocessing applicati ons . THE 2900 Series IS NOT FOR HUMAN MEDICAL DIAGNOSTIC USE OR FOR HUMAN

PERFORMANC E EVALUATION.

The 2900 Series can be set up to measure up to 6 different analytes in a sample. The total number of analytes depends

on the number of sample modules installed (up to two analytes per module) and the number of different buffers required

(up to three buffers). Available analytes are listed below.

Additional analytes are currently under development. For a current listing, please contact YSI Life Sciences Technical

Support (937 767-2769 or 800 659-8895 extension 2) or visit the YSI Life Sciences web site at www.ysi.com

/lifesciences.

User Features 1.2

Multiple units use much less bench space

of

or access it in a searchable database anytime

Models 1.3

• 2900D 2900 Biochemistry Analyzer with 1 biosensor module

• 2900M 2900 Online Monitor & Control System

• 2950D-0 2950 Biochemistry Analyzer with 1 biosensor module

• 2950D-1 2950 Biochemistry Analyzer with 2 biosensor modules

• 2950D-2 2950 Biochemistry Analyzer with 3 biosensor modules

• 2950D-3 2950 Biochemistry Analyzer with 2 biosensor modules and 1 ISE module

• 2950D-4 2950 Biochemistry Analyzer with 1 biosensor module and 1 ISE module

1

YSI does not currently offer calibration standards for this analyte.

5

Page 7

2900 Series General Specifications 1.4

Sample size ................................................. Adj us table f rom 10 to 50 m icr oliters ( as pirated volume), per module

Response time ............................................ Enzyme Sensors

• Sample results in 60 seconds ( average) for one module

• 100 seconds for 2 modules

• 135 seconds for 3 modules

• Complete sample-to-sample cycle in less than 3 minutes

(May vary with analyte and sample m atr ix.)

Ion Selective Electrodes (ISE)

• Sample results in 150 seconds (aver age) f or 2 modules

• 195 seconds for 3 modules

• Complete sample-to-sample cycle in less than 5 minutes

(May vary with analyte and sample m atr ix)

Output signals:

Serial .......................................................... USB and RS232

Power requirement ............................... 100–240 VAC ±10%

50–60 Hz ±5%

42 Watts nominal

Working environment:

Ambient temperature ................................ 15–35°C

Relative humidity ...................................... 10–75% (non-condensing)

Regulatory compliance .................................. ETL, CE, RoHS

61010-1 compliance:

• Pollution degree 2

• Installation category 2

• Altitude 2000m

• Atmosphere 75 KPa to 106 KPa

• Indoor use only

Instrument dimensions ................................ 14.0" wide x 20.5" deep x 15.75" h igh

35.6 cm x 52.1 cm x 40.0 cm

Instrument weight ........................................ 39 pounds

17.7 kilograms

2960 Online Monitor Specifications 1.5

1.5.1 Monitor

Size:

Monitor Cup ............................................... 0.75 x 0.75 x 0.88 inches

Pump Head ................................................ 2.0 x 2.2 x 0.85 inches

Sample Inlet Tubing ...................................... Silicone, 0.08 OD x 0.02 ID (inches)

Volume ....................................................... 5.1 microliters/inch

Inlet Channel Pump Tubing ........................... PharMed

, 0.13 OD x 0.035 ID (inches)

6

Page 8

Valve Tubing ................................................. 0.03 ID (inches)

Wasteline Tubing .......................................... Silicone, 0.16 OD x 0.10 ID (inches)

Nominal Flow Rate (inlet line) ....................... 100–2500 microliters/minute (± 8% @ ± 6 PSI)

1.5.2 Analog/Control

Full Scale Voltage ......................................... Selectable: +10.00 VDC or +5.00 VDC

Full Scale Concentration ............................... User selectable

Resolution ..................................................... 1:65,536 or 0.0015% FS,

0.153 mv on +10.00 VFS,

0.076 mv on +5.00 VFS

Maximum Gain Error ..................................... ±12 LSB

Linearity ......................................................... ±1 LSB

Minimum analog output Load Impedance ..... 2K Ohms

Logic output drive .......................................... 0 and 5 VDC nominal at 10 milliamps

Logic Input levels .......................................... < 0.8 VDC = logic 0,

...................................................................... > 2.0 VDC = logic 1

2. Safety

Important Safety Instructions 2.1

DO NOT PLUG THE INSTRUMENT IN AT THIS TIME. You should apply power only when directed to do so in the setup

instructions.

1. Use ONLY the line power cord supplied with the instrument. When directed to, connect the plug to a matching threepronged wall receptacle.

2. Use ONLY fuses of the type supplied. Replacement power cords and fuses can be obtained from YSI, or your Dealer

Representative.

3. Do NOT use an extension cord without protective grounding.

4. Do NOT remove rear cover. There are no user serviceable parts inside.

5. Repairs are to be performed only by trained and approved personnel.

6. This instrument must be connected to a protectively grounded (earthed) outlet.

7. The following notice is provided in compliance with IEC1010 Part 1 1990.

See Appendix for mains plug wiring and fusing instructions.

8. If the equipment is used in a manner not specified by YSI, the protection provided by the equipment may be impaired.

WARNING: For RS232 or USB connection, equipment should be EN/CSA/UL 61010 or EN/CSA/UL 60950

approved only.

9. The mains (power) switch is for functional purposes ONLY. To disconnect the instrument from the mains supply,

unplug the mains power cord from the back of the instrument.

10. Personal protective equipment (PPE) recommended—protective gloves and safety goggles or glasses.

7

Page 9

Warning indicates that misuse of the instrument could result in

Caution, consult accompanying documents. Caution indicates

Biological Risks

Chemical Irritant

Manufacturer

Authorized Representative in the European Union

Catalog number

Lot number

Date of manufacture

Use by Date

Temperature Limitation

REF

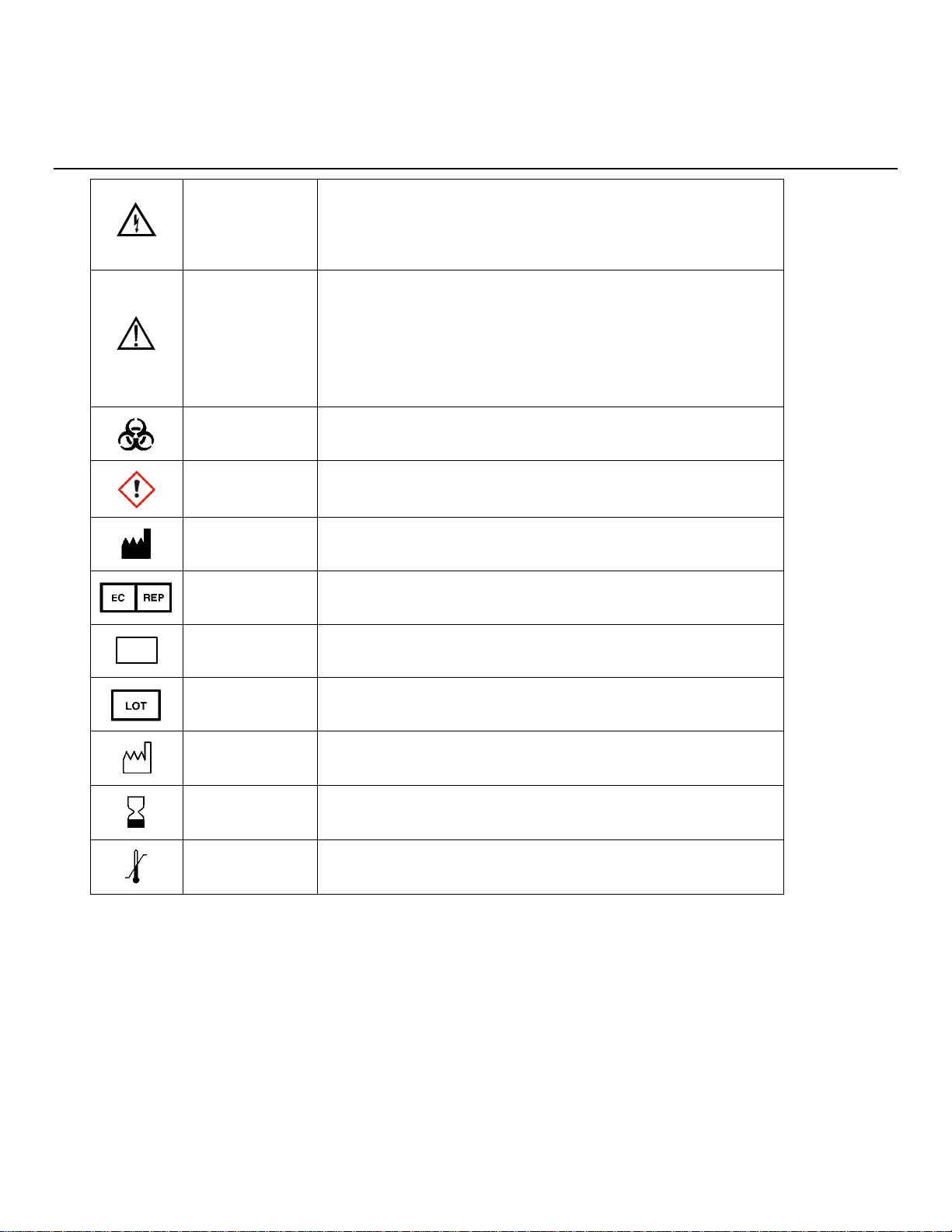

Explanation of Symbols 2.2

WARNING

AVERTISSEMENT

CAUTION

ATTENTION

2776

death or serious injury to a person.

Un avertissement indique qu'une mauvaise utilisation de l'instrument

peut entraîner la mort ou une blessure grave chez une personne.

that misuse of the instrument could result in mild or serious injury

to a person and/or damage to equipment.

Attention, consulter la documentation jointe. Cette mise en garde

indique qu'une mauvaise utilisation de l'instrument peut entraîner une

blessure légère ou grave chez une personne et/ou un endommagement

du matériel.

Risques biologiques

Irritant chimique

Fabricant

Représentant agréé dans l'Union européenne

Numéro de référence

15A100549

Numéro de lot

YEAR-MO

Date de fabrication

YEAR-MO

Date limite d'utilisation

Limite de température

8

Page 10

3. Getting Started

Remove tie strap

Unpacking 3.1

When you unpack your new 2900 Series for the first time, check the packing list to make sure you have received

everything listed. Note that reagents for the 2900 Series are not packaged in the same carton as the instrument. If there is

anything missing or damaged, call the dealer from whom you purchased the 2900 Series. If you do not know which of our

authorized dealers sold the system to you, call YSI Life Sciences Customer Service at 800 659-8895 or 937 767-7241,

and we'll be happy to help you.

1. After removing the instrument from the shipping box, tilt the display to the full upright position.

Figure 3.1

2. Grasp the hand hold in the right side cover of the instrument and pull up and out to remove the cover.

NOTE: Leave the cover off the instrument until you have aligned the sipper and installed the membranes as

described in the following sections.

3. Carefully cut the tie strap holding the sipper.

Figure 3.2

9

Page 11

Warranty Card 3.2

Cover

Sipper

Display/

Touch Panel

USB Port

Station 2

Bottle Rack

Station 1

Please complete the Warranty Card and return it to YSI. This will record your purchase of this instrument in our computer

system. Once your purchase is recorded, you will receive prompt, efficient service in the event any part of your 2900

Series should ever need repair.

What You Need 3.3

Several things are needed in order to analyze samples using the 2900 Series. The following list shows the basic items

required.

• 2900 Series Instrument (with AC Power Cord)

• Bottle Racks wi th Reagent Level Sensing (YSI 2936, 2938), or Bottles without Reagent Level Sensing (YSI

2934, 2937)

• YSI Buffer(s)

• YSI Calibrator Standard(s)

• YSI Linearity Standard(s )

• YSI Membrane(s)

• YSI ISE probes (2950D-3 and 2950D-4 models only)

• YSI 2960 Online Monitor (optional)

• YSI 2901 Printer (optional)

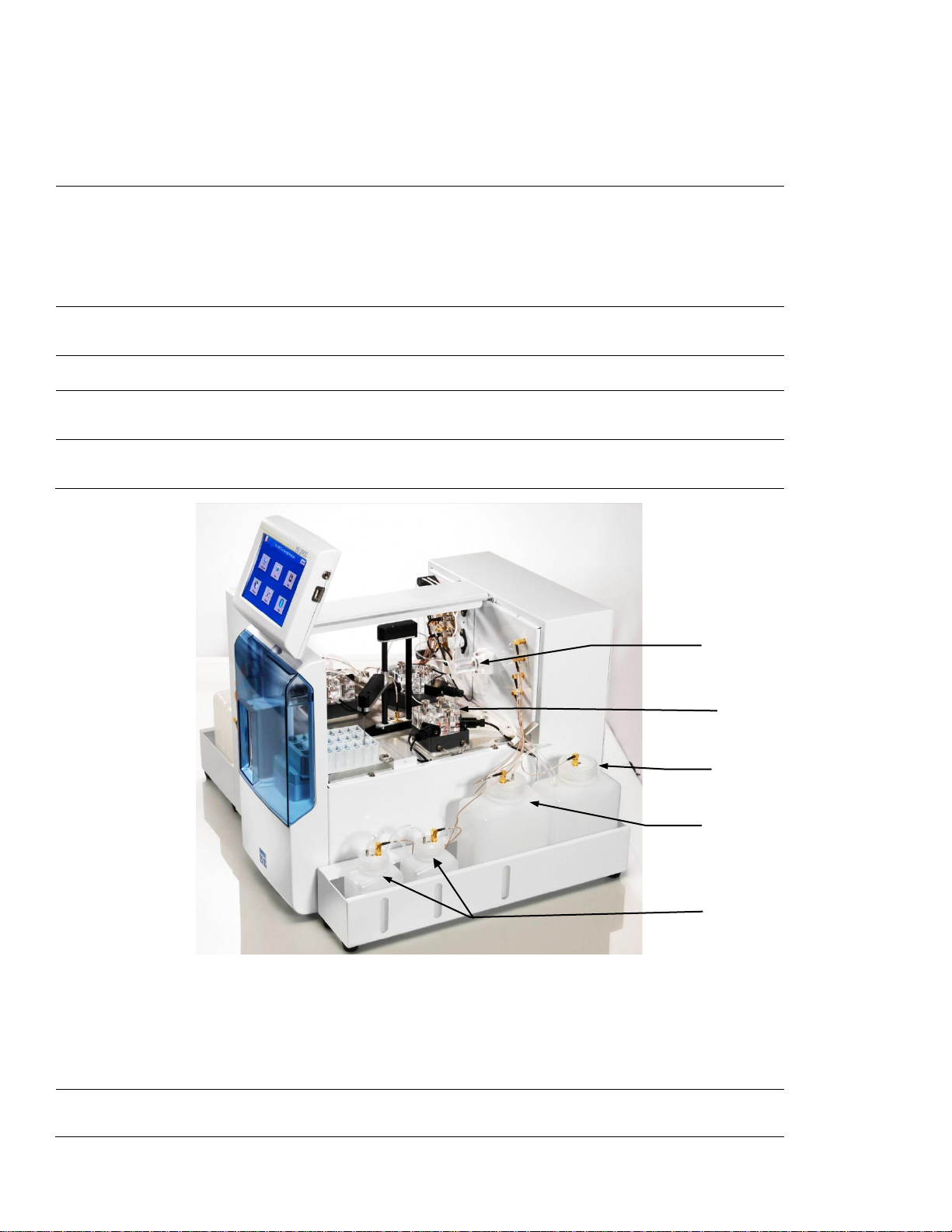

Major Components 3.4

Display

Figure 3.3

Graphical color LCD covered by a touc h s cr een

10

Page 12

USB ports

Sample Module

Sipper Pump

Waste Bottle

Buffer Bottle

Calibrator Bottles

The USB ports allow a flash drive to be con nected to the 2900

Series to download sample results or upgrade the ins trument’s

software. A USB port is located on the right s ide of the dis play. An

additional USB port is located on the rear of the ins trum ent . T he rear

port is used to connect the 2960 Online Monitor to the 2900 Series.

Sipper

Station 1

Station 2

Buffer Pumps

(not shown)

Calibrator Pumps

(not shown)

Can be raised, lowered, rotated, and moved horizontally to its

various positions.

The positions are: Calibrator W ells, Sam ple Module, Stations 1 an d

2, and Monitor Sample Cup.

The Sipper senses fluid level to control immersion depth and detect

errors.

Plate and rack holder accepts mos t standard plates /racks for batch

sampling of up to 96 samples.

Test tube holder for manual sampling.

Draw buffer from the buffer bottles, pump it through the Valves,

Sipper Pump and the Sipper, and flus h the Sample Module.

Draw the appropriate standard s olution f rom the C alibrator Bottles

and fill the Calibrator Wells.

Sipper pump

Sample modules

Figure 3.4

It retracts its piston to draw standar d f rom the Calibrator Wells or

sample from the sample stations.

It extends its piston to dispense standard or sample into the sample

module.

They are made of clear acrylic plastic . Sensor probes are screwed

into either side of the module.

11

Page 13

In biosensor modules, the imm obilized enz yme membranes are

mounted on O-rings which act as fluid s eals.

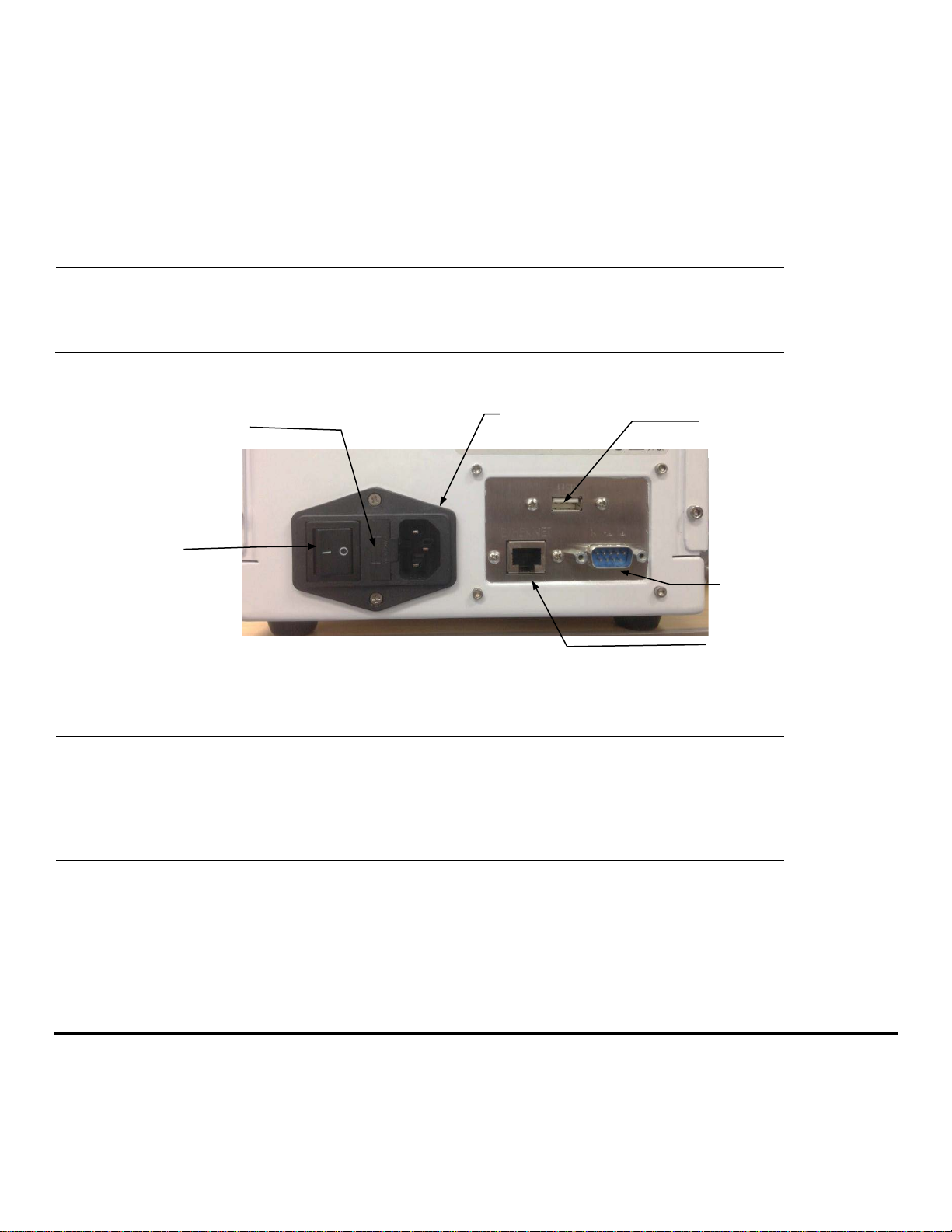

Power

Receptacle

RS232 Port

Power Switch

Fuse

Holder

Ethernet Port

USB Port

In ISE modules, an O-ring is pos itioned insid e a sleev e on the end of

the electrode.

A reference or auxiliary electrode is housed in the temperature probe

and positioned at the back of the Sam ple m odule.

Stir Bars

(not shown)

Buffer, Waste and

Calibrator Bottles

Power Switch

They are plastic encapsulat ed magnets. They are activated by

motors housed below the sample m odules. They provide thorough

mixing inside the sample modules.

Are conveniently located for m aintenanc e.

Fluid levels are monitored by sensors .

Operation is automatically halted when the B uf fer or Calibrator

Bottles are empty, or when the W aste bott les ar e full.

Rear Panel

Figure 3.5

The main power switch is an on/off rock er switch ( 0-off and I-on)

located on the back of the instrument

Fuse Holder

Power Receptacle

Ethernet Port

RS232 Serial Port

The fuse holder houses the power line fus e and ope n s up f or fuse

replacement.

One end of the power cord (supplied) plugs into t his rec eptac le,

while the other end plugs into a properl y grounded e l ect ric al outlet.

The instrument will automatically adj ust the voltage as needed.

It allows connection to a network or r outer via a RJ 45 Ethernet por t.

The RS232 connection is a standard D B9F c onnect or. It is used to

interface with the YSI 2901 Printer or a r em ote hos t.

4. Basic Setu p

The following list describes the basic steps necessary for sampling with the 2900 Series.

1. Install Bottle Racks

2. Connect Printer (optional)

3. Connect AC Power

12

Page 14

4. Connect 2960 Online Monitor (optional)

Buffer Bottle 1

Waste Bottle

Calibrator Bottle

CAL 1B

Waste 1

Buffer 1

CAL 1A

CAL 1B

Calibrator Bottle

5. Align Sipper

6. Configure Instrument Chemistries

7. Prepare and Install Buffer solution(s)

8. Install Calibrator Solution(s)

9. Install Membrane(s) and ISEs

10. Prime the Fluid System

11. Check Probe Currents

Install Bottle Racks 4.1

4.1.1 Right Side

1. Install the YSI 2938 Bottle Rack with Reagent Level Sensing onto the right side of the instrument by sliding the

slots in the tray over the pins on the side of the instrument.

If you are not using the reagent level sensing option, place the YSI 2934 Bottles on the right side of the

instrument.

2. Then remove the packing material holding the tubing to the right side of the instrument.

3. Next, connect bottle tubing and cables

a. Insert the large diameter waste tube into the hole in waste bottle 1.

b. Connect one end of a short cable marked to the threaded fitting on the waste bottle 1 cap and connect

the other end to the Waste 1 (top) fitting on the instrument.

c. Connect the tubing marked “B1” and one end of a short cable to the fittings on the buffer bottle 1 cap and

connect the other end of the cable to the Buffer 1 (2nd) fitting on the instrument.

d. Connect the tubing marked “C1B” and one end of a long cable to the fittings on the second calibrator

bottle cap and connect the other end of the cable to the CAL 1B (3rd) fitting on the instrument.

e. Connect the tubing marked “C1A” and one end of a long cable to the fittings on the first calibrator bottle

cap and connect the other end of the cable to the CAL 1A (bottom) fitting on the instrument.

CAL 1A

Figure 4.1

13

Page 15

4.1.2 Left Side (2950 models only)

Buffer Bottle 2

Waste Bottle 3

Waste Bottle 2

Calibrator Bottle

Buffer Bottle 3

Calibrator Bottle

1. Install the YSI 2936 Bottle Rack with Reagent Level Sensing onto the left side of the instrument by sliding the

slots in the tray over the pins on the side of the instrument.

2. If you are not using the reagent level sensing option, place the YSI 2937 Bottles on the left side of the instrument.

3. Then remove the packing material holding the tubing to the left side of the instrument.

4. Next, connect bottle tubing and cables

a. Insert the large diameter waste tubing into the holes in waste bottles 2 and 3.

b. Connect one end of a long cable to the threaded fitting on the waste bottle 2 cap and connect the other

end to the W2 (top left) fitting on the instrument.

c. Connect one end of a long cable to the threaded fitting on the waste bottle 3 cap and connect the other

end to the W3 (top right) fitting on the instrument.

d. Connect the tubing marked “B2” and one end of a long cable to the fittings on the buffer 2 bottle cap and

connect the other end of the cable to the B2 (2

e. Connect the tubing marked “B3” and one end of a long cable to the fittings on the buffer 3 bottle cap and

connect the other end of the cable to the B3 (2

nd

from top on left) fitting on the instrument.

nd

from top on right) fitting on the instrument.

f. Connect the tubing marked “C2A” and one end of a short cable to the fittings on the calibrator 2A bottle

cap and connect the other end of the cable to the 2A (bottom left) fitting on the instrument.

g. Connect the tubing marked “C2B” and one end of a short cable to the fittings on the calibrator 2B bottle

cap and connect the other end of the cable to the 2B (3

rd

from top on left) fitting on the instrument.

h. Connect the tubing marked “C3A” and one end of a short cable to the fittings on the calibrator 3A bottle

cap and connect the other end of the cable to the 3A (bottom right) fitting on the instrument.

i. Connect the tubing marked “C3B” and one end of a short cable to the fittings on the calibrator 3B bottle

cap and connect the other end of the cable to the 3B (3

rd

from top on right) fitting on the instrument.

CAL 2A

CAL 3A

Figure 4.2

14

Page 16

Connect Printer 4.2

Connect the YSI 2901 Printer to the 2900 Series Biochemistry Analyzer using the data cable provided. The small RJ12

connector plugs into the bottom of the printer and the large DB9 connector plugs into the RS232 port on the back of the

analyzer. Refer to the instruction sheet included with the printer for details of printer operation.

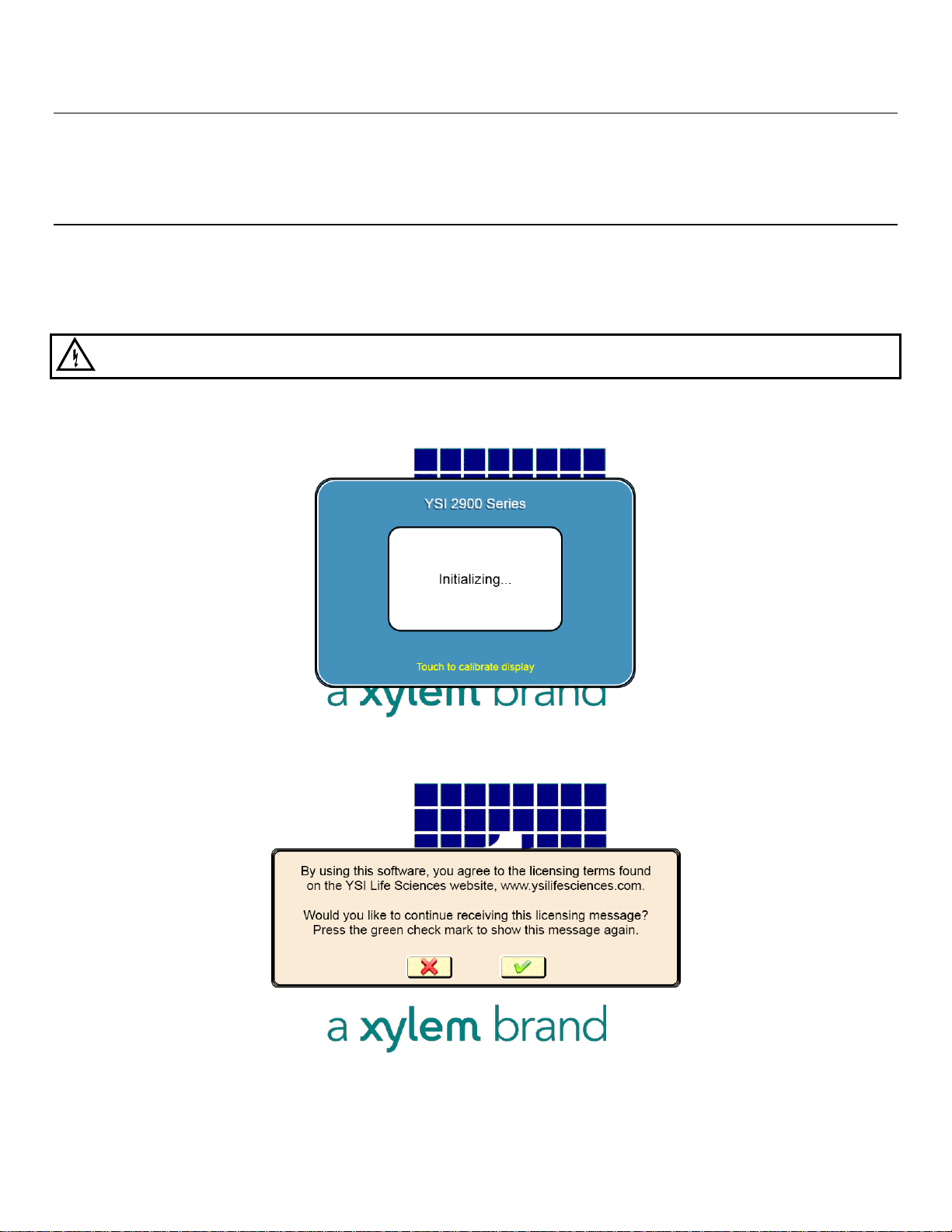

Connect AC Power 4.3

1. Plug the power cord (included with the 2900 Series Analyzer) into the power receptacle on the back of the

instrument, then into a properly grounded electrical outlet provided with a 15 or 20 Amp circuit breaker. The

instrument will automatically adjust the voltage as needed.

If you are located outside the United States, see Appendix for Line Power Cord and Plug Wiring.

WARNING: Keep your hands clear of the sipper while the instrument is in operation.

2. Turn the instrument on with the main power switch on the rear panel. After about 30 seconds, the Initializing

window should appear.

3. The first time the instrument is powered up, the software license window will appear. Touch [X] to prevent the

license screen from appearing each time the instrument is turned on.

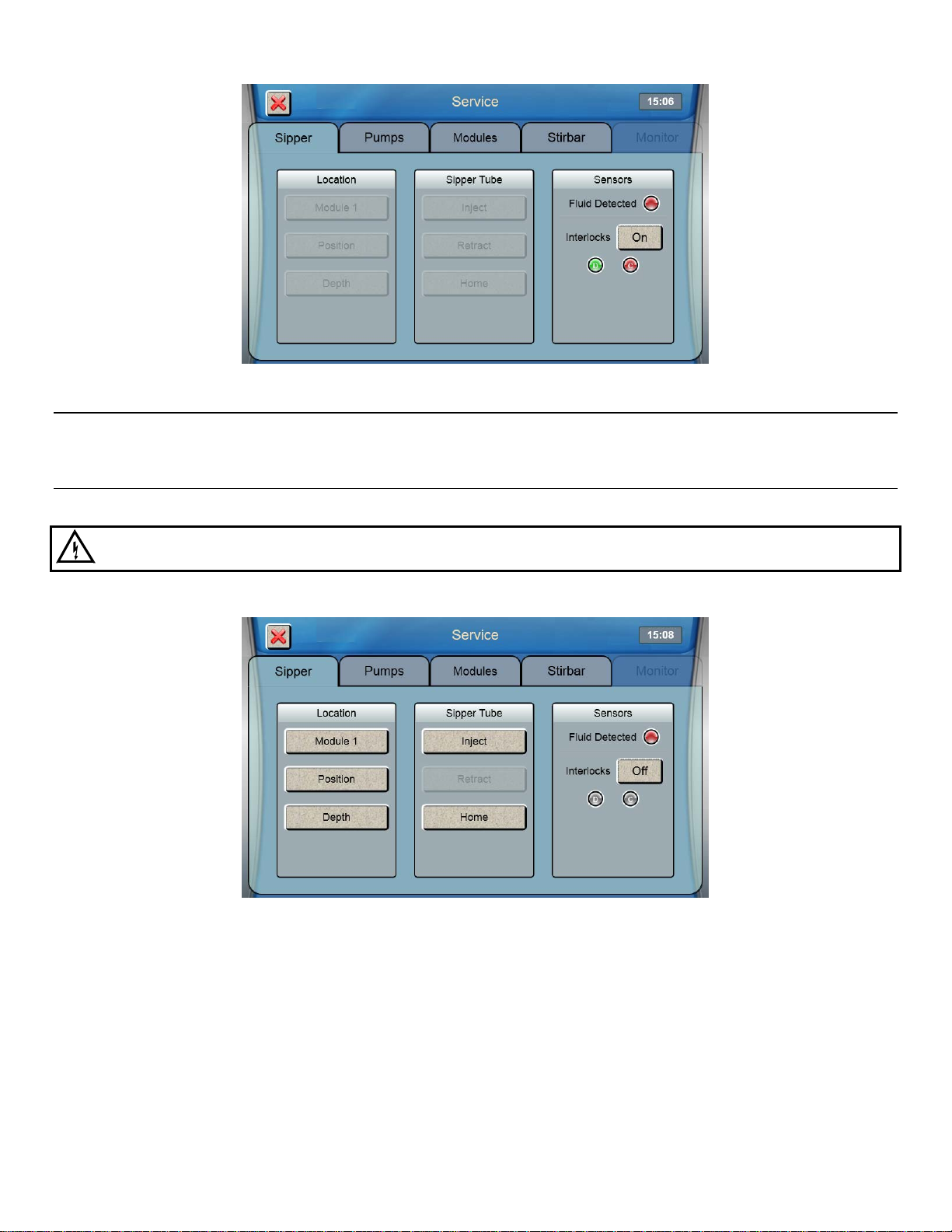

4. Since the top cover of the instrument is removed, the Service screen will appear. Touch the Interlock [On] button

and change it to [Off] to disable the safety interlock, and then press to confirm.

15

Page 17

Connect 2960 Online Monitor 4.4

If you will be using the 2960 Online Monitor, see Section 6.1 for instructions on how to connect it.

Align Sipper 4.5

It is very important that the sipper be accurately adjusted.

WARNING: Keep your hands clear of the sipper while the instrument is in operation.

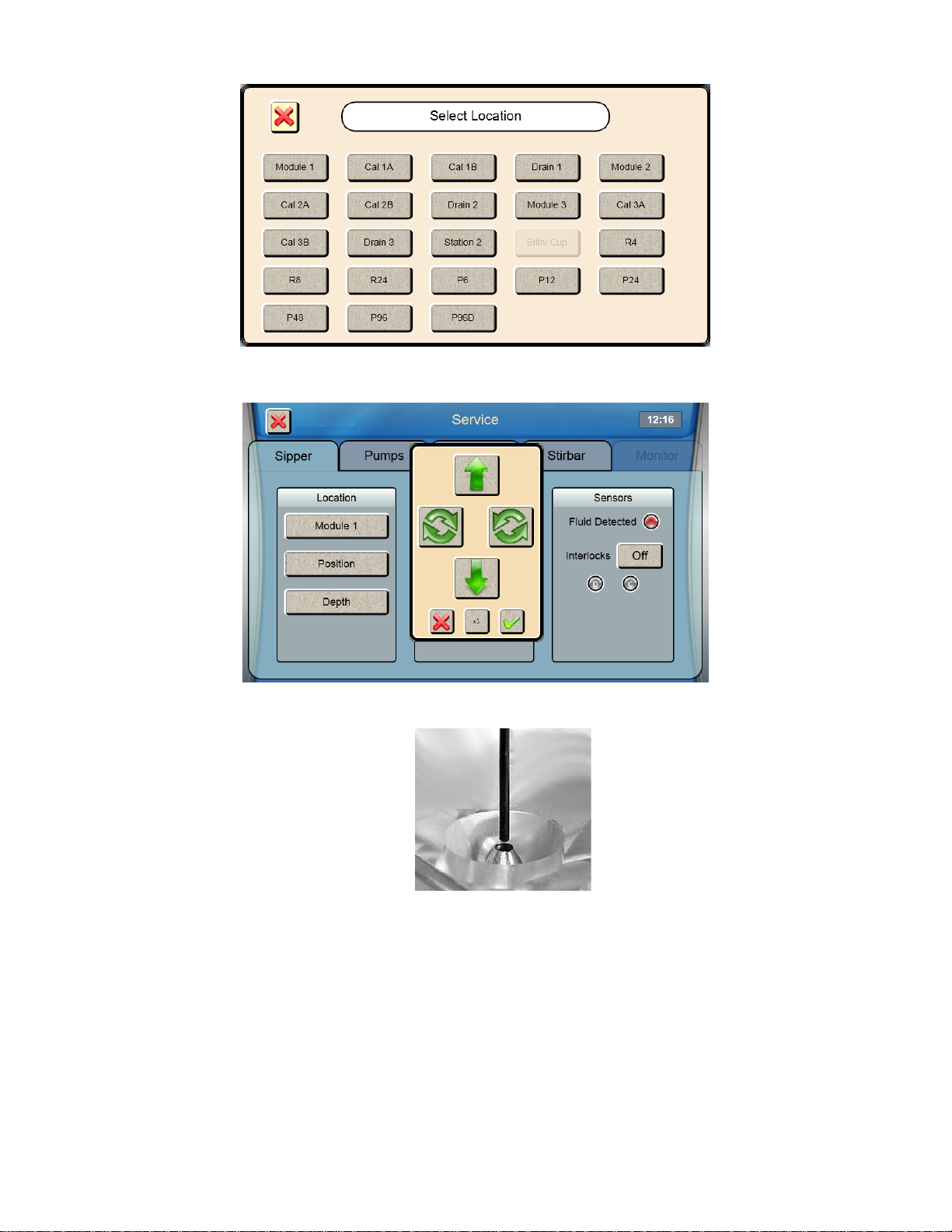

1. From the Sipper tab of the Service screen, touch [Module 1].

2. The Select Location screen will appear. Select [Module 1]. The sipper will move to sample module 1 and should

be centered above the cone shaped opening in the top of the module.

If the sipper does not move, make sure the packing material was removed.

16

Page 18

3. If the sipper is not centered, touch [Position] and use the arrow buttons to center the sipper.

4. Make certain the Sipper is centered, then touch at the bottom right of the adjustment window.

Sipper Adjustment Position

Figure 4.3

5. Touch to save the position and close the confirmation window.

6. To test the alignment of the sipper, Touch [Inject] to lower the sipper, then touch [Retract] to raise the sipper back

up.

If necessary, touch [Position] and repeat the adjustment.

17

Page 19

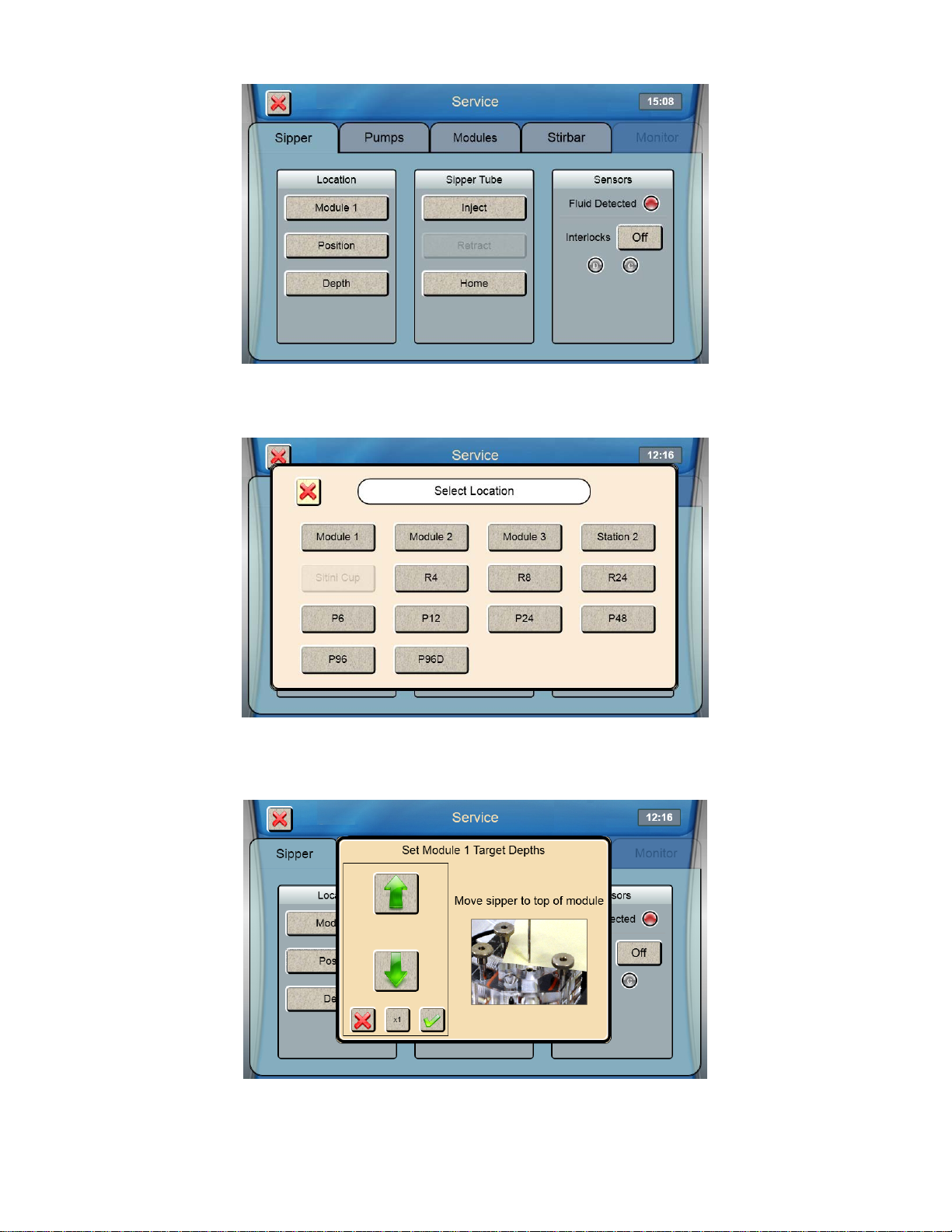

7. Once the sipper enters the sample module without hitting the cone, touch [Depth] to set the sipper depth. The

Select Location screen will appear.

8. Select [Module 1]. The tip of the sipper should be right at the top of the module. Use the arrow buttons to lower or

raise the sipper until the tip of the sipper is even with the top of the module.

9. Then touch at the bottom right of the adjustment window.

10. Touch to save the depth and close the confirmation window.

11. Check the sipper alignment at the Cal 1A, Cal 1B and Drain 1 locations and adjust the position if necessary.

18

Page 20

12. Once you have aligned the sipper and properly set the depth, sipper alignment for Module 1 is complete. Touch

[X] at the top left of the screen to return to the main display.

Repeat this procedure for any additi on al modules installed on your 2950 analyzer.

After you have aligned the sipper with all installed modules, touch the Interlock button and change it back to [On]

to enable the safety interlocks.

Configure Instrument Chemistries 4.6

Before operating the 2900 Series, you must set the instrument parameters.

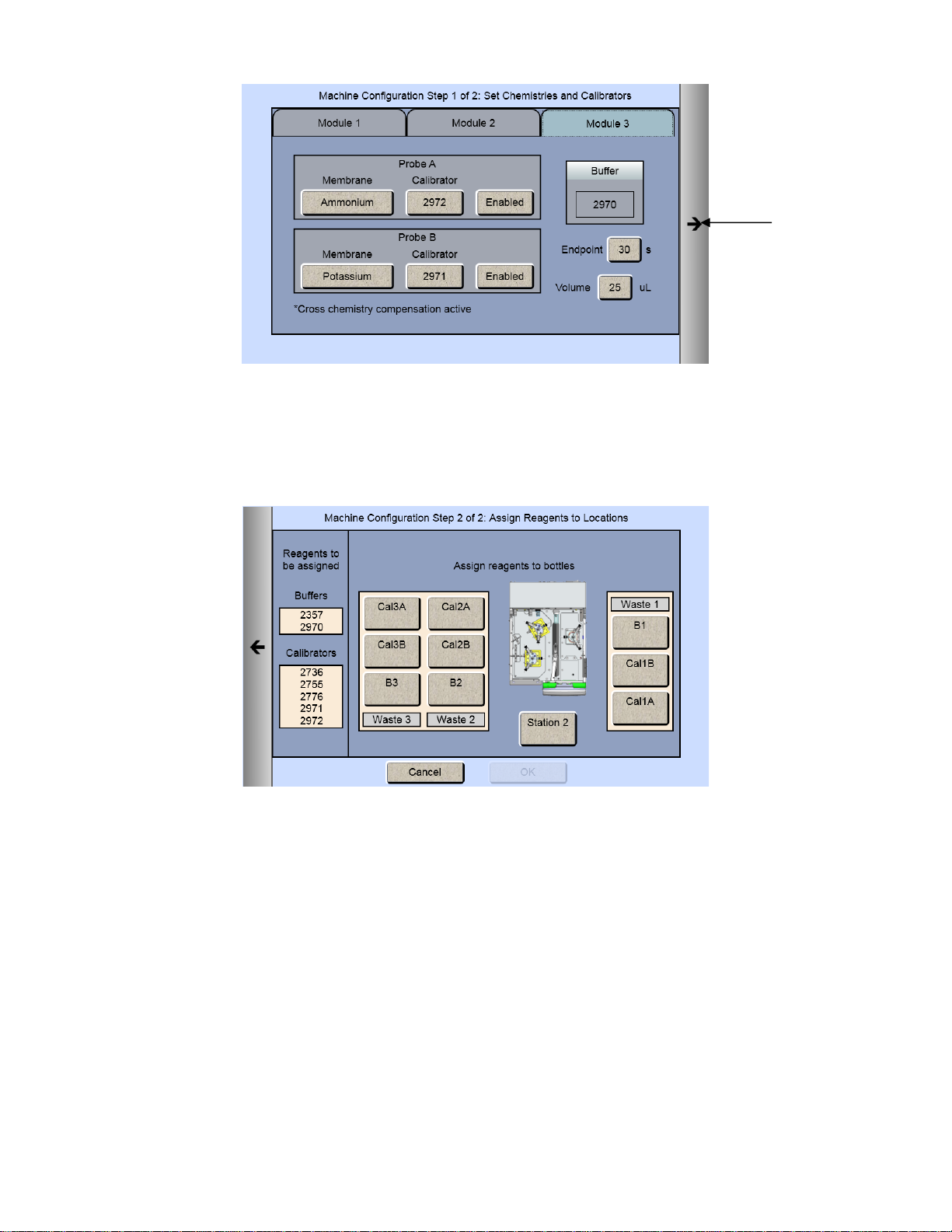

4.6.1 Assign Chemistries to Probes

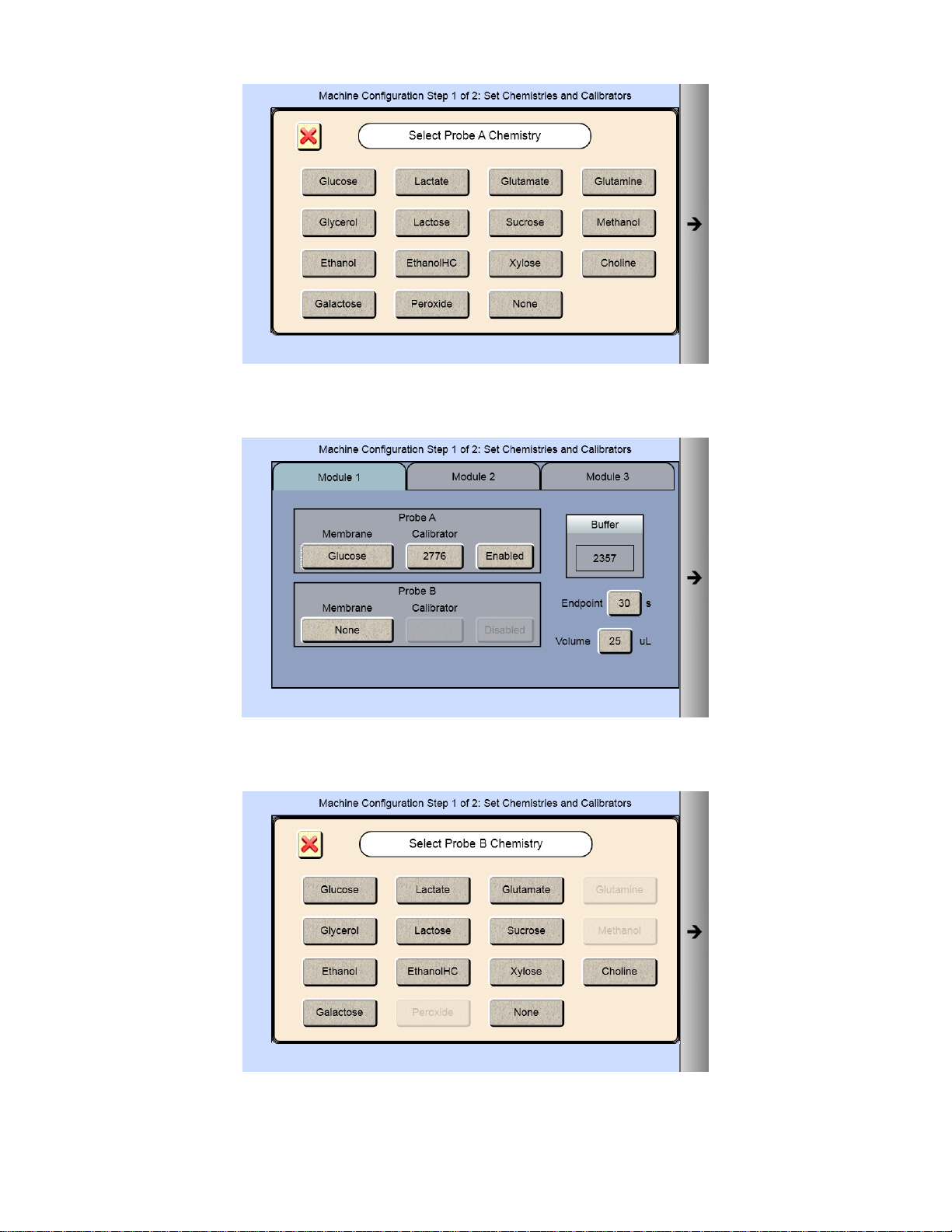

1. From the main display, touch

2. From the [Module 1] tab, touch the Probe A membrane button.

.

3. Select the chemistry you want to measure

19

Page 21

4. The Probe A Membrane button will now show the chemistry you have selected. The screen also indicates which

reagents should be installed.

5. To run a second chemistry in module 1, touch the Probe B membrane button. Only chemistries that can be run

simultaneously with your selected chemistry will be displayed.

6. Select the chemistry you want to measure. The Probe B Membrane button will now show the chemistry you have

selected.

20

Page 22

NOTE: The default Sample Volume and Endpoint for the chemistries are also displayed. Use the default settings unless

a particular application instruction specifies another value (see Section 8 Chemistry Setup for details).

7. Once you have selected one or two chemistries for the first module, proceed to the next installed module on your

instrument, and repeat the procedure.

NOTE: Changing chemistry assignments will change the calibrator values back to the default settings.

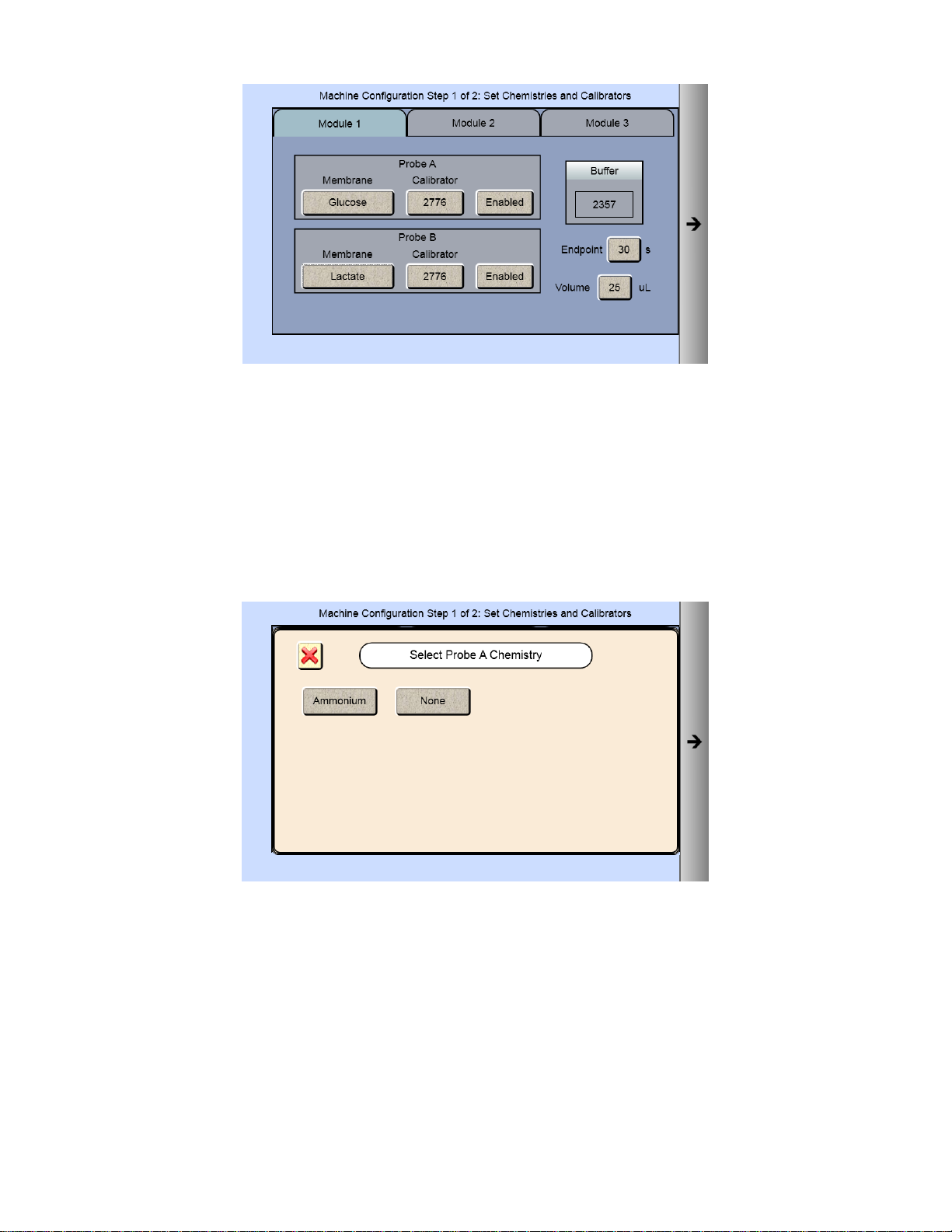

If your instrument has an ISE module:

1. From the [Module 3] tab, touch the Probe A membrane button and select Ammonium.

2. The Probe A Membrane button will now show the chemistry you have selected.

Potassium will automatically be selected for Probe B.

21

Page 23

Next Arrow

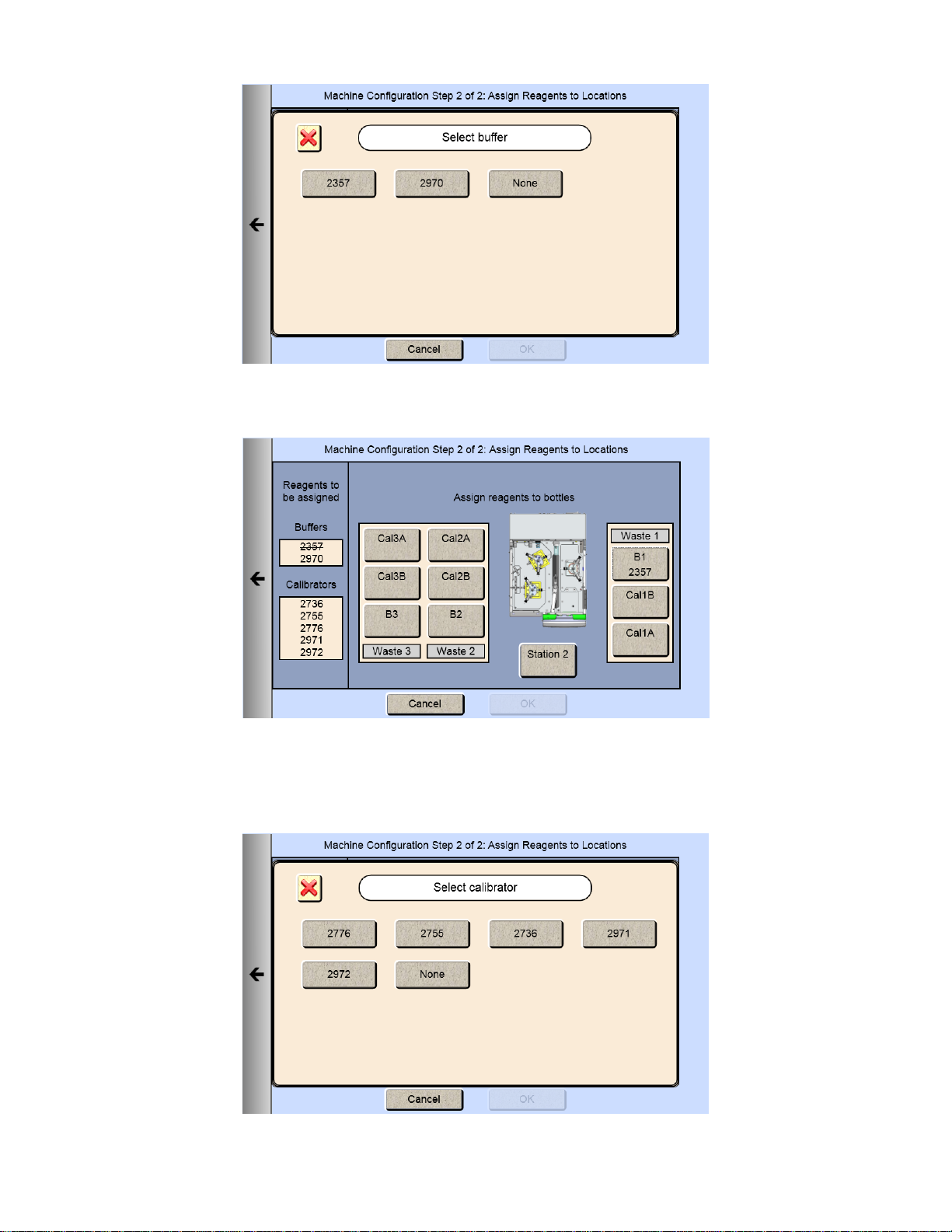

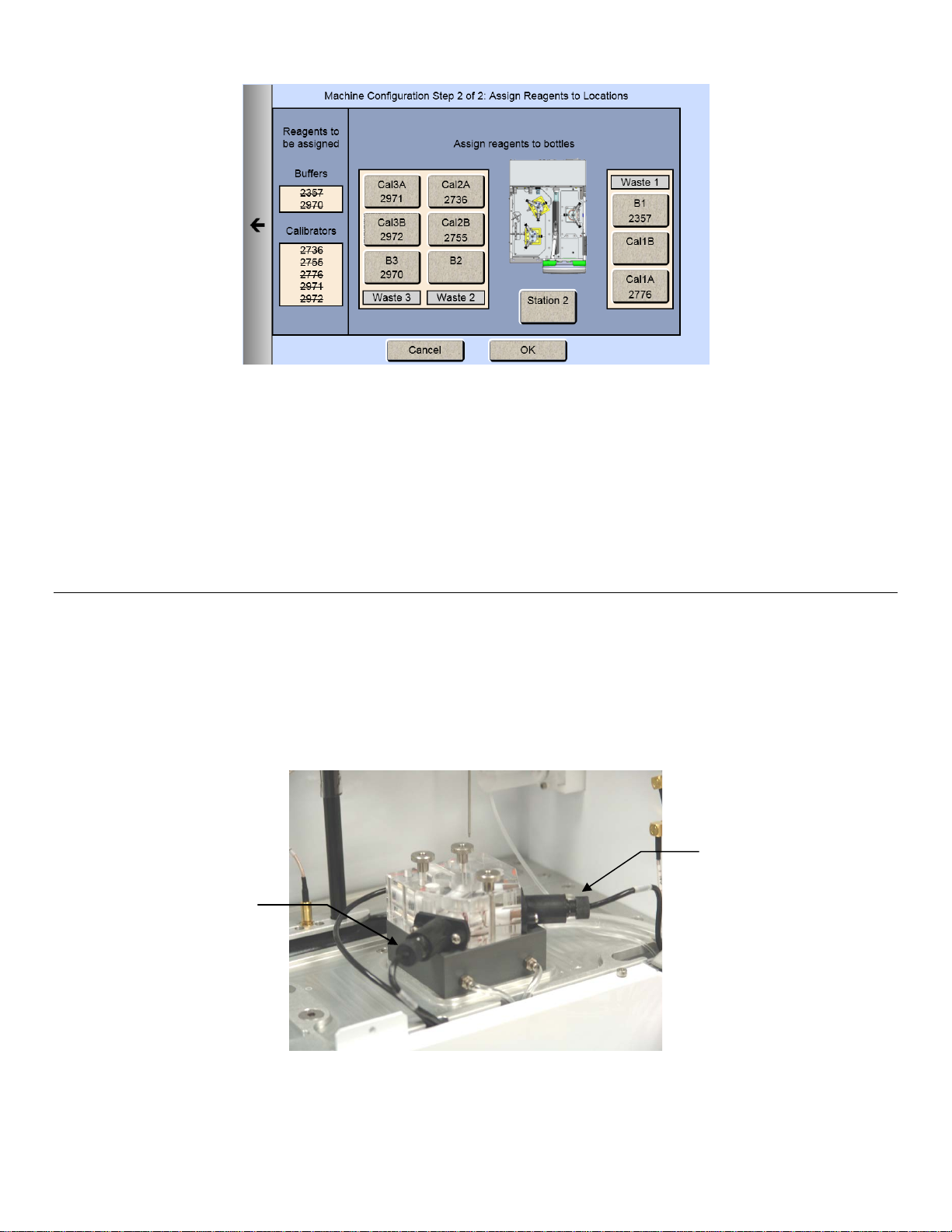

4.6.2 Assign Reagents

Once you have selected all the chemistries you want to measure, touch the Next arrow on the right of the screen. The

Assign Reagents screen will be displayed.

Reagents needed are listed on the left of the screen. Bottle positions are listed on the right. Each reagent must be

assigned to a bottle position.

4.6.2.1 Buffers

1. Touch the [B1] button to display the Select Buffer screen.

22

Page 24

2. Pick your appropriate buffer and it will be assigned to the B1 button.

Note that the selected buffer is now marked out in the list of reagents needed.

3. For additional buffer assignment, please repeat process.

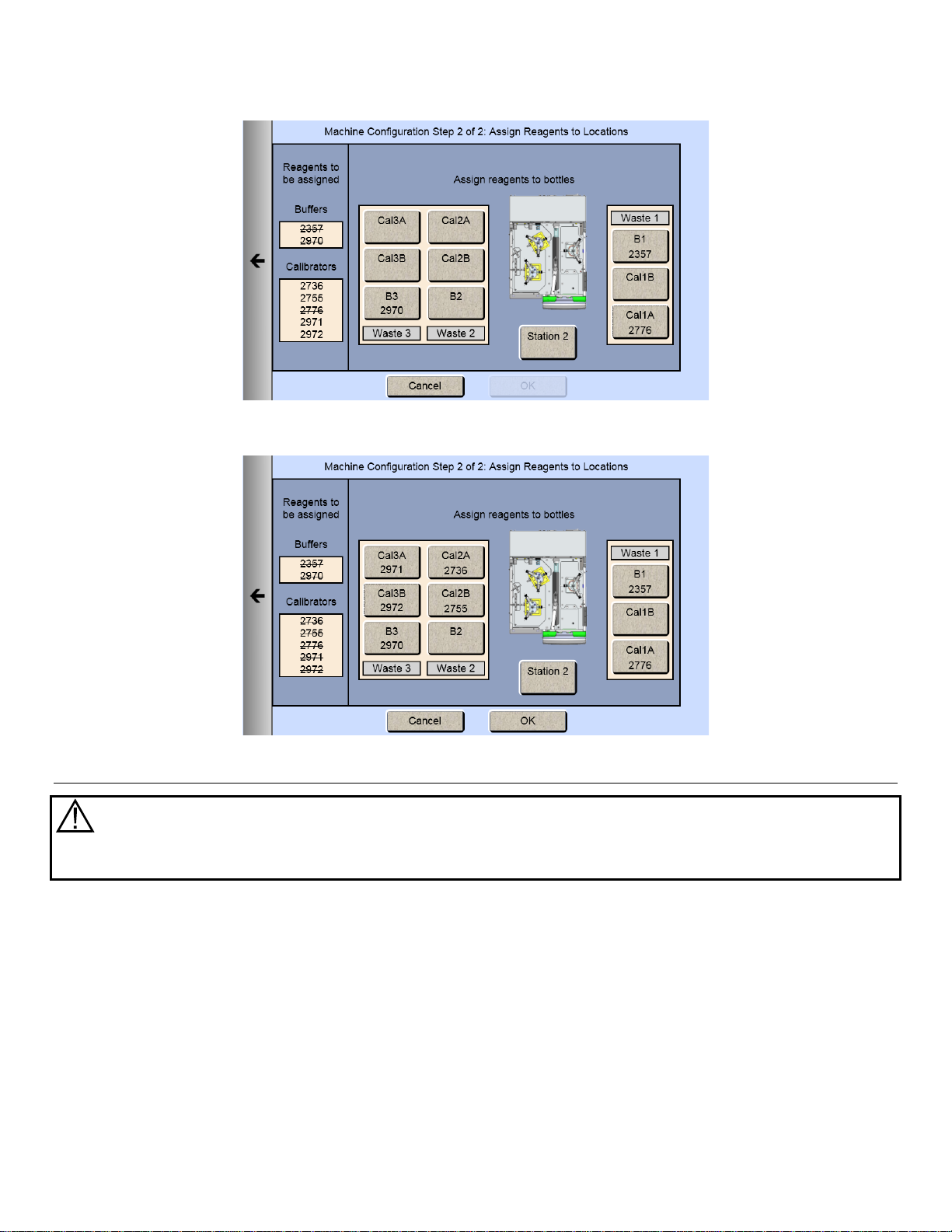

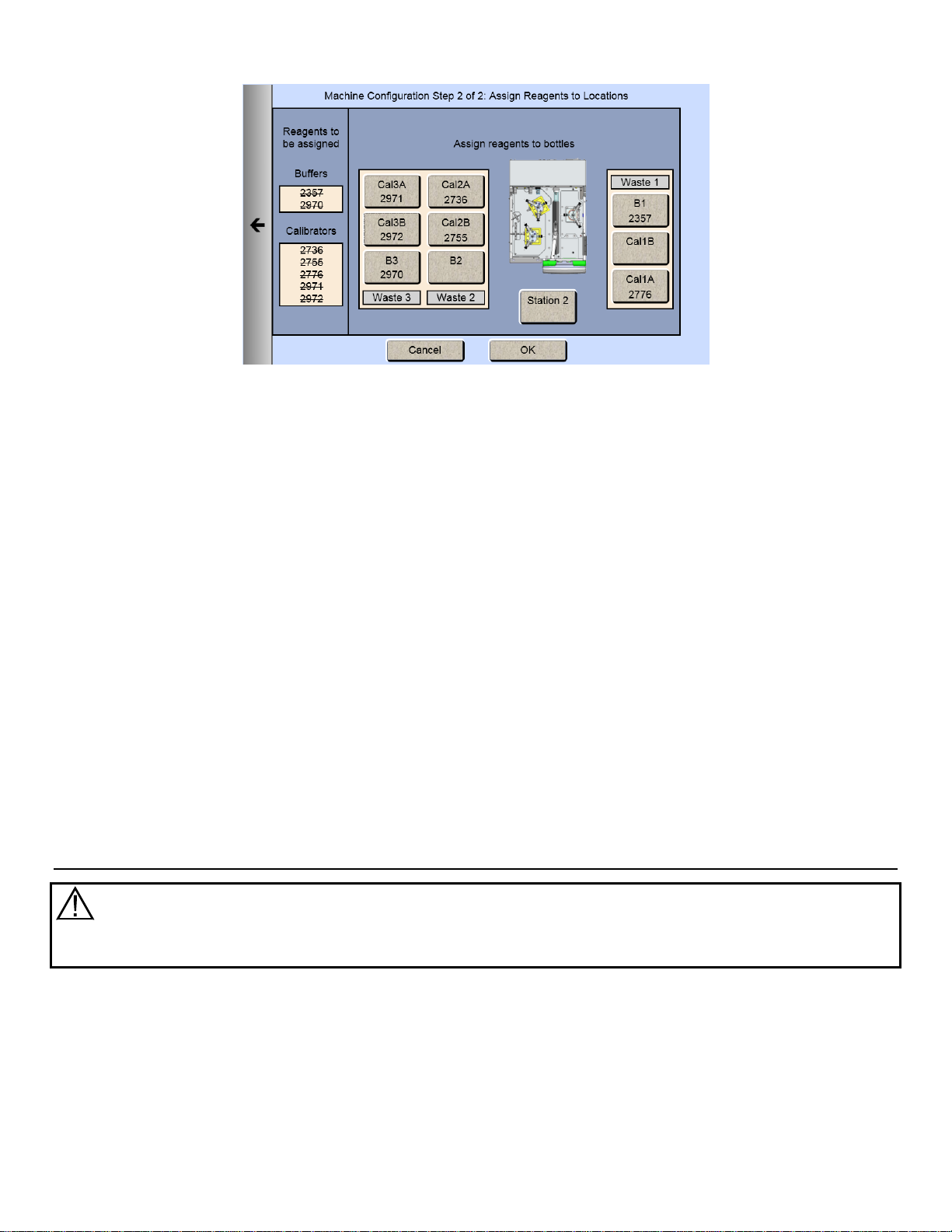

4.6.2.2 Calibrators

1. Touch the [Cal 1A] button. The Select Calibrator screen appears.

23

Page 25

2. Pick the appropriate calibrator.

3. Select additional bottles until all reagents on the left side of the screen have been assigned and marked out.

Prepare and Install Buffer Solutions 4.7

Caution: To prevent possible damage due to an electrostatic discharge, do NOT touch the metal

tips of the connectors located at the ends of the bottle leads. Handle only the insulated section of

the connectors.

Prepare the system buffers and fill the buffer bottles as indicated on the display.

24

Page 26

4.7.1 Prepare Buffer

4.7.1.1 From powder concentrate:

1. Place about 500 mL of reagent water (distilled or deionized) into a 1000 mL flask or other clean container.

2. Add two packages of powder buffer concentrate and stir.

3. Add more reagent water until the total volume of solution is between 900 and 1000 mL.

4. Stir as necessary until the buffer chemicals have completely dissolved.

4.7.1.2 From liquid concentrate:

Mix the content of the bottle of liquid buffer concentrate with enough reagent water (distilled or deionized) to make

1000 mL.

4.7.2 Install Buffer Solution(s)

Unscrew and remove the lid from one of the buffer bottles.

IMPORTANT: When adding fresh buffer to the Buffer Supply Bottles, m ak e every effort to avoid contamination of

the lid and level sensor assemblies.

Pour the prepared buffer into the buffer bottle.

Install the bottle in the rack as indicated on the dis play.

Replace the bottle lid.

Install Calibrator Solution(s) 4.8

Caution: To prevent possible damage due to an electrostatic discharge, do NOT touch the metal

tips of the connectors located at the ends of the bottle leads. Handle only the insulated section of

the connectors.

25

Page 27

Probe B

Probe A

Unscrew and remove the lid from the empty calibrator bottle (Cal1A–Cal3B as indicated).

IMPORTANT: make every effort to avoid contamination of the lid and level sensor as s emblies.

Mark the date of installation on the label of the ne w bot tle of YSI calibrator soluti on.

Place the new bottle of calibrator in the bottle rack as indicated on the display.

Screw the lid and level sensor assem bl y onto it.

Repeat this process for any additional c alibrator bot tles ( Cal1A–Cal3B as indicated).

Install Membranes and ISEs 4.9

4.9.1 Enzyme Membranes

Each biosensor probe installed in your instrument is fitted with a protective "shipping membrane" which must be removed

and replaced with a new membrane. Make sure you install the correct membrane for each chemistry you are

measuring.

Enzyme membranes are color-coded for each type of chemistry. It is important that you install the specific membrane as

indicated on each probe (A or B).

.

Probe A is always on the left when looking in from the side of the instrument

Figure 4.4

26

Page 28

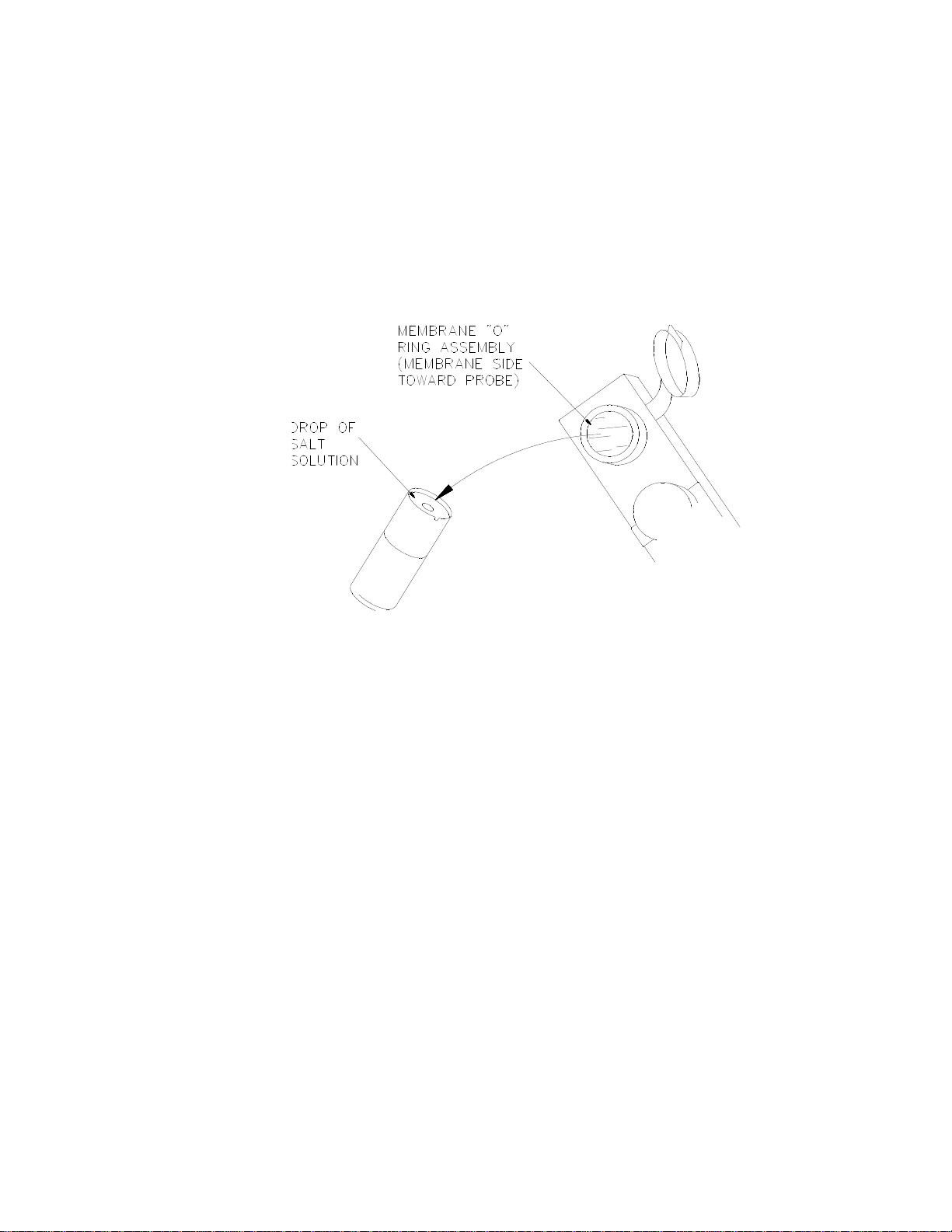

To install a membrane:

1. Make sure the top cover(s) are removed from the instrument.

2. Next, unscrew the appropriate enzyme probe retainer and gently pull the probe out of the module.

3. Remove the existing O-ring membrane assembly from the end of the enzyme probe. A lint free tissue or toothpick

or pipet tip may be needed to unseat the old membrane. Be careful not to scratch the enzyme probe face.

4. Examine the enzyme probe surface and remove any pieces of membrane that remained.

5. Open a cavity of the plastic membrane holder.

6. Rinse the membrane inside with a few drops of salt solution (YSI 2392).

7. Place one drop of salt solution on the enzyme probe face.

8. Using the plastic membrane holder, press the O-ring membrane assembly gently onto the probe face.

Figure 4.5

9. Wipe excess salt solution from the probe body.

10. Install a stir bar in the module.

11. Then return the enzyme probe to the module.

12. Finger tighten the probe retainer so that the O-ring seals the probe in place. Do not overtighten.

13. Return the membrane holder to the foil pouch and refrigerate it.

14. Note the expiration date on the membrane package

15. Repeat this procedure for the remaining enzyme probes.

You may want to maintain an instrument log book in which dates and lot numbers of reagents are recorded, along with

information from daily operational checks and other relevant information.

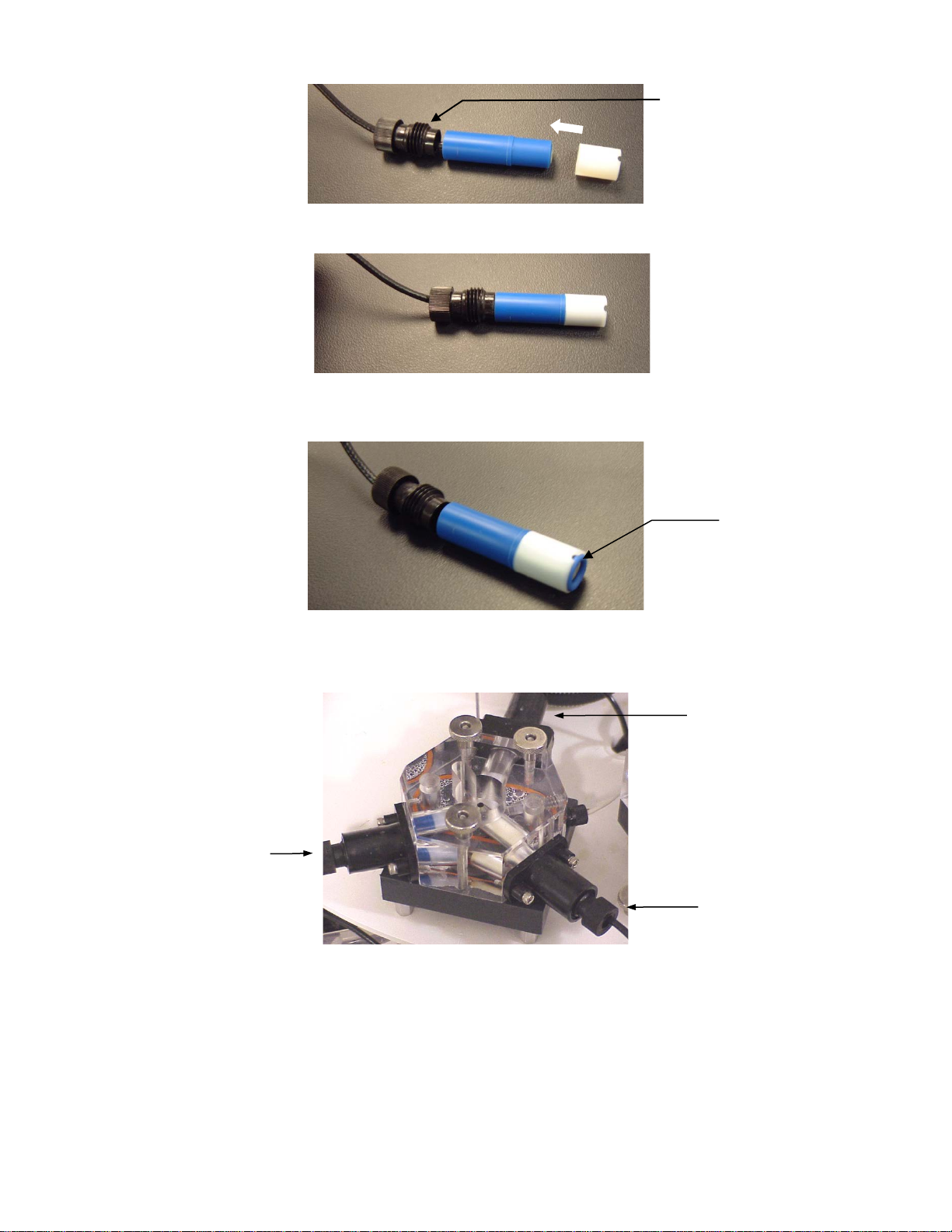

4.9.2 Ion Selective Electrodes

The 2900 Series is shipped without the Ion Selective Electrodes installed in module 3. To install an ISE:

1. First remove the packaging material and the cap from the ISE (save the cap for later use).

2. Slide a black probe retainer over each ISE cable (threaded end first).

3. Slide a white probe sleeve (notched end out) over the end of each ISE.

27

Page 29

O-ring

Retainer

Potassium ISE

Reference Electrode

Ammonium ISE

Figure 4.6

Figure 4.7

4. Place an O-ring into the end of each sleeve, pushing the O-ring gently so that it is secured by the sleeve.

Figure 4.8

5. Install the reference electrode by screwing the probe retainer into the module (finger tighten only; do not

overtighten).

6. Install a stir bar in the module.

7. Secure the ammonium and potassium ISEs in place by screwing the probe retainers into the module (finger

tighten only; do not overtighten).

8. Connect the ISE cables to the matching connectors located at the rear of the instrument.

Figure 4.9

28

Page 30

Ammonium—NH4

Potassium—K

Reference—REF

Figure 4.10

9. Install the top covers on the instrument.

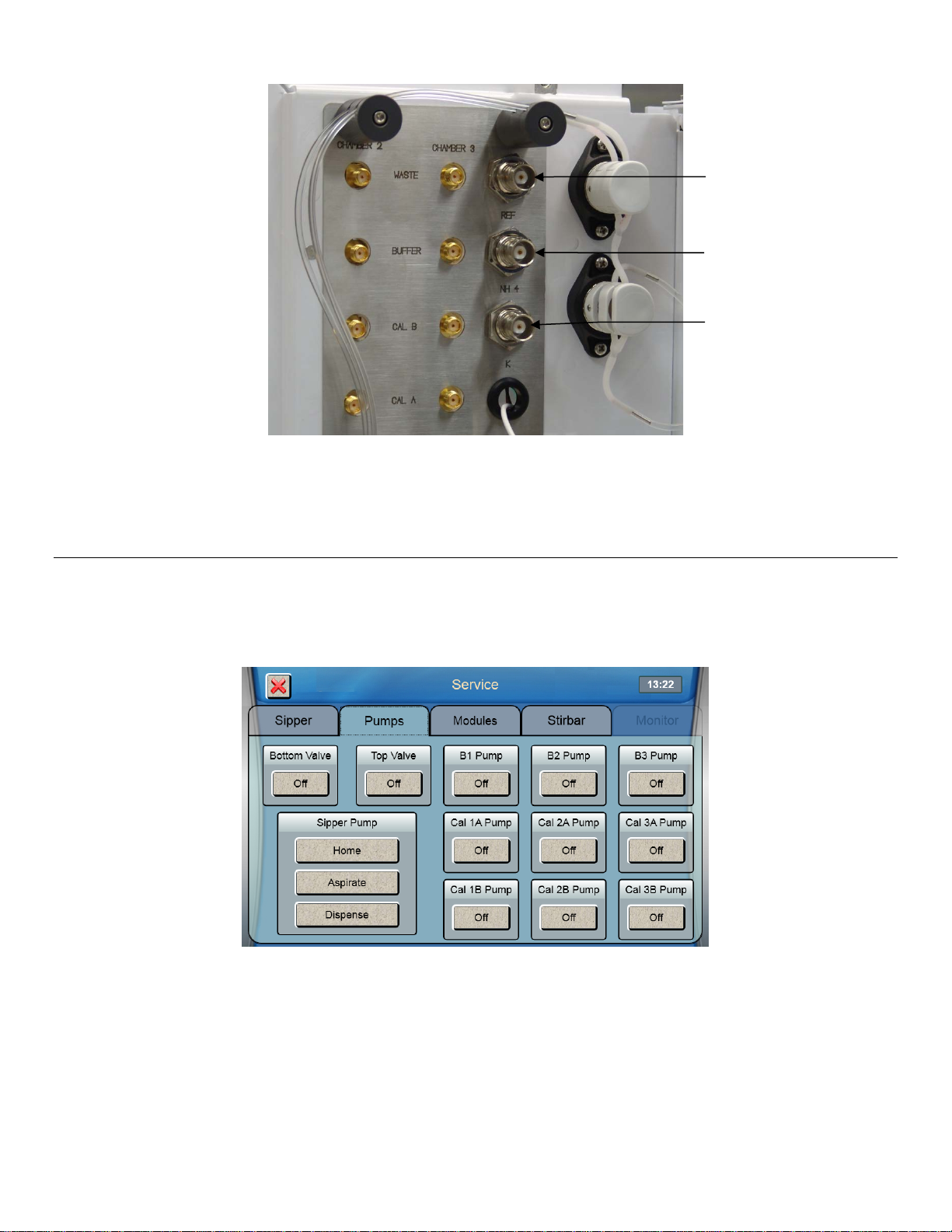

Prime the Fluid System 4.10

Please note that it may take from several minutes to more than an hour to initially stabilize the probes when setting up for

the first time.

To prime the fluid system:

1. From the Service screen, touch the [Pumps] tab.

2. Touch the button under B1 Pump to turn it on.

3. The instrument will prime the B1 buffer solution.

4. Once buffer flows from the end of the sipper, touch the button under B1 Pump to stop the pump.

5. Repeat this procedure to prime all other buffer bottles and calibrator bottles you have installed.

Prime all installed calibrator bottles daily to remove air bubbles from the tubing.

29

Page 31

Check Probe Currents 4.11

Flush Module 1

Enzyme Probe

Flush ISE Module 3

ISE Voltages

4.11.1 Biosensor Probes

1. From the [Modules] tab of the Service screen, touch the [Flush] button under Module 1 to flush the selected

sample module with buffer.

Currents

2. Observe the probe current values (baseline). They must be below 6 nA and stable.

3. Check to see if they are decreasing in value.

4. Check the sample module; it should be full of buffer.

5. If necessary, touch the [Flush] Button to flush the sample module again.

6. Flush any additional modules by touching the [Flush] button under the Module.

Please note that when the instrument is first powered up, it may take several hours for the baseline currents to drop below

6 nA.

4.11.2 ISE Probes

1. Touch the [Flush] button under Module 3 to flush the selected sample module with ISE buffer.

Note that the instrument will purge buffer to waste if the incorrect buffer is in the line.

2. Observe the ISE voltage values. They should be between -40 and 60mV and stable.

3. Check the module; it should be full of buffer.

4. If necessary, touch the [Flush] button to flush the sample module again.

Please note that when the instrument is first powered up, it may take an hour for the voltages to stabilize.

Once biosensor probe currents and ISE voltages are acceptable, touch the [X] button at the top left of the screen to exit to

the main display.

Enable 21 CFR Part 11 Mode 4.12

If you will be using the optional 21CFR Part 11 compliance features, enable 21 CFR Part 11 Mode (see Section 7.1.5.1 for

details).

5. Running the Instrument

Perform Daily Operational Checks 5.1

To ensure that your 2900 Series is operating properly, perform the Membrane Integrity and Linearity checks on a daily

basis before running samples.

30

Page 32

5.1.1 Enzyme Membrane Integrity Test

Use YSI 2363 Potassium Ferrocyanide (FCN) Standard to determine if your enzyme membranes are structurally intact.

1. Pour small amount of FCN standard (1000 mg/dL) in a test tube or multi-well plate

2. Press the Run icon to process it as a sample.

3. From the Run Batch tab, touch [New]

4. Choose from the selection of supported racks and plates.

5. We highly recommend renaming the rack/plate “Daily Checks” by touching its ID to indicate that it contains your

daily check batches.

6. After selecting your plate/rack, touch the [Edit] button

7. Touch the location of each sample for the first batch. Selected locations will be blue.

31

Page 33

8. Touch the [Batch] button.

9. Select only the chemistries that require the FCN test.

10. To change the Batch Name from the default value of TestBatch- #, touch the [TestBatch- #] button. The keypad

window will appear.

11. Type your new batch name and touch [DONE].

12. Touch

to save the batch.

32

Page 34

5.1.2 Linearity Test

13. Pour small amount of linearity standard in a test tube or multi-well plate.

14. Touch additional sample locations to create new batch for the linearity tests.

15. For the daily linearity checks, select only the chemistry that corresponds to the linearity standard in that sample

location.

16. Touch

17. Create additional batches for each linearity solution.

18. Touch [Close] when all batches are created.

19. Load the plate/rack in the sampling station 1.

20. Touch [Start] to run the FCN and the linearity standards as sa mples.

The analyzer will calibrate as required and run the batches.

to save the batch.

5.1.3 Results

21. Touch the Results tab

22. Select a sample location.

33

Page 35

Chemistry

Membrane

Calibration Standard

FCN Limit2

Ethanol

2786

2790 (2.00 g/L)

0.05 g/L

Ethanol-HC

7150

7151 (25.0 g/L)

0.10 g/L

Glucose

2365

2776 or 2747

0.05 g/L

L-Glutamate

2754

2755

0.06 g/L

L-Glutamine

2735

2736

0.06 g/L

L-Lactate

2329

2776

0.03 g/L

Methanol

2725

2726 (1.00 g/L)

0.05 g/L

Sucrose

2703

2780

0.10 g/L

Xylose

2761

2767

0.05 g/L

Select to show

Select a

sample

23. Touch a chemistry to show details

24. Listed in table 6-1 below are the recommended FCN limits.

a. Values less or equal to FCN limits indicate integral membranes

b. Values greater than FCN limits indicate membrane structural failure

c. If readings are high, recalibrate and repeat all the steps above to confirm.

d. If the reading is still out of tolerance, refer to the Troubleshooting Section.

details

Choline 2771 2772 0.02 g/L

2

If you are using units other than g/L for the FCN test, refer to 16 Appendix B – Concentration Unit Conversion for conversion values.

Table 6-1

34

Page 36

Chemistry

Calibration Std

Linearity Std

Acceptable Range (g/L)

25. See the list of acceptable valu es in table 6-2 below to interpret linearity readings.

a. Values that are ± 5% of specified tolerance limits indicate good membranes.

b. Values that are out of tolerance indicate an aging enzyme membrane.

c. If readings are out of tolerance limits, recalibrate and repeat all the steps above to confirm.

d. If the reading is still out of tolerance, refer to the Troubleshooting Section.

Ammonium3 2972 (0.50 g/L) 7179 (0.10 g/L) 0.095 to 0.105

Choline 2772 (0.175 g/L) 2773 (0.450 g/L) 0.43 to 0.47

Ethanol 2790 (2.00 g/L) 2790 (3.20 g/L) 3.04 to 3.36

Ethanol-HC 7151 (25.0 g/L) 7152 (40.0 g/L) 38.0 to 42.0

Glucose 2776 (2.50 g/L) 1531 (9.00 g/L) 8.55 to 9.45

L-Glutamate 2755 (0.73 g/L) 2756 (1.46 g/L) 1.39 to 1.53

L-Glutamine 2736 (0.73 g/L) 2737 (1. 17 g/L) 1.11 to 1.23

Glycerol 7141 (25.00 g/L) 7142 (40.00 g/L) 38.0 to 42.0

L-Lactate 2776 (0.50 g/L) 1530 (2.67 g/L) 2.54 to 2.80

Lactose 2783 (5.00 g/L) 2784 (25.00 g/L) 23.75 to 26.25

Methanol 2726 (1.00 g/L) 2726 (2.50 g/L) 2.38 to 2.63

Potassium

3

2971 (1.00 g/L) 7179 (0.20 g/L) 0.190 to 0.21 0

Sucrose 2780 (5.00 g/L) 2778 (25.00 g/L) 23.75 to 26.25

Xylose 2767 (20 g/L) 2768 (30 g/L) 25.5 to 34.5

Table 6-2

Sample Preparation 5.2

A variety of sample types can be analyzed with the 2900 Series. Generally, the only sample preparation that may be

required is dilution of the sample to bring the substrate concentration within the linear range of the instrument. (see

Section 8 Chemistry Setup for the working range of each chemistry).

Neither color nor turbidity interferes with measurements.

Small particles do not affect the reaction in the sample module that houses the probes, but samples with particles large

enough to clog the sipper should be avoided.

Run Batch 5.3

5.3.1 Create Batches

1. From the Run Batch tab of the Run screen, select a sample rack/plate and create batches for your samples.

3

Range for single linearity check. Refer to 8.2.14 Simultaneous Ammonium and Potassium for sample to s ample precision.

35

Page 37

Arrows

2. Touch [New] and choose from the selection of supported racks and plates. Alternatively, use the arrows to scroll

through the saved racks and plates until you find the type that you are using.

3. You may rename the rack/plate by touching its ID.

4. After selecting your plate or rack, touch the [Edit] button.

5. Touch the location of each sample for the first batch (selected locations are blue).

6. Touch [Batch].

7. Select the chemistries to run in this batch.

8. Enter any optional parameters, such as Batch Name (separate name for this batch), Dilution Factor, Units, MultiSample (multiples of each sample location in this batch), or Repeats (multiples of the entire batch).

Please note that the instrument does not auto m atically dilute samples.

9. If you diluted your samples:

a. Touch the Dilution Factor [1] button.

b. Enter your dilution factor then touch [OK].

10. To change the number of sample replicates:

a. Touch the Multi-Sample [1] button.

b. Enter the number of times each sample in the batch should be run, then touch [OK].

11. To repeat the entire batch:

a. Touch the Repeats [0] button

b. Enter the number of times the entire batch should be repeated.

12. Touch to save the batch.

13. You may also create one or more batches for samples. Alternatively, you may create a separate rack for sample

batches.

36

Page 38

14. Touch [Close] when all batches are created.

15. To save your plate configurations to a flash drive, touch [Export].

16. Select the plates you want to export, and then touch [Export].

17. Previously exported plates can be imported later using the [Import] button.

5.3.2 Load Samples

5.3.2.1 R24 and P6-P96 Racks/Plates

1. Open the front door of the instrument

2. Insert the plate/rack (end marked A1 first) into the instrument. Slide the front edge of the plate/rack in until it

stops.

Figure 5.1

3. Gently lower the rear of the plate/rack and push it down into position.

37

Page 39

Figure 5.2

R8 Tube Rack

5.3.2.2 R4 or R8 Tube Racks

1. Open the front door of the instrument.

2. Insert the R4 or R8 tube rack into the cavity just inside the front door.

3. Insert your sample tubes into the tube rack you installed.

Figure 5.3

38

Page 40

5.3.3 Start

Select module

Virtual Printer

Figure 5.4

Touch

The 2900 Series will calibrate as required and run the batches.

to run the current batches.

5.3.4 Status

1. Touch the Status tab.

2. Then select a module to view its status.

to view status

3. The virtual printer window displays details of previous samples and calibrations.

4. Use the arrow buttons to scroll the printer window.

Run Stat 5.4

A Stat sample at Station 2 runs without stopping a plate analysis or monitor session that is in progress.

NOTE: The Sipper is not designed to pierce septa.

39

Page 41

1. Touch the Run Stat tab

2. Place the sample in Station 2:

a. Insert your sample tube into the tube holder (Station 2) from below the spring clip

b. Slide it up all the way until it rests below the notch at the top.

The test tube holder accepts tubes sizes up to 16x100mm.

Any container other than this should be sampled manually by holding the sample at Station 2.

Figure 5.5

3. Touch [Configure] to setup the Stat sample.

4. Select the chemistries and units for the sample.

40

Page 42

5. Touch to return to the Run Stat screen.

Stat sample

6. Touch

7. The Stat sample results are displayed on the Run Stat tab.

If a Station 1 batch is in progress, the Stat sample will run as soon as the required module(s) is available.

to run the Stat sample at Station 2.

results

41

Page 43

Select a

Select to show

Results 5.5

1. Touch the Results tab.

2. Then select a sample position to display the results.

sample

3. Select a chemistry to display details.

details

6. Online Monitor and Control

The YSI 2960 Online Monitor and Control System allows “on-line” monitoring and control of sterile systems over long

periods of time without contamination. It also provides an alternative means of interfacing the 2900 Series with external

measurement/control systems.

The 2960 may draw sample from a process stream, bioreactor or other suitable source and deliver sample to the

analyzer. The system can operate unattended for days or weeks, provided sufficient reagent supply is considered.

The sample volume required for each analysis varies somewhat depending on the distance, flow rate and fluid interface

used, however, typically 1.5 milliliters is sufficient to purge the 2960 sample cup and deliver fresh sample.

The 2960 preserves sterility by filling the end of the sampling line with an antiseptic after every sample.

42

Page 44

2960

Online

Monitor

YSI 2900M Online Monitoring an d Control System

The analog output of the 2960 provides a voltage signal which is proportional to the concentration of the analyte. The

2960 provides this voltage output for up to two chemistries, two "handshake" signals, and a system status signal. In

addition, the user has the ability to adjust full scale analog output for each chemistry .

The 2960 also provides three discrete signal outputs (TTL logic level) to control external pumps which can be used to

replenish nutrients or optimize byproduct concentrations.

Figure 6.1

2960 Installation 6.1

1. Connect the small end of the supplied USB cable to the mini USB socket on the back of the 2960.

2. Connect the large end of the USB cable to the USB socket on the back of the 2900 Series.

43

Page 45

Power

Mini USB

Connection

Analog/Control

Remove

Connection

Connection

Rear panel of 2960 Online Monitor

Figure 6.2

3. Install the correct AC plug for your location onto the 2960 power supply, then plug the power supply into an AC

power outlet.

4. Connect the cable from the power supply to the power socket on the back of the 2960.

5. Using a 3/32” Allen hex wrench, remove the screw from the right rear of the 2900 Series deck as shown below.

Discard the screw.

screw

Figure 6.3

6. Using a 9/64” Allen hex wrench and the long hex screw provided with the 2960, install the Monitor Sample Cup on

the 2900 Series deck (see figure below).

44

Page 46

Monitor

Sample

To a waste

To bottom of

To side of

Cup

Figure 6.4

7. Connect the small sample tubing from the left side of the 2960 Online Monitor to the bottom of the Monitor Cup

you just installed inside the 2900 Series.

Monitor Cup

Monitor Cup

container

Figure 6.5

8. Connect the larger diameter waste tubing from the fitting on the left side of the 2960 Online Monitor to the waste

fitting on the side of the Monitor Sample Cup inside the 2900 Series.

9. Run the larger diameter waste tubing from the fitting on the right side of the 2960 Online Monitor to an appropriate

waste container.

45

Page 47

Align Sipper 6.2

Touch Sitini

Touch Sitini

1. From the Service menu, touch the Location button. The Select Location screen will appear.

Cup

2. Select [Sitini Cup]. The sipper will move to the Monitor Sample Cup and should be centered above the funnel

shaped opening in the top of the cup.

3. If the sipper is not centered, touch [Position] and use the arrow buttons to center the sipper.

4. Make certain the Sipper is centered, then touch at the bottom right of the adjustment window.

5. Touch [Depth] and select [Sitini Cup] to set the sipper depth.

Cup

6. Use the Up and Down Arrow buttons to adjust the sipper so the tip is flush with the top of the Monitor Sample

Cup.

7. Touch at the bottom right of the adjustment window to save the depth setting.

Sample Interface 6.3

When configured appropriately the 2960 automatically samples a bioreactor, process stream, or other suitable sample

source. Since color, turbidity, optical density and many other physical factors do not affect the YSI enzyme biosensor,

filtration and/or dilution may not be necessary and the 2960 may draw the sample directly. If cell loss is a concern, or if

high cell density is expected, a filtration device (e.g., tangential flow filter) which separates broth and cells may be

installed between the sample source and the 2960.

Using the additional tubing included with the 2960, connect the tubing from the outside slot of the 2960 valve to your

sample source—bioreactor, process stream, etc. Keep the tubing as short as possible to minimize purge time.

46

Page 48

From

source

From

Antiseptic

Sample

Figure 6.6

If you are using an antiseptic, connect the tubing from the inside slot of the 2960 valve to your antiseptic container. Typical

solutions might include 1% sodium hydroxide or 0.25% hypochlorite in reagent water. Even if you are not using an

antiseptic solution, the solenoid valve still switches to the antiseptic position and air or fluid is pumped through the

antiseptic line during sample aspiration. The antiseptic line must be kept free from obstructions. A dry 0.2 micron filter may

be connected to the antiseptic line to prevent contamination in the air from entering the line.

6.3.1 Sterilization

If your application requires aseptic monitoring, all tubing and connectors should be sterilized (autoclaved) prior to use. The

tubing, connectors and pump head should be assembled, the open ends of the tubing should be clamped off (two clamps

are provided) and the entire assembly (tubing with pump head) should be sterilized along with the bioreactor.

If the tubing is connected to the bioreactor after sterilization, a sterile connection must be made.

After sterilization the pump should be remounted onto the 2960 (see Section 9.6 2960 Maintenance for details). The

antiseptic cycle must be enabled and the antiseptic solution must be primed immediately after the tubing is reconnected.

Electrical Interface 6.4

6.4.1 Analog Outputs

The 2960 interface provides additional signals to aid in synchronizing the reading of the analog outputs. In addition to the

two analog outputs, three logical signals are provided. These "handshake signals" are nominally +5 volts for a logic 1 and

ground (0 volts) for a logic 0. The "READY" signals are output from the 2960 and are set to a logic 1 when the analog

output signal for that channel has been updated. This signal indicates to the host system that the analog voltage is "new"

and that it represents the most recent reading of the analyte concentration. The host system (the external system to which

the 2960 is connected) then can send a logic 0 to the "ACK" input of the 2960. This "ACK" (acknowledge) signal response

from the host resets the READY line of the 2960 to its low state before the next sample is ready.

The figure below shows the typical signal pattern that would occur during two sample update cycles. The READY signals

will reset themselves immediately prior to updating the analog output if not reset externally via the ACK\ signal input.

47

Page 49

Analog Output

Ready

Ack\

Figure 6.7

6.4.2 Pump Control Outputs