Page 1

IQ SENSOR NET

MIQ/TC 2020 XT

Operating manual

ba76019e01 12/2012

Modular multiparameter measuring system,

Terminal/Controller MIQ/TC 2020 XT

Page 2

MIQ/TC 2020 XT

Note

For the most recent version of the manual, please visit www.ysi.com

.

Up-to-dateness of

instrument software

The continuous development of the instrument software is part of the

consequent improvement process of the instrument software. The

current instrument software for the MIQ/TC 2020 XT is available on the

Internet. It can be transferred to your instrument with the aid of USB

memory device. More detailed information is given on the Internet

under www.ysi.com

.

Saving the password If access control is enabled for the IQ S

administrator password is lost, quick administrator acces to the

IQ S

ENSOR NET is not possible (access control: see section 5.4).

To avoid the loss of the password we recommend to create a back-up

of the administrator password. This also applies to the use of the

electronic key.

To be on the safe side, you can store the administrator password on an

electronic key and/or note it on paper or a PC. Store the passwords in

a safe place.

ENSOR NET and the

Contact YSI

1725 Brannum Lane

Yellow Springs, OH 45387 USA

Tel: +1 937-767-7241

800-765-4974

Email: environmental@ysi.com

Internet: www.ysi.com

Copyright © 2011 Xylem Inc.

2

ba76019e01 12/2012

Page 3

System 2020 XT USB Contents

IQ SENSOR NET System 2020 XT USB - Contents

1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

1.1 How to use this system operating manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

1.2 The IQ S

1.2.1 Structure of the system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

1.2.2 Functions in the IQ S

1.2.3 Possible ways to communicate with the IQ S

1.2.4 Components of the system 2020 XT USB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

1.2.5 MIQ modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-10

1.3 MIQ/TC 2020 XT terminal/controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-12

1.3.1 Operation as terminal/controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-13

1.3.2 Operation as a terminal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-14

1.3.3 Operation as backup controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-15

1.3.4 USB interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-16

1.3.5 Status LED . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-17

1.4 Behavior of the IQ S

1.4.1 Behavior of the IQ S

1.4.2 Behavior of the IQ S

1.4.3 Availability of the system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-19

ENSOR NET system 2020 XT USB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

ENSOR NET . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

ENSOR NET . . . . . . . . . . . . . . . . . . . 1-5

ENSOR NET in case of error . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-18

ENSOR NET in case of power failure . . . . . . . . . . . . . . . . . . 1-18

ENSOR NET if a components fails . . . . . . . . . . . . . . . . . . . . 1-18

2 Safety instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

2.1 User qualification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

2.2 Authorized use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

2.3 General safety instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

3 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

3.1 Scopes of delivery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

3.1.1 MIQ modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

3.1.2 Terminal/Controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

3.2 Requirements of the measurement location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

3.3 System planning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

3.4 Basic requirements for optimum installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

3.4.1 General information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

3.4.2 Drawing up the power rating . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

3.4.3 Effect of the cable length . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

3.4.4 Optimum installation of MIQ power supply modules . . . . . . . . . . . . . . . . . . . . . 3-10

3.4.5 Installation guidelines for lightning protection . . . . . . . . . . . . . . . . . . . . . . . . . . 3-10

3.5 Connecting system components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-13

3.5.1 General information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-13

3.5.2 Stacked mounting of MIQ modules: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-14

3.5.3 Distributed mounting of MIQ modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-21

ba76019e01 12/2012

0 - 1

Page 4

Contents System 2020 XT USB

3.5.4 Connecting IQ sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-25

3.5.5 Installing terminal components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-27

3.6 Installation of the MIQ modules at the installation location . . . . . . . . . . . . . . . . . . . . . . .3-29

3.6.1 General information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-29

3.6.2 Mounting on a mounting stand with the SSH/IQ sun shield . . . . . . . . . . . . . . . .3-30

3.6.3 Mounting under the SD/K 170 sun shield . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-32

3.6.4 Panel mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-34

3.6.5 Top hat rail mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-36

3.7 Electrical connections: General instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-37

3.8 Connecting the voltage supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-39

3.9 Commissioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-39

3.9.1 Topology and terminator switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-39

3.9.2 Start checklist and system start . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-42

3.9.3 Checking the voltage supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-45

3.10 System extension and modification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-47

3.10.1 General information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-47

3.11 Configuration of the MIQ/TC 2020 XT as a terminal/controller or terminal . . . . . . . . . . .3-48

4 Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

4.1 MIQ/TC 2020 XT terminal/controllers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-1

4.1.1 Overview of the operating elements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-2

4.1.2 Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-3

4.1.3 Keys . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-5

4.1.4 Arrow keys . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-5

4.2 General operating principles . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-6

4.2.1 Navigating in menus, lists and tables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-7

4.2.2 Entering texts or numerals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-8

4.3 Access to the IQ S

4.3.1 Simple access control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-11

4.3.2 Extended access control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-12

4.3.3 Extended access control with instrument block . . . . . . . . . . . . . . . . . . . . . . . . .4-13

4.4 Display of current measured values . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-14

4.4.1 Displaying a single measured value . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-15

4.4.2 Displaying four measured values . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-15

4.4.3 Displaying eight measured values . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-16

4.4.4 Displaying recorded measured values . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-17

4.4.5 Display of the measured values of a measurement location or of all

IQ sensors in the system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-19

4.5 Messages and log book . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-20

4.5.1 Message types . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-20

4.5.2 Log book . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-20

4.5.3 Viewing detailed message texts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-23

4.5.4 Acknowledge all messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-24

4.6 Calibration data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-25

4.6.1 Calibration entries in the log book . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-25

4.6.2 Calibration history . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-26

4.7 Status info of sensors and outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-27

ENSOR NET with enabled access control . . . . . . . . . . . . . . . . . . . . . .4-11

0 - 2

ba76019e01 12/2012

Page 5

System 2020 XT USB Contents

4.8 General course when calibrating, cleaning, servicing or repairing an IQ sensor . 4-28

4.8.1 Maintenance condition of IQ sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-29

4.8.2 Switching on the maintenance condition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-30

4.8.3 Switching off the maintenance condition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-31

4.9 Data exchange via the USB interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-32

4.9.1 Saving IQ S

ENSOR NET data on a USB memory device . . . . . . . . . . . . . . . . . . . 4-32

4.9.2 Transmitting recorded measurement data to a PC . . . . . . . . . . . . . . . . . . . . . . 4-34

4.9.3 Manual backup of the system configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-35

4.9.4 Restoring the system configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-35

4.10 Software update for IQ S

ENSOR NET components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-37

4.10.1 Information on software versions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-38

4.11 MIQ/TC 2020 XT in its function as terminal and backup controller . . . . . . . . . . . . . . . . . 4-39

5 Settings/setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

5.1 Selecting the language . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-1

5.2 Configuration of the MIQ/TC 2020 XT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

5.3 Terminal settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

5.4 Access control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-5

5.4.1 Simple access control (Unlock/lock settings) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-6

5.4.2 Extended access control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-8

5.4.3 Instrument block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-10

5.4.4 Electronic key . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-10

5.5 Editing the list of sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-12

5.5.1 Entering / editing a name for an IQ sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-12

5.5.2 Changing the display position . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-13

5.5.3 Erasing inactive sensor datasets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-14

5.6 Setting up IQ sensors/differential sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-15

5.6.1 Creating a differential sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-15

5.6.2 Erasing a differential sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-16

5.6.3 Adjusting the settings for sensors/differential sensors . . . . . . . . . . . . . . . . . . . . 5-17

5.7 Sensor-sensor link

(automatic inclusion of an influence quantity) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-18

5.7.1 Establishing a sensor-sensor link . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-19

5.7.2 Erasing a Sensor-sensor link . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-22

5.8 Editing the list of outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-23

5.8.1 Entering / editing the name of an output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-23

5.8.2 Erasing an inactive dataset for an MIQ output module . . . . . . . . . . . . . . . . . . . 5-24

5.8.3 Output links/settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-25

5.9 Settings for a measurement location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-26

5.10 Alarm settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-28

5.10.1 General information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-28

5.10.2 Setting up / editing alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-29

5.10.3 Alarm output to display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-32

5.10.4 Alarm output as relay action . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-33

5.10.5 Alarm message as an SMS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-33

5.11 System settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-34

ba76019e01 12/2012

0 - 3

Page 6

Contents System 2020 XT USB

5.11.1 Setting the date and time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-34

5.11.2 Site altitude / setting the medium air pressure . . . . . . . . . . . . . . . . . . . . . . . . . .5-35

5.12 Measured value logging . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-36

5.12.1 Setting the recording interval (dt) and recording duration (Dur.) . . . . . . . . . . . . .5-37

6 Maintenance and cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

6.1 Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-1

6.2 Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-1

7 What to do if ... . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

7.1 Information on errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-1

7.2 Diagnosing faults in the voltage supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-1

7.2.1 Options for checking the voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-1

7.2.2 Measuring the voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-2

7.2.3 Tips for clearing errors in the voltage supply . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-4

7.3 Other errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-6

7.4 Replacing system components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-8

7.4.1 Replacing passive components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-8

7.4.2 Adding and replacing IQ sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-8

7.4.3 Adding and replacing MIQ output modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-12

8 Technical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-1

8.1 General system data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-1

8.2 General data of MIQ modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-4

8.3 MIQ/TC 2020 XT terminal/controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-6

8.4 Space required by mounted components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-7

9 Contact Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-1

9.1 Ordering & Technical Support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9-1

9.2 Service Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9-1

10 Accessories and options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-1

11 Indexes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-1

11.1 Index of all displays . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12-1

11.2 Explanation of the message codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10-2

11.2.1 Error messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10-2

11.2.2 Info messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10-3

11.3 Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10-4

12 Appendix . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-1

12.1 Forgotten the password? (store separately if required) . . . . . . . . . . . . . . . . . . . . . . . . . .11-1

12.2 Default password . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11-2

0 - 4

ba76019e01 12/2012

Page 7

System 2020 XT USB Overview

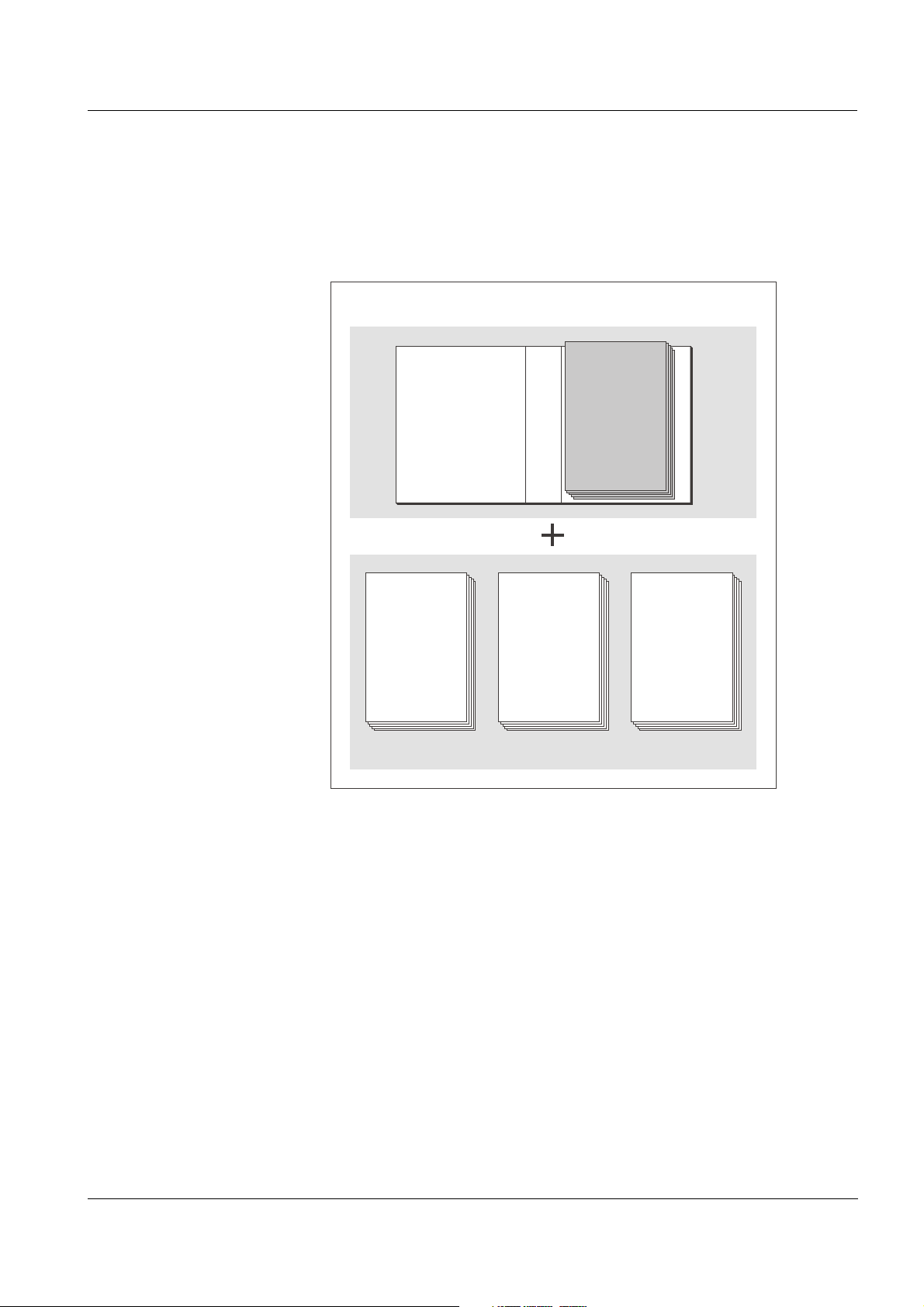

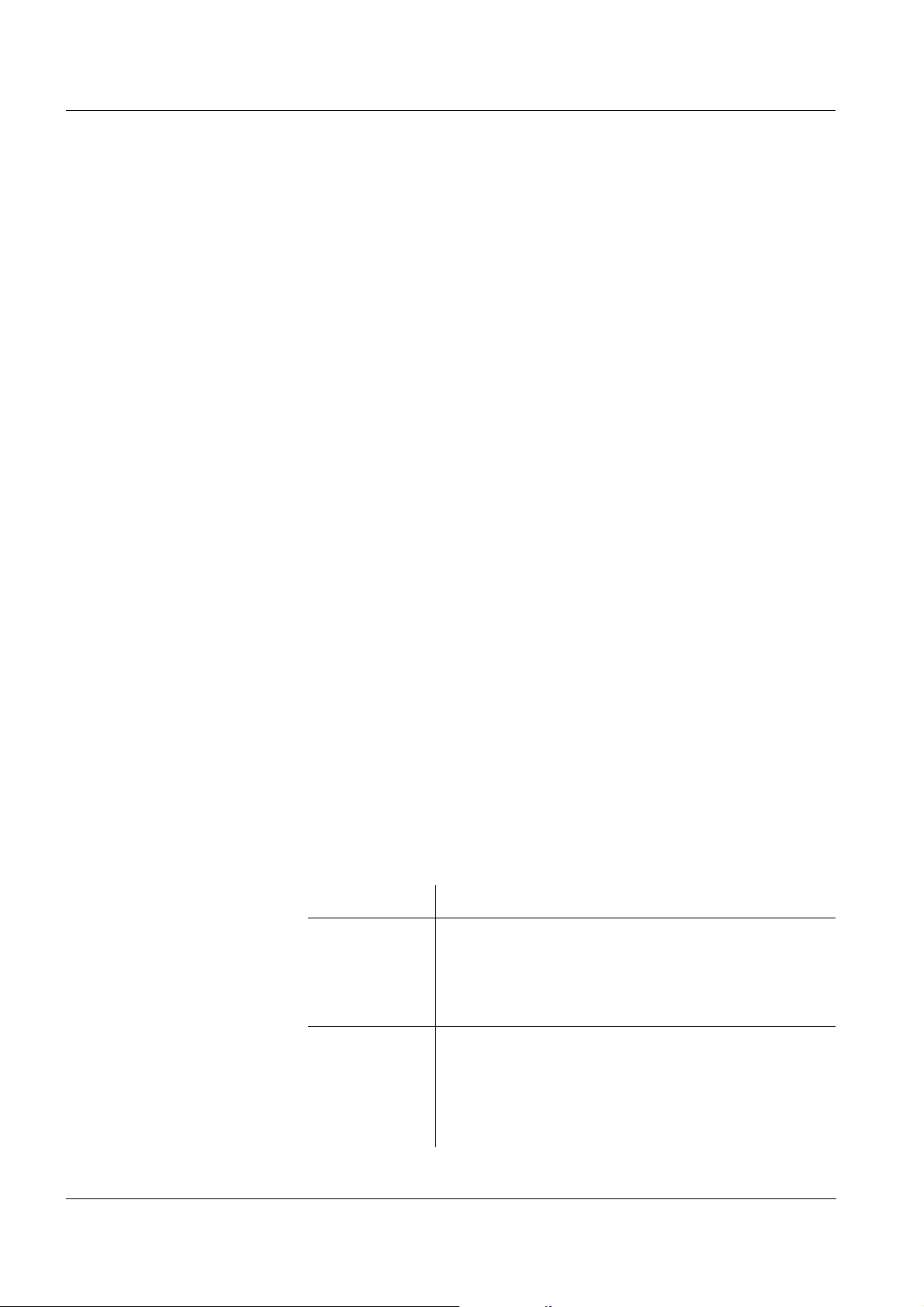

IQ Sensor Net Operating Manual

System

Operating

Manual

(Ring Binder)

IQ Sensor

Operating

Manual

MIQ Module

Operating

Manual

MIQ Terminal

Operating

Manual

Component Operating Manuals

1Overview

1.1 How to use this system operating manual

Structure of the

ENSOR NET

IQ S

operating manual

ba76019e01 12/2012

Fig. 1-1 Structure of the IQ SENSOR NET operating manual

The IQ SENSOR NET operating manual has a modular structure like the

IQ S

ENSOR NET system itself. It consists of this system operating

manual and the operating manuals of all the components used.

The space in the ring binder behind the system operating manual is

intended for filing the component operating manuals. Please file all

component operating manuals here so that all information is quickly

available in one location.

1 - 1

Page 8

Overview System 2020 XT USB

1.2 The IQ SENSOR NET system 2020 XT USB

1.2.1 Structure of the system

The IQ S

ENSOR NET is a modular measuring system for online analysis.

Modular means that the essential functional units of the measuring

system are distributed in components that can be individually compiled

for special applications.

The essential functional units of the IQ S

ENSOR NET

system 2020 XT USB include:

Terminal/controller

IQ sensors

Inputs (current inputs)

Outputs (relay contacts, current outputs, valve outputs)

Additional terminals (mobile terminals, software terminal)

Help functions (e.g. power supply unit).

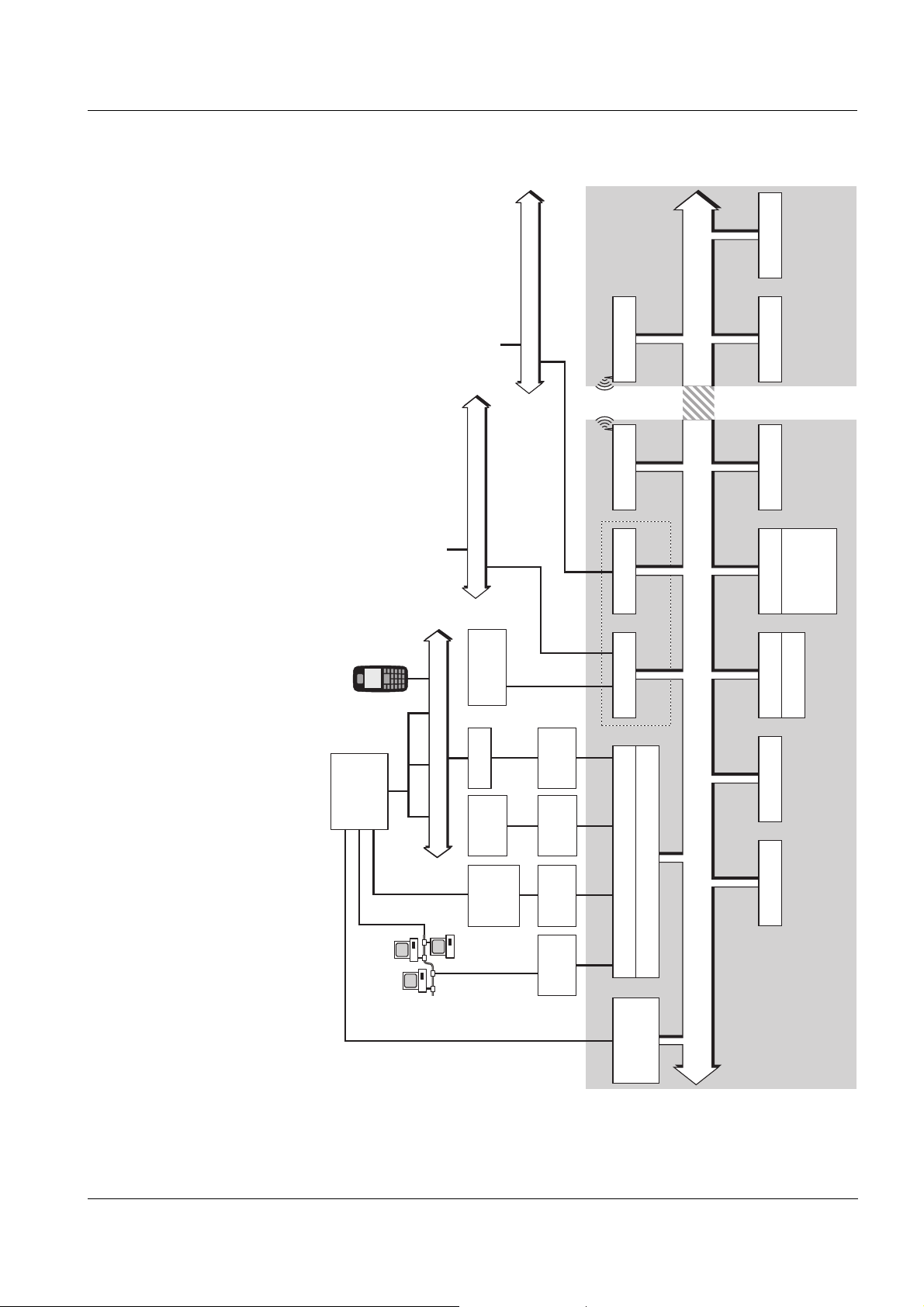

System communication The functional units are connected with one another via a common line

(Fig. 1-2). The line consists of two wires and a shield. It transports

digital information between the controller and the other modules. At the

same time, the line is used to supply all modules with electrical voltage

from a power supply unit. The power supply unit is only required for the

power supply and is not used in the system communication.

1 - 2

ba76019e01 12/2012

Page 9

System 2020 XT USB Overview

IQ Sensor

IQ Sensor Net

USB

Memory

Modem

Terminal

IQ SENSOR NET Island 1 IQ SENSOR NET Island 2

Eingänge

mA

mA

RS 232

Adapter

Data

Transfer

Modbus

SPSSPS

SPS

PROFIBUS

IQ Sensor Terminal

MIQ/(A)-PR

MIQ/(A)-MOD

Network

RS 232

Adapter

Ethernet

adapter

MIQ/IF232

PC+

IQ Software

Pack

(Diagnostics and

service only)

Mobile

phone

IQ Sensor Net (Data+Energy)

Radio moduleRadio module

Radio

100 m

Power supplyOutputs

Relay

mA

Valve

Inputs

RS 485

Device

Land line / GSM / Radio / SMS

Null

modem

cable

USB Interface

Terminal/Controller

Interface

modules

ba76019e01 12/2012

Fig. 1-2 Functional units of the IQ SENSOR NET System 2020 XT USB

1 - 3

Page 10

Overview System 2020 XT USB

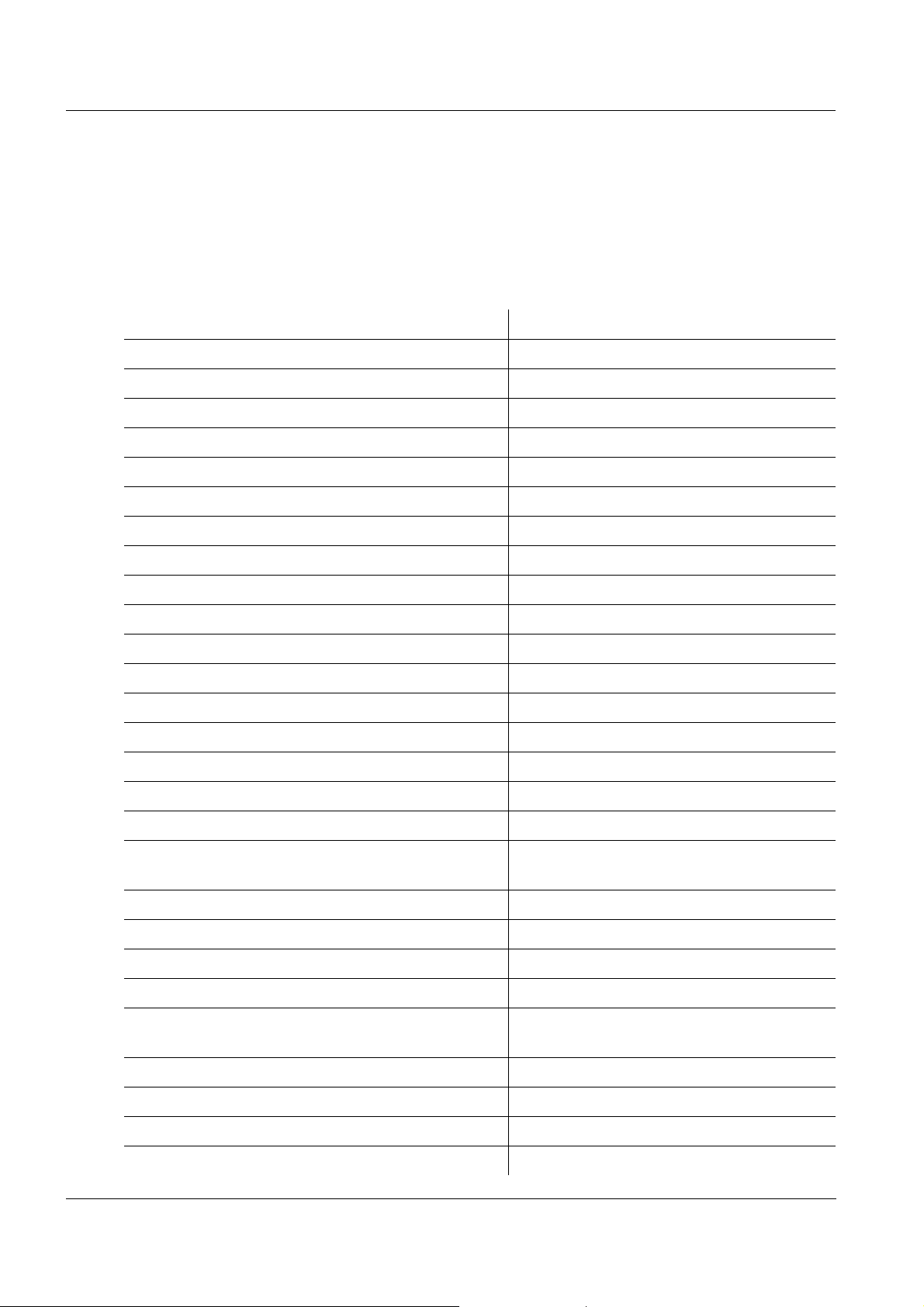

1.2.2 Functions in the IQ SENSOR NET

The functions of the IQ SENSOR NET are provided by the system

(controller) and the retrofitting components. Details on the functions

listed can be found in the relevant system or components operating

manuals.

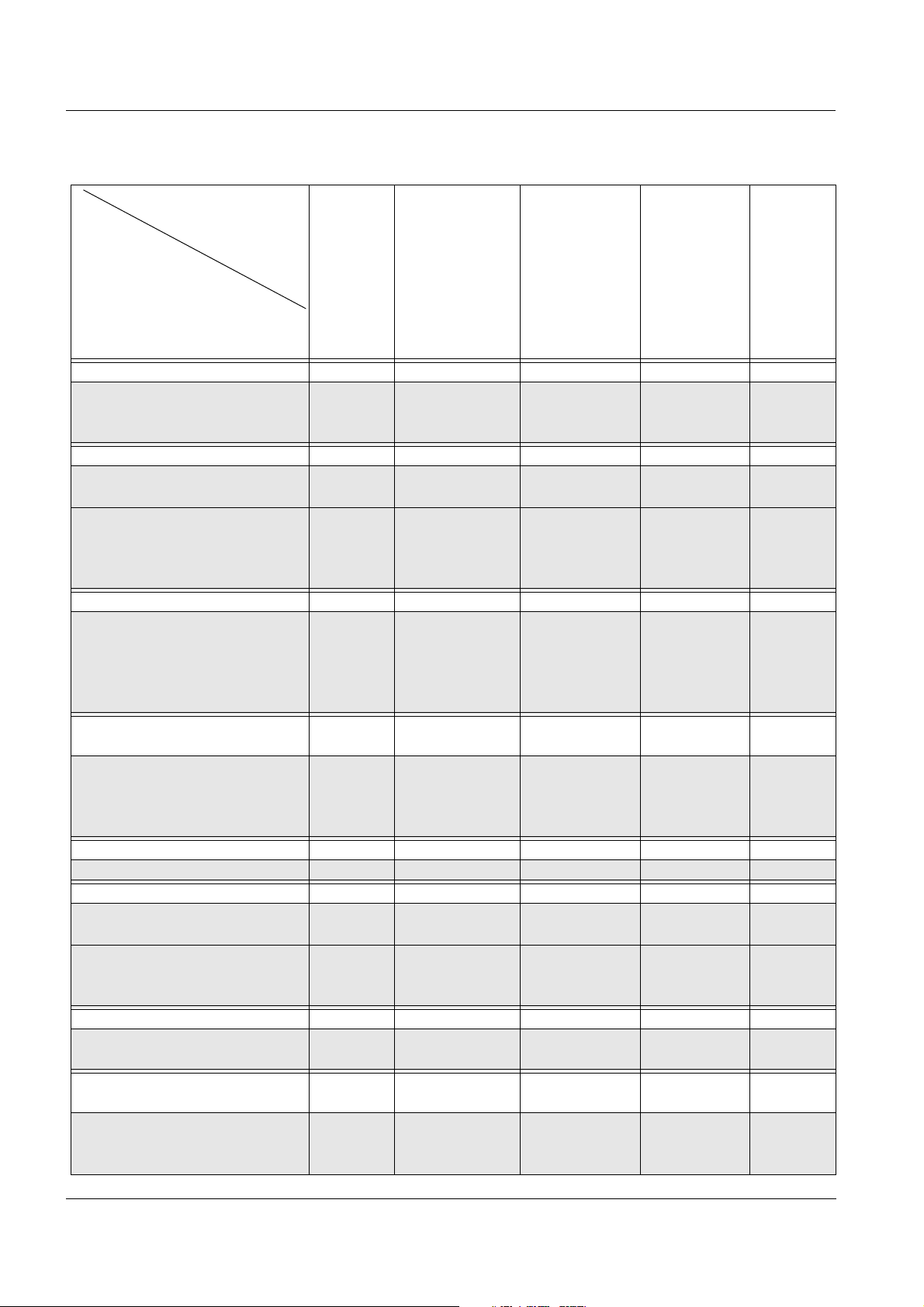

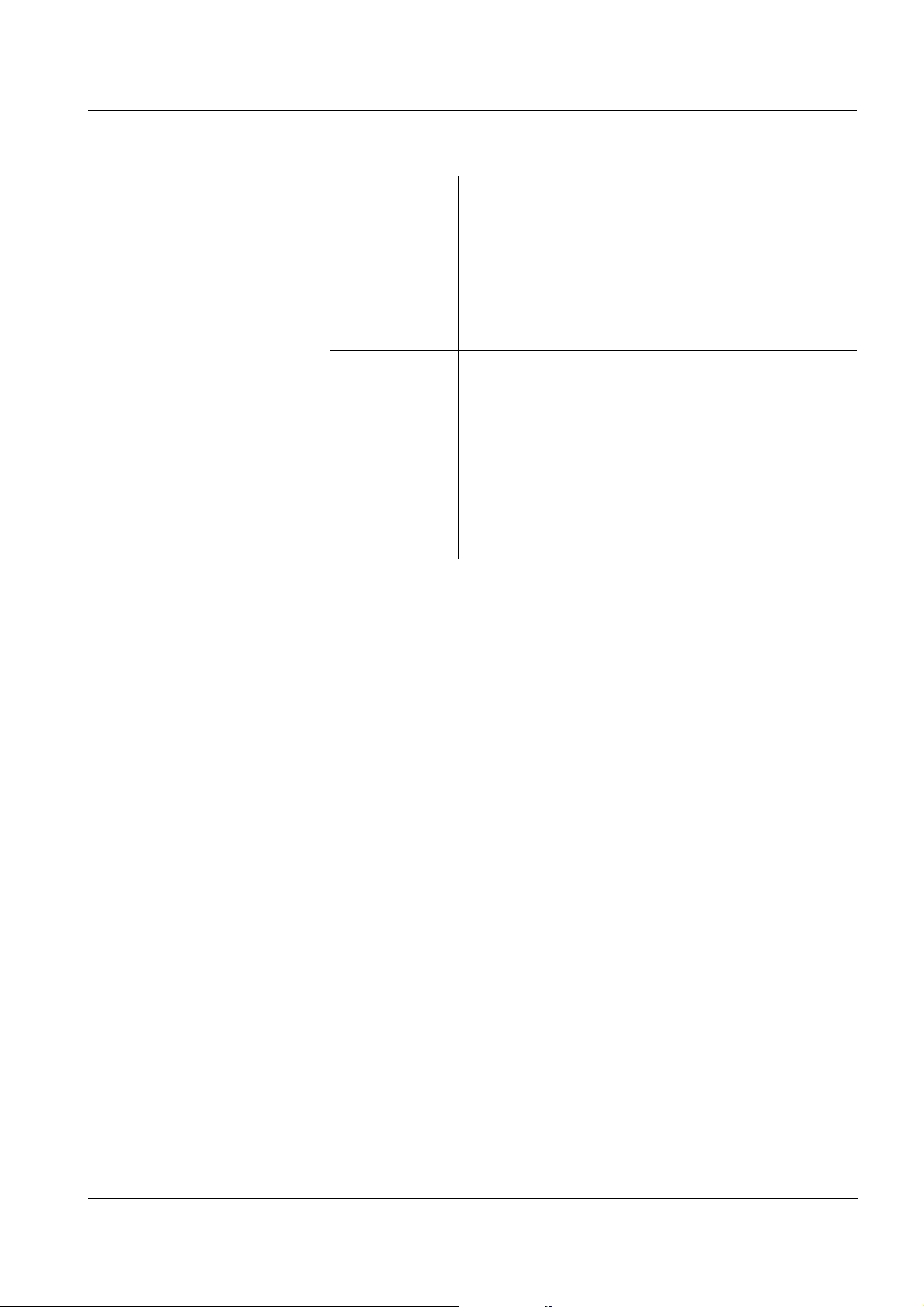

Function Component

Alarm messages System

Analog output Current output module

Data logging System

Data recording (PC) IQ software pack

Data transmission (PC) IQ software pack

Data backup on USB memory device MIQ/TC 2020 XT

Data communication (Profibus) MIQ/(A)-PR

Data communication (Modbus) MIQ/(A)-MOD

Remote data transmission (modem) MIQ/TC 2020 XT + USB RS232 adapter

Datalogger IQ software pack

Data server IQ software pack

Differential sensor System

Frequency output Relay output module

Limit monitor Relay output module

Calibration history System

List of outputs, list of sensors System

Log book System

Log book (messages from components) IQ sensor

Output module

Measured value representation (4 types) System

Password System

PID controller Current output module

Pulse-width output Relay output module

1 - 4

Sensor cleaning Relay output module

Valve module

Local settings System

Daily, weekly, monthly load diagram System

Monitoring functions (sensors, system) Output module

Access control System

ba76019e01 12/2012

Page 11

System 2020 XT USB Overview

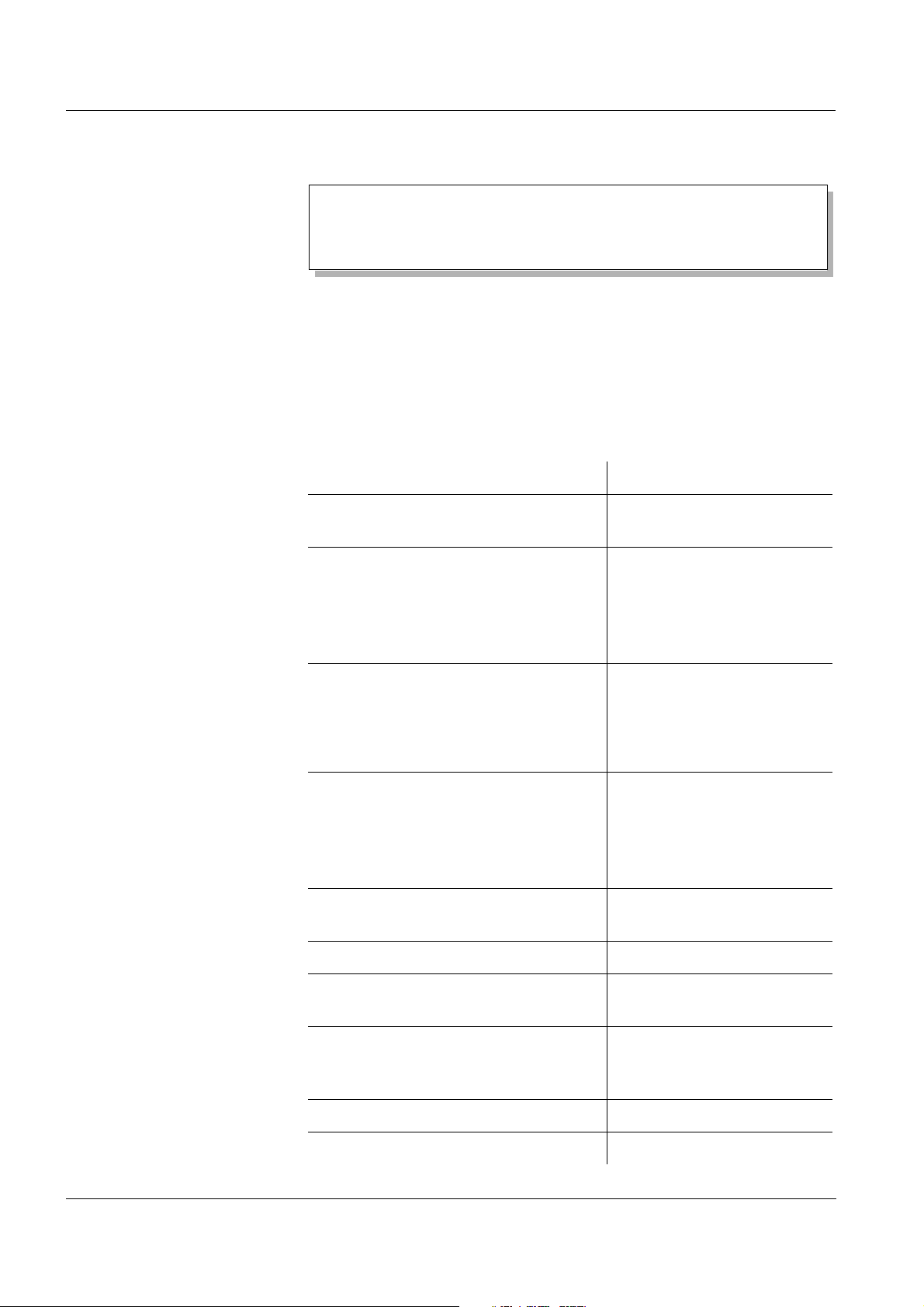

1.2.3 Possible ways to communicate with the IQ SENSOR NET

Digital communication The IQ SENSOR NET can communicate with humans and machines via

different interfaces.

The following page provides an overview:

Current and relay

interfaces

who can communicate with the IQ S

ENSOR NET

what interfaces and components are required for this

which functions are available with which interface

In addition to the digital communication, output modules provide relay

and current outputs. These can be used for control, feedback control

and monitoring functions.

ba76019e01 12/2012

1 - 5

Page 12

Overview System 2020 XT USB

Available

functions

Who communicates

with the IQ Sensor Net

via which interface/

component

Direct

actions

via the

terminal

user

interface

Viewing/transmitting

current data:

–Measured

values

– Status info

–Alarm

messages

Human

Terminal/controller

X X X X X

MIQ/TC 2020 XT

+ USB memory device

Human + PC

MIQ/IF232

X X X X X

+ IQ software pack

MIQ/TC 2020 XT

X X X X X

+ USB RS232 adapter

+ null modem cable

+ IQ software pack

Human + PC + modem

MIQ/TC 2020 XT

X X X X X

+ USB RS232 adapter

+ modem (analog, GSM, or

radio)

+ IQ software pack

Human + PC/mobile phone

+ modem

MIQ/TC 2020 XT

+ USB RS232 adapter

+ GSM modem

communication via SMS

PROFIBUS DP-V1

MIQ/(A-)PR X

Modbus

MIQ/(A-)MOD;

Modbus RTU operation

MIQ/(A-)MOD;

Point-to-point communication

via RS485

Network (TCP/IP)

MIQ/TC 2020 XT

X X X X X

+ USB Ethernet adapter

Client + Server + PC

("data logger")

MIQ/IF232

+ IQ software pack

(+ network)

Viewing/transmitting

logged data:

–Measured

values

–Measured

System configuration,

–save

/

load

–view

–print

Calibration data,

view

transmit

value

status

X

X

X

X X

/

1 - 6

ba76019e01 12/2012

Page 13

System 2020 XT USB Overview

Each main measured value occupies a sensor location in the

IQ S

ENSOR NET. A double sensor with two active main measured

values thus occupies two sensor locations. The available sensor

locations can be occupied by any single or double sensors.

1.2.4 Components of the system 2020 XT USB

Minimum configuration

(basic components)

IQ sensors, main and

secondary measured

values

The following basic components are required for a 2020 XT USB

system:

An MIQ/TC 2020 XT, configured as controller

A power supply module (e.g. MIQ/PS)

At least one IQ sensor.

Sensors provide main measured values (e.g. pH, D. O. concentration,

turbidity value...) and additionally, depending on the type, secondary

measured values (e.g. temperature). In the System 2020 XT USB,

digital YSI single sensors and double sensors can be used:

Single sensors provide a main measured value and normally a

secondary measured value (example: TriOxmatic 700 IQ

→ D. O. +

temperature).

All active 0/4-20 mA inputs of the MIQ/IC2 input module rank among

the single sensors. Via a 0/4-20 mA input, any external instruments

can be connected to the IQ S

ENSOR NET via their current output.

Each input provides a main measured value.

Double sensors provide up to two main measured values and

normally a secondary measured value (example: VARiON 700 IQ

→ ammonium + nitrate + temperature).

Extension components The system can be adapted to fulfill different specifications by adding

further components, e.g. by:

Terminals. They are the operation and communication units for the

IQ S

ENSOR NET. Available are:

– MIQ/TC 2020 XT for operation of the system from various

locations, e.g. calibration of IQ sensors on site (compatible

terminals, see section 1.4)

– MIQ/T2020 PC software terminals. The connection to the PC can

be established with the MIQ/IF232 interface module and the

RS 232 interface of the PC or a remote connection with a modem

(set for radio transmission, see chapter 10).

Output modules with relay, current and valve outputs. Valve outputs

enable the time controlled, compressed air operated cleaning of the

sensor.

ba76019e01 12/2012

1 - 7

Page 14

Overview System 2020 XT USB

Each current output, relay output and valve output occupies an

output channel in the IQ S

ENSOR NET. The available output

channels can be assigned to outputs arbitrarily.

Power supply modules for power supply

MIQ/JB and MIQ/JBR branching modules to branch the system and

to connect IQ sensors and terminals

MIQ/Blue PS radio modules for wireless connection within the

ENSOR NET.

IQ S

Maximum configuration Maximum configuration of the IQ S

Component or resource Maximum number

Terminal/controller

MIQ/TC 2020 XT

Sensor locations, can be occupied by:

– Single sensors

– Double sensors

– 0/4-20 mA inputs

Terminal locations, can be occupied by:

– Mobile terminals

(MIQ/TC 2020 XT)

– MIQ/T2020 PC software terminal.

Output channels, can be occupied by:

– Current outputs

– Relay outputs

– Valve outputs

ENSOR NET system 2020 XT USB:

1 (registered as a controller)

20

3

48

Power supply modules

(e.g. MIQ/PS)

MIQ/JB branching modules 25

MIQ/JBR branching modules with

integrated signal processing

MIQ/Blue PS radio modules Several transmission paths

Modbus module 1

PROFIBUS module 1

1 - 8

6

2

(see operating manual of the

MIQ/Blue PS)

ba76019e01 12/2012

Page 15

System 2020 XT USB Overview

Power

!

O

K

Power

!

O

K

MIQ/PS

MIQ/CR3

MIQ/TC 2020 XT

SNCIQ

SACIQ

+ IQ Sensor

SNCIQ

MIQ/JB MIQ/JB

MIQ/TC 2020 XT

stacked mounting

distributed mounting

C

M

S

E

S

C

O

K

C

M

S

E

SC

O

K

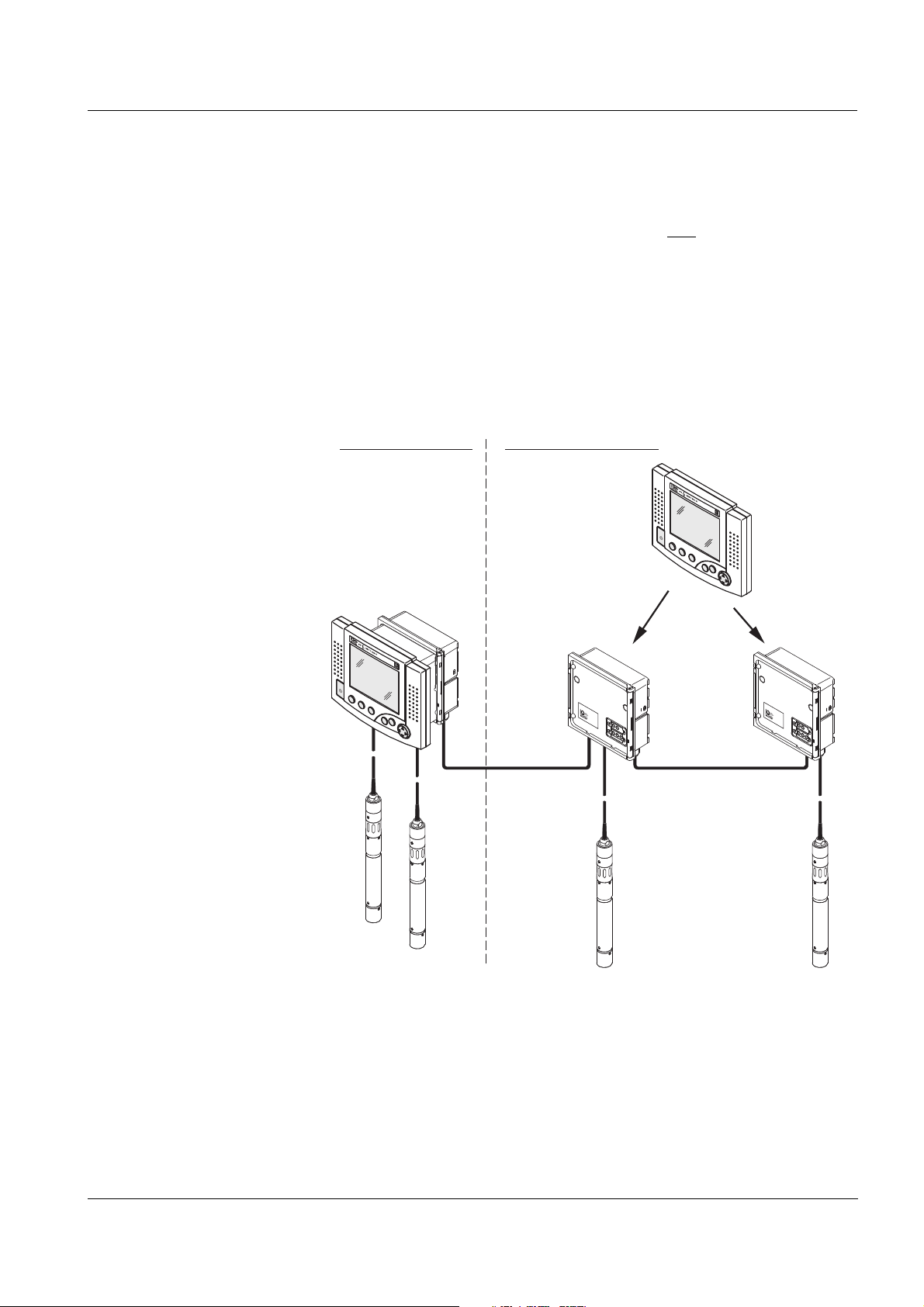

Connecting

MIQ modules

There are two basic mounting variants for connecting the

MIQ modules:

Stack mounting - permanent mechanical and

electrical connection.

The housings of the MIQ modules are permanently mounted on one

another to form a stack. No cabling is necessary.

Distributed mounting - electrical connection via cable.

Locally separated MIQ modules or module stacks are connected

with one another via the SNCIQ or SNCIQ/UG cable.

The following diagram shows an IQ S

ENSOR NET system with two

mounting variants (Fig. 1-3).

ba76019e01 12/2012

Fig. 1-3 Example of an IQ SENSOR NET system configuration

IQ sensors Up to 20 IQ sensors of any type can be used in the system

2020 XT USB. They can be connected to any MIQ module that has a

free connection for the IQ S

ENSOR NET. The connection between the

IQ sensor and MIQ module is made via the SACIQ sensor connection

cable. The IQ sensor connection cable is connected with the plug head

connector of the IQ sensor via a screwable socket to form a watertight

connection. As a result, the IQ sensor can be quickly removed for

maintenance activities and then connected again.

1 - 9

Page 16

Overview System 2020 XT USB

7

1

2

3

4

5

6

Power

!

O

K

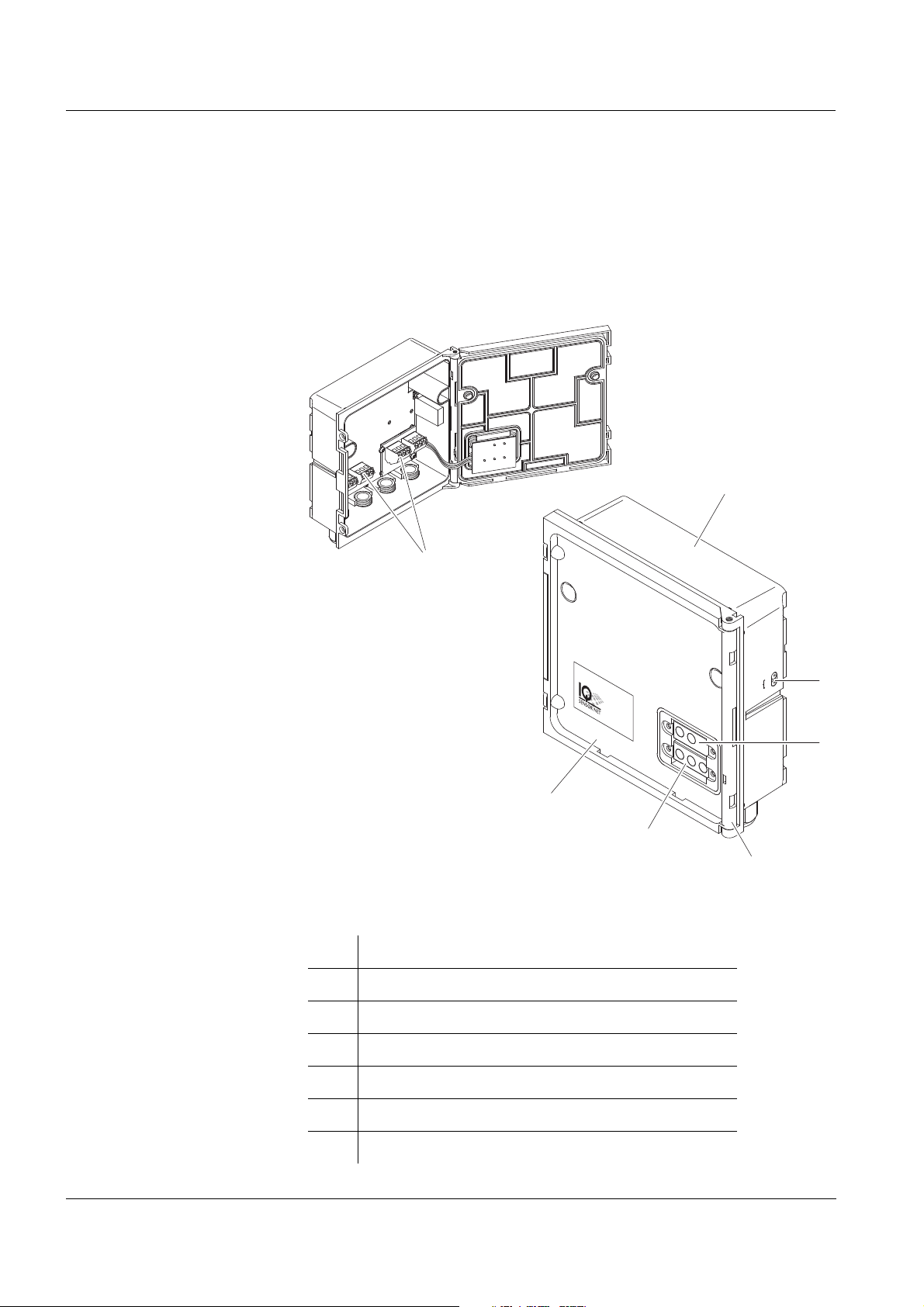

1.2.5 MIQ modules

Some of the IQ S

ENSOR NET components are so-called MIQ modules

with different functions.

All MIQ modules have a standard housing with the following features

(Fig. 1-4):

1 - 10

Fig. 1-4 MIQ module

1 Housing

2 Lid

3 Hinge

4 Contacts for voltage and communication

5 Contacts for the local identity function

6 Voltage LEDs

7 Terminal strip (example)

ba76019e01 12/2012

Page 17

System 2020 XT USB Overview

Common characteristics

of the MIQ modules

Module lid with hinge

Due to its wide opening angle, the lid provides a large space for

working inside the module (e.g. for connecting lines to the terminal

strip).

Docking facility

MIQ modules can be mechanically docked onto one another. As a

result, several MIQ modules can be mounted in the form of a stack

to create a single unit (stack mounting). At the same time, docking

enables the MIQ modules to be electrically connected with one

another via the module contacts on the front and back so that no

cabling is required. Even when it is part of a stack, each MIQ module

can be opened. In addition, a terminal component can be docked

onto each free lid front.

Terminal strip

Further IQ S

ENSOR NET components can be connected by cable to

the terminal strip inside the housing (distributed mounting). The

terminal strip enables IQ sensors to be connected via the SACIQ

sensor connection cable or the IQ S

ENSOR NET can be further

branched and extended here. Certain MIQ modules have a terminal

strip with further specific connections (e.g. power connection, relay

contacts, current outputs).

Local identity function

The local identity function is integrated in each MIQ module in the

form of a memory chip. This memory chip can store information such

as the designation of the measurement location and a specific

selection of IQ sensors for the measured value display. This

information is output when a terminal is docked and, thus, e.g.

enables the rapid finding of local IQ sensors for calibration.

Voltage diagnosis via LEDs

Two LEDs, yellow and red, on the side of the housing are used to

monitor the operational voltage of each MIQ module.

ba76019e01 12/2012

1 - 11

Page 18

Overview System 2020 XT USB

C

M

S

ESC

OK

1

3

4

5

76

2

Back

Front

1.3 MIQ/TC 2020 XT terminal/controller

The MIQ/TC 2020 XT can be configured in the IQ SENSOR NET as a

controller (see section 1.3.1) or as a terminal (see section 1.3.2).

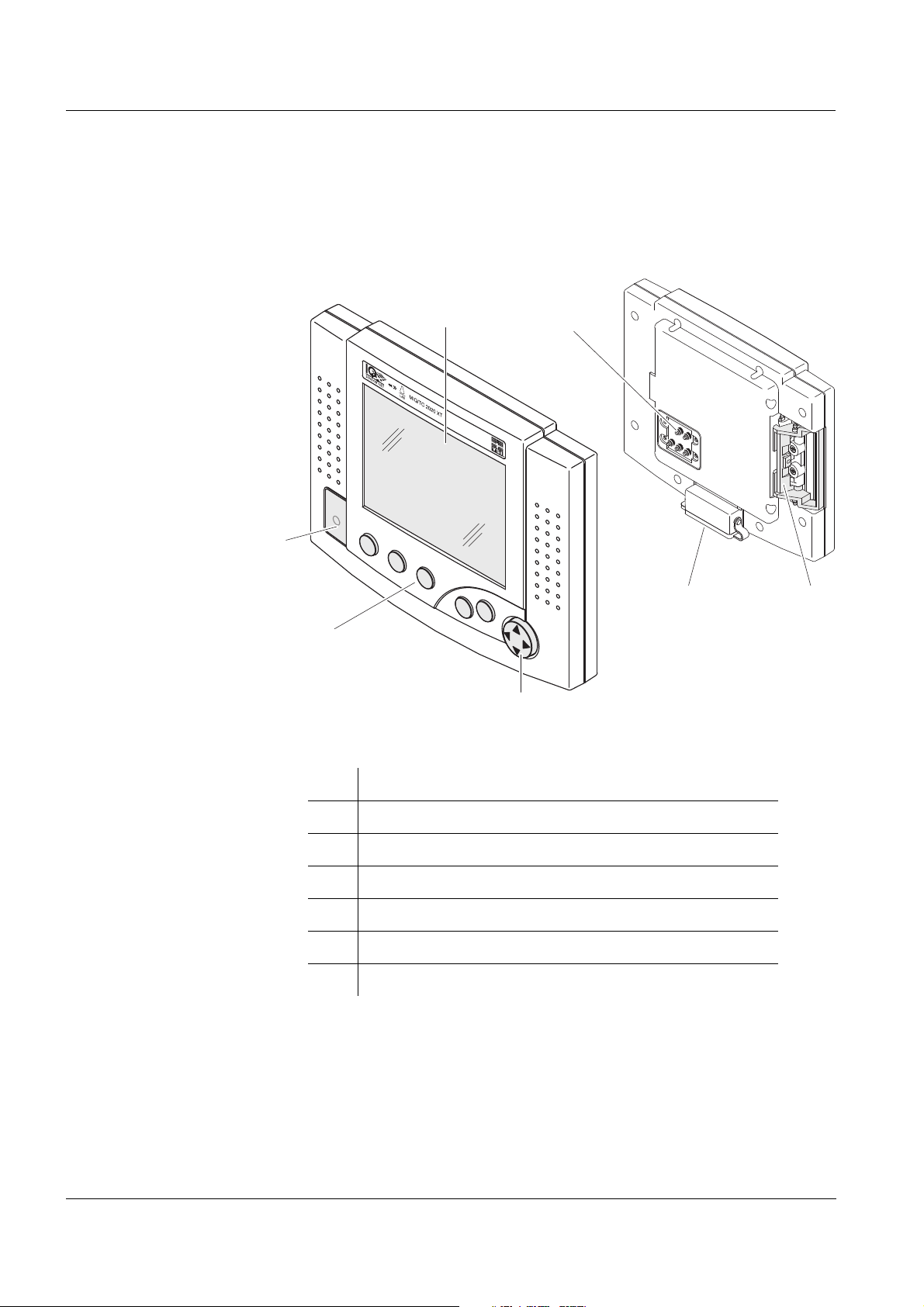

Fig. 1-5 MIQ/TC 2020 XT terminal/controller

1 Graphical display

2 Status LED

3 Keys

4 Arrow keys

5 Module contacts

6 USB-A interface with cover plate

7 Docking mechanism

1 - 12

ba76019e01 12/2012

Page 19

System 2020 XT USB Overview

M

C

S

OK

ESC

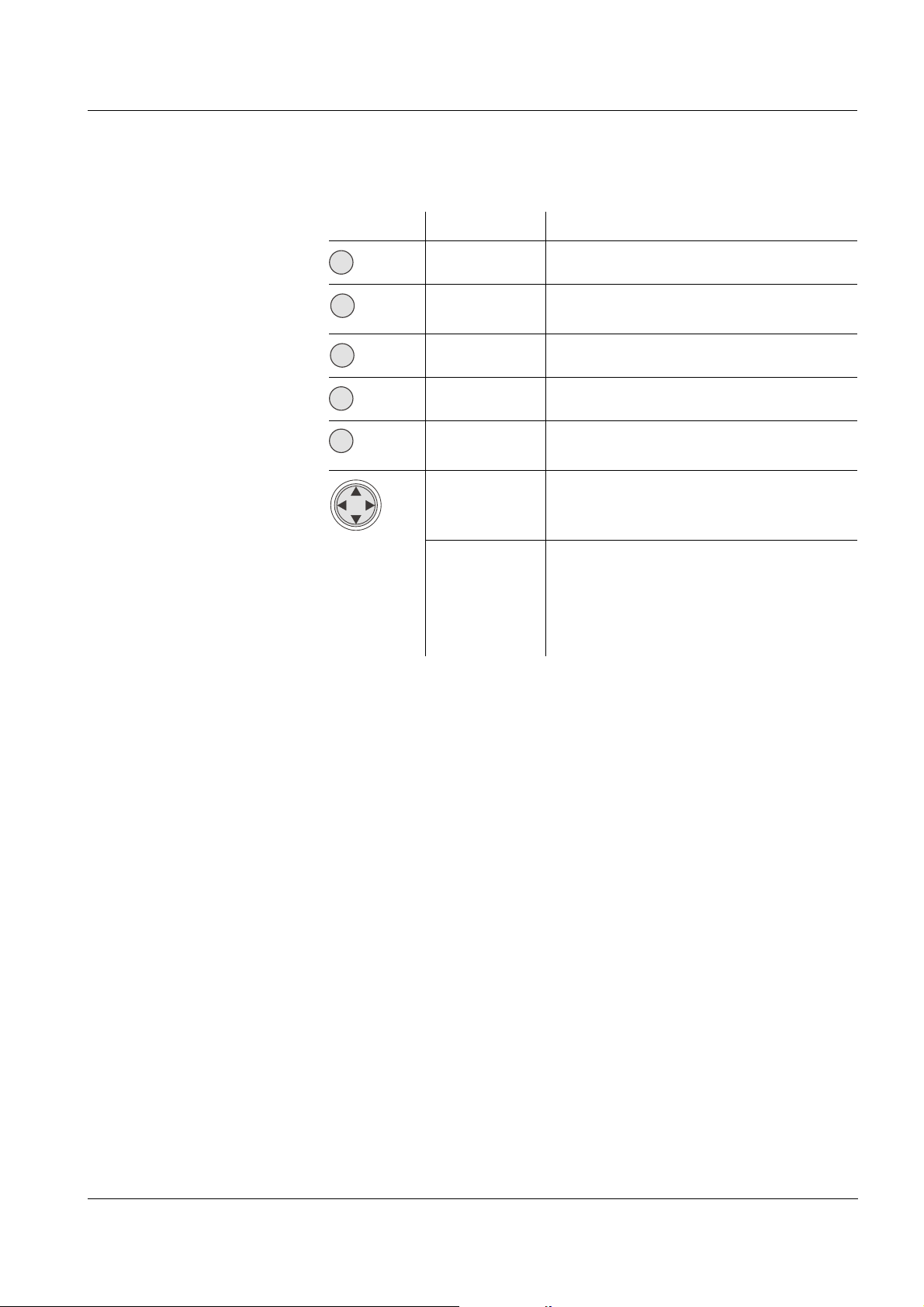

Keys The keys have the following functions:

Key Designation Functions

<M> – Switches the photometer on and off

<C> – Starts the calibration procedure for

the selected sensor

<S> – Opens the menu, System settings

<OK> – Opens the menu, Display/Options

<ESC> – Quits the current menu without

changing any settings

<▲> or

– Moves the selection in menus, lists

<▼>

and table columns by one position

upwards or downwards

(Arrow

keys)

<> or

– Moves the selection in tables by one

<>

position to the left or to the right

– Erases the character left of the

insertion point when entering

characters

1.3.1 Operation as terminal/controller

When configured as a controller, the MIQ/TC 2020 XT is a basic

component of the 2020 XT USB system and must therefore

permanently remain in the system.

The MIQ/TC 2020 XT is connected to the system by docking on the

free front cover of an MIQ module.

The controller function takes over the following tasks:

Control and monitoring of all IQ sensors

Control and monitoring of all current and relay outputs

Continuous diagnosis of the system, i.e. recording the information

and error messages of all modules and entering them in the system

log book (e.g.: voltage monitoring)

Recording measured data in the fixed interval

Communication with external digital interfaces such as

– USB memory device

– Modem

– PROFIBUS, Modbus, RS485

–PC

ba76019e01 12/2012

1 - 13

Page 20

Overview System 2020 XT USB

A terminal is required to display and set up the functions of the

controller. The following terminal components are suitable:

MIQ/TC 2020 XT configured as terminal/controller or as terminal

(compatible terminals, see section 1.4)

MIQ/T2020 PC

(with MIQ/IF232 interface module, PC, modem connection or

PROFIBUS environment).

The present component operating manual of the IQ S

ENSOR NET

System 2020 XT USB includes all functions of the MIQ/TC 2020 XT.

The connection to Profibus or Modbus is established with the

MIQ/(A-)PR and MIQ/(A-)MOD extension modules.

1.3.2 Operation as a terminal

The MIQ/TC 2020 XT configured as a terminal is an extension

component for the IQ S

ENSOR NET System. The MIQ/TC 2020 XT can

be used as a mobile control unit and docked on and removed from all

free front covers of MIQ modules. The docking is simply done by hand,

without using any tools.

The terminal function is the graphical user interface of the system. It

is used for the following purposes:

Display of measured values

Setting of IQ sensors, outputs, terminal characteristics, date, time,

etc.

Execution of maintenance and calibration work

Display of calibration data

1 - 14

Display of components lists (IQ sensors and outputs)

Display of the log book entries

If the MIQ/TC 2020 XT is registered in the system as a terminal, it is

mobile and can be removed at any time. If the main controller of the

system fails, the MIQ/TC 2020 XT automatically assumes the job of the

failed controller (see section 1.3.3).

ba76019e01 12/2012

Page 21

System 2020 XT USB Overview

1.3.3 Operation as backup controller

Automatic backup

function

If the MIQ/TC 2020 XT is configured as a terminal, it has a backup

controller that assumes the basic functions of the IQ S

ENSOR NET

controller in the case of its failure. Thus the operating safety of the

system is considerably increased. For these purposes the MIQ/

TC 2020 XT regularly and automatically saves the system

configuration during the normal terminal operation.

System configuration The system configuration incudes the following allocations and

settings:

Settings of sensors and diff. sensors

Settings of outputs and links

Edit list of sensors

Edit list of outputs

Measured value recording (datalogger settings)

List of all components including software versions but without

terminal information.

Application-related sensor calibration (e.g. matrix adjustment)

In the IQ S

ENSOR NET, the system configuration is stored in the

controller (MIQ/TC 2020 XT).

Functions of the MIQ/

TC 2020 XT

when operating as a

If the MIQ/TC 2020 XT operates as a backup controller, all basic

IQ S

ENSOR NET functions are carried out. Relay interfaces and current

interfaces, PROFIBUS, Modbus and RS485 work without restrictions.

backup controller

Restrictions of the MIQ/

TC 2020 XT

The following functions are not supported

:

Continuation of the data logger operation of the main controller

when operating as a

backup controller

Continuation of the modem communication of the main controller if

the modem is connected to the interface of the MIQ/TC 2020 XT

(configured as controller).

A redundant data logging function can be set up with the aid of the

MIQ/IF232 interface module.

Manual backup function In addition to the automatic backup of the system configuration you can

manually store the system configuration on a USB memory device at

any time. In the case of a system failure you can then transfer the

stored configuration from the USB memory device to another controller.

ba76019e01 12/2012

1 - 15

Page 22

Overview System 2020 XT USB

1.3.4 USB interface

The USB interface of the MIQ/TC 2020 XT provides the following

functions:

Connection of a USB memory device for data transmission (see

section 4.9)

– Measurement data

– Calibration data

– Configuration data

– Log book

Connection of a PC for data transmission or for control via the MIQ/

T2020 PC software terminal (see operating manual ba64108

"IQ S

ENSOR NET Softwarepack"). The various connection options

(direct connection, modem, network etc.) are described in the

operating manual ba75790 "Remote connection to the

IQ S

ENSOR NET 2020 XT USB".

Operation of the

MIQ/TC 2020 XT

in the open

Connection of an electronic key for simple system access with

enabled access control (see section 5.4.2)

Connection of a USB hub to multiply the USB interface

Note

The USB interface is equipped with a protective cover.

Only remove the protective cover if you want to connect a USB device.

Close the connection immeditaley after disconnecting the USB device.

If the USB connection remains open there is the risk of corrosion.

Do not leave any USB devices permanently connected to the USB

interface. There is the risk of corrosion.

1 - 16

ba76019e01 12/2012

Page 23

System 2020 XT USB Overview

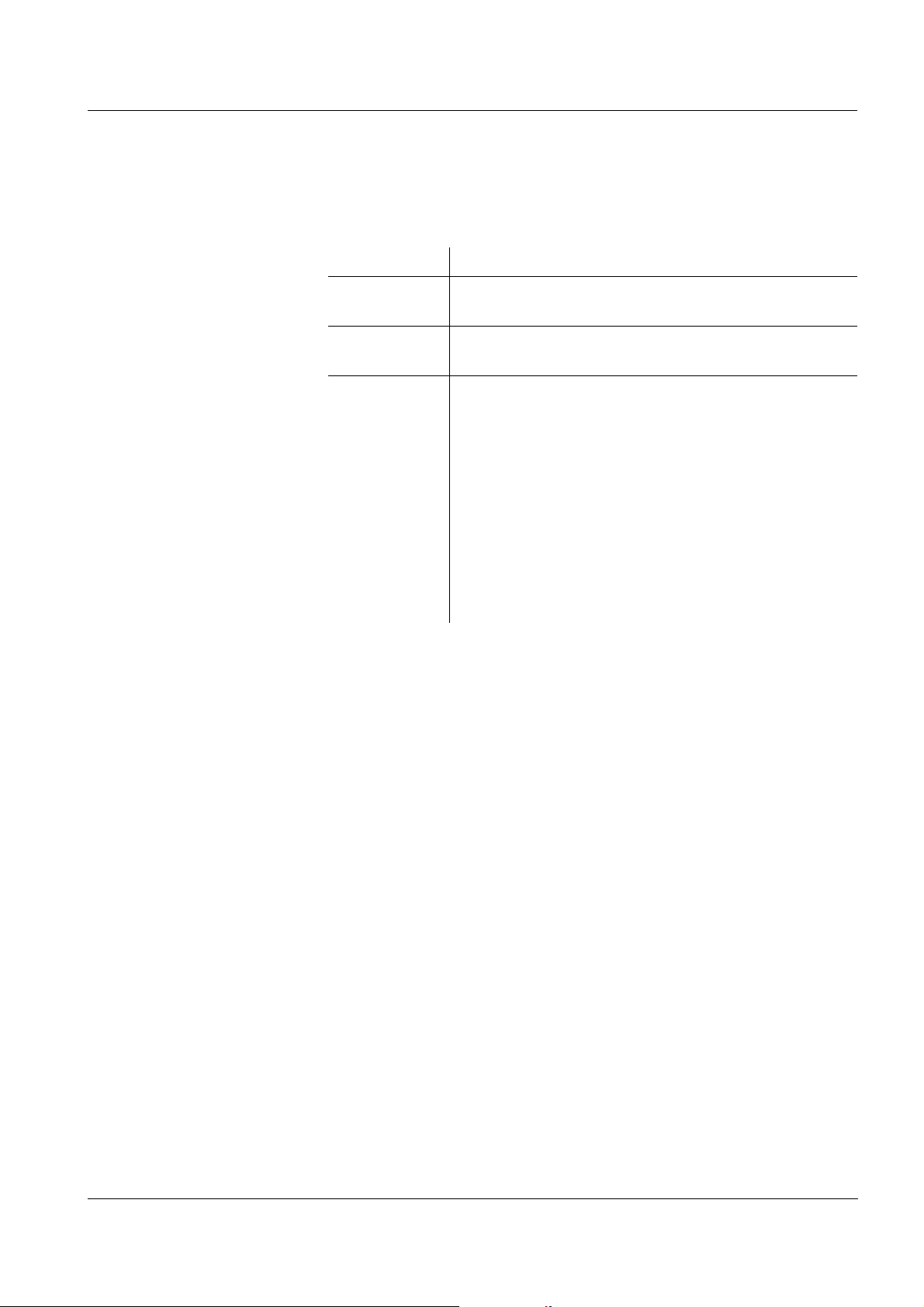

1.3.5 Status LED

The status LED informs you of the state of the system:

Status LED Meaning

Permanently on–The IQS

Permanently

– No power supply

off

Flashes – The IQ S

–The IQS

– A communication error in the IQ S

– An invalid measure value

– The backup controller has assumed controller

function

The LED flashes as long as the error is present

(even if the log book message of the error has

already been acknowledged). More detailed

information on the error is given in the log book.

ENSOR NET is running fault-free

ENSOR NET discovered an alarm.

ENSOR NET discovered an error, e.g.:

ENSOR NET

ba76019e01 12/2012

1 - 17

Page 24

Overview System 2020 XT USB

1.4 Behavior of the IQ SENSOR NET in case of error

1.4.1 Behavior of the IQ SENSOR NET in case of power failure

The system configuration (Settings of sensors and diff. sensors and

Settings of outputs and links) is stored permanently

All stored measured data remain permanently available

Linked current outputs and relay outputs switch to the non-active

condition.

Current output: 0 mA current

Relay output: Relays open

For details, refer to the component operating manual of the current

or relay output module.

When the power supply is available again, the system is

automatically restarted, starts working again and switches to the

measured value display

During the restart, an entry informing of the power failure is made in

the log book.

1.4.2 Behavior of the IQ S

ENSOR NET if a components fails

If the operating voltage is too low, the LEDs on the MIQ modules

extinguish.

The blue status LED of the MIQ/TC 2020 XT flashes

If active components (e.g. sensors or output modules) cannot be

contacted, an entry is made in the log book. The error symbol

flashes on the display.

The Edit list of sensors or Edit list of outputs display shows a

question mark "?" for the component.

Component Behavior

IQ sensor The configuration for the IQ sensor (Settings of

sensors and diff. sensors) remains stored.

Current measured values are not available.

The measured value display shows ERROR.

MIQ modules If an active module fails, an entry is made in the

log book. The error symbol flashes on the

display.

1 - 18

The configuration for these modules is retained

(e.g. links with output modules).

ba76019e01 12/2012

Page 25

System 2020 XT USB Overview

Component Behavior

Controller No current measured data can be displayed,

processed or stored.

If communication with the controller is disturbed,

output modules activate the error behavior after

2 minutes (see component operating manual of

the output module).

Terminal The measured value display is not updated.

The display does not react to entries.

The system continues working.

Stored measured data and the system

configuration remain stored in the MIQ/

TC 2020 XT.

Power supply

like power failure (see section 1.4.1)

module

1.4.3 Availability of the system

As a basic principle, the IQ S

ENSOR NET offers a very high availability.

This is achieved by

The two-wire connection technique that is not interference-prone

The digital signal transmission resulting from this

Tools for error diagnosis

– LEDs on the MIQ modules to check the available voltage

– Log book messages with instructions to eliminate problems

The possibility to simply assign substitute components for

components to be exchanged.

Replacing components is simple and can be performed very quickly

(see section 7.4). The system configuration (Settings of sensors and

diff. sensors and Settings of outputs and links) and the measured

data are stored in the controller and remain stored when other

components are used.

ba76019e01 12/2012

1 - 19

Page 26

Overview System 2020 XT USB

Preventive actions to

optimize the availability

of the system

If the requirements of the availability are especially high, you can

further improve the availability of the system as follows:

Install identical components in the system.

If the requirements of the availability are high, components can be

installed doubly in the system (exception: controller component).

Back up the controller function with the aid of a second MIQ/

TC 2020 XT configured as a terminal.

The MIQ/TC 2020 XT has a redundant controller function. It

maintains all essential functions of the system in the case of a

controller malfunction and saves all settings. The controller

operation starts automatically.

Keep substitute components ready.

The system automatically recognizes substitute components of

active components (IQ sensors and the output modules). They are

easily integrated in the system by assigning them as substitute

components.

Save the system configuration.

The system configuration (Settings of sensors and diff. sensors and

Settings of outputs and links) can be saved on a PC. Transmission

takes place via the USB interface (alternative options: see section

1.2.3). The stored system configuration can be loaded from the PC

on a substitute controller if necessary.

1 - 20

ba76019e01 12/2012

Page 27

System 2020 XT USB Safety instructions

2 Safety instructions

This operating manual contains essential instructions that must be

followed during the commissioning, operation and maintenance of the

ENSOR NET system. Thus, it is essential for the operator to read this

IQ S

component operating manual before carrying out any work with the

system.

Some components such as IQ sensors and special MIQ modules are

delivered with their own component operating manual. It is also

important to read the S

and all component operating manuals in the vicinity of the

ENSOR NET system if possible.

IQ S

AFETY chapter in this manual. Keep the system

General safety

instructions

Other labels

Safety instructions in this operating manual are indicated by the

warning symbol (triangle) in the left column. The signal word (e.g.

"Caution") indicates the danger level:

Warning

indicates instructions that must be followed precisely in order to

prevent serious dangers to personnel.

Caution

indicates instructions that must be followed precisely in order to

avoid slight injuries to personnel or damage to the instrument or

the environment.

Note

indicates notes that draw your attention to special features.

Note

indicates cross-references to other documents, e.g. component

operating manuals.

Target group The IQ SENSOR NET system was developed for online analysis. Some

ba76019e01 12/2012

2.1 User qualification

maintenance activities, e.g. changing the membrane caps in D.O.

sensors, require the safe handling of chemicals. Thus, we assume that

the maintenance personnel is familiar with the necessary precautions

to take when dealing with chemicals as a result of their professional

training and experience.

2 - 1

Page 28

Safety instructions System 2020 XT USB

Special user

qualifications

The following installation activities may only be performed by a

qualified electrician:

Connection of the MIQ/PS power supply module to the power line

(see MIQ/PS module manual).

Connection of external, line voltage-carrying circuits to relay

contacts (see module manual of the relay output module).

2.2 Authorized use

The authorized use of the IQ SENSOR NET system consists only of its

use in online analysis.

Please observe the technical specifications according to chapter 8

T

ECHNICAL DATA. Only operation and running according to the

instructions in this component operating manual is authorized.

Any other use is considered to be unauthorized. Unauthorized use

invalidates any claims with regard to the guarantee.

2.3 General safety instructions

All components of the System IQ SENSOR NET are constructed and

inspected in accordance with the relevant guidelines and norms for

electronic instruments (see chapter 8 T

They left the factory in a safe and secure technical condition.

ECHNICAL DATA).

Function and

operational safety

The failure-free function and operational safety of the IQ S

ENSOR NET

components are only guaranteed if the generally applicable safety

measures and the special safety instructions in this operating manual

are followed during their use.

The failure-free function and operational safety of the IQ S

ENSOR NET

components are only guaranteed under the environmental conditions

that are specified in chapter 8 T

If IQ S

ENSOR NET components are transported from a cold environment

ECHNICAL DATA.

into a warm environment, this can cause a functional malfunction

through the formation of condensation. In this case, wait for the

components to adjust to room temperature before recommissioning.

2 - 2

ba76019e01 12/2012

Page 29

System 2020 XT USB Safety instructions

Safe operation If safe operation is no longer possible, the IQ SENSOR NET must be

taken out of operation and secured against inadvertent operation.

Safe operation is no longer possible if components:

have been damaged in transport

have been stored under adverse conditions for a lengthy period of

time

are visibly damaged

no longer operate as described in this manual.

Obligations of the

operator

If you are in any doubt, contact the supplier of your IQ S

The operator of the IQ S

ENSOR NET system must ensure that the

ENSOR NET.

regulations and guidelines listed below are followed when dealing with

dangerous substances:

EEC guidelines relating to safety at work

National laws relating to safety at work

Safety regulations

Safety datasheets of the chemicals manufacturers.

Warning

A circuit (except for the line power supply), that is connected to an

ENSOR NET component, must not feed any voltages or

IQ S

currents that are not allowed. It has to be made sure that the

circuit at any time meets all requirements of a Limited circuit or

Limited Power as well as of SELV (Safety Extra Low Voltage).

These include the following limiting value specifications:

AC voltage: max. 30 V effective / 42.4 V peak

DC voltage: max. 60 V

Current limit: max. 8 A

Power output limitation: max. 150 VA

ba76019e01 12/2012

2 - 3

Page 30

Safety instructions System 2020 XT USB

2 - 4

ba76019e01 12/2012

Page 31

System 2020 XT USB Installation

3 Installation

3.1 Scopes of delivery

3.1.1 MIQ modules

The following parts are contained in the scope of delivery of an

MIQ module:

MIQ module

Accessory kit with:

– Contact carrier with screws

– ISO cap nuts with screws and ring washers

– Cable glands with sealing gaskets

Operating manual.

3.1.2 Terminal/Controller

The following parts are contained in the scope of delivery of the MIQ/

TC 2020 XT terminal/controller:

MIQ/TC 2020 XT

Screw to fix the terminal on the MIQ module

Operating manual.

3.2 Requirements of the measurement location

The respective measurement location of all IQ SENSOR NET

components must meet the environmental conditions specified in

section 8.1 G

ENERAL SYSTEM DATA.

ba76019e01 12/2012

3 - 1

Page 32

Installation System 2020 XT USB

- Sum of all line lengths max. 1000 m

- Of these, max. 500 m branch lines

altogether

- Single branch line max. 250 m

Total line lengths of > 1000 m

can be realized with the

signal amplifier module

MIQ/JBR

Total line lengths < 400 m

not have to be taken into account

do

More power required due to cable losses:

From 1 watt per

100 m additional line length.

400 m total line length

- Position power supply modules near

main consumers (e. g. UV/VIS sensor)

- Further power supply module or adjustment of infrastructure if necessary.

Power requirement = SP of all consumers

- Number and types of required sensors

- Measuring locations to be designed

- Number of required operating locations

- Distances

- Infrastructure, process environment etc.

Rough planning

Rough determination of power requirement

Consideration of cable losses

Rating

Fine adjustment

IQ topology + layoutS

ENSORNET

Power requirement of components

Total power requirement

Number of power supply modules

required

Fundamentals of planning

Start

End

SP of all power supply modules >

total power requirement

Arrangement of

power supply modules

3.3 System planning

Overview of the

planning steps

3 - 2

Fig. 3-1 System planning

ba76019e01 12/2012

Page 33

System 2020 XT USB Installation

3.4 Basic requirements for optimum installation

3.4.1 General information

The IQ S

ENSOR NET supplies all components with low voltage as well

as digital communication via a shielded 2-wire line.

Due to this characteristic, the following factors must be taken into

account in the planning of an IQ S

ENSOR NET system:

Power consumption of all components (power rating). Primarily, this

determines the number of power supply modules required (section

3.4.2).

Distance of the components from one another. Large distances may

require a further MIQ/PS power supply module and/or an MIQ/JBR

signal amplifier module (section 3.4.3).

Placement of the MIQ/PS power supply modules in the

IQ S

ENSOR NET (effect on the power supply - section 3.4.3).

Caution

Only IQ SENSOR NET products may be used in the IQ SENSOR NET.

3.4.2 Drawing up the power rating

Power rating - why? All components in the system require a specific level of electrical power

for operation. Thus, it is necessary to draw up a power rating after

selecting all the components. At the same time, this can determine

whether the entire power requirement of all components (consumers)

is covered by the existing MIQ power supply modules. If this is not the

case, the power available in the system must be increased by further

MIQ power supply modules.

ba76019e01 12/2012

Note

The power rating provides an initial guide value. In specific limiting

cases, the power supply may be insufficient despite the positive power

rating. Long cable lines, for example, result in additional power losses

that may have to be compensated by further MIQ power supply

modules. This can be checked for the planned installation by following

section 3.4.3.

The total power requirement P of all consumers can be determined

from the following table:

3 - 3

Page 34

Installation System 2020 XT USB

Power requirement of

ENSOR NET

IQ S

components

Component Power requirement [W]

IQ sensors

®

SensoLyt

TriOxmatic

TriOxmatic

TriOxmatic

FDO

TetraCon

VisoTurb

ViSolid

AmmoLyt

NitraLyt

VARiON

NitraVis

CarboVis

NiCaVis

700 IQ (SW) 0.2

®

700 IQ (SW) 0.2

®

701 IQ 0.2

®

702 IQ 0.2

®

70x IQ (SW) 0.7

®

700 IQ (SW) 0.2

®

700 IQ 1.5

®

700 IQ 1.5

® Plus

700 IQ 0.2

® Plus

700 IQ 0.2

® Plus

700 IQ 0.2

®

70x IQ (TS) 8.0

®

70x IQ (TS) 8.0

®

70x IQ 8.0

MIQ modules

MIQ/JB 0

MIQ/JBR 0

MIQ/CR3 3.0

MIQ/C6 3.0

MIQ/R6 1.5

MIQ/IC2 0.2

+ 2.2 W per connected

WG 20 A2 power supply/isolator

MIQ/CHV 2.0

MIQ/CHV PLUS 1.0

MIQ/Blue PS 0.6

MIQ/A 1.5

MIQ/(A)-PR 3.0

MIQ/(A)-MOD 3.0

Terminal, Controller

MIQ/TC 2020 XT 3.0

MIQ/IF232 (+ MIQ/T2020 PC) 0.2

3 - 4

ba76019e01 12/2012

Page 35

System 2020 XT USB Installation

Determining the number

of MIQ power supply

From the value determined for the power requirement, determine the

number of the MIQ power supply modules as follows:

modules

Total power requirement P Number of MIQ power supply

P

18 W

36 W

54 W

72 W

90 W

Sample configuration Power

requirement [W]

(component)

modules

≤ 18 W 1

< P ≤ 36 W 2

< P ≤ 54 W 3

< P ≤ 72 W 4

< P ≤ 90 W 5

< P ≤ 108 W 6

Total power

requirement P [W] (sum

of the components)

Number of

power supply

modules

required

1 MIQ/TC 2020 XT

3.0 3.0 1

(terminal/controller)

+ 1 MIQ/TC 2020 XT

+ 3.0 6.0 1

(terminal)

®

+ 1 NiCaVis

+ 1 VisoTurb

+ 1 SensoLyt

705 IQ + 8.0 14,0 1

®

700 IQ + 1.5 15,5 1

®

700 IQ + 0.2 15,7 1

+ 1 MIQ/CR3 + 3.0 18.7 2

+ 1 MIQ/CR3 + 3.0 21.7 2

+ 1 MIQ/TC 2020 XT

+ 3.0 24,7 2

(terminal)

Note

The determined number of power supply modules required in the

IQ S

ENSOR NET can increase if the cables are very long (see section

3.4.3).

Power supply with the

aid of the MIQ/Blue PS

radio module

ba76019e01 12/2012

The MIQ/Blue PS radio module can provide power for components with

a total of up to 7 W power consumption on an IQ S

ENSOR NET island.

The relevant details are given in the operating manual of the MIQ/

Blue PS.

3 - 5

Page 36

Installation System 2020 XT USB

A cable section is the longest continuous length of cable from an

MIQ power supply module to a consumer. Sensor connection

cables up to 15 m are not taken into account in this.

3.4.3 Effect of the cable length

Voltage drop due to

cable lengths

Guideline If the power supply modules are positioned in the vicinity of the main

The length of the cables in the IQ S

ENSOR NET affects

the operating voltage available for a component

the quality of data transmission.

Note

All information applies to SNCIQ cable material only. As regards the

copper wire diameter and dielectric, this cable is especially designed

for the combined energy and data transmission via great distances and

ensures the lightning protection characteristics stated in chapter 8

T

ECHNICAL DATA.

Very long cables in the IQ S

ENSOR NET cause voltage drops with

growing distance from the power supply module. If the voltage is under

the limit values, further IQ power supply modules must be used to

compensate.

consumers and the total cable length is no more than 400 m, no

additional cable losses have normally to be taken into account. Main

consumers are components with a power consumption of 5 W or more.

Note

When determining the number of power supply modules required, the

most unfavorable design has to be taken into account for mobile

components (Terminals). I. e., take into account

Determining the length

of the cable section

the maximum number of mobile components and

their greatest possible installation distance from the power supply

module.

A diagram is used to determine whether an additional MIQ power

supply module is necessary for the planned installation. To do so, the

length of the cable section must be determined.

3 - 6

ba76019e01 12/2012

Page 37

System 2020 XT USB Installation

L1

= 150 m

L4 = 200 m

L2 = 200 m L3 = 300 m

MIQ/PS

MIQ/24V

C

M

S

ESC

OK

MIQ/TC 2020 XT

<<

LAB

Example The following figure shows the length of the cable section L made up of

the partial lengths L1, L2 and L3 as the cable section L4 is shorter than

L3:

L = L1 + L2 + L3

Fig. 3-2 Example of determining the cable section

ba76019e01 12/2012

3 - 7

Page 38

Installation System 2020 XT USB

Checking the power

supply

1 Determine the length of the cable section for the planned

installation.

2 Determine the sum of the power consumption of all consumers

along the cable section (including IQ sensors).

3 Enter both determined values as a point in the following

diagram.

Note

To make it easier it is assumed that all consumers are located at the

end of the cable section.

3 - 8

Fig. 3-3 Diagram to check the power supply

4 Evaluation:

If the point is in the lower, valid range, no additional power

supply module is required.

If the point is in the upper, invalid range, an additional power

supply module is required. Install this power supply module in

the vicinity of the main consumers of this section, or, if not

possible, - starting from the primary MIQ power supply module

- approx. at that point of the section where the maximum cable

length is exceeded (see following example).

ba76019e01 12/2012

Page 39

System 2020 XT USB Installation

Example Problem:

Consumers with a total power requirement of 9 W are positioned on a

cable section of 650 m. Is the power supply with one power supply

module sufficient? At which point must a further power supply module

be installed if necessary?

Proceeding:

Enter both values as a point in the diagram (point "x" in Fig. 3-3).

Result: the point is in the invalid range. I. e. the power supply is not

sufficient.

Draw down a vertical line from the point until the line crosses the limit

between the upper and lower range. The intersecting point specifies

the maximum cable length for the existing power requirement (at

approx. 470 m). This is the place where the additional power supply

module is required.

If any main consumers are near the place, the power supply module

should be installed in their vicinity (ideally, directly on them).

Quality of data

transmission

Note

After commissioning, you can check the voltage directly on the

MIQ modules or on the terminal connections of the IQ sensors (see

section 7.2.2). The limits of the voltage levels are given in section

7.2.2 M

EASURING THE VOLTAGE of this operating manual.

If the sum of all line lengths (including the SACIQ sensor connection

cable) exceeds 1000 m, an MIQ/JBR signal amplifier module must be

installed in the system. More details of this are given in the MIQ/JBR

component operating manual.

ba76019e01 12/2012

3 - 9

Page 40

Installation System 2020 XT USB

3.4.4 Optimum installation of MIQ power supply modules

Basic rules Install the MIQ power supply modules as near as possible to the

ENSOR NET components with the highest power consumption.

IQ S

This also applies in the case of several MIQ power supply modules

in the system.

If possible, assemble the IQ S

ENSOR NET in a star configuration from

the MIQ power supply modules.

3.4.5 Installation guidelines for lightning protection

When using the IQ S

ENSOR NET measuring technique, particularly in

outdoor areas, adequate protection against (electrical) surges must be

provided. A surge is a summation phenomenon of surge voltage and

surge current. It is generated through the indirect effect of a lightning

event or switching operation in the mains, in the grounding system and

in information technology lines.

To be adequately protected against the damaging effects of surges, an

integrated concept of the following protective measures is required:

technical protective measures inside the instrument, and

exterior protective measures of the installation environment.

With YSI online measuring technique, the technical protective

measures inside the instrument are already integrated as the so-called

lightning protection (see chapter 8 T

ECHNICAL DATA).

The exterior protective measures of the installation environment can be

carried out observing the following guidelines:

1 All lines of IQ S

ENSOR NET systems must be

a) installed inside (or else close to) the grounded metallic mounting

constructions, e.g. handrails, pipes and posts if possible

b) or, particularly in the case of longer lines, laid in the ground.

Background: the small distance from the grounded metal

construction or the installation in the ground prevents the

development of induction loops between the cable and the ground

hazardous in the case of lightning strikes.

3 - 10

ba76019e01 12/2012

Page 41

System 2020 XT USB Installation

2 The SNCIQ or SNCIQ-UG cable material must be used exclusively.

This cable material, particularly the high line cross section of the

cable shielding (1.5 mm²), is an important prerequisite for the

hazard-free discharging of the surge without inadmissibly high

overvoltages developing along the line at the same time that could

have a damaging effect on the individual IQ S

ENSOR NET

components. We strongly recommend not to use any other cables,

which normally have a considerably lower shielding wire crosssection.

3 All metallic mounting constructions, handrails, pipes, posts etc. on

which MIQ modules are installed must be connected to the local

potential equalization system and the grounding system or must be

individually sufficiently grounded locally according to the codes of

practice.

For the individual grounding of the measuring point the mounting

construction must be solidly connected by means of a large-area

auxiliary electrode with the measuring medium.

Metallic control shafts/pipes and other large-area metallic bodies

that reach into the measuring medium are, for example, ideal for use

in the grounding of the mounting construction.

This creates a set path for the main surge. As a result it is possible

to avoid the surge being discharged via the IQ IQ S

ENSOR NET cable

and via the valuable sensors in the measuring medium.

4 The contacts of the MIQ modules always have to be protected with

the respective contact covers when they are not used by terminal

components. The contact covers improve the insulation against

electric fields of a thunderstorm by enlarging air gaps and creepage

distances.

5 We recommend to install a metal or nonmetal sun shield at each

open air location of MIQ modules. Sun shields protect the electric

field lines in the area of the MIQ module through an advantageous

development of the electrical field lines in the area of the MIQ

module and promote the dissipation of the surge via the mounting

construction.

6 The line voltage that supports the measuring system must

correspond to overvoltage category II. Normally this is ensured by

the public operators of the supply network systems. In companyowned networks, e.g. in all power supply systems owned by

wastewater treatment plants, this must be kept separate by a

potential equalization and asurge protection system for the plant.

ba76019e01 12/2012

3 - 11

Page 42

Installation System 2020 XT USB

7 The IQ SENSOR NET safety and lightning protection concept is partly

based on the high-quality protective insulation of the line power

supply units and the total system. It does not have or require any

protective ground (PG) conductor or earth terminal. Avoid any direct

connection of the IQ S

ENSOR NET connections or the metallic sensor

enclosures with the local grounding or potential equalization system

and with metallic construction elements (see point 9).

8 Additional external lightning protection measures directly on the

ENSOR NET system or its components, e.g. the use of

IQ S

overvoltage surge arresters, are not necessary for protection

against the indirect effects of lightning and could possibly result in

malfunctions.

9 For the realisation of the internal lightning protection of the system

(e.g. wastewater treatment plant control stands) and for the

protection of IQ S

into buildings or distributions coming from the IQ S

ENSOR NET external resources, cable entry points

ENSOR NET must

be carried out as follows:

– The shield of SNCIQ or SNCIQ-UG cables can be connected to

the local potential equalization with a gas overvoltage surge

arrester. Use shielding terminals for the contacting of the shield

(e.g. those of the PROFIBUS-System). The shield of the cable

must not be opened under any circumstances.

– 0/4-20 mA interfaces must be realized with shielded cables. The

cable shield must be connected directly to the potential

equalization(s) provided. If plant potential equalization systems

are provided on both sides, the shield must also be connected on

both sides. The inner conductors must have no contact with the

potential equalization.

– PROFIBUS cables and Modbus cables have to be installed

according to the prescriptions of the respective bus system.

– Relay lines should be connected to the local potential

equalization in order to provide general and consistent protection

via gas overvoltage surge arresters.

3 - 12

ba76019e01 12/2012

Page 43

System 2020 XT USB Installation

3.5 Connecting system components

3.5.1 General information

The IQ S

ENSOR NET system components are connected to form a

functioning unit in the following ways:

Stacked mounting of MIQ modules

Up to three MIQ modules can be installed and mechanically

connected with one another to form a stack at a single location. The

contacts on the front and rear automatically create the electrical

connection between the MIQ modules in the stack (section 3.5.2).

Distributed mounting of MIQ modules

Individual MIQ modules or an assembled module stack are installed

at various locations (for example, a central control unit and an

MIQ branching module for connecting IQ sensors at the edge of the

basin). The spatial distance is bridged with the aid of the SNCIQ or

SNCIQ/UG cable (section 3.5.3).

Connection of IQ sensors:

IQ sensors are connected to an MIQ module with the aid of the

SACIQ cable. This cable is available in different lengths. The

MIQ module must have a free SENSORNET connection on the

terminal strip. On the sensor side, the connection is made via a plug

that is standard for all IQ sensors (section 3.5.4).

Docking of a terminal unit:

A terminal unit is attached to the lid of a free MIQ module with the

aid of a quick-release locking mechanism (section 3.5.5).

Caution

Distributed mounting is only allowed in a star configuration. The

system must nowhere be closed to form a ring. Only use the

assembly material provided for the installation.

ba76019e01 12/2012

3 - 13

Page 44

Installation System 2020 XT USB

3.5.2 Stacked mounting of MIQ modules:

Caution

For optimum stability, a maximum of three MIQ modules can be

mounted in any one stack. Only one MIQ power supply module