Page 1

OPERATING MANUAL

TruLine ORP 51

MODE

INSTRUCCIONES DE

T

D’EMPLOI

OPERACIÓN

814246 04/2014

TruLine

Page 2

TruLine

Operating

Technical data ............................................................................................................................. 5

Commissioning, measuring, testing ............................................................................................. 6

Storage ........................................................................................................................................ 8

Aging ........................................................................................................................................... 8

Activating platinum electrodes ..................................................................................................... 9

W ear parts and accessories ...................................................................................................... 10

Mode d'emploi ...................................................................................................................... 13

Caractéristiques techniques ....................................................................................................... 15

Mise en service, mesure, verification ......................................................................................... 16

Stockage ................................................................................................................................... 18

Vieillissement ............................................................................................................................ 18

Activation d'électrodes de platine ............................................................................... 19

Pièces d'usure et accessoires .................................................................................................... 20

Instrucciones de

Especificaciones técnicas .......................................................................................................... 25

Puesta en funcionamiento, medición, verificación ..................................................................... 26

Almacenamiento ........................................................................................................................ 28

Envejecimiento .......................................................................................................................... 28

Activar electrodos de platino ...................................................................................................... 29

Piezas de desgaste y accesorios ............................................................................................... 30

Contact Information......................................................................................... 31

Manual ............................................................................................................................

operación .........................................................................................................

3

23

Page 3

OPERATING MANUAL

TruLine ORP 51

T

814246 04/2014

TruLine

ORP ELECTRODE

Page 4

TruLine

For the most recent version of the manual, please visit www.ysi.com.

Contact YSI

1725 Brannum Lane

Yellow Springs, OH 45387 USA

Tel: +1 937-767-7241

800-765-4974

Email: environmental@ysi.com

Internet: www.ysi.com

Copyright © 2014 Xylem Inc.

Page 5

TruLine

Technical

data

5

T 814246

04/2014

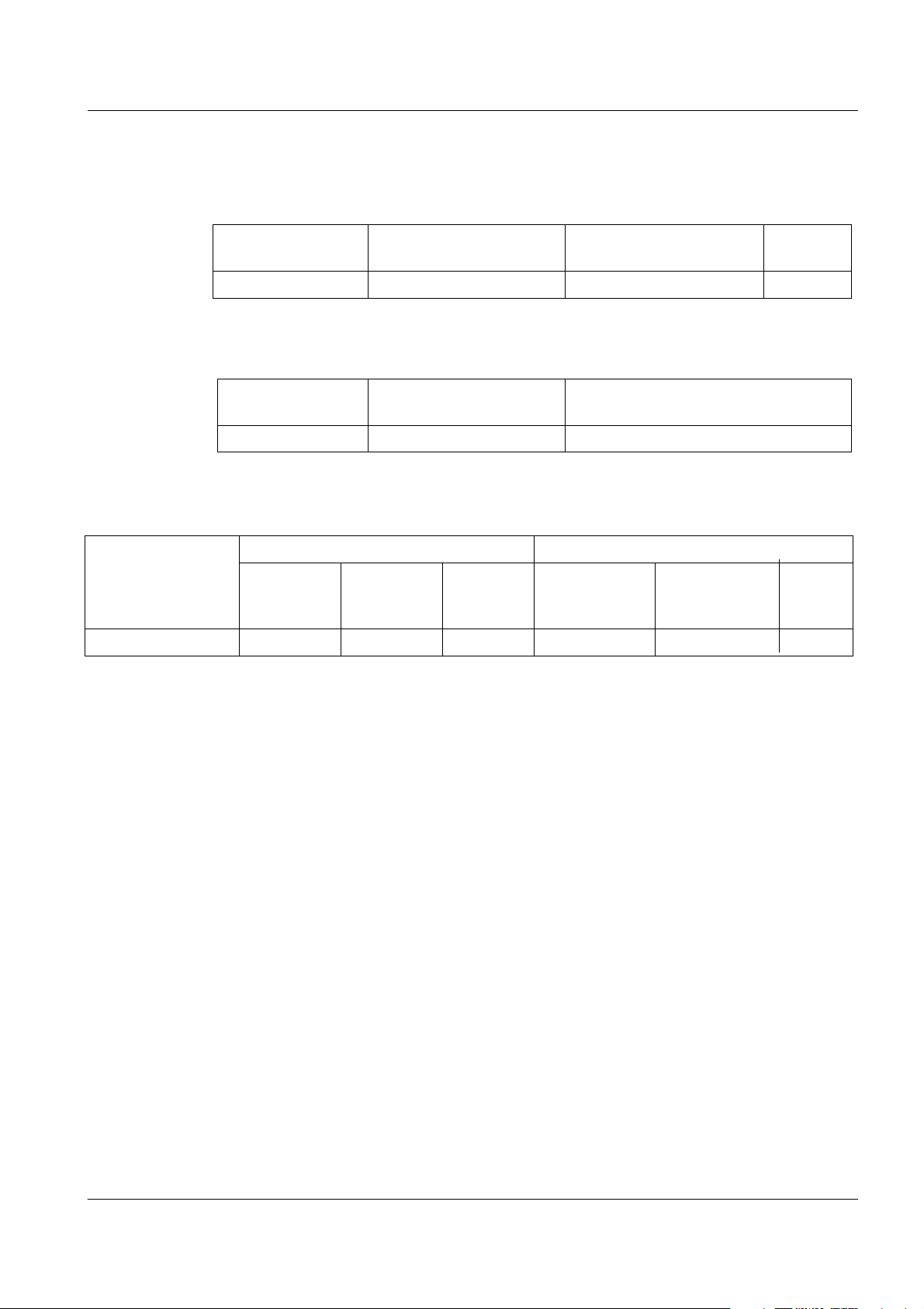

Model

Reference electrolyte

Electrode material and

Junction

TruLine ORP 51

Gel

Platinum pin 1 mm

Fiber

Model

Allow ed

Typical application

TruLine ORP 51

-5 ... 80 °C

Field

Model

Shaft Electrical connection

Length

Ø [mm]

Material

Combination

Cabel

Cable

TruLine ORP 51

120

12 Plastic

Plug head

LB1BNC

1 m

Technical

General data

data

shape

Measurement and application characteristics

temperature range

Shaft dimensions, shaft material, electrical connection

[mm]

electrode

connection

length

Page 6

Commissioning, measuring,

testing

TruLine

6

T 814246

04/2014

Commissioning, measuring,

testing

Note

For ORP electrodes with platinum electrode, please observe the instructions

in section A

Commissioning Prepare the combination electrode for measuring as follows:

CTIVATING PLATINUM ELECTRODES.

Remove the watering cap from the electrode tip. Possible salt deposits in

the area of the watering cap do not affect the measuring characteristics

and can easily be removed with deionized water.

Note

Please keep the watering cap. It is required for storing the combination

electrode. Always keep the watering cap clean.

Connect the combination electrode to the meter.

Measure with the combination electrode according to the operating man-

ual of the meter and observe the following rules while doing so:

General rules for

measuring

TruLine ORP 51: Make sure the refilling opening for the reference electro-

lyte solution is open.

Avoid displacement of the sample solution from one measurement to the

next by taking the following measures:

– Briefly rinse the calibration beakers with the solution the beakers are to

be f illed with next.

– Between measurements, rinse the combination electrode with the so-

lution specified below. Alternatively, you can also rinse the combination

electrode with deionized water and then carefully dab it dry.

Immerse the combination electrode in the solution in a vertical or slightly

tilted position.

Make sure the immersion depth is correct. The junction must be complete-

ly submersed in the solution. The junction is in the area of the bottom end of

the shaft (see arrow).

The level of the reference

electrolyte

must be at least 2 cm above the level of

the solution.

Page 7

7

T 814246

04/2014

TruLine

Commissioning, measuring,

testing

T (°C)

U

[mV]

T (°C)

U

[mV]

0 +221

35

+187

5 +216

40

+181

10

+212

45

+176

15

+207

50

+171

20

+202

55

+165

25

+197

60

+160

30

+192

Conversion to the

standard hydrogen

electrode potential

= U

U

H

Meas

where: U

H

U

Meas

+ U

Ref

= ORP voltage, relative to the

standard hydrogen electrode

= measured ORP voltage

U

= voltage of the reference system relative to the

Ref

standard hydrogen electrode

U

is temperature dependent and can be taken from the following table

Ref

(also refer to DIN 38404-6):

Ref

TruLine ORP 51

Ref

TruLine ORP 51

Page 8

8

T 814246

04/2014

Storage, Aging

TruLine

Combination

Reference electrolyte

YSI Model

TruLine ORP 51

KCl-250 (250 ml)

During short

measuring breaks

Overnight

longer

or

Storage

Immerse the electrode in the reference electrolyte.

electrode

(see page 11)

3 mol/l KCl, Ag+-free

Prior to the next measurement, briefly rinse the combination electrode with

the test sample or deionized water.

Insert the clean electrode into the watering cap filled with reference

electrolyte.

Note

During longer storage periods, salt deposits may develop on the watering

cap. They do not affect the measuring characteristics and can easily be removed with deionized water when the combination electrode is put into operation again.

Aging

Every ORP combination electrode undergoes a natural aging process. Extreme operating conditions can considerably shorten the lif etime of the combination electrode. These are:

Strong acids or lyes, hydrof luoric acid, organic solvents, oils, fats, bro-

mides, sulf ides, iodides, proteins

High temperatures

Great changes in pH and temperature.

The warranty does not cover failure caused by measuring conditions and

mechanical damage.

Page 9

9

T 814246

04/2014

TruLine

Activating platinum

electrodes

Contamination

Cleaning procedure

Fat and oil

Rinse with water containing household wash-

Lime and hydroxide deposits

Rinse with citric acid (10 % by weight)

CleaningIL Remove water-soluble contamination by rinsing with deionized water. Re-

move other contamination as follows:

ing-up liquid

After cleaning Rinse the combination electrode with deionized water.

First-time

activation

during

installation and

required

as

Activating platinum

electrodes

For the first-time activation use the activation powder from the SORT/RH

reagent set (component of the SORT/RH reagent set). Immerse the moist

(but not dripping) platinum electrode into the activation powder and rotate the

electrode several times in the powder. Then remove the activation powder

under flowing water with a soft brush (e.g. toothbrush).

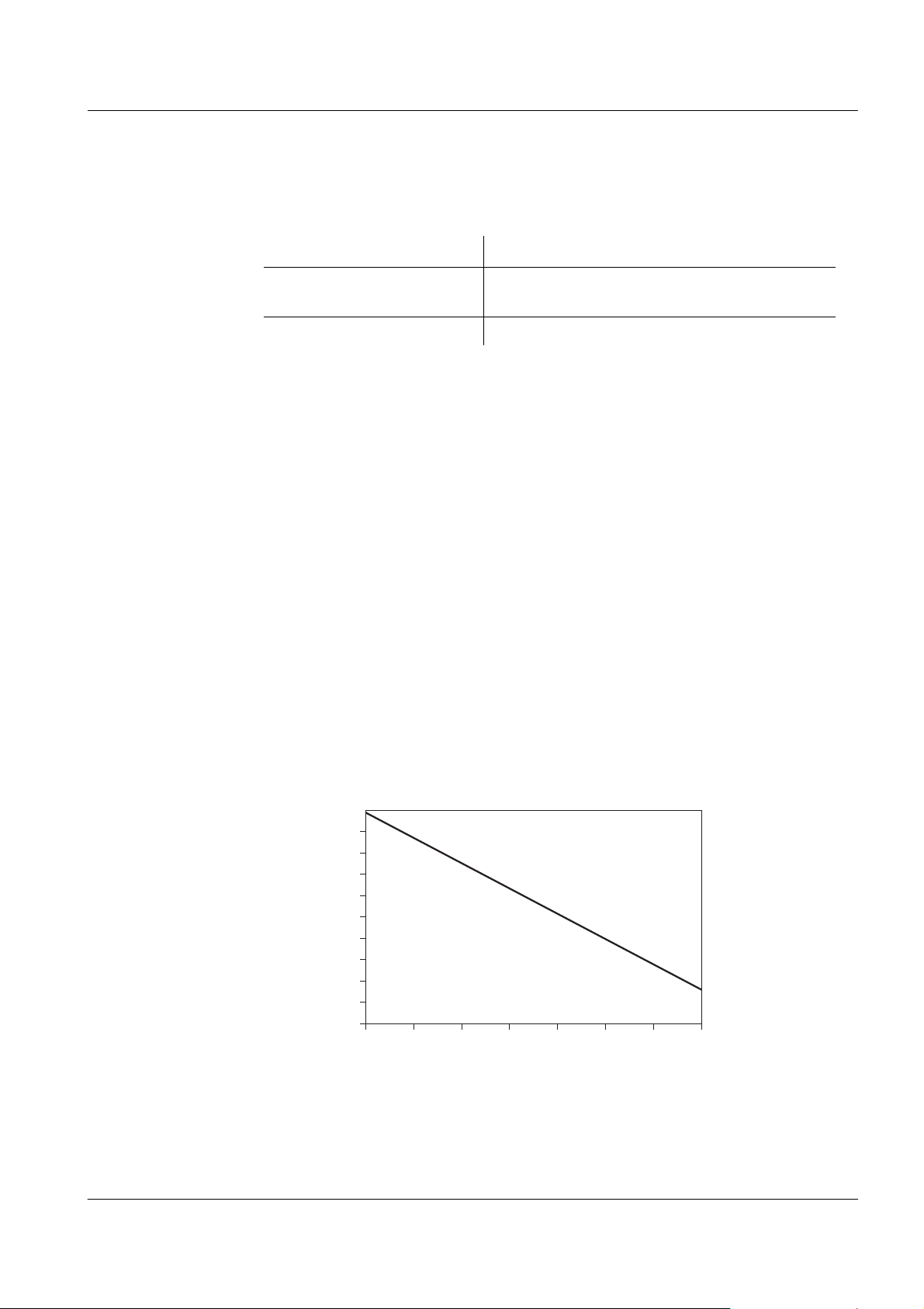

Activation during

very long

set-up times

W hen changing from oxidizing to reducing test solutions and vice versa this

can result in set-up times that can take significantly more than an hour. In this

case pretreatment (activation) of the platinum surface can shorten the set-up

time. The type of pretreatment (reducing or oxidizing) is based on the pH value and the ORP voltage (U

timated for the f irst measurement.

) of the test solution where the latter must be es-

H

The type of pretreatment can then be determined using the following diagram

where U

U

H

is based on the normal hydrogen electrode:

H

1000

in mV

800

600

400

200

reducing

pretreatment

oxidizing pretreatm

0

2

4

6

8

0

10 12

ent

pH

14

value

Page 10

10

T 814246

04/2014

Wear parts

and accessories

TruLine

Description

Model

Order no.

Storage electrolyte solution 3 mol/l KCl,

A

KCl-250

109 705Y

Reagent set for regenerating ORP platinum

e

p

SORT/RH

109 730Y

Zobell ORP buffer solution (125 ml)

3682

061320

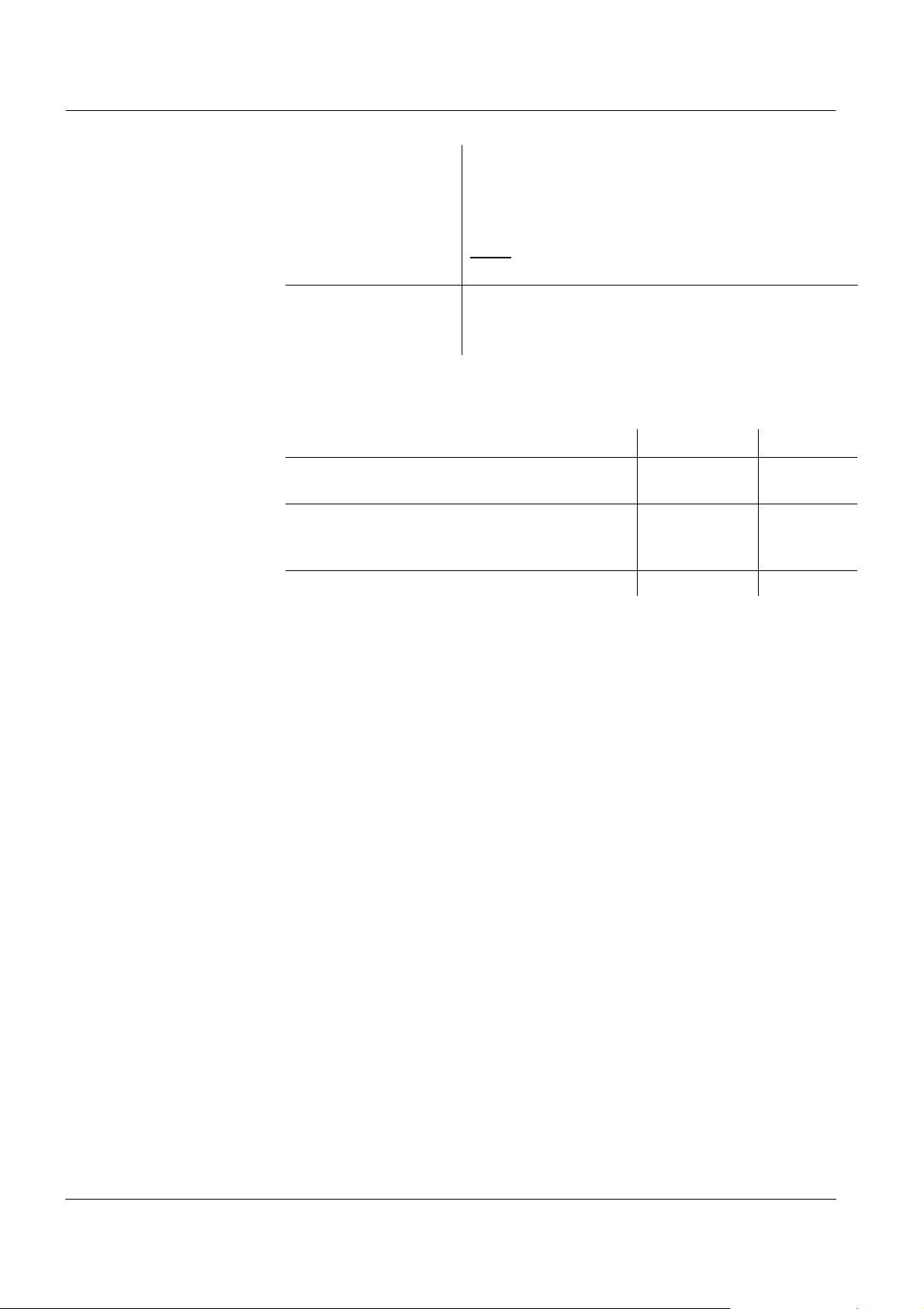

Oxidizing

pretreatment

Reducing

pretreatment

Immerse the platinum electrode for two to three

days in a sulfuric acid chlorine solution. Chlorine

powder f or producing the solution is included in the

SORT/RH reagent set.

Note: The diaphragm must not be immersed in the

chlorine solution!

W hen the electrode is ready f or the test immerse it

in the Zobell ORP buffer solution and wait f or a stable measured value.

Wear parts

and accessories

g+-free (250 ml)

lectrodes, consisting of 10 g activation

owder and 30 g chlorine powder

Page 11

Notes TruLine

Page 12

Notes TruLine

Page 13

TruLine ORP 51

MODE

T

D'EMPLOI

814246 04/2014

TruLine

CHAÎNE DE

MESURE

REDOX

Page 14

Coordonnées YSI

Copyright © 2014 Xylem Inc.

TruLine

La version actuelle du mode d'emploi est disponible sur Internet à l'adresse www.ysi.com.

1725 Brannum Lane

Yellow Springs, OH 45387 USA

Tel: +1 937-767-7241

800-765-4974

Email: environmental@ysi.com

Internet: www.ysi.com

Page 15

TruLine

Caractéristiques

techniques

15

T 814246

04/2014

Modèle

Electrolyte de réfé-

Matière et forme

Dia-

TruLine ORP 51

Gel

Platine / ronde

Fibre

Modèle

Gamme de tempéra-

Application typique

TruLine ORP 51

-5 ... 80 °C

Terrain

Modèle

Corps

Raccordement électrique

Longueur

Ø

Matériau

Raccordement

Raccorde-

Longueur

TruLine ORP 51

120

12

Plastique

Tête enfichable

LB1BNC

1 m

Caractéristiques

Caractéristiques générales

techniques

rence

d'électrode

phragme

Propriétés de mesure et caractéristiques d'utilisation

ture admissible

Dimensions du corps, matériau utilisé pour le corps,

raccordement électrique

[mm]

[mm]

chaîne de mesure

ment appareil

de câble

Page 16

Mise

en

service, mesure,

vérification

TruLine

16

T 814246

04/2014

Mise en

service, mesure,

vérification

Remarque

Pour les chaînes de mesure du potentiel Redox à électrode de platine,

veuillez respecter les instructions du paragraphe A

DE PLATINE

Mise en service Avant la mesure, préparer la chaîne de mesure comme suit:

.

TruLine ORP 51: Ouvrir l'orifice de remplissage pour la solution d'électro-

lyte de reference

Règles

générales

fonctionnement

pour

le

de

mesure

L'orifice de remplissage doit être toujours ouvert pendant la mesure!

Retirer le capuchon de lavage de la pointe de l'électrode. Les éventuels

dépôts salins dans la zone du capuchon de lavage n'ont pas d'influence

sur les propriétés de mesure et il suff it de les éliminer avec de l'eau désionisée.

Remarque

Conserver le capuchon de lavage avec soin. Il sera nécessaire pour le

stockage de la chaîne de mesure. Toujours veiller à la propreté du capuchon

de lavage.

Raccorder la chaîne de mesure à l'appareil de mesure.

Mesurer avec la chaîne de mesure conformément au mode d'emploi de

l'appareil de mesure et en veillant au respect des règles suivantes:

TruLine ORP 51: Veiller à ce que l'orifice de remplissage pour la solution

d'électrolyte de référence soit ouvert.

Eviter le transfert de solution de mesure d'une mesure à l'autre en prenant

les précautions suivantes:

– Rincer rapidement les récipients à échantillon avec la solution avec la-

quelle le récipient sera ensuite rempli.

CTIVATION D'ÉLECTRODES

– Entre les différentes mesures, rincer la chaîne de mesure avec la solu-

tion suivante. Alternativement, il est également possible de rincer la

chaîne de mesure à l'eau désionisée et de l'essuyer ensuite avec précaution, en tamponnant et sans frotter.

Plonger la chaîne de mesure dans la solution à la verticale ou légèrement

incline.

Respecter la profondeur d'immersion correcte. Le diaphragme doit être

entièrement immergé dans la solution. Le diaphragme se trouve dans la

zone de l'extrémité inférieure du corps (voir flèche):

Page 17

17

T 814246

04/2014

TruLine

Mise

en

service, mesure,

vérification

T (°C)

U

[mV]

T (°C)

U

[mV]

TruLine ORP 51

0 +221

35

+187

5 +216

40

+181

10

+212

45

+176

15

+207

50

+171

20

+202

55

+165

25

+197

60

+160

30

+192

électrode

Conversion

normale

à

hydrogène

sur

Le niveau de l' électrolyte de référence doit se trouver à 2 cm au-dessus

du niveau de la solution.

UH = U

mes

+ U

réf

avec : U

U

= Potentiel Redox, en référence à l'électrode normale à hy-

H

drogène

= Potentiel Redox mesuré

mes

U

= Potentiel du système de référence par rapport à l'électrode

réf

normale à hydrogène

U

est dépendant de la température et peut être relevé dans le tableau

réf

suivant (voir également DIN 38404-6):

réf

TruLine ORP 51

réf

Page 18

18

T 814246

04/2014

Stockage,

Vieillissement

TruLine

Chaîne de mesure

Electrolyte de référence

Modèle

TruLine ORP 51

+

KCl-250 (250 ml)

Pour de courtes

pauses de mesure

Pour la nuit

ou

plus

Stockage

Plonger la chaîne de mesure dans de l'électrolyte de référence.

(voir page 21)

3 mol/l KCl, sans Ag

Avant la mesure suivante, rincer rapidement la chaîne de mesure avec la

solution de mesure ou avec de l'eau désionisée.

Insérer la chaîne de mesure propre dans le capuchon de lavage rempli

d'électrolyte de référence.

Remarque

Lors de durées de stockage relativement

longues,

des dépôts de sel peuvent

se former sur le capuchon de lavage. Ceux-ci n'ont pas d'influence sur les

propriétés de mesure et peuvent être éliminés simplement avec de l'eau désionisée lors de la remise en service.

Vieillissement

Toute chaîne de mesure du potentiel Redox est soumise à un vieillissement

naturel. La durée de vie peut être considérablement raccourcie par des

conditions d'utilisation extrêmes, parmi lesquelles figurent:

les acides et bases forts, l'acide fluorhydrique, les solvants organiques,

huiles, graisses, bromures, sulf ures, iodures et albumens

les températures élevées

les fortes variations de pH et de températures.

Les défaillances ou dommages mécaniques causés par de telles conditions

ne sont pas couverts par la garantie.

Page 19

19

T 814246

04/2014

TruLine

Activation d'électrodes

de platine

Type de salissure

Méthode de nettoyage

Graisse et huile

Rincer avec de l'eau additionnée de produit à

Dépôts de calcaire et d'hy-

Rincer avec de l'acide citrique (10 % en

Nettoyage Eliminer les salissures solubles dans l'eau par rinçage à l'eau désionisée.

Pour les autres types de souillures, procéder ainsi:

vaisselle

droxide

poids)

Après le nettoyage Rincer la chaîne de mesure à l'eau désionisée.

activation

mise en service

en cas de

Première

pour

et

besoin

Activation d'électrodes

de platine

Pour la première activation, utiliser la poudre d'activation

de réactif s SORT/RH (composant du kit de réactifs SORT/RH). Immerger

l'électrode de platine humide (mais ne dégouttant pas) dans la poudre

d'activation et tourner la chaîne de mesure plusieurs fois dedans. Ensuite,

enlever la poudre d'activation sous l'eau courante au moyen d'une brosse

douce (p. ex. brosse à dents).

Activation

temps de

réglage

très

pour

longs

En cas de changement de solutions de mesure oxydantes à réductrices et

inversement, les temps de réglages peuvent s'élever à nettement plus d'une

heure. Dans ce cas, un traitement préalable (activation) de la surface de platine peut réduire le temps de réglage. Le type de traitement préalable (réducteur ou oxydant) dépend de la valeur de pH et du potentiel Redox U

solution de mesure, ce dernier devant être estimé pour la première mesure.

Le type de traitement préalable peut être déterminé au moyen du diagramme

suivant, U

U

en m V

H

faisant référence à l'électrode normale à hydrogène:

H

1000

traitem ent préalable ox

800

600

400

200

traitem ent préalable

réducteur

comprise

ydant

dans le kit

de la

H

0

0

2

4

6

8

10 12

valeur de

14

pH

Page 20

20

T 814246

04/2014

Pièces d'usure

et accessoires

TruLine

Description

Modèle

Référence

Solution d'électrolyte de réf érence 3 mol/l KCl,

sans

KCl-250

109 705Y

Kit de réactifs pour la régénération des élect

des

o

d

109 730Y

Zobell solution tampon Redox (125 ml)

3682

061320

Traitement préalable

oxydant

Traitement préalable

réducteur

Plonger l'électrode de platine pendant deux ou trois

jours dans une solution de Chlorina à l'acide sulfurique. La poudre de Chlorina permettant de préparer la solution est contenue dans le kit de réactifs

SORT/RH.

Remarque: Le diaphragme ne doit pas être immergé dans la solution de Chlorina!

Immerger la chaîne de mesure opérationnelle dans

la solution tampon Zobell et attendre une va- leur

mesurée stable.

Pièces d'usure

et accessoires

Ag+ (250 ml)

de platine Redox comprenant 10 g de p

re d'activation et 30 g de poudre Chlorina

Page 21

Notes TruLine

Page 22

Notes TruLine

Page 23

TruLine ORP 51

INSTRUCCIONES DE

T

OPERACIÓN

814246 04/2014

TruLine

SONDA DE

MEDICIÓN

REDOX

Page 24

TruLine

La versión actual de las instrucciones de operación lo encuentra Ud.

en el internet www.ysi.com.

Contacto YSI

1725 Brannum Lane

Yellow Springs, OH 45387 USA

Tel: +1 937-767-7241

800-765-4974

Email: environmental@ysi.com

Internet: www.ysi.com

Copyright © 2014 Xylem Inc.

Page 25

TruLine

Especificaciones

técnicas

25

T 814246

04/2014

Modelo

Electrolito de refe-

Material y forma del

Dia-

TruLine ORP 51

Gel

Platino / plano circular

Fibra

Modelo

Rango de temperatura

Aplicación típica

TruLine ORP 51

-5 ... 80 °C

Campo

Modelo

Vástago

Conexión eléctrica

Longi-

Ø

Material

Conexión de la

Conexión del

Longitud

TruLine ORP 51

120

12

PPE/PS

Enchufe cabezal

LB1BNC

1 m

Especificaciones

Datos generales

técnicas

rencia

electrodo

fragma

Características de medición y aplicaciones

admisible

Dimensiones y material del vástago, conexión eléctrica

tud [mm]

[mm]

sonda de medición

instrumento

cable

Page 26

Puesta

en

funcionamiento, medición,

verificación

TruLine

26

T 814246

04/2014

Puesta en

funcionamiento

Reglas generales

seguir durante

mediciones

a

las

Puesta

en

funcionamiento,

medición,

verificación

Observación

En el caso de las sondas de medición Redox con electrodo de platino, tenga

presente por favor las observaciones en el párrafo A

PLATINO

Prepare la sonda de la siguiente manera para comenzar con la medición:

.

TruLine ORP 51: Abra el agujero de llenado para la solución electrolítica

de referencia. Dependiendo del tipo de sonda, el cierre del agujero de llenado puede ser un tapón elastómero o bien, una corredera.

¡El agujero de llenado tiene que estar siempre abierto durante la medición!

Quite la cubierta de remoje de la punta del electrodo. Eventuales incrus-

taciones de sal en la zona de la cubierta de remoje no influyen las características de medición y pueden ser eliminadas fácilmente con agua

desionizada.

Observación

Guarde la cubierta de remoje. Es necesaria para el almacenamiento de la

sonda de medición. Mantenga siempre limpia la cubierta de remoje.

Conecte la sonda de medición al instrumento de medición

Lleve a cabo las mediciones con la sonda de medición siguiendo las ins-

trucciones del manual del instrumento y teniendo en cuenta las siguientes

reglas:

TruLine ORP 51: Preste atención que el agujero de llenado de la solución

electrolítica de referencia esté abierto.

Evite la contaminación de las soluciones de medición de una medición a

la otra tomando las siguiente medidas preventivas:

– Enjuague brevemente los envases de las muestras con la solución que

pretende llenar a continuación.

CTIVAR ELECTRODOS DE

– Enjuague la sonda entre cada medición con la solución que va a usar

en el siguiente paso. Como alternativa puede enjuagar la sonda de medición con agua desionizada, secándola a continuación con cuidado.

Sumerja la sonda de medición verticalmente en la solución, o bien,

ligeramente inclinada.

Page 27

27

T 814246

04/2014

TruLine

Puesta

en

funcionamiento, medición,

verificación

T (°C)

U

[mV]

T (°C)

U

[mV]

0 +221

35

+187

5 +216

40

+181

10

+212

45

+176

15

+207

50

+171

20

+202

55

+165

25

+197

60

+160

30

+192

Conversión

electrodo

de

hidrógeno

al

normal

Preste atención de sumergir la sonda a la profundidad de inmersión co-

rrecta. El diafragma debe quedar completamente sumergido en la solución. El diafragma se encuentra en la zona f inal del vástago inferior (vea

la f lecha):

El nivel del electrolito de ref erencia tiene que estar simultáneamente a

2 cm sobre el nivel de la solución.

UH = U

con : U

med

H

+ U

Ref

= Potencial Redox, referido al

electrodo normal de hidrógeno

U

U

= Potencial Redox medido

med

= Potencial del sistema de referencia con respecto al

Ref

electrodo normal de hidrógeno

U

depende de la temperatura y aparece en la siguiente tabla (vea además

Ref

la DIN 38404-6):

TruLine ORP 51

Ref

Ref

TruLine ORP 51

Page 28

28

T 814246

04/2014

Almacenamiento,

Envejecimiento

TruLine

Sonda de medición

Electrolito de referencia

Modelo

TruLine ORP 51

+

KCl-250 (250 ml)

Durante

interrupciones

el transcurso

las

mediciones

Durante la noche

por un

más

prolongado

breves

en

de

o

período

Almacenamiento

Sumerja la sonda de medición en el electrolito de referencia.

KCl 3 mol/l, sin Ag

Enjuague la sonda con la solución de medición o bien, con agua desionizada, antes de la siguiente medición.

Introduzca la sonda de medición limpia en la cubierta de remoje llena de

electrolito de referencia y cierre.

Observación

Durante el almacenamiento prolongado se pueden formar incrustaciones de

sal en la cubierta de remoje. Estas incrustaciones no influyen las propiedades de medición y pueden ser eliminadas fácilmente con agua desionizada

antes de comenzar con el trabajo.

(vea la pagina 31)

Envejecimiento

Toda sonda de medición Redox está expuesta al envejecimiento natural.

Bajo condiciones de trabajo extremas, su vida útil puede acortarse considerablemente. Por ejemplo:

Ácidos o lejías fuertes, soluciones de ácido fluorhídrico, disolventes orgá-

nicos, aceites, grasas, bromuros, sulfuros, yoduros, proteínas

Altas temperaturas

Cambios bruscos del pH y de la temperatura.

Si el instrumento falla o es deteriorado mecánicamente por trabajar bajo

estas condiciones extremas, se pierde el derecho de garantía.

Page 29

29

T 814246

04/2014

TruLine

Actiar

electrodos

de platino

Impurezas/contaminación

Procedimientos de limpieza

Grasas y aceites

enjuagar con agua y detergente

enjuagar con ácido cítrico (al 10 % en peso)

Limpieza Elimine impurezas y residuos solubles en agua enjuagando con agua desio-

Después de

Activación

durante la

en

funcionamiento

y a

requerimiento

Activación

tiempos de

de larga

la

limpieza

inicial

puesta

durante

ajuste

duración

nizada. Elimine otras impurezas de la siguiente manera:

Incrustaciones de cal e hi-

dróxido

Enjuague la sonda de medición con agua desionizada.

Activar electrodos

de platino

Para la activación inicial emplee el polvo activante del juego de reactivos

SORT/RH (incluido en este juego). Sumerja el electrodos de platino

humedecido (pero no goteando) en el polvo activante y gire la sonda de

medición repetidas veces en el polvo. Elimine los resíduos del polvo

activante bajo agua corriente empleando un cepillo suave (por ejemplo un

cepillo de dientes blando).

Al cambiar de soluciones de medición oxidantes a soluciones reductoras y

viceversa pueden resultar tiempos de ajuste de una hora y más de duración.

En estos casos el tiempo de ajuste puede ser acortado considerablemente

sometiendo

la superficie del electrodo de platino previamente a un tratamiento de activación. El tipo de tratamiento preliminar (reductor u oxidante ) depende del valor pH y del potencial Redox U

donde el potencial deberá ser estimado en la primera medición.

de la solución de medición, y

H

El tipo de tratamiento preliminar puede ser determinado en base al siguiente

diagrama, donde U

1000

U

en m V

H

800

600

400

200

0

0

está referido al electrodo normal de hidrógeno:

H

tratamiento preliminar

tratamiento preliminar

2

4

6

reductor

8

oxidante

10 12

valor

14

pH

Page 30

30

T 814246

04/2014

Notes

TruLine

Descripción

Modelo

No. de pe-

Solución de electrolito de referencia 3 mol/l

KCl

KCl-250

109 705Y

Juego de reactivos para la regeneración de

e

10

r

SORT/RH

109 730Y

Zobell solución tamponada Redox (125 ml)

3682

061320

Tratamiento

preliminar

oxidante

Tratamiento

preliminar

reductor

Sumergir el electrodo de platino durante dos a tres

días en una solución de clorina de ácido sulfúrico.

El polvo de clorina para preparar la solución está incluido en el juego de reactivos SORT/RH.

Observación: ¡No sumergir el diafragma en la solución de clorina!

Sumergir la sonda de medición lista para medir en

la solución tamponada Redox Zobelly esperar hasta que el valor medido se estabilice.

Piezas

de

desgaste

y accesorios

dido

, sin Ag+ (250 ml)

lectrodos de platino Redox, compuesto por

g de polvo activante y 30 g de polvo de clo-

ina

Page 31

TruLine

Contact

Contact

Information

Ordering & Technical Support

Telephone: (800) 897-4151

(937) 767-7241

Monday through Friday, 8:00 AM to 5:00 PM ET

Fax: (937) 767-1058

Email: environmental@ysi.com

Mail: YSI Incorporated

1725 Brannum Lane

Yellow Springs, OH 45387

USA

Internet: www.ysi.com

W hen placing an order please have the following information available:

YSI account number (if available) Name and Phone Number

Model number or brief description Billing and shipping address

Quantity Purchase Order or Credit Card

Service Information

Information

YSI has authorized service centers throughout the United States and

Internationally. For the nearest service center information, please visit

www.ysi.com

and click ‘Support’ or contact YSI Technical Support

directly at 800-897-4151.

W hen returning a product for service, include the Product Return form

with cleaning certification. The form must be completely f illed out for an

YSI Service Center to accept the instrument for service. The Product

Return form may be downloaded at www.ysi.com

and clicking on the

‘Support‘ tab.

Page 32

What can Xylem do for you?

We’re 12,500 people unified in a common purpose: creating innovative solutions to

meet our world’s water needs. Developing new technologies that will improve the way

water is used, conserved, and re-used in the future is central to our work. We move,

treat, analyze, and return water to the environment, and we help people use water

efficiently, in their homes, buildings, factories and farms. In more than 150 countries, we

have strong, long-standing relationships with customers who know us for our powerful

combination of leading product brands and applications expertise, backed by a legacy

of innovation.

For more information on how Xylem can help you, go to www.xyleminc.com

YSI

Brannum Lane

1725

Yellow

Tel: +1

Fax: +1

Email: environmental@ysi.com

Web:

Springs,

937-767-7241;

937-767-1058

www.ysi.com

©Xylem Inc

OH

45387

800-765-4974

Loading...

Loading...