Page 1

OPERATOR'S MANUAL

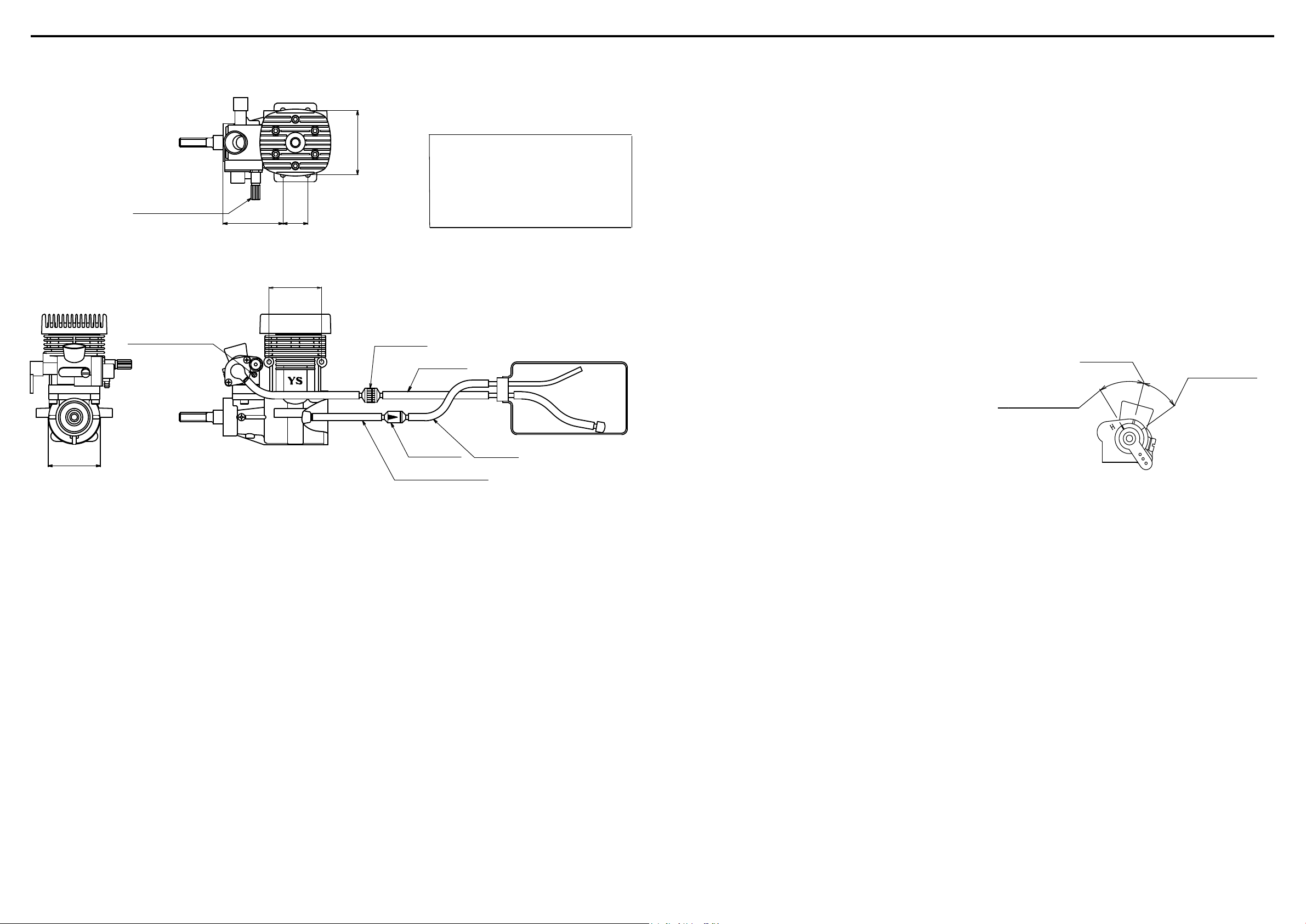

42.3 17.5

37

Fuel Filter

Low Speed Needle

Main Needle Valve

Tube (B)

Tube (A)

Check Valve

Tube (C) : 35mm

37

44

B

A

High Speed 100%

Hover 40%

Low Speed 0%

50ST

(Part No.YS0030)

STARTING PROCEDURE

HIGH SPEED ADJUSTMENT

Fig,1

Bore 22,0mm

Stroke 21,5mm

Displacement 8,17cc

Weight 398g

Practical rpm 2,000-20,000rpm

SPECIFICATION

For the best overall performance with your 50ST Helicopter

Engine, we recommend 30% nitro fuel blended especially for

helicopter use. Lower nitro percentages may be used, but

reduced performance will result.

1. Always remove tube (A) at the check valve rst. The fuel

tank is pressurized by the engine and you need to relieve

the pressure. Then, disconnect tube (B) and ll between

the lter and the tank. If you make a mistake in the proce dure, fuel will squirt out. An easy method is to use T-Fittings

tings between the check valve and the tank, and between

the fuel lter and the tank with plugs that can be removed

for pressure relief and fuel lling.

2. From the fully closed (clockwise) position, open the main

needle valve 1,75 turns. Close the idle needle fully (clockwise)

and open 1 turn.

These are the initial settings and will be re-adjusted as you

set up the engine and helicopter.

High speed is also adjusted with the main needle valve.

Turning the needle valve clockwise will lean the fuel mixture,

and counter-clockwise will richen the fuel mixture.

Adjust carefully as this setting will also affect the hover adjustment.

THROTTLE LINKAGE

Set the throttle stick on the transmitter at the center, and

adjust the linkage to put the mark on the carb body and the

mark on the throttle barrel in line. Hovering should take place

with the throttle stick near the center position if the linkage

ratio is properly set. If the ratio is incorrect, the throttle bar-

rel will be too far open at the center position on the stick and

hovering will commence at a lower stick position.

Fig.2

FEATURES

The YS 50ST Engine features the patented YS regulated

fuel system for positive fuel ow during all types of ight

conditions.

Factory authorized parts and service available worldwide.

CAUTIONS

1. Take care not to touch the engine immediately after shut-

down to avoid painful burns.

2. Do not attempt to y with engine problems as it can be

dangerous. Fix the problem prior to ying.

3. When starting the engine, do not use full throttle but set

throttle to low speed before applying the glow driver.

4. This engine is intended for helicopter use. Aircraft conver sion parts are available from our service department.

5. This engine is intended for use by experienced modelers

only. If you are not properly trained to operate this engine,

please get assistance from a skilled modeler.

6. The user is responsible for operating this engine in a safe

safe manner.

INSTALLATION

1. The fuel lines should be connected to the fuel tank as

shown in the above diagram. Be careful to install the

check valve in the correct direction. Since the tank is

exposed to high pressures, be sure that all connections

are secure to prevent pressure leakage.

2. Since the engine is sensitive to dirt in the fuel, a fuel lter

must be used.

3. Tube (C) should be set exactly at 35mm between the

engine and the check valve.

4. The check valve is designed exclusively for the 50ST.

Use only YS factory parts for replacement.

MUFFLER

1. Use an expansion chamber mufer intended for 50 size

helicopter engines. If there is a fuel tank pressure tting

on the mufer you choose, plug it, as it is not necessary

to use mufer pressure with the YS system.

2. Please note that the use of tuned pipes and tuned mufer

systems can interfere with the operation of the regulator

system and result in poor engine performance.

3. Open the throttle fully and run the engine with an electric

starter for about 10 seconds without connecting the glow

driver. This pressurizes the fuel tank and the engine is now

now ready for starting. Set the throttle barrel to low speed

and connect the glow driver before starting the engine

with the electric starter.

4. If the engine refuses to start, remove the glow driver, open

the main needle valve 2 turns from its present setting and

repeat Step 3. Return to low throttle and start the engine.

After starting, return the main needle to its running setting

before advancing the throttle.

IDLE ADJUSTMENT

Begin with the idle needle with 1 turn open from closed

(clockwise) and adjust from that point. Turning this needle

clockwise will lean the fuel mixture, and counter-clockwise

will richen the fuel mixture. Changes in fuel and weather

conditions may require re-adjustment.

HOVER ADJUSTMENT

Hover is adjusted with the main needle valve. There is some

interaction between the hover setting and full throttle setting,

so be aware that one adjustment will affect the other.

BREAK-IN

It is not necessary to mount this engine on a test stand for

break-in. However, the engine should be adjusted slightly on

the rich setting for the rst few ights to ensure proper breakin. Always use a good quality fuel which contains 30% nitro

and an oil content of 20-30%.

GLOW PLIG

1. We have found that the glow plugs listed below will give

the best engine performance;

YS #2

OS #8

Enya #3

2. Replace the glow plug when idling or top end performance

decreases.

IMPORTANT!

Silicone rubber is used in many parts of the YS Engine. Use

only glow fuel for cleaning. Gasoline or other solvents will

damage silicone if used.

Page 2

2

3

5

10

11

13

15

18

24

21

22

20

32

33

37

41

9

30

6

9

17

12

14

7

4

27

28

31

29

8

38

40

25

34

26

23

35

19

16

1

2

3

5

11

13

15

18

24

21

22

20

32

33

37

9

30

6

9

17

42

12

14

7

4

28

31

29

8

38

25

34

26

23

35

19

16

1

39

36

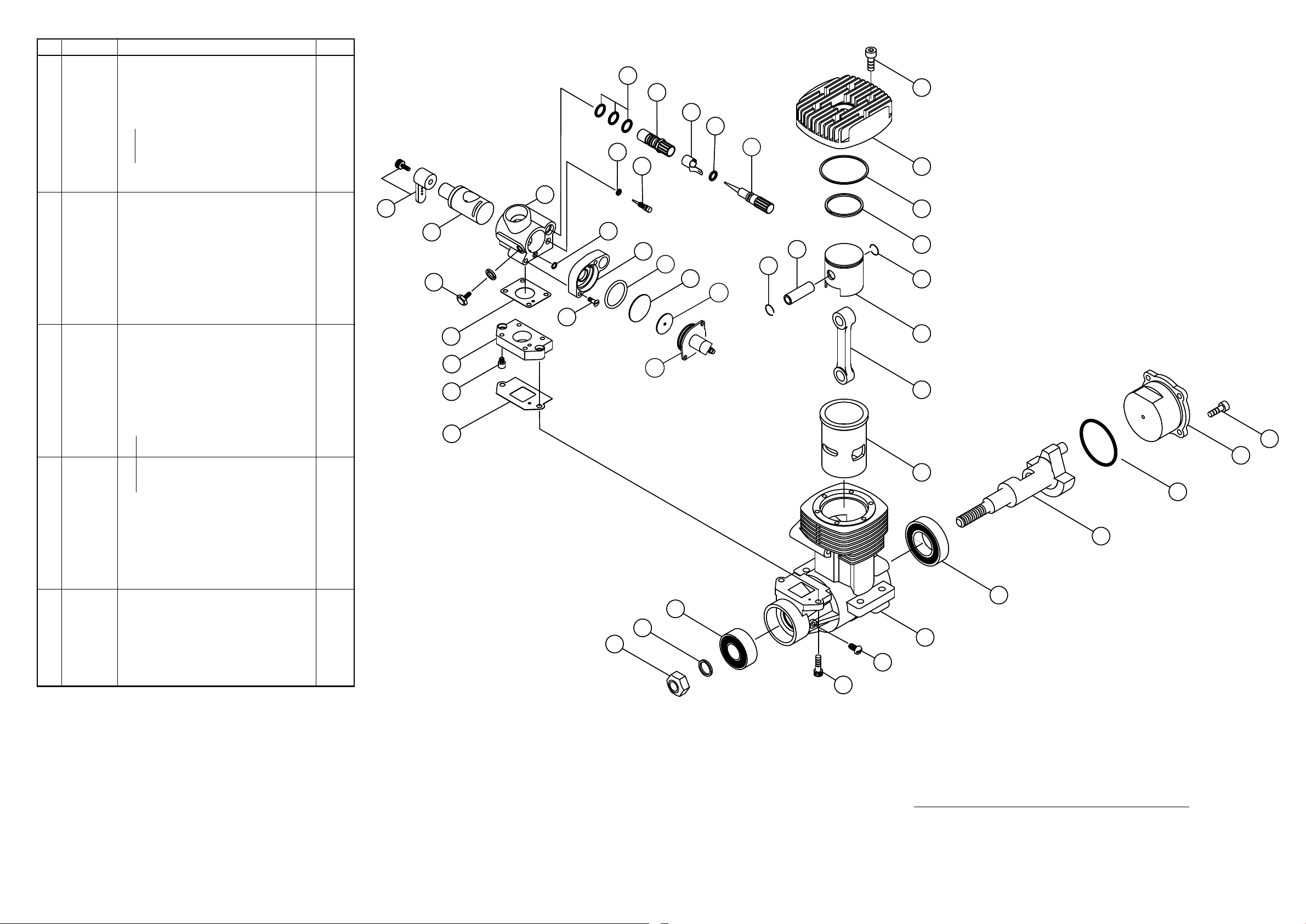

NO. PART# DESCRIPTION QTY

YS5180 Crankcase 1

1

2 YS5185 Cylinder head 1

3 YS5190 Head gasket 1

4 YS5195 Head set screws 6

YS5200 Liner and piston set

5 YS5205 Liner 1

6 YS5210 piston 1

7 YS5215 Piston ring 1

8 YS5220 Wrist pin 1

9 YS5362 Wrist pin retainers 2

10 YS5230 Con rod 1

11 YS5235 Crankshaft 1

1 2 Y S 1 0 5 0 F r o n t b e a r i n g 1

13 YS5240 Rear bearing 1

14 YS5243 Drive washer spacer 1

15 YS5245 Prop nut 1

16 YS5250 Back plate 1

17 YS5255 Back plate O ring 1

18 YS5260 Back plate set screws 4

19 YS5270 Carburetor body 1

20 YS5275 Carburetor gasket 1

21 YS5280 Carburetor O ring 1

22 YS5285 Carburetor insulator 1

23 YS5290 Insulator set screws 4

24 YS5295 Insulator gasket 1

25 YS5300 Throttle barrel 1

26 YS0380 Throttle barrel retainer screw 1

YS5305 Needle valve set

27 YS5310 Needle valve 1

28 YS2695 Needle valve O ring 1

29 YS5315 Needle socket 1

30 YS5320 Needle socket O ring 3

31 YS2710 Needle valve detent 1

32 YS4845 Low speed needle 1

33 YS4150 Low speed needle O ring 1

34 YS0200 Throttle arm set 1

35 YS5325 Carburetor screws 2

36 YS5332 Regulator body A 1

37 YS5335 Regulator body B 1

38 YS5340 Diaghram 1

39 YS5343 Regulator valve 1

40 YS5345 Regulator O ring 1

41 YS5362 Regulator set screws 2

42 YS5365 Crankcase plug 1

YS2510 Check valve 1

YS5370 Gasket set 2

YS5375 O ring set 8

WARRANTY

Strict quality control is implemented by our factory in all phases, from

parts manufacturing to nal assembly.

If performance deteriorates or a part fails due to a manufacturing error,

YS Parts and Service will repair or replace the engine at no charge in the

period of one year from date of purchase.

Warranty does not cover normal maintenance.

Should the engine be modied, incorrectly assembled or abused, there will

be a normal charge for parts and labor.

Specications may be changed without prior notice. 2007 JAN

YS Parts and Service

1370PorterDriveMindenNV89423

Phone:775-267-9252

Fax:775-267-9690

Loading...

Loading...