Construction Guide of High-Performance 4-Band Backpack

SSB/CW/AM Transceiver Kit

TJ4A is a 4-band SSB/CW/AM backpack transceiver suitable for field operation. With high

performance DDS LO, TJ4A offers wider and clean tuning range (Photo below is the LO spectrum

in 40m).

Doubly-Balanced Diode Ring Mixer is used as the receiving mixer, featuring low noise and

strong signal handling ability.

Features

New MCU (STM8S105C6T6)

User Friendly Operation System

New DDS LO with no birdies in

tuning range

Dual VFO system

Multi-Mode (SSB / CW /AM)

Automatic Bandwidth System

99 memo ries

Automatic keyer and straight key

compatible

Dual Data Input

Dual ANT Connector

RX Frequency Coverage

With Standard BPF

BAND 1: 3.5 – 4.0 MHz

BAND 2: 6.5 – 7.5 MHz

BAND 3: 13.5 – 14.5 MHz

BAND 4: 21 – 22 MHz

With Optional BPF

BAND 1: 1.6 – 4.0 MHz

BAND 2: 4 – 7.5 MHz

BAND 3: 7.5 – 14.5 MHz

BAND 4: 14.5 – 22 MHz

Note: Standard BPF is supplied with the kit.

1

TX Frequency Coverage

With Standard BPF

BAND 1: 3.5 – 4.0 MHz

BAND 2: 7 – 7.5 MHz

BAND 3: 14 – 14.5 MHz

BAND 4: 21 – 21.5 MHz

Sensitivity

0.3 uV

Band Width

SSB: 2.1 KHz

CW: 1 KHz

AM: 6 KHz

Power Output

20 W

Note: Output power is adjustable.

Power Supply

10 V – 12.5 V

2

Construction

Coils

Main Board

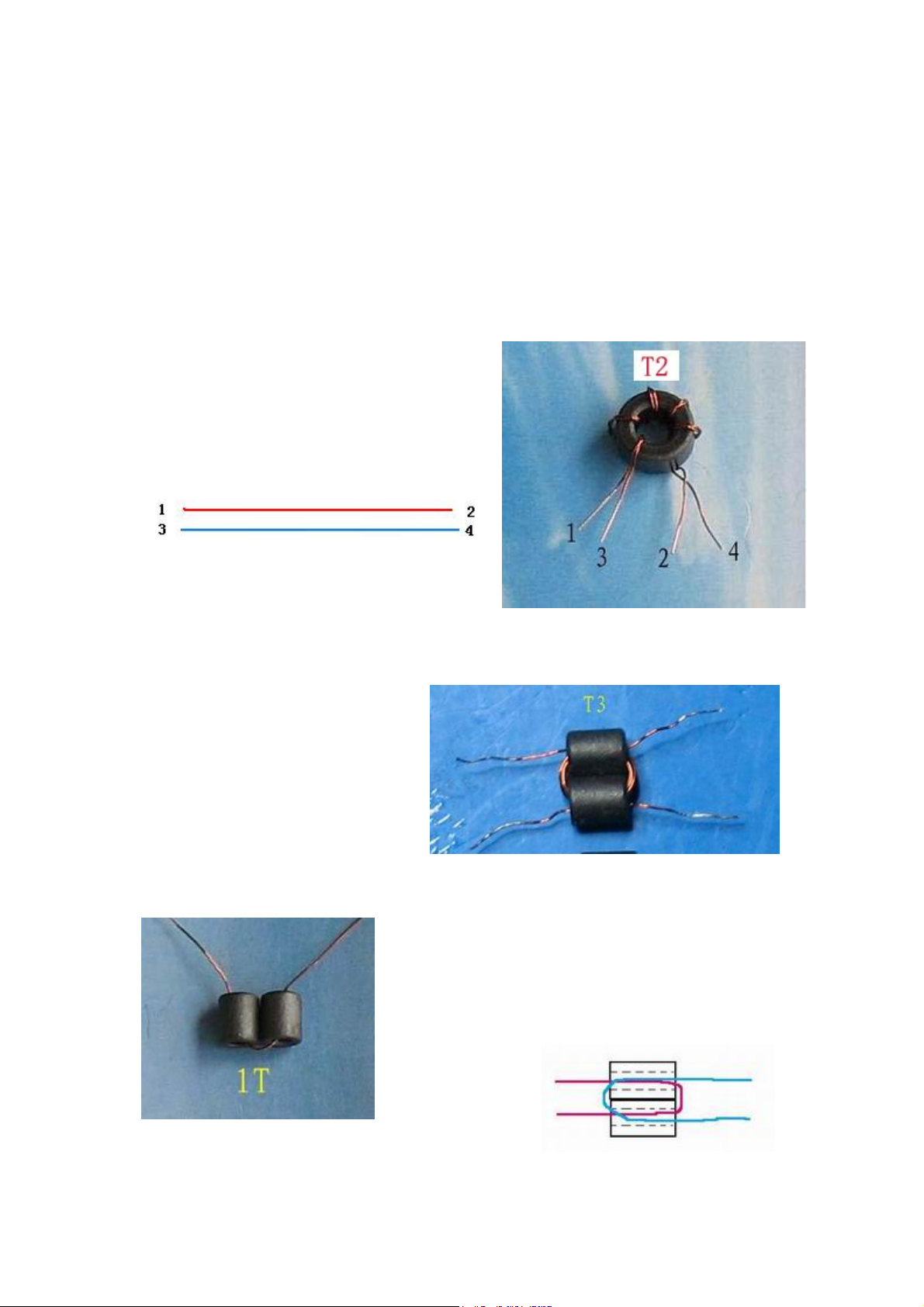

T2(Component Side): Broadband transformer, 8 turns on FB43-2401 core. Cut 10 cm long

enameled wires. Say Wire A is red, Wire B blue. Twist the wires before winding. Connect 2 (the

finish of A) with 3 (the start of B) as the tap. Leave

about 1 cm for each lead. Remove about 5 mm

enamel from the leads, and tin. Note: the illustrated

coil is 5 turns.

T3 : Broadband transformer, 3-turn

primary (C11 side), 9-turn secondary (U2

side), 0.31 enameled wire threading

through the binocular core made up of 2

small sleeves. A length of 7.5 cm wire is

the exact length for 3 turns with about 1

cm on each end. A length of 20.2 cm wire

is the exact length for 9 turns with about 1 cm on each end. Wind primary first. Remove about 5

mm enamel from the leads, and tin.

Red wire stands for the primary, blue for secondary.

Mark the primary or the secondary with a mark pen to avoid

getting confused.

3

T4, T5: 9MHz transformer, Can coil, no number on the can.

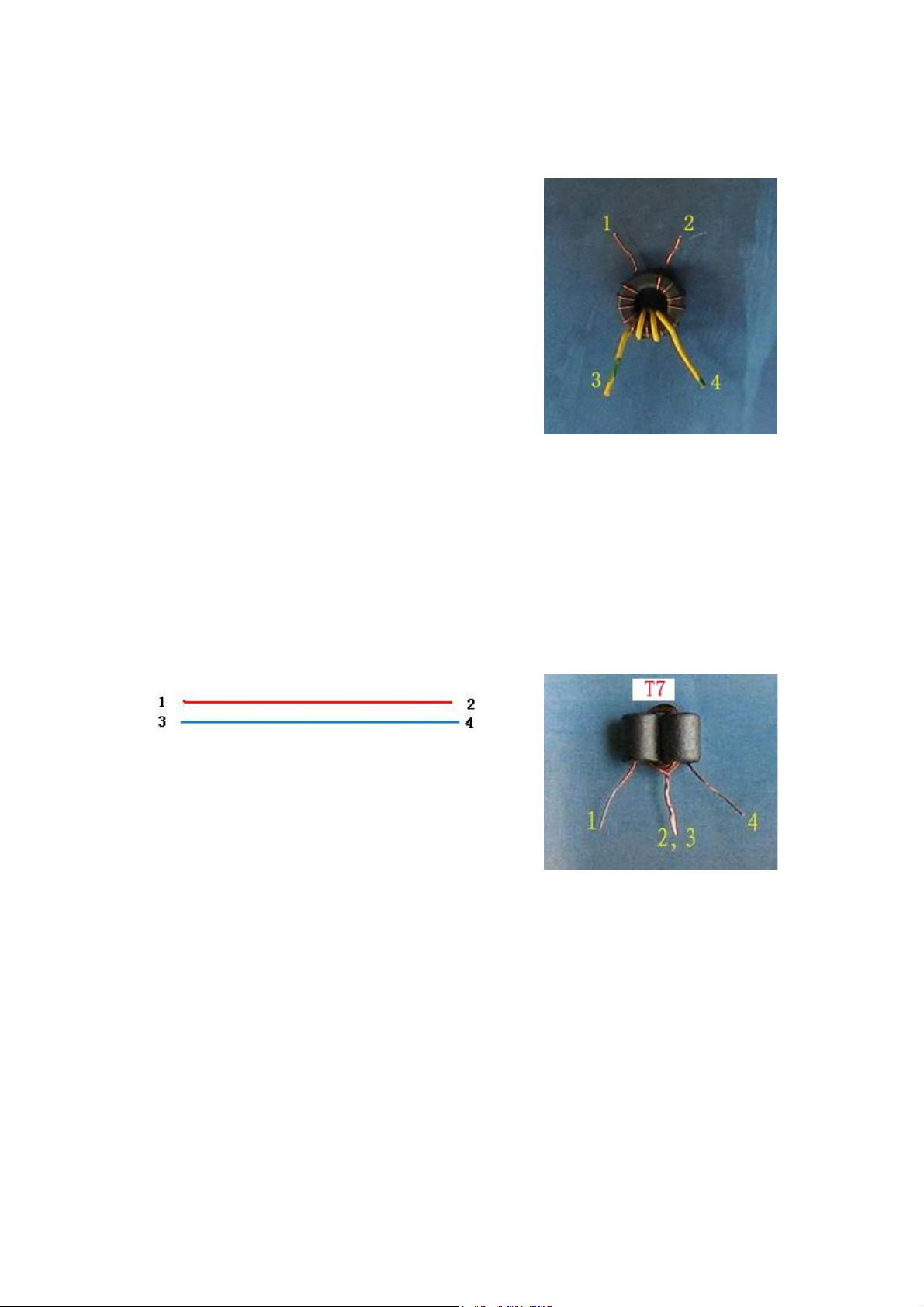

T6 : Broadband transformer, 12-turn primary, 3-turn

secondary, 0.31 enameled wire on FB-43-2402 core. The

3-turn primary is wound on middle part the secondary. For

clearer instruction, the yellow wire is used as the primary.

The photo shows the actual turns. Remove about 5 mm

enamel from the leads, and tin. Cut 19.5 cm length of

enameled wire for the 12-turn secondary, leaving about 1

cm for each lead. The length is the exact length for 12 turns

with about 1 cm lead on each end. You wouldn’t wind the

wrong turns, because you don’t have extra length of wire to wind more turns. Remove about 5 mm

enamel from the leads, and tin.

T7,T8:Broadband transformer, 5 bifilar turns 0.31 enameled wire on the binocular core made up

of 2 small sleeves. Cut a pair of 12 cm long enameled wire, and thread through the core. Say Wire

A is red, Wire B blue. Connect 2 (the finish of A) with 3 (the start of B) as the tap. You don’t have

to twist the wire. Leave about 1 cm for each lead. Remove about 5 mm enamel from the leads, and

tin.

L1:23 turns on T37-2 core. Cut 30 cm length of 0.31enameled wire for the winding, leaving about

1 cm for each lead.

L2, L3:BFO inductor, can coil labeled 3.

L4, L5:80m BPF inductor, can coil labeled 3.

L6,L7:40m BPF inductor, can coil labeled 2.

L8,L9:20m BPF inductor, can coil labeled 1.

L10,L11:15m BPF inductor, can coil labeled 0.

4

T1, T2 (on the PCB back): mixer transformers, handled with care.

Solder Components

Resistors and caps are not difficult to solder. However, some SMD components are tiny.

Solder carefully. Use magnifying glass, if necessary. They are not damaged easily, but they would

fly away and hide. The transistor 108T is very small (smaller than the SMD transistor labeled J6).

Handle carefully.

V11 is MOSFET. The wider lead is “S”. Solder

According too the silk print .

Lead definition of 2N4427 is illustrated in the picture.

Q1 is hot when working. Please use a heat sink.

Use an IC socket for U6.

Notice the white line when mount RL1. There is also a

line one the relay.

Solder a 10K resister across Pin 2 and Pin 5 of CN4.

5

Use the jumper cap for A and B. Or jumper with a resistor

lead.

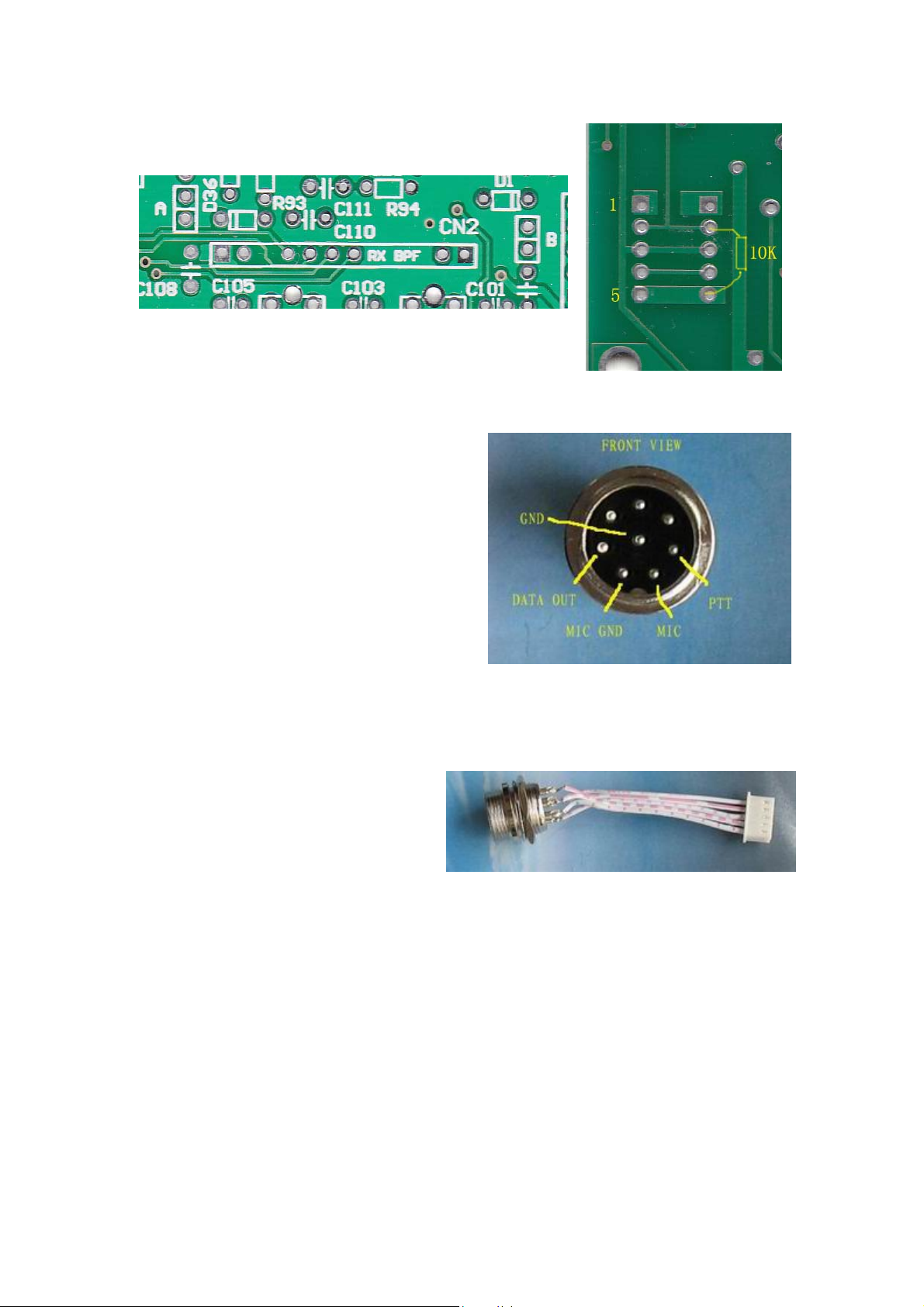

Definition of Connectors

CN1:Control port. Connect it to CN1 of PA board

with the supplied 14-wire cable.

CN4, CN5:8-PIN aviation plug Connector. The 5

pins are defined (starting from top) as MIC GND,

MIC INPUT, DATA OUT (for PSK service), PTT,

GND. Connect to the 8-pin sockets with 5-wire

cable.

CN3:AF gain control connector. Connect it to the AF gain pot with 3-wir cable.

CN6:Control port. Connect to CN3 of DDS board with 14-wire cable.

CN7:LO input. Connect to CN4 of DDS board with coaxial cable.

CN8:Power level(DRIVE)control

connector. Connect to the PWR pot with

3-wire cable.

CN9:TX output. Connect to CN2 of PA

board.

KEY:CW key socket.

PH:Audio out for earphones or louder speaker.

6

Solder coils according to the following illustrations.

7

Front Face Assembly

Do not use the long crews supplied with the handles.

nd

Fi 4 shorter ones in the kit to fasten the handle to the

front face. Remove the stopper of the pot with pliers. The

power switch should be installed at a certain angle (See

illustration).

8

Connect the AF gain pot leads to CN3 as the number indicated. DRIVE pot is also connected

the same way. Number 3 pin is connected to the GND pad.

Solder 4 wires to the power switch: Supply control (illustrated in yellow) and key lock

control (blue) .

Bridge the 2 contact leads as indicated. Connect the bridged leads and the arm lead to the

2-pin connector below CN3 of the Switch board.

Connect another 2 contact leads to CN5 of the DDS board(Illustrated in blue).If you do not

want LOCK function, doo not bother to solder these 2 wires. Bridge CN5 of DDS board.

You have completed the most difficult wiring job.

9

DDS Unit

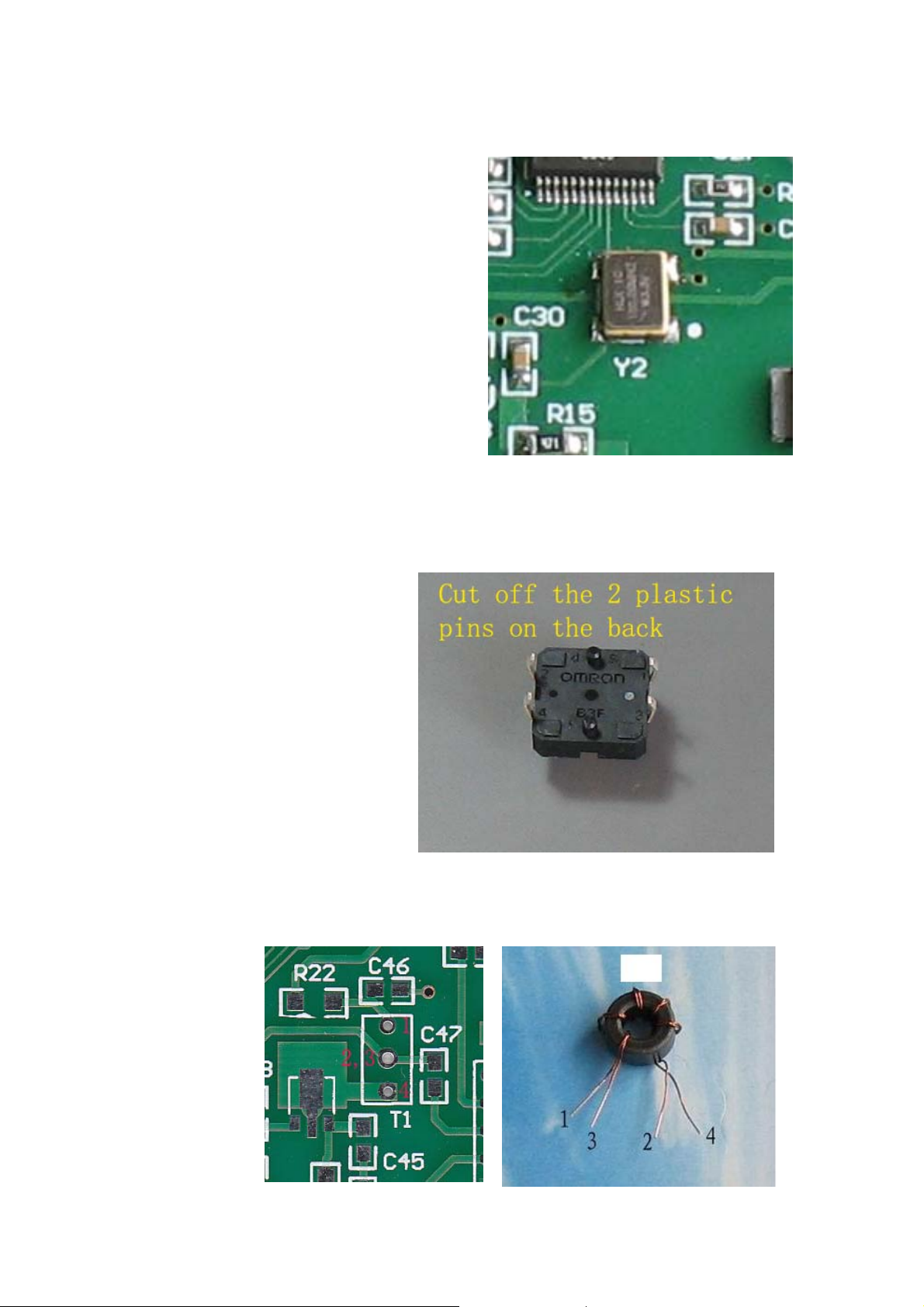

T1: Broad band transformer, same as T2 of

the main board, 5 turns on FB43-2401 core.

Most of the components have been installed

in the factory. However, still some components are

left for you to solder. Install 100MHz XTL as

indicated. Pat attention to the dot.

Definition of Connectors

z CN1:MCU communication port, for factory

only. No connection.

z CN2:LCD port. Connect to LCD with pins.

z CN3:Control port. Connect to CN6 of main board with 14-wire cable.。

z CN4:LO output. Connect to CN7 of main board with 50 ohm coaxial cable.

z CN5:LOCK control port. If you do not need lock function, simply short circuit this port.

z CN6:Key port. Connect to key pad

with pins.

Construct DDS Assembly

Key board

Remove the 2 plastic pins on then

button back with pliers.

The clearance between the key and

the key opening in the front face is a

round 1mm. The PCB mounting holes

are manufactured with some clearance

so that the keys project through the key openings with suitable clearance on all sides.

Plug in the connecting pins. Install 3 shorter (10 mm) brass pillars. Fasten it to the DDS board.

10

If the buttons can not achieve a running fit,

use a file to trim the mounting holes of the 4 long

pillars. Remove about 0.2mm from the right side

(see the yellow mark), i.e., to make the 4 mounting

holes a little oblong.

Cut the button card, select the color you prefer.

Insert the card into the button cap.

Fasten 4 long brass pillars to the front face,

using the socket head cap screws. Place a space

between the front face and the pillar. Install the

DDS assembly to the front face, and make sure

that the buttons achieve running fit (work

smoothly). If not, observe the clearance, adjust the

screws, until the buttons meet no resistance. Now

remove the DDS assembly. Solder the connector

pins.

Don’t forget to install the IF SET button on

the back. This button is seldom used. No need to put on a cap.

11

Now, let’s move to SWITCH board construction.

12

Switch Board

This board has only a few components. It is mounted to the back of the DDS board (Note: R2

is a 4.7K resistor.)

Definition of the

connectors.

z CN1:External

power input

connector.

z CN2:Battery

input connector.

z CN3:Charging

connector.

Important! CN3

directly routes to

the external

power, and does not have current limiting device. This connector only suits the battery

pack with charging management. Insert a diode between the connector and the battery

charging port, if necessary, to prevent the current flow back.

z CN4:Power supply output. The power to operate the rig is from this connector. Connect to

CN3 of PA with the heavy duty wires supplied with the kit. Turn the power switch to OFF

before plug in or disconnect external power.

13

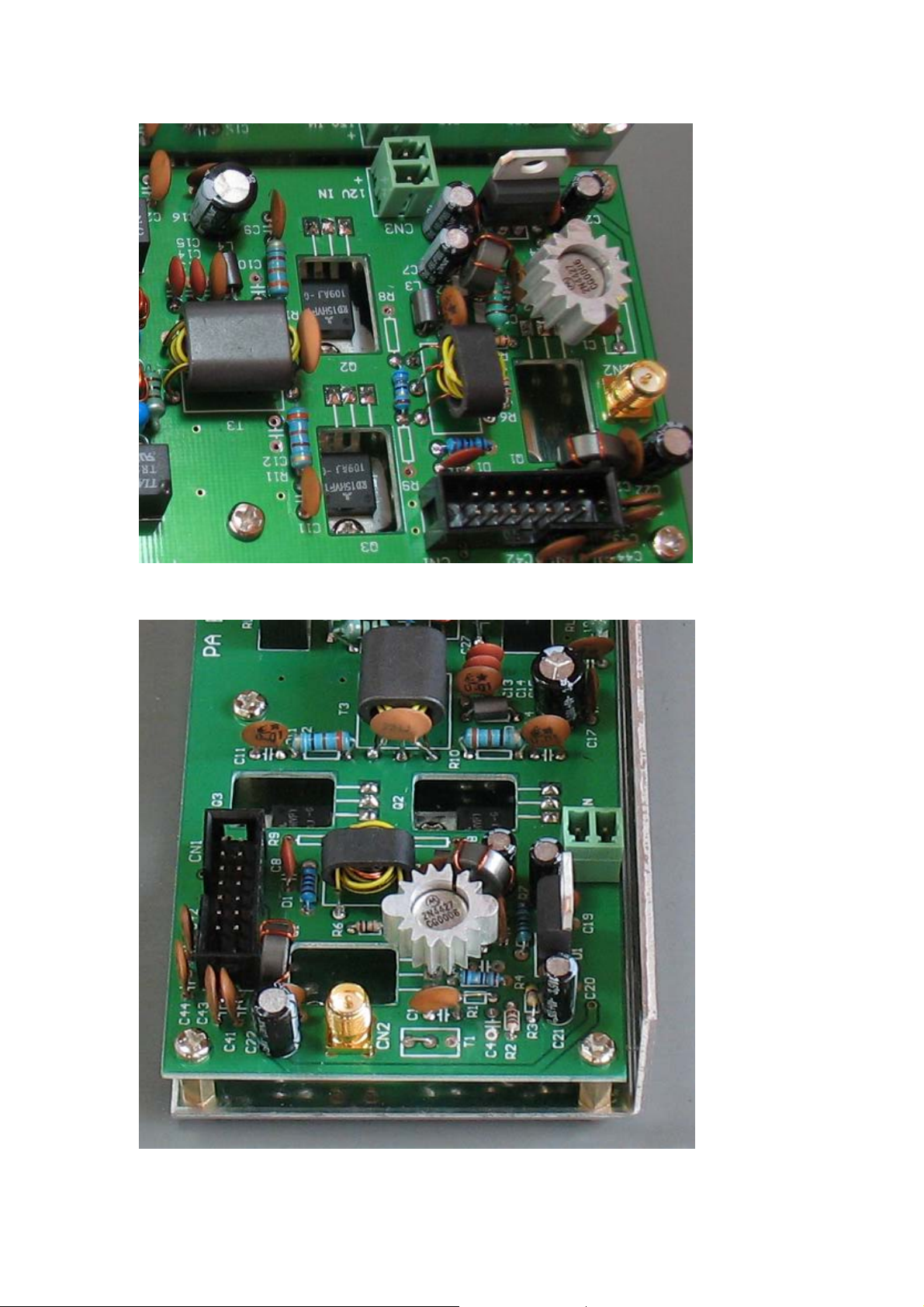

PA Board

Transformers and Inductors

T2:Broad band transformer, 4 turn-primary, 2 turn-secondary center tapped, through the small

binocular core. Use insulated wire supplied with the kit for primary, 0.31 enameled wire for

secondary. Wind secondary first.

T3:Broad band transformer, through BN43-202 core. 2-turn primary, 0.47 enameled wire, center

tapped, 4-turn secondary. Use insulated wire for the secondary winding. The illustrations below

show how to count turns and tap.

L2, L5:3 turns on the RFC toroid, 0.47 enameled wire. The RFC core is

smaller than FB43-2401.

L3, L4:A piece of wire through a bead. Resistor lead can be used as the

wire.

L6, L7:0.47 wire, 10 turns on T37-2 core. Cut 14

cm long enameled wire. Remove about 5 mm

enamel from the leads, and tin.

L8, L9:20m LPF inductor, 12 t, 0.47 enameled

wire on T37-2 core. Cut 16 cm long enameled wire.

Leave about 1 cm for each lead. Remove about 5

mm enamel from the leads, and tin.

L10, L11:40m LPF inductor, 17 turns 0.47

enameled wire on T37-2 core. Cut 22 cm long enameled wire. Leave about 1 cm for each lead.

Remove about 5 mm enamel from the leads, and tin.

L12、L13:0.47 wire, 23 turns on T37-2 core. Cut 30 cm long

enameled wire. Remove about 5 mm enamel from the leads,

and tin.

The photo on the right indicates 17 turns.

14

Notes:

z Q1 is very hot when working. Use a heat sink. Q1 mounting pads are for C1971, but now a

2N4427is used instead. Please shape 2N4427’s leads to fit

the pads. B, E, C are marked.

z No transformer for T1. Please bridge the pads (See photo).

z Bridge R1 with a resistor lead.。

z U1 does not need a heat sink.

z R8 and R9 are not used.

z Solder an 8.2K resistor to the pads of D1.

z Solder a 68-ohm (1/4W) resistor across the secondary of T2.

z Solder a 220P ceramic cap (larger disc) across the primary of

T3.

z Wrap a piece of tape to prevent the sharp edges of T2 to

damage the insulation of the wire.

Install Q1 and 2. Bend the leads and insert to the mounting

pads. Do not solder. Place 4 pillars (10 mm brass pillar) on the

aluminum plate (heat sink), and fasten the PA board. Align the mounting holes of Q1 and Q2.

Once aligned, use the screw to hold. If you h appen to h ave si licon grease, app ly some bet ween the

transistors and the plate before installing the transistors. Now solder the leads.

Position the PA assembly upright and use 2 screws to fasten it. The coaxial cable runs from

underside of the PA assembly. Use 2 thick wires to connect CN4 to the ANT sockets. Use wires as

short as possible. The 2 sockets are in parallel.

Do not run the power lines over the main board. Run them along the gap between the main

board and DDS board.

15

See how to tap.

16

Close-up pictures of T2 and T3

17

Now let’s assemble the assemblies to the bottom case.

First, place the DDS assembly. Fasten it with flat screws.

Place the main board. Use 4 screws to fasten it to the case.

18

Place the power switch unit, place the PA assembly, plug in the connectors, place the battery wall.

Please notice how to run the heavy duty power lines. Run them along the edge.

19

20

Place the back cover.

Let’s move to alignment work.

21

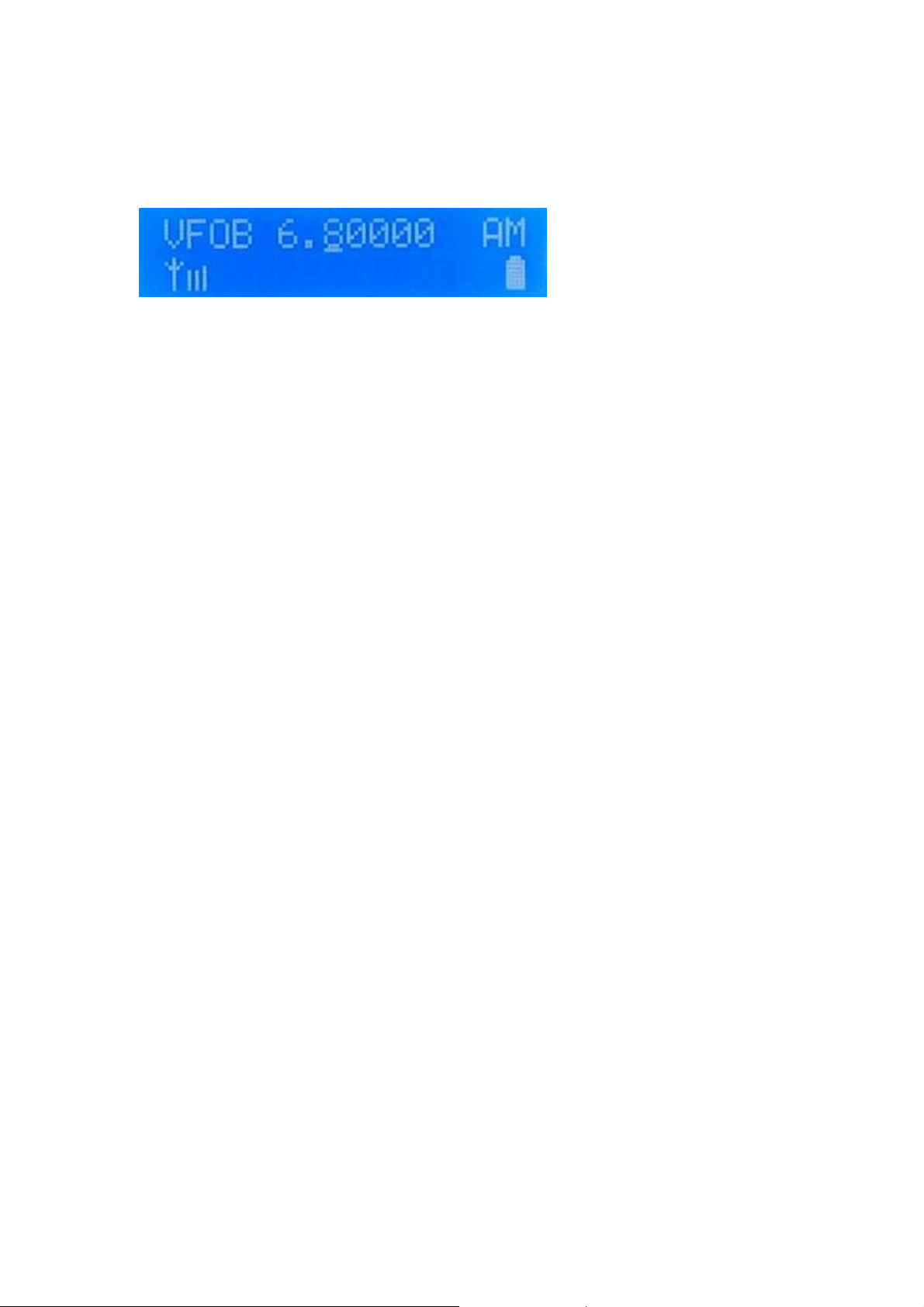

Alignment

Alignment is

earphones, and antenna. Plug in power connector. Double check the polarity of the plug. Turn the

w

po er switch to “ON”. Now, you can hear the relay a click sound of the relay, a Morse code of

“R”. LCD lightens. That means the switch board, U4, U6, DDS unit work.

DDS Unit

If no letters appear on the LCD, do not worry. Adjust VR1 until letters

You hav

SET

UP appears:

not very complicated. However, you need a frequency counter. Plug in

appear.

e set up the parameter before using. Press IF SET button on the PCB back, and LSB

This is for setting up the LSB offset. Use the default valu P

USB SETUP appears:

e 0000. ress the IF SET again, and

Set up the USB offset. Press the front panel F+ and F- to ab

Press the IF SET again, and CW SETUP appears:

Set up the CW offset. Press the front panel F+ and F- to set th

ess the IF SET again, and AM SETUP appears:

Pr

Set up the AM offset. Press F+ and F- to set the above display

Press the IF SET again, and IF SETUP display appears:

set the ove displayed data, +2100.

e above displayed data, +0920.

ed data, +2000.

Set up the XTL filter offset. Press F+ and F- to set the abo

ve displayed data, +8.998430. The

22

cursor indicates the tuning rate. Press STEP to select 10Hz, 100Hz, 1KHz rate.

ress the IF SET again, and DDS clock SETUP appears:

P

Set up the DDS clock. The default value is 125MHz. 100 u

F- to set the above displayed value, 100000000. The cursor indicate tuning rate. Press STEP

MHz is sed in the kit. Press F+ and

s the

to select 10Hz, 100Hz, 1KHz rate.

Press the IF SET again to exit setup.

Now, press B+, B-, STEP, MODE, V/M, A/B to see if they function.

Press A/B to shift VFO A to VF

and Hold the button, tuning would be automatic. Band is

AM. Press F+ or F- to tune frequency.

chan

ged automatically during tuning.

O B and vice versa. Press MODE to select LSB, USB, CW,

Press V/M to enter the saved frequencies. M01 indicates m m

in memories. F+ and F- function as the memory number selectio ttons. As many as 99

e ory N01. Mode can be changed

n bu

frequencies can be saved. Press V/M again to exit the memory.

How to save the frequency? For example, the present frequ cy

en is 7.050. Press SAVE, and

the following display appears:

The system suggests you to save the frequency in 01. How ve

e r, you may save it in a different

memory number. Press F+ or F- to select the memory number where you want to save the

frequency. Press SAVE, and the frequency is saved.

Connect the frequency counter to TP2 of the main board

. LO frequen

The measured frequency is always IF offset + displayed frequency.

FN is used to set up the keyer, such as speed, wpm, excha he paddles, etc., which will

nging t

be discussed in detail later.

Switch the power switch to LCK, buttons are disabled.

cy can be measured.

23

Now let’s proceed to the alignment of the main board.

Main Board

BFO

Connect the frequency counter TP3. Adjust the slug of

insi around the resonant position. See photo on P26 for reference). If you

de the can. This is

h volt meter, trim T5 to peak. If you don’t have, never mind. It can be

appen to have an RF

rated later.

calib

Set the mode to LSB. Adjust L2, until the frequency counter reading is around8.99843MHz.

Set the mode to USB. Adjust VC1, until the frequency counter reading is around 9.00055. Set the

mode to CW. Adjust VC2, until the reading is around 9.00000MHz.

T5 half way into the can (About 2mm

Before carryin

wron

g values are used (In this case the transistors would be very hot when KEY or PTT is

pressed).

bias voltage of the PA transistors. Press KEY of PTT. The voltage rea

the reading is very high, say, close to 4V, stop immediately, and check the bias network (8.2k and

6.8K) to see if the wrong resistor value s are used. If the reading is within the range, and the heat

sink is not hot, you can carry out CW transmission calibration.

Disconnect CN9. Connect the volt meter between T2 tap and GND to measure the DC

g out CW transmission calibration, check the bias of the PA transistors in case

ding is around 2.6 – 2.7V. If

Connect a 50-ohm dummy load at ANT (You could use two 2W 100-ohm resistors in parallel

to act as a 50-ohm dummy load now). Set the mode to CW, with the frequency connected to TP3.

For the convenience of calibration, set the KEY to the straight key mode. Hold FN button until

you hear the Morse code “.-.”, input “-.-” using your key. Now you will

instruction has been received. Press KEY and adjust L3, until the frequency counter reads

8.99935MHz。

Switch to AM mode. You will hear the relay working. In this mode BFO stop working. No

frequency will be detected at TP3.

hear “.-.”, indicating your

Automatic Band

Connect volt meter between R22 and ground (See th e photo at

right, the yellow arrow indicating

sugge o use high impedance volt meter such as digital meter.

sted t

Adjust VR1 until the voltage

LSB: 5.5V

USB:5.5 V

CW:

4.1 V

AM:8.5V

Note: To

width Control

the test point of R22). It is

reading meets the requirement:

lerances are allowed.

24

AGC and U2

Do not co

U2. Adjust V

AG ort-circuit pins 2 and 3. This would damage the IC.

C works properly. Never sh

Another s

VR2

, until you hear a relatively louder hiss sound. Adjust T4. Listen the carefully. Turn the slug to

nnect the antenna. Use a digital volt meter to measure the voltage of pins 4 and 6 of

R2 until voltage of pin 4 is around 1.19V, pin 6 around 0.65. Now the chip works and

imple way to adjust U2 is to listen carefully with the maximum volume, and adjust

peak the weak hiss sound until you hear a relatively louder hiss sound. Notice the position of the

slug of T4. The slug is about half way inside the shielding case (about 2 mm inside

phot

o below illustrates the slug height.

the can). The

Checking Band and Mode Control Voltages

U9 – U13 and Q20 form the band and mode control switches, sending out control voltages

under the control of MCU.

nd 1

Ba

D27: 6.8V

D29

, D31, D33: 0V

Band 2

D29: 6.8V

D27, D31, D33: 0V

Band 3

D31: 6.8V

25

D29, D27, D33: 0V

Band 4

D33: 6.8V

D29, D31, D27: 0V

e mode and band control voltages are not correct, please check the test points as indicated.

If th

Control vol

tage failure is usually caused by the cold solder.

However, the voltages can be measured on the top side:

26

BPF

emove the dummy load, and connect the antenna. Connect the antenna.

R

Switch to Band 1. Set the slugs of L4 and L5 about 1.5 – 2 mm above the

illus

trates the slug height). Tune the frequency to around 3.8MHz to get a signal or the noise. Trim

L4 and L5 to peak the received signals. Adjust the inductors one by one. After peaking L4, adjust

L5 to peak. Then adjust L5 to peak again. Trim T4 to peak again. If the peak is not very sharp, use

a smaller value for C24, say 4.3P. C24 ranges from 4.3P – 20P. Never forget T5. Trim T5 to peak.

Switch to Band 2. Set the slugs of L6 and L7 about 1.5 mm above the can. Tune the

frequ

ency to 7.050 – 7.1 to get a signal or the noise. Trim L6 and L7 to peak the received signals.

Switch to Band 3. Set the slugs of L8 and L9 about 1.5 mm above the can. Tune the

frequ

ency to 14.1 – 14.2 to get a signal or the noise. Trim L8 and L9 to peak the received signals

Switch to Band 4. Set the slugs of L10 and L11 about 1.5 mm above the can. Tune the

frequ

ency to 21.1 – 21.2 to get a signal or the noise. Trim L10 and L11 to peak the received

signals.

Calibrating Battery Level

can (Photo below

VR4 is the battery sampling device. Adjust it until the ba

the s

upply of 12.5V.

ttery level is full or one bar to full at

27

Calibrating S Meter

The bars at the L

.,

i.e S2 – S59+30dB. Receive a very strong signal, and adjust VR3 until all the bars appear.

ransmission

T

Connect a 5

Let’s take 40m for example. Tun

POW

ER to LOW POWER (Counter-clockwise to the end). Press the key, around 1W will be

measured. If you happen to have an oscilloscope, 20V p-p will be measured. Trim L6 and l7 to

peak. Now Increase the drive by PWR LEVEL, 18 – 20W will be obtained. Warning: If you use

two 2W 100-ohm resistor as the dummy load, do not use too much power. Or measure instantly.

Otherwise the resistors would be burned.

Switch to LSB, press PTT, speak to th

trans

mission condition, and the output is around 18 – 20W at the HIGH power level.

CD left corner represent the signal strength, each long bar representing 1S,

0-ohm dummy load.

e the frequency to 7.050, switch the mode to CW, with

e microphone, LCD S meter bars also work, indicating

If the output power is more than 20W, increase R72 to 470 ohms to reduce the driv

e.

QSK

120(1uF)determines QSK delay. For full QSK, C120 is not necessary. In this case, the

C

relays release as soon as the key is up. However, the TR relays have to withstand the frequent

switching. With C120 in position, there will be a short delay, i.e., the relay does not release at the

short key-up intervals to avoid the frequent relay contact motion.

Miscellaneous

C122 -- Optional. A 470uF/

C121 -- absorbs interferences. 821 or 103 ceram

C24 -- This capacitor ranges from 4.3P – 20P. If the sound is a little

signal is tuned in, use a smaller value, say, 4.3P ceramic. The value is not very strict.

eyer

K

U6

sp d, WPM, call sign, etc. would not be remembered. Next you turn on the rig, keyer will be

has no backup battery. When the rig is turned off, all the settings of the keyer, such as

ee

16V could be used.

ic disc can be used.

distorted when very strong

loaded with the default values.

28

Some Pictures of the Main Board

29

30

31

32

Spectrum

TJ4A complies with the FCC spectral purity requirement. The output spurious signals are

43dB below the carrier.

33

34

Loading...

Loading...