Page 1

Warning:

ALWAYS make sure bench

size and capacity to hold work

grease main screw regularly.

Never use a hammer, extension

Misuse of vises can cause serious injury to eyes, hands and or other body parts. Vises must be

set up and used properly. Before setup and use, read, understand and follow all instructions

outlined.

tops are properly secured.

ALWAYS use proper

mounting hardware in all

mounting holes to hold vise

securely.

ALWAYS inspect mounting

hardware to ensure vise is

securely fastened to work

bench.

ALWAYS inspect vise for

stress fatigue or damage to

the vise before using.

ALWAYS use vise of proper

object.

ALWAYS wear eye, face, and

ear protection when using a

vise.

ALWAYS wear dust mask or

respirator when working with

wood, metal, chemical dusts

or mists.

ALWAYS rest work piece

against front jaw and guide

rods.

ALWAYS wear restrictive hair

covering and anti slip

footwear while operating vise.

ALWAYS only hand tighten

vise.

ALWAYS maintain the vise –

pipe, or cheater bar on spindle

handle of vise.

NEVER unscrew movable jaw

beyond maximum specified

opening of vise.

NEVER weld vise to any metal

object.

NEVER use a vise to press an

object into or out of another

object.

NEVER place pressurized

containers or combustible

materials in vise.

NEVER wear loose clothing or

jewelry while operating vise.

NEVER apply extreme heat or

prolong heat to the vise as it may

alter structural properties.

NEVER tighten work piece at the

edge (top or side) of the vise as

this may break vise casting

Page 2

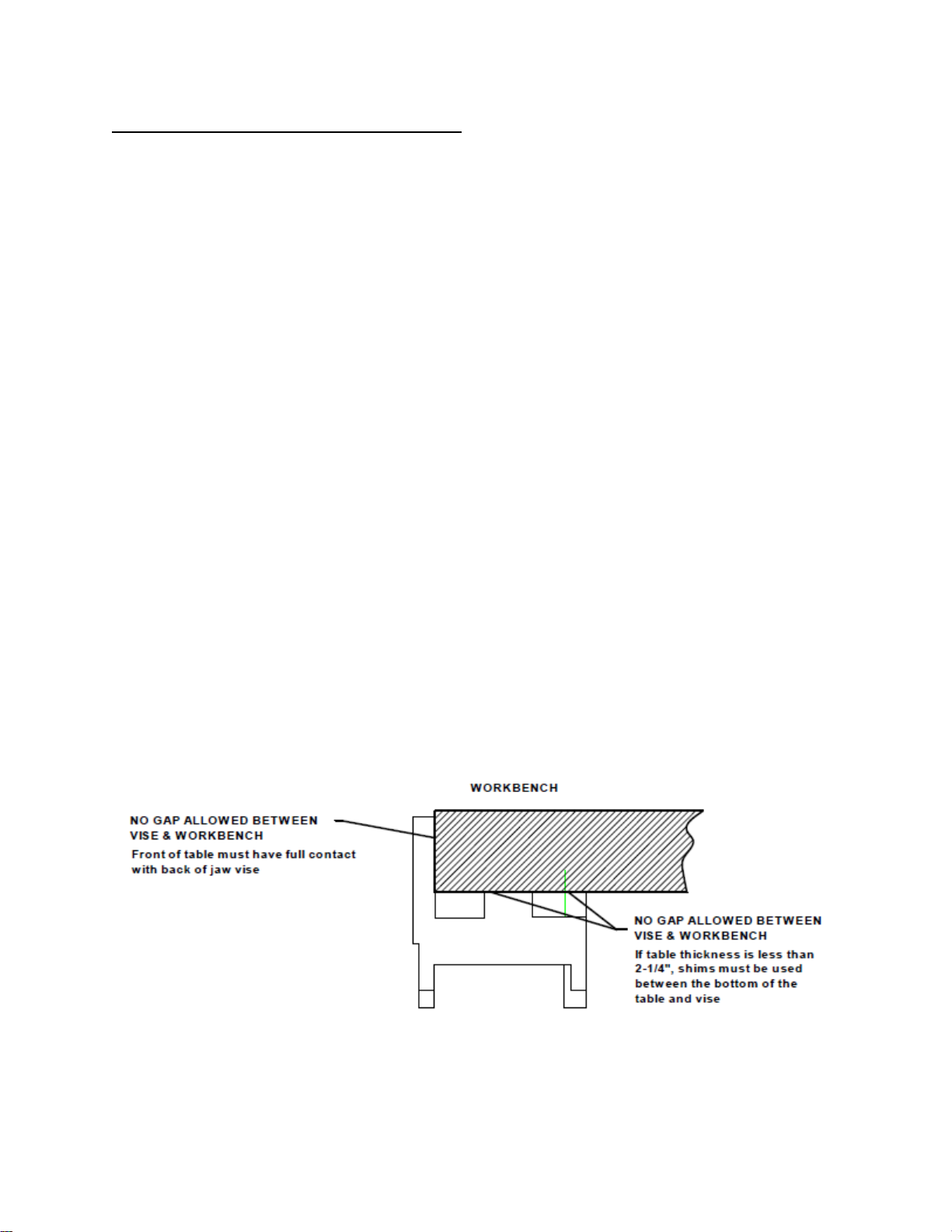

Mount Back Jaw Casting to Workbench

• Pre-drill holes for mounting screws using template provided. Be sure to drill

holes straight and deep enough to accommodate the full length of the screw.

Use recommended drill sizes only (see template provided).

• It is CRITICAL that the back jaw casting is mounted firmly and accurately to the

workbench surface. NO GAPS between the casting and the workbench should

be present. Use shims as needed. Refer to figure #1 below.

• DO NOT attach the vise to the end grain side of the workbench. By attaching the

vise to the side grain side of the workbench the mounting screw will have a much

stronger hold.

• When attaching the back jaw casting to the workbench, take care to ensure there

is full contact of the casting to the workbench surface before tightening the

mounting screws.

• The vertical portion of the back jaw against the front edge of the workbench and

the horizontal portion of the casting on the underside of the bench must have full

contact with the workbench. Use shims to eliminate any gaps that may be

present.

• Any gaps between the casting and the workbench surface will cause flexing of

the casting when tightened down, which could result in failure of the casting.

Figure 1.

• MOUNTING HARDWARE: Use the #14 x 2-1/2” Counter-Sink Wood Screws (2)

for the front edge mounting holes and the 5/16” x 2-1/2” Lag Screws (2) and the

5/16” Flat Washers (2) for underneath the workbench

Figure 1: Mount Back Jaw Casting to Work Bench

Page 3

100 lbs.

Max

Page 4

.300 .300

Yost 10WW Mounting Template

Loading...

Loading...