MODEL SY-40 Series

STRAINER

PRODUCT MANUAL .

Thank you very much for choosing the Yoshitake’s product. To ensure the correct and safe use

of the product, please read this manual before use. This manual shall be kept with care for

future references.

The symbols used in this manual have the following meanings.

Warning

Caution

This symbol indicates a potentially hazardous situation that, if not

avoided, could result in death or serious injury.

This symbol indicates a hazardous situation that, if not avoided, may

result in minor or moderate injury or may result in only property

damage.

Table of Contents

Usage of the product ····················································· 1

1. Features ···································································· 1

2. Specifications ···························································· 1

3. Dimensions and weights ··········································· 2

4. Operating mechanism ··············································· 3

5. Selection of nominal size

5.1 Selection of nominal size ···································· 4

5.2 Selection of piping nominal size ························· 4

5.3 Nominal size selection chart ······························· 5

6. Installation procedure

6.1 Example of piping ··············································· 6

6.2 Caution in installing the product ······················ 6-7

7. Operation procedure

7.1 Caution in operating the product ························ 7

8. Maintenance procedure

8.1 Troubleshooting ·················································· 7

8.2 Caution in maintenance and inspection ·············· 8

8.3 Disassembly procedure ······································ 8

8.4 Caution in assembling after disassembly ··········· 8

8.5 Assembly procedure ··········································· 8

9. Exploded view ··························································· 9

Information on after-sales services

■EPDT-167b■

Usage of the product

The product is widely used for dust removal from various types of pipelines. Especially, a strainer shall

be installed upstream of a pressure reducing, temperature regulating, solenoid or trap valve to protect

and maintain it.

1. Features

(1) The product is a high-flow marine type with as large a filtration area as possible to avoid clogging and

consequent problems such as flow rate drop.

(2) Ones with a nominal size of 65A or above have been downsized to the possible minimum sizes and

thus ease the piping.

(3) SY-40C/40C-N is highly resistant to corrosion as it has the internal and external body surfaces coated

with nylon 11 or nylon 12.

(4) For the standard screens, 80 mesh ones are used for SY-40/4 0H and 60 mesh ones for

SY-40C/40C-N according to the common specifications for machinery and equipment installation

work.

2. Specifications

Model

Nominal size

Application

SY-40 SY-40C SY-40C-N SY-40H

15-300A 15-150A

Steam, air, hot or cold

water, Oil and other

non-dangerous fluids

Air, hot or cold water and other

non-dangerous fluids

Steam, air, hot or cold

non-dangerous fluids

water and other

Maximum pressure 1.0MPa 2.0MPa

Maximum temperature

Material

Body Ductile cast iron

Screen Stainless steel

Connection JIS 10K FF flanged

Standard

screen

Perforations

Mesh 80 mesh 60 mesh 80 mesh

220℃ 60℃ 220℃

JIS 20K FF

flanged

2

φ2.5-7.21 holes/cm

・ SY-40C has the external and internal body surfaces coated with nylon 11 (15A to 200A) or nylon 12

(250A and 300A).

・ SY-40C-N has the external and internal body surfaces coated with nylon 12 (15A to 150A).

・ Ones with 20 to 100 mesh filter are also available upon request.

・ Ones with single layer of perforations are also available upon request.

Nominal size 15 to 80A…φ1.3-16.2 holes/cm

100A or above…φ1.5-11.2 holes/cm

2

2

・ Ones with brass plug may also be manufactured.(except for SY-40C-N)

・ Rust-proof (hot dip galvanized) ones are also available with nominal sizes of 65A or above.(except

for SY-40C/40C-N)

- 1 - ■EPDT-167b■

3. Dimensions and weights

[Figure 1] 15-50A [Figure 2] 65-300A

(No plug is provided with 15 to 32A ones.)

■SY-40,40C, 40C-N (mm)

Nominal

size

L H

1

ds Ls Connection Weight (kg)

15A 130 61 22 40 --- 1.9

20A 140 75 27 56 --- 2.5

25A 160 88 34 66 --- 4.0

32A 175 104 43 76 --- 5.2

40A 190 115 50 85 R 1/2 6.7

50A 225 140 61 107 R 1/2 10.2

65A 255 167 73 125 R 1/2 14.5

80A 330 190 88 130 R 1/2 18.3

100A 370 225 108 180 R 3/4 29.7

125A 415 263 136 200 R 3/4 40.5

150A 495 315 160 250 R 3/4 66.0

200A 565 385 210 300 R 3/4 95.8

250A 690 460 260 370 R 3/4 167.5

300A 840 556 315 442 R 3/4 286.0

■SY-40H (mm)

Nominal

size

L H

1

ds Ls Connection Weight (kg)

15A 130 61 22 40 --- 1.9

20A 140 75 27 56 --- 2.5

25A 160 88 34 66 --- 4.0

32A 175 104 43 76 --- 5.2

40A 190 115 50 85 R 1/2 6.7

50A 233 140 61 107 R 1/2 10.2

65A 290 167 73 125 R 1/2 15

80A 316 190 88 130 R 1/2 19

100A 360 225 108 180 R 3/4 28

125A 415 263 136 200 R 3/4 42

150A 495 315 160 250 R 3/4 68

- 2 - ■EPDT-167b■

4. Operating mechanism

[Figure 3] 15-50A

(No plug is provided with 15 to 32A ones)

[Figure4] 65-300A

(No strainer retainer is provided with 65 to 80A ones.)

Dust, scale and other foreign matter from the fluid flowing into the strainer through the

inlet port are removed by the screen (2).

№

1 Body

2 Screen

3 Gasket

4 Cap

5 Cover

6 Plug

7 Strainer retainer

8 Hexagon nut

9 Stud bolt

10 Washer

Part name

- 3 - ■EPDT-167b■

5. Selection of nominal size

To make the best use of the strainer and satisfy the operating requirements to the maximum,

take notice of the following.

The preferred initial pressure loss is 0.02-0.03 MPa.

5.1 Selection of nominal size

Select a nominal size equivalent to that of the pipe (piping n ominal size = nominal

size of strainer). Note that the use of a smaller nominal s ize increases the pressure loss

through the strainer, possibly reducing the machine inlet pressure below the specified limit.

5.2 Selection of piping nominal size

When selecting the piping nominal size, it is necessary to consider the fluid type, maximum

flow rate, permissible pressure loss, piping and equipment co st, etc. With a smaller piping nominal

size, the piping and equipment cost decreases but the pressure loss through the pipe increases to

generate disturbances, possibly resulting in pipe wear, noise and/or vibration. With too large a piping

nominal size, however, not only the piping and equipment cost but also the thermal loss increase. The

standard fluid velocity has been specified in the Japa nese Industrial Standards (JIS) as a guide to

select an appropriate piping nominal size.

<<Standard fluid velocity>>

Fluid Remarks

Auxiliary piping for vacuum or small-diameter

Saturated steam

Superheated steam

Inlet of steam coil 0.3-0.7MPa

Air

Water or oil

* This table shows a standard flow velocity of each type of fluid set based on the

requirements defined in JIS F 7101 (Shipbuilding – Pipes of machinery –

Standard velocity of flow).

piping

Large-diameter piping

Piping diameter: approx. φ75 – φ250

Piping of high-grade material

Higher pressure: 1.0 MPa or more

Lower pressure

Extremely low pressure: 0.1 MPa or less

Standard

flow velocity

15 m/s

(10-20)

30 m/s

(20-40)

40 m/s

(30-50)

70 m/s

(65-80)

30 m/s

(25-30)

20 m/s

(20-25)

15 m/s

( 5-15)

10 m/s

( 3-10)

2 m/s

( 2- 4)

- 4 - ■EPDT-167b■

5.3 Nominal size selection chart (Fluid: Water)

(

)

Screen:φ1.3-16.2 holes/cm2 (φ1.5-11.2 holes/cm2) perforations without mesh filter

2

Screen:φ2.5-7.21 holes/cm

perforations with 80 mesh filter

L/min

ND

V: Flow rate

ΔP: Pressure loss(MPa)

- 5 - ■EPDT-167b■

6. Installation procedure

6.1 Example of piping

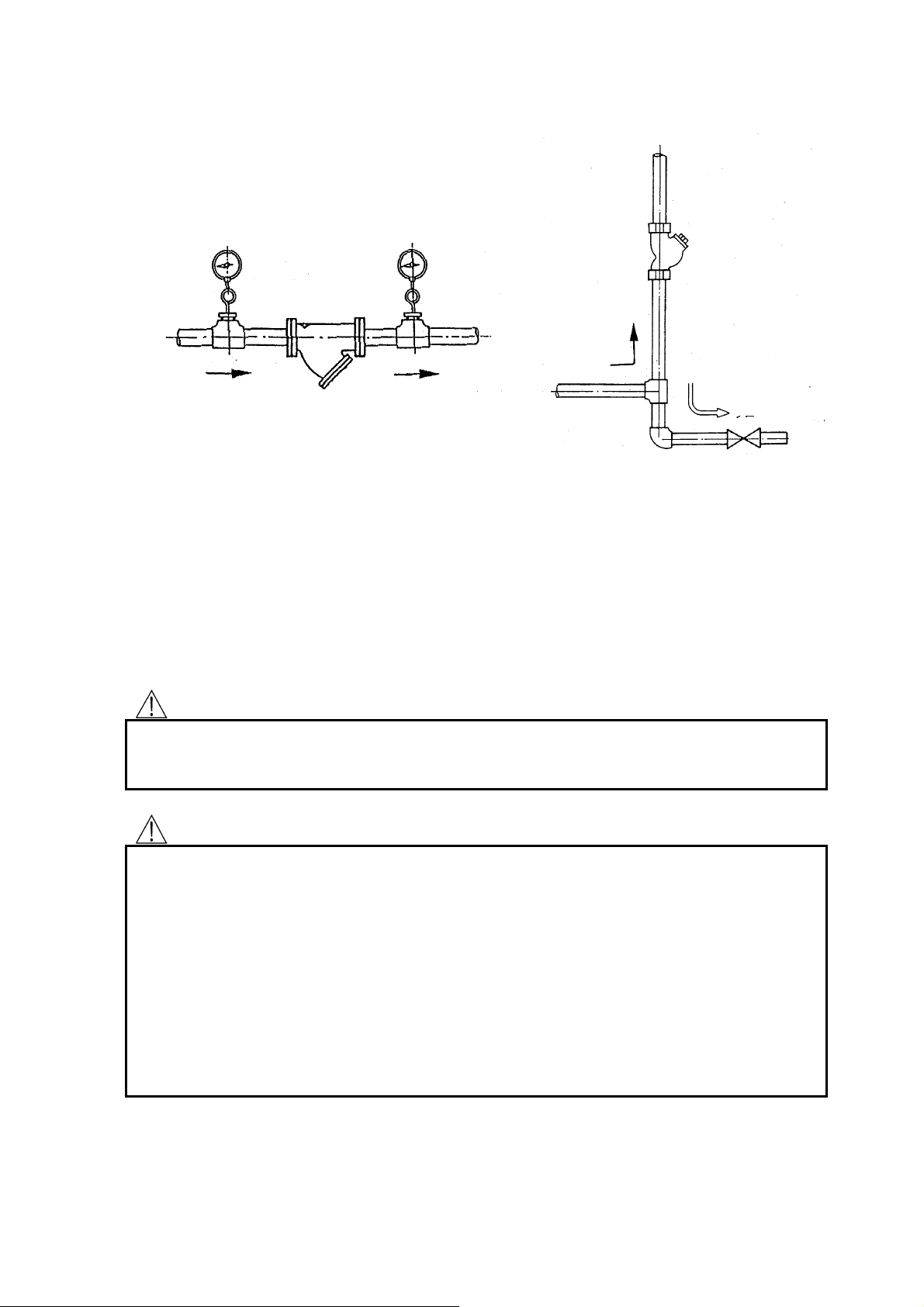

[Figure 5] Horizontal piping [Figure 6] Vertical piping

(1) The amount of clogging matter may be estimated from the differential pressure measured with

pressure gauges installed upstream and downstream of the strainer. (See Figure 5.)

(2) They shall be installed with the cap (4) or cover (5) facing down ward. If drainage or similar

problem may occur in a steam line, the cap (4) or cover (5) shall be installed so that the cap or

cover faces sideways.

(3) If the product can only be piped to run the fluid from the bottom to the top, a blow valve shall be

installed to remove the scale accumulated at the bottom of the riser pipe. (See Figure 6.)

6.2 Caution in installing the product

Blow

Warning

(1) The product is heavy and shall be securely suspended with a hoist or the like when

installed.

For the weight of the product, see section 3 “Dimensions and weight s.”

* Failure to suspend the product may cause it to fall down, possibly resulting in injury.

Caution

(1) When installing, install the pipe so that the fluid flowing direction follows arrow on the body.

* Connecting pipes in wrong directions prevents the product from performing as intended.

(2) Firmly support pipes and secure the product.

* If an excessive stress is applied to the pipes, the product may be deformed.

(3) When installing the product, reserve a space required for maintenance and inspection

(cleaning of the screen) as specified in Figure 7.

* Failure to do so prevents later maintenance and inspection (cleaning of the screen).

(4) Firmly connect pipes.

* If incompletely connected, the fluid may leak from pipes when vibration is applied. The

fluid may scald your skin.

(5) If no foreign matter is allowed to pass through the product, please contact us.

* The foreign matter corresponding to the specified mesh size may not be completely

caught constitutionally.

- 6 - ■EPDT-167b■

[Figure 7] Space for removing the screen

7. Operation procedure

7.1 Caution in operating the product

(mm)

Nominal

size

15A 80

20A 105

25A 125

32A 145

40A 160

50A 200

65A 220

80A 245

100A 310

125A 365

150A 445

200A 550

250A 675

300A 805

H

Warning

(1) Before letting the fluid into the product, check that there will be no possibility of danger if

fluid flows into the ends of piping.

* The hot fluid, if spouted out, may scald your skin.

* The fluid outflow may cause physical damage.

(2) After aerating, do not retighten the cap or cover gasket.

* Doing so may break the gasket, possibly resulting in external leak.

Caution

(1) Use the product with the maximum pressure loss below 0.1MPa. Periodically clean the

screen.

* The screen may be broken.

(1) The amount of screen clogging matter can be monitored with pressure gauges installed

upstream and downstream of the strainer.

8. Maintenance procedure

8.1 Troubleshooting

Problem Cause Solution

1. Screen (2) is clogged.

Fluid does not flow .

2. Upstream and downstream of

stop valves are closed.

1. Overhaul and clean screen (2).

2. Open the stop valves.

Excessive pressure

loss

1. Screen (2) is clogged.

2. Pressure gauge is out of order.

3. Nominal size is much

smaller than specified.

- 7 - ■EPDT-167b■

1. Overhaul and clean screen (2).

2. Replace pressure gauge with a

new one.

3. Change to adequate nominal size.

8.2 Caution in maintenance and inspection

Warning

(1) When overhauling or inspecting the product, check that the product and piping internal

pressures have been released to the atmosphere.

When the fluid is hot, cool it down until it can be touched by bare hand.

*The residual pressure in the product or piping may lead to injury or burn.

(2) When using a hot fluid, do not touch the product by bare hand.

*Doing so may scald your skin.

(3) Clean the screen periodically.

*Scale clogging to the screen may cause its damage.

8.3 Disassembly procedure

(1) After checking that no pressure remains in the strainer, remove the cap (4) and gasket (3) for 50A

or smaller ones or the hexagon nut (8), cover (5) and gasket (3 ) in this order for 65A or larger

ones.

(2) Remove the screen (2) from the body (1) and clean it. For 100A or larger ones, the screen (2) is

equipped with a strainer retainer (7). The strainer retainer (7) has usually been hung on the body

(1) and the screen (2) shall be removed by rotating to the point where the notch on the body (1)

is aligned with the strainer retainer (7). (See Figure 8.)

8.4 Caution in assembling after disassembly

Caution

(1) When assembling, completely assemble all parts.

*The parts may be deformed or broken.

(2) When assembling, replace the gasket with a new one and uniformly tighten bolts in the

diagonally opposite directions to prevent uneven tightening.

*The fluid may leak out. If hot, it may scald your skin.

8.5 Assembly procedure

(1) Clean the gasket mating faces of the body (1) and cap (4) or cover (5) and install the cleaned

screen (2) to the body (1). For 100A or larger ones, the screen (2) shall be installed with the

strainer retainer (7) aligned with the notch on the body (1) and rotated until the strainer retainer

(7) is hung on the body (1). (See Figure 8.)

(2) Install a new gasket (3) and install the cap (4) or cover (5).

Notch

(7) Strainer retainer

(2) Screen

(1) Body

[Figure 8]

- 8 - ■EPDT-167b■

9. Exploded view

(2)

(9) Stud bolt

(7) Strainer retainer

Not provided with 65 to 80A ones.

(10) Washer(SY-40C/40C-N)

(8) Hexagon nut

(1) Body

Screen

(3) Gasket

(4) Cap

(6) Plug

Not provided with 15 to

32A ones.

【図9】15-50A

[Figure 9] 15 to 50A

(1) Body

(2) Screen

(3) Gasket

(5) Cover

(6) Plug

[Figure 10] 65 to 300A

is provided as consumable parts.

- 9 - ■EPDT-167b■

Loading...

Loading...