Yoshitake GP-1000, GP-1010, GP-1000SS, GP-1000H, GP-1002 Installation & Operation Manual

...

■EPDT-081a■

Model GP-1000 Series

PRESSURE REDUCING VALVE

Installation & Operation Manual

Please read this bulletin thoroughly before using the pressure reducing valve, so that you may

do so correctly and safely. Please carefully store this bulletin in a handy place.

―――――――――The following safety symbols are used in this manual. ――――――――

Warning

Caution

Contents

1. Features・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・ 1

2. Specifications・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・ 1

3. Dimensions and Weights・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・ 2

4. Operation ・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・ 3

5. Nominal Size Selection Method

5.1 Specifications selection chart ・・・・・・・・・・・・・・・・・・・・・・・・・・・・・ 4

5.2 Safety valve setting pressure ・・・・・・・・・・・・・・・・・・・・・・・・・・・・・ 4

5.3 Characteristics chart・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・ 4

5.4 Nominal size selection chart ・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・ 5

5.5 Nominal size selection calculation formula ・・・・・・・・・・・・・・・・ 6

6. Installation

6.1 Example of piping ・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・ 6

6.2 Precautions during installation ・・・・・・・・・・・・・・・・・・・・・・・・・・・・ 7

7. Operating Procedure

7.1 Precautions during operation ・・・・・・・・・・・・・・・・・・・・・・・・・・・・・ 8

7.2 Adjustment procedures ・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・ 8

8. Maintenance Procedure

8.1 Troubleshooting ・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・ 9

8.2 Precautions during maintenance and inspection ・・・・・・・・・ 10

8.3 Disassembly・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・ 10

8.4 Precautions during reassembly ・・・・・・・・・・・・・・・・・・・・・・・・・・ 11

8.5 Exploded drawing ・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・ 12

After Sale Service

This symbol indicates a potentially hazardous situation that, if not

avoided, could result in deat h or serious injury .

This symbol indicates a hazardous situation that, if not avoided, may

result in minor or moderate injury. (“Caution” may also be used to

indicate other unsafe practices or ris ks of property damage.)

■EPDT-081a■

-1-

1. Features

GP-1000 Series pressure reducing valves for steam are pilot-operated valves which can be used with

confidence for small to large flow rate, in a host of applications ranging from building u tilities systems,

air-conditioning systems, and factory systems, etc.

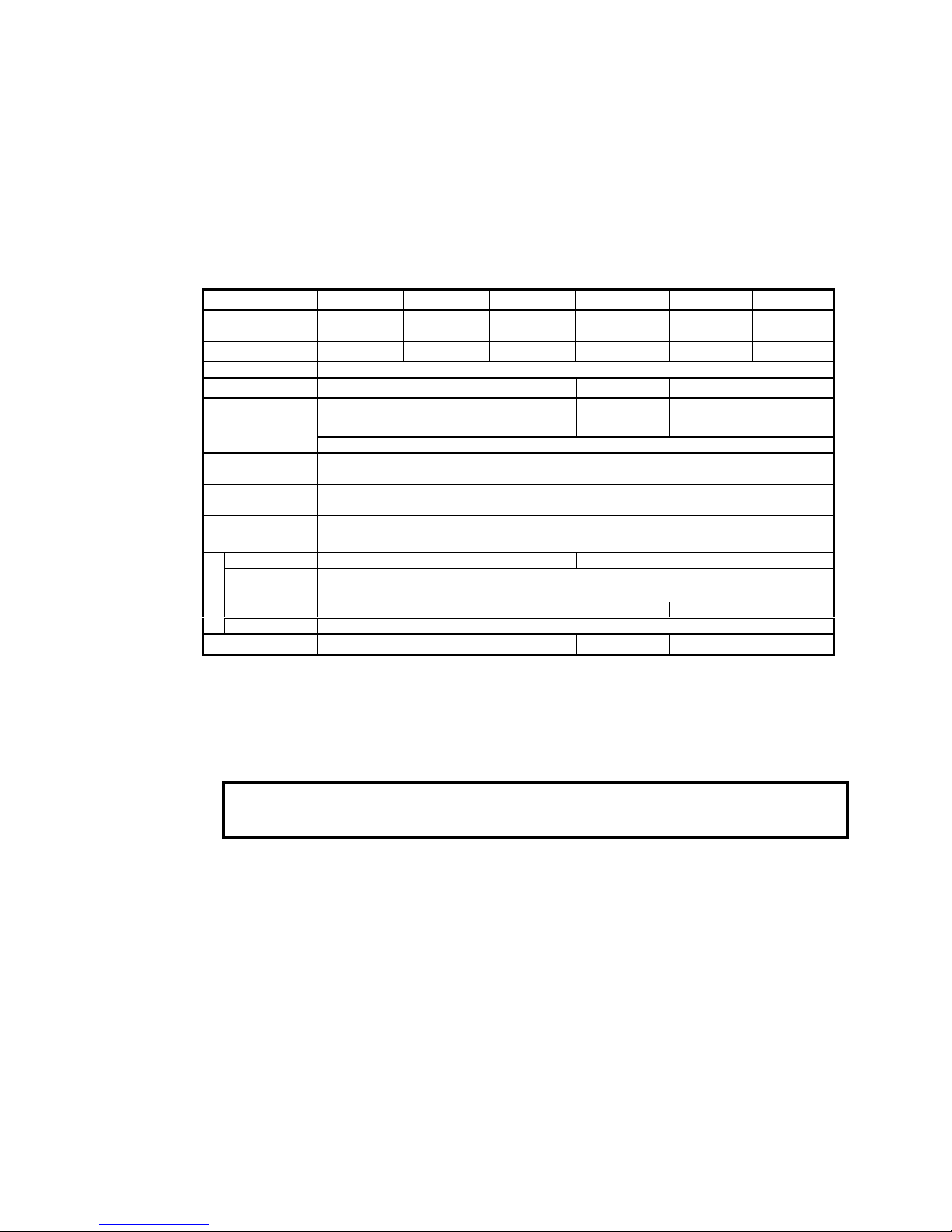

2. Specifications

Model

GP-1000 GP-1010GP-1000SS GP-1000H GP-1002 GP-1012

Connection

Flanged

(JIS 10K FF)

JIS Rc Screw

Flanged

(JIS 10K FF)

Flanged

(JIS 16K FF)

Flanged

(JIS 10K FF)

JIS Rc Screw

Nominal size

15~100A 15~50A 15~100A 15~100A 15~100A 15~50A

Application Steam

Inlet pressure

0.1~1.0 MPa 0.1~1.6 MPa 0.1~0.5 MPa

0.05~0.9 MPa

0.05~0.9 MPa

0.9~1.4 MPa

0.03~0.15 MPa

Reduced pressure

90% or less of inlet pressure (gauge pressure)

Min. differential

pressure

0.05 MPa

Max. pressure

reducing ratio

20:1

Max. temperature

220℃

Valve seat leakage 0.01% or less of rated flow

Body Ductile cast iron Stainless steel Ductile cast iron

Valve Stainless steel

Valve seat Stainless steel

Piston/Cylinder Brass or Bronze Stainless steel Brass or Bronze

Material

Gasket Non asbestos

Body hydraulic test

2.0 MPa 3.2 MPa 1.0 MPa

l Stainless steel main components (piston & cylinder) are also available.(GP-1□□□S)

l All stainless steel types are also available for GP-1000.

l Adjusting handle types are also available for GP-1000 and GP-1010.(GP-1001,1011)

Caution

(1) Please collate with att ached nameplate and specification of ordered model.

※Please consult factory in case they do not match each other.

■EPDT-081a■

-2-

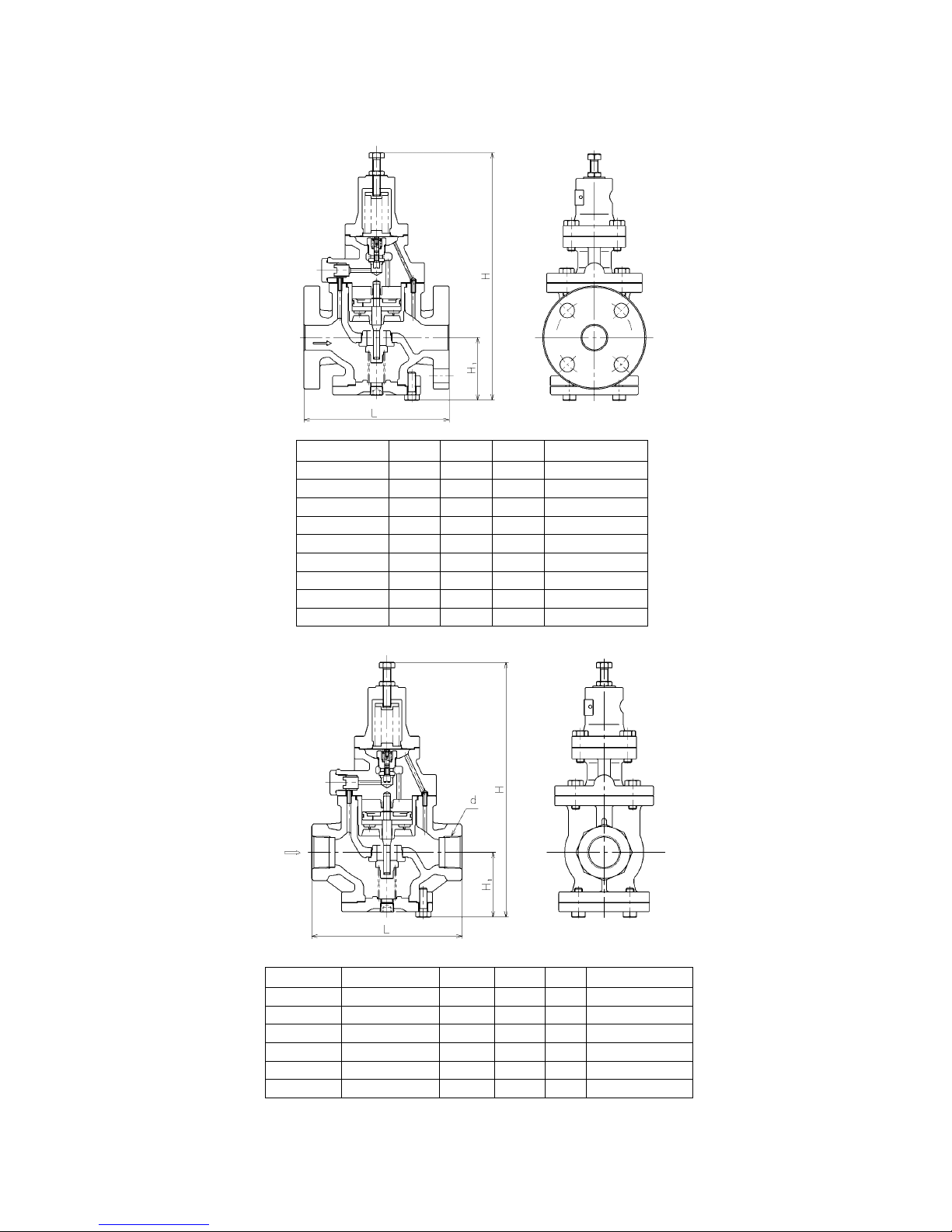

3. Dimensions and Weights

• GP‑1000,1000H,1002

(㎜)

Size

LHH

1

Weight(kg)

15A 150 285 64 8.0

20A 155 285 64 8.5

25A 160 300 67 10.0

32A 190 323 82 14.0

40A 190 323 82 14.5

50A 220 347 93 20.0

65A 245 357 100 30.0

80A 290 404 122 35.0

100A 330 450 144 52.5

• GP‑1010,1012

(㎜)

Size d

LHH

1

Weight(kg)

15A Rc 1/2 150 285 64 7.0

20A Rc 3/4 155 285 64 7.0

25A Rc 1 160 300 67 8.5

32A Rc 1-1/4 190 323 82 12.0

40A Rc 1-1/2 190 323 82 12.5

50A Rc 2 220 347 93 18.0

■EPDT-081a■

-3-

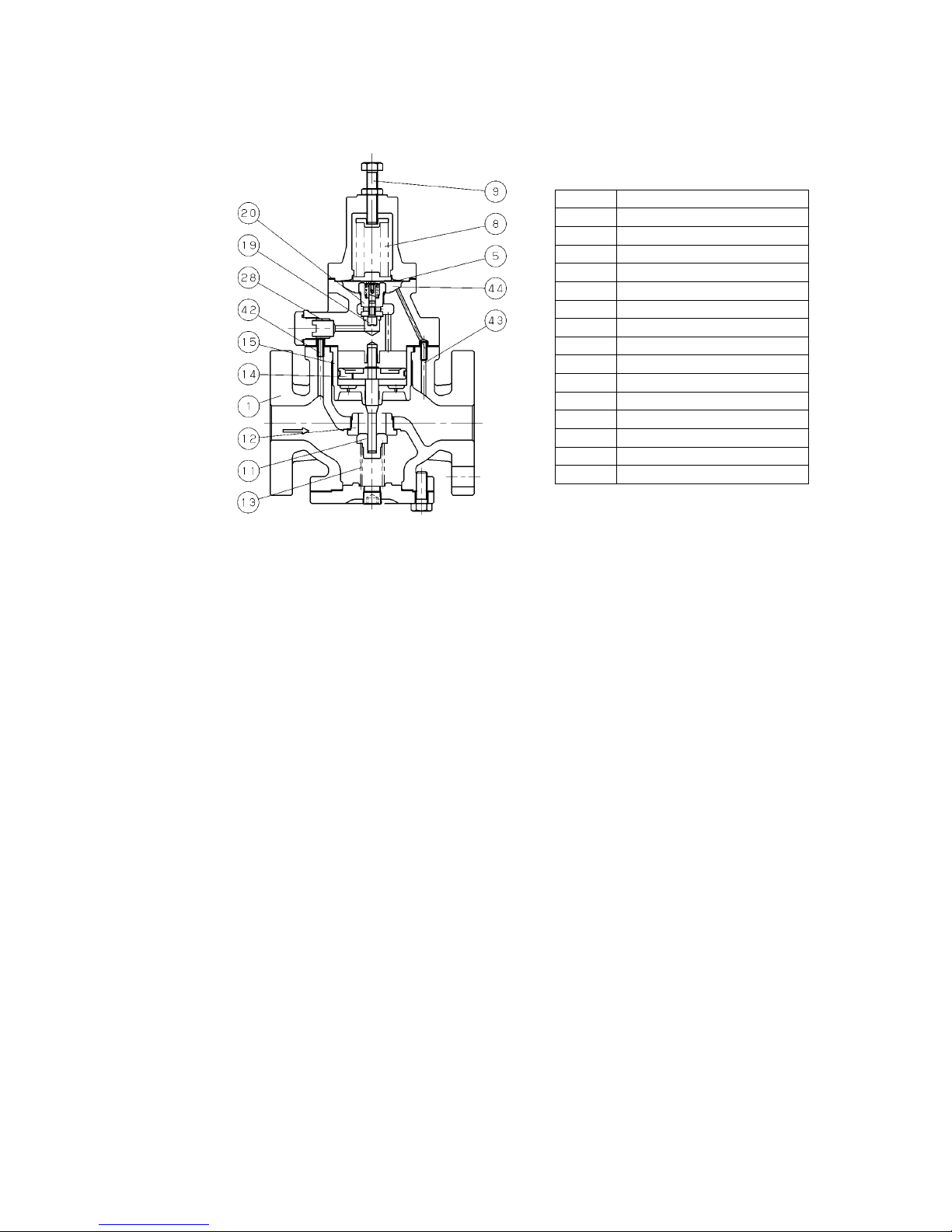

4. Operation

No. Parts name

1 Body

5 Diaphragm

8 Adjusting spring

9 Adjusting screw

11 Main valve

12 Main valve seat

13 Main valve spring

14 Piston

15 Cylinder

19 Pilot valve

20 Pilot valve seat

28 Strainer

42 Inlet press. passage

43 Reduced press. Sensing port

44 Diaphragm chamber

The pressure-reducing valve reduces pressure by the throttling the valve. The valve is composed of the

main valve and main valve seat for throttling, and adjusting spring, diaphragm, pilot valve, and piston

for pressure sensing and activation.

(1) When the pressure-reducing valve is mounted correctly, releasing the compression of adjusting

spring [8] allows the spring to close main valve [11] and pilot valve [19]. Slowly open the gate valve

and allow the high-pressure fluid to flow in. Inlet pressure is applied to the downside of the main

valve. High-pressure fluid passes through strainer [28] via inlet pressure passage [42] to also apply

inlet pressure to the downside of the pilot valve.

(2) Turing adjusting screw [9] clockwise compresses the spring, which flexes diaphragm [5] to open the

pilot valve.

(3) Inlet pressure via inlet pressure passage and pilot valve enters the upside of the piston. The pressure

overrides the pressure on the downside of the main valve and the load of main valve spring[13], to

open the main valve. The fluid then begins to flow from the inlet side.

(4) Reduced pressure is led to diaphragm chamber [44] via reduced pressure sensing port [43]. The

diaphragm receives the reduced pressure to be balanced with the adjusting spring load, and control

the pilot valve travel.

(5) The change of pilot valve travel changes the flow rate of fluid to the upside of the piston, and

controls the main valve travel to obtain appropriate reduced pressure.

Loading...

Loading...