Yoshimura SUXR-341 Service Manual

SPECIAL PARTS TECHNICAL SERVICE MANUAL

SUZUKI ‘99-01 GSX-R1300

ST-1 CAMSHAFT

(PART NO.SUXR-341)

This product is designed for racetrack use only. Do not use on the public road.

Be sure to carefully read the instruction manual before starting installation.

During installation, keep these instructions at hand and proceed with the work in

accordance with the instructions.

These instructions should be retained until the product is scrapped.

Danger

Danger

CautionCaution

(Reference)

KIT contents

: Indicates a potential hazard that could result in death or injury.

: Indicates a potential hazard that could result in motorcycle damage.

: Indicates special information for smooth work.

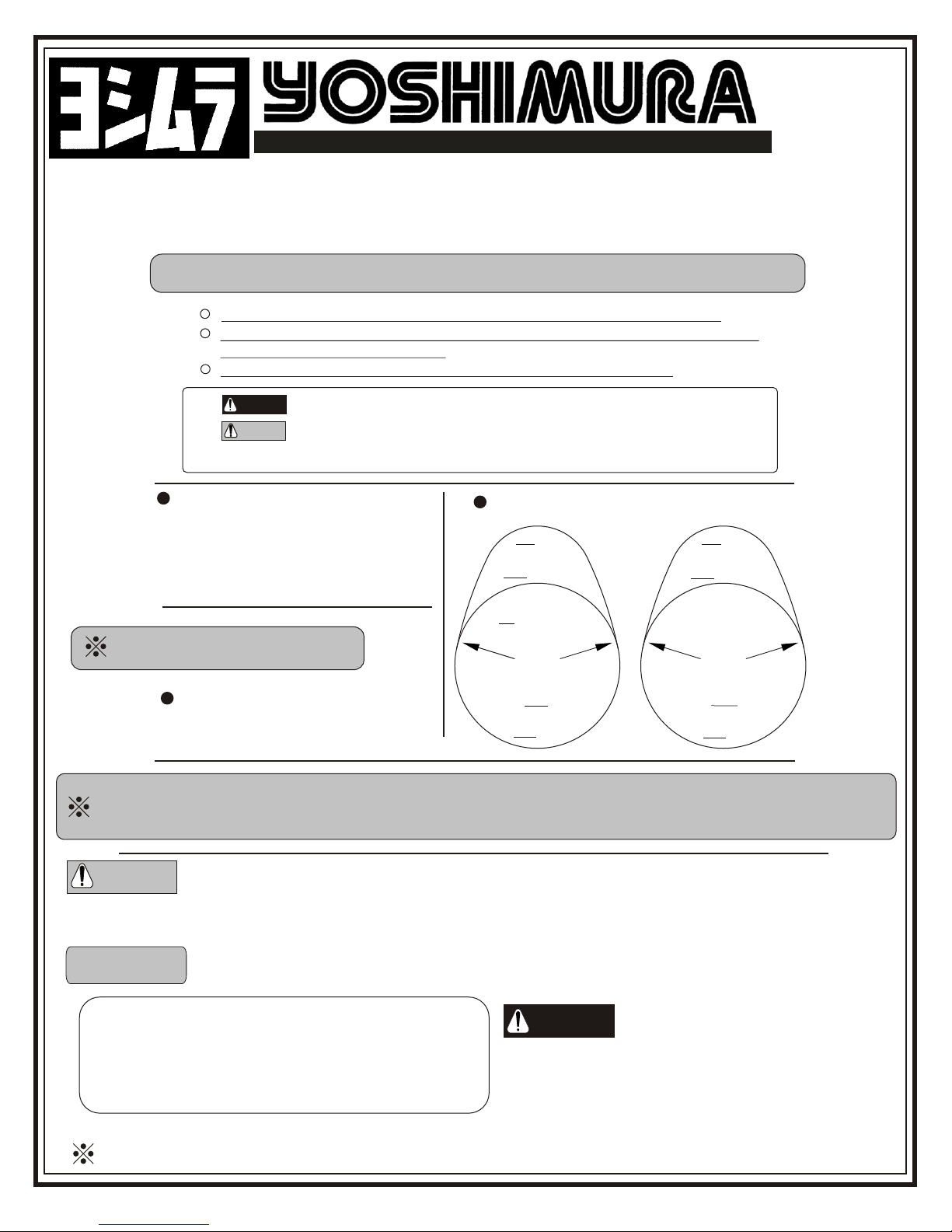

Cam Profile

- Intake camshaft X 1

- Exhaust camshaft X 1

(Including Cam Sprockets, Flanges, Bolts)

This product is only intended for use

with the model & year listed below.

Applicable model

SUZUKI GSX-R1300 (1999-01)

9.0 mm

MAX LIFT

102 L.C.°

20°

BTDC

1mm

OPEN

INTAKE

DURATION 250 AT 1 mm°

Tappet Clearance

0.20 mm

44°

ABDC

1mm

CLOSE

OPEN

EXHAUST

DURATION 230 AT 1 mm°

7.8 mm

MAX LIFT

105 L.C.°

BBDC

1mm

10°

ATDC

1mm

0.20 mm

40°

Tappet Clearance

CLOSE

To remove, install and adjust valve lash for camshafts use the SUZUKI genuine service manual

procedures.

CautionCaution

During the disassembling procedure do not drop any parts into the

crankcase. All removed parts should be thoroughly cleaned and dried.

InspectionsInspections

Check Items:

Wear and damage to valve retainers, valve cotter pins,

valve springs, spring seats and lifter buckets.

Wear, damage and looseness of valves and valve guides.

Surface contact positions and contact width of valve

seats.

Wear and damage to cylinder head camshaft journals.

Other than mentioned, please inspect each part in accordance with the SUZUKI genuine service manual

Danger

Parts inspection and

replacement of

consumable parts must be

done correctly, otherwise

it may cause serious

damage to the engine.

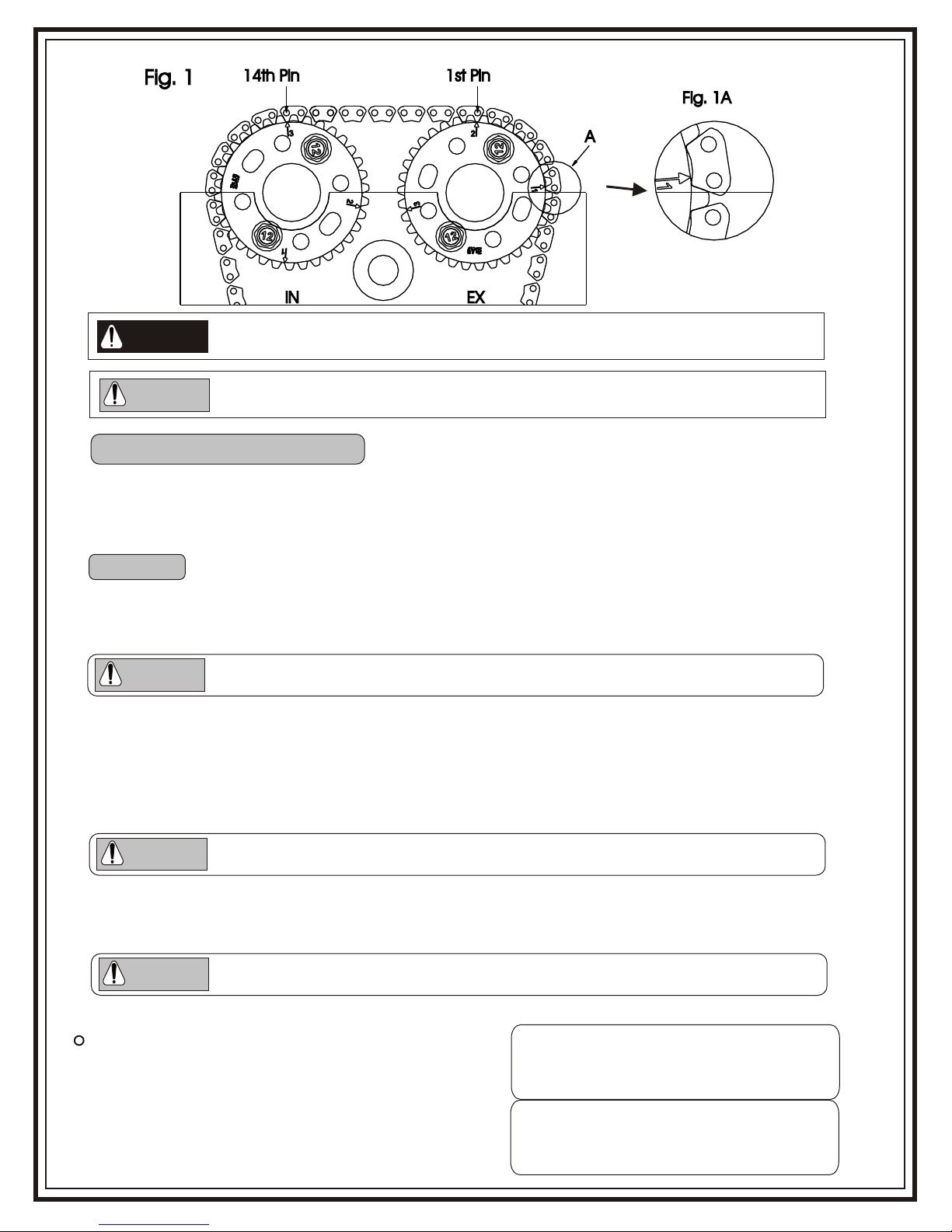

Enlargement of Fig. Of A

Danger

CautionCaution

point flush with cylinder head gasket surface (See Fig.1 and Enlarged Fig. of A)

Tappet clearances must be adjusted to the specifications supplied below.

Tappet Clearances with Engine Cold

INTAKE: 0.20

EXHAUST: 0.20

Break-in

1. Put in a specified amount of new engine oil.

(Reference) Use engine oil higher than API-SF grade and SAE 10W-40~15W-50.

2. With the spark plugs removed spin the crankshaft to lubricate the engine by using the electric starter.

An arrow marked 1 on the exhaust cam sprocket and the cam chain pin should

CautionCaution

3. Leave the machine for several minutes and check the oil level. If the level is low add suitable amount of oil.

4. Install the spark plugs.

5. Start the engine. Inspect work for oil leakage. Once the engine has reached operating temperature adjust idle.

6. Up to 100km, engine RPM should not exceed 4000RPM

7. Until 200km, engine should not exceed 5000RPM, and up to 300km engine RPM should not exceed 6000RPM.

The starter motor must be used intermittently to prevent starter motor damage.

CautionCaution

8. Once the break-in procedure has been completed, check tappet clearances and adjust as necessary. Check that

there are not irregular noises from the engine. If an irregular sound is heard disassemble the engine and inspect.

rapid acceleration should be avoided.

During normal start-up after camshaft break-in has been completed engine oil

During the break-in procedure, heavy loading action such as sudden starts and

CautionCaution

must reach normal operating temperature before applying load to the engine.

After the installation

Quality control is implemented in all products. If, however,

any defects or failure should be found please notify

Yoshimura Japan (Yoshimura-RD in the US) through the

selling dealer. Necessary technical service or replacement

will be made. Prices and Specifications are subject to

change without notice.

6748 Nakatu, Aikawa, Aiko, Kanagawa 243-0303 Japan

YOSHIMURA JAPAN Co., LTD

Phone +81-46-286-0321 FAX +81-46-286-1919

Email: yj-world@netmove.co.jp

YOSHIMURA-RD of America Inc.

5420 Daniels Street Suite A, Chino, CA 91786

Phone 1-800-634-9166 FAX 909/591-2198

Email: sales@yoshimura-rd.com

Loading...

Loading...