WEB ACCESS: http://www.yorkville.com

Manual-Service-ycv50-00-1v8.pdf

WORLD HEADQUARTERS

CANADA

SERVICE MANUAL

TYPE: YS1003

YCV50

U.S.A.

Yorkville Sound

550 Granite Court

Pickering, Ontario

L1W-3Y8 CANADA

Voice: (905) 837-8481

Fax: (905) 837-8746

Quality and Innovation Since 1963

Yorkville Sound Inc.

4625 Witmer Industrial Estate

Niagara Falls, New York

14305 USA

Voice: (716) 297-2920

Fax: (716) 297-3689

Printed in Canada

IMPORTANT SAFETY INSTRUCTIONS

INSTRUCTIONS PERTAINING TO A

RISK OF FIRE, ELECTRIC SHOCK,

OR INJURY TO PERSONS

CAUTION:

TO REDUCE THE RISK OF ELECTRIC SHOCK, DO

NOT REMOVE COVER (OR BACK).

NO USER SERVICEABLE PARTS INSIDE.

REFER SERVICING TO QUALIFIED

SERVICE PERSONNEL.

Read Instructions

The Owner’s Manualshould be read and understood

before operation of your unit. Please, save these instruc

tions for future reference.

Packaging

Keep the box and packaging materials, in case the unit

needs to be returned for service.

Warning

When using electric products, basic precautions should

always be followed, including the following:

Power Sources

Your unit should be connected to a power source only of the voltage

specified in the owners manual or as marked on the unit. This unit has

a polarized plug. Do not use with an extension cord or receptacle

unless the plug can be fully inserted. Precautions should be taken so

that the grounding scheme on the unit is not defeated.

Hazards

Do not place this product on an unstable cart, stand, tripod, bracket or

table. The product may fall, causing serious personal injury and serious

damage to the product. Use only with cart, stand, tripod, bracket, or

table recommended by the manufacturer or sold with the product.

Follow the manufacturer’s instructions when installing the product and

use mounting accessories recommended by the manufacturer.

The apparatus should not be exposed to dripping or splashing water;

no objects filled with liquids should be placed on the apparatus.

Terminals marked with the “lightning bolt” are hazardous live; the

external wiring connected to these terminals require installation by an

instructed person or the use of ready made leads or cords.

No naked flame sources, such as lighted candles, should be

placed on the apparatus.

Power Cord

The AC supply cord should be routed so that it is unlikely that it will be

damaged. If the AC supply cord is damaged DO NOT OPERATE THE UNIT.

Service

The unit should be serviced only by qualified service personnel.

INSTRUCTIONS RELATIVES AU RISQUE

DE FEU, CHOC ÉLECTRIQUE, OU

BLESSURES AUX PERSONNES

AVIS:

AFIN DE REDUIRE LES RISQUE DE CHOC ELECTRIQUE,

N’ENLEVEZ PAS LE COUVERT (OU LE PANNEAU ARRIERE)

NE CONTIENT AUCUNE PIECE

REPARABLE PAR L’UTILISATEUR.

CONSULTEZ UN TECHNICIEN QUALIFIE

POUR L’ENTRETIENT

Veuillez Lire le Manuel

Il contient des informations qui devraient êtres comprises

-

avant l’opération de votre appareil. Conservez S.V.P. ces

instructions pour consultations ultérieures.

Emballage

Conservez la boite au cas ou l’appareil devait être

retourner pour réparation.

Attention:

Lors de l’utilisation de produits électrique, assurez-vous

d’adhérer à des précautions de bases incluant celle qui

suivent:

Alimentation

L’appareil ne doit être branché qu’à une source d’alimentation

correspondant au voltage spécifié dans le manuel ou tel qu’indiqué sur

l’appareil. Cet appareil est équipé d’une prise d’alimentation polarisée.

Ne pas utiliser cet appareil avec un cordon de raccordement à moins

qu’il soit possible d’insérer complètement les trois lames. Des

précautions doivent êtres prises afin d’eviter que le système de mise à

la terre de l’appareil ne soit désengagé.

Risque

Ne pas placer cet appareil sur un chariot, un support, un trépied ou une

table instables. L’appareil pourrait tomber et blesser quelqu’un ou subir

des dommages importants. Utiliser seulement un chariot, un support,

un trépied ou une table recommandés par le fabricant ou vendus avec

le produit. Suivre les instructions du fabricant pour installer l’appareil et

utiliser les accessoires recommandés par le fabricant.

Il convient de ne pas placer sur l’appareil de sources de flammes

nues, telles que des bougies allumées.

L’appeil ne doit pas être exposé à des égouttements d’eau ou des

éclaboussures et qu’aucun objet rempli de liquide tel que des vases

ne doit être placé sur l’appareil.

Les dispositifs marqués d’une symbole “d’éclair” sont des parties

dangereuses au toucher et que les câblages extérieurs connectés à

ces dispositifs de connection extérieure doivent être effectivés par un

opérateur formé ou en utilisant des cordons déjà préparés.

Cordon d’Alimentation

Évitez d’endommager le cordon d’alimentation. N’UTILISEZ PAS

L’APPAREIL si le cordon d’alimentation est endommagé.

Service

Consultez un technicien qualifié pour l’entretien de votre appareil.

safety-4v2.eps Aug 26/05

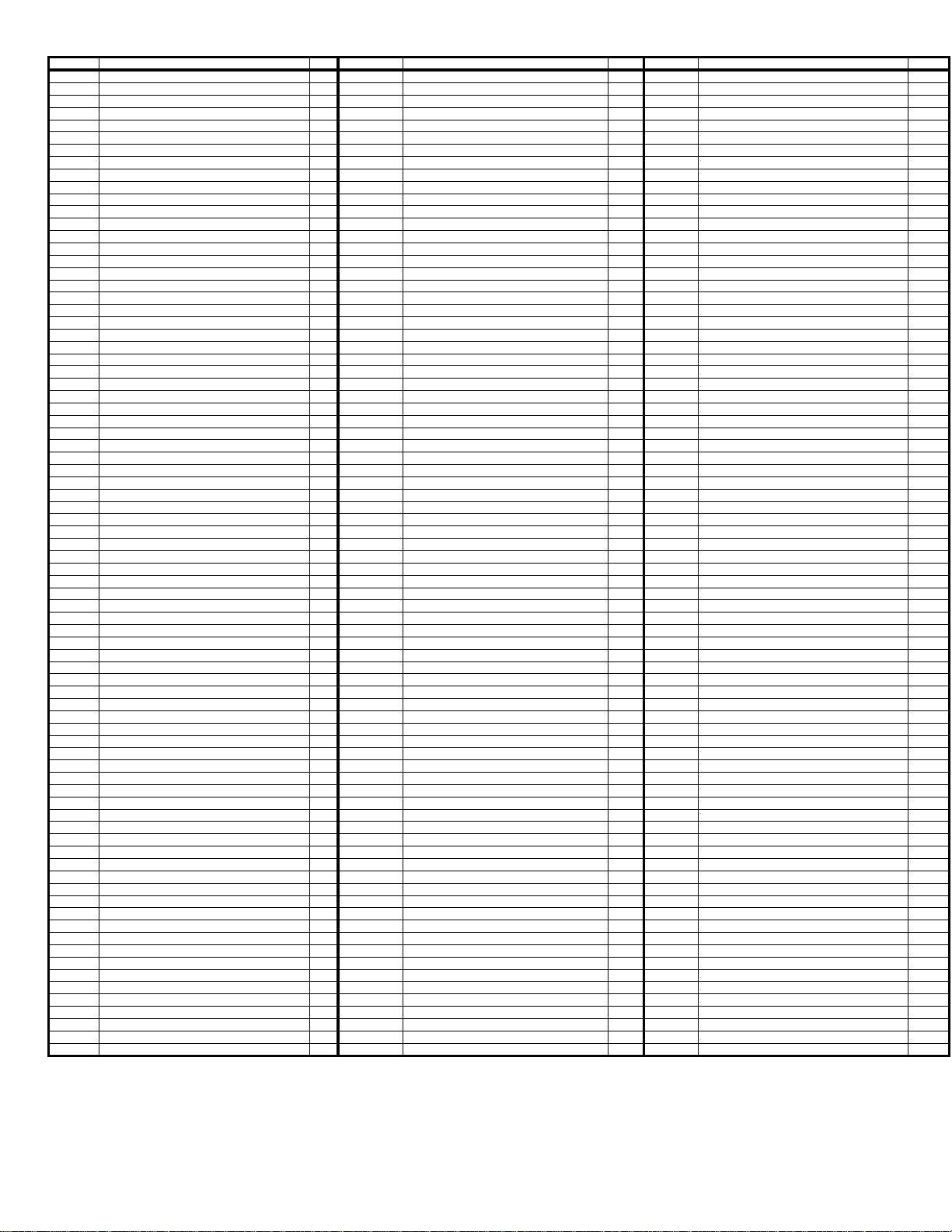

YCV50BLUE Parts List 2/15/2005

YS # Description Qty. YS # Description Qty. YS # Description Qty.

6397 JEWELED PILOT LAMP AMBER REG V1 1 3438 IEC PWR SOC W/.205TAB &FUSE 10A250V 1 3865 1/2 PLASTIC HEX SPACER #6 11

5906 RED 3MM LED 1V9 20MA .4SPCER T&R 1 3552 NYLON SPRING CLAMP 4 3858 3/4 PLASTIC HEX SPACER #4 7

6398 RED 5MM LED 1V5 20MA HIGH EFF 1 3810 4" NYLON CABLE TIE 14 7081 12" 8R 60WPGM SPKR CELEST VINT30 1

6399 YEL 5MM LED 1V5 20MA HIGH EFF 1 8430 YCV40 CHICKEN-BEAK KNOB 11 8482 3/8 1D FLAT WASHER 1

5907 YEL 3MM LED 1V9 20MA .4SPCER T&R 1 8638 AP MIXER SERIES PUSH SW BUTTON GREY 4 8488 3/8 INT TOOTH LOCKWASHE ZINC 1

5908 GRN 3MM LED 1V9 20MA .4SPCER T&R 1 3428 8' 3/18 SJT AC LINE CORD REMOVABLE 1 3511 #6 FLAT WASHER NYLON 2

6825 1N4148 75V 0A45 DIODE T&R 6 8264 YBA200/YCV LOGO EMBOSSED ALUMINUM 1 8491 #10 SPLIT LOCK WASHER BO 8

6438 1N4007 400V 1A0 DIODE T&R 10 8910 YORKVILLE PRODUCT MANUAL 1 8820 #8 FLAT WASHER JS500 4

6461 1N5240BRL 10V0 0W5 ZENER 5% T&R 1 8900 YORKVILLE WARRANTY CARD 2-YR UNLTD. 1 8817 #10 FLAT WASHER FOR 3/16" BOLT 8

6432 1N5248B 18V0 0W5 ZENER 5% T&R 1 YCV40POP YCV40/WR/T POINT OF PURCHASE BOOK 1 3522 DPDT MINI PC VERT SNP ALT 4

6475 1N5262B 51V0 0W5 ZENER 5% T&R 6 3674 9 CIR CABLE HOLDER .098 4 3698 SPST ROKR SW QUIK 180" AC PWR BL/BL 1

6731 7824 TO220 P 24V0 REG 1 8701 4-40 KEPS NUT ZINC 2 3731 SPRING RETAINER FOR OUTPUT TUBE 2

5101 BC550C TO92 NPN TRAN T&R TB 4 8800 6-32 KEPS NUT ZINC 4 3732 9 PIN PC MOUNT TUBE SOCKET BE 3

5103 MPSA06 TO92 NPN TRANSISTOR T&R TA 3 8890 1/4-20 CAGE NUT C79-88142027 4 3733 8 PIN PC MOUNT TUBE SOCKET 2

5104 MPSA56 TO92 PNP TRAN T&R TA 2 3830 TO218 PREGREASED MICA 56-78-2AP 2 12AX7 12AX7 DUAL TRIODE PREAMP TUBE 3

6873 MJE340 TO126 NPN TRANSISTOR TG 1 3850 TO-220 PLASTIC TRANSISTOR INSULATOR 2 EL34 EL34 E.H. EARLY MULLARD STYLE 2

6730 IRF830 TO220 NCH MFET TN 1 4599 22AWG SOLID SC WIR T&R JMP 58 1324 YCV40 POWER 120VAC 60HZ XFMR 1

6884 NE5532N IC DUAL OP AMP 2 5299 24AWG SOLID SC WIR RAD JMP 1 1324M YCV40 OUTPUT XFMR 1

6880 4N35 OPTO-COUPLER 1 4748 2.0W 3R9 5% T&R 1

6467 10K 10% THERMISTOR NTC TO-92 1 2008 1.0W 10R 5%FLAME PROOF T&R RES 2

5203 _47P 100V 2%CAP T&R RAD CER.2"NPO 1 4817 1/4W 47R 5% T&R RES 3

5197 220P 100V 2%CAP T&R RAD CER.2"NPO 2 2019 1/8W 100R0 1%FLAME PROOF T&R RES 2

5194 470P 1000V 10%CAP T&R RAD CER.2"Y5P 1 4852 1/4W 100R 5% T&R RES 2

5201 470P 100V 5%CAP T&R RAD CER.2"NPO 3 2022 1.0W 220R 5%FLAME PROOF T&R RES 2

5206 __1N 400V 5%CAP T&R RAD .2"FLM 3 4821 1/4W 470R 5% T&R RES 2

5422 __1N 50V 10%CAP T&R BEAD NPO 2 4891 1/4W 620R 5% T&R RES 2

5273 __1N5 200V 5%CAP T&R RAD CER.2"NPO 1 4822 1/4W 820R 5% T&R RES 2

5606 1N5 50V 5%CAP T&R RAD CER.2" X7R 1 4726 5.0W 1K 5% BLK RES 1

5208 __2N2 400V 5%CAP T&R RAD .2"FLM 2 4823 1/4W 1K 5% T&R RES 1

5274 __2N2 200V 5%CAP T&R RAD CER.2"NPO 1 4913 1.0W 1K 5% T&R RES 2

5209 __4N7 250V 5%CAP T&R RAD .2"FLM 3 4824 1/4W 1K5 5% T&R RES 5

6451 __4N7 250V 20%CAP BLK 'Y' 10MM AC 1 4631 1/2W 2K 5% T&R RES 2

5204 _10N 100V 10%CAP T&R RAD .2"FLM 1 4808 1/4W 2K 5% T&R RES 1

5840 _22N 400V 10%CAP BLK RAD POLY FLM 3 4847 1/4W 2K2 5% T&R RES 5

6435 _22N 275V 20%CAP BLK 'X2' 15MM AC 1 4827 1/4W 4K7 5% T&R RES 2

5224 _47N 100V 10%CAP T&R RAD .2"FLM 4 4828 1/4W 6K8 5% T&R RES 1

5841 _47N 250V 10%CAP RAD POLYFILM BULK 1 4663 1/2W 8K2 5% T&R RES 2

5227 _82N 100V 5%CAP T&R RAD .2"FLM 1 4829 1/4W 10K 5% T&R RES 10

5228 100N 100V 5%CAP T&R RAD .2"FLM 5 4983 1/4W 10K 5%MINI T&R RES 1

5314 100N 50V 10%CAP T&R BEAD X7R 1 4831 1/4W 18K 5% T&R RES 2

5865 100N 250V 10%CAP BLK RAD POLY FLM 2 4833 1/4W 27K 5% T&R RES 5

5231 220N 63V 10%CAP T&R RAD .2"FLM 2 4840 1/4W 33K 5% T&R RES 1

5882 220N 250V 10%CAP BLK RAD POLY FLM 2 4868 1/4W 36K 5% T&R RES 2

5233 330N 63V 5%CAP T&R RAD .2"FLM 1 4834 1/4W 47K 5% T&R RES 9

5234 470N 63V 10%CAP T&R RAD .2"FLM 2 4927 1/4W 47K 5% .2"U T&R RES 1

5254 __1U 63V 20%CAP T&R 4X7MM .2"EL 1 4586 1/4W 82K 5%MINI T&R RES 1

5257 __2U2 63V 20%CAP T&R RAD .2"EL 1 4838 1/4W 100K 5% T&R RES 11

5945 _10U 63V 20%CAP T&R RAD .2"EL 1 4942 1/4W 100K 5% .2"U T&R RES 1

5959 _10U 450V 20%CAP BLK EL 4 6120 1/4W 100K 5%MINI T&R RES 1

5631 _22U 50V 20%CAP T&R 6X7MM .2"EL 13 4776 1/4W 113K 1% T&R RES 3

5902 82U 450V 20%CAP BLK 22X30MM 1 4851 1/4W 120K 5% T&R RES 5

5267 100U 25V 20%CAP T&R RAD .2"EL 1 4668 2.0W 220K 5%10MM BODY T&R RES 1

5879 100U 16V 20%CAP T&R 8X7MM .2"EL 2 4841 1/4W 220K 5% T&R RES 2

5914 100U 63V 20%CAP BLK 10X13MM EL 1 6126 1/4W 220K 5%MINI T&R RES 4

5621 470U 63V 20%CAP BLK 12X25MM EL 1 6145 1/4W 249K 1%MINI T&R RES 1

TFS-2B TRAYNOR DUAL FOOTSWCH 10' CORD-BULK 1 4842 1/4W 330K 5% T&R RES 2

4423 _20K 15AAUDIO 9MM P32 4 4843 1/4W 470K 5% T&R RES 3

4424 100K 1B LIN 9MM P32 2 4844 1/4W 1M 5% T&R RES 6

4425 500K 15AAUDIO 9MM P32 5 4845 1/4W 2M2 5% T&R RES 1

713 25 X 20 X 50 2 MIL PLASTIC BAG 1 3610 10" 9C-26AWG RIB 3/4" NOTCH 0.1" 2

3976 SNAP ON 0.843" INSULATING BUSHING 2 3700 RELAY 2C 01AMP DC24 015MA PC-S 2

8522 RUBBER BUMPER WITH WASHER -SMALL- 4 3537 ACC# 4EB3C1B LONG REVERB 1

8563 CORNER, 2 LEGS NOTCED BLK PLASTIC 8 8865 4-40 X 5/16 PAN PH MS JS500 18

3478 CLIP 205/187X032 18-22AWG DISCO/INS 5 8741 4-40 X 1/2 PAN PH MS JS500 2

3489 CLIP 250X032 18-22AWG DISCO/INSL 2 8832 6-32 X 1/4 PAN PH TAPTITE JS500 11

3494 CLIP 205/187X020 14-16AWG DISCO/INS 2 8807 6-32 X 5/16 PAN PH MS JS500 3

3602 RING TERMINAL 18AWG WIRE & #8 SCREW 1 8801 6-32 X 3/8 PAN PH TAPTITE JS500 4

3682 250 MALE PCB TAB REEL 16 8829 6-32 X 3/8 FLAT PH TAPTITE BO#4 HEA 11

NYS224 280 PLUG NEUTRIK NYS224 1 8755 #6 X 5/8 PAN PH TYPE A JS500 BLACK 2

3498 1/4" JCK PCB MT HORZ 3 8785 #8 X 3/4 OVAL PH TYPE A BLACK OXIDE 16

3523 1/4" JCK PCB MT HORZ GOLD T__ 1 8722 #8 X 1" PAN QUAD TYPE AB B/O 4

3528 1/4" JCK PCB MT HORZ GOLD TR_ 1 8809 10-32 X 1/4 PAN PH TAPTITE JS500 25

3921 1/4" JCK PCB MT VERT STER RT SWT 1 8756 #10 X 3/4 PAN PH TYPE A BLACK OXIDE 2

3890 36"90'RCA DUAL RED-WHITE PREFAB CBL 1 8727 #10 X 1" PAN PH TYPE A JS500 BLACK 4

3914 RCA SNGL PCB MT HORZ 2 8843 10-32 X 1 1/8 FLAT PH MS JS500 2

3451 EYELET SMALL 0.089 OD PLATED 13 8786 10-32 X 1 1/4 PAN QD MS JS500 BLACK 4

2403 T2A 5X20MM FUSE 1 8862 #10 X 1 1/2 PAN PH TYPE A JS500 4

8451 10" STRAP HANDLE,BLACK METAL ENDCAP 1 8770 1/4-20 X 1 5/16 TRUSS PH MS JS500 4

8604 10-32 T NUT 6 8905 YORKVILLE PRODUCT SCHEMATIC 1

8889 RUBBER GROMMET #2183-034-BL

K 4 3741 .5 SPACER ID-.171 OD-.25 #912-500 4

MODEL TYPE: YS1003

Block Diagram for YCV50

DESIGNED AND MANUFACTURED BY YORKVILLE SOUND

EQ

Treble/Bass/Mid

Preamp

V2:B

Ch. 2

Volume

Treble/Bass/Mid

Input

Mono

1/4-inch

0 dB

Channel

Select

K1

Preamp

V1:A

Boost

Preamp

V1:B

SPLITTER

12AX7

V3

DISCONNECT POWER W HE N

REPLACING TUBES

DÉBRANCHÉ L’AP PAREIL AVA NT

DE REMPLACER LES L AM PES

Preamp

V2:A

Channel

Select

EQ

K1

Ch. 1

Volume

12AX7

V2

PREAMP

Pre-Amp

Out

EL34

V5

12AX7

V1

POWER

EL34

V4

Reverb

Drive

U2

B

Footswitch

Accutronics ©

4EBC1B

Channel Select

Boost

Reverb

U1

B

Reverb

Rtn

Master

Volume

Splitter

V3

Power

Amp

V4

V5

Amp In

External

Speaker Out

+

12-inch Speaker

8-ohms

YS#7081

-

-

External

Speaker Out

+

BLOCK-DIAG-ycv50-1v20.ai

A

1 1

2 2

J1

3 3

4 4

5 5

B

RING

K1:A

6 6

7 7

8 8

9 9

-50Vdc

R74

R73

1/4W

1N5262B 51V0

C13

D14 0W5

SPST Switch

S7

1/4W

2K2

63V 100U

10 10

1M

11 11

12 12

F1

T2A

13 13

IEC_RECT

W11

14 14

15 15

16 16

17 17

"STYLE_P32"

A

3682

IRF830

TO-220

DSG

B

YELLOW

BLACK

3682

W9

C54

W1

1N 400V

C80

15A

M

C44

63V 10U

3682

W8

22N 275V

C53

W10

3682

4N7 250V

MJE340

TO-126

W2

500K

P1:A

E

YELLOW

DRIVE

4007

D11

Transformer

1

BLK

T2

1324

BLK

CB

C

W3

BLACK

W4

36K

C

K2:A

116Vdc

0.8Vdc

R75

1/4W

3682

W27

3Vac

MPSA06

BC

E

TO-92

V1:B

36K

RED

RED

GRY

YEL

GRY

GRN

GRN

D

+158Vdc

R4

1/4W

47K

+1.2Vdc

R2

1M

1/4W

.

R6

249K

1/4W

1N 400V

C81

C17

2N2 400V

PRE-AMP

12AX7A

R7

1K5

1/4W

C26

330N 63V

C52

100N250V

1/4W

R113

3682

W26

3

3682

W28

4

3682

W13

5

3682

W12

6

72

W16

3682

8

3Vac

FLMP

R96

R95

1/8W

1/8W

100R0

100R0

BE

C

TO-92

D

W20

FLMP

RED

R1

1/4W 113K

R3

1/4W

+249Vdc

R8

R10

4007

4007

12AX7A

V3:C

{Body}

+249Vdc

PRE-AMP

12AX7A

V1:A

2X_TRIODE_HCT

{Body}

1K5

C18

1N5 200V

1/4W 120K

1/4W 120K

+33Vdc

D3

D4

4007

D5

4007

D6

{Voltage}

Val

E

C16

47N 250V

63V1U

C1

63V470U

C38

V5:B

E

F

C33

1N 400V

47K

R15

1/4W

C23

47N 100V

R5

MINI

C22

1/4W

220K

47N 100V

PRE-AMP

12AX7A

R114

1/4W

100K

R9

1/4W 120K

1N 50V

C31

10K

6467

R53

Q1

+24Vdc

7824

OUTIN

GND

6731

TO220

25V100U

C5

C57

100N 100V

V4:B

F

P8:A

159Vdc

V2:A

63V

C27

470N

R63

NTC

.

2K7

1/4W

2X_TRIODE_HCT

K2:B

V1:C

M

M

M

R11

1/4W 113K

R12

Q9

BC550C

100K

1B

TREBLE

500K

15A

P7:A

BASS

20K

15A

P6:A

MID

1.2Vdc

1K5

1/4W

TO92

5101

D7

4007

D8

4007

4007

D9

4007

D10

C82

G

470P 1000V

C19

100N 250V

D24 0W5

G

M

CLEAN VOLUME

+249Vdc

1N5250B 20V0

450V82U

C55

V2:C

2X_TRIODE_HCT

C34

4N7 250V

R56

1/4W

47K

C35

220P 100V

500K

15A

P9:A

1

2

U3:A

2.0W

R110

R13

220K

C37

C32

470P 100V

.

33K

1/4W

C20

47N 100V

C21

47N 100V

6880

6880

4N35

4N35

10MM

H

1N5 50V

R54

YEL

6399

RED

6398

6

5

4

U3:B

H

I

R58

1/4W

220K

.

R57

1/4W

220K

.

R21

1/4W

100K

BRIGHT

DOWN UP

DOWN UP

S6:B

S6:A

100K

1B

R14

1/4W

100K

P2:A

RAD

M

TREBLE

500K

15A

P3:A

M

BASS

C83

20K

15A

P4:A

M

MID

R33

1/4W

Mini

1K

1.0W

STANDBY

S3:B

LD1

LD2

R52

1/4W

2K2

D12

4007

R81

2M2

1/4W

250V

C28

220N

250V220N

C84

R93

5.0W

1K

450V10U

C39

I

J

+249Vdc

R18

1/4W 113K

+162Vdc

+1.2Vdc

1M

1K5

R16

R17

1/4W

1/4W

500K

15A

4N7 250V

47K

5101

TO92

RAD

S3:A

DOWN UP

4148

4148

R98

1/4W.330K

R50

1/4W.330K

Q12

BC550C

+400Vdc

C40

M

D15

D23

R94

8K2

1/2W

450V10U

P5:A

MASTER

R55

1/4W

1/4W 470K

R103

R102

1/4W

470R

R106

1/4W

100K

R24

1/4W

47K

4K7

R65

1N5240BRL

R101

1/4W

2K2

R94B

8K2

1/2W

450V10U

C60

J

C24

22N 400V

V2:B

PRE-AMP

12AX7A

C15

C7

50V 22U

4148

47K

1/4W

G

10V0

D130W5

W21

3682

50V22U

D16

D17

D

S

R100

1N5262B

0W5

1N5262B

0W5

1N5262B

0W5

1N5262B

0W5

1N5262B

0W5

R64

1/4W

47K

4148

R97

1/4W

10K

R66

1/4W

47R

+415Vdc

IRF830Q8

.

3R9

2.0W

K

R112

1/4W

R19

1/4W 470K

2.0W

R104

+410Vdc

Q10

MJE340

D22

51V0

D21

51V0

D20

51V0

D19

51V0

D18

51V0

K

27K

150K

K1:B

8

V+

V-

4

10MM

3682

L

C71

470P 100V

R22

1/4W

100K

R20

1/4W 100K

U2:B

U2:C

NE5532N

R67

1/4W

10K

REVERB SEND

C64

4N7 250V

16V

C8

100U

18K

R70

1/4W

200V 2N2

R68

1/4W 120K

C11

100N 100V

50V22U

R69

1/4W 120K

C10

RED

W19

C63

47P 100V

+249Vdc

450V10U

C41

L

R23

1/4W

100K

J8

C75

100U16V

C9

1/4W

R119

8

V+

U1:C

V-

4

1/4W

D1

REVERB RTN

18K

U1:B

NE5532N

R72

1M

R79

1/4W

47K

-37Vdc

M

4148

M

R88

Q2

MPSA06

5103

TO92

50V 22U

N

Mini

1K

1.0W

Q11

MPSA06

5103

TO92

D2

4148

Q3

MPSA06

TO92

5103

10K

R25

1/4W

Q7

BC550C

TO92

2K2

R34

1/4W

5101

20K

15A

M

P10:A

MASTER VOLUME

20K

15A

J7

M

P11:A

REVERB

10K

R71

1/4W

C12

10K

{T}

4520

P12

M

BIAS

.

16K

R78

1/4W

Q4

MPSA56

5104

TO92

C29

220N 63V

50V22U

27K

R76

1/4W

C61

N

O

K2:C

C46

1N 50V

K1:C

63V2U2

C69

10K

R28

1/4W

5908

GRN

Q6

R111

1/4W

BC550C

1K

50V22U

TO92

5101

C70

R26

R83

47R

R82

1/4W

R32

1/4W

10K

2K2

R27

RED

5906

1/4W

C36

2N2 400V

R51

1/4W

470K

PRE-AMP

C47

10N 100V

1M

R45

1/4W

R48

1/4W

10K

1M

PRE-AMP

R46

1/4W

C48

100N 100V

C51

82N 100V

4K7

1K5

R49

R35

1/4W

1/4W

NA: BIAS 350 mV ACROSS R91

AND 350mV ACROSS R92

CE: BIAS 300 mV ACROSS R91

AND 300mV ACROSS R92

R80

1/4W

47K

Q5

MPSA56

5104

TO92

C30

220N 63V

-38Vdc

50V22U

27K

R77

1/4W

C62

O

4K7

1/4W

1/2W

1/4W

12AX7A

+28Vdc

R47

1/4W

470R

12AX7A

P

R99

2K

R29

1/2W

LD5

CHNL2

C45

100N

50V

47R

R85

1/4W

R31

1/4W

10K

2K2

R30

1/4W

2K

100R

LD4

BOOST

+170Vdc

V3:A

R43

R44

V3:B

+168Vdc

P

5907

BOOST

DOWN UP

R62

1/4W

270K

C49

22N 400V

82K

1/4W

1/4W 100K

C50

22N 400V

R84

YEL

S4:A

+249V

1/4W

100R

LD3

CHNL1

DOWN UP

3700_DRW

S4:B

R41

1/4W

R42

1/4W

Q

CHANNEL

R87

1/4W

820R

MINI

220K

-37Vdc

-38Vdc

MINI

220K

R86

1/4W

820R

Q

R

S5:A

S5:B

DOWN UP

DOWN UP

C3

50V22U

1K

1/4W

R105

Val

V4:A

-36 to

-38Vdc

R91

R92

-36 to

-38Vdc

V5:A

Val

MODEL(S):-

1

2

3

4

5

6

7

8

9

10

11

12

13

1

2

3

4

5

6

7

8

9

10

11

12

13

R

10R

1.0W

FLMP

10R

1.0W

FLMP

OUTPUT

DATE VER# DESCRIPTION OF CHANGE#

OCT-15-2004

.

.

.

DEC-02-2004

MAR-04-2005

APR-26-2005

.

MAY-27-2005

.

.

.

.

NOV-25-2005

DEC-14-2005

.

.

.

MAY-17-2006

.

.

D

D

D

D

S

R36

1/4W 100K

C68

100N 100V

50V22U

C4

NE5532N

3682

W17

R89

1.0W

220R

FLMP

R90

1.0W

220R

FLMP

3682

W18

YCV50

1.00

2.00

.

.

.

.

2.10

2.20

.

3.00

.

.

.

.

.

3.01

4.00

.

.

.

.

.

V

V

V

V

S

T

Gold

U2:A

50V 22U

C2

NE5532N

R109

1/4W

100K

C66

220P 100V

R37

1/4W 100K

C67

U1:A

R40

1/4W

27K

C65

470P 100V

C25

100N 100V

470N 63V

C6

50V 22U

R38

1/4W 100K

MINI

10K

R59

1/4W

R39

1/4W 100K

C14

OUTPUT XFMR

5

BLU

RED

1324M

3

BRN

4

T1

GRN

BLK

-

2

3682

W15

1

-

M613 REVISION HISTORY

GT:DERIVED FROM M581 V11.00SEPT-23-2004

GT: PC#6748 R101 -> 2K2 (4847), R55 -> 4K7 (4827), D24 ->

20V0 (6465), ADD R104: 150K/2W (4790)

Increased route cutaway on preamp board

R53->3K9 (4850), R62->270K (4879), C19->100N (5865)

GT:PC#6776 MOVED TOP MULTIPLE TO ADD ZIPPER

GT:PC#6836:R78 27K #4833 --> 18K7 #5021 for bias

GT:PC#6865:STDBY FIX, ADDED #4599 x 3 AND #5299 x 1

GT:PC#6889: X61 #4599 --> 1K #4823 RESISTOR

GT:PC#6886:ADD #4520 TRIMPOT 10K, R78->#4876 16R

AH: Moved some parts, Autoinsert needs more space

PC#6937, MODIFY TUBE SOCKET ROUTING AND DRILLING

PC#6965, MOVE ARC TRACE AWAY FROM TUBES

PC#6967, INCREASE CLEARANCS NEAR OUTPUT TUBES

PC#7041:GT:UPDATED BIAS NOTE FOR R91&R92

PC#7053:GT:R53 4850 3K9->4864 2K7, NEW BIAS FOR CE

BALVINDER CORRECTED TESTNODE PADS

SPACED W8 TRACE 6MM FROM SCREW HOLE

UPDATED K1,K2 FOR CLINCH

PC#7125:GT:CHANGE #3914 RCA JACK TO #6541.

PC#7091:ENLARGE HOLE SIZE FOR #3522 KINK LEADS (S3

TO S6)

N

N

N

N

Product

Product

YCV50

Date:

Mon Sep 11, 2006

Date:

Mon Sep 11, 2006

Filename:

Filename:

YCV50

PCB# ofSheet

PCB# ofSheet

M613-4V00sch.sch2002

M613-4V00sch.sch2002

T

U

R60

1/4W

620R

50V22U

--

--

M613TUBE GUITAR AMP

M613TUBE GUITAR AMP

U

Gold .

ST R

-

PRE-AMP-OUT

R108

1/4W

10K

Gold

OUTPUT

ST R

J5

3682

EXTENSION

ST R

J6

Rev:214V00

Rev:214V00

V

FOOTSWITCH

J2

R61

1/4W

620R

ST R

J4

--

ST R

..

PWR-AMP-IN

J3

R107

1/4W

10K

W14

V

50V22U

C56

ORIGI

N

MULTIPLE

DON'T MOVE

CLINCH

ORIGIN

SHEAR

P1

INPUT

J1

3921

TIP

TIP-SW

W2

TO W3

YELLOW

500K

4425

DRIVE

BlankSize - 18600x12800

5908

M613

22N

R106

R

400V

PRE-AMP

W23

100K

T

V

4V00

V2

YCV50

TREBLE

100K

X21

12AX7A

X60

R73

D14

R74

T

R

8K28K2

1/2W

1/2W

R94B

1/4

1B

P8

C15

1K5

X51

51V0

V

63V

100U

C13

R94

R104

RED

TO W20

2.0W

150K

W25

X23

X22

220P

3522

C35

50V

22U

113K

X24

3674

X25

X34

1M 100N

2K2

C40

10U

450V

C41

T

R

V

10U

450V

BRIGHT

NOL

NOR

WHT

CL CR

NCL

NCR

S6

R18

R17

W34

R113

36K

36K

4007

C44

T

R

V

10U

R

450V

C39

M613

X53

500K

4425

R43

C49

82K

R44

22N

400V

100K

22N

400V

C50

C48

5865

R75

D11

D7

10U

63V

D8

220K

R110

2.0W

T

V

82U

450V

T

R

V

C55

4V00Pcb Mech

C4

15A

P7

X54

1M

R46

100N

C52

4007

4007

4007

T

R

V

5907

LD3

LD4

+

-

RED

BOOST

4148

D1

R19

15A

RELAY 2C

C80

NC NOC

470K

X2

1N

BOOST

NOR

WHT

3522

NCR

S4

RING-SW

RING

SLEEV

E

W37GREEN

W1

TO W4

BLACK

XFMR

BLUE

W17

NOL

CL CR

NCL

X5

EL34EH

OUTPUT

R33

K2

47K

P5

500K

X4

4425

220K

R2

R3X3R4

R5

1U

1M

1K5

47K

63V

C16

C1

YELLOW

W3

TO W2

BLACK

W4

TO W1

BROWN

W18

XFMR

W19

RED

SHORT AXIS

INSERT

VCD

ORIGIN

+

CHNL1

-

YEL

R22

R20

RELAY 2C

100K

PRE-AMP

NC NOC

12AX7A

3984

220R

Val

27K

100K

R112

K1

TREBLE

100K

4424

C71

470P

100K

R14

P2

R13

33K

3732

113K

R1

V1

EL34EH

OUTPUT

R93

R89

T

R

V

W35

Val

X47

3984

1.0W

1K

5.0W

W39

T

R

V

100R0

100R0

R96

R95

SHEAR

C83

R24

R23

4N7

15A

X7

47K

100K

X6

5841

47N

1K5

330N

C26

R7

X48

V4

LONG AXIS

R83

D2

100R

X8

4148

R25

C46

1B

C20

C21

1N

10K

47N

47N

C69

C32

470P

2U2

63V

BC550C

MPSA06

Q2

2K2

C19

R34

5865

100N

113K

R11

V5

100R

R84

C45

100N

R85

2K

1/2W

X9

P3

R26

500K

15A

4425 4424

2K

1/2W

X10

X11

X1

Q7

ETCH

GUIDE

C70

MPSA06

Q11

C82

2K2

10K

47R

R6

470P

249K

1N

R27

R32

R82

C81

R86

R87

R42

R91

R90

X45

220K

820R

820R

10R

1.0W

1.0W

220R

50V

22U

47K

220N

10R

1.0W

X46

X59

C30

R80

R92

250V

C28

220N

5882

250V

5882

220N

C84

47R

X12

R88

R29

R28

R31

R30

1K

1.0W

10K

X13

2K24148

10K

BC550C

MPSA06

22U

50V

RED

TO W25

R77

27K

X44

C62

330K

R50

Q6

Q3

1K

R111

R9

W20

R8

120K

120K

C18C17

1N52N2

R76

R41

R78

R79

P12

27K

220K

47K

16K

10K

50V

BIAS

C29

22U

R

1

C61

R

0

9

3

8

R101

220N

MPSA56

MPSA56

Q4Q5

2K2

330K

470K

4148

D23

D15

Q12

BC550C

R15

X19

47K

C22

C33

C23

X20

1N

CLEAN VOLUME

47N

X18

20K

15A

X17

4423

MID BASS

C31

1N

470R

R102

C34

P4

4N7

R56

WHT

47K

CHANNEL

S5

R10

X14

120K

XC163

Z352

6730 6731

IRF830

R100

100U

Q8

25V

C5

3R9

4007

6880

10V0

4N35

U3

D12

2M2

R81

D13

500K

4425

C57

100N

NOL

NOR

X61

3522

R57

R58

R16

CL CR

NCL

NCR

1M

1K5

X49

220K 47N

220K

X16

1N5

R12

C37

X15

7824

10K

TO220

R63

Q9

Q1

2.0W

BC550C

X43

X40

2K7

20V0

D24

R53

LD5

+

R99

-

4K7

15A

100K

R21

R52

2K2

GRN

CHNL2

X52

X65

P9

C27

470N

100K

R114

D21

51V0

51V0

C24

X50

3732

3674

GREEN

X36

X37

X58

X35

W24

TO W7

C60

D19

D20

10U

D18

450V

X38

X41

51V0

MJE340

51V0

51V0

Q10

D22

W21

METAL BACK

C67

22U

50V

SPLITTER

4007

470N

RED

D9

D10

C68

X56

100K

100K

100K

R36

R37

R109

12AX7A

3732

GREEN

W26

W28

M613 YCV50

RED

4V00

W29

BLACK

TO W6

T

470U

R

V

63V

C38

Top Assy

100N

V3

W27

R66

C66

U2

220P

NE5532N

47K

R65

20K

15A

4423

MIDMASTER

R45

R47

R48

1M

X55

10K

470R

2N2

C36

W16

T

R

22N

V

275V

2/4

4007

4007

4007

4007

D16

D17

4148

4148

22U

50V

P6

R62

X30

X31

270K

X33

X32

GREEN

6435

C53

D6

D4

D3

D5

M613

R64

47K

C7

C56

47R

C8

100U

16V

22U

50V

R61

R49

C51

4K7

620R

470K

C54

4N7 250V

R

6451

SHEAR

R67

R97

10K

10K

82N

C47

W5

W9

W10

T

V

W11

W12

W13

C64

C9

4N7

22U

50V

R35

1K

X28

1K5

R105

10N

R51

BLACK

W8

LINE

NEUTRAL

WHITE

GREY

4V00

BlankSize - 18600x12800

R39

R38

R40

R72

R68

R71

U1

C65

100U

16V

470P

C3

MASTER VOLUME

20K

4423

X29

P10

G2

RCA

REVERB SEND

3674

+24V

X26

100K

100K

15A

22U

50V

C25

SIG

G3

FOOTSWITCH

OUTPUT XFMR

BLACK

GREEN

OUTPUT

27K

NE5532N

C11

R59

C10

100N

10K

C6

R70

18K

18K

22U

100N

50V

X63

J7

G2

G1

J8

6541

REVERB RTN

.

7 7

Gold

Gold

J2

22U

C2

50V

BLACK

W14

TO W29

GREEN

W15

TO W24

1M

10K

120K

R69

22U

50V

X27

120K

2N2

R119

C75

X64

SIG

G1

G3

6541

RCA

X57

3674

PWR-AMP-IN

W30

W6

W7

C12

22U

50V

47P

C63

20K

15A

4423

P11

REVERBBASS

X39

R55

.

.

Gold

J3

M613 YCV50

4V00

-

7

-

-

StepAndRepeat - X1@0.000Y2@6.400

LD1

STANDBY

YEL

R54

STANDBY

NOR

1.0W

NCR

S3

PRE-AMP-OUT

4/4

4V00

6399

X62

LD2C14

RED

ON

6398

WHT

NOL

CL CR

NCL

3522

-

7

-

-

J4

R107

R108

W36

-

OUTPUT

7

-

M613

-

SHEAR

J5

X42

1K

4K7

R60

620R

10K

10K

3/4

EXTENSION

J6

SEE LAYOUT DOCUMENTATION

MODEL(S):-

# VER#DATE

1

SEPT-23-2004 1.00 GT:DERIVED FROM M581 V11.00

2

OCT-15-2004 2.00 GT: PC#6748 R101 -> 2K2 (4847), R55 -> 4K7 (4827), D24 ->

3

4

5

6

DEC-02-2004 . GT:PC#6776 MOVED TOP MULTIPLE TO ADD ZIPPER

7

MAR-04-2005 2.10 GT:PC#6836:R78 27K #4833 --> 18K7 #5021 for bias

8

9

..

10

11

. . AH: Moved some parts, Autoinsert needs more space

12

..

13

. . PC#6965, MOVE ARC TRACE AWAY FROM TUBES

1

. . PC#6967, INCREASE CLEARANCS NEAR OUTPUT TUBES

2

NOV-25-2005 PC#7041:GT:UPDATED BIAS NOTE FOR R91&R92

3

DEC-14-2005

4

.

5

.

6

..

7

MAY-17-2006

8

. PC#7091:ENLARGE HOLE SIZE FOR #3522 KINK LEADS (S3

9

10

D

11

DVN

12

D

13

D

D

1

D

2

D

3

D

4

D

5

D

6

D

7

D

8

D

9

D

10

D

11

D

12

D

13

M613 REVISION HISTORY

YCV50

DESCRIPTION OF CHANGE

20V0 (6465), ADD R104: 150K/2W (4790)..

. Increased route cutaway on preamp board.

.. R53->3K9 (4850), R62->270K (4879), C19->100N (5865)

GT:PC#6865:STDBY FIX, ADDED #4599 x 3 AND #5299 x 12.20APR-26-2005

GT:PC#6889: X61 #4599 --> 1K #4823 RESISTOR

3.00MAY-27-2005 GT:PC#6886:ADD #4520 TRIMPOT 10K, R78->#4876 16R

PC#6937, MODIFY TUBE SOCKET ROUTING AND DRILLING

.

PC#7053:GT:R53 4850 3K9->4864 2K7, NEW BIAS FOR CE3.01

BALVINDER CORRECTED TESTNODE PADS4.00

SPACED W8 TRACE 6MM FROM SCREW HOLE

.

UPDATED K1,K2 FOR CLINCH

. PC#7125:GT:CHANGE #3914 RCA JACK TO #6541.

.

TO S6)..

V

N

V

N

V

N

V

N

V

N

V

N

V

N

V

N

V

N

V

N

V

N

V

N

V

N

V

N

V

N

V

N

SEE LAYOUT DIAGRAM

MODEL(S):-

#

DATE

1

D

2

D

3

D

4

D

5

D

6

D

MODEL(S):-

#

PC#

1

PC

2

PC

3

PC

4

PC

5

PC

6

PC

*PLACE IMPLEMENTED CHANGES INTO BOARD HISTORY

MODEL(S):-

DRIVE

P1

TREBLE

P2

BASS

P3

MID

P4

MASTER

P5

MID

P6

BASS

P7

TREBLE

P8

CLEAN VOLUME

P9

MASTER VOLUME 23/04

P10

REVERB

P11

.

.

M581 DRILL HISTORY

YCV50

VER# DESCRIPTION OF CHANGE

V

N

N

V

N

V

N

VVN

V

N

M581 PENDING CHANGES

YCV50

PENDING CHANGE

X

X

X

X

X

X

M613 POT LIST

YCV50 TUBE AMP

KNOBPART#FUNCTIONREF

AS OF

11/00

#8430

#4425

#4424

#4425

#4423

#4425

#4423

#4425

#4424

#4425

#4423

#4424

.

11/00

#8430

11/00

#8430

11/00

#8430

11/00

#8430

11/00

#8430

11/00

#8430

11/00

#8430

11/00

#8430

#8430

11/00

#8430

.

.

"STYLE_P32"

PRODUCTION NOTES

1. RTV MUST BE ADDED TO THE FOLLOWING CAPS

C1,C16,C19,C17,C70 BETWEEN C84,C28,C60,C15

BETWEEN C49,C50, ADDED TO C15,C7,C8,C3,C9

C56,C14,C6,C10,C4,C2 AND C12

2. C53 IS 22N FOR BOTH NORTH AMERICA AND CE

3. C3,C7,C6 MUST BE LOW PROFILE PT#5631

4. C8,C9 MUST BE LOW PROFILE PT#5879

3796 on this

device only.

Z352

5. R63 #6467: APPLY THERMAL

COMPOUND GENEROUSLY

BETWEEN PART AND HEATSINK

6. NA: BIAS 350mV ACROSS R91

AND 350mV ACROSS R92

CE: BIAS 300mV ACROSS R91

AND 300mV ACROSS R92

LEAD/PIN REFERENCE

IRF830

MJE340

GSD

EBC

TO-220

TO-126

MPSA56

MPSA06

ECB

TO-92

BC550C

CEB

TO-92

G2

P

3

2

H

4N35 NE5532N

G1

4

5

1

8

4H6

2K

NC

6

3

7

2

H

2G

1 9

K

Lots of goop

on the thermistor.

COM1 COM2

NC1

NC2

NO1

NO2

3700_DRW

H

1P

5

1G

7

8

1K

2 of 8701

2 of 3850

2 of 8829

- to hold z352 in place

PCB

2 of 8741

YCV50BLUE m613 Service Update for V2.10 boards

April 2005 boards have been reworked as described in this document.

To address PC#6865 a 22AWG wire, part # 3947 jumper, needs to be soldered from P10

to S3 on the bottom side of the board as shown:

YCV50BLUE m613 Service Update for V2.10 boards (additional)

1. First complete the Service fix PC#6865 as described in the pdf:

Service_YCV50-m613_Update_for_V2.10_PC#6865.pdf

To upgrade the unit from v2.10 to v2.20 PC#6889, complete the following:

2. Replace jumper X61 with a 1K resistor, #4823:

132 4E

wiring-YCV50-CE-AC

GR A Y

GR AY

WH ITE

BL UE

NE UTR AL

BR OW N

BL AC K

GR E E N

GR E E N

SU PP L Y

GR AY

WHI TE

BLA CK

R E D

R E D

+24V

INP U T

JB 1

EY E8

TO _EY 8

TO _EY 7

EY E7

BLAC K

YE L LOW

GR EE N

ME TA L_ BA CK

TO E YE 9

GR AY

WC 8

TO E Y4

F

EY E5

BL K

WC 7

WC 2

WC 4

LIV E

WC 1

WC 3

GR N

WC 6

RE D

WC 10

C53

250V AC

680N

WC 9

WC 5

GR N

Gr n/Y el wire

solde red to grou nd lug

JB 5

F

EY 9

C41

EY E6

F

GR E E N

#3638

TO E YE6

RE D

RE D

GR N

F

JB 6

OUTP UT

EX TE NSIO N

BL K

TO EY 5

EY 2

EY 4

TO OUTP UT

TRA NSFO RMER

WC 14

WC 15

TO OUTP UT

F

TRA NSFO RMER

BL K

WC 11

RE D

OUT PUT-TUBE

6L6B

V4

OUT PUT-TUBE

RE D

RE D

6L6B

BL AC K

BR OWN

WC 13

WC 12

BLU E

GR EE N

R E D

BR OWN

BL UE

Y C V 5 0C E

E X POR T AC

WIR ING

April 14/05

By G.K

132 4M

Loading...

Loading...