Page 1

The Yorkville In-House Method for Repairing AP Series Amps

At Yorkville, we have developed a method of rebuilding AP series

power boards in the shortest possible time. This method is valid for

repairing about 95% of all AP amp failures and is essentially the same

process for each of the different models in the AP line.

This process was not designed to correct problems other than blown

outputs and collateral losses. We still see an occasional failure in other

areas, but about 95% of all amps that you receive in PROTECT mode,

will benefit directly from this method.

This uniformity of approach is possible because all AP series amps

share the same basic circuit topography and protection circuits. The

rail voltages and the number of output devices may change, but overall

they remain more alike than they are different. Only the AP800 &

AP1020 have enough differences to warrant a comment or two.

The entire program rests on the experience we gained while rebuilding

these boards. What became apparent was the fact that we needed to

focus on rebuilding the board and not trying to ANALYZE the

problem. As you can imagine, this practice goes against just about

everything we have practiced as repair technicians. But, by using this

method, we were able to reduce turn-around time and expense by more

than 50%. In fact, with practice, an average technician can do a full

meltdown rebuild in about 90 minutes. The exception to this rule would

be the AP 6040, which runs about 3 hours for an average rebuild.

The root of this system is the practice of NEVER measuring TO-92 style

transistors. They are always replaced because it takes about 5 minutes

to replace them and they cost next to nothing compared to the cost of

analysis and the risk of a failed rebuild. I instituted this policy after

discovering that these little transistors have a really nasty habit of “halffailing”. By this I mean that we were testing these things in the normal

fashion and they were showing “good”, but when powered up to

operating voltage, they would do all kinds of inexplicable things. As

soon as I mandated the practice of always replacing these little

transistors, these strange post-rebuild malfunctions disappeared and

departmental efficiency went way up.

Page 2

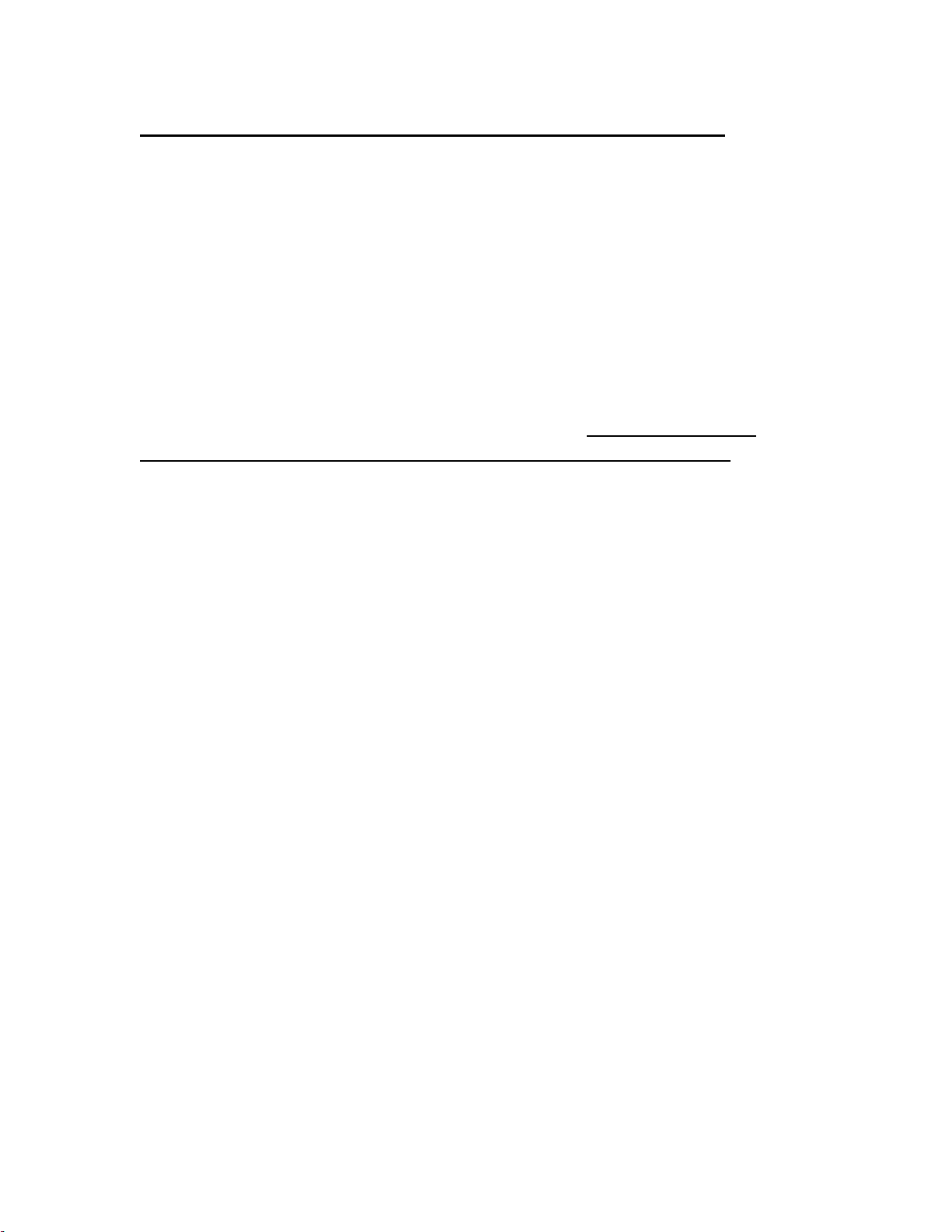

Determining which channel is blown

In order to determine which channel(s) requires repair, it is only

necessary to open the chassis and flip the upper circuit board out of the

chassis without disconnecting any wires ( be sure to insulate the board

from touching the chassis when in this position). Then all you need to

do, is turn on the power and measure the voltage across ZD7 on each

power board. (The location of ZD7 is shown on the M1146 Diodes &

Semi’s PDF) If the voltage here is less than the zener rated voltage of

16volts, the board under test is blown and probably in DC offset.

Locating Defective Parts

Attached to this file are 3 PDF’s that locate and identify all the

components which require measuring. For the purpose of clarity I have

divided the components into 4 groups, each with its own colour. Further

to this, I separated the parts into 2 PDF’s, one for resistors and one for

semiconductors. In order to provide maximum clarity, I have expanded

isolated areas of the circuit board, showing only the area of the board,

which is home to the suspect components. By doing this I have cropped

out half of the output transistors, emitter resistors and tier diodes

(MR854) from view. Please be certain to test these none-visible parts

along with the rest of the output devices , resistors and diodes.

The PDF Colour Coding

Green

Blue

show 4 of the 8 MR854 tier diodes which must all be measured). The

only significant measurement in this group will be a short circuit which

signifies a diode to be replaced.

These are the large transistors and Fet’s.

Simply test these with your diode checker and replace any

shorted units. You will almost never need to replace the tier Fet’s,

they never seem to fail, but we check them anyway. Although it is

not shown on the PDF, you will need to check the output crowbar

TRIAC for shorts, along with everything else.

These are all the diodes to be measured (remember, we only

Page 3

Red

NEVER MEASURE THESE, Always replace these 8

transistors

Yellow

These are the resistors to be measured. You are only interested

in units, which measure open circuit, all other readings are meaningless

at this time Please note that we are only measuring resistors of 249 ohms

or less, with the exception of the 2 x 3K resistors and the 10K trim pot.

The Process

With the component side up and the heatsinks farthest from you.

We use a continuity checker (you may use a diode checker) and begin

by checking the 8 emitter resistors for open circuit. I immediately cut

out any components that measure defective, We do not unsolder the

lead fragments until I have cut away all the various bad parts.

Next. Measure the MR854 tier diodes and cutout any bad ones.

Now measure all the transistors outlined in GREEN, cut out or remove

any which are shorted. The output devices must obviously be

unsoldered to remove them from the board. Please note that it is not

uncommon to find it necessary to unsolder and isolate all of the output

bases and emitters in order to find all the shorted output devices.

Now measure all diodes in BLUE (except theMR854 that you have

already done) and cut out any that read short. When that is done you

may measure all resistors shown in YELLOW, and cut out any

that

read open circuit. It is also a good idea to check the bias trim pot

(orange colour) just to be safe.

Once you have located and cut out all the short and open

components, it is time to unsolder and remove all the remaining pieces

of the component lead wires from the board. After that, collect all the

parts you need and install them to the board.

For the sake of efficiency, I have small parts bins on the bench

which have quantities of all the values of resistors I need and all the

diodes as well. I only go to the main parts bins to get the big transistors

required for the job. (10 different resistors and 6 different diodes will

cover 90% of the work). I also keep the mandatory TO-92 devices on

my desk because they are always replaced on every job.

Page 4

After you have replaced all the defective parts, it is time to repeat

the measurement process. This is a precaution against installing the

wrong value or inverting the polarity of a diode and things like that.

This time the values you measure will be quite close to the value of the

installed resistors (except for R11 which usually reads about 16ohms).

When you are satisfied that all the right parts are in the right

places and measuring the appropriate value, you may proceed to a soft

start power up of the board. If all goes well, you need only set the bias

and return the board to the chassis.

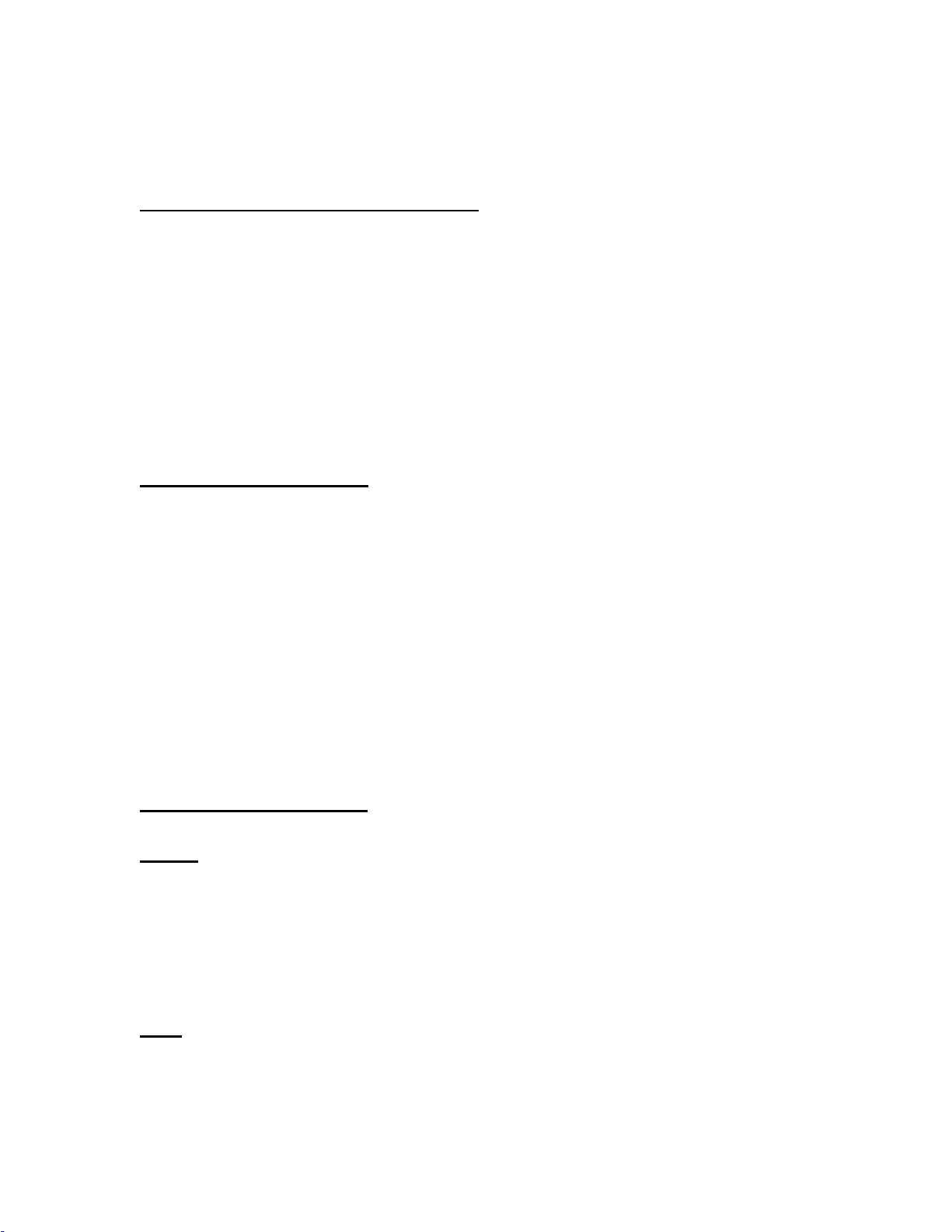

Exceptions to the rules

There will be rare occasions when the voltage amp will be

compromised as well as the current amp. In this case it is only necessary

to use the same basic process to repair the voltage stage. And as always,

just replace the small signal transistors as we do for the current amp

stage. In order to effectively deal with the voltage amp, it will probably

be necessary to electrically isolate the voltage amp from the current

amp. To do this I have created a PDF called “Separate voltage and

current amps AP4040”. When you are finished the repair, just restore

the original connections for normal operation.

The AP6040 is a special case as a rebuild. This is due to the fact

that a 6040 is really pretty much 2 AP4020’s on each output circuit

board. In order to repair these boards, you should treat them as a

permanently bridged AP4020. Repair each half of each channel as if

they were separate AP4020’s. Due to the high currents generated in the

bridged condition, these amps are more susceptible to destroying circuit

board traces than their un-bridged counterparts. Please keep a sharp

lookout for bad traces on this board. Because this amp is really 4

complete amps an two boards, we found the rebuild times to be twice

what they are for our regular two channel amps.

Page 5

P:\1146V60.PRN

In order to separate the voltage amp from the

current amp. It is only necessary to remove jumpers

J11 and J12 (highlighted in red) and then make the

two new connections as shown by the BLUE dotted

lines.

PRODUCTION NOTES

MARCONI

HOLE

Q15

Q16

D13

MR854

YS6900

YS6900

.

.

R56

0R1

5WATT

M1146 AP-4040

YEL

EY9

YS6900

.

2

D14

MR854

1

Q18

YS6900

.

Q17

R58

5WATT

WC6

0R1

BLUE

Q19

D15

MR854

Q20

YS6900

YS6900

.

.

R60

0R1

5WATT

MARCONI

HOLE

Q13

D22

Q14

MR854

YS6900

.

YS6900

.

R53

0R15

5WATT

J24

1

2

MOUNTING HARDWARE FOR Q5,Q6

MOUNTING DETAILS FOR 5W

ADD #8629 SPACERS ONLY ON

5 WATT RESISTORS

R29, R29A R45 AND R45A

#8871 4-40X 1/2" BOLT

#3501 BELL WASHER

T264 DEVICE

#3797 THERMO PAD

HEATSPREADER

PCB

Q28

Q26

Q22

Q1

BC550

TORQUE 4 INCH/LB

#8701 4-40 KEPS NUT

Q24

Q23

NOTE #6

2oz.COPPER

Q30

4700u

80V

#5896

V

R

T

V

T

V

R

T

C28

+78V

22K

0.5W

22K

0.5W

C23

R69

R68

C29

+145V

TAB1

22K

0.5W

22K

0.5W

V

R

T

C22

4700u

80V

#5896

V

R

T

V

R

T

V

T

BLANK SIZE=14.750"X10.850"

R

R66

R67

80V

#5896

4700u

TAB2

ASSEMBLY M1146-6.00

BLANK SIZE=14.750"X10.850"

M1146.PCB_DATABASE_HISTORY

MODEL(S):-

AP4040

VCD

PCBMECH M1146-6.00

# DESCRIPTION OF CHANGEVER#DATE

1

FEB/12/98

2

JUN/19/98

3

JUL/45/98

4

SEP/10/98

5

.

6

JAN/27/99

7

JUL/08/99

8

AUG/12/99

9

OCT/12/00

10

.

11

D

1.00

1.01

1.02

2.00

.

3.00

4.00

5.00

6.00

.

V

RENAMED_M1126A->M1146

PC#5767_C10/C15/C20A_2N2_TO_PT#5427

PC#5798_R72_4K7_1/2W->4K7_1W

PC#5806_ADD_33R_33u/16V_ACROSS_R57A

R64A_C30A/R72A_C31A/R71A

PC#5908_U1,U2_4N35->TLP621

SPKON_JACKS_RE-CONFIGURED

CORRECT_ERROR_IN_SPKONS

PC#6278_ADD_R86-C17_AT_Q41

PC#6083_REDO_GND_TRACKS

N

.

YS6927

YS6927

TRIAC

DC_PROT

MAC224-4

-

OUTPUT

R

.

TAB7

V

R

T

10R

MBS4992

J6

J5

C27

80V

#5896

4700u

5WATT

MR854

R64

R65

Q29

0R1

R57

D17

33K

16V

10U

V

R

T

TAB3

TAB6

OUTPUT

C21

C19

V

R

T

4700u

GND

L1

+

10N

250V

80V

#5896

C24

V

T

.

0R1

5WATT

YS6927

.

0R1

5WATT

YS6927

1

.

0R15

5WATT

BC560

Q2

3

MOUNTING HARDWARE FOR Q40,Q41

YS6927

MR854

R61

D19

MR854

R59

D18

R52

MR854

D16

#8741 4-40X 1/2" BOLT

#3501 BELL WASHER

Q27

.

YS6927

AS35

Q31

YS6927

.

Q25

Q21

.

HEATSPREADER

YS6927

T126 TYPE DEVICE

#3797 THERMO PAD

PCB

#8701 4-40 KEPS NUT

TORQUE 4 INCH/LB

R29

D20

R63

5WATT

5R6

4uH

5.5"PUR

WC6

16AWG

2WATT

3R9

TP10

R62

V

R

80V

#5896

4700u

-78V

T

TAB4

R59A

10R

C19A

C18A

R41A

7K5

C27A

C26

V

R

T

R

J3

D21

56K

22U

16V

22U

16V

7K5

MR854

MR854

4700u

C25

R42A

R38A56K

R39A

160V

10u

200V

R30

80V

V

R

T

R71

4148

D16A

D13A

C9

4N7

620R

#5896

V

R

T

100K

4148

D15A

4148

4148

D14A

R43A

3K6

5WATT

C20A2N2/500V

R40A220R

Q12A

MPSA42

R44A

R45A

Q13A

1K

1K

MPSA92

3K

160V

17K8

R56A

R29A

R31

39R

C10 2N2/500V

V

R

T

4700u

MJE350

Q15A

#3894

C22A

R50A

4K7

10u

C28A

3K6

80V

#5896

10R

R65A

10P

D17A

4K7

4148

R46A

Q14A

MTP10N15L

G

GS

5WATT

WC7

R32

16V/1W

7"YEL

16AWG

ZD8

1R

R28

1/2W

S

39R

TP6

Q11

3K6

R45

5WATT

J1

R72

250V

TAB5

-145V

500V

R47A

D18A

1K5

4148

BC560

J9

THIS CAPS IS

USED AS A

MJE340

Q16A

C23A

10P

#3894

500V

R58A

39R

R51A

R53A

1K5

Q17A

BC550

150R

16V

33u

C31A

R64A

2K

M1146 2 oz. COPPER

220N

C11

SPACER

R70A

33R

10K

R71A

Q21A

250V

220N

C14

R69A

3K3

R57A

4K7

22N

2W

220K

HS2

1W

MJE340

C26A

4U7

10V

R60A

10V

4U7

BC560

J10

330R

R74

R73 2K

C152N2/500V

3K6

1K

R46

J21

33V

C32

10U

63V

4N35

U2

Q18A

R68A

3K3

J4

C25A

Q20A

2K

150R

33R

R72A

MTP8P20

Q12

D

G

GS

ZD9

16V/1W

5WATT

R47

J2

R45A

ZD13

R81

220R

4N35

U1

D19A4148

#3894

R61A47R

R67A

10K

BC550

R49A

16V

33u

C30A

39R

1R

R44

R80

R63A

39R

D20A

4148

4148

D22A

C29A

C16

470P

D31

1/2W

ZD10

4V7

220R

D30

#3894

MJE350

D21A4148

330U

16V

SOLDER

WIRE TO

JUMPER

J20

39R

R48

1N4004

R37

4V7

ZD11

91K

J34

R36

1N4004

J11

Q19A

R62A

D23A4148

47R5

R66A

TP5A

27K

D11 BAV21

HS1

J19

10R

TP7

J29

R55A21K5

MX1

Q41

C17

J22

220P

R86

D7

4148

R35A

J12

1

470P

C4

J30

Q8

20K

BC550

1U

63V

R21

J14

2K2

J13

47K

R205

1

GND

SIG

NFB

GND

TSENSE

PRTCT

CLIM

CLIP

HOLDER=#3676

CABLE=#3706

MJE350

FUNCTION

200R

470R

12K

150R

R16

D5

R15

R42

4K7

18K

C8

R70

R84

Q6

R83

J23

Q4

249R

4148

10K0

R19

D3

4148

4K7

R23

249R

R18

16V/.5W

R22 3K

ZD7

Q7

2N6517

RED 2.5"

RED 13"

BLK

MJL1302A

.

.

200R

BC550

R17

10V

22U

C5

R25

220K

220K

R24

27K

R13

C6

ZD5

C7

BC560

330U

4"

14"BLK

22U

10V

TP5

16V

330U

12V

16V

MJE340

FUNCTION

Q40

Q3

R82

C3

RED

M1126

BLK

BLK

R5

200R

249R

TP4

12V

ZD4

EY2

EY6

EY5

EY1

J26

R6

10K0

JZD3

L+

L-

Q5

R8

12K

1-

R7

150R

J15

3K

R20

.

B

MJL3281A

.

.

1R/1W

1R/1W

R33

R39

D10

J16

249R

D4

R9

4148

470R

BC560

Q10

J17

R12 39R

R50

39R

270R

R51 220R0

R14

R43

22N

C31

M1146

AP-4040

R85

R47/1W

4V7

ZD12

1N5

1N

4148

C2

D2

1K

R35

D1 4148

20K

R40B

470R

BC550

R26

22N

Q9

D9 4148

C12

27K

R38

J33

J32

R49

91K

BAV21

1K

R40

C13

R27 2R2

22R

R11

22N

R41 2R2

VER:6.00

DRILL M1146-6.00

SOLDERSIDE M1146-6.00

JB3

1+

.

B

BLK

EY8

BLK 3.5"

BLK 18"

BLK

R-

EY3

A

A

1-

2-

2+

.

YELL

2.5"

YEL

EY4

EY7

YEL

.

R+

YELL

19"

J18

R104K7

TP1

R3

2R2

39R

R1

R4

2R2

68R

R2

C1

BRIDGE

.

1+

2+

.

RT1

VBE

10K

270R

R34

C30

22N

TP9

220R0

R55

M1146-6.00

TP8

JB2

BRIDGE

2-

MOUNTING HARDWARE FOR Q11,Q12

4

#8741 4-40X 1/2" BOLT

#3501 BELL WASHER

#8667 SHOULDER WASHER

T-220 DEVICE

#3846 MICA

HEATSPREADER

PCB

#8701 4-40 KEPS NUT

TORQUE 4 INCH/LB

MOUNTING HARDWARE FOR TO3 OUTPUTS

5

#8835 BOLT

TO-3 TRANSISTOR

#3815 MICA

HEATSPREADER

#8663 SPACER

MICA GREASE IS REQUIRED ON

BOTH SIDES OF THE MICA PAD

#8800 6-32 KEPS NUT

INITIAL TORQUE FOR TO-3’S IS 8 INCH/LB

FINAL TORQUE AFTER HEATSINK HAS

COOLED FROM WAVE SOLDER IS 6 INCH/LB

6

USE #XXXX SMALL BODY 1R 1W

FOR R33,R49

7

MOUNTING DETAILS FOR Q30 TRIAC

USE #8799 TO MOUNT TRIAC Q30

1

IMPORTANT

AFTER MOUNTING DEVICE

DO NOT CUT LEGS

2

3

1/4"

BEND DOWN 1/4" FROM BODY

OF TRANSISTOR

BEND LEGS IN DIRECTION SHOWN

IT IS IMPERATIVE THAT LEGS

MARKED 2 AND 3 ARE BENT FLAT

AGAINST THE COPPER SURFACE

9

10

Q31 IS HAND INSERTED AND BENT OVER

WITH FLAT SIDE UP AS SHOWN.

8

TAB WIRE COLOURS

TAB 1

TAB 2

TAB 3

TAB 4

TAB 5

TAB 6

TAB 7

RED

YEL

BLK

WHT

BLU

16AWG

16AWG

16AWG

16AWG

16AWG

OUTPUT +

OUTPUT -

Page 6

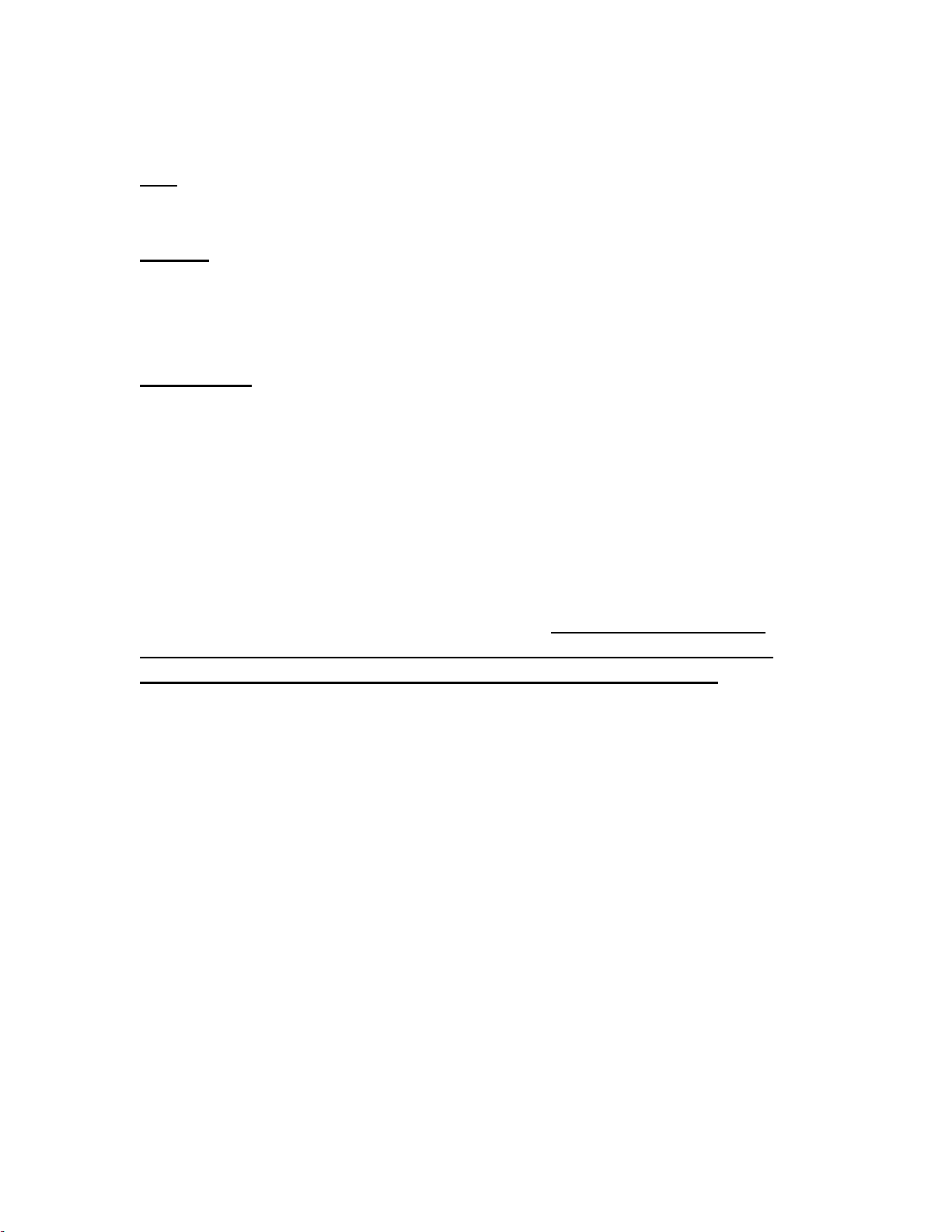

Q17

There are 8

TO-92

transistors ( RED

dots). NEVER

measure them ALWAYS replace

them

if you

measure less

than 16volts

on this zener,

this channel is

blown.(ZD7)

Q19

MJ21196

Q13

MJ21196

ETCH

GUIDE

R58R61

0R1

5.0W

BLUE

W11

0R1

5.0W

D19

Q31

AS35FN

R74

R73

2K

X10

5.0W

330R

ZD9

C15

16V0

2N2

3K6

5.0W

1K

R46

X2

R54

X1

R80

X21

R72

33V0

ZD13

C32

R81

63V

10U

4K7

1.0W

6880

4N35

4N35

6880

220K

U2

R88

6752

IRF630NPBF

Function

{Watts}

TO220

Q11

WC7

R32

16V0

39R0

YELL

ZD8

3K6

1R

R28

1/2W

TP6

R45

5882

5882

250V

250V

220N

220N

C11

C14

X9

6925

MTP8P20

Function

{Watts}

TO220

Q12

39R39R0

R47

1R

R44

220R

U1

470P

1/2W

220R

Q26

Q25

C16

ZD10

4V7

Q20

4007

D31

4V7

4007

MJ21196

MJ21195

SOLDER

WIRE TO

JUMPER

X20

TP7

39R0

R48

R37

D7

4148

27K

ZD11

R36

R89

BAV21

91K

220K

D11

X35

MJ21195

Q41

R84

220P

X22

C17

R35A

20K0

X30

BC550C

X29

X13

R60R59

MR854

D14

R53R52

Q14

0R1

5.0W

0R15

5.0W

X24

MJ21196

BC550C

Q1

0R1

5.0W

Q22

0R15

5.0W

Q2

MJ21195

BC560C

MR854

MR854

D18

X7

Q21

D16

MJ21195

R49D4R33

1R

1R

1.0W

1.0W

Q5

91K

R39

BAV21

D10

R9

1K2R2

27K

X16

22R

4148

4148

D9

D1

R40B

20K0

22N

X32

R38

R11

R40

C13

R27

R41

M1146 1/2

22N

4148

2R2

BC560C

AP4040

9V30

249R

470R

R14

R51

39R

220R0

R50

R43

22N

C31

Q10

X18

R4

RT1

R3R1

R10

R12

R85

0R47

BIAS TRIM

4K7

2R2

2R239R0

10K

1.0W

270R

R34

C30

22N

68R

4V7

TP1

ZD12

R2

C1

1N5

TP9

R55

220R0

TP8

X17

39R

270R

TO3P

R25

ZD5

X25

43K

C5

200R

R13

330U

BC560C

TP5

12V0

25V

C7

22U

50V

C6

330U

MJE340

TO126

E

200R

Q3

R82

C3

25V

70057004

2SC5949-0

TO3P

B

C

FunctionFunction

Q40

X26

470R

R87

R5

R8

R7

220P

R6

C18

12K

1N

151R

4148

150R

10K0

C2

D2

TP4

X15

C12

R35

ZD4

12V0

R26

R20

1K

3K

470R

XZD3

BC550C

Q9

X8

X33

MJE350

2SA2121-0

TO126

E

B

C

Q6

200R

X23

470R

R86

R83

BC550C

Q4

R18

249R

4148

12K

470P

150R

151R

10K0

R19

22U

50V

C4

R15

Q8

R42

1U

63V

C8

2K2

X14

R17

D3

R16

D5

3K

4K7

220K

4148

16V0

ZD7

R22

18K

4K7

220K

2N6517

Q7

R70

R23

R24

Page 7

A

these are the

transistors ( 8pcs

in red) which we

always replace

1 1

2 2

3 3

W1:H

W1:G

W1:F

W1:E

W1:D

4 4

W1:C

W1:B

W1:A

5 5

6 6

7 7

8 8

9 9

10 10

C32

11 11

12 12

13 13

14 14

15 15

16 16

B

8

8

8

8

8

8

8

8

1/4W

R71

100K

C19A

.

1.0W

R72

4K7

GND

OUT

VCC

AS35FN

Q31

.

2K

1/4W

R73

33V0

10U 63V

0W5 ZD13

17 17

A

B

C18A

22U 50V

C

.

1/4W

56K

R38A

.

1/4W

7K5

R39A

4148

D13A

22U 50V

4148

D14A

R40A

1/4W

C20A

220R

4148

D15A

4148

D16A

.

1/4W

7K5

R41A

.

1/4W

56K

R42A

.

1/4W

R74

330R

C29

C28

C27

C26

C

R205

1/4W

47K

R55A

1/4W

21K5

R56A

1/4W

17K8

400V2N2

4700U 80V

4700U 80V

80V

4700U

80V4700U

.

.

R43A

1/4W

C23

C25

3K

D

MPSA42

MPSA92

80V

C22

4700U

4700U

80V

C24

4700U

80V

4700U 80V

D

R49A

R47A

R46A

R44A

1K

R50A

R51A

R53A

R69

R66

E

33U 16V

C30A

1/8W

FLMP

33R

R72A

.

2K

1/4W

BC560C

1/4W

1K5

10P 500V

4148

C22A

Q15A

D17A

1/4W

4K7

Q12A

1K

1/4W

1/4W

R45A

Q13A

1/4W

4K7

4148

D18A

1/4W

1K5

10P 500V

C23A

Q17A

BC550C

MINI

2K

1/4W

C31A

33U 16V

1/8W

FLMP

33R

R71A

.

.

1/2W

1/2W

R68

22K

22K

.

.

1/2W

1/2W

R67

22K

22K

E

4148

4148

4148

R57A

R64A

1/4W

Q14A

1/4W

151R

D19A

D20A

D21A

151R

FUSIBLE

FUSIBLE

D22A

4148

D23A

4148

R67A

R68A

R58A

MJE350

MJE340

Q16A

R63A

R69A

R70A

F

1/4W

10K

1/4W

3K3

1/4W

39R0

1/4W

39R0

.

1/4W

3K3

BC560C

1/4W

10K

F

G

Q20A

4U7 63V

C26A

BC550C

C27A

FUSIBLE

2.0W

220K

R60A

1/4W

R61A

Q19A

MJE350

FUSIBLE

Q21A

4U7 63V

C25A

G

R59A

10U 160V

MJE340

Q18A

47R0

FUSIBLE

1/4W

R62A

C28A

1/4W

47R0

10U 160V

H

10R

FUSIBLE

C29A

1/4W

10R

R66A

FUSIBLE

25V 330U

BC550C

R1

1/4W

FUSIBLE

39R0

FUSIBLE

.

R2

1/4W

68R

BC560C

C1

1N5 200V

1/4W

10R

R65A

FUSIBLE

H

BC560C

Q1

Q2

Q3

R3

R4

R17

R5

1/4W

.

1/4W

2R2

.

1/4W

2R2

BC550C

1/4W

151R

FUSIBLE

151R

FUSIBLE

R6

C2

R7

1/4W

10K

RT1

M

1/4W

R10

1/4W

R15

C4

Q4

1/4W

R18

MBS4942

MT2

I

1/4W

1N 50V

150R

4K7

150R

470P 50V

N/C

I

10K0

R8

249R

R16

10K0

MT1

J

C3

22U 50V

1/4W

R87

470R

R82

1/4W

200R

.

1/4W

12K

R9

1/8W

FLMP

FLMP

1/4W

F

R11

22R

R12

R14

R19

1/8W

249R

FLMP

R84

1/4W

.

.

1/4W

200R

R13

43K

1/4W

12K

C5

22U 50V

BC550C

BC560C

BE

C

TO-92

R86

1/4W

470R

FLMP

GDS

J

220P200V

C18

MJE340

Q40

1/4W

1/8W

FLMP

R83

39R

200R

.

1/4W

39R

MJE350

Q41

C17

220P 200V

2N5401

2N5551

2N6517

MPSA13

MPSA43

MPSA56

MPSA63

BC

E

TO-92

STM-BTB-600BRG

G

MT1

MT2

1.0W

R85

0W5

4148

D4

4148

2SA2121-0

Q6

7004

TO3P

K

4148

4148

0R47

4V7

D3

AS35

K

2SC5949-0

Q5

7005

TO3P

D1

D2

FLMP

ZD12

IN

OUT

L

R20

C6

330U 25V

ZD5

25V330U

C7

1/4W

R22

ZD40W5

3K

M

R33

1.0W

1R

FLMP

3K

1/4W

12V00W5

.

1/4W

R21

2K2

Q7

2N6517

12V0

1/4W

R23

4K7

D5

4148

220N 250V

C8

C14

1/4W

R89

220K

R30

1/4W

620R

.

R29A

R24

1/4W

220K

R70

18K

BC550C

1U 63V

C13

22N 100V

R46

1/4W

1K

1/4W

R88

220K

1/4W

R29

3K6

5.0W

3K6

5.0W

U1:B

.

.

Q8

U2:B

N

6

5

4

4N7 250V

C12

22N 100V

1/4W

R25

220K

R54

3K6

5.0W

R45

3K6

5.0W

6

5

4

4N35

C9

C11

220N 250V

ZD7

0W5 16V0

1/4W

R42

4K7

R49

1.0W

1R

FLMP

R44

1/2W

1R

.

.

C15

2N2 400V

6880

4N35

O

1

R80

U1:A

1/4W

220R

2

R31

1/4W

39R

.

IRF630NPBF

ZD8

R26

1/4W

470R

BC550C

Q9

.

1/4W

R27

2R2

R35A

20K0

MINI

20K0

1/4W

R40B

.

1/4W

R41

2R2

BC560C

Q10

R43

1/4W

470R

.

R47

1/4W

39R

.

R81

1/4W

1

220R

MINI

U2:A

2

R28

1/2W

1R

1/4W

MINI

ZD10

4V7

C10

2N2 400V

Q11

1W016V0

.

1K

1/4W

R35

D7

4148

D9

4148

1K

1/4W

R40

C31

22N 100V

1W0 16V0

C16

470P 100V

ZD11

4V7 0W5

P

0W5

4007

D

N

G

S

C30

22N 100V

R36

1/4W

91K

.

R37

1/4W

27K

.

R38

1/4W

27K

ZD9

G

DS

4007

1/4W

R32

.

R39

1/4W

91K

R48

D30

39R0

FUSIBLE

R55

1/8W

220R0

FLMP

.

1/4W

39R0

MTP8P20

Q12

D31

Q

Q13

MJ21196

MJ21196

Q14

R34

1/4W

270R

D11

BAV21

D10

BAV21

R51

1/

220R0

R50

1/4W

270R

.

FUSIBLE

R53

R52

D14

MR854

.

5.0W

0R15

.

5.0W

0R15

MJ21195

Q22

D16

MR854

MJ21195

Q21

MJ21196

Q15

Q16

MJ21196

R

MR854

R56

R57

MJ21195

MR854

D13

.

5.0W

0R1

0R1

Q24

D17

MJ21196

Q17

Q18

MJ21196

.

5.0W

MJ21195

Q23

S

R58

D22

MR854

.

5.0W

0R1

.

R59

0R1

MJ21195

Q26

D18

MR854

MJ21195

Q25

MJ21196

Q19

Q20

MJ21196

5.0W

R60

T

MR854

D15

MR854

.

5.0W

0R1

R61

0R1

MJ21195

Q28

D19

MR854

MJ21195

Q27

D21

.

5.0W

D20

MR854

{AWG}

BLK

{Function}

U

{AWG}

RED

EY1

{Function}

R63

5R6

.

5.0W

L1

EY2

Function

SPEAKON 4C

3628

1_

SPEAKON 4C

Function

SPEAKON 4C

3628

1_

SPEAKON 4C

V

J1:A

1+

2_

2+

3628

J1:B

J2:A

Function

1+

2_

2+

3628

Function

J2:B

4UH

.

2.0W

R62

3R9

C19

10N 250V

.

1/4W

R64

33K

MT1 MT2

G

MBS4992

C21

10U 16V

Q29:A

STM-BTB-600BRG

R65

1/4W

10R

.

YS6909

MODEL(S):-

DATE VER# DESCRIPTION OF CHANGE#

E

B

BOTTOM

VIEW

REF

ECB

CEB

L

1

JUN/19/98

2

JUL/4/98

3

SEP/10/98

4

.

5

JAN/27/99

6

JUL/08/99

7

AUG/12/99

8

OCT/12/00

9

AUG/28/01

10

SEP/18/01

11

MAY/03/02

12

.

13

MAY/16/03

1

FEB/09/04

2

SEP/2004

3

APR/25/06

4

MAY/02/06

5

JUL/04/06

6

.

7

D

8

D

9

10

D

D

11

D

12

13

D

M

N

M1146 Database History

AP4040

DERIVED FROM M1126FEB/12/98

1.00

1.10

PC#5767 C10,C15,C20A 2N2 TO PT#5427

1.20

PC#5798 R72 4K7 1/2W TO 4K7 1W

2.00

PC#5806 ADD 33R, 33u/16V ACROSS R57A,R64A,C30A,

.

-R72A,C31A,R71A

3.00

PC#5908 U1,U2 4N35 TO TLP621

4.00

SPKON JACKS RE-CONFIGURED

5.00

CORRECT ERROR IN SPKONS

PC#6278 ADD R86,C17 AT Q41. PC#6083 REDO GND TRA

6.00

PC#6429 ADD R87,C18 AT Q40

7.00

PC#6438 ADD R88,R89 AT U1, U2

8.00

PC#6517 Q13->20 #6900->#6909. Q21-Q28 #6927->#6910

8.10

R13 27K-<43K,C18 1N->220P,R87 100R->470R

.

8.20

PC#6607 C10,C15, C20A #5427->#5208

8.30

PC#6658 CHANGE BREAKAWAY AND ROUTE

9.00

CONVERT TO PCAD2002

9.10

PC#7007 MAC-224-4 TO STM-BTB-600BRG

9.20

PC#7083 MTP10N15L TO IRF630NPBF

9.30

HA, PC#7076, REPLACE Q5 #6989 WITH #7004

.

Q6 #6990 WITH #7005

V

N

V

N

V

N

V

N

V

N

V

N

O

P

Product

Product

POWER AMP

POWER AMP

Date:

Tue Apr 03, 2007

Date:

Tue Apr 03, 2007

Filename:

Q

R

Filename:

S

PCB# ofSheet

PCB# ofSheet

M1146-9V30sch.sch2002

M1146-9V30sch.sch2002

T

U

M1146AP4040

M1146AP4040

Rev:219V30

Rev:219V30

V

Q30

Page 8

R74

R73

C9

4N7

3K6

D21

620R100K

R30

R29 R29A

V

T

R

4700U

80V

V

T

R

R71

5.0W

R31

6752

IRF630NPBF

3K6

R65A

5.0W

W10

BLUE 6"

-145V

10R

Function

{Watts}

TO220

Q11

WC7

16V0

ZD8

R28

YELL

1R

1/2W

X9

R32

39R0

TP6

5882

5882

250V

220N

C11

THIS CAP IS

39R

2N2

C10

C25

V

T

R

6

9

8

5

R45

220N

3K6

250V

C14

5.0W

2K

X10

330R

6925

SOLDER

MTP8P20

WIRE TO

Function

JUMPER

{Watts}

ZD9

TO220

C15

2N2

1K

R46

R54

X1

R72

33V0

63V

10U

4K7

1.0W

4N35

6880

U2

Q12

X20

16V0

470P

C16

39R0

39R39R0

3K6

5.0W

R47

R44

X2

R80

X21

ZD13

C32

R81

220R

4N35

6880

220K

U1

R88

1R

220R

1/2W

R48

4007

R37

D31

ZD10

27K

ZD11

4V7

4V7

R36

R89

91K

220K

4007

X35

TP7

D7

4148

BAV21

D11

MJE350

2SA2121-0

TO126

Q41

E

B

C

R84

220P

X22

C17

R35A

Q8

20K0

X30

BC550C

1U

63V

X29

X13

2K2

470P

C4

Q6

200R

X23

470R

R86

R83

BC550C

Q4

R18

249R

4148

12K

150R

151R

10K0

R19

22U

50V

R17

D3

R16

R15

D5

R42

3K

4K7

220K

4148

16V0

ZD7

R22

18K

4K7

C8

X14

220K

2N6517

Q7

R70

R23

R24

TO3P

R25

ZD5

X25

200R

43K

C5

R13

330U

BC560C

22U

50V

TP5

12V0

25V

C7

C6

330U

MJE340

TO126

E

200R

Q3

R82

C3

25V

70057004

2SC5949-0

TO3P

B

C

FunctionFunction

Q40

X26

470R

R87

R5

R8

R7

220P

R6

C18

12K

1N

151R

4148

150R

10K0

C2

D2

TP4

X15

C12

R35

ZD4

12V0

R26

R20

1K

3K

470R

XZD3

BC550C

Q9

X8

X33

R49D4R33

1R

1R

1.0W

1.0W

Q5

91K

R39

BAV21

D10

R9

1K2R2

27K

X16

22R

4148

4148

D9

D1

R40B

20K0

22N

X32

R38

R40

C13

R27

M1146 1/2

R11

22N

4148

R41

2R2

BC560C

AP4040

9V30

249R

470R

R14

R51

39R

220R0

R50

R43

22N

C31

Q10

X18

R4

RT1

R3R1

R10

R12

R85

0R47

4V7

ZD12

1N5

1.0W

C1

BIAS TRIM

4K7

2R2

2R239R0

10K

270R

R34

C30

22N

68R

TP1

R2

TP9

R55

220R0

TP8

X17

39R

270R

Loading...

Loading...