Page 1

351579-YTS-C-0111

ISO 9001

Certified Quality

Management System

TECHNICAL APPLICATION

AND

PROGRAMMING GUIDE

MILLENNIUM® SINGLE PACKAGE

ROOFTOP UNITS

25, 30 & 40 TON EQUIPPED WITH

SIMPLICITY

®

ELITE CONTROLS

MILLENNIUM® 25-40 TON SINGLE PACKAGE COMMERCIAL ROOFTOP UNIT EQUIPPED WITH SIMPLICITY® CONTROLS

This manual includes application, programming and service

procedures for the Millennium® 25-40 Ton Single Package

Commercial Rooftop Unit equipped with Simplicity

These procedures are the same for all 25-40 Ton Millennium®

Rooftop units in this series except as noted.

This manual covers Simplicity

information please refer to the following.

®

controls only, for unit installation

®

Controls.

RECOMMENDED TECHNICAL AND INSTALLATION AIDS

Millennium® 25-40 Ton Single Package Installation and Operation

Manual - 524158

®

Millennium

25-40 Ton Technical Guide - 246837

Page 2

351579-YTS-C-0111

TABLE OF CONTENTS

MILLENNIUM® 25-40 TON SINGLE PACKAGE

COMMERCIAL ROOFTOP UNIT EQUIPPED WITH

SIMPLICITY® CONTROLS . . . . . . . . . . . . . . . . . . . .1

RECOMMENDED TECHNICAL AND

INSTALLATION AIDS . . . . . . . . . . . . . . . . . . . . . . . . 1

THE MILLENNIUM® SIMPLICITY® CONTROL . . . .3

INTRODUCTION AND OVERVIEW. . . . . . . . . . . . . . . . . 3

DIGITAL LINGO . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

ANALOG TO DIGITAL CONVERTER . . . . . . . . . . . . . . . 4

COMMUNICATIONS BUS . . . . . . . . . . . . . . . . . . . . . . . . 5

OPTIONAL Simplicity

COMPONENT DESCRIPTION. . . . . . . . . . . . . . . . . . . . . 5

®

LINC TRANSLATOR. . . . . . . . . . 5

SIMPLICITY® PROGRAMMING OPTIONS . . . . . . .11

INTERACTING THROUGH THE MILLENNIUM®

SIMPLICITY® . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

INITIAL STARTUP OPTIONS . . . . . . . . . . . . . . . . . . . . 11

METRIC OPERATION (ENGLISH) . . . . . . . . . . . . . . . . 11

SETTABLE SYSTEM PARAMETERS . . . . . . . . . . . 11

MILLENNIUM® SEQUENCE OF OPERATION . . . .18

OVERVIEW . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

RUN SEQUENCE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

UNIT CONTROLS SEQUENCE. . . . . . . . . . . . . . . . . . . 18

VARIABLE AIR VOLUME UNIT (VFD & IGV) . . . . . . . . 20

OCCUPIED / UNOCCUPIED / MORNING WARM-UP . 21

UNIT CONTROLS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

HEAD PRESSURE CONTROL . . . . . . . . . . . . . . . . . . . 26

SEQUENCE OF OPERATION - FOR HEAD PRESSURE

CONTROL. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

INTELLI-START . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

DEVICES AND RULES . . . . . . . . . . . . . . . . . . . . . . . . . 27

COMFORT VENTILATION MODE. . . . . . . . . . . . . . . . . 28

HYDRONIC HEAT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

COOLING LOCKOUT ON OAT . . . . . . . . . . . . . . . . . . . 29

WATER COIL FREEZE STAT (FSI). . . . . . . . . . . . . . . . 29

CV OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

THERMOSTAT OPERATION FOR COOLING WITH Y1,

Y2, Y3 AND Y4 INPUTS. . . . . . . . . . . . . . . . . . . . . . . . 30

OPERATION FOR HEATING WITH W1, W2, AND W3

INPUTS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

SENSOR OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . 30

TYPES OF SPACE SENSORS . . . . . . . . . . . . . . . . . . . 31

VAV OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

SUPPLY DUCT PRESSURE CONTROL ALGORITHM. 34

MORNING WARM UP / VAV OCCUPIED HEATING

CONTROL ALGORITHM . . . . . . . . . . . . . . . . . . . . . . . 34

CONTROLLING EXCESSIVE SAT (SUPPLY AIR

TEMPERATURE) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .35

SAT SETPOINTS USED DURING COOLING WITH

ECONOMIZER OPERATION . . . . . . . . . . . . . . . . . . . . .36

DEMAND VENTILATION . . . . . . . . . . . . . . . . . . . . . . . . .39

EXHAUST OPERATION . . . . . . . . . . . . . . . . . . . . . . . . .40

SCHEDULING OPERATION . . . . . . . . . . . . . . . . . . . . . .41

COMPRESSOR STATUS MONITORING . . . . . . . . . . . .41

TROUBLESHOOTING A MILLENNIUM®

SIMPLICITY® CONTROL . . . . . . . . . . . . . . . . . . . . 43

STATUS LED CHART . . . . . . . . . . . . . . . . . . . . . . . . . . .43

FAILURE MODES AND DEFAULT OPERATION . . . . . .43

SENSOR FAILURES AND DEFAULT OPERATION . . . .43

SYSTEM ERRORS . . . . . . . . . . . . . . . . . . . . . . . . . . . . .44

LIST OF FIGURES

Fig. # Pg. #

1 SIMPLICITY® CONTROLLER. . . . . . . . . . . . . . . . . . . 3

2 SIMPLICITY® CONTROLS PUSH BUTTONS . . . . . . 3

3 ANALOG TO DIGITAL CONVERTER . . . . . . . . . . . . . 4

4 VFD CONTROL WIRING. . . . . . . . . . . . . . . . . . . . . . . 8

5 SEQUENCE OF SETTING THE SET POINTS . . . . . 14

6 COMFORT VENTILATION ECONOMIZER

CONTROL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28

7 SAT CONTROL BAND . . . . . . . . . . . . . . . . . . . . . . . 34

LIST OF TABLES

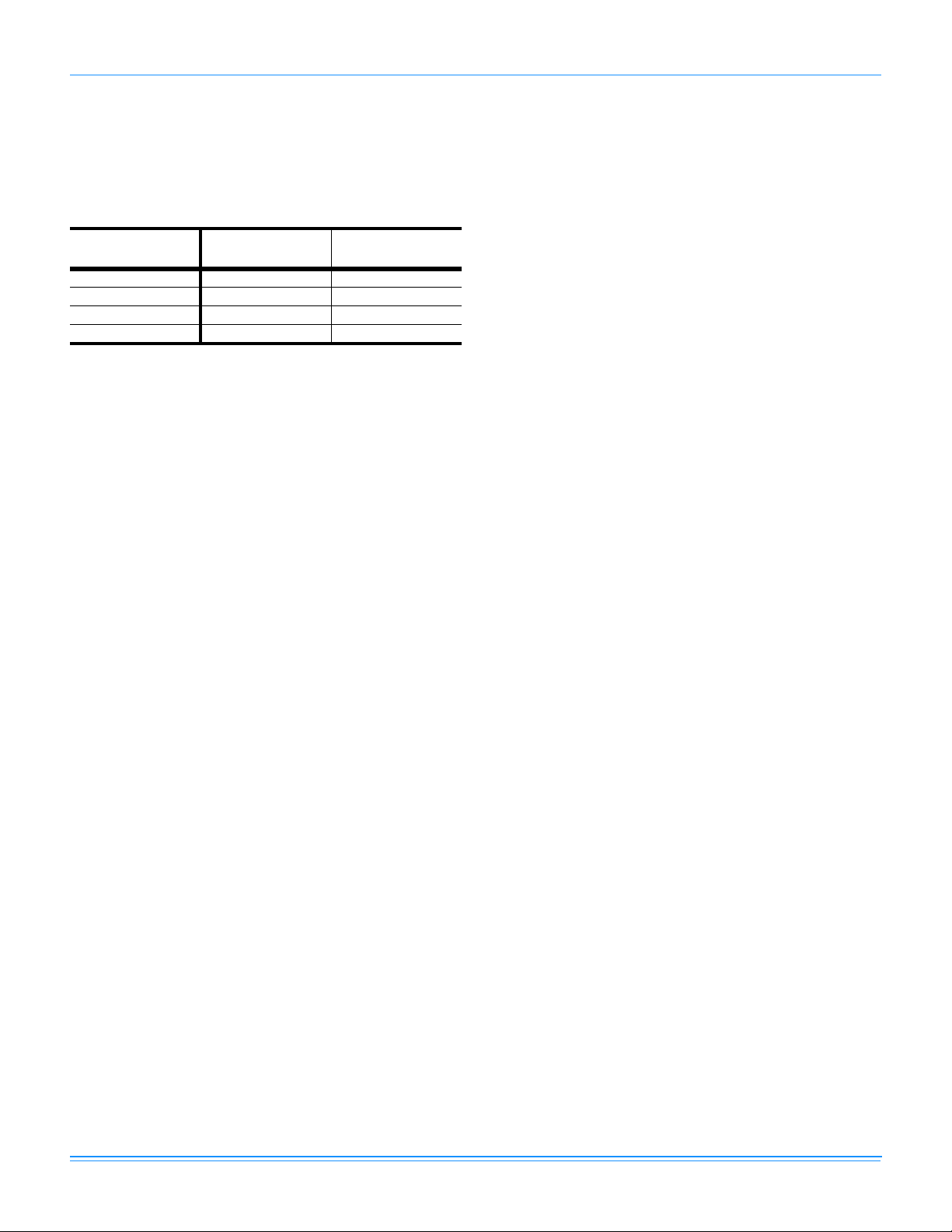

Tbl. # Pg. #

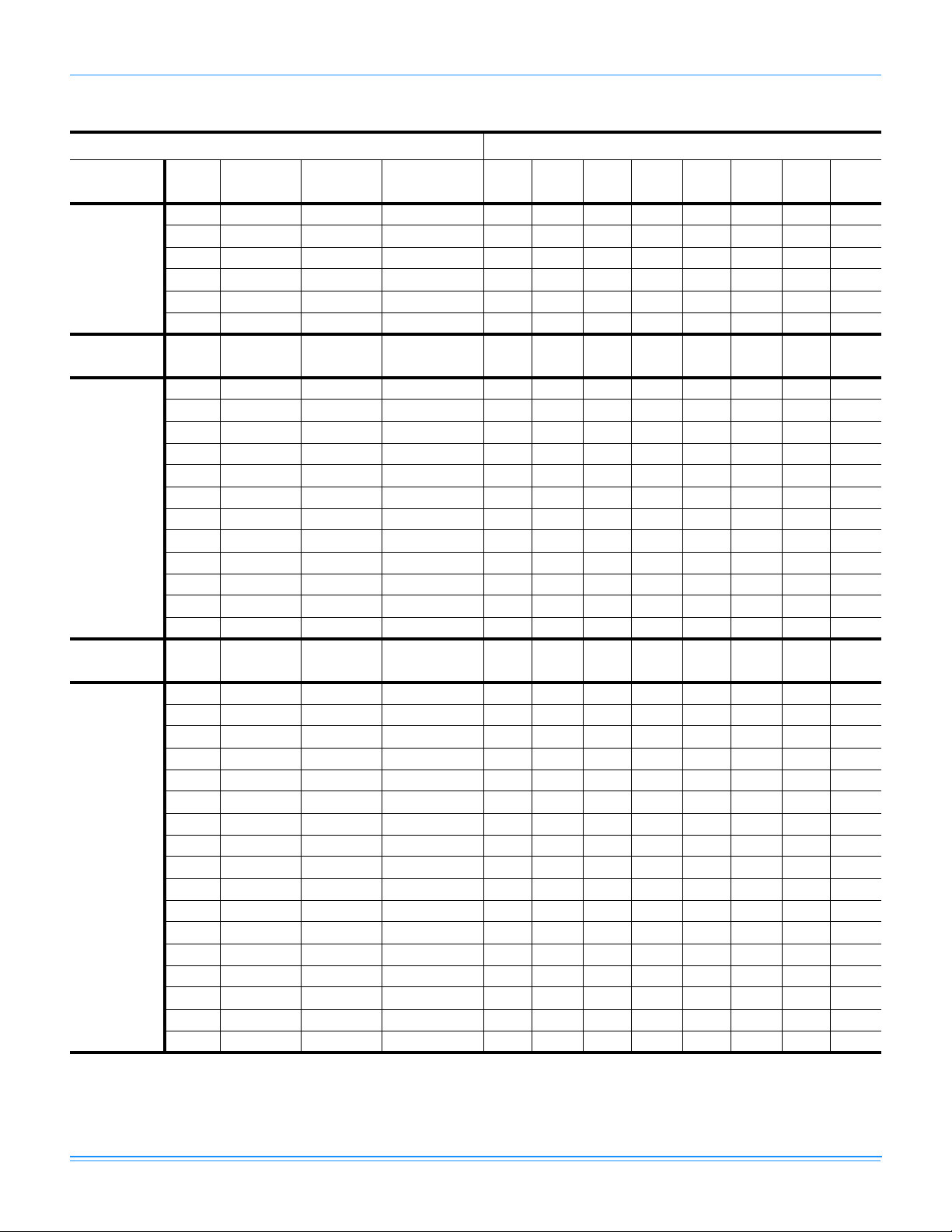

1 ACRONYMS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2 INPUT SIGNAL TO Y1 ACTUATOR POSITION . . . . . 8

3 SIMPLICITY® CONTROL INPUTS . . . . . . . . . . . . . . . 9

4 SIMPLICITY® CONTROL OUTPUTS . . . . . . . . . . . . 10

5 SETTABLE SYSTEM PARAMETERS. . . . . . . . . . . . 16

6 COOLING STAGE . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

7 IGNITION CONTROL BOARD FLASH CODES . . . . 23

8 MODULATING GAS HEAT . . . . . . . . . . . . . . . . . . . . 24

9 MODULATING GAS HEAT CONTROL BOARD FLASH

CODES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

10 COMPRESSOR MINIMUM OFF TIMES . . . . . . . . . . 30

11 WEEKLY SCHEDULE . . . . . . . . . . . . . . . . . . . . . . . . 34

12 HOLIDAY SCHEDULE. . . . . . . . . . . . . . . . . . . . . . . . 35

13 ALARM DEFAULT CODES . . . . . . . . . . . . . . . . . . . . 42

14 STATUS LED CHART . . . . . . . . . . . . . . . . . . . . . . . . 43

2 Johnson Controls Unitary Products

Page 3

THE MILLENNIUM® SIMPLICITY® CONTROL

Program

Alarms / Change Data Address / Down

Test / Reset / Up

INTRODUCTION AND OVERVIEW

Welcome to the new Millennium® Simplicity® control, a digital

control system designed specifically for the Millennium® 25 to 40

Ton single package rooftop unit. The Simp licity

72 monitored and controlled input and output points. The control

logic of the Simplicity

®

extends on the rules built in to the

Synthesys control, and provides character displays in additi on to

LED flashes to display information to the technician.

The Simplicity

®

digital control performs all of the control and

monitoring functions that were originally done by separate

discrete relays, controls, and interlocking hardware. This

reduces manufacturing, service, and maintenance costs. The

Simplicity

®

digital controller includes sophisticated control of

the individual components of the HVAC cooling/heating unit,

and has built-in rules that protect those components and

optimize the control to its environment. The cooling and heating

modes are protected against frequent cycling, slugging,

multiple restarts, etc.

®

is composed of

351579-YTS-C-0111

®

The Millennium

Simplicity® control is resistor-configured for

Constant Volume (CV) units or Variable Air Volume (VAV) units.

The option settings for a specific option configuration will be

made as part of unit test at the factory; however, if there is

doubt about how a unit is responding in the field, check the

option setting for the unexplained action.

If connected to a network, the control requests an address by a

press of the Address/Down button.

DIAGNOSTICS VIA LED

There is an LED on the board that shows the status of the

control and alarms (see Status LED Table). There are two

character displays, one 2-digit and one 4-digit, to indicate

details of run conditions and alarms (see Alarms Table in the

Trouble Shooting section of this manual).

When the Alarm / Change Data button (See Figure 2 Simplicity

Controller Push Buttons) is pushed and released one time within

five seconds, it will re-enunciate the last five alarms on the

Display.

®

®

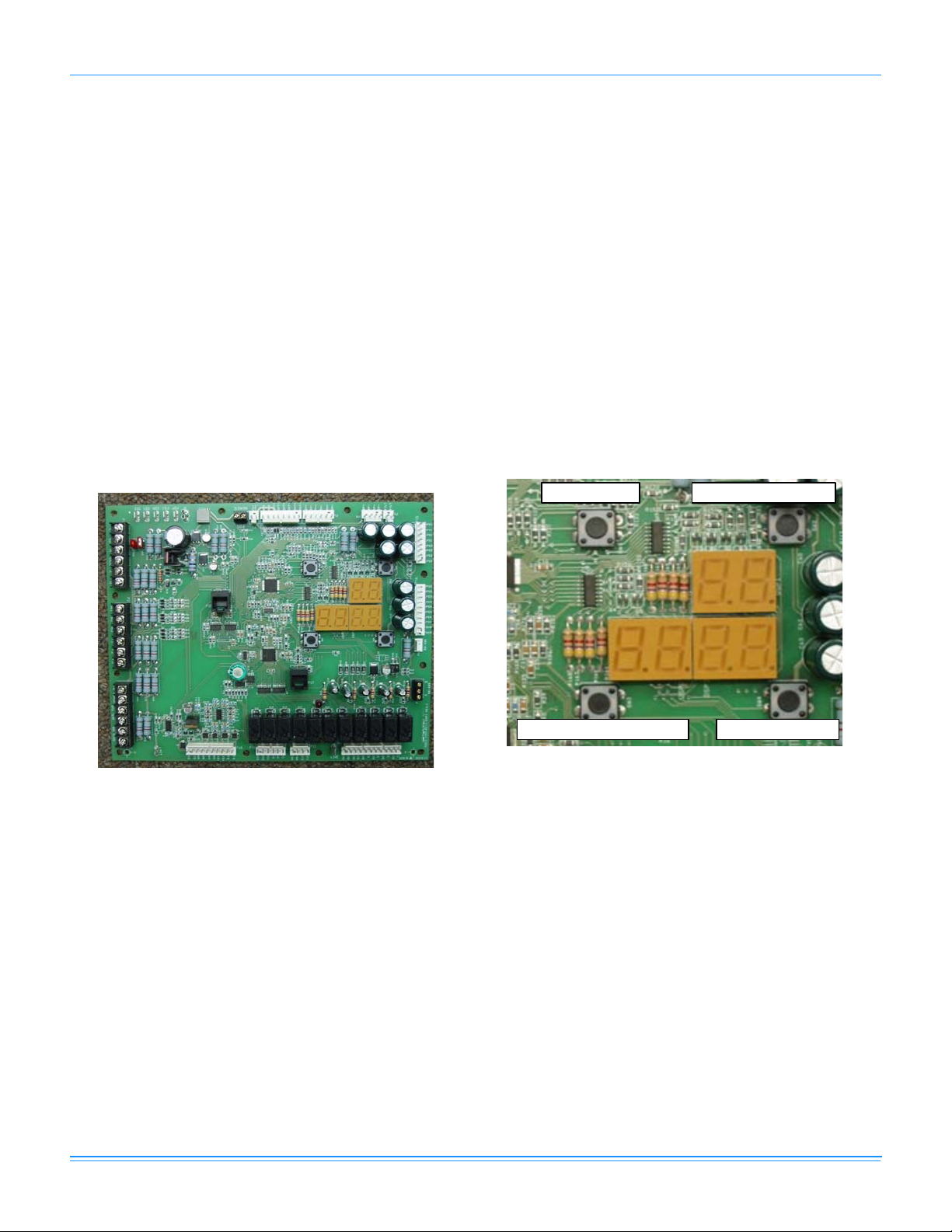

Figure 1: Simplicity

Controller

One result is that the system may not immediately respond as

you expect. For example, internal digital timers may delay the

start of a compressor even though the thermostat calls for

cooling. The control may be in the middle of a timing sequence;

without the observer knowing what has already happened and

the status of current inputs, the system may take action not

expected by the tech.

®

In the Simplicity

• a list of user-selected option settings and setpoints

recorded within the control;

control, there are:

• inputs monitored by the Simplicity®;

• specific fixed rules and timings built in to the control

• outputs to compressors, heat, economizers, and other

options.

The Simplicity

®

has a real-time clock function, with minimum of

ten hours “Time-of-day retention” with unit power off.

Johnson Controls Unitary Products 3

Figure 2: Simplicity® Controls Push Buttons

When this button is pushed and released two times within five

seconds, it will clear all stored alarms.

The error details for most conditions are stored in summary in

the Simplicity

®

Control and can be accessed by the digital

display, personal computer interface, or Palm Pilot (Some

interfaces still in development).

Diagnosing requires patience because of internal timings.

Normal observable conditions are the same - contactor 1M

pulled in, compressor 1 running - but the control does not

identify what it has just done or is about to do. The Simplicity

®

control will take action according to its internal rules even

though action requests come from smart thermostats. A call for

cooling, for example, will be compared with supply air

temperature before energizing a cooling stage.

ERROR HISTORY

®

The Simplicity

control stores up to 5 of the most recent alarms

in a First In, First Out (FIFO) manner. As the control collects

Page 4

351579-YTS-C-0111

BINARY NUMBER EQUIVALENT

0 1 2 3 4 5 6 7------------- n

alarms, it will overwrite the oldest alarm after the history buffer

becomes full.

Some system errors will initiate a controlling response as well

as being stored in the error memory buffer. See the

“Troubleshooting” chapter in this manual for a detailed

description of how controller errors are handled.

Data items stored for maintenance / run history, in addition to

Alarms:

• Accumulated run times for each compressor and heat st age

• Unit model number

• Unit serial number

•Unit Name

DIGITAL LINGO

This training manual is intended to help you with the

commissioning process by illustrating the use of tools like the

control’s digital input and software engineered specifically for

starting up and servicing a Millennium

You should become familiar with some common terminology

and lingo used in the digital controls industry. (If you are familiar

with the Synthesys controller, the logic of the Simplicity® will be

familiar territory.)

®

rooftop unit.

depending on how long the sensed value remains away from its

desired setpoint.

Fortunately, you do not have to determine all of these

parameters since they are pre-programmed at the factory. You

need only to set a desired setpoint and ensure that the inputs

and outputs are properly wired and working. This is referred to

as commissioning a system.

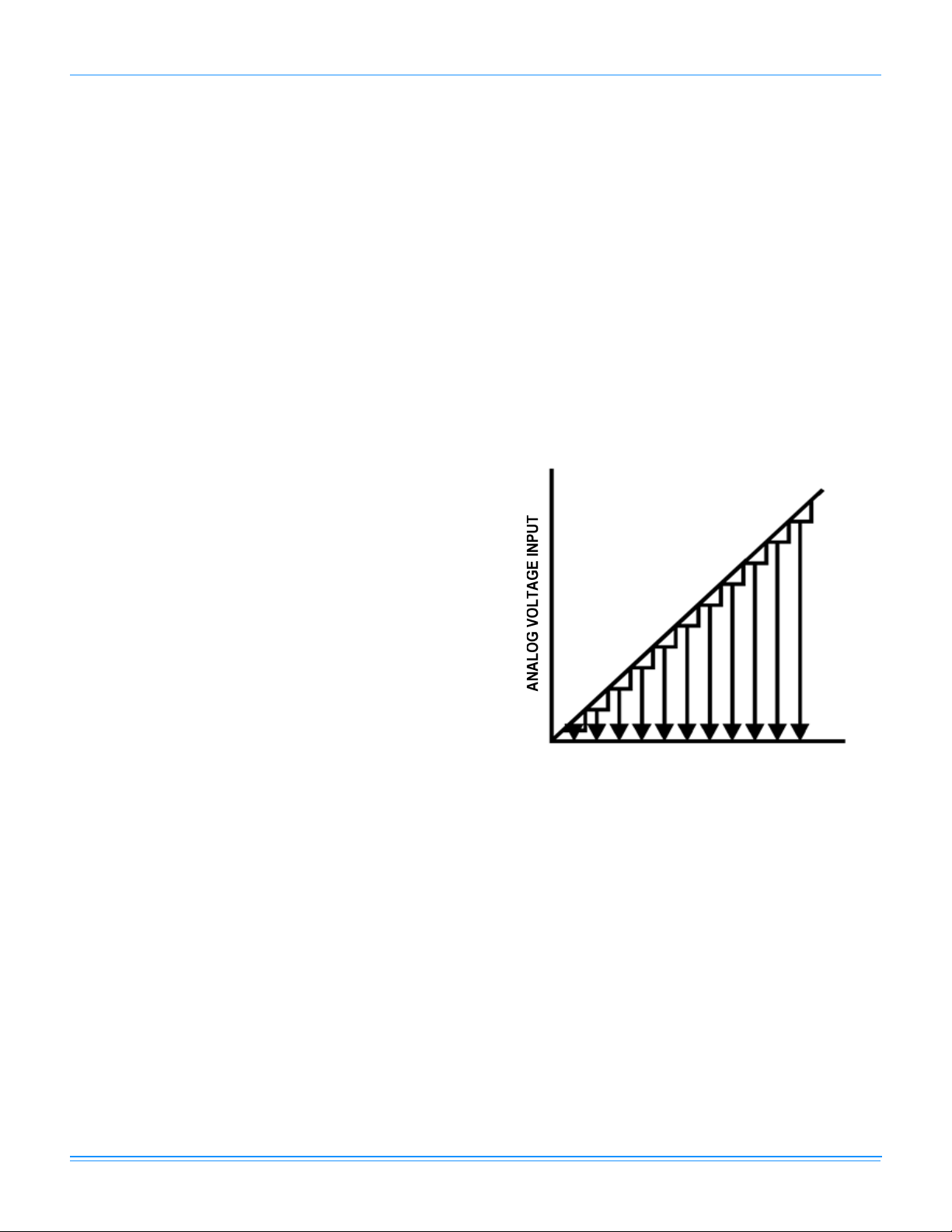

ANALOG TO DIGITAL CONVERTER

Computers can only understand a simple binary language.

Remember, “binary” means two states - ON or OFF. Analog

(continuous) values of voltages, currents, and resistances are

supplied by sensors and transducers to the control. These

values must be converted in to a binary code so that the

computer can understand them. This conversion process is

performed through a combination of hardware and software.

For example, the 0-5VDC analog value from a static pressure

transducer is divided into thousands of steps with a binary

coded number, often called “counts”, assigned to each step.

If this is your first exposure to the world of digital controls you

may experience a lot of new terms, acronyms and technical

lingo commonly used in the controls industry. For example, the

Simplicity

®

input and output hardware points are described as

analog, relating to a continuous scale of value readings such

as a temperature sensor ranging from -400F to 1600F range, or

binary, meaning 2-states, either on or off, open or closed, true

or false, one or zero. The term “digital” also means two states

and its use is often interchanged with “binary”. These points

may be either factory- or field-set.

THE PI ALGORITHM

Another common “digital controls” term is the PI algorithm or

Proportional-Integral control loop. The PI algorithm is a

continuously updated math calculation that the controller uses

to modulate an analog output point. For example, a variable

speed drive uses a PI loop to maintain a desired setpoint (in this

case, a duct static pressure value). The algorithm takes into

account several parameters to calculate the output. The PI loop

needs parameters such as the proportional operating

bandwidth, integral time constant, deadband, desired setpoint

value, sensed input value(s), start up ramp time, initial start

value, maximum output control value, a status point to initiate

the control action (i.e. a fan ON status), Direct or Reverse

Controlling Action, and several other parameters to calculate a

simple 0 to 100% analog output control. The PI algorithm is also

called a PI loop because it “loops” the output back to the input

(feedback) and determines a new output value based on the

“error” or difference between the setpoint value and the sensed

input value, and how that difference relates proportionally to the

0 to 100% output value. Time is the ”integral” constant that is

factored in to increase or decrease the controlling output action

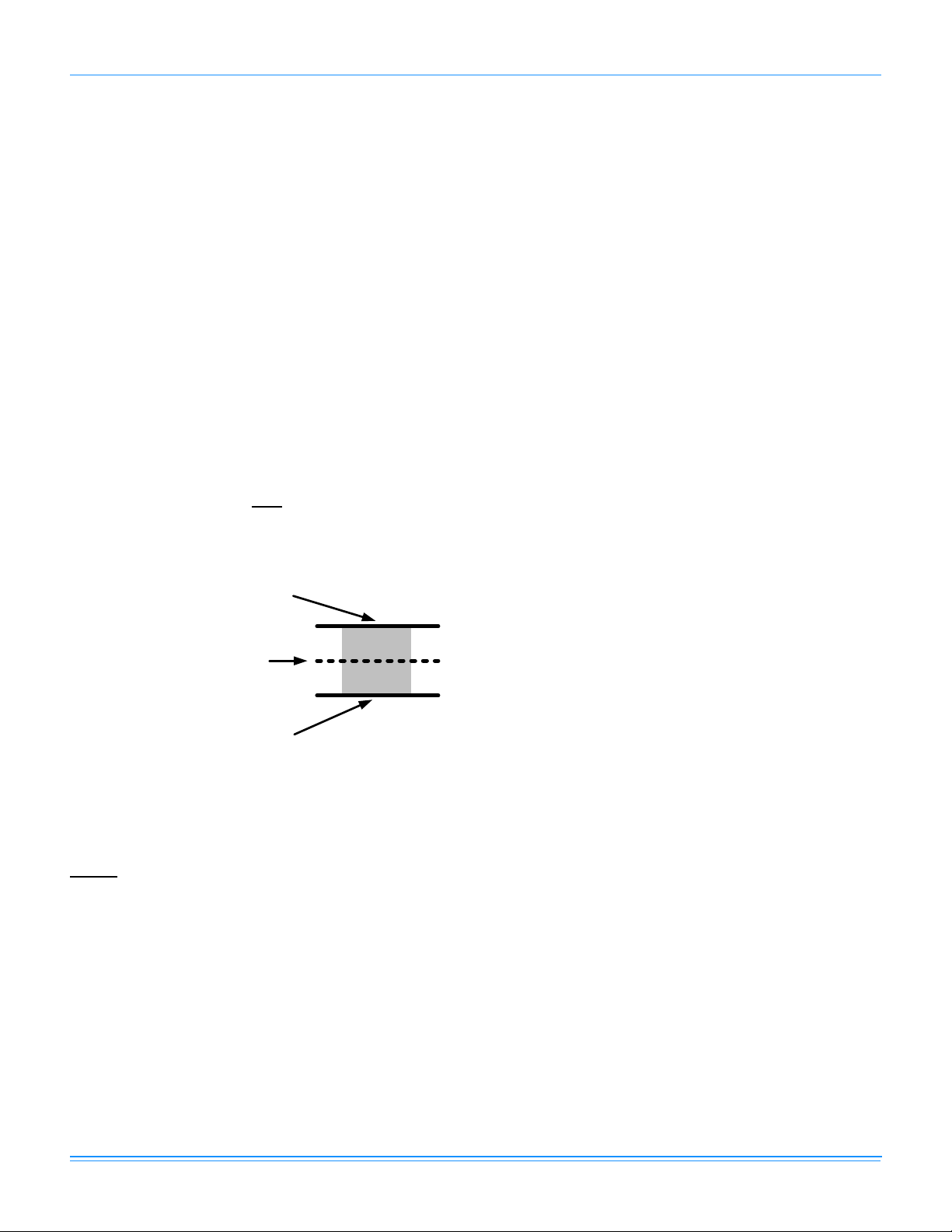

Figure 3: Analog to Digital Converter

SOFTWARE TERMINOLOGY

A digital controller handles its control functions through software

programming rather than with interlocking hardware and wiring.

The software then becomes key to how controlled functions are

handled. Software is a set of statements (referred to as the

“program”) that define the function of the controller’s internal

microprocessor computer.

Software procedurally tells the computer the sequence and

order of tasks that need to be performed using a language that

the computer can understand.

Software is stored in a computer’s memory. There are several

types of memory in a computer. Each type has a specific

function to perform.

4 Johnson Controls Unitary Products

Page 5

351579-YTS-C-0111

EPROM - This is “nonvolatile” memory , meanin g it will not be

erased on a power loss. This memory is usually programmed

prior to assembly of the controller. Since this me mo ry is n ot

changed during normal operation of the Simplicity

®

control, only

basic operation instructions are stored in this type of memory.

EEPROM (Double “E” Prom) - Is also non-volatile, but this

type of memory requires a specia l process t o be writt en to. Thi s

memory can be written to and changed by the microprocessor.

This is the type of memory that the control program is stored in

the Simplicity® control.

ROM - Read Only Memory is non-volatile but can not be written

to. This memory is programmed only once before the controller

is assembled. ROM contains instructions specifically for the

internal microprocessor computer in the controller.

FIRMWARE - “Firmware” is software, program instructions or

applications, but stored in EPROM or ROM memory.

RAM - Random Access Memory is a volatile memory. It will be

erased when a power fail occurs. This memory is used as a

kind of “scratch pad” for the controller. Temporary instructions

and information such as an output controlling action like driving

the economizer dampers open is stored here. When a power

loss occurs or if the controller is sent a manual reset using a

control push button, this memory is cleared and initialized.

Other filtered inputs include temperature and humidity sensors.

You should be aware of this filtering effect because it will

appear the controller is not acting as fast as you may think it

should. In reality, it is acting and controlling on these timeaveraged and weighted values.

®

FAULT TOLERANCE - Fault Tolerance of the Simplicity

control

involves two issues: Hardware fault tolerance deals specifically

with the electrical characteristics of the controller - how much

over voltage or power surge the controller can withstand before

damage occurs, and whether internal comparisons are verifying

that the control is calculating and communicating properly.

Software fault tolerance in this technology consists of comparing

results to previous values and to reasonable values.

COMMUNICATIONS BUS

Networked communications may also be new to you. It relates

to connecting several Millennium

that can be monitored and controlled remotely from network

computer workstations. You will find this typically on large

installations where central control, monitoring, and energy

management issues become a critical factor in operating a

large complex such as a manufacturing facility.

®

The Simplicity

Control has the ability to be networke d in to a

larger system using the MODBUS communication protocol. A

communication protocol is simply a set of rules that determine

how two systems communicate with each other over some

medium such as a pair of wires, phone line, radio waves, etc.

The transmission medium may also be called a gateway,

pathway, or bus. An “open” protocol such as MODBUS is a

publicly published set of rules that any equipment manufacturer

can use to network into another manufacturers equipment.

®

rooftop units to a network

OPTIONAL Simplicity® LINC TRANSLATOR

OVERVIEW

The Simplicity

®

LINC translator operates as a Modbus® Client

providing an interface between a BACnet® control system and

devices that communicate using the Modbus® RTU protocol. The

Simplicity

®

LINC is preconfigured to provide an interface to

YORK UPG products equipped with an Intelli-Comfort or

Simplicity Elite™ controller and allows monitoring and control by

a third-party BACnet

The Simplicity

®

Building Automation System (BAS).

®

LINC communicates using the Modbus® RTU

protocol on one port and BACnet® MS/TP . By providing different

communication protocols on the two ports, data can be

retrieved from and provided to two different systems.

®

The Simplicity

LINC mounts inside the control panel of the

UPG unit and utilizes 24 VAC power from the unit's control

transformer. One port is connected to the UPG controller. The

other port must be connected to the BACnet

The Simplicity

operational data points from the controller and expose them on

a BACnet

"The Simplicity

®

LINC translator is preconfigured to obtain

®

network.

®

LINC device is primary a control offered and

configured by York's ESG (Engineering Systems Group). The

device is designed to tie into and function with a BACnet

®

network.

®

MS/TP network. The device can be used with other BACnet®

MS/TP systems, but a qualified controls contractor must be

involved. UPG cannot support the Simplicity

®

LINC device

beyond its hardware functionality and cannot guarantee

functionality with other third party BAS devices."

®

Please refer to the Simplicity

LINC Installation Manual P/N

514066 and Application Guide Part Number 514067.

COMPONENT DESCRIPTION

This section describes the main components of Millennium®

Simplicity

controllers, hardware to handle signal input and control output

and the Tstat interface terminals.

THE Simplicity® CONTROLLER

Simplicity

use in HVAC applications. The controller provides monitoring

and control for either VAV or CAV for a total of 22 outputs.

WIRING AND TERMINATION, COMMUNICATIONS

Most connections to the Simplicity

harnesses. There are also screw terminal connections for

thermostat inputs and for communications via an RS-485 port.

COMMUNICATION ADDRESS

The communication address button (lower right of the display)

is used to identify a Millennium

“capture” the next available network address for that unit.

Millenniums can be networked together for centralized

®

control. These components consist primarily of

®

is a proprietary , microprocessor-based controller for

®

Control are by wiring

®

rooftop unit to a network, and

Johnson Controls Unitary Products 5

Page 6

351579-YTS-C-0111

monitoring and control. Much like we need a unique street

address in our homes so we can receive our postal mail or

emergency services, these units also need a unique address so

the central Facilities Management System (FMS) can “talk” to

each unit individually. The Simplicity

®

board has the model and

serial number of the specific unit and has a memory space for a

customer name to be applied. So the entire identification for a

specific unit available to the network could be, for example,

Y2AC04M3KDGABA, NCNM123456, SOUTH OFFICE.

The one-time commands to Override ASCD timers and/or to

start Run Test can be issued by the Test/Reset/Up pushbutton.

When this button is pushed and released within five seconds,

the control will zero all ASCD’s for one cycle.

ACRONYMS

A number of acronyms are used throughout this training

manual. These are specific to the Simplicity

®

control. They are

also used in the T echnical Guide and Installation and Operation

manuals. Acronyms are used to refer to input and output

hardware points and software parameters such as timing delays

and setpoints.

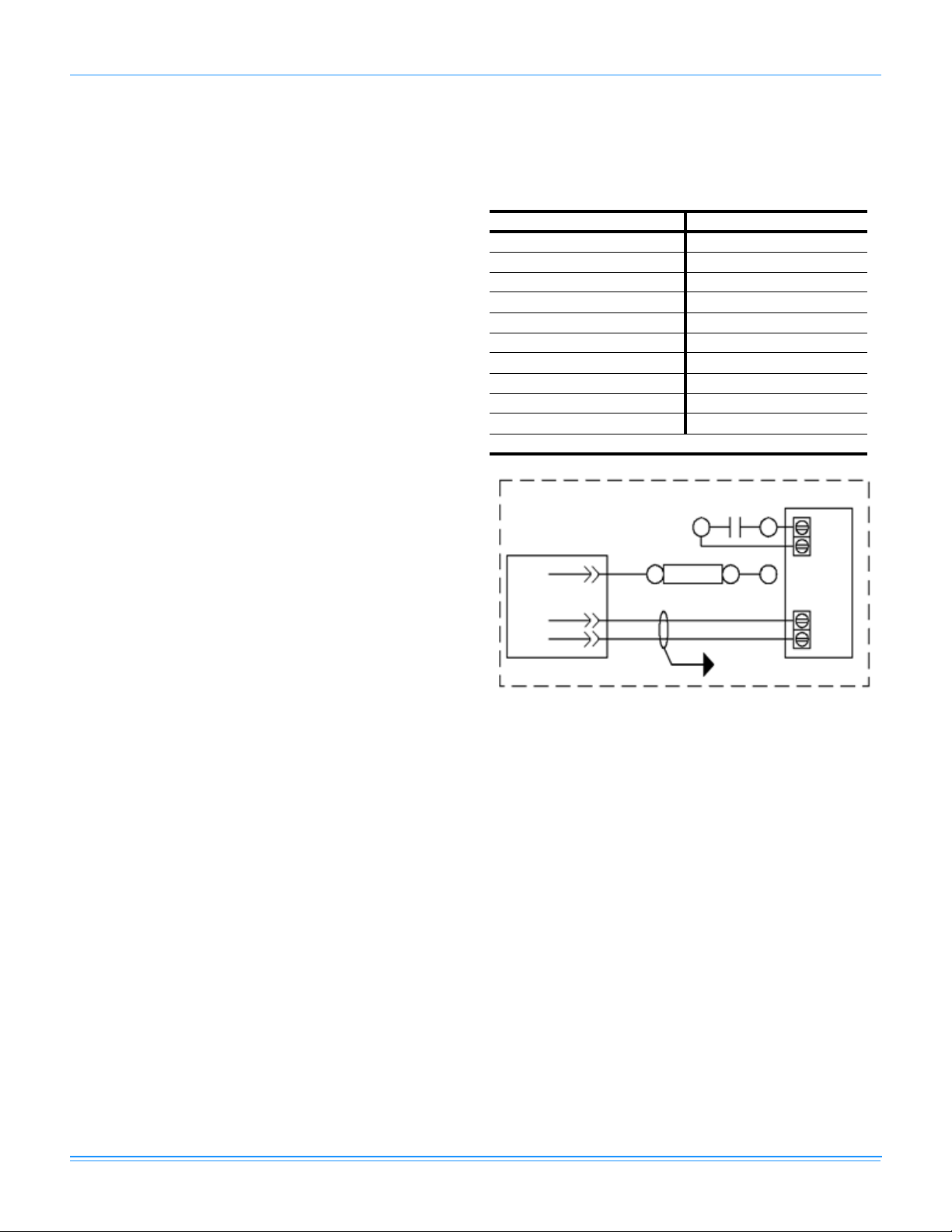

Table 1: Acronyms

Inputs Description

APS Air Proving Switch

IAQ Air Quality (CO2 Sensor)

BAS Economizer

BPS Building Pressure Sensor

C1O-C4O Compressor Status

DF Dirty Filter Status

DPS Duct Pressure Sensor

FSI Hot Water Coil Freeze Input

G Thermostat input for Fan

GV1-3 Monitors gas valve actuation call

HPS1-4

LPS1-4

Lim 1-3 Over-temperature limit switch from heat stages

OAT Outside Air Temperature

OCC Building Occupied Status

Purge Building Purge input

RAT Return Air Temperature

SAT Supply Air Temperature

SD System Shutdown Connector

OAH Outside Air Enthalpy

RAH Return Air Enthalpy

SSA Setpoint Adjust

ST Space Temperature

W1, 2, 3 Heating Stages from Tstat

Y1,2 3, 4 Cooling Stages from Tstat

Passes BAS economizer command through to

Economizer output

High pressure switch monitored for

compressor discharge

Low pressure switch monitored for compressor

suction

Table 1: Acronyms (Continued)

Pushbuttons Description

Test/Reset / 'Up 'Test / control reset / Data value increment

Address / 'Down 'Change data / Data value decrement

Alarms / Advance data Show alarms / go to next data point

Program Go to program mode

Real Time Clock Incorporated on the board

Outputs Description

Status LED

Digital displays One 2-character and one 4-character

C1-C4 Cooling Outputs 1 through 4

CF1, 2 Cond Fan Bank 1, 2

ECO Economizer damper output

EXH Exhaust Fan relay output

EXD

Fan

H1, 2, 3 Heating Stages 1, 2, and 3 output

HGR Hot gas reheat [future]

HWV Hot Water Valve output

VFD Supply Fan IGV or VFD Signal Output

X Alarm signal

Miscellaneous Description

AI Analog Input

AO Analog Output

BI Binary Input same as

BO Binary Output

CAV Constant Air Volume

VAV Variable Air Volume

VFD Variable Frequency Drive

IGV Inlet Guide Vane

IAQ Indoor Air Quality

PI Proportional-Integral Control

ASCD Anti Short Cycle Timer (Compressor)

Flash to indicate alarm, otherwise

'heartbeat'

Exhaust Air Damper / Exhaust VFD Signal

Output

Supply Fan relay output [contactor or

permission relay]

The acronyms used throughout this training manual are listed in

the Acronym Table 1. They are described in much more detail

below.

INPUTS

There are two types of hardwired input points on the Simplicity

control: Analog and Binary. These may be sensors, feedback,

or adjustable setpoints. Typical analog inputs [AI] include Sp ace

Temperature (ST), Supply and Return Air Temperatures (SAT,

RAT), and Building Pressure Sensor (BPS). The binary inputs

(BI) on the Millennium

®

Simplicity® use a dry contact input to

determine the status of a monitored point. Typical BI points are

Fan Status (APS), Filter Status (DFS), and Compressor Status

(HPS1-4, LPS1-4, C1O-4O).

®

6 Johnson Controls Unitary Products

Page 7

351579-YTS-C-0111

ANALOG INPUTS (AI)

Analog inputs require parameters that define the input’s

characteristics. Attributes of an AI include the linear range,

alarm limits, alarm differential, change of state (COS) enable,

and filter weight. The input values may be overridden by a

external system command or by using the input buttons on

the Simplicity

®

board. This is useful to override current

conditions to test certain control functions or modes.

BAS - Economizer override; if this option is enabled, an

external BAS system will control the economizer 2-10 VDC

signal through this pair of terminals.

ST - Space Temperature sensor is a field installed sensor

(PN: 025-38928-000 - w/ Override Button). The sequence of

control for space temperature is different depending on

whether the system is a VAV or CAV. See chapter on

Sequence of Operation for a detailed description of the ST

control modes.

SSA - Space Temperature Adjust is field installed. It is a slide

adjustment located on a space sensor (PN: 025-38927-000)

with a slide bar potentiometer . It is used to offset the space

temperature setpoint. This slide-bar is a 10K ohm

potentiometer. The programmable rang e fo r the Setpoint

adjust is +/- 5 °F. For example, if the Space Temperature

setpoint is set to 74 °F, the SSA is programmed to +/- 3 °F and

the SSA is adjusted fully to the + position, the new controlling

space setpoint will be 78 °F.

OAT - The outside air temperature sensor (PN: 031-01916000A) is a factory-installed 10 K NTC sensor. Its linear

ranging is from -50 °F to 250 °F.

voltage and drop the contactors and shut down if the voltage

drops below 16 VAC and flash the appropriate flash code.

REMOTE - the control will use 0-10 VDC from third-party

BAS to control SAT set points. Thermostat input s override if in

conflict with Remote Control voltage input.

SPC TEMP - offset value from the space sensor offset

potentiometer.

CV/VAV - resistive value across terminals, to determine

which supply fan rules the control will follow.

Demand Ventilation / IAQ - Indoor Air Quality. The IAQ

expects a 0-10 VDC signal to the control from a field supplied

and installed Carbon Dioxide (CO

) sensor. Indoor air quality

2

is monitored for adequate ventilation. In Demand Ventilation

Mode, as the CO

levels in the building rise above the

2

programmed setpoint, more fresh air must be brought in. The

economizer is therefore adjusted to a more open position as

necessary. The linear ranging for IAQ sensor input is from 0

to 10,000 ppm. The Demand Ventilation setpoint is adjustable

from 0 to 2000 ppm and is set at the factory at 1000 ppm.

DPS - Duct Pressure Sensor is monitored by a factoryinstalled 0-5 VDC transducer (PN: 031-01209-000A). The

high-pressure port sensing tube is installed in the field. The

sense tube should be located approximately two thirds of the

way down the duct plenum. To prevent an unstable signal

due to air turbulence, there should be no obstructions, turns

or VAV terminal boxes up or down-stream of the sense tube

location for at least 6 to 10 times the diameter of the duct.

The sensor is located in the control box just below the

Millennium

®

Simplicity® control.

OAH - Outside Air Humidity (PN: 031-09127-000-A) is a

factory-installed sensor manufactured by MAMAO. The OAH

sensor, installed only with enthalpy economizer , provides a 010 VDC signal to the controller over a range of 0 to 100%

relative humidity. This input is used for the economizer

calculation to determine whether free cooling is available and

to switch between minimum outside air and using outside air

as the first stage of cooling.

SAT - Supply Air T emperature sensor (PN: 031-01915-000A)

is a factory-installed -50 °F to 250 °F, 10 K NTC sensor.

RAT - Return Air Temperature sensor (PN: 031-01917-000A)

is a factory-installed -50 °F to 250 °F, 10 K NTC sensor.

RAH - Return Air Humidity (PN: 031-09127-000-A) is a

factory-installed sensor manufactured by MAMAO, installed

only with dual enthalpy economizer. The control will calculate

the return air enthalpy using the relative humidity and return

temperature inputs.

LOW VOLTAGE DETECTION - This input monitors the 24

VAC for low voltage conditions. The input has two thresholds,

one at 16 VAC and one at 19.2 VAC. If the control needs to

turn on a contactor, it will look to see if the voltage is

above19.2 VAC before it will turn it on. If the voltage is not

above 19.2 VAC, it will hold off the contactor and flash the

appropriate flash code. This flash code is not an alarm. If the

control already has contactors pulled in, it will monitor the

BPS - The Building Pressure Sensor (PN: 031-01262-000A) is

a factory-installed Johnson Controls DPT -2640-522 transducer

that provides a 0 to 5 VDC signal to the controller over a range

from -0.25”WC to +0.25”WC. The transducer is located in the

control box just below the Millennium® Simplicity® control. The

sense tubes are field installed with the outside pressure being

sensed external to the unit. To avoid an erratic pressure

reading, the building pressure sense tube should be mounted

in an area away from the return air grill, discharge diffusers,

doors and windows.

BINARY INPUTS (BI)

APS - Supply Fan status is monitored by an Air Proving

Status switch (PN: 024-27557-000A) installed at the factory.

The APS monitors the difference in pressure between the

suction and discharge of the fan.

FOVR - Monitoring loop through the supply fan overload

module or VFD over torque indication.

HPS1-4, LPS1-4 - The refrigerant high pressure (HP) and low

pressure (LP) safety switches, are independently monitored

by the Millennium

®

Simplicity®. If any switch opens, the

control voltage from the control binary output is interrupted

and the status is monitored by the control.

G, OCC, P - These signals represent Fan (G), Building

Occupancy (OCC), and Building Purge (P) calls from the

Johnson Controls Unitary Products 7

Page 8

351579-YTS-C-0111

VFD

FR

FR

Fan

VFD +

VFD -

Simplicity

12

18

53

55

P13-1

P14-1

P14-2

Wht

Blk

TB2

thermostat. If a thermostat is installed on the system, these

inputs are connected to the thermostat interface board just as

are the cooling/heating calls. These inputs are connected

through the Tstat Interface board directly to the respective

binary inputs of the Controller. These signals are, however,

each loaded with a resistor to maintain voltage levels and to

prevent “floating” of signals. Thermostat wiring is typically not

shielded and may have induced voltages that could cause

errant signal readings by the controller.

FILT - Dirty Filter switch [customer supplied, field installed on

factory-provided harness connections] input to provide a filter

status to the control. The control will alarm only after 24V has

been sensed for ten minutes.

GV1-3 - Monitoring that voltage is being supplied to gas valves

on optional heat stages.

LIM1-3 - Overtemperature inputs from optional heat stages.

FSI - Freeze Stat is a customer installed temperature switch on

the FSI input to the controller to tell the control that a

temperature has occurred that risks the hot water or steam coil.

Y1-4, W1-3 - If a thermostat is installed on the system, these

inputs will take priority over software programmed setpoints and

limits.

SD - This terminal set allows attachment of an external

shutdown NC contact. 24VAC power is supplied to the board at

SD2; a factory installed jumper passes that power to terminal R

to power the Simplicity Elite™ board. If an external shutdown

signal is required at a particular installation, remove the jumper

and connect the NC shutdown circuit between SD1 and R.

position of the guide vane. If the unit has a factory-installed

Variable Frequency Drive, the 2 to 10 VDC signal is wired from

VFD+/- output directly to the VFD’s signal input terminals to

control fan motor speed.

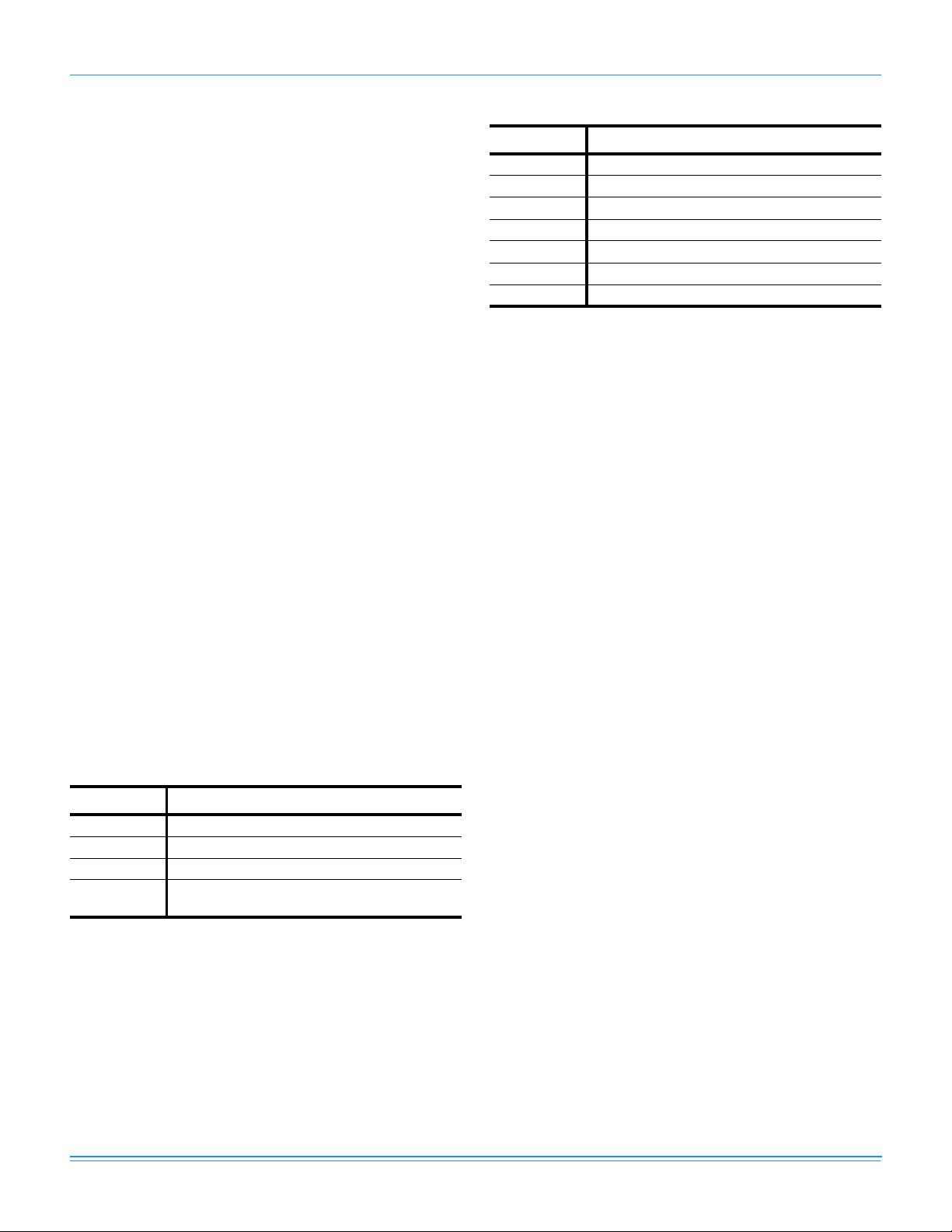

Table 2: Input Signal to Y1 Actuator Position

Input Signal to Y1 Actuator Position

10 VDC 90 degrees

978

867

756

645

533

422

311

20

0-5

8VDC over a 90 degree Span = 11.25 degrees/VDC

OUTPUTS

Analog Outputs (AO) - Analog outputs provide a 2-10 VDC

signal to operate controlled devices. The Simplicity

configured to use only 2-10 VDC outputs to the Variable

Frequency Drive, Inlet Guide Vane, Economizer Damper,

Power Exhaust Dampers or VFD, and Heating water valves.

Since these outputs are analog, they are continuous between 2

and 10 Volts and are proportional to the 0 to 100% drive

position of the device.

ECO - Economizer Actuator - The modulating Economizer uses

a Johnson Controls M9220GGAYK30 spring-return actuator

(PN: 025-30869-000A). This actuator uses a 2-10 VDC signal

to drive the dampers open. The actuator drives 95 degree

rotation. Note the chart below for a correlation between the

input drive signal at terminal 3 (Y1) of the actuator and the

corresponding output drive position of the damper:

VFD - Inlet Guide Vane or VFD - The Inlet Guide Vane uses a

Johnson Controls M9220GGAYK30 spring-return actuator. This

actuator uses the 2-10 VDC signal from VFD+/- terminals to

drive the dampers open. The actuator drives 95 degree rotation.

Note the chart below for a correlation between the input drive

signal at terminal 3 (Y1) and the corresponding output drive

8 Johnson Controls Unitary Products

®

is currently

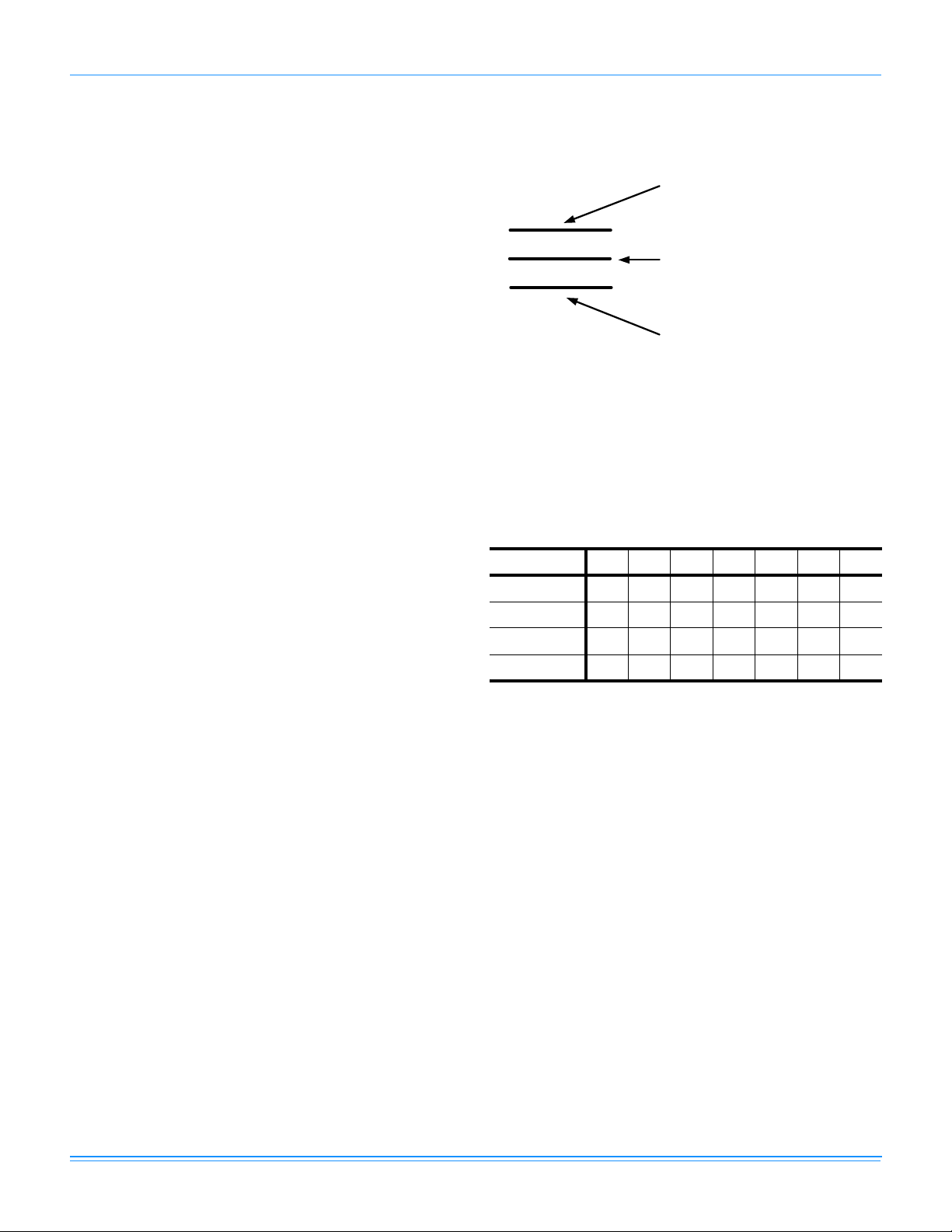

Figure 4: VFD Control Wiring

EXD - Power Exhaust Damper Vane or VFD - Power Exhaust

Damper Actuator is a Johnson Controls M9220GGAYK30. It

uses a full open/ Full Closed scheme and operates a 95 degree

rotation. If VFD Power Exhaust is configured, the same signal

controls the exhaust fan motor drive frequency.

HWV - Heating W ater V alve - Customer supplied and installed,

connect to factory-provided harness.

BINARY OUTPUTS (BO)

FAN - Fan Start/Stop Relay, VFD “permission” relay FR

H1-3 - HEAT STAGES 1 TO 3 [OPTIONAL]

C1 through C4 - Cooling Stages 1 through 4

CF1 & CF2 - Condenser Fan Banks 1 and 2

X - Controller Alarm is field-wired from the thermostat interface

board to signify a controller alarm has occurred.

Page 9

351579-YTS-C-0111

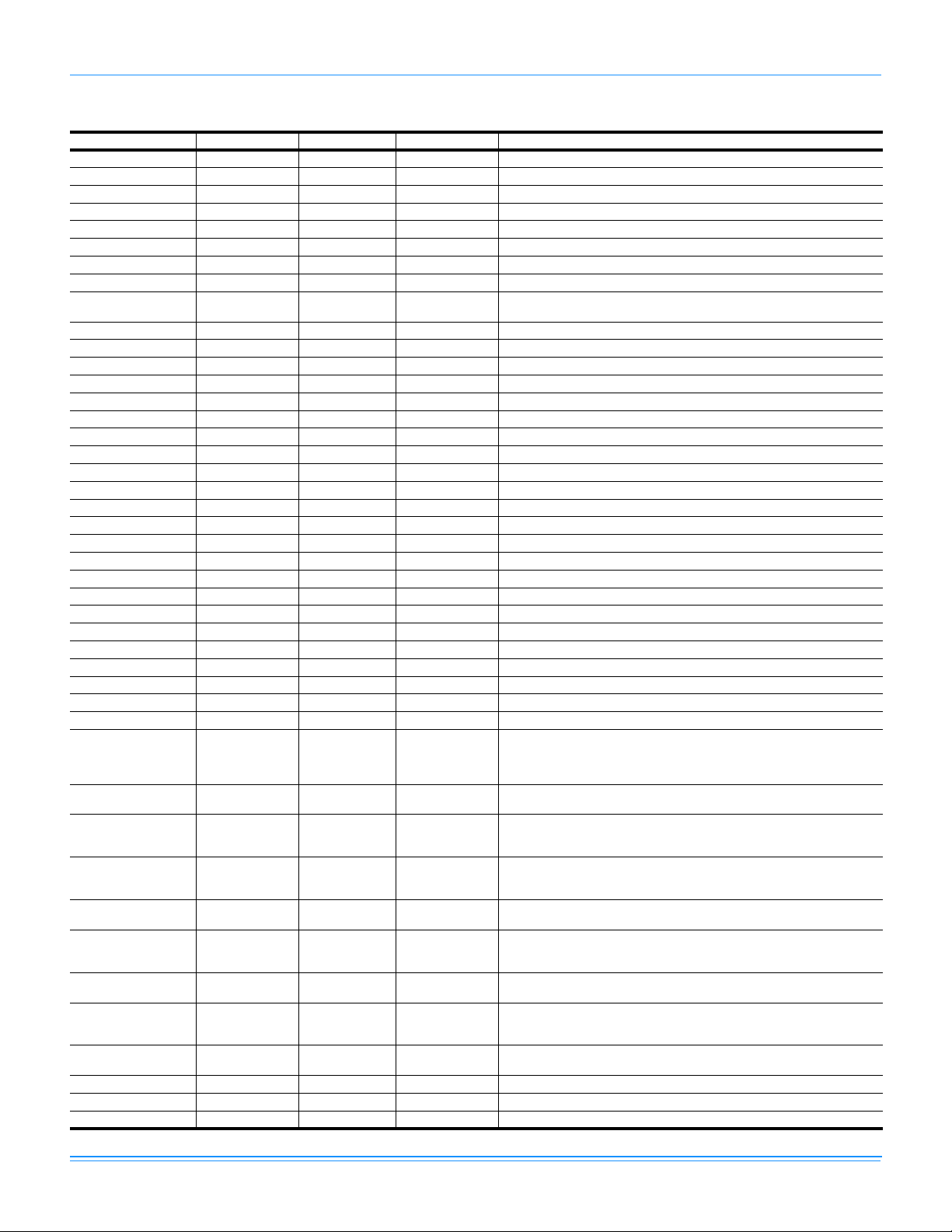

Table 3: Simplicity® Control Inputs

Name Range Resolution Precision Description

Y1 18 - 30 VAC On - Off +/- .5 VAC Request for the first stage of Cooling (24 VAC sense) Tstat Screw Terminal

Y2 18 - 30 VAC On - Off +/- .5 VAC Request for the second stage of Cooling (24 VAC sense) Tstat Screw Terminal

Y3 18 - 30 VAC On - Off +/- .5 VAC Request for the third stage of Cooling (24 VAC sense) Tstat Screw Terminal

Y4 18 - 30 VAC On - Off +/- .5 VAC Request for the fourth stage of Cooling (24 VAC sense) Tstat Screw Terminal

W1 18 - 30 VAC On - Off +/- .5 VAC Request for the first Stage of Heating (24 VAC sense) Tstat Screw Terminal

W2 18 - 30 VAC On - Off +/- .5 VAC Request for the second Stage of Heating (24 VAC sense) Tstat Screw Terminal

W3 18 - 30 VAC On - Off +/- .5 VAC Request for the third Stage of Heating (24 VAC sense) Tstat Screw Terminal

G 18 - 30 VAC On - Off +/- .5 VAC Request for the Fan (24 VAC sense) Tstat Screw Terminal

R 18 - 30 VAC - C Earth Ground - - These terminals are a ¼' Faston and a Thermostat Screw terminal.

OCC 18 - 30 VAC On - Off +/- .5 VAC Occupied input (24 VAC sense) Tstat Screw Terminal

SD 18 - 30 VAC - +/- .5 VAC Shut Down input Tstat Screw Terminal

Purge 18 - 30 VAC On - Off +/- .5 VAC Building Purge input (24 VAC sense) Tstat Screw Terminal

BAS Economizer 2 - 10 VDC Not Read by micro - Input that routes to the Economizer output Two Tstat Screw Terminals +&-

HPS1 18 - 30 VAC On - Off +/- .5 VAC High Pressure Switch for Circuit # 1 (24 VAC sense)

HPS2 18 - 30 VAC On - Off +/- .5 VAC High Pressure Switch for Circuit # 2 (24 VAC sense)

HPS3 18 - 30 VAC On - Off +/- .5 VAC High Pressure Switch for Circuit # 3 (24 VAC sense)

HPS4 18 - 30 VAC On - Off +/- .5 VAC High Pressure Switch for Circuit # 4 (24 VAC sense)

LPS1 18 - 30 VAC On - Off +/- .5 VAC Low Pressure Switch for Circuit # 1 (24 VA C sense)

LPS2 18 - 30 VAC On - Off +/- .5 VAC Low Pressure Switch for Circuit # 2 (24 VA C sense)

LPS3 18 - 30 VAC On - Off +/- .5 VAC Low Pressure Switch for Circuit # 3 (24 VA C sense)

LPS4 18 - 30 VAC On - Off +/- .5 VAC Low Pressure Switch for Circuit # 4 (24 VA C sense)

Limit Switch 1 18 - 30 VAC On - Off +/- .5 VAC High Limit Switch input (24 VAC sense) For Burner sect ion 1

Limit Switch 2 18 - 30 VAC On - Off +/- .5 VAC High Limit Switch input (24 VAC sense) For Burner section 2

Limit Switch 3 18 - 30 VAC On - Off +/- .5 VAC High Limit Switch input (24 VAC sense) For Burner section 3

GV1 18 - 30 VAC On - Off +/- .5 VAC Gas Valve input (24 VAC sense) For Burner section 1

GV2 18 - 30 VAC On - Off +/- .5 VAC Gas Valve input (24 VAC sense) For Burner section 2

GV3 18 - 30 VAC On - Off +/- .5 VAC Gas Valve input (24 VAC sense) For Burner section 3

Test / Reset / Up ON - Off ON - Off - Test / Reset Button and Increment Data Input

Address / Down ON - Off ON - Off - Address Button and Decrement Data Input

Alarms / Advance Data ON - Off ON - Off - Alarm Button and Advance Data Input

Program ON - Off ON - Off - Program Button Input

24 hours, 365 Days

Real Time Clock

Water Coil Freeze Stat

(FSI)

Supply Air Temp Sensor

(SAT)

Outside Air Temp Sensor

(OAT)

Space Temp Sensor

(ST)

Return Air Temp Sensor

(RAT)

Space Setpoint Offset

(SSA)

Building Pressure

Sensor

(BPS)

Duct Pressure Sensor

(DPS)

APS (APS) 18 - 30 VAC On - Off +/- .5 VAC Air Proving Switch (24 VAC sense)

Fan Overload (FOVR) 18 - 30 VAC On - Off +/- .5 VAC Fan Overload Switch (24 VAC sense)

CV / VAV Input 0 - 20 K 1 + / - 5

including Leap year

and Daylight

Savings Time

18 - 30 VAC On - Off +/- .5 VAC Hot Water Freeze Stat (24 VAC sense) two ¼ Fastons

-40° - +180° F .1° F

-40° - +180° F .1° F

32° - 100° F .1° F .5° F This is a 10K type 3 Thermistor

-40° - +180° F .1° F

0 - 20 K 1 K + and - 250

0 - 5 VDC-.25 - +.25

"WC

0 - 5 VDC0 - 5 "WC .01 "WC

Seconds - Real Time Clock Chip

-40° - 180 °F

+/- 2 °F across

range

-40° - 180 °F

+/- 2 °F across

range

-4 0° - 1 80 °F

+/- 2 °F across

range

.001 "WC

.005 "WC

1% Across range

.0 5 " W C 1 %

across range

These terminals are a ¼' Female Faston and a Thermostat Screw terminal

connected to the power supply of the board.

This is a 10K type 3 Thermistor

This is a 10K type 3 Thermistor

This is a 10K type 3 Thermistor

3 position Mini Screw Terminal shared with S pace Temp The common terminal

in the center is common for both the Space Temp and Setpoint Offset.

0 - 5 volt input

0 - 5 volt input

Resistive Input 0 - 5.5K = CV 10K - 20K = VAV

Johnson Controls Unitary Products 9

Page 10

351579-YTS-C-0111

Table 3: Simplicity® Control Inputs (Continu e d)

Name Range Resolution Precision Description

Demand Ventilation

Input

Remote Control 0 - 10 VDC .05 VDC 0.01 0 - 10 VDC Screw terminal two position Small screw terminal

Dirty Filter Switch

(FILT)

Low Voltage Detection 12 - 35 VAC .1 VAC .5 VAC This input monitors the 24 VAC for Low Voltage Detection

Return Air Humidity

(RAH)

Outside Air Humidity

(OAH)

Comm Port 128 nodes

24 VAC - Class 1 18 - 30 VAC - - ¼'' quick connect for power to the contactors through the Relays.

0 - 10 VDC

0 - 2000 PPM

of CO2

18 - 30 VAC On - Off +/- .5 VAC This is the Dirty Filter Switch (24 VAC sense)

0 - 5 VDC0 - 100%

RH

0 - 5 VDC0 - 100%

RH

1 PPM

.05 VDC1% RH

.05 VDC1% RH

See

Communications

20 PP M

1% Across Range

.1 VD C

2% Across Range

.1 VD C

2% Across Range

- Asynchronous Serial Port (RS485) three position Small screw terminal

0 - 10 volt input

Scaleable 0 - 10 volts Screw terminal two position Small screw terminal

Scaleable 0 - 10 volts Screw terminal two position Small screw terminal

Table 4: Simplicity® Control Outputs

Name Range Resolution Precision Description

LED On - Off - - Status LED

Display

H1

H2

H3

C1

C2

C3

C4

CF1

CF2

Fan

Exhaust Fan (EXH)

Supply Fan VFD 2 - 10 VDC - - This is a 2 - 10 volt output capable of 10 ma

Exhaust Fan Damper

(EXD)

Hot Water V alve

(HWV)

Hot Gas Reheat 2 - 10 VDC .1 VDC .1 VDC This is a 2 - 10 volt output capa bl e of 10 ma

Economizer (ECO) 2 - 10 VDC .1 VDC .1 VDC This is a 2 - 10 volt output capable of 10 ma

X 24VDC - - This is a 24VDC output for Alarms

7 segment W/

Decimal Point

Class 1 Relay

Contacts

Class 1 Relay

Contacts

Class 1 Relay

Contacts

Class 1 Relay

Contacts

Class 1 Relay

Contacts

Class 1 Relay

Contacts

Class 1 Relay

Contacts

Class 1 Relay

Contacts

Class 1 Relay

Contacts

Class 1 Relay

Contacts

Class 1 Relay

Contacts

- - Heat 1 contactor output (Relay Contacts - 24 VAC/120 VAC)

- - Heat 2 contactor output (Relay Contacts - 24 VAC/120 VAC)

- - Heat 3 contactor output (Relay Contacts - 24 VAC/120 VAC)

--

--

--

--

- - Condenser Fan contactor output (Relay Contacts - 24 VAC/120 VAC)

- - Condenser Fan contactor output (Relay Contacts - 24 VAC/120 VAC)

- - Fan contactor output (Relay Contacts - 24 VAC/120 VAC)

- - Exhaust Fan contactor output (Relay Contacts - 24 VAC/120 VAC)

6 "Seven Segment LED /W decimal point"

Compressor number one contactor output

(Relay Contacts - 24 VAC/120 VAC)

Compressor number two contactor output

(Relay Contacts - 24 VAC/120 VAC)

Compressor number three contactor outpu t

(Relay Contacts - 24 VAC/120 VAC)

Compressor number four contactor output

(Relay Contacts - 24 VAC/120 VAC)

2 - 10 VDC .1 VDC .1 VDC This is a 2 - 10 volt output capable of 10 ma

2 - 10 VDC .1 VDC .1 VDC This is a 2 - 10 volt output capable of 10 ma

10 Johnson Controls Unitary Products

Page 11

351579-YTS-C-0111

SIMPLICITY

The paragraphs below provide a definition of, and specify the

function related to, each of the parameters that are fieldadjustable using the interfaces available. The Millennium

is shipped from the factory with the necessary options preprogrammed as indicated by the model nomenclature. It is

always a good practice, though, to verify that the correct

parameters are properly configured for the unit you are

commissioning. You can find a complete list of field-adjustable

parameters in the “Settable System Parameters”.

For a description of the parameters, see the Settable System

Parameters below and Table 5.

INTERACTING THROUGH THE MILLENNIUM

SIMPLICITY

SET THE CLOCK

• Power up the unit.

• Press the Program button [upper left].

• Press the Test/Up button [upper right]. Hold it in and it will

step through the parameters, or push in to advance one

parameter at a time. Advance to parameter 63, Hours.

• Press Change [lower left] Press Up [upper right] or Down

[lower right] to the correct hour [24 hour time].

• Press Change to en te r th e ne w valu e.

• Press Up to get to parameter 64, Minutes.

• Press Change.

• Press Up or Down to get to the correct minute value. Press

Change to enter the new value.

• If you are done changing parameters, press Program to

exit the program mode.

PARAMETER SETTING

The buttons allow the operator to go to a specific parameter and

to view and change the data in that parameter.

• To enter the parameter setting mode, press the Program

button. The control will display the current parameter number in the two-digit display, and the present value of that

parameter in the four-digit display.

• To change to another parameter, press the /Up or /Down

button to move to the address of the desired parameter.

The present value of that parameter will display.

• To change the data, press the /Change button. The value

will flash. While it is flashing, press the /Up or /Down button to increase or decrease the value.

• When the desired new value is showing, press the

/Change Data button again to tell the control to store the

new value. You can verify that the new value is in place

when the value stops flashing.

• To exit Program mode, press the Program button again.

®

PROGRAMMING OPTIONS

®

®

Unit

®

INITIAL STARTUP OPTIONS

Commissioning a new Millennium® installation requires some

field adjustments to the Simplicity

these adjustments simply involve setting up the various

®

control program. Most of

setpoints that are specific to your customer’s needs (i.e.

building pressure) or enabling some extended options that are

integrated into the Simplicity control. Also, if there are field

changes, i.e. a modulating power exhaust option, the control

configuration will need to be modified for the new option.

METRIC OPERATION (ENGLISH)

The factory default for this option is OFF. The metric (SI)

conversions are part of the controller software; when the Metric

parameter is selected, temperature setpoints and readings will

convert to Centigrade (°C).

SETTABLE SYSTEM PARAMETERS

The following headings list each parameter’s name and its

default setting. The control is set at the factory for the options of

the specific unit; if a replacement control is being installed, the

entire parameter set must be matched to the unit. The number

in (parentheses) is the value of a parameter in an un-configured

control.

Compressors - (2) - This tells the control the number of

compressors available. The Factory Default [the value in an

unconfigured replacement control] is 2 and can be adjusted

from 1 to 4.

Heat Stages - (2) - This tells the control the number of heating

stages available. This parameter may be set from 0 to 3. The

default setting is 2 stages of heat. When modulating gas heat is

installed the parameters is always set to 2.

Hydronic Heat - (OFF) - This tells the control that a Hot Water Coil

is installed. If the control is going to modulate the Hot Water Va lve

it will also turn on the Heat One output. This is to energize the VAV

heat relay for the VAV boxes. The default is OFF for this option. If

this parameter is enabled, remember to set the Hydronic Heat First

and Second Stage Setpoints and the Economizer Loading

Setpoint found in the ”Simplicity

Stage 1 Hydronic Heat SAT Setpoint - (120 °F) - When the

Hydronic Heat option is enabled, the control will maintain this SAT

setpoint for a call for first stage Heating, by modulating the Hot

Water Valve. This is the reset temperature when operating a VAV

unit in the Heating mode. The reset range for SAT setpoint is from

80 °F to 180 °F with 120 °F shipped as the default.

Hydronic Heat Reverse Actuated Valve - (OFF) - Th is setting

is to allow convenient use of reverse acting w at er valves;

setting this parameter to (ON) will change the signal to 2VDC =

open, 10 VDC = closed.

SAT Control for Cooling - (ON) - This tells the control if it is

going to do excessive SAT monitoring and tripping or not, for

Cooling. The SAT should be maintained in an acceptable

range in order to achieve reliable compressor operation. The

compressor trip limits are user adjustable between 40 °F and

65 °F in one degree increments. The default cooling trip

limits are 50 °F for stages 2-4, and 45 °F for stage 1. When

the SAT drops below the trip limit for each respective

compressor, that compressor is locked out and a 5 minute

ASCD is initiated for that compressor. If this option is

enabled, remember to set the compressor cooling limits for

low limit trip.

®

Setpoints”.

Johnson Controls Unitary Products 11

Page 12

351579-YTS-C-0111

Power Exhaust - (ON) - This tells the control if it has the Power

Exhaust option installed.

Economizer Damper Position for Exhaust Fan to turn ON

(Non-Modulating PE Only) - (60%) - This tells the control the

Economizer Damper position to turn on the Exhaust Fan. This

value is based on the 0%-100% output drive signal from the

controller to the economizer damper actuator.

Economizer Damper Position for Exhaust Fan to turn OFF

(Non-Modulating PE only) - (20%) - This tells the control the

Economizer Damper position to turn off the Exhaust Fan. This

value is based on the 0%-100% output drive signal from the

controller to the economizer damper actuator.

Modulating Exhaust - (OFF) - This tells the control if the

Power Exhaust is Modulating or not. A modulating exhaust will

be equipped with a Building Pressure Sensor [BPS]. A NonModulating exhaust will look to the economizer damper position

to energize the EXD output. If the sensor gets disconnected, or

fails, an alarm is set. The alarm can be turned off by correcting

the sensor problem (or; by turning off this option). The control is

not in this case self-configuring. It will not automatically use the

Building Pressure Sensor if the sensor is connected.

Exhaust VFD Installed - (OFF) - If the unit has a VFD, the EXD

output will be enabled when the supply fan is ON.

Exhaust Damper Position For The Exhaust Fan To Turn On

(Modulating Only) - (80%) - This tells the control the Exhaust

Damper position at which to turn on the Exhaust Fan. This

value is based on the 0%-100% output drive signal from the

controller to the damper actuator.

Exhaust Damper Position For Exhaust Fan To Turn Off

(Modulating Only) - (20%) - This tells the control the Exhaust

Damper position to turn off the Exhaust Fan. This value is

based on the 0%-100% output drive signal from the controller to

the damper actuator.

Building Pressure Setpoint - (+0.100”WG) - This is the

pressure setpoint the control will maintain when op era ting a

Power Exhaust. The Building Pressure Setpoint is adjustable

from -0.200”WG to +0.200”WG. The factory programmed default

is +0.100”WC. This setpoint is used when the exhaust control is

implemented as Proportional Control (with a Modulating Exhaust

Air Damper or VFD controlled from building static pressure), or

as a Two-posi tion Co ntrol using bui lding static (Power Exhaust

Fan controlled on-off from building static pressure).

Economizer - (ON) - This tells the control that there is an

Economizer Installed.

Economizer Min Position - (20%) - This tells the control what

the minimum outdoor damper position will be for the Occupied

mode. Adjustable from 0-100%, the Economizer Minimum

Position default is 20%.

Economizer First Stage Setpoint - (55 °F) - This tells the

control what Supply Air Temperature to maintain for a call for

first stage of cooling. This is used only during Constant Volume

cooling mode with Economizer operation. The setpoint is set at

55 °F with an adjustable range from 40 °F to 65 °F.

Economizer Second Stage Setpoint - (50 °F) - This tells the

control what Supply Air Temperature to maintain for a call for

second stage of cooling. This is used only during Constant

Volume cooling mode with Economizer operation. This setpoint

is set at 50 °F with a range from 40 °F to 65 °F.

Outside Air Humidity (OAH) Sensor Enable - (OFF) - This

setting tells the control that it is expected to use Outside Air

Enthalpy (calculated from Outside Air Temperature and Outside

Air Relative Humidity sensed values) to decide if Outside Air

can be used for cooling.

The control is self-configuring to the best available decision

strategy for free cooling availability. For example, if it detects

that OAT and OAH and RAT and RAH sensors are all

connected and reliable, will self-configure for Differential

Enthalpy operation. If one of the return air sensors should fail,

the control will reconfigure for Outside Enthalpy operation, etc.

If the OAH Sensor Enable option is turned ON, it means that the

Outside Enthalpy Operation, or better decision strategy, is

expected (and supported by installed sensors). If the

appropriate sensors are not installed, or one of them failed, a

sensor failure alarm is set. The alarm can be turned off by

turning off the OAH Sensor Enable option. Thus, the option

setting is used to reflect the desired operation and mainly to

control sensor failure alarms

.

The option setting can be viewed as specifying that (the selfconfigured economizer decision strategy has to be at least this,

or better, otherwise an alarm is set). If the option is OFF, the

control still may self configure to Outside Enthalpy Operation, or

even to Differential Enthalpy Operation (if all needed sensors

are available), but this option setting will allow also the decision

strategy based on only OAT (in case other sensors fail, or are

not installed) without setting an alarm.

Outside Air Enthalpy Setpoint - (27 BTU/LB) - This tells the

control an outside air enthalpy limit. Below this limit, outside air

is available for cooling. See enthalpy chart. This parameter

uses a one BTU/LB hysteresis on each side of the limit. The

limit is preset to 27 BTU/ LB with an adjustable range from 10 to

50 BTU/LB.

Return Air Humidity (RAH) Sensor enable - (OFF) - This tells

the control that it will compare Outside Air Enthalpy (calculated

from Outside Air Temperature an d Outside Air Relative

Humidity sensed values) and Return Air Enthalpy (calculated

from Return Air Temperature and Return Air Relative Humidity

sensed values). The control will use the air stream with the

lower enthalpy for cooling.

The control is self-configuring to the best available decision

strategy for free cooling availability . For example, if it detect s that

OA T and OAH and RAT and RAH sensors are all connected and

reliable, will self-configure for Differential Enthalpy operation. If

one of the return air sensors should fail, the control will stop using

rules that involve RAH and set an alarm.

If the RAH Sensor Enable option is turned ON (and supported

by installed sensors), Differential Enthalpy Operation can be

enabled. If the appropriate sensors are not installed, or one of

them failed, a sensor failure alarm is set. The RAH alarm can

12 Johnson Controls Unitary Products

Page 13

351579-YTS-C-0111

be turned off by turning off the RAH Sensor Enable option.

Thus, the option setting is used to reflect the desired operation

and mainly to control sensor failure alarms.

Economizer Loading to Control SAT - (ON) - This tells the

control if it is going to use Economizer Loading to control

excessive SAT [supplying warmer outside air to keep SAT from

going too low]. This parameter is only applicable outside the

normal Economizer operation. During the Economizer

operation, the loading function is always performed and is an

integral part of the control algorithm.

Duct Static Setpoint - (1.5”WG) - This parameter is applicable

only to V A V mode of operation. This is the pressure setpoint that

the control will maintain when operating the fan in a VAV unit.

This setpoint is adjustable between 0”WG and 5”WG with the

default set to 1.5”WG.

Duct Static High Limit Setpoint - (4.5”WG) - This parameter is

applicable only to V AV mode of operation. This tells the control at

what Static Pressure to shu t down the unit due to a Fan control

failure. This setpoint is to insure that we don't continue to operate

the Fan with an Inlet Guide Vane or VFD problem that could

cause the ductwork to fail from duct pressure. When the St a tic

Pressure reaches this setpoint (4.5”WG default), the control will

drive the supply fan control output to zero. If the static pressure

does decrease below the “Duct St at ic High Li mit Setpoi nt” within

3 seconds after decreasing the supply fan control output to zero,

the control will resume normal operation. If there is no change in

static pressure after 3 seconds, the control will generate a High

Duct Static alarm, shut do wn all the outputs including the Fan and

shut down the unit. The alarm is written to the Error History Buffer

and will trigger storing a snapshot of Points Screen data alon g

with a date and time stamp. In networked applications, the ala rm

flag is readable by the network. This parameter can be adjusted

from 0”WG to 5”WG with the factory default set to 4.5”WG.

The customer must be aware of the duct pressure design limit,

and what the duct pressure sensor will be reading when the peak

pressure is reached [the pressure pickup tube may not have

been located at the place of highest pressure in the system].

The alarm must be reset (after the problem that caused the

alarm is corrected) by resetting the controller by turning power

to the unit off and back on, or by reset command issued by an

external connection.

Morning Warm Up - Is inferred from the entries in

Occupied/Unoccupied

Occupied - (from settings in Weekly Schedule and Holiday

Schedule Tables 11 and 12.) - See discussion in Sequence of

Operation.

Unoccupied - (from settings in Weekly Schedule and Holiday

Schedule Tables 11 and 12.) - See discussion in Sequence of

Operation.

VAV High Temperature SAT Setpoint for Cooling - (60 °F) -

The control will maintain this SAT when operating in VAV mode

with a thermostat that is calling for first stage cooling. This

parameter may be adjusted from 40 °F to 70 °F with 60 °F set

as the default value.

VAV Low Temperature SAT Setpoint for Cooling - (55 °F) -

The control will maintain this SAT when operating in VAV mode

with a thermostat that is calling for second stage cooling. This

parameter may also be adjusted from 40 °F to 70 °F with 55 °F

set as the default value.

VAV SAT Reset Setpoint - (72 °F) - This parameter is used

only in V AV mode with a Space Sensor. The control will switch

from the VAV Lower Cooling SAT Setpoint to the VAV Upper

Cooling SAT Setpoint when this Space Temperature Setpoint

minus 0.5 °F is reached. The control will switch from High

setpoint back to Low setpoint when the space temperature gets

2 °F above this setpoint. This is SAT reset based on Space

Temperature. The reset occurs in both Occupied and

Unoccupied modes and may be adjusted from 40 °F to 85 °F.

The factory default is 72 °F.

V AV Occupied Heating - (OFF) - This option applies in VAV

mode with a Space Sensor and does not affect VAV Occupied

heating if requested by a thermostat. When this option is

toggled on, a VAV unit is able to operate heating in the occupied

mode as long as it is operating with a Space Sensor. If the

Space Temperature drops to 2 °F below the VAV SAT Reset

Setpoint the control will read the RAT. If the RAT is below the

Morning Warm Up RAT Setpoint the unit will enter the Occupied

Heating mode. Operation is the same as Morning Warm Up.

This parameter is factory set to OFF.

Comfort Ventilation Mode - (OFF) - Comfort Ventilation is a

SAT control mode that controls SAT during “satisfied” periods in

a fairly wide temperature band, using mostly Outside Air, and

also cooling and heating stages as necessary. It is available

only on the Constant Volume unit.

To enable Comfort Ventilation, the programmable parameter

“Comfort Ventilation Mode” must be set to ON (default setting is

OFF).

For a detailed explanation of Comfort Ventilation, refer to the

Sequence of Operation in this manual.

Comfort Ventilation High Supply Air Setpoint - (80 °F) - This

is the High Limit Setpoint for the Comfort Ventilation mode. For

a stable operation of Comfort Ventilation function, the High

Supply Air Setpoint should be set 10.0 °F or more above the

Low Setpoint.

Comfort Ventilation Low Supply Air Setpoint - (70 °F) - This

is the Low Limit Setpoint for the Comfort Ventilation mode. For

a stable operation of Comfort Ventilation function, the Low

Supply Air Setpoint should be set 10.0 °F or more below the

High Setpoint.

Dirty Filter Switch - (OFF) - This tells the control that a Dirty

Filter Switch is connected to it. The control will wait for ten

minutes after the switch has closed before declaring a Dirty

Filter Alarm. The alarm is written to the Error History Buffer. In

networked applications, the error flag is readable by the

network. The alarm will automatically reset when the error

condition is corrected.

The default is OFF.

Johnson Controls Unitary Products 13

Page 14

351579-YTS-C-0111

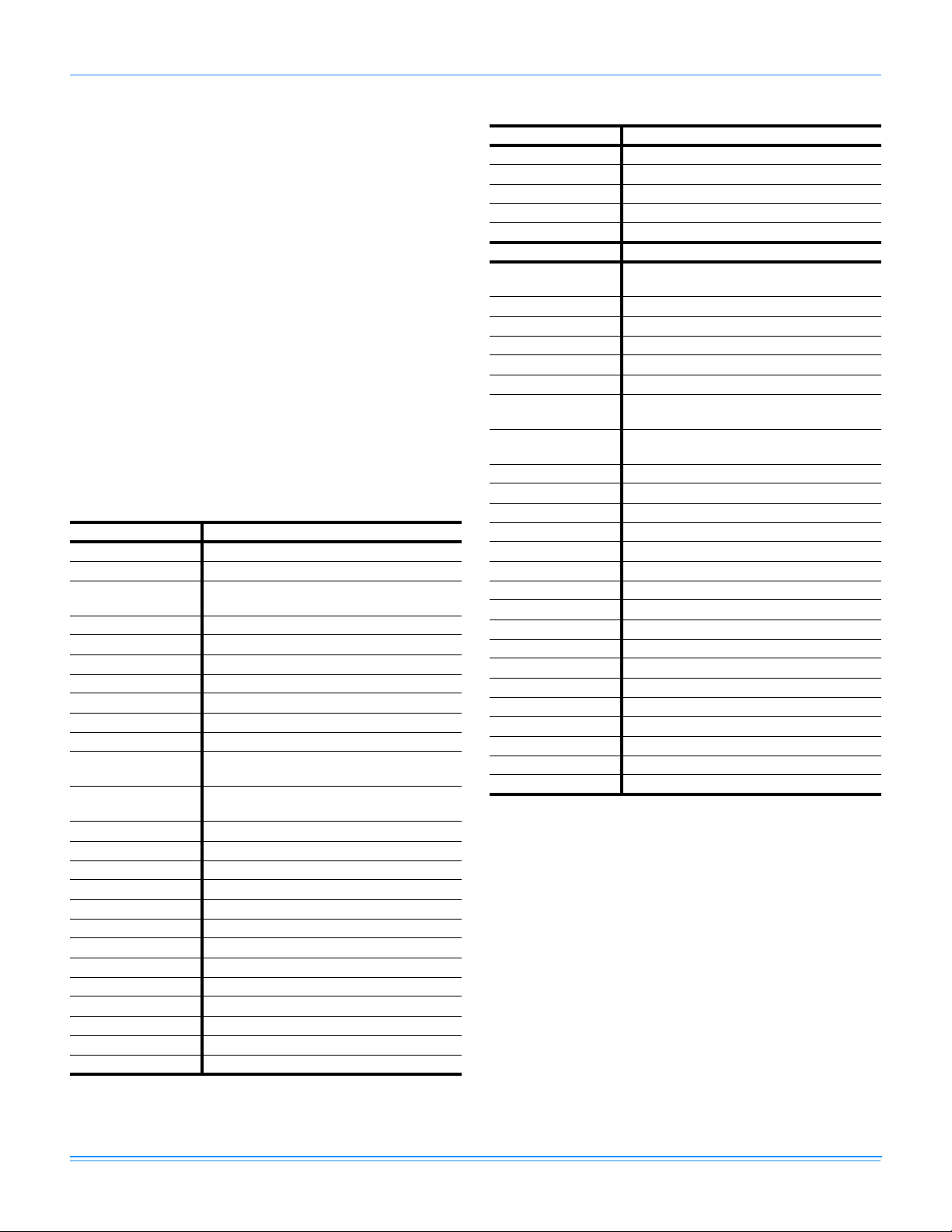

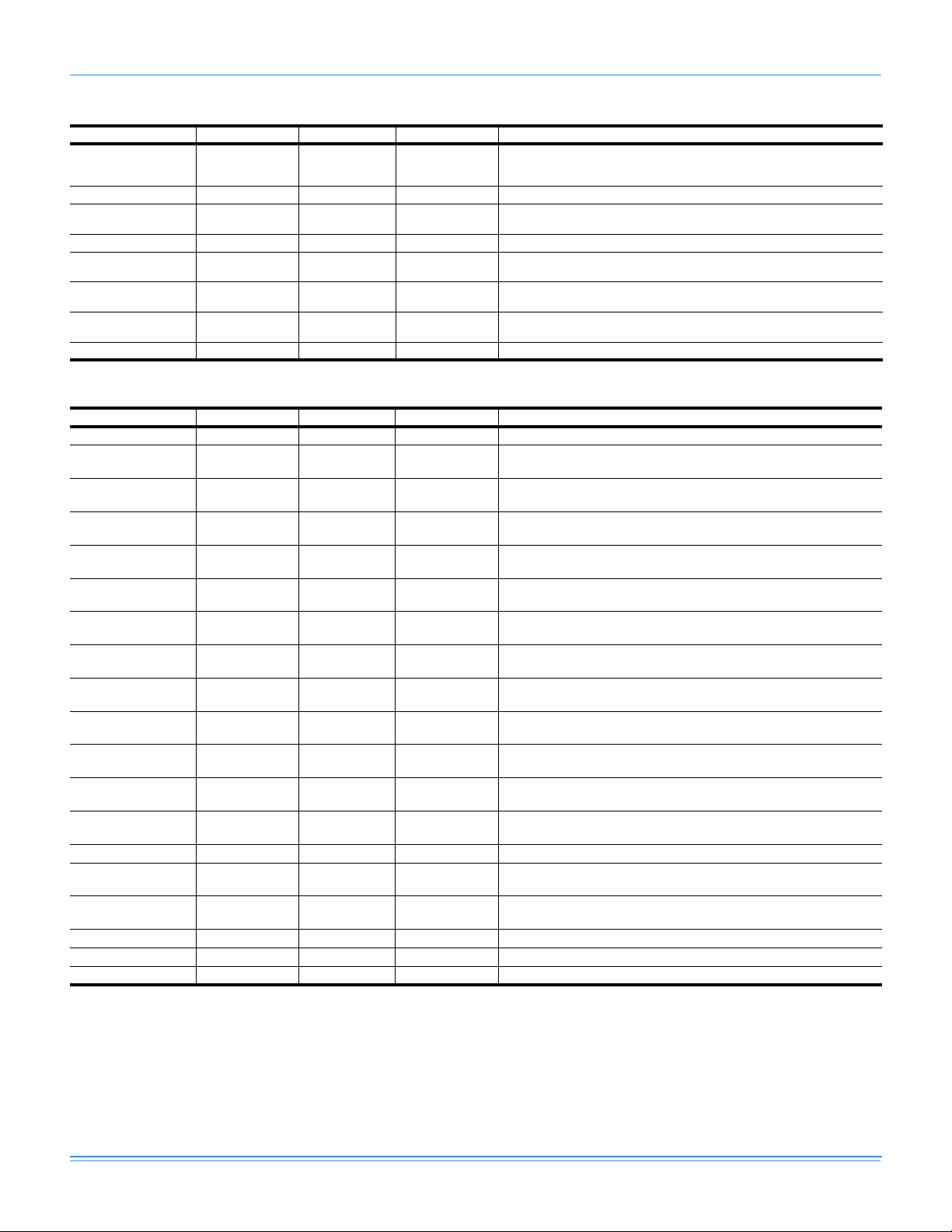

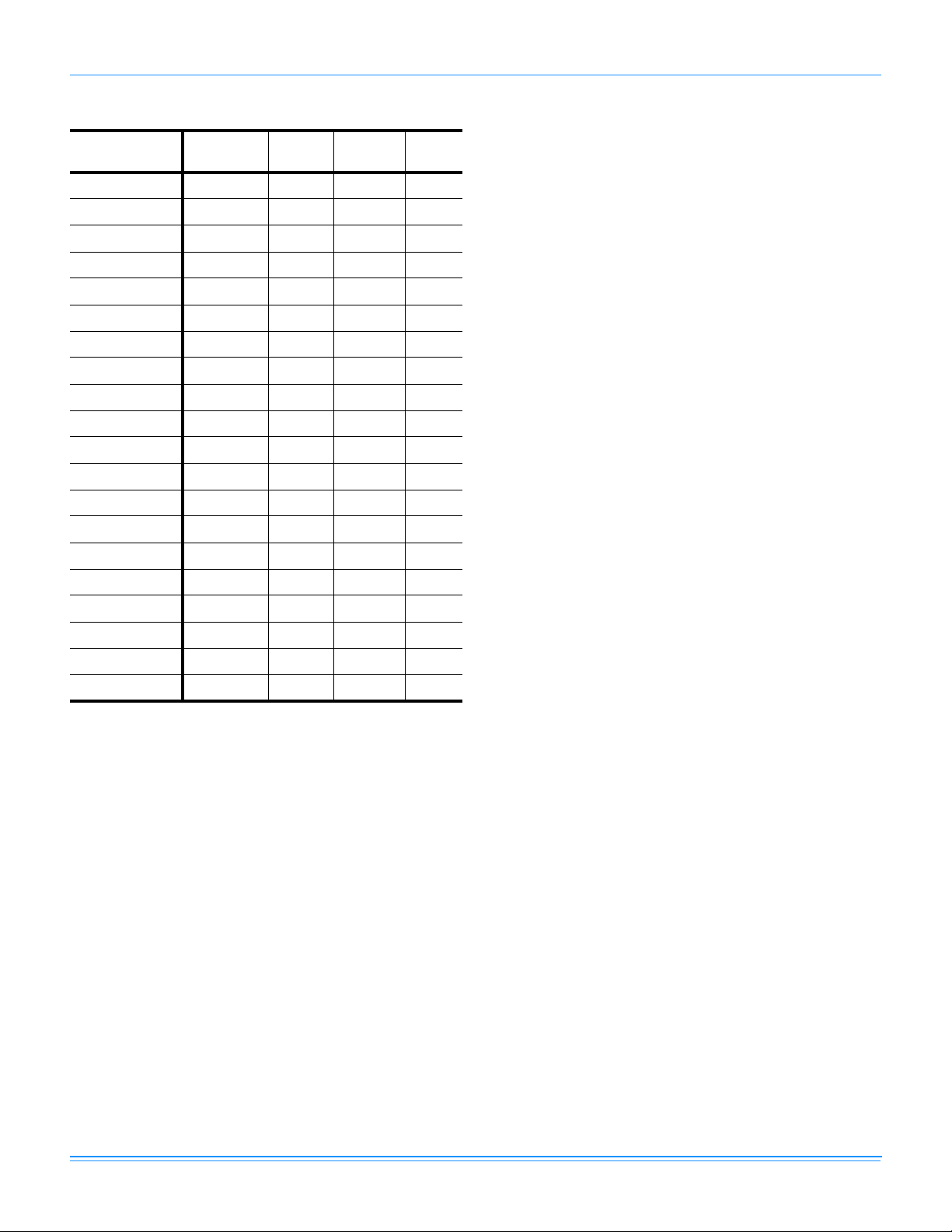

UnOcc.

Htg.

Occ.

Htg.

UnOcc.

Clg.

Occ.

Clg.

Heating Lockout on OAT - (75 °F) - This is the Outside Air

Temperature Setpoint that the control will use to lock out Heating

when the OA T is a bove this setpoint. There is a one-degree

hysteresis on each side of the setpoint. This parameter is

adjustable between 0 °F and 100 °F with the default set to 75 °F.

Heating Lockout on OAT affect s only staged heating, it does not

affect hydronic heat. If the heating is energized when OAT

reaches this setpoint, the Status LED will indicate the lockout

condition immediately, but the control will finish the heating

mode and then lock out the heating.

Note that a Heating Lockout on OAT may occur while the

control is in a heating mode and there is a demand for heating.

If the OAT then decreases below the lockout setting while the

call for several heat stages exists, the heat stages will turn on

simultaneously. This is considered acceptable as this situation

is not expected to occur frequently.

Cooling Lockout on OAT - (45 °F) - This is the Outside Air

Temperature Setpoint that the control uses to lock out Cooling

when the OAT is below this setpoint. Adjustable from 0 °F to

100 °F, the default is 45 °F.

Unoccupied Heating Setpoint - (60 °F) - This value is the

Unoccupied Heating Setpoint. It is used in both CV and VAV

mode of operation (in VAV, it controls Unoccupied heating with

a Space Sensor).

Figure 5: Sequence Of Setting The Set Points

The control will attempt to correct wrong temperature overlap

settings; for example, if a change is made that would put

Occupied Heating above Occupied Cooling, the Occupied

Cooling setting will change to stay above the heating setpoint.

Occupied Heating Setpoint - (68 °F) - This value is the

Occupied Heating Setpoint. It is used only in CV mode of

operation. Its relationship to the related setpoints is as defined

in the Unoccupied Heating Setpoint paragraph above.

Unoccupied Cooling Setpoint - (85 °F) - This value is the

Unoccupied Cooling Setpoint. It is used in both CV and VAV

mode of operation (in VAV, it controls Unoccupied cooling with a

Space Sensor).

Occupied Cooling Setpoint - (72 °F) - This value is the

Occupied Cooling Setpoint. It is used only in CV mode of

operation. Its relationship to the related setpoints is as defined

in the Unoccupied Heating Setpoint paragraph above.

[Input] FSI (Hot Water Freeze Protection) - (OFF) - This

option is used only on rooftop units with hydronic heat

(Hydronic Heat Option is turned ON). Freeze protection should

always be placed on units that use hydronic heating. When the

control senses 24VAC, the control will turn on the Hot Water

valve to 100%. The control will continue to drive the valve at

100% until five minutes after the switch has opened. Then the

valve will revert to normal operation. If the control is operating

the Fan, it will close the Economizer fully until the freeze

condition is over. If the fan is off and the RA T drops below 40 °F,

the Hot Water Valve will turn on 100%.

Supply AirTemp (SA T) Alarm Setpoint for Cooling - (0 °F) - If

the SAT does not drive below this setpoint when all stages of

compression are operating and 10 minutes has elapsed since

the last compressor was energized, the control will declare a

Cooling SAT Failure Alarm.

The alarm is written to the Error History Buffer. In networked

applications, the alarm flag is readable by the network.

The alarm will reset automatically if the SAT does decrease

below the setpoint (the alarm condition no longer exists), or

when a compressor is turned off (the control does not request

all compressors operate). The SAT Alarm Setpoint for Cooling

can be adjusted from 50 °F - 80 °F. If the value is set to 0 °F

(default) this feature is disabled.

Before the control declares an error, it will read the OAT and the

Economizer position. If the OAT is more than 20 °F warmer than

the setpoint and the Economizer is open more than 20%, the

control will close the Economizer for 10 minutes and then read

the SAT. If the SAT falls below the setpoint, the control will

declare an Economizer Minimum Position alarm. The control

will keep the Economizer closed and finish the Cooling mode.

After the Cooling mode has been satisfied, the control will move

the Economizer back to the minimum position.

Supply Air Temp (SAT) Alarm Setpoint for Heating - (0 °F) -

The SAT must drive above this setpoint when all stages of heating

are operating and 10 minutes has elapsed since the last stage was

energized. If this does not happen, the control will declare a

Heating SAT Failure Alarm. The alarm is written to the Error

History Buffer. In networked applications, the alarm flag is readable

by the network. The alarm will reset automatically if the SAT does

increase above the setpoint (the alarm condition no longer exists),

or when a heating stage is turned off (the control does not request

all heat stages to operate).

The SAT Alarm Setpoint for Cooling can be adjusted from 70 °F 120 °F. If the value is set to 0 °F (default) this feature is disabled.

Before the control declares an error, it will read the OAT and the

Economizer position. If the OAT is more than 20 °F colder than

the setpoint and the Economizer is open more than 20%, the

control will close the Economizer for 10 minutes and then read

the SAT. If the SAT rises above the setpoint, the control will

declare an Economizer Minimum Position alarm. The control

will keep the Economizer closed and finish the Heating mode.

After the Heating mode has been satisfied, the control will move

the Economizer back to the minimum position.

Unoccupied Override Time Period - (60 min) - The

Unoccupied Override Time Limit function will determine how

long the unit will operate in the Unoccupied Override mode

when the Override button is pressed on the Space Sensor.

14 Johnson Controls Unitary Products

Page 15

351579-YTS-C-0111

Once the Unoccupied Override mode is initiated, it will continue

until the programmed Unoccupied Override Time Limit is

reached. The Override mode can not be cancelled by, for

example, a change of state of the Occupied input to ON

(occupied) and then back to OFF (unoccupied).

This parameter is adjustable from 0 to 240 minutes. The default

is 60 minutes.

Fan Delays (ON) & (OFF) - Any time the control starts a

compressor it will load the Fan On Delay for Cool with the

programmed value. Any time the control turns off all the

compressors it will load the Fan Off Delay for Cool with the

programmed value.

When the control turns on a gas heat stage, it will begin

monitoring the gas valve and load the Fan On Delay For Heat

with the programmed value when it senses gas valve voltage. If

modulating gas heat is installed, then Fan Off Delay in heating

must be set to Off.

When the thermostat terminates the call for W1 the control will

turn off H1 output and load the Fan Off Delay for Heat with the

programmed value.

After the control has turned on heat, it will start monitoring the

Gas Valve. If at any time the Gas Valve (24 VAC) is not present

for five minutes while H1 is on, the control will flag an Alarm.

Anytime GV1/H1 goes off during the fan on delay, the control

will force the fan on, for the fan off delay period. The control will

wait for GV1 to be on at least 15 seconds before forcing the fan

on. If GV1 has been on for at least 15 seconds, and then goes

away before the Fan On Delay has finished, the fan will turn on

anyway far a length of time equal to the Fan Off Delay period.

If the control senses this input along with a Y signal, it will not

turn on the compressors and it will run the Heating mode.

Heating takes priority.

Fan ON Mode with the Sensor Option - (ON) - When this

option is turned ON, the supply fan will continue running when

the zone sensor based temperature control is satisfied. This

option applies only in systems using a zone sensor and only in

Occupied mode. With this option turned OFF, or in Unoccupied

mode, the fan will go off when the zone sensor based

temperature control is satisfied and will go on only when there is

a call for heating or cooling. Turning this opti on ON is an

equivalent of selecting fan ON (rather than AUTO) in systems

with a thermostat. In a thermostat system, the fan control follows

the thermostat's G signal. In sensor systems and in the Occupied

mode, the fan control follows the Fan ON Mode option.

Space Sensor Enable - (OFF) (INTERNALLY SET) - The

control will use this input if it detects the device.

RA T Sensor Enable - (OFF) (INTERNALLY SET) - The control

will use this input if it detects the device.

Demand Ventilation (ON) - Setting this parameter on tells the

control to expect a signal from a 0-10VDC CO

default setting for CO

is 1,000 ppm.

2

sensor. The

2

Demand Ventilation Setpoint - (1000 ppm) - This Setpoint is

the maximum Indoor Air Quality (IAQ) level that the control will

allow. It is adjustable from 700 ppm to 1500 ppm.

IAQ Sensor Range - (5,000 ppm) - This tells the control what

the full range is for a specific IAQ sensor. It can be changed

from 0 to 10,000 ppm.

Cooling Mode Enable (ON) - This tells the control if it has

Cooling Available (Mode Switch). If this option is turned off,

cooling operation is disabled. Note that this parameter does not

affect cooling operation in Comfort Ventilation mode.

Heating Mode Enable - (ON) - This tells the control if it has

Heating Available (Mode Switch). If this option is turned off,

heating operation is disabled. Note that this parameter does not

affect heating operation in Comfort Ventilation mode.

Space Setpoint Offset - (3 °F) - The Space Setpoint Offset is

the +/- value the control will use to offset the Space Setpoint

when the slidebar Space Sensor is used. For example, if the

Space Setpoint Offset value is set to 3.0 °F, shifting the slidebar

all the way in minus direction will decrease the Space Setpoint

by 3.0 °F and shifting it all the way in plus direction will increase

the Space Setpoint by 3.0 °F. It is adjustable from 0 °F to 5 °F.

ASCD Override - This is not an option parameter but rather a

one-time command issued by pressing the Test / Reset / Up

button pressed and released within five seconds; the ASCD’s

will be set to zero for one cycle.

Run Test (Commissioning Test) - This is not an option

parameter but rather a one-time command, activated by setting

parameter 1 ON.

When the Run T est command is issued, the control will shut the

unit down if it is running and then start a Run test sequence:

1. Turn on the Fan and then turn on all the compressors, one

at a time, with a 15-second delay between them. Condenser fan #1 turns on with compressor #1, condenser fan

#2 turns on with compressor #2. After the last compressor

has been turned on, the control will run the compressors

for the programmed minimum run time and then turn them

all off. Condenser fans are also turned off.

2. The control will then turn on the Heat stages, one at a time,

with a 15 second delay between them. The control will run

each Heat stage for three minutes and then turn all the

Heat off.

3. The control will then open the Economizer to the 100%

open position and wait five minutes before closing it to the