Page 1

TECHNICAL GUIDE

AFFINITY

SPLIT -SYSTEM HEAT PUMPS

13 SEER – R-410A

MODELS: YZB018 THRU 060

(1.5 THRU 5 NOMINAL TONS)

ISO 9001

Certified Quality

LISTED

Due to continuous product improvement, spec i f ic ations

are subject to change without notice.

Visit us on the web at www.york.com

Additional rating information can be found at

www.ahridirectory.org

Management System

271457-YTG-B-0908

DESCRIPTION

The YZB Series unit is the outdoor part of a versatile heat pump

system. It is designed to be custom matched with one of our complete line of evaporator sections, each designed to serve a specific

function. Matching air handlers are available for upflow, downflow,

and horizontal left or right applicat ion to provide a compl ete system.

Electric heaters are available if required. Add-on coils are available

for use with upflow, downflow, or horizontal furnaces. Field installed

accessories are available as needed.

WARRANTY

5-year limited parts warranty.

10-year limited compressor warranty.

FEATURES

• Superior Coil Protection – A stamped decorative metal coil

guard completely protects coil from debris and other large damaging material while a polymer mesh further protects the coil

against smaller particles.

• Isolated Compressor Compartment – A molded composite

bulkhead isolates the compressor from the rest of the uni t reducing sound and vibration.

• Protected Compressors – Each compressor is protected

against high and low pressure as well as excessiv e temp erature.

This is accomplished by by the simultaneous operation of a high

pressure relief valve and temperature sensors which protect the

compressor if undesirable conditions occur.

• Environmentally Friendly Refrigerant – Next generation

refrigerant R-410A delivers environmentally friendly performance, with zero ozone depletion.

• Durable Finish – Automotive quality finish provides the ultimate

protection from harmful U.V. rays as well as rust creep ensuring

long-lasting high quality appearance. A powder-paint topcoat is

applied over a baked-on primer, using a galvanized, zinc coated

steel base material. The result is a finish that has been prove n in

testing to provide 33% greater durability than conventional powder-coat finishes.

• Lower Installed Cost – Designed to provide enhanced install-

ability by featuring a slide-down control compartment allowing

easy access to control components along with angled service

valves to reduce overall installation time and cost.

• Low Operating Sound Levels – A fan design boasting technology adapted from aeronautic and defense engineering provides

for whisper quiet operation by allowing airflow to flow smoothly

and efficiently across the fan tips .

• Filter-Drier – A factory installed, solid core liquid line filter-drier

filters harmful debris and moisture from the system.

• Easy Service Access – A full end, full service, access panel

with handle makes for easy entry to internal components.

• Long Lasting Operation – Strong and durable composite base

pan provides added strength while resisting rust and corrosion

as well as reducing sound and vibration.

• Complete System Control – These heat pumps utilize the

unique microprocessor defrost control system to provide optimal

comfort as well as monitor the overall system for reliable operation. The defrost control system continuously monitors the sp ace

environment to maintain optimum efficiency. It initiates defrost

only when necessary to further reduced heating costs and

improve reliability. Supplemental heat can only operate below

the balance point and then only upon need. In the event

improper operating conditions occur (high temperature and/or

high pressure), the wil l automatically shut the system down t o

extend the life of the heat pump. Rapid cycling is prevented by

use of an internal anti-recycle timer. The defrost control features

an internal memory to aid the technician in troubleshooting,

reducing service time and cost.

• Agency Listed - U.L. and C.U.L. listed - approved for outdoor

application. The unit is certified in accordance with the Unitary

Small Equipment cerification program, which is based on ARI

Standard 210/240.

FOR DISTRIBUTION USE ONLY - NOT TO BE USED AT POINT OF RETAIL SALE

Page 2

271457-YTG-B-0908

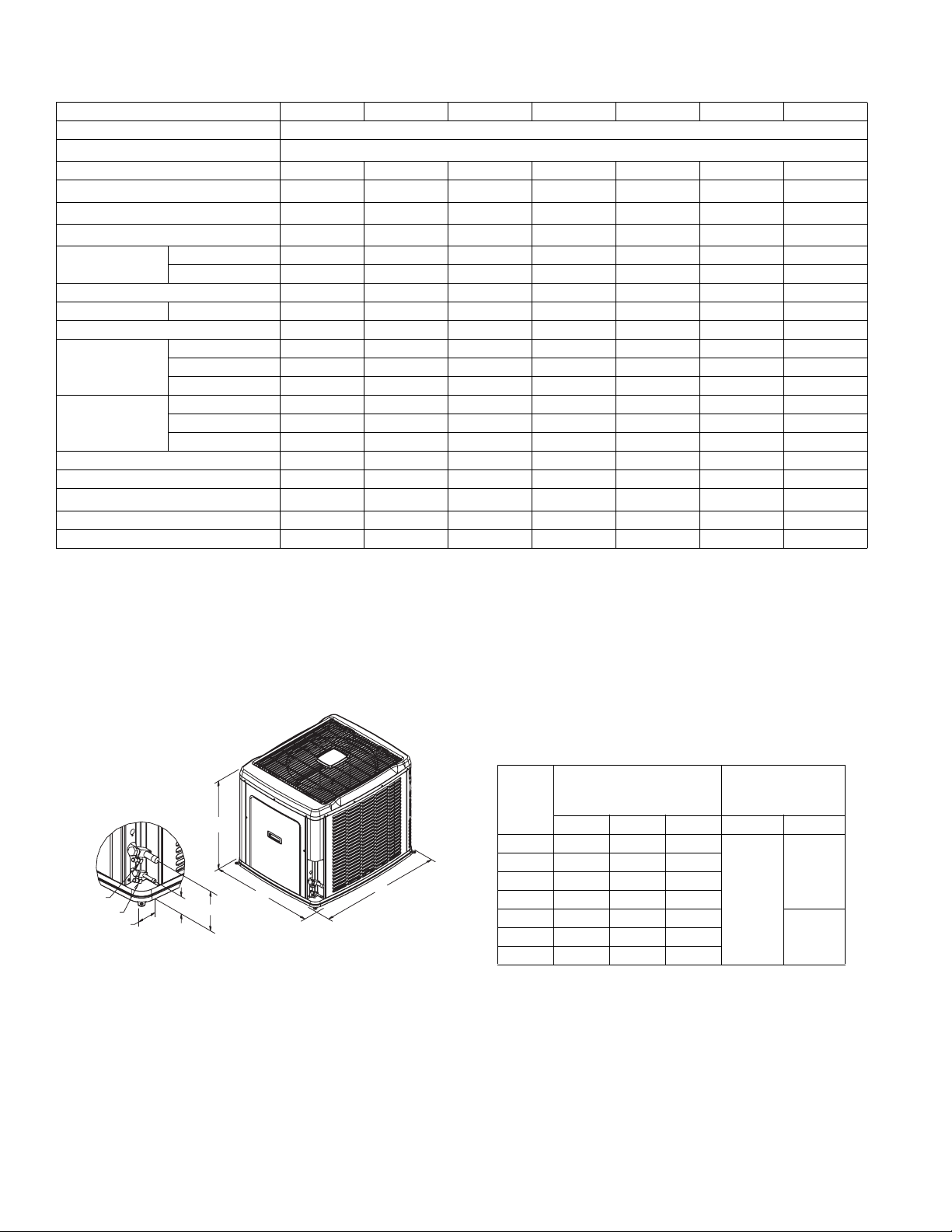

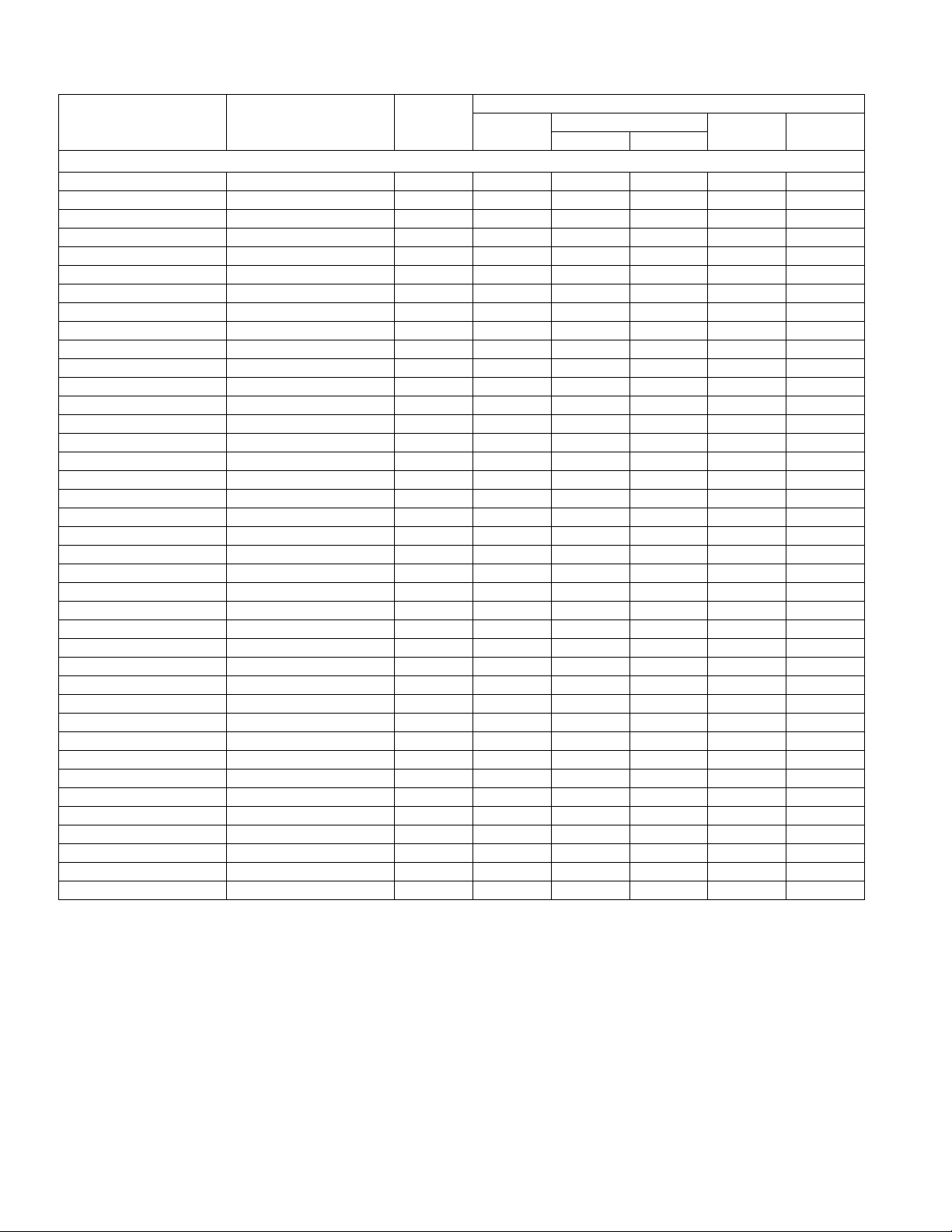

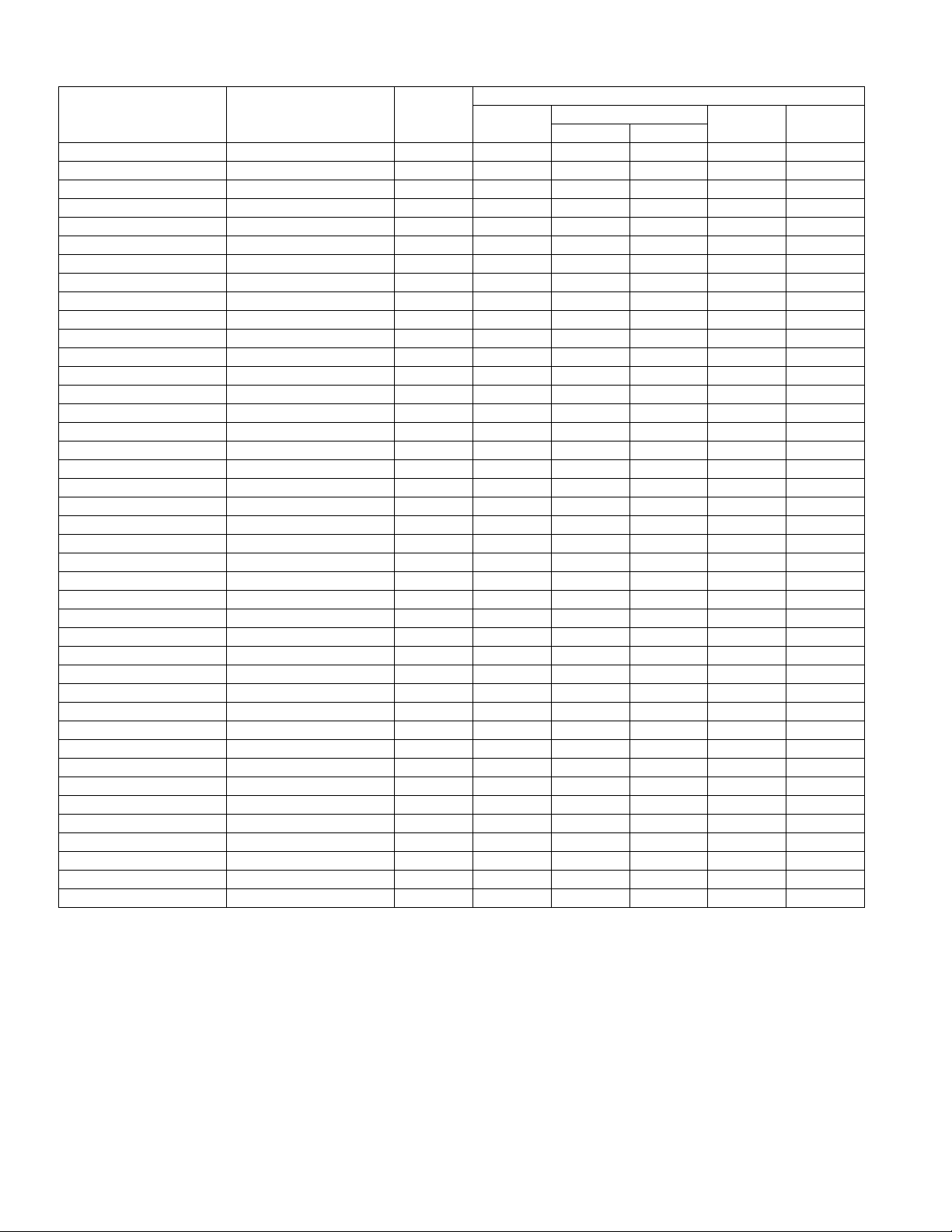

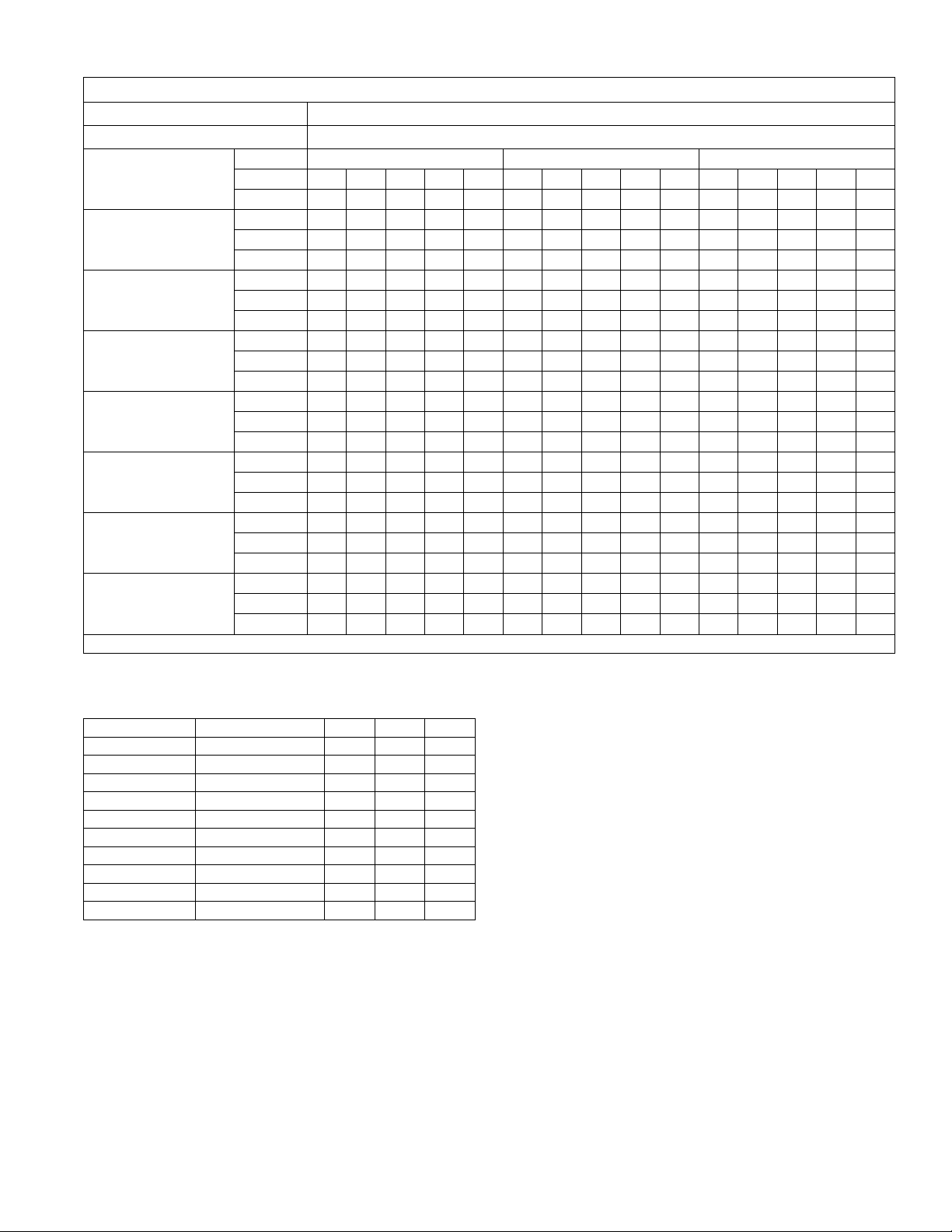

Physical and Electrical Data

MODEL YZB1811 YZB02411 YZB03011 YZB03611 YZB04211 YZB04811 YZB06012

Unit Supply Voltage 208/230 – 1 – 60

Normal Voltage Range

1

Minimum Circuit Ampacity 14.2 18.8 22.0 25.6 32.1 35.3 37.5

Max. Overcurrent Device Amps

Min. Overcurrent Device Amps

Compressor Type

Compressor Amps

4

Rated Load 11.0 14.7 16.4 19.3 24.5 27.0 25.0

Locked Rotor 51 60 73 88 105 113 150

2

3

25 30 35 40 50 60 60

15 20 25 30 35 40 40

Scroll Scroll Scroll Scroll Scroll Scroll Scroll

Crankcase Heater No No No No No No No

Fan Motor Amps Rated Load 0.5 0.5 1.5 1.5 1.5 1.5 1.5

Fan Diameter Inches 22 22 22 22 22 22 24

Rated HP 1/15 1/15 1/4 1/4 1/4 1/4 1/4

Fan Motor

Nominal RPM 850 850 850 850 850 850 850

Nominal CFM 2,050 2,250 3,200 3,250 3,250 3,500 3,500

Face Area Sq Ft 14.86 17.15 17.15 20.58 20.58 20.58 23.58

Coil

Rows Deep 1111122

Fin /Inch 22 22 22 22 22 22 18

Liquid Line Set OD (Field Installed) 3/8 3/8 3/8 3/8 3/8 3/8 3/8

Vapor Line Set OD (Field Installed) 3/4 3/4 3/4 3/4 7/8 7/8 7/8

Unit Charge (Lbs - Oz)

5

7-1 7-10 7-9 9-5 9-2 12-5 16-8

Charge Per Foot, oz. 0.62 0.62 0.62 0.62 0.67 0.67 0.67

Operating Weight Lbs 175 190 195 220 220 260 265

1. Rated in accordance with ARI Standard 110, utilization range “A”.

2. Dual element fuses or HACR circuit breaker. Maximum allowable overcurrent protection.

3. Dual element fuses or HACR circuit breaker. Minimum recommended overcurrent protection.

4. All scrolls listed with superscript “B” are Bristol scrolls. All scrolls listed with superscripts “C” are Copeland scrolls.

5. The Unit Charge is correct for the outdoor unit, matched indoor coil and 15 feet of refrigerant tubing. For tubing lengths other than 15 feet,

add or subtract the amount of refrigerant, using the difference in length multiplied by the per foot value.

187 to 252

VAPOR

LIQUID

2-3/8

3-1/8

6-1/2

All dimensions are in inches. They are subject to change without notice. Certified dimensions will be provided upon request.

DIMENSIONS

Unit

Model

A

Dimensions

(Inches)

A B C Liquid Vapor

018 29-1/2 37 31

024 33-1/2 37 31

C

B

030 33-1/2 37 31

036 39-1/2 37 31

042 39-1/2 37 31

060 39-1/2 42 34

Refrigerant

Connection

Service Valve Size

3/4”

3/8”

7/8”048 39-1/2 37 31

2 Johnson Controls Unitary Products

Page 3

271457-YTG-B-0908

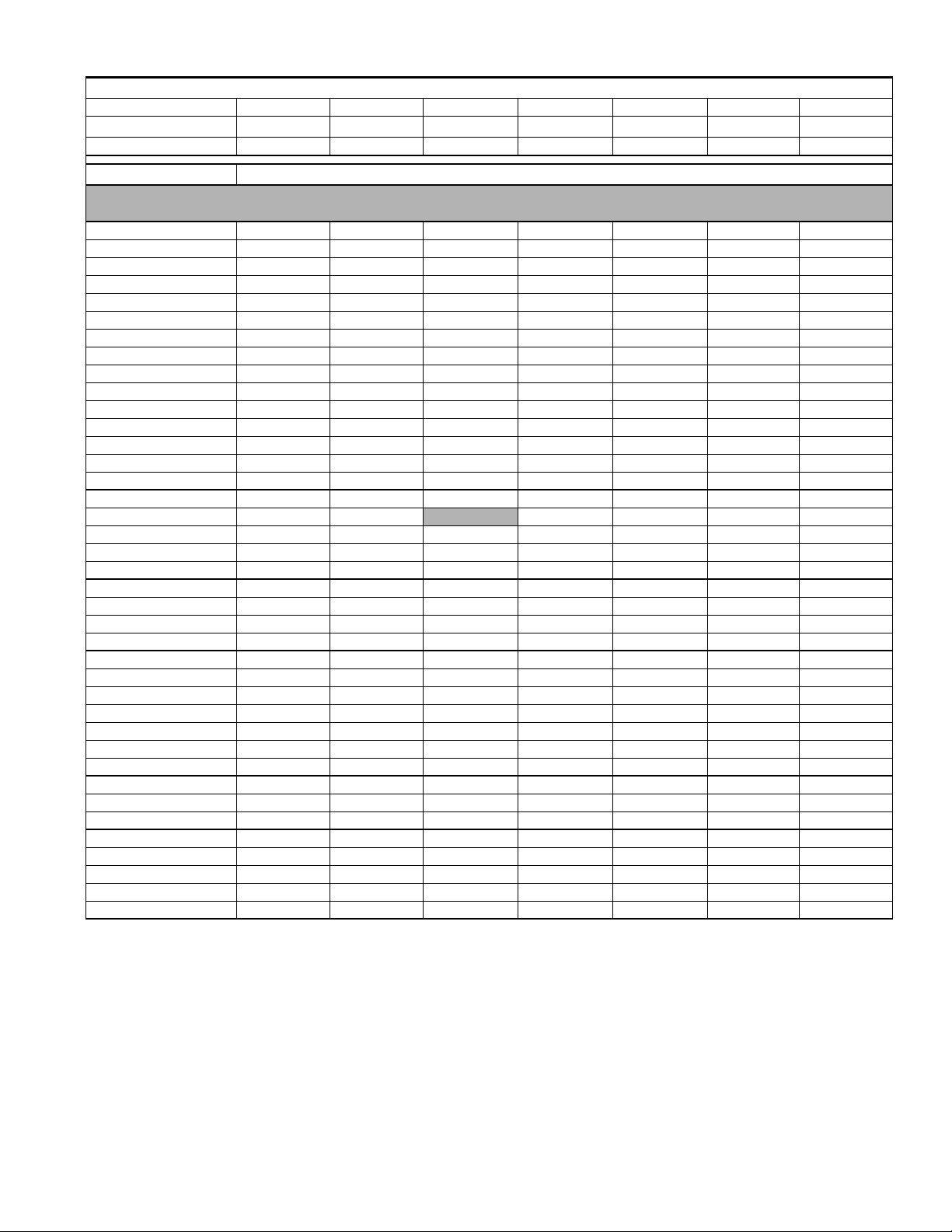

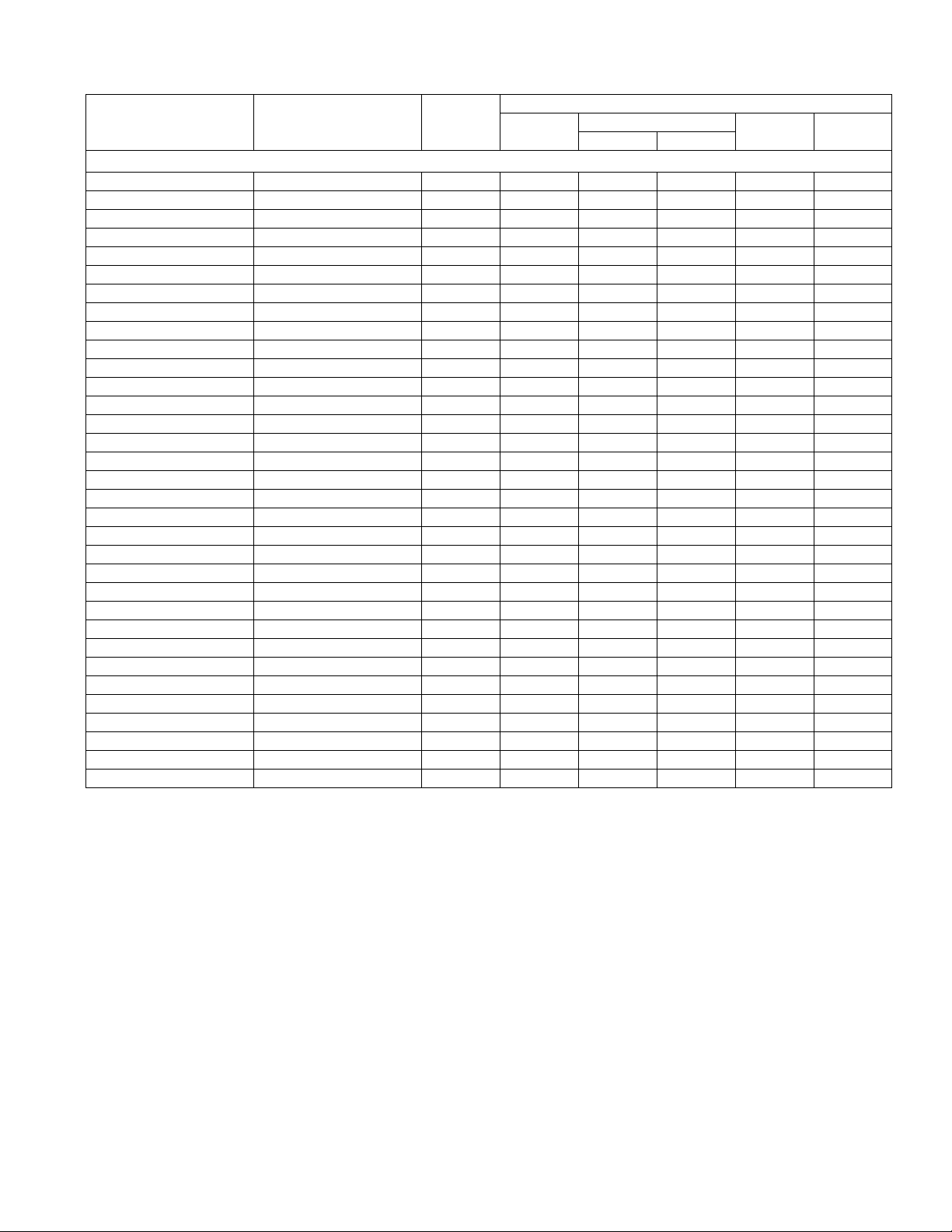

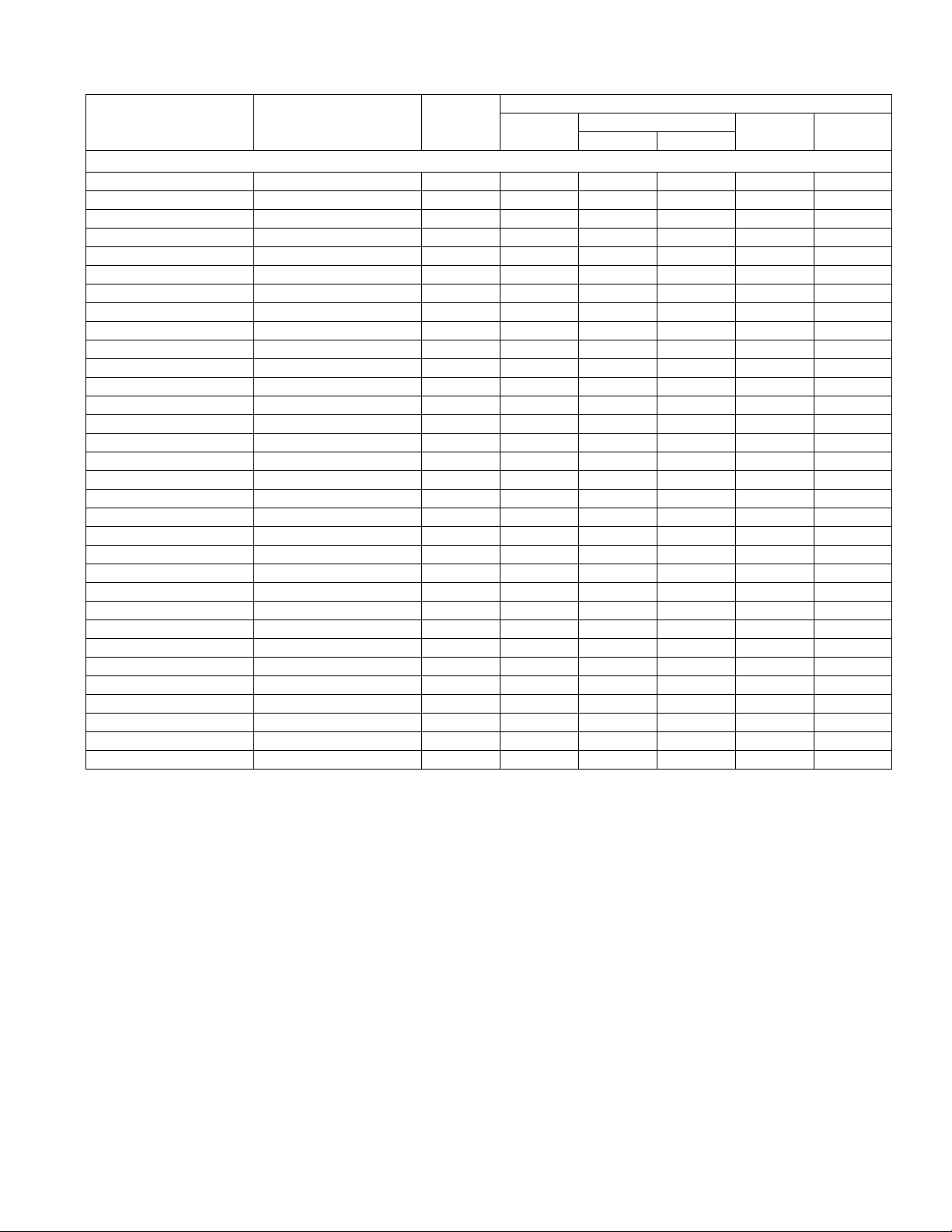

Additional R-410A Charge / TXV Size for Va rious Matched Systems

Outdoor Unit YZB1811 YZB02411 YZB03011 YZB03611 YZB04211 YZB04811 YZB06012

Required TXV

Factory Charge, lbs-oz 7-1 7-10 7-9 9-5 9-2 12-5 16-8

Indoor Coil

1

2

Shaded areas indicate matches that require variable sp eed indoor unit to meet minimum efficiently standards.

Data provided for charge adder information only.

FC/MC/PC/UC18A 901 + 0 – – – – – –

FC/MC/PC/UC18B 901 + 0 – – – – – –

FC/MC/PC/UC24A – 902 + 5 – – – – –

FC/MC/PC/UC24B – 902 + 5 – – – – –

FC/MC/PC/UC30A – 902 + 5 – – – – –

FC/MC/PC/UC30B – 902 + 5 – – – – –

FC/MC/PC/UC36A – – 903 + 5 904 + 3 – – –

FC/MC/PC/UC36B – – 903 + 5 904 + 3 – – –

FC/MC/PC/UC36C – – 903 + 5 904 + 3 – – –

FC/MC/PC/UC48C – – – – 904 + 7 – –

FC/MC/PC/UC48D – – – – 904 + 7 – –

FC/PC/UC60C – – – – – 905 + 12 –

FC/MC/PC/UC60D – – – – – 905 + 12 –

MC61D – – – – – 905 + 16 –

FC/MC62D – – – – – – 906 + 0

HC18A 901 + 0 – – – – – –

HC30A – 902 + 7

HC36B – – – 904 + 5 – – –

HC42C – – – – 904 + 5 – –

HC60D – – – – – 905 + 10 –

HD24A 901 + 9 902 + 7 – – – – –

HD36B – – 903 + 9 904 + 10 – –

HD48C – – – – 904 + 5 –

HD60D – – – – – 905 + 10 –

AHP18B 901 + 0 – – – – – –

AHP24B – 902 + 6 – – – – –

AHP30B – – 903 + 9 – – – –

AHP36C – – 903 + 14 904 + 13 – – –

AHP42C – – – 904 + 13 – – –

AHP/SHP48D – – – – 904 + 7 905 + 8 –

AHP/SHP60D – – – – – 905 + 8 –

AV24B 901 + 3 902 + 6 – – – – –

AV36C – – 903 + 14 904 + 13 – – –

AV/SV48D – – – 904 + 20 904 + 10 905 + 8 –

F*FP024H06T2A 901 + 0 – – – – – –

F*FP024H06T2B 901 + 0 – – – – – –

F*FP030H06T2A – 902 + 3 – – – – –

F*FP036H06T2A – – 903 + 7 904 + 5 – – –

F*FP042H06T2A – – – 904 + 7 – – –

FOOTNOTES:

1. If indoor coil comes with a factory-installed TXV, it must be removed and replaced with the required TXV.

2. Systems matched with furnace or air handlers not equipped with blower-off delays may require blower Time Delay Kit 2FD06700224.

3. A TXV kit must be used with these coils to obtain system performance (901, 902, 903, 904, 905 indicates 1TVM …series).

* Does not achieve 13 SEER with PSC furnaces. For ratings, see technical guide or visit www.aridirectory.org/ari/unitary.html.

PROCEDURES:

1. Unit factory charge listed on the unit nameplate includes refrigerant for the condenser, the smallest evaporator and 15 feet

of interconnecting line tubing.

2. Verify the TXV and additional charge required for specific evaporator coil in the system using the above table.

3. Additional charge for the amount of interconnecting line tubing greater than 15 feet at the rate specified on the previous page.

4. Permanently mark the unit nameplate with the total system charge. Total System Charge = Base Charge (as shipped) + adder for

evaporator + adder for line set.

1TVM(901/4E1) 1TVM(902/4F1) 1TVM(903/4G1) 1TVM(904/4H1) 1TVM(904/4H1) 1TVM(905/4J1) 1TVM(906/4K1)

TXV Kit3 - Additional Charge, Oz

903 + 5 – – – –

Johnson Controls Unitary Products 3

Page 4

271457-YTG-B-0908

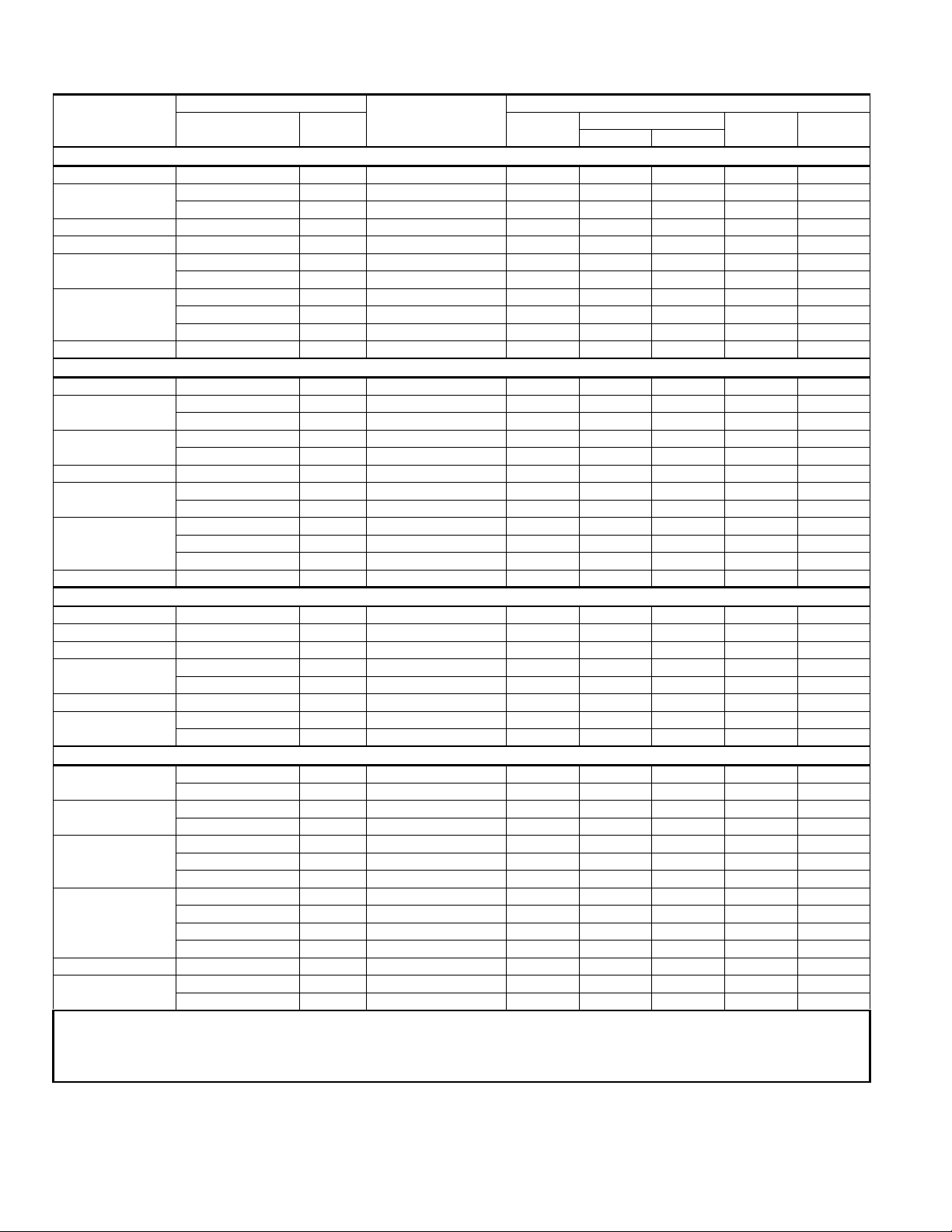

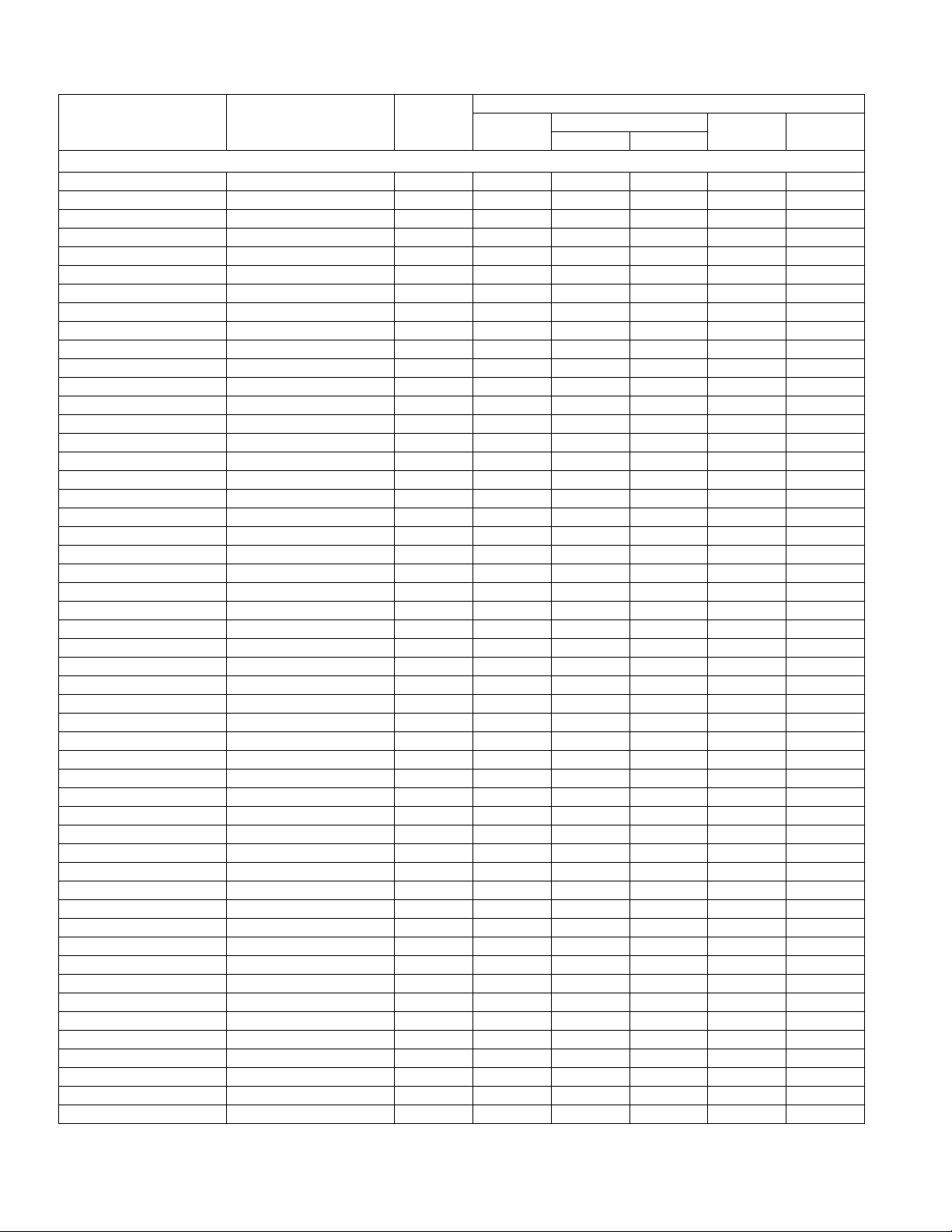

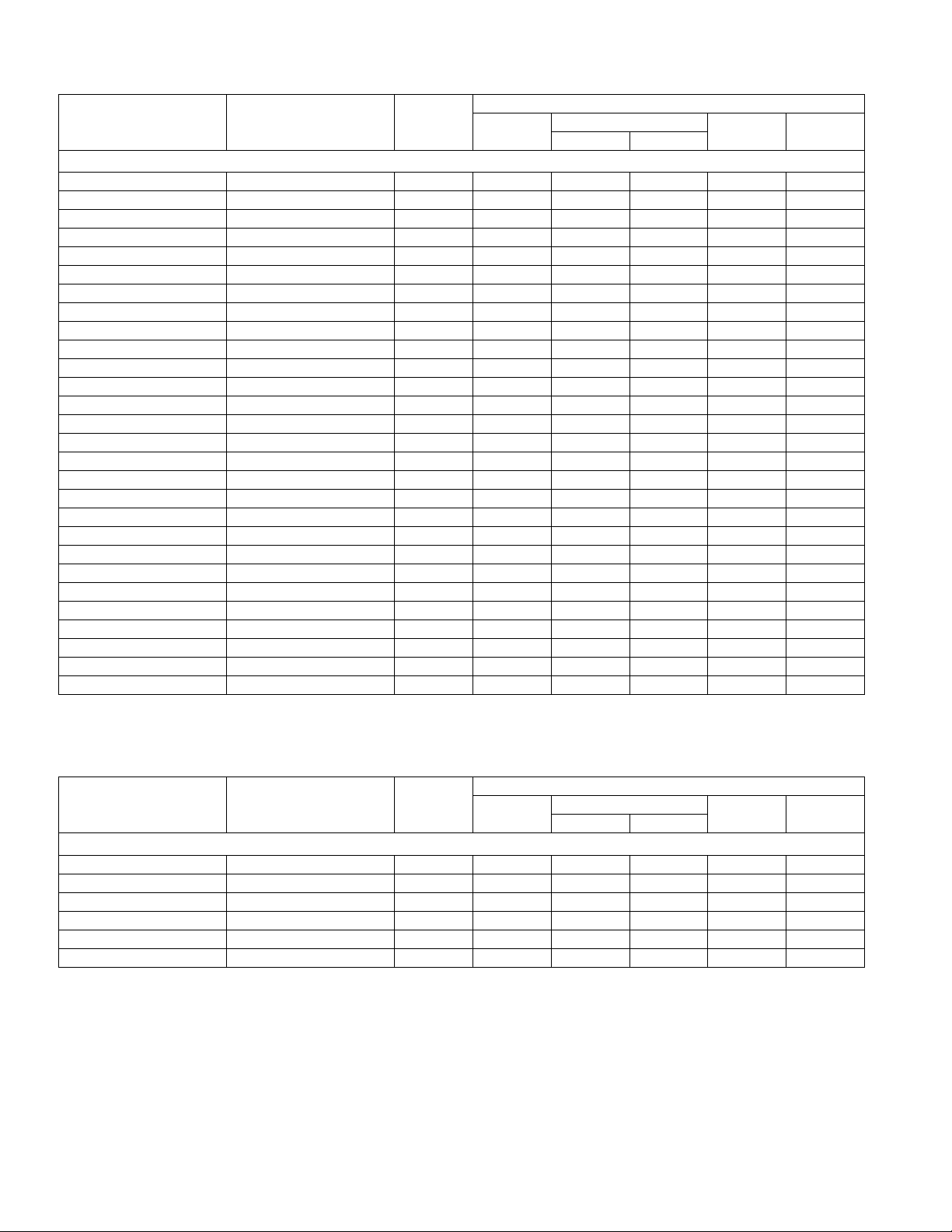

COOLING CAPACITY - With Air Handler Coils

UNIT

MODEL

AIR HANDLER

MODEL W

COIL MODEL

1

RATED

CFM

TOTAL SENS.

1 PH 13 SEER HP WITH MA

YZB01811 MA08B 17 FC/MC18B 600 18.0 13.2 13.00 11.00

YZB02411

MA08B 17 FC/MC24B 800 22.8 16.7 13.00 11.00

MA08B 17 FC/MC30B 800 22.8 16.7 13.00 11.00

YZB03011 MA12B 17 FC/MC36B 1000 29.2 21.3 13.00 11.00

YZB03611 MA12B 17 FC/MC36B 1200 34.4 25.7 13.00 11.00

YZB04211

MA16C 21 FC/MC48C 1400 41.0 31.8 13.00 11.00

MA14D 21 FC/MC48D 1400 41.0 31.8 13.00 11.00

MA16C 21 FC60C 1600 46.0 34.3 13.00 11.00

YZB04811

MA20D 21 FC/MC60D 1600 46.0 34.3 13.00 11.00

MA20D 24 MC61 1600 46.5 34.9 13.00 11.00

YZB06012 MA20D 24 FC/MC62D 1800 54.0 40.0 13.00 11.00

1 PH 13 SEER HP WITH MV - VARIABLE SPEED

YZB01811 MV12B 17 FC/MC18B 600 17.5 13.0 14.00 11.50

YZB02411

YZB03011

MV12B 17 FC/MC24B 800 23.4 17.1 14.00 11.50

MV12B 17 FC/MC30B 800 23.4 17.1 14.00 11.50

MV12B 17 FC/MC36B 1000 29.0 21.2 14.00 12.00

MV16C 21 FC/MC36C 1000 29.0 21.2 14.00 11.00

YZB03611 MV16C 21 FC/MC36C 1200 36.0 26.9 14.00 11.50

YZB04211

MV16C 21 FC/MC48C 1400 42.0 32.6 14.00 11.50

MV20D 24 FC/MC48D 1400 42.0 32.6 14.00 11.50

MV20D 21 FC60C 1600 46.5 34.7 13.25 11.00

YZB04811

MV20D 24 FC/MC60D 1600 47.0 35.0 13.50 11.00

MV20D 24 MC61D 1600 47.5 35.4 13.50 11.00

YZB06012 MV20D 24 FC/MC62D 1800 54.0 40.5 13.50 11.00

1 PH 13 SEER HP WITH AV / SV / F*FV - VARIABLE SPEED

YZB01811 AV24 17 – 600 18.0 13.0 14.00 11.50

YZB02411 AV24 17 – 800 23.4 17.1 14.00 11.50

YZB03011 AV36 17 – 1000 30.0 21.2 14.00 11.50

YZB03611

AV36 17 – 1200 35.8 26.9 14.00 12.00

AV/SV48 24 – 1200 35.8 26.9 14.00 11.50

YZB04211 AV/SV48 24 – 1400 41.5 32.6 14.00 11.50

YZB04811

AV/SV48 24 – 1600 46.5 34.7 13.50 11.00

F*FV060 24 – 1600 46.5 33.6 13.25 11.00

1 PH 13 SEER AHP WITH AHP / SHP / F*FP

YZB01811

YZB02411

AHP18 17 – 600 18.0 13.2 13.00 11.00

F*FP024 18 – 600 17.9 13.2 13.00 11.00

AHP24 17 – 800 22.8 16.7 13.00 11.00

F*FP030 18 – 800 22.8 16.7 13.00 11.00

AHP30 17 – 1000 29.2 21.1 13.00 11.00

YZB03011

AHP36 17 – 1000 29.2 21.1 13.00 11.00

F*FP036 21 – 1000 29.4 21.2 13.00 11.00

AHP36 21 – 1200 34.4 25.8 13.00 11.00

YZB03611

AHP42 21 – 1200 34.4 25.8 13.00 11.00

F*FP036 21 – 1200 35.0 26.2 13.00 11.00

F*FP042 21 – 1200 35.3 26.2 13.00 11.00

YZB04211 AHP/SHP48 24 – 1400 41.0 31.8 13.00 11.00

YZB04811

Rated in accordance with DOE test procedures (Federal Register 12-27-79 and 3-18-88) and ARI Standards 210.

Cooling MBH based on 80°F entering air temperature, 50% RH, and rated air flow.

EER (Energy Efficiency Ratio) is the total cooling output in BTU’s at 95°F outdoor ambient divided by the total electric power in watt-hours at those conditions.

SEER (Seasonal Energy Efficiency Ratio) is the total cooling output in BTU’s during a normal annual usage period for cooling divided by the total electric power

input in watt-hours during the same period.

AHP/SHP48 24 – 1600 46.0 33.0 13.00 11.00

AHP/SHP60 24 – 1600 46.0 33.0 13.25 11.00

1. MC coils available with a factory installed horizontal drain pan. See price pages for specific model number.

— = Not applicable.

Go to www.ari.org/aridirectory for the latest additional matches.

COOLING

NET MBH

SEER EER

4 Johnson Controls Unitary Products

Page 5

271457-YTG-B-0908

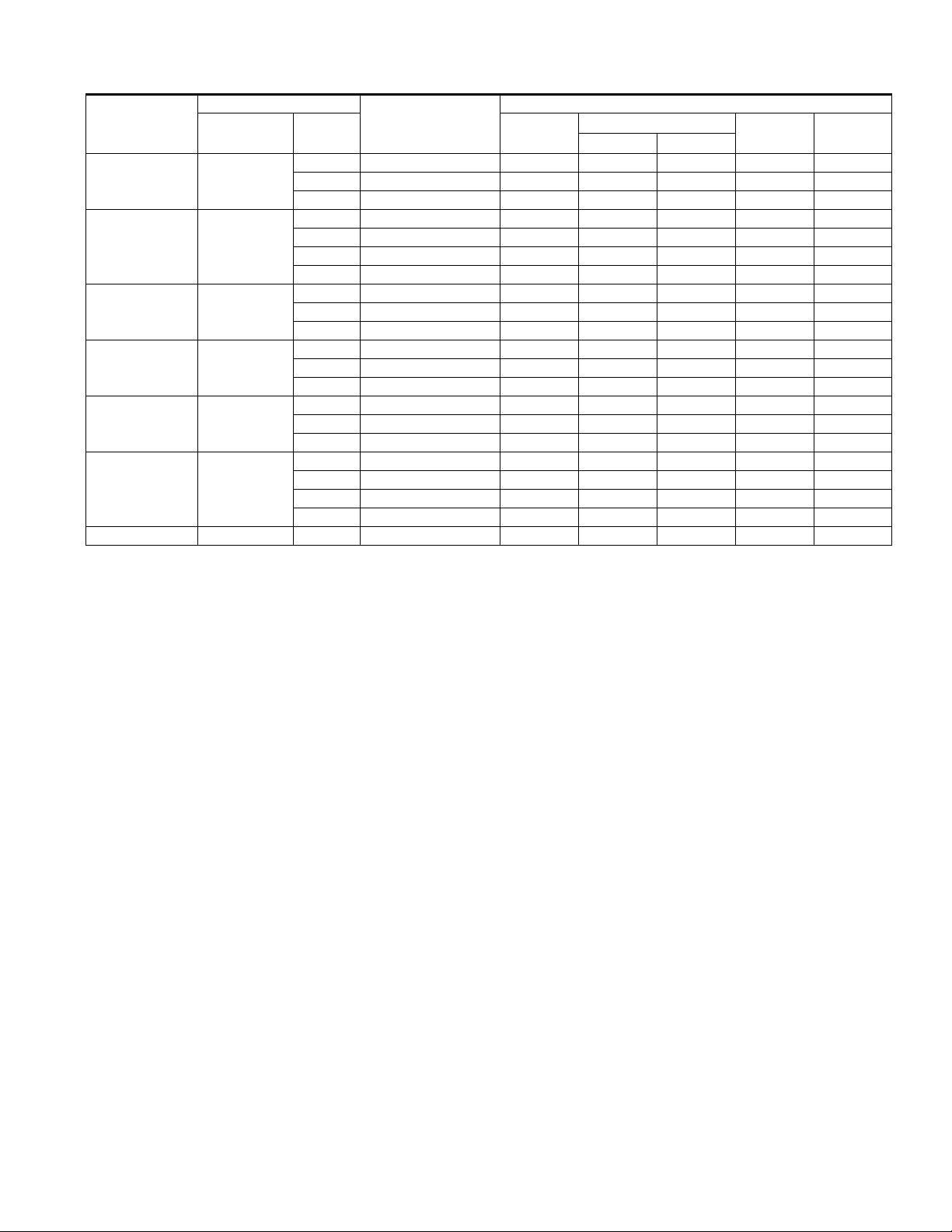

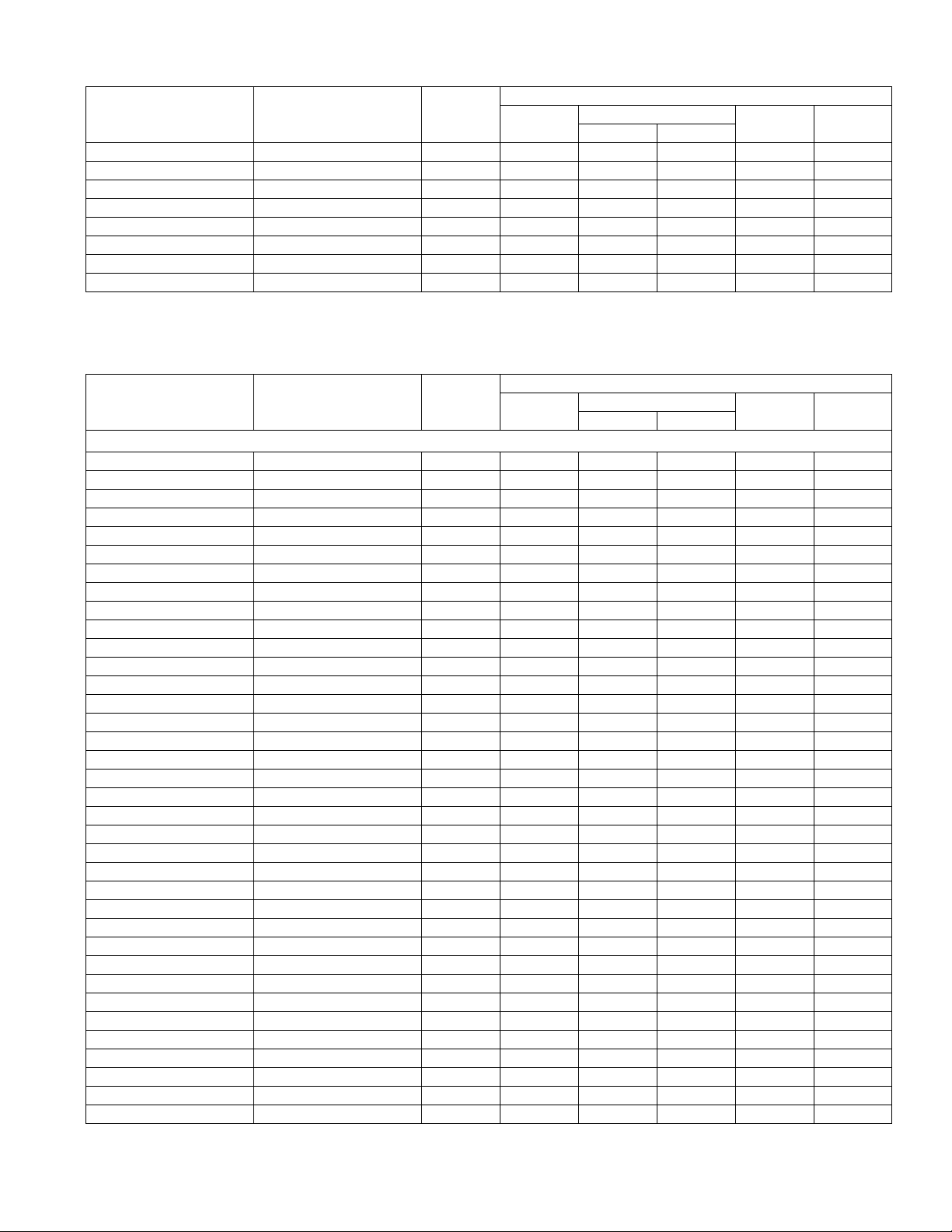

COOLING CAPACITY - Upflow, Downflow & Horizontal Furnaces and Coils

FURNACE

UNIT MODEL

YZB01811

YZB02411

YZB03011

YZB03611

YZB04211

YZB04811

YZB06012 1600 - 2000 24 FC/MC62D 1800 54.0 40.0 13.00 11.00

1. Requires a 2FD06700224 Blower Time Delay unless a standard furnace is equipped with one.

CFM RANGE

(MIN.-MAX.)

450

750

600

1000

800

1200

1000

1400

1200

1600

1400

1800

W

14,17 FC/MC/PC/UC18 600 18.0 13.2 13.00 11.00

14 HC18 600 18.0 13.2 13.00 11.00

- HD24 600 18.0 13.2 13.00 11.00

14,17 FC/MC/PC/UC24 800 22.8 16.7 13.00 11.00

14,17 FC/MC/PC/UC30 800 22.8 16.7 13.00 11.00

14 HC30 800 22.8 16.7 13.00 11.00

- HD24 800 22.4 17.8 13.00 11.00

14,17,21 FC/MC/PC/UC36 1000 29.2 21.3 13.00 11.00

17 HC36 1000 29.6 21.0 13.00 11.00

- HD36 1000 29.6 21.6 13.00 11.00

14,17,21 FC/MC/PC/UC36 1200 34.4 25.7 13.00 11.00

17 HC36 1200 35.2 25.7 13.00 11.00

- HD36 1200 34.8 26.1 13.00 11.00

21,24 FC/MC/PC/UC48 1400 41.0 31.8 13.00 11.00

21 HC42 1400 40.0 30.7 13.00 11.00

- HD48 1400 40.0 31.2 13.00 11.00

21,24 FC/MC/PC/UC60 1600 46.0 34.3 13.00 11.00

24 HC60 1600 46.0 33.5 13.00 11.00

- HD60 1600 46.0 33.2 13.00 11.00

24 MC61 1600 46.5 34.9 13.00 11.00

COIL

MODEL

RATED

CFM

TOTAL SENS.

COOLING

NET MBH

SEER

1

EER

Johnson Controls Unitary Products 5

Page 6

271457-YTG-B-0908

COOLING CAP ACITY - YZB01811 With Variable Speed Furnaces

VARIABLE SPEED

FURNACE MODEL

PV8*A12 FC/MC/PC18A 14 600 18.4 12.9 14.00 11.50

PV9*A12 FC/MC/PC18A 14 600 18.3 12.8 14.00 11.50

P(C,V)9*B12 FC/MC/PC18B 17 600 18.3 12.8 14.00 11.50

Y*(8,L)C*A12 FC/MC/PC18A 14 620 18.0 12.3 14.90 12.70

Y*(8,L)C*B12 FC/MC/PC18B 17 580 18.0 12.0 14.80 12.70

Y*9C*B12 FC/MC/PC18B 17 610 18.0 12.2 15.00 12.90

Y*(8,L)C*A12 FC/MC/PC24A 14 640 18.0 12.6 15.10 12.70

Y*(8,L)C*B12 FC/MC/PC24B 17 575 18.0 12.1 15.20 13.00

Y*9C*B12 FC/MC/PC24B 17 610 18.0 12.6 15.20 12.90

Y*(8,L)C*A12 FC/MC/PC30A 14 640 18.0 12.6 15.10 12.70

Y*(8,L)C*B12 FC/MC/PC30B 17 575 18.0 12.1 15.20 13.00

Y*9C*B12 FC/MC/PC30B 17 610 18.0 12.6 15.20 12.90

Y*(8,L)C*A12 HC18 14 620 18.0 12.3 14.90 12.70

Y*(8,L)C*A12 HD24 14 640 18.0 12.5 15.20 13.00

Y*(8,L)C*B12 HD24 17 575 18.0 12.0 15.30 13.10

Y*9C*B12 HD24 17 610 18.0 12.5 15.40 13.10

Y*(8,L)C*A12 UC18A 14 620 18.0 12.3 15.00 12.80

Y*(8,L)C*B12 UC18B 17 580 18.0 12.1 14.90 12.80

Y*9C*B12 UC18B 17 610 18.0 12.3 15.00 12.90

Y*(8,L)C*A12 UC24A 14 640 18.0 12.6 15.20 12.90

Y*(8,L)C*B12 UC24B 17 575 18.0 12.2 15.30 13.10

Y*9C*B12 UC24B 17 610 18.0 12.6 15.30 13.00

Y*(8,L)C*A12 UC30A 14 640 18.0 12.6 15.20 12.90

Y*(8,L)C*B12 UC30B 17 575 18.0 12.2 15.30 13.10

Y*9C*B12 UC30B 17 610 18.0 12.6 15.30 13.00

G*9V*A12 FC/MC/PC18A 14 625 18.0 12.3 14.50 12.50

G*9V*B12 FC/MC/PC18B 17 610 18.0 12.2 15.00 12.90

G*9V*A12 FC/MC/PC24A 14 625 18.0 12.4 14.80 12.70

G*9V*B12 FC/MC/PC24B 17 610 18.0 12.6 15.20 12.90

G*9V*A12 FC/MC/PC30A 14 625 18.0 12.4 14.80 12.70

G*9V*B12 FC/MC/PC30B 17 610 18.0 12.6 15.20 12.90

G*9V*A12 HC18 14 625 18.0 12.3 14.50 12.50

G*9V*A12 HD24 14 625 18.0 12.3 14.90 12.80

G*9V*B12 HD24 17 610 18.0 12.5 15.40 13.10

G*9V*A12 UC18A 14 625 18.0 12.4 14.70 12.50

G*9V*B12 UC18B 17 610 18.0 12.3 15.00 12.90

G*9V*B12 UC24B 17 610 18.0 12.6 15.30 13.00

G*9V*A12 UC30A 14 625 18.0 12.5 14.70 12.70

G*9V*B12 UC30B 17 610 18.0 12.6 15.30 13.00

1. MC coils available with a factory installed horizontal drain pan. See price pages for specific model number.

2. Variable speed furnaces have B.O.D (Blower on Delay) standard.

COIL

1

MODEL

1 PH 13 SEER HP WITH VARIABLE SPEED FURNACES

W

RATED

CFM

TOTAL SENS.

NET MBH

COOLING

SEER EER

2

6 Johnson Controls Unitary Products

Page 7

271457-YTG-B-0908

COOLING CAPACITY - YZB02411With Variable Speed Furnaces

VARIABLE SPEED

FURNACE MODEL

PV8*A12 FC/MC/PC24A 14 750 23.0 16.1 13.50 11.00

PV9*A12 FC/MC/PC24A 14 800 23.0 16.1 14.00 11.50

PV8*A12 FC/MC/PC30A 14 750 23.0 16.1 13.50 11.00

PV9*A12 FC/MC/PC30A 14 800 23.0 16.1 14.00 11.50

Y*(8,L)C*A12 FC/MC/PC24A 14 805 23.2 17.7 14.60 12.20

Y*(8,L)C*B12 FC/MC/PC24B 17 815 23.4 17.7 14.90 12.30

Y*9C*B12 FC/MC/PC24B 17 790 23.2 17.7 14.60 12.20

Y*(8,L)C*A12 FC/MC/PC30A 14 805 23.2 17.7 14.60 12.20

Y*(8,L)C*B12 FC/MC/PC30B 17 815 23.4 17.7 14.90 12.30

Y*9C*B12 FC/MC/PC30B 17 790 23.2 17.7 14.60 12.20

Y*(8,L)C*A12 FC/MC/PC32A 14 775 23.4 17.5 14.50 12.10

Y*(8,L)C*A12 HC30 14 775 23.2 17.3 14.30 12.00

Y*(8,L)C*A12 HD24 14 805 23.6 17.8 14.90 12.40

Y*(8,L)C*B12 HD24 17 815 23.8 17.9 15.10 12.50

Y*9C*B12 HD24 17 790 23.6 17.8 14.90 12.40

Y*(8,L)C*A12 UC24A 14 805 23.6 17.8 14.80 12.30

Y*(8,L)C*B12 UC24B 17 815 23.6 17.8 15.10 12.50

Y*9C*B12 UC24B 17 790 23.6 17.8 14.80 12.30

Y*(8,L)C*A12 UC30A 14 805 23.6 17.8 14.80 12.30

Y*(8,L)C*B12 UC30B 17 815 23.6 17.8 15.10 12.50

Y*9C*B12 UC30B 17 790 23.6 17.8 14.80 12.30

G*9V*A12 FC/MC/PC24A 14 800 23.2 17.5 14.20 11.90

G*9V*B12 FC/MC/PC24B 17 790 23.2 17.7 14.60 12.20

G*9V*A12 FC/MC/PC30A 14 800 23.2 17.5 14.20 11.90

G*9V*B12 FC/MC/PC30B 17 790 23.2 17.7 14.60 12.20

G*9V*A12 FC/MC/PC32A 14 800 23.4 17.6 14.10 11.80

G*9V*A12 HC30 14 800 23.4 17.5 14.40 12.00

G*9V*A12 HD24 14 800 23.6 17.7 14.60 12.10

G*9V*B12 HD24 17 790 23.6 17.8 14.90 12.40

G*9V*A12 UC24A 14 800 23.4 17.6 14.40 12.10

G*9V*B12 UC24B 17 790 23.6 17.8 14.80 12.30

G*9V*A12 UC30A 14 800 23.4 17.6 14.40 12.10

G*9V*B12 UC30B 17 790 23.6 17.8 14.80 12.30

1. MC coils available with a factory installed horizontal drain pan. See price pages for specific model number.

2. Variable speed furnaces have B.O.D (Blower on Delay) standard.

COIL

1

MODEL

1 PH 13 SEER HP WITH VARIABLE SPEED FURNACES

W

RATED

CFM

TOTAL SENS.

COOLING

NET MBH

2

SEER EER

Johnson Controls Unitary Products 7

Page 8

271457-YTG-B-0908

COOLING CAPACITY - YZB03011With Variable Speed Furnaces

VARIABLE SPEED

FURNACE MODEL

PV8*A12 FC/MC/PC36A 14 1050 30.0 21.0 13.25 11.00

PV9*A12 FC/MC/PC36A 14 1000 29.6 20.7 13.25 11.00

PV8*B16 FC/MC/PC36B 17 1050 30.0 21.0 13.50 11.00

P(C,V)9*B12 FC/MC/PC36B 17 1000 29.6 20.7 13.25 11.00

PV8*C16 FC/MC/PC36C 21 1050 30.0 21.0 13.50 11.00

P(C,V)9*C16 FC/MC/PC36C 21 1050 30.0 21.0 13.50 11.00

Y*(8,L)C*A12 FC/MC/PC32A 14 1045 29.6 21.6 13.10 11.20

Y*(8,L)C*B12 FC/MC/PC35B 17 995 29.8 21.8 13.90 11.90

Y*9C*B12 FC/MC/PC35B 17 1045 29.6 21.8 13.50 11.50

Y*(8,L)C*C16 FC/MC/PC35C 21 1025 30.0 21.8 14.40 12.10

Y*(8,L)C*C20 FC/MC/PC35C 21 1080 30.0 22.4 14.30 12.10

Y*9C*C16 FC/MC/PC35C 21 1005 29.8 21.8 14.30 12.00

Y*9C*C20 FC/MC/PC35C 21 985 29.8 21.8 14.30 12.00

Y*(8,L)C*A12 FC/MC/PC36A 14 1000 29.4 21.2 13.90 11.60

Y*(8,L)C*B12 FC/MC/PC36B 17 985 29.6 21.2 14.20 11.90

Y*9C*B12 FC/MC/PC36B 17 985 29.4 21.2 14.10 11.80

Y*(8,L)C*C16 FC/MC/PC36C 21 1020 29.6 21.6 14.20 12.00

Y*(8,L)C*C20 FC/MC/PC36C 21 1055 29.6 21.6 14.30 12.00

Y*9C*C16 FC/MC/PC36C 21 1005 29.6 21.6 14.20 12.00

Y*9C*C20 FC/MC/PC36C 21 1045 29.6 21.4 14.10 11.90

Y*(8,L)C*A12 FC/MC/PC37A 14 980 29.8 21.4 13.80 11.60

Y*(8,L)C*A12 HC30 14 1045 29.0 21.2 13.20 11.00

Y*(8,L)C*B12 HC36 17 995 29.6 21.4 13.90 11.80

Y*9C*B12 HC36 17 1045 29.6 21.8 13.50 11.50

Y*(8,L)C*A12 HD36 14 1000 29.0 20.6 13.50 11.50

Y*(8,L)C*B12 HD36 17 985 29.2 20.8 13.80 11.80

Y*(8,L)C*C16 HD36 21 1020 29.2 20.8 13.90 11.90

Y*(8,L)C*C20 HD36 21 1055 29.6 21.4 14.30 12.00

Y*9C*B12 HD36 17 985 29.2 20.8 13.70 11.70

Y*9C*C16 HD36 21 1005 29.2 20.8 13.90 11.90

Y*9C*C20 HD36 21 1045 29.2 20.8 13.80 11.70

Y*(8,L)C*A12 UC36A 14 1000 29.2 21.2 13.90 11.60

Y*(8,L)C*B12 UC36B 17 985 29.4 21.2 14.20 11.80

Y*9C*B12 UC36B 17 985 29.4 21.2 14.10 11.80

Y*(8,L)C*C16 UC36C 21 1020 29.6 21.4 14.20 12.00

Y*(8,L)C*C20 UC36C 21 1055 29.6 21.4 14.20 12.00

Y*9C*C16 UC36C 21 1000 29.6 21.4 14.20 12.00

Y*9C*C20 UC36C 21 1045 29.4 21.4 14.00 11.80

G*9V*A12 FC/MC/PC30A 14 1000 29.2 21.0 13.70 11.50

G*9V*A12 FC/MC/PC32A 14 1000 29.6 21.4 13.80 11.60

G*9V*B12 FC/MC/PC35B 17 1045 29.6 21.8 13.50 11.50

G*9V*C16 FC/MC/PC35C 21 1005 29.8 21.8 14.30 12.00

G*9V*C20 FC/MC/PC35C 21 985 29.8 21.8 14.30 12.00

G*9V*A12 FC/MC/PC36A 14 1000 29.4 21.0 13.80 11.60

G*9V*B12 FC/MC/PC36B 17 985 29.4 21.2 14.10 11.80

G*9V*C16 FC/MC/PC36C 21 1005 29.6 21.6 14.20 12.00

G*9V*C20 FC/MC/PC36C 21 1045 29.6 21.4 14.10 11.90

G*9V*A12 FC/MC/PC37A 14 1000 29.6 21.6 13.80 11.50

G*9V*A12 HC30 14 1000 29.0 21.0 13.70 11.50

G*9V*B12 HC36 17 1045 29.6 21.8 13.50 11.50

G*9V*A12 HD36 14 1000 29.0 20.6 13.40 11.50

For Notes See Page 9.

COIL

1

MODEL

1 PH 13 SEER HP WITH VARIABLE SPEED FURNACES

W

RATED

CFM

COOLING

NET MBH

TOTAL SENS.

2

SEER EER

8 Johnson Controls Unitary Products

Page 9

271457-YTG-B-0908

COOLING CAPACITY - YZB03011With Variable Speed Furnaces (Continued)

VARIABLE SPEED

FURNACE MODEL

G*9V*B12 HD36 17 985 29.2 20.8 13.70 11.70

G*9V*C16 HD36 21 1005 29.2 20.8 13.90 11.90

G*9V*C20 HD36 21 1045 29.2 20.8 13.80 11.70

G*9V*A12 UC30A 14 1000 29.4 21.0 13.80 11.60

G*9V*A12 UC36A 14 1000 29.4 21.0 13.80 11.60

G*9V*B12 UC36B 17 985 29.4 21.2 14.10 11.80

G*9V*C16 UC36C 21 1000 29.6 21.4 14.20 12.00

G*9V*C20 UC36C 21 1045 29.4 21.4 14.00 11.80

1. MC coils available with a factory installed horizontal drain pan. See price pages for specific model number.

2. Variable speed furnaces have B.O.D (Blower on Delay) standard.

COIL

MODEL

1

W

RATED

CFM

TOTAL SENS.

COOLING

NET MBH

SEER EER

COOLING CAPACITY - YZB03611With Variable Speed Furnaces

VARIABLE SPEED

FURNACE MODEL

PV8*A12 FC/MC/PC36A 14 1200 34.8 24.4 13.30 11.00

PV9*A12 FC/MC/PC36A 14 1200 34.6 24.2 13.30 11.00

PV8*B16 FC/MC/PC36B 17 1200 34.8 24.4 13.50 11.00

P(C,V)9*B12 FC/MC/PC36B 17 1200 34.6 24.2 13.30 11.00

PV8*C16 FC/MC/PC36C 21 1200 34.8 24.4 13.50 11.00

PV8*C20 FC/MC/PC36C 21 1200 34.8 24.4 13.50 11.00

P(C,V)9*C16 FC/MC/PC36C 21 1200 34.8 24.4 13.50 11.00

P(C,V)9*C20 FC/MC/PC36C 21 1200 34.8 24.4 13.50 11.00

Y*(8,L)C*B12 FC/MC/PC35B 17 1220 34.2 25.2 13.30 11.10

Y*9C*B12 FC/MC/PC35B 17 1190 34.0 25.0 13.30 11.20

Y*(8,L)C*C16 FC/MC/PC35C 21 1235 34.6 25.8 13.90 11.60

Y*(8,L)C*C20 FC/MC/PC35C 21 1170 34.6 25.6 14.10 11.80

Y*9C*C16 FC/MC/PC35C 21 1215 34.6 25.8 13.80 11.50

Y*9C*C20 FC/MC/PC35C 21 1295 34.6 26.4 13.20 11.30

Y*(8,L)C*A12 FC/MC/PC36A 14 1190 33.4 24.4 13.00 10.90

Y*(8,L)C*B12 FC/MC/PC36B 17 1220 33.6 24.6 13.20 11.10

Y*9C*B12 FC/MC/PC36B 17 1165 33.6 24.6 13.30 11.20

Y*(8,L)C*C16 FC/MC/PC36C 21 1235 34.2 25.4 13.70 11.60

Y*(8,L)C*C20 FC/MC/PC36C 21 1240 34.2 25.4 13.80 11.60

Y*9C*C16 FC/MC/PC36C 21 1185 34.2 25.4 13.70 11.60

Y*9C*C20 FC/MC/PC36C 21 1285 34.4 26.0 13.40 11.30

Y*(8,L)C*A12 FC/MC/PC37A 14 980 33.4 23.4 13.60 11.30

Y*(8,L)C*B12 FC/MC/PC43B 17 1210 34.6 25.8 13.40 11.40

Y*9C*B12 FC/MC/PC43B 17 1200 34.6 25.8 13.40 11.40

Y*(8,L)C*C16 FC/MC/PC43C 21 1205 35.0 26.0 14.10 11.90

Y*(8,L)C*C20 FC/MC/PC43C 21 1190 35.0 26.0 14.20 12.00

Y*9C*C16 FC/MC/PC43C 21 1240 34.8 25.8 13.60 11.50

Y*9C*C20 FC/MC/PC43C 21 1200 35.0 26.0 13.90 11.80

Y*(8,L)C*C16 FC/MC/PC48C 21 1210 35.4 26.4 14.40 12.00

Y*(8,L)C*C20 FC/MC/PC48C 21 1155 35.4 26.6 14.60 12.20

Y*9C*C16 FC/MC/PC48C 21 1195 35.2 26.4 14.20 11.90

Y*9C*C20 FC/MC/PC48C 21 1330 35.6 27.4 13.90 11.70

Y*(8,L)C*C16 HC42 21 1205 35.0 26.0 14.10 11.90

Y*(8,L)C*C20 HC42 21 1190 35.0 26.2 14.30 12.00

Y*9C*C16 HC42 21 1240 34.8 26.0 13.60 11.50

Y*9C*C20 HC42 21 1200 35.0 26.0 14.00 11.80

For Notes See Page 10.

COIL

1

MODEL

1 PH 13 SEER HP WITH VARIABLE SPEED FURNACES

W

RATED

CFM

TOTAL SENS.

COOLING

NET MBH

2

SEER EER

Johnson Controls Unitary Products 9

Page 10

271457-YTG-B-0908

COOLING CAP ACITY - YZB03611Wit h Variable Speed Furnaces (Continued)

VARIABLE SPEED

FURNACE MODEL

Y*(8,L)C*B12 HD48 17 1210 34.0 25.4 13.60 11.30

Y*(8,L)C*C16 HD48 21 1210 34.2 25.6 14.10 11.70

Y*(8,L)C*C20 HD48 21 1155 34.4 25.8 14.30 11.80

Y*9C*B12 HD48 17 1150 34.0 25.4 13.50 11.20

Y*9C*C16 HD48 21 1195 34.2 25.6 13.90 11.50

Y*9C*C20 HD48 21 1315 35.2 27.0 13.90 11.60

Y*(8,L)C*A12 UC36A 14 1190 33.6 24.6 13.00 10.90

Y*(8,L)C*B12 UC36B 17 1220 33.6 24.6 13.20 11.10

Y*9C*B12 UC36B 17 1165 33.8 24.6 13.30 11.20

Y*(8,L)C*C16 UC36C 21 1235 34.2 25.2 13.70 11.60

Y*(8,L)C*C20 UC36C 21 1240 34.2 25.4 13.80 11.70

Y*9C*C16 UC36C 21 1185 34.2 25.2 13.70 11.60

Y*9C*C20 UC36C 21 1275 34.2 26.0 13.40 11.30

Y*(8,L)C*C16 UC48C 21 1210 34.8 26.4 14.40 11.90

Y*(8,L)C*C20 UC48C 21 1155 35.0 26.4 14.60 12.00

Y*9C*C16 UC48C 21 1195 34.8 26.2 14.20 11.70

Y*9C*C20 UC48C 21 1325 35.4 27.4 13.80 11.60

G*9V*B12 FC/MC/PC35B 17 1190 34.0 25.0 13.30 11.20

G*9V*C16 FC/MC/PC35C 21 1215 34.6 25.8 13.80 11.50

G*9V*C20 FC/MC/PC35C 21 1295 34.6 26.4 13.20 11.30

G*9V*A12 FC/MC/PC36A 14 1200 33.6 24.6 12.90 10.90

G*9V*B12 FC/MC/PC36B 17 1165 33.6 24.6 13.30 11.20

G*9V*C16 FC/MC/PC36C 21 1185 34.2 25.4 13.70 11.60

G*9V*C20 FC/MC/PC36C 21 1285 34.4 26.0 13.40 11.30

G*9V*A12 FC/MC/PC37A 14 1100 34.0 24.6 13.30 11.20

G*9V*B12 FC/MC/PC43B 17 1200 34.6 25.8 13.40 11.40

G*9V*C16 FC/MC/PC43C 21 1240 34.8 25.8 13.60 11.50

G*9V*C20 FC/MC/PC43C 21 1200 35.0 26.0 13.90 11.80

G*9V*C16 FC/MC/PC48C 21 1195 35.2 26.4 14.20 11.90

G*9V*C20 FC/MC/PC48C 21 1330 35.6 27.4 13.90 11.70

G*9V*C16 HC42 21 1240 34.8 26.0 13.60 11.50

G*9V*C20 HC42 21 1200 35.0 26.0 14.00 11.80

G*9V*B12 HD48 17 1150 34.0 25.4 13.50 11.20

G*9V*C16 HD48 21 1195 34.2 25.6 13.90 11.50

G*9V*C20 HD48 21 1315 35.2 27.0 13.90 11.60

G*9V*A12 UC36A 14 1200 33.6 24.6 12.90 10.90

G*9V*B12 UC36B 17 1165 33.8 24.6 13.30 11.20

G*9V*C16 UC36C 21 1185 34.2 25.2 13.70 11.60

G*9V*C20 UC36C 21 1275 34.2 26.0 13.40 11.30

G*9V*C16 UC48C 21 1195 34.8 26.2 14.20 11.70

G*9V*C20 UC48C 21 1325 35.4 27.4 13.80 11.60

1. MC coils available with a factory installed horizontal drain pan. See price pages for specific model number.

2. Variable speed furnaces have B.O.D (Blower on Delay) standard.

COIL

MODEL

1

W

RATED

CFM

NET MBH

TOTAL SENS.

COOLING

SEER EER

10 Johnson Controls Unitary Products

Page 11

271457-YTG-B-0908

COOLING CAPACITY - YZB04211With Variable Speed Furnaces

VARIABLE SPEED

FURNACE MODEL

PV8*C16 FC/MC/PC48C 21 1400 41.0 28.7 13.25 11.00

PV8*C20 FC/MC/PC48C 21 1400 41.0 28.7 13.50 11.00

P(C,V)9*C16 FC/MC/PC48C 21 1400 41.0 28.7 13.50 11.00

P(C,V)9*C20 FC/MC/PC48C 21 1400 41.0 28.7 13.25 11.00

P(C,V)9*D20 FC/MC/PC48D 24 1400 41.0 28.7 13.50 11.00

Y*(8,L)C*C16 FC/MC/PC48C 21 1435 41.5 31.2 13.80 11.60

Y*(8,L)C*C20 FC/MC/PC48C 21 1410 42.0 31.2 13.90 11.70

Y*9C*C16 FC/MC/PC48C 21 1395 41.5 31.2 13.60 11.50

Y*9C*C20 FC/MC/PC48C 21 1430 41.5 31.0 13.50 11.40

Y*9C*D20 FC/MC/PC48D 24 1450 41.5 31.2 13.70 11.60

Y*(8,L)C*B12 HD48 17 1350 40.5 29.4 13.20 11.20

Y*(8,L)C*C16 HD48 21 1435 42.0 30.8 13.40 11.80

Y*(8,L)C*C20 HD48 21 1410 42.0 30.8 13.50 11.90

Y*9C*B12 HD48 17 1150 39.5 27.6 13.30 11.30

Y*9C*C16 HD48 21 1395 40.5 30.0 13.30 11.20

Y*9C*C20 HD48 21 1430 40.5 30.0 13.20 11.20

Y*9C*D20 HD48 24 1450 42.0 30.8 13.30 11.70

Y*(8,L)C*C16 UC48C 21 1435 41.5 31.2 13.80 11.50

Y*(8,L)C*C20 UC48C 21 1410 41.5 31.2 13.90 11.60

Y*9C*C16 UC48C 21 1395 41.0 31.0 13.60 11.40

Y*9C*C20 UC48C 21 1430 41.0 31.0 13.50 11.30

Y*9C*D20 UC48D 24 1450 41.0 31.0 13.70 11.50

G*9V*C16 FC/MC/PC48C 21 1395 41.5 31.2 13.60 11.50

G*9V*C20 FC/MC/PC48C 21 1430 41.5 31.0 13.50 11.40

G*9V*D20 FC/MC/PC48D 24 1450 41.5 31.2 13.70 11.60

G*9V*B12 HD48 17 1150 39.5 27.6 13.30 11.30

G*9V*C16 HD48 21 1395 40.5 30.0 13.30 11.20

G*9V*C20 HD48 21 1430 40.5 30.0 13.20 11.20

G*9V*D20 HD48 24 1450 42.0 30.8 13.30 11.70

G*9V*C16 UC48C 21 1395 41.0 31.0 13.60 11.40

G*9V*C20 UC48C 21 1430 41.0 31.0 13.50 11.30

G*9V*D20 UC48D 24 1450 41.0 31.0 13.70 11.50

1. MC coils available with a factory installed horizontal drain pan. See price pages for specific model number.

2. Variable speed furnaces have B.O.D (Blower on Delay) standard.

COIL

1

MODEL

1 PH 13 SEER HP WITH VARIABLE SPEED FURNACES

W

RATED

CFM

TOTAL SENS.

COOLING

NET MBH

2

SEER EER

Johnson Controls Unitary Products 11

Page 12

271457-YTG-B-0908

COOLING CAPACITY - YZB04811With Variable Speed Furnaces

VARIABLE SPEED

FURNACE MODEL

P(C,V)9*D20 FC/MC/PC60D 24 1600 46.0 32.2 13.25 11.00

P(C,V)9*D20 MC61D 24 1600 46.5 32.6 13.25 11.00

Y*9C*D20 FC/MC/PC60D 24 1615 47.0 35.8 13.40 11.50

Y*9C*D20 FC/MC62D 24 1630 47.5 36.2 13.40 11.50

Y*(8,L)C*C16 FC/PC60C 21 1625 47.5 36.0 13.60 11.60

Y*(8,L)C*C20 FC/PC60C 21 1605 47.5 36.2 13.90 11.80

Y*9C*C16 FC/PC60C 21 1590 47.0 35.8 13.40 11.40

Y*9C*C20 FC/PC60C 21 1655 47.0 35.8 13.40 11.40

Y*(8,L)C*C16 HD60 21 1625 47.0 35.6 13.50 11.50

Y*(8,L)C*C20 HD60 21 1605 47.5 35.8 13.70 11.80

Y*9C*C16 HD60 21 1590 47.0 35.4 13.20 11.40

Y*9C*C20 HD60 21 1655 47.0 35.4 13.20 11.40

Y*9C*D20 HD60 24 1615 47.0 35.6 13.40 11.50

Y*(8,L)C*C16 UC60C 21 1625 46.5 35.0 13.40 11.40

Y*(8,L)C*C20 UC60C 21 1605 47.0 35.2 13.60 11.70

Y*9C*C16 UC60C 21 1590 46.5 35.0 13.10 11.30

Y*9C*C20 UC60C 21 1655 46.5 35.0 13.10 11.30

Y*9C*D20 UC60D 24 1615 46.5 34.8 13.30 11.40

G*9V*D20 FC/MC/PC60D 24 1615 47.0 35.8 13.40 11.50

G*9V*D20 FC/MC62D 24 1630 47.5 36.2 13.40 11.50

G*9V*C16 FC/PC60C 21 1590 47.0 35.8 13.40 11.40

G*9V*C20 FC/PC60C 21 1655 47.0 35.8 13.40 11.40

G*9V*C16 HD60 21 1590 47.0 35.4 13.20 11.40

G*9V*C20 HD60 21 1655 47.0 35.4 13.20 11.40

G*9V*D20 HD60 24 1615 47.0 35.6 13.40 11.50

G*9V*C16 UC60C 21 1590 46.5 35.0 13.10 11.30

G*9V*C20 UC60C 21 1655 46.5 35.0 13.10 11.30

G*9V*D20 UC60D 24 1615 46.5 34.8 13.30 11.40

1. MC coils available with a factory installed horizontal drain pan. See price pages for specific model number.

2. Variable speed furnaces have B.O.D (Blower on Delay) standard.

COIL

MODEL

1

W

RATED

CFM

TOTAL SENS.

1 PH 13 SEER HP WITH VARIABLE SPEED FURNACES

NET MBH

COOLING

SEER EER

2

COOLING CAPACITY - YZB06012With Variable Speed Furnaces

VARIABLE SPEED

FURNACE MODEL

COIL

MODEL

1

W

RATED

CFM

TOTAL SENS.

1 PH 13 SEER HP WITH VARIABLE SPEED FURNACES

P(C,V)9*D20 FC/MC62D 24 1620.0 54.0 40.5 13.5 11.0

Y*(8,L)C*C20 FC/MC62D 21 1615 56.0 40.5 13.60 11.50

Y*9C*C20 FC/MC62D 21 1655 55.5 40.0 13.20 11.10

Y*9C*D20 FC/MC62D 24 1630 55.5 40.0 13.30 11.20

G*9V*C20 FC/MC62D 21 1655 55.5 40.0 13.20 11.10

G*9V*D20 FC/MC62D 24 1630 55.5 40.0 13.30 11.20

1. MC coils available with a factory installed horizontal drain pan. See price pages for specific model number.

2. Variable speed furnaces have B.O.D (Blower on Delay) standard.

12 Johnson Controls Unitary Products

COOLING

NET MBH

2

SEER EER

Page 13

271457-YTG-B-0908

HEATING PERFORMANCE - With Air Handler

UNIT

MODEL*

AIR

HANDLER

COIL

MODEL

1

47°F17°F HSPF

MBH COP KW MBH COP KW

ARI HEATING

1 PH 13 SEER HP WITH MA

YZB01811 MA08B

YZB02411

MA08B FC/MC24B 24.0 3.44 2.04 14.2 2.38 1.75 8.00

MA08B FC/MC30B 24.0 3.44 2.04 14.2 2.38 1.75 8.00

FC/M

C18B

18.0 3.28 1.61 11.6 2.32 1.46 8.00

YZB03011 MA12B FC/MC36B 30.0 3.44 2.56 18.3 2.28 2.35 8.00

YZB03611 MA12B FC/MC36B 36.0 3.36 3.14 24.4 2.32 3.08 8.00

YZB04211

MA16C FC/MC48C 42.0 3.66 3.36 28.4 2.54 3.28 8.00

MA14D FC/MC48D 42.0 3.66 3.36 28.4 2.54 3.28 8.00

MA16C FC60C 48.0 3.50 4.10 33.2 2.30 4.23 8.00

YZB04811

MA20D FC/MC60D 48.0 3.50 4.10 33.2 2.30 4.23 8.00

MA20D MC61D 48.0 3.50 4.10 33.2 2.30 4.23 8.00

YZB06012 MA20D FC/MC62D 57.0 3.54 4.77 37.0 2.44 4.49 8.55

1 PH 13 SEER HP WITH MV - VARIABLE SPEED

YZB01811 MV12B FC/MC18B 18.0 3.46 1.52 11.1 2.46 1.32 8.35

YZB02411

YZB03011

MV12B FC/MC24B 23.4 3.44 1.99 14.2 2.38 1.75 8.30

MV12B FC/MC30B 23.4 3.44 1.99 14.2 2.38 1.75 8.30

MV12B FC/MC36B 29.4 3.44 2.50 18.3 2.28 2.35 8.20

MV16C FC/MC36C 29.4 3.44 2.50 18.3 2.28 2.35 8.20

YZB03611 MV12B FC/MC36B 36.0 3.36 3.14 24.4 2.32 3.08 8.30

YZB04211

MV16C FC/MC48C 42.0 3.66 3.36 28.4 2.54 3.28 8.60

MV20D FC/MC48D 42.0 3.66 3.36 28.4 2.54 3.28 8.60

MV16C FC/MC60C 48.0 3.50 4.02 33.2 2.30 4.23 8.10

YZB04811

MV20D FC/MC60D 48.0 3.50 4.02 33.2 2.30 4.23 8.10

MV20D MC61D 48.0 3.50 4.02 33.2 2.30 4.23 8.10

YZB06012 MV20D FC/MC62D 56.0 3.56 4.65 37.0 2.48 4.37 8.65

1 PH 13 SEER HP WITH AV / SV / F*FV - VARIABLE SPEED

YZB01811 AV24 – 18.0 3.42 1.54 11.2 2.24 1.46 8.25

YZB02411 AV24 – 23.2 3.68 1.85 13.5 2.28 1.73 8.25

YZB03011 AV36 – 29.2 3.66 2.34 17.6 2.20 2.34 8.15

YZB03611

AV36 – 36.03.363.1424.42.323.088.30

AV/SV48 – 36.03.503.0123.62.263.068.30

YZB04211 AV/SV48 – 42.0 3.82 3.22 27.8 2.48 3.28 8.20

YZB04811

AV/SV48 – 48.03.603.9132.62.264.238.10

F*FV060 – 48.03.504.2333.22.304.238.10

1 PH 13 SEER HP WITH AHP / SHP / F*FP

YZB01811

YZB02411

AHP18 – 18.0 3.28 1.61 11.6 2.32 1.46 8.00

F*FP024 – 18.0 3.30 1.77 11.5 2.32 1.45 8.05

AHP24 – 24.03.442.0414.22.381.758.00

F*FP030 – 23.83.442.0314.22.381.758.00

AHP30 – 30.03.442.5618.32.282.358.00

YZB03011

AHP36 – 30.03.442.5618.32.282.358.00

F*FP036 – 29.63.442.5218.32.282.358.00

AHP36 – 36.03.363.1424.42.323.088.00

YZB03611

AHP42 – 36.03.363.1424.42.323.088.00

F*FP036 – 36.03.363.2324.42.323.088.00

F*FP042 – 36.03.363.2324.42.323.088.00

YZB04211 AHP/SHP48 – 42.0 3.66 3.36 28.4 2.54 3.28 8.00

YZB04811

AHP/SHP48 – 48.03.504.1033.22.304.238.00

AHP/SHP60 – 48.03.504.1033.22.304.238.00

1. Rated CFM same as for cooling.

2. Heating MBH based on ARI standards of 70° DB entering indoor air, 72% RH outdoor air with 25 feet of interconnecting piping and no

supplemental electric heat operation.

CP equals MBH output divided by (total KW input x 3.412).

HSPF (Heating Seasonal Performance Factor) is the total heating output during a normal annual usage period for heating divided by the

total electric power input during the same period.

— = Not Applicable.

2

STD

Johnson Controls Unitary Products 13

Page 14

271457-YTG-B-0908

HEATING PERFORMANCE - Upflow Furnace Coils

UNIT

MODEL*

COIL

MODEL

1

47°F17°FHSPF

MBH COP KW MBH COP KW STD

ARI HEATING

FC/MC/PC/UC18 18.0 3.28 1.61 11.6 2.32 1.46 8.00

YZB01811

HC24 18.0 3.28 1.61 11.6 2.32 1.46 8.00

HD24 18.0 3.28 1.61 11.6 2.32 1.46 8.00

FC/MC/PC/UC24 24.0 3.44 2.04 14.2 2.38 1.75 8.00

YZB02411

FC/MC/PC/UC30 24.0 3.44 2.04 14.2 2.38 1.75 8.00

HC30 24.03.442.0414.22.381.758.00

HD24 24.03.442.0414.22.381.758.00

FC/MC/PC/UC36 30.0 3.44 2.56 18.3 2.28 2.35 8.00

YZB03011

HC36 30.03.442.5618.32.282.358.00

HD36 30.03.442.5618.32.282.358.00

FC/MC/PC/UC36 36.0 3.36 3.14 24.4 2.32 3.08 8.00

YZB03611

HC36 36.03.363.1424.42.323.088.00

HD36 36.03.363.1424.42.323.088.00

FC/MC/PC/UC48 42.0 3.66 3.36 28.4 2.54 3.28 8.00

YZB04211

HC48 42.03.663.3628.42.543.288.00

HD48 42.03.663.3628.42.543.288.00

FC/MC/PC/UC60 48.0 3.50 4.10 33.2 2.30 4.23 8.00

YZB04811

HC60 48.03.504.1033.22.304.238.00

HD60 48.03.504.1033.22.304.238.00

MC61 48.03.504.1033.22.304.238.00

YZB06012 FC/MC62D 57.0 3.54 4.77 37.0 2.44 4.49 8.55

1. Rated CFM same as for cooling.

2. Heating MBH based on ARI standards of 70° DB entering indoor air, 72% RH outdoor air with 25 feet of interconnecting piping and no

supplemental electric heat operation.

CP equals MBH output divided by (total KW input x 3.412).

HSPF (Heating Seasonal Performance Factor) is the total heating output during a normal annual usage period for heating divided by the

total electric power input during the same period.

— = Not Applicable.

2

14 Johnson Controls Unitary Products

Page 15

271457-YTG-B-0908

HEATING CAPACITY - YZB01811With Variable Speed Furnaces

VARIABLE

SPEED

FURNACE

COIL

MODEL

1

47°F17°F HSPF

MBH COP KW MBH COP KW STD

ARI HEATING

13 SEER HP WITH VARIABLE SPEED FURNACES

PV8*A12 FC/MC/PC18A 18.0 3.46 1.52 11.1 2.46 1.32 8.35

PV9*A12 FC/MC/PC18A 18.0 3.42 1.54 11.2 2.42 1.36 8.30

P(C,V)9*B12 FC/MC/PC18B 18.0 3.46 1.52 11.1 2.46 1.32 8.35

Y*(8,L)C*A12 FC/MC/PC18A 19.5 3.52 1.62 11.2 2.44 1.35 8.30

Y*(8,L)C*B12 FC/MC/PC18B 19.5 3.46 1.65 11.2 2.44 1.35 8.30

Y*9C*B12 FC/MC/PC18B 19.5 3.52 1.62 11.2 2.44 1.35 8.30

Y*(8,L)C*A12 FC/MC/PC24A 19.6 3.70 1.55 10.9 2.64 1.21 8.30

Y*(8,L)C*B12 FC/MC/PC24B 19.5 3.64 1.57 10.8 2.62 1.21 8.40

Y*9C*B12 FC/MC/PC24B 19.6 3.72 1.54 10.8 2.66 1.19 8.30

Y*(8,L)C*A12 FC/MC/PC30A 19.6 3.70 1.55 10.9 2.64 1.21 8.30

Y*(8,L)C*B12 FC/MC/PC30B 19.5 3.64 1.57 10.8 2.62 1.21 8.40

Y*9C*B12 FC/MC/PC30B 19.6 3.72 1.54 10.8 2.66 1.19 8.30

Y*(8,L)C*A12 HC18 19.5 3.52 1.62 11.2 2.44 1.35 8.30

Y*(8,L)C*A12 HD24 19.5 3.48 1.64 10.7 2.44 1.29 8.30

Y*(8,L)C*B12 HD24 19.4 3.36 1.69 10.7 2.38 1.32 8.30

Y*9C*B12 HD24 19.5 3.50 1.63 10.7 2.44 1.29 8.30

Y*(8,L)C*A12 UC18A 19.6 3.58 1.60 11.0 2.54 1.27 8.30

Y*(8,L)C*B12 UC18B 19.5 3.52 1.62 11.0 2.50 1.29 8.30

Y*9C*B12 UC18B 19.5 3.58 1.60 11.0 2.54 1.27 8.30

Y*(8,L)C*A12 UC24A 19.6 3.74 1.54 10.9 2.66 1.20 8.30

Y*(8,L)C*B12 UC24B 19.5 3.66 1.56 10.8 2.64 1.20 8.30

Y*9C*B12 UC24B 19.6 3.76 1.53 10.8 2.68 1.18 8.30

Y*(8,L)C*A12 UC30A 19.6 3.74 1.54 10.9 2.66 1.20 8.30

Y*(8,L)C*B12 UC30B 19.5 3.66 1.56 10.8 2.64 1.20 8.30

Y*9C*B12 UC30B 19.6 3.76 1.53 10.8 2.68 1.18 8.30

G*9V*A12 FC/MC/PC18A 19.6 3.48 1.65 11.3 2.42 1.37 8.20

G*9V*B12 FC/MC/PC18B 19.5 3.52 1.62 11.2 2.44 1.35 8.30

G*9V*A12 FC/MC/PC24A 19.6 3.64 1.58 11.1 2.58 1.26 8.30

G*9V*B12 FC/MC/PC24B 19.6 3.72 1.54 10.8 2.66 1.19 8.30

G*9V*A12 FC/MC/PC30A 19.6 3.64 1.58 11.1 2.58 1.26 8.30

G*9V*B12 FC/MC/PC30B 19.6 3.72 1.54 10.8 2.66 1.19 8.30

G*9V*A12 HC18 19.6 3.48 1.65 11.3 2.42 1.37 8.20

G*9V*A12 HD24 19.6 3.42 1.68 10.8 2.40 1.32 8.20

G*9V*B12 HD24 19.5 3.50 1.63 10.7 2.44 1.29 8.30

G*9V*A12 UC18A 19.6 3.56 1.61 11.1 2.52 1.29 8.30

G*9V*B12 UC18B 19.5 3.58 1.60 11.0 2.54 1.27 8.30

G*9V*B12 UC24B 19.6 3.76 1.53 10.8 2.68 1.18 8.30

G*9V*A12 UC30A 19.7 3.68 1.57 11.1 2.60 1.25 8.30

G*9V*B12 UC30B 19.6 3.76 1.53 10.8 2.68 1.18 8.30

1. Rated CFM same as for cooling.

2. Heating MBH based on ARI standards of 70° DB entering indoor air, 72% RH outdoor air with 25 feet of interconnecting piping and no

supplemental electric heat operation.

3. Variable speed furnaces have B.O.D (Blower on Delay) standard.

CP equals MBH output divided by (total KW input x 3.412).

HSPF (Heating Seasonal Performance Factor) is the total heating output during a normal annual usage period for heating divided by the

total electric power input during the same period.

2

3

Johnson Controls Unitary Products 15

Page 16

271457-YTG-B-0908

HEATING CAPACITY - YZB02411With Variable Speed Furnaces

VARIABLE

SPEED

FURNACE

PV8*A12 FC/MC/PC24A 23.43.441.9914.22.381.758.00

PV9*A12 FC/MC/PC24A 23.43.621.8913.72.501.618.40

PV8*A12 FC/MC/PC30A 23.43.441.9914.22.381.758.00

PV9*A12 FC/MC/PC30A 23.43.621.8913.72.501.618.40

PV8*A12 HC30 23.43.441.9914.22.381.758.00

PV8*A12 HD24 23.43.441.9914.22.381.758.00

Y*(8,L)C*A12 FC/MC/PC24A 23.6 3.72 1.86 14.2 2.58 1.61 8.20

Y*(8,L)C*B12 FC/MC/PC24B 23.4 3.76 1.82 14.2 2.60 1.60 8.30

Y*9C*B12 FC/MC/PC24B 23.6 3.72 1.86 14.2 2.58 1.61 8.20

Y*(8,L)C*A12 FC/MC/PC30A 23.6 3.72 1.86 14.2 2.58 1.61 8.20

Y*(8,L)C*B12 FC/MC/PC30B 23.4 3.76 1.82 14.2 2.60 1.60 8.30

Y*9C*B12 FC/MC/PC30B 23.6 3.72 1.86 14.2 2.58 1.61 8.20

Y*(8,L)C*A12 FC/MC/PC32A 23.6 3.68 1.88 14.2 2.56 1.63 8.20

Y*(8,L)C*A12 HC30 23.6 3.58 1.93 14.3 2.48 1.69 8.20

Y*(8,L)C*A12 HD24 23.6 3.58 1.93 14.0 2.46 1.67 8.30

Y*(8,L)C*B12 HD24 23.4 3.62 1.89 14.0 2.48 1.65 8.30

Y*9C*B12 HD24 23.6 3.58 1.93 14.0 2.46 1.67 8.30

Y*(8,L)C*A12 UC24A 23.6 3.76 1.84 14.1 2.60 1.59 8.20

Y*(8,L)C*B12 UC24B 23.4 3.80 1.80 14.1 2.62 1.58 8.30

Y*9C*B12 UC24B 23.6 3.76 1.84 14.1 2.60 1.59 8.20

Y*(8,L)C*A12 UC30A 23.6 3.76 1.84 14.1 2.60 1.59 8.20

Y*(8,L)C*B12 UC30B 23.4 3.80 1.80 14.1 2.62 1.58 8.30

Y*9C*B12 UC30B 23.6 3.76 1.84 14.1 2.60 1.59 8.20

G*9V*A12 FC/MC/PC24A 23.6 3.66 1.89 13.9 2.52 1.62 8.20

G*9V*B12 FC/MC/PC24B 23.6 3.72 1.86 14.2 2.58 1.61 8.20

G*9V*A12 FC/MC/PC30A 23.6 3.66 1.89 13.9 2.52 1.62 8.20

G*9V*B12 FC/MC/PC30B 23.6 3.72 1.86 14.2 2.58 1.61 8.20

G*9V*A12 FC/MC/PC32A 23.6 3.64 1.90 14.3 2.52 1.66 8.10

G*9V*A12 HC30 23.6 3.60 1.92 13.8 2.48 1.63 8.20

G*9V*A12 HD24 23.6 3.54 1.95 13.8 2.42 1.67 8.20

G*9V*B12 HD24 23.6 3.58 1.93 14.0 2.46 1.67 8.30

G*9V*A12 UC24A 23.6 3.70 1.87 14.2 2.58 1.61 8.20

G*9V*B12 UC24B 23.6 3.76 1.84 14.1 2.60 1.59 8.20

G*9V*A12 UC30A 23.6 3.70 1.87 14.2 2.58 1.61 8.20

G*9V*B12 UC30B 23.6 3.76 1.84 14.1 2.60 1.59 8.20

1. Rated CFM same as for cooling.

2. Heating MBH based on ARI standards of 70° DB entering indoor air, 72% RH outdoor air with 25 feet of interconnecting piping and no

supplemental electric heat operation.

CP equals MBH output divided by (total KW input x 3.412).

HSPF (Heating Seasonal Performance Factor) is the total heating output during a normal annual usage period for heating divided by the

total electric power input during the same period.

1

COIL

MODEL

1 PH 13 SEER HP WITH VARIABLE SPEED FURNACES

MBH COP KW MBH COP KW STD

47°F17°FHSPF

ARI HEATING

2

16 Johnson Controls Unitary Products

Page 17

271457-YTG-B-0908

HEATING CAPACITY - YZB03011With Variable Speed Furnaces

VARIABLE

SPEED

FURNACE

PV8*A12 FC/MC/PC36A 29.4 3.44 2.50 18.3 2.28 2.35 8.00

PV9*A12 FC/MC/PC36A 29.4 3.60 2.39 17.7 2.38 2.18 8.10

PV8*B16 FC/MC/PC36B 29.4 3.44 2.50 18.3 2.28 2.35 8.00

P(C,V)9*B12 FC/MC/PC36B 29.4 3.60 2.39 17.7 2.38 2.18 8.10

PV8*C16 FC/MC/PC36C 29.4 3.44 2.50 18.3 2.28 2.35 8.00

P(C,V)9*C16 FC/MC/PC36C 29.4 3.44 2.50 18.3 2.28 2.35 8.00

PV8*B16 HC36 29.43.442.5018.32.282.358.00

PV8*A12 HD36 29.43.442.5018.32.282.358.00

PV9*A12 HD36 29.63.522.4618.02.322.278.05

Y*(8,L)C*A12 FC/MC/PC32A 30.0 3.50 2.51 18.5 2.30 2.36 8.10

Y*(8,L)C*B12 FC/MC/PC35B 29.6 3.62 2.40 18.2 2.38 2.24 8.20

Y*9C*B12 FC/MC/PC35B 29.8 3.56 2.45 18.4 2.34 2.30 8.10

Y*(8,L)C*C16 FC/MC/PC35C 29.4 3.64 2.37 17.6 2.40 2.15 8.20

Y*(8,L)C*C20 FC/MC/PC35C 29.6 3.66 2.37 17.9 2.40 2.19 8.20

Y*9C*C16 FC/MC/PC35C 29.4 3.64 2.37 17.6 2.40 2.15 8.20

Y*9C*C20 FC/MC/PC35C 29.4 3.64 2.37 17.6 2.40 2.15 8.20

Y*(8,L)C*A12 FC/MC/PC36A 29.6 3.58 2.42 17.8 2.36 2.21 8.20

Y*(8,L)C*B12 FC/MC/PC36B 29.4 3.62 2.38 17.7 2.40 2.16 8.20

Y*9C*B12 FC/MC/PC36B 29.6 3.62 2.40 17.7 2.40 2.16 8.20

Y*(8,L)C*C16 FC/MC/PC36C 29.4 3.66 2.35 18.0 2.42 2.18 8.20

Y*(8,L)C*C20 FC/MC/PC36C 29.4 3.66 2.35 18.0 2.42 2.18 8.20

Y*9C*C16 FC/MC/PC36C 29.4 3.66 2.35 18.0 2.42 2.18 8.20

Y*9C*C20 FC/MC/PC36C 29.6 3.64 2.38 18.1 2.40 2.21 8.20

Y*(8,L)C*A12 FC/MC/PC37A 29.8 3.60 2.43 18.1 2.38 2.23 8.20

Y*(8,L)C*A12 HC30 29.8 3.42 2.55 18.6 2.26 2.41 8.00

Y*(8,L)C*B12 HC36 29.6 3.58 2.42 17.9 2.36 2.22 8.20

Y*9C*B12 HC36 29.8 3.56 2.45 18.4 2.34 2.30 8.10

Y*(8,L)C*A12 HD36 28.8 3.04 2.78 18.0 1.94 2.72 7.80

Y*(8,L)C*B12 HD36 28.6 3.06 2.74 17.9 1.96 2.68 7.90

Y*(8,L)C*C16 HD36 28.6 3.08 2.72 17.8 1.96 2.66 7.90

Y*(8,L)C*C20 HD36 30.4 3.32 2.68 17.1 2.06 2.43 8.60

Y*9C*B12 HD36 28.6 3.06 2.74 17.9 1.94 2.70 7.90

Y*9C*C16 HD36 28.6 3.08 2.72 17.8 1.96 2.66 7.90

Y*9C*C20 HD36 28.6 3.06 2.74 17.9 1.94 2.70 7.90

Y*(8,L)C*A12 UC36A 29.4 3.50 2.46 16.8 2.12 2.32 8.10

Y*(8,L)C*B12 UC36B 29.4 3.54 2.43 16.7 2.16 2.27 8.20

Y*9C*B12 UC36B 29.4 3.54 2.43 16.7 2.14 2.29 8.10

Y*(8,L)C*C16 UC36C 29.4 3.58 2.41 17.3 2.30 2.20 8.20

Y*(8,L)C*C20 UC36C 29.2 3.58 2.39 17.3 2.30 2.20 8.20

Y*9C*C16 UC36C 29.4 3.58 2.41 17.3 2.30 2.20 8.20

Y*9C*C20 UC36C 29.4 3.56 2.42 17.3 2.28 2.22 8.20

G*9V*A12 FC/MC/PC30A 29.6 3.52 2.46 18.0 2.34 2.25 8.10

G*9V*A12 FC/MC/PC32A 29.6 3.54 2.45 18.2 2.36 2.26 8.10

G*9V*B12 FC/MC/PC35B 29.8 3.56 2.45 18.4 2.34 2.30 8.10

G*9V*C16 FC/MC/PC35C 29.4 3.64 2.37 17.6 2.40 2.15 8.20

G*9V*C20 FC/MC/PC35C 29.4 3.64 2.37 17.6 2.40 2.15 8.20

G*9V*A12 FC/MC/PC36A 29.6 3.56 2.44 17.8 2.36 2.21 8.20

G*9V*B12 FC/MC/PC36B 29.6 3.62 2.40 17.7 2.40 2.16 8.20

G*9V*C16 FC/MC/PC36C 29.4 3.66 2.35 18.0 2.42 2.18 8.20

G*9V*C20 FC/MC/PC36C 29.6 3.64 2.38 18.1 2.40 2.21 8.20

G*9V*A12 FC/MC/PC37A 30.0 3.62 2.43 17.9 2.38 2.20 8.20

G*9V*A12 HC30 29.4 3.48 2.48 17.9 2.30 2.28 8.10

G*9V*B12 HC36 29.8 3.56 2.45 18.4 2.34 2.30 8.10

For Notes See Page 18.

1

COIL

MODEL

1 PH 13 SEER HP WITH VARIABLE SPEED FURNACES

MBH COP KW MBH COP KW STD

47°F17°F HSPF

ARI HEATING

2

Johnson Controls Unitary Products 17

Page 18

271457-YTG-B-0908

HEATING CAPACITY - YZB03011With Variable Speed Furnaces (Continued)

VARIABLE

SPEED

FURNACE

COIL

MODEL

1

47°F17°FHSPF

MBH COP KW MBH COP KW STD

ARI HEATING

G*9V*A12 HD36 28.8 3.02 2.79 18.0 1.92 2.75 7.80

G*9V*B12 HD36 28.6 3.06 2.74 17.9 1.94 2.70 7.90

G*9V*C16 HD36 28.6 3.08 2.72 17.8 1.96 2.66 7.90

G*9V*C20 HD36 28.6 3.06 2.74 17.9 1.94 2.70 7.90

G*9V*A12 UC30A 29.6 3.54 2.45 18.3 2.34 2.29 8.10

G*9V*A12 UC36A 29.6 3.54 2.45 18.3 2.36 2.27 8.10

G*9V*B12 UC36B 29.4 3.54 2.43 16.7 2.14 2.29 8.10

G*9V*C16 UC36C 29.4 3.58 2.41 17.3 2.30 2.20 8.20

G*9V*C20 UC36C 29.4 3.56 2.42 17.3 2.28 2.22 8.20

1. Rated CFM same as for cooling.

2. Heating MBH based on ARI standards of 70° DB entering indoor air, 72% RH outdoor air with 25 feet of interconnecting piping and no

supplemental electric heat operation.

CP equals MBH output divided by (total KW input x 3.412).

HSPF (Heating Seasonal Performance Factor) is the total heating output during a normal annual usage period for heating divided by the

total electric power input during the same period.

2

HEATING CAPACITY - YZB03611With Variable Speed Furnaces

VARIABLE

SPEED

FURNACE

COIL

MODEL

1

47°F17°FHSPF

MBH COP KW MBH COP KW STD

ARI HEATING

1 PH 13 SEER HP WITH VARIABLE SPEED FURNACES

PV8*A12 FC/MC/PC36A 36.03.363.1424.42.323.088.00

PV9*A12 FC/MC/PC36A 36.03.423.0824.02.362.988.35

PV8*B16 FC/MC/PC36B 36.03.363.1424.42.323.088.00

P(C,V)9*B12 FC/MC/PC36B 36.03.423.0824.02.362.988.35

PV8*C16 FC/MC/PC36C 36.03.363.1424.42.323.088.00

PV8*C20 FC/MC/PC36C 36.03.363.1424.42.323.088.00

P(C,V)9*C16 FC/MC/PC36C 36.03.363.1424.42.323.088.00

P(C,V)9*C20 FC/MC/PC36C 36.03.363.1424.42.323.088.00

PV8*B16 HC36 36.03.363.1424.42.323.088.00

P(C,V)9*B12 HC36 36.03.363.1424.42.323.088.00

PV8*B16 HD36 36.03.363.1424.42.323.088.00

P(C,V)9*B12 HD36 36.03.363.1424.42.323.088.00

Y*(8,L)C*B12 FC/MC/PC35B 35.6 3.30 3.16 24.6 2.32 3.11 8.00

Y*9C*B12 FC/MC/PC35B 35.4 3.30 3.14 24.0 2.30 3.06 8.00

Y*(8,L)C*C16 FC/MC/PC35C 35.4 3.40 3.05 24.2 2.38 2.98 8.10

Y*(8,L)C*C20 FC/MC/PC35C 35.2 3.42 3.02 24.2 2.40 2.96 8.10

Y*9C*C16 FC/MC/PC35C 35.4 3.38 3.07 24.4 2.36 3.03 8.10

Y*9C*C20 FC/MC/PC35C 35.8 3.38 3.10 23.8 2.30 3.03 8.10

Y*(8,L)C*A12 FC/MC/PC36A 35.6 3.28 3.18 24.6 2.32 3.11 8.00

Y*(8,L)C*B12 FC/MC/PC36B 35.4 3.32 3.13 24.4 2.34 3.06 8.00

Y*9C*B12 FC/MC/PC36B 35.4 3.34 3.11 24.4 2.36 3.03 8.00

Y*(8,L)C*C16 FC/MC/PC36C 35.2 3.40 3.03 24.4 2.38 3.00 8.10

Y*(8,L)C*C20 FC/MC/PC36C 35.2 3.42 3.02 24.4 2.40 2.98 8.10

Y*9C*C16 FC/MC/PC36C 35.2 3.42 3.02 24.4 2.40 2.98 8.10

Y*9C*C20 FC/MC/PC36C 35.6 3.42 3.05 23.6 2.32 2.98 8.10

Y*(8,L)C*A12 FC/MC/PC37A 35.0 3.26 3.15 24.2 2.34 3.03 8.00

Y*(8,L)C*B12 FC/MC/PC43B 35.8 3.42 3.07 24.2 2.36 3.01 8.10

Y*9C*B12 FC/MC/PC43B 35.8 3.42 3.07 24.2 2.36 3.01 8.10

Y*(8,L)C*C16 FC/MC/PC43C 35.4 3.52 2.95 23.8 2.42 2.88 8.20

Y*(8,L)C*C20 FC/MC/PC43C 35.4 3.52 2.95 23.8 2.42 2.88 8.20

Y*9C*C16 FC/MC/PC43C 35.6 3.46 3.02 24.0 2.38 2.96 8.10

Y*9C*C20 FC/MC/PC43C 35.4 3.50 2.96 24.0 2.42 2.91 8.20

Y*(8,L)C*C16 FC/MC/PC48C 35.4 3.54 2.93 23.8 2.44 2.86 8.20

For Notes See Page 19.

2

18 Johnson Controls Unitary Products

Page 19

271457-YTG-B-0908

HEATING CAPACITY - YZB03611With Variable Speed Furnaces (Continued)

VARIABLE

SPEED

FURNACE

Y*(8,L)C*C20 FC/MC/PC48C 35.4 3.58 2.90 23.8 2.46 2.84 8.20

Y*9C*C16 FC/MC/PC48C 35.6 3.52 2.96 24.0 2.42 2.91 8.20

Y*9C*C20 FC/MC/PC48C 36.0 3.54 2.98 24.2 2.42 2.93 8.20

Y*(8,L)C*C16 HC42 35.4 3.50 2.96 23.8 2.42 2.88 8.20

Y*(8,L)C*C20 HC42 35.4 3.54 2.93 23.8 2.44 2.86 8.20

Y*9C*C16 HC42 35.6 3.46 3.02 24.0 2.38 2.96 8.10

Y*9C*C20 HC42 35.4 3.50 2.96 24.0 2.42 2.91 8.20

Y*(8,L)C*B12 HD48 34.8 3.10 3.29 23.8 2.10 3.32 7.90

Y*(8,L)C*C16 HD48 34.6 3.16 3.21 23.4 2.14 3.20 8.00

Y*(8,L)C*C20 HD48 34.6 3.18 3.19 23.4 2.14 3.20 8.00

Y*9C*B12 HD48 35.0 3.10 3.31 23.8 2.10 3.32 7.90

Y*9C*C16 HD48 34.8 3.14 3.25 23.6 2.12 3.26 7.90

Y*9C*C20 HD48 35.2 3.20 3.22 24.2 2.18 3.25 7.90

Y*(8,L)C*A12 UC36A 35.4 3.24 3.20 24.8 2.24 3.24 8.00

Y*(8,L)C*B12 UC36B 35.2 3.26 3.16 24.6 2.26 3.19 8.00

Y*9C*B12 UC36B 35.2 3.28 3.15 24.6 2.28 3.16 8.00

Y*(8,L)C*C16 UC36C 35.2 3.34 3.09 23.8 2.32 3.01 8.10

Y*(8,L)C*C20 UC36C 35.0 3.36 3.05 23.8 2.32 3.01 8.10

Y*9C*C16 UC36C 35.2 3.36 3.07 23.8 2.32 3.01 8.10

Y*9C*C20 UC36C 35.6 3.34 3.12 23.8 2.26 3.09 8.00

Y*(8,L)C*C16 UC48C 35.6 3.66 2.85 24.0 2.52 2.79 8.30

Y*(8,L)C*C20 UC48C 35.6 3.68 2.84 23.8 2.54 2.75 8.30

Y*9C*C16 UC48C 35.8 3.62 2.90 24.0 2.50 2.81 8.20

Y*9C*C20 UC48C 36.2 3.64 2.91 24.4 2.48 2.88 8.20

G*9V*B12 FC/MC/PC35B 35.4 3.30 3.14 24.0 2.30 3.06 8.00

G*9V*C16 FC/MC/PC35C 35.4 3.38 3.07 24.4 2.36 3.03 8.10

G*9V*C20 FC/MC/PC35C 35.8 3.38 3.10 23.8 2.30 3.03 8.10

G*9V*A12 FC/MC/PC36A 35.6 3.28 3.18 24.2 2.30 3.08 8.00

G*9V*B12 FC/MC/PC36B 35.4 3.34 3.11 24.4 2.36 3.03 8.00

G*9V*C16 FC/MC/PC36C 35.2 3.42 3.02 24.4 2.40 2.98 8.10

G*9V*C20 FC/MC/PC36C 35.6 3.42 3.05 23.6 2.32 2.98 8.10

G*9V*A12 FC/MC/PC37A 35.6 3.32 3.14 24.6 2.34 3.08 8.00

G*9V*B12 FC/MC/PC43B 35.8 3.42 3.07 24.2 2.36 3.01 8.10

G*9V*C16 FC/MC/PC43C 35.6 3.46 3.02 24.0 2.38 2.96 8.10

G*9V*C20 FC/MC/PC43C 35.4 3.50 2.96 24.0 2.42 2.91 8.20

G*9V*C16 FC/MC/PC48C 35.6 3.52 2.96 24.0 2.42 2.91 8.20

G*9V*C20 FC/MC/PC48C 36.0 3.54 2.98 24.2 2.42 2.93 8.20

G*9V*C16 HC42 35.6 3.46 3.02 24.0 2.38 2.96 8.10

G*9V*C20 HC42 35.4 3.50 2.96 24.0 2.42 2.91 8.20

G*9V*B12 HD48 35.0 3.10 3.31 23.8 2.10 3.32 7.90

G*9V*C16 HD48 34.8 3.14 3.25 23.6 2.12 3.26 7.90

G*9V*C20 HD48 35.2 3.20 3.22 24.2 2.18 3.25 7.90

G*9V*A12 UC36A 35.6 3.22 3.24 24.8 2.24 3.24 7.90

G*9V*B12 UC36B 35.2 3.28 3.15 24.6 2.28 3.16 8.00

G*9V*C16 UC36C 35.2 3.36 3.07 23.8 2.32 3.01 8.10

G*9V*C20 UC36C 35.6 3.34 3.12 23.8 2.26 3.09 8.00

G*9V*C16 UC48C 35.8 3.62 2.90 24.0 2.50 2.81 8.20

G*9V*C20 UC48C 36.2 3.64 2.91 24.4 2.48 2.88 8.20

1. Rated CFM same as for cooling.

2. Heating MBH based on ARI standards of 70° DB entering indoor air, 72% RH outdoor air with 25 feet of interconnecting piping and no

supplemental electric heat operation.

CP equals MBH output divided by (total KW input x 3.412).

HSPF (Heating Seasonal Performance Factor) is the total heating output during a normal annual usage period for heating divided by the

total electric power input during the same period.

COIL

MODEL

1

47°F17°F HSPF

MBH COP KW MBH COP KW STD

ARI HEATING

2

Johnson Controls Unitary Products 19

Page 20

271457-YTG-B-0908

HEATING CAPACITY - YZB04211With Variable Speed Furnaces

VARIABLE

SPEED

FURNACE

PV8*C16 FC/MC/PC48C 42.03.663.3628.42.543.288.00

PV8*C20 FC/MC/PC48C 42.03.663.3628.42.543.288.00

P(C,V)9*C16 FC/MC/PC48C 42.03.743.2928.02.583.188.60

P(C,V)9*C20 FC/MC/PC48C 42.03.763.2728.02.603.168.60

P(C,V)9*D20 FC/MC/PC48D 42.03.743.2928.02.583.188.60

PV8*C20 HC48 42.03.663.3628.42.543.288.00

P(C,V)9*C20 HC48 42.03.663.3628.42.543.288.00

PV8*C20 HD48 42.03.663.3628.42.543.288.00

P(C,V)9*C20 HD48 42.03.663.3628.42.543.288.00

Y*(8,L)C*C16 FC/MC/PC48C 41.5 3.80 3.20 28.0 2.62 3.13 8.10

Y*(8,L)C*C20 FC/MC/PC48C 41.5 3.82 3.18 27.8 2.64 3.09 8.20

Y*9C*C16 FC/MC/PC48C 41.5 3.78 3.22 28.0 2.60 3.16 8.10

Y*9C*C20 FC/MC/PC48C 42.0 3.76 3.27 28.2 2.60 3.18 8.10

Y*9C*D20 FC/MC/PC48D 41.5 3.78 3.22 28.0 2.62 3.13 8.10

Y*(8,L)C*B12 HD48 41.0 3.32 3.62 27.2 2.30 3.47 7.80

Y*(8,L)C*C16 HD48 41.0 3.46 3.47 27.0 2.36 3.35 7.90

Y*(8,L)C*C20 HD48 40.5 3.48 3.41 26.8 2.36 3.33 7.90

Y*9C*B12 HD48 40.0 3.16 3.71 27.0 2.24 3.53 7.80

Y*9C*C16 HD48 41.0 3.40 3.53 27.6 2.32 3.49 7.90

Y*9C*C20 HD48 41.0 3.38 3.56 27.6 2.32 3.49 7.90

Y*9C*D20 HD48 41.0 3.44 3.49 27.0 2.34 3.38 7.90

Y*(8,L)C*C16 UC48C 42.0 3.90 3.16 28.0 2.68 3.06 8.20

Y*(8,L)C*C20 UC48C 42.0 3.94 3.12 28.0 2.70 3.04 8.20

Y*9C*C16 UC48C 42.0 3.88 3.17 28.2 2.66 3.11 8.20

Y*9C*C20 UC48C 42.0 3.86 3.19 28.2 2.64 3.13 8.20

Y*9C*D20 UC48D 42.0 3.90 3.16 28.0 2.66 3.09 8.20

G*9V*C16 FC/MC/PC48C 41.5 3.78 3.22 28.0 2.60 3.16 8.10

G*9V*C20 FC/MC/PC48C 42.0 3.76 3.27 28.2 2.60 3.18 8.10

G*9V*D20 FC/MC/PC48D 41.5 3.78 3.22 28.0 2.62 3.13 8.10

G*9V*B12 HD48 40.0 3.16 3.71 27.0 2.24 3.53 7.80

G*9V*C16 HD48 41.0 3.40 3.53 27.6 2.32 3.49 7.90

G*9V*C20 HD48 41.0 3.38 3.56 27.6 2.32 3.49 7.90

G*9V*D20 HD48 41.0 3.44 3.49 27.0 2.34 3.38 7.90

G*9V*C16 UC48C 42.0 3.88 3.17 28.2 2.66 3.11 8.20

G*9V*C20 UC48C 42.0 3.86 3.19 28.2 2.64 3.13 8.20

G*9V*D20 UC48D 42.0 3.90 3.16 28.0 2.66 3.09 8.20

1. Rated CFM same as for cooling.

2. Heating MBH based on ARI standards of 70° DB entering indoor air, 72% RH outdoor air with 25 feet of interconnecting piping and no

supplemental electric heat operation.

CP equals MBH output divided by (total KW input x 3.412).

HSPF (Heating Seasonal Performance Factor) is the total heating output during a normal annual usage period for heating divided by the

total electric power input during the same period.

1

COIL

MODEL

1 PH 13 SEER HP WITH VARIABLE SPEED FURNACES

MBH COP KW MBH COP KW STD

47°F17°FHSPF

ARI HEATING

2

20 Johnson Controls Unitary Products

Page 21

271457-YTG-B-0908

HEATING CAPACITY - YZB04811With Variable Speed Furnaces

VARIABLE

SPEED

FURNACE

COIL

MODEL

1

47°F17°F HSPF

MBH COP KW MBH COP KW STD

ARI HEATING

1 PH 13 SEER HP WITH VARIABLE SPEED FURNACES

P(C,V)9*D20 FC/MC/PC60D 48.0 3.54 3.97 32.8 2.32 4.14 8.50

PV8*C20 FC/PC60C 48.0 3.50 4.02 33.2 2.30 4.23 8.00

P(C,V)9*C20 FC/PC60C 48.0 3.52 4.00 33.0 2.32 4.17 8.50

PV8*C20 HC60 48.03.504.0233.22.304.238.00

P(C,V)9*D20 HC60 48.03.504.0233.22.304.238.00

PV8*C20 HD60 48.03.504.0233.22.304.238.00

P(C,V)9*D20 HD60 48.03.504.0233.22.304.238.00

P(C,V)9*D20 MC61D 48.0 3.54 3.97 32.8 2.32 4.14 8.50

Y*9C*D20 FC/MC/PC60D 47.5 3.48 4.00 33.0 2.28 4.24 8.00

Y*9C*D20 FC/MC62D 48.0 3.54 3.97 32.8 2.30 4.18 8.10

Y*(8,L)C*C16 FC/PC60C 47.5 3.50 3.98 33.0 2.30 4.21 8.00

Y*(8,L)C*C20 FC/PC60C 47.5 3.54 3.93 32.8 2.32 4.14 8.10

Y*9C*C16 FC/PC60C 47.5 3.48 4.00 33.2 2.28 4.27 8.00

Y*9C*C20 FC/PC60C 47.5 3.48 4.00 33.2 2.28 4.27 8.00

Y*(8,L)C*C16 HD60 47.0 3.30 4.17 32.6 2.14 4.46 7.90

Y*(8,L)C*C20 HD60 47.0 3.32 4.15 32.4 2.16 4.40 7.90

Y*9C*C16 HD60 47.0 3.26 4.23 32.6 2.12 4.51 7.90

Y*9C*C20 HD60 47.0 3.26 4.23 32.6 2.12 4.51 7.90

Y*9C*D20 HD60 47.0 3.28 4.20 32.6 2.14 4.46 7.90

Y*(8,L)C*C16 UC60C 47.5 3.56 3.91 32.6 2.32 4.12 8.10

Y*(8,L)C*C20 UC60C 47.5 3.62 3.85 32.4 2.36 4.02 8.10

Y*9C*C16 UC60C 48.0 3.54 3.97 32.8 2.30 4.18 8.10

Y*9C*C20 UC60C 48.0 3.54 3.97 32.8 2.30 4.18 8.10

Y*9C*D20 UC60D 48.0 3.54 3.97 32.8 2.32 4.14 8.10

G*9V*D20 FC/MC/PC60D 47.5 3.48 4.00 33.0 2.28 4.24 8.00

G*9V*D20 FC/MC62D 48.0 3.54 3.97 32.8 2.30 4.18 8.10

G*9V*C16 FC/PC60C 47.5 3.48 4.00 33.2 2.28 4.27 8.00

G*9V*C20 FC/PC60C 47.5 3.48 4.00 33.2 2.28 4.27 8.00

G*9V*C16 HD60 47.0 3.26 4.23 32.6 2.12 4.51 7.90

G*9V*C20 HD60 47.0 3.26 4.23 32.6 2.12 4.51 7.90

G*9V*D20 HD60 47.0 3.28 4.20 32.6 2.14 4.46 7.90

G*9V*C16 UC60C 48.0 3.54 3.97 32.8 2.30 4.18 8.10

G*9V*C20 UC60C 48.0 3.54 3.97 32.8 2.30 4.18 8.10

G*9V*D20 UC60D 48.0 3.54 3.97 32.8 2.32 4.14 8.10

Notes listed below.

2

HEATING CAPACITY - YZB06012With Variable Speed Furnaces

VARIABLE

SPEED

FURNACE

COIL

MODEL

1

47°F17°F HSPF

MBH COP KW MBH COP KW STD

ARI HEATING

1 PH 13 SEER HP WITH VARIABLE SPEED FURNACES

P(C,V)9*D20 FC/MC62D 55 3.54 4.55 37 2.46 4.35 8.65

Y*(8,L)C*C20 FC/MC62D 56.5 3.56 4.65 34.0 2.40 4.15 8.10

Y*9C*C20 FC/MC62D 57.0 3.50 4.77 34.2 2.36 4.25 8.00

Y*9C*D20 FC/MC62D 57.0 3.50 4.77 34.0 2.38 4.19 8.10

G*9V*C20 FC/MC62D 57.0 3.50 4.77 34.2 2.36 4.25 8.00

G*9V*D20 FC/MC62D 57.0 3.50 4.77 34.0 2.38 4.19 8.10

1. Rated CFM same as for cooling.

2. Heating MBH based on ARI standards of 70° DB entering indoor air, 72% RH outdoor air with 25 feet of interconnecting piping and no

supplemental electric heat operation.

CP equals MBH output divided by (total KW input x 3.412).

HSPF (Heating Seasonal Performance Factor) is the total heating output during a normal annual usage period for heating divided by the

total electric power input during the same period.

Johnson Controls Unitary Products 21

2

Page 22

271457-YTG-B-0908

ACCESSORIES*

Hard Start Kit (024-31994-000, 024-31995-000) - Provides

increased starting torque for areas with low voltage.

TXV Kits - 1TV09 series thermal expansion valves precisely

meter refrigerant for optimum performance.

Compressor Discharge Temperature Sensor

(2SN02700124) - Adds an additional safety for improved com-

pressor reliability and diagnostics. Compatible only with 13

SEER and higher heat pumps.

Bonnet Sensor (2SB13700124) - The bonnet sensor is used to

sense plenum temperature, and is optional with a gas or oil

back-up heat source. Compatible only with 13 SEER and higher

heat pumps.

Dehumidistat (2HU16700124) - Provides increased dehumidification when matched with variable speed furnace or air handler.

Heat Pump Risers - (526-35389-000, 526-35390-000, 52635391-000) - 3", 6", or 12" risers mount easily in composite

base pan recesses, ensuring the unit stays clear of snow and

ice build-up in harsh winter weather.

Room Thermostats - A wide selection of matching thermostats

is available to provide features required for any installation.

2H/1C, manual changeover electronic non-programmable thermostat.

3H/2C, non-programmable digital thermostat.

3H/2C, auto/manual changeover, electronic programmable, 7-

day, thermost at.

* For the most current accessory information, refer to the price

book or consult factroy.

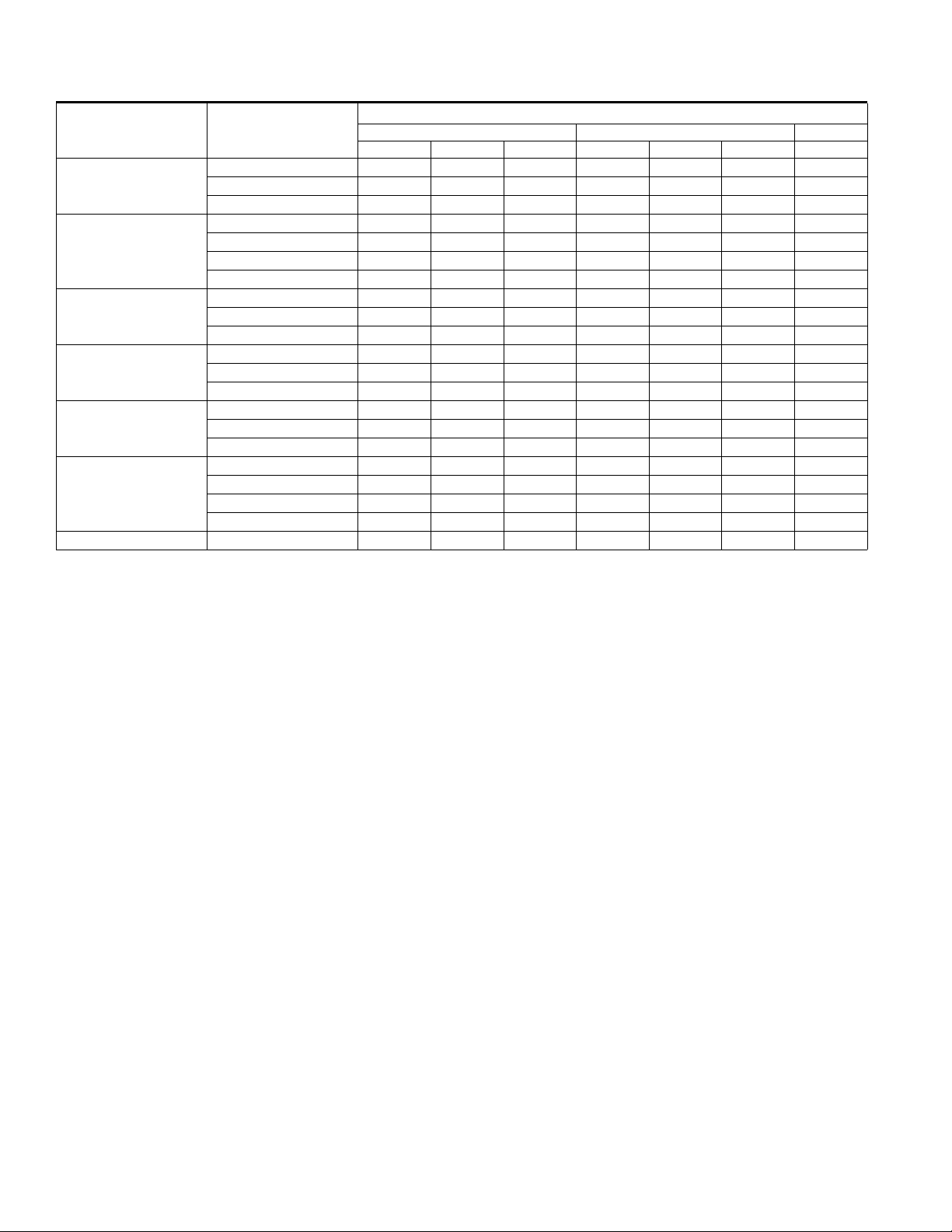

SOUND POWER RATINGS*

UNIT MODEL

018 65 66

024 70 70

030 70 71

036 71 72

042 74 74

048 74 75

060 74 75

Cooling Heating

* Rated in accordance with ARI 270-95 Standards.

(dBA)

COLOR GRILLES

CHOICE OF SEVERAL COLOR COIL GRILLES TO

COMPLIMENT ANY HOME.

Color Grill Color Description

1CP0126 Terra Cotta 018

1CP0130 Terra Cotta 024, 030

1CP0136 Terra Cotta 036, 042, 048

1CP1136 Terra Cotta 060

1CP0226 Jet Black 018

1CP0230 Jet Black 024, 030

1CP0236 Jet Black 036, 042, 048

1CP1236 Jet Black 060

1CP0326 Stone 018

1CP0330 Stone 024, 030

1CP0336 Stone 036, 042, 048

1CP1336 Stone 060

1CP0426 Bermuda 018

1CP0430 Bermuda 024, 030

1CP0436 Bermuda 036, 042, 048

1CP1436 Bermuda 060

1CP0526 Gunmetal 018

1CP0530 Gunmetal 024, 030

1CP0536 Gunmetal 036, 042, 048

1CP1536 Gunmetal 060

1CP0626 Chocolate 018

1CP0630 Chocolate 024, 030

1CP0636 Chocolate 036, 042, 048

1CP1636 Chocolate 060

22 Johnson Controls Unitary Products

Page 23

271457-YTG-B-0908

COOLING PERFORMANCE DATA

AIR CONDITIONER MODEL NO. YZB01811

INDOOR COIL MODEL NO. FC/MC/PC/UC18

CONDENSING

ENTERING AIR

TEMPERATURE

65

75

85

95

105

115

125

NOTE: ALL CAPACITIES INCLUDE INDOOR FAN HEAT AT 1250 BTUH/1000 CFM.

Multipliers for determining the performance with other indoor sections.

NOTE: For dry bulb temperatures different than those listed (between 73-87 F), sensible capacity increases by 1060 BTUH per 1000 CFM per degree above the listed

temperature and decreases by 1060 BTUH per 1000 CFM per degree below the listed temperature.

Air Handler Coil T.C. S.C. KW

MA08B FC/MC18B 1.00 1.00 1.00

MV12B FC/MC18B 0.97 0.98 0.96

AHP18 – 1.00 1.00 1.00

AV24 – 1.00 0.98 0.96

F*FP024 – 0.99 1.00 1.00

– HC18 1.00 1.00 1.00

– HD24 1.00 1.00 1.00

Variable Speed

Furnace

PV8*A12 FC/MC/PC18A 1.02 0.97 1.07

PV9*A12 FC/MC/PC18A 1.01 0.97 1.07

P(C,V)9*B12 FC/MC/PC18B 1.01 0.97 1.07

Y*(8,L)C*A12 FC/MC/PC18A 1.00 1.02 0.92

Y*(8,L)C*B12 FC/MC/PC18B 1.00 1.00 0.91

Y*9C*B12 FC/MC/PC18B 1.00 1.01 0.91

Y*(8,L)C*A12 FC/MC/PC24A 1.00 1.04 0.92

Y*(8,L)C*B12 FC/MC/PC24B 1.00 1.00 0.90

Y*9C*B12 FC/MC/PC24B 1.00 1.04 0.91

Y*(8,L)C*A12 FC/MC/PC30A 1.00 1.04 0.92

Y*(8,L)C*B12 FC/MC/PC30B 1.00 1.00 0.90

Y*9C*B12 FC/MC/PC30B 1.00 1.04 0.91

Y*(8,L)C*A12 HC18 1.00 1.02 0.92

Y*(8,L)C*A12 HD24 1.00 1.03 0.92

Y*(8,L)C*B12 HD24 1.00 1.00 0.90

IDCFM 450 600 750

ID DB (°F) 80 80 75 80 80 80 80 75 80 80 80 80 75 80 80

ID WB (°F) 57 62 62 67 72 57 62 62 67 72 57 62 62 67 72

T.C. 14.4 17.2 16.4 18.9 21.3 16.8 19.1 18.1 20.7 22.2 19.2 20.9 19.8 22.6 23.1

S.C. 14.5 12.8 10.6 11.1 9.0 16.9 15.4 12.7 13.1 10.1 19.4 18.1 14.9 15.1 11.2

KW 1.1 1.1 1.1 1.1 1.1 1.1 1.1 1.1 1.1 1.1 1.1 1.1 1.1 1.1 1.1

T.C. 13.9 16.5 15.8 18.2 20.2 16.0 18.1 17.4 19.8 21.1 18.2 19.8 18.9 21.5 22.0

S.C. 14.0 12.4 10.3 10.7 8.6 16.1 14.9 12.5 12.7 9.7 18.3 17.4 14.6 14.7 10.8

KW 1.3 1.3 1.3 1.3 1.2 1.3 1.3 1.3 1.3 1.2 1.3 1.3 1.3 1.2 1.2

T.C. 13.3 15.7 15.3 17.4 19.0 15.2 17.2 16.7 18.9 19.9 17.1 18.6 18.1 20.4 20.8

S.C. 13.4 12.1 10.1 10.4 8.1 15.3 14.4 12.2 12.4 9.3 17.2 16.8 14.2 14.3 10.4

KW 1.4 1.4 1.4 1.4 1.4 1.4 1.4 1.4 1.4 1.4 1.4 1.4 1.4 1.4 1.4

T.C. 12.7 14.9 14.7 16.7 17.9 14.4 16.2 15.9 18.0 18.8 16.1 17.5 17.2 19.3 19.7

S.C. 12.8 11.8 9.9 10.1 7.7 14.5 13.9 11.9 12.0 8.9 16.1 16.1 13.9 13.9 10.0

KW 1.6 1.6 1.6 1.6 1.6 1.6 1.6 1.6 1.6 1.6 1.6 1.6 1.6 1.6 1.6

T.C. 12.2 14.1 13.8 15.7 16.9 13.8 15.5 14.9 16.9 17.7 15.4 16.8 16.1 18.1 18.5

S.C. 12.3 11.5 9.6 9.7 7.3 13.9 13.5 11.4 11.5 8.4 15.4 15.5 13.3 13.4 9.5

KW 1.9 1.9 1.8 1.9 1.8 1.9 1.9 1.8 1.8 1.8 1.9 1.8 1.8 1.8 1.8

T.C. 11.7 13.4 12.9 14.7 15.9 13.2 14.8 13.9 15.8 16.6 14.7 16.1 15.0 16.9 17.3

S.C. 11.8 11.3 9.2 9.3 7.0 13.3 13.0 11.0 11.1 8.0 14.8 14.8 12.7 12.9 9.0

KW 2.1 2.1 2.1 2.1 2.1 2.1 2.1 2.1 2.1 2.1 2.1 2.1 2.1 2.1 2.1

T.C. 11.2 12.7 11.9 13.8 14.8 12.6 14.1 12.9 14.7 15.5 14.1 15.5 13.9 15.7 16.1

S.C. 11.3 11.0 8.9 8.9 6.6 12.7 12.6 10.5 10.6 7.5 14.1 14.2 12.2 12.3 8.4

KW 2.4 2.3 2.3 2.3 2.3 2.3 2.3 2.3 2.3 2.3 2.3 2.3 2.3 2.3 2.3

Coil T.C. S.C. KW

Variable Speed

Furnace

Y*9C*B12 HD24 1.00 1.03 0.91

Y*(8,L)C*A12 UC18A 1.00 1.02 0.92

Y*(8,L)C*B12 UC18B 1.00 1.00 0.91

Y*9C*B12 UC18B 1.00 1.02 0.91

Y*(8,L)C*A12 UC24A 1.00 1.04 0.92

Y*(8,L)C*B12 UC24B 1.00 1.01 0.90

Y*9C*B12 UC24B 1.00 1.04 0.91

Y*(8,L)C*A12 UC30A 1.00 1.04 0.92

Y*(8,L)C*B12 UC30B 1.00 1.01 0.90

Y*9C*B12 UC30B 1.00 1.04 0.91

G*9V*A12 FC/MC/PC18A 1.00 1.02 0.93

G*9V*B12 FC/MC/PC18B 1.00 1.01 0.91

G*9V*A12 FC/MC/PC24A 1.00 1.03 0.93

G*9V*B12 FC/MC/PC24B 1.00 1.04 0.91

G*9V*A12 FC/MC/PC30A 1.00 1.03 0.93

G*9V*B12 FC/MC/PC30B 1.00 1.04 0.91

G*9V*A12 HC18 1.00 1.02 0.93

G*9V*A12 HD24 1.00 1.02 0.93

G*9V*B12 HD24 1.00 1.03 0.91

G*9V*A12 UC18A 1.00 1.03 0.93

G*9V*B12 UC18B 1.00 1.02 0.91

G*9V*B12 UC24B 1.00 1.04 0.91

G*9V*A12 UC30A 1.00 1.03 0.93

G*9V*B12 UC30B 1.00 1.04 0.91

Coil T.C. S.C. KW

Johnson Controls Unitary Products 23

Page 24

271457-YTG-B-0908

COOLING PERFORMANCE DATA

OUTDOOR UNIT MODEL NO. YZB02411

INDOOR COIL MODEL NO. AHP24

CONDENSER

ENTERING AIR

TEMPERATURE

65

75

85

95

105

115

125

NOTE: ALL CAPACITIES ARE NET (KBTUH) WITH INDOOR FAN HEAT ALREADY DEDUCTED AT 1250 BTUH/1000 CFM.

Multipliers for determining the performance with other indoor sections.

NOTE: For dry bulb temperatures different than those listed (between 73-87 F), sensible capacity increases by 1060 BTUH per 1000 CFM per degree above the listed

temperature and decreases by 1060 BTUH per 1000 CFM per degree below the listed temperature.

Air Handler Coil T.C. S.C. KW

MA08B FC/MC24B 1.00 1.00 1.00

MA08B FC/MC30B 1.00 1.00 1.00

MV12B FC/MC24B 1.03 1.02 0.96

MV12B FC/MC30B 1.03 1.02 0.96

AV24 – 1.03 1.02 0.96

F*FP030 – 1.00 1.00 1.00

– FC/MC/PC/UC24 1.00 1.00 1.00

– FC/MC/PC/UC30 1.00 1.00 1.00

– HC30 1.00 1.00 1.00

– HD24 0.98 1.06 1.00

Variable Speed

Furnace

PV8*A12 FC/MC/PC24A 1.00 0.96 1.03

PV9*A12 FC/MC/PC24A 1.00 0.96 1.07

PV8*A12 FC/MC/PC30A 1.00 0.96 1.03

PV9*A12 FC/MC/PC30A 1.00 0.96 1.07

Y*(8,L)C*A12 FC/MC/PC24A 1.02 1.05 0.92

Y*(8,L)C*B12 FC/MC/PC24B 1.02 1.05 0.91

Y*9C*B12 FC/MC/PC24B 1.02 1.05 0.93

Y*(8,L)C*A12 FC/MC/PC30A 1.02 1.05 0.92

Y*(8,L)C*B12 FC/MC/PC30B 1.02 1.05 0.91

Y*9C*B12 FC/MC/PC30B 1.02 1.05 0.93

ID CFM 600 800 1000

ID DB (°F) 80 80 75 80 80 80 80 75 80 80 80 80 75 80 80

ID WB (°F) 57 62 62 67 72 57 62 62 67 57 57 62 62 67 72

T.C. 21.7 24.5 23.6 27.4 29.9 24.0 25.4 24.8 28.4 30.8 26.4 26.3 26.0 29.5 31.7

S.C. 21.9 20.9 16.6 17.8 14.0 24.3 23.9 19.3 19.9 15.6 26.7 24.3 22.0 22.0 17.2

K.W. 1.3 1.3 1.3 1.3 1.3 1.3 1.3 1.3 1.3 1.3 1.3 1.3 1.3 1.3 1.3

T.C. 20.9 23.1 22.3 25.5 28.0 23.1 24.2 23.4 26.6 28.9 25.3 25.4 24.5 27.6 29.9

S.C. 21.1 19.9 15.9 16.6 13.3 23.4 22.8 18.3 18.9 14.8 25.6 25.7 20.8 21.2 16.4

K.W. 1.6 1.6 1.6 1.6 1.6 1.6 1.6 1.6 1.6 1.6 1.6 1.6 1.6 1.6 1.6

T.C. 20.2 21.7 21.1 23.6 26.1 22.2 23.1 22.0 24.7 27.1 24.3 24.5 23.0 25.8 28.1

S.C. 20.4 18.9 15.1 15.5 12.5 22.4 21.7 17.4 18.0 14.1 24.5 24.5 19.6 20.4 15.6

K.W. 1.8 1.8 1.8 1.8 1.8 1.8 1.8 1.8 1.8 1.8 1.8 1.8 1.8 1.8 1.8

T.C. 19.5 20.2 19.8 21.7 24.1 21.4 21.9 20.6 22.8 25.2 23.2 23.6 21.4 23.9 26.3

S.C. 19.6 17.9 14.4 14.3 11.8 21.5 20.6 16.4 17.0 13.3 23.4 23.3 18.5 19.7 14.8

K.W. 2.0 2.0 2.1 2.0 2.0 2.0 2.0 2.1 2.0 2.0 2.0 2.0 2.1 2.0 2.0

T.C. 18.1 18.7 18.3 20.1 22.6 19.8 20.2 19.0 21.1 23.6 21.5 21.8 19.7 22.0 24.5

S.C. 18.2 17.0 13.7 13.7 11.2 19.9 19.2 15.7 16.2 12.8 21.7 21.4 17.7 18.8 14.3

K.W. 2.4 2.4 2.4 2.4 2.4 2.4 2.4 2.4 2.4 2.4 2.4 2.4 2.4 2.4 2.4

T.C. 16.7 17.2 16.8 18.6 21.2 18.2 18.6 17.4 19.4 21.9 19.8 20.0 18.0 20.2 22.7

S.C. 16.8 16.1 13.0 13.0 10.7 18.4 17.8 15.0 15.4 12.2 20.0 19.5 17.0 17.9 13.8

K.W. 2.7 2.7 2.7 2.7 2.7 2.7 2.7 2.7 2.7 2.7 2.7 2.7 2.7 2.7 2.7

T.C. 15.3 15.7 15.3 17.1 19.7 16.7 17.0 15.8 17.7 20.3 18.1 18.3 16.3 18.4 20.9

S.C. 15.4 15.2 12.4 12.3 10.2 16.9 16.4 14.3 14.7 11.7 18.3 17.7 16.3 17.0 13.3

K.W. 3.0 3.1 3.1 3.1 3.0 3.0 3.1 3.1 3.1 3.0 3.0 3.1 3.1 3.1 3.0

Coil T.C. S.C. KW

Variable Speed

Furnace

Y*(8,L)C*A12 FC/MC/PC32A 1.02 1.04 0.93

Y*(8,L)C*A12 HC30 1.02 1.02 0.93

Y*(8,L)C*A12 HD24 1.04 1.06 0.93

Y*(8,L)C*B12 HD24 1.04 1.06 0.92

Y*9C*B12 HD24 1.04 1.06 0.93

Y*(8,L)C*A12 UC24A 1.04 1.05 0.93

Y*(8,L)C*B12 UC24B 1.04 1.06 0.92

Y*9C*B12 UC24B 1.03 1.05 0.93

Y*(8,L)C*A12 UC30A 1.04 1.05 0.93

Y*(8,L)C*B12 UC30B 1.04 1.06 0.92

Y*9C*B12 UC30B 1.03 1.05 0.93

G*9V*A12 FC/MC/PC24A 1.02 1.04 0.94

G*9V*B12 FC/MC/PC24B 1.02 1.05 0.93

G*9V*A12 FC/MC/PC30A 1.02 1.04 0.94

G*9V*B12 FC/MC/PC30B 1.02 1.05 0.93

G*9V*A12 FC/MC/PC32A 1.02 1.04 0.96

G*9V*A12 HC30 1.02 1.04 0.94

G*9V*A12 HD24 1.03 1.05 0.94

G*9V*B12 HD24 1.04 1.06 0.93

G*9V*A12 UC24A 1.03 1.04 0.94

G*9V*B12 UC24B 1.03 1.05 0.93

G*9V*A12 UC30A 1.03 1.04 0.94

G*9V*B12 UC30B 1.03 1.05 0.93

Coil T.C. S.C. KW

24 Johnson Controls Unitary Products

Page 25

271457-YTG-B-0908

COOLING PERFORMANCE DATA

OUTDOOR UNIT MODEL NO. YZB03011

INDOOR COIL MODEL NO. FC/MC/PC/UC36

CONDENSER

ENTERING AIR

TEMPERATURE

65

75

85

95

105

115

125

NOTE: ALL CAPACITIES ARE NET (KBTUH) WITH INDOOR FAN HEAT ALREADY DEDUCTED AT 1250 BTUH/1000 CFM.

ID CFM 800 1000 1200

ID DB (°F) 80 80 75 80 80 80 80 75 80 80 80 80 75 80 80

ID WB (°F) 57 62 62 67 72 57 62 62 67 57 57 62 62 67 72

T.C. 27.1 29.1 29.2 33.5 37.3 29.0 30.7 30.7 34.8 38.8 31.0 32.2 32.2 36.1 40.2

S.C. 26.7 23.3 20.0 20.6 16.9 28.7 26.6 22.6 23.0 18.3 30.7 29.9 25.1 25.3 19.7

K.W. 1.9 1.9 1.9 1.9 1.9 1.9 1.9 1.9 1.9 1.9 1.9 1.9 1.9 1.9 1.9

T.C. 26.2 27.9 27.8 31.7 35.7 28.1 29.3 29.1 33.0 37.0 29.9 30.7 30.5 34.3 38.2

S.C. 25.9 22.9 19.3 19.9 16.2 27.7 26.0 21.7 22.3 17.6 29.6 29.0 24.1 24.7 19.1

K.W. 2.2 2.2 2.2 2.2 2.2 2.2 2.2 2.2 2.2 2.2 2.2 2.2 2.2 2.2 2.2

T.C. 25.4 26.6 26.3 29.9 34.1 27.1 27.9 27.5 31.2 35.2 28.8 29.1 28.7 32.5 36.2

S.C. 25.1 22.6 18.5 19.1 15.6 26.8 25.3 20.8 21.7 17.0 28.4 28.1 23.2 24.2 18.4

K.W. 2.4 2.4 2.4 2.4 2.4 2.4 2.4 2.4 2.4 2.4 2.4 2.4 2.4 2.4 2.4

T.C. 24.5 25.4 24.8 28.1 32.6 26.1 26.5 25.9 29.4 33.4 27.7 27.6 27.0 30.7 34.2

S.C. 24.3 22.3 17.7 18.4 14.9 25.8 24.7 19.9 21.0 16.4 27.3 27.2 22.2 23.6 17.8

K.W. 2.7 2.7 2.7 2.7 2.7 2.7 2.7 2.7 2.7 2.7 2.7 2.7 2.7 2.7 2.7

T.C. 23.1 23.7 23.4 26.3 30.3 24.5 24.8 24.3 27.4 30.4 26.0 26.0 25.2 28.4 30.4

S.C. 22.9 21.4 17.2 17.8 14.2 24.3 23.5 19.4 20.2 16.9 25.7 25.6 21.6 22.7 19.5

K.W. 3.1 3.1 3.1 3.0 3.0 3.1 3.1 3.1 3.0 3.0 3.1 3.0 3.1 3.0 3.0

T.C. 21.7 22.0 21.9 24.6 28.2 23.0 23.2 22.6 25.4 27.4 24.3 24.4 23.4 26.1 26.7

S.C. 21.5 20.6 16.8 17.2 13.5 22.8 22.4 18.9 19.5 17.4 24.0 24.1 21.1 21.8 21.2

K.W. 3.4 3.4 3.4 3.4 3.4 3.4 3.4 3.4 3.4 3.4 3.4 3.4 3.4 3.4 3.4

T.C. 20.3 20.4 20.5 22.9 26.0 21.5 21.6 21.0 23.4 24.5 22.7 22.9 21.6 23.9 23.1

S.C. 20.1 19.8 16.4 16.5 12.9 21.3 21.2 18.4 18.8 17.9 22.4 22.7 20.5 21.0 22.9

K.W. 3.8 3.8 3.8 3.8 3.7 3.8 3.8 3.8 3.8 3.7 3.8 3.8 3.8 3.8 3.7

Multipliers for determining the performance with other indoor sections.

NOTE: For dry bulb temperatures different than those listed (between 73-87 F), sensible capacity increases by 1060 BTUH per 1000 CFM per degree above the listed

temperature and decreases by 1060 BTUH per 1000 CFM per degree below the listed temperature.

Air Handler Coil T.C. S.C. KW

MA12B FC/MC36B 1.00 1.00 1.00

MV12B FC/MC36B 0.99 1.00 0.96

MV16C FC/MC36C 0.99 1.00 0.96

AHP30 – 1.00 1.00 1.00

AHP36 – 1.00 0.99 1.00

F2FP036 – 1.01 1.00 1.00

AV36 – 1.03 1.00 0.96

– HC36 1.01 0.99 1.00

– HD36 1.01 1.02 1.00

Continued on Page 26.

Johnson Controls Unitary Products 25

Page 26

271457-YTG-B-0908

Variable Speed

Furnace

PV8*A12 FC/MC/PC36A 1.02 0.98 1.01

PV9*A12 FC/MC/PC36A 1.01 0.97 1.01

PV8*B16 FC/MC/PC36B 1.02 0.98 1.03

P(C,V)9*B12 FC/MC/PC36B 1.01 0.97 1.01

PV8*C16 FC/MC/PC36C 1.02 0.98 1.03

P(C,V)9*C16 FC/MC/PC36C 1.02 0.98 1.03

Y*(8,L)C*A12 FC/MC/PC32A 1.01 1.03 0.99

Y*(8,L)C*B12 FC/MC/PC35B 1.02 1.04 0.95

Y*9C*B12 FC/MC/PC35B 1.02 1.03 0.97

Y*(8,L)C*C16 FC/MC/PC35C 1.02 1.04 0.94

Y*(8,L)C*C20 FC/MC/PC35C 1.03 1.06 0.94

Y*9C*C16 FC/MC/PC35C 1.02 1.04 0.94

Y*9C*C20 FC/MC/PC35C 1.02 1.04 0.94

Y*(8,L)C*A12 FC/MC/PC36A 1.01 1.00 0.95