A

Y

628770-YTG-C-0712

®

TECHNICAL GUIDE

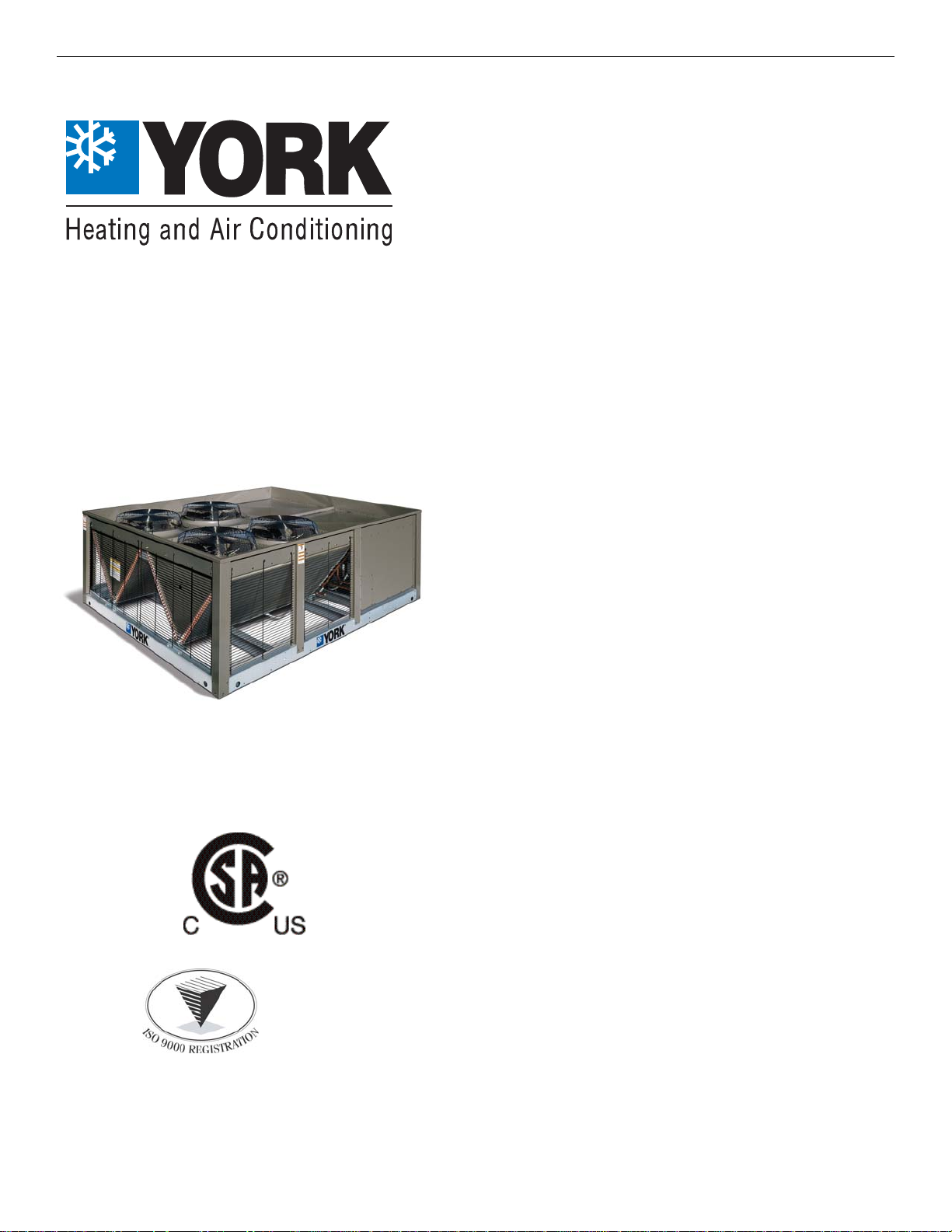

SPLIT-SYSTEM

IR-COOLED CONDENSING UNITS

D360, 480 & 600

30 THRU 50 NOMINAL TONS

Description

These units are completely assembled, piped and wired at the factory

to provide one-piece shipment and rigging. Each unit is pressurized

with a holding charge of Refrigerant R-410A for storage and/or shipping.

The compact design, clean styling, low silhouette, and quiet operation

make these condensing units suitable for almost any outdoor location.

On rooftops . . . because they weigh much less than a single package

unit of similar capacity and are much easier to rig and support. At

ground level . . . because their ample sub-cooling capacity allows them

to be located three or more stories below the evaporator coil.

Every condenser coil is pressurized with air to 325 psig and leak

tested under water. After assembly, the unit is pressurized with a combination of Refrigerant R-410A and nitrogen to 450 psig for pressure

testing and additional leak testing. During this pressure test, the operation of the high pressure control is checked. As the unit is being evacuated and dehydrated, the operation of the low pressure control is

checked. Every compressor, condenser fan motor, crankcase heater,

and electrical control circuit is checked to assure a trouble-free startup and years of reliable operation.

The condenser fan guards are vinyl-coated to provide additional rust

protection and to enhance the appearance of the unit.

Compressors are mounted on rubber isolators to reduce the transmission of vibration. Vertical discharge condenser fans direct sound

upward and away from any surrounding structures.

ISO 9001

Certified Quality

Management System

All sheet metal parts are constructed of commercial grade galvanized

steel. After fabrication, each part is thoroughly cleaned to remove any

grease or dirt from its surfaces. The external parts are coated with a

powder paint to assure a quality finish for many years. This UL

approved coating system has passed the 1000 hour, 20% salt spray

test per ASTM Standard B117.

All models include a 1-year limited warranty on the complete unit. An

additional 4-year extended compressor warranty is available as an

option on all models.

A matching line of Evaporator Blower units is also offered to meet your

precise capacity and air handling requirements.

628770-YTG-C-0712

Table of Contents

Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Table of Contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Condensing Unit Accessories. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Guide Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Physical Data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Unit Limitations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Cooling Ratings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Capacity Performance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Sound Performance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Electrical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Typical Wiring Diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Typical Field Wiring Diagrams. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Weight And Dimension’s . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

2 Unitary Products Group

628770-YTG-C-0712

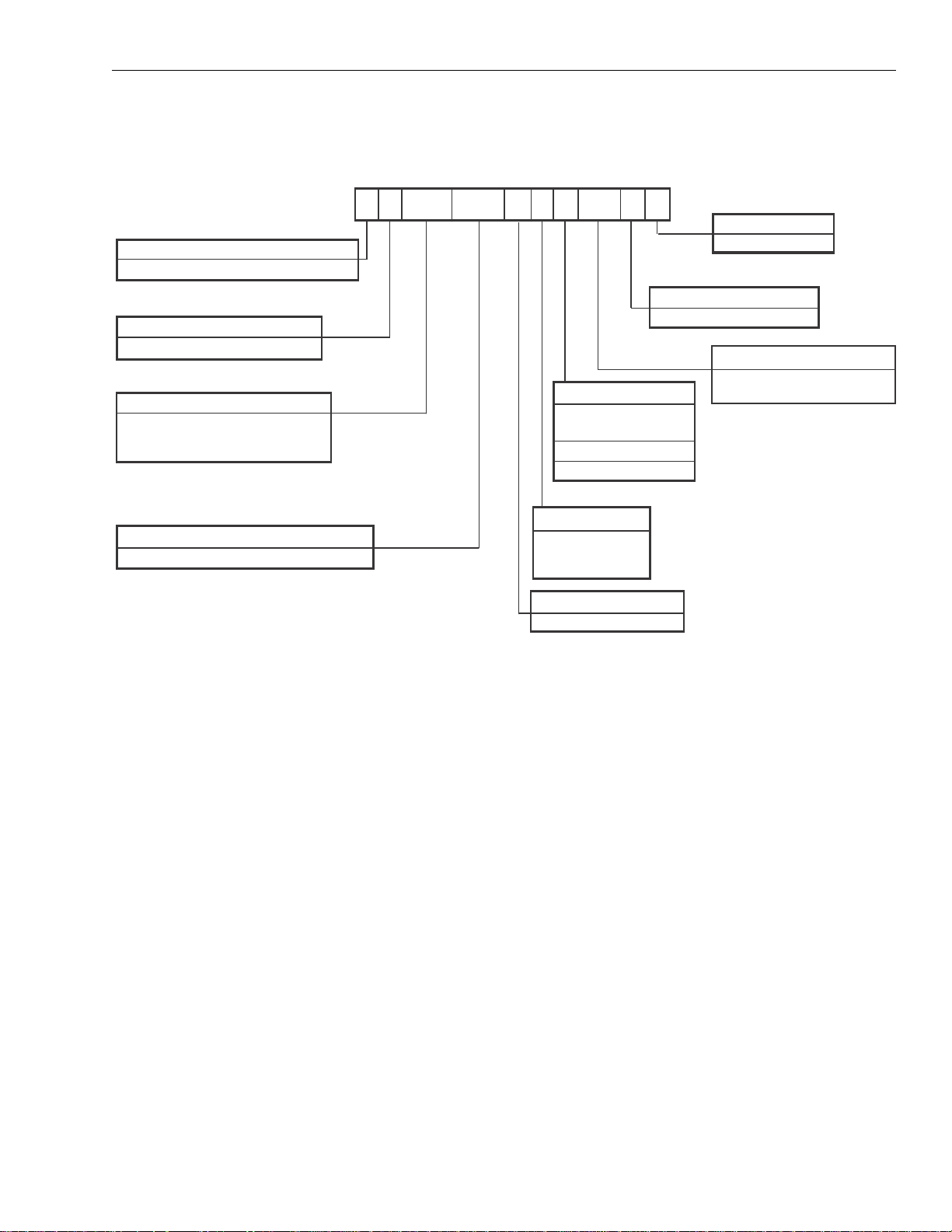

Product Nomenclature

Configured Split Condenser Model Number Nomenclature

Product Category

Y = Split System, Condenser, AC, R-410A

Product Identifier

D = Standard Efficiency, 4-Pipe, R-410A

Nominal Cooling Capacity - MBH

360 = 30 Ton

480 = 40 Ton

600 = 50 Ton

Heat Type & Nominal Heat Capacity

C00 = Cooling Only

Y

D

360

C00 A

A

2

Installation Options

A = None

B = Option 1

Options

1 = Disconnect

Voltage

2 = 208/230-3-60

4 = 460-3-60

5 = 575-3-60

A = Standard Motor

AA

Airflow

2

A

Product Style

A = Style A

Product Generation

1 = First Generation

Product Options

AA = None

TA = Technicoat Condenser Coil

Unitary Products Group 3

Condensing Unit Features and Benefits

628770-YTG-C-0712

• Meets or exceeds ASHRAE 90.1 standards.

• Scroll compressors provide both high efficiency and reliability.

• Simplicity

• Dual refrigerant circuits.

• Condenser coils are constructed of copper tubes and

aluminum fins for durability and long lasting efficient

operation.

• Crankcase heaters that will be de-energized when the

compressor is operating.

• Both high and low pressure controls. Since these controls are self-contained, there are no capillary lines to be

damaged.

• Solid state or internal line break compressor motor protection.

• Class 2, 24-volt thermostat control circuit.

• Factory installed service valves are standard.

• Two filter-driers are shipped in the unit's control box for

field installation in the liquid line near the condensing

unit.

• Copper stub-outs are factory mounted on the suction

and liquid line service valves to simplify the field piping

connections.

• Multiple controls to provide stable system operation at

ambient temperatures down to 40ºF with kits available

for operation to 0ºF.

®

Controls

• Capacity staging for more economical operation and

more even temperature levels within the conditioned

space.

• A lockout circuit to prevent the unit from cycling on safety

control.

• Pump-out on unit startup to prevent liquid refrigerant

returning to the compressor is standard on all models.

• Inherently protected condenser fan motors.

• V-Coil Design with exterior service port connections.

• Five-minute anti-short cycle timer and minimum compressor run time.

• Factory installed disconnect and Technicoat coils option.

• Self contained high and low pressure controls.

Condensing Unit Accessories

• Low ambient VFD control to 0° F.

• Phase Monitors - Designed to prevent unit damage. The

phase monitor will shut the unit down and out-of phase

condition.

• Hot Gas Bypass Kit - That will provide a metered flow of

compressor discharge gas to the system’s evaporator

coil during reduced load operation.

• Optional skid for fork truck handling (requires 96” length

forks).

4 Unitary Products Group

628770-YTG-C-0712

Guide Specifications

SPLIT SYSTEM COOLING ONLY CONDENSING

UNITS

MODELS YD360, YD480 AND YD600

THE INSTALLER SHALL:

• Furnish York

in accordance with the performance schedule shown on

the plans, and

• Install each unit as shown on the plans in accordance

with:

• The manufacturers recommendations and

• All applicable national and local codes

EACH UNIT SHALL BE:

• CSA approved.

• Completely assembled for one-piece shipping and rigging.

• Leak pressure and functionally tested at the factory to

assure a trouble-free start-up after installation.

• Covered by a 1-year limited parts warranty on the complete unit.

• In current production with published literature available

to check performance, limitations, specifications, power

requirements, dimensions, operation and appearance.

EACH UNIT SHALL HAVE:

• A steel angle frame to provide the rigid support required

for shipping, rigging and years of dependable operation.

• Zinc-coated steel that has been finished by a powder

paint process to provide a long lasting, quality appearance.

• Removable panels for easy access to all internal components during maintenance and service.

®

air-cooled condensing units or equivalent

THE DIMENSIONS OF EACH UNIT SHALL:

• Not exceed those specified on the plans.

EACH COMPRESSOR SHALL:

• Be mounted on isolators to minimize the transmission of

vibration.

ALL CONDENSER COILS SHALL:

• Be draw through design.

• Be constructed of copper tubes arranged in staggered

rows and mechanically expanded into aluminum fins.

THE CONDENSER FAN MOTOR(S) SHALL:

• Be directly connected to the condenser fans.

• Have permanently lubricated ball bearings.

• Have inherent overload protection.

• Motors shall be three phase.

• The propeller-type condenser fans shall be arranged for

vertical discharge of the condenser air.

THE WIRING FOR EACH UNIT SHALL INCLUDE:

• A crankcase heater (one per compressor)

• All 24-volt temperature control circuit.

• Both high and low pressure cutouts.

• Solid-state or internal line break compressor motor protection.

• Condenser fan motor control to assure stable operation

at ambient temperatures down to 40ºF.

THE REFRIGERANT PIPING of each system shall include:

• A filter-drier shipped for field installation.

Unitary Products Group 5

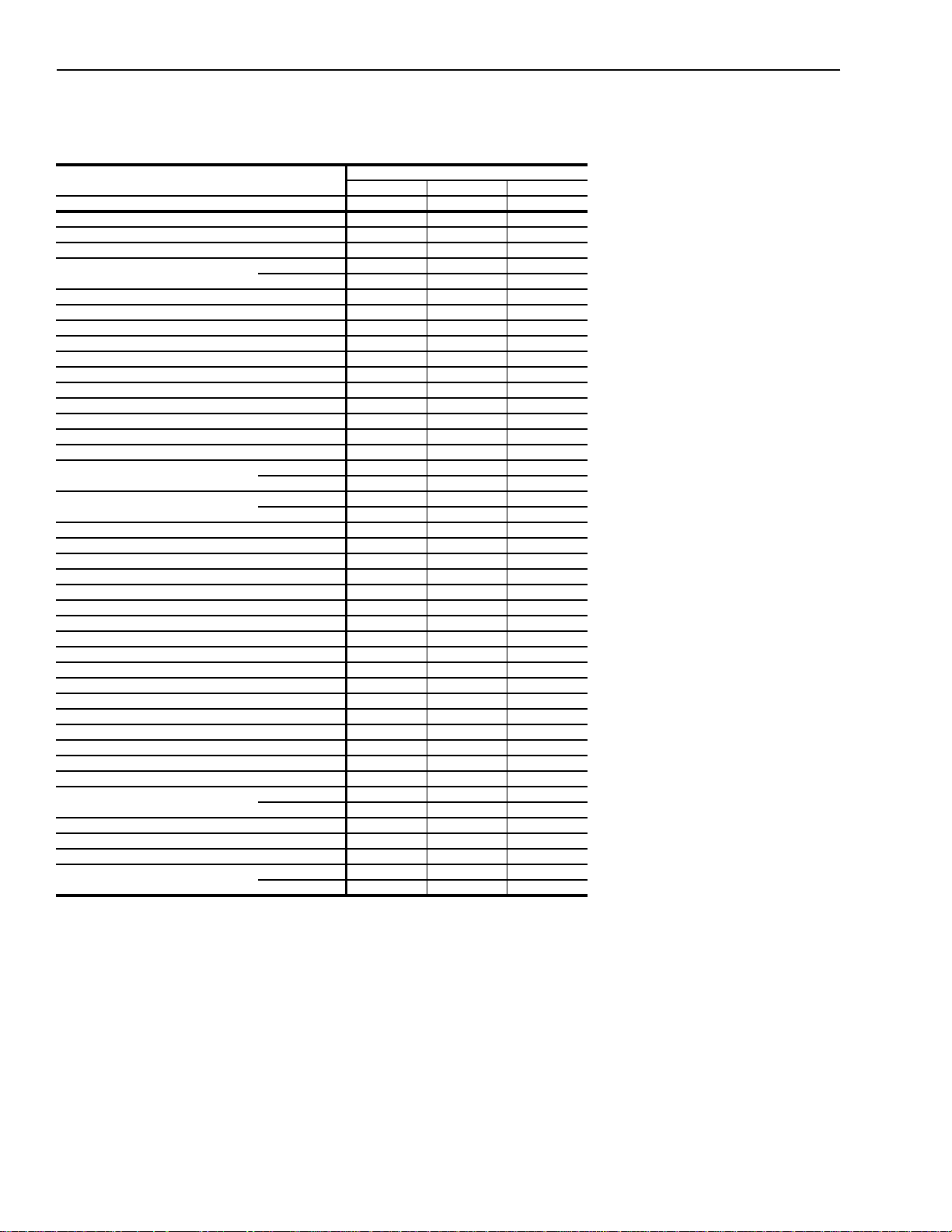

Physical Data

YD360 thru 600 Physical Data

Component

YD360 YD480 YD600

Nominal Tonnage 30 40 50

REFRIGERANT

Refrigerant type R-410A R-410A R-410A

Holding charge (lb)

Operating Charge (lb)

1

2

System #1 35.0 47.0 51.0

System #2 35.0 47.0 51.0

1.0 1.0 1.0

DIMENSIONS (inches)

Length 128.5 128.5 128.5

Width 88.5 88.5 88.5

Height 37.5 57.7 57.7

WEIGHTS (lb)

Shipping 1875 2315 2345

Operating 1895 2347 2381

COMPRESSORS

Type Tandem Scroll Tandem Scroll Tandem Scroll

Quantity 2 2 2

Cooling

Nominal Capacity (Tons)

Capacity Stages

System #1 15 20 25

System #2 15 20 25

System #1 2 2 2

System #2 2 2 2

SYSTEM DATA

No. Refrigeration Circuits 2 2 2

Suction Line OD (in.) 1 5/8 1 5/8 1 5/8

Liquid Line OD (in.) 7/8 7/8 7/8

OUTDOOR COIL DATA

Face area (Sq. Ft.) System #1 32.5 45.5 52.0

System #2 32.5 45.5 52.0

Rows 2 2 2

Fins per inch 16 16 16

Tube diameter (in.) 3/8 3/8 3/8

Circuitry Type Interlaced Interlaced Interlaced

Refrigerant Control --- --- ---

CONDENSER FAN DATA

No. Fans / Diameter (in.) 4/30 4/30 4/30

Type Axial Axial Axial

Drive type Direct Direct Direct

No. speeds 1 1 1

Number of motors

Motor HP (ea.) 1 1/2 1 1/2 1 1/2

3

Rotation

System #1 2 2 2

System #2 2 2 2

CW CW CW

RPM 1140 1140 1140

Nominal CFM

1

Holding Charge is the amount in the unit as shipped from the factory.

2

Includes matched evaporator unit with 25 ft of piping.

3

When viewing the shaft end of the motor.

System #1 15400 19400 19900

System #2 15400 19400 19900

Models

628770-YTG-C-0712

6 Unitary Products Group

628770-YTG-C-0712

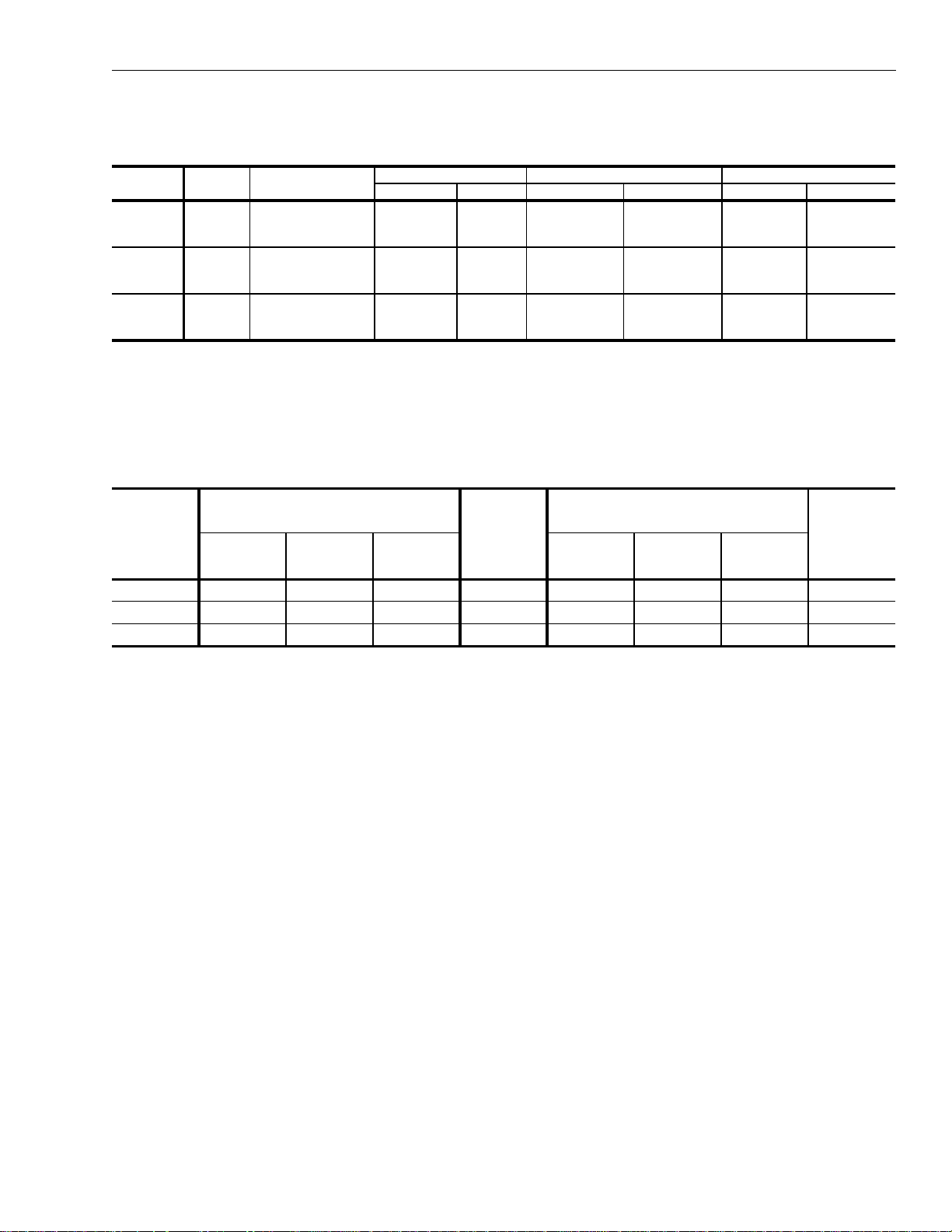

Unit Limitations

Condenser Unit limitations

Model

YD360 30

YD480 40

YD600 50

1

2

Nominal

Tonnage

Unit Voltage

208/230-3-60 187 252

575-3-60 540 630

208/230-3-60 187 252

575-3-60 540 630

208/230-3-60 187 252

575-3-60 540 630

Rated in accordance with AHRI Standard 110, Range “A” Utilization Voltage.

Low Ambient accessories are available to permit stable system operation at ambient temperatures down to 0°F.

Applied Voltage

2

Min

1

Outdoor DB Temp Cooling (°F) Indoor DB Temp Cooling (°F)

Max Max Min

125 40 86 68460-3-60 432 504

125 40 86 68460-3-60 432 504

125 40 86 68460-3-60 432 504

†

Max Min

Cooling Ratings

Cooling Ratings

Condensing Unit Only

Outdoor

Unit

YD360 333 29.9 11.1 ND360 375 10.0 11.1 12,000

YD480 469 37.4 12.5 ND480 500 10.0 10.8 16,000

YD600 576 50.0 11.5 ND600 620 10.0 10.4 17,500

1

2

3

Gross Capacity

(MBH)

Testing in accordance with the Unitary Large Equipment certification program, which is based on AHRI Standard 340/360.

Condensing unit only ratings are at 45 F SST and 95 F entering-air temperature.

Deduct 1 MBH when a unit operates at 208 volts.

2

kW EER

Indoor

Unit

Gross Capacity

System Cooling Capacity

3

(MBH)

EER IEER

1

Rated

Airflow

(CFM)

EER = Energy Efficiency Ratio at full load - the cooling capacity in Btu’s per hour (Btuh) divided by the power input in watts, expressed in Btuh per

watt (Btuh/watt).

EER; condensing unit only ratings based on 45º F SST and 95ºF entering outdoor air temperature.

IEER - A single number cooling part-load efficiency figure that is calculated based on equipment stages and EER at these capacity stages (ANSI/

AHRI STD 340/360 - 2007)

LEGEND

EER = Energy Efficiency Ratio

SST = Saturated Suction Temperature

AHRI = Air Conditioning and Refrigeration Institute

IEER = Integrated Energy Efficiency Ratio

Unitary Products Group 7

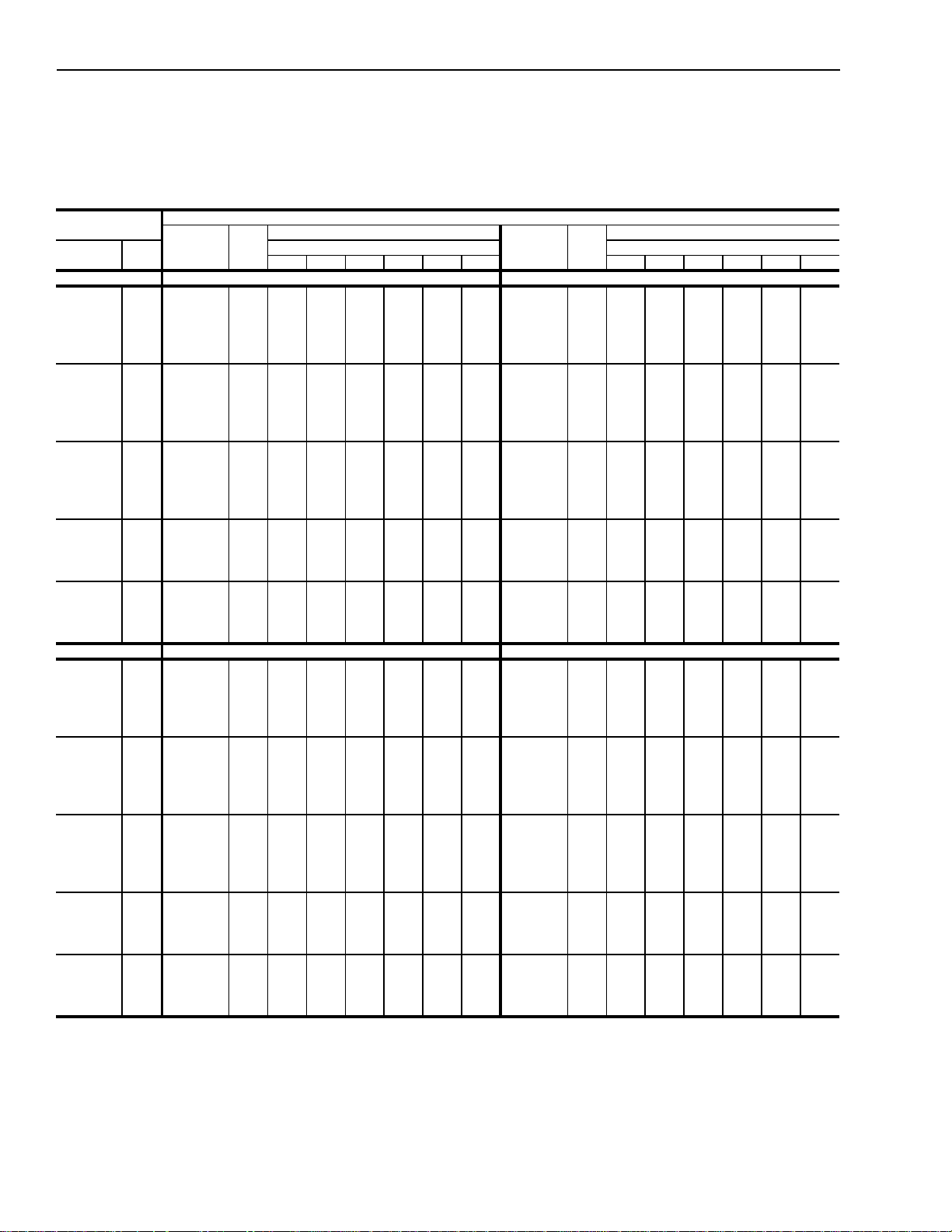

Capacity Performance

Condenser and Air Handling Cooling Capacities

YD360/ND360 (30 Ton)

Air on

Evaporator Coil

CFM

9000

10500

12000

13500

15000

9000

10500

12000

13500

15000

WB

(°F)

Total

Capacity

(MBh)

77 440.3 26.1 221.9 185.2 148.6 - - - 424.8 28.5 215.2 179.0 142.8 - - 72 411.6 25.5 272.6 235.9 199.2 162.5 - - 396.5 28.0 265.3 229.1 192.9 156.7 - 67 382.9 24.9 323.2 286.6 249.9 213.2 176.5 - 368.3 27.5 315.5 279.3 243.1 206.8 170.6 62 318.5 24.4 318.5 301.8 265.1 228.4 191.8 155.1 311.2 26.9 311.2 300.3 264.1 227.9 191.7 155.5

57 347.4 24.2 347.4 347.4 312.7 276.0 239.3 202.7 335.5 26.8 335.5 335.5 304.9 268.7 232.5 196.3

77 454.2 26.4 247.9 202.9 157.8 - - - 437.9 28.7 236.3 194.0 151.8 - - 72 424.6 25.8 301.8 256.7 211.7 166.6 - - 408.7 28.2 289.6 247.3 205.1 162.8 - 67 394.9 25.2 355.6 310.6 265.5 220.5 175.4 - 379.6 27.7 342.9 300.6 258.4 216.1 173.9 62 328.6 24.6 328.6 320.2 281.7 238.2 191.6 146.6 320.8 27.2 320.8 315.4 280.7 238.5 196.2 154.0

57 358.3 24.4 358.3 358.3 332.3 290.0 242.2 197.1 345.9 27.0 345.9 345.9 324.2 281.9 239.6 197.4

77 468.1 26.7 274.0 220.6 167.1 - - - 451.0 29.0 257.4 209.1 160.8 - - 72 437.5 26.1 331.0 277.6 224.1 170.7 - - 421.0 28.5 313.9 265.5 217.2 168.9 - 67 407.0 25.4 388.0 334.6 281.1 227.7 174.3 - 391.0 27.9 370.3 322.0 273.7 225.4 177.1 62 338.6 24.9 338.6 338.6 298.3 248.0 191.5 138.1 330.4 27.4 330.4 330.4 297.4 249.1 200.8 152.4

57 369.3 24.7 369.3 369.3 351.8 303.9 245.0 191.6 356.2 27.2 356.2 356.2 343.4 295.1 246.7 198.4

72 448.4 26.2 338.1 287.0 235.8 184.6 - - 430.4 28.6 326.0 277.3 228.5 179.8 - 67 417.1 25.5 399.7 346.9 295.7 244.5 193.3 - 399.7 28.0 385.4 336.7 288.0 239.2 190.5 62 347.0 25.0 347.0 347.0 313.7 264.1 211.4 160.2 337.8 27.5 337.8 337.8 312.9 264.2 215.4 166.7

57 378.4 24.8 378.4 378.4 369.7 321.3 267.3 216.1 364.1 27.3 364.1 364.1 357.7 309.0 260.3 211.5

72 459.3 26.3 345.3 296.3 247.4 198.4 - - 439.7 28.7 338.2 289.0 239.9 190.7 - 67 427.2 25.7 411.4 359.3 310.3 261.3 212.3 - 408.4 28.1 400.5 351.4 302.2 253.1 203.9 62 355.5 25.1 355.5 355.5 329.2 280.2 231.2 182.3 345.2 27.6 345.2 345.2 328.4 279.3 230.1 181.0

57 387.6 24.9 387.6 387.6 387.6 338.6 289.6 240.7 372.1 27.4 372.1 372.1 372.1 322.9 273.8 224.7

77 409.2 30.9 208.5 172.7 137.0 - - - 388.6 34.2 199.2 164.5 129.8 - - 72 381.4 30.4 258.1 222.4 186.6 150.9 - - 362.5 33.7 248.3 213.6 178.9 144.2 - 67 353.7 30.0 307.7 272.0 236.2 200.5 164.8 - 336.3 33.2 297.4 262.7 228.0 193.3 158.6 62 303.9 29.5 303.9 298.8 263.1 227.3 191.6 155.8 295.7 32.8 295.7 293.1 262.5 227.8 193.1 158.4

57 323.6 29.4 323.6 323.6 297.2 261.4 225.7 189.9 309.1 32.7 309.1 309.1 286.3 251.6 216.9 182.2

77 421.5 31.1 224.6 185.1 145.7 - - - 400.6 34.3 223.8 179.3 138.3 - - 72 392.9 30.6 277.4 237.9 198.5 159.0 - - 373.6 33.9 272.7 231.7 190.7 149.6 - 67 364.3 30.2 330.2 290.7 251.2 211.8 172.3 - 346.6 33.4 321.6 284.0 243.0 202.0 160.9 62 313.1 29.7 313.1 310.6 279.8 238.8 200.8 161.3 304.8 33.0 304.8 303.5 279.8 238.0 197.8 156.8

57 333.4 29.6 333.4 333.4 316.1 273.8 237.1 197.6 318.6 32.9 318.6 318.6 305.2 262.8 223.1 182.1

77 433.9 31.3 240.8 197.6 154.4 - - - 412.5 34.5 248.5 194.2 146.9 - - 72 404.4 30.9 296.7 253.5 210.3 167.1 - - 384.7 34.0 297.2 249.8 202.4 155.1 - 67 375.0 30.4 352.7 309.5 266.3 223.0 179.8 - 357.0 33.6 345.8 305.4 258.0 210.7 163.3 62 322.3 29.9 322.3 322.3 296.5 250.2 210.1 166.8 313.9 33.1 313.9 313.9 297.2 248.3 202.4 155.1

57 343.2 29.8 343.2 343.2 334.9 286.2 248.5 205.3 328.1 33.1 328.1 328.1 324.0 273.9 229.3 181.9

72 412.3 31.0 313.9 267.6 221.3 175.1 - - 384.1 34.2 311.6 263.0 214.5 165.9 - 67 382.3 30.5 371.2 326.5 280.2 234.0 187.7 - 356.4 33.8 350.8 319.0 273.4 224.8 176.2 62 328.6 30.0 328.6 328.6 312.1 264.2 219.5 173.3 313.2 33.3 313.2 313.2 303.0 253.7 205.9 157.3

57 349.9 29.9 349.9 349.9 345.7 296.7 253.2 206.9 327.6 33.3 327.6 327.6 325.5 275.5 228.4 179.8

72 420.2 31.0 331.0 281.7 232.4 183.1 - - 383.5 34.4 326.1 276.3 226.5 176.7 - 67 389.7 30.6 389.7 343.5 294.2 244.9 195.6 - 355.8 34.0 355.8 332.7 288.7 239.0 189.2 62 334.9 30.1 334.9 334.9 327.6 278.3 229.0 179.7 312.5 33.5 312.5 312.5 308.9 259.1 209.3 159.5

57 356.6 29.9 356.6 356.6 356.6 307.3 257.9 208.6 327.0 33.5 327.0 327.0 327.0 277.2 227.4 177.6

Total

1

Input

2

(kW)

Sensible Capacity (MBh)

Return Dry Bulb (°F) Return Dry Bulb (°F)

90 85 80 75 70 65 90 85 80 75 70 65

75°F 85°F

95°F 105°F

Temperature of Air on Condenser Coil

Total

Capacity

(MBh)

Total

1

Input

(kW)

628770-YTG-C-0712

Sensible Capacity (MBh)

2

8 Unitary Products Group

628770-YTG-C-0712

YD360/ND360 (30 Ton) (Continued)

Air on

Evaporator Coil

CFM

9000

10500

12000

13500

15000

1

WB

(°F)

These capacities are gross ratings. For net capacity, deduct supply air blower motor, MBh. Example: Refer to the appropriate Blower

Total

Capacity

(MBh)

77 368.1 37.4 189.9 156.2 122.6 - - - 347.5 40.7 180.6 148.0 115.4 - - 72 343.5 37.0 238.5 204.8 171.2 137.5 - - 324.5 40.2 228.6 196.0 163.4 130.8 - 67 318.9 36.5 287.0 253.4 219.7 186.1 152.4 - 301.5 39.7 276.7 244.1 211.5 178.9 146.3 62 287.4 36.1 287.4 287.4 262.0 228.3 194.7 161.0 279.1 39.5 279.1 279.1 261.4 228.8 196.2 163.6

57 294.6 36.1 294.6 294.6 275.4 241.8 208.1 174.5 280.1 39.5 280.1 280.1 264.5 231.9 199.3 166.7

77 379.6 37.5 223.1 173.6 131.0 - - - 358.7 40.7 222.3 167.8 123.6 - - 72 354.3 37.1 268.0 225.4 182.9 140.3 - - 335.0 40.3 263.3 219.2 175.1 131.0 - 67 328.9 36.6 313.0 277.3 234.8 192.2 149.6 - 311.2 39.8 304.4 270.6 226.5 182.4 138.3 62 296.4 36.3 296.4 296.4 279.9 237.3 194.7 152.2 288.1 39.5 288.1 288.1 280.0 236.6 191.7 147.6

57 303.9 36.2 303.9 303.9 294.3 251.7 209.1 166.5 289.1 39.6 289.1 289.1 283.4 240.6 195.1 151.0

77 391.2 37.6 256.2 190.9 139.4 - - - 369.9 40.8 264.0 187.5 131.9 - - 72 365.1 37.2 297.6 246.1 194.6 143.1 - - 345.4 40.3 298.0 242.4 186.7 131.1 - 67 338.9 36.7 338.9 301.3 249.8 198.3 146.8 - 320.9 39.9 320.9 297.2 241.6 185.9 130.3 62 305.5 36.4 305.5 305.5 297.8 246.3 194.8 143.3 297.1 39.6 297.1 297.1 297.1 244.4 187.2 131.6

57 313.1 36.4 313.1 313.1 313.1 261.6 210.1 158.6 298.1 39.7 298.1 298.1 298.1 249.3 190.9 135.3

72 355.9 37.5 309.4 258.5 207.6 156.7 - - 327.7 40.8 307.1 253.9 200.8 147.6 - 67 330.4 37.0 330.4 311.6 266.5 215.7 164.8 - 304.5 40.3 304.5 304.2 259.7 206.5 153.3 62 297.8 36.7 297.8 297.8 294.0 243.1 192.2 141.4 282.4 40.0 282.4 282.4 282.4 232.5 178.6 125.4

57 305.2 36.7 305.2 305.2 305.2 254.4 203.5 152.6 282.9 40.1 282.9 282.9 282.9 233.2 178.6 125.5

72 346.7 37.8 321.1 270.9 220.7 170.4 - - 310.0 41.2 310.0 265.5 214.8 164.1 - 67 321.9 37.3 321.9 321.9 283.3 233.0 182.8 - 288.0 40.7 288.0 288.0 277.8 227.1 176.4 62 290.1 37.0 290.1 290.1 290.1 239.9 189.6 139.4 267.7 40.4 267.7 267.7 267.7 220.7 170.0 119.3

57 297.4 37.0 297.4 297.4 297.4 247.1 196.9 146.7 267.8 40.5 267.8 267.8 267.8 217.1 166.4 115.7

Total

1

Input

2

(kW)

Sensible Capacity (MBh)

Return Dry Bulb (°F) Return Dry Bulb (°F)

90 85 80 75 70 65 90 85 80 75 70 65

115°F 125°F

Performance Table for the BHP of the supply air blower motor, MBh = 3.415 x kW and kW = BHP x 0.746 nameplate rated motor

efficiency.

2

These ratings include the condenser fan motors and the compressor motors but not the supply air blower motor.

Temperature of Air on Condenser Coil

Total

Capacity

(MBh)

Total

1

Input

(kW)

Sensible Capacity (MBh)

2

Unitary Products Group 9

YD480/ND480 (40 Ton)

Air on

Evaporator Coil

CFM

WB

(°F)

12000

14000

16000

18000

20000

12000

14000

16000

18000

20000

77 579.6 32.8 292.9 247.9 202.9 - - - 530.5 35.1 268.7 224.3 179.9 - - 72 530.4 31.6 355.0 310.0 265.0 220.0 - - 496.5 34.4 333.0 288.6 244.2 199.8 - 67 481.2 30.3 417.1 372.1 327.1 282.2 237.2 - 462.6 33.7 397.3 352.9 308.5 264.1 219.7 62 451.0 30.3 455.0 418.2 373.2 328.2 283.2 238.2 429.4 33.2 429.4 389.1 344.7 300.3 255.9 211.5

57 448.9 29.6 448.9 448.9 437.7 392.7 347.7 302.7 421.3 33.0 421.3 421.3 395.3 351.0 306.6 262.2

77 600.7 32.8 308.8 259.6 210.4 - - - 556.3 35.3 292.2 242.4 192.5 - - 72 549.4 31.5 372.5 323.3 274.1 224.9 - - 520.6 34.6 361.0 311.2 261.3 211.4 - 67 498.0 30.3 436.1 386.9 337.7 288.5 239.3 - 485.0 34.0 429.8 380.0 330.1 280.2 230.3 62 466.9 30.3 468.9 435.1 385.9 337.8 287.4 238.2 450.2 33.4 450.2 418.7 368.8 318.9 269.0 219.1

57 464.9 29.5 464.9 464.9 453.3 406.6 354.9 305.7 441.7 33.2 441.7 441.7 423.0 373.1 323.2 273.3

77 621.8 32.8 324.8 271.4 217.9 - - - 582.0 35.6 315.8 260.4 205.1 - - 72 568.3 31.5 390.0 336.6 283.1 229.7 - - 544.7 34.9 389.1 333.7 278.4 223.0 - 67 514.9 30.3 455.2 401.7 348.3 294.9 241.4 - 507.4 34.2 462.4 407.0 351.6 296.3 240.9 62 482.8 30.2 482.8 452.0 398.5 347.3 291.7 238.2 471.1 33.6 471.1 448.2 392.9 337.5 282.1 226.7

57 481.0 29.5 481.0 481.0 468.9 420.5 362.1 308.6 462.2 33.5 462.2 462.2 450.6 395.2 339.9 284.5

72 583.2 32.0 421.4 367.3 313.2 259.1 - - 554.4 35.0 419.5 362.4 305.3 248.3 - 67 528.6 30.8 498.7 439.6 385.5 331.4 277.3 - 516.5 34.4 493.9 442.9 385.8 328.7 271.6 62 495.6 30.7 495.6 480.2 440.9 387.9 332.7 278.6 479.4 33.8 479.4 468.0 431.0 373.9 316.8 259.7

57 493.6 30.0 493.6 493.6 487.6 435.9 379.4 325.3 470.4 33.6 470.4 470.4 464.6 407.5 350.4 293.3

72 598.1 32.5 452.8 398.0 343.3 288.5 - - 564.1 35.2 450.0 391.2 332.3 273.5 - 67 542.3 31.3 542.3 477.4 422.6 367.9 313.1 - 525.5 34.5 525.5 478.7 419.9 361.0 302.2 62 508.4 31.2 508.4 508.4 483.2 428.5 373.7 318.9 487.8 33.9 487.8 487.8 469.1 410.3 351.4 292.6

57 506.2 30.5 506.2 506.2 506.2 451.4 396.7 341.9 478.6 33.8 478.6 478.6 478.6 419.8 361.0 302.1

77 481.4 37.4 244.5 200.7 156.9 - - - 462.2 41.8 256.0 212.6 169.1 - - 72 462.7 37.3 311.0 267.2 223.4 179.6 - - 446.3 41.6 315.8 272.4 229.0 185.5 - 67 443.9 37.1 377.5 333.7 289.9 246.1 202.3 - 430.4 41.4 375.6 332.2 288.8 245.4 201.9 62 407.8 36.1 403.8 360.0 316.2 272.4 228.6 184.8 405.5 40.9 403.5 363.1 319.7 276.2 232.8 189.4

57 393.7 36.5 393.7 393.7 353.0 309.2 265.4 221.6 382.2 41.0 382.2 382.2 345.7 302.2 258.8 215.4

77 511.8 37.9 275.6 225.1 174.5 - - - 487.2 42.1 293.1 237.7 185.2 - - 72 491.9 37.7 349.6 299.0 248.5 197.9 - - 470.4 41.8 355.9 303.4 250.8 198.3 - 67 472.0 37.6 423.5 373.0 322.4 271.9 221.3 - 453.7 41.6 418.7 369.0 316.5 264.0 211.5 62 433.6 36.5 431.5 402.2 351.7 300.0 250.6 200.0 427.3 41.1 426.3 402.4 350.3 297.2 245.2 192.7

57 418.5 37.0 418.5 418.5 392.7 339.6 291.6 241.0 402.8 41.2 402.8 402.8 378.9 325.2 273.9 221.4

77 542.2 38.3 306.8 249.5 192.2 - - - 512.1 42.3 330.2 262.8 201.2 - - 72 521.1 38.2 388.2 330.9 273.6 216.3 - - 494.5 42.1 395.9 334.3 272.7 211.1 - 67 500.0 38.1 469.6 412.3 355.0 297.7 240.4 - 476.9 41.8 461.7 405.8 344.2 282.6 221.0 62 459.3 37.0 459.3 444.5 387.2 327.6 272.6 215.3 449.1 41.4 449.1 441.7 380.9 318.2 257.7 196.1

57 443.4 37.4 443.4 443.4 432.3 370.0 317.7 260.4 423.4 41.4 423.4 423.4 412.2 348.1 289.0 227.4

72 525.6 38.1 417.7 357.6 297.5 237.4 - - 497.0 42.1 415.9 352.5 289.0 225.5 - 67 504.3 37.9 489.1 446.1 386.0 325.9 265.9 - 479.3 41.8 471.7 428.5 365.1 301.6 238.1 62 463.3 36.9 463.3 455.9 421.1 359.8 300.9 240.8 451.3 41.4 451.3 447.6 403.8 339.7 276.8 213.4

57 447.2 37.3 447.2 447.2 441.7 379.1 321.5 261.4 425.6 41.4 425.6 425.6 420.0 355.3 293.0 229.6

72 530.1 37.9 447.2 384.3 321.4 258.5 - - 499.5 42.1 435.9 370.6 305.3 240.0 - 67 508.6 37.8 508.6 480.0 417.1 354.2 291.3 - 481.7 41.8 481.7 451.2 385.9 320.6 255.2 62 467.2 36.7 467.2 467.2 454.9 392.0 329.2 266.3 453.5 41.3 453.5 453.5 426.7 361.3 296.0 230.7

57 451.0 37.1 451.0 451.0 451.0 388.2 325.3 262.4 427.7 41.4 427.7 427.7 427.7 362.4 297.0 231.7

Total

Capacity

(MBh)

628770-YTG-C-0712

Total

1

Input

2

(kW)

Sensible Capacity (MBh)

Return Dry Bulb (°F) Return Dry Bulb (°F)

90 85 80 75 70 65 90 85 80 75 70 65

75°F 85°F

95°F 105°F

Temperature of Air on Condenser Coil

Total

Capacity

(MBh)

Total

1

Input

(kW)

Sensible Capacity (MBh)

2

10 Unitary Products Group

628770-YTG-C-0712

YD480/ND480 (40 Ton) (Continued)

Air on

Evaporator Coil

CFM

12000

14000

16000

18000

20000

1

WB

(°F)

These capacities are gross ratings. For net capacity, deduct supply air blower motor, MBh. Example: Refer to the appropriate Blower

Total

Capacity

(MBh)

77 443.0 46.3 267.5 224.4 181.3 - - - 423.8 50.8 278.9 236.2 193.6 - - 72 430.0 46.0 320.6 277.6 234.5 191.5 - - 413.6 50.3 325.5 282.8 240.1 197.4 - 67 416.9 45.6 373.8 330.7 287.7 244.6 201.6 - 403.4 49.8 372.0 329.3 286.6 243.9 201.2 62 403.3 45.7 403.3 366.2 323.1 280.1 237.0 193.9 401.0 50.6 401.0 369.3 326.6 283.9 241.2 198.5

57 370.8 45.5 370.8 370.8 338.3 295.2 252.2 209.1 359.3 50.0 359.3 359.3 331.0 288.3 245.6 202.9

77 462.5 46.3 310.5 250.3 195.8 - - - 437.9 50.5 328.0 262.8 206.4 - - 72 448.9 45.9 362.1 307.7 253.2 198.7 - - 427.4 50.0 368.4 312.0 255.5 199.1 - 67 435.3 45.6 413.8 365.1 310.6 256.1 201.6 - 417.0 49.6 408.9 361.1 304.7 248.2 191.8 62 421.1 45.7 421.1 402.5 348.8 294.4 239.9 185.4 414.8 50.3 414.8 402.6 347.4 291.5 234.5 178.1

57 387.1 45.5 387.1 387.1 365.2 310.8 256.3 201.8 371.4 49.8 371.4 371.4 351.5 296.3 238.6 182.2

77 482.1 46.3 353.6 276.1 210.2 - - - 452.0 50.2 377.0 289.4 219.2 - - 72 467.9 45.9 403.6 337.7 271.9 206.0 - - 441.3 49.8 411.4 341.2 271.0 200.8 - 67 453.7 45.6 453.7 399.4 333.5 267.6 201.7 - 430.6 49.3 430.6 392.9 322.7 252.5 182.3 62 438.8 45.7 438.8 438.8 374.6 308.7 242.8 176.9 428.6 50.1 428.6 428.6 368.2 299.2 227.8 157.7

57 403.5 45.5 403.5 403.5 392.2 326.3 260.4 194.5 383.5 49.5 383.5 383.5 372.1 304.4 231.7 161.5

72 468.4 46.1 414.2 347.3 280.5 213.7 - - 439.8 50.1 412.4 342.2 272.0 201.8 - 67 454.2 45.7 454.2 410.9 344.1 277.3 210.4 - 429.2 49.6 429.2 393.3 323.1 252.9 182.7 62 439.3 45.9 439.3 439.3 386.5 319.6 252.8 186.0 427.4 50.4 427.4 427.4 369.2 299.5 228.8 158.5

57 403.9 45.6 403.9 403.9 398.3 331.4 264.6 197.8 382.3 49.8 382.3 382.3 376.6 307.6 236.2 165.9

72 469.0 46.2 424.7 356.9 289.1 221.4 - - 438.4 50.4 413.5 343.2 273.0 202.8 - 67 454.8 45.9 454.8 422.5 354.7 286.9 219.1 - 427.8 49.9 427.8 393.8 323.5 253.3 183.1 62 439.8 46.0 439.8 439.8 398.4 330.6 262.8 195.0 426.1 50.6 426.1 426.1 370.1 299.9 229.7 159.4

57 404.4 45.8 404.4 404.4 404.4 336.6 268.8 201.0 381.1 50.1 381.1 381.1 381.1 310.8 240.6 170.3

Total

1

Input

2

(kW)

Sensible Capacity (MBh)

Return Dry Bulb (°F) Return Dry Bulb (°F)

90 85 80 75 70 65 90 85 80 75 70 65

115°F 125°F

Performance Table for the BHP of the supply air blower motor, MBh = 3.415 x kW and kW = BHP x 0.746 nameplate rated motor

efficiency.

2

These ratings include the condenser fan motors and the compressor motors but not the supply air blower motor.

Temperature of Air on Condenser Coil

Total

Capacity

(MBh)

Total

1

Input

(kW)

Sensible Capacity (MBh)

2

Unitary Products Group 11

YD600/ND600 Air Handler with M1CZ600A Evaporator Coil (50 Ton)

Air on

Evaporator Coil

CFM

WB

(°F)

15000

17500

20000

21750

23500

15000

17500

20000

21750

23500

Total

Capacity

(MBh)

Total

1

Input

2

(kW)

Sensible Capacity (MBh)

Return Dry Bulb (°F) Return Dry Bulb (°F)

90 85 80 75 70 65 90 85 80 75 70 65

75°F 85°F

77 778.4 38.3 415.3 359.0 302.7 - - - 739.6 44.5 405.1 348.7 292.3 - - 72 711.3 40.7 471.4 415.1 358.8 302.5 - - 679.6 45.7 463.0 406.7 350.3 293.9 - 67 644.1 43.1 527.5 471.2 415.0 358.7 302.4 - 619.5 46.8 521.0 464.7 408.3 351.9 295.5 62 618.5 41.7 618.5 580.0 523.8 467.5 411.2 354.9 599.2 45.6 599.2 560.7 504.3 447.9 391.6 335.2

57 629.2 40.1 629.2 573.3 517.0 460.7 404.4 348.1 616.4 44.2 616.4 561.2 504.8 448.4 392.1 335.7

77 803.9 38.1 456.4 392.7 329.1 - - - 760.9 44.6 443.3 379.7 316.2 - - 72 734.5 40.5 517.4 453.8 390.2 326.6 - - 699.1 45.7 506.0 442.5 378.9 315.4 - 67 665.2 42.9 578.5 514.9 451.3 387.7 324.1 - 637.4 46.9 568.7 505.2 441.6 378.1 314.6 62 638.8 41.5 638.8 619.6 569.5 508.3 442.3 378.7 616.4 45.7 616.4 597.1 545.5 482.0 418.4 354.9

57 649.9 39.9 649.9 621.9 562.2 501.2 435.0 371.4 634.1 44.3 634.1 606.5 546.1 482.5 419.0 355.5

77 829.3 37.9 497.4 426.5 355.6 - - - 782.2 44.7 481.5 410.8 340.1 - - 72 757.8 40.3 563.4 492.5 421.6 350.7 - - 718.7 45.8 549.0 478.3 407.6 336.9 - 67 686.3 42.7 629.5 558.5 487.6 416.7 345.8 - 655.2 46.9 616.4 545.7 475.0 404.3 333.6 62 659.1 41.2 659.1 659.1 615.2 549.1 473.3 402.4 633.6 45.7 633.6 633.6 586.7 516.0 445.3 374.6

57 670.6 39.7 670.6 670.6 607.4 541.7 465.5 394.6 651.9 44.3 651.9 651.9 587.3 516.6 445.9 375.2

72 784.2 39.9 617.2 540.1 463.0 386.0 - - 737.6 45.5 588.6 512.9 437.2 361.5 - 67 710.3 42.3 681.9 612.8 535.7 458.7 381.6 - 672.4 46.6 653.0 585.3 509.6 433.8 358.1 62 682.2 40.8 682.2 682.2 670.1 595.4 515.9 438.8 650.3 45.4 650.3 650.3 626.8 551.1 475.4 399.7

57 694.3 39.3 694.3 694.3 667.1 592.6 513.0 435.9 669.0 44.0 669.0 669.0 630.0 554.3 478.6 402.9

72 810.6 39.5 671.0 587.7 504.5 421.2 - - 756.4 45.1 628.3 547.5 466.8 386.1 - 67 734.3 41.9 734.3 667.1 583.9 500.6 417.4 - 689.6 46.3 689.6 624.8 544.1 463.4 382.7 62 705.3 40.5 705.3 705.3 725.0 641.7 558.5 475.2 666.9 45.1 666.9 666.9 666.9 586.2 505.5 424.8

57 717.9 38.9 717.9 717.9 726.8 643.6 560.4 477.1 686.1 43.7 686.1 686.1 672.7 592.0 511.3 430.6

95°F 105°F

77 700.8 50.7 394.8 338.4 281.9 - - - 643.6 56.8 367.7 311.4 255.1 - - 72 647.9 50.6 454.7 398.2 341.8 285.3 - - 603.3 56.7 434.4 378.1 321.8 265.5 - 67 595.0 50.4 514.5 458.1 401.6 345.2 288.7 - 563.1 56.6 501.2 444.9 388.6 332.3 276.0 62 579.8 49.5 579.8 541.3 484.9 428.4 371.9 315.5 542.8 55.9 542.8 508.1 451.8 395.5 339.2 282.9

57 603.6 48.3 603.6 549.1 492.7 436.2 379.7 323.3 564.5 55.9 564.5 510.2 453.9 397.6 341.3 285.0

77 717.9 51.1 430.2 366.7 303.3 - - - 663.4 56.8 416.1 342.4 277.3 - - 72 663.7 50.9 494.6 431.1 367.6 304.2 - - 621.9 56.7 480.2 415.1 350.0 284.9 - 67 609.5 50.8 559.0 495.5 432.0 368.6 305.1 - 580.5 56.7 544.4 487.8 422.7 357.5 292.4 62 594.0 49.8 594.0 574.7 521.6 455.7 394.6 331.2 559.6 56.0 559.6 542.3 491.3 425.0 361.0 295.9

57 618.3 48.7 618.3 591.1 530.0 463.9 403.0 339.6 581.9 55.9 581.9 554.8 493.5 427.0 363.2 298.1

77 735.0 51.5 465.6 395.1 324.6 - - - 683.2 56.9 464.5 373.4 299.5 - - 72 679.5 51.3 534.5 464.0 393.5 323.0 - - 640.5 56.8 526.0 452.1 378.1 304.2 - 67 624.1 51.2 603.4 532.9 462.4 391.9 321.5 - 597.9 56.7 587.6 530.7 456.8 382.8 308.9 62 608.1 50.2 608.1 608.1 558.3 483.0 417.3 346.8 576.4 56.0 576.4 576.4 530.7 454.4 382.8 308.9

57 633.1 49.0 633.1 633.1 567.2 491.6 426.3 355.8 599.3 56.0 599.3 599.3 533.0 456.5 385.1 311.1

72 690.9 51.1 560.0 485.7 411.3 337.0 - - 648.5 56.6 546.8 470.5 394.3 318.0 - 67 634.5 50.9 624.1 557.7 483.4 409.0 334.7 - 605.3 56.5 600.2 552.5 476.2 400.0 323.7 62 618.3 49.9 618.3 618.3 583.6 506.8 434.9 360.6 583.5 55.8 583.5 583.5 553.4 476.0 400.9 324.7

57 643.7 48.8 643.7 643.7 593.0 516.0 444.3 369.9 606.8 55.8 606.8 606.8 555.8 478.3 403.3 327.1

72 702.3 50.8 585.6 507.4 429.2 351.0 - - 656.5 56.4 567.5 488.9 410.4 331.9 - 67 644.9 50.7 644.9 582.5 504.3 426.1 347.9 - 612.7 56.3 612.7 574.2 495.7 417.2 338.6 62 628.5 49.7 628.5 628.5 608.9 530.7 452.5 374.3 590.7 55.6 590.7 590.7 576.1 497.5 419.0 340.5

57 654.3 48.5 654.3 654.3 618.7 540.5 462.3 384.1 614.2 55.6 614.2 614.2 578.6 500.0 421.5 343.0

Temperature of Air on Condenser Coil

Total

Capacity

(MBh)

628770-YTG-C-0712

Total

1

Input

2

(kW)

Sensible Capacity (MBh)

12 Unitary Products Group

628770-YTG-C-0712

YD600/ND600 Air Handler with M1CZ600A Evaporator Coil (50 Ton) (Continued)

Air on

Evaporator Coil

CFM

WB

(°F)

Total

Capacity

(MBh)

Total

1

Input

2

(kW)

Sensible Capacity (MBh)

Return Dry Bulb (°F) Return Dry Bulb (°F)

90 85 80 75 70 65 90 85 80 75 70 65

115°F 125°F

77 586.4 62.8 340.6 284.5 228.3 - - - 529.2 68.8 313.5 257.5 201.5 - - 72 558.8 62.8 414.2 358.1 301.9 245.8 - - 514.2 68.8 394.0 338.0 282.0 226.0 - -

15000

67 531.1 62.7 487.8 431.7 375.5 319.4 263.2 - 499.2 68.9 474.4 418.4 362.5 306.5 250.5 62 505.9 62.3 505.9 475.0 418.8 362.7 306.5 250.4 468.9 68.7 468.9 441.8 385.8 329.8 273.8 217.9

57 525.3 63.4 525.3 471.3 415.2 359.0 302.9 246.7 486.2 70.9 486.2 432.4 376.4 320.4 264.4 208.5

77 608.8 62.6 402.0 318.1 251.3 - - - 554.3 68.3 387.9 293.8 225.3 - - 72 580.2 62.5 465.9 399.1 332.3 265.5 - - 538.4 68.3 451.6 383.1 314.7 246.2 - -

17500

67 551.5 62.5 529.8 480.1 413.3 346.5 279.7 - 522.4 68.3 515.2 472.4 404.0 335.5 267.1 62 525.2 62.1 525.2 509.8 461.0 394.2 327.4 260.6 490.9 68.2 490.9 477.3 430.7 363.5 293.8 225.4

57 545.4 63.2 545.4 518.4 457.0 390.2 323.4 256.6 509.0 70.4 509.0 482.1 420.5 353.3 283.6 215.1

77 631.3 62.4 463.4 351.8 274.3 - - - 579.4 67.8 462.4 330.1 249.2 - - 72 601.5 62.3 517.6 440.2 362.7 285.3 - - 562.6 67.8 509.2 428.3 347.3 266.4 - -

20000

67 571.8 62.3 571.8 528.6 451.2 373.7 296.3 - 545.7 67.8 545.7 526.4 445.5 364.6 283.7 62 544.6 61.9 544.6 544.6 503.2 425.8 348.3 270.9 512.8 67.7 512.8 512.8 475.7 397.1 313.8 232.9

57 565.5 63.0 565.5 565.5 498.8 421.4 343.9 266.5 531.8 69.9 531.8 531.8 464.6 386.2 302.7 221.8

72 606.1 62.2 533.5 455.3 377.2 299.0 - - 563.8 67.7 520.2 440.2 360.1 280.0 - -

21750

67 576.2 62.1 576.2 547.3 469.1 390.9 312.8 - 547.0 67.7 547.0 542.0 462.0 381.9 301.8 62 548.7 61.7 548.7 548.7 523.2 445.1 366.9 288.8 514.0 67.6 514.0 514.0 493.1 414.2 332.9 252.9

57 569.8 62.8 569.8 569.8 518.7 440.5 362.3 284.2 532.9 69.8 532.9 532.9 481.5 402.7 321.4 241.3

72 610.7 62.0 549.4 470.5 391.6 312.7 - - 565.0 67.6 531.3 452.0 372.8 293.6 - -

23500

67 580.5 61.9 580.5 565.9 487.1 408.2 329.3 - 548.3 67.6 548.3 548.3 478.4 399.2 320.0 62 552.9 61.5 552.9 552.9 543.3 464.4 385.5 306.6 515.1 67.5 515.1 515.1 510.5 431.2 352.0 272.8

57 574.2 62.6 574.2 574.2 538.5 459.6 380.8 301.9 534.1 69.7 534.1 534.1 498.4 419.2 340.0 260.8

1

These capacities are gross ratings. For net capacity, deduct supply air blower motor, MBh. Example: Refer to the appropriate Blower

Performance Table for the BHP of the supply air blower motor, MBh = 3.415 x kW and kW = BHP x 0.746 nameplate rated motor

efficiency.

2

These ratings include the condenser fan motors and the compressor motors but not the supply air blower motor.

Temperature of Air on Condenser Coil

Total

Capacity

(MBh)

Total

1

Input

(kW)

Sensible Capacity (MBh)

2

Condenser Only Cooling Capacities

YD360 thru 600 Condenser Only Capacities

Suction Press. &

MODEL

YD360

YD480

YD600

Corresponding

Temp. @ Saturation

PSIG °F MBH KW EER MBH KW EER MBH KW EER MBH KW EER MBH KW EER MBH KW EER

104 35 275.4 28.5 9.6 264.0 27.4 9.6 250.0 26.4 9.5 238.2 28.8 8.3 231.8 32.0 7.2 228.5 35.1 6.5

117 40 327.9 29.2 11.2 316.0 28.1 11.3 302.0 27.0 11.2 285.8 29.4 9.7 273.0 32.5 8.4 263.3 35.6 7.4

129 45 380.4 29.8 12.8 368.0 28.7 12.8 354.0 27.5 12.9 333.5 29.9 11.1 314.2 33.0 9.5 298.1 36.2 8.2

142 50 432.9 30.4 14.3 420.0 29.3 14.3 406.0 28.1 14.4 381.1 30.5 12.5 355.4 33.6 10.6 332.9 36.7 9.1

154 55 485.4 31.0 15.7 472.0 30.0 15.8 458.0 28.7 16.0 428.8 31.0 13.8 396.6 34.1 11.6 367.7 37.2 9.9

105 35 418.0 33.2 12.6 408.0 32.4 12.6 399.2 32.4 12.3 397.3 36.2 11.0 389.6 40.4 9.6 389.2 45.0 8.6

117 40 461.0 34.4 13.4 451.0 33.5 13.5 441.6 33.1 13.3 433.0 36.8 11.8 419.2 40.9 10.3 410.8 45.2 9.1

130 45 504.0 35.6 14.1 494.0 34.6 14.3 484.1 33.8 14.3 468.8 37.4 12.5 448.9 41.3 10.9 432.4 45.4 9.5

142 50 547.0 36.9 14.8 537.0 35.7 15.0 526.5 34.5 15.3 504.5 38.0 13.3 478.5 41.8 11.5 454.0 45.6 9.9

155 55 590.0 38.1 15.5 580.0 36.8 15.8 569.0 35.2 16.2 540.3 38.5 14.0 508.2 42.2 12.0 475.6 45.8 10.4

105 35 489.4 45.3 10.8 487.2 44.1 11.0 482.6 43.4 11.1 442.2 48.4 9.1 391.3 54.4 7.2 334.0 60.7 5.5

118 40 561.4 46.2 12.1 558.7 45.2 12.4 554.6 44.4 12.5 509.2 49.4 10.3 456.8 55.1 8.3 400.0 61.1 6.5

130 45 633.4 47.2 13.4 630.2 46.3 13.6 626.6 45.4 13.8 576.2 50.5 11.4 522.3 55.9 9.3 466.0 61.5 7.6

142 50 705.4 48.2 14.6 701.7 47.4 14.8 698.6 46.4 15.1 643.2 51.3 12.5 587.8 56.6 10.4 532.0 62.0 8.6

154 55 777.4 49.2 15.8 773.2 48.5 15.9 770.6 47.4 16.2 710.2 52.3 13.6 653.3 57.4 11.4 598.0 62.4 9.6

65 75 85 95 105 115

Temperature of Air on Condenser Coil, °F

Unitary Products Group 13

Sound Performance

Outdoor Sound Power Levels (dB), 60 Hz

628770-YTG-C-0712

Nominal

Model

YD360 30

YD480 40

YD600 50

1

Tonnage

dB(A)

92 90 93 91 89 87 83 79 74

92 90 93 91 89 87 84 80 75

93 91 94 92 90 87 84 80 75

Rated in accordance with AHRI 270 Standard.

Electrical Data

YD360 thru 600 Electrical Data

Compressors Outdoor Fan Motor

Model

YD360

YD480

YD600

Power

Supply

208/230-3-60 4 25.0 39 164 208/230-3-60 1 1/2 4 5.8 129.5 150

460-3-60 4 12.2 19 100 460-3-60 1 1/2 4 2.9 63.5 70

575-3-60 4 9.0 14 78 575-3-60 1 1/2 4 2.2 47.1 50

208/230-3-60 4 30.1 47 225 208/230-3-60 1 1/2 4 5.8 151.1 175

460-3-60 4 16.7 26 114 460-3-60 1 1/2 4 2.9 82.6 90

575-3-60 4 12.2 19 80 575-3-60 1 1/2 4 2.2 60.7 70

208/230-3-60 4 48.1 75 245 208/230-3-60 1 1/2 4 5.8 227.6 250

460-3-60 4 18.6 29 125 460-3-60 1 1/2 4 2.9 90.7 100

575-3-60 4 14.7 23 100 575-3-60 1 1/2 4 2.2 71.3 80

Qty

1

63 125 250 500 1000 2000 4000 8000

RLA

(each)

MCC

(each)

LRA

(each)

Octave Bands (Hz)

Power

Supply

HP Qty

FLA

(each)

Minimum

Circuit

Ampacity

Maximum

Fuse Size

(A)

14 Unitary Products Group

628770-YTG-C-0712

Typical Wiring Diagrams

Typical 208/230 Volt, YD360/480/600 Condensing Unit Wiring Diagram

Unitary Products Group 15

Typical Wiring Diagrams

628770-YTG-C-0712

Typical 460/575 Volt, YD360/480/600 Condensing Unit Wiring Diagram

16 Unitary Products Group

628770-YTG-C-0712

Typical Field Wiring Diagrams

Typical Field Wiring Diagram ND360/480 Evaporator Units, ND600 Air Handler and M1CZ600A Evaporator Coil when

Matched with YD360, 480, 600 Condenser

NOTE: Typical field wiring when OD unit is matched with ND

air handler. When matching condensing unit with

models other than ND an additional control

transformer is required on the Indoor unit.

Typical ND360/480 & M1CZ600A Liquid Line Solenoid Wiring

Unitary Products Group 17

NOTE: For applications on airhandlers/evaporator DX coils

other than ND360-600 certified matchups liquid line

solenoids may be required for proper operation and

refrigerant system dump out.

628770-YTG-C-0712

Standard Terminal Block on ND360/480 and

ND600 with M1CZ600A models. On non ND

models isolation relays must be installed to avoid

overloading on 75 VA transformer on condensing

unit.

Primary side of transformer

connect to line side of power

supply.

Typical Liquid Line Solenoid Wiring

Primary side of transformer

connect to line side of power

supply.

Non ND units may not include any or all of the

components required to wire the unit. Use the

diagram as general reference only.

18 Unitary Products Group

628770-YTG-C-0712

Weight And Dimension’s

Corner Weights & Center Of Gravity (Inches)

Unit Model

YD360 1875 1895 128.5 88.5 404 537 533 401 55.2 44.1 934 941

YD480 2315 2347 128.5 88.5 486 675 671 483 53.8 44.1 1154 1161

YD600 2345 2381 128.5 88.5 486 693 685 481 53.0 44.0 1166 1179

Unit Weight (Lbs.)

Shipping Operation Length Width

Unit Dimensions

(Inches)

A B C D Dim X Dim Y

Weight

A to B

Weight

D to C

Corner Weights & Center Of Gravity

Unitary Products Group 19

REAR

628770-YTG-C-0712

YD Unit Dimensions

LEFT

A

FRONT

B

C

G

H

D

E

RIGHT

F

Unit Dimensions (Inches)

Model A B C D E F G H

YD360 128.5 88.5 37.5 41.8 40.0 46.1 37.1 23.6

YD480 128.5 88.5 57.7 41.8 40.0 46.1 37.1 23.6

YD600 128.5 88.5 57.7 41.8 40.0 46.1 37.1 23.6

Piping And Electrical Connections

Piping connections are made from the rear of the unit. Connections can be made directly to the suction and liquid line

service valves.

Piping can be routed to the unit from the left or right side.

Electrical connections for power and control wiring is made

from the front of all units, left of the electrical control box

access. See piping sizes and electrical knockout details.

Unit Clearances

Location Dimensions

Overhead (Top)

Front access panels 36”

Left Side 30”

Right Side 30”

Rear 24”

Bottom

1

Units must be installed outdoors. Overhanging structures or

shrubs should not obstruct condenser air discharge.

2

Adequate snow clearance must be provided if winter operation

is expected.

1

2

120”

0”

20 Unitary Products Group

628770-YTG-C-0712

Piping And Electrical Connection Sizes (30/40/50T) (Inches)

Connection Entry Size

Suction Line Sys #1 1-5/8 OD

Liquid Line Sys #1 7/8 OD

Suction Line Sys #2 1-5/8 OD

Liquid Line Sys #2 7/8 OD

Power Wiring Knockout SEE BELOW

Control Wiring 7/8 HOLE

Electrical Power Knockout Sizes (Inches)

Connection Entry 30-40-50T/230V 30-40-50T/460-575V

Power Wiring 2-1/2” 1-1/2”

37.518

Liquid (Sys 2)

30 Ton Piping Connections

Suction (Sys 2)

Suction (Sys 1)

Liquid (Sys 1)

88.140

46.190

50.313

37.826

41.859

10.984

11.385

Unitary Products Group 21

628770-YTG-C-0712

57.689

Liquid (Sys 2)

Suction (Sys 2)

Suction (Sys 1)

Liquid (Sys 1)

40 & 50 Ton Piping Connections

Control Wiring

Power Wiring

37.518

12.878

9.628

88.140

37.731

41.934

46.206

50.409

10.974

11.385

SEE DETAIL RIGGING HOLES

19.358

20.858

22.358

2.750

2.500

DETAIL RIGGING HOLES

SCALE 0.250

2.313

5.183

88.140

30 Ton Power And Control Wiring Connections

22 Unitary Products Group

628770-YTG-C-0712

Control Wiring

Power Wiring

57.689

33.049

29.799

19.358

20.858

22.358

40 & 50 Ton Power and Control Wiring Connections

88.140

Unitary Products Group 23

Subject to change without notice. Printed in U.S.A. 628770-YTG-C-0712

Copyright © August 1, 2012 by Johnson Controls, Inc. All rights reserved. Supersedes: 628770-YTG-B-0811

Johnson Controls Unitary Products

5005 York Drive

Norman, OK 73069

Loading...

Loading...