Page 1

TECHNICAL GUIDE

R-410A

SPLIT-SYSTEM

AIR-COOLED CONDENSING UNITS

AND AIR HANDLERS

PREDATOR® SERIES

YC090-300 and YD120-240

CONDENSING UNIT MODELS

PC090-180 and PD180-240

HEAT PUMP UNIT MODELS

NC090-300 and ND120-240

AIR HANDLING UNIT MODELS

7.5 - 25 Ton

60 Hertz

®

ISO 9001

Certified Quality

Management System

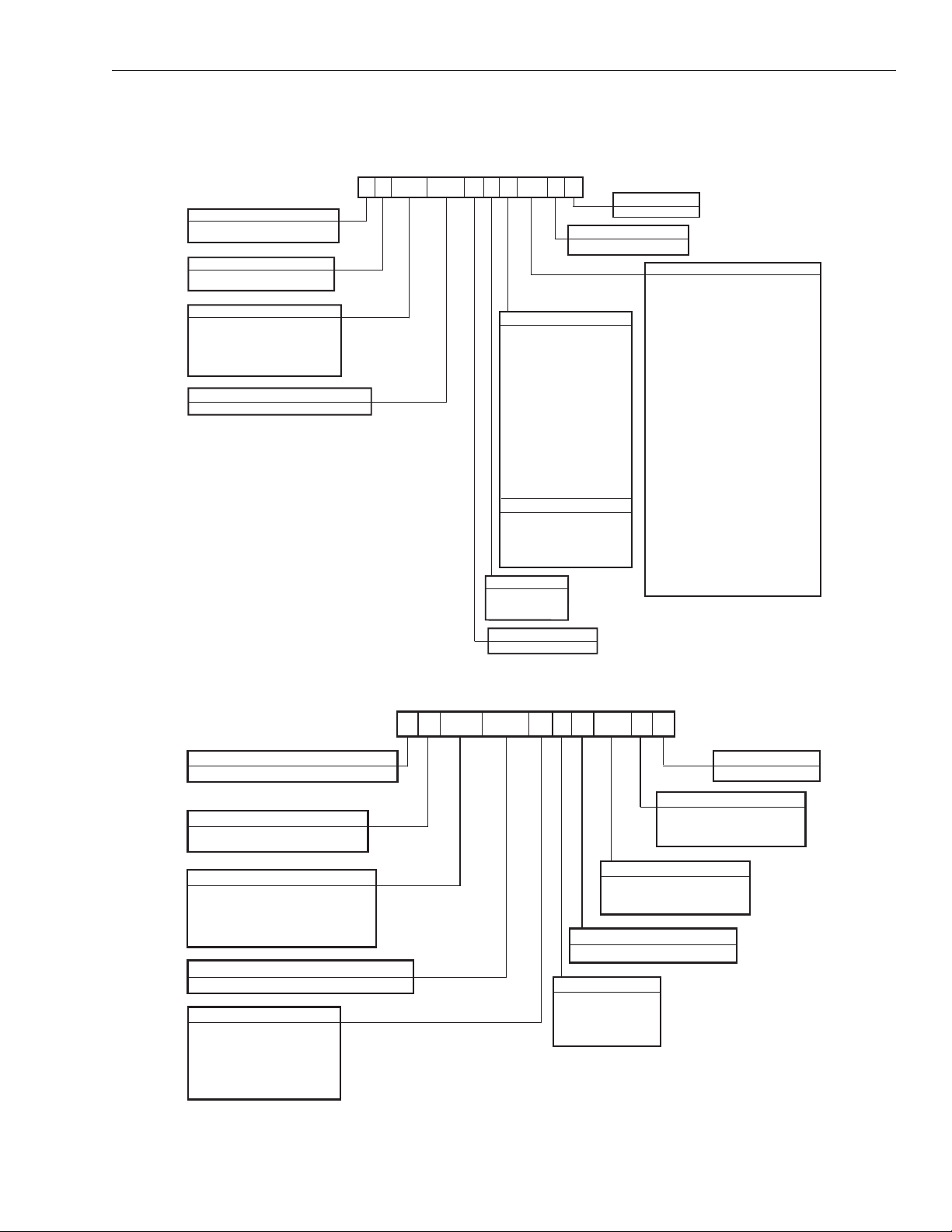

YC/YD/PC/PD Outdoor Units

NC/ND Indoor Units

YC/YD/PC Outdoor Units

505428-YTG-R-1114

Description

Predator® condensing units and heat pumps are completely

assembled, piped and wired at the factory to provide a single-piece

unit for shipment and rigging. Each unit is pressurized with a holding

charge of refrigerant R-410A for storage and/or shipping.

The compact design, clean styling, small footprint, and quiet operation

make these condensing units and heat pumps suitable for almost any

outdoor location. On rooftops... because they weigh much less than a

single package unit of similar capacity and are much easier to rig and

support. On the ground... because the footprint is compact allowing a

variety of applications.

Both the Predator® condensing units and heat pumps are equipped

with reliable Simplicity® SE microprocessor controls to assure proper

operation and unit protection for long product life. Products from 10 to

20 tons are available in single or dual (2 or 4 pipe) refrigerant circuits

for redundancy in operation and various application choices such as

one outdoor unit matched with two indoor units.

The Predator® air handling units are completely assembled units,

including a well-insulated cabinet, a DX cooling coil with copper tubing,

aluminum fins, expansion valve(s), distributor(s), 2” throwaway filters,

a centrifugal blower, a blower motor, an adjustable belt drive, a blower

motor contactor and a small holding charge of nitrogen.

Units are shipped in the vertical

position ready for field installation,

but can be easily converted to

horizontal position. An added

benefit of the Predator® air

handling units is they are designed

to operate with either a

condensing unit or a heat pump

and no field modification or special

unit is required for heat pump

applications.

(Except YC300)

Page 2

505428-YTG-R-1114

Table of Contents

Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Table of Contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Nomenclature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Condensing Unit Features and Benefits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Outdoor Unit Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Air Handling Unit Features and Benefits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Guide Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Physical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Unit Limitations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Cooling and Heating Ratings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Capacity Performance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Air Handling and Hot Water Coil Accessory Heating Capacity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Air Handling and Steam Coil Accessory Heating Capacity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Airflow Performance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Sound Performance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

Electrical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

Typical Wiring Diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

Weights And Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

2 Johnson Controls Unitary Products

Page 3

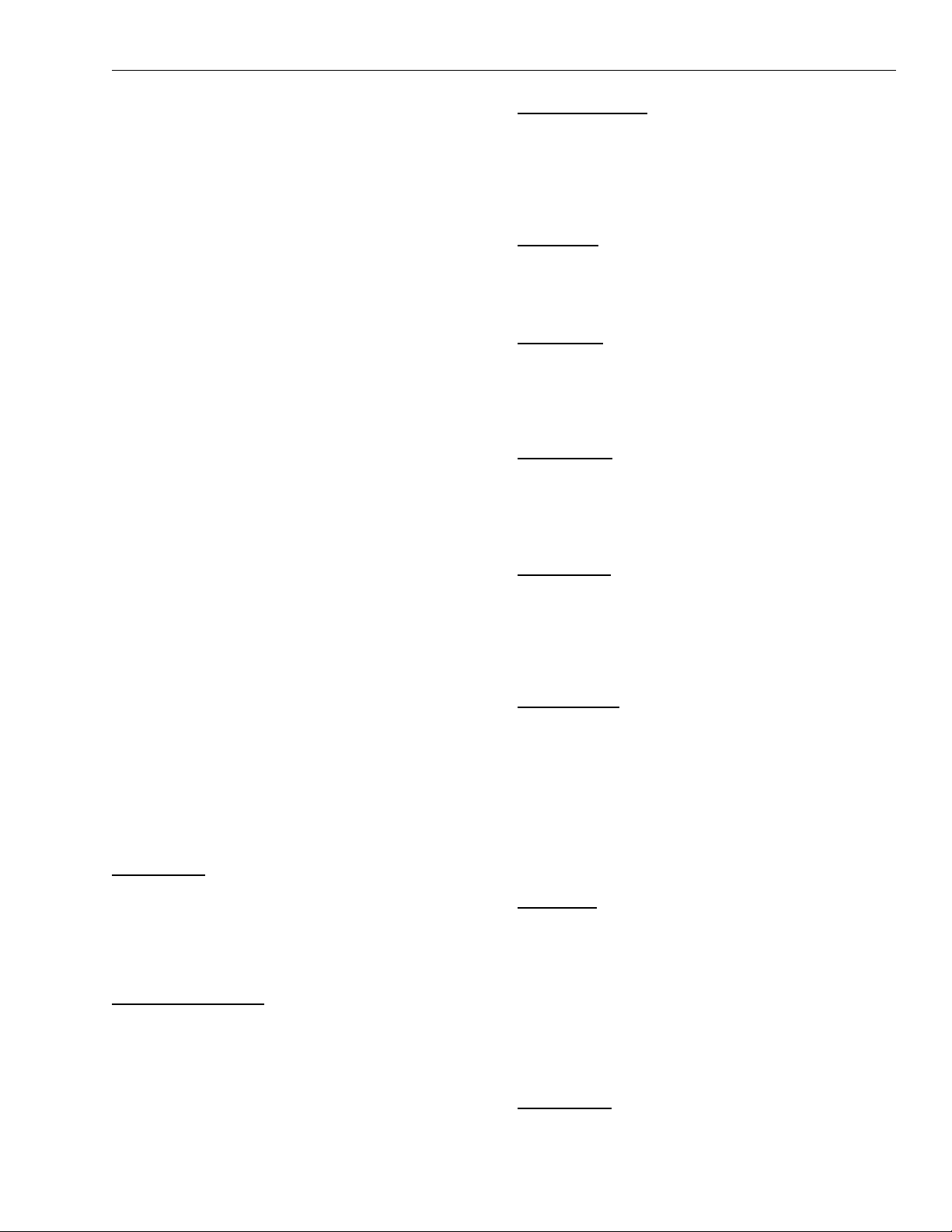

Nomenclature

Product Category

Y = Split System, Condenser, AC, R-410A

Product Identifier

C = Standard Efficiency, 2-Pipe, R-410A

D = Standard Efficiency, 4-Pipe, R-410A

Nominal Cooling Capacity - MBH

090 = 7.5 Ton

120 = 10 Ton

150 = 12.5 Ton

180 = 15 Ton

240 = 20 Ton

300 = 25 Ton

C00 = Cooling Only

Product Options

AA = None

AB = Phase Monitor

AC = Coil Guard

AE = Phase Monitor + Coil Guard

EA = E-Coat Condenser Coil

EB = E-Coat Condenser Coil + Phase Monitor

EC = E-Coat Condenser Coil + Coil Guard

EE = E-Coat Condenser Coil + Coil Guard

+ Phase Monitor

LA = Low Ambient

LB = Low Ambient + Phase Monitor

LC = Low Ambient + Coil Guard

LD = Low Ambient + Phase Monitor

+ Coil Guard

LE = Low Ambient + Technicoat Cond. Coil

LF = Low Ambient + Technicoat Cond. Coil

+ Phase Monitor

LG = Low Ambient + Technicoat Cond. Coil

+ Coil Guard

LH = Low Ambient + Technicoat Cond. Coil

+ Phase Monitor + Coil Guard

LJ = Low Ambient + ElectroFin Cond. Coil

LK = Low Ambient + ElectroFin Cond. Coil

+ Phase Monitor

LL = Low Ambient + ElectroFin Cond. Coil

+ Coil Guard

LM = Low Ambient + ElectroFin Cond. Coil

+ Phase Monitor + Coil Guard

TA = Technicoat Condenser Coil

TB = Technicoat Condenser Coil + Phase

Monitor

TC = Technicoat Condenser Coil + Coil Guard

TE = Technicoat Condenser Coil + Coil Guard

+ Phase Monitor

Installation Options

A = None

B = Option 1

C = Option 2

D = Options 1 & 2

E = Option 3

F = Option 4

G = Options 1 & 3

H = Options 2 & 3

J = Options 1, 2 & 3

K = Options 1 & 4

L = Options 2 & 4

M = Options 1, 2 &4

P = Options 3 & 5

Q = Options 1, 3 & 5

R = Options 4 & 5

S = Option 5

T = Options 1 & 5

V = Options 1, 4 & 5

2 = 208/230-3-60

4 = 460-3-60

5 = 575-3-60

Configured Split Condenser Model Number Nomenclature

A = Standard Motor

Airflow

Product Generation

4 = Fourth Generation

Voltage

Heat Type & Nominal Heat Capacity

YC300

C00 A

2AAA

4

A

Product Style

A = Style A

P = Split System, Condenser, HP, R-410A

1 = Disconnect

2 = Non Pwr’d Conv Outlet

3 = BACnet MS/TP on Simplicity SE

4 = Fault Detection Device

5 = Pwr’d Conv Outlet

Options

Product Category

N = Split System, Air Handler, AC & HP R-410A

Product Identifier

C = Standard Efficiency, 2-Pipe, R-410A

D = Standard Efficiency, 4-Pipe, R-410A

Nominal Cooling Capacity - MBH

090 = 7-1/2 Ton

120 = 10 Ton

180 = 15 Ton

240 = 20 Ton

300 = 25 Ton

C00 = Cooling Only

Product Options

AA = No Options Installed

EJ = E-Coat Evaporator Coil

TJ = Technicoat Evaporator Coil

Installation Options

A = None

2 = 208/230-3-60

2

4 = 460-3-60

2

5 = 575-3-60

6 = 208/230/460-3-60

Configured Split Air Handler Model Number Nomenclature

B = 1.5 HP Motor

C = 2.0 HP Motor

D = 3.0 HP Motor

E = 5.0 HP Motor

F = 7.5 HP Motor

N = None (Motor Drive Kit Reg)

1

Airflow

Product Generation

1 = First Generation

2 = Second Generation

3 = Third Generation

Voltage

Heat Type & Nominal Heat Capacity

NC240

C00 B

6AAA

3

A

Product Style

A = Style A

1. Motors are not shipped with 25 ton AH units.

2. Models NC/ND240 Airflow Option "F" Only.

505428-YTG-R-1114

Johnson Controls Unitary Products 3

Page 4

505428-YTG-R-1114

Condensing Unit Features and Benefits

Features

• Meets or exceed s ASHRAE 90.1 standards.

• Scroll compressors provide both high efficiency and

reliability.

• Simplicity

• Dual refrigerant circuits on PD and YD models.

• Condensing unit coils are constructed of reliable and

durable Micro-Channel aluminum tube and fins for long

lasting, efficient operation. Mirco-Channel technology

provides exceptional durability along with reduced

product weight and less refrigerant charge. Heat pumps

units are equipped with aluminum fin, copper tube coils

providing durability, reliability and value.

• Multiple condensing unit and air handler match-ups

provide a wide range of application choices from

oversized indoor motors to dual indoor units matchedup with single outdoor units.

• Crankcase heaters that de-energize when compressors

are operating.

• Both high and low pressure controls. Since these

controls are self-contained, there are no capillary lines

to be damaged.

• Internal compressor motor protection.

• Class 2, 24-volt thermostat control circuit protected by a

re-settable breaker.

• Standard factory installed service valves.

• Filter-driers are shipped in the unit's control box for field

installation in the liquid line leaving the outdoor unit.

• Copper stub-outs are factory mounted on the suction

and liquid lines to simplify the field piping connections.

• Simplicity® SE Controls provide stable cooling

operation at ambient temperatures down to 40°F with

low ambient kits available for operation to 0°F.

• Capacity staging for more economical operation and

stable temperature levels within the conditioned space.

• Simplicity® SE Controls control board uses a three

times, you're out philosophy. The high, low-pressure

switch, anti-freeze protection, low voltage or heating

high limit must trip three times within two hours before

the unit control board will lock out the associated

compressor. An alarm message will be displayed on the

LCD screen

• Simplicity® SE Controls monitor each safety

independently (High pressure, low pressure, low

voltage) allowing ease of troubleshooting if any

problems arise.

• Inh erently protected condenser fan motors.

• Technicoat or E-coat coated outdoor coils for sea coast

or corrosive environment applications .

• Factory installe d disconnect to allow power to be

removed from the unit when performing periodic

maintenance or for service.

®

SE Controls

• Factory installed powered or non-powered 115 volt GFI

outlet.

• Factory installed phase monitor to protect the unit from

phase loss or phase reversal.

Benefits

The Predator® condensing units and heat pumps can be

applied on a rooftop or at ground level... due to their ample

sub-cooling capacity which allows them to be located three or

more stories below the evaporator coil.

After assembly, the unit is pressurized with a combination of

Refrigerant R-410A and nitrogen for pressure testing and

additional leak testing. During this pressure test, the

operation of the high pressure control is checked. As the unit

is being evacuated and dehydrated, the operation of the low

pressure control is also checked.

Every compressor, condenser fan motor, crankcase heater,

and electrical control circuit is checked to assure a troublefree start-up and years of reliable operation. The condenser

fan guards are vinyl-coated to provide additional rust

protection and to enhance the appearance of the unit.

Compressors are mounted on rubber isolators to reduce the

transmission of vibration. Vertical discharge condenser fans

direct sound upward and away from any surrounding

structures.

All sheet metal parts are constructed of commercial grade

galvanized steel. After fabrication, each part is thoroughly

cleaned to remove any grease or dirt from its surfaces. The

external parts are coated with a powder paint to assure a

quality finish for many years. This UL approved coating

system has passed the 1000 hour, 20% salt spray test per

ASTM Standard B117.

All condensing unit and heat pump models include a 5-year

limited warranty on the compressor(s) and 1-year limited

warranty on all other parts. The matching line of air handling

units carries a 1-year limited parts warranty.

Outdoor Unit Accessories

Coil Guards: Wire-form coil guards for added protection of

outdoor coils. Designed to mount on each side of the product

if required to provide protection from minor impacts or large

debris.

Hail Guards:

outdoor coils from hail. Can be installed on a single side or

both to provide protection from storms that may produce hail.

Low Ambient Kits:

units to operate between 0°F and 40°F in the cooling mode.

Standard cooling is allowed to 40°F. (Not designed for

operation on heat pump units).

Hood type hail guards designed to protect the

Kits designed to allow the cooling only

Air Handling Unit Features and Benefits

Features

These air handlers can be arranged for a variety of air

discharge patterns in either the horizontal or vertical position.

4 Johnson Controls Unitary Products

Page 5

505428-YTG-R-1114

Refer to the unit installation instructions for other application

possibilities.

Benefits

Air handling units are designed with two distinct modules to

provide maximum application flexibility. All are shipped as

single packages with the blower module mounted on top of

the coil module. The blower module can be repositioned in

the field to meet a large number of vertical and horizontal

applications.

The 7.5 thru 20 Ton blower module includes the blower

wheels along with factory-mounted motor and drive. The 25

Ton blower module includes the blower wheels with field

mounted motor and drives. All models offer two motor

horsepower options to meet both standard and high static

airflow requirements.

The coil module includes direct expansion coils, 2 in.

throwaway filters with the option to accept 4” filters, liquid line

solenoid valves for capacity reduction, thermal expansion

valves, distributors and a non-corrosive, composite

condensate drain pan.

Every air handling coil is pressurized with air and leak tested

under water. After the headers are brazed onto the coil and

the coil is installed in the unit, the coil is pressurized with

nitrogen for pressure testing and additional leak testing. After

the coil is evacuated and dehydrated, it is pressurized with a

holding charge of nitrogen for storage and/or shipping.

These air handlers, combined with condensing units, provide

years of quiet, efficient and dependable operation. These

units are manufactured under ISO 9001 Quality System

Certification.

Unit Installation

Units may be bottom-supported or ceiling-suspended and

can be arranged to meet almost any space or duct

requirements. Each unit is available with a choice of blower

motors horsepower and other accessories to make them

suitable for most applications.

Air Handling units are availabl e in either two or four pipe

configurations from 7.5 to 25 tons. The dual and single circuit

options provide a wide variety of application and unit matchup possibilities.

Blower Motors:

Different HP motors are available for each

unit to meet almost any air delivery requirement. All motors

are UL approved, have permanently lubricated ball bearings

and are mounted within the insulated cabinet of the units to

minimize the transmission of sound to the surrounding space.

1.5-5 HP motors are inherently protected. 7.5 HP motors

require motor overload protection.

Overload Relay (7.5HP):

These blower motors do not have

inherent protection and require external motor overload

protection. NC/ND240 "F" models Overload Relays are

factory installed. NC300 models Overload Relays are field

installed. Power wiring for blower motor is supplied in the

Overload Relay Kit. See details in Overload Relay Kit and

Overload Relay Setting Tables on Page 70.

Factory-Mounted Components

Part Load Operation:

These air handlers with DX (Direct

Expansion) coils rated at 10 tons of capacity and above have

multiple coils with pre-piped distributors, expansion valves

and solenoid valves. Field modifications are not required for

part load operations. Capacity reduction not only provides

economical operation, but also maintains stable temperature

and humidity levels in the conditioned space.

BAS Control:

Simplicity® SE with Communication Option

Control - The York® Simplicity® SE with Communication

Option Control is factory installed. It includes all the features

of the Simplicity® SE control with an additional gateway to

BACnet MS/TP (programmable to Modbus or N2 protocols).

Easy Service: Serviceable expansion valves are provided on

every unit. These valves are factory-installed to provide many

years of trouble-free operation. If service is required, it is not

necessary to unbraze any joints. The expansion valves also

include a tee fitting to allow easy installation of hot gas

bypass if required.

Coil Protection: The indoor coils of these air handlers can

have factory applied Technicoat or Electrofin coating to

provide extended life to the indoor coil in standard

applications and additional corrosion protection on those

applications in sea coast or corrosive environments.

Accessories

Base Sections:

Base sections can be used to elevate units

above the floor. If desired, a moderate percentage of outdoor

air may be introduced through these sections by cutting an

access opening to accommodate the outdoor air duct

connection. These bases include a durable finish to match

the evaporator blower unit. The base may have to be

insulated for certain applications.

Hot Water Coils:

Drain-able water coils are available for field

installation between the blower and the coil modules of both

horizontal and vertical units. Since their casings match the

dimensions and the finish of the basic units, they become an

integral part of the unit after installation. The coils slide out of

their casings for easy installation. Hot water coils have

copper tubes that have been mechanically expanded into

aluminum fins. Both headers are located on the same end of

the coil. Coils are leak-tested at 325 psig under water and

dried before their connections are capped for storage and

shipping.

Steam Coils:

Steam coils are available for installation

between the blower and coil modules of both horizontal and

vertical units. Since the casing matches the dimensions and

the finish of the basic unit, it becomes an integral part of the

unit after installation. The coil slides out of the casings for

easy installation and is pitched in the casings to facilitate

condensate drainage. The coil has copper tubes that have

been mechanically expanded into aluminum fins. Both

headers are located on the same end of the coil. The coil is

leak-tested at 325 psig and dried before the connections are

capped for storage and shipping.

Bottom Return:

Air handling unit can be quickly converted to

bottom return for both vertical and horizontal applications. All

that is required is the removal of several screws and a single

Johnson Controls Unitary Products 5

Page 6

505428-YTG-R-1114

panel on 7.5-15 ton and two panels on the 20 ton AHU.

Optional painted panel can be ordered to cover the side

return opening when utilizing the bottom return.

Supply Air Plenums:

available for free standing units located within the conditioned

space. They are shipped fully assembled for easy field

installation, are finished to match the exterior of the basic

unit, and include double deflection grills that can be adjusted

to vary the throw, spread and drop of the supply air.

These fully insulated plenums are

Guide Specifications

Split System Cooling Only Condensing Units

Models: YC090-300, YD120-240 & Split System Heat

Pump Models: PC090-240, PD180-240

General

• Factory assembled, single piece, air cooled condensing

unit designed for outdoor installation.

• Factory wired, pip ed, and tested for leakage and

functionality to assure trouble-free installation and startup.

• Rated in accordance with AHRI Standard 340/360.

• Manufactured in a facility registered under the ISO 9002

manufacturing quality standard.

• Designed and tested in accordance with ASHRAE 15

Safety Code for Mechanical Refrigeration and comply

with NEC.

• Cooling performance rated in accordance with DOE

and AHRI test procedures.

• CSA listed and classified to UL 1995/CAN/CSA No.

236- M90 standards.

• One year limited parts warranty on complete unit with

an additional four year compressor warranty.

Unit Operating Characteristics

Operating Range shall be between 125° F to 40° F in cooling

as standard from factory.

• The capacity of the condensing unit shall meet or

exceed _____ Btuh at a suction temperature of _____

F. The power consumption at full load shall not exceed

_____ kW.

• The combination of the condensing unit and the

evaporator or fan coil unit shall have a total net cooling

capacity of _____ Btuh or greater at conditions of

_____ cfm entering-air temperature at the evaporator at

_____ F wet bulb and _____ F dry bulb, and air

entering the condensing unit at _____F.

• The system shall have an EER of _____ Btuh/ Watt or

greater at standard AHRI conditions.

Installer Shall

• Furnish York® air-cooled condensing units, heat pump

or equivalent in accordance with the performance

schedule shown on the plans, and

• Unit shall be stored and handled in accordance with unit

manufacturer's instructions.

• Install each unit as shown on the plans in accordance

with the manufacturer’s recommendations and all

applicable national and local codes

Unit Construction

• Constructed of zinc-c oated, galvanized steel.

• Exterior surfaces bonded and coated with baked

enamel finish by a powder paint process capable of

withstanding a minimum of 1000 salt spray hours

according to ASTM B117.

• Cabinet screws that comply with ASTM B117 salt spray

test for a minimum of 750 hours.

• Permanently attached heavy-gage perimeter base rails

with forklift slots and lifting holes.

• Removable access panels to all internal components.

• S eparate access panel to controls.

• Access panels to allow outdoor coil cleaning.

Compressor(s)

• Hermetic scroll type, internally protected with highpressure relief and over temperature protection.

• Two stage units operate in 50% capacity increments.

• Suction gas cooled

• V oltage range of ±10% of unit nameplate voltage.

• Neoprene isolators minimize sound transmission and

vibration.

• B elly-band crankcase heaters keep refrigerant from

diluting sump oil.

• Full charge of compressor oil

Outdoor Condenser Unit Coils

• Draw thru configuration

• Constructed with Micro-c hannel aluminum fins and

aluminum tubing. All refrigerant tubing must share a

common header.

Heat Pump Unit Outdoor Unit Coils

• Draw thru configuration

• Constructed with aluminum plate fins mechanically

bonded to seamless internally enhanced copper tubes

with all joints brazed.

Condenser Fans

• Direct driven propeller-type fans

• S tatically and dynamically balanced

• Aluminum blades riveted to corrosion resistant steel

spider brackets.

• A rranged for vertical air discharge.

• Equipped with PVC coated steel wire safety guards.

6 Johnson Controls Unitary Products

Page 7

505428-YTG-R-1114

Condenser Motors

• Totally enclosed, air over cooled.

• Inherent overload protection.

• Permanently lubricated bearings.

• M ust cycle to allow cooling operation down to 40°F.

Refrigerant Piping

• S olid core filter-drier(s) ship loose for field installation.

• Liquid and suction line service valves with gauge ports.

• S uction and discharge line service ports accessible

from unit. Ports capped for leak prevention.

• Liquid line magnetic check valves

• Holding charge of R410A refrigerant.

Electrical Requirements

• S ingle-point connection electrical power.

• Nominal unit electrical characteristics shall be _____ v,

3-ph, 60 Hz. The unit shall be capable of satisfactory

operation within voltage limits of ____ v to _____ v.

• Condenser fan motors and secondary of transformers

shall be grounded.

Unit Controls

• All 24-volt control circuit, powered by a 24 volt

transformer(s) and protected by a resettable breaker.

• Conventional thermostat must provide operation for

both condensing units and heat pumps without an “O”

output from the thermostat.

• Low voltage terminal strip for simple hook-up.

• Compressor motor protection shuts down unit for motor

over-current, over-temperature or low voltage

conditions.

• S afety lockouts provide reset capability at the space

thermostat or base unit should any of the following

standard safety devices trip and shut off compressor:

a. Loss-of-charge/Low-pressure switch.

b. High-pressure switch.

c. Control board diagnostics and fault message display.

d. Safety lockouts send a 24 volt signal to the control

board's "X" terminal, allowing notification to the user

via the thermostat fault light (if present).

e. In the unlikely event any faults should occur, the unit

control board will store the faults in its internal

memory. The LCD display will scroll the 5 MOST

critical faults, however, all fault messages can be

extracted via USB device, displayed real-time via the

MAP Gateway as well as be broad-casted through a

BAS system (if applicable). The UCB will provide fault

messages in plain English to ensure the user can

easily understand the specific fault.

Non-fused Disconnect Switch

• Factory-in stalled, internally mounted.

• Accessible from outside the unit.

• NEC and UL approved non-fused switch.

• P rovides power off lockout capability.

Convenience Outlet

• Factory-in stalled, internally mounted.

• Accessible from outside the unit.

• 115V, 15 amp GFI receptacle with independent fuse

protection.

• Required voltage provided by factory-installed stepdown transformer or field supplied 115v circuit.

Low-ambient Head Pressure Control

• S tandard operation down to 40 °F without a low

ambient kit.

• Operation down to 0°F with a field-installed low ambient

kit accessory. The controller modulates the fan motor

speed in response to liquid line temperature or

pressure.

Coil Guard

Factory or field installed decorative grille shall be placed on

the units to protect condenser coil after installation.

Hail Guard Package

Field installed hail guard package shall protect coils against

damage from hail and other flying debris.

Coated Condenser Coils

Special phenolic or epoxy polymer coating available as a

factory option on both outdoor and indoor coils.

Each Unit Shall Be:

• Covered by a 1-year limited parts warranty on the

complete unit and 5-year on compressor(s).

• In current prod uction with published literature available

to check performance, limitations, specifications, power

requirements, dimensions, operation and appearance.

• Indoor unit shall be equipped with a V-belt drive option

that will permit the blower RPM to be adjusted to meet

the CFM requirements of the air delivery system. (Refer

to Technical Guide for Airflow Capabilities.)

Johnson Controls Unitary Products 7

Page 8

505428-YTG-R-1114

Each Unit Enclosure Shall Have:

• Exterio r panels of 18 gauge steel, finished with baked

enamel to provide a long lasting quality appearance

• Removable panels to provide easy access to the

internal components for maintenance and service on

condensing units, heat pumps and air handlers

• Ai r handling units must have a filter rack that accepts

both 2” and 4” filters.

• The dimensions of each unit shall not exceed those

specified in the manufacturers literature.

• The minimum application clearances for condensing

units, heat pumps and air handlers must meet those

specified in the manufacturer’s litera tu re .

The Blower Motor Shall:

• Be mounted within the insulated cabinet to minimize the

transmission of sound to the surrounding space, and

any motor 7.5 HP or greater must have a service factor

of 1.15.

The Evaporator Coil Shall:

• Consist of copper tubes arranged in staggered rows,

mechanically expanded into aluminum fins,

• Be draw-through, and

• Include factory-mounted distributors, expansion valves

and solenoid valves for capacity reduction.

The Blower Wheels Shall:

Be dynamically balanced to minimize the levels of sound and

vibration generated by the unit.

8 Johnson Controls Unitary Products

Page 9

505428-YTG-R-1114

Physical Data

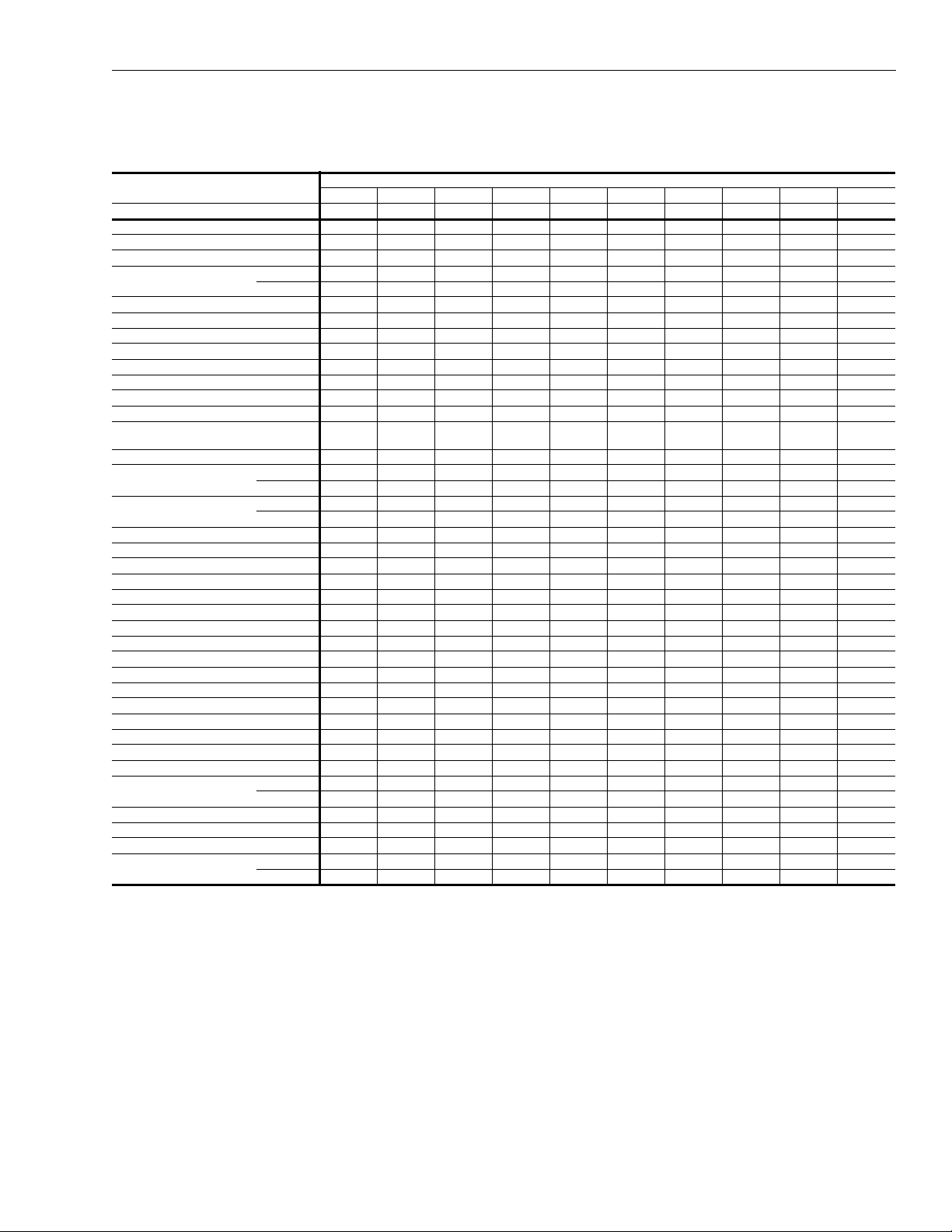

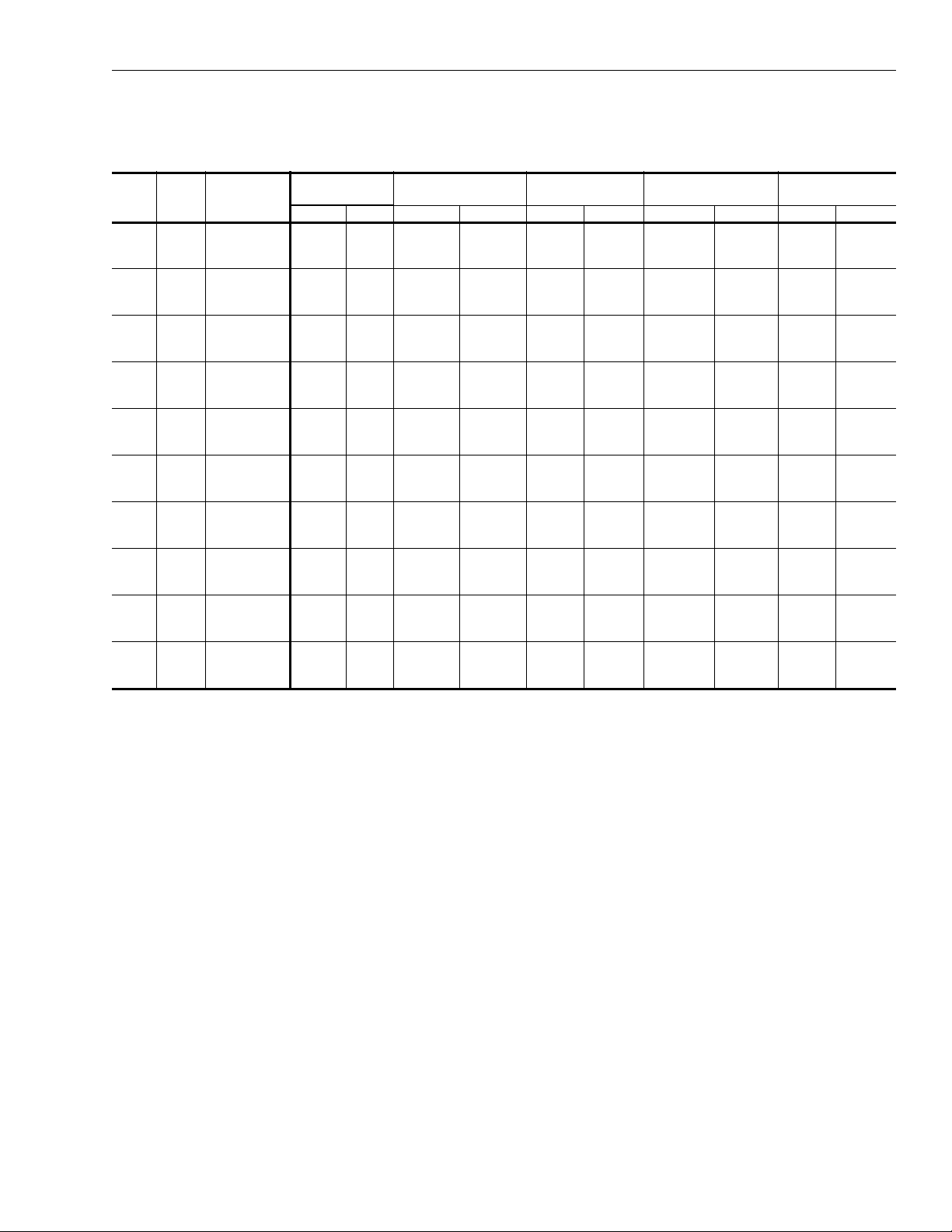

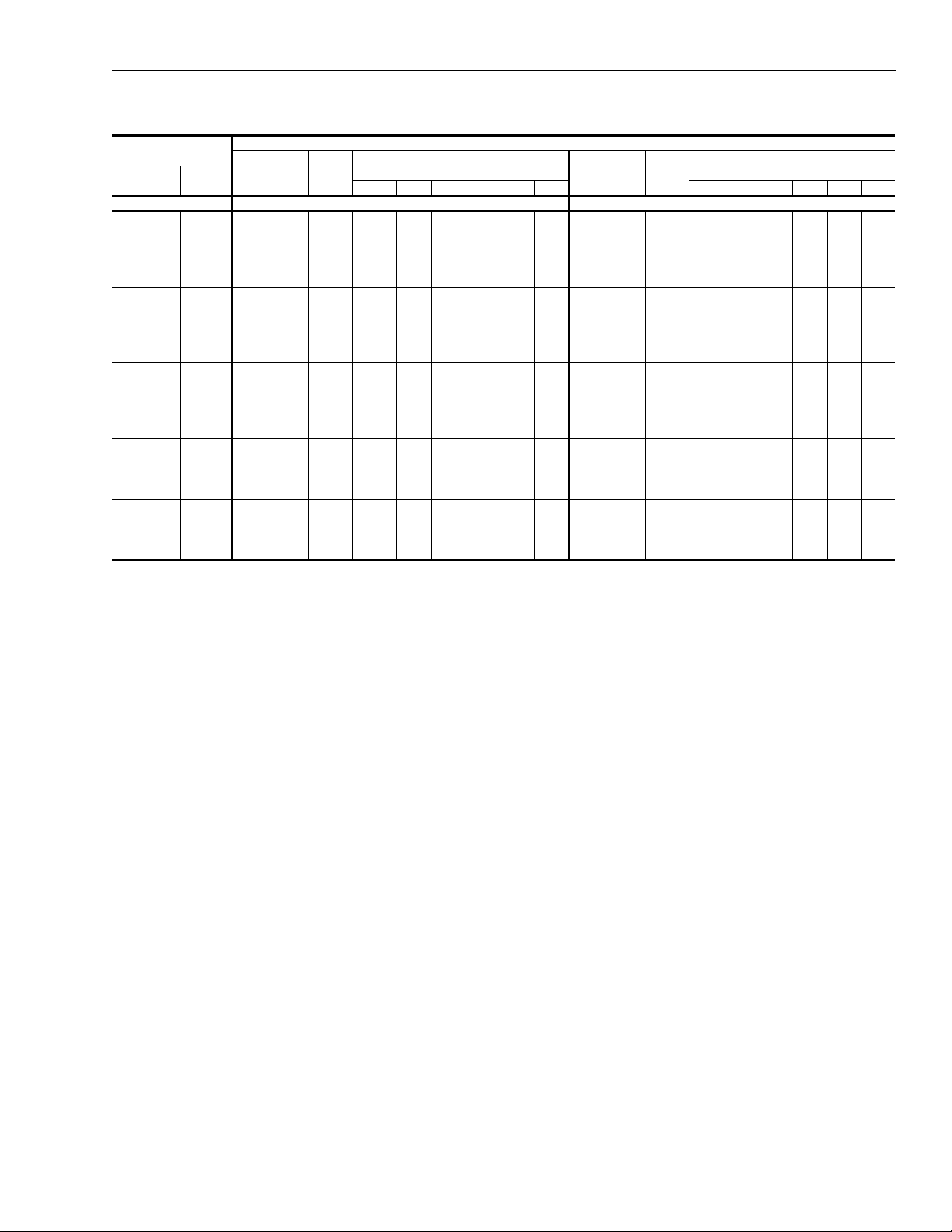

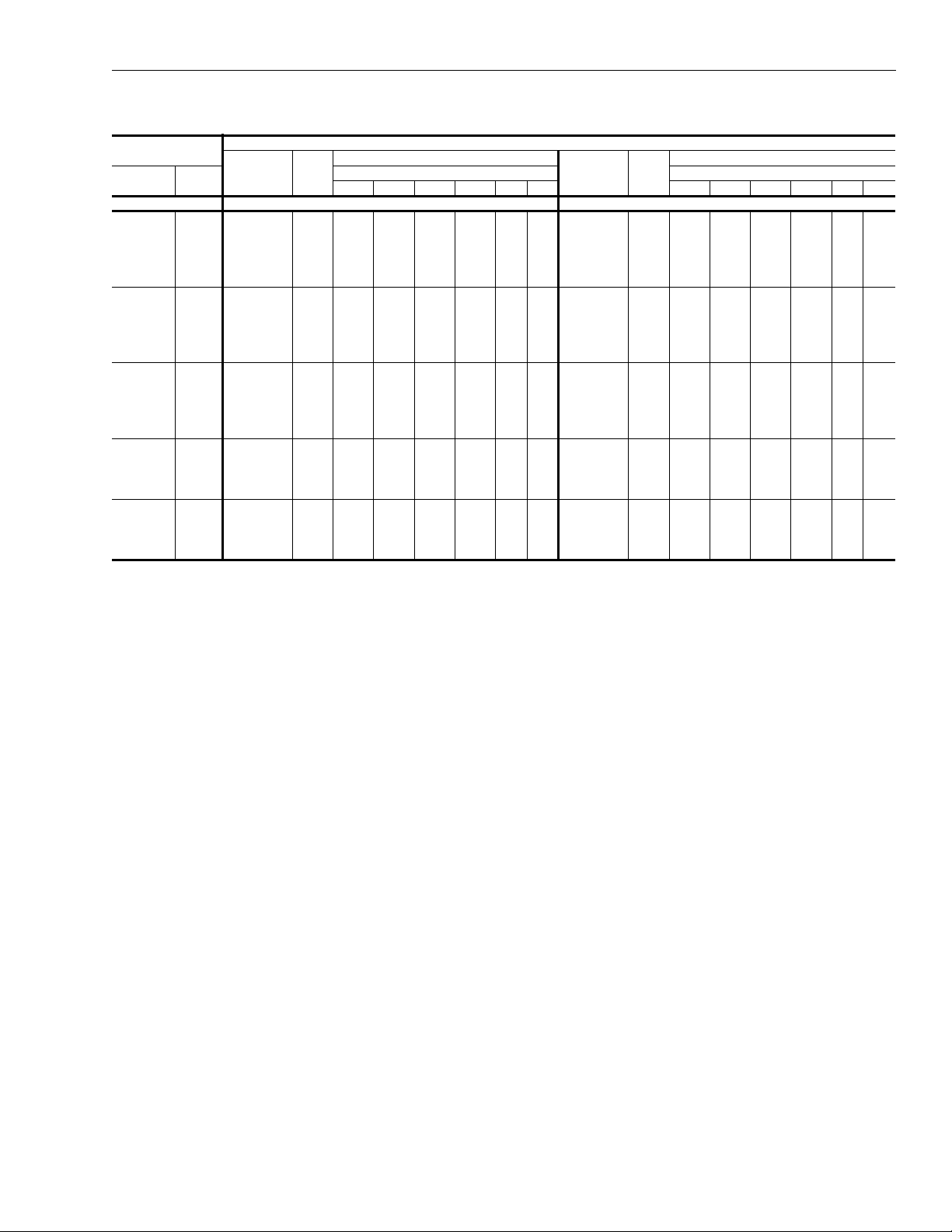

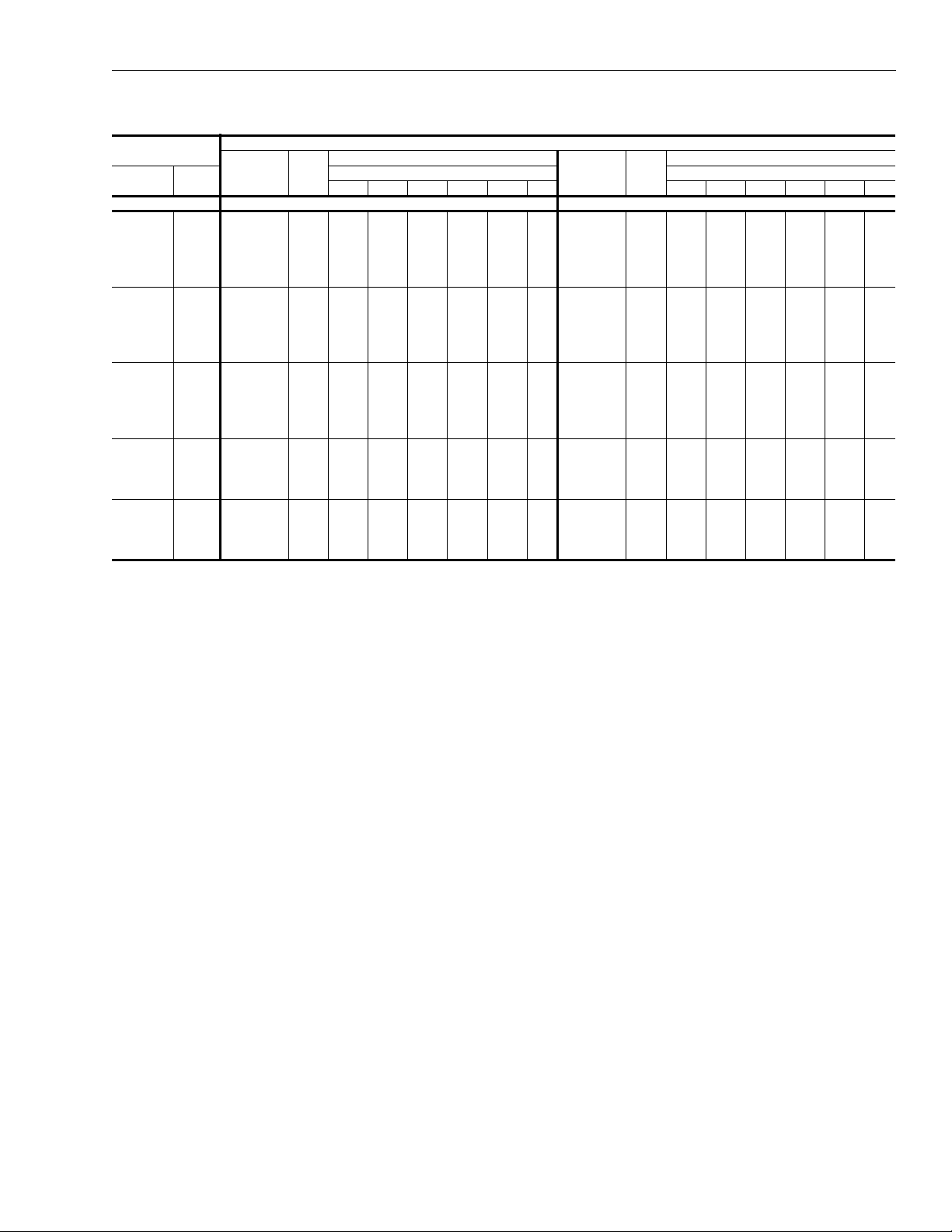

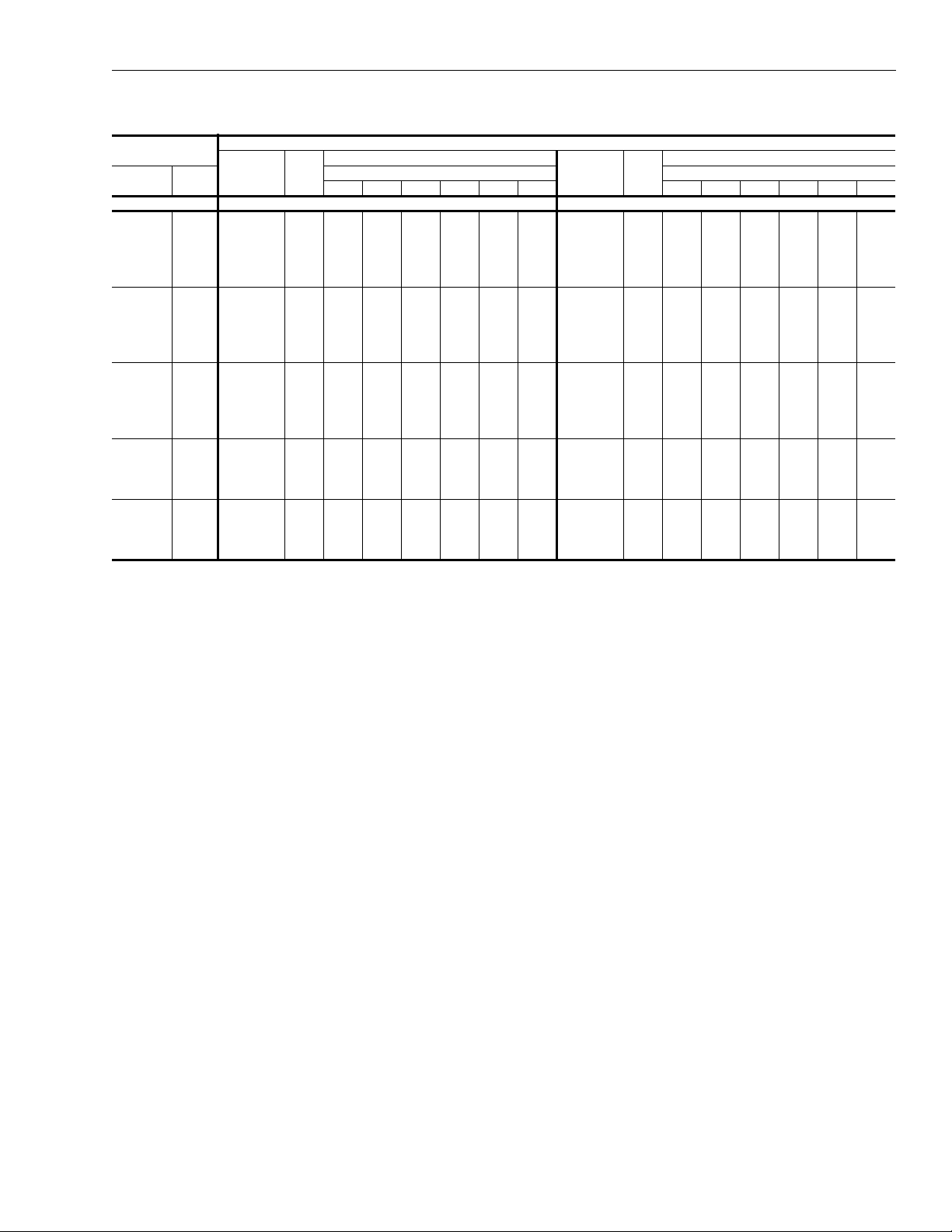

YC090 - 300 and YD120 - 240 Physical Data

Single

Scroll

Models

Tandem

Scroll

Single

Scroll

Tandem

Scroll

Single

Scroll

Tandem

Scroll

Component

Nominal Tonnage 7.5101012.512.51515202025

REFRIGERANT

Refrigerant type R-410A R-410A R-410A R-410A R-410A R-410A R-410A R-410A R-410A R-410A

Holding charge (lb)

Operating Charge (lb)

DIMENSIONS (inches)

Length 59.1 59.1 59.1 59.1 59.1 59.1 59.1 59.1 59.1 59.1

Width 31.9 31.9 31.9 31.9 31.9 64.1 64.1 64.1 64.1 64.1

Height 44.5 50.0 50.0 50.0 50.0 44.5 44.5 50.0 50.0 50.0

WEIGHTS (lb)

Shipping 390 499 493 499 493 914 899 945 930 945

Operating 387 497 490 497 490 909 894 942 927 942

COMPRESSORS

Type

Quantity 1121212121

Nominal Capacity (Tons)

Capacity Stages

SYSTEM DATA

No. Refrigeration Circuits 1121212121

Suction Line OD (in.) 1 1/8 1 3/8 1 1/8 1 3/8 1 1/8 1 5/8 1 3/8 1 5/8 1 3/8 1 5/8

Liquid Line OD (in.) 5/8 7/8 5/8 7/8 5/8 7/8 5/8 7/8 5/8 7/8

OUTDOOR COIL DATA

Face area (Sq. Ft.) 23.8 29.0 29.0 29.0 29.0 47.5 47.5 58.1 58.1 58.1

Rows 1111111111

Fins per inch 23 23 23 23 23 23 23 23 23 23

Tube diameter (in./MM) 0.71 / 18 0.71 / 18 0.71 / 18 0.71 / 18 0.71 / 18 0.71 / 18 0.71 / 18 0.71 / 18 0.71 / 18 0.71 / 18

Circuitry Type 2-pass 2-pass 2-pass 2-pass 2-pass 2-pass 2-pass 2-pass 2-pass 2-pass

Refrigerant Control --- --- --- --- --- --- --- --- --- ---

CONDENSER FAN DATA

No. Fans / Diameter (in.) 2/24 2/24 2/24 2/24 2/24 4/24 4/24 4/24 4/24 4/24

Type Axial Axial Axial Axial Axial A xial Axial Axial Axial Axial

Drive type Direct Direct Direct Direct Direct Direct Direct Direct Direct Direct

No. speeds 1111111111

Number of motors

Motor HP (ea.) 1/3 3/4 3/4 3/4 3/4 1/3 1/3 3/4 3/4 3/4

4

Rotation

RPM 850 1100 1100 1100 1100 850 850 1100 1100 1100

Nominal CFM

1

Holding Charge is the amount in the unit as shipped from the factory.

2

Includes matched indoor blower unit with 25 ft of piping.

3

All compressors include crankcase heaters.

4

When viewing the shaft end of the motor.

1

(each system)

System #1 14.0 18.0 9.9 24.0 11.5 27.0 13.5 33.5 18.8 35

2

System #2 --- --- 9.9 --- 11.5 --- 13.5 --- 18.8 ---

System #1 7.5 10 5 12.5 6.3 15 7.5 20 10 25

System #2 --- --- 5 --- 6.3 --- 7.5 --- 10 --System #11212121212

System #2 --- --- 1 --- 1 --- 1 --- 1 ---

3

System #12222242424

System #2 --- --- --- --- --- --- 2 --- 2 ---

System #1 7500 9800 9800 9800 9800 15000 7500 19600 9800 19600

System #2 --- --- --- --- --- --- 7500 --- 9800 ---

YC090 YC120 YD120 YC150 YD150 YC180 YD180 YC240 YD240 YC300

1.0 1.0 1.0 1.0 1.0 1.0 1.0 1.0 1.0 1.0

Single

Scroll

CW CW CW CW CW CW CW CW CW CW

Tandem

Scroll

Single

Scroll

Tandem

Scroll

Johnson Controls Unitary Products 9

Page 10

505428-YTG-R-1114

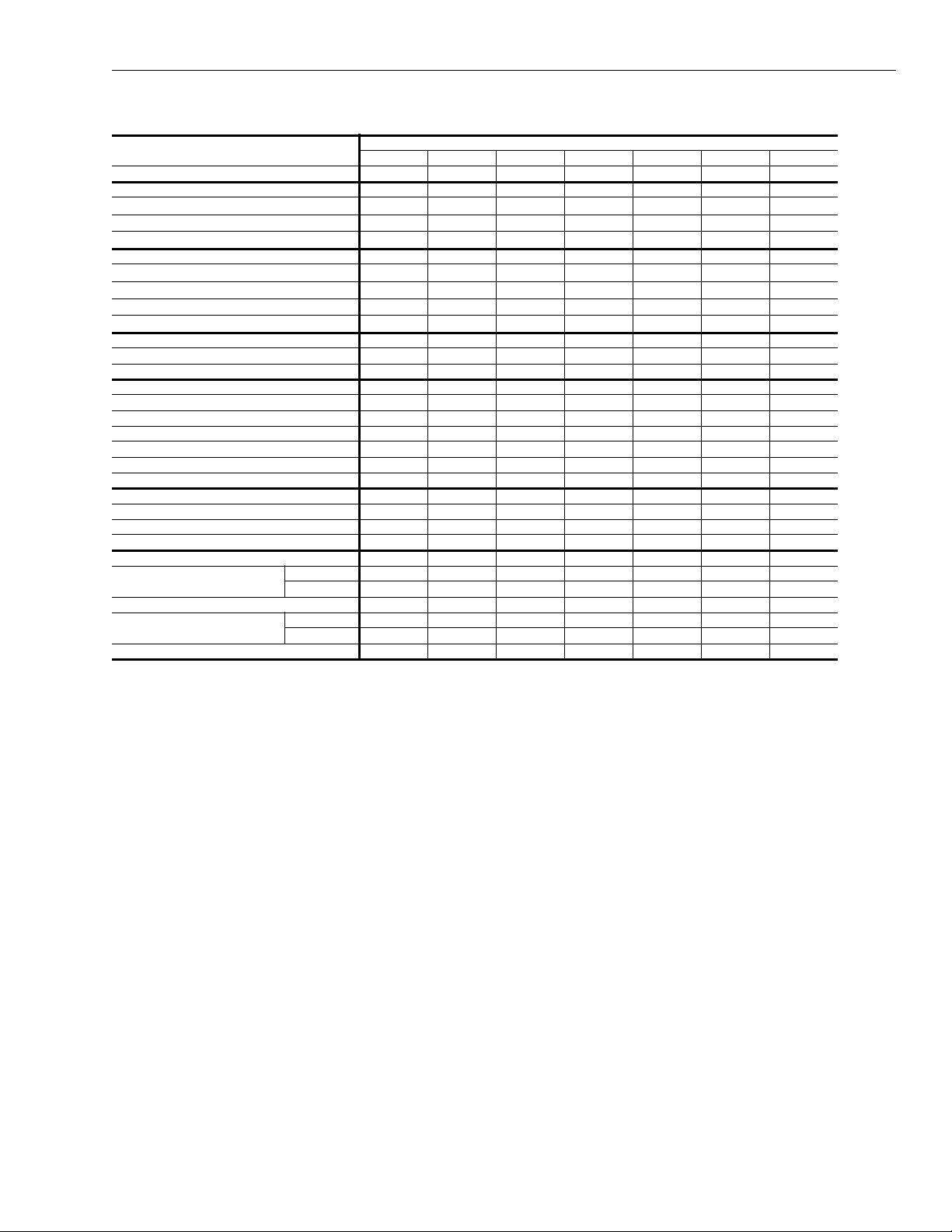

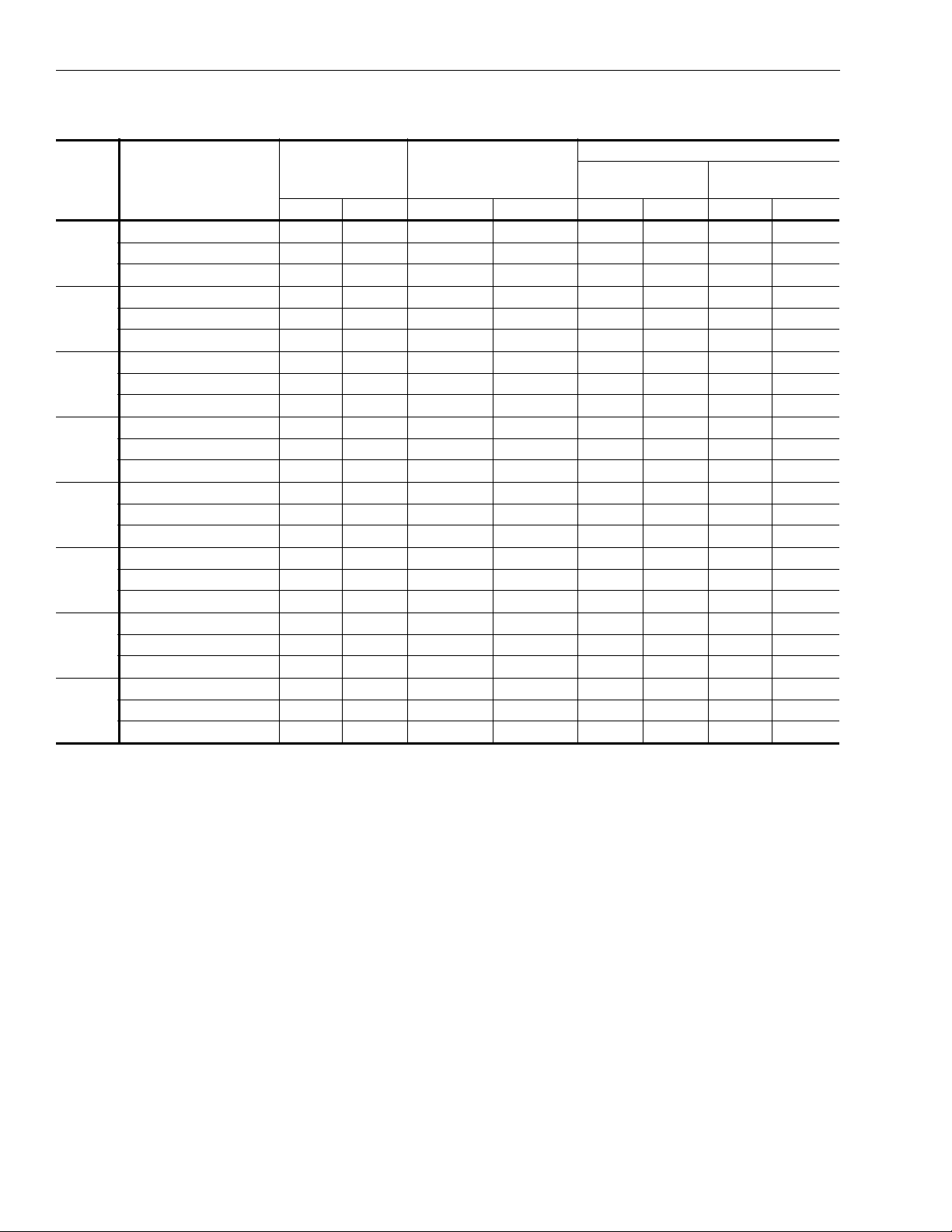

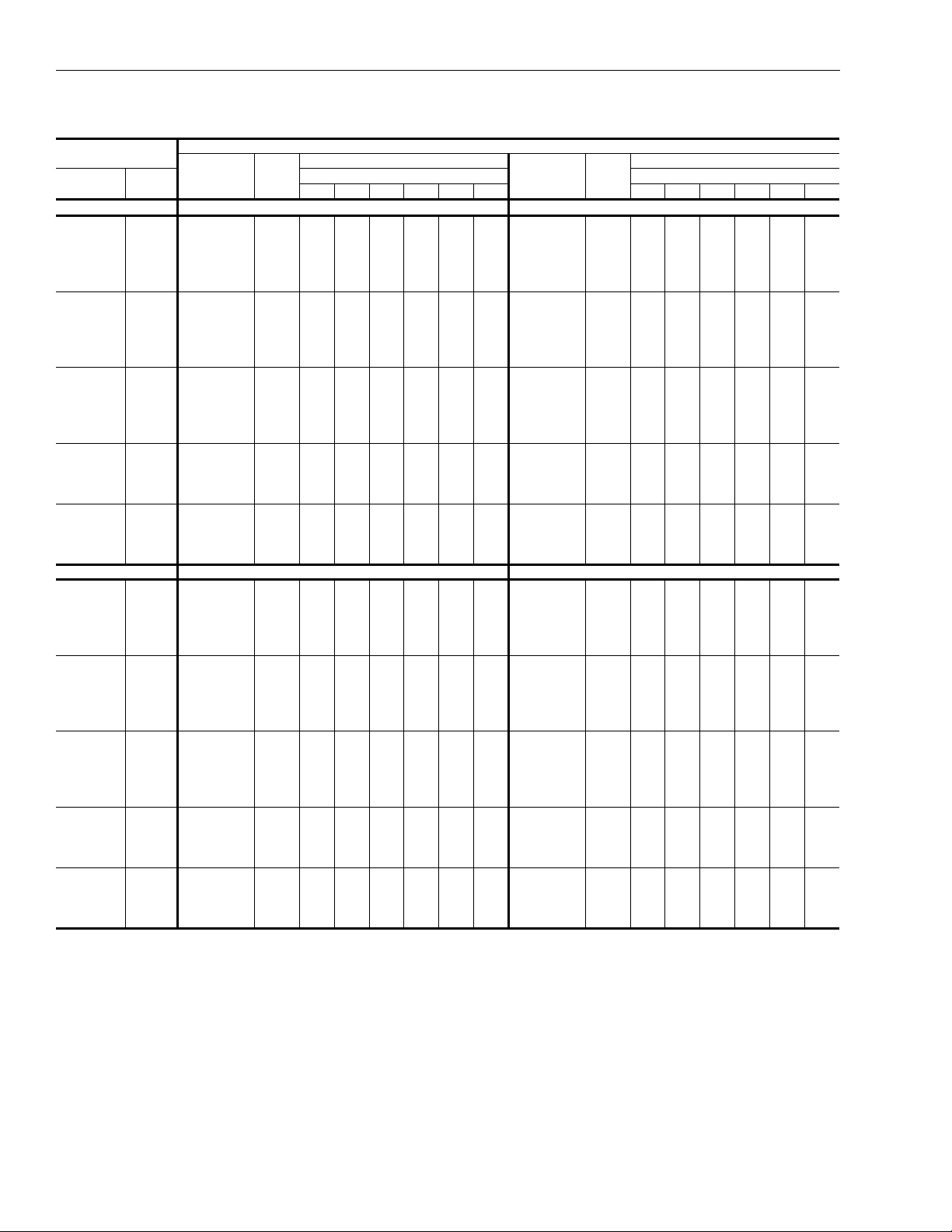

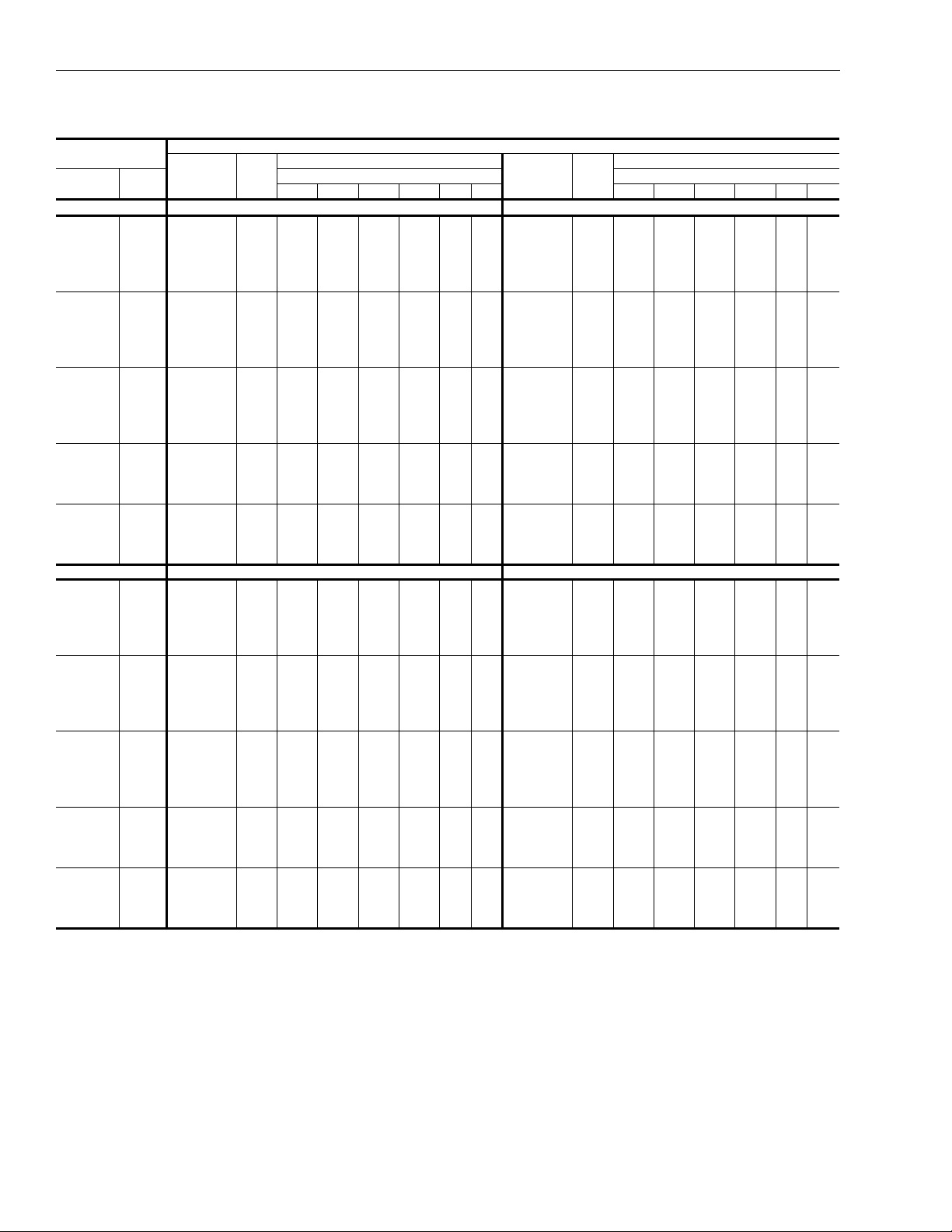

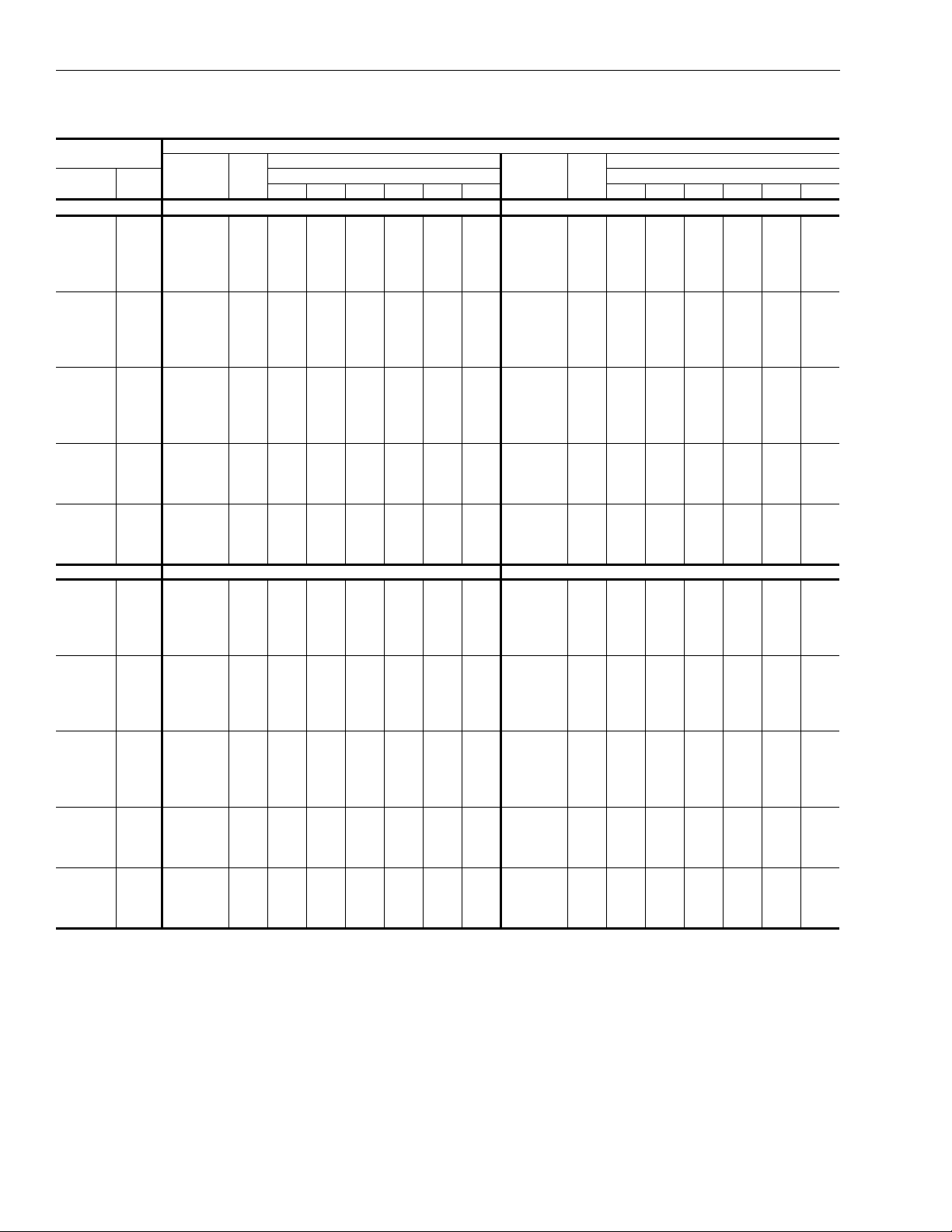

PC090 - 240 and PD180 - 240 Physical Data

Component

PC090 PC120 PC180 PD180 PD240

Nominal Tonnage 7.5 10 15 15 20

REFRIGERANT

Refrigerant type R-410A R-410A R-410A R-410A R-410A

Holding charge (lb)

Operating Charge (lb)

1

1.0 1.0 1.0 1.0 1.0

2

System #1 23.9 31.75 54.0 27.0 34.0

System #2 --- --- --- 27.0 34.0

DIMENSIONS (inches)

Length 59.1 59.1 59.1 59.1 59.1

Width 31.9 31.9 64.1 64.1 64.1

Height 44.5 50.0 44.5 44.5 50.0

WEIGHTS (lb)

Shipping 421 543 947 921 1090

Operating 430 574 968 942 1126

COMPRESSORS

3

Type Single Scroll Tandem Scroll Tandem Scroll Single Scroll Single Scroll

Quantity 1 1 1 2 2

Cooling

Nominal Capacity (Tons)

Capacity Stages

System #1 7.5 10 15 7.5 10

System #2 --- - -- --- 7.5 10

System #112211

System #2 --- --- --- 1 1

Heating

Nominal Capacity (Tons) System #1 & #2 7.5 10 15 15 20

Capacity Stages System #1 & #2 1 1 1 1 1

SYSTEM DATA

No. Refrigeration Circuits 1 1 1 2 2

Suction Line OD (in.) 1 1/8 1 3/8 1 5/8 1 3/8 1 3/8

Liquid Line OD (in.) 5/8 7/8 7/8 5/8 5/8

OUTDOOR COIL DATA

Face area (Sq. Ft.) 23.8 29.0 47.5 47.5 58.1

Rows 22222

Fins per inch 20 20 20 20 20

Tube diameter (in./MM) 0.38 / 10 0.38 / 10 0.38 / 10 0.38 / 10 0.38 / 10

Circuitry Type Interlaced Interlaced Interlaced Interlaced Interlaced

Refrigerant Control TXV TXV TXV TXV TXV

CONDENSER FAN DATA

No. Fans / Diameter (in.) 2/24 2/24 4/24 4/24 4/24

Type Axial Axial Axial Axial Axial

Drive type Direct Direct Direct Direct Direct

No. speeds 1 1 1 1 1

Number of motors

Motor HP (ea.) 1/3 3/4 1/3 1/3 3/4

4

Rotation

System #122422

System #2 --- --- --- 2 2

CW CW CW CW CW

RPM 850 1100 850 850 1100

Nominal CFM

1

Holding Charge is the amount in the unit as shipped from the factory.

2

Includes matched evaporator unit with 25 ft of piping.

3

All compressors include crankcase heaters.

4

When viewing the shaft end of the motor.

System #1 7500 9800 15000 7500 9800

System #2 --- --- --- 7500 9800

Models

10 Johnson Controls Unitary Products

Page 11

505428-YTG-R-1114

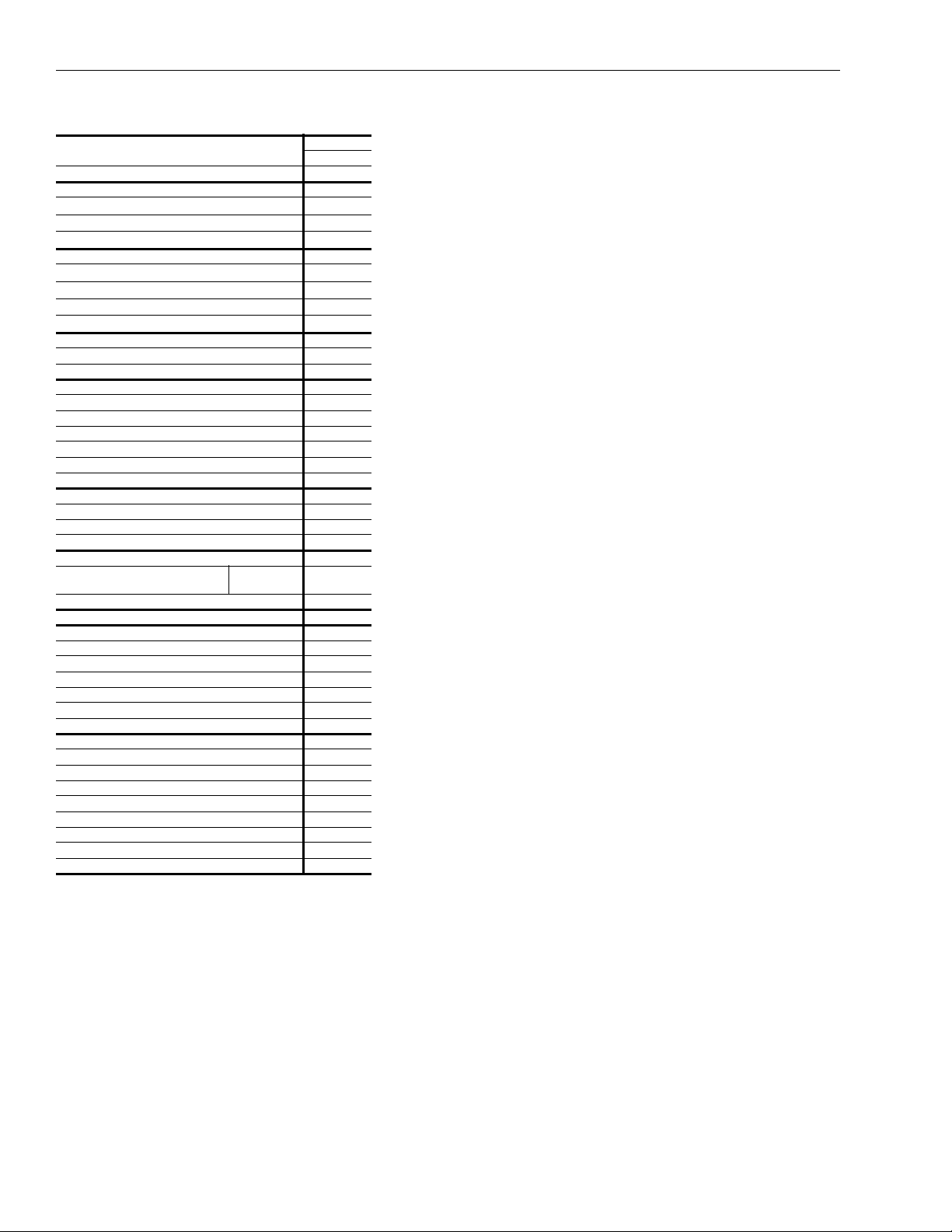

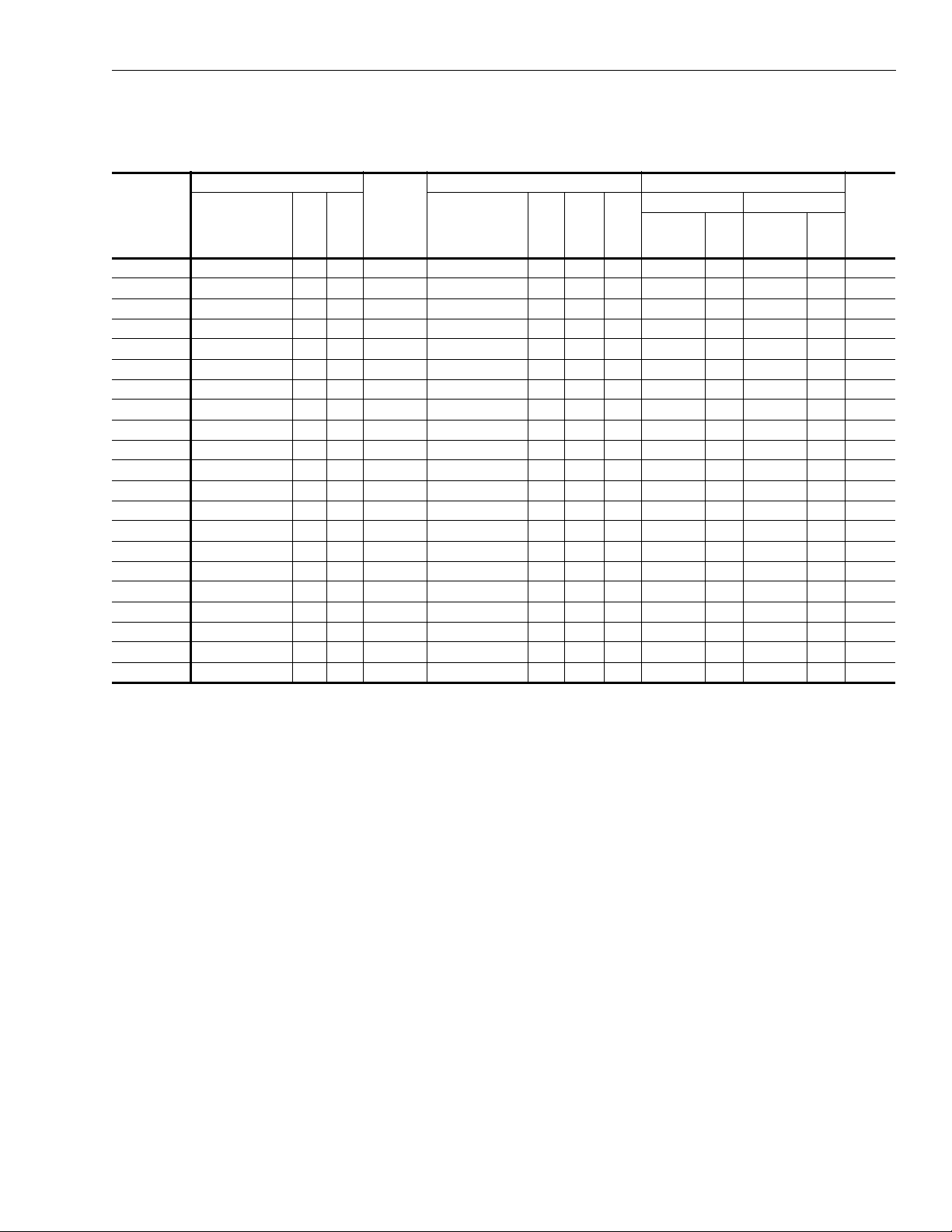

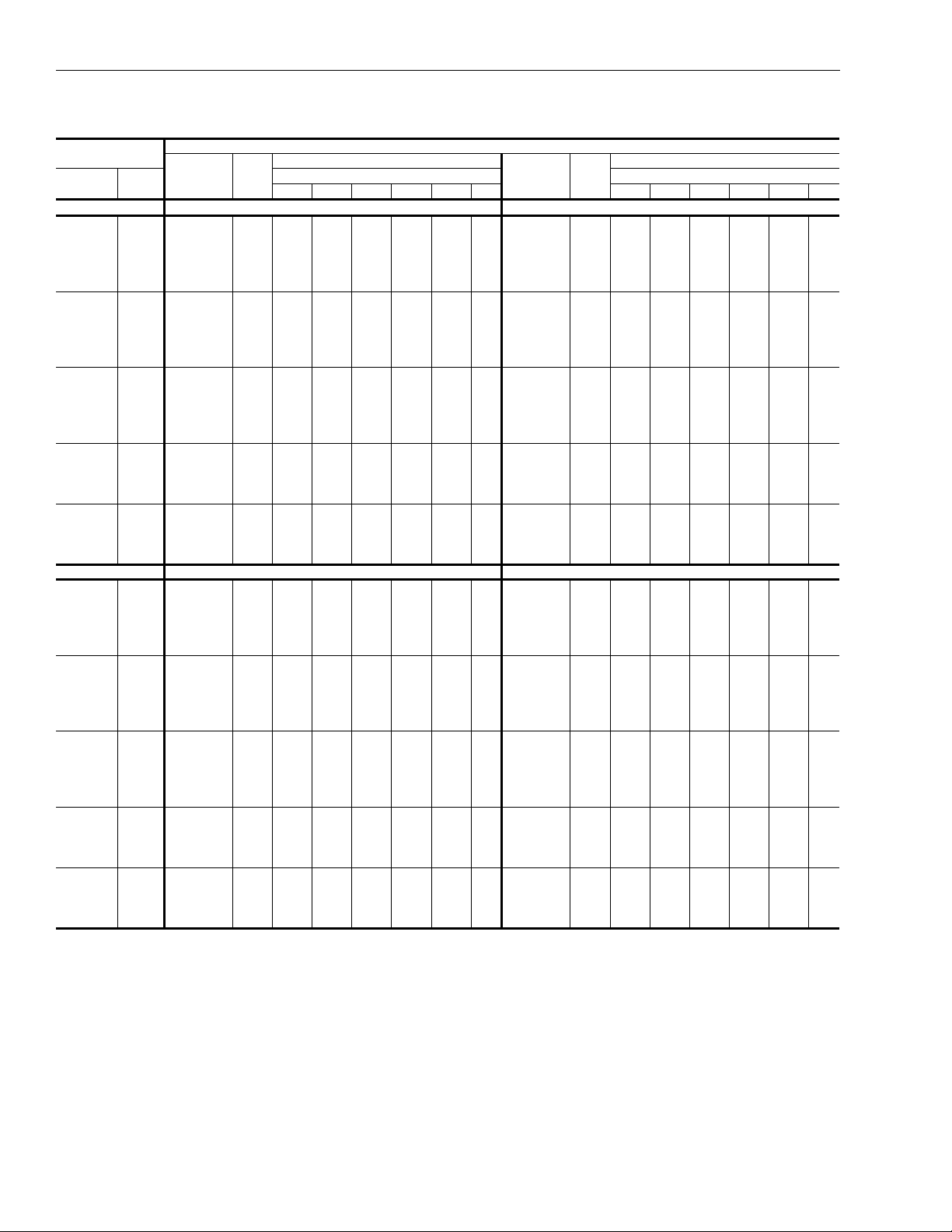

NC090 - 240 and ND120 - 240 Indoor Unit Physical Data

Component

Nominal Tonnage 7 1/2101015152020

DIMENSIONS (inches)

Length

Width

Height

WEIGHTS (lb)

Unit Shipping

Unit Operating With

Standard Motor and Drive

High Static Motor and Drive

INDOOR BLOWER (Forward Curve)

Diameter x Width 12 x 12 15 x 15 15 x 15 18 x 18 18 x 18 15 x 15 15 x 15

Quantity 1111122

Face area (Sq. Ft.) 10.6 10.6 10.6 18.3 18.3 20.0 20.0

Rows 3443444

Fins per inch 15 15 15 15 15 15 15

Tube diameter 3/8 3/8 3/8 3/8 3/8 3/8 3/8

Circuitry Type Interlaced Interlaced Interlaced Interlaced Interlaced Interlaced Interlaced

Refrigerant Control TXV TXV TXV TXV TXV TXV TXV

No. Refrigeration Circuits 1121212

Suction Line OD (in.) 1 1/8 1 3/8 1 1/8 1 5/8 1 3/8 1 5/8 1 3/8

Liquid Line OD (in.) 5/8 7/8 5/8 7/8 5/8 7/8 7/8

Size and Quantity Per

Model (In.)

Size and Quantity Per

Model (In.)

INDOOR COIL

SYSTEM DATA

FILTERS

16 x 25 x 2 4 4 4 --- --- 8 8

20 x 24 x 2 --- --- --- 6 6 --- ---

FACE AREA (SQ. FT.) 11.1 11.1 11.1 20.0 20.0 22.2 22.2

16 x 25 x 4 4 4 4 --- --- 8 8

20 x 24 x 4 --- --- --- 6 6 --- ---

FACE AREA (SQ. FT.) 11.1 11.1 11.1 18.0 18.0 22.2 22.2

NC090 NC120 ND120 NC180 ND180 NC240 ND240

56.0 56.0 56.0 74.5 74.5 98.5 98.5

30.0 30.0 30.0 33.0 33.0 30.0 30.0

65.0 65.0 65.0 75.0 75.0 65.0 65.0

526 573 575 796 796 938 938

498 539 541 764 764 873 873

500 550 552 792 792 903 903

Models

Johnson Controls Unitary Products 11

Page 12

505428-YTG-R-1114

NC300 Indoor Unit Physical Data

Component

Nominal Tonnage 25

DIMENSIONS (inches)

Length

Width

Height

WEIGHTS

Unit Shipping

Unit Operating With

5 hp Motor and Drive

7.5 hp Motor and Drive

INDOOR BLOWER (Forward Curve)

Diameter x Width 18 X 18

Quantity 2

Face area (Sq. Ft.) 25.8

Rows 4

Fins per inch 16

Tube diameter 3/8

Circuitry Type Interlaced

Refrigerant Control TEV

No. Refrigeration Circuits 1

Suction Line OD (in.) 2 1/8

Liquid Line OD (in.) 7/8

Size and Quantity Per

Face area (Sq. Ft.) 21.2

Rows 2

Fins per inch 12

Tube diameter (Copper) OD (In.) 1/2

Connections (Supply and Return) OD (In.) 1 3/8

Weight (lb) 150

Face area (Sq. Ft.) 18.2

Rows 1

Fins per inch 8

Tube diameter (Copper) (In.) 1

Connection, (NPTE) (In.)

Inlet 2

Outlet 1-1/2

Weight (lb) 160

1

Motors, Drive and Overload Kits must be

INDOOR COIL

SYSTEM DATA

Model (In.)

FACE AREA (SQ. FT.) 34.7

ACCESSORY

HOT WATER COIL DATA

SYSTEM COIL DATA

FILTERS

1

(lb)

20 x 25 x 2 10

ordered separately for the NC300. The Motor

Drive and Overload Kits are to be field installed.

Models

NC300

100.1

38.1

74.6

1067

1130

1157

12 Johnson Controls Unitary Products

Page 13

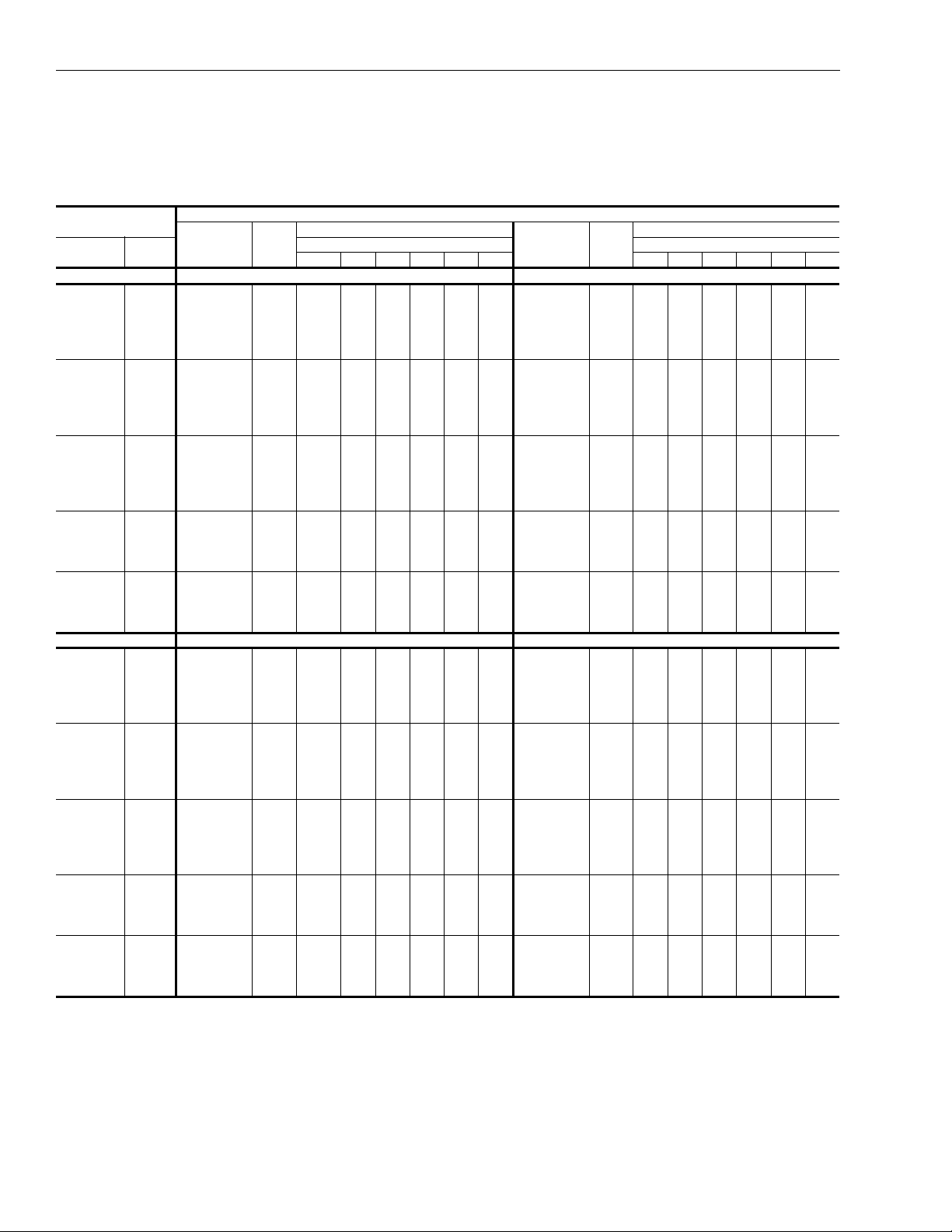

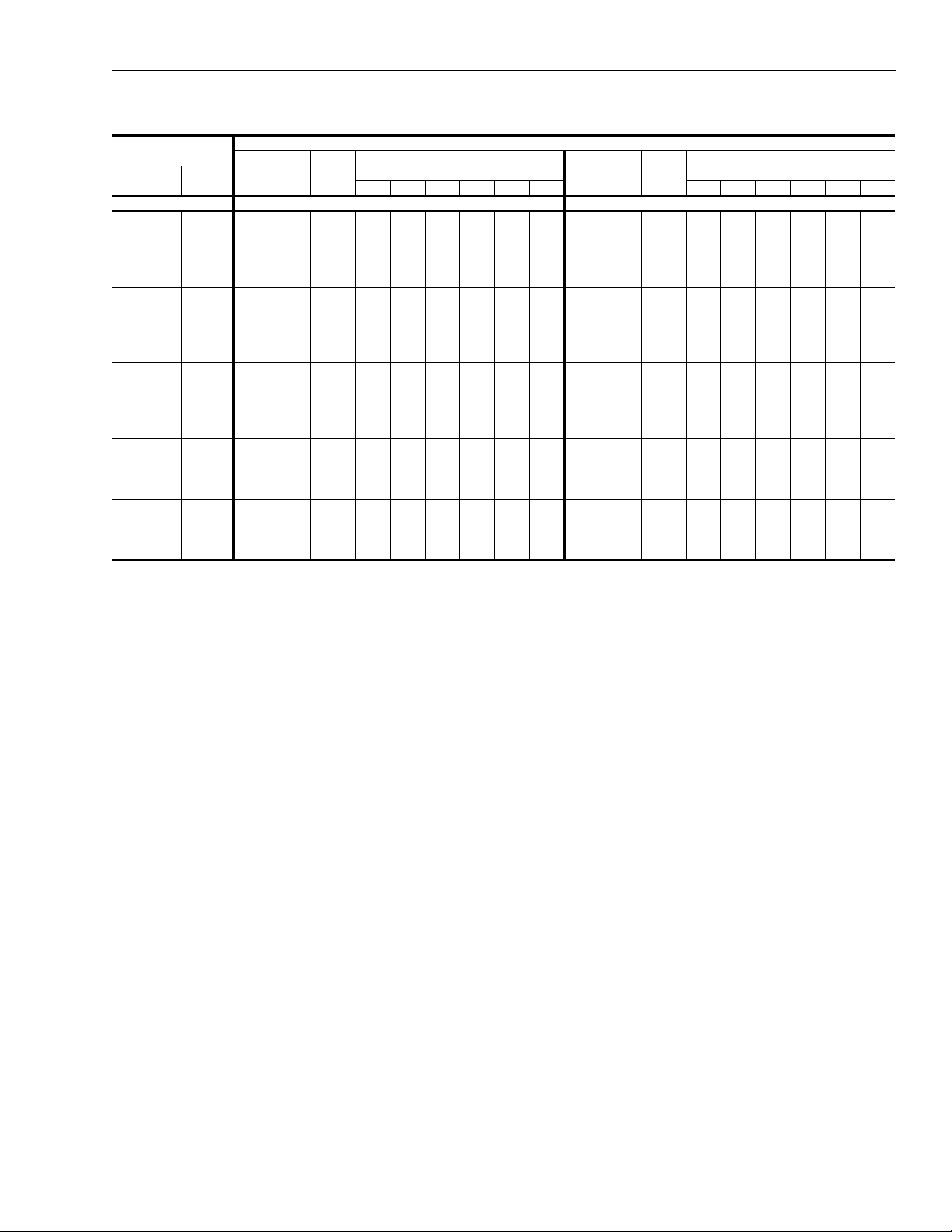

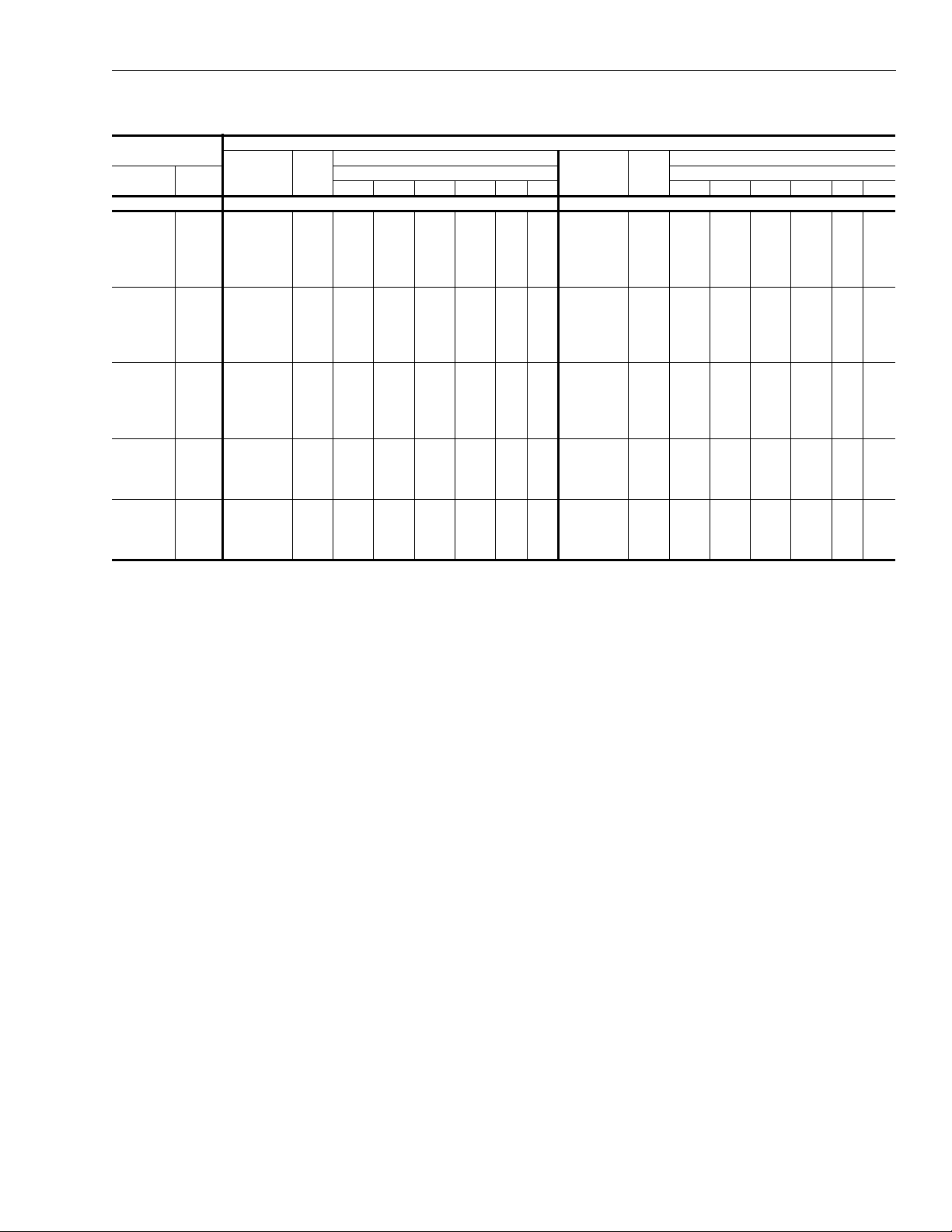

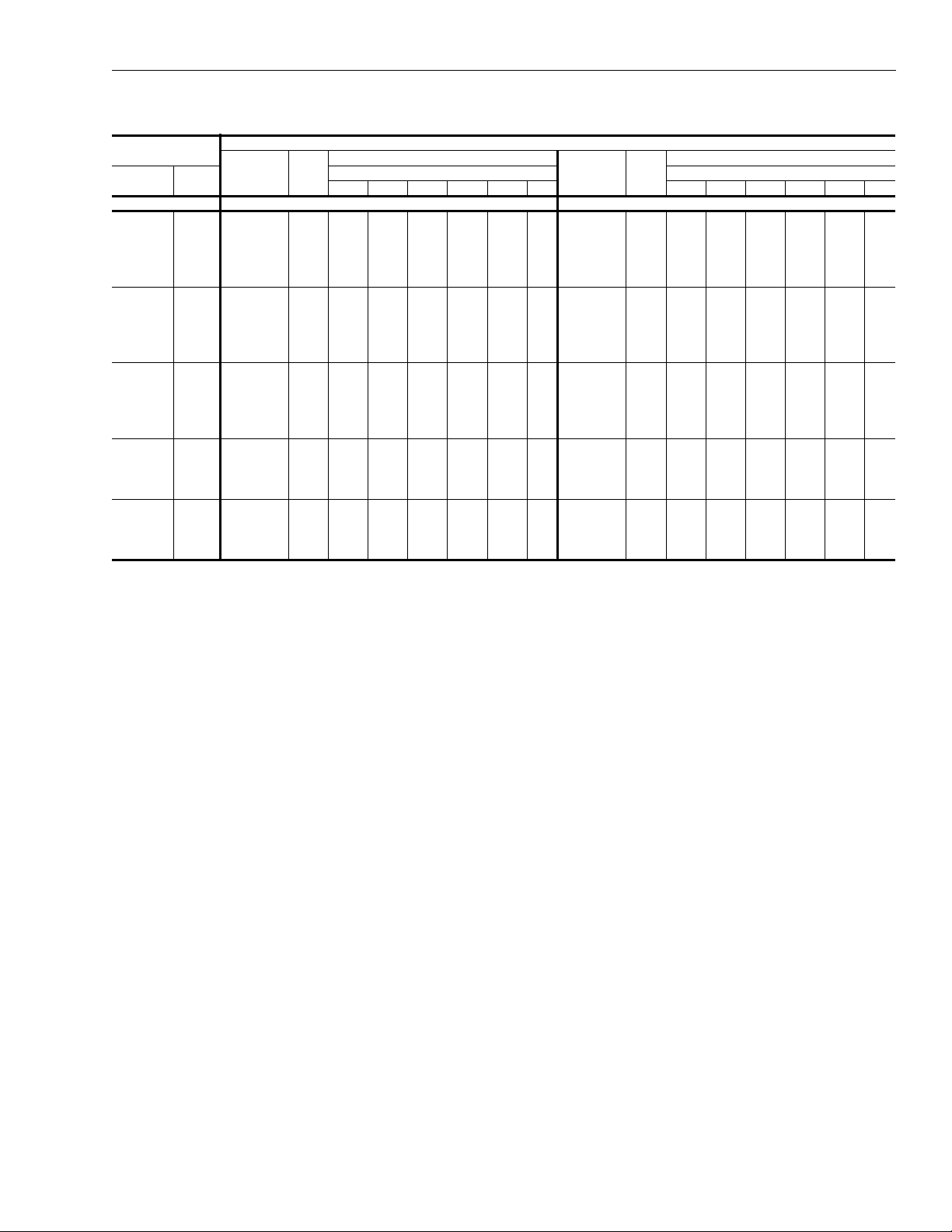

Unit Limitations

Condenser Unit limitations

Outdoor DB Temp

Size

(Tons)

090

(7.5)

090

(7.5)

120

(10)

120

(10)

150

(12.5)

180

(15)

180

(15)

240

(20)

240

(20)

300

(25)

Model

PC

YC

PC

YC/YD

YC/YD

PC/PD

YC/YD

PC/PD

YC/YD

YC

Unit Voltage

Applied Voltage

Min Max Max Min

208/230-3-60 187 252

575-3-60 540 630

208/230-3-60 187 252

575-3-60 540 630

208/230-3-60 187 252

575-3-60 540 630

208/230-3-60 187 252

575-3-60 540 630

208/230-3-60 187 252

575-3-60 540 630

208/230-3-60 187 252

575-3-60 540 630

208/230-3-60 187 252

575-3-60 540 630

208/230-3-60 187 252

575-3-60 540 630

208/230-3-60 187 252

575-3-60 540 630

208/230-3-60 187 252

575-3-60 540 630

1

Cooling (°F)

125 40 86 68 70 0 80 50460-3-60 432 504

125 40 86 68 - - - -460-3-60 432 504

125 40 86 68 70 0 80 50460-3-60 432 504

125 40 86 68 - - - -460-3-60 432 504

125 40 86 68 - - - -460-3-60 432 504

125 40 86 68 70 0 80 50460-3-60 432 504

125 40 86 68 - - - -460-3-60 432 504

125 40 86 68 70 0 80 50460-3-60 432 504

125 40 86 68 - - - -460-3-60 432 504

125 40 86 68 - - - -460-3-60 432 504

1. Rated in accordance with AHRI Standard 110, Range “A” Utilization Voltage.

†. Low Ambient accessories are available to permit stable system operation at ambient temperatures down to 0°F.

Indoor DB Temp

†

Cooling (°F)

Max Min Max Min Max Min

Outdoor DB Temp

Heating (°F)

505428-YTG-R-1114

Indoor DB Temp

Heating (°F)

Johnson Controls Unitary Products 13

Page 14

505428-YTG-R-1114

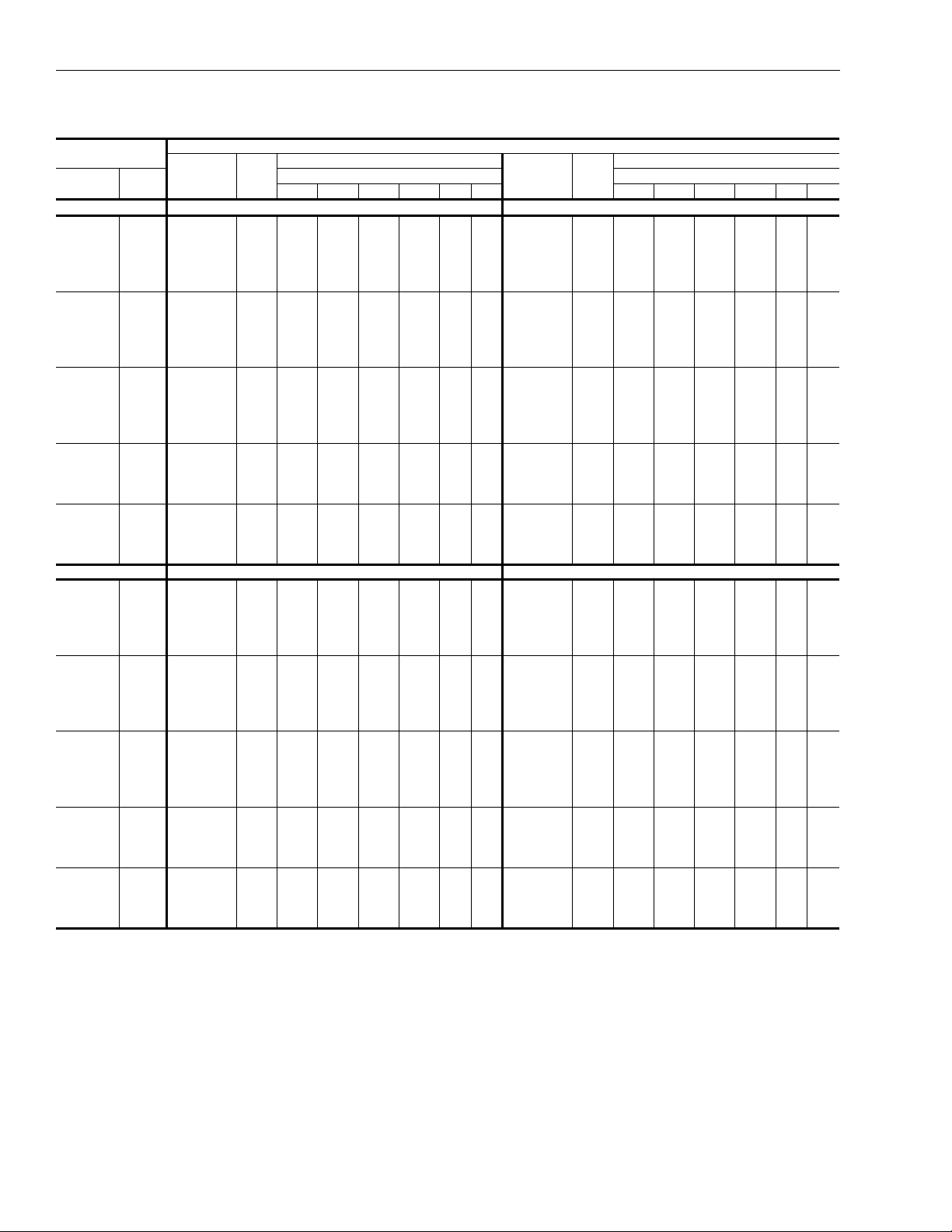

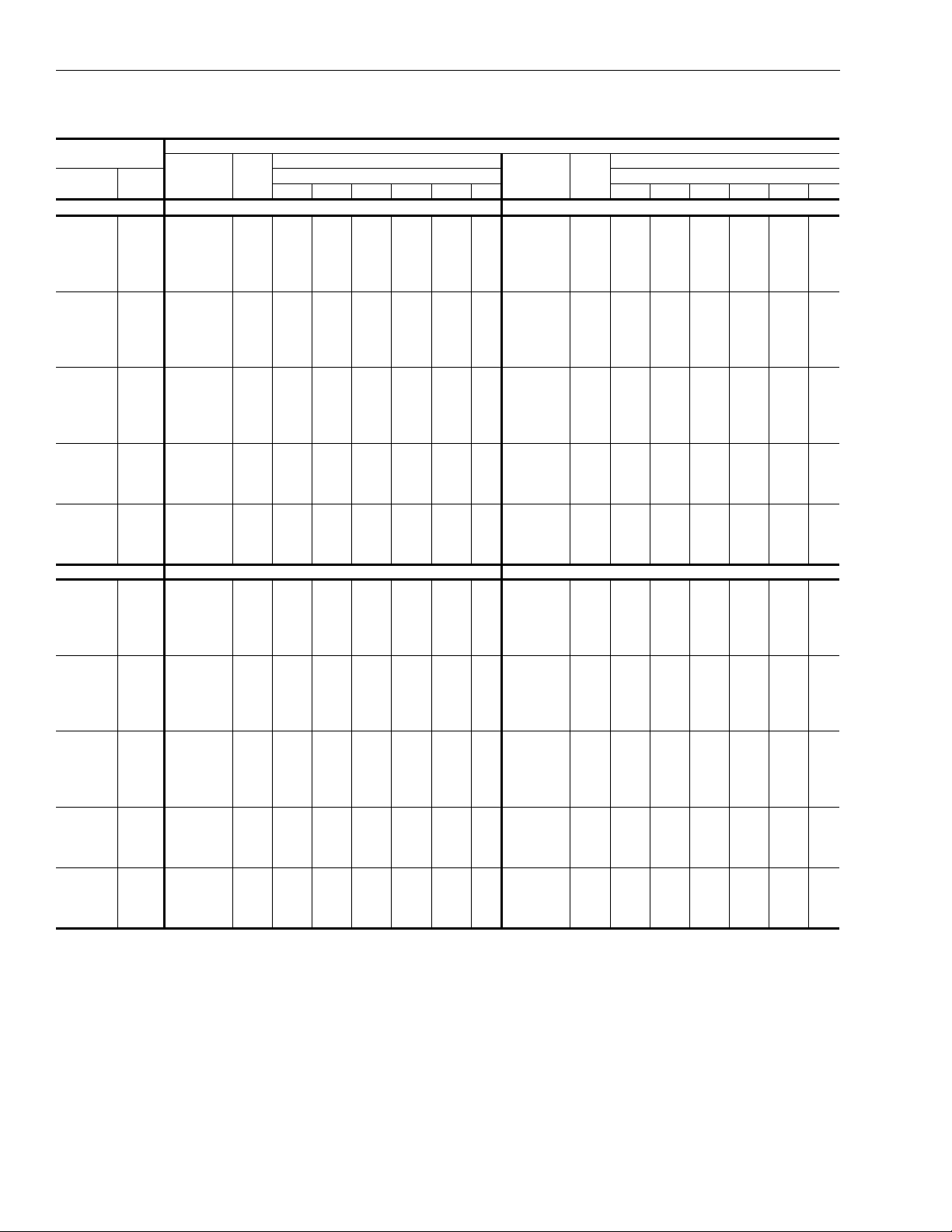

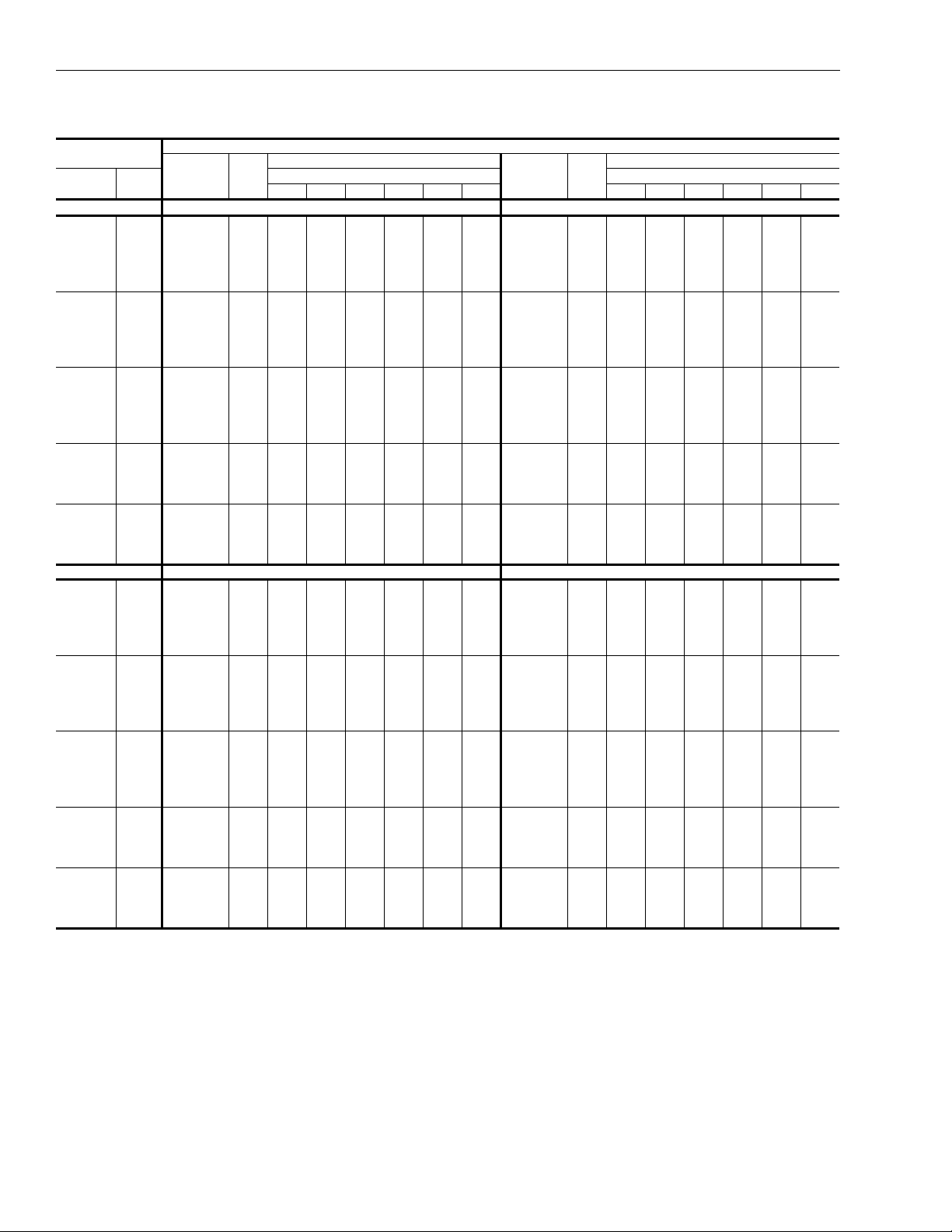

Air Handling Unit Limitations

Entering Air Temperature Degrees °F

Model Power Supply Voltage

Voltage Variation Supply Air Range CFM

Cooling

DB/WB

Min. Max. Min. Max. Min. Max. Min. Max.

208/230-3-60 187 253 2,250 3,750 65/57 90/77 40 80

NC090

460-3-60 414 506 2,250 3,750 65/57 90/77 40 80

575-3-60 540 630 2,250 3,750 65/57 90/77 40 80

208/230-3-60 187 253 3,000 5,000 65/57 90/77 40 80

NC120

460-3-60 414 506 3,000 5,000 65/57 90/77 40 80

575-3-60 540 630 3,000 5,000 65/57 90/77 40 80

208/230-3-60 187 253 3,000 5,000 65/57 90/77 40 80

ND120

460-3-60 414 506 3,000 5,000 65/57 90/77 40 80

575-3-60 540 630 3,000 5,000 65/57 90/77 40 80

208/230-3-60 187 253 4,500 7,500 65/57 90/77 40 80

NC180

460-3-60 414 506 4,500 7,500 65/57 90/77 40 80

575-3-60 540 630 4,500 7,500 65/57 90/77 40 80

208/230-3-60 187 253 4,500 7,500 65/57 90/77 40 80

ND180

460-3-60 414 506 4,500 7,500 65/57 90/77 40 80

575-3-60 540 630 4,500 7,500 65/57 90/77 40 80

208/230-3-60 187 253 6,000 10,000 65/57 90/77 40 80

NC240

460-3-60 414 506 6,000 10,000 65/57 90/77 40 80

575-3-60 540 630 6,000 10,000 65/57 90/77 40 80

208/230-3-60 187 253 6,000 10,000 65/57 90/77 40 80

ND240

460-3-60 414 506 6,000 10,000 65/57 90/77 40 80

575-3-60 540 630 6,000 10,000 65/57 90/77 40 80

208/230-3-60 187 253 8,000 12,000 65/57 90/77 40 80

NC300

460-3-60 414 506 8,000 12,000 65/57 90/77 40 80

575-3-60 540 630 8,000 12,000 65/57 90/77 40 80

1

Heating Min/Max temperatures apply to steam and hot water coils. NOTE: Do not apply steam to hot water coils.

Heating DB

1

14 Johnson Controls Unitary Products

Page 15

505428-YTG-R-1114

Cooling and Heating Ratings

Cooling And Heating Rating

Condensing Unit Only

Outdoor Unit

PC090

PC120

PC180

PD180

PD240

YC090 85 6.8 12.4 NC090 94 11.2 13.0 --- N/A N/A N/A N/A 3000

YC090 85 6.8 12.4 NC120 99 11.9 13.0 --- N/A N/A N/A N/A 3000

YC120 110 9.3 11.9 NC120 124 11.4 12.5 12.9 N/A N/A N/A N/A 4000

YD120 108 9.1 11.8 ND120 124 11.2 11.2 11.6 N/A N/A N/A N/A 4000

YC150 133 11.6 11.5 NC180 150 11.0 13.3 13.8 N/A N/A N/A N/A 5000

YD150 136 11.5 11.8 ND180 150 11.0 12.1 12.3 N/A N/A N/A N/A 5000

YC180 160 13.4 12.0 NC180 181 11.2 12.2 12.5 N/A N/A N/A N/A 6000

YC180 160 13.4 12.0 NC240 190 11.7 12.7 12.5 N/A N/A N/A N/A 6000

YD180 166 12.3 13.4 ND180 181 11.2 11.6 12.4 N/A N/A N/A N/A 6000

YD180 166 12.3 13.4 (2)NC090 187 11.2 -- -- N/A N/A N/A N/A 6000

YD180 166 12.3 13.4 (2)NC120 187 11.2 -- -- N/A N/A N/A N/A 6000

YD180 166 12.3 13.4 ND240 190 11.7 13.4 11.2 N/A N/A N/A N/A 6000

YC240 233 17.5 13.2 NC240 242 11.3 13.6 13.1 N/A N/A N/A N/A 8000

YD240 222 17.3 12.8 ND240 242 11.3 11.9 12.6 N/A N/A N/A N/A 8000

YD240 222 17.3 12.8 (2)NC120 240 11.6 -- -- N/A N/A N/A N/A 8000

YC300 271 23.7 11.4 NC300 299 10.2 12.2 -- N/A N/A N/A N/A 10000

1

Certified in accordance with the Unitary Large Equipment certification program, which is based on AHRI Standard 340/360. (Except

YC300)

2

Condensing unit only ratings are at 45°F SST and 95°F entering-air temperature.

3

Gross capacity does not include heat added by blower motor. Refer to appropriate table for blower horsepower.

4

Heat Pumps designed for matched systems only.

Gross Capacity

(MBH)

4

4

4

4

4

2

KW EER

N/A N/A N/A NC090 92 11.0 11.4 --- 82 3.3 49 2.3 3000

N/A N/A N/A NC120 124 11.0 11.4 11.8 109 3.3 63 2.1 4000

N/A N/A N/A NC180 180 10.6 11.5 12.4 168 3.3 104 2.3 6000

N/A N/A N/A ND180 180 10.6 11.5 12.0 168 3.4 103 2.4 6000

N/A N/A N/A ND240 238 10.6 11.7 12.1 220 3.4 124 2.2 8000

Indoor

Unit

System Cooling Capacity

Gross Capacity

(MBH)

3

EER IEER IPLV

1

Capacity

Heating Capacity

High Outdoor Low Outdoor

Gross

2

(MBh)

COP

Gross

Capacity

(MBh)

1

2

COP

Rated

Airflow

(CFM)

LEGEND

EER = Energy Efficiency Ratio

AHRI = Air Conditioning and Refrigeration Institute

IPLV = Integration Part-Load Value

IEER = Integrated Energy Efficiency Ratio

Johnson Controls Unitary Products 15

Page 16

505428-YTG-R-1114

Capacity Performance

Condenser and Air Handling Cooling Capacities

YC090/NC090

Air on

Evaporator Coil

CFM

2250

2625

3000

3375

3750

2250

2625

3000

3375

3750

WB

(°F)

Total

Capacity

(MBh)

77 110.8 6.0 51.5 42.0 32.6 - - - 107.2 6.5 49.8 40.4 30.9 - - 72 103.3 5.7 66.5 57.0 47.6 38.1 - - 99.9 6.3 64.9 55.4 46.0 36.5 - 67 95.9 5.5 81.5 72.0 62.6 53.1 43.6 - 92.6 6.2 80.0 70.5 61.0 51.6 42.1 62 88.0 5.4 88.0 86.3 76.8 67.3 57.8 48.3 84.8 6.1 84.8 83.9 74.5 65.0 55.5 46.1

57 77.7 5.2 77.7 77.7 72.2 62.8 53.3 43.8 80.1 6.0 80.1 80.1 73.1 63.6 54.2 44.7

77 114.0 6.0 56.3 45.6 34.8 - - - 110.2 6.5 54.6 44.0 33.3 - - 72 106.3 5.7 72.3 61.6 50.9 40.1 - - 102.7 6.3 70.8 60.2 49.6 38.9 - 67 98.7 5.4 88.4 77.6 66.9 56.2 45.5 - 95.2 6.2 87.1 76.4 65.8 55.2 44.5 62 90.6 5.4 90.6 89.7 82.2 71.9 60.7 50.0 87.1 6.1 87.1 86.7 80.3 69.6 59.0 48.3

57 79.9 5.2 79.9 79.9 77.2 67.3 55.8 45.0 82.3 6.0 82.3 82.3 78.8 68.2 57.5 46.9

77 117.2 5.9 61.0 49.1 37.1 - - - 113.1 6.5 59.4 47.5 35.7 - - 72 109.3 5.7 78.1 66.2 54.2 42.2 - - 105.4 6.4 76.8 65.0 53.1 41.3 - 67 101.4 5.4 95.2 83.2 71.3 59.3 47.3 - 97.7 6.2 94.2 82.4 70.5 58.7 46.9 62 93.1 5.4 93.1 93.1 87.5 76.5 63.6 51.6 89.5 6.1 89.5 89.5 86.1 74.2 62.4 50.6

57 82.2 5.2 82.2 82.2 82.2 71.7 58.3 46.3 84.5 6.0 84.5 84.5 84.5 72.7 60.8 49.0

72 109.2 5.8 83.0 70.2 57.3 44.4 - - 105.4 6.4 81.6 68.8 56.0 43.2 - 67 101.3 5.5 98.2 88.2 75.3 62.5 49.6 - 97.7 6.3 96.0 87.2 74.3 61.5 48.7 62 93.0 5.5 93.0 93.0 90.2 77.8 64.5 51.6 89.5 6.2 89.5 89.5 87.8 75.0 62.1 49.3

57 82.1 5.3 82.1 82.1 82.1 70.0 56.4 43.5 84.5 6.1 84.5 84.5 84.5 71.7 58.9 46.0

72 109.1 5.9 87.9 74.2 60.4 46.6 - - 105.5 6.5 86.5 72.6 58.8 45.0 - 67 101.2 5.6 101.2 93.2 79.4 65.7 51.9 - 97.8 6.3 97.8 91.9 78.1 64.3 50.5 62 92.9 5.6 92.9 92.9 92.9 79.1 65.3 51.6 89.5 6.2 89.5 89.5 89.5 75.7 61.9 48.1

57 82.0 5.4 82.0 82.0 82.0 68.2 54.4 40.7 84.5 6.1 84.5 84.5 84.5 70.7 56.9 43.1

77 103.7 6.9 48.1 38.7 29.2 - - - 99.2 8.0 47.5 38.1 28.6 - - 72 96.5 6.9 63.3 53.8 44.4 35.0 - - 92.2 8.0 62.1 52.6 43.2 33.7 - 67 89.4 6.9 78.4 69.0 59.5 50.1 40.7 - 85.2 8.0 76.6 67.2 57.7 48.3 38.8 62 81.6 6.7 81.6 81.6 72.1 62.7 53.3 43.8 77.9 7.7 77.9 77.9 69.2 59.7 50.3 40.9

57 82.5 6.7 82.5 82.5 74.0 64.5 55.1 45.7 78.8 7.8 78.8 78.8 70.0 60.5 51.1 41.6

77 106.4 7.0 52.9 42.3 31.8 - - - 101.7 8.1 53.5 41.7 31.1 - - 72 99.0 7.0 69.4 58.8 48.2 37.7 - - 94.5 8.1 68.1 57.5 46.9 36.3 - 67 91.7 6.9 85.8 75.3 64.7 54.1 43.6 - 87.3 8.0 82.8 73.3 62.7 52.1 41.5 62 83.7 6.8 83.7 83.7 78.4 67.3 57.2 46.7 79.9 7.8 79.9 79.9 75.2 64.4 54.0 43.4

57 84.6 6.7 84.6 84.6 80.4 69.1 59.2 48.7 80.7 7.9 80.7 80.7 76.1 65.1 54.8 44.2

77 109.0 7.1 57.7 46.0 34.3 - - - 104.1 8.1 59.4 45.4 33.6 - - 72 101.5 7.0 75.5 63.8 52.1 40.4 - - 96.8 8.1 74.2 62.5 50.7 38.9 - 67 94.0 7.0 93.3 81.5 69.8 58.1 46.4 - 89.4 8.1 89.0 79.5 67.8 56.0 44.3 62 85.8 6.8 85.8 85.8 84.6 72.0 61.2 49.5 81.8 7.9 81.8 81.8 81.2 69.0 57.7 46.0

57 86.8 6.8 86.8 86.8 86.8 73.6 63.4 51.7 82.7 7.9 82.7 82.7 82.1 69.6 58.6 46.9

72 101.7 7.1 80.2 67.5 54.7 41.9 - - 96.9 8.1 79.2 66.3 53.5 40.7 - 67 94.2 7.0 93.8 86.1 73.3 60.5 47.7 - 89.5 8.1 89.4 83.7 71.5 58.7 45.8 62 86.0 6.8 86.0 86.0 85.4 72.1 59.8 47.0 82.0 7.9 82.0 82.0 81.7 68.6 56.0 43.2

57 86.9 6.8 86.9 86.9 86.9 73.4 61.4 48.6 82.8 7.9 82.8 82.8 82.6 69.3 56.9 44.1

72 101.9 7.1 85.0 71.1 57.3 43.4 - - 97.1 8.1 84.1 70.2 56.3 42.4 - 67 94.3 7.0 94.3 90.7 76.8 62.9 49.1 - 89.7 8.1 89.7 87.9 75.3 61.4 47.4 62 86.1 6.9 86.1 86.1 86.1 72.3 58.4 44.5 82.1 7.9 82.1 82.1 82.1 68.2 54.3 40.4

57 87.1 6.9 87.1 87.1 87.1 73.2 59.4 45.5 83.0 7.9 83.0 83.0 83.0 69.1 55.2 41.2

Total

1

Input

2

(kW)

Sensible Capacity (MBh)

Return Dry Bulb (°F) Return Dry Bulb (°F)

90 85 80 75 70 65 90 85 80 75 70 65

75°F 85°F

95°F 105°F

Temperature of Air on Condenser Coil

Total

1

Capacity

(MBh)

Total

Input

(kW)

Sensible Capacity (MBh)

2

16 Johnson Controls Unitary Products

Page 17

505428-YTG-R-1114

YC090/NC090 (Continued)

Air on

Evaporator Coil

CFM

2250

2625

3000

3375

3750

1

These capacities are gross ratings. For net capacity, deduct supply air blower motor, MBh. Example: Refer to the appropriate Blower

WB

(°F)

77 94.7 9.0 46.9 37.5 28.0 - - - 90.2 10.1 46.3 36.9 27.4 - - 72 87.8 9.1 60.9 51.4 42.0 32.5 - - 83.4 10.2 59.7 50.2 40.8 31.3 - 67 80.9 9.1 74.8 65.4 55.9 46.5 37.0 - 76.7 10.3 73.0 63.6 54.1 44.6 35.2 62 74.3 8.8 74.3 74.3 66.2 56.8 47.3 37.9 70.6 9.9 70.6 70.6 63.3 53.8 44.3 34.9

57 75.0 8.9 75.0 75.0 66.0 56.5 47.0 37.6 71.3 10.0 71.3 71.3 61.9 52.5 43.0 33.5

77 97.0 9.1 54.0 41.1 30.5 - - - 92.3 10.1 54.6 40.5 29.8 - - 72 89.9 9.1 66.9 56.3 45.6 35.0 - - 85.3 10.2 65.7 55.0 44.3 33.7 - 67 82.8 9.2 79.8 71.4 60.8 50.2 39.5 - 78.4 10.3 76.8 69.5 58.9 48.2 37.5 62 76.1 8.8 76.1 76.1 72.0 61.4 50.8 40.1 72.2 9.9 72.2 72.2 68.9 58.4 47.5 36.9

57 76.8 9.0 76.8 76.8 71.7 61.1 50.5 39.8 72.9 10.1 72.9 72.9 67.4 57.1 46.1 35.4

77 99.2 9.1 61.1 44.7 32.9 - - - 94.3 10.2 62.8 44.1 32.2 - - 72 92.0 9.2 72.9 61.1 49.3 37.5 - - 87.2 10.3 71.7 59.8 47.9 36.1 - 67 84.8 9.2 84.8 77.5 65.7 53.9 42.1 - 80.2 10.3 80.2 75.5 63.6 51.8 39.9 62 77.8 8.9 77.8 77.8 77.8 66.0 54.2 42.4 73.8 9.9 73.8 73.8 73.8 63.0 50.7 38.8

57 78.6 9.0 78.6 78.6 77.5 65.7 53.9 42.1 74.5 10.1 74.5 74.5 72.9 61.8 49.1 37.3

72 92.2 9.2 78.1 65.2 52.3 39.4 - - 87.4 10.2 77.0 64.1 51.2 38.2 - 67 84.9 9.2 84.9 81.3 69.7 56.8 44.0 - 80.3 10.3 80.3 78.9 67.9 55.0 42.1 62 78.0 8.9 78.0 78.0 78.0 65.1 52.2 39.3 74.0 9.9 74.0 74.0 74.0 61.5 48.4 35.4

57 78.7 9.0 78.7 78.7 78.2 65.3 52.4 39.5 74.6 10.1 74.6 74.6 73.8 61.3 47.9 35.0

72 92.3 9.1 83.3 69.3 55.4 41.4 - - 87.5 10.2 82.4 68.4 54.4 40.4 - 67 85.1 9.2 85.1 85.1 73.8 59.8 45.8 - 80.4 10.3 80.4 80.4 72.2 58.2 44.2 62 78.1 8.9 78.1 78.1 78.1 64.1 50.2 36.2 74.1 9.9 74.1 74.1 74.1 60.1 46.1 32.1

57 78.9 9.0 78.9 78.9 78.9 64.9 51.0 37.0 74.8 10.0 74.8 74.8 74.8 60.8 46.8 32.8

Total

Capacity

(MBh)

Total

1

Input

2

(kW)

Sensible Capacity (MBh)

Return Dry Bulb (°F) Return Dry Bulb (°F)

90 85 80 75 70 65 90 85 80 75 70 65

115°F 125°F

Performance Table for the BHP of the supply air blower motor, MBh = 3.415 x kW and kW = BHP x 0.746

efficiency.

2

These ratings include the condenser fan motors and the compressor motors but not the supply air blower motor.

Temperature of Air on Condenser Coil

Total

1

Capacity

(MBh)

Total

Input

(kW)

Sensible Capacity (MBh)

2

nameplate rated motor

Johnson Controls Unitary Products 17

Page 18

505428-YTG-R-1114

YC090/NC120

Air on

Evaporator Coil

CFM

2250

2625

3000

3375

3750

2250

2625

3000

3375

3750

Total

WB

(°F)

77 105.1 6.0 49.2 40.2 31.1 - - - 108.2 6.6 50.3 41.2 32.1 - - 72 100.1 5.8 63.3 54.2 45.1 36.0 - - 101.4 6.5 63.6 54.6 45.5 36.4 - 67 95.1 5.7 77.3 68.2 59.1 50.0 40.9 - 94.6 6.3 77.0 67.9 58.8 49.7 40.7 62 87.9 5.6 87.9 80.9 71.8 62.7 53.7 44.6 87.7 6.2 87.7 80.9 71.8 62.7 53.7 44.6

57 83.1 5.5 83.1 83.1 76.8 67.7 58.6 49.5 84.1 6.2 84.1 84.1 77.2 68.2 59.1 50.0

77 109.8 6.0 53.6 43.4 33.2 - - - 112.0 6.7 54.5 44.3 34.1 - - 72 104.5 5.9 68.6 58.3 48.1 37.9 - - 105.0 6.5 68.6 58.4 48.3 38.1 - 67 99.3 5.7 83.5 73.3 63.1 52.9 42.6 - 97.9 6.4 82.8 72.6 62.4 52.2 42.1 62 91.8 5.6 91.8 86.9 76.7 66.8 56.2 46.0 90.7 6.2 90.7 86.4 76.2 66.0 55.8 45.7

57 86.7 5.6 86.7 86.7 82.0 72.3 61.5 51.3 87.1 6.2 87.1 87.1 82.0 71.8 61.6 51.4

77 114.5 6.1 58.0 46.6 35.3 - - - 115.8 6.7 58.7 47.4 36.1 - - 72 109.0 5.9 73.9 62.5 51.2 39.8 - - 108.5 6.6 73.6 62.3 51.1 39.8 - 67 103.5 5.8 89.8 78.4 67.1 55.7 44.4 - 101.2 6.4 88.6 77.3 66.0 54.7 43.4 62 95.7 5.7 95.7 92.9 81.5 70.8 58.8 47.5 93.8 6.3 93.8 91.9 80.6 69.3 58.0 46.7

57 90.4 5.6 90.4 90.4 87.1 76.9 64.4 53.1 90.0 6.3 90.0 90.0 86.7 75.4 64.1 52.8

72 110.2 6.0 77.6 65.3 53.1 40.8 - - 110.3 6.6 77.7 65.4 53.2 40.9 - 67 104.6 5.8 94.1 81.8 69.5 57.3 45.0 - 102.9 6.5 93.3 81.0 68.8 56.5 44.3 62 96.7 5.7 96.7 95.3 84.5 72.6 60.0 47.7 95.3 6.3 95.3 94.4 84.0 71.7 59.5 47.2

57 91.4 5.6 91.4 91.4 89.8 78.0 65.2 53.0 91.5 6.3 91.5 91.5 89.8 77.6 65.3 53.1

72 111.4 6.0 81.3 68.1 54.9 41.8 - - 112.1 6.6 81.7 68.5 55.3 42.1 - 67 105.8 5.9 98.4 85.2 72.0 58.8 45.6 - 104.5 6.5 97.9 84.7 71.5 58.3 45.1 62 97.8 5.7 97.8 97.8 87.5 74.3 61.1 47.9 96.8 6.4 96.8 96.8 87.3 74.1 60.9 47.7

57 92.4 5.7 92.4 92.4 92.4 79.2 66.0 52.8 93.0 6.3 93.0 93.0 93.0 79.8 66.6 53.4

77 111.4 7.2 51.3 42.3 33.2 - - - 107.2 8.2 49.9 40.9 31.8 - - 72 102.8 7.1 64.0 54.9 45.9 36.8 - - 99.1 8.0 62.6 53.5 44.5 35.4 - 67 94.2 7.0 76.7 67.6 58.5 49.5 40.4 - 90.9 7.9 75.3 66.2 57.1 48.1 39.0 62 87.4 6.8 87.4 80.9 71.8 62.7 53.6 44.6 84.0 7.8 84.0 79.3 70.2 61.1 52.0 43.0

57 85.2 6.8 85.2 85.2 77.7 68.6 59.6 50.5 82.3 7.7 82.3 82.3 74.9 65.8 56.8 47.7

77 114.2 7.3 55.3 45.2 35.0 - - - 110.2 8.3 53.9 43.8 33.6 - - 72 105.4 7.2 68.7 58.5 48.4 38.2 - - 101.8 8.1 67.4 57.2 47.0 36.9 - 67 96.6 7.0 82.1 71.9 61.8 51.6 41.5 - 93.4 8.0 80.8 70.6 60.5 50.3 40.1 62 89.6 6.9 89.6 85.9 75.8 65.3 55.5 45.3 86.3 7.9 86.3 83.7 74.3 63.9 53.9 43.8

57 87.4 6.8 87.4 87.4 82.0 71.3 61.7 51.6 84.6 7.8 84.6 84.6 79.3 68.8 58.9 48.8

77 117.1 7.3 59.3 48.1 36.9 - - - 113.1 8.3 58.0 46.7 35.5 - - 72 108.0 7.2 73.4 62.2 50.9 39.7 - - 104.5 8.2 72.1 60.9 49.6 38.4 - 67 99.0 7.1 87.5 76.2 65.0 53.8 42.5 - 95.9 8.1 86.3 75.0 63.8 52.5 41.3 62 91.9 6.9 91.9 91.0 79.7 67.9 57.3 46.0 88.6 7.9 88.6 88.2 78.3 66.8 55.8 44.6

57 89.6 6.9 89.6 89.6 86.3 74.0 63.8 52.6 86.9 7.8 86.9 86.9 83.6 71.8 61.1 49.8

72 110.4 7.2 77.7 65.5 53.3 41.1 - - 106.7 8.2 76.4 64.2 52.0 39.7 - 67 101.2 7.1 92.5 80.2 68.0 55.8 43.6 - 97.9 8.1 91.3 79.0 66.8 54.6 42.3 62 93.9 7.0 93.9 93.4 83.4 70.9 59.0 46.8 90.5 8.0 90.5 90.3 82.0 69.7 57.6 45.3

57 91.5 6.9 91.5 91.5 89.9 77.1 65.5 53.2 88.7 7.9 88.7 88.7 87.1 74.6 62.6 50.4

72 112.8 7.3 82.1 68.9 55.7 42.4 - - 108.9 8.3 80.8 67.6 54.3 41.1 - 67 103.3 7.1 97.4 84.2 71.0 57.8 44.6 - 100.0 8.1 96.3 83.0 69.8 56.6 43.4 62 95.9 7.0 95.9 95.9 87.1 73.9 60.7 47.5 92.4 8.0 92.4 92.4 85.8 72.5 59.3 46.1

57 93.5 6.9 93.5 93.5 93.5 80.3 67.1 53.9 90.5 7.9 90.5 90.5 90.5 77.3 64.1 50.9

Capacity

(MBh)

Total

1

Input

2

(kW)

Sensible Capacity (MBh)

Return Dry Bulb (°F) Return Dry Bulb (°F)

90 85 80 75 70 65 90 85 80 75 70 65

75°F 85°F

95°F 105°F

Temperature of Air on Condenser Coil

Total

1

Capacity

(MBh)

Total

Input

(kW)

Sensible Capacity (MBh)

2

18 Johnson Controls Unitary Products

Page 19

505428-YTG-R-1114

YC090/NC120 (Continued)

Air on

Evaporator Coil

CFM

2250

2625

3000

3375

3750

1

These capacities are gross ratings. For net capacity, deduct supply air blower motor, MBh. Example: Refer to the appropriate Blower

WB

(°F)

77 103.1 9.1 48.5 39.5 30.4 - - - 98.9 10.1 47.1 38.0 29.0 - - 72 95.4 9.0 61.2 52.1 43.1 34.0 - - 91.6 9.9 59.8 50.7 41.7 32.6 - 67 87.6 8.9 73.9 64.8 55.8 46.7 37.6 - 84.4 9.8 72.5 63.4 54.4 45.3 36.2 62 80.6 8.7 80.6 77.7 68.6 59.5 50.4 41.4 77.2 9.7 77.2 76.0 67.0 57.9 48.8 39.8

57 79.5 8.6 79.5 79.5 72.1 63.0 54.0 44.9 76.6 9.5 76.6 76.6 69.3 60.2 51.2 42.1

77 106.1 9.2 52.6 42.4 32.2 - - - 102.1 10.2 51.2 41.0 30.8 - - 72 98.2 9.1 66.0 55.9 45.7 35.5 - - 94.6 10.1 64.7 54.5 44.3 34.2 - 67 90.3 9.0 79.5 69.3 59.1 49.0 38.8 - 87.1 9.9 78.2 68.0 57.8 47.7 37.5 62 83.0 8.8 83.0 81.5 72.8 62.6 52.4 42.3 79.7 9.8 79.7 79.3 71.2 61.2 50.9 40.7

57 81.8 8.7 81.8 81.8 76.5 66.3 56.2 46.0 79.0 9.6 79.0 79.0 73.7 63.8 53.4 43.2

77 109.2 9.3 56.6 45.3 34.1 - - - 105.3 10.3 55.2 44.0 32.7 - - 72 101.0 9.2 70.8 59.6 48.3 37.0 - - 97.5 10.2 69.5 58.3 47.0 35.7 - 67 92.9 9.1 85.1 73.8 62.5 51.3 40.0 - 89.8 10.1 83.9 72.6 61.3 50.0 38.7 62 85.4 8.9 85.4 85.4 76.9 65.7 54.4 43.1 82.2 10.0 82.2 82.2 75.5 64.5 53.0 41.7

57 84.2 8.8 84.2 84.2 80.9 69.6 58.4 47.1 81.5 9.8 81.5 81.5 78.2 67.4 55.6 44.3

72 103.1 9.2 75.2 62.9 50.7 38.4 - - 99.4 10.2 73.9 61.6 49.3 37.1 - 67 94.7 9.1 90.1 77.8 65.6 53.3 41.1 - 91.5 10.1 88.9 76.6 64.4 52.1 39.8 62 87.1 9.0 87.1 87.1 80.7 68.4 56.2 43.9 83.7 10.0 83.7 83.7 79.3 67.2 54.7 42.5

57 85.9 8.8 85.9 85.9 84.2 72.0 59.7 47.5 83.0 9.8 83.0 83.0 81.4 69.4 56.8 44.6

72 105.1 9.2 79.5 66.2 53.0 39.8 - - 101.3 10.2 78.2 64.9 51.7 38.4 - 67 96.6 9.1 95.1 81.9 68.6 55.4 42.1 - 93.2 10.1 93.2 80.7 67.4 54.2 40.9 62 88.8 9.0 88.8 88.8 84.4 71.2 57.9 44.7 85.3 10.0 85.3 85.3 83.1 69.8 56.5 43.3

57 87.6 8.8 87.6 87.6 87.6 74.3 61.1 47.8 84.6 9.8 84.6 84.6 84.6 71.3 58.1 44.8

Total

Capacity

(MBh)

Total

1

Input

2

(kW)

Sensible Capacity (MBh)

Return Dry Bulb (°F) Return Dry Bulb (°F)

90 85 80 75 70 65 90 85 80 75 70 65

115°F 125°F

Performance Table for the BHP of the supply air blower motor, MBh = 3.415 x kW and kW = BHP x 0.746

efficiency.

2

These ratings include the condenser fan motors and the compressor motors but not the supply air blower motor.

Temperature of Air on Condenser Coil

Total

1

Capacity

(MBh)

Total

Input

(kW)

Sensible Capacity (MBh)

2

nameplate rated motor

Johnson Controls Unitary Products 19

Page 20

505428-YTG-R-1114

YC120/NC120

Air on

Evaporator Coil

CFM

3000

3500

4000

4500

5000

3000

3500

4000

4500

5000

WB

(°F)

77 142.3 7.5 64.7 52.6 40.5 - - - 139.4 8.5 67.1 54.6 42.1 - - 72 133.9 7.4 84.4 72.2 60.1 48.0 - - 129.5 8.4 85.3 72.8 60.3 47.8 - 67 125.5 7.3 104.0 91.9 79.8 67.7 55.6 - 119.6 8.3 103.4 90.9 78.5 66.0 53.5 62 115.0 7.3 115.0 109.5 94.2 82.0 69.9 57.8 111.3 8.2 111.3 108.6 96.1 83.6 71.1 58.6

57 111.2 7.2 111.2 111.2 99.9 87.8 75.7 63.6 108.8 8.3 108.8 108.8 99.2 86.7 74.2 61.7

77 151.4 7.5 72.3 58.7 45.2 - - - 147.0 8.5 74.2 60.2 46.1 - - 72 142.4 7.4 94.1 80.6 67.0 53.5 - - 136.6 8.4 94.1 80.0 66.0 51.9 - 67 133.4 7.3 116.0 102.5 88.9 75.4 61.8 - 126.1 8.3 114.0 99.9 85.9 71.8 57.8 62 122.3 7.3 122.3 119.6 105.0 92.1 77.9 64.4 117.4 8.3 117.4 116.1 105.2 91.1 77.1 63.1

57 118.3 7.2 118.3 118.3 111.3 98.6 84.2 70.7 114.8 8.3 114.8 114.8 108.6 94.6 80.5 66.5

77 160.5 7.5 79.8 64.9 49.9 - - - 154.6 8.6 81.3 65.7 50.1 - - 72 150.9 7.4 103.9 88.9 73.9 59.0 - - 143.7 8.5 102.9 87.3 71.7 56.1 - 67 141.4 7.3 128.0 113.0 98.0 83.0 68.1 - 132.7 8.4 124.5 108.9 93.3 77.7 62.1 62 129.6 7.3 129.6 129.6 115.9 102.2 86.0 71.0 123.5 8.3 123.5 123.5 114.3 98.7 83.1 67.5

57 125.4 7.2 125.4 125.4 122.8 109.5 92.8 77.8 120.7 8.3 120.7 120.7 118.0 102.4 86.8 71.2

72 154.4 7.5 110.8 94.3 77.8 61.4 - - 148.2 8.5 110.7 93.7 76.6 59.6 - 67 144.7 7.4 138.0 119.7 103.2 86.8 70.3 - 136.9 8.4 132.8 116.7 99.7 82.6 65.6 62 132.6 7.3 132.6 132.6 124.4 108.6 91.5 75.0 127.4 8.3 127.4 127.4 122.1 105.1 88.0 70.9

57 128.3 7.3 128.3 128.3 127.0 111.4 94.0 77.6 124.6 8.3 124.6 124.6 123.2 106.1 89.1 72.0

72 157.9 7.5 117.6 99.7 81.7 63.8 - - 152.7 8.5 118.6 100.0 81.5 63.0 - 67 148.0 7.4 148.0 126.4 108.5 90.5 72.6 - 141.1 8.4 141.1 124.6 106.1 87.6 69.1 62 135.6 7.3 135.6 135.6 132.9 114.9 97.0 79.1 131.3 8.3 131.3 131.3 129.9 111.4 92.9 74.4

57 131.2 7.3 131.2 131.2 131.2 113.2 95.3 77.4 128.4 8.4 128.4 128.4 128.4 109.9 91.4 72.8

77 136.4 9.5 69.6 56.7 43.8 - - - 127.0 10.7 66.5 53.5 40.6 - - 72 125.1 9.4 86.2 73.3 60.5 47.6 - - 117.1 10.7 83.6 70.6 57.7 44.8 - 67 113.7 9.3 102.9 90.0 77.1 64.2 51.3 - 107.2 10.6 100.7 87.8 74.8 61.9 48.9 62 107.7 9.2 107.7 107.7 98.1 85.2 72.3 59.4 100.8 10.5 100.8 100.8 93.7 80.8 67.9 54.9

57 106.5 9.3 106.5 106.5 98.6 85.7 72.8 59.9 100.2 10.6 100.2 100.2 91.6 78.7 65.8 52.8

77 142.6 9.5 76.1 61.6 47.1 - - - 133.4 10.8 75.3 58.7 44.1 - - 72 130.7 9.4 94.0 79.5 64.9 50.4 - - 123.1 10.7 92.0 77.3 62.7 48.1 - 67 118.9 9.4 111.9 97.4 82.8 68.3 53.7 - 112.7 10.6 108.7 96.0 81.3 66.7 52.0 62 112.6 9.2 112.6 112.6 105.3 90.2 76.3 61.7 106.0 10.5 106.0 106.0 101.9 86.9 72.6 57.9

57 111.3 9.4 111.3 111.3 105.9 90.5 76.8 62.3 105.3 10.6 105.3 105.3 99.5 84.5 70.3 55.6

77 148.8 9.6 82.7 66.5 50.3 - - - 139.9 10.8 84.1 63.9 47.6 - - 72 136.4 9.5 101.8 85.6 69.4 53.2 - - 129.0 10.7 100.4 84.0 67.7 51.3 - 67 124.0 9.4 120.9 104.7 88.5 72.3 56.1 - 118.2 10.6 116.6 104.1 87.8 71.5 55.1 62 117.4 9.2 117.4 117.4 112.6 95.1 80.2 64.0 111.1 10.5 111.1 111.1 110.0 93.0 77.3 60.9

57 116.1 9.4 116.1 116.1 113.2 95.3 80.8 64.6 110.5 10.6 110.5 110.5 107.4 90.2 74.7 58.4

72 142.0 9.5 110.7 93.0 75.4 57.7 - - 133.3 10.7 109.1 91.2 73.2 55.2 - 67 129.1 9.4 127.5 113.8 96.1 78.5 60.8 - 122.1 10.6 121.3 112.3 95.0 77.0 59.0 62 122.2 9.3 122.2 122.2 119.8 101.5 84.5 66.9 114.8 10.5 114.8 114.8 114.3 96.0 78.3 60.4

57 120.8 9.4 120.8 120.8 119.4 100.9 84.1 66.4 114.1 10.6 114.1 114.1 112.6 94.2 76.7 58.7

72 147.5 9.5 119.5 100.4 81.3 62.2 - - 137.7 10.7 117.9 98.3 78.7 59.1 - 67 134.1 9.4 134.1 122.8 103.7 84.6 65.5 - 126.1 10.7 126.1 120.4 102.1 82.5 62.9 62 127.0 9.3 127.0 127.0 127.0 107.9 88.8 69.7 118.5 10.5 118.5 118.5 118.5 99.0 79.4 59.8

57 125.6 9.4 125.6 125.6 125.6 106.5 87.4 68.3 117.8 10.6 117.8 117.8 117.8 98.2 78.7 59.1

Total

Capacity

(MBh)

Total

1

Input

2

(kW)

Sensible Capacity (MBh)

Return Dry Bulb (°F) Return Dry Bulb (°F)

90 85 80 75 70 65 90 85 80 75 70 65

75°F 85°F

95°F 105°F

Temperature of Air on Condenser Coil

Total

Capacity

(MBh)

Total

1

Input

(kW)

Sensible Capacity (MBh)

2

20 Johnson Controls Unitary Products

Page 21

505428-YTG-R-1114

YC120/NC120 (Continued)

Air on

Evaporator Coil

CFM

3000

3500

4000

4500

5000

1

WB

(°F)

77 117.5 12.0 63.4 50.4 37.4 - - - 108.0 13.2 60.3 47.2 34.1 - - 72 109.1 11.9 81.0 68.0 55.0 41.9 - - 101.2 13.2 78.4 65.3 52.2 39.1 - 67 100.8 11.9 98.6 85.6 72.6 59.5 46.5 - 94.3 13.1 94.3 83.4 70.3 57.2 44.1 62 94.0 11.8 94.0 94.0 89.4 76.4 63.4 50.4 87.2 13.0 87.2 87.2 85.1 72.0 59.0 45.9

57 94.0 11.8 94.0 94.0 84.7 71.7 58.7 45.7 87.8 13.1 87.8 87.8 77.8 64.7 51.7 38.6

77 124.2 12.0 74.4 55.8 41.1 - - - 115.1 13.2 73.6 53.0 38.1 - - 72 115.4 11.9 89.9 75.2 60.4 45.7 - - 107.7 13.2 87.9 73.1 58.2 43.4 - 67 106.6 11.9 105.5 94.6 79.8 65.1 50.3 - 100.4 13.1 100.4 93.2 78.3 63.5 48.6 62 99.4 11.8 99.4 99.4 98.4 83.6 68.9 54.1 92.8 13.0 92.8 92.8 92.8 80.4 65.2 50.3

57 99.4 11.8 99.4 99.4 93.2 78.5 63.7 49.0 93.5 13.1 93.5 93.5 86.9 72.4 57.2 42.3

77 131.0 12.0 85.5 61.3 44.8 - - - 122.1 13.2 86.9 58.7 42.1 - - 72 121.7 11.9 98.9 82.4 65.9 49.5 - - 114.3 13.2 97.5 80.8 64.2 47.6 - 67 112.3 11.9 112.3 103.5 87.1 70.6 54.1 - 106.5 13.1 106.5 103.0 86.3 69.7 53.1 62 104.8 11.8 104.8 104.8 107.3 90.8 74.4 57.9 98.5 13.1 98.5 98.5 98.5 88.7 71.4 54.8

57 104.8 11.8 104.8 104.8 101.7 85.2 68.7 52.2 99.2 13.1 99.2 99.2 95.9 80.1 62.7 46.0

72 124.7 11.9 107.6 89.3 71.0 52.8 - - 116.1 13.2 106.1 87.5 68.9 50.3 - 67 115.2 11.9 115.2 110.8 93.8 75.5 57.2 - 108.2 13.1 108.2 108.2 92.6 74.0 55.4 62 107.4 11.8 107.4 107.4 108.7 90.4 72.1 53.8 100.0 13.1 100.0 100.0 100.0 84.9 65.9 47.3

57 107.4 11.8 107.4 107.4 105.9 87.6 69.3 51.0 100.7 13.1 100.7 100.7 99.1 80.9 61.9 43.3

72 127.8 12.0 116.3 96.2 76.1 56.1 - - 117.9 13.2 114.7 94.1 73.6 53.0 - 67 118.0 11.9 118.0 118.0 100.5 80.4 60.4 - 109.9 13.1 109.9 109.9 98.9 78.4 57.8 62 110.1 11.8 110.1 110.1 110.1 90.0 69.9 49.8 101.6 13.0 101.6 101.6 101.6 81.0 60.4 39.9

57 110.1 11.9 110.1 110.1 110.1 90.0 69.9 49.8 102.3 13.1 102.3 102.3 102.3 81.7 61.2 40.6

These capacities are gross ratings. For net capacity, deduct supply air blower motor, MBh. Example: Refer to the appropriate Blower

Total

Capacity

(MBh)

Total

1

Input

2

(kW)

Sensible Capacity (MBh)

Return Dry Bulb (°F) Return Dry Bulb (°F)

90 85 80 75 70 65 90 85 80 75 70 65

115°F 125°F

Performance Table for the BHP of the supply air blower motor, MBh = 3.415 x kW and kW = BHP x 0.746

efficiency.

2

These ratings include the condenser fan motors and the compressor motors but not the supply air blower motor.

Temperature of Air on Condenser Coil

Total

Capacity

(MBh)

Total

1

Input

(kW)

Sensible Capacity (MBh)

2

nameplate rated motor

Johnson Controls Unitary Products 21

Page 22

505428-YTG-R-1114

YD120/ND120

Air on

Evaporator Coil

CFM

3000

3500

4000

4500

5000

3000

3500

4000

4500

5000

WB

(°F)

77 138.1 7.5 63.6 51.7 39.9 - - - 132.8 8.6 62.9 50.8 38.7 - - 72 130.1 7.4 82.9 71.0 59.2 47.4 - - 124.4 8.4 81.7 69.6 57.5 45.4 - 67 122.0 7.2 102.2 90.4 78.5 66.7 54.8 - 115.9 8.3 100.6 88.5 76.4 64.3 52.2 62 112.3 7.2 112.3 108.5 94.8 83.0 71.1 59.3 106.3 8.2 106.3 104.4 92.3 80.2 68.1 56.0

57 108.2 7.1 108.2 108.6 99.9 88.0 76.2 64.3 105.7 8.2 105.7 105.7 95.1 83.0 70.9 58.8

77 147.1 7.5 70.5 57.3 44.0 - - - 141.3 8.6 70.1 56.5 42.8 - - 72 138.4 7.4 91.8 78.6 65.3 52.0 - - 132.4 8.4 91.0 77.3 63.6 50.0 - 67 129.8 7.3 113.1 99.9 86.6 73.3 60.0 - 123.4 8.3 111.9 98.2 84.5 70.8 57.1 62 119.5 7.2 119.5 117.6 104.6 91.9 78.0 64.7 113.2 8.2 113.2 112.2 102.1 88.5 74.8 61.1

57 115.1 7.2 115.1 115.4 110.1 97.8 83.6 70.3 112.5 8.2 112.5 112.5 105.3 91.6 77.9 64.2

77 156.0 7.6 77.5 62.8 48.1 - - - 149.9 8.6 77.4 62.1 46.9 - - 72 146.8 7.4 100.8 86.1 71.4 56.7 - - 140.4 8.4 100.3 85.0 69.8 54.5 - 67 137.7 7.3 124.1 109.4 94.6 79.9 65.2 - 130.9 8.3 123.2 107.9 92.6 77.4 62.1 62 126.8 7.2 126.8 126.8 114.3 100.8 84.9 70.2 120.0 8.2 120.0 120.0 112.0 96.7 81.4 66.2

57 122.1 7.2 122.1 122.1 120.4 107.5 91.0 76.3 119.3 8.2 119.3 119.3 115.4 100.1 84.9 69.6

72 152.4 7.5 108.1 92.0 76.0 60.0 - - 145.8 8.5 107.7 91.1 74.5 57.9 - 67 142.9 7.3 136.1 116.8 100.8 84.8 68.8 - 135.9 8.3 132.1 115.5 98.9 82.3 65.7 62 131.5 7.2 131.5 131.5 123.1 107.7 91.1 75.1 124.6 8.2 124.6 124.6 119.5 102.9 86.3 69.7

57 126.7 7.2 126.7 126.7 125.9 110.8 93.9 77.8 123.9 8.2 123.9 123.9 121.9 105.3 88.7 72.1

72 157.9 7.5 115.3 98.0 80.7 63.4 - - 151.2 8.5 115.2 97.2 79.2 61.2 - 67 148.1 7.4 148.1 124.3 107.0 89.7 72.4 - 141.0 8.3 141.0 123.1 105.1 87.2 69.2 62 136.3 7.3 136.3 136.3 132.0 114.6 97.3 80.0 129.3 8.3 129.3 129.3 127.1 109.1 91.1 73.1

57 131.3 7.3 131.3 131.3 131.3 114.0 96.7 79.4 128.5 8.2 128.5 128.5 128.5 110.5 92.5 74.6

77 127.4 9.6 62.2 49.8 37.4 - - - 122.1 10.8 60.4 48.0 35.6 - - 72 118.7 9.5 80.6 68.2 55.9 43.5 - - 112.7 10.7 78.3 65.8 53.4 41.0 - 67 109.9 9.3 99.0 86.6 74.3 61.9 49.5 - 103.2 10.6 96.1 83.7 71.2 58.8 46.4 62 100.4 9.2 100.4 100.4 89.8 77.5 65.1 52.7 95.0 10.5 95.0 95.0 86.6 74.1 61.7 49.3

57 103.2 9.2 103.2 102.8 90.4 78.0 65.7 53.3 98.1 10.5 98.1 97.9 85.4 73.0 60.5 48.1

77 135.6 9.6 69.7 55.6 41.6 - - - 129.2 10.8 70.6 53.8 39.6 - - 72 126.3 9.5 90.2 76.1 62.0 47.9 - - 119.2 10.7 87.9 73.7 59.5 45.3 - 67 116.9 9.3 110.6 96.6 82.5 68.4 54.3 - 109.2 10.6 105.2 93.6 79.4 65.2 51.0 62 106.8 9.2 106.8 106.8 99.7 85.0 71.5 57.4 100.5 10.5 100.5 100.5 96.5 82.0 68.1 53.9

57 109.9 9.2 109.9 109.6 100.4 85.4 72.2 58.1 103.8 10.5 103.8 103.6 95.2 80.5 66.8 52.6

77 143.8 9.6 77.3 61.5 45.7 - - - 136.2 10.8 80.8 59.7 43.7 - - 72 133.9 9.5 99.8 84.0 68.2 52.3 - - 125.7 10.7 97.5 81.6 65.6 49.6 - 67 124.0 9.3 122.3 106.5 90.6 74.8 59.0 - 115.1 10.6 114.3 103.5 87.5 71.6 55.6 62 113.3 9.2 113.3 113.3 109.6 92.6 78.0 62.2 106.0 10.5 106.0 106.0 106.4 89.8 74.4 58.5

57 116.5 9.2 116.5 116.5 110.3 92.7 78.7 62.9 109.4 10.5 109.4 109.4 104.9 88.1 73.0 57.1

72 139.2 9.5 107.4 90.2 72.9 55.7 - - 131.0 10.7 105.2 87.7 70.3 52.8 - 67 128.9 9.3 128.0 114.2 97.0 79.7 62.5 - 120.1 10.6 119.6 111.2 93.7 76.3 58.8 62 117.7 9.2 117.7 117.7 115.9 98.1 81.4 64.2 110.5 10.5 110.5 110.5 110.7 92.9 75.8 58.3

57 121.1 9.2 121.1 121.1 118.0 99.9 83.5 66.3 114.1 10.5 114.1 114.1 111.8 93.9 76.9 59.4

72 144.5 9.5 115.0 96.3 77.7 59.0 - - 136.4 10.7 112.9 93.9 74.9 56.0 - 67 133.8 9.3 133.8 121.9 103.3 84.6 66.0 - 125.0 10.6 125.0 118.9 99.9 81.0 62.0 62 122.2 9.2 122.2 122.2 122.2 103.5 84.9 66.2 115.0 10.5 115.0 115.0 115.0 96.1 77.1 58.1

57 125.7 9.2 125.7 125.7 125.7 107.0 88.4 69.7 118.7 10.5 118.7 118.7 118.7 99.8 80.8 61.8

Total

Capacity

(MBh)

Total

1

Input

2

(kW)

Sensible Capacity (MBh)

Return Dry Bulb (°F) Return Dry Bulb (°F)

90 85 80 75 70 65 90 85 80 75 70 65

75°F 85°F

95°F 105°F

Temperature of Air on Condenser Coil

Total

Capacity

(MBh)

Total

1

Input

(kW)

Sensible Capacity (MBh)

2

22 Johnson Controls Unitary Products

Page 23

505428-YTG-R-1114

YD120/ND120 (Continued)

Air on

Evaporator Coil

CFM

3000

3500

4000

4500

5000

1

WB

(°F)

77 116.8 12.1 58.7 46.2 33.7 - - - 111.5 13.3 57.0 44.4 31.8 - - 72 106.7 11.9 75.9 63.4 50.9 38.4 - - 100.7 13.2 73.6 61.1 48.5 35.9 - 67 96.6 11.8 93.2 80.7 68.2 55.7 43.2 - 89.9 13.1 89.9 77.7 65.1 52.6 40.0 62 89.7 11.7 89.7 89.7 83.3 70.8 58.3 45.8 84.4 12.9 84.4 84.4 80.0 67.5 54.9 42.3

57 93.0 11.7 93.0 92.9 80.4 67.9 55.4 42.9 87.9 12.9 87.9 87.9 75.5 62.9 50.3 37.8

77 122.7 12.1 71.5 52.0 37.7 - - - 116.2 13.3 72.4 50.2 35.8 - - 72 112.1 11.9 85.6 71.3 57.0 42.7 - - 105.0 13.2 83.3 68.9 54.5 40.1 - 67 101.4 11.8 99.7 90.6 76.3 62.0 47.7 - 93.7 13.1 93.7 87.6 73.2 58.8 44.4 62 94.2 11.7 94.2 94.2 93.2 78.9 64.6 50.3 88.0 12.9 88.0 88.0 88.0 75.8 61.1 46.7

57 97.7 11.7 97.7 97.6 90.0 75.7 61.4 47.1 91.5 13.0 91.5 91.5 84.8 70.9 56.0 41.6

77 128.6 12.1 84.3 57.8 41.7 - - - 120.9 13.3 87.7 56.0 39.7 - - 72 117.4 11.9 95.3 79.2 63.1 46.9 - - 109.2 13.2 93.0 76.8 60.5 44.2 - 67 106.3 11.8 106.3 100.5 84.4 68.3 52.2 - 97.4 13.1 97.4 97.4 81.3 65.0 48.8 62 98.8 11.7 98.8 98.8 103.1 87.0 70.9 54.8 91.5 12.9 91.5 91.5 91.5 84.2 67.3 51.1

57 102.3 11.7 102.3 102.3 99.6 83.5 67.3 51.2 95.2 13.0 95.2 95.2 94.2 78.8 61.7 45.4

72 122.9 12.0 103.0 85.3 67.6 49.9 - - 114.7 13.2 100.8 82.9 65.0 47.0 - 67 111.2 11.8 111.2 108.2 90.5 72.8 55.1 - 102.4 13.1 102.4 102.4 87.3 69.3 51.4 62 103.3 11.7 103.3 103.3 105.5 87.8 70.1 52.4 96.1 12.9 96.1 96.1 96.1 82.6 64.4 46.5

57 107.1 11.7 107.1 107.1 105.7 88.0 70.3 52.6 100.0 13.0 100.0 100.0 99.5 82.0 63.6 45.7

72 128.3 12.0 110.8 91.5 72.2 52.9 - - 120.2 13.3 108.7 89.0 69.4 49.8 - 67 116.1 11.9 116.1 115.9 96.6 77.3 58.0 - 107.3 13.2 107.3 107.3 93.3 73.7 54.1 62 107.9 11.7 107.9 107.9 107.9 88.6 69.3 50.0 100.7 13.0 100.7 100.7 100.7 81.1 61.5 41.9

57 111.8 11.8 111.8 111.8 111.8 92.5 73.2 53.9 104.8 13.0 104.8 104.8 104.8 85.2 65.6 46.0

These capacities are gross ratings. For net capacity, deduct supply air blower motor, MBh. Example: Refer to the appropriate Blower

Total

Capacity

(MBh)

Total

1

Input

2

(kW)

Sensible Capacity (MBh)

Return Dry Bulb (°F) Return Dry Bulb (°F)

90 85 80 75 70 65 90 85 80 75 70 65

115°F 125°F

Performance Table for the BHP of the supply air blower motor, MBh = 3.415 x kW and kW = BHP x 0.746

efficiency.

2

These ratings include the condenser fan motors and the compressor motors but not the supply air blower motor.

Temperature of Air on Condenser Coil

Total

Capacity

(MBh)

Total

1

Input

(kW)

Sensible Capacity (MBh)

2

nameplate rated motor

Johnson Controls Unitary Products 23

Page 24

505428-YTG-R-1114

YC150/NC180

Air on

Evaporator Coil

CFM

3750

4375

5000

5625

6250

3750

4375

5000

5625

6250

WB

(°F)

77 178.5 10.2 87.6 71.1 54.7 - - - 172.2 11.3 84.0 67.6 51.2 - - 72 168.2 9.9 111.9 95.4 78.9 62.4 - - 161.2 11.0 108.3 91.9 75.5 59.2 - 67 157.9 9.6 136.1 119.6 103.1 86.7 70.2 - 150.1 10.7 132.5 116.2 99.8 83.4 67.1 62 144.8 9.4 144.8 144.8 129.3 112.8 96.3 79.8 138.9 10.6 138.9 138.9 126.4 110.1 93.7 77.3

57 149.7 9.5 149.7 149.7 137.7 121.2 104.7 88.3 143.9 10.7 143.9 143.9 130.6 114.3 97.9 81.5

77 184.7 10.2 94.2 77.2 58.5 - - - 177.6 11.3 92.4 73.7 55.0 - - 72 174.0 9.9 121.8 103.1 84.4 65.7 - - 166.2 11.0 118.4 99.8 81.1 62.4 - 67 163.4 9.6 149.5 129.0 110.3 91.6 72.9 - 154.7 10.8 144.5 125.8 107.1 88.4 69.8 62 149.9 9.4 149.9 149.9 138.2 119.8 100.8 82.1 143.2 10.6 143.2 143.2 135.7 117.0 98.4 79.7

57 154.9 9.5 154.9 154.9 147.3 129.1 109.8 91.1 148.4 10.7 148.4 148.4 140.2 121.6 102.9 84.2

77 190.9 10.3 100.7 83.2 62.3 - - - 182.9 11.3 100.8 79.8 58.8 - - 72 179.9 9.9 131.8 110.8 89.9 68.9 - - 171.2 11.0 128.6 107.6 86.6 65.6 - 67 168.8 9.6 162.9 138.4 117.5 96.5 75.5 - 159.4 10.8 156.5 135.5 114.5 93.5 72.5 62 154.9 9.4 154.9 154.9 147.2 126.8 105.3 84.3 147.5 10.6 147.5 147.5 145.0 124.0 103.0 82.0

57 160.1 9.6 160.1 160.1 156.9 137.0 114.9 94.0 152.9 10.7 152.9 152.9 149.8 128.8 107.8 86.8

72 182.3 10.1 142.7 119.7 96.7 73.7 - - 174.1 11.2 139.0 116.1 93.1 70.2 - 67 171.1 9.8 168.1 149.4 126.4 103.4 80.4 - 162.1 10.9 160.6 146.0 123.1 100.1 77.2 62 157.0 9.6 157.0 157.0 153.1 130.4 107.1 84.1 150.0 10.7 150.0 150.0 148.8 125.8 102.9 79.9

57 162.2 9.7 162.2 162.2 160.6 138.1 114.6 91.6 155.5 10.8 155.5 155.5 153.9 131.0 108.1 85.1

72 184.7 10.2 153.7 128.6 103.6 78.5 - - 177.0 11.3 149.4 124.5 99.7 74.8 - 67 173.4 9.9 173.4 160.4 135.4 110.4 85.3 - 164.8 11.0 164.8 156.6 131.7 106.8 81.9 62 159.0 9.7 159.0 159.0 159.0 134.0 108.9 83.9 152.5 10.8 152.5 152.5 152.5 127.6 102.7 77.8

57 164.4 9.8 164.4 164.4 164.4 139.3 114.3 89.2 158.1 10.9 158.1 158.1 158.1 133.2 108.3 83.4