Page 1

Millennium

TM

AIR COOLED SCREW LIQUID CHILLERS

(STYLE F)

WIRING DIAGRAM

MODELS YCAS0130 THRU YCAS0230

Supersedes: 201.18-W1 (798)

Form 201.18-W1 (1298)

28971A(r)

Page 2

W ARNING

HIGH VOL T A GE

is used in the operation of this equipment

DEATH OR SERIOUS INJURY

may result if personnel fail to observe precautions.

Work on electronic equipment should not be undertaken unless the individual(s) has (have) been

trained in the proper maintenance of the equipment and is (are) familiar with its potential hazards.

Shut off power supply to equipment before beginning work and follow lockout procedures. When

working inside equipment with power off, take special care to discharge every capacitor likely to

hold dangerous potential.

Be careful not to contact high voltage connections when installing or operating this equipment.

LOW V OL T A GE

DO NOT be misled by the term “low voltage”. Voltages as low as 50 volts

may cause death.

2

YORK INTERNATIONAL

Page 3

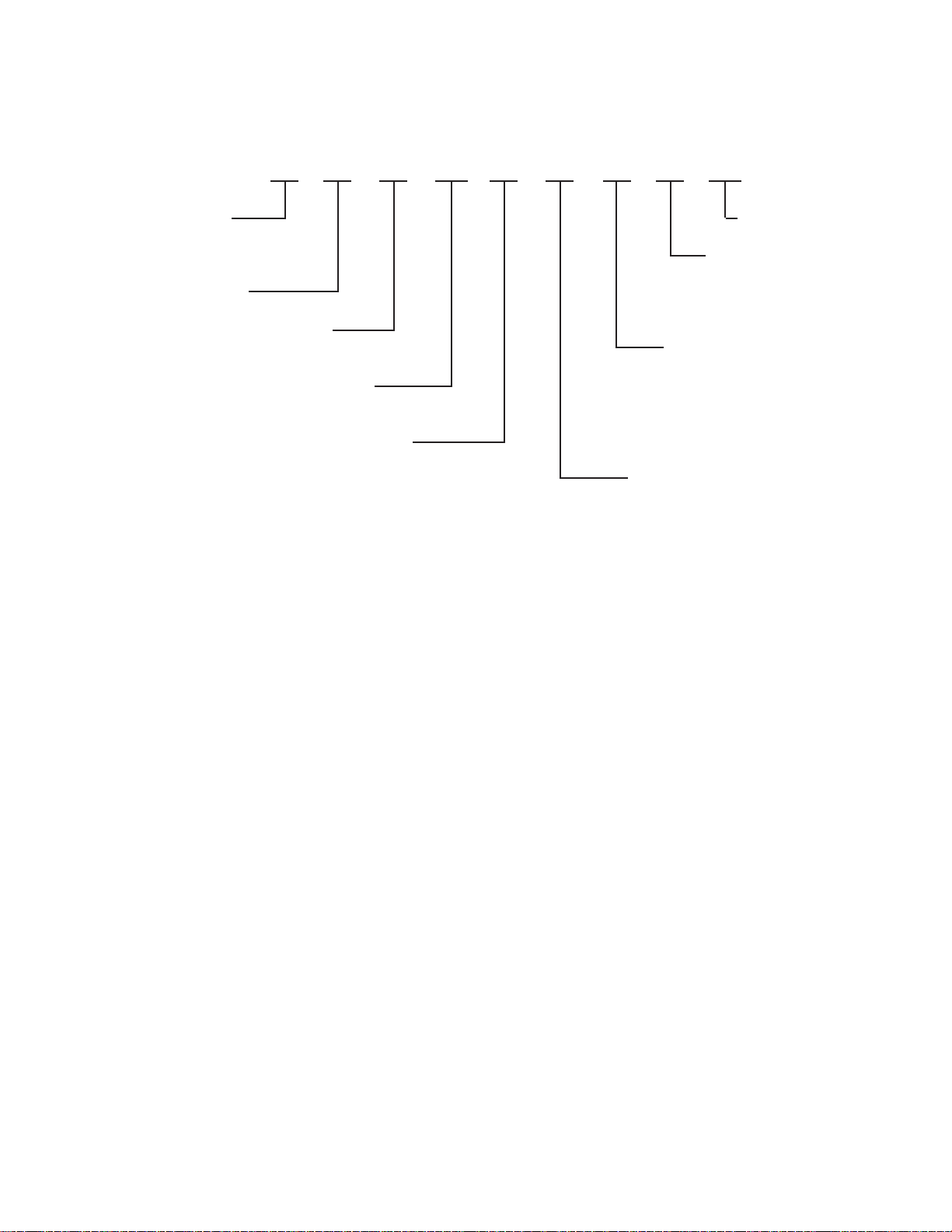

NOMENCLATURE

The Model Number denotes the following characteristics of the unit:

YC A S 0140 E C 17 Y F

FORM 201.18-W1

YORK Chiller

YC = YORK Chiller

Air-Cooled

Compressor Type

S = Screw

Nominal Capacity

Unit Designator

S = Standard Unit

E = High Efficiency

Design Series

Type Start

Y = Star (WYE)-Delta

X = Across-the-Line

Voltage Code

17 = 200-3-60

28 = 230-3-60

40 = 380-3-60

46 = 460-3-60

58 = 575-3-60

Refrigerant

C = R-22

YORK INTERNATIONAL

3

Page 4

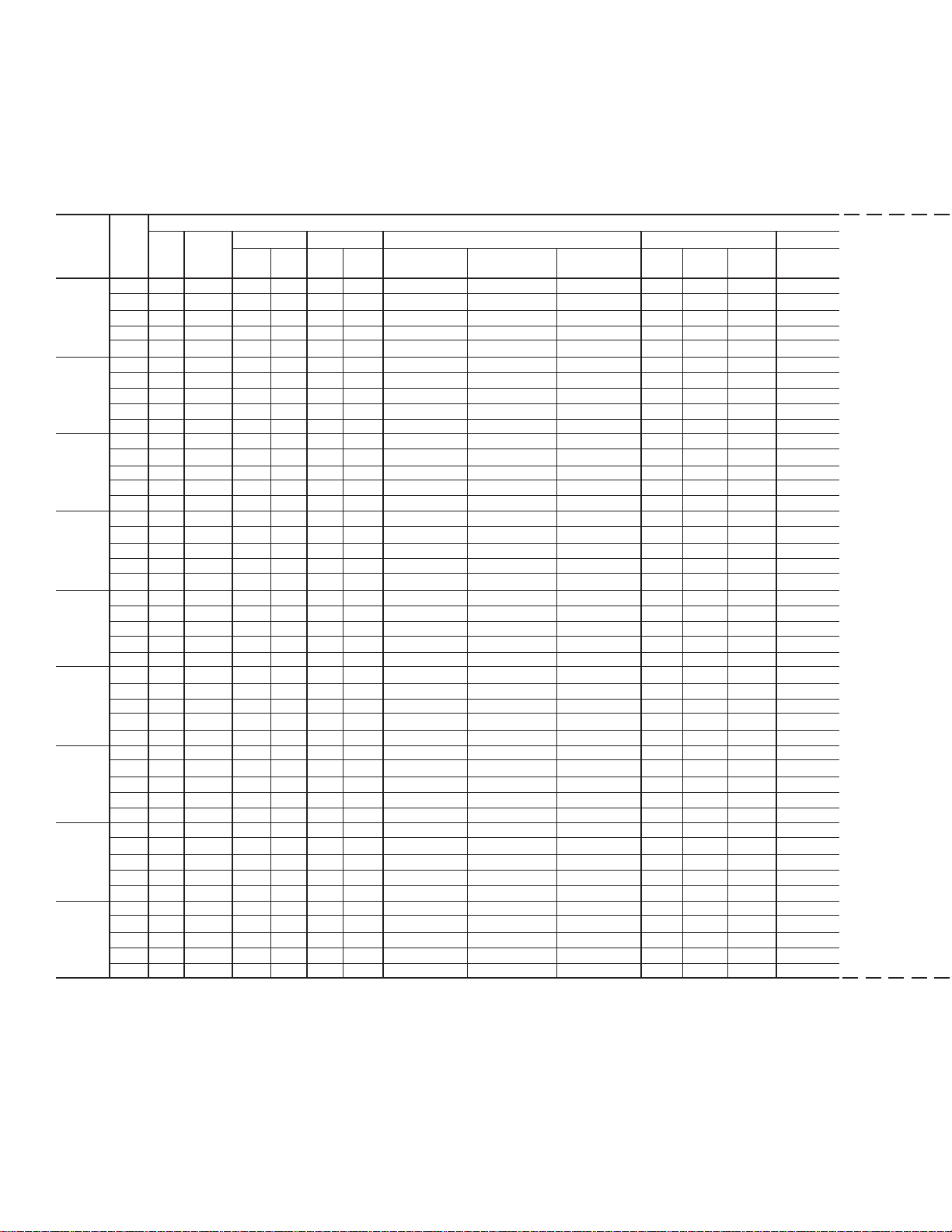

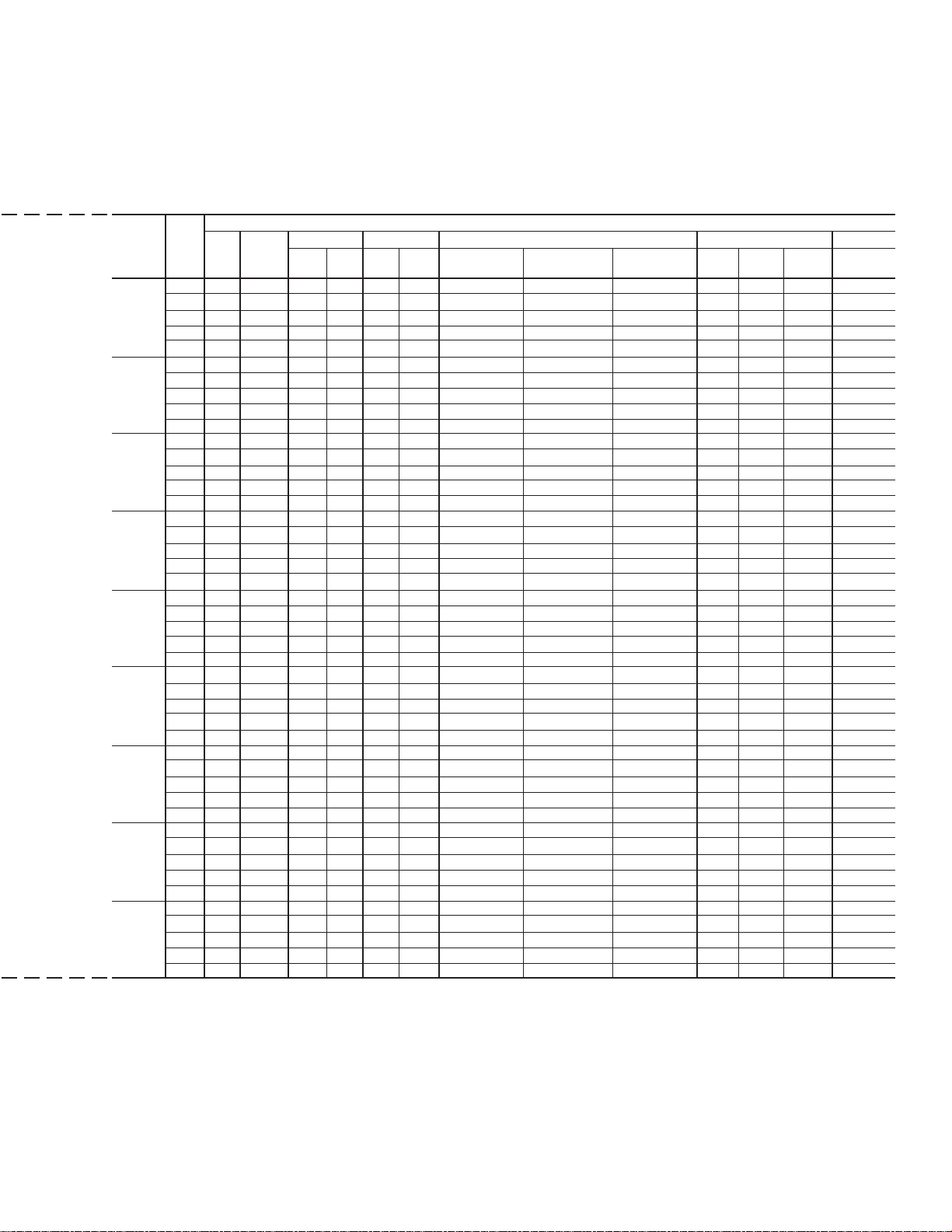

ELECTRICAL DATA

MULTIPLE POINT POWER SUPPLY CONNECTION

Field Connections to Factory provided Terminal Block (Std), Disconnects (Opt), or Breakers(Opt) in each of the two Motor Control Centers.)

MODEL

VOLTS MIN NF

YCAS MCA

200 340 400 450 600 450 600 (2) # 2 - 300 (2) 3/0-250 (3) 2/0-400 246 444 1332 8.2

0130EC 380 181 200 225 350 225 350 # 2 - 300 # 6 AWG - 350 # 6 AWG - 350 130 234 701 4.8

0140EC 380 195 200 250 350 250 350 # 2 - 300 # 6 AWG - 350 # 6 AWG - 350 140 234 701 4.8

0150EC 380 213 250 300 400 300 400 # 1 - 500 # 6 AWG - 350 (2) 3/0-250 155 360 1081 4.8

0160EC 380 213 250 300 400 300 400 # 1 - 500 # 6 AWG - 350 (2) 3/0-250 155 360 1081 4.8

0170EC 380 230 250 300 400 300 400 # 1 - 500 # 6 AWG - 350 (2) 3/0-250 169 360 1081 4.8

0180EC 380 230 250 300 400 300 400 # 1 - 500 # 6 AWG - 350 (2) 3/0-250 169 360 1081 4.8

0200EC 380 250 250 300 450 300 450 # 1 - 500 # 6 AWG - 350 (2) 3/0-250 181 360 1081 4.8

0210EC 380 270 400 350 500 350 500 # 1 - 500 (2) 3/0-250 (2) 3/0-250 197 360 1081 4.8

0230EC 380 270 400 350 500 350 500 # 1 - 500 (2) 3/0-250 (2) 3/0-250 197 360 1081 4.8

230 299 400 400 600 400 600 (2) # 2 - 300 (2) 3/0-250 (2) 3/0-250 214 386 1158 7.8

460 150 150 200 300 200 300 # 2 - 4/0 # 6 AWG - 350 # 6 AWG - 350 107 193 579 4.0

575 119 150 150 225 150 225 # 2 - 4/0 # 6 AWG - 350 # 6 AWG - 350 86 154 463 3.1

200 366 400 450 700 450 700 (2) # 2 - 300 (2) 3/0-250 (3) 2/0-400 267 444 1332 8.2

230 321 400 400 600 400 600 (2) # 2 - 300 (2) 3/0-250 (2) 3/0-250 232 386 1158 7.8

460 161 200 200 300 200 300 # 2 - 300 # 6 AWG - 350 # 6 AWG - 350 116 193 579 4.0

575 128 150 175 225 175 225 # 2 - 4/0 # 6 AWG - 350 # 6 AWG - 350 93 154 463 3.1

200 402 400 500 700 500 700 (2) # 1 - 500 (2) 3/0-250 (3) 2/0-400 295 656 1969 8.2

230 351 400 450 700 450 700 (2) # 2 - 300 (2) 3/0-250 (3) 2/0-400 256 571 1712 7.8

460 176 200 225 350 225 350 # 2 - 300 # 6 AWG - 350 # 6 AWG - 350 128 285 856 4.0

575 141 150 175 250 175 250 # 2 - 4/0 # 6 AWG - 350 # 6 AWG - 350 103 238 715 3.1

200 402 400 500 700 500 700 (2) # 1 - 500 (2) 3/0-250 (3) 2/0-400 295 656 1969 8.2

230 351 400 450 700 450 700 (2) # 2 - 300 (2) 3/0-250 (3) 2/0-400 256 571 1712 7.8

460 176 200 225 350 225 350 # 2 - 300 # 6 AWG - 350 # 6 AWG - 350 128 285 856 4.0

575 141 150 175 250 175 250 # 2 - 4/0 # 6 AWG - 350 # 6 AWG - 350 103 238 715 3.1

200 434 600 600 800 600 800 (2) # 1 - 500 (3) 2/0-400 (3) 2/0-400 321 656 1969 8.2

230 380 400 450 700 450 700 (2) # 1 - 500 (2) 3/0-250 (3) 2/0-400 279 571 1712 7.8

460 191 200 250 350 250 350 # 2 - 300 # 6 AWG - 350 # 6 AWG - 350 140 285 856 4.0

575 152 150 200 300 200 300 # 2 - 4/0 # 6 AWG - 350 # 6 AWG - 350 112 238 715 3.1

200 434 600 600 800 600 800 (2) # 1 - 500 (3) 2/0-400 (3) 2/0-400 321 656 1969 8.2

230 380 400 450 700 450 700 (2) # 1 - 500 (2) 3/0-250 (3) 2/0-400 279 571 1712 7.8

460 191 200 250 350 250 350 # 2 - 300 # 6 AWG - 350 # 6 AWG - 350 140 285 856 4.0

575 152 150 200 300 200 300 # 2 - 4/0 # 6 AWG - 350 # 6 AWG - 350 112 238 715 3.1

200 469 600 600 1000 600 1000 (2) # 1 - 500 (3) 2/0-400 (3) 2/0-400 342 656 1969 8.2

230 412 400 500 800 500 800 (2) # 1 - 500 (2) 3/0-250 (3) 2/0-400 298 571 1712 7.8

460 206 200 250 400 250 400 # 1 - 500 # 6 AWG - 350 # 6 AWG - 350 149 285 856 4.0

575 164 200 200 300 200 300 # 2 - 300 # 6 AWG - 350 # 6 AWG - 350 119 238 715 3.1

200 509 600 700 1000 700 1000 (2) # 1 - 500 (3) 2/0-400 (3) 2/0-400 374 656 1969 8.2

230 445 600 600 800 600 800 (2) # 1 - 500 (3) 2/0-400 (3) 2/0-400 325 571 1712 7.8

460 224 250 300 400 300 400 # 1 - 500 # 6 AWG - 350 (2) 3/0-250 163 285 856 4.0

575 178 200 225 350 225 350 # 2 - 300 # 6 AWG - 350 # 6 AWG - 350 130 238 715 3.1

200 509 600 700 1000 700 1000 (2) # 1 - 500 (3) 2/0-400 (3) 2/0-400 374 656 1969 8.2

230 445 600 600 800 600 800 (2) # 1 - 500 (3) 2/0-400 (3) 2/0-400 325 571 1712 7.8

460 224 250 300 400 300 400 # 1 - 500 # 6 AWG - 350 (2) 3/0-250 163 285 856 4.0

575 178 200 225 350 225 350 # 2 - 300 # 6 AWG - 350 # 6 AWG - 350 130 238 715 3.1

(Each of Two Field Provided Power Supply Circuits individually protected with Branch Circuit Protection.

1

DISC SW2MIN.3MAX.4MIN.5MAX.

D.E. FUSE C.B. FACTORY PROVIDED (LUGS) WIRE RANGE

SYSTEM #1 FIELD-SUPPLIED WIRING

STD. TERMINAL OPT. NF SVC.

6

BLOCK DISC SW.

7

OPT. C.B. RLA Y-LRA X-LRA FLA (EA)

COMPRESSOR FANS

See page 6 for notes.

4

YORK INTERNATIONAL

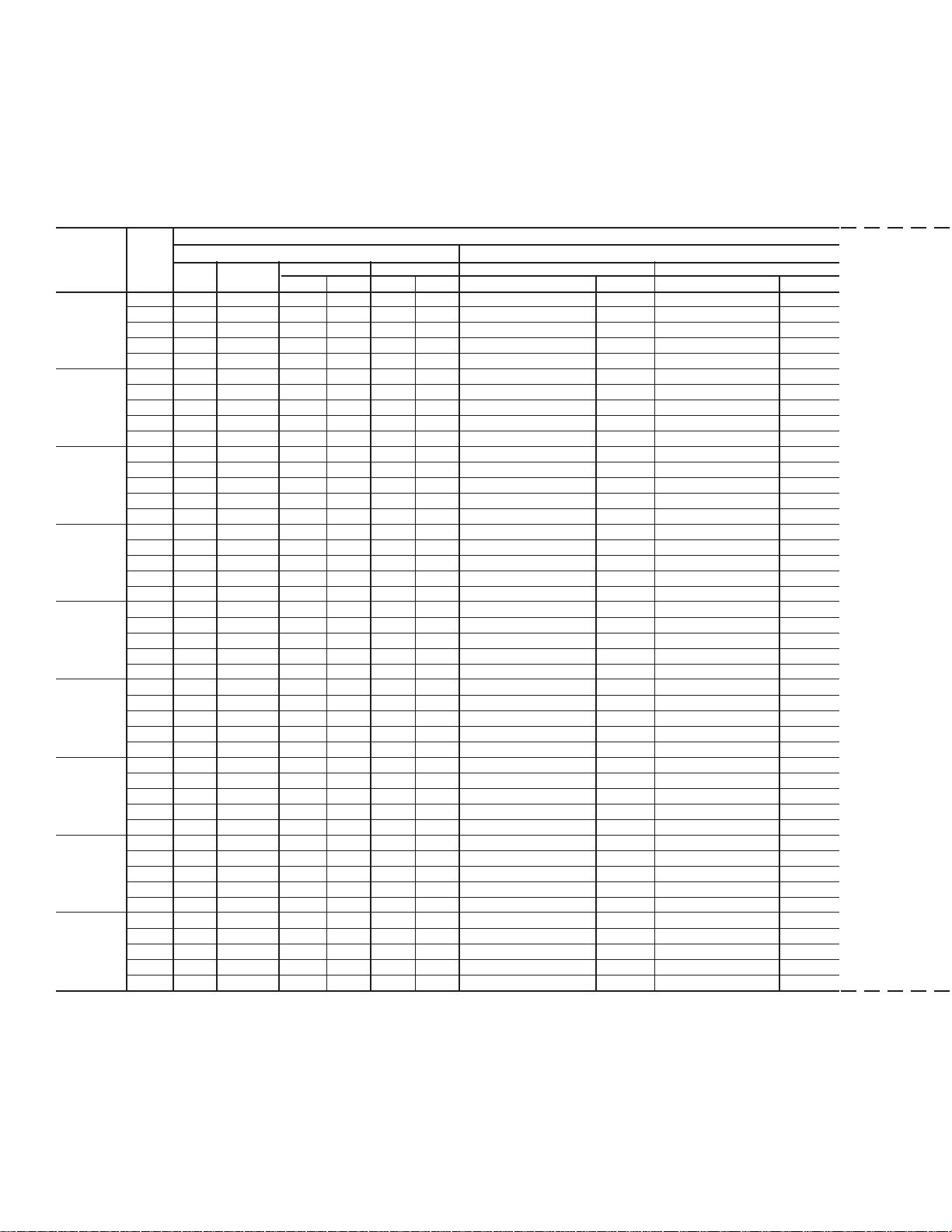

Page 5

FORM 201.18-W1

MODEL

VOLTS MIN NF

YCAS MCA

1

DISC SW2MIN.3MAX.4MIN.3MAX.

D.E. FUSE C.B. FACTORY PROVIDED (LUGS) WIRE RANGE

SYSTEM #2 FIELD-SUPPLIED WIRING

STD. TERMINAL OPT. NF SVC.

4

BLOCK DISC SW.

7

COMPRESSOR FANS

OPT. C.B. RLA Y-LRA X-LRA FLA (EA)

200 340 400 450 600 450 600 (2) # 2 - 300 (2) 3/0-250 (3) 2/0-400 246 444 1332 8.2

230 299 400 400 600 400 600 (2) # 2 - 300 (2) 3/0-250 (2) 3/0-250 214 386 1158 7.8

0130EC 380 181 200 225 350 225 350 # 2 - 300 # 6 AWG - 350 # 6 AWG - 350 130 234 701 4.8

460 150 150 200 300 200 300 # 2 - 4/0 # 6 AWG - 350 # 6 AWG - 350 107 193 579 4.0

575 119 150 150 225 150 225 # 2 - 4/0 # 6 AWG - 350 # 6 AWG - 350 86 154 463 3.1

200 366 400 450 700 450 700 (2) # 2 - 300 (2) 3/0-250 (3) 2/0-400 267 444 1332 8.2

230 321 400 400 600 400 600 (2) # 2 - 300 (2) 3/0-250 (2) 3/0-250 232 386 1158 7.8

0140EC 380 195 200 250 350 250 350 # 2 - 300 # 6 AWG - 350 # 6 AWG - 350 140 234 701 4.8

460 161 200 200 300 200 300 # 2 - 300 # 6 AWG - 350 # 6 AWG - 350 116 193 579 4.0

575 128 150 175 225 175 225 # 2 - 4/0 # 6 AWG - 350 # 6 AWG - 350 93 154 463 3.1

200 363 400 450 700 450 700 (2) # 2 - 300 (2) 3/0-250 (3) 2/0-400 265 444 1332 8.2

230 319 400 400 600 400 600 (2) # 2 - 300 (2) 3/0-250 (2) 3/0-250 230 386 1158 7.8

0150EC 380 193 200 250 350 250 350 # 2 - 300 # 6 AWG - 350 # 6 AWG - 350 139 234 701 4.8

460 160 150 200 300 200 300 # 2 - 300 # 6 AWG - 350 # 6 AWG - 350 115 193 579 4.0

575 127 150 175 225 175 225 # 2 - 4/0 # 6 AWG - 350 # 6 AWG - 350 92 154 463 3.1

200 402 400 500 700 500 700 (2) # 1 - 500 (2) 3/0-250 (3) 2/0-400 295 656 1969 8.2

230 351 400 450 700 450 700 (2) # 2 - 300 (2) 3/0-250 (3) 2/0-400 256 571 1712 7.8

0160EC 380 213 200 300 400 300 400 # 1 - 500 # 6 AWG - 350 (2) 3/0-250 155 360 1081 4.8

460 176 200 225 350 225 350 # 2 - 300 # 6 AWG - 350 # 6 AWG - 350 128 285 856 4.0

575 141 150 175 250 175 250 # 2 - 4/0 # 6 AWG - 350 # 6 AWG - 350 103 238 715 3.1

200 402 400 500 700 500 700 (2) # 1 - 500 (2) 3/0-250 (3) 2/0-400 295 656 1969 8.2

230 351 400 450 700 450 700 (2) # 2 - 300 (2) 3/0-250 (3) 2/0-400 256 571 1712 7.8

0170EC 380 213 200 300 400 300 400 # 1 - 500 # 6 AWG - 350 (2) 3/0-250 155 360 1081 4.8

460 176 200 225 350 225 350 # 2 - 300 # 6 AWG - 350 # 6 AWG - 350 128 285 856 4.0

575 141 150 175 250 175 250 # 2 - 4/0 # 6 AWG - 350 # 6 AWG - 350 103 238 715 3.1

200 434 600 600 800 600 800 (2) # 1 - 500 (3) 2/0-400 (3) 2/0-400 321 656 1969 8.2

230 380 400 450 700 450 700 (2) # 1 - 500 (2) 3/0-250 (3) 2/0-400 279 571 1712 7.8

0180EC 380 230 250 300 400 300 400 # 1 - 500 # 6 AWG - 350 (2) 3/0-250 169 360 1081 4.8

460 191 200 250 350 250 350 # 2 - 300 # 6 AWG - 350 # 6 AWG - 350 140 285 856 4.0

575 152 150 200 300 200 300 # 2 - 4/0 # 6 AWG - 350 # 6 AWG - 350 112 238 715 3.1

200 469 600 600 1000 600 1000 (2) # 1 - 500 (3) 2/0-400 (3) 2/0-400 342 656 1969 8.2

230 412 400 500 800 500 800 (2) # 1 - 500 (2) 3/0-250 (3) 2/0-400 298 571 1712 7.8

0200EC 380 250 250 300 450 300 450 # 1 - 500 # 6 AWG - 350 (2) 3/0-250 181 360 1081 4.8

460 206 200 250 400 250 400 # 1 - 500 # 6 AWG - 350 # 6 AWG - 350 149 285 856 4.0

575 164 200 200 300 200 300 # 2 - 300 # 6 AWG - 350 # 6 AWG - 350 119 238 715 3.1

200 469 600 600 1000 600 1000 (2) # 1 - 500 (3) 2/0-400 (3) 2/0-400 342 656 1969 8.2

230 412 400 500 800 500 800 (2) # 1 - 500 (2) 3/0-250 (3) 2/0-400 298 571 1712 7.8

0210EC 380 250 250 300 450 300 450 # 1 - 500 # 6 AWG - 350 (2) 3/0-250 181 360 1081 4.8

460 206 200 250 400 250 400 # 1 - 500 # 6 AWG - 350 # 6 AWG - 350 149 285 856 4.0

575 164 200 200 300 200 300 # 2 - 300 # 6 AWG - 350 # 6 AWG - 350 119 238 715 3.1

200 509 600 700 1000 700 1000 (2) # 1 - 500 (3) 2/0-400 (3) 2/0-400 374 656 1969 8.2

230 445 600 600 800 600 800 (2) # 1 - 500 (3) 2/0-400 (3) 2/0-400 325 571 1712 7.8

0230EC 380 270 400 350 500 350 500 # 1 - 500 (2) 3/0-250 (2) 3/0-250 197 360 1081 4.8

460 224 250 300 400 300 400 # 1 - 500 # 6 AWG - 350 (2) 3/0-250 163 285 856 4.0

575 178 200 225 350 225 350 # 2 - 300 # 6 AWG - 350 # 6 AWG - 350 130 238 715 3.1

YORK INTERNATIONAL

5

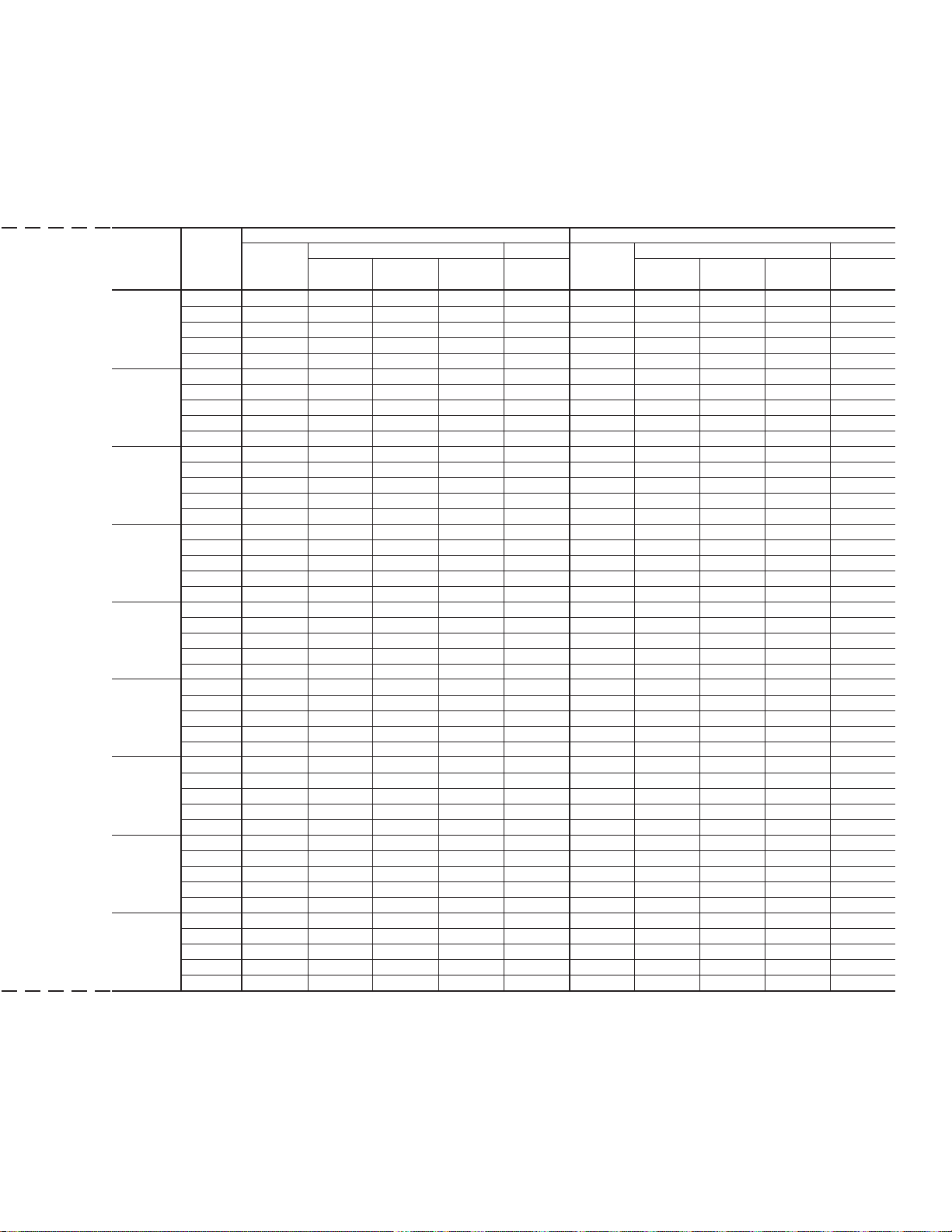

Page 6

ELECTRICAL DATA (Continued)

OPTIONAL SINGLE-POINT POWER SUPPLY WITH INTERNAL CIRCUIT BREAKERS

(One Field Provided Power Supply Circuit to the chiller. Field connections to Power Terminal Block or Non-Fused Disconnect in Option Panel.

MODEL

YCAS MIN NF D.E. FUSE C.B. TERMINAL BLOCK NF SERVICE DISC SW

0130EC 380 330 400 400 500 400 500 (2) # 2 - 300 550 (2) 3/0-250 400

0140EC 380 354 400 400 500 400 500 (2) # 2 - 300 550 (2) 3/0-250 400

0150EC 380 371 400 450 600 450 600 (2) # 1 - 500 760 (2) 3/0-250 400

0160EC 380 387 600 450 600 450 600 (2) # 1 - 500 760 (3) 2/0-400 600

0170EC 380 405 600 450 600 450 600 (2) # 1 - 500 760 (3) 2/0-400 600

0180EC 380 419 600 500 600 500 600 (2) # 1 - 500 760 (3) 2/0-400 600

0200EC 380 455 600 600 700 600 700 (2) # 1 - 500 760 (3) 2/0-400 600

0210EC 380 475 600 600 700 600 700 (2) # 1 - 500 760 (3) 2/0-400 600

0230EC 380 491 600 600 700 600 700 (2) # 1 - 500 760 (3) 2/0-400 600

VOLTS

MCA

200 619 800 700 1000 700 1000 (3) # 1 - 500 1140 (3) 2/0-400 800

230 544 600 600 800 600 800 (2) # 1 - 500 760 (3) 2/0-400 600

460 273 400 300 400 300 400 # 1 - 500 380 (2) 3/0-250 400

575 217 250 250 350 250 350 # 1 - 500 380 # 6 AWG - 350 250

200 666 800 800 1000 800 1000 (3) # 1 - 500 1140 (3) 2/0-400 800

230 584 800 700 1000 700 1000 (3) # 1 - 500 1140 (3) 2/0-400 600

460 293 400 350 450 350 450 (2) # 2 - 300 550 (2) 3/0-250 400

575 234 250 300 350 300 350 # 1 - 500 380 # 6 AWG - 350 250

200 699 800 800 1000 800 1000 (3) # 1 - 500 1140 (3) 2/0-400 800

230 612 800 700 1000 700 1000 (3) # 1 - 500 1140 (3) 2/0-400 800

460 307 400 350 450 350 450 (2) # 2 - 300 550 (2) 3/0-250 400

575 246 400 300 350 300 350 # 1 - 500 380 (2) 3/0-250 400

200 729 800 1000 1200 1000 1200 (3) # 1 - 500 1140 (3) 2/0-400 800

230 638 800 800 1000 800 1000 (3) # 1 - 500 1140 (3) 2/0-400 800

460 320 400 400 450 400 450 (2) # 2 - 300 550 (2) 3/0-250 400

575 257 400 300 400 300 400 # 1 - 500 380 (2) 3/0-250 400

200 762 800 1000 1200 1000 1200 (3) # 1 - 500 1140 (3) 2/0-400 800

230 667 800 800 1000 800 1000 (3) # 1 - 500 1140 (3) 2/0-400 800

460 335 400 400 500 400 500 (2) # 2 - 300 550 (2) 3/0-250 400

575 268 400 300 400 300 400 # 1 - 500 380 (2) 3/0-250 400

200 788 1000 1000 1200 1000 1200 (3) # 1 - 500 1140 (4) 4/0-500 1000

230 690 800 800 1000 800 1000 (3) # 1 - 500 1140 (3) 2/0-400 800

460 347 400 400 500 400 500 (2) # 2 - 300 550 (2) 3/0-250 400

575 277 400 350 400 350 400 (2) # 2 - 300 550 (2) 3/0-250 400

200 852 1000 1000 1200 1000 1200 (3) # 1 - 500 1140 (4) 4/0-500 1000

230 749 800 1000 1200 1000 1200 (3) # 1 - 500 1140 (3) 2/0-400 800

460 375 400 450 600 450 600 (2) # 1 - 500 760 (2) 3/0-250 400

575 299 400 350 450 350 450 (2) # 2 - 300 550 (2) 3/0-250 400

200 892 1000 1000 1600 1000 1600 (3) # 1 - 500 1140 (4) 4/0-500 1000

230 782 1000 1000 1200 1000 1200 (3) # 1 - 500 1140 (4) 4/0-500 1000

460 393 600 450 600 450 600 (2) # 1 - 500 760 (3) 2/0-400 600

575 313 400 350 450 350 450 (2) # 2 - 300 550 (2) 3/0-250 400

200 924 1000 1200 1600 1200 1600 (3) # 1 - 500 1140 (4) 4/0-500 1000

230 809 1000 1000 1200 1000 1200 (3) # 1 - 500 1140 (4) 4/0-500 1000

460 407 600 450 600 450 600 (2) # 1 - 500 760 (3) 2/0-400 600

575 324 400 400 500 400 500 (2) # 2 - 300 550 (2) 3/0-250 400

FIELD PROVIDED POWER SUPPLY FACTORY PROVIDED (LUGS) WIRE RANGE

1

DISC SW2MIN.3MAX.4MIN.3MAX.4(LUGS) WIRE RANGE7RATING2(LUGS) WIRE RANGE7RATING

Internal Branch Circuit Protection (Breakers) per Motor Control Center)

FIELD-SUPPLIED WIRING

2

See page 6 for notes.

6

YORK INTERNATIONAL

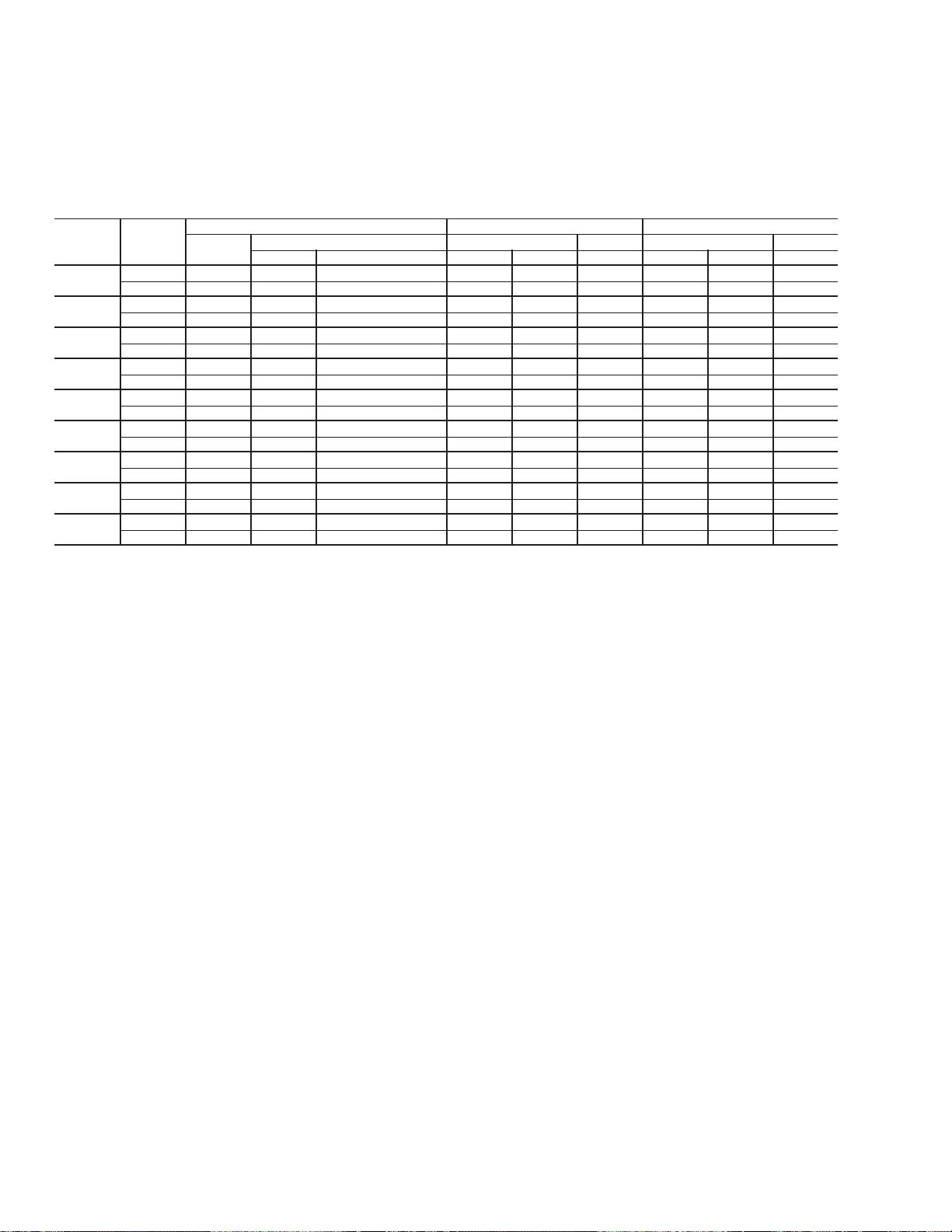

Page 7

FORM 201.18-W1

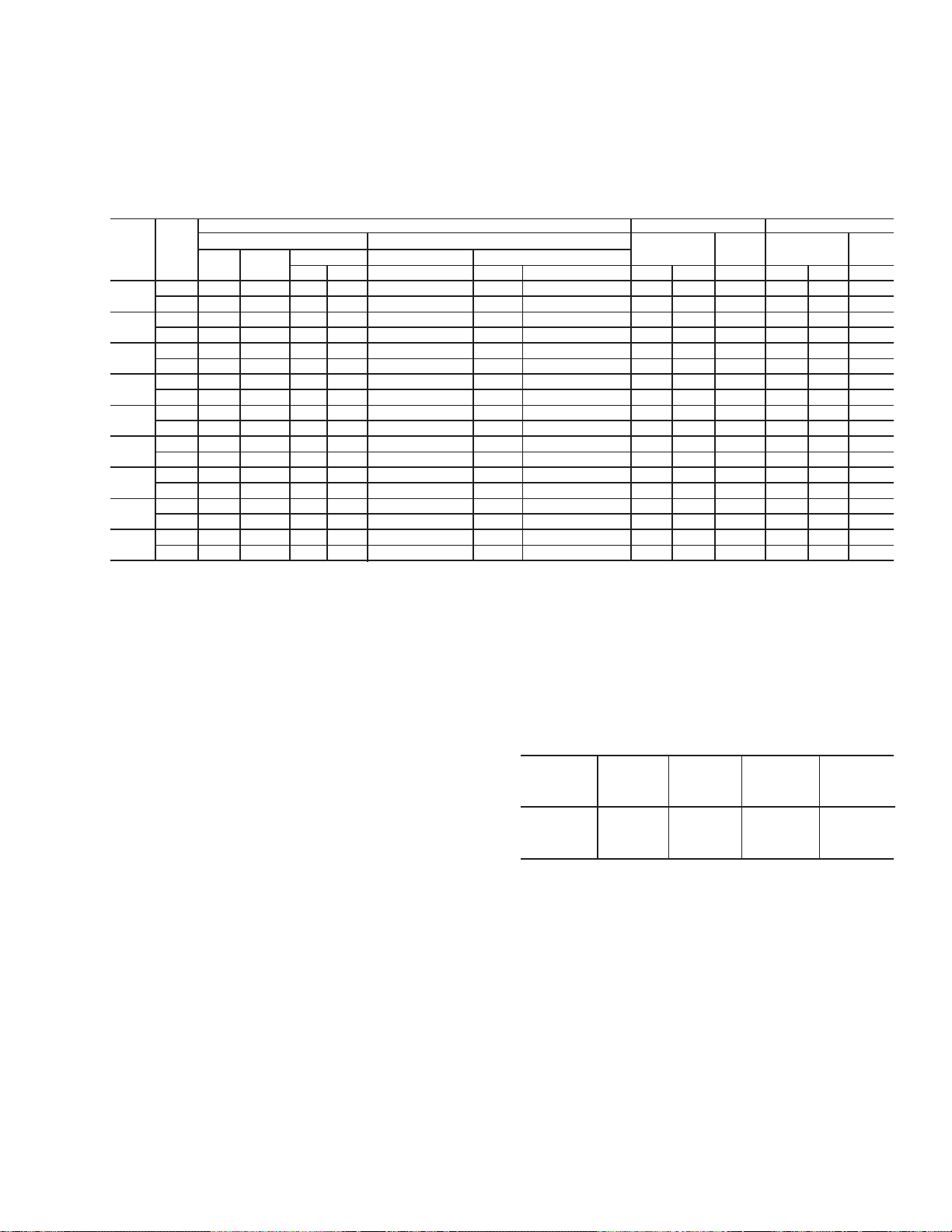

MODEL

YCAS

0130EC 380 250 130 234 701 4.8 250 130 234 701 4.8

0140EC 380 250 140 234 701 4.8 250 140 234 701 4.8

0150EC 380 400 155 360 1081 4.8 250 139 234 701 4.8

0160EC 380 400 155 360 1081 4.8 400 155 360 1081 4.8

0170EC 380 400 169 360 1081 4.8 400 155 360 1081 4.8

0180EC 380 400 169 360 1081 4.8 400 169 360 1081 4.8

0200EC 380 400 181 360 1081 4.8 400 181 360 1081 4.8

0210EC 380 400 197 360 1081 4.8 400 181 360 1081 4.8

0230EC 380 400 197 360 1081 4.8 400 197 360 1081 4.8

VOLTS FACTORY

C.B. RLA Y-LRA X-LRA FLA (EA) C.B. RLA Y-LRA X-LRA FLA (EA)

200 600 246 444 1332 8.2 600 246 444 1332 8.2

230 400 214 386 1158 7.8 400 214 386 1158 7.8

460 250 107 193 579 4.0 250 107 193 579 4.0

575 160 86 154 463 3.1 160 86 154 463 3.1

200 600 267 444 1332 8.2 600 267 444 1332 8.2

230 400 232 386 1158 7.8 400 232 386 1158 7.8

460 250 116 193 579 4.0 250 116 193 579 4.0

575 160 93 154 463 3.1 160 93 154 463 3.1

200 600 295 656 1969 8.2 600 265 444 1332 8.2

230 600 256 571 1712 7.8 400 230 386 1158 7.8

460 250 128 285 856 4.0 250 115 193 579 4.0

575 250 103 238 715 3.1 160 92 154 463 3.1

200 600 295 656 1969 8.2 600 295 656 1969 8.2

230 600 256 571 1712 7.8 600 256 571 1712 7.8

460 250 128 285 856 4.0 250 128 285 856 4.0

575 250 103 238 715 3.1 250 103 238 715 3.1

200 600 321 656 1969 8.2 600 295 656 1969 8.2

230 600 279 571 1712 7.8 600 256 571 1712 7.8

460 250 140 285 856 4.0 250 128 285 856 4.0

575 250 112 238 715 3.1 250 103 238 715 3.1

200 600 321 656 1969 8.2 600 321 656 1969 8.2

230 600 279 571 1712 7.8 600 279 571 1712 7.8

460 250 140 285 856 4.0 250 140 285 856 4.0

575 250 112 238 715 3.1 250 112 238 715 3.1

200 600 342 656 1969 8.2 600 342 656 1969 8.2

230 600 298 571 1712 7.8 600 298 571 1712 7.8

460 250 149 285 856 4.0 250 149 285 856 4.0

575 250 119 238 715 3.1 250 119 238 715 3.1

200 600 374 656 1969 8.2 600 342 656 1969 8.2

230 600 325 571 1712 7.8 600 298 571 1712 7.8

460 400 163 285 856 4.0 250 149 285 856 4.0

575 250 130 238 715 3.1 250 119 238 715 3.1

200 600 374 656 1969 8.2 600 374 656 1969 8.2

230 600 325 571 1712 7.8 600 325 571 1712 7.8

460 400 163 285 856 4.0 400 163 285 856 4.0

575 250 130 238 715 3.1 250 130 238 715 3.1

SYSTEM #1 SYSTEM #2

COMPRESSOR DATA FAN DATA

FACTORY

COMPRESSOR DATA FAN DATA

YORK INTERNATIONAL

7

Page 8

ELECTRICAL DATA (Continued)

OPTIONAL SINGLE POINT POWER SUPPLY CONNECTION TO FACTORY CIRCUIT BREAKER

(One Field Provided Power Supply Circuit to the chiller. Field Connection to Circuit Breaker in Option Panel.

No internal Branch Circuit Protection per Motor Control Center.)

MODEL

YCAS

0130EC

0140EC

0150EC

0160EC

0170EC

0180EC

0200EC

0210EC

0230EC

VOLTS

460 273 400 (2) 3/0-250 107 579 4.0 107 579 4.0

575 217 250 # 6 AWG - 350 86 463 3.1 86 463 3.1

460 293 400 (2) 3/0-250 116 579 4.0 116 579 4.0

575 234 400 (2) 3/0-250 93 463 3.1 93 463 3.1

460 307 400 (2) 3/0-250 128 856 4.0 115 579 4.0

575 246 400 (2) 3/0-250 103 715 3.1 92 463 3.1

460 320 400 (2) 3/0-250 128 856 4.0 128 856 4.0

575 257 400 (2) 3/0-250 103 715 3.1 103 715 3.1

460 335 400 (2) 3/0-250 140 856 4.0 128 856 4.0

575 268 400 (2) 3/0-250 112 715 3.1 103 715 3.1

460 347 400 (2) 3/0-250 140 856 4.0 140 856 4.0

575 277 400 (2) 3/0-250 112 715 3.1 112 715 3.1

460 375 630 (3) 2/0-400 149 856 4.0 149 856 4.0

575 299 400 (2) 3/0-250 119 715 3.1 119 715 3.1

460 393 630 (3) 2/0-400 163 856 4.0 149 856 4.0

575 313 400 (2) 3/0-250 130 715 3.1 119 715 3.1

460 407 630 (3) 2/0-400 163 856 4.0 163 856 4.0

575 324 400 (2) 3/0-250 130 715 3.1 130 715 3.1

FIELD SUPPLIED WIRING SYSTEM #1 SYSTEM #2

FACTORY SUPPLIED BREAKER COMPRESSOR FANS COMPRESSOR FANS

1

MCA

RATING2WIRE RANGE7 (LUGS) RLA X-LRA FLA (EA) RLA X-LRA FLA (EA)

NOTE: Wye-Delta Compressor Start not available with this option.

NOTES (pages 2 - 7)

1. Minimum circuit ampacity (MCA) is based on 125% of the rated load amps for the largest motor plus 100% of the rated load amps for all

other loads included in the circuit, per N.E.C. Article 430-24. If a Factory Mounted Control Transformer is provided, add the following to

the system #2 MCA values in the YCAS Tables: -17, add 10 amps; -28, add 9 amps; -40, add 5 amps; -46, add 4 amps; -58, add 3 amps.

2. The recommendation disconnect switch is based on a minimum of 115% of the summation rated load amps of all the loads included in the

circuit, per N.E.C. 440 - 12A1.

3. Minimum fuse size is based on 150% of the largest motor RLA plus 100% of the remaining RLAs (U.L. Standard 1995, Section 36.1).

Minimum fuse rating = (1.5 x largest compressor RLA) + other compressor RLAs + (# fans x each fan motor FLA).

4. Maximum dual element fuse size is based on 225% maximum plus 100% of the rated load amps for all other loads included in the circuit,

per N.E.C. 440-22. Maximum fuse rating = (2.25 x largest compressor RLA) + other compressor RLAs + (# fans x each fan motor FLA).

5. Minimum circuit breaker is 150% maximum plus 100% of rated load amps included in the circuit, per circuit per U.L. 1995 Fig. 36.2.

Minimum circuit breaker rating = (1.5 x largest compressor RLA) + other compressor RLAs + (# fans x each fan motor FLA).

6. Maximum circuit breaker is based on 225% maximum plus 100% of the rated load amps for all loads included in the circuit, per circuit, per

U.L. 1995 Fig. 36.2. Maximum circuit breaker rating = (2.25 x largest compressor RLA) + other compressor RLAs + ( # fans x each fan

motor FLA).

7. The Incoming Wire Range is the minimum and maximum wire size that can be accommodated by unit wiring lugs. The (1), (2), or (3)

indicate the number of termination points or lugs which are available per phase. Actual wire size and number of wires per phase must be

determined based on ampacity and job requirements using N.E.C. wire sizing information. The above recommendations are based on the

National Electric Code and using copper connectors only. Field wiring must also comply with local codes.

8. A ground lug is provided for each compressor system to accommodate field grounding conductor per N.E.C. Article 250-54. A control

circuit grounding lug is also supplied. Incoming ground wire range is #6 - 350 MCM.

9. The field supplied disconnect is a Disconnecting Means as defined in N.E.C. 100.B, and is intended for isolating the unit from the

available power supply to perform maintenance and troubleshooting. This disconnect is not intended to be a Load Break Device.

10. Units equipped with Star-Delta compressor motor start must also include Factory provided circuit breakers in each motor control center.

11. The wiring recommendations are based on the National Electrical Code using copper connectors only. Field wiring must also comply with

local codes.

8

YORK INTERNATIONAL

Page 9

FORM 201.18-W1

OPTIONAL SINGLE POINT POWER SUPPLY CONNECTION WITH FIELD SUPPLIED CIRCUIT PROTECTION

(One Field Provided Power Supply Circuit to the chiller. Field Connection to Power Terminal Block or Disconnect Switch in the Option Panel.

No internal Branch Circuit Protection per Motor Control Center.)

MODEL

YCAS

0130EC

0140EC

0150EC

0160EC

0170EC

0180EC

0200EC

0210EC

0230EC

FIELD PROVIDED POWER SUPPLY FACTORY PROVIDED (LUGS) WIRE RANGE COMPRESSOR FANS COMPRESSOR FANS

VOLTS

460 273 400 300 400 # 1 - 500 400 (2) 3/0-250 107 579 4.0 107 579 4.0

575 217 250 250 350 # 1 - 500 250 # 6 AWG - 350 86 463.2 3.1 86 463 3.1

460 293 400 350 450 (2) # 2 - 300 400 (2) 3/0-250 116 579 4.0 116 579 4.0

575 234 250 300 350 # 1 - 500 250 # 6 AWG - 350 93 463.2 3.1 93 463 3.1

460 307 400 350 450 (2) # 2 - 300 400 (2) 3/0-250 128 856 4.0 115 579 4.0

575 246 400 300 350 # 1 - 500 250 # 6 AWG - 350 103 715 3.1 92 463 3.1

460 320 400 400 450 (2) # 2 - 300 400 (2) 3/0-250 128 856 4.0 128 856 4.0

575 257 400 300 400 # 1 - 500 400 (2) 3/0-250 103 715 3.1 103 715 3.1

460 335 400 400 500 (2) # 2 - 300 400 (2) 3/0-250 140 856 4.0 128 856 4.0

575 268 400 300 400 # 1 - 500 400 (2) 3/0-250 112 715 3.1 103 715 3.1

460 347 400 400 500 (2) # 2 - 300 400 (2) 3/0-250 140 856 4.0 140 856 4.0

575 277 400 350 400 (2) # 2 - 300 400 (2) 3/0-250 112 715 3.1 112 715 3.1

460 375 400 450 600 (2) # 1 - 500 400 (2) 3/0-250 149 856 4.0 149 856 4.0

575 299 400 350 450 (2) # 2 - 300 400 (2) 3/0-250 119 715 3.1 119 715 3.1

460 393 600 450 600 (2) # 1 - 500 400 (2) 3/0-250 163 856 4.0 149 856 4.0

575 313 400 350 450 (2) # 2 - 300 400 (2) 3/0-250 130 715 3.1 119 715 3.1

460 407 600 450 600 (2) # 1 - 500 630 (3) 2/0-400 163 856 4.0 163 856 4.0

575 324 400 400 500 (2) # 2 - 300 400 (2) 3/0-250 130 715 3.1 130 715 3.1

MIN NF D.E. FUSE TERMINAL BLOCK NF SERV DISC SW DATA DATA DATA DATA

1

MCA

DISC SW2MIN3MAX4(LUGS) WIRE RANGE7RATING2(LUGS) WIRE RANGE7RLA X-LRA FLA (EA) RLA X-LRA FLA (EA)

FIELD SUPPLIED WIRING SYSTEM #1 SYSTEM #2

LEGEND

ACR-LINE ACROSS THE LINE START

C.B. CIRCUIT BREAKER

D.E. DUAL ELEMENT FUSE

DISC SW DISCONNECT SWITCH

FACT MOUNT CB FACTORY-MOUNTED CIRCUIT BREAKER

FLA FULL LOAD AMPS

HZ HERTZ

MAX MAXIMUM

UNIT

VOLTAGE

Standard

Models w/o 115-1-60 20A 20A 30A

Transformers

CONTROL POWER SUPPLY

CONTROL MIN MAX DUAL NON-FUSED

POWER CIRCUIT ELEMENT DISC. SW.

SUPPLY AMPACITY FUSE SIZE SIZE

MCA MINIMUM CIRCUIT AMPACITY

MIN MINIMUM

MIN NF MINIMUM NON-FUSED

RLA RUNNING LOAD AMPS

S.P. WIRE SINGLE-POINT WIRING

UNIT MTD SERV SW UNIT-MOUNTED SERVICE (NON-FUSED DISCONNECT SWITCH)

WYE-DELTA WYE-DELTA START

X-LRA ACROSS-THE-LINE INRUSH LOCKED ROTOR AMPS

Y-LRA WYE-DELTA INRUSH LOCKED ROTOR AMPS

VOLTAGE CODE

-17 = 200-3-60

-28 = 230-3-60

-40 = 380-3-60

-46 = 460-3-60

-58 = 575-3-60

YORK INTERNATIONAL

9

Page 10

ACROSS-THE-LINE START

NOTES:

1. Field wiring to be in accordance with the current

edition of the National Electrical Code as well as all

other applicable codes and specifications.

2. Numbers along the right side of a diagram are line

identification numbers. The numbers at each line

indicate the line number location of relay contacts.

An unlined contact location signifies a normally closed

contact. Numbers adjacent to circuit lines are the

circuit identification numbers.

3. Any customer supplied contacts must be suitable

for switching 24VDC. (Gold contacts recommended.) Control Wiring must not be run in the same

conduit with any line voltage wiring.

4. To cycle unit on and off automatically with contact

shown, install a cycling device in series with the

flow switch (FSLW). See Note 3 for contact rating

and wiring specifications. Also refer to cautions on

the following page.

5. To stop unit (Emergency Stop) with contacts other

than those shown, install the stop contact between

5 and 1. If a stop device is not installed, a jumper

must be connected between terminals 5 and 1. Device must have a minimum contact rating of 100VA

at 115 volts A.C.

6. Alarm contacts are for annunciating alarm/unit malfunction. Contacts are rated at 115V, 100VA, resistive load only, and must be suppressed at load by

user.

7. See Installation, Operation and Maintenance Manual

when optional equipment is used.

8. Control panel to be securely connected to earth

ground.

9. Us 2KVA transformer in optional transformer kit unless there are optional oil separator sump heaters

which necessitates using a 3KVA transformer.

WIRING DIAGRAM

LD03226

LEGEND

T S

Transient Voltage Suppression

Terminal Block for Customer Connections

Terminal Block for Customer Low Voltage

(Class 2) Connections. See Note 2

Terminal Block for YORK Connections Only

Wiring and Components by YORK

Optional Equipment

Wiring and/or Components by Others

FIG. 1 – ELEMENTARY DIAGRAM – ACROSS-THE-LINE START

10

LD03227

YORK INTERNATIONAL

Page 11

WIRING DIAGRAM

ACROSS-THE-LINE START

FORM 201.18-W1

YORK INTERNATIONAL

LD03228

11

Page 12

ELEMENTARY DIAGRAM

FIG. 1 – CONTINUED

12

YORK INTERNATIONAL

Page 13

ELEMENTARY DIAGRAM

FORM 201.18-W1

LD03279

CAUTION:

No Controls (relays, etc.) should

be mounted in the Smart Panel

enclosure or connected to power

supplies in the control panel.

Additionally, control wiring not

connected to the Smart Panel

should not be run through the

cabinet. This could result in nuisance faults.

CAUTION:

Any inductive devices (relays)

wired in series with the flow

switch for start/stop, into the

Alarm circuitry, or pilot relays

for pump starters wired through

motor contactor auxiliary contacts must be suppressed with

YORK P/N 031-00808-000 suppressor across the relay/

contactor coil.

Any contacts connected to flow

switch inputs or BAS inputs on

terminals 13 - 19 or TB3, or any

other terminals, must be suppressed with a YORK P/N 03100808-000 suppressor across

the relay/contactor coil.

YORK INTERNATIONAL

CAUTION:

Control wiring connected to the

control panel should never be

run in the same conduit with

power wiring.

CONTROL POWER SUPPLY

UNIT

VOLTAGE

ALL MODELS

W/O TRANS.

MODELS -1 7 200-1-60 15A 15A 250V 30A 240V

WITH -2 8 230-1-60 15A 15A 250V 30A 240V

TRANS. - 46 400-1-60 8A 8A 600V 30A 480V

* -58 575-1-60 8A 8A 600V 30A 600V

* All primary and secondary wiring between transformer and control panel included.

CONTROL MIN MAX DUAL NON-FUSED

POWER CIRCUIT ELEMENT DISC.

SUPPLY AMP. FUSE SIZE SWITCH SIZE

115-1-50/60 20A 20A 250V 30A 240V

13

Page 14

NOTES:

1. Field wiring to be in accordance with the current

edition of the National Electrical Code as well as all

other applicable codes and specifications.

2. Numbers along the right side of a diagram are line

identification numbers. The numbers at each line

indicate the line number location of relay contacts.

An unlined contact location signifies a normally closed

contact. Numbers adjacent to circuit lines are the

circuit identification numbers.

3. Any customer supplied contacts must be suitable

for switching 24VDC. (Gold contacts recommended.) Control Wiring must not be run in the same

conduit with any line voltage wiring.

4. To cycle unit on and off automatically with contact

shown, install a cycling device in series with the

flow switch (FSLW). See Note 3 for contact rating

and wiring specifications. Also refer to cautions on

the following page.

5. To stop unit (Emergency Stop) with contacts other

than those shown, install the stop contact between

5 and 1. If a stop device is not installed, a jumper

must be connected between terminals 5 and 1. Device must have a minimum contact rating of 100VA

at 115 volts A.C.

6. Alarm contacts are for annunciating alarm/unit malfunction. Contacts are rated at 115V, 100VA, resistive load only, and must be suppressed at load by

user.

7. See Installation, Operation and Maintenance Manual

when optional equipment is used.

8. Control panel to be securely connected to earth

ground.

9. Us 2KVA transformer in optional transformer kit unless there are optional oil separator sump heaters

which necessitates using a 3KVA transformer.

WIRING DIAGRAM

WYE-DELTA START

LD03226

LEGEND

T S

Transient Voltage Suppression

Terminal Block for Customer Connections

Terminal Block for Customer Low Voltage

(Class 2) Connections. See Note 2

Terminal Block for YORK Connections Only

Wiring and Components by YORK

Optional Equipment

Wiring and/or Components by Others

FIG. 1 – ELEMENTAR Y DIAGRAM – WYE-DEL TA ST AR T

14

LD03227

YORK INTERNATIONAL

Page 15

WIRING DIAGRAM

WYE-DELTA START

FORM 201.18-W1

YORK INTERNATIONAL

LD03229

15

Page 16

ELEMENTARY DIAGRAM

FIG. 1 – CONTINUED

16

YORK INTERNATIONAL

Page 17

ELEMENTARY DIAGRAM

FORM 201.18-W1

LD03279

CAUTION:

No Controls (relays, etc.) should

be mounted in the Smart Panel

enclosure or connected to power

supplies in the control panel.

Additionally, control wiring not

connected to the Smart Panel

should not be run through the

cabinet. This could result in nuisance faults.

CAUTION:

Any inductive devices (relays)

wired in series with the flow

switch for start/stop, into the

Alarm circuitry, or pilot relays

for pump starters wired through

motor contactor auxiliary contacts must be suppressed with

YORK P/N 031-00808-000 suppressor across the relay/

contactor coil.

Any contacts connected to flow

switch inputs or BAS inputs on

terminals 13 - 19 or TB3, or any

other terminals, must be suppressed with a YORK P/N 03100808-000 suppressor across

the relay/contactor coil.

YORK INTERNATIONAL

CAUTION:

Control wiring connected to the

control panel should never be

run in the same conduit with

power wiring.

CONTROL POWER SUPPLY

UNIT

VOLTAGE

ALL MODELS

W/O TRANS.

MODELS -1 7 200-1-60 15A 15A 250V 30A 240V

WITH -2 8 230-1-60 15A 15A 250V 30A 240V

TRANS. - 46 400-1-60 8A 8A 600V 30A 480V

* -58 575-1-60 8A 8A 600V 30A 600V

* All primary and secondary wiring between transformer and control panel included.

CONTROL MIN MAX DUAL NON-FUSED

POWER CIRCUIT ELEMENT DISC.

SUPPLY AMP. FUSE SIZE SWITCH SIZE

115-1-50/60 20A 20A 250V 30A 240V

17

Page 18

18

YORK INTERNATIONAL

Page 19

FORM 201.18-W1

YORK INTERNATIONAL

LD03280

19

Page 20

LEGEND

20

LD03281

YORK INTERNATIONAL

Page 21

LD03282

FORM 201.18-W1

LD03283

YORK INTERNATIONAL

LD03284

21

Page 22

CONNECTION DIAGRAM (SYSTEM WIRING)

LD03230

22

LD03231

LD03232

YORK INTERNATIONAL

Page 23

COMPRESSOR TERMINAL BOX

FORM 201.18-W1

YORK INTERNATIONAL

LD03233

23

Page 24

MULTI-POINT POWER SUPPLY WIRING STANDARD UNIT

LD03254

SINGLE POINT POWER SUPPLY WIRING WITH CIRCUIT BREAKERS

24

LD03255

YORK INTERNATIONAL

Page 25

FORM 201.18-W1

SINGLE POINT POWER WIRING WITH FIELD SUPPLIED CIRCUIT PROTECTION

LD03256

SINGLE POINT POWER WIRING WITH CIRCUIT BREAKERS

YORK INTERNATIONAL

LD03257

25

Page 26

ELECTRICAL POWER WIRING OPTIONS: TERMINAL BLOCKS

LD03258

ELECTRICAL POWER WIRING OPTIONS: NON FUSED DISCONNECT SWITCH

26

LD03259

ELECTRICAL POWER WIRING OPTIONS: TERMINAL BLOCKS

LD03260

YORK INTERNATIONAL

Page 27

FORM 201.18-W1

LD03286

YORK INTERNATIONAL

27

Page 28

LD03286

P.O.Box 1592, York,Pennsylvania USA 17405-1592 Subject to change without notice. Printed in USA

Copyright © by York International Corporation 1998 ALL RIGHTS RESERVED

Form 201.18-W1 (1298)

Supersedes: 201.18-W1 (798)

Loading...

Loading...