Page 1

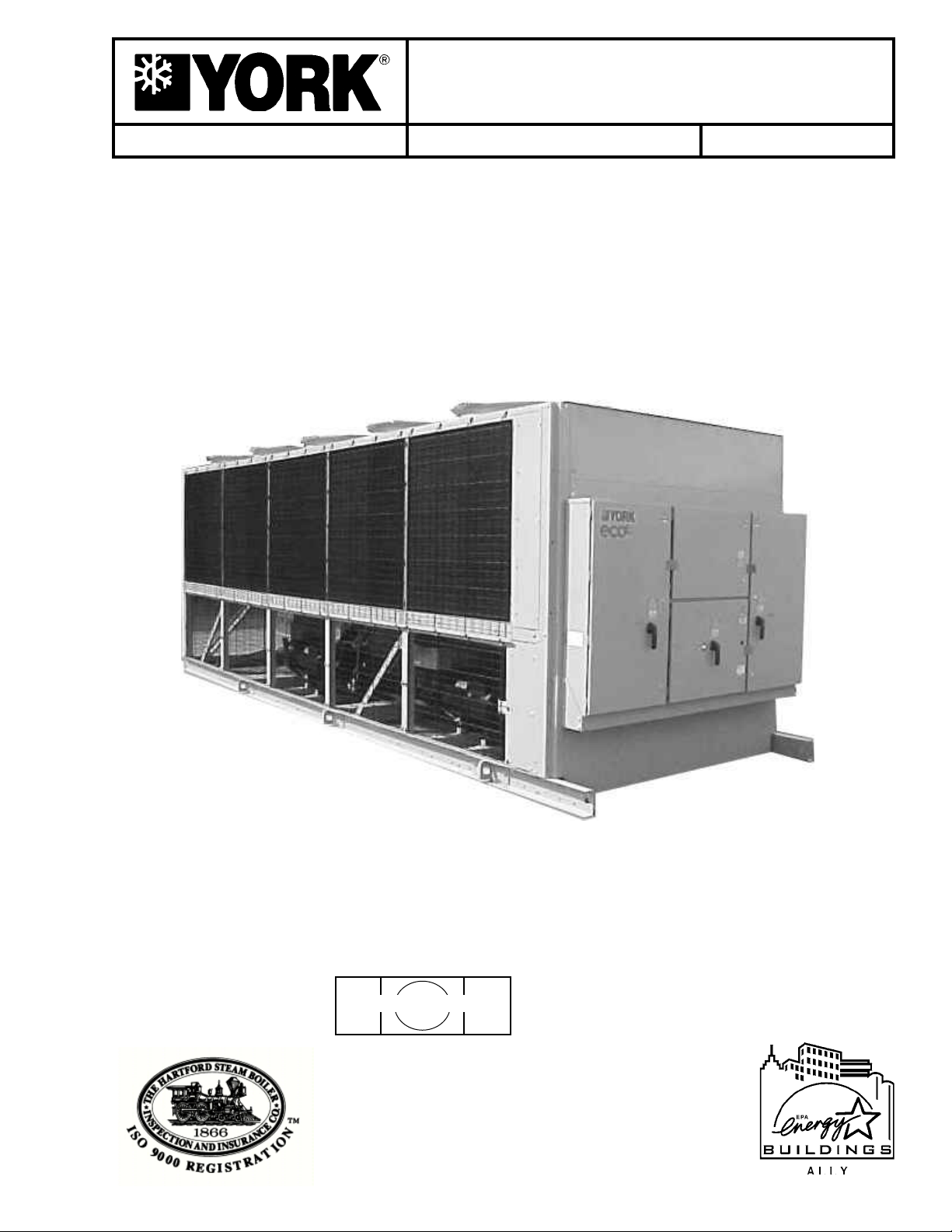

AIR-COOLED SCREW LIQUID CHILLERS

INSTALLATION, OPERATION & MAIN TE NANCE

YCAS AIR-COOLED LIQUID CHILLERS

YCAS0130 THROUGH YCAS0230

New Release

STYLE G

Form 201.19-NM1 (204)

035-20319-000

028971-G

60 Hz

YCAS 2 SYSTEM EPROM 031-01798-001 (STANDARD, BRINE & METRIC MODELS COM BINED)

Page 2

FORM 201.19-NM1 (204)

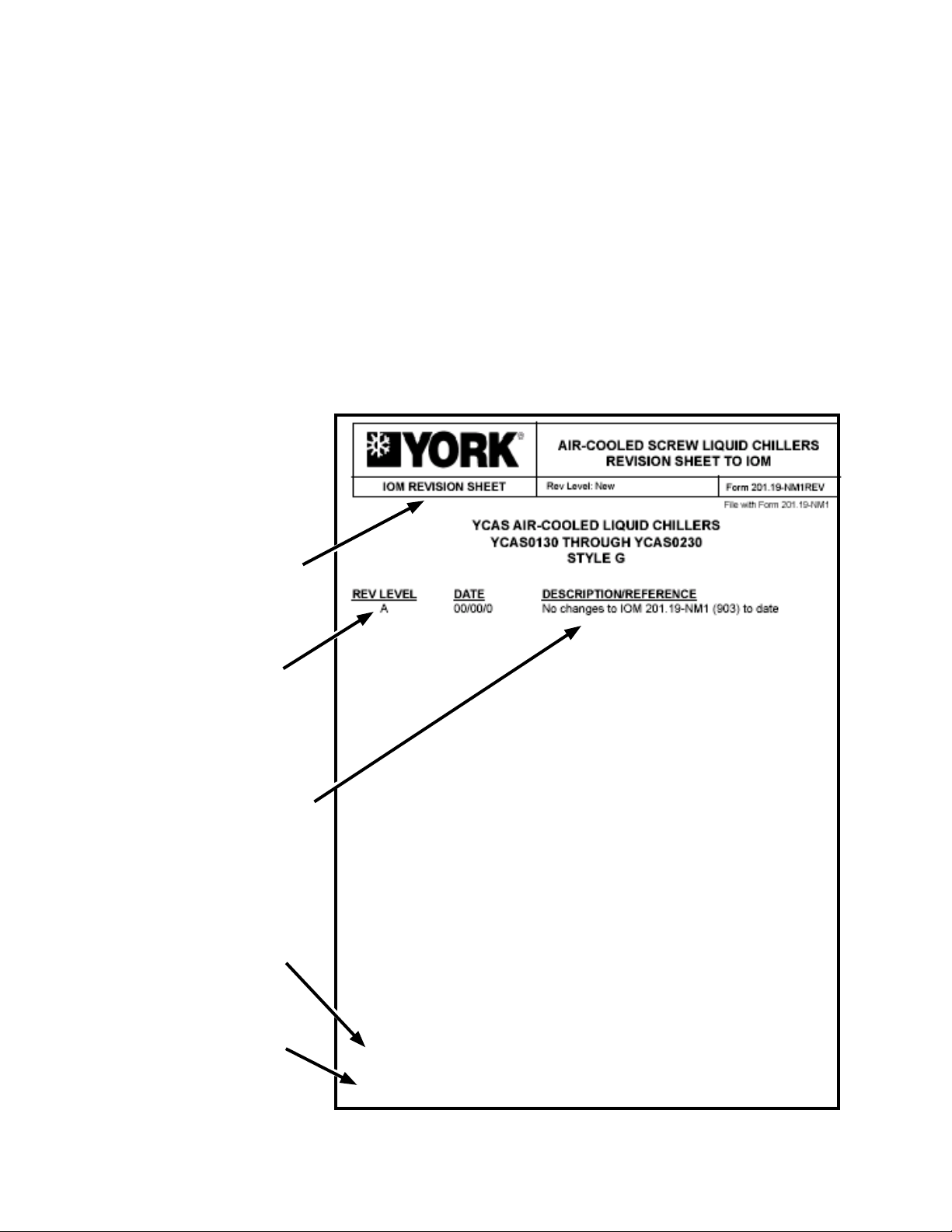

CHANGEABILITY OF THIS DOCUMENT

In complying with YORK’s policy for continuous prod uct improvement, the information contained in this

doc u ment is subject to change without notice. Literature updates that may occur will be printed on the

Revision Sheet and included with the Installation, Operation & Maintenance (IOM) man, which is provided

with new equipment. If not found with the manual, the current Revision Sheet containing any applicable

revisions, and the manual, can be found on the internet at www.york.com. The Renewal Parts (RP) manual

and revision sheet for this equipment can also be found at this internet site.

It is the responsibility of installing/operating/service personnel to determine prior to working on the equip ment, that they have all of the applicable literature, that it is current and that the equipment has not been

modifi ed since manufacture.

Revision Sheets are available for

the IOM and Renewal Parts

Each update will be assigned a

sequential Rev. Level with the

date it was introduced

The Description/Change will explain

the change. If necessary it will

refer the reader to an additional

supplement or bulletin.

YORK part number for the Revision

Sheet to aid manufacturing and

distribution

Web address for the Revision Sheet

2

035-XXXXX-XXX

www.york.com

YORK INTERNATIONAL

Page 3

IMPORTANT!

READ BEFORE PROCEEDING!

GENERAL SAFETY GUIDELINES

FORM 201.19-NM1 (204)

This equipment is a relatively complicated ap pa ra tus.

Dur ing installation, operation, maintenance or service,

in di vid u als may be exposed to certain com po nents or

conditions in clud ing, but not limited to: re frig er ants,

oils, materials un der pressure, rotating com po nents, and

both high and low voltage. Each of these items has the

po ten tial, if misused or handled im prop er ly, to cause

bodi ly injury or death. It is the obligation and re spon si bil i ty of operating/service per son nel to iden ti fy and

rec og nize these inherent hazards, protect them selves,

and pro ceed safely in completing their tasks. Failure

to com ply with any of these requirements could re sult

in se ri ous dam age to the equipment and the prop er ty in

which it is sit u at ed, as well as severe personal injury or

death to them selves and people at the site.

This document is intended for use by owner-authorized

operating/service personnel. It is expected that this in di vid u al possesses independent training that will en able

them to perform their assigned tasks properly and safe ly.

It is essential that, prior to performing any task on this

equipment, this individual shall have read and un der stood this document and any referenced materials. This

in di vid u al shall also be familiar with and comply with

all ap pli ca ble governmental standards and regulations

per tain ing to the task in question.

SAFETY SYMBOLS

The following symbols are used in this document to alert the reader to areas of potential hazard:

DANGER indicates an im mi nent ly

hazardous situation which, if not

avoid ed, will re sult in death or se ri ous

injury.

CAUTION identifi es a hazard which

could lead to damage to the ma chine,

damage to other equip ment and/or

en vi ron men tal pollution. Usually

an in struc tion will be given, together

with a brief ex pla na tion.

WARNING indicates a potentially

haz ard ous sit u a tion which, if not

avoid ed, could result in death or se ri ous in ju ry.

External wiring, unless specifi ed as an optional connection in the man u fac tur er’s prod uct

line, is NOT to be connected inside the micro pan el cab i net. De vic es such as re lays, switch es,

transducers and controls may NOT be installed inside the mi cro pan el. NO external wiring

is al lowed to be run through the micro panel. All wir ing must be in ac cor dance with YORK’s

pub lished spec i fi ca tions and must be per formed ONLY by qual i fi ed YORK personnel. YORK

will not be re spon si ble for dam ag es/problems re sult ing from im prop er con nec tions to the

con trols or ap pli ca tion of im prop er con trol sig nals. Failure to fol low this will void the

man u fac tur er’s warranty and cause serious dam age to property or injury to per sons.

YORK INTERNATIONAL

NOTE is used to highlight ad di tion al

information which may be helpful to

you.

3

Page 4

TABLE OF CONTENTS

FORM 201.19-NM1 (204)

SECTION 1 - GENERAL CHILLER

INFORMATION & SAFETY

INTRODUCTION ...........................................................9

WARRANTY...................................................................9

SAFETY...........................................................................9

Standards for Safety ...............................................9

RESPONSIBILITY FOR SAFETY...............................10

ABOUT THIS MANUAL..............................................10

MISUSE OF EQUIPMENT...........................................10

Suitability for Application.................................... 10

Structural Support ................................................10

Mechanical Strength............................................. 10

General Access .....................................................10

Pressure Systems.................................................. 10

Electrical...............................................................10

Rotating Parts .......................................................11

Sharp Edges.......................................................... 11

Refrigerants and Oils............................................ 11

High Temperature and Pressure Cleaning ............11

Emergency Shutdown...........................................11

SECTION 2 - PRODUCT DESCRIPTION

INTRODUCTION .........................................................12

General Description..............................................12

Compressor...........................................................12

Evaporator ............................................................13

Condenser.............................................................13

Economizer...........................................................14

Oil Separator/System............................................14

Oil Cooling...........................................................14

Capacity Control ..................................................14

Power and Control Panel......................................14

Each power compartment contains: .....................15

The control section contains:................................15

The options sections contain: ...............................15

Microprocessor Controls...................................... 15

Motor Current Protection .....................................15

Motor Protection Modules (2ACE)......................16

Current Overload..................................................16

Thermal Overload ................................................17

Current Imbalance (Loaded & Unloaded)............ 17

Loss of Phase........................................................ 17

Improper Phase Sequence ....................................17

MOTOR STARTING..................................................... 22

KEYPAD CONTROLS.................................................. 22

Display .................................................................22

Program ................................................................23

ACCESSORIES AND OPTIONS .................................23

Multiple Point Power Connection (Standard) ......23

Single-Point Power Connection with Individual

Circuit Protection .................................................23

Single-Point Power Connection with Combined

Circuit Protection ................................................23

Single-Point Power Connection without Circuit

Protection ............................................................23

Control Circuit Terminal Block............................23

Building Automation System (BAS) Interface.....23

Condenser Coil Protection ..................................23

DX EVAPORATOR AND STARTER OPTIONS .........24

UNIT ENCLOSURES OPTIONS .................................24

FAN OPTIONS ..............................................................24

SOUND REDUCTION OPTIONS................................ 24

VIBRATION ISOLATION ...........................................24

UNIT NOMENCLATURE ............................................25

NAMEPLATE ENGINEERING DATA ........................ 25

PRODUCT IDENTIFICATION NUMBER (PIN) ........26

SECTION 3 - HANDLING AND STORAGE

DELIVERY AND STORAGE....................................... 27

INSPECTION ................................................................27

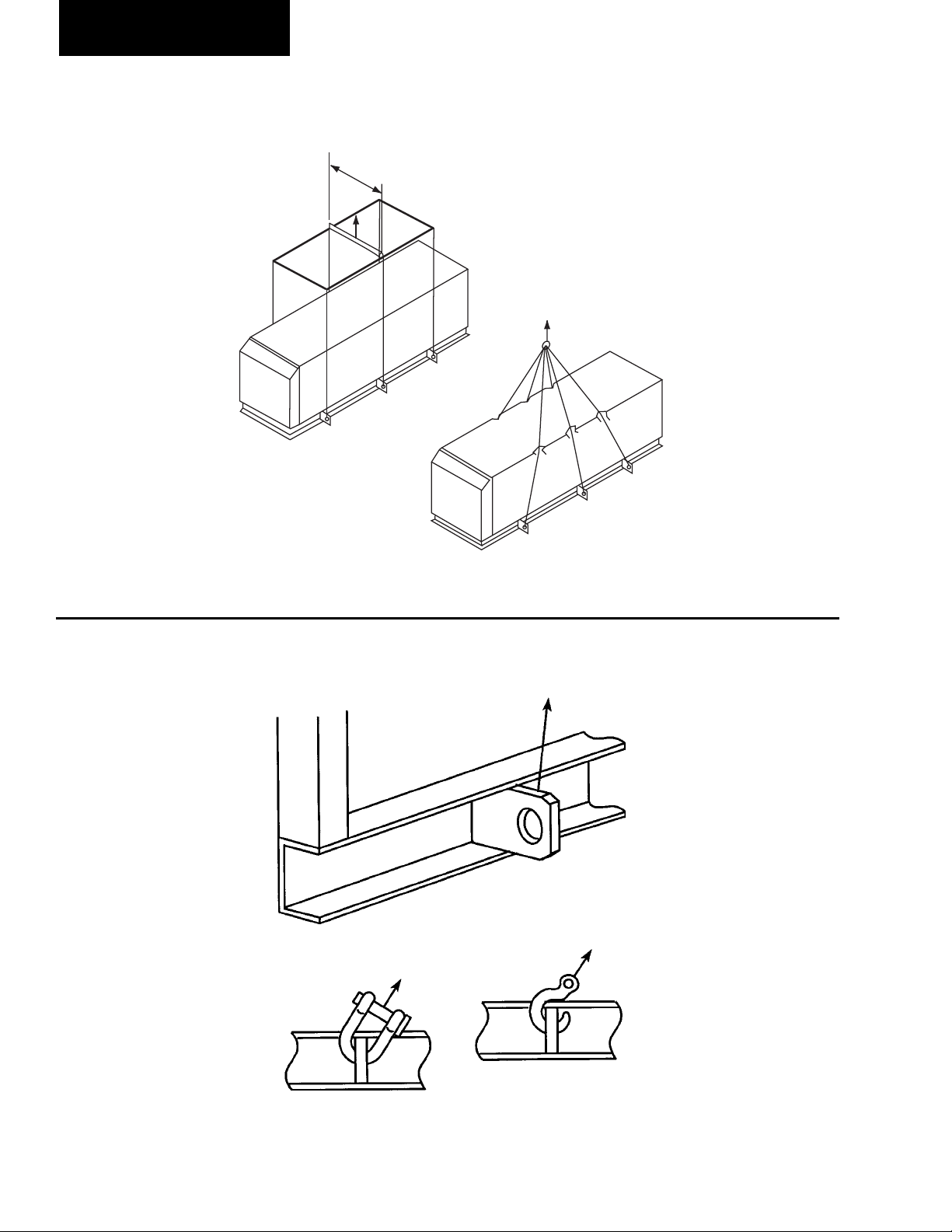

MOVING THE CHILLER ............................................27

Lifting Weights..................................................... 27

UNIT RIGGING ............................................................ 28

SECTION 4 - INSTALLATION

LOCATION REQUIREMENTS.................................... 29

OUTDOOR INSTALLATIONS ....................................29

INDOOR INSTALLATIONS ........................................29

LOCATION CLEARANCES ........................................29

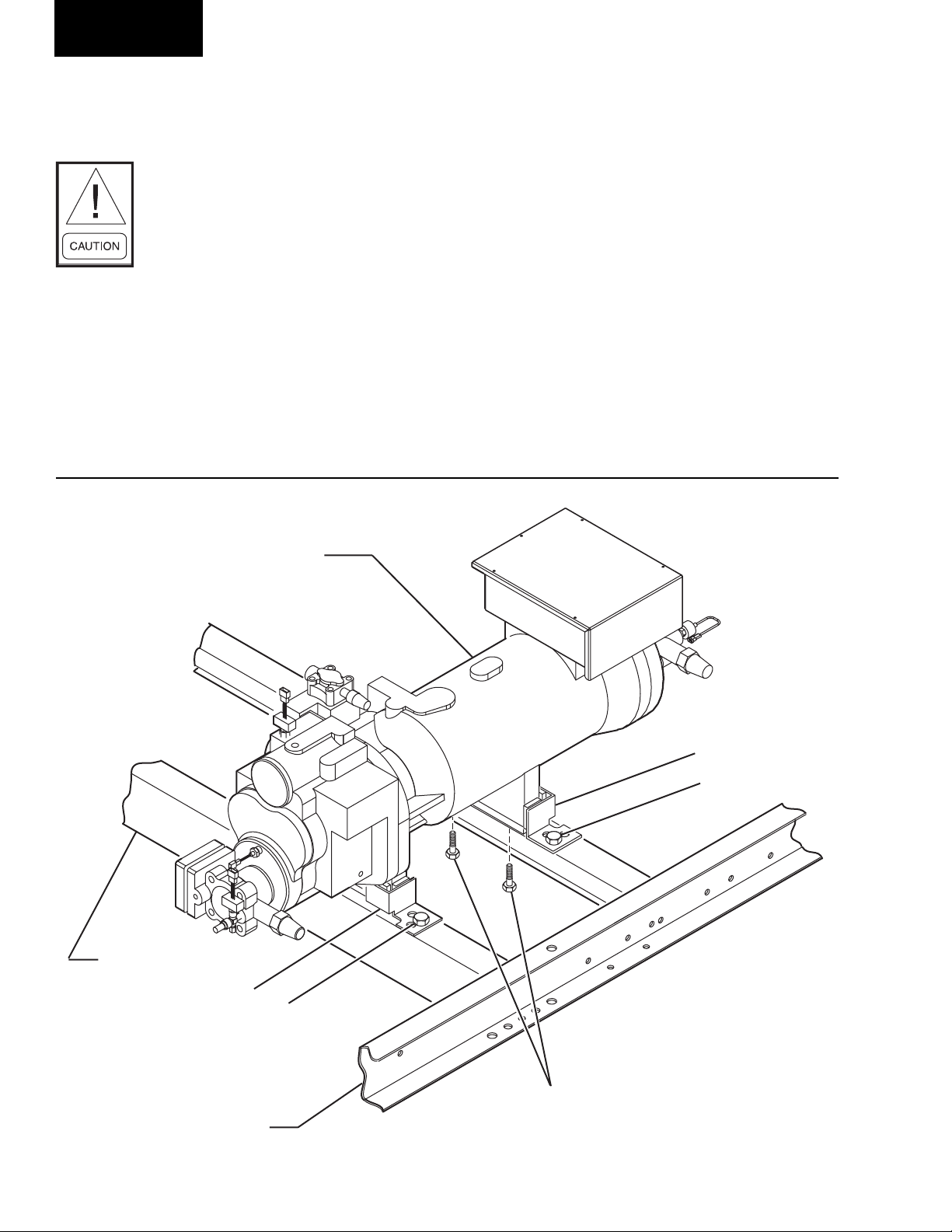

COMPRESSOR FEET BOLT REMOVAL ...................30

VIBRATION ISOLATORS ..........................................31

Installation............................................................31

SHIPPING BRACES.....................................................31

PIPEWORK CONNECTION ........................................ 31

General Requirements.......................................... 31

WATER TREATMENT..................................................32

PIPEWORK ARRANGEMENT....................................33

CONNECTION TYPES & SIZES.................................33

EVAPORATOR CONNECTIONS ................................33

Optional Flanges ..................................................33

REFRIGERANT RELIEF VALVE PIPING.................. 33

DUCTWORK CONNECTION .....................................33

General Requirements.......................................... 33

ELECTRICAL CONNECTION .................................... 34

POWER WIRING.......................................................... 34

STANDARD UNITS WITH MULTI POINT POWER

SUPPLY WIRING .........................................................34

4

YORK INTERNATIONAL

Page 5

TABLE OF CONTENTS (CONT’D)

FORM 201.19-NM1 (204)

Units with Single-Point Power Supply Wiring ....34

115VAC CONTROL SUPPLY TRANSFORMER........ 34

Remote Emergency Stop Device..........................35

CONTROL PANEL WIRING........................................35

VOLTS FREE CONTACTS ..........................................35

Chilled Liquid Pump Starter ................................35

Run Contact..........................................................35

Alarm Contacts..................................................... 35

SYSTEM INPUTS......................................................... 35

Flow Switch..........................................................35

Remote Run / Stop ...............................................35

Remote Print......................................................... 35

Remote Setpoint Offset – Temperature ................35

Remote Setpoint Offset – Current........................35

SECTION 5 - COMMISSIONING

PREPARATION.............................................................42

PREPARATION – POWER OFF ..................................42

Inspection .............................................................42

Refrigerant Charge ...............................................42

Valves ...................................................................42

Compressor Oil ....................................................42

Fans ......................................................................42

Isolation/Protection ..............................................42

Control Panel........................................................42

Power Connections............................................... 42

Grounding.............................................................42

Overloads .............................................................42

Supply Voltage .....................................................42

Control Transformer............................................. 42

Switch Settings.....................................................43

Crankcase Heaters ................................................ 43

Water System........................................................43

Flow Switch..........................................................43

Temperature Sensor(s)..........................................43

Control Supply .....................................................43

Programmed Options............................................43

Programmed Settings ...........................................43

Date and Time ......................................................43

Start/Stop Schedule ..............................................43

Setpoint and Remote Offset .................................43

FIRST TIME START-UP...............................................44

Interlocks..............................................................44

System Switches................................................... 44

Start-up................................................................. 44

Oil Pressure ..........................................................44

Refrigerant Flow ..................................................44

Fan Rotation .........................................................44

Suction Superheat................................................. 44

Expansion Valve ..................................................44

Economizer Superheat .........................................44

Subcooling............................................................ 44

General Operation ................................................44

SECTION 6 - OPERATION

GENERAL DESCRIPTION..........................................46

START-UP .....................................................................46

NORMAL RUNNING AND CYCLING....................... 46

SHUTDOWN.................................................................46

SECTION 7 - TECHNICAL DATA

FLOW RATE AND PRESSURE DROP CHARTS.......48

GLYCOL CORRECTION FACTORS........................... 48

TEMPERATURE AND FLOWS ...................................49

PHYSICAL DATA......................................................... 51

OPERATING LIMITATIONS AND SOUND POWER

DATA .............................................................................53

Electrical Data ...................................................... 54

Electrical Notes ....................................................62

WIRING DIAGRAM.....................................................64

ELEMENTARY DIAGRAM......................................... 66

CONNECTION DIAGRAM (SYSTEM WIRING) ...... 77

COMPRESSOR TERMINAL BOX ..............................78

DIMENSIONS–YCAS0130-YCAS0180 (ENGLISH) .82

DIMENSIONS–YCAS0130-YCAS0180 (SI)............... 84

DIMENSIONS–YCAS0200-YCAS0230 (ENGLISH) .86

DIMENSIONS–YCAS0200-YCAS0230 (SI)............... 88

TECHNICAL DATA......................................................90

WEIGHT DISTRIBUTION AND ISOLATOR

MOUNTING POSITIONS ............................................91

INSTALLATION INSTRUCTIONS FOR VMC SERIES

AWR/AWMR AND CP RESTRAINED

MOUNTINGS..............................................................107

COMPRESSOR COMPONENTS............................... 111

UNIT CHECKS (NO POWER)................................... 117

SYSTEM STARTUP CHECKLIST.............................117

PANEL CHECKS ........................................................118

PROGRAMMED VALUES......................................... 118

INITIAL START-UP.................................................... 119

CHECKING SUBCOOLING AND SUPERHEAT ....119

CHECKING ECONOMIZER SUPERHEAT ............. 120

LEAK CHECKING .....................................................120

YORK INTERNATIONAL

5

Page 6

TABLE OF CONTENTS (CONT’D)

FORM 201.19-NM1 (204)

SECTION 8 - MICRO PANEL CONTENTS

CHILLERLER CONTROL PANEL

PROGRAMMING AND DATA ACCESS KEYS .......122

DISPLAY AND STATUS INFORMATION KEYS ....122

ON / OFF ROCKER SWITCH.................................... 122

PROGRAM & SETUP KEYS.....................................122

1. INTRODUCTION & PHYSICAL DESCRIPTION123

1.1 General .........................................................123

1.2 Keypad & Display........................................123

1.3 Unit (chiller) ON/OFF Switch......................124

1.4 Microprocessor Board.................................. 124

1.5 Ancillary Circuit Boards...............................124

1.6 Circuit Breakers ...........................................125

1.8 Transformers.................................................125

1.9 Motor Protection Modules ...........................125

1.10 EMS/BAS Controls.................................... 128

1.11 Microprocessor Board Layout.................... 130

1.12 Logic Section Layout .................................131

1.13 Anti-Recycle Timer ....................................132

1.14 Anti-Coincidence Timer .............................132

1.15 Evaporator Pump Control...........................132

1.16 Compressor Heater Control........................ 132

1.17 Evaporator Heater Control .........................132

1.18 Pumpdown (EEV) Control......................... 132

1.19 Alarms ........................................................133

1.20 Run Status (chiller) ....................................133

1.21 Lead / Lag Compressor Selection ..............133

1.22 Economizer Solenoid Control ....................134

2. STATUS KEY: GENERAL STATUS MESSAGES &

FAULT WARNINGS...............................................136

2.1 General .........................................................136

2.2 General Status Messages..............................136

2.3 Unit Warnings............................................... 137

2.4 Anticipation Control Status..........................138

2.5 Unit Fault Status Messages ..........................139

2.6 System Fault (SAFETY) status ................... 140

2.7 Printout on Fault Shutdown..........................143

3. DISPLAY KEYS & OPTION SWITCHES.............144

3.1 General .........................................................144

3.2 Chilled Liquid Temps key ............................144

3.3 System # Data Keys .....................................145

3.4 Ambient Temp Key ......................................145

3.5 % Motor Current key....................................146

3.6 Operating Hrs / Start Counter key................146

3.7 Options key & .............................................146

3.8 Funtion Key..................................................148

4. PRINT KEYS...........................................................149

4.1 General .........................................................149

4.2 Oper Data Key.............................................. 149

4.3 Operating Data – Software Version.............. 149

4.4 Operating Data – Remote Printout............... 151

4.5 History Key ..................................................152

4.6 Fault History Data – Local Display

Messages ......................................................152

4.7 Fault History Data – Remote Printout..........156

5. ENTRY KEYS .........................................................157

5.1 General .........................................................157

5.2 Numerical Keypad........................................157

5.3 Enter Key......................................................157

5.4 Cancel Key ...................................................157

5.5 KEYS ...............................................157

6. SETPOINTS KEYS & CHILLED LIQUID

CONTROL...............................................................158

6.1 General .........................................................158

6.2 Chilled Liquid Temperature Control ............158

6.3 Local Cooling Setpoints Key .......................162

6.4 Remote cooling setpoints Key......................162

7. CLOCK KEYS ........................................................163

7.1 GENERAL ...................................................163

7.2 SET TIME KEY...........................................163

7.3 set schedule / holiday key.............................164

7.4 Manual Override key.................................... 165

8. PROGRAM KEY.....................................................166

8.1 General .........................................................166

8.2 Program Key – User Programmable Value ..166

8.3 Programming "Default" Values.................... 170

8.4 Electronic Expansion Valve..........................172

8.5 EEV Operation .............................................173

8.6 EEV Programming .......................................175

8.7 EEV Troubleshooting ...................................176

8.8 Condenser Fan Control.................................177

8.9 Service Mode: Unit Setup ............................179

8.10 Sensor Calibration Charts...........................185

8.11 Control Inputs/Outputs...............................186

8.12 ISN Control ...............................................189

6

YORK INTERNATIONAL

Page 7

TABLE OF CONTENTS (CONT’D)

SECTION 9 - MAINTENANCE

GENERAL REQUIREMENTS................................... 194

CONDENSER COILS................................................. 194

Chiller / Compressor Operating Log..................195

Scheduled Maintenance......................................195

ON-BOARD BATTERY BACK-UP ...........................195

OVERALL UNIT INSPECTION................................ 195

COMPRESSOR UNIT OPERATION .........................196

GENERAL PERIODIC MAINTENANCE CHECKS 198

STANDARD UNITS ...................................................198

SECTION 10 - SPARE PARTS

Recommended Spares ........................................199

Recommended Compressor Oils........................199

FORM 201.19-NM1 (204)

SECTION 11 - TROUBLE SHOOTING

TROUBLESHOOTING GUIDE .................................200

LIMITED WARRANTY YORK AMERICAS

ENGINEERED SYSTEMS .........................................202

WARRANTY ON NEW EQUIPMENT......................202

WARRANTY ON RECONDITIONED OR

REPLACEMENT MATERIALS................................. 202

TEMPERATURE CONVERSION CHART................203

TEMPERATURE CONVERSION CHART

ACTUAL TEMPERATURES......................................203

TEMPERATURE CONVERSION CHART

DIFFERENTIAL TEMPERATURES..........................203

PRESSURE CONVERSION CHARRT - GAUGE

OR DIFFERENTIAL................................................... 203

LIST OF TABLES

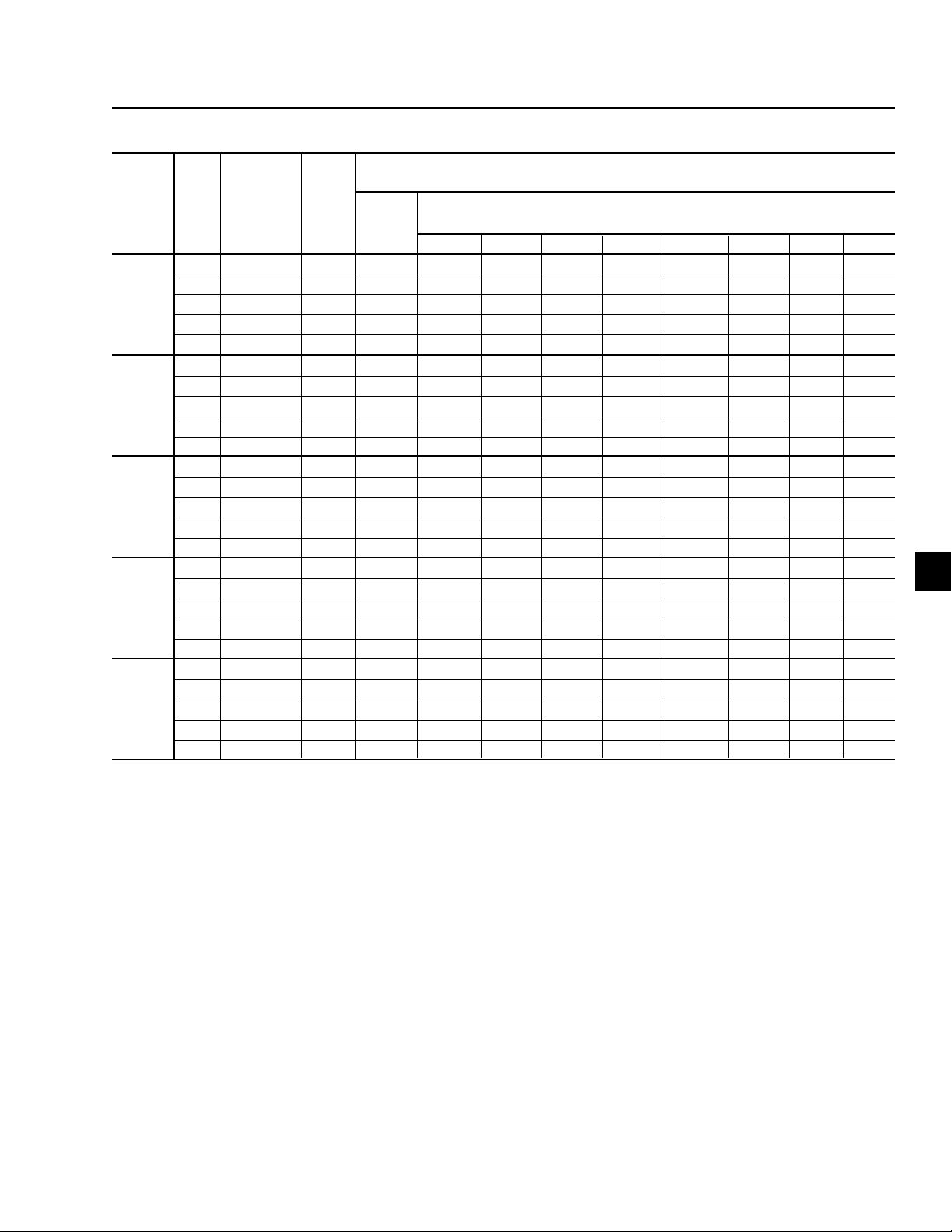

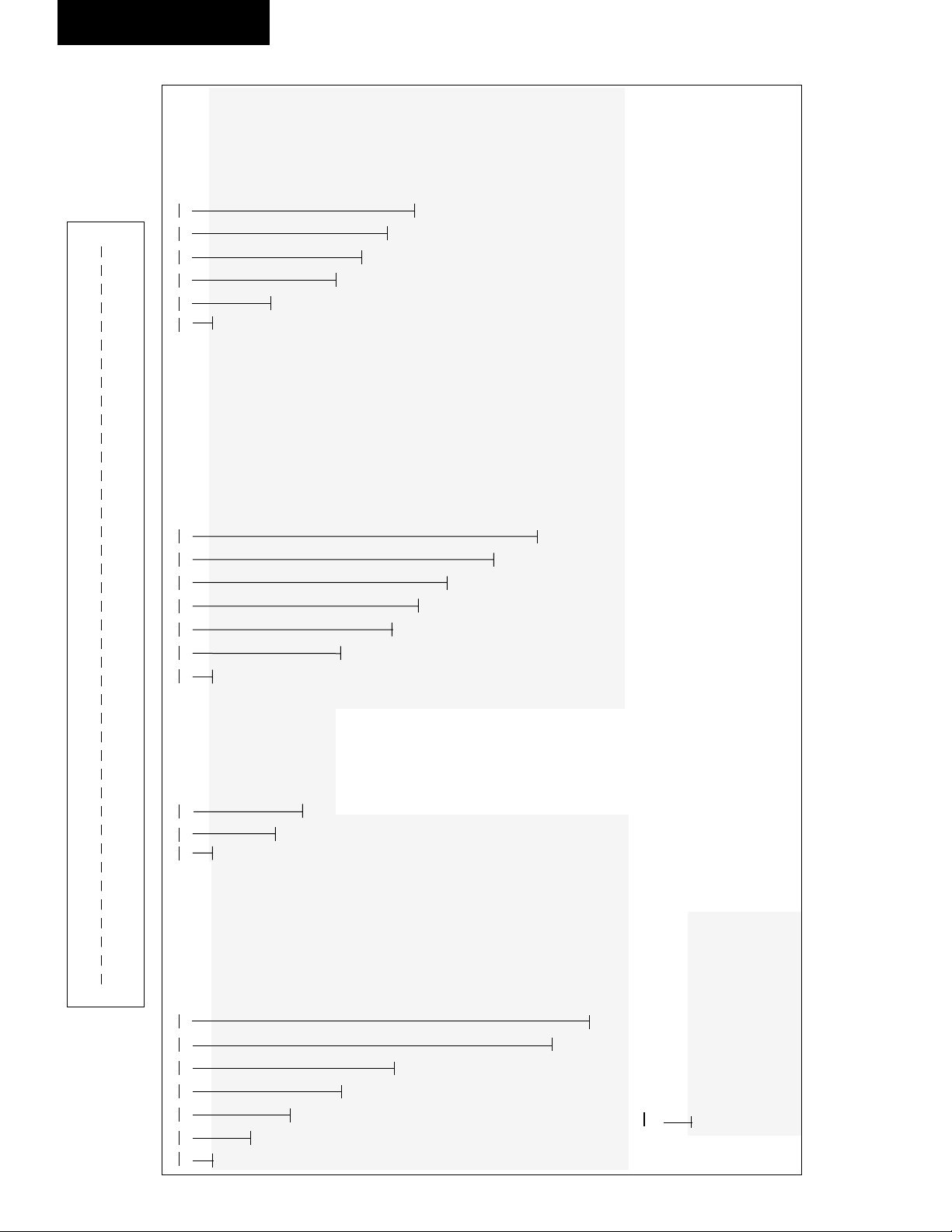

TABLE 1 – Motor Protector Dip Switch Setting .......... 18

TABLE 2 – Programmable Values Table

(minimum/maximum)............................... 175

TABLE 3 – Condenser Fan Control and Fan Contactor

Data for DXST Units with 4

Fans/System ............................................. 178

TABLE 4 – Condenser Fan Control and Fan Contactor

Data For DXST Units With 5

Fans/System.. ........................................... 178

TABLE 5 – Service Mode Programmable Values ......179

TABLE 6 – YCAS Style G, Across the Line Start .....180

TABLE 7 – YCAS Style G, Wye Delta Start ............. 182

TABLE 8 - Digital Outputs.......................................... 186

TABLE 9 - Analog Inputs............................................ 187

TABLE 10 - Digital Inputs .......................................... 188

TABLE 11 - Analog Outputs........................................188

TABLE 12 – ISN Received Data .................................189

TABLE 13 – ISN Transmitted Data.............................189

TABLE 14 – ISN Operational and Fault Codes...........192

YORK INTERNATIONAL

7

Page 8

LIST OF FIGURES

FORM 201.19-NM1 (204)

FIG. 1 – COMPONENT LOCATIONS......................... 12

FIG. 2 – SCREW COMPRESSOR................................13

FIG. 3 – UNIT RIGGING..............................................28

FIG. 4 – LIFTING LUGS .............................................. 28

FIG. 5 – COMPRESSOR MOUNTING........................30

FIG. 7 – VICTAULIC GROOVE ..................................33

FIG. 8 – FLANGE ATTACHMENTS ...........................33

FIG. 9 – POWER PANEL SECTION............................ 36

FIG. 10 – OPTION PANEL SECTION .........................37

FIG. 11 – LOGIC SECTION LAYOUT........................ 38

FIG. 12 – LOGIC SECTION LAYOUT WITH

CONTROL PANEL LAYOUT...................... 39

FIG. 13 – CUSTOMER CONNECTIONS .................... 40

FIG. 14 – CUSTOMER CONNECTIONS .................... 41

FIG. 16 – GLYCOL CORRECTION FACTORS ..........48

FIG. 15 – FLOW RATE AND PRESSURE DROP

CHARTS ........................................................48

FIG. 17 – WIRING DIAGRAM –

ACROSS-THE-LINE START....................... 64

FIG. 18 – WIRING DIAGRAM –

ACROSS-THE-LINE START....................... 65

FIG. 19 – ELEMENTARY DIAGRAM –

ACROSS-THE-LINE START...................... 66

FIG. 20 – WIRING DIAGRAM –

WYE-DELTA START ...................................68

FIG. 21 – ELEMENTARY DIAGRAM –

WYE-DELTA START ...................................69

FIG. 22 – ELEMENTARY DIAGRAM –

WYE-DELTA START ...................................70

FIG. 22A – POWER PANEL (SYSTEM #1)

COMPONENT LOCATIONS.....................72

FIG. 22B – CONTROL PANEL COMPONENT

LOCATION................................................73

FIG. 22C – POWER PANEL (SYSTEM #2)

COMPONENT LOCATIONS.....................74

FIG. 23 – MODEL YCAS0130 - 0180

DIMENSIONS (ENGLISH) ......................... 82

FIG. 25 – MODEL YCAS0200 - YCAS0230

DIMENSIONS (ENGLISH) ......................... 86

FIG. 26 – MODEL YCAS0200 - YCAS0230

DIMENSIONS (SI).......................................88

FIG. 27 – CLEARANCES.............................................90

FIG. 28 – CP-2-XX........................................................ 92

FIG. 29 – ISOLATOR DETAILS .................................93

FIG. 30 – CP-2-XX........................................................ 96

FIG. 31 – ISOLATOR DETAILS .................................97

FIG. 32 – CP-2-XX...................................................... 100

FIG. 33 – ISOLATOR DETAILS ...............................101

FIG. 34 – CP-2-XX...................................................... 104

FIG. 35 – ISOLATOR DETAILS ...............................105

FIG. 36 – REFRIGERANT FLOW DIAGRAM ......... 108

FIG. 37 – PROCESS AND INSTRUMENTATION

DIAGRAM..................................................109

FIG. 38 – COMPONENT LOCATIONS..................... 110

FIG. 39 – COMPRESSOR COMPONENTS .............. 111

FIG. 40 – COMPRESSOR COMPONENTS .............. 112

FIG. 41 – COMPRESSOR COMPONENTS .............. 113

FIG. 42 – COMPRESSOR COMPONENTS .............. 114

FIG. 43 – COMPRESSOR COMPONENTS .............. 115

FIG. 44 – COMPRESSOR COMPONENTS .............. 116

FIG. 45 – MOTOR PROTECTION MODULE...........127

FIG. 46 – COMPONENT LAYOUT ...........................130

FIG. 47 – LOGIC SECTION LAYOUT...................... 131

FIG. 47A – PROCESS AND INSTRUMENTATION

DIAGRAM ............................................... 135

FIG. 48 – SUCTION PRESSURE CUTOUT ............. 141

FIG. 49 – ENLARGED PHOTOGRAPH OF DIP

SWITCHES ON MICROPROCESSOR

BOARD.......................................................147

FIG. 50 – ELECTRONIC EXPANSION VALVE .....172

FIG. 51 – CONDENSER FAN LAYOUT FOR

DXST 2 COMPRESSOR UNITS .............177

8

YORK INTERNATIONAL

Page 9

GENERAL CHILLER INFORMATION & SAFETY

FORM 201.19-NM1 (204)

INTRODUCTION

YORK YCAS chillers are manufactured to the high est

design and construction standards to en sure high

performance, reliability and adaptability to all types of

air conditioning installations.

The unit is intended for cooling water or glycol so lu tions

and is not suitable for purposes other than those spec i fi ed

in this manual.

This manual and the Microprocessor Operating

In struc tions contain all the information required for

correct in stal la tion and commissioning of the unit,

together with operating and maintenance instructions.

The manuals should be read thoroughly before

attempting to operate or service the unit.

All procedures detailed in the manuals, including

in stal la tion, commissioning and maintenance tasks

must only be performed by suitably trained and

qualifi ed per son nel.

The manufacturer will not be liable for any injury or

dam age caused by incorrect installation, com mis sion ing,

op er a tion or maintenance resulting from a failure to

fol low the procedures and instructions detailed in the

manuals.

1

For warranty purposes, the following conditions must

be satisfi ed:

• The initial start of the unit should be carried out

by trained personnel from an Authorized YORK

Ser vice Cen ter. See Commissioning, page 42.

• Only genuine YORK approved spare parts, oils

and re frig er ants must be used. Recommendations

on spare parts can be found on page 199.

• All the scheduled maintenance operations detailed

in this manual must be performed at the specifi ed

times by suitably trained and qualifi ed personnel.

See Main te nance Section, page 194.

• Failure to satisfy any of these conditions will

au to mat i cal ly void the warranty. See Warranty

Policy, page 202.

SAFETY

Standards for Safety

YCAS chillers are designed and built with in an ISO

9002 accredited design and manufacturing or ga ni za tion.

The chillers comply with the applicable sec tions of the

following Standards and Codes:

WARRANTY

York International warrants all equipment and ma te ri als

against defects in workmanship and materials for a

pe ri od of eighteen months from deliveryunless extended

warranty has been agreed upon as part of the contract.

The warranty is limited to parts only replacement and

ship ping of any faulty part, or sub-assembly which has

failed due to poor quality or manufacturing errors. All

claims must be supported by evidence that the failure

has oc curred with in the warranty period, and that the

unit has been op er at ed within the designed parameters

specifi ed.

All warranty claims must specify the unit model, serial

number, order number. These de tails are print ed on the

unit identifi cation plate.

The unit warranty will be void if any modifi cation to the

unit is carried out without prior written approval from

York International.

• ANSI/ASHRAE Standard 15, Safety Code for

Me chan i cal Refrigeration

• ANSI/NFPA Standard 70, National Electrical Code

(N.E.C.)

• ASME Boiler and Pressure Vessel Code, Section

VIII Division 1

• ARI Standard 550/590-98, Centrifugal and Rotary

Screw Water Chilling Packages

In addition, the chillers conform to Underwriters

Lab o ra to ries (U.L.) for construction of chillers and

provide U.L./cU.L. listing label.

YORK INTERNATIONAL

9

Page 10

General Chiller Information & Safety

FORM 201.19-NM1 (204)

RESPONSIBILITY FOR SAFETY

Every care has been taken in the design and man u fac ture

of the unit to ensure compliance with the safety requirements listed above. However, the individual op er at ing

or working on any machinery is primarily re spon si ble

for:

• Personal safety, safety of other personnel, and the

ma chin ery.

• Correct utilization of the machinery in accordance

with the procedures detailed in the manuals.

ABOUT THIS MANUAL

The following terms are used in this document to alert

the reader to areas of potential hazard.

A Warning is given in this document

to identify a haz ard which could lead to

per son al injury. Usually an in struc tion

will be given, to geth er with a brief ex pla na tion and the possible result of ignoring

the in struc tion.

A Caution identifi es a hazard which could

lead to dam age to the machine, dam age to

other equip ment and/or en vi ron men tal pollution. Usu al ly an in struc tion will be given,

together with a brief explanation and the

pos si ble result of ig nor ing the in struc tion.

A Note is used to highlight additional

in for ma tion which may be helpful to you

but where there are no special safety im pli ca tions.

MISUSE OF EQUIPMENT

Suitability for Application

The unit is intended for cooling water or glycol so lu tions

and is not suitable for purposes other than those spec i fi ed

in these instructions. Any use of the equip ment oth er than

its intended use, or operation of the equip ment con trary

to the relevant procedures may re sult in injury to the

op er a tor, or damage to the equip ment.

The unit must not be operated outside the design pa ram e ters specifi ed in this manual.

Structural Support

Structural support of the unit must be provided as in di cat ed in these instructions. Failure to provide proper

support may result in injury to the operator, or damage

to the equipment and/or building.

Mechanical Strength

The unit is not designed to withstand loads or stresses

from adjacent equipment, pipework or structures. Ad di tion al components must not be mounted on the unit.

Any such extraneous loads may cause structural fail ure

and may result in injury to the operator, or damage to

the equipment.

General Access

There are a number of areas and features which may

be a hazard and potentially cause injury when working

on the unit unless suitable safety precautions are tak en.

It is important to ensure access to the unit is restricted

to suitably qualifi ed persons who are familiar with the

po ten tial hazards and precautions necessary for safe

op er a tion and maintenance of equipment containing

high temperatures, pressures and voltages.

The contents of this manual include sug gest ed best

working practices and pro ce dures. These are issued for

guidance only, and they do not take pre ce dence over

the above stated individual responsibility and/or local

safety regulations.

This manual and any other document supplied with

the unit, are the property of YORK which reserves all

rights. They may not be reproduced, in whole or in part,

with out prior written authorization from an authorized

YORK representative.

10

Pressure Systems

The unit contains refrigerant vapor and liquid under pres sure, release of which can be a danger and cause in ju ry.

The user should ensure that care is taken during in stal la tion, operation and maintenance to avoid dam age to

the pressure system. No attempt should be made to gain

ac cess to the component parts of the pressure sys tem other

than by suitably trained and qualifi ed per son nel.

Electrical

The unit must be grounded. No in stal la tion or main te nance work should be attempted on the electrical

equip ment without fi rst switching OFF, isolating and

lock ing-off the power supply. Work on live equipment

must only be carried out by suitably trained and qualifi ed

YORK INTERNATIONAL

Page 11

FORM 201.19-NM1 (204)

per son nel. No attempt should be made to gain access to

the con trol panel or electrical enclosures during nor mal

op er a tion of the unit.

Rotating Parts

Fan guards must be fi tted at all times and not removed

unless the power supply has been isolated. If ductwork is

to be fi tted, requiring the wire fan guards to be re moved,

alternative safety measures must be taken to protect

against the risk of injury from rotating fans.

Sharp Edges

The fi nning on the air cooled con dens er coils has sharp

metal edges. Reasonable care should be taken when

working in contact with the coils to avoid the risk of

mi nor abra sions and lac er a tions. The use of gloves is

recommended.

Refrigerants and Oils

Refrigerants and oils used in the unit are generally nontoxic, non-fl ammable and non-corrosive, and pose no

spe cial safety hazards. Use of gloves and safety glass es

are, however, recommended when working on the unit.

The build up of refrigerant vapor, from a leak for ex-

am ple, does pose a risk of asphyxiation in confi ned or

enclosed spac es and attention should be given to good

ven ti la tion.

High Temperature and Pressure Cleaning

High temperature and pressure cleaning methods (e.g.

steam cleaning) should not be used on any part of the

pressure system as this may cause operation of the pres sure relief device(s). Detergents and solvents which may

cause corrosion should also be avoided.

EMERGENCY SHUTDOWN

In case of emergency the electrical option panel is fi t ted

with an emergency stop switch CB3 (Circuit Break er

3). Separate Circuit Break ers, CB1 (Sys tem 1) and CB2

(Sys tem 2), can also be used to stop the re spec tive sys tem in an emer gen cy. When op er at ed, CB3 re moves the

elec tri cal supply from the con trol sys tem, thus shut ting

down the unit.

1

YORK INTERNATIONAL

11

Page 12

Product Description

1 System Fans

2 System 1 Power Panel

3 System 2 Power Panel

4 Control Panel

5 Power Entry

6 System 1 Compressor

7 Evaporator

8 System 2 Compressor

9 System 1 Condenser

10 Option Box

9

PRODUCT DESCRIPTION

1

FORM 201.19-NM1 (204)

2

4

3

10

8

7

6

FIG. 1 – COMPONENT LOCATIONS

INTRODUCTION

YORK YCAS chillers are designed for water or wa ter-glycol cooling. All units are designed to be lo cat ed

outside on the roof of a building or at ground level.

The units are completely assembled with all in ter con nect ing refrigerant piping and internal wiring, ready for

fi eld installation.

Prior to delivery, the unit is pressure tested, evacuated,

and fully charged with refrigerant and oil in each of the

two independent refrigerant circuits. After assembly,

an operational test is performed with water fl owing

through the evaporator to ensure that each refrigerant

cir cuit operates correctly.

The unit structure is manufactured from heavy gauge,

galvanized steel. All external structural parts are coat ed

with “Desert Sand” baked-on enamel powder paint. This

provides a fi nish which, when subjected to ASTM B117,

500 hour, 5% salt spray conditions, shows breakdown

of less than 1/8" either side of a scribed line (equiv a lent

to ASTM D1654 rating of “6”).

5

028971-G

All exposed power wiring is be routed through liquidtight, non-metallic conduit.

General Description

The Air Cooled Screw Chiller utilizes many com po nents

which are the same or nearly the same as a stan dard

reciprocating chiller of a similar size. This in cludes

mod u lar frame rails, condenser, fans and evap o ra tor.

The chiller consists of 2 screw compressors in a cor re spond ing number of separate refrigerant circuits, a sin gle

shell and tube DX counterfl ow evaporator, econ o miz ers,

an air cooled condenser, and expansion valves.

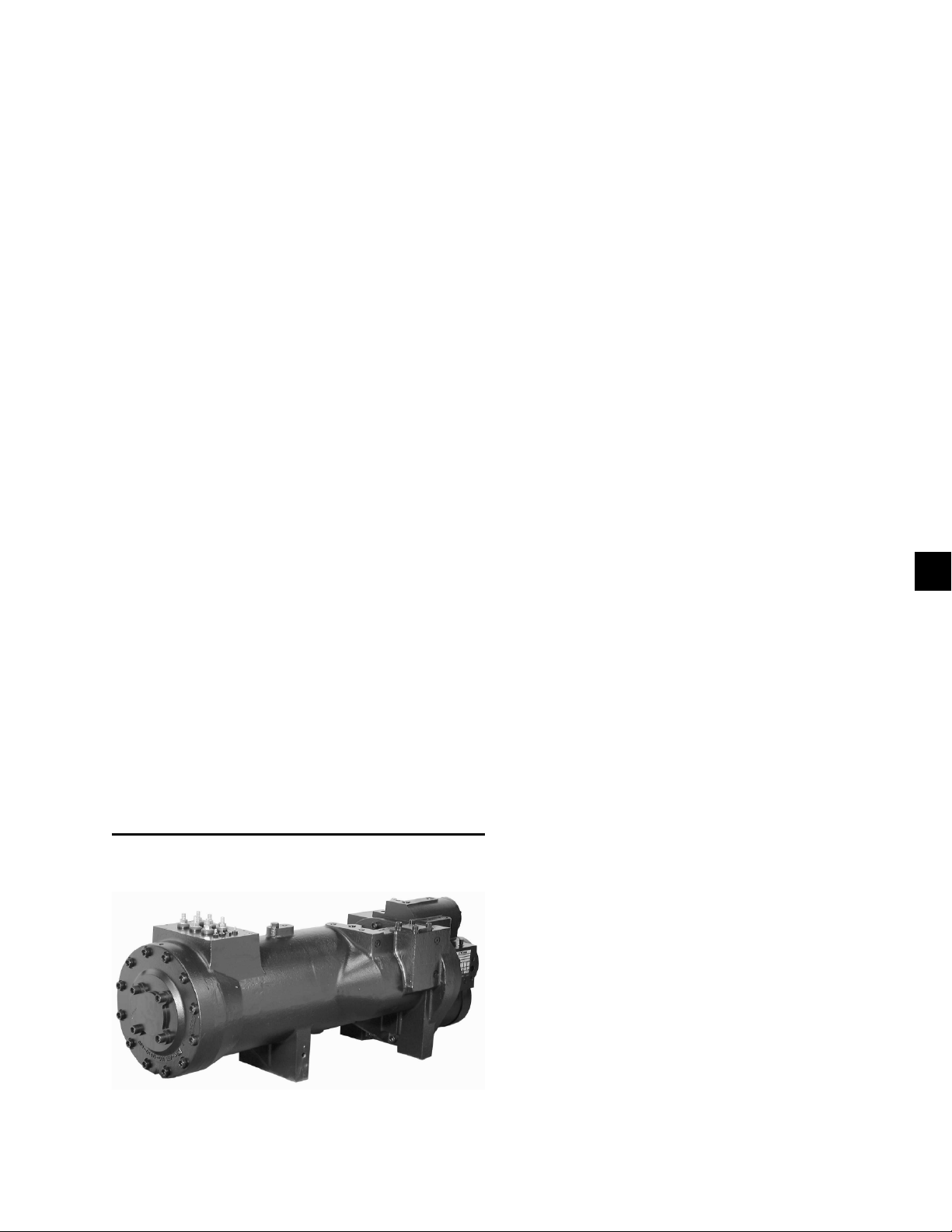

Compressor

The semi-hermetic rotary twin-screw compressor is

designed for industrial refrigeration applications and

ensures high operational effi ciencies and reliable per-

for mance. Capacity control is achieved through a sin gle

slide valve. The compressor is a positive dis place ment

type characterized by two helically grooved rotors which

are manufactured from forged steel. The 60 Hz motor operates at 3550 RPM to direct drive the male rotor which

in turn drives the female rotor on a light fi lm of oil.

12

YORK INTERNATIONAL

Page 13

FORM 201.19-NM1 (204)

Refrigerant gas is drawn into the void created by the

unmeshing of the fi ve lobed male and seven lobed

fe male rotor. Further meshing of the rotors closes

the ro tor threads to the suction port and progressively

com press es the gas in an axial direction to the discharge

port. The gas is compressed in volume and increased

in pressure before exiting at a designed volume at the

dis charge end of the rotor casing. Since the intake and

dis charge cy cles overlap, a resulting smooth fl ow of gas

is maintained.

The rotors are housed in a cast iron compressor hous ing

precision machined to provide optimal clearances for

the rotors. Contact between the male and female rotor

is pri ma ri ly rolling on a contact band on each of the

rotor’s pitch circle. This results in virtually no rotor

wear and in creased reliability, a trademark of the screw

com pres sor.

The compressor incorporates a complete anti-friction

bearing design for reduced power input and increased

reliability. Four separated, cylindrical, roller bearings

handle radial loads. Angular-contact ball bearings

han dle axial loads. Together they maintain accurate rotor

po si tion ing at all pressure ratios, thereby min i miz ing

leak age and maintaining effi ciency. A springless check

valve is installed in the compressor discharge housing

to pre vent compressor rotor backspin due to system

re frig er ant pressure gradients during shut down.

The compressor is lubricated by removing oil from

the refrigerant using an external oil separator. The

pres sur ized oil from the oil separator is then cooled in

the condenser coils and piped back to the compressor for

lubrication. The com pres sor design working pressure is

450 PSIG (31 bar). Each chill er receives a 300 PSIG (21

bar) low side and a 450 PSIG (31 bar) high side factory

test. A 350 watt (115-1-60) cartridge heat er is located

in the com pres sor. The heat er is tem per a ture activated

to prevent re frig er ant condensation.

The following items are also included:

• An acoustically tuned, internal discharge muffl er to

min i mize noise, while maintaining max i mum fl ow

and performance.

• Discharge shutoff valve.

• A rain-tight terminal box.

• A suction gas screen and serviceable, 0.5 - 3.0

micron full fl ow oil fi lter within the compressor

housing.

Evaporator

The system uses a high effi ciency Shell and Tube type

Di rect Ex pan sion Evaporator. Each of the 2 re frig er ant

circuits consists of 4 passes with the chilled liq uid

cir cu lat ing back and forth across the tubes from one

end to the other.

2

Motor cooling is provided by suction gas from the

evap o ra tor flowing across the motor. Redundant

over load pro tec tion is provided using both thermistor

and cur rent over load protection.

00485VIP

FIG. 2 – SCREW COMPRESSOR

The design working pressure of the standard evaporator

on the shell side is 150 PSIG (10 bar), and 350 PSIG (24

bar) for the tube (refrigerant side). The water baffl es

are fab ri cat ed from galvanized steel to resist corrosion.

Re mov able heads are provided for access to internally

en hanced, seamless, copper tubes. Water vent and drain

con nec tions are included.

The evaporator is equipped with a heater for protection

to -20°F (-29°C) ambient and in su lat ed with 3/4" (19

mm) fl exible closed-cell foam.

The water nozzles are provided with grooves for

me chan i cal couplings and should be insulated by the

con trac tor after pipe installation.

Condenser

The fi n and tube condenser coils are manufactured

from seamless, internally enhanced, high condensing

co ef fi cient, corrosion resistant copper tubes arranged in

YORK INTERNATIONAL

13

Page 14

Product Description

FORM 201.19-NM1 (204)

stag gered rows and mechanically expanded into cor ro sion

resistant aluminum alloy fi ns with full height fi n col lars.

They have a design working pressure of 450 PSIG

(31 bar). Each coil is rested to 495 PSIG (34 bar).

Multiple fans move air through the coils. They are

dy nam i cal ly and statically balanced, direct drive with

cor ro sion re sis tant glass fi ber reinforced composite

blades mold ed into low noise, full airfoil cross section,

pro vid ing vertical air discharge from extended orifi ces

for ef fi cien cy and low sound. Each fan is located in a

sep a rate com part ment to prevent cross fl ow during fan

cy cling. Guards of heavy gauge, PVC coated galvanized

steel are pro vid ed.

The fan motors are high effi ciency, direct drive, 6-pole,

3-phase, Class- “F,” current overload protected, totally

en closed (TEAO) type with double sealed, per ma nent ly

lubricated ball bearings.

Economizer

Economizer is a refrigerant to refrigerant, compact platetype heat exchanger to maximize chiller capacity and

effi ciency by subcooling liquid refrigerant delivered to

the cooler expansion valve. Constructed of corrosion

resistant stainless steel plates formed to induce turbulent

fl ow and enhance heat transfer, then oven brazed and

pressure tested for reliability. Designed and constructed

with ASME and TÜV certifi cation for 31 bar (450 psig).

UL/CSA listed.

Oil Separator/System

The external oil separator, with no moving parts and

de signed for minimum oil carry-over, is mounted in

the dis charge line of the compressor. The high pressure

dis charge gas is forced around a 90 degree bend. Oil is

forced to the outside of the separator through cen trif u gal

action and captured on wire mesh where it drains to the

bottom of the oil separator and fl ows to the condenser

for cooling before returning to the compressor.

assure re frig er ant compression (volumetric ef fi cien cy).

The oil also provides cooling by transferring much of

the heat of com pres sion from the gas to the oil keeping

dis charge tem per a tures down and reducing the chance

for oil breakdown. Oil injected into the rotor cage fl ows

into the ro tors at a point about 1.2x suction. This assures

that a required minimum differential of at least 30 PSID

(2.1 bar) exists between discharge and 1.2x suc tion, to

force oil into the rotor case. A minimum of 10 PSID

(0.6 bar) is all that is re quired to assure pro tec tion of

the compressor. Oil pressure safety is mon i tored as the

dif fer ence between suction and the pres sure of the oil

en ter ing the ro tor case.

Maximum working pressure of the oil separator is 450

PSIG (31 bar). Oil level should be above the midpoint

of the “low er” oil sight glass when the compressor is

run ning. Oil level should not be above the top of the

“up per” sight glass.

Oil Cooling

Oil cooling is provided by routing oil from the oil sep a ra tor through several of the top rows of the con dens er

coils and back to the compressor.

Capacity Control

The compressors will start at the minimum load po si tion

and provide a capacity control range from 10% - 100%

of the full unit load using a continuous function slide

valve. The microprocessor modulates a voltage signal to

a 3-way pres sure reg u lat ing capacity control valve which

controls com pres sor capacity, in de pen dent of system

pressures, and balances the com pres sor ca pac i ty with

the cool ing load. Loading is ac com plished by varying

pressure through the pressure regulating ca pac i ty control

valve to move the slide valve against the spring pressure

to promote stable smooth loading.

Automatic spring return of the slide valve to the min i mum load position will ensure compressor start ing at

min i mum motor load.

The oil (YORK “L” oil – a POE oil used for all re frig er ant applications), which fl ows back into the com-

pres sor through a replaceable 0.5 - 3.0 micron oil fi lter,

is at high pressure. This high pres sure “oil injection”

forces the oil into the com pres sor where it is fed to the

bearings for lubrication. After lubricating the bearings,

it is injected through orifi ces on a closed thread near

the suction end of the rotors. The oil is automatically

in ject ed because of the pressure difference between the

discharge pres sure and the reduced pressure at the suc tion end of the rotors. This lubricates the rotors as well as

provides an oil seal against leakage around the ro tors to

14

Power and Control Panel

All controls and motor starting equipment are factory

wired and function tested. The panel enclosures are

de signed to IP55 and are manufactured from powder

paint ed galvanized steel.

The Power and Control Panel are divided into power

sec tions for each compressor and associated fans, a con trol section and an electrical options section. The pow er

and control sections have separate hinged, latched, and

gasket sealed doors equipped with wind struts.

YORK INTERNATIONAL

Page 15

FORM 201.19-NM1 (204)

Each power compartment contains:

Compressor and fan starting contactors, fan motor

ex ter nal overloads, control circuit serving compressor

ca pac i ty control, compressor and fan contactor coils and

compressor motor overloads. (Fig #1, page 12)

Current transformers in the 2ACE module provide

compressor motor over load protection and sense each

phase. This protects the compressor motors from

dam age due to: low current input, high input current,

un bal anced current, single phasing, phase reversal, and

com pres sor locked rotor.

The control section contains:

ON/OFF switch, microcomputer keypad and display,

mi cro pro ces sor board, I/O expansion board, relay boards

and power supply board.

The options sections contain:

A control circuit transformer complete with service

switch providing 115/1/60 Hz power to the unit con trol

system.

Electrical options as described in “Accessories and

Options.”

Microprocessor Controls

The microprocessor has the following functions and

displays:

• A liquid crystal 40 character display with text pro vid ed on two lines and light emitting diode back light ing out door viewing.

Motor Current Protection

The microprocessor motor protection provides high

cur rent protection to assure that the motor is not

damaged due to voltage, excess refrigerant, or other

problems that could cause excessive motor current. This

is ac com plished by sending a current signal pro por tion al

to motor current from the Motor Protector mod ule to the

I/O Expansion board to be multiplexed and sent to the

Microprocessor Board. If the motor cur rent exceeds

the 115% FLA trip point after 3 seconds of op er a tion

on either Wye-Delta or ACL starters, the mi cro will

shut the system down and lock it out after one fault.

A manual reset of the re spec tive system switch is

re quired to clear the fault and restart the system. A

thor ough check of the mo tor, wiring, and refrigerant

system should be done be fore restarting a system that

has fault ed on high motor current.

The micro also provides low motor current protection

when it senses a motor current less than 10% FLA.

The micro will shut the system down whenever low

motor current is sensed and will lock out a system if

three faults occur in 90 minutes. Low motor current

pro tec tion is activated 4 seconds after start on both

Wye-Delta and ACL starters to assure the motor starts,

the sys tem doesn’t run with out refrigerant, the motor

protector is not tripped, and the mechanical high pres sure

cut-out is not tripped. Once the system is locked out

on Low Motor Current, it must be manually reset with

the sys tem switch. See also Motor Protection Module

section below.

2

• A color coded, 35 button, sealed keypad with sec tions for Display, Entry, Setpoints, Clock, Print,

Pro gram and Unit ON/OFF.

The standard controls shall include: brine chilling,

ther mal storage, automatic pump down, run signal

con tacts, demand load limit from external building

automation sys tem input, remote reset liquid temperature

reset in put, unit alarm contacts, chilled liquid pump

control, au to mat ic reset after power failure, automatic

system op ti mi za tion to match operating conditions.

The software is stored in non-volatile memory (EPROM)

to eliminate chiller failure due to AC power failure. The

Programmed Setpoints are stored in lithium battery

backed memory.

YORK INTERNATIONAL

The micro senses low motor current whenever a HPCO

or Motor Protector contact opens. This occurs because

the MP and HPCO contacts are in series with the mo tor

contactor. Whenever either of these devices are open,

the contactor de-energizes and the motor shuts down.

Since the micro is sending a run signal to the contactor,

it senses the low motor current below 10% FLA and

shuts the system down.

15

Page 16

Product Description

FORM 201.19-NM1 (204)

Motor Protection Modules (2ACE)

The mechanical motor protector is a Texas In stru ments

2ACE Three Phase Protection Module (Fig. 45, page

127), provides thermal and cur rent motor overload pro tec tion. This mod ule also pro tects against phase to phase

cur rent im bal ance, over cur rent, under current, and phase

ro ta tion. The mod ules, mount ed in the power pan els,

uti liz es a 7 seg ment display which provides op er at ing

sta tus and fault di ag nos tic in for ma tion. The 7 segment

dis play will dis play ei ther a sta tion ary or a fl ash ing al-

pha nu mer ic value which can be de cod ed by the op er a tor.

A list of the codes follows:

HAXXX Normal motor OFF display. Sequentially

sweeps through the motor protection dip

switch setting.

0 Normal - no fault detected (Running)

Flashing “0” Motor off or un load ed < 5A (Running)

AC current lev el.

1 High cur rent fault.

Loaded phase to phase cur rent

2

imbalance >

Unloaded phase to phase cur rent

3

imbalance >

4 Improper in com ing phase ro ta tion.

High motor tem per a ture. Trip point =

5

13kW, re set = 3.25kW.

6 Communication error.

7 Unload imbalance ( >

8 Phase Loss (> 60%)

E Out of range of RLA cal i bra tion.

Other symbols Defective module or supply volt age.

Working voltage 18 - 30 VAC, 24 VAC nominal.

Low volt age trip = 15 VAC.

17%.

25%.

50%)

Whenever a motor protector trips, the motor pro tec tor

contacts wired in series with the motor contacts opens

and the motor contactor de-energizes causing the mo tor

to stop. The micro senses the low motor current and

shuts the system down. The micro will try two more

starts be fore locking the system out. The system locks

out be cause the motor protector is a man u al re set

de vice. Af ter the fi rst start, the modules’ contacts

will be open pre vent ing the motor contactors from

en er giz ing. Power must be removed and re applied to

re set the mod ule. Use CB3 in the Micro Panel to cycle

power.

Current Overload

The 2ACE module design uses one integral current

trans form er per phase to provide protection against

rap id current over load conditions. The module re sponds

to changes in current and must be cal i brat ed using DIP

switches lo cat ed on the module. Integral trip curves al low for in-rush cur rents dur ing Wye-Delta, part wind,

or ACL starts with out nuisance tripping.

To check the factory setting of the 2ACE module cur rent

overload trip value. See Table 1 (pages 18 and 21).

For the location of the dip switches and determining the

ON side of the switches, refer to Fig ure 45, page 127. As

in di cat ed, to place a switch in the ON po si tion re quires

push ing the switch to the left.

A switch must be pushed to the left to

place the switch in the ON position.

The numerical value for the combination of "ON" switches equals the

overload setting.

It is recommended that a YORK Ser vice Tech ni cian or the YORK fac to ry

be con sult ed before chang ing these

settings for any rea son, since dam age to the com pres sor could re sult.

Chang es should nev er be made un less it is ver i fi ed that the set tings are

in cor rect.

Anytime a dip switch change is made,

pow er must be cycled off and on to the

module to re pro gram the mod ule to the

new value.

16

YORK INTERNATIONAL

Page 17

FORM 201.19-NM1 (204)

Thermal Overload

Three PTC (positive temperature co ef fi cient) ther mistors

in the motor windings provides thermal pro tec tion. The

sensor re sis tance stays rel a tive ly con stant at 1k

Ω until

a tem per a ture of 266°F (130°C) is sensed. The sensor

ex pe ri enc es a rapid rise in re sis tance be yond this tem per a ture. When ev er the re sis tance of one of the sen sors

reach es 13k

Ω, +/− 3kΩ, the 2ACE module trips, which

ul ti mate ly de-energizes the mo tor’s pi lot cir cuit. Re set

is manual after the mo tor cools and the sen sor re sis tance

drops to 3.25k

Ω, +/− 0.5kΩ.

Current Imbalance (Loaded & Unloaded)/

Loss of Phase

A 2 second delay at start-up allows for any imbalances

resulting during normal starting conditions. After this

ini tial delay, the 2ACE module compares the “Op er at ing Current” to the measured half line current. The

“Op er at ing Current” is given by 0.65 X factory overload

cur rent setting.

An unloaded compressor condition occurs when any

measured half line current is less than the “Operating

Current.” A current imbalance exceeding an unloaded

level of 25% will result in the motor pilot circuit being

de-energized.

A loaded compressor condition occurs when any mea-

sured half line current is great er than or equal to the

“Operating Current.” A cur rent imbalance exceeding a

loaded level of 17% will result in the motor pilot cir cuit

being de-energized.

Imbalance is defi ned as

(High Phase - Low Phase)/High Phase

Improper Phase Sequence

The 2ACE module calculates the phase sequence at

start-up using the three cur rent transformers to de ter mine wheth er the three phase sequence on the load

side of the main contactor is miswired. Upon de tec tion

of a miswired motor load, the mod ule will de-energize

the main contactor pi lot circuit within 50 millisecond

re sponse time.

Additional information on the 2ACE MP module may

be found on page 125.

2

YORK INTERNATIONAL

17

Page 18

Product Description

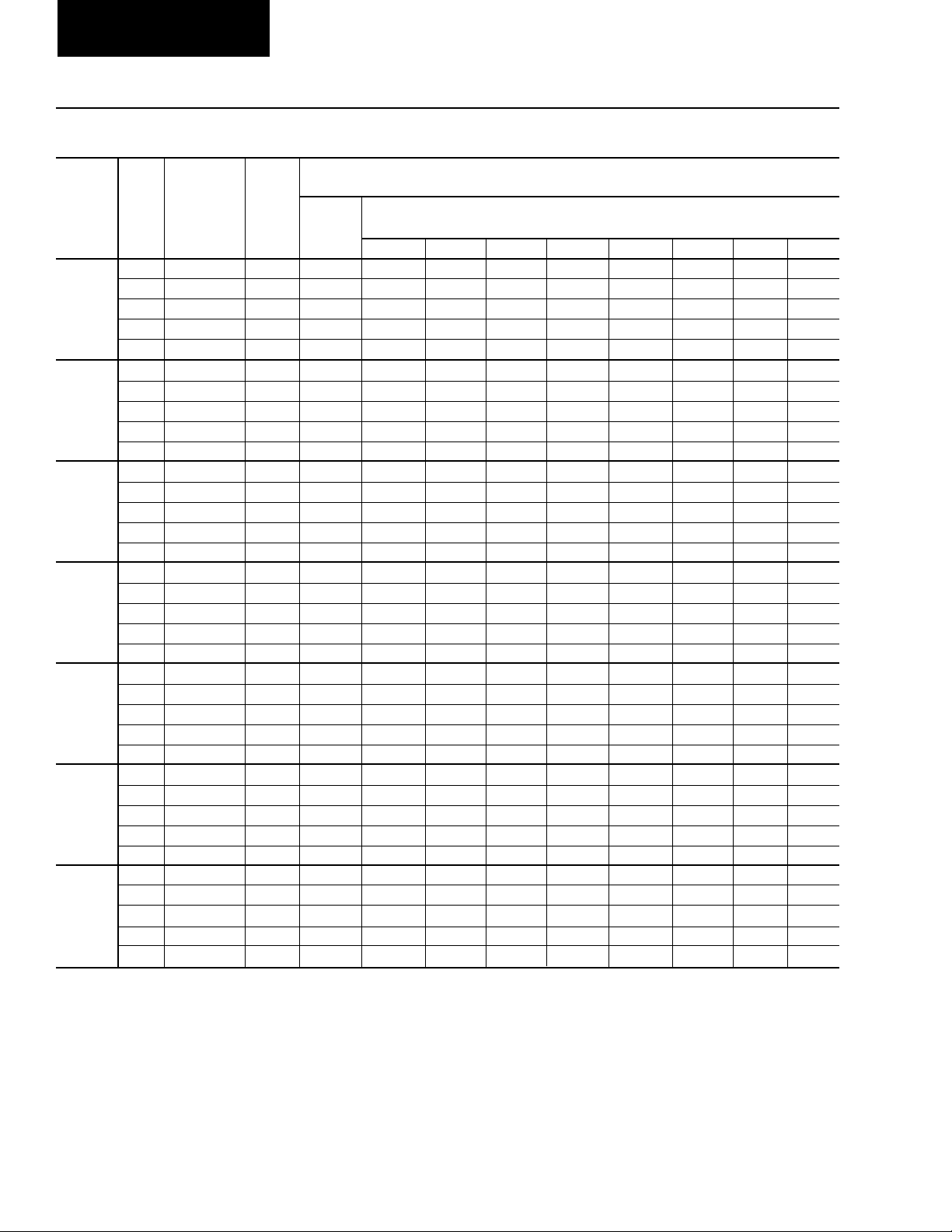

TABLE 1 – MOTOR PROTECTOR DIP SWITCH SETTING

YCAS STYLE G, ACROSS-THE-LINE – 60 HZ

FORM 201.19-NM1 (204)

17 246 *2 166 1 0 1 0 0 1 1 0

28 214 2 144 1 0 0 1 0 0 0 0

130 40 130 2 175 1 0 1 0 1 1 1 1

46 107 1 144 1 0 0 1 0 0 0 0

58 86 1 116 0 1 1 1 0 1 0 0

17 267 *4 90 0 1 0 1 1 0 1 0

28 232 *2 157 1 0 0 1 1 1 0 1

140 40 140 2 189 1 0 1 1 1 1 0 1

46 116 1 157 1 0 0 1 1 1 0 1

58 93 1 125 0 1 1 1 1 1 1 0

17 295 *4 99 0 1 1 0 0 0 1 1

0150

SYS. 1

46 128 2 173 1 0 1 0 1 1 0 1

58 103 1 139 1 0 0 0 1 0 1 1

17 265 *4 89 0 1 0 1 1 0 0 1

46 115 1 155 1 0 0 1 1 0 1 1

58 92 1 124 0 1 1 1 1 1 0 0

17 295 *4 99 0 1 1 0 0 0 1 1

28 256 *4 86 0 1 0 1 0 1 1 1

46 128 2 173 1 0 1 0 1 1 0 1

58 103 1 139 1 0 0 0 1 0 1 1

17 321 *4 108 0 1 1 0 1 1 0 0

46 140 2 189 1 0 1 1 1 1 0 1

58 112 1 151 1 0 0 1 0 1 1 1

17 295 *4 99 0 1 1 0 0 0 1 1

46 128 2 173 1 0 1 0 1 1 0 1

58 103 1 139 1 0 0 0 1 0 1 1

MODEL

NO.

28 256 *4 86 0 1 0 1 0 1 1 0

40 155 2 209 1 1 0 1 0 0 0 1

28 230 *2 155 1 0 0 1 1 0 1 1

0150

40 139 2 188 1 0 1 1 1 1 0 0

SYS. 2

40 155 2 209 1 1 0 1 0 0 0 1

0160

28 279 *4 94 0 1 0 1 1 1 1 0

0170

40 169 *2 114 0 1 1 1 0 0 1 0

SYS. 1

28 256 *4 86 0 1 0 1 0 1 1 1

0170

40 155 2 209 1 1 0 1 0 0 0 1

SYS. 2

VOLT

CODE

CHILLER

NAMEPLATE

RLA

NO.

LEADS

MP

PER

DISPLAY

PHASE

HA XXX

128 64 32 16 8 4 2 1

MO TOR PROTECTOR

DIP SWITCH SETTINGS ON MP (“1” INDICATES ON)

* Indicates one lead/phase through motor protector.

18

YORK INTERNATIONAL

Page 19

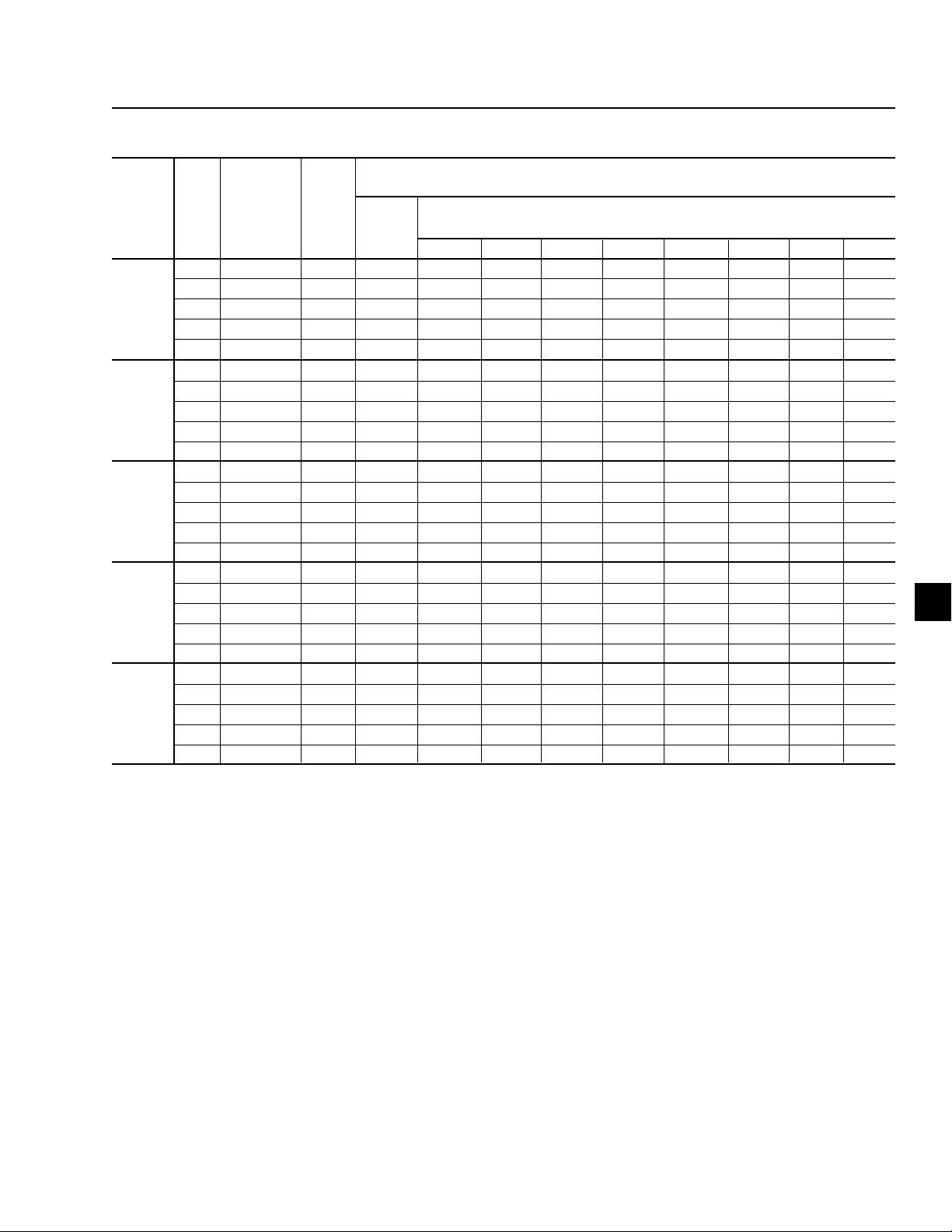

TABLE 1 – MOTOR PROTECTOR DIP SWITCH SETTING (CONT’D)

YCAS STYLE G, ACROSS-THE-LINE – 60 HZ

FORM 201.19-NM1 (204)

17 321 *4 108 0 1 1 0 1 1 0 0

180 40 169 *2 114 0 1 1 1 0 0 1 0

46 140 2 189 1 0 1 1 1 1 0 1

58 112 1 151 1 0 0 1 0 1 1 1

17 342 *4 115 0 1 1 1 0 1 0 0

28 298 *4 101 0 1 1 0 0 1 0 1

200 40 181 *2 122 0 1 1 1 1 1 1 0

46 149 2 201 1 1 0 0 1 0 0 1

58 119 1 161 1 0 1 0 0 0 0 1

17 374 *4 126 0 1 1 1 1 1 1 0

46 163 *2 110 0 1 1 0 1 1 1 0

58 130 2 175 1 0 1 0 1 1 1 1

17 342 *4 115 0 1 1 1 0 1 0 0

46 149 2 201 1 1 0 0 1 0 0 1

58 119 1 161 1 0 1 0 0 0 0 1

17 374 *4 126 0 1 1 1 1 1 1 0

28 325 *4 110 0 1 1 0 1 1 1 0

230 40 197 *2 133 1 0 0 0 0 1 0 1

46 163 *2 110 0 1 1 0 1 1 1 0

58 130 2 175 1 0 1 0 1 1 1 1

MODEL

NO.

28 325 *4 110 0 1 1 0 1 1 1 0

210

40 197 *2 133 1 0 0 0 0 1 0 1

SYS. 1

28 298 *4 101 0 1 1 0 0 1 0 1

210

40 181 *2 122 0 1 1 1 1 1 1 0

SYS. 2

CHILLER

VOLT

NAMEPLATE

CODE

28 279 *4 94 0 1 0 1 1 1 1 0

RLA

NO.

LEADS

MP

PER

DISPLAY

PHASE

HA XXX

128 64 32 16 8 4 2 1

MO TOR PROTECTOR

DIP SWITCH SETTINGS ON MP (“1” INDICATES ON)

2

* Indicates one lead/phase through motor protector

YORK INTERNATIONAL

19

Page 20

Product Description

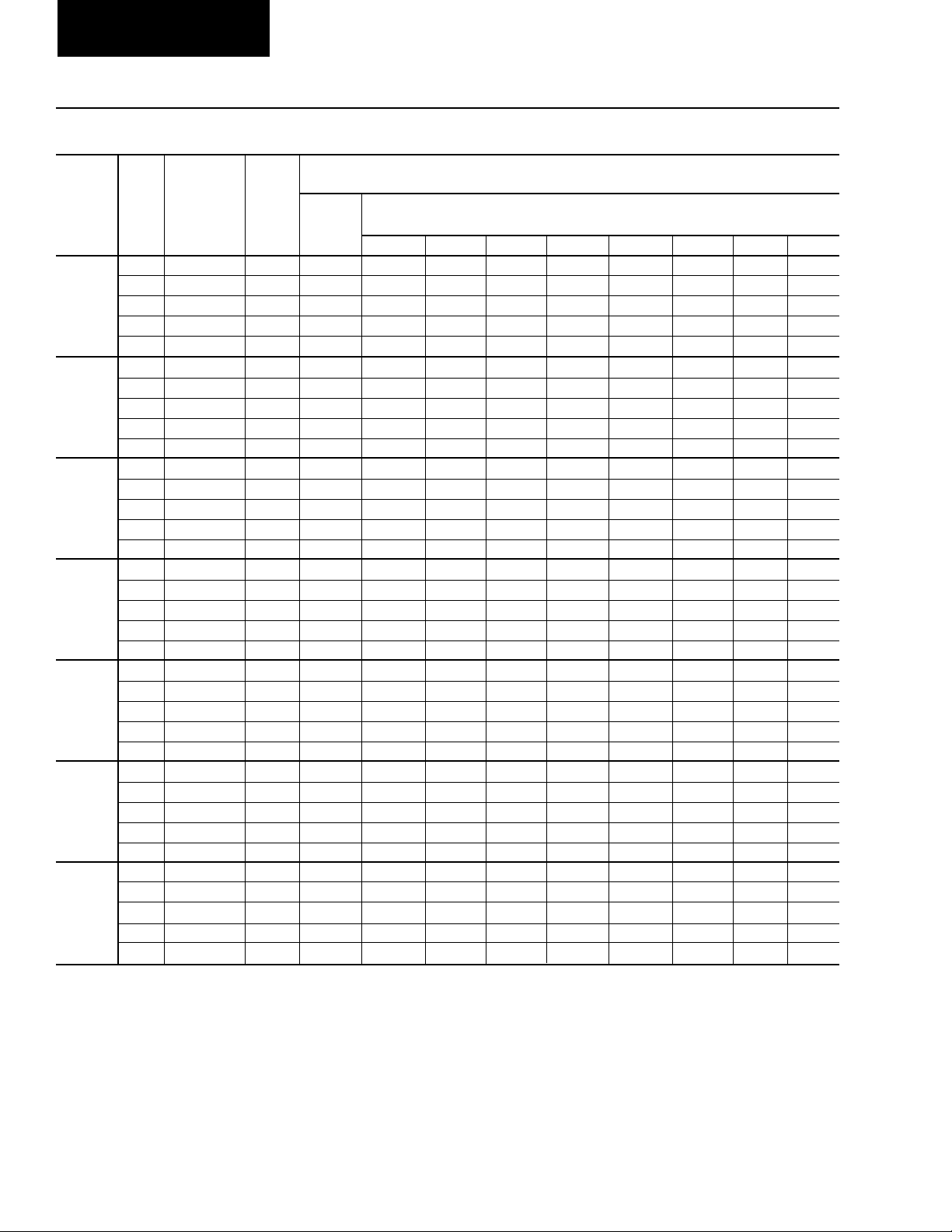

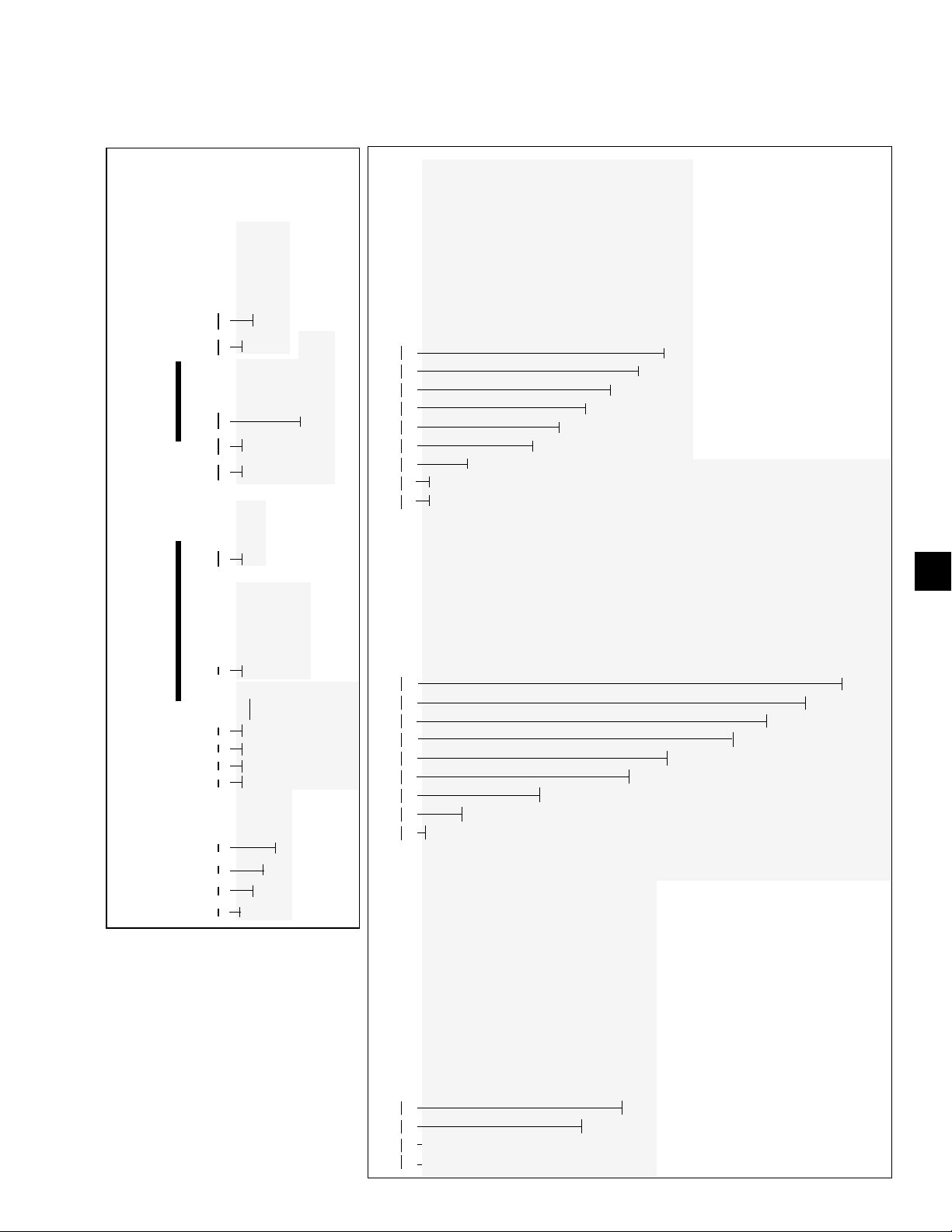

TABLE 1 – MOTOR PROTECTOR DIP SWITCH SETTING (CONT’D)

YCAS STYLE G, WYE DELTA START – 60 HZ

FORM 201.19-NM1 (204)

17 246 *4 96 0 1 1 0 0 0 0 0

28 214 *2 167 1 0 1 0 0 1 1 1

130 40 130 2 175 1 0 1 0 1 1 1 1

46 107 2 144 1 0 0 1 0 0 0 0

58 86 2 116 0 1 1 1 0 1 0 0

17 267 *4 105 0 1 1 0 1 0 0 1

28 232 *4 91 0 1 0 1 1 0 1 1

140 40 140 2 189 1 0 1 1 1 1 0 1

46 116 2 157 1 0 0 1 1 1 0 1

58 93 2 126 0 1 1 1 1 1 1 0

17 295 *4 115 0 1 1 1 0 0 1 1

0150

SYS. 1

46 128 2 173 1 0 1 0 1 1 0 1

58 103 2 139 1 0 0 0 1 0 1 1

17 265 *4 104 0 1 1 0 1 0 0 0

46 115 2 155 1 0 0 1 1 0 1 1

58 92 2 124 0 1 1 1 1 1 0 0

17 295 *4 115 0 1 1 1 0 0 1 1

28 256 *4 100 0 1 1 0 0 1 0 0

46 128 2 173 1 0 1 0 1 1 0 1

58 103 2 139 1 0 0 0 1 0 1 1

17 321 *4 126 0 1 1 1 1 1 1 0

46 140 2 189 1 0 1 1 1 1 0 1

58 112 2 151 1 0 0 1 0 1 1 1

17 295 *4 115 0 1 1 1 0 0 1 1

46 128 2 173 1 0 1 0 1 1 0 1

58 103 2 139 1 0 0 0 1 0 1 1

MODEL

NO.

28 256 *4 100 0 1 1 0 0 1 0 0

40 155 2 209 1 1 0 1 0 0 0 1

28 230 *4 90 1 1 0 1 1 0 1 0

0150

40 139 2 188 1 0 1 1 1 1 0 0

SYS. 2

40 155 2 209 1 1 0 1 0 0 0 1

0160

28 279 *4 109 0 1 1 0 1 1 0 1

0170

40 169 *2 132 1 0 0 0 0 1 0 0

SYS. 1

28 256 *4 100 0 1 1 0 0 1 0 0

0170

40 155 2 209 1 1 0 1 0 0 0 1

SYS. 2

VOLT

CODE

CHILLER

NAMEPLATE

RLA

NO.

LEADS

MP

PER

DISPLAY

PHASE

HA XXX

128 64 32 16 8 4 2 1

MO TOR PROTECTOR

DIP SWITCH SETTINGS ON MP (“1” INDICATES ON)

* Indicates one lead/phase through motor protector.

20

YORK INTERNATIONAL

Page 21

TABLE 1 – MOTOR PROTECTOR DIP SWITCH SETTING (CONT’D)

YCAS STYLE G, WYE DELTA START – 60 HZ

FORM 201.19-NM1 (204)

17 321 *4 126 1 0 0 0 0 0 1 0

180 40 169 *2 132 1 0 0 0 0 1 0 0

46 140 2 189 1 0 1 1 1 1 0 1

58 112 2 151 1 0 0 1 0 1 1 1

17 342 *4 134 1 0 0 0 0 1 1 0

28 298 *4 117 0 1 1 1 0 1 0 1

200 40 181 *2 142 1 0 0 0 1 1 1 0

46 149 2 201 1 1 0 0 1 0 0 1

58 119 2 161 1 0 1 0 0 0 0 1

17 374 *4 146 1 0 0 1 0 0 1 0

46 163 *2 128 1 0 0 0 0 0 0 0

58 130 2 175 1 0 1 0 1 1 1 1

17 342 *4 134 1 0 0 0 0 1 1 0

46 149 2 201 1 1 0 0 1 0 0 1

58 119 2 161 1 0 1 0 0 0 0 1

17 374 *4 146 1 0 0 1 0 0 1 0

28 325 *4 127 0 1 1 1 1 1 1 1

230 40 197 *2 154 1 0 0 1 1 0 1 0

46 163 *2 128 1 0 0 0 0 0 0 0

58 130 2 175 1 0 1 0 1 1 1 1

MODEL

NO.

28 325 *4 127 0 1 1 1 1 1 1 1

210

40 197 *2 154 1 0 0 1 1 0 1 0

SYS. 1

28 298 *4 117 0 1 1 1 0 1 0 1

210

40 181 *2 142 1 0 0 0 1 1 1 0

SYS. 2

CHILLER

VOLT

NAMEPLATE

CODE

28 279 *4 109 0 1 1 0 1 1 0 1

RLA

NO.

LEADS

MP

PER

DISPLAY

PHASE

HA XXX

128 64 32 16 8 4 2 1

MO TOR PROTECTOR

DIP SWITCH SETTINGS ON MP (“1” INDICATES ON)

2

* Indicates one lead/phase through motor protector.

YORK INTERNATIONAL

21

Page 22

Product Description

FORM 201.19-NM1 (204)

MOTOR STARTING

Two types of compressor motor starting are available:

Across-the-Line and optional Wye-Delta Open Tran si tion Start er.

Across-the-Line starters will utilize one contactor and

one start relay per compressor. The optional Wye-Delta

start er utilizes 4 motor contactors, a transition delay

re lay, a start relay, and a start-wye relay.

The Wye-Delta start allows inrush current to be limited

to approximately 33% LRA for the fi rst 4 to 7 sec onds,

with current increasing to normal running cur rent when

the Delta connection is completed.

When the micro initiates a start signal at Relay Output

Board #1 (SYS 1) Terminal 20 or Relay Output Board

#2 (SYS 2) Ter mi nal 20 to run a com pres sor, the 1CR

(SYS 1) or 2CR (SYS 2) relay is en er gized. The tran si tion of the 1CR (SYS 1) or 2CR (SYS 2) relay contacts

en er giz es the 1S (SYS 1) or 2S (SYS 2) relay approx.

16ms later. The 1S/2S con tacts in turn en er gize the 1M

(SYS 1) or 3M (SYS 2) mo tor con tacts 16ms later. This

com pletes the “WYE” con nec tion of the motor start.

At the same time, the normally closed 1S/2S auxiliary

in ter lock con tact opens pre vent ing the 2M and 1 TRX

(SYS 1) or 4M and 2 TRX (SYS 2) mo tor contactors

from en er giz ing. 2 sets of aux il ia ry con tacts from 1M

(SYS 1) or 3M (SYS 2) close, in ter lock ing the 1M (SYS

1) or 3M (SYS 2) contactors, keep ing them en er gized

in par al lel with 1S (SYS 1) or 2S (SYS 2).

The “WYE” connection of the motor start is enabled

for 4 to 7 seconds depending upon motor current as

sensed by the microprocessor. The tran si tion to Delta

takes 7 seconds if current is below 110% FLA. If mo tor current exceeds 110% FLA, the transition is made

to Delta as long as the WYE has been enabled for at

least 4 seconds.

After the “WYE” connection is enabled for 4 to 7

sec onds, the 1TR (SYS 1) or 2TR (SYS 2) transition

delay relay is enabled by the microprocessor from Relay

Out put Board #1 Terminal 8 (SYS 1) or Relay Out put

Board #2 Terminal 6 (SYS 2). The 1TR (SYS 1) or 2TR

(SYS 2) contacts open, de-energizing 1S (SYS 1) or 2S

(SYS 2). 1M (SYS 1) or 3M (SYS 2) remain energizes

through 2 sets of interlocking con tacts 1M (SYS 1) or

3M (SYS 2). Open ing of the 1TR (SYS 1) or 2TR (SYS

2) con tacts deenergizes 1S/2S and clos es the nor mal ly

closed 1S (SYS 1) or 2S (SYS 2) con tacts, en er giz ing

1 TRX (SYS 1) or 2 TRX (SYS 2). 1TRX or 2TRX

subsequently energizes motor contactor 2M (SYS 1) or

4M (SYS 2), com plet ing the “DELTA” con nec tion of

the motor.

1 TR, 1 TRX, 2 TR, and 2 TRX are

NOT “tim ing” re lays. These devices

are sim ply pilot relays iden ti cal to

1CR and 2CR.

KEYPAD CONTROLS

Display

Parameters are displayed in English (°F and PSIG) or

Metric (°C and Bars) units, and for each circuit, the

following items can be displayed:

• Return and leaving chilled liquid, and ambient tem per a ture.

• Day, date and time. Daily start/stop times. Holiday

and Manual Override status.

• Compressor operating hours and starts. Automatic or

manual lead/lag. Lead compressor iden ti fi ca tion.

• Run permissive status. No cooling load condition.

Com pres sor run status.

• Anti-recycle timer and anti-coincident start timer

sta tus per compressor.

• System suction (and suction superheat), discharge,

and oil pressures and temperatures.

• Percent full load compressor motor current per phase

and average per phase. Compressor ca pac i ty con trol

valve input steps.

• Cutout status and setpoints for: supply fl uid tem-

per a ture, low suction pressure, high discharge pres sure and temperature, high oil temperature, low and

high am bi ent, phase rotation safety, and low leav ing

liq uid tem per a ture.

• Unloading limit setpoints for high discharge pres sure and compressor motor current.

• Status of: evaporator heater, condenser fans, load

and unload timers, chilled water pump.

• “Out of range” message.

• Up to 6 fault shut down conditions.

The standard display language is English, with 4 other

languages available.

22

YORK INTERNATIONAL

Page 23

FORM 201.19-NM1 (204)

Entry – Used to confi rm Set Point changes, cancel

in puts, advance day, and change AM/PM.

Setpoints – For setting chilled liquid temperature,

chilled liquid range, remote reset temperature range.

Clock – Used to set time, daily or holiday start/stop

schedule and manual override for servicing.

Print – Used to display or print operating data or sys tem fault shutdown history for last six faults. Printouts

through an RS-232 port via a separate print er.

Program

For setting low leaving liquid temperature cutout, 300

to 600 second anti-recycle timer, average motor cur rent

unload point, liquid temperature setpoint reset sig nal

from YORK ISN or building automation system.

Additional functions (password protected) for pro gram ming by a qualifi ed service technician:

Cutouts for low and high ambient, low suction pres sure and high discharge pressure, refrigerant type, high

dis charge pressure unload setpoint.

ACCESSORIES AND OPTIONS

Multiple Point Power Connection (Standard)

Standard fi eld power wiring connection on all models

is Multiple Point Power Connection. Field provided

pow er supply circuits, with appropriate branch circuit

pro tec tion, are connected to factory provided terminal

blocks, non-fused disconnect switches or circuit break ers

with lockable external handles located in the two power

com part ments.

Single-Point Power Connection with Individual

Circuit Protection

A single-point supply circuit with fi eld provided pro-

tec tion is connected to a factory provided terminal block

or non-fused disconnect switch located in the options

com part ment. Factory wiring is provided from the ter mi nal block or disconnect switch to factory supplied

internal branch circuit breakers with lockable external

handles in the power compartments.

Single-Point Power Connection with Combined

Cir cuit Protection

A single-point supply circuit with field provided

pro tec tion is connected to a factory provided circuit

break er with lockable external handle located in the

options com part ment. Factory wiring is provided from

the cir cuit breaker to factory supplied terminal blocks

in the power compartments.

Single-Point Power Connection without Circuit

Protection

A single-point supply circuit with fi eld provided pro-

tec tion is connected to a factory provided terminal block

or non-fused disconnect switch located in the options

com part ment. Factory wiring is provided from the ter mi nal block or disconnect switch to factory supplied

terminal blocks in the power compartments.

Control Circuit Terminal Block

A 120V, 20A control circuit power terminal strip lo cat ed

in the control panel to accept a fi eld provided control

power supply, rather than the standard factory mounted

control circuit transformer. The supply with appropriate

branch circuit protection in accordance with applicable

Local codes, provides the unit control cir cuit power sup ply via the panel mounted Emergency Stop Switch.

Building Automation System (BAS) Interface

Provides a means to reset the leaving chilled liquid tem per a ture or percent full load amps (current limiting) from

the BAS (Factory-mounted):

Printed circuit board to accept 4 to 20mA, 0 to 10VDC,

or dry contact closure input from the BAS.

A YORK ISN Building Automation System can pro vide a Pulse Width Modulated (PWM) signal direct to

the standard control panel via the standard on-board

RS485 port.

Condenser Coil Protection

The standard condenser coils have Aluminum fi ns, cop-

per tubes, and galvanized steel supports for generally

adequate corrosion resistance. However, these ma te ri als

are not adequate for all environments.

2

YORK INTERNATIONAL

23

Page 24

Product Description

FORM 201.19-NM1 (204)

The following options provide added protection:

Black fi n condenser coils – Condenser coils con struct ed

using black epoxy coated Aluminum fi n stock for cor-

ro sion resistance comparable to copper fin coils in

typ i cal seashore locations.

Copper fi n condenser coils – Coils constructed with