Page 1

TECHNICAL GUIDE

ADD - ON COILS

FOR USE WITH SPLIT -SYSTEM

COOLING & HEAT PUMPS

MODELS: MC, PC, FC, HD, UC

600 - 2000 CFM 1.5 - 5 TON COILS

Due to continuous product improve m ent, specifications

are subject to change without notice.

Visit us on the web at www.york.com for the most

up-to-date technical information.

Additional rating information can be found at

www.ahridirectory.org

UPFLOW/DOWNFLOW

FULL CASED

FC

FULL CASED

MULTI-POSITION

MC

UPFLOW

PARTIAL CASED

PC

HORIZONTAL

DUCT

HD

UPFLOW

UNCASED

UC

ISO 9001

Certified Quality

Management System

Heating Air Conditioning

R

FOR DISTRIBUTION USE ONLY - NOT TO BE USED AT POINT OF RETAIL SALE

813517-YTG-E-0114

DESCRIPTION

These evaporator coils are designed to be installed with UPG furnaces or modular air handlers and matched with UPG cooling

and heat pump outdoor units. All coil models are available as

“flex-coil” units without a factory installed metering device. Flexcoil models allow these coils to be used with R-22 or R-410A for

added flexibility to meet refrigerant system choice. An orifice

metering device or a R-410A TXV should be installed in the field

to meet your system requirements.

FC Models, Full Case Coils - Full cased coils are suitable for

use in upflow or downflow applications.

MC Models, Multi-Position Coils - MC coils have the added

flexibility that allow them to be installed in any position - upflow,

downflow, or horizontal right or left. This coil can be easily

installed with a UPG furnace or modular air handler in any configuration.

PC Models, Partial Case Coils - These coils are designed for

installation on top of upflow furnaces. The partial case height on

these coils allows for the flexibility of fabricating the upper portion

of the coil casing in the field. The partial cased coils are for use in

upflow only applications.

UC Models, Uncased Coils - These coils are designed for installation on top of upflow furnaces, and they are to be used for only

upflow applications. The uncased coils allows field modification of

the furnace duct for the coil installation.

HD Models, Horizontal Duct Coils - Dedicated horizontal, slab

coil available for both cooling and heat pump applications. Field

transition may be required.

FEATURES

Rust-proof plastic drain pans - The vertical and horizontal drain

pans on these coils are made of a fiberglass reinforced thermoset

polymer that will not rust or compromise stability at high temperatures.

Insulated Cabinet - Evaporator coil cabinets are thermally insulated with foil faced insulation to prevent sweating. HD coils use

fiberglass Tuf-Skin® insulation.

Internally Clean - All evaporator coils are factory leak-tested,

dehydrated, sealed and shipped with a holding charge. The suction and liquid lines are sealed with spun copper fittings with easy

access to attach line set.

Durable Finish Inside and Out - Coil casings are made of prepainted steel. Pre-treated flat galvanized steel provides a better

paint to steel bond, which resists corrosion and rust creep. All

internal metal parts are made of G90 galvanized steel.

Optimum Heat Transfer - Using the latest in heat transfer technology, staggered rows of copper tubes are mechanically

expanded into aluminum fins to provide optimum air to surface

contact for ample moisture removal as well as high performance

ratings.

ACCESSORIES

Refer to Price Manual for specific model numbers.

TXV Kits - Thermal expansion valve kits are available for flex-coil

applications, for converting R-22 to R-410A refrigerant, or as a

service replacement. All TXV kits are non-braze. All connections

are bolt-on including the valve assembly and equalizer tube. No

orifice or any other metering device is to be used in conjunction

with the TXV.

Coil Casing Without Coil - Coil casings are available in four

widths that can be installed with the furnace or modular air handler during initial installation. This option is available to allow the

installer the flexibility to add the coil at a later date without duct

modifications.

UVC Germicidal Light - The UVC technology effectively prevents mold, bacteria, and other microorganisms that develop in

air handling systems. The UVC Light Kit provides safe, continuous cleaning while actually saving money by reducing HVAC system maintenance and energy consumption.

Page 2

813517-YTG-E-0114

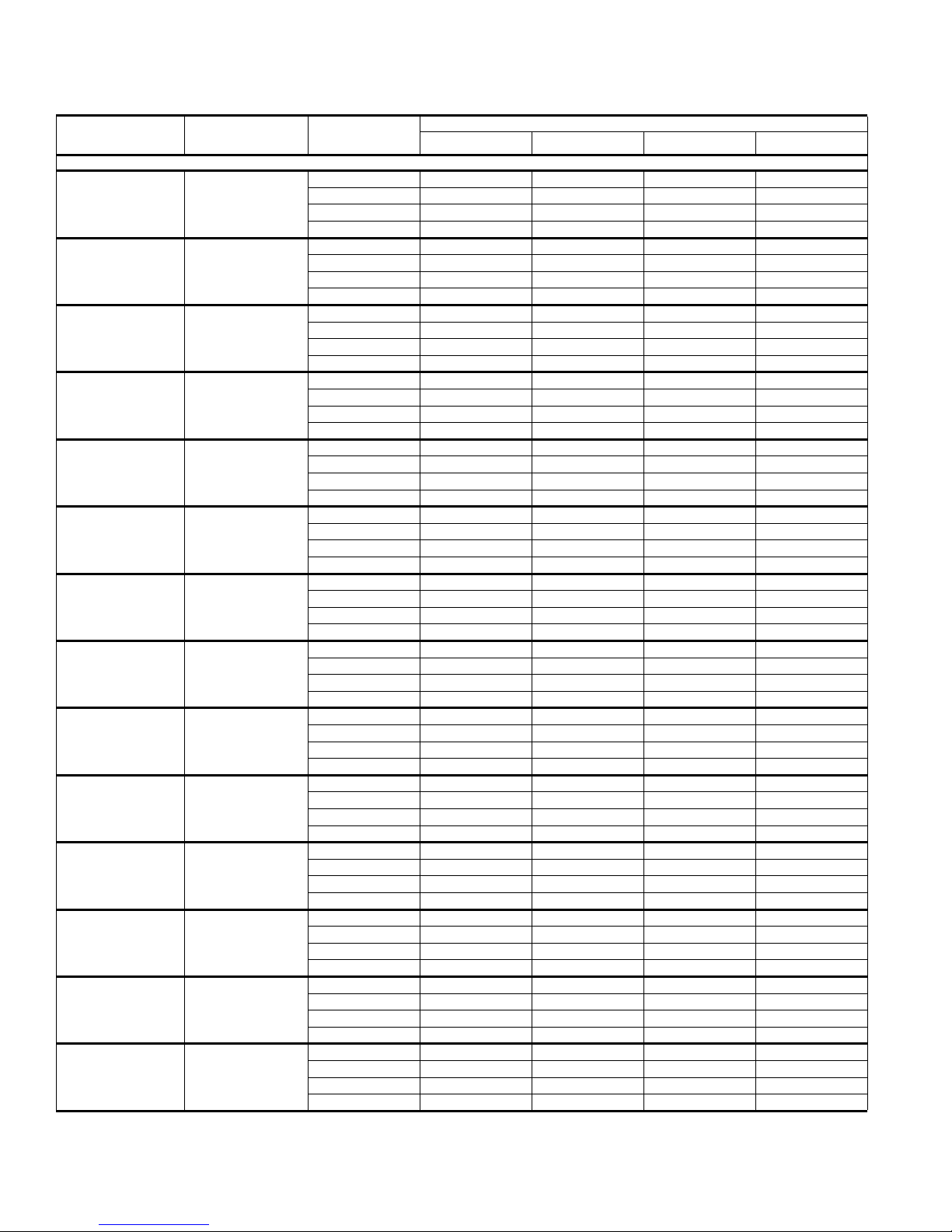

Rated

CFM

1

Entering

Air °F

(Dry/Wet Bulb)

MBH @ Evaporator Temperature and Corresponding Pressure °F / PSIG

35 / 61.5 40 / 68.5 45 / 76.0 50 / 84.0

UPFLOW "A" TYPE

COOLING CAPACITY - Coil Only

Model

85/72 25.3 23.1 20.6 17.9

FC18A

PC18A

675

80/67 23.4 21.1 18.7 16.1

75/62 19.2 12.0 18.7 12.4

70/57 15.6 13.5 11.3 8.8

85/72 28.1 25.7 22.9 19.9

FC18B

PC18B

675

80/67 26.0 23.5 20.8 17.9

75/62 21.3 18.9 16.4 13.7

70/57 17.3 15.0 12.6 9.8

85/72 35.6 32.5 29.0 25.2

FC24A

PC24A

850

80/67 32.9 29.7 26.3 22.7

75/62 27.0 23.9 20.7 17.4

70/57 21.9 19.0 15.9 12.4

85/72 35.6 32.5 29.0 25.2

FC24B

PC24B

850

80/67 32.9 29.7 26.3 22.7

75/62 27.0 23.9 20.7 17.4

70/57 21.9 19.0 15.9 12.4

FC30(A,B)

PC30(A,B)

FC32A

PC32A

FC35(B,C)

PC35(B,C)

FC37A

PC37A

1025

1200

85/72 38.9 35.4 31.6 27.6

80/67 33.9 30.3 26.8 23.0

75/62 27.3 23.7 22.5 18.0

70/57 22.6 20.1 17.5 14.8

85/72 58.7 50.5 42.1 33.2

80/67 47.0 39.5 32.2 24.6

75/62 36.7 29.2 23.8 19.9

70/57 31.5 27.6 22.4 18.8

85/72 46.0 41.9 37.4 32.9

FC36A

PC36A

1150

80/67 36.8 32.5 28.5 24.2

75/62 28.8 24.1 26.4 19.6

70/57 24.7 22.9 21.1 19.6

85/72 51.1 46.5 41.5 36.6

FC36(B,C)

PC36(B,C)

1250

80/67 40.9 36.1 31.7 26.9

75/62 32.0 26.8 29.3 21.8

70/57 27.4 25.4 23.4 21.8

85/72 73.1 62.9 52.4 41.4

FC42(B,C)

PC42(B,C)

1400

80/67 58.6 49.1 40.0 30.6

75/62 45.7 36.3 29.6 24.7

70/57 39.2 34.3 27.9 23.4

85/72 76.8 66.0 55.0 43.4

FC43(B,C)

PC43(B,C)

1400

80/67 61.5 51.6 42.0 32.1

75/62 47.9 38.1 31.1 26.0

70/57 41.2 36.0 29.3 24.6

85/72 82.2 70.7 58.9 46.5

FC48(C,D)

PC48(C,D)

1620

80/67 65.8 55.3 45.0 34.4

75/62 51.4 40.9 33.3 27.9

70/57 44.1 38.6 32.3 26.5

85/72 100.9 85.0 68.9 52.3

FC60(C,D)

PC60(C,D)

1850

80/67 80.8 66.6 52.6 38.6

75/62 62.9 49.3 38.8 31.2

70/57 54.1 46.6 37.4 29.8

85/72 105.9 89.3 72.4 54.9

FC62D 1850

80/67 84.8 70.0 55.2 40.5

75/62 66.0 51.8 40.8 32.8

70/57 56.8 48.9 39.3 31.2

85/72 124.4 109.4 94.1 78.0

FC64D 1850

80/67 100.9 87.0 72.1 56.2

75/62 80.3 66.7 52.5 37.2

70/57 61.8 48.2 34.8 24.3

1 - See Condensing Unit or Heat Pump Technical Guide for Total Cooling Capacity and Sensible Capacity.

2 Johnson Controls Unitary Products

Page 3

813517-YTG-E-0114

COOLING CAPACITY - COIL ONLY

Model Coil Rated CFM

MC18A 550

MC18B 650

MC24(A,B) 850

MC30(A,B)

MC32A

MC35(B,C)

MC37A

MC36A 1150

MC36B 1250

MC36C 1250

MC42(B,C) 1400

MC43(B,C) 1400

MC48(C,D) 1650

MC60D 1825

MC62D 2000

1 See Condensing Unit or Heat Pump Technical Guide for Total Coolin g Capacity and Sensible Capacity.

1025

1200

1

Entering Air °F

(Dry/Wet Bulb)

MBH@ Evaporator Temperature and Corresponding Pressure °F / PSIG

35 / 61.5 40 / 68.5 45 / 76.0 50 / 84.0

FULL-CASED “A” TYPE MULTI-POSITION

85/72 25.8 23.5 21.0 18.2

80/67 23.7 21.5 19.0 16.4

75/62 19.5 17.3 14.9 12.6

70/57 15.8 13.5 11.5 9.0

85/72 28.7 26.1 23.3 20.2

80/67 26.4 23.9 21.1 18.2

75/62 21.6 19.2 16.6 14.0

70/57 17.5 15.2 12.8 10.0

85/72 36.3 33.0 29.5 25.6

80/67 33.4 30.2 26.7 23.1

75/62 27.4 24.3 21.0 17.7

70/57 22.2 19.3 16.2 12.6

85/72 41.5 37.8 33.7 29.5

80/67 36.2 32.4 28.6 24.5

75/62 29.1 25.3 24.0 19.2

70/57 24.1 21.5 18.7 15.8

85/72 59.9 51.5 42.9 33.9

80/67 48.0 40.3 32.8 25.1

75/62 37.4 29.8 24.3 20.3

70/57 32.1 28.1 22.9 19.2

85/72 46.8 42.6 38.1 33.6

80/67 37.5 33.1 29.1 24.7

75/62 29.3 24.6 26.8 20.0

70/57 25.1 23.2 21.4 20.0

85/72 52.0 47.3 42.3 37.3

80/67 41.7 36.8 32.3 27.4

75/62 32.5 27.3 29.8 22.2

70/57 27.9 25.8 23.8 22.2

85/72 53.4 48.6 43.4 38.3

80/67 42.8 37.8 33.1 28.2

75/62 33.4 28.1 30.6 22.8

70/57 28.7 26.5 24.5 22.8

85/72 74.6 64.1 53.4 42.2

80/67 59.8 50.1 40.8 31.2

75/62 46.6 37.1 30.2 25.2

70/57 40.0 35.0 28.5 23.9

85/72 78.3 67.4 56.1 44.3

80/67 62.7 52.6 42.9 32.8

75/62 48.9 38.9 31.7 26.5

70/57 42.0 36.8 29.9 25.1

85/72 83.9 72.1 60.1 47.4

80/67 67.2 56.4 45.9 35.1

75/62 52.4 41.7 33.9 28.4

70/57 45.0 39.4 33.0 27.0

85/72 102.9 86.7 70.3 53.3

80/67 82.4 68.0 53.7 39.4

75/62 64.2 50.3 39.6 31.8

70/57 55.1 47.5 38.1 30.3

85/72 107.0 90.2 73.1 55.5

80/67 85.7 70.7 55.8 40.9

75/62 66.7 52.3 41.2 33.1

70/57 57.4 49.4 39.7 31.6

Johnson Controls Unitary Products 3

Page 4

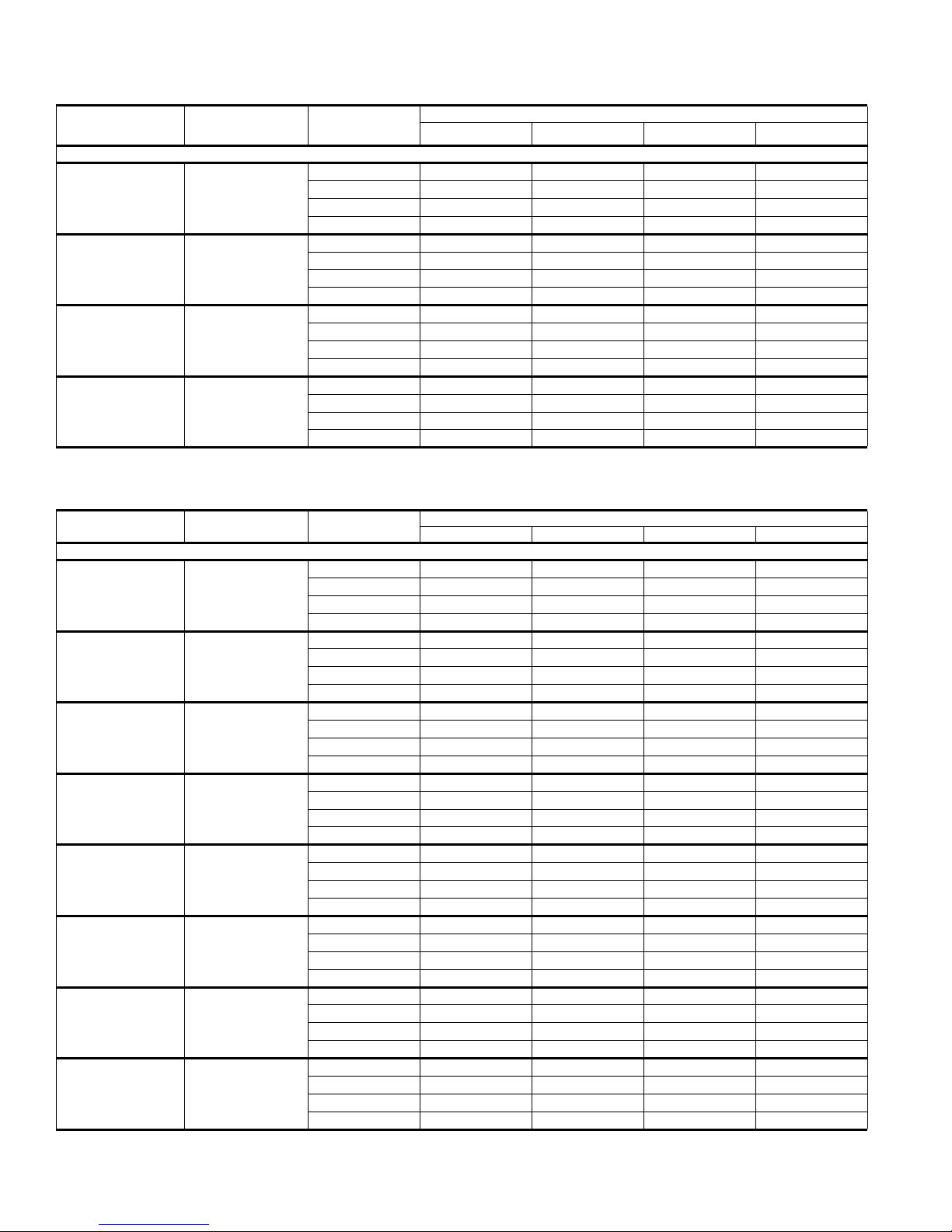

813517-YTG-E-0114

RATED

CFM

1

ENTERING

AIR F

(Dry/Wet Bulb)

HORIZONTAL DUCT TYPE

MBH @ Evaporator Temperature and Corresponding Pressure °F/ PSIG

35 / 61.5 40 / 68.5 45 / 76.0 50 / 84.0

85/72 35.3 32.4 28.7 24.9

80/67 32.6 29.4 26.0 22.5

75/62 26.7 23.7 20.5 17.2

70/57 21.7 18.8 15.7 12.3

85/72 57.9 52.7 47.1 41.5

80/67 46.4 41.1 35.9 30.4

75/62 36.2 30.4 26.5 24.7

70/57 31.1 28.7 26.5 24.7

85/72 83.4 71.7 59.7 47.1

80/67 66.8 56.1 45.6 34.9

75/62 52.1 41.5 33.7 28.3

70/57 44.7 39.2 33.7 28.3

85/72 133.0 112.4 90.9 69.2

80/67 106.5 87.9 69.4 50.0

75/62 83.0 65.0 51.3 41.1

70/57 71.2 61.4 51.3 41.1

COOLING CAPACITY - Coil Only

MODEL

HD24S 815

HD36S 1192

HD48S 1610

HD60S 2100

1 See Condensing Unit or Heat Pump Technical Guide for Total Cooling Capacity and Sensible Capacity.

COOLING CAPACITY - COIL ONLY

Model Coil Rated CFM

1

Entering Air °F

(Dry/Wet Bulb)

MBH@ Evaporator Temperature and Corresponding Pressure °F / PSIG

35 / 61.5 40 / 68.5 45 / 76.0 50 / 84.0

Uncased Upflow

85/72 23.3 21.3 19.0 17.5

UC18(A,B) 600

80/67 21.5 19.5 17.3 14.9

75/62 17.7 15.6 13.5 11.4

70/57 14.4 12.4 10.4 8.0

85/72 27.4 25.0 22.3 19.4

UC24(A,B) 800

80/67 25.3 22.9 20.3 17.5

75/62 20.8 18.4 15.9 13.4

70/57 16.9 14.6 12.2 9.4

85/72 35.2 32.0 28.6 24.8

UC30(A,B) 1000

80/67 32.4 28.6 25.3 21.9

75/62 26.6 23.6 21.5 18.7

70/57 25.2 22.7 20.2 17.6

85/72 46.8 42.7 37.9 33.0

UC36A 1150

80/67 43.1 39.2 34.9 30.4

75/62 35.3 32.1 28.6 24.9

70/57 33.3 26.9 26.9 23.4

85/72 49.3 44.9 39.9 34.7

UC36(B,C) 1200

80/67 45.4 41.3 36.7 32.0

75/62 37.2 33.8 30.1 26.2

70/57 35.0 28.3 28.3 24.6

85/72 86.7 73.0 59.2 44.9

UC42(B,C) 1400

80/67 69.4 57.2 45.2 33.1

75/62 54.0 42.3 33.4 26.8

70/57 46.4 40.0 33.4 26.8

85/72 62.4 56.8 50.5 44.4

UC48(C,D) 1600

80/67 57.4 53.2 46.5 40.5

75/62 47.1 42.8 38.1 33.2

70/57 44.3 40.3 35.8 31.2

85/72 95.4 82.1 68.4 54.0

UC60(C,D) 1800

80/67 76.4 64.1 52.2 39.9

75/62 59.6 47.4 38.6 32.4

70/57 51.2 44.8 38.6 32.4

1 See Condensing Unit or Heat Pump Technical Guide for Total Cooling Capacity and Sensible Capacity.

4 Johnson Controls Unitary Products

Page 5

813517-YTG-E-0114

APPLICATION FACTOR-RATED CFM VS. ACTUAL CFM

% OF RATED AIR FLOW 80% 90% RATED CFM 110% 120%

CAPACITY FACTOR 0.96 0.98 1.00 1.02 1.03

* Do not exceed minimum/maximum CFM limits shown under Air Flow Data.

APPLICA TION LIMITATIONS

These units must be installed in accordance with all national

and local safety codes.

Air flow must be within the minimum and maximum limits

approved for electric heat, evaporator coils and outdoor units.

STATIC PRESSURE VS. AIRFLOW

(BASED ON WET COIL)

HORIZONTAL - DUCT TYPE

Model Airflow Wet Coil

600 0.02

HD24S

HD36S

HD48S

HD60S

800 0.09

1000 0.19

1000 0.19

1200 0.28

1400 0.38

1200 0.14

1400 0.19

1600 0.25

1800 0.32

1600 0.16

1800 0.20

2000 0.25

2200 0.30

UNCASED UPFLOW - “A” TYPE

Model Airflow Wet Coil

UC18A

UC18B

UC24A

UC24B

UC30A

UC30B

UC36A

UC36B

UC36C

UC42B

UC42C

UC48C

UC48D

UC60C

UC60D

600 0.16

800 0.23

1000 0.30

600 0.14

800 0.20

1000 0.26

600 0.15

800 0.21

1000 0.27

600 0.13

800 0.18

1000 0.23

800 0.21

1000 0.27

1200 0.33

800 0.18

1000 0.23

1200 0.29

1000 0.24

1200 0.32

1400 0.40

1000 0.15

1200 0.22

1400 0.28

1000 0.10

1200 0.15

1400 0.20

1200 0.21

1400 0.28

1600 0.34

1200 0.14

1400 0.19

1600 0.24

1800 0.28

1200 0.18

1400 0.24

1600 0.29

1800 0.35

1200 0.14

1400 0.20

1600 0.25

1800 0.30

1600 0.28

1800 0.33

2000 0.38

2200 0.43

1600 0.21

1800 0.27

2000 0.32

2200 0.38

Johnson Controls Unitary Products 5

Page 6

813517-YTG-E-0114

UPFLOW CASED “A” TYPE

Model Airflow Wet Coil

FC18A

PC18A

FC18B

PC18B

FC24A

PC24A

FC24B

PC24B

FC30A, PC30A

FC32A, PC32A

FC30B

PC30B

FC35B

PC35B

FC35C

PC35C

FC36A

PC36A

FC36B

PC36B

FC37A

PC37A

FC36C

PC36C

FC42B

PC42B

FC42C, PC42C

FC43B, PC43B

FC43C

PC43C

FC48C

PC48C

FC48D

PC48D

FC60C

PC60C

FC60D

PC60D

FC62D

4D

FC6

CASED “A” TYPE MULTI-POSITION

600 0.16

800 0.23

1000 0.30

600 0.14

800 0.20

1000 0.26

600 0.15

800 0.21

1000 0.27

600 0.13

800 0.18

1000 0.23

800 0.21

1000 0.27

1200 0.33

800 0.18

1000 0.23

1200 0.29

800 0.16

1000 0.22

1200 0.29

800 0.14

1000 0.20

1200 0.27

1000 0.24

1200 0.32

1400 0.40

1000 0.15

1200 0.22

1400 0.28

800 0.13

1000 0.19

1200 0.26

1000 0.10

1200 0.15

1400 0.20

1200 0.21

1400 0.28

1600 0.34

1800 0.40

1200 0.14

1400 0.19

1600 0.24

1800 0.28

1000 0.15

1200 0.21

1400 0.28

1600 0.34

1600 0.29

1800 0.35

2000 0.40

2200 0.46

1600 0.25

1800 0.30

2000 0.35

2200 0.40

1600 0.28

1800 0.33

2000 0.38

2200 0.43

1600 0.21

1800 0.27

2000 0.32

2200 0.38

1600 0.18

1800 0.23

2000 0.29

1600 0.21

1800 0.26

2000 0.30

Model Airflow Wet Coil

MC18A

MC18B

MC24A

MC24B

MC30A

MC32A

MC30B

MC35B

MC35C

MC36A

MC37A

MC36B

MC36C

MC42B

MC42C

MC43C

MC48C

MC48D

MC60D

MC62D

600 0.22

800 0.29

1000 0.36

600 0.20

800 0.26

1000 0.32

600 0.21

800 0.27

1000 0.33

600 0.19

800 0.24

1000 0.29

600 0.21

800 0.27

1000 0.33

600 0.19

800 0.24

1000 0.29

600 0.22

800 0.26

1000 0.34

600 0.20

800 0.24

1000 0.32

800 0.22

1000 0.30

1200 0.38

800 0.19

1000 0.25

1200 0.32

800 0.15

1000 0.21

1200 0.28

1000 0.16

1200 0.21

1400 0.26

1200 0.27

1400 0.34

1600 0.40

1200 0.20

1400 0.25

1600 0.30

1800 0.34

1200 0.26

1400 0.31

1600 0.36

1800 0.41

1200 0.24

1400 0.30

1600 0.35

1800 0.41

1200 0.20

1400 0.26

1600 0.31

1800 0.36

1600 0.27

1800 0.33

2000 0.38

2200 0.44

1600 0.24

1800 0.29

2000 0.34

6 Johnson Controls Unitary Products

Page 7

813517-YTG-E-0114

PHYSICAL DATA

UNCASED UPFLOW - “A” TYPE

Model Application

UC18A3XC1

UC18B3XC1 Sweat 3.67 2 14 (2) 16 x 16.5 1 x 0.866 3/8 Enhanced None 20

UC24A3XC1

UC24B3XC1 Sweat 4.58 2 14 (2) 20 x 16.5 1 x 0.866 3/8 Enhanced None 23

UC30A3XC1

UC30B3XC1 Sweat 4.58 2 14 (2) 20 x 16.5 1 x 0.866 3/8 Enhanced None 23

UC36A3XC1

UC36B3XC1 Sweat 5.04 2 14 (2) 22 x 16.5 1 x 0.866 3/8 Enhanced None 28

UC36C3XC1 Sweat 5.04 2 14 (2) 22 x 16.5 1 x 0.866 3/8 Enhanced None 30

UC42B3XC1

UC42C3XC1 Sweat 5.96 2 14 (2) 26 x 16.5 1 x 0.866 3/8 Enhanced None 36

UC48C3XC1

UC48D3XC1 Sweat 5.50 3 12 (2) 24 x 16.5 1 x 0.866 3/8 Enhanced None 42

UC60C3XC1

UC60D3XC1 Sweat 5.96 3 12 (2) 26 x 16.5 1 x 0.866 3/8 Enhanced None 45

Cooling/ Heat

Pump

Cooling/ Heat

Pump

Cooling/ Heat

Pump

Cooling/ Heat

Pump

Cooling/ Heat

Pump

Cooling/ Heat

Pump

Cooling/ Heat

Pump

Refrig.

Conn.

Types

Sweat 3.67 2 14 (2) 16 x 16.5 1 x 0.866 3/8 Enhanced None 18

Sweat 4.58 2 14 (2) 20 x 16.5 1 x 0.866 3/8 Enhanced None 22

Sweat 4.58 2 14 (2) 20 x 16.5 1 x 0.866 3/8 Enhanced None 22

Sweat 5.04 2 14 (2) 22 x 16.5 1 x 0.866 3/8 Enhanced None 25

Sweat 5.96 2 14 (2) 26 x 16.5 1 x 0.866 3/8 Enhanced None 34

Sweat 5.50 3 12 (2) 24 x 16.5 1 x 0.866 3/8 Enhanced None 38

Sweat 5.96 3 12 (2) 26 x 16.5 1 x 0.866 3/8 Enhanced None 42

HORIZONTAL - DUCT TYPE

Model Application

HD24S3XC1

HD36S3XC1

HD48S3XC1

HD60S3XC1

Cooling/ Heat

Cooling/ Heat

Cooling/ Heat

Cooling/ Heat

Pump

Pump

Pump

Pump

Refrig.

Conn.

Types

Sweat 3.67 3 12 22 x 24 1 x 0.866 3/8 Enhanced None 33

Sweat 4.23 3 12 26 x 24 1 x 0.866 3/8 Enhanced None 35

Sweat 5.29 3 12 26 x 30 1 x 0.866 3/8 Enhanced None 38

Sweat 5.71 3 12 28 x 30 1 x 0.866 3/8 Enhanced None 46

Face

Area

(Sq. Ft.)

Face

Area

(Sq. Ft.)

Rows

Deep

Rows

Deep

Fin

Per

In.

Fin

Per

In.

Coil Size

Coil Size

Tube

Geometry

Tube

Geometry

Tube

Dia.

Tube

Dia.

Fin

Type

Fin

Type

TXV

TXV

Operating

Weight

(Lbs.)

Operating

Weight

(Lbs.)

CASED UPFLOW/DOWNFLOW AND PARTIAL CASED

Model Application

FC18A3XC1

FC18B3XC1

FC24A3XC1

FC24B3XC1

FC30A3XC1

FC30B3XC1

FC32A3XC1

FC35B3XC1

FC35C3XC1

FC36A3XC1

FC36B3XC1

Cooling/

Heat Pump

Cooling/

Heat Pump

Cooling/

Heat Pump

Cooling/

Heat Pump

Cooling/

Heat Pump

Cooling/

Heat Pump

Cooling/

Heat Pump

Cooling/

Heat Pump

Cooling/

Heat Pump

Cooling/

Heat Pump

Cooling/

Heat Pump

Refrig.

Conn.

Types

Sweat 3.4 2 14 (2) 14 x 17.5 1 x 0.866 3/8 Enhanced None 42

Sweat 3.4 2 14 (2) 14 x 17.5 1 x 0.866 3/8 Enhanced None 44

Sweat 4.38 2 14 (2) 18 x 17.5 1 x 0.866 3/8 Enhanced None 46

Sweat 4.38 2 14 (2) 18 x 17.5 1 x 0.866 3/8 Enhanced None 50

Sweat 4.38 2 14 (2) 18 x 17.5 1 x 0.866 3/8 Enhanced None 46

Sweat 4.38 2 14 (2) 18 x 17.5 1 x 0.866 3/8 Enhanced None 50

Sweat 3.9 3 12 (2) 16 x 17.5 1 x 0.866 3/8 Enhanced None 49

Sweat 3.9 3 12 (2) 16 x 17.5 1 x 0.866 3/8 Enhanced None 53

Sweat 3.9 3 12 (2) 16 x 17.5 1 x 0.866 3/8 Enhanced None 55

Sweat 4.86 2 14 (2) 20 x 17.5 1 x 0.866 3/8 Enhanced None 49

Sweat 4.86 2 14 (2) 20 x 17.5 1 x 0.866 3/8 Enhanced None 51

Face

Area

(Sq. Ft.)

Rows

Deep

Fin

Per

In.

Coil Size

Tube

Geometry

Tube

Dia.

Fin

Type

TXV

Operating

Weight

(Lbs.)

Johnson Controls Unitary Products 7

Page 8

813517-YTG-E-0114

CASED UPFLOW/DOWNFLOW AND PARTIAL CASED

Model Application

FC36C3XC1

FC37A3XC1

FC42B3XC1

FC42C3XC1

FC43B3XC1

FC43C3XC1

FC48C3XC1

FC48D3XC1

FC60C3XC1

FC60D3XC1

FC62D3XC1

FC64D3XC1

Cooling/

Heat Pump

Cooling/

Heat Pump

Cooling/

Heat Pump

Cooling/

Heat Pump

Cooling/

Heat Pump

Cooling/

Heat Pump

Cooling/

Heat Pump

Cooling/

Heat Pump

Cooling/

Heat Pump

Cooling/

Heat Pump

Cooling/

Heat Pump

Cooling/Heat

Pump

Refrig.

Conn.

Types

Sweat 4.86 2 14 (2) 20 x 17.5 1 x 0.866 3/8 Enhanced None 53

Sweat 4.86 3 12 (2) 20 x 17.5 1 x 0.866 3/8 Enhanced None 56

Sweat 5.83 2 14 (2) 24 x 17.5 1 x 0.866 3/8 Enhanced None 60

Sweat 5.83 2 14 (2) 24 x 17.5 1 x 0.866 3/8 Enhanced None 62

Sweat 4.86 3 12 (3) 20 x 17.5 1 x 0.866 3/8 Enhanced None 56

Sweat 4.86 3 12 (2) 20 x 17.5 1 x 0.866 3/8 Enhanced None 58

Sweat 5.35 3 12 (2) 22 x 17.5 1 x 0.866 3/8 Enhanced None 63

Sweat 5.35 3 12 (2) 22 x 17.5 1 x 0.866 3/8 Enhanced None 71

Sweat 5.83 3 12 (2) 24 x 17.5 1 x 0.866 3/8 Enhanced None 63

Sweat 5.83 3 12 (2) 24 x 17.5 1 x 0.866 3/8 Enhanced None 76

Sweat 6.8 3 12 (2) 28 x 17.5 1 x 0.866 3/8 Enhanced None 88

Sweat 7.78 3 13 (2) 32x17.5 1 x 0.866 3/8 Enhanced None 92

Face

Area

(Sq. Ft.)

Rows

Deep

Fin

Per

In.

Coil Size

Tube

Geometry

Tube

Dia.

Fin

Type

TXV

Operating

Weight

(Lbs.)

CASED UPFLOW “A” TYPE

Model Application

PC18A3XC1

PC18B3XC1 Sweat 3.4 2 14 (2) 14 x 17.5 1 x 0.866 3/8 Enhanced None 37

PC24A3XC1

PC24B3XC1 Sweat 4.38 2 14 (2) 18 x 17.5 1 x 0.866 3/8 Enhanced None 42

PC30A3XC1

PC30B3XC1 Sweat 4.38 2 14 (2) 18 x 17.5 1 x 0.866 3/8 Enhanced None 42

PC32A3XC1

PC35B3XC1

PC35C3XC1 Sweat 3.9 3 12 (2) 16 x 17.5 1 x 0.866 3/8 Enhanced None 46

PC36A3XC1

PC36B3XC1 Sweat 4.86 2 14 (2) 20 x 17.5 1 x 0.866 3/8 Enhanced None 45

PC36C3XC1 Sweat 4.86 2 14 (2) 20 x 17.5 1 x 0.866 3/8 Enhanced None 46

PC37A3XC1

PC42B3XC1

PC42C3XC1 Sweat 5.83 2 14 (2) 24 x 17.5 1 x 0.866 3/8 Enhanced None 54

PC43B3XC1

PC43C3XC1 Sweat 4.86 3 12 (2) 20 x 17.5 1 x 0.866 3/8 Enhanced None 49

PC48C3XC1

PC48D3XC1 Sweat 5.35 3 12 (2) 22 x 17.5 1 x 0.866 3/8 Enhanced None 58

PC60C3XC1

PC60D3XC1 Sweat 5.83 3 12 (2) 24 x 17.5 1 x 0.866 3/8 Enhanced None 60

Cooling/

Heat Pump

Cooling/

Heat Pump

Cooling/

Heat Pump

Cooling/

Heat Pump

Cooling/

Heat Pump

Cooling/

Heat Pump

Cooling/

Heat Pump

Cooling/

Heat Pump

Cooling/

Heat Pump

Cooling/

Heat Pump

Cooling/

Heat Pump

Refrig.

Conn.

Types

Sweat 3.4 2 14 (2) 14 x 17.5 1 x 0.866 3/8 Enhanced None 36

Sweat 4.38 2 14 (2) 18 x 17.5 1 x 0.866 3/8 Enhanced None 40

Sweat 4.38 2 14 (2) 18 x 17.5 1 x 0.866 3/8 Enhanced None 40

Sweat 3.9 3 12 (2) 16 x 17.5 1 x 0.866 3/8 Enhanced None 41

Sweat 3.9 3 12 (2) 16 x 17.5 1 x 0.866 3/8 Enhanced None 45

Sweat 4.86 2 14 (2) 20 x 17.5 1 x 0.866 3/8 Enhanced None 44

Sweat 4.86 3 12 (2) 20 x 17.5 1 x 0.866 3/8 Enhanced None 48

Sweat 5.83 2 14 (2) 24 x 17.5 1 x 0.866 3/8 Enhanced None 50

Sweat 4.86 3 12 (3) 20 x 17.5 1 x 0.866 3/8 Enhanced None 47

Sweat 5.35 3 12 (2) 22 x 17.5 1 x 0.866 3/8 Enhanced None 56

Sweat 5.83 3 12 (2) 24 x 17.5 1 x 0.866 3/8 Enhanced None 58

Face

Area

(Sq. Ft.)

Rows

Deep

Fin

Per

In.

Coil Size

Tube

Geometry

Tube

Dia.

Fin

Type

TXV

Operating

Weight

(Lbs.)

8 Johnson Controls Unitary Products

Page 9

FULL CASED “A” TYPE MULTI-POSITION

Model Application

MC18A3XC1

MC18B3XC1

MC24A3XC1

MC24B3XC1

MC30A3XC1

MC30B3XC1

MC32A3XC1

MC35B3XC1

MC35C3XC1

MC36A3XC1

MC36B3XC1

MC36C3XC1

MC37A3XC1

MC42B3XC1

MC42C3XC1

MC43B3XC1

MC43C3XC1

MC48C3XC1

MC48D3XC1

MC60D3XC1

MC62D3XC1

Note: MC coils supplied with a factory installed horizontal drain pan (H).

Cooling / Heat

Pump

Cooling / Heat

Pump

Cooling / Heat

Pump

Cooling / Heat

Pump

Cooling / Heat

Pump

Cooling / Heat

Pump

Cooling / Heat

Pump

Cooling / Heat

Pump

Cooling / Heat

Pump

Cooling / Heat

Pump

Cooling / Heat

Pump

Cooling / Heat

Pump

Cooling / Heat

Pump

Cooling / Heat

Pump

Cooling / Heat

Pump

Cooling / Heat

Pump

Cooling / Heat

Pump

Cooling / Heat

Pump

Cooling / Heat

Pump

Cooling / Heat

Pump

Cooling / Heat

Pump

Refrig.

Conn.

Types

Sweat 3.40 2 14 (2) 14 x 17.5 1 x 0.866 3/8 Enhanced None 51

Sweat 3.40 2 14 (2) 14 x 17.5 1 x 0.866 3/8 Enhanced None 51

Sweat 4.38 2 14 (2) 18 x 17.5 1 x 0.866 3/8 Enhanced None 54

Sweat 4.38 2 14 (2) 18 x 17.5 1 x 0.866 3/8 Enhanced None 54

Sweat 4.38 2 14 (2) 18 x 17.5 1 x 0.866 3/8 Enhanced None 54

Sweat 4.38 2 14 (2) 18 x 17.5 1 x 0.866 3/8 Enhanced None 54

Sweat 3.9 3 12 (2) 16 x 17.5 1 x 0.866 3/8 Enhanced None 59

Sweat 3.9 3 12 (2) 16 x 17.5 1 x 0.866 3/8 Enhanced None 65

Sweat 3.9 3 12 (2) 16 x 17.5 1 x 0.866 3/8 Enhanced None 67

Sweat 4.86 2 14 (2) 20 x 17.5 1 x 0.866 3/8 Enhanced None 64

Sweat 4.86 2 14 (2) 20 x 17.5 1 x 0.866 3/8 Enhanced None 65

Sweat 4.86 2 14 (2) 20 x 17.5 1 x 0.866 3/8 Enhanced None 65

Sweat 4.86 3 12 (2) 20 x 17.5 1 x 0.866 3/8 Enhanced None 63

Sweat 5.83 2 14 (2) 24 x 17.5 1 x 0.866 3/8 Enhanced None 72

Sweat 5.83 2 14 (2) 24 x 17.5 1 x 0.866 3/8 Enhanced None 72

Sweat 4.86 3 12 (2) 20 x 17.5 1 x 0.866 3/8 Enhanced None 73

Sweat 4.86 3 12 (2) 20 x 17.5 1 x 0.866 3/8 Enhanced None 75

Sweat 5.35 3 12 (2) 22 x 17.5 1 x 0.866 3/8 Enhanced None 82

Sweat 5.35 3 12 (2) 22 x 17.5 1 x 0.866 3/8 Enhanced None 82

Sweat 5.83 3 12 (2) 24 x 17.5 1 x 0.866 3/8 Enhanced None 86

Sweat 6.80 3 12 (2) 28 x 17.5 1 x 0.866 3/8 Enhanced None 98

Face

Area

(Sq. Ft.)

Rows

Deep

Fin

Per

In.

Coil

Size

Tube

Geometry

Tube

Dia.

Fin

Type

813517-YTG-E-0114

TXV

Operating

Weight

(Lbs.)

Johnson Controls Unitary Products 9

Page 10

813517-YTG-E-0114

20 1/4”

D

20 3/8”

(Opening)

C

A

B

21 1/2”

BOTTOM OPENING

DIMENSIONS

-

-

-

BOTTOM OPENING

DIMENSIONS

21-1/2”

20-1/4”

C

(Opening)

20-3/8”

(Opening)

B

A

D

DIMENSIONS

Dimensions

Models

MC18A 22 14-1/2 13-3/8 13-1/2

MC18B 22 17-1/2 16-3/8 16-1/2

MC24A 26-1/2 14-1/2 13-3/8 13-1/2

MC24B 26-1/2 17-1/2 16-3/8 16-1/2

MC30A 26-1/2 14-1/2 13-3/8 13-1/2

MC30B 26-1/2 17-1/2 16-3/8 16-1/2

MC32A 22 14-1/2 13-3/8 13-1/2

MC35B 22 17-1/2 16-3/8 16-1/2

MC35C 22 21 19-7/8 20

MC36A 26-1/2 14-1/2 13-3/8 13-1/2

MC36C 26-1/2 21 19-7/8 20

MC37A 26-1/2 14-1/2 13-3/8 13-1/2 3/4

MC42B 32 17-1/2 16-3/8 16-1/2

MC42C 32 21 19-7/8 20

MC43B 26-1/2 17-1/2 16-3/8 16-1/2

MC43C 26-1/2 21 19-7/8 20

MC48C 32 21 19-7/8 20

MC48D 32 24-1/2 23-3/8 23-1/2

MC60D 32 24-1/2 23-3/8 23-1/2

MC62D 36 24-1/2 23-3/8 23-1/2

1 All dimensions are in inches.

2 Refrigerant line sizes may require larger lines for extended line lengths. See Application Data part number 247077.

Height Width Opening Widths Line Size

ABCDLiquidVapor

1

Refrigerant

Connections

3/8

2

3/4

7/8MC36B 26-1/2 17-1/2 16-3/8 16-1/2

7/8

1 All dimensions are in inches.

2 Refrigerant line sizes may require larger lines for extended line lengths. See Application Data part number 247077.

10 Johnson Controls Unitary Products

Dimensions

Models

FC18A 18 14-1/2 13-3/8 13-1/2

FC18B 18 17-1/2 16-3/8 16-1/2

FC24A 22 14-1/2 13-3/8 13-1/2

FC24B 22 17-1/2 16-3/8 16-1/2

FC30A 22 14-1/2 13-3/8 13-1/2

FC30B 22 17-1/2 16-3/8 16-1/2

FC32A 20 14-1/2 13-3/8 13-1/2

FC35B 20 17-1/2 16-3/8 16-1/2

FC35C 20 21 19-7/8 20

FC36A 24-1/2 14-1/2 13-3/8 13-1/2

FC36C 24-1/2 21 19-7/8 20

FC37A 24-1/2 14-1/2 13-3/8 13-1/2 3/4

FC42B 28 17-1/2 16-3/8 16-1/2

FC42C 28 21 19-7/8 20

FC43B 24-1/2 17-1/2 16-3/8 16-1/2

FC43C 24-1/2 21 19-7/8 20

FC48C 28 21 19-7/8 20

FC48D 28 24-1/2 23-3/8 23-1/2

FC60C 28 21 19-7/8 20

FC60D 28 24-1/2 23-3/8 23-1/2

FC62D 32 24-1/2 23-3/8 23-1/2

FC64D 36 24-1/2 23-3/8 23-1/2

Height Width Opening Widths Line Size

ABCDLiquidVapor

1

Refrigerant

Connections

3/4

7/8FC36B 24-1/2 17-1/2 16-3/8 16-1/2

3/8

7/8

2

Page 11

813517-YTG-E-0114

BOTTOM

OPENING

DIMENSIONS

20 1/4”

D

-

20 3/8”

(Opening)

A

C

(Opening)

12”

B

21 1/2”

-

-

21.0

A

B

1

Models

Dimensions

Height Width Opening Widths Line Size

ABCDLiquidVapor

PC18A 17-3/4 14-1/2 13-3/8 13-1/2

PC18B 17 17-1/2 16-3/8 16-1/2

PC24A 21-7/8 14-1/2 13-3/8 13-1/2

PC24B 21-3/8 17-1/2 16-3/8 16-1/2

PC30A 21-7/8 14-1/2 13-3/8 13-/2

PC30B 21-3/8 17-1/2 16-3/8 16-1/2

PC32A 20 14-1/2 13-3/8 13-1/2

PC35B 18-7/8 17-1/2 16-3/8 16-1/2

PC35C 18-3/4 21 19-7/8 20

PC36A 23-7/8 14-1/2 13-3/8 13-1/2

PC36C 22-7/8 21 19-7/8 20

PC37A 23-7/8 14-1/2 13-3/8 13-1/2 3/4

PC42B 27-5/8 17-1/2 16-3/8 16-1/2

PC42C 27-1/8 21 19-7/8 20

PC43B 23-1/8 17-1/2 16-3/8 16-1/2

PC43C 22-5/8 21 19-7/8 20

PC48C 25-3/8 21 19-7/8 20

PC48D 24-5/8 24-1/2 23-3/8 23-1/2

PC60C 27-1/2 21 19-7/8 20

PC60D 26-7/8 24-1/2 23-3/8 23-1/2

1 All dimensions are in inches.

2 Refrigerant line sizes may require larger lines for extended line lengths. See Application Data part number 247077.

Refrigerant

Connections

3/4

3/8

7/8PC36B 23-1/8 17-1/2 16-3/8 16-1/2

7/8

2

Refrigerant

Connections

2

Models

Dimensions

1

Height Width Line Size

A B Liquid Vapor

UC18A 17 13

UC18B 16-1/2 16

UC24A 21 13

UC24B 20-1/2 16

UC30A 21 13

UC30B 20-1/2 16

UC36A 23-1/2 13

UC36B 22-1/2 16

3/8

UC36C 22 19-1/2

UC42B 26-1/2 16

UC42C 25-1/2 19-1/2

UC48C 23-1/2 19-1/2

UC48D 23 23

UC60C 25-1/2 19-1/2

UC60D 25 23

1 All dimensions are in inches.

2 Refrigerant line sizes may require larger lines for extended line lengths. See Application Data part number 247077.

3/4

7/8

Johnson Controls Unitary Products 11

Page 12

COIL - HD

1-3/4

D

5-5/8

A

B

C

3-3/4

2-5/8

1-3/8

OPENING

FOR

VAPOR

CONN.

OPENING

FOR

LIQUID

CONN.

OPENING

FOR

3/4 NPT

SECONDARY

DRAIN CONN.

OPENING

FOR

3/4 NPT

PRIMARY

DRAIN CONN.

7/8

1-7/8

4-1/8

1-3/8

OUTLET SAME

SIZE AS INLET

(3/4” FLANGE)

DIMENSIONS - HD Coils

Models

Dimensions

1

Height Width Opening Widths Line Size

Refrigerant Connections

ABCDLiquid Vapor

HD24S 24 28-3/4 21-5/8 23-3/4

HD36S 28 28-3/4 25-5/8 23-3/4

3/8

HD60S 30 34-3/4 27-5/8 29-3/4

1 All dimensions are in inches.

2 Refrigerant line sizes may require larger lines for extended line lengths. See Application Data part number 247077.

2

3/4

7/8HD48S 28 34-3/4 25-5/8 29-3/4

Subject to change without notice. Published in U.S.A. 813517-YTG-E-0114

Copyright © 2014 by Johnson Controls, Inc. All rights reserved. Supersedes: 813517-YTG-D-0813

York International Corp.

5005 York Drive

Norman, OK 73069

Loading...

Loading...